Installation manual

Communication box

BRR9B1V1

Table of contents

Table of contents

1 About the documentation 3

1.1 About this document ...................................................................................................................................................... 3

2 General safety precautions 4

2.1 About the documentation .............................................................................................................................................. 4

2.1.1 Meaning of warnings and symbols ................................................................................................................ 4

2.2 For the installer............................................................................................................................................................... 5

2.2.1 General ........................................................................................................................................................... 5

2.2.2 Installation site ............................................................................................................................................... 6

2.2.3 Electrical ......................................................................................................................................................... 7

3 Specific installer safety instructions 9

4 About the box 10

4.1 Communication box........................................................................................................................................................ 10

4.1.1 To remove the accessories from the communication box ............................................................................ 10

5 About the communication box 11

5.1 Identification ................................................................................................................................................................... 11

5.1.1 Identification label: Communication box ....................................................................................................... 11

6 Unit installation 12

6.1 Preparing the installation site......................................................................................................................................... 12

6.1.1 Installation site requirements of the communication box ............................................................................ 12

6.2 Opening and closing the unit.......................................................................................................................................... 12

6.2.1 To open the communication box ................................................................................................................... 12

6.2.2 To close the communication box ................................................................................................................... 13

6.3 Installing the communication box .................................................................................................................................. 13

6.3.1 Precautions when installing the communication box ................................................................................... 13

6.3.2 To install the communication box .................................................................................................................. 13

7 Electrical installation 14

7.1 General overview of the field wiring .............................................................................................................................. 14

7.2 Field wiring: Overview .................................................................................................................................................... 15

7.3 Guidelines when connecting the electrical wiring ......................................................................................................... 16

7.4 Specifications of standard wiring components .............................................................................................................. 16

7.5 To connect the electrical wiring on the communication box ........................................................................................ 17

7.6 To connect the transmission wiring ............................................................................................................................... 18

7.6.1 Between communication box and outdoor unit ........................................................................................... 18

7.6.2 Between communication box and monitoring system.................................................................................. 18

7.7 To fix the wiring cables with cable ties........................................................................................................................... 19

8 Configuration 20

8.1 About the PCBs ............................................................................................................................................................... 20

8.2 Setting the addresses of outdoor units and indoor units .............................................................................................. 20

8.3 To set the addresses of the outdoor unit and capacity up unit..................................................................................... 21

8.4 To set the addresses of the indoor units........................................................................................................................ 22

8.5 Configuring the communication box.............................................................................................................................. 22

8.5.1 To configure the communication box PCB for the indoor units.................................................................... 23

8.5.2 To configure the communication box PCB for the outdoor unit and capacity up unit................................. 24

9 Commissioning 28

10 Troubleshooting 29

10.1 Troubleshooting for PCB for indoor unit communication ............................................................................................. 29

10.2 Troubleshooting for PCB for outdoor unit and capacity up unit communication......................................................... 29

11 Technical data 33

11.1 Wiring diagram: Communication box............................................................................................................................. 33

12 Glossary 34

Installation manual

2

BRR9B1V1

Communication box

4P617761-1B – 2020.10

1 About the documentation

1.1 About this document

Target audience

Authorised installers

WARNING

Make sure installation, servicing, maintenance, repair and applied materials follow

the instructions from Daikin and, in addition, comply with applicable legislation and

are performed by qualified persons only. In Europe and areas where IEC standards

apply, EN/IEC 60335-2-40 is the applicable standard.

Documentation set

This document is part of a documentation set. The complete set consists of:

▪ Installation manual:

- Installation instructions, configuration,…

1 | About the documentation

- Format: Paper (supplied in the kit) + digital files on http://

www.daikineurope.com/support-and-manuals/product-information/

Latest revisions of the supplied documentation may be available on the regional

Daikin website or via your dealer.

The original documentation is written in English. All other languages are

translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional Daikin website

(publicly accessible).

▪ The full set of latest technical data is available on the Daikin Business Portal

(authentication required).

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

3

2 | General safety precautions

2 General safety precautions

2.1 About the documentation

▪ The original documentation is written in English. All other languages are

translations.

▪ The precautions described in this document cover very important topics, follow

them carefully.

▪ The installation of the system, and all activities described in the installation

manual and in the installer reference guide MUST be performed by an authorised

installer.

2.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING/SCALDING

Indicates a situation that could result in burning/scalding because of extreme hot or

cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate injury.

Installation manual

4

NOTICE

Indicates a situation that could result in equipment or property damage.

INFORMATION

Indicates useful tips or additional information.

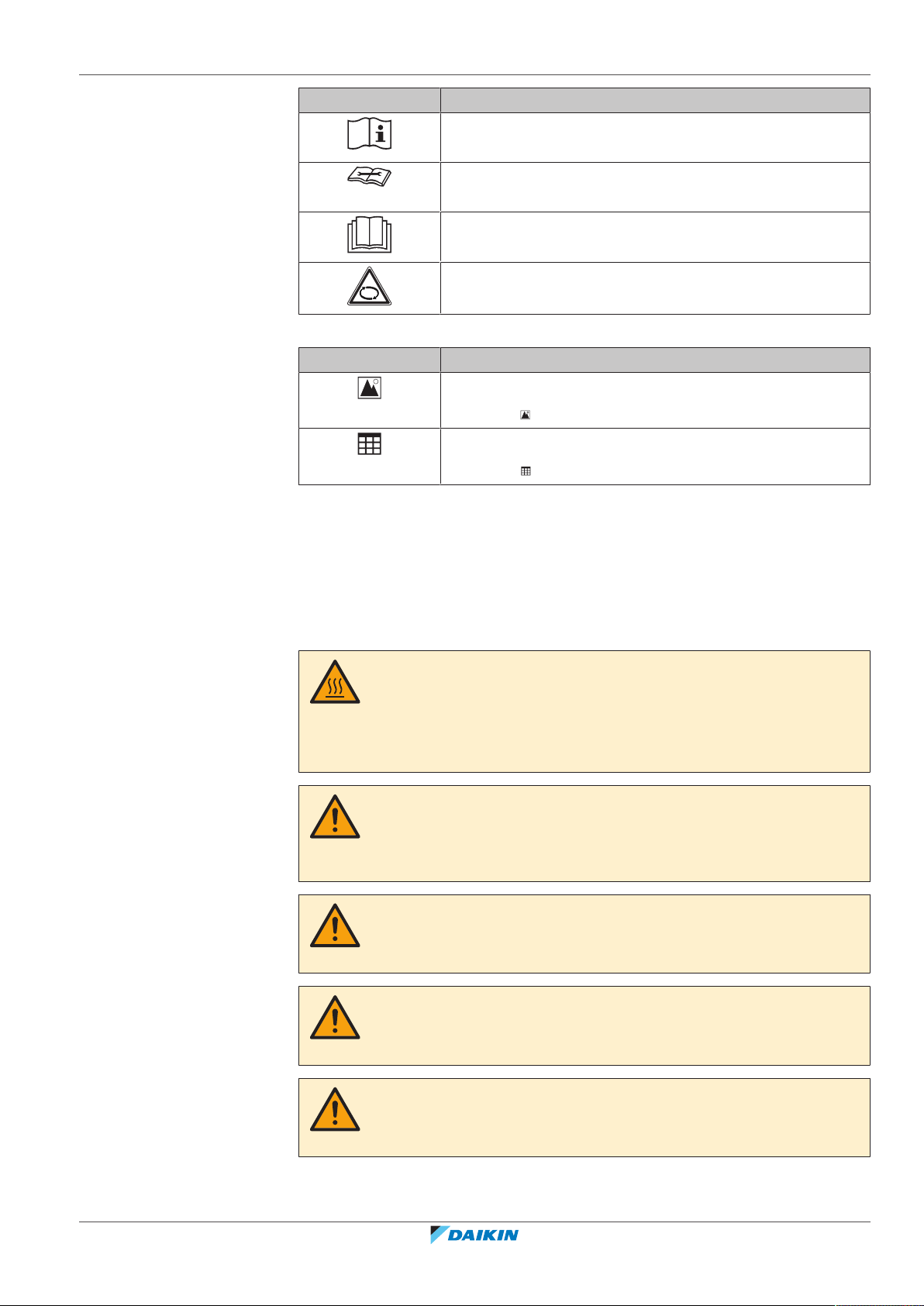

Symbols used on the unit:

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Symbol Explanation

Before installation, read the installation and operation

manual, and the wiring instruction sheet.

Before performing maintenance and service tasks, read the

service manual.

For more information, see the installer and user reference

guide.

The unit contains rotating parts. Be careful when servicing or

inspecting the unit.

Symbols used in the documentation:

Symbol Explanation

Indicates a figure title or a reference to it.

Example: " 1–3 Figure title" means "Figure 3 in chapter 1".

Indicates a table title or a reference to it.

Example: " 1–3 Table title" means "Table 3 in chapter 1".

2 | General safety precautions

2.2 For the installer

2.2.1 General

If you are NOT sure how to install or operate the unit, contact your dealer.

DANGER: RISK OF BURNING/SCALDING

▪ Do NOT touch the refrigerant piping, water piping or internal parts during and

immediately after operation. It could be too hot or too cold. Give it time to return

to normal temperature. If you must touch it, wear protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Improper installation or attachment of equipment or accessories could result in

electrical shock, short-circuit, leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or approved by Daikin.

WARNING

Make sure installation, testing and applied materials comply with applicable

legislation (on top of the instructions described in the Daikin documentation).

BRR9B1V1

Communication box

4P617761-1B – 2020.10

CAUTION

Wear adequate personal protective equipment (protective gloves, safety glasses,…)

when installing, maintaining or servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that nobody, especially

children, can play with them. Possible risk: suffocation.

Installation manual

5

2 | General safety precautions

In accordance with the applicable legislation, it might be necessary to provide a

logbook with the product containing at least: information on maintenance, repair

work, results of tests, stand-by periods,…

WARNING

Provide adequate measures to prevent that the unit can be used as a shelter by small

animals. Small animals that make contact with electrical parts can cause

malfunctions, smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

CAUTION

▪ Do NOT place any objects or equipment on top of the unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under dry weather conditions to

avoid water ingress.

2.2.2 Installation site

Also, at least, following information MUST be provided at an accessible place at the

product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

▪ Provide sufficient space around the unit for servicing and air circulation.

▪ Make sure the installation site withstands the weight and vibration of the unit.

▪ Make sure the area is well ventilated. Do NOT block any ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic waves.

Electromagnetic waves may disturb the control system, and cause malfunction of

the equipment.

▪ In places where there is a risk of fire due to the leakage of flammable gases

(example: thinner or gasoline), carbon fibre, ignitable dust.

Installation manual

6

▪ In places where corrosive gas (example: sulphurous acid gas) is produced.

Corrosion of copper pipes or soldered parts may cause the refrigerant to leak.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

2.2.3 Electrical

2 | General safety precautions

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the switch box cover, connecting

electrical wiring or touching electrical parts.

▪ Disconnect the power supply for more than 10minutes, and measure the voltage

at the terminals of main circuit capacitors or electrical components before

servicing. The voltage MUST be less than 50VDC before you can touch electrical

components. For the location of the terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service cover is removed.

WARNING

If NOT factory installed, a main switch or other means for disconnection, having a

contact separation in all poles providing full disconnection under overvoltage

categoryIII condition, MUST be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable legislation.

▪ All field wiring MUST be performed in accordance with the wiring diagram

supplied with the product.

▪ NEVER squeeze bundled cables and make sure they do NOT come in contact with

the piping and sharp edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit to a utility pipe, surge

absorber, or telephone earth. Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER use a power supply shared by

another appliance.

▪ Make sure to install the required fuses or circuit breakers.

▪ Make sure to install an earth leakage protector. Failure to do so may cause

electrical shock or fire.

▪ When installing the earth leakage protector, make sure it is compatible with the

inverter (resistant to high frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

CAUTION

▪ When connecting the power supply: connect the earth cable first, before making

the current-carrying connections.

▪ When disconnecting the power supply: disconnect the current-carrying cables

first, before separating the earth connection.

▪ The length of the conductors between the power supply stress relief and the

terminal block itself must be as such that the current-carrying wires are tautened

before the earth wire is in case the power supply is pulled loose from the stress

relief.

Installation manual

7

2 | General safety precautions

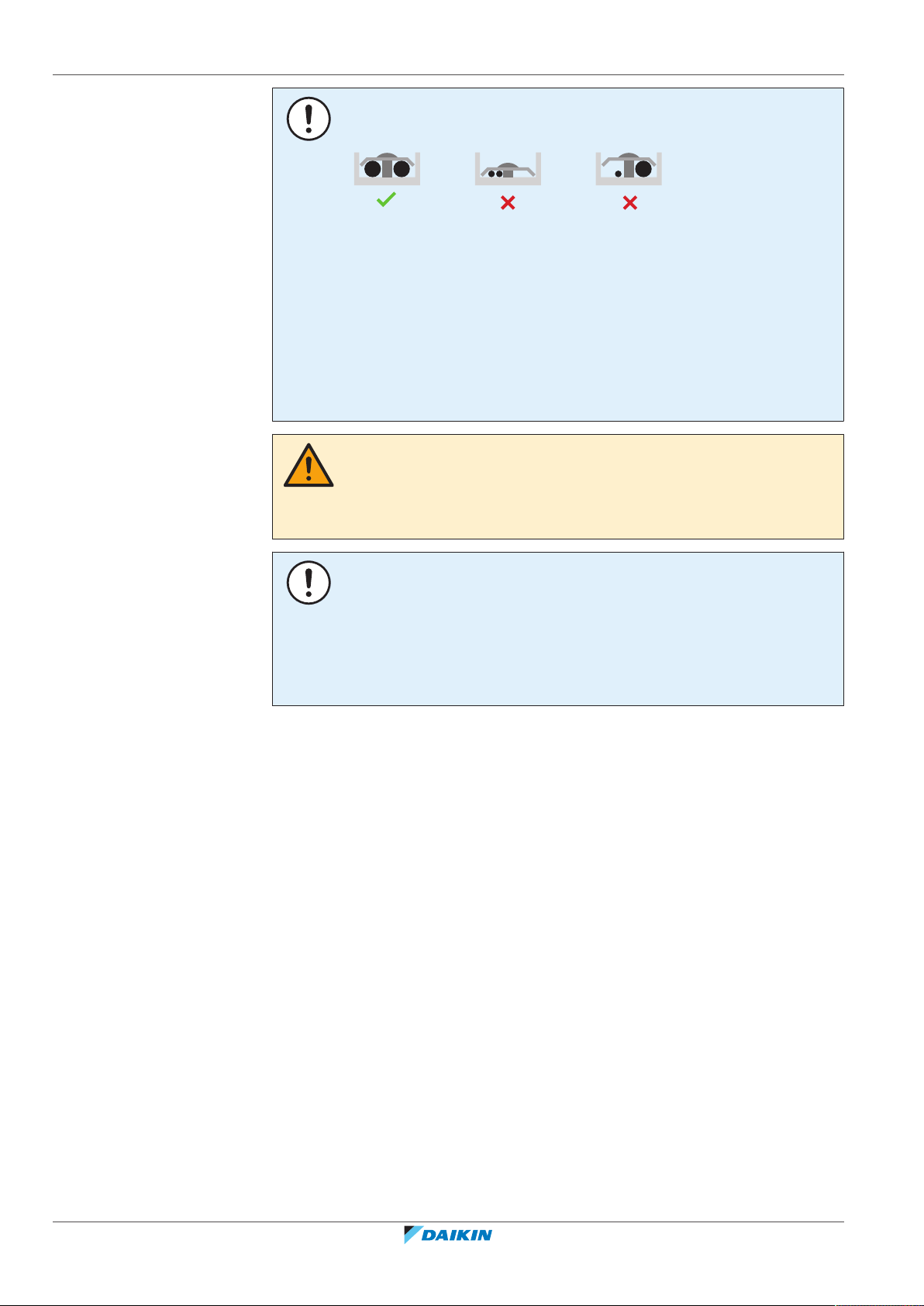

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the power terminal block (slack

in the power wiring may cause abnormal heat).

▪ When connecting wiring which is the same thickness, do as shown in the figure

above.

▪ For wiring, use the designated power wire and connect firmly, then secure to

prevent outside pressure being exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the terminal screws. A screwdriver

with a small head will damage the head and make proper tightening impossible.

▪ Over-tightening the terminal screws may break them.

WARNING

▪ After finishing the electrical work, confirm that each electrical component and

terminal inside the electrical components box is connected securely.

▪ Make sure all covers are closed before starting up the unit.

NOTICE

Only applicable if the power supply is three‑phase, and the compressor has an ON/

OFF starting method.

If there exists the possibility of reversed phase after a momentary black out and the

power goes on and off while the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed phase can break the

compressor and other parts.

Installation manual

8

BRR9B1V1

Communication box

4P617761-1B – 2020.10

3 | Specific installer safety instructions

3 Specific installer safety instructions

Always observe the following safety instructions and regulations.

WARNING

Installation shall be done by an installer, the choice of materials and installation shall

comply with the applicable legislation. In Europe, EN378 is the applicable standard.

WARNING

Provide adequate measures to prevent that the unit can be used as a shelter by small

animals. Small animals that make contact with electrical parts can cause

malfunctions, smoke or fire.

WARNING

▪ Make sure the electrical wiring does NOT obstruct correct reattachment of the

communication box cover. Incorrect reattachment of the communication box

cover might result in electrical shocks, fire, or terminal overheating.

▪ Do NOT connect the power supply wires to the terminal block for the

transmission wiring. Incorrect connection is very dangerous, results in damage,

and possible burnout of the electrical components.

▪ Do NOT use stranded wires with a solder finish applied. A loose wire or other

abnormalities might cause abnormal heating.

WARNING

▪ When opening the front plate of an outdoor unit during operation, be careful of a

rotating fan. The fan continues rotating for a while even after the operation is

stopped.

▪ Before turning ON the power supply, make sure that the operation switch of the

outdoor unit is turned OFF. You can check this via the inspection hole of the

electrical component box (middle) of the outdoor unit.

▪ After turning ON the power supply, operate the push buttons and check the LED

indication via the inspection hole of the electrical component box (middle) of the

outdoor unit. Operating with the cover open might cause an electrical shock.

▪ For more information on how to configure the monitoring system (field supply),

see the manual of the supplier.

WARNING

▪ Do NOT turn ON the power when the communication box cover is open. An

electrical shock might occur.

▪ Before turning ON the power, make sure that the communication box cover is

closed.

CAUTION: Precautions when setting the slave address

▪ Do NOT set the same slave address for devices connected to the Modbus master

device.

▪ Apart from the slave address set in the communication box, there are 2 other

slave addresses that cannot be set. When the slave address on the PCB for the

outdoor unit (A2P) is set to "A", slave addresses "A+1" and "A+2" CANNOT be set.

Slave address "A" is used for the outdoor unit, "A+1" is used for the capacity up

unit, and "A+2" may NOT be used.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

9

4 | About the box

×1

×2

4 About the box

4.1 Communication box

4.1.1 To remove the accessories from the communication box

a Installation manual

b Cable tie (2×)

Installation manual

10

BRR9B1V1

Communication box

4P617761-1B – 2020.10

5 | About the communication box

5 About the communication box

Communication box (BRR9B1V1)

Install the modbus communication box to fully integrate your CO2 Conveni-Pack

system with building control automation networks and other monitoring systems.

NOTICE

ALWAYS check with the reference guide of the installed outdoor unit if the

communication box is compatible with it. Do NOT connect the communication box to

any other unit.

Also see: "8.1About the PCBs"[420].

General names and product names

In this manual, we use the following names:

General name Product name

Communication box BRR9B1V1

Outdoor unit Main outdoor unit. For example:

LRYEN10A7Y1

Capacity up unit Additional outdoor unit for extra

5.1 Identification

5.1.1 Identification label: Communication box

Location

refrigeration capacity. For example:

LRNUN5A7Y1

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

11

6 | Unit installation

≥100 mm ≥50 mm≥300 mm

≥50 mm ≥50 mm

a

b

4×

6 Unit installation

In this chapter

6.1 Preparing the installation site

6.1.1 Installation site requirements of the communication box

6.1 Preparing the installation site ................................................................................................................................................ 12

6.1.1 Installation site requirements of the communication box.................................................................................... 12

6.2 Opening and closing the unit ................................................................................................................................................. 12

6.2.1 To open the communication box ........................................................................................................................... 12

6.2.2 To close the communication box ........................................................................................................................... 13

6.3 Installing the communication box.......................................................................................................................................... 13

6.3.1 Precautions when installing the communication box ........................................................................................... 13

6.3.2 To install the communication box ......................................................................................................................... 13

▪ Mind the following spacing installation guidelines:

6.2 Opening and closing the unit

6.2.1 To open the communication box

a Front view

b Top view

▪ The communication box is designed for indoor installation only and for ambient

temperatures ranging from –5~35°C.

Installation manual

12

4P617761-1B – 2020.10

BRR9B1V1

Communication box

6.2.2 To close the communication box

4×

a

a

aa

515

529

100

120

b

40

87

(mm)

6.3 Installing the communication box

6.3.1 Precautions when installing the communication box

INFORMATION

Also read the precautions and requirements in the following chapters:

▪ General safety precautions

▪ Preparation

6 | Unit installation

6.3.2 To install the communication box

1 Drill 4 holes at the fixing points.

a Hole for a M5 self-tapping screw (4 fixing points)

b Wiring intake

2 Secure the communication box using 4 screws (field supply).

INFORMATION

Install the communication box on a sufficiently strong wall using fixing screws (field

supply) suitable for the wall.

INFORMATION

▪ Make sure that the wiring intakes face downward.

▪ Make sure that dew or rainwater will not drop on the field wiring.

▪ Provide traps in front of the wiring intakes.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

13

7 | Electrical installation

7 Electrical installation

In this chapter

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

7.1 General overview of the field wiring...................................................................................................................................... 14

7.2 Field wiring: Overview ............................................................................................................................................................ 15

7.3 Guidelines when connecting the electrical wiring................................................................................................................. 16

7.4 Specifications of standard wiring components...................................................................................................................... 16

7.5 To connect the electrical wiring on the communication box................................................................................................ 17

7.6 To connect the transmission wiring ....................................................................................................................................... 18

7.6.1 Between communication box and outdoor unit ................................................................................................... 18

7.6.2 Between communication box and monitoring system ......................................................................................... 18

7.7 To fix the wiring cables with cable ties .................................................................................................................................. 19

7.1 General overview of the field wiring

INFORMATION

Indoor units (air conditioning). This field wiring overview shows only one possible

wiring for the indoor units (air conditioning). For more possibilities, see the indoor

unit manual.

Installation manual

14

BRR9B1V1

Communication box

4P617761-1B – 2020.10

7 | Electrical installation

g

F2F1 F1

X1M (A1P)

F2 Q1 Q2

TO

MULTI UNIT

TO

OUT/D UNIT

TO

IN/D UNIT

L1 L2 L3 N

X1M PE X2M

C C1 W1 R P1 P2

21 3

X3M

L N

X2M

P1 P2 F1 F2 T1 T2

F2F1 F1

X1M (A1P)

F2 Q1 Q2

TO

MULTI UNIT

TO

OUT/D UNIT

TO

IN/D UNIT

L1 L2 L3 N

X1M PEX4M

C C1 W1 R P1 P2

21 3

X5M

L N

X2M

X1M

X1M

P1 P2 F1 F2 T1 T2

P1 P2

L N

X1M PEX3M

A+ B- F1 F2

220-240 V AC

220-240 V AC

220-240 V AC

12 V DC

12 V DC

12 V DC

12 V DC

220-240 V AC

220-240 V AC

220-240 V AC

220-240 V AC

1N~ 50 Hz

220-240 V AC

RS-485

DIII

DIII

DIII

DIII

DIII

f gf

d

ed e

a

i

i

b

d1 d2

h

h1 h2

d1 d2

X1M (A1P)

X5M

X4M

X1M

PE

X1M

X3M

PE

X1M (A1P)

X2M

X1M

X3M

PE

k1

k

l

m

k2

k4

k3

j

3N~ 50 Hz

380-415 V AC

c1

c2

3N~ 50 Hz

380-415 V AC

c1

c2

c1

c2

1N~ 50 Hz

220-240 V AC

c1

c2

k5

R1

R1

RS-485

DIII

R1

BRR9B1V1

Communication box

4P617761-1B – 2020.10

a Capacity up unit (LRNUN5A7Y1) i Indoor unit (air conditioning)

b Outdoor unit (LRYEN10A7Y1) j User interface for indoor units (air conditioning)

c1 Overcurrent fuse (field supply) k Safety system (field supply). Example:

c2 Earth leakage circuit breaker (field supply) k1: Control panel

d Alarm panel (field supply) for: k2: CO2 refrigerant leak detector

d1: Caution output signal k3: Safety alarm (lamp)

d2: Warning output signal k4: Ventilation (natural or mechanical)

e Control panel (field supply) for operation output

signal

f Remote operation switch (field supply) l Communication box (BRR9B1V1)

g Remote low noise switch (field supply) m Monitoring system (field supply)

OFF: normal mode

ON: low noise mode

h Operation output signal to expansion valves of all:

h1: Blower coils (field supply)

h2: Showcases (field supply)

7.2 Field wiring: Overview

Field wiring consists of:

▪ power supply (including earth),

k5: Shut off valve

Wiring:

RS-485 transmission wiring (mind polarity)

DIII transmission wiring (no polarity)

Operation output

Installation manual

15

7 | Electrical installation

▪ DIII transmission wiring between communication box and outdoor unit,

▪ RS‑485 transmission wiring between communication box and monitoring system.

NOTICE

▪ Be sure to keep the power line and transmission line apart from each other.

Transmission wiring and power supply wiring may cross, but may NOT run

parallel.

▪ In order to avoid any electrical interference the distance between both wirings

should ALWAYS be at least 50mm.

Transmission wiring

7‒1 DIII weak current – Transmission wiring between each unit except monitoring system

Transmission wiring specification and limits

(a)

Vinyl cords with 0.75 to 1.25mm² sheath or cables (2‑core wires)

Maximum wiring length 1000m

Total wiring length ≤2000m

(a)

If the total transmission wiring exceeds these limits, communication errors might occur.

7‒2 RS-485 weak current – Transmission wiring between monitoring system and communication

box

Transmission wiring specification and limits

Vinyl cords with 0.75 to 1.25mm² sheath or cables (2‑core wires)

Maximum wiring length 1200m

(a)

If the total transmission wiring exceeds these limits, communication errors might occur.

7.3 Guidelines when connecting the electrical wiring

7‒3 Tightening torque for power supply

Item Tightening torque (N•m)

Terminal block (X1M) (M4) 1.18~1.44

Earth terminal (M5) 3.02~4.08

7‒4 Tightening torque for transmission wiring

Item Tightening torque (N•m)

Communication box terminal block

(X3M) (M3.5)

(a)

0.79~0.97

7.4 Specifications of standard wiring components

Installation manual

16

Outdoor unit terminal block (X1M

0.80~0.96

(A1P)) (M3.5)

7‒5 Power supply and earth wire

Component Specification

Power supply wire Minimum cable section of 2mm²

(Ø1.6mm)

BRR9B1V1

Communication box

4P617761-1B – 2020.10

7 | Electrical installation

a

m

k

j

l

j

≥50 mm

h

g

i

A1P A2P

d

e

f

n

o

p

n

o

p

7±2 mm

a

X1M

c

b

Component Specification

Power supply wire – maximum wiring length 250m

Earth wire 2mm2 (Ø1.6mm)

7.5 To connect the electrical wiring on the communication box

WARNING

▪ Make sure the electrical wiring does NOT obstruct correct reattachment of the

communication box cover. Incorrect reattachment of the communication box

cover might result in electrical shocks, fire, or terminal overheating.

▪ Do NOT connect the power supply wires to the terminal block for the

transmission wiring. Incorrect connection is very dangerous, results in damage,

and possible burnout of the electrical components.

▪ Do NOT use stranded wires with a solder finish applied. A loose wire or other

abnormalities might cause abnormal heating.

See also "7.1General overview of the field wiring"[414].

1 Insert the wiring in the intake hole from the bottom of the communication

box.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

a Intake hole

2 Remove the sheath of the transmission cables.

3 Twist the transmission cables.

4 Connect the power supply to the terminal block (X1M) of the communication

box.

a Sheath

b Twist together before connecting.

c Connect to X1M.

d Round crimp-style terminal

e Insulation sleeve

f Wire

g Round crimp-style terminal

h Cutout section

i Cup washer

j Wiring intake

k Transmission wiring (RS‑485 weak current) to the monitoring system (mind polarity)

Installation manual

17

7 | Electrical installation

7±2 mm

a

X3M

c

b

l Transmission wiring (DIII weak current) to outdoor unit (no polarity)

m Power wire and earth wire (copper)

n Cable clamp

o Cable tie

p Wiring

7.6 To connect the transmission wiring

7.6.1 Between communication box and outdoor unit

5 Connect the earth wire to the earth terminal.

6 Connect the transmission wiring as described in "7.6 To connect the

transmission wiring"[418].

INFORMATION

▪ Mind the maximum length of the transmission wiring. Otherwise transmission

errors might occur.

▪ Use sheathed vinyl cords or cables (2 cores).

▪ Use ONLY 2-core cables. Do NOT use cables with 3 or more cores, otherwise

transmission errors might occur.

Prerequisite: Use DIII weak current wire.

Prerequisite: Cut the end portion of the transmission wiring that has to be

connected. Strip insulation from the wire before connecting it to the terminal block

(X3M).

Prerequisite: Twist the wires together before connecting the wires.

1 Connect F1 and F2 of the X3M terminal block of the communication box to F1

and F2 (TO OUT/D UNIT) of the X1M (A1P) terminal block of the outdoor unit.

2 Connect F1 and F2 (TO OUT/D UNIT) of the X1M (A1P) terminal block of the

outdoor unit to F1 and F2, respectively, of the terminal block of the capacity

up unit.

7‒1 Cut, twist, and connect the wire to the terminal block

a Sheath

b Twist together before connecting.

c Connect to X3M.

7.6.2 Between communication box and monitoring system

Installation manual

18

NOTICE

Mind the polarity of the transmission wiring.

See also "7.1General overview of the field wiring"[414].

Prerequisite: Use RS‑485 weak current wire.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

7 | Electrical installation

7±2 mm

a

X3M

c

b

a

b

c

a

b

c

Prerequisite: Cut the end portion of the transmission wiring that has to be

connected. Strip insulation from the wire before connecting it to the terminal block

(X3M).

Prerequisite: Use wires with the same diameter and twist the core wires together

before connecting the wires.

1 Connect wires from A+ and B– of the terminal block of the communication box

to the monitoring system.

2 Connect the wires to the X3M terminal block in the same way as "Between

communication box and outdoor unit"[418].

7‒2 Cut, twist, and connect the wire to the terminal block

a Sheath

b Twist together before connecting.

c Connect to X3M.

7.7 To fix the wiring cables with cable ties

NOTICE

Transmission wiring is used for communication between the units. Do NOT fix the

transmission wiring together with the power wiring or earth wire. Otherwise

communication errors might occur.

1 Fix the transmission wires using a cable tie (delivered as accessory).

a Cable clamp

b Cable tie

c Wiring

2 Fix the power and earth wires using a cable tie (delivered as accessory).

BRR9B1V1

Communication box

4P617761-1B – 2020.10

a Cable clamp

b Cable tie

c Wiring

3 Cut off the excess part of the cable ties.

4 Seal all gaps to prevent small animals from entering the wiring intake (sealing

material is field supply).

Installation manual

19

8 | Configuration

A1P A2P

8 Configuration

In this chapter

INFORMATION

It is important that all information in this chapter is read sequentially by the installer

and that the system is configured as applicable.

DANGER: RISK OF ELECTROCUTION

8.1 About the PCBs ....................................................................................................................................................................... 20

8.2 Setting the addresses of outdoor units and indoor units...................................................................................................... 20

8.3 To set the addresses of the outdoor unit and capacity up unit ............................................................................................ 21

8.4 To set the addresses of the indoor units ............................................................................................................................... 22

8.5 Configuring the communication box...................................................................................................................................... 22

8.5.1 To configure the communication box PCB for the indoor units ........................................................................... 23

8.5.2 To configure the communication box PCB for the outdoor unit and capacity up unit ........................................ 24

8.1 About the PCBs

The communication box is for connection to an outdoor unit only. Do NOT connect

any other types of units.

The communication box contains 2 PCBs:

A1P PCB for communication with the indoor unit.

A2P PCB for communication with the outdoor unit and capacity up unit.

NOTICE

Communication settings (slave address, baud rate, parity and stop bits) MUST be

made for A1P and A2P.

8.2 Setting the addresses of outdoor units and indoor units

WARNING

▪ When opening the front plate of an outdoor unit during operation, be careful of a

rotating fan. The fan continues rotating for a while even after the operation is

stopped.

▪ Before turning ON the power supply, make sure that the operation switch of the

outdoor unit is turned OFF. You can check this via the inspection hole of the

electrical component box (middle) of the outdoor unit.

▪ After turning ON the power supply, operate the push buttons and check the LED

indication via the inspection hole of the electrical component box (middle) of the

outdoor unit. Operating with the cover open might cause an electrical shock.

▪ For more information on how to configure the monitoring system (field supply),

see the manual of the supplier.

Installation manual

20

BRR9B1V1

Communication box

4P617761-1B – 2020.10

8 | Configuration

a

g

f

i

h

e

d

c

b

OFF

ON

REMOTE

HAP

BS1

DS1 DS2

BS2 BS3

MODEMODE

MODE

MODE

About the effective address range

Set an address in accordance with the model to be connected to the

communication box. The following table shows the numbers to which an address

can be set.

Model Effective address range

Outdoor unit + capacity up unit

1-7

(LRYEN10A7Y1 + LRNUN5A7Y1)

Indoor unit 1‑00 – 4‑15

INFORMATION

The numbers in the table show the effective range of address setting. For the

number of outdoor units that can communicate with 1 communication box, see the

specifications.

▪ The address of an outdoor unit and capacity up unit needs to be different.

▪ Setting an address outside the effective range disables proper communication.

▪ After an address of the outdoor unit and capacity up unit is set or changed, reset

the power supply of the communication box.

8.3 To set the addresses of the outdoor unit and capacity up unit

1 Open the left inspection hole cover.

2 Turn OFF the power supply.

3 Turn OFF the operation switch.

a Inspection hole (left)

b Inspection hole (right)

c Electrical component box

d Operation switch

e PCB (A1P)

f Push buttons (BS1~BS3)

g 7-segments display

h DIP switch

i HAP LED

4 Turn the power supply ON and leave the operation switch OFF.

5 Open the right inspection hole cover.

6 Set the addresses as described in the table below.

Procedure 7-segments display Remarks

Initial indication Show the initial indication in a

normal condition.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

21

8 | Configuration

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

BS1 BS2 BS3

MODEMODE

MODE

MODE

Procedure 7-segments display Remarks

Press and hold BS1 for 5seconds.

Press BS2 6times.

Press BS3 once.

Press BS2 to

No address set 0 is factory setting. If no setting

select the

desired setting.

Address 1 Displays the total number of

⁞ ⁞ ⁞

Address 63 An address can be setup to 63.

Make sure that the left 7segment is 2.

Check the number of button

presses with the right 7-segment.

(You see number 6 in the right 7segment, this means that you

pressed 6 times on BS2).

This displays the Airnet address.

has been made, communication

cannot be established.

button presses in the 7-segment

(center and right).

When BS2 is pressed after that,

the setting will change to

"Address not set".

Press BS3 once.

Press BS3 once.

Press BS1 once.

8.4 To set the addresses of the indoor units

8.5 Configuring the communication box

When the value is determined,

the 7-segment display changes

from blinking to lit.

—

Returns to the initial indication.

Refer to the installation manual of the controller.

WARNING

▪ Do NOT turn ON the power when the communication box cover is open. An

electrical shock might occur.

▪ Before turning ON the power, make sure that the communication box cover is

closed.

Installation manual

22

BRR9B1V1

Communication box

4P617761-1B – 2020.10

8.5.1 To configure the communication box PCB for the indoor units

A1P

BS1

H1P H2P H3P H4P H5P H6P H7P

SS2 SS3

BS2 BS3 BS4 BS5

1234

DS1

ON

OFF

DS2

1234

120Ω100Ω

SS1

X2M

a

A1P A2P

1 2 3 4 1 2 3 4

DS1 DS2

ON

OFF

Overview of buttons, switches, and other parts

a DIP switches (DS1, DS2)

You can configure 3 different settings on PCB A1P:

▪ RS‑485 Modbus baud rate

▪ Modbus communication parity/stop bit

▪ Modbus slave address setting

RS‑485 Modbus baud rate setting

Setting

8 | Configuration

DS1 pin 2: OFF 9600bps

DS1 pin 2: ON 19200bps

Modbus communication parity/stop bit

Setting

DS1 pin 3: OFF, pin 4: OFF Even 1 stop bit

DS1 pin 3: OFF, pin 4: ON Odd 1 stop bit

DS1 pin 3: ON, pin 4: OFF None 2 stop bits

DS1 pin 3: ON, pin 4: ON None 1 stop bit

Modbus slave address setting

Setting

DS2 pin 1/2/3/4 When Modbus address is set (e.g. 1, ….,

15), then Modbus RS‑485 is enabled.

OFF/OFF/OFF/OFF No Modbus address is set, this means

no Modbus RS‑485 communication.

OFF/OFF/OFF/ON

OFF/OFF/ON/OFF

Address 1

Address 2

BRR9B1V1

Communication box

4P617761-1B – 2020.10

…

ON/ON/ON/ON

…

Address 15

DS1 Switch 2 = baud rate.

DS1 Switch 3+4 = parity stop bits.

DS2 Switch 1~4 = Modbus slave address.

Installation manual

23

8 | Configuration

b

a

c

A2P

BS1

H1P H2P H3P H4P H5P H6P H7P

SS2 SS3

BS2 BS3 BS4 BS5

1234

DS1

ON

OFF

DS2

1234

120Ω100Ω

SS1

X2M

a

b

c

d

A1P A2P

INFORMATION

For more information, see the design guide of Modbus Interface DIII (EKMBDX*).

CAUTION: Precautions when setting the slave address

▪ Do NOT set the same slave address for devices connected to the Modbus master

device.

▪ Apart from the slave address set in the communication box, there are 2 other

slave addresses that cannot be set. When the slave address on the PCB for the

outdoor unit (A2P) is set to "A", slave addresses "A+1" and "A+2" CANNOT be set.

Slave address "A" is used for the outdoor unit, "A+1" is used for the capacity up

unit, and "A+2" may NOT be used.

a Modbus master device

b Communication box 1

c Communication box 2

8‒1 Settings for slave address for communication box 1

PCB A1P A2P

Address set 1 2

Unit/system Indoor Outdoor Capacity up

unit

Valid slave

1 2 3 4

Reserved

address

address

8‒2 Settings for slave address for communication box 2

PCB A1P A2P

Address set 8 5

Unit/system Indoor Outdoor Capacity up

unit

Valid slave

8 5 6 7

Reserved

address

address

8.5.2 To configure the communication box PCB for the outdoor unit and capacity up unit

Overview of buttons, switches, and other parts

Installation manual

24

a LEDs

b Push buttons (BS1~BS5)

BRR9B1V1

Communication box

4P617761-1B – 2020.10

8 | Configuration

DS1

1 2 3 4

DS2

1 2 3 4

ON

OFF

OFF

ON

SS2

120 Ω

SS3

100 Ω

SS2

120 Ω

SS3

100 Ω

OFF

ON

SS2

120 Ω

SS3

100 Ω

SS2

120 Ω

SS3

100 Ω

c DIP switches (DS1, DS2)

d Switches to set the terminating resistance (SS1~SS3)

1 Set the slave address using the DIP switches (DS1, DS2) on PCB A2P of the

communication box.

INFORMATION

Make sure to set the slave address before you turn the power ON. The setting is

invalid when the setting was done after power ON.

Slave

address

1 2 3 4 1 2 3 4

DS1 DS2 Remarks

0 OFF OFF OFF OFF OFF OFF OFF OFF Default

value

1 OFF OFF OFF OFF OFF OFF OFF ON —

2 OFF OFF OFF OFF OFF OFF ON OFF

3 OFF OFF OFF OFF OFF OFF ON ON

…

26 OFF OFF OFF ON ON OFF ON OFF

…

245 ON ON ON ON OFF ON OFF ON Maximum

effective

address

2 If needed, set the terminating resistance. You can set this setting with 2 slide

switches (SS2, SS3). If both switches are "OFF" (default setting), the

terminating resistance is 0Ω.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

8‒1 Example of slide switch settings when resistance is 120Ω

8‒2 Example of slide switch settings when resistance is 100Ω

3 Check all transmission wiring (DIII weak current).

4 Check all transmission wiring (RS‑485 weak current) from the monitoring

system to the communication box.

5 Close the communication box cover when you turn ON the power supply.

6 Set the parity using the push buttons (BS1~BS5) on the A2P PCB of the

communication box. The table below shows the setting method. Set the parity

as specified by the monitoring system.

Installation manual

25

8 | Configuration

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Initial indication Shows the initial indication in

normal conditions.

Press and hold BS1 for 5seconds. Make sure that the H1P LED has

turned ON.

Press BS2 2 times. Check the pressing count against

the LED indication.

Press BS3 once. Indicates the last setting status.

Press BS2 to

select the

desired setting.

None Factory setting

Odd —

Even

Press BS3 once. The LED indication will change

from flashing to ON.

Press BS3 once. —

Press BS1 once. Returns to the initial indication

(a)

= OFF, = ON, and = flashing.

7 Set the baud rate setting using the push buttons (BS1~BS5) on PCB A2P of the

communication box. The following table shows the setting method. Set the

baud rate as specified by the monitoring system.

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Initial indication Shows the initial indication in

normal conditions.

Press and hold BS1 for 5seconds. Make sure that the H1P LED has

turned ON.

Press BS2 once. Check the pressing count against

the LED indication.

Press BS3 once. Indicates the last setting status.

Press BS2 to

select the

desired setting.

9600bps Factory setting

19200bps —

Press BS3 once. The LED indication will change

from flashing to ON.

Press BS3 once. —

Press BS1 once. Returns to the initial indication

(a)

= OFF, = ON, and = flashing.

8 Set the stop bit settings using the push buttons (BS1~BS5) on PCB A2P of the

communication box. The following table shows the setting method. Set the

stop bit settings as specified on the monitoring system.

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Initial indication Shows the initial indication in

normal conditions.

Installation manual

26

Communication box

4P617761-1B – 2020.10

BRR9B1V1

8 | Configuration

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Press and hold BS1 for 5seconds. Make sure that the H1P LED has

turned ON.

Press BS2 6 times. Check the pressing count against

the LED indication.

Press BS3 once. Indicates the last setting status.

Press BS2 to

select the

desired setting.

Auto LED indication is the desired

1 stop bit

setting.

2 stop bits

Press BS3 once. The LED indication will change

from flashing to ON.

Press BS3 once. —

Press BS1 once. Returns to the initial indication

(a)

= OFF, = ON, and = flashing.

9 After the settings are set, reset the power supply of the communication box.

INFORMATION

The power supply must be reset before the settings of parity, baud rate, and stop

bits become effective.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

27

9 | Commissioning

9 Commissioning

INFORMATION

For more information on how to do a test run of each unit, see the installation

manual or installer reference guide of each unit.

Are the LEDs (H1P~H4P) on the PCB (A1P) flashing?

▪ H1P: DIII connection (send).

▪ H2P: DIII connection (receive).

▪ H3P: RS‑485 connection (send).

▪ H4P: RS‑485 connection (receive).

Are the LEDs (H6P, H7P) on the PCB (A2P) ON?

If the LEDs are still flashing, communication is not established.

▪ H6P ON: RS‑485 communication is established.

▪ H7P ON: DIII communication of 1 or more units is established.

Can the operation data of each address be monitored on the monitoring

system?

Make sure that the power supply to each unit is turned ON.

Check that the address set on each unit corresponds with the address

displayed on the monitoring system.

Make sure that the power supply to each unit is turned ON.

Result: If there are no problems with the operation data and the remote settings,

the H2P LED will be OFF and the H6P and H7P LEDs will be ON. The test run is then

complete for A2P.

INFORMATION

▪ Confirmation of an error takes about 12 minutes.

▪ If there is no communication from the monitoring system (e.g. monitoring system

is turned OFF, incorrect polarity or disconnection), a communication error occurs

on the RS‑485 side.

What to do in case of a communication error?

▪ The operation data cannot be checked on the monitoring system.

▪ Check all items in "10Troubleshooting"[429] and correct any problem.

▪ " 10‒1 Operation procedure step 1" [4 30] describes how you can check

some errors.

Installation manual

28

BRR9B1V1

Communication box

4P617761-1B – 2020.10

10 Troubleshooting

In this chapter

10.1 Troubleshooting for PCB for indoor unit communication ..................................................................................................... 29

10.2 Troubleshooting for PCB for outdoor unit and capacity up unit communication ................................................................ 29

10.1 Troubleshooting for PCB for indoor unit communication

What to check? How to check? Solution

10 | Troubleshooting

No Modbus

communication

Incorrect Modbus address setting was present at

power ON on the Modbus interface DIII.

No Modbus address is set (=DS2: OFF/OFF/OFF/

OFF).

During power OFF, set DS2 on A1P to

the required Modbus address. See

"8.4To set the addresses of the

indoor units"[422]. The ON/OFF

status of the DIP switch is detected

only at the time of power ON of the

PCB.

Set DS2 on A1P to the required

Modbus address. See "8.4To set the

addresses of the indoor units"[422].

10.2 Troubleshooting for PCB for outdoor unit and capacity up unit communication

What to check? How to check? Solution

Address setting of each

unit

Slave address setting DIP switches (DS1, DS2) of the communication

Data of each address can be checked on the

monitoring system.

box PCB (A2P).

Set the addresses of the outdoor

unit and capacity up unit again. See

"8Configuration"[420].

Set the slave address correctly. See

"To configure the communication

box PCB for the outdoor unit and

capacity up unit"[424].

Parity setting Parity setting on the monitoring system against

the parity setting on the communication box.

Stop bit setting Stop bit setting on the monitoring system against

the stop bit setting on the communication box.

Baud rate setting Baud rate setting on the monitoring system

against the baud rate setting on the

communication box.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Set the parity setting correctly. See

"To configure the communication

box PCB for the outdoor unit and

capacity up unit"[424].

Set the stop bit setting correctly. See

"To configure the communication

box PCB for the outdoor unit and

capacity up unit"[424].

Set the baud rate setting correctly.

See "To configure the

communication box PCB for the

outdoor unit and capacity up

unit"[424].

Installation manual

29

10 | Troubleshooting

What to check? How to check? Solution

DIII weak current

Data of each address on the monitoring system. Check the wiring of the unit with

transmission wiring

H2P is ON and H7P is flashing on the

communication box. Follow the instructions in "

10‒1 Operation procedure step 1"[430] to

diagnose the communication box.

RS‑485 weak current

transmission wiring

Make sure that the field settings are made

correctly, check whether the data can be checked

on the monitoring system.

Refrigerator connection

other than an outdoor

unit and capacity up

unit

H2P is ON on the communication box. Follow the

instructions in " 10‒2 Operation procedure

step 2"[431] to diagnose the communication

box.

PCB error H2P is ON on the communication box. Follow the

instructions in " 10‒1 Operation procedure

step 1"[430] to diagnose the communication

box.

No LED is ON on PCB (A2P).

data that cannot be checked and

correct the wiring.

Communication cannot be

established with any of the outdoor

units. Check the transmission wiring

(DIII weak current) and address

settings.

Check RS‑485 weak current

transmission wiring and correct it

(e.g. disconnection, incorrect

polarity).

Disconnect the non-CO₂ refrigerator.

Replace PCB (A2P).

Check conditions of all units (indoor unit, outdoor

unit and capacity up unit).

10‒1 Operation procedure step 1

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Initial indication

(b)

Press BS1 once. —

Press BS2 twice.

H6P flashing: RS‑485

communication error

H7P flashing: DIII communication

error (if communication is not

established with any of the

indoor units).

Installation manual

30

BRR9B1V1

Communication box

4P617761-1B – 2020.10

10 | Troubleshooting

Procedure LED indication

H1P H2P H3P H4P H5P H6P H7P

Press BS3 once

(error check).

DIII side

(c)

communication

error

RS‑485

communication

error

Board error Error of the PCB (A2P) of the

Duplicate

outdoor unit

addresses

Outdoor unit

address not set

Slave address

setting error

(a)

Remarks

Communication error of all

outdoor units.

(d)

Communication error on the

RS‑485 side. An error is detected

even when the polarity is correct.

Check the address settings and

the RS‑485 wiring.

(d)

communication box. Replace the

PCB.

Duplicate outdoor unit addresses.

Check the address settings and

DIII wiring.

The address of an outdoor unit is

not set. Check the address setting

and DIII wiring.

Slave address setting error. Check

the slave address setting and

wiring.

Press BS1 once. In normal conditions, H2P is OFF,

and H6P and H7P are ON.

(a)

= OFF, = ON, and = flashing.

(b)

The initial indication in the table shows the indication when an error is detected. If there are no communication errors, the H2P

LED is OFF and the H6P and H7P LEDs are ON.

(c)

When multiple errors are detected, multiple LEDs (H2P to H7P) are flashing.

(d)

For both DIII side and RS‑485 side, if a communication error occurs after the communication is confirmed, an error is generated. If

the communication has not been confirmed, errors are not detected.

10‒2 Operation procedure step 2

Procedure LED indication

(a)

Remarks

H1P H2P H3P H4P H5P H6P H7P

Initial indication

(b)

H6P flashing: RS‑485

communication error.

H7P flashing: DIII communication

error (if communication is not

established with any of the

indoor units).

Press BS1 once. —

Press BS2 3 times.

Press BS3 once

(error check).

Reserve

Reserve

Different

refrigerator

A non-CO₂ refrigerator is

connected.

Press BS1 once. In normal conditions, H2P turns

OFF, and H6P and H7P turn ON.

BRR9B1V1

Communication box

4P617761-1B – 2020.10

Installation manual

31

10 | Troubleshooting

(a)

= OFF, = ON, and = flashing.

(b)

The initial indication in the table shows the indication when an error is detected. If there are no communication errors, the H2P

LED is OFF and the H6P and H7P LEDs are ON.

Installation manual

32

BRR9B1V1

Communication box

4P617761-1B – 2020.10

11 Technical data

11.1 Wiring diagram: Communication box

A1P PCB (communication with indoor unit for air

conditioning)

A2P PCB (communication with outdoor unit and capacity

up unit)

A3P PCB

BS1~BS5 Push buttons (see Note1)

DS1, DS2 DIP switches (see Note1)

F1S Varistor

F1U Fuse (T, 3.15A, 250V)

H1P~H7P LED

HAP LED

11 | Technical data

SS1~SS3 Switches to set the terminating resistance (see Note

1)

T1R Transformer (220~240V/22V)

X3A~X11A Connectors

X1M~X3M Terminal strips

Field wiring

Terminal strip

Connector

Protective earth

BLK Black

ORG Orange

WHT White

YLW Yellow

HIGH VOLTAGE High voltage

LOW VOLTAGE Low voltage

BRR9B1V1

Communication box

4P617761-1B – 2020.10

MONITORING SYSTEM Monitoring system

OUTDOOR UNIT Outdoor unit

POWER SUPPLY Power supply

SWITCH BOX Switch box

Note1

Communication settings can be changed using the push buttons. For information

on how to do this, see the installation manual of the outdoor unit and the capacity

up unit.

Installation manual

33

12 | Glossary

12 Glossary

Dealer

Sales distributor for the product.

Authorised installer

Technical skilled person who is qualified to install the product.

User

Person who is owner of the product and/or operates the product.

Applicable legislation

All international, European, national and local directives, laws, regulations

and/or codes that are relevant and applicable for a certain product or

domain.

Service company

Qualified company which can perform or coordinate the required service to

the product.

Installation manual

Instruction manual specified for a certain product or application, explaining

how to install, configure and maintain it.

Operation manual

Instruction manual specified for a certain product or application, explaining

how to operate it.

Maintenance instructions

Instruction manual specified for a certain product or application, which

explains (if relevant) how to install, configure, operate and/or maintain the

product or application.

Accessories

Labels, manuals, information sheets and equipment that are delivered with

the product and that need to be installed according to the instructions in

the accompanying documentation.

Optional equipment

Equipment made or approved by Daikin that can be combined with the

product according to the instructions in the accompanying documentation.

Field supply

Equipment NOT made by Daikin that can be combined with the product

according to the instructions in the accompanying documentation.

Installation manual

34

BRR9B1V1

Communication box

4P617761-1B – 2020.10

4P617761-1 B 0000000%

Verantwortung für Energie und Umwelt

Copyright 2020 Daikin

4P617761-1B 2020.10

Loading...

Loading...