DAIKIN

INSTALLATION

MANUAL

R410A SPLIT SERIES

<INVERTER>

MODELS

ATXN2SMV187

ATXN3SMV187

ATXNSOMV187

ATXN60MV187

ATXN2SNV18

ATXN3SNV18

ATXNSONV18

ATXN60NV18

ATXN20MV16

ATXN2SMV16

ATXN3SMV16

ATXNSOMV16

ATXN60MV16

ARXN2SMV187

ARXN3SMV187

ARXNSOMV187

ARXN60MV187

ARXN2SNV18

ARXN3SNV18

ARXNSONV18

ARXN60NV18

ARXN20MV16

ARXN2SMV16

ARXN3SMV16

ARXNSOMV16

ARXN60MV16

Cepll1R

R410A c pa3,QeJlbHOIiI

In

stallation Manual

R41

OA

Split Series

Manuale d'installazione

Serie Multiambienti

In

stallationsanleitung

Split-Baureihe

Manual de instalaci6n

Serie Split

Manuel d'installation

Serie split

Mo

ntaj kylavuzlary

R41

PYKOBO,QCTBO no MOHTa>K)'

R41

OA

R41

OA

R41

OA

R41

OA

OA

Split serisi

YCTaHoBKoliI

English

Italiano

Deutsch

Espanol

Franc;ais

Turkc;e

PYCCKIiIM

~H[

(Applicable to cenified models only)

IM-5WMYJR-1113(4)-DAIKIN SIESTA

Part Number.: ROa019039397D

OUTLINE

AND DIMENSIONS

Indoor

Unit [ATXN]

TIlE MARK (

~

) S

HOW

S PIPING DIRECTION

A

RIGID

-

c

TOP

VIEW

-

t--

SIGNAL RECEIVER

j

c-_~~~~~~~~~~~~~~~~~~

BOTTOM.

LOUVER

FRONT

(INSIDE)

GRilLE

AXED

BOTIOM

SCREWS

___

INDOORUNITT

ON

t

ROOM TEMPERATURE TIIERMISTOR

(INSIDE)

FRONT VIEW

/OFF SWITCH

::::

"---

SIDE VIEW

rrc

NAMEPlATE

r--

TERMINAL

r---

BLOCK

WITHEARTII

TERMIN

AL

NOTE: PLEASE BASED

20125/35 DIMENSION REFERENCE AT PAGE 1 &

* Reco

mmended

(5 spots in all)

ON

ACTUAL INSTALLATION PLATE DESIGN IN

mOllming plate retention

spo

o

Liquid pipe

ts

~"lT-

cnd

INSTALLATION

2.

PLATE

Usc

tape

Position

Gas

pipe

mea

we

end

cnd

20/25/35

TIlE

UNIT

sure as shown.

of

a tape measure at

FOR

INSTALLATION PLATE

..

lbrough

hole

065nun

the

wall

~n

Model

20/25/35 MV

25/35

NV

A B C D E F G H I

800

859

288 212

288 209

166

166

184

184

42 46

42 46

55

55

I-I

J

56

154

56

154

All dimensions are

K L M

182

263

182

263

in

52

52

mm

D

.//

'@

l.

_____________

H

"

__

*

Reconunended

(5 spots

in

"'

___ ~ ___

!-

__

"1_

L M

mOllming piate retention spots

all)

••

A

E

lbr

ough the wall

hole

tIr

65mm

i

_J

~

Drai n ho

se

K

position

~n

Model

20/25/35

25/35

NV

* Re

(7 s

MV

conmle

pot

s in all)

~

I

ndcd mo

\ D

A B C

800

859

unting

piate retention spots

\

\.

-

""

,

.,-

Liquid pipe end Gas pipe

ALTERNATIVE

D

288

212

10

288

209

10

,

I' ·'n ., ,' I

end

INST

AUAllON PLATE

E F G H

4

141

4

141

I'

· ' ' ·

30

30

46

46

'j)'

20125/35

55

55

I ' I

All dimensions are

I

J

1

56

56

E

i

53

1

53

N/"

in

K L M

181

207

181

207

~

I

...,..-Through the wall

hol,

065mm

mm

52

52

~n

Model

50/60

MV

50/60

NV

tH

~~~

J

~==

A B C D E F G H I

10

65 310

11

24 3

\l

'"

L

~

[j

~qlli~-d="~-"~'~"

10

d

==

~

~M~_

L~:~

~

_"~

-

"~'~"d

INSTAUATION

228 190

237 190

173

173

1·

2

____

PLATE SO/(JJ

61 40 45 48 91 219

61 40 45 48 91 219

~~

-=-=-=~

"K

====:

~:

I

j

~

All dimensions are

J

Drain

ho

se position

in

mm

K L M

580

580

45

45

Outdoor

Unit

[ARXN]

~n

Model

20/25/35

~

J

r-

H I

'"

t:l

1::1

1:1

51

II

'"

273

E F o B c

A B C D E F G H I

550

658

L K L

cl

I tI

I

I

\i

I

16

14 470

1

hi

1:

1

~

.,

J

96 93

20

1

All dimensions are

o

K L M N 0

94

60

14

133

All dimensions are in mm

in

p

8 W

mm

Q

299

~n

Model

50NV

60

NV, 50/

60

3.0

MV

I

I

I

~~

I

Q

20T

LJ

LJ

LJ

['

l

A B C D E F G H I

855

628

328

520

179

46

93

149

855

730

328

520

179

46

93

149

~L

"'

J

WI

113 603 126

WI

113 603 126

c

G H

a

•

•

T

K L M N 0

164

164

15 34

15

34

~n

Model

60

NV, 50/

50NV

60

MV

p

23

23

Q

R S T U

362

73

362

73

75

75

V

8

67

7

8

67

7

1-

3

Tills

mannal

S

pecial

Before using

Tills appliance

persons.

Tills

experience

for

their s

C

hildren shOlild

• Insta

perso

experienced

• All

wiri

• Ensure that

the

the

• The

to insulation fai

•

All

movi

• Con

or

•

Risk

remain

•

DO NOT

may

fire hazards.

• K

wiri

pictures

electrical

1m

provid

adjustment may

your air

is

intended

appliance

servicing the

eep

is

1I0t

and

knowledge, unl

afet

y.

be s

lla

tion and maintenance

ns who

are

with

field wiring must be installed

ng

regulation.

the

name plate

wiri

ng

diagram.

Imit

must

be

electrical

finn that

ng,

away

ng

parts

of el

ectric

electric

plill

cause seri

the

indoor

at

least

and static

waves, static

}.

wiri

of

the unit

out the

INSTALLATION MANUAL

es

the

procedures of inst

be

nec

ess

conditi

intended

upervised

Lh

WARNING

familiar

this

type

rated

voltage

before

GROUNDED

lure

.

ng

must not

the fan

has

unit.

shock, can cause injury

power supp

power cord when

ous

electrical

and

outdoor

1m

from TVs

. {Depending

ary

oner,

plea

to

be

use

for use by

ess

they have

to ens

shou

with

local

of

appliance

in

of

the

commenci

ng wiri

to prevent

touch the

motors.

been

switc

lies

before

shocks which may result

Imi

ts,

and

on

may

be heard

allation

to suit loc

se

d by

ure

al

read this instruc

expert

or

person

s,

been

given supervision

that

they do

SAFETY PRECAUTIONS

ld

be

perfonned

code

and

regulation

.

accordance with th

unit

corresponds

ng work

possib

water piping or any

hed

OFF

before installi

or

deat

h. D

servicing.

the

power is

power

cable

radios, to preve

the

and

type

and

even when

to ensure a safe

requirement.

tion

tra

ined

users

including

by

accordi

le

iscOimec

transmission

nt

source

not play

qualified

, and

e n

ati

ona

to

that

ng

hazard

due

ng

t a

ON.

Thi

in

the

distorted

of

the

more than

children, with

of

to

ll

Ulallllal

in shop

or

with

l

s

and

good standard

carefully and

s,

ill

light

reduced

instruc

tion

the

appliance

Plea

se take

installing.

•

Do

not ins

occur.

'"

\.y

• Ens

ure

O

•

Do

uot

o O

• Eusure that the unit's

installation.

o

• Sharp

ma

y cause injury

these

• Before turning

controller

the nuis

fans

will

a

hazard

•

Do

not insta

Do

not

•

conditioner

or

oil steam

deform

•

When

into suction

•

This unit

mist

•

Do

not ins

plant

• Ensurethecolorofwires

markin

• IM

PORTANT:

C

ONDITIONER UNIT

•

Don

s

uppl

The

•

explosive atmosphere

of

keep

industry

physical, senso

con

cerning

.

note

tall

If

gas

leaks

fire

ignition.

that draina

If

the

drainage piping

cause

water

overcharge

This Imit

vercharge will

compressor.

Unsecured

edg

es

and

place

s.

's ON/

ance

tripping

start

hmling

to

service persomlel

ll

operate any hea

unit

exi

as a res

the

unit

of

is

not suitable

or

iron

powder exist or

tall

where sulphide gas

gs

are s

't lise joined

y.

equipment is

operation

it

and

Lh

of

the

is

panels w

OFF switch

the

or use

st,

ult

is

used

the

the

ame

DO

for

the

for

future

referen

011

farm

s,

or

ry or

use

oCtile

ment

appliance

CAUTION

the

following

unit

where

leakage

and

accumulates

ge

piping

leakage

the

unit.

factory pre-charged

calise

coil

surfac

hazards.

off

the power suppl

of

automatically when

uni

ts

in

this

of

exc

in

unit.

units at

to

the

NOT INS

and

not

.

arOlmd

is

connected

is

not

which

will

over-current or d

panel

is

ill

cause

es are

Avoid

to

the

the

unit.

or the

at

or near

ting

apparatllS

room

where

may callSe plas

ess

ive heat

kitchen, keep

for

factory

volta

area

like

exist

s.

of

the

outdoor

indoor

TALL

IN A LAUNDRY

twisted

wires for

intended

air conditioner

ce.

for commercial use

al capabiliti

by a

important points

ofnammable gas may

the

connected properly, it

dampe

.

closed

the un

it

potenti

from

being

y,

''OFF''

If

this

is n

power

use

r.

doorwa

to'o

mineral

tic

or

chemical

flour

llSed

ge

fluctuat

hot

spring

unit

s respectivel

OR

for use

unit.

es,

or

pe

rso

n responsible

Imit, it

may

properl

y.

n the

fumiture.

amage

after service or

to

operate noisily.

al

locations which

in

contact

set the remote

position

to

ot done, the

resmnes, posing

y.

clo

se

to

oil, oil

part

to

reaction.

away from

where

cutting

es

greatly.

or

oil

refinery

and

the

tenninal

y.

USE

THE

ROOM

.

incoming

in

a potentially

by

la

lack

when

calise

may

to

the

with

prevent

unit'

the

air

vapour

melt

or

going

oil

AIR

power

y

of

s

Disposal

Your air

un

Do

other parts

Air con

disposed

the

Batteries

legislat

requiremen

conditioning

sorted household

not

try

to

must

ditioners

of

correctly,

installer

or

must be removed from the

ion.

ts

product

waste.

dismant

le

the

be

done

by a qualified

must

be treated

you will

local authority for

is

marked

system

yourself:

at a specialized

help

more infonnatio

to

prevent

remo

\vith

this symbol. This

the

dismantling

installe

r in

accordance with

treatment facility

potential negative con

n.

te

controller

NOTICE

means

of the

and

dispose{)

that

elec

air con

ditioni

relevant

local and

for re-

use

sequences for

of

separate

1-4

tri

cal

and electronic

ng

system, treatment

national

, r

ecycli

ng

and

the

environme

ly in

accordance

products sha

of

the refri

legislation.

recovery. By

nt

and hum

wit

h r

ll

not

gerant, of

ensu

ring

an

health. Please con

elevant

local and

be

mixed with

oil

this

product

national

and

of

is

tact

-

IMPORTANT

Important

TItis product contains

Do

not vent gases into the atmosphere.

Refrigerant

GWP

(I)

GWP

Please fill

•

<D

information

type:

R410A

(I)

value: 2087.5

= Global

the factory refrigerant charge

Wanning

in

with indelible ink,

regarding

flu

orinated greenhouse gases.

Potential

the

refrigerant

of

the product,

used

• ® the additional refrigerant amount charged in the field and

•

<D

+ ® the total refrigerant charge

on

the refrigerant charge label supplied with the product.

ftlled out label must

TIle

W

onnw.lld,.......

1

8410A

I

<D=

, ,

(2)

In

case

of

mnltiple indoor systems, only I label must

indoor units connected in the refrigerant system.

Periodical inspections for refrigerant leaks

local dealer for more infonnation.

*

on

the outdoor unit

...

r------'

be

adhered in the proximity

1 factory refrigerant charge

•

s

ee

k9

unit name plate

2 additional refrigerant amount charged in the field

3 total refrigerant charge

4 contains fluorinated greenhouse gases

5 outdoor unit

6 refrigerant cylinder and manifold for charging

may

of

the product charging port (e.g. onto the inside

(2)

be

adhered*, mentioning the total factory refrigerant charge

be

required depending on European

of

the product:

of

the service cover).

or

local legislation. Please contact

of

your

all

1-5

I

Indoor

Unit

SOmm

or

more

(on both sides)

Air

filler 0

gK

I

Outdoor

INSTALLATION DIAGRAM

M.:'m

-;:=----

Unit

S.~;"l;d

•

Opening

5enice lid

Service lid

is

closing

•

Opening

I) Remove

2)

3)

opening!

type

method

the

0111

the

service lid

of

the

service lid

screws

pun

diagonally down

dllection

PuUdown

in

arrow

the

Where

a wall

or

below.

For

any

of

I Wall facing o

More wauSO More

other obstacle is

the below installation patterns, the wall height on the exhaust side should

ne

side Wall facing two sides

c::;

1200

less

I

Side View Top View

INSTALLATION

in

the path

than

100

I

or

rc-

~

I

OF

THE

of

outdoor unit's intake

More

OUTDOOR

or

than

50

Wall facing three sides

UNIT

exhaust airflow, follow the installation guidelines

be

1200mm

or

More

less.

th~

150

I

w

D

More

than

50

1-6

Top View

Unit:

nun

Drain

work.

(Heat

Pump

Unit

Only)

1) Use drain plug for drainage.

If

the drain port is covered

2)

additional foot bases

unit's feet.

3)

In cold areas, do not use a drain hose with the ontdoor unit. (Otherwise,

drain water may freeze, impairing heating perfonnance.)

by

a mOllllting base or floor surface, place

of

at least 30mm in height under the outdoor

Bottom frame

Drain

Plug

Hose (available comercially,

innerdia.l6nun

)

INSTALLATION

TIle ontdoor unit must be installed in snch a way, so as to

of

prevent short circuit

the smooth air flow.

shown in the figure. Select the coolest possible place where

intake air temperature is not greater than the outside air

temperahrre (Refer to operating range).

the hot discharged air or obstruction to

Please follow the installation clearances

OF

Installation clearances

Dimension

Minimum Distance, mm 300 1000 300

Note:

If

there

is

any obstacle higher than half,

(II)

height

in the above table.

, please allow more space than the figure indicated

A B C D

SOO

of

the unit's

THE

OUTDOOR UNIT

g

]

0

B

-.

•

E

€I

~

(>

o

Condensed

(Heat

TIlere are 2 holes on the base

water to flow out. Insert the drain elbow to one

holes.

To install the drain elbow, first insert one portion

hook to the base (portion A), then pull the drain elbow in

the direction shown

portion to the base.

the drain elbow clings to base finnly.

If

the unit

water may freeze in the base. In such case, please remove

plug at the bottom

Water

Disposal

Pump

Unit

Only)

by

Mter

is

installed in a snowy and chilly area, condensed

of

Of

Outdoor

of

Outdoor Unit for condensed

the arrow while inserting the other

installation, check to ensure that

unit to smooth the drainage.

Unit

of

of

the

the

BASE

1-7

~

CJ

A

~

~llll

l

PLUG

-

'-1,1114'1

11

DRAINELBOW

DRAIN ELBOW

+---111-

"f''4-I

---'!!!fI

Please remove side

1--

plate when cOlUlecting

.}~

the piping and

COlUlecting

&

cord

PULL

UP

INSTALLATION

OF

THE

INDOOR UNIT

The indoor unit must be installed in such a way

short circuit

Please follow the installation clearance shown in the figure. Do

not place the indoor unit where there could

shining

and

of

the cool discharged air

on

it.

Also, this location must

drainage, and

min. 50

(Space for

mainte!lallct")

be

away from doors

'-"

ReqUired space

All dimensions

so

as

to prevent

with

the hot renIDl air.

be

direct sunlight

be

suitable for piping

or

windows.

min. 50

(Space for

maimenanct')

are

in

mm

The

refrigerant piping

of

ways (left

cut-out holes

pipes carefully to the required position in order to align it with

the holes.

piping and then position it to the required direction (see fignre).

The

condensation drain hose can

Right-side, right-back

Right side piping

Wemo

here:

Left-side, left-back

or

on

For

the side

..... e pipe:

pon cover

for right-side: piping

can

be

right from the

the casing

of

and

bottom ant, hold the bottom

or

---'

l

Right-bottom

piping

Wemove

pipe:

here

pon cover g I

for right-bottom piping

or

left-bottom piping

routed to the unit in a

back

of

the unit) ,

the unit (see figure). Bend the

be

taped to the pipes.

right-bottom lliping

by

using the

number

of

the

~

~

R;,h,~oo,kpipin,

tape:.

pipe:

pipe:

pon

Bind coolant

and drain hose

together with

insulating

Remove

cover here for

left-side piping

Mounting

En

sure that the wall is strong

of the unit. Otherwise. it is necessary to reinforce the wall

with plates, beams

Use the level gauge for horizontal mounting, fix it with

5 suitable screw s for

50/

60.

In

case

diameter with a cone drill, slightly lower

(see figure).

20f25f35

Installation

the

rear

or

pillars.

piping

Plate

enough

20125/35

draws

to withstand the weight

and 7 suitable screws for

out, drill a

hole 65mm

on

the outside wall

in

\Il~~~~~~~~~~~r~~E

Remo

..... e pipe:

here:

20f25f35 (ALlERNATIVE INSTALLATION PLATE)

~ fixing screw

50

f60

pon cover Left-back piping

for left-bottom piping

Left-bottom piping

~

~

\/

~

MO=

""",

'.

/"

__

'N

Mounting plate

Left-side: piping

~

",,-

Pl"'

~

Mounting plate

(~~

Mounting plate fixing screw

I

Mounting plate J

flXing

1~8

screw

Recommended

Dimen

sion s

20/25/35

t

RecommeOOed

tetentioo.pOlS

tnOU1Iting

(5 spots

Mounting

pt:.te

in

all)

Plate

Retention

Use tape measure as

Position the end of a tape measure at

All

diml'n

SOO"'lI

sions

Spots

are

in

And

~

mm

Mount

The Unit

Onto

The

Installation

Plate

Hook the indoor unit onto the upper portion of the installation

plate (Engage the two h

with the upper edge of the installation plate). Ens

hoo ks are properly seated on the installation plate

oo

ks at the rear top of the indoor unit

ur

e that the

by

mov ing

it to the left and right.

How

To

Attach

The

Indoor

Unit

Hook the claws of the bottom frame to the mounting plate.

How

To

Push up the marked area (at the l

Remove

The

Indoor

Unit

ower

part

of

the front grille)

to release the claws .

20/25/35 (ALTERNATIVE INSTAllATION

t

R=

......

ndrd

IIIOUIlIint

I

pipe eDd

plair

All

All

(S

spOOl

",:ill)

Uquid

pipe eDd

G~

50/60

t

RI'COllllliE'llded

(7 spots

o~'

mounting

in

all)

plate retention spots

'.~~

4.1

91

Hole With Cone Drill

Inside

Wall

embedded pipe

(Field supply)

......

PLATE)

R:lrntiao

spOOl

dimensions are in

diml'nsions are

Outside

Caulking

in

mm

mm

Mark

Fro nt grille

When str

ends

of

interconnecting

wires

in advance,

right ends

insulating tape.

Water

Drainage

ipping

of

wires with

Hang in

the

bind

Piping

door unit' s hook

Wire guide

here.

(rear side)

Momning plate

TIle indoor drain pipe must be in a downward gradient f

smooth drainage. Avo id situations that are likely to cause

water to leak.

Water Drainage

••

w

Retention

Wa~

leaking •

Wrong

End dipped

mto

water

Drai n

(2)

Corrw

Wa~

leaking'

@ @ @

W=,

Wrong

or

Wall

hole

cover

(Field supply)

Lh

CAUTION

• Do not install the unit at altihlde over 2000m for both

indoor and outdoor.

1-

9

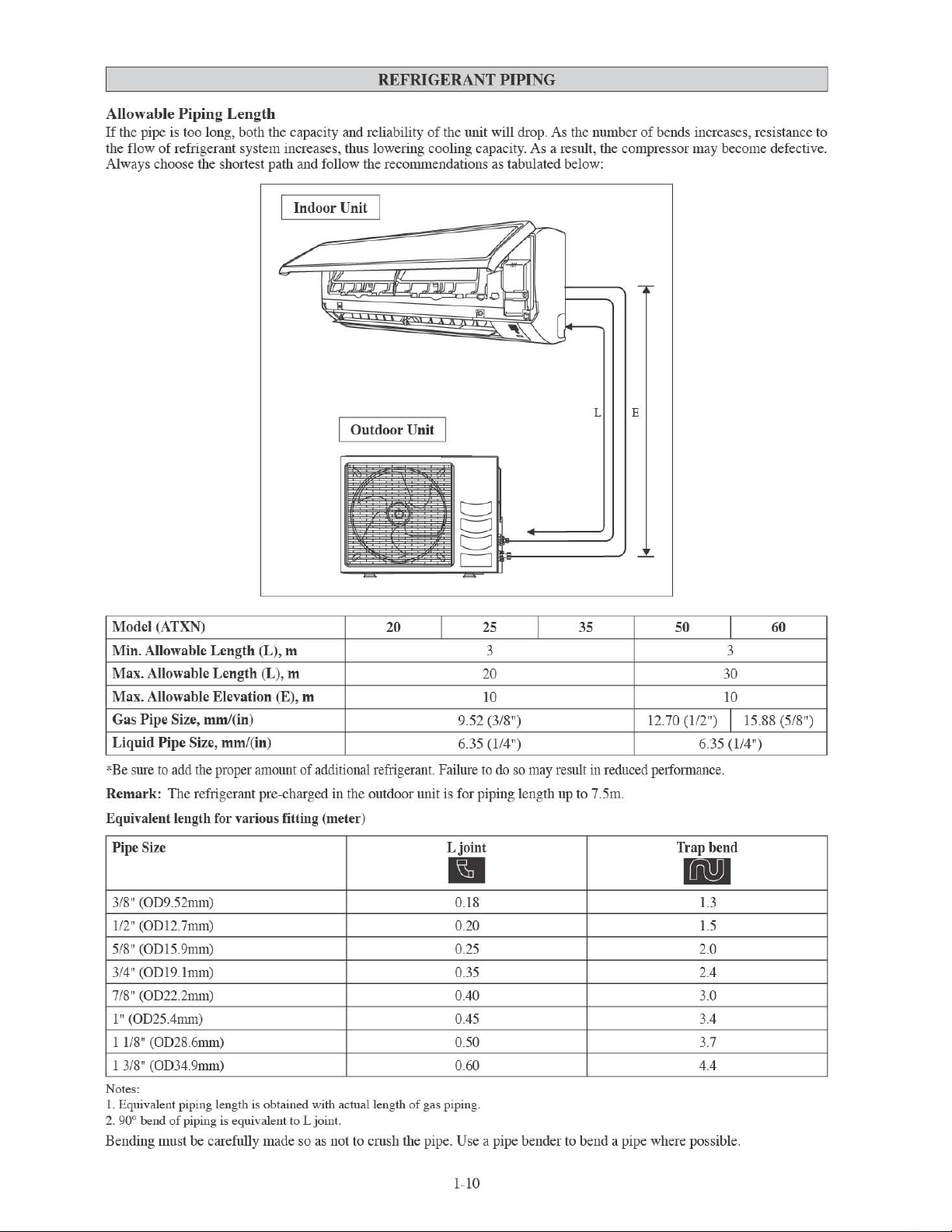

REFRIGERANT

PIPING

Allowable

If

the pipe is too long, both the capacity and reliability

the fl

Always choose the shortest path and foll

Piping

ow

of refrigerant sys

Length

tem

increases, thus lowering cooling capacity.

I Indoor Unit

ow

the recommendations as tabulated below:

Outdoor Unit

of

the unit will drop .

As

the

number

As

a result, the compressor may become defective.

of bends increases, resistance to

E

Model

(ATXN)

Min.

Allowable

Max.

Allowable

Max.

Allowable

Gas

Pipe

Liquid

Pille

"'

Be

sure to

Remark:

Equivalent length for

Pipe

Size

3/8" (OD

1/2" (ODl2.7mm)

5/8" (ODl5.9mm)

3/

4" (ODl9

7/8"

(OD22.2mm)

1" (OD25Anlln)

1 1/8" (OD28.6mm)

3/8" (OD34.9mm

1

Notes:

1.

Equivalent piping length is obtained with

90° bend

2.

Bending mnst be carefully made

Length

Size,

mml(in

Size, mml

add

the proper amou

TIle refrigerant pre-charged

9.52mm)

.1mm

)

of

piping is equivalent to L joint.

(L), m 3 3

Length

Elevation (E)

various

)

(L), m

)

(in)

, m

nt

of additional refrigerant. Failure

fitting (

so

20

in

the outdoor unit is for piping length up to 7.5m.

meter)

acntallength

as

not to

of

gas piping.

cmsh

the pipe. Use a pipe bender to bend a pipe where possible.

25

I

20

10 10

9.52 (3/8")

6.

35

(114")

to

Ljoint

•

0

.18

0.20

0.25

0.35

O

AO

O

A5

0.50

0.60

do

so may res

I

35

12

ult

in

reduced perfonnance.

50

.70

(1

/2") I

6.

Trap

11.1

1.3

1.5

2.0

2A

3.0

3.4

3.7

4A

30

35

(114")

bend

I

15.88 (5

60

/8")

1-10

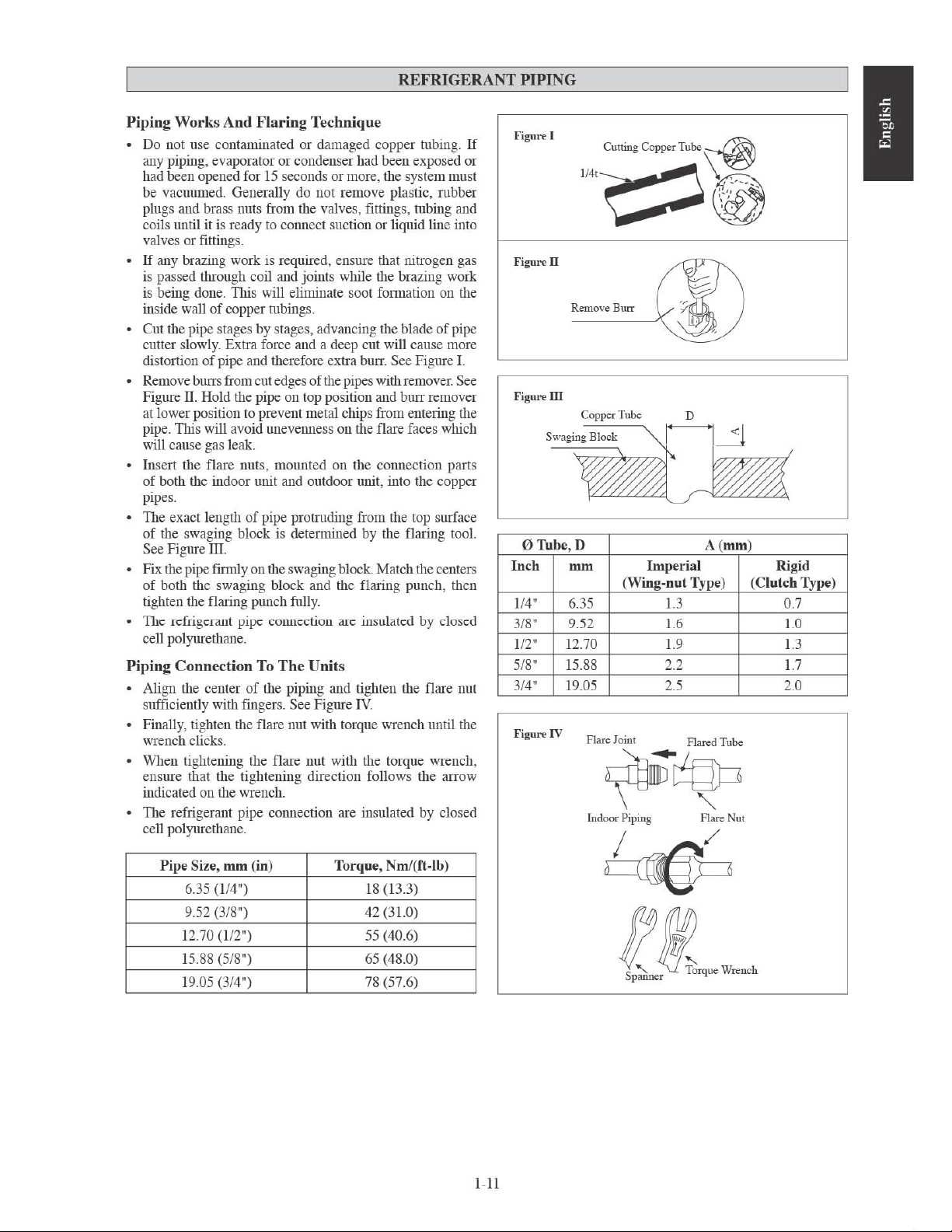

REFRIGERANT PIPING

Piping

Piping

Works

Do not use contaminated or damaged copper tubing.

any piping, evaporator or condenser had been exposed or

had been opened for

be vacuumed. Generally do not remove plastic, mbber

plugs and brass nuts from the valves, fittings, hlbing and

coils until

valves or fittings.

If

any brazing work is required, ensure that nitrogen gas

is passed through coil and joints while the brazing work

being done.

is

inside wall

Cut the pipe stages by stages, advancing the blade

cutter slowly. Extra force and a deep cut will cause more

distortion

Remove burrs from cut edges

Figure II. Hold the pipe on top position and burr remover

at lower position to prevent metal chips from entering the

TIus will avoid unevenness on the flare faces wluch

pipe.

will cause gas leak.

Insert the flare nuts, mounted on the connection parts

of both the indoor

pipes.

TIle exact length

of

the swaging block is determined by the flaring tool.

See Figure III.

Fix the pipe fmuly on the swaging block. Match the centers

of

both the swaging block and the flaring punch, then

tighten the flaring punch fully.

TIlC refrigerant pipe connection arc insulatcd by closed

cell polyurethane.

Connection

Align the center

sufficiently with fmger

Finally, tighten the flare nut with torque wrench until the

wrench clicks.

When tightening the flare nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe cOimection are insulated by closed

cell polyurethane.

And

Flaring

it

is ready to connect suction or liquid line into

lltis

will eliminate soot fonnation on the

of

copper hlbing

of

pipe and therefore extra burr. See Figure I.

mut and outdoor mut , into the copper

of

pipe protmding from the top surface

To

of

the piping and tighten the flare nut

Technique

15

seconds or more, the system must

s.

of

the pipes with remover. See

The

Units

s.

See Figure

IV.

of

If

pipe

Figun'" I

Cutting Copper Tube

1I4'

~\Y;::

~

" '

.;','

, .

----

~

Figun'"

II

Remove

Burr

Figun'"

III

CoppcrTube

sw"m_l1~

,

o Tube, D A

Inch

114"

3/8" 9.52 1.6 1.0

112"

5/

3/4" 19.

Figun'"IV

mm

(Wing-nut Type)

6.35

12.70 1.9

S"

15.SS 2.2 1.7

05

Flare Joint

~~

Indoor Piping Flare Nut

0

~!

(mm)

Imperial

(Clutch

1.3

2.5 2.0

flared

Tube

Rigid

0.7

1.3

,

Type)

Pipe

Size,

mm

(in)

6.35

(114")

9.52 (3/S") 42 (31.0)

12.70 (112")

15.SS (5/S") 65 (4S.0)

19.05 (3/4")

Torque,

NmJ(ft,lb)

IS (13.3)

55 (40.6)

7S

(57.6)

~

I-ll

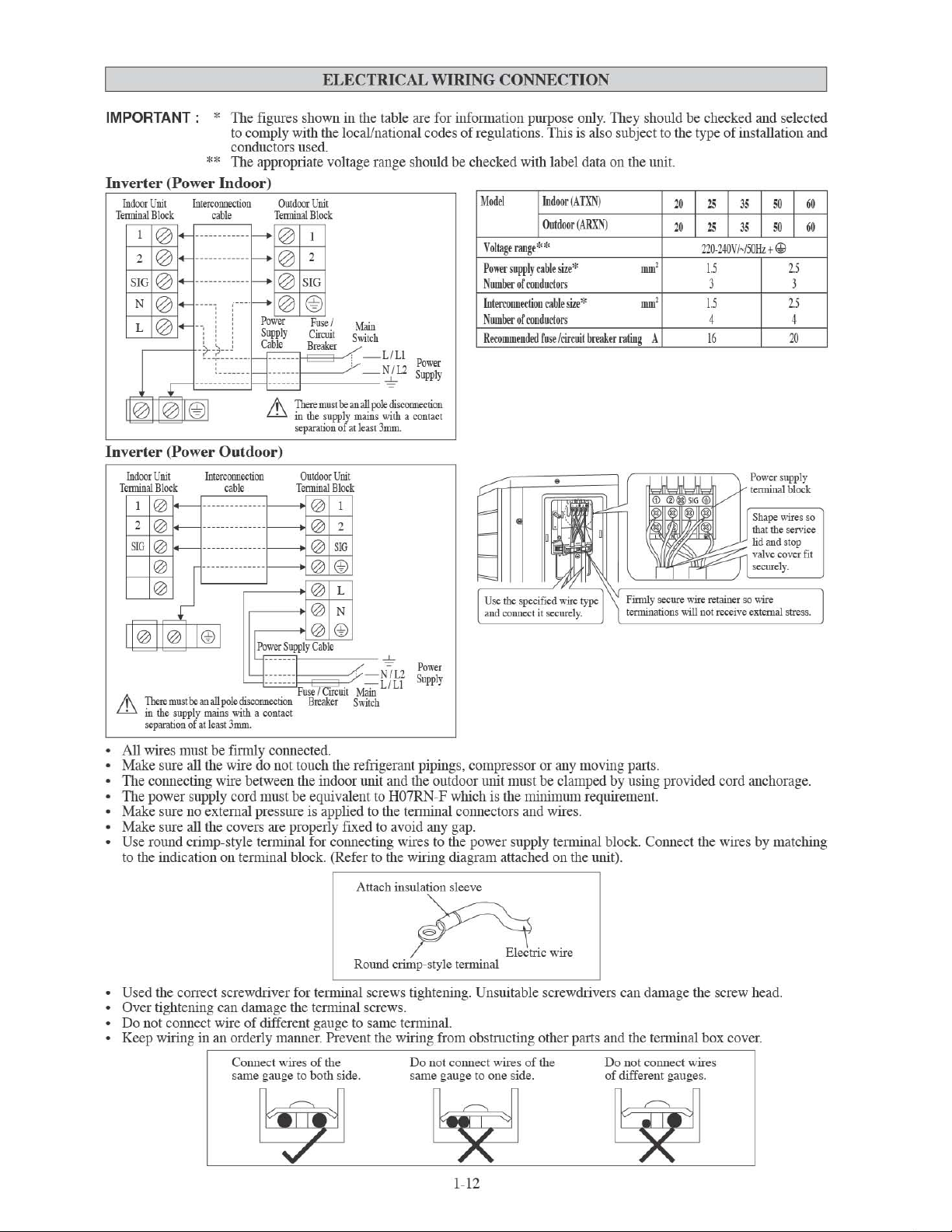

ELECTRICAL

WIRING CONNECTION

IMPORTANT: *

**

Inverter

Terminal

(Power

Indooc

Unit

Interconnection

Bloc

k

cable

1

2

SIG

N

L

------------

@ @

------------

@

..........

@

@

@

--

I

~L

~

....

--'-

II@II@II@I

Inverter

Terminal

ill

(Power

hxIoor

Unit

Block

1 @

2

@

51G

@

@

@

II@II@

n..

Th=mustbcanallpokdisconncctJoo

in

the

separation

~

~

~

j

supply

of

I

nterconnection

------------

--------------

--------------

-------------

I@I

mains

at

kast

The figur

to comply

conductors used.

Th

Indoor

i.

........

~~~~~~~~

es shown

wi

e appropriate voltage range should be checked with label data on the unit.

in

th the local/national codes of regulation

the table are for

infonnati

on pu

rpose

onl

s.

TItis is also subject to the type of installation a

y_ They

)

fum(A

**

Out

ble

rablt

fnst

doo

r (

sizt*

sizt

l

cirruit

TXN)

ARX

*

break

N)

Outdoor

Unit

Terminal

Block

~

~

_-

~

~~~

Power

Supply

EB"""

1

2

@

@

SIG

@ @

F~

I

M.m

Cirruil

S\\1tch

of

at

LlLl

N 1

~

pole

with

kasl 3mm

-------

~~~~~~~

6

~~:'7y~ns

separauon

""~

12

Supply

disconncct:ion

a contact

ll

OOcl

VoHag

t

range

Po

Wl'r su

Nu

mber

of

Inte

rronn

Number

or

R

erommtnded

pply ca

rondnclors

ect

ion

rondnclors

Outdoor)

OuiOOor

Unit

Terminal

"b'

--

-----<

-----<

-----<

-----<

Block

@ 1

@ 2

@

51G

@ @

@

L

@

N

@ @

Power

Supply

Cable

Fuse

i C

Breaker

iiC

uit

<'

Main

Switch

N 1

LfLi

12

Power

Supply

with

31IU1L

.......

.......

.......

a contact

should

mm

'

mm

'

er

raling

A

Finnly secure ",ire

tcnuinations will

be

checked and selected

-,

l<I

l<I

1<

'"

-,

1<

'"

220-240

VI~I

50Hz t~

1.5

3 3

1.5

4 4

16

Power supply

j--,=

Shape

that the service

lid and stop

valve cover

seeurdy.

re

taioer

so

receive ex

",ire

tCTllilI stre

00{

"

"

,;",I

15

25

2Il

block

",ires

nd

OJ

OJ

so

fit

ss.

All wires must

Make sure all the wire do not touch the refrigerant pipings, compress

Th

e connecting wire betwe

The po

wer supply cord must

Make sure no exte

Make sure all the covers are properly fixed to avo

U

se

round crimp- style tenninal for c

to the indication

be

finlll y connected.

en

mal

press ure is appli

on tennin

al block. (Refer to the wiring diagram attach

the indoor unit and the outdoor unit must be clamped by using provided cord anchorage .

be

equivalent to H

ed

Oime

07RN

to the te

cting wires to the power supply te

Attach insulation sleeve

-F which is the minimum requirement.

nnin

al connectors and wires.

id

any gap.

n

Used the correct screwdrive r for te

Over tightening can damage the te

Do not co

Keep wiring

nn

ect wire of different gauge to same te

in

an orderly maIme

Connec

t wires of the

same gauge to both side.

Round crimp-

nmn

al screws hghtening. Unsllltable screwdrivers can damage the scr

nnin

al screws.

r.

Prevent the wiring from obstmcting other parts and the tenllinal box cove

sty

le temun

al

nnin

al.

Do not connect wires

same gauge to one side.

1~1

2

or

or any movin

nnin

ed

tri

ow

of

the

al block. Conn

on the unit).

rr

,

g parts.

Do not connec

of

different gauges.

ect the wires by matching

ew

head.

r.

t wires

SPECIAL PRECAUTIONS

R410A

is a new HFC refrigerant

ozone laye

1.6 times

proper installation

r.

The

working pressure

lilgher tllan conventional refrigerant (R22), thus

/se

rvicing is essential.

Never use refrigerant other than

which is

POE

which

de

signed to operate witll R41OA.

or

PYE

oil is used as lubricant for R41

is

different

from

compressor. During installation

must be taken not to expose tile

to moist air. Residual

components can absorb moisture from tile air.

To pre v

ent mischarging, the diameter

on tile flare valve is different from that

POE

which

does not damage the

of

tlils

R410Ain

the

mineral

or

servicing, extra precaution

R410A

or

PVE

oil

new

refrigerant is

an air conditioner

0Aco

oil use

system t

in

tile piping and

of

tile service port

of

R22.

WHEN

mpressor,

d f

or

R22

oo

long

DEALING

Use tools

Tools exclusively for

ho

se, pressure gauge, gas leak detector, flare tools, torque

wrench, vacuum

As

an

than

R22

correctly.

If

the refri gerant gas leakage occurs during installation/

servicing , be sure to ventilate fully.

comes into contact with fire, a poisonous gas

When

allow air

VACUUMING AND CHARGING

Vacuuming is necessary to eliminate all moisture and air from the system.

Vacuuming

Except

refrigerant , the indoor unit and tile refri gerant connection

pipes must be air-purged because tile air containing moisture

that remains in tile refrigerant cycle may cause malftmction

of

the compressor.

Remove

Connect the center

pump.

Connect the charging gauge to tile service port

valve.

Start tile vacuum pump. Evacuate for approximately

nilnutes. TIle evacuation time varies with different vacuum

pump

mov

Caution

If

tile gauge needle

to

check

and outdoor

tile next step.

Close the valve

pump.

On

liquid valve (2 way) (in anti-clockwise direction) with

ke

y for hexagon sacked screw.

Charge

TIils operation must

precise weighing machine.

into the outdoor

port.

Remove

Connect tile

suction service port center

tile

service

Start tile air conditioner unit.

Open tile gas cylinder

When

tile milt, close the

valve.

Disconnect the service

tile service port cap.

The

for

the outdoor

Piping

And

unit

The

which

Indoor

is

pre-charged

Unit

with

the caps from the valve and tile se rvice port .

of

tile charging gauge to tile vacuum

of

tile 3-way

30

capacity.

ed

Confmn

tllat the charging gauge needle has

towards -760mmHg.

doe

s not move to -

760

mmHg, be

sure

for leakage at flare type connection of the indoor

milt and repair the leak before proceeding to

of

tile changing gauge

tile outdoor milt,

open

tile suction valve (3 way)

and

stop the vacuum

and

4mm

Operation

be

done

by

using a gas cylinder and a

The

milt nsing the suction valve via tile service

the service port cap.

low

pressure s

lilgh pressure side of the gauge. Purge tile air from tile

ho

se.

the required refri gerant quantity is

low

additional charge is topped-up

ide

of

the charging gauge to tile

of

the cylinder tank and

and

low

pressure charging valve.

pumped

pressure s

ho

ide

and the gas cylinder

se from service port. Put

clo

into

back

se

,----------------------,

WITH

and

R410A

R410A UNIT

materials exclusively for refrigerant R41OA.

R410A

are manifold valve, charging

pump

and

refrigerant cylinder.

air

conditioner

incurs

higher

units, it is essential to choose the

If

the refrigerant gas

installing

or

rem

oving an air conditioner,

or

moisture to remain in the refrigerant cycle.

lUGH

LOW

PRESSURE GAU

GE

VALVE

PRESSURE

CO!'.'HGURATION

PURGE

lUGH

PRESSURE

CO!'.'HGURATIO:-.l

PURGE

HOSE

pressure

copper

may

GAUGE

OIECKVALVE

BY

CHARGIXG

GAUGE

CHECK

BY

CHARGL"G

pipes

occur.

do

not

OF

AIR

VALVE

OF

AIR

1-13

ADDITIONAL

CHARGE

TIle refrigerant is pre-charged in

is not

neces

sary.

If

the piping length is

Additional

Indoor

Outdoor

Additional

Examllie:

ATXN25 &

Additional

refrigerant

(ATXN)

(ARXN)

charge

ARXN25

charge

[glm]

with

= 4.5[m] x

=

9O.0

the

charge

outdoor

[g]

unit.

more

than

per

additiona11m

If

the

piping length is le ss

7.5m, then

20

20

20 20

12m

piping length, additional piping length is 4.5m.

20[glm]

[g]

INDICATOR

IR

Signal Receiver

When an infrared remote control operating signal has been

transmitted, the signal

as

below

to confmll acceptance

ON

to OFF 1 Long Beep

OFF

to

Pump

Others

Cooling

The table shows the LED indicator lights for the air conditioner

unit under nonnal operation and fault conditions.

TIle

conditioner unit.

The heat pump units are equipped with an

sensor whereby

by switching automatically to either

according to the

ON 2 Short

down I Cool force on

UnitlHeat

LED indicator lights arc located at the side

receiver

Pump

it

will provide reasonable room temperature

temperattrre set by the user.

on

the

indoor

unit will

of

the

signal transmi ssion.

I Short Beep

Unit

"cool" or "heat" mode

respond

Beep

of

the air

"auto" mode

use

the

additional charge

length

25

25

LIGHTS

LED

Unit

than

as

tabulated

Indicator

7 .Sm,

35

35

20

Thu

Lights

ON/OFF

then

additional charge after

value

as indicated in the table.

50

50

20 20

s,

~

ill

Receiver

for

-+

E±==c

:

./

Coohng

___

-+-+---ON/OFF switch

vacuuming

60

60

~

,,(~

UmtlHeat

ill

Receiver

oollHeat

Timer

Sleep

Pump

LED

Indicator

~

Lights: Normal

MV

/JX

[(5]

~~,

(GREENJRED)

0

G~'

0 0

= =

0 0

= =

0

G~'

0 0 0

0 0 0

0

G~'

0

G~'

ct

= =

ct

G~'

O

ON

NV

[(5]

CooUHEAT

(BLUEIRED)

0

,,~

0

,,~

0

,,~

0

,,~

ct

ct

,,~

Operation

[ed]

ct

Blinking

And

Fault

Conditions

Model

Operation

Cool mode

Heat mode

Auto mode in Heating operation

Auto mode in Cooling operation

Timer

on

Sleep mode on

Fan mode on

Dry mode on

Defrost operation

Unit error

1-14

For

CoolinglHeat

Pump

Unit

Mode

l:

ATXN20/25/35

ARXN20/

50

46

43

40

o

10

25

/35

COO

14

15

I

NDOOR TE

LING

1920

MP ("eW

B)

OPERATING RAN

23

25

§

!3

-

o

-

20

18

10

20

GE

'--

__

--'

10 15

INDOOR TE

___

HEAT

ING

-'-20

MP

__

___"'----'--_ _'

("C

DB)

25 27

30

Model: ATXN50/60

ARXN50/60

50

46

43

40

i£'

30

t

~

20

"

f-

"'

'"

10

§

~

0

o

-

20

.:------':-:':,---:::-:::---:::---:!_

10

COO

1415

LING

1920

23 25

DB

: D

ry

bul

b

H

EATING

20

18

$'

10

C

"

'-

~

0

;-

§

:... -10

0,

o -

15 . __

. _ . _ .

_~.

--"--"'--'7-''-''--''--''--''

-2O'---~---~-----"-~--'

10

15

20

WB: Wet bul

25 27

b

30

I

NDOOR TEMP ("eW

B)

1-1

INDOO

R

TE

MP ("CDB)

D

B: Dry

bul

b

WB: Wet bulb

5

1.

Open

the

front

panel.

Hold the panel at the recesses

(2 recesses

stops.

2.

Pull

out

Push a little upwards the tab at the center

filter, then pull

3.

Take

virustatic

Hold the recessed parts

four claws.

Titanium Apatite Fiiler (Bio Fiiler)

Attached Concept

oft

the

the

on

right and left sides) and lift

air

filters.

it

down.

Bio filter

with

bacteriostatic,

functions.

of

the frame and unhook the

on

the main unit

it

until

of

each air

AIR FILTER

4.

Clean

See figure.

it

When shaking off remaining water, do not wring the

filter.

S.

Set

virustatic

front

Insert claws

Close the front panel slowly and push the panel at the

3 points.

The air filter and Bio filter with bacteriostatic,

vimstatic functions have a symmetrical

horizontal direction.

the

or

replace

air

ruter

functions

panel.

(Ion

each

filter.

Bio filter with

bacteriostatic,

vlruslatic functions

and

Bio

filter

with

bacteriostatic,

as

they

were

and

of

the filters into slots

each side and 1 in the middle.)

of

the front panel.

close

fonn

the

in the

<±tltt---=

_.--..

...

---

* Rio Filter ami Titanium Apatite Filter are optional accessories

Installation

hemletically-sealed b3g.

Procedure

for

Bio

Filter

Take it out Bio Filter packs in a

3t

we

time

of

installation.

LhCAUTION

Please use this Bio Filter during

Storage,

Operation

(1) cannot deodorize the

(2) cannot clean the air. (4) may cause odo

To order Bio Filter, contact the service shop where you bought tile air conditioner.

handling

The lifetime

In case you do not use tllis Bio Filter right away, please

subjected to direct sunlight, high temperatures and/or

There can be slight differences between Bio Filter color because

on

the mlit perfonnance.

Please open tllis bag right before you use it. Bio Filter should remain unopened and sealed in its packaging

right before usage. (It may cause perfonllance deterioration

To avoid danger

remove the Bio Filter. Keep out

If

you keep tllis Bio Filter for a long time, please keep it unopened and store in a cool place avoiding direct

sUlllight.

Please dispose tile old Bio Filter as nonflammable garbage after use.

and

disposal

of

tllis Bio Filter is about a year after opening.

of

suffocation and any unexpected accident, please dispose tile plastic bag immediately after you

with

dirty

filters:

air.

dry

season

methods.

of

reach

such as winter.

don't

lligh hunlidity.

of

babies and children.

(3) results in poor heating or cooling.

place the Bio Filter in any place where it will be

of

or

quality change.)

ur.

Slip the Filter in between Filter frame and

Titarumn Apatite Filter.

Filter frame

o!'

=""

Bio Filter

Titanium Apatite Filter

the manufacntring reasons, there is no effect

Ulltil

1-16

SERVICE AND MAINTENANCE

Note is valid for

Service

Indoor

Indoor unit

Parts

air

filter

Turkey

only:

The

lifetime

1.

Remove

illlukewann

2.

Rinse the filter well and dry before placing

3.

Do

1.

Clean any dirt or dust on the grille or panel by wiping

soaked in lukewann water (below 40°C/

solution.

2.

Do not use gasoline, volatile substances

any dust adhering to the filter by using a

not use gasoline, volatile substances

of

water (below

unit.

• Avoid direct contact

of

chemical reaction.

1.

Open

the

front

Hold

the

(2 recesses

stops.

2.

Remove

the

While lifting the front panel further, slide it to the right

and

pull it to the front side. TIle left rotating shaft is

detached.

pull it to the front side to remove it.

Slide the right rotating shaft to the left and

panel

on

front

of

any coil treatment cleaners on plastic part. 1b.is may

panel.

at

the

right

recesses

and

left sides) and lift it until it

on

the

panel.

our

products

Maintenance

40

°C/I04°

Lh

CAUTION

main

unit

is

ten

(10)

years

Procedures

vacuum

F)

with a neutral cleaning detergent. 2 weeks.

it

back

or

chemicals to clean the filter. necessary.

104

°F) and a neutral detergent 2 weeks.

or

chemicals to clean the indoor

cleaner

or

wash At least once every

onto the unit. More frequently

it

with a soft cloth At least once every

cause

plastic part to defonll as a result

Period

More frequently

necessary.

if

if

3.

Attach

the

front

panel.

Align the right

with the grooves and push them all the way in.

Gently close the front panel.

center on the front panel.)

and

left rotating shafts

(Push

of

the front panel

both

ends and the

\,~

1-17

Don't to

When

For

compmUld, scmbbing

After cl

uch

the metal parts

removing

cleaning, do not u

ea

ning.

When

or

attaching the front panel, support the panel securely with hand to prevent

mak

The

e sure that the front panel is securely fixed.

LhCAUTION

of

the in

doo

r unit. It may cause an injury.

it

from falling.

se

hot water above 40°C, benzine. gasoline, thilmer, nor other volatile oils, polishing

bru

shes, nor other

Unit

Is

Not To

han

Be

d stuff.

Used

For

An

Extended

Long

Period

Of

Time

Operate the unit for 2 hours with

th

e following setting.

Operating mode : cool

Tem

perature :

3Q

°C/86"F

Remove the power plug.

If

you

ind

epende

circuit

o

ff the circ

Rem

ove

th

e remo

TROUBLESHOOTING

For

any

enquiries

conditioner

conditions

1.

TIle co

conditioner unit is started. for the compre ss

and

mpr

2. TIle air conditioner unit does not operate.

3. TIle air fl

ow

on

spare

unit

is

noted, immediately switch

causes

essor does not

is t

for

oo low.

part

, please

some

simple

Fault

oper

ate 3 minute s after the a

contact your

ofT

the

troubleshooting

ir

authorized

power

suppl

tips.

-

Protection again st frequent starting. Wait for 3to 4 minutes

-

Power failure,

-

TIle power plug is disc

-

It is possible that yo

in

correctly.

-

If

the fault persist aft

contact the air conditioner unit install

-

TIle air filter is dirty.

-

TIle doors or windows are open.

-

TIle air suction and disc harge are cl

-

TIle regulated te

are using an

nt

electric

for your unit, cui

uit.

the

batteri

es

te contro

dealer.

l.

When

y to

the

Causes I Action

or

to start operating.

or

the fuse needs to

ur

er

mper

unit.

ahrre is not high enough.

in

any

malfunction

Check

Olme

cred.

delay timer h

all these verifications, please

the

be

replaced.

as

been set

er

ogge

of

following

.

d.

the

air

fault

4.

Dischar

5. C

ond

6. Water fl

If

the

fault

ge air fl

ensation

on

ow

ing out from the a

persists

ow has

bad

odo

the front air grille

ir condition

, please

caU

ur.

your

of

the indo

local

or

unit.

er

mtit.

dealer I serviceman.

1-18

-

Od

oms may be cau se d by cigarettes, smoke particles,

et

c.

whi

perfume

-

TItis is caused

od

of

peri

-

TIle set te

setting and operate the mtit at ltigh fan speed.

-

Switch o

ff

ch might have adher

by air

oper

ation.

mperatm

e is too low, increase the te

mtit a

nd call dealer.

huntidity after an extended long

ed

onto the coil.

mperatm

e

Unit.

Interna

DISEGNI E DIMENSIONIS

[ATXNj

IL SEGNQ

(

~

)

MOSTRA

LA

DIREZIONE

A

DEl

TUB!

c

VISTA

DALL'

ALTO

t--

RICEVITORE

SEGNALE

'---_~J~~~~~~~~~~~~~~~~~L

J

IN

IN

BASSO

t

FERITOIADI

AERAZJONE

NOTA: IN BASE ALLA EFFETTrVA INSTALLAZIONE DESIGN DELLA PIASTRA

L'INSTALLAZIONE

vm

INSERlTE

FRONTALE (ALL' I

A

20125/35

NELLA

NTE

DIMENSIONE PIASTRA RlFERIMENTO A PAGINA 1 & 2.

BASSO

GRIGUA

RNO)

t

VISTA

-

UNITA

INTERRUTIORE ON/

TEMPERATURA

(ALL' INTERNO)

FRO

NTALE

DI

INTERNA

OFF

AMBIENTE

DELL

~~

""--

VI

STA

LATERA

TERMOSTATO

'VNITA PER

r

r--

r---

LE

PIASTRA

MORSEITlERA

CONTERMINALE

AmRA

t Punt; di ritenzione raccomandati per la piastra di

montaggio (5 punt; in

'"

0

~i

Modello

20/25/35

25/35 NV

MY

tc11

H

tUIIO)

0

--liE!>

0

0=0

=

0

0 0 0

00=

=0

0=

=0

0=

=00

0

Estremita del tubo

A B C D E F G H I

8

00

288

859

288

L

M

A

delliquido

LASTRA DI INSTALLAZIQ

212

166 184

209

166

184

Utiliuare

Posizione

misura di nastro, come mostralo .

l'estremittt di una misura di nastro

o

20f25f35

o

o

o

55

55 56

o

o

Estremittl del tuho del gas

NE

42 46

42 46

o

o ·

o 0

o

56

E

J

154 182

154 182

..

F

Foro nel muro

di 0 65mm

Posizione del

tubo

di scarico

K L M

263 52

263

52

2-1

Thtte Ie dimensioni sono in

mm

D

.//

l.

_____________

'@

H

Estremit~

"

__

del mho del liquido

t Punti di ritcnzionc raccomandati per la piastra di montaggio

(5

punti

in

MIO)

••

,,,

___ ~ ___

...

__ ~ _____

____

L M

IN

ALTERNATIVA

__________________________________

A

EstremitA del

PIASTRA

tubo

del gas

OJ

INSTALLAZIONE

?JI-!

-'"

K

20/25135

E

i

_J~

Tutte

Ie

dimensioni sono in mm

Foro

nel

muro

di

065mm

Posizione dellUbo di scarico

~i

Madella

20/25135

25/35

MV

NV

t Punti di rileozione raccomandati per

(7 punti in tutto)

_ \ D

800

859

\

~l

'n

I ' n

~.~

.

'"

D D

f\

O.

,\1.)/

r

-

H

EslImlitli

J

L M

A B C D E F G H

288

212

104

del

U

288

la

piastra di montaggio

-

'n'

tubo

delliquido

141

209

104

141

-

'n

I

'X

U

flfl/

--'

L

Estmtll

del

A

LASTRA DllNSTALLAZIONE 50/60

tuoo

del

30

30

' -

g~

'n

46

46

I'

.

~._

r-

n

55

55

I

I

56

153

56

153

E

K L M

J

181

181

207

207

52

52

~l

Foro

nel

muro di 0 65mm

~

(~

Of

\I.

~

K

1'--

Thtte

Posizione del tubo

Ie

dimensioni sono in mm

di

seanco

~ni

Modella

50/60

MV

50/60

NY

A B

1065

1124

310

310

C

228

237

D E F

190

173

190

173

2-2

61

61

G

40

40

H

45

45

I

48

48

K L M

J

91

219

91

219

580

580

45

45

Vnita Esterna [ARXN]

j~E~mF

2,0

Jr

-

"'~

k1

I,

I::l

'"

_D

".-

_____

H I

I

I

I

I

<>

B ____

t1

1::

1

1:

1

~

t:J

~,._

c_.,

Thtte

o

Ie

dimensioni sono in mm

-

~ni

Modello

20/25/35

3,0

A B C D E

550

658

51

II

L K

rl

I

I

o

F G H I

273

16

1

LJ

LJ

LJ

c-=J 1

14 470

L

I

30

p

I

11B1

1B

f-=

1f-

---:;t

96

p

K L M N 0

J

93

94

60

14

133 8 W

Thtte

Ie

z

dimensioni sono in mm

c

G H

Q

299

L

It'

•

~i

Modello

50NV

60

NV, 50/

~ni

Modello

50NV

60

NV, 50/

60

60

MV

MV

A B C D

855

628

328

855

730

328

p

Q

R S

23

362

73

23

362

73

520

520

75

75

E

F G H

17

9 46

179 46

T U

8

67

67

8

2-3

93

93

V

7

7

149

149

I

WI

WI

I

J

T

K L M N 0

J

11

3

603

126

11

3

603

126

164

164

15

15

34

34

MANU

II

preseute

mauuale

Degli

adatlamenti POSSO

Prima

di

utilizzare

Questo apparecchio

da

parte

di perso

II prese

nte

es

perienza e COll

loro

Ie

istruzioni

Tenere i bambini sotto

• L'i

nstallazione e la

qnalificato, competeute

leggi e regolamenti

•

Tutti gli

alia

regolamentazione

•

Prima

presentato

corrisponda a quello

•

Dotare

rischi

originati

• I fili

elettrici

rotanti dei

•

Prima

manutenzione,

• n

rischio

tutte

Ie

procedure

• N

ON

rimuome

acceso.

•

Mantenere

il

cablaggio

per

evitare

sorgente

pi

udi

descri\

il

e d

lle

non

apparerrhio

oscenza, a

per I'uso

Lh

allacciamenti

di

procedere

pill

avant

il

condizionatore

da

non

motori

di

installare

accertars.i

di

scosse

restanti fouti

di

assisteuza e manuteuzione.

Questo

pu6

l'unita

di

trasmissione

imrnagini

di

onde

elettriche

Imdidistanza}.

ALE

'e

come

IlO

cOlldizionatore,

es

addette.

nOll e destiuato

la supen'isiolle

procedere

rin'

larsi

tiuato

all'll

menD

chI'

dell'appare«hio.

AVVERTENZA

manutenzione

in

questa

in

agli

i,

della

eventuali deficienze

devono

del

veutilatore.

il

elettriche

di

il

cavo

causare

interna e quella

distorte e scariche

geuere

vigore.

elettrici

devouo

elettrica

in

allacciamenti secondo

accertarsi che

rete.

di

una

presa

toccare

ne i condotti

condizionatore 0 di

che

s.ia

spento

PUQ

alimentazione

di

alimentazione

seri

shock elettrici e pericolo d'inceudio.

ad

almeno

, si

possono

all'installaziolle

uec

essa

ri

per

Ipggere attentarnente

so

da

parte

di

all'lI

so

,"eug

di

un

adllito

essere

di

apparecchi e al

essere

il

voltaggio

di

TERRA

del

sistema

(OFF).

les.ioni 0 morte.

di

corrente

quando

esterna, il

1m

statiche.

sentire

da

ano

eseguiti

dell'acqua,

procedere

cavo

di

distanza

scariche

nOll

devouo

vigore.

causare

D'INSTALLAZIONE

rispondl're a particolari esigeuze loc

pt'rsone esperte 0 (onnate

parte

poste sotto

per e\'ita

dl'lroudizionatore

Ie

presenti

di

persolle, indll

la supen'isione

re

che gioc

istruzioni

hino

NORME DI SICUREZZA

eseguite

da

personale

corrente

delle

comorrueu1ellte

10

schema

elettrico

dell'apparecchio

al

[me

di

prevenire

di

isolamento.

ne

ad

interventi

prima

di eff

il

condizionatore

di

alimentazione

da

TV

{A

secouda

statiche

i

gli

organi

di

Scollegare

ettuare

e

e

e

e r

adio

,

del

tipo

e

anche

a

per ass

Consen'arle

ill

negozi, nell'iudustria legg

si

bambini, con

di

una

con

l'apparecchio.

Durante

•

•

•

•

• I

•

•

•

•

•

•

•

•

•

•

icllraru

e il

corretto

alL

per

ogni

ridotle

pl'rsona

Non

fughe

~

\..y

Verificare

installati.

O

Non sOl'foccaricare

o

Dopo

rimeltere a posto

O

bordl

possono

con

Prima

dl'l

noci\'a

automaticamente

lesioni

Non

Non

al c

so

no prew

fusione 0 la

o

di

Quando I'unit

da

Questa

pre;enti

forte

Non

petrolifere

Accertar

contr

IMPORTANTE: NON INS

C

ONDIZIONATORE

Non

L'apparecchio

esplosh'o.

caparita

res

pousabile

I'installazione, wrificare

procedere

di

gas

.

Pericolo d'incelldio

intorno

che i condotli

Un'

installazione

danneggiare

L'apparecchio e precaricato

Qualsiasi

il

compressore.

l'installazione 0 gli

Una

difettosa

fiuJzionamento.

aflilati e Ie

causare

tali

aree.

dl speguere

telecomando suUa

dl'lI'mlitit III

al

personale

installare

mettl're

in

ondizionatore d'aria 0 non

nti

olio

deformazione

una

reazione

Hitare

chI.' I'mlitii

unitii

nebbie

osc

illazione

install are

in

cui e prewnt

si

chI.' i colori

asse

gui

dei

usare

fili

fllllzionameuto

ereuil'llza futura.

era 0 in

fisiche, se

della

loro

Lh

CAUTELA

all'installazione

al

sovraccarico

Ie

fmlzione

ii t utilizzata

non t idonea

Ie

congiunti e intrecriati

non t destinato aU'

in

condizionatore.

di

illcorretta

il

mobilio.

il condizionatore.

provoca

internnti

il

pannl'llo

chiusura

superfici

pericolo

di les

I'app

arec

posizione "Off"

caso

contrario,

quan

do

si

riaccende

di

servizio

unita sui \'ano

apparecchi

minl'rale

0 \'

dl'lla

chimica.

in

la aspiri.

di

olio

da

taglio

dl

tensione.

unitii

in

aree

e g

dei

dl'lI'unit

D'

ARIA

fili

morsetti

in

cOlldiziolli

azil'ude agricola 0 all'uso

nsoriali 0 mentali

sicurezza

0

che

accurataml'nte i punti seguenti.

in

luoghi

don poss

caso

di

flIghe 0 di

drenaggio siano stati

PUQ

causare

in

fabbrica.

una

sonacorrente e PUQ

di

di

del

dl'lIa serpentina sono

chio, impostare I'intl'rruttore ON/

ed

apori

curin

all'utiliz

as solforoso.

manutenzione

chiusura.

pannello e causa

ioni. E\'

itare

in

modo

Ie

ventole

dell

I'

apparecchio, causando

agli

utenti.

della

porta 0 nl'll

peril

utiliuare I'unitii

riscaldaml'nto

da

olio, rio

plastica a se

0 polnri

quali

dl'll'unita est

TALLARE 0 UTILIZZARE

IN UNA

a,

tenl're

zo

in stabilimenti

Ie sorgl'nti

ii

intl'rna.

ZONA

pH

I'aliml'ntazione

uso

in

ml

guito

la

metalliche

ambiente

di sic

urezza.

commHdale

, 0 sen

za

tale

concentrazioni

delle

di

di

entrare in

da

'unita

e sue

in

potreb

dl'l

farina

calde 0 Ie

l'rna

LAVANDERIA.

la

pe

rso

na

ano

nrificarsi

correttamente

penlite

d'acqua

danneggiare

accertarsi

nunori

durante

possibili

aree

contalto

e\itare

l'apertura

iniziano a ruotare

pericoli

\'icinanze

troppo

1111

ambil'nte

be

pro\'ocare

calore

ecc

lontana

in

don s

0 don c

rafli.llerie

corrispondano

in

ing

potl'nziahnl'nte

domta

fornisca

di

gas

e

di

il

chI.'

OFF

di

.

\irini

in cui

la

l'SS

im

modo

ono

'e

una

ai

IL

ress

o.

S

pl'Cificbe

II

dOlllestici non

N

altra

I

eviteci

Le

di smaltinu:nto

climatizzatore e contrasseguato

on

climatizzatori

batterie

cercare

parte

devo

Ie

possibili

devono

differenziati.

di

demolire

il

no

devono

sisteula

essere

eseguiti

essere

conseguenze negative

essere

tolte

trattati

con

questa

Silllbolo,

da

soli:

la

da

da1

te1ecomando e slllaitite

demolizione

un

installatore

presso

una

struttura

all'ambiente e alia

CiQ

significa

del

qualificato

speciaIiu.ata

salute

separatameute com

cbe i prodotti

sistema

di

in

conforruita

nel

dell'uomo.

AVVISO

elettrici

condizionamento,

alia

legislazione

riutilizzo,

ricic1aggio e recupero

Per

maggiori

ornlemente

2-4

ed

elettronici

nouche

locale

infonnazioni

alia

legislazione

non

possono

il

recupero

e n

azionale

dei

materiali.

contattare

locale e nazionale

essere

del

refrigerante,

vigeute

in

materia

Il

corretto

l'installatore 0 Ie

smaltiti

insieme

dell'olio e di

smaltimento

autorita

vigente

in

materia

ai

qualsiasi

del

prodotto

loca1i.

rifiuti

-

IMPORTANTE

Informazioni

Questa prodotto contiene gas fluorurati ad effetto serra.

Non liberare tali gas nell' atmosfera.

Tipo

di

refrigerante:

Valore

GWP

(I)

GWP

Compilare con inchiostro indelebile,

•

<D

la carica di refrigerante di fabbrica del prodotto ,

importanti

R410A

(I)

: 2087,5

= Global Wanning Potential (Potenziale Di Riscaldamento Globale)

sui

refrigerante

utilizzato

• ® la qualltita di refrigerante aggilllltiva nel campo e

•

<D

+ ® la carica di refrigerante totale

it

sull'etichetta di carica del refrigerante fomita con

L' etichetta compilata deve essere collocata

in

di ispezione).

1 carica di refrigerante di fabbrica del prodotto:

vedi targhetta con il nome

2 qualltita di refrigerante aggimltiva nel campo

3 carica di refrigerante totale

4 contiene gas fluomrati ad effetto serra

5

unita estema

6 cilindro del refrigerante e collettore di carica

prodotto.

prossimita della porta di carica del prodotto (ad esempio, all

dell'unita

'intemo

del copercbio

(2)

(2)

Se sono pre senti sistemi con piu unita inteme, applicare una sola etichetta*, indicante la carica totale di refrigerante eseguita

Ie

in fabbrica di hltte

E possibile che siano necessarie ispezioni periodiche per controllare evenhlali perdite di refrigerante secondo

e/o europee.

locali

unita inteme collegate al sistema refrigerante.

Per