Daikin 3MXM40N2V1B, 3MXM52N2V1B, 3AMXM52M3V1B, 3MXM68N2V1B, 3AMXF52A2V1B Installer reference guide

...

Installer reference guide

R32 Split series

3MXM40N2V1B

3MXM52N2V1B

3AMXM52M3V1B

3MXM68N2V1B

3AMXF52A2V1B

3MXF52A2V1B

3MXF68A2V1B

4MXM68N2V1B

4MXM80N2V1B

5MXM90N2V1B

Installer reference guide

R32 Split series

English

Table of contents

Table of contents

1 General safety precautions 3

1.1 About the documentation .......................................................... 3

1.1.1 Meaning of warnings and symbols.............................. 3

1.2 For the installer.......................................................................... 3

1.2.1 General ....................................................................... 3

1.2.2 Installation site ............................................................ 3

1.2.3 Refrigerant .................................................................. 5

1.2.4 Brine............................................................................ 6

1.2.5 Water .......................................................................... 6

1.2.6 Electrical ..................................................................... 6

2 About the documentation 7

2.1 About this document.................................................................. 7

2.2 Installer reference guide at a glance ......................................... 7

3 About the box 7

3.1 Overview: About the box ........................................................... 7

3.2 Outdoor unit............................................................................... 7

3.2.1 To unpack the outdoor unit ......................................... 7

3.2.2 To remove the accessories from the outdoor unit....... 8

4 About the units and options 8

4.1 Overview: About the units and options...................................... 8

4.2 Identification .............................................................................. 8

4.2.1 Identification label: Outdoor unit ................................. 8

5 Preparation 8

5.1 Overview: Preparation............................................................... 8

5.2 Preparing the installation site .................................................... 8

5.2.1 Installation site requirements of the outdoor unit ........ 9

5.2.2 Additional installation site requirements of the

outdoor unit in cold climates ....................................... 10

5.2.3 Refrigerant piping length and height difference .......... 10

5.3 Preparing refrigerant piping....................................................... 10

5.3.1 Refrigerant piping requirements.................................. 10

5.3.2 Refrigerant piping insulation ....................................... 11

5.4 Preparing electrical wiring ......................................................... 11

5.4.1 About preparing electrical wiring................................. 11

6 Installation 11

6.1 Overview: Installation ................................................................ 11

6.2 Opening the unit ........................................................................ 12

6.2.1 About opening the unit................................................ 12

6.2.2 To open the outdoor unit............................................. 12

6.3 Mounting the outdoor unit.......................................................... 12

6.3.1 About mounting the outdoor unit................................. 12

6.3.2 Precautions when mounting the outdoor unit.............. 12

6.3.3 To provide the installation structure............................ 12

6.3.4 To install the outdoor unit............................................ 13

6.3.5 To provide drainage.................................................... 13

6.3.6 To prevent the outdoor unit from falling over .............. 13

6.4 Connecting the refrigerant piping .............................................. 13

6.4.1 About connecting the refrigerant piping ...................... 13

6.4.2 Precautions when connecting the refrigerant piping... 14

6.4.3 Guidelines when connecting the refrigerant piping..... 14

6.4.4 Pipe bending guidelines.............................................. 14

6.4.5 To flare the pipe end................................................... 15

6.4.6 Connections between outdoor and indoor unit using

reducers ...................................................................... 15

6.4.7 Using the stop valve and service port......................... 16

6.4.8 To connect the refrigerant piping to the outdoor unit .. 17

6.5 Checking the refrigerant piping ................................................. 17

6.5.1 About checking the refrigerant piping ......................... 17

6.5.2 Precautions when checking the refrigerant piping ...... 17

6.5.3 To check for leaks....................................................... 17

6.5.4 To perform vacuum drying .......................................... 17

6.6 Charging refrigerant ................................................................... 18

6.6.1 About charging refrigerant ........................................... 18

6.6.2 Precautions when charging refrigerant ........................ 18

6.6.3 About the refrigerant .................................................... 18

6.6.4 To determine the additional refrigerant amount........... 19

6.6.5 To determine the complete recharge amount.............. 19

6.6.6 To charge additional refrigerant ................................... 19

6.6.7 To fix the fluorinated greenhouse gases label ............. 19

6.7 Connecting the electrical wiring.................................................. 19

6.7.1 About connecting the electrical wiring.......................... 19

6.7.2 Precautions when connecting the electrical wiring ...... 19

6.7.3 Guidelines when connecting the electrical wiring ........ 20

6.7.4 Specifications of standard wiring components............. 20

6.7.5 To connect the electrical wiring on the outdoor unit..... 21

6.8 Finishing the outdoor unit installation ......................................... 21

6.8.1 To finish the outdoor unit installation ........................... 21

6.8.2 About standby electricity saving function..................... 22

6.8.3 About priority room function ......................................... 22

6.8.4 About night quiet mode ................................................ 22

6.8.5 About heat mode lock .................................................. 22

6.8.6 About cool mode lock................................................... 23

6.8.7 To close the outdoor unit ............................................. 23

7 Commissioning 23

7.1 Overview: Commissioning.......................................................... 23

7.2 Precautions when commissioning .............................................. 23

7.3 Checklist before commissioning................................................. 23

7.4 Checklist during commissioning ................................................. 23

7.5 Trial operation and testing.......................................................... 24

7.5.1 About wiring error check .............................................. 24

7.5.2 To perform a test run ................................................... 24

7.6 Starting up the outdoor unit ........................................................ 24

7.7 Fault diagnosis using LED on outdoor unit PCB ........................ 25

8 Hand-over to the user 25

9 Maintenance and service 25

9.1 Overview: Maintenance and service .......................................... 25

9.2 Maintenance safety precautions................................................. 25

9.3 Checklist for yearly maintenance of the outdoor unit ................. 25

9.4 About the compressor ................................................................ 25

10 Troubleshooting 26

10.1 Overview: Troubleshooting......................................................... 26

10.2 Precautions when troubleshooting ............................................. 26

10.3 Solving problems based on symptoms....................................... 26

10.3.1 Symptom: Indoor units fall, vibrate or make noise ....... 26

10.3.2 Symptom: The unit is NOT heating or cooling as

expected ...................................................................... 26

10.3.3 Symptom: Water leakage............................................. 26

10.3.4 Symptom: Electrical leakage........................................ 26

10.3.5 Symptom: Priority room setting does NOT function ..... 26

10.3.6 Symptom: Unit does NOT function or burn damage .... 26

11 Disposal 27

11.1 Overview: Disposal..................................................................... 27

11.2 To pump down............................................................................ 27

11.3 To start and stop forced cooling ................................................. 27

12 Technical data 28

12.1 Wiring diagram ........................................................................... 28

12.1.1 Unified wiring diagram legend...................................... 28

12.2 Piping diagram: Outdoor unit...................................................... 29

13 Glossary 31

Installer reference guide

2

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

1 General safety precautions

1 General safety precautions

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and in the installer reference guide MUST be

performed by an authorised installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious

injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol Explanation

Before installation, read the installation and

operation manual, and the wiring instruction sheet.

Before performing maintenance and service tasks,

read the service manual.

For more information, see the installer and user

reference guide.

1.2 For the installer

1.2.1 General

If you are NOT sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.2.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the weight and vibration

of the unit.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

Installer reference guide

3

1 General safety precautions

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO2eq

1000

GWP × kg

=

=

+

kg

=

kg

=

GWP: xxx

R32

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

500

510

520

530

540

550

1.822.2

2.4

2.6

2.833.2

3.4

3.6

3.844.2

4.4

4.6

4.855.2

5.4

5.6

5.866.2

6.4

6.6

6.877.2

7.4

7.6

7.8

1.843 7.956

8.0

A

min

(m2)

Floor-standing unit

(c)

Wall-mounted unit

(b)

Ceiling-mounted unit

(a)

m (kg)

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

Instructions for equipment using R32 refrigerant

If applicable.

WARNING

▪ Do NOT pierce or burn.

▪ Do NOT use means to accelerate the defrosting

process or to clean the equipment, other than those

recommended by the manufacturer.

▪ Be aware that R32 refrigerant does NOT contain an

odour.

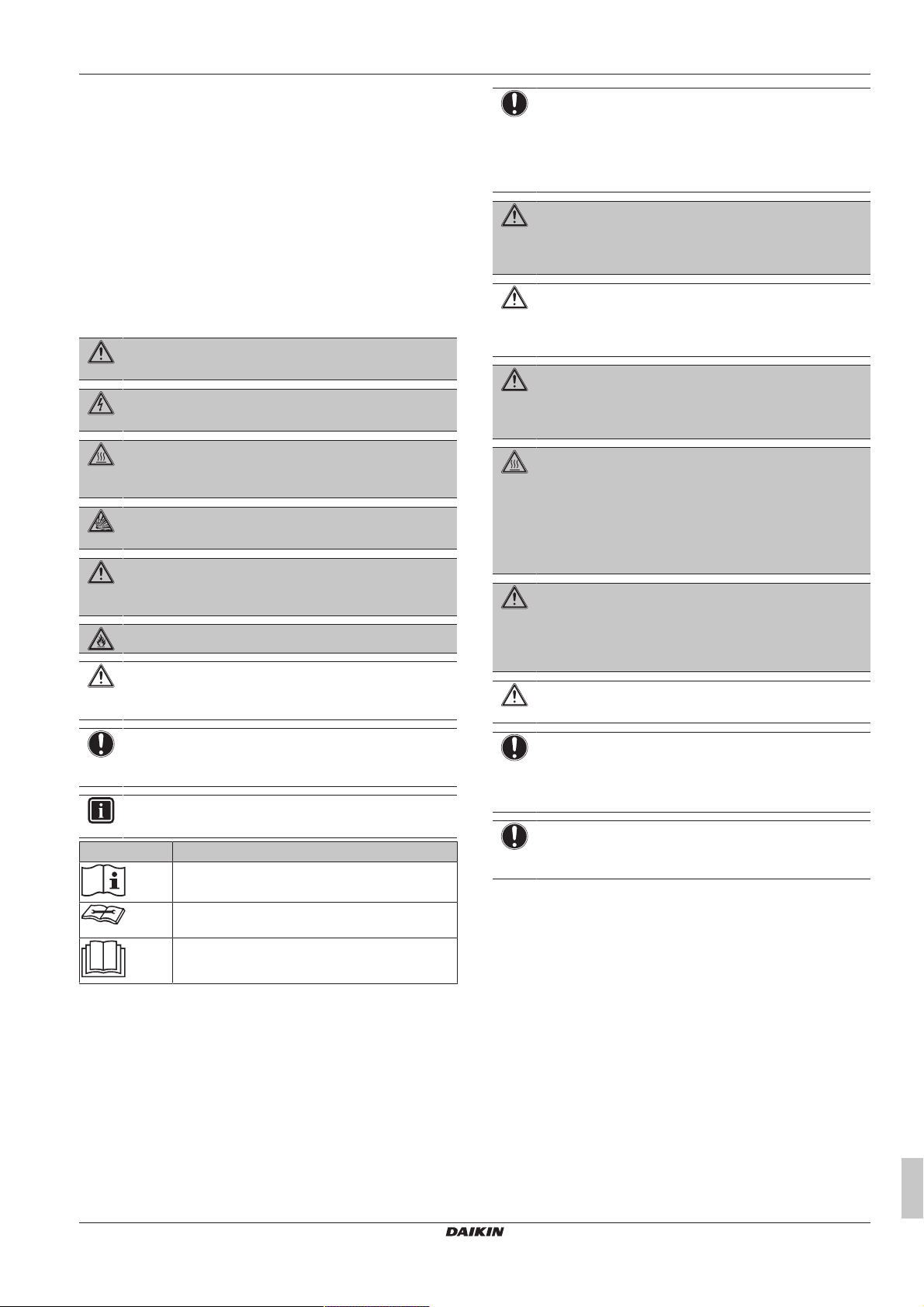

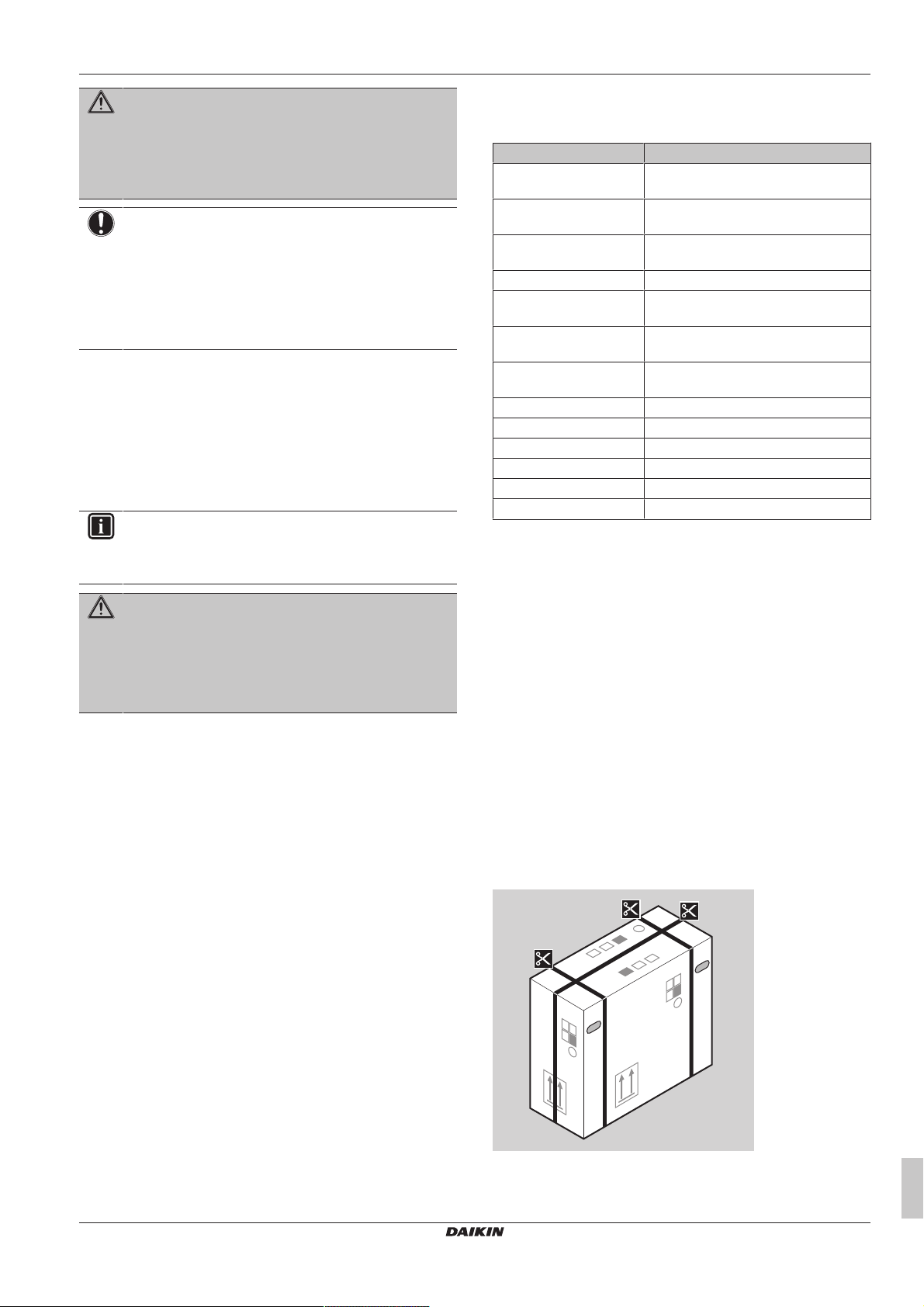

To determine the minimum floor area

1 Determine the total refrigerant charge in the system (= factory

refrigerant charge + additional refrigerant amount

charged).

2 Determine which graph or table to use.

▪ For indoor units: Is the unit ceiling-mounted, wall-mounted or

floor-standing?

▪ For outdoor units installed or stored indoors, and field piping

in unventilated spaces, this depends on the installation

height:

If the installation height is… Then use the graph or table for…

<1.8m Floor-standing units

1.8≤x<2.2m Wall-mounted units

≥2.2m Ceiling-mounted units

3 Use the graph or table to determine the minimum floor area.

WARNING

The appliance shall be stored so as to prevent mechanical

damage and in a well-ventilated room without continuously

operating ignition sources (example: open flames, an

operating gas appliance or an operating electric heater)

and have a room size as specified below.

NOTICE

▪ Do NOT re-use joints which have been used already.

▪ Joints made in installation between parts of refrigerant

system shall be accessible for maintenance purposes.

WARNING

Make sure installation, servicing, maintenance and repair

comply with instructions from Daikin and with applicable

legislation (for example national gas regulation) and are

executed only by authorised persons.

Installation space requirements

NOTICE

▪ Pipework shall be protected from physical damage.

▪ Installation of pipework shall be kept to a minimum.

WARNING

If appliances contain R32 refrigerant, the floor area of the

room in which the appliances are installed, operated and

stored MUST be larger than the minimum floor area

defined in table below A (m2). This applies to:

▪ Indoor units without a refrigerant leakage sensor; in

case of indoor units with refrigerant leakage sensor,

consult the installation manual

▪ Outdoor units installed or stored indoors (e.g. winter

garden, garage, machinery room)

▪ Pipework in unventilated spaces

Installer reference guide

4

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

1 General safety precautions

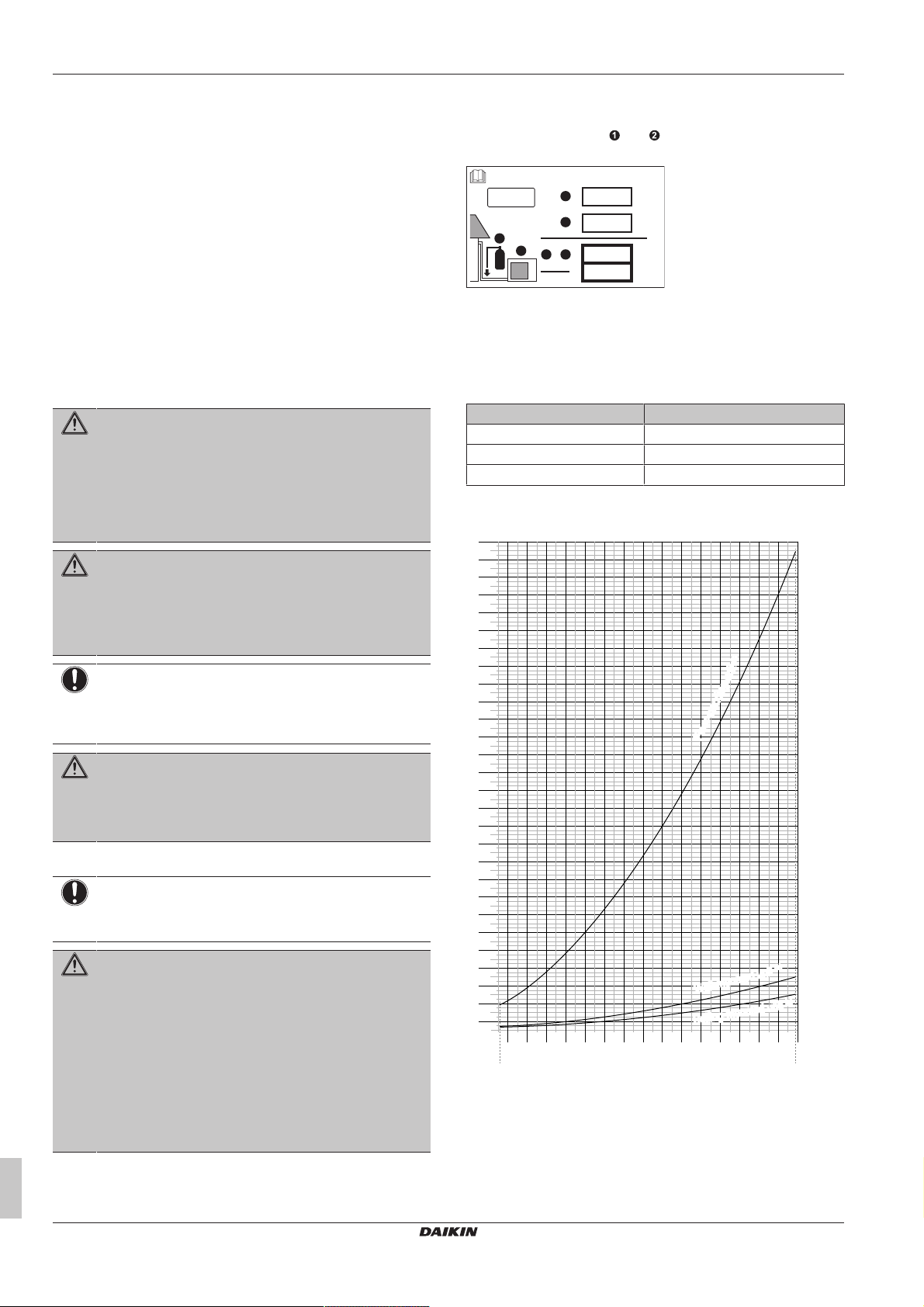

Ceiling-mounted

unit

(a)

4.6 13.4

4.6 180

4.8 14.6

4.8 196

5.0 15.8

5.0 213

≤1.842 —

5.2 17.1

≤1.842 —

5.2 230

1.843 3.64

5.4 18.5

1.843 28.9

5.4 248

2.0 3.95

5.6 19.9

2.0 34.0

5.6 267

2.2 4.34

5.8 21.3

2.2 41.2

5.8 286

2.4 4.74

6.0 22.8

2.4 49.0

6.0 306

2.6 5.13

6.2 24.3

2.6 57.5

6.2 327

2.8 5.53

6.4 25.9

2.8 66.7

6.4 349

3.0 5.92

6.6 27.6

3.0 76.6

6.6 371

3.2 6.48

6.8 29.3

3.2 87.2

6.8 394

3.4 7.32

7.0 31.0

3.4 98.4

7.0 417

3.6 8.20

7.2 32.8

3.6 110

7.2 441

3.8 9.14

7.4 34.7

3.8 123

7.4 466

4.0 10.1

7.6 36.6

4.0 136

7.6 492

4.2 11.2

7.8 38.5

4.2 150

7.8 518

4.4 12.3

7.956 40.1

4.4 165

7.956 539

m (kg)

A

min

(m2)

4.6 20.0

4.8 21.8

5.0 23.6

≤1.842 —

5.2 25.6

1.843 4.45

5.4 27.6

2.0 4.83

5.6 29.7

2.2 5.31

5.8 31.8

2.4 5.79

6.0 34.0

2.6 6.39

6.2 36.4

2.8 7.41

6.4 38.7

3.0 8.51

6.6 41.2

3.2 9.68

6.8 43.7

3.4 10.9

7.0 46.3

3.6 12.3

7.2 49.0

3.8 13.7

7.4 51.8

4.0 15.1

7.6 54.6

4.2 16.7

7.8 57.5

4.4 18.3

7.956 59.9

Wall-mounted

unit

(b)

m (kg)

A

min

(m2)

Floor-standing

unit

(c)

m (kg)

A

min

(m2)

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit. Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant MUST be treated according to the applicable

legislation.

m Total refrigerant charge in the system

A

Minimum floor area

min

(a) Ceiling-mounted unit (= Ceiling-mounted unit)

(b) Wall-mounted unit (= Wall-mounted unit)

(c) Floor-standing unit (= Floor-standing unit)

1.2.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are NOT

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case recharge is required, see the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

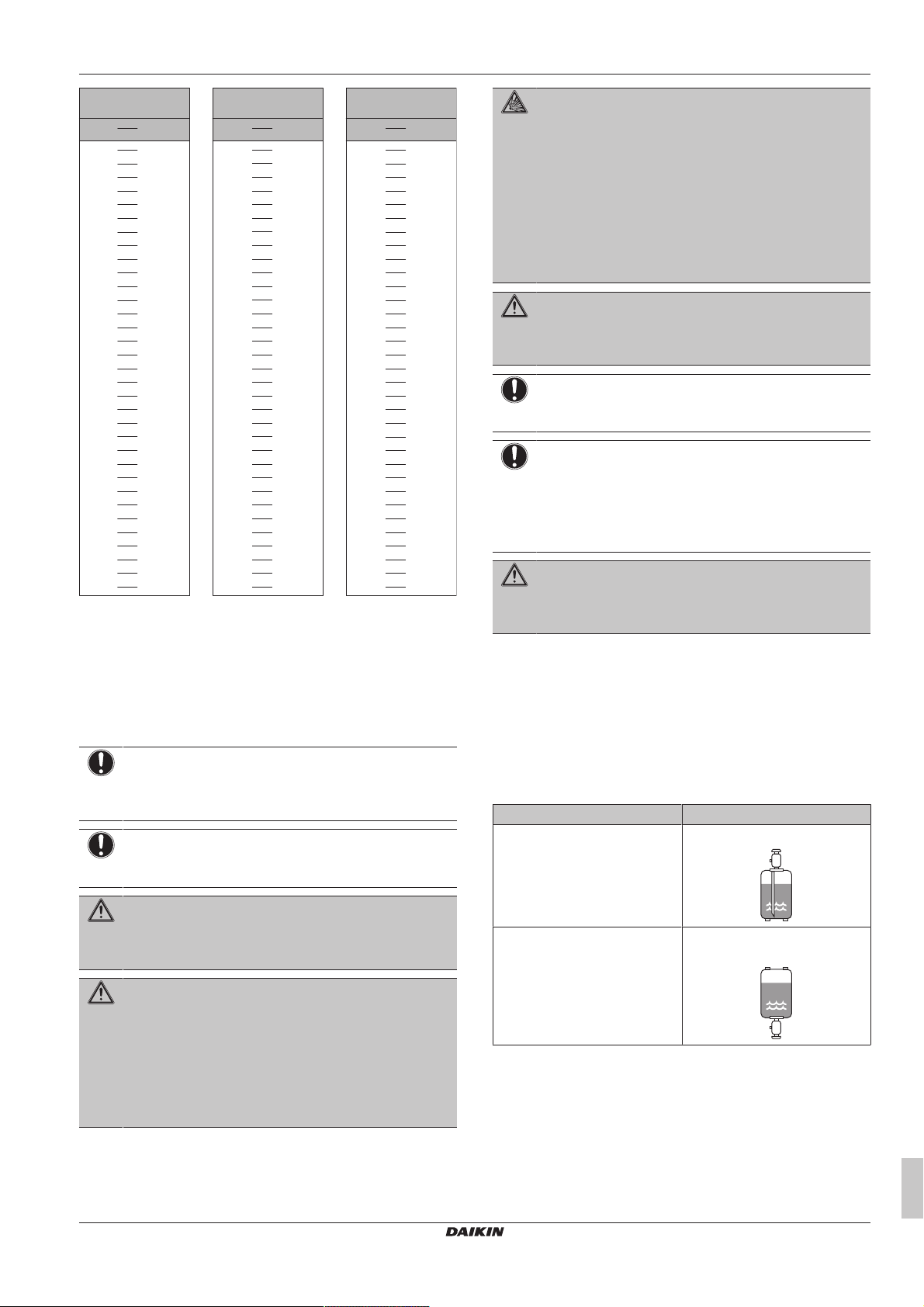

▪ Charge the liquid refrigerant as follows:

If Then

A siphon tube is present

Charge with the cylinder upright.

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside

down.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

Installer reference guide

5

1 General safety precautions

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is NOT closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

1.2.4 Brine

If applicable. See the installation manual or installer reference guide

of your application for more information.

WARNING

The selection of the brine MUST be in accordance with the

applicable legislation.

WARNING

Take sufficient precautions in case of brine leakage. If

brine leaks, ventilate the area immediately and contact

your local dealer.

WARNING

The ambient temperature inside the unit can get much

higher than that of the room, e.g. 70°C. In case of a brine

leak, hot parts inside the unit can create a hazardous

situation.

WARNING

The use and installation of the application MUST comply

with the safety and environmental precautions specified in

the applicable legislation.

1.2.5 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring MUST be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do NOT come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

When connecting the power supply, the earth connection

must be made before the current-carrying connections are

established. When disconnecting the power supply, the

current-carrying connections must be separated before the

earth connection is. The length of the conductors between

the power supply stress relief and the terminal block itself

must be as such that the current-carrying wires are

tautened before the earth wire is in case the power supply

is pulled loose from the stress relief.

NOTICE

Precautions when laying power wiring:

1.2.6 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, MUST be installed in the fixed wiring.

▪ Do NOT connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure above.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1 metre away from televisions or radios

to prevent interference. Depending on the radio waves, a distance of

1metre may not be sufficient.

Installer reference guide

6

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

2 About the documentation

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

2 About the documentation

2.1 About this document

Target audience

Authorised installers

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry, and on farms, or for

commercial and household use by lay persons.

2.2 Installer reference guide at a glance

Chapter Description

General safety

precautions

About the documentation What documentation exists for the

About the box How to unpack the units and remove

About the unit How to identify the unit

Preparation What to do and know before going

Installation What to do and know to install the

Commissioning What to do and know to commission the

Hand‑over to the user What to give and explain to the user

Maintenance and service How to maintain and service the units

Troubleshooting What to do in case of problems

Disposal How to dispose of the system

Technical data Specifications of the system

Glossary Definition of terms

Safety instructions that you MUST read

before installing

installer

their accessories

on‑site

system

system after it is configured

3 About the box

WARNING

Make sure installation, servicing, maintenance, repair and

applied materials follow the instructions from Daikin and, in

addition, comply with applicable legislation and are

performed by qualified persons only. In Europe and areas

where IEC standards apply, EN/IEC 60335-2-40 is the

applicable standard.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you MUST read before installing

▪ Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer reference guide:

▪ Preparation of the installation, reference data,…

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

3.1 Overview: About the box

This chapter describes what you have to do after the boxes with the

outdoor and indoor unit are delivered on-site.

Keep the following in mind:

▪ At delivery, the unit MUST be checked for damage. Any damage

MUST be reported immediately to the claims agent of the carrier.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

▪ Prepare the path along which you want to bring the unit inside in

advance.

3.2 Outdoor unit

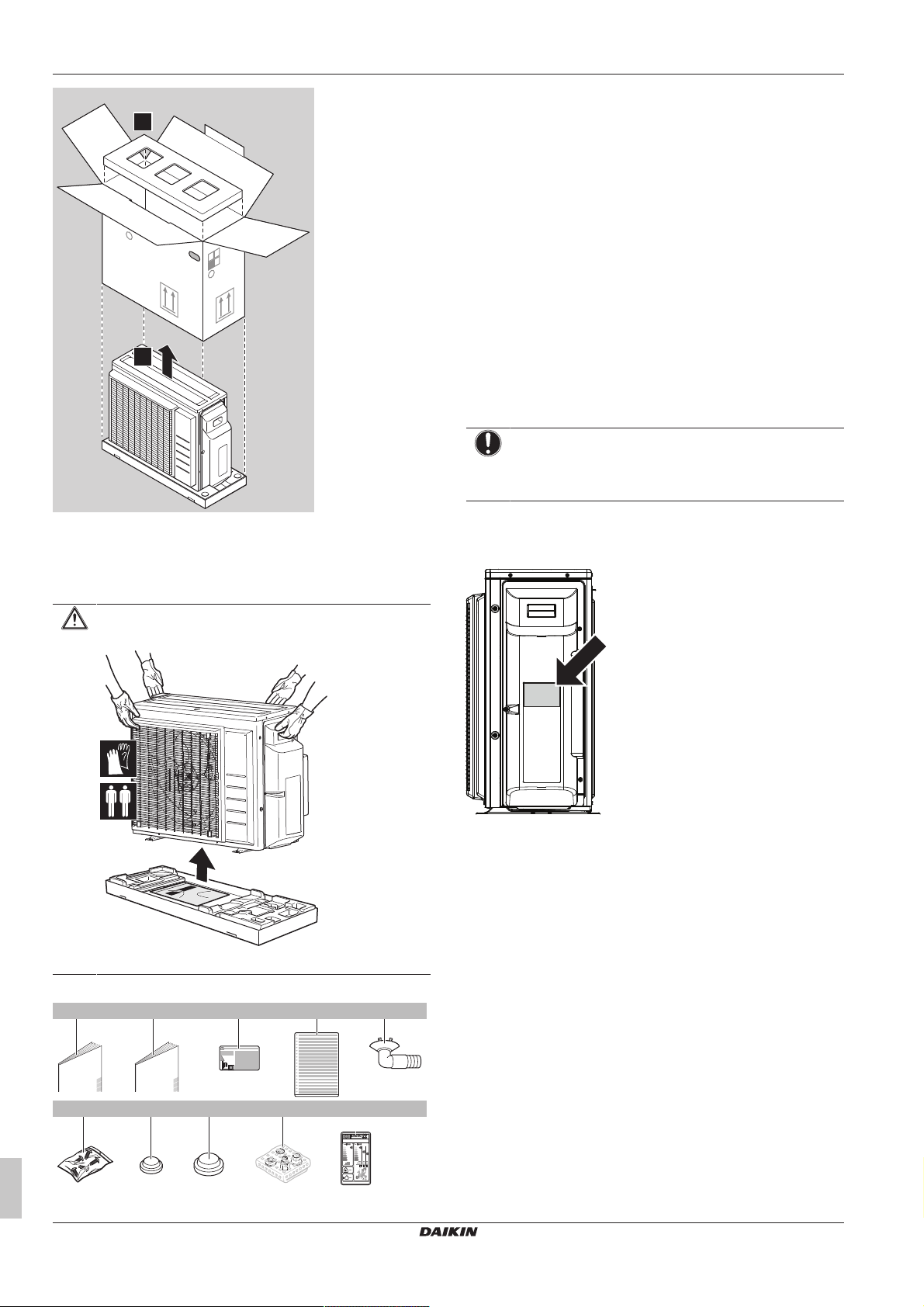

3.2.1 To unpack the outdoor unit

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

Installer reference guide

7

4 About the units and options

1

2

1× 1× 1×

1×

6×

1×

a

1×

b c d e

3×

1×

1×

i j

g h

f

c Fluorinated greenhouse gases label

d Multilingual fluorinated greenhouse gases label

e Drain socket

f Screw bag. The screws will be used for fixing the electrical

wire anchor bands.

g Drain cap (small)

h Drain cap (large)

i Reducer assembly

j Energy label

4 About the units and options

4.1 Overview: About the units and options

This chapter contains information about:

▪ Identification of the outdoor unit

4.2 Identification

NOTICE

When installing or servicing several units at the same time,

make sure NOT to switch the service panels between

different models.

3.2.2 To remove the accessories from the outdoor unit

1 Lift the outdoor unit.

CAUTION

Only handle the outdoor unit as follows:

2 Remove the accessories at the bottom of the package.

4.2.1 Identification label: Outdoor unit

Location

5 Preparation

5.1 Overview: Preparation

This chapter describes what you have to do and know before going

on-site.

It contains information about:

▪ Preparing the installation site

▪ Preparing the refrigerant piping

▪ Preparing the electrical wiring

Installer reference guide

8

a Outdoor unit installation manual

b General safety precautions

5.2 Preparing the installation site

Do NOT install the unit in places often used as work place. In case

of construction works (e.g. grinding works) where a lot of dust is

created, the unit MUST be covered.

Choose an installation location with sufficient space for carrying the

unit in and out of the site.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

5 Preparation

≤1200

>100

>100

>50

>350

>350

(mm)(mm)

a

b

b

a

>250

>300

(mm)

b

a

b

c

▪ Choose a location where the hot/cold air discharged from the unit

or the operation noise, will NOT disturb anyone.

WARNING

Do NOT install the air conditioner at any place where

flammable gas may leak out. If the gas leaks out and stays

around the air conditioner, a fire may break out.

▪ Install units, power cables and communication wiring at least 3m

away from televisions or radios to prevent interference. Depending

on the radio waves, a distance of 3m may not be sufficient.

▪ Objects placed under the unit may be damaged by water from the

drain.

WARNING

If appliances contain R32 refrigerant, then the floor area of

the room in which the appliances are installed, operated

and stored must be larger than the minimum floor area.

This applies to:

▪ Indoor units without refrigerant leakage sensor; in

case of indoor units with refrigerant leakage sensor,

consult the installation manual

▪ Outdoor units installed or stored indoors (example:

winter garden, garage, machinery room)

▪ Field piping in unventilated spaces

WARNING

The appliance shall be stored in a room without

continuously operating ignition sources (example: open

flames, an operating gas appliance or an operating electric

heater).

NOTICE

▪ Do NOT stack the units on each other.

▪ Do NOT hang the unit on a ceiling.

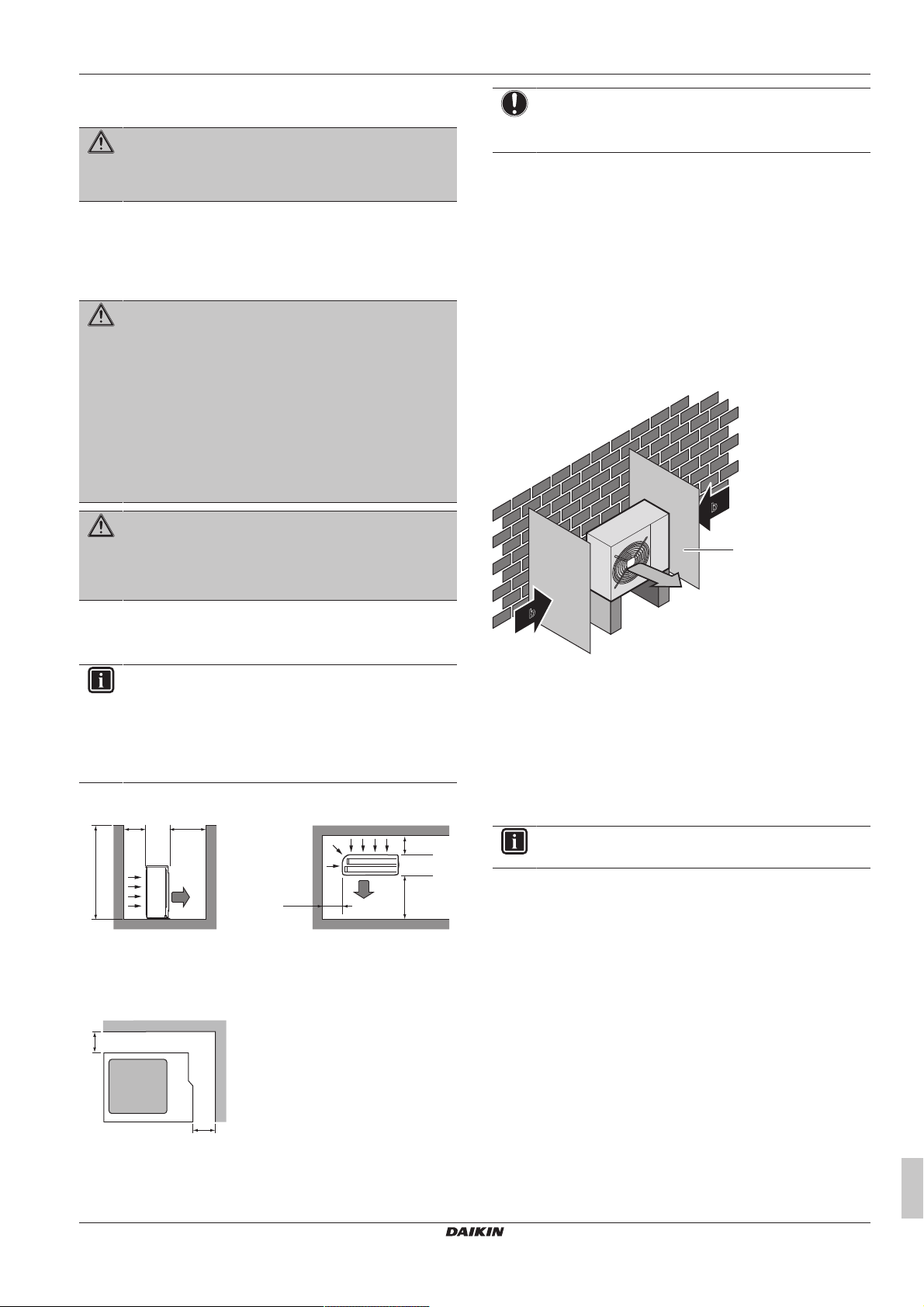

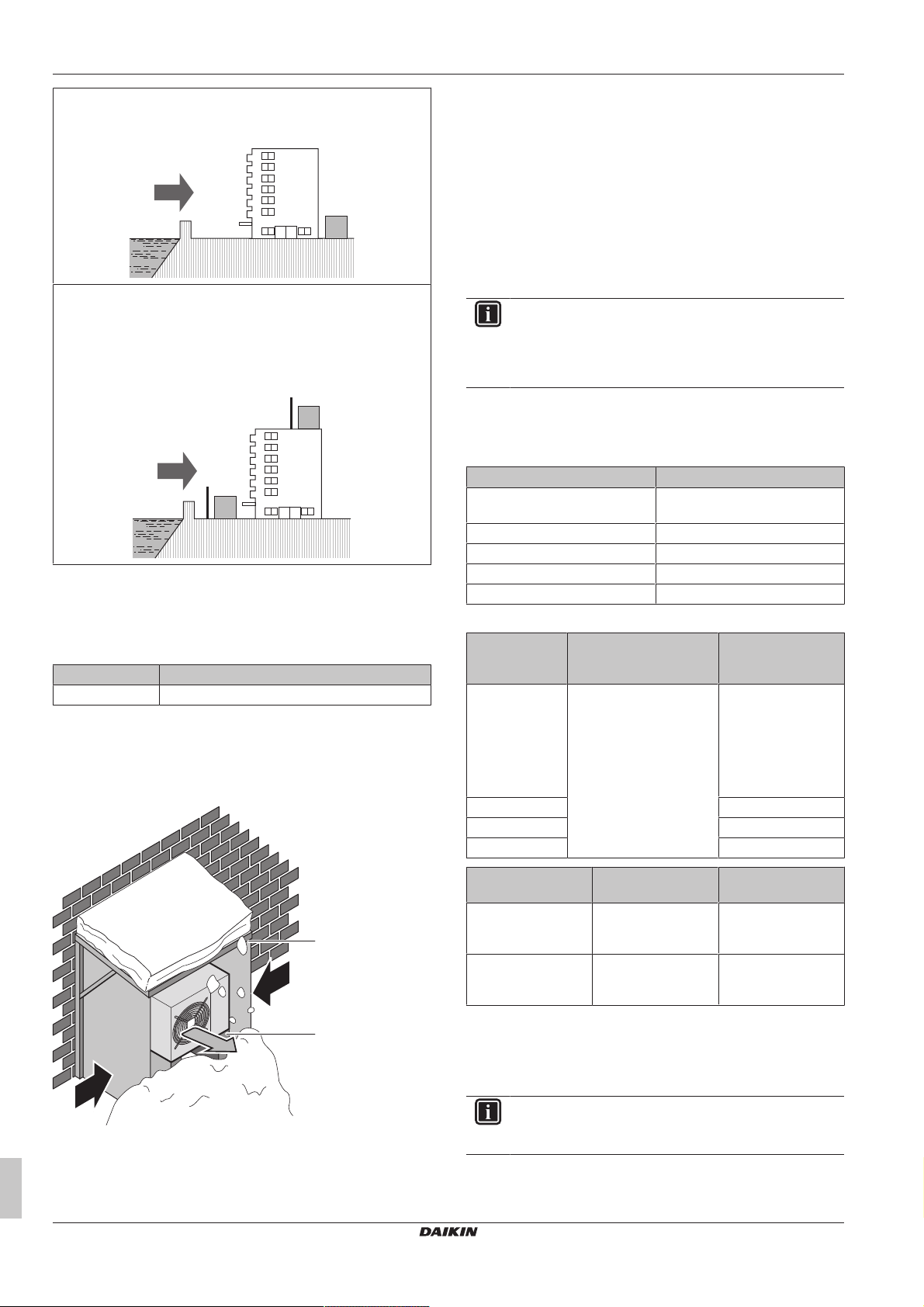

Strong winds (≥18 km/h) blowing against the outdoor unit’s air outlet

causes short circuit (suction of discharge air). This may result in:

▪ deterioration of the operational capacity;

▪ frequent frost acceleration in heating operation;

▪ disruption of operation due to decrease of low pressure or

increase of high pressure;

▪ a broken fan (if a strong wind blows continuously on the fan, it

may start rotating very fast, until it breaks).

It is recommended to install a baffle plate when the air outlet is

exposed to wind.

It is recommended to install the outdoor unit with the air inlet facing

the wall and NOT directly exposed to the wind.

5.2.1 Installation site requirements of the outdoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

Mind the following spacing guidelines:

a Air outlet

b Air inlet

Allow 300mm of work space below the ceiling surface and 250mm

for piping and electrical servicing.

a Baffle plate

b Prevailing wind direction

c Air outlet

Do NOT install the unit in the following places:

▪ Sound sensitive areas (e.g. near a bedroom), so that the

operation noise will cause no trouble.

Note: If the sound is measured under actual installation

conditions, the measured value might be higher than the sound

pressure level mentioned in Sound spectrum in the data book due

to environmental noise and sound reflections.

INFORMATION

The sound pressure level is less than 70dBA.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

It is NOT recommended to install the unit in the following places

because it may shorten the life of the unit:

▪ Where the voltage fluctuates a lot

▪ In vehicles or vessels

▪ Where acidic or alkaline vapour is present

Seaside installation. Make sure the outdoor unit is NOT directly

exposed to sea winds. This is to prevent corrosion caused by high

levels of salt in the air, which might shorten the life of the unit.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

Installer reference guide

9

5 Preparation

b

c

a

a

b

c

d

c

d

a

b

c

c

d

Install the outdoor unit away from direct sea winds.

Example: Behind the building.

If the outdoor unit is exposed to direct sea winds, install a

windbreaker.

▪ Height of windbreaker≥1.5×height of outdoor unit

▪ Mind the service space requirements when installing the

windbreaker.

a Sea wind

b Building

c Outdoor unit

d Windbreaker

The outdoor unit is designed for outdoor installation only, and for

ambient temperatures within the following ranges:

Cooling mode Heating mode

–10~46°C DB –15~24°C DB

5.2.2 Additional installation site requirements of the outdoor unit in cold climates

Protect the outdoor unit against direct snowfall and take care that the

outdoor unit is NEVER snowed up.

It is recommended to provide at least 150mm of free space below

the unit (300mm for heavy snowfall areas). Additionally, make sure

the unit is positioned at least 100mm above the maximum expected

level of snow. If necessary, construct a pedestal. See "6.3Mounting

the outdoor unit"[412] for more details.

In heavy snowfall areas it is very important to select an installation

site where the snow will NOT affect the unit. If lateral snowfall is

possible, make sure that the heat exchanger coil is NOT affected by

the snow. If necessary, install a snow cover or shed and a pedestal.

5.2.3 Refrigerant piping length and height difference

INFORMATION

For the Hybrid for Multi application and the DHW generator

for Multi, see the indoor unit installation manual for the

maximum allowable refrigerant piping length and height

difference.

The shorter the refrigerant piping, the better the performance of the

system.

The piping length and height differences must comply with the

following requirements.

Model Minimum required space

3MXM40, 3MXM52, 3AMXM52,

3MXF52, 3AMXF52

3MXM68, 3MXF68 5.5m

4MXM68 6.5m

4MXM80 9.8m

5MXM90 10.4m

Shortest allowable length per room is 3m.

Outdoor unit Refrigerant piping

length to each indoor

unit

3MXM40,

≤25m ≤50m

3MXM52,

3AMXM52,

3MXM68,

3MXF52,

3AMXF52,

3MXF68

4MXM68 ≤60m

4MXM80 ≤70m

5MXM90 ≤75m

2

4.7m

2

2

2

2

Refrigerant piping

total length

Installer reference guide

10

a Snow cover or shed

b Pedestal

c Prevailing wind direction

d Air outlet

Outdoor unit installed

Height difference

outdoor-indoor

≤15m ≤7.5m

Height difference

indoor-indoor

higher than indoor

unit

Outdoor unit installed

≤7.5m ≤15m

lower than at least 1

indoor unit

5.3 Preparing refrigerant piping

5.3.1 Refrigerant piping requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping diameter:

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6 Installation

t

Ø

ØiØ

i

t

ØpØ

p

3MXM40, 3MXM52, 3MXM68, 3AMXM52, 3MXF52, 3AMXF52,

3MXF68

Liquid piping 3× Ø6.4mm (1/4")

Gas piping 1× Ø9.5mm (3/8")

2× Ø12.7mm (1/2")

4MXM68

Liquid piping 4× Ø6.4mm (1/4")

Gas piping 2× Ø9.5mm (3/8")

2× Ø12.7mm (1/2")

4MXM80

Liquid piping 4× Ø6.4mm (1/4")

Gas piping 1× Ø9.5mm (3/8")

1× Ø12.7mm (1/2")

2× Ø15.9mm (5/8")

5MXM90

Liquid piping 5× Ø6.4mm (1/4")

Gas piping 2× Ø9.5mm (3/8")

1× Ø12.7mm (1/2")

2× Ø15.9mm (5/8")

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

6.4mm (1/4")

9.5mm (3/8")

12.7mm (1/2")

15.9mm (5/8") ≥1mm

Usage of reducers might be required based on the indoor unit. See

"6.4.6 Connections between outdoor and indoor unit using

reducers"[415] for more information.

Temper grade Thickness (t)

Annealed (O) ≥0.8mm

(a)

Depending on the applicable legislation and the unit's

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.

(a)

5.3.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Øp)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 10~14mm ≥13mm

12.7mm (1/2") 14~16mm ≥13mm

15.9mm (5/8") 16~20mm ≥13mm

If the temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

Use separate thermal insulation pipes for the gas and liquid

refrigerant piping.

Insulation inner

diameter (Øi)

Insulation thickness

(t)

5.4 Preparing electrical wiring

5.4.1 About preparing electrical wiring

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

WARNING

▪ If the power supply has a missing or wrong N-phase,

equipment might break down.

▪ Establish proper earthing. Do NOT earth the unit to a

utility pipe, surge absorber, or telephone earth.

Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the

cables do NOT come in contact with sharp edges or

piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires,

extension cords, or connections from a star system.

They can cause overheating, electrical shock or fire.

▪ Do NOT install a phase advancing capacitor, because

this unit is equipped with an inverter. A phase

advancing capacitor will reduce performance and may

cause accidents.

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

WARNING

The backup heater MUST have a dedicated power supply

and MUST be protected by the safety devices required by

the applicable legislation.

WARNING

ALWAYS use multicore cable for power supply cables.

6 Installation

WARNING

Installation shall be done by an installer, the choice of

materials and installation shall comply with the applicable

legislation. In Europe, EN378 is the applicable standard.

6.1 Overview: Installation

This chapter describes what you have to do and know on-site to

install the system.

Typical workflow

Installation typically consists of the following stages:

1 Mounting the outdoor unit.

2 Connecting the refrigerant piping.

3 Checking the refrigerant piping.

4 Charging refrigerant.

5 Connecting the electrical wiring.

6 Finishing the outdoor installation.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

Installer reference guide

11

6 Installation

3×

2

1

20 mm

(mm)

353

600

240

240

a

INFORMATION

For installation of the indoor unit (mounting the indoor unit,

connecting the refrigerant piping to the indoor unit,

connecting the electrical wiring to the indoor unit …), see

the installation manual of the indoor unit.

INFORMATION

Depending on the units and/or the installation conditions, it

might be necessary to connect electrical wiring before you

can charge refrigerant.

INFORMATION

It is NOT possible to connect an indoor unit of 1 room only.

Be sure to connect indoor units of at least 2 rooms.

The Hybrid for Multi or the DHW generator for Multi are considered

as 1 room connection.

For the correct combination, see the combination table and the

installation manual of the Hybrid for Multi or the DHW generator for

Multi.

6.2 Opening the unit

6.2.1 About opening the unit

At certain times, you have to open the unit. Example:

▪ When connecting the refrigerant piping

▪ When connecting the electrical wiring

▪ When maintaining or servicing the unit

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover

is removed.

Typical workflow

Mounting the outdoor unit typically consists of the following stages:

1 Providing the installation structure.

2 Installing the outdoor unit.

3 Providing drainage.

4 Protecting the unit against snow and wind by installing a snow

cover and baffle plates. See "Preparing installation site" in

"5Preparation"[48].

6.3.2 Precautions when mounting the outdoor unit

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

6.3.3 To provide the installation structure

Check the strength and level of the installation ground so that the

unit will not cause any operating vibration or noise.

Use a vibration-proof rubber (field supply) in cases where vibrations

may be transmitted to the building.

The unit may be installed directly on a concrete veranda or another

solid surface as long as it provides proper drainage.

Fix the unit securely by means of foundation bolts in accordance

with the foundation drawing.

Prepare 4 sets of M8 or M10 anchor bolts, nuts and washers (field

supply).

6.2.2 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

6.3 Mounting the outdoor unit

6.3.1 About mounting the outdoor unit

When

The outdoor and indoor unit must be mounted before the refrigerant

piping can be connected.

a 100mm above expected level of snow

Installer reference guide

12

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6.3.4 To install the outdoor unit

4× M8/M10

a

a cb b b

a

a

6.3.5 To provide drainage

▪ Make sure that condensation water can be evacuated properly.

▪ Install the unit on a base to make sure that there is proper

drainage in order to avoid ice accumulation.

▪ Prepare a water drainage channel around the foundation to drain

waste water away from the unit.

▪ Avoid drain water flowing over the footpath, so that it does NOT

become slippery in case of ambient freezing temperatures.

▪ If you install the unit on a frame, install a waterproof plate within

150 mm of the bottom side of the unit in order to prevent water

from getting into the unit and to avoid drain water dripping (see the

following figure).

6 Installation

a Drain hole. Install a drain cap (large).

b Drain hole. Install a drain cap (small).

c Drain hole for drain socket

6.3.6 To prevent the outdoor unit from falling over

In case the unit is installed in places where strong wind can tilt the

unit, take following measure:

1 Prepare 2 cables as indicated in the following illustration (field

supply).

2 Place the 2 cables over the outdoor unit.

3 Insert a rubber sheet between the cables and the outdoor unit

to prevent the cables from scratching the paint (field supply).

4 Attach the ends of the cables and tighten them.

NOTICE

In cold areas, do NOT use a drain socket, hose and caps

(large, small) with the outdoor unit. Take adequate

measures so that the evacuated condensate CANNOT

freeze.

NOTICE

If the drain holes of the outdoor unit are blocked up by a

mounting base or floor surface, place additional foot bases

≤30mm under the outdoor unit's feet.

▪ Use a drain socket for drainage if necessary.

a Drain hole

To close the drain holes and attach the drain socket

1 Install drain caps (accessory f) and (accessory g). Make sure

the edges of the drain caps close off the holes completely.

2 Install the drain socket.

6.4 Connecting the refrigerant piping

CAUTION

▪ No brazing or welding on site for units with R32

refrigerant charge during shipment.

▪ During installation of the refrigeration system, joining of

parts with at least one part charged shall be performed

taking into account the following requirements:

ð inside occupied spaces non permanent joints are not

allowed for R32 refrigerant except for site made joints

directly connecting the indoor unit to piping. Site made

joints directly connecting piping to indoor units shall

be of non permanent type.

CAUTION

Do NOT connect the embedded branch piping and the

outdoor unit when only carrying out piping work without

connecting the indoor unit in order to add another indoor

unit later.

6.4.1 About connecting the refrigerant piping

Before connecting the refrigerant piping

Make sure the outdoor and indoor unit are mounted.

Typical workflow

Connecting the refrigerant piping involves:

▪ Connecting the refrigerant piping to the indoor unit

▪ Connecting the refrigerant piping to the outdoor unit

▪ Insulating the refrigerant piping

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

Installer reference guide

13

6 Installation

a

b

c

d

R=

0.4~0.8

±2

45°

90°

±2

ØA

▪ Keeping in mind the guidelines for:

▪ Pipe bending

▪ Flaring pipe ends

▪ Using the stop valves

6.4.2 Precautions when connecting the refrigerant piping

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

DANGER: RISK OF BURNING

CAUTION

▪ Do NOT use mineral oil on flared part.

▪ Do NOT reuse piping from previous installations.

▪ NEVER install a drier to this R32 unit to guarantee its

lifetime. The drying material may dissolve and damage

the system.

CAUTION

▪ Use the flare nut fixed to the main unit.

▪ To prevent gas leakage, apply refrigeration oil only to

the inside of the flare. Use refrigeration oil for R32.

▪ Do NOT reuse joints.

NOTICE

Take the following precautions on refrigerant piping into

account:

▪ Avoid anything but the designated refrigerant to get

mixed into the refrigerant cycle (e.g. air).

▪ Only use R32 when adding refrigerant.

▪ Only use installation tools (e.g. manifold gauge set) that

are exclusively used for R32 installations to withstand

the pressure and to prevent foreign materials (e.g.

mineral oils and moisture) from mixing into the system.

▪ Install the piping so that the flare is NOT subjected to

mechanical stress.

▪ Protect the piping as described in the following table to

prevent dirt, liquid or dust from entering the piping.

▪ Use caution when passing copper tubes through walls

(see figure below).

INFORMATION

Do NOT open the refrigerant stop valve before checking

the refrigerant piping. When you need to charge additional

refrigerant it is recommended to open the refrigerant stop

valve after charging.

WARNING

Connect the refrigerant piping securely before running the

compressor. If the refrigerant piping is NOT connected and

the stop valve is open when the compressor is run, air will

be sucked in. This will cause abnormal pressure in the

refrigeration cycle, which may result in equipment damage

and even injury.

NOTICE

Even if the stop valve is fully closed, the refrigerant may

slowly leak out. Do NOT leave the flare nut removed for

long period of time.

6.4.3 Guidelines when connecting the refrigerant piping

Take the following guidelines into account when connecting pipes:

▪ Coat the flare inner surface with ether oil or ester oil when

connecting a flare nut. Tighten 3 or 4 turns by hand, before

tightening firmly.

▪ ALWAYS use 2 wrenches together when loosening a flare nut.

▪ ALWAYS use a spanner and torque wrench together to tighten the

flare nut when connecting the piping. This to prevent nut cracking

and leaks.

a Torque wrench

b Spanner

c Piping union

d Flare nut

Piping size

(mm)

Ø6.4 15~17 8.7~9.1

Ø9.5 33~39 12.8~13.2

Ø12.7 50~60 16.2~16.6

Ø15.9 63~75 19.3~19.7

Tightening

torque (N•m)

Flare

dimensions (A)

(mm)

Flare shape

(mm)

6.4.4 Pipe bending guidelines

Unit Installation period Protection method

Outdoor unit >1month Pinch the pipe

<1month Pinch or tape the pipe

Indoor unit Regardless of the

period

Installer reference guide

14

Use a pipe bender for bending. All pipe bends should be as gentle

as possible (bending radius should be 30~40mm or larger).

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6 Installation

a b

A

a b

c

1 2 3 4 5 6

a b d ec

6.4.5 To flare the pipe end

CAUTION

▪ Incomplete flaring may cause refrigerant gas leakage.

▪ Do NOT re-use flares. Use new flares to prevent

refrigerant gas leakage.

▪ Use flare nuts that are included with the unit. Using

different flare nuts may cause refrigerant gas leakage.

1 Cut the pipe end with a pipe cutter.

2 Remove burrs with the cut surface facing down so that the

chips do NOT enter the pipe.

a Cut exactly at right angles.

b Remove burrs.

3 Remove the flare nut from the stop valve and put the flare nut

on the pipe.

4 Flare the pipe. Set exactly at the position as shown in the

following figure.

Flare tool for R32

(clutch type)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

5 Check that the flaring is properly made.

Conventional flare tool

Clutch type

(Ridgid-type)

Wing nut type

(Imperial-type)

Port Class Reducer

3MXM40

A 15, 20, 25, 35 —

B + C 15, 20, 25, 35 2+4

3MXM52, 3AMXM52

A 15, 20, 25, 35 —

B + C 15, 20, 25, 35 2+4

42, 50 —

3MXM68

A 15, 20, 25, 35 —

B + C 15, 20, 25, 35 2+4

42, 50, 60 —

3MXF52, 3AMXF52, 3MXF68

A 20, 25, 35 —

B + C 20, 25, 35 2+4

4MXM68

A + B 15, 20, 25, 35 —

C + D 15, 20, 25, 35 2+4

42, 50, 60 —

4MXM80

A 15, 20, 25, 35 —

B 15, 20, 25, 35 2+4

42, 50, 60 —

C + D 15, 20, 25, 35 5+6

42, 50, 60 1+3

71 —

5MXM90

A + B 15, 20, 25, 35 —

C 15, 20, 25, 35 2+4

42, 50, 60 —

D + E 15, 20, 25, 35 5+6

42, 50, 60 1+3

71 —

6.4.6 Connections between outdoor and indoor unit using reducers

INFORMATION

▪ For the DHW generator for Multi use the same reducer

as for the 20 class indoor unit.

▪ For the Hybrid for Multi, see the indoor unit installation

manual for the capacity class and applicable reducer.

Total indoor unit capacity class that can be connected to this

outdoor unit:

Outdoor unit Total indoor unit capacity

3MXM40 ≤7.0kW

3MXM52, 3AMXM52, 3MXF52,

3AMXF52

3MXM68, 4MXM68, 3MXF68 ≤11.0kW

4MXM80 ≤14.5kW

5MXM90 ≤15.6kW

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

a Flare’s inner surface MUST be flawless.

b The pipe end MUST be evenly flared in a perfect circle.

c Make sure the flare nut is fitted.

class

≤9.0kW

Reducer type Connection

1 Ø15.9mm → Ø12.7mm

2 Ø12.7mm → Ø9.5mm

3 Ø15.9mm → Ø12.7mm

4 Ø12.7mm → Ø9.5mm

5 Ø15.9mm → Ø9.5mm

6 Ø15.9mm → Ø9.5mm

Connection examples:

▪ Connecting a Ø12.7mm pipe to a Ø15.9mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 1

Installer reference guide

15

6 Installation

a b d ec

a b d ec

c

d

a

b

a

b

c Reducer no. 3

d Flare nut for Ø15.9mm

e Inter-unit piping

▪ Connecting a Ø9.5 mm pipe to a Ø15.9mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 6

c Reducer no. 5

d Flare nut for Ø9.5mm

e Inter-unit piping

▪ Connecting a Ø9.5 mm pipe to a Ø12.7mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 2

c Reducer no. 4

d Flare nut for Ø12.7mm

e Inter-unit piping

Coat the threaded connection port of the outdoor unit where the flare

nut comes in with refrigeration oil.

Flare nut for (mm) Tightening torque (N•m)

Ø9.5 33~39

Ø12.7 50~60

Ø15.9 62~75

NOTICE

Use an appropriate wrench to avoid damaging the

connection thread by overtightening the flare nut. Be

careful NOT to overtighten the nut, or the smaller pipe may

be damaged (about 2/3-1× the normal torque).

6.4.7 Using the stop valve and service port

To handle the stop valve

Take the following guidelines into account:

▪ The stop valves are factory closed.

▪ The following figure shows the stop valve parts required when

handling the valve.

a Service port and service port cap

b Valve stem

c Field piping connection

d Stem cap

▪ Keep both stop valves open during operation.

▪ Do NOT apply excessive force to the valve stem. Doing so may

break the valve body.

▪ ALWAYS make sure to secure the stop valve with a spanner, then

loosen or tighten the flare nut with a torque wrench. Do NOT place

the spanner on the stem cap, as this could cause a refrigerant

leak.

a Spanner

b Torque wrench

▪ When it is expected that the operating pressure will be low (e.g.

when cooling will be performed while the outside air temperature

is low), sufficiently seal the flare nut in the stop valve on the gas

line with silicon sealant to prevent freezing.

Silicon sealant; make sure there is no gap.

To open/close the stop valve

1 Remove the stop valve cover.

2 Insert a hexagon wrench (liquid side: 4mm, gas side: 6mm)

into the valve stem and turn the valve stem:

Counterclockwise to open.

Clockwise to close.

3 When the stop valve CANNOT be turned any further, stop

turning.

4 Install the stop valve cover.

Result: The valve is now open/closed.

To handle the stem cap

▪ The stem cap is sealed where indicated with the arrow. Do NOT

damage it.

▪ After handling the stop valve, tighten the stem cap, and check for

refrigerant leaks.

Piping Ø (mm) Width across flats

Tightening torque (N∙m)

(mm)

6.4 17 15~17

9.5 19 18~20

12.7 22 22~27

15.9 27 48~59

To handle the service cap

▪ ALWAYS use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

▪ After handling the service port, tighten the service port cap, and

check for refrigerant leaks.

Item Tightening torque (N∙m)

Service port cap 11~14

Installer reference guide

16

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6 Installation

a

c

b

c

a

h

b

f

h

i

e

c

d

e

g

j

6.4.8 To connect the refrigerant piping to the outdoor unit

▪ Piping length. Keep field piping as short as possible.

▪ Piping protection. Protect the field piping against physical

damage.

1 Connect the liquid refrigerant connection from the indoor unit to

the liquid stop valve of the outdoor unit.

a Liquid stop valve

b Gas stop valve

c Service port

2 Connect the gas refrigerant connection from the indoor unit to

the gas stop valve of the outdoor unit.

NOTICE

It is recommended that the refrigerant piping between

indoor and outdoor unit is installed in a ducting or the

refrigerant piping is wrapped with finishing tape.

6.5 Checking the refrigerant piping

6.5.1 About checking the refrigerant piping

The outdoor unit's internal refrigerant piping has been factory tested

for leaks. You only have to check the outdoor unit's external

refrigerant piping.

Before checking the refrigerant piping

Make sure the refrigerant piping is connected between the outdoor

unit and the indoor unit.

Typical workflow

Checking the refrigerant piping typically consists of the following

stages:

1 Checking for leaks in the refrigerant piping.

2 Performing vacuum drying to remove all moisture, air or

nitrogen from the refrigerant piping.

If there is a possibility of moisture being present in the refrigerant

piping (for example, water may have entered the piping), first carry

out the vacuum drying procedure below until all moisture has been

removed.

NOTICE

Use a 2-stage vacuum pump with a non-return valve that

can evacuate to a gauge pressure of −100.7 kPa

(−1.007 bar)(5 Torr absolute). Make sure the pump oil

does not flow oppositely into the system while the pump is

not working.

NOTICE

Use this vacuum pump for R32 exclusively. Using the

same pump for other refrigerants may damage the pump

and the unit.

NOTICE

▪ Connect the vacuum pump to the service port of the

gas stop valve.

▪ Make sure that the gas stop valve and liquid stop valve

are firmly closed before performing the leak test or

vacuum drying.

6.5.3 To check for leaks

NOTICE

Do NOT exceed the unit's maximum working pressure (see

"PS High" on the unit name plate).

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

cause cracking of flare nuts (soap water may contain salt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effect between the brass flare nut and the copper flare).

1 Charge the system with nitrogen gas up to a gauge pressure of

at least 200 kPa (2 bar). It is recommended to pressurize to

3000kPa (30bar) in order to detect small leaks.

2 Check for leaks by applying the bubble test solution to all

connections.

3 Discharge all nitrogen gas.

6.5.4 To perform vacuum drying

Connect the vacuum pump and manifold as follows:

6.5.2 Precautions when checking the refrigerant piping

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

1 Vacuum the system until the pressure on the manifold indicates

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

2 Leave as is for 4-5minutes and check the pressure:

a Pressure meter

b Gauge manifold

c Low-pressure valve (Lo)

d High-pressure valve (Hi)

e Charging hoses

f Vacuum pump

g Service port

h Valve lids

i Gas stop valve

j Liquid stop valve

−0.1MPa (−1bar).

Installer reference guide

17

6 Installation

If the pressure… Then…

Does not change There is no moisture in the

system. This procedure is

finished.

Increases There is moisture in the

system. Go to the next step.

3 Vacuum the system for at least 2hours to a manifold pressure

of −0.1MPa (−1bar).

4 After turning the pump OFF, check the pressure for at least

1hour.

5 If you do NOT reach the target vacuum or CANNOT maintain

the vacuum for 1hour, do the following:

▪ Check for leaks again.

▪ Perform vacuum drying again.

NOTICE

Be sure to open the gas stop valve after piping installation

and vacuuming. Running the system with the valve closed,

the compressor may break down.

INFORMATION

After opening the stop valve, it is possible that the pressure

in the refrigerant piping does NOT increase. This might be

caused by e.g. the closed state of the expansion valve in

the outdoor unit circuit, but does NOT present any problem

for correct operation of the unit.

6.6 Charging refrigerant

6.6.1 About charging refrigerant

The outdoor unit is factory charged with refrigerant, but in some

cases the following might be necessary:

What When

Charging additional refrigerant When the total liquid piping

length is more than specified

(see later).

Completely recharging refrigerant Example:

▪ When relocating the system.

▪ After a leak.

Charging additional refrigerant

Before charging additional refrigerant, make sure the outdoor unit's

external refrigerant piping is checked (leak test, vacuum drying).

INFORMATION

Depending on the units and/or the installation conditions, it

might be necessary to connect electrical wiring before you

can charge refrigerant.

Typical workflow – Charging additional refrigerant typically consists

of the following stages:

1 Determining if and how much you have to charge additionally.

2 If necessary, charging additional refrigerant.

3 Filling in the fluorinated greenhouse gases label, and fixing it to

the inside of the outdoor unit.

3 Vacuum drying on the outdoor unit's internal refrigerant piping is

performed.

NOTICE

Before completely recharging, perform vacuum drying on

the outdoor unit's internal refrigerant piping as well.

Typical workflow – Completely recharging refrigerant typically

consists of the following stages:

1 Determining how much refrigerant to charge.

2 Charging refrigerant.

3 Filling in the fluorinated greenhouse gases label, and fixing it to

the inside of the outdoor unit.

6.6.2 Precautions when charging refrigerant

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

6.6.3 About the refrigerant

This product contains fluorinated greenhouse gases. Do NOT vent

gases into the atmosphere.

Refrigerant type: R32

Global warming potential (GWP) value: 675

NOTICE

Applicable legislation on fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO2 equivalent.

Formula to calculate the quantity in CO2 equivalent

tonnes: GWP value of the refrigerant × total refrigerant

charge [in kg] / 1000

Please contact your installer for more information.

WARNING: FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

WARNING

The appliance shall be stored in a room without

continuously operating ignition sources (example: open

flames, an operating gas appliance or an operating electric

heater).

WARNING

▪ Do NOT pierce or burn refrigerant cycle parts.

▪ Do NOT use cleaning materials or means to accelerate

the defrosting process other than those recommended

by the manufacturer.

▪ Be aware that the refrigerant inside the system is

odourless.

Completely recharging refrigerant

Before completely recharging refrigerant, make sure the following is

done:

1 All refrigerant is recovered from the system.

2 The outdoor unit's external refrigerant piping is checked (leak

test, vacuum drying).

Installer reference guide

18

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6 Installation

b

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO2eq

GWP × kg

1000

=

=

+

kg

=

kg

=

GWP: XXX

RXXX

a

f

c

d

e

WARNING

The refrigerant inside the unit is mildly flammable, but

normally does NOT leak. If the refrigerant leaks in the

room and comes in contact with fire from a burner, a

6.6.7 To fix the fluorinated greenhouse gases label

1 Fill in the label as follows:

heater, or a cooker, this may result in fire, or the formation

of a harmful gas.

Turn off any combustible heating devices, ventilate the

room, and contact the dealer where you purchased the

unit.

Do NOT use the unit until a service person confirms that

the part from which the refrigerant leaked has been

repaired.

6.6.4 To determine the additional refrigerant amount

If the total liquid

piping length is…

≤30m Do NOT add additional refrigerant.

>30m R=(total length (m) of liquid piping–

30m)×0.020

R=Additional charge (kg) (rounded in units

of 0.1kg)

INFORMATION

Piping length is the one-way length of liquid piping.

Maximum allowable refrigerant charge amount

3MXM40, 3MXM52, 3AMXM52, 3MXF52, 3AMXF52 2.2kg

3MXM68, 3MXF68 2.4kg

4MXM68 2.6kg

4MXM80 3.2kg

Then…

2 Fix the label on the inside of the outdoor unit near the gas and

a If a multilingual fluorinated greenhouse gases label is

delivered with the unit (see accessories), peel off the

applicable language and stick it on top of a.

b Factory refrigerant charge: see unit name plate

c Additional refrigerant amount charged

d Total refrigerant charge

e Quantity of fluorinated greenhouse gases of the total

refrigerant charge expressed as tonnes CO2 equivalent.

f GWP = Global warming potential

NOTICE

Applicable legislation on fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO2 equivalent.

Formula to calculate the quantity in CO2 equivalent

tonnes: GWP value of the refrigerant × total refrigerant

charge [in kg] / 1000

Use the GWP value mentioned on the refrigerant charge

label. That GWP is based on the current legislation on

fluorinated greenhouse gases. The GWP mentioned in the

manual might be outdated.

liquid stop valves.

5MXM90 3.3kg

6.7 Connecting the electrical wiring

6.6.5 To determine the complete recharge amount

INFORMATION

If a complete recharge is necessary, the total refrigerant

charge is: the factory refrigerant charge (see unit name

plate) + the determined additional amount.

6.6.6 To charge additional refrigerant

WARNING

▪ Only use R32 as refrigerant. Other substances may

cause explosions and accidents.

▪ R32 contains fluorinated greenhouse gases. Its global

warming potential (GWP) value is 675. Do NOT vent

these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective

gloves and safety glasses.

CAUTION

To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

Prerequisite: Before charging refrigerant, make sure the refrigerant

piping is connected and checked (leak test and vacuum drying).

1 Connect the refrigerant cylinder to the service port.

2 Charge the additional refrigerant amount.

3 Open the gas stop valve.

3(A)MXM+3(A)MXF+4MXM+5MXM

R32 Split series

4P600463-1 – 2019.10

6.7.1 About connecting the electrical wiring

Typical workflow

Connecting the electrical wiring typically consists of the following

stages:

1 Making sure the power supply system complies with the

electrical specifications of the heat pump.

2 Connecting the electrical wiring to the outdoor unit.

3 Connecting the electrical wiring to the indoor unit.

4 Connecting the main power supply of the indoor unit.

5 Connecting the main power supply of the gas boiler.

6 Connecting the communication cable between the gas boiler

and the indoor unit.

7 Connecting the user interface.

8 Connecting the shut–off valves.

9 Connecting the domestic hot water pump.

10 Connecting the alarm output.

11 Connecting the space heating ON/OFF output.

12 Connecting the safety thermostat.

6.7.2 Precautions when connecting the electrical wiring

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

Installer reference guide

19

6 Installation

AC

DC

DC

S20 S21 S22 S23

S92

S93

S40

S80

S70

U W

V

DC-

FU2

S90

S24

AL2 AL1

e

f

g

h

a

b

c

d

DC(-)

FU2

b a

c b

c

aa

A

AA´

A´

c b ba c

a

B

B

1-3

INFORMATION

Appliance shall be installed in accordance with national

wiring regulations.

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

Use an all-pole disconnection type breaker with at least