Page 1

Product Presentation

Dough Mixers

Page 2

2

Page 3

World class Dough Mixers

with Fixed or Removable Bowl

Sveba-Dahlen now oers a complete range of Dough Mixers,

with numerous models enhanced by an extensive list of

accessories capable of covering all the needs of both artisans

and industry. Our machines are renowned for their sturdiness,

durability, accurate finishes, and for the quality of the dough

they produce. Dough Mixers that meets the needs of a variety of

clients and dierent types of markets.

3

Page 4

Page 5

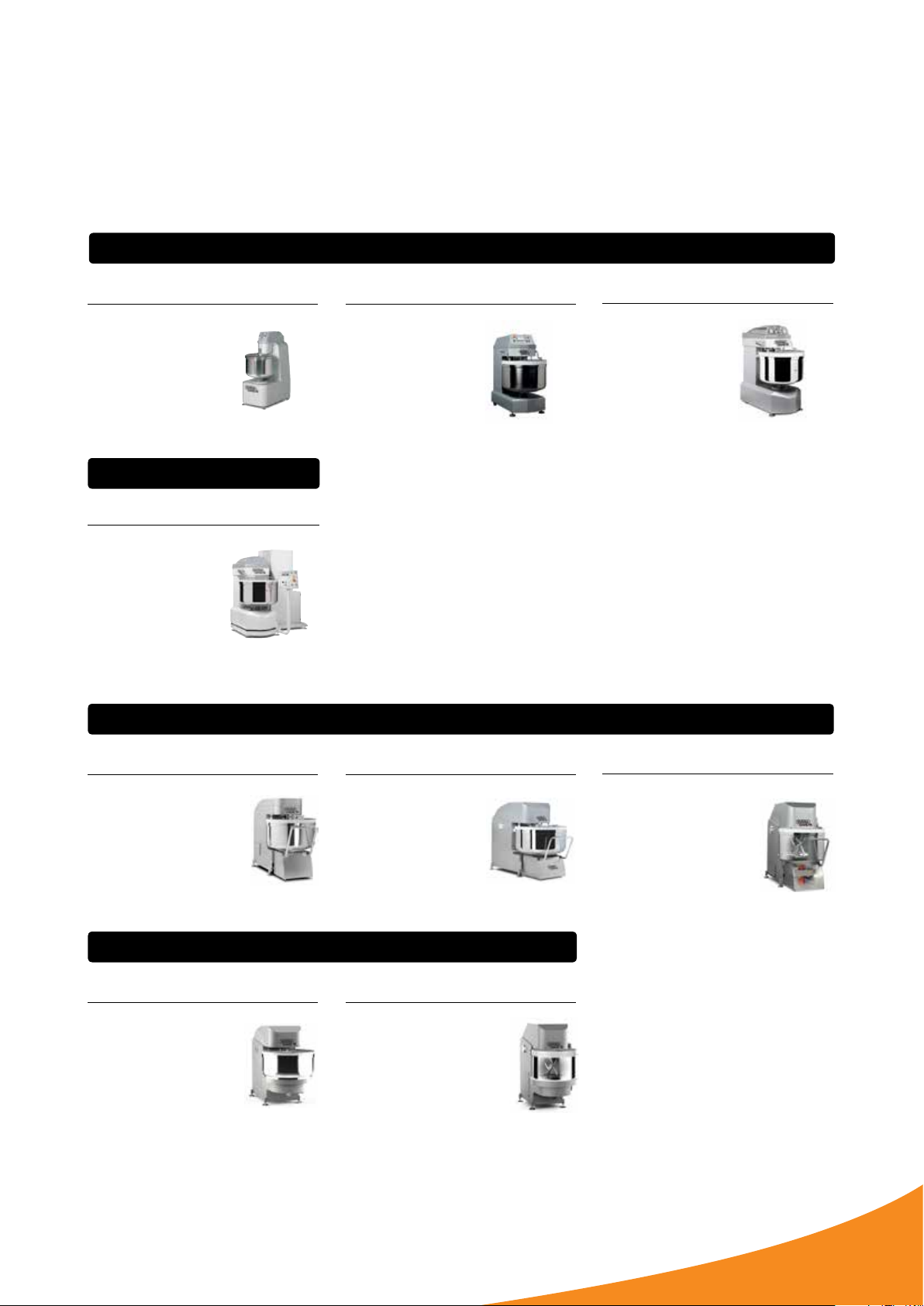

Dough Mixer Programme

Fixed Bowl Mixers

M1

Spiral Mixer

Fixed Bowl

Capacity:

30 and 40 kg

Fixed Bowl – Self-tipping

MT Premium

Spiral Mixer

Fixed Bowl

Self-tipping

Capacity:

80, 120, 160,

200 and 240 kg

Removable Bowl Mixers

MX

Spiral Mixer

Fixed Bowl

Capacity:

60, 80, 120,

160 and 200 kg

M Premium

Spiral Mixer

Fixed Bowl

Capacity:

50, 60, 80, 120,

160 and 200 kg

MR Professional

Spiral Mixer

Removable Bowl

Capacity:

80, 120, 160,

200 and 240 kg

Bottom Discharge Mixers

MD

Spiral Mixer

Bottom Discharge

Capacity:

160, 240, 350,

400 and 500 kg

MR Professional

Spiral Mixer

Removable Bowl

Capacity:

300, 350, 400

and 500 kg

MD-W

Double Tool Mixer

Bottom Discharge

Capacity:

160, 240 and 400 kg

MW

Double Tool Mixer

Removable Bowl

Capacity:

160, 240 and 400 kg

5

Page 6

Fixed Bowl

M1 – Spiral Mixer with Fixed Bowl

Capacity: 30 and 40 kg

Silent and reliable mixer, designed for an intense

use. M1 is our basic model that can satisfy the

daily production needs of a small-medium

bakery, a pizzeria or a Supermarket.

The M1 has two speeds, one-way bowl rotation, belt transmissions,

automatic version with electronic timers. Available with single-phase

motor and inverter.

The central part of the bowl is raised and rounded in order to improve

dough quality and to reduce mixing times.

Options

–––––––––––––––––––––––––––––––––––––––––––––––––––

l Single phase motor and inverter

l Independent bowl transmission with bowl reverse

l Stainless steel execution

Simple and reliable

construction

aB

Technical Measurements

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral

caPacity caPacity volUMe 1st sPeed/2nd sPeed weiGHt diMensions MM

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M1 30 30 kg 18 kg 50 l 1.0 kW/2.0 kW 259 kg 540 875 1305

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M1 40 40 kg 25 kg 60 l 1.5 kW/3.0 kW 284 kg 540 915 1305

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

c

6

Page 7

Fixed Bowl

MX - Spiral Mixer with Fixed Bowl

Capacity: 60, 80, 120, 160 and 200 kg

Steady, compact and easy to handle spiral mixer with

power reserves for most doughs.

Fixed bowl spiral mixers with two motors, two speeds with two way bowl

rotation allowing to reverse the bowl in 1st speed. Automatic timer.

Standard with stainless steel bowl, spiral tool and breaker bar.

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Bowl scraper, fixed

l Infrared temp. measure system

l Beater for pastry dough

l Bowl with drain plug

l Stainless steel execution

c

Reliable heavy-duty

construction

Ergonomic construction

aB

Technical Measurements

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

MX 60 60 kg 37 kg 112 l 1.5 kW/3.0 kW 350 kg 668 1170 1256

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

MX 80 80 kg 50 kg 154 l 2.1 kW/3.7 kW 380 kg 698 1185 1256

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

MX 120 120 kg 75 kg 185 l 2.1 kW/4.8 kW 431 kg 779 1295 1384

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

MX 160 160 kg 100 kg 270 l 7.5 kW/12.5 kW 570 kg 885 1404 1466

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

MX 200 200 kg 125 kg 310 l 7.5 kW/12.5 kW 615 kg 946 1465 1466

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

7

Page 8

Fixed Bowl

M Premium - Spiral Mixer with Fixed Bowl

Capacity: 50, 60, 80, 120, 160 and 200 kg

Premium models for intensive use and stier doughs

suitable for bakeries of all sizes. The M Premium

models are designed for intensive use around the

clock and stier doughs.

All the same features as the MX line plus Premium drive system with a dual

belt resulting in more power being delivered to the spiral tool and energy

savings. Fixed bowl spiral mixers with two motors, two speeds with two way

bowl rotation allowing to reverse the bowl in 1st speed. Automatic timer.

Standard with stainless steel bowl, stainless steel lid, spiral tool and breaker bar.

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Bowl scraper, fixed

l Infrared temp. measure system

l Beater for pastry dough

l PTC Temperature probe

l Bowl with drain plug

l Touch screen

l Stainless steel execution

l Stronger motors on request

c

Reliable heavy-duty

construction

Ergonomic construction Touch screen

(Optional)

aB

Technical Measurements

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

Model

caPacity caPacity volUMe 1:st/2:nd sPeed a B c

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 50 P 50 kg 30 kg 80 l 2.1 kW/3.7 kW 440 kg 605 1067 1345

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 60 P 60 kg 37 kg 100 l 2.1 kW/3.7 kW 449 kg 660 1140 1345

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 80 P 80 kg 50 kg 123 l 2.1 kW/3.7 kW 448 kg 678 1146 1345

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 120 P 120 kg 75 kg 185 l 3.0 kW/5.2 kW 549 kg 780 1300 1470

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 160 P 160 kg 100 kg 270 l 7.5 kW/12.5 kW 780 kg 885 1401 1565

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

M 200 P 200 kg 125 kg 310 l 7.5 kW/12.5 kW 815 kg 946 1490 1565

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––

doUGH FloUr Bowl Power oF sPiral weiGHt diMensions MM

8

Page 9

Fixed Bowl – self-tipping

MT Premium - Spiral Mixer with Fixed Bowl, self-tipping

Capacity: 80, 120, 160, 200 and 240 kg

Premium models specifically designed for intensive

use and stier doughs. Fixed bowl spiral mixers with

two motors and a hydraulic lift to tip the dough onto

a 1500 mm high table or 2000 mm divider.

Fixed bowl spiral mixer with hydraulic elevator and two motors with two

speeds and two way bowl rotation allowing to reverse the bowl in 1st

speed. Bowl with jog facility, belt transmission, automatic timers, stainless

steel bowl, spiral tool and breaker bar.

Premium drive system with a dual belt resulting in more power being delive-

red to the spiral tool and energy savings.

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Bowl scraper

l Infrared temp. measure

l PTC temperature probe

l Beater for pastry dough

l Bowl with drain plug

l Stainless steel finish

l Also available in left tipping execution

l Stronger motors on request

Also available in left

tipping execution

1 - Low model

c

F

d

aB

e

2 - High model

Reliable heavy-duty

construction

Standard bowl

self-tipping

Bowl safety lid

Easy to operate

c

aB

e

Technical Measurements

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ––––––––––––––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed oF Bowl a B c d e F

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

1

MT 80 PT 80 kg 50 kg 154 l 3.0 kW/5.2 kW 0.55 kW 963 kg 1650 1650 1525 1540 280 2530

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

2

MT 80 PD 80 kg 50 kg 154 l 3.0 kW/5.2 kW 0.55 kW 1347 kg 1650 1650 1750 2025 280 3015

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

1

MT 120 PT 120 kg 75 kg 185 l 3.0 kW/5.2 kW 0.55 kW 1004 kg 1685 1650 1525 1510 280 2530

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

2

MT 120 PD 120 kg 75 kg 185 l 3.0 kW/5.2 kW 0.55 kW 1388 kg 1685 1650 1750 2015 280 3035

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

1

MT 160 PT 160 kg 100 kg 270 l 7.5 kW/12.5 kW 0.75 kW 1395 kg 1770 1795 1670 1480 215 2660

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

2

MT 160 PD 160 kg 100 kg 270 l 7.5 kW/12.5 kW 0.75 kW 1820 kg 1770 1795 1750 2000 215 3180

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

1

MT 200 PT 200 kg 125 kg 310 l 7.5 kW/12.5 kW 0.75 kW 1485 kg 1800 1795 1670 1450 215 2695

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

2

MT 200 PD 200 kg 125 kg 310 l 7.5 kW/12.5 kW 0.75 kW 1900 kg 1800 1795 1750 1970 215 3215

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

1

MT 240 PT 240 kg 125 kg 386 l 7.5 kW/12.5 kW 1.10 kW 1535 kg 1800 1795 1670 1450 215 2740

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

2

MT 240 PD 240 kg 125 kg 386 l 7.5 kW/12.5 kW 1.10 kW 1950 kg 1800 1795 1750 1940 215 3260

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––––––––––––––

F

d

9

Page 10

Removable Bowl

locking and motion system

MR Professional - Spiral Mixers with Removable Bowl

Capacity: 80, 120, 160, 200 and 240 kg

High performance spiral mixers with removable bowl.

Patented taper bowl locking and motion system.

Suitable for medium and larger bakeries.

The patented taper bowl locking and motion system utilizes a taper coupling to

join the machine and the trolley. The trolley is locked by means of a taper shaft

that, as it ascends, centres the bowl and moves it into the working position.

The hydraulically controlled cone engages under the bowl, maintains constant

pressure during use and eliminates any possibility of slippage or wear.

The taper shaft gives rotating motion to the bowl and guarantees a constant

number of bowl revolutions thereby increasing the dough quality and machine

performance. The motion system is noiseless and free of mechanical play.

Elimination of the oscillating movements of the head while mixing a fully loaded

bowl and with particularly dry doughs. This feature translates into a constant

distance of the spiral from the bottom of the bowl to improve the quality of the

dough mixture and sheeting.

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Extra bowl, MRC

l Bowl scraper, fixed

l Infrared temperature measure

Patented

l PTC temperature probe

l Beater for pastry dough

l Quick change syst. for tools

l Spiral for quick change system

l Beater for quick change system

l Bowl with drain plug

l Touch screen

l Vario drive system

l Removable bowl scraper

l Stainless steel

l Stronger motors on request

Soft moving bowl lid

Reliable mixer

drive system

Removable bowl

on trolley as standard

d

c

a B

Patented bowl locking and motion system

Optional touch screen

Technical Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power oF Bowl weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c d

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 80 P 80 kg 50 kg 154 l 3.0 kW/6.25 kW 1.1 kW 1100 kg 1775 904 1470 1920

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 120 P 120 kg 75 kg 181 l 3.0 kW/6.25 kW 1.1 kW 1150 kg 1815 939 1470 1920

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 160 P 160 kg 100 kg 270 l 7.5 kW/12.5 kW 1.1 kW 1250 kg 2001 1027 1500 2051

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 200 P 200 kg 125 kg 310 l 7.5 kW/12.5 kW 1.1 kW 1390 kg 2031 1060 1500 2058

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 240 P 240 kg 150 kg 380 l 9.0 kW/15.0 kW 1.1 kW 1500 kg 2056 1105 1500 2136

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

10

Page 11

Removable Bowl

locking and motion system

MR Professional - Spiral Mixers with Removable Bowl

Capacity: 300, 350, 400 and 500 kg

Large capacity professional spiral mixers with removable bowl and patented taper bowl locking and motion

system. Suitable for larger bakeries and industrial use.

The new taper bowl locking and motion system is technically superior to the

traditional systems as it utilizes a taper coupling to join the machine and the trolley. The trolley is locked by means of a taper shaft that, as it ascends, centres

the bowl and moves it into the working position.

The hydraulically controlled cone engages under the bowl, maintains constant

pressure during use and eliminates any possibility of slippage or wear.

The taper shaft gives rotating motion to the bowl and guarantees a constant

number of bowl revolutions thereby increasing the dough quality and machine

performance. The motion system is noiseless and free of mechanical play.

Elimination of the oscillating movements of the head while mixing a fully loaded

bowl and with particularly dry doughs. This feature translates into a constant

distance of the spiral from the bottom of the bowl to improve the quality of the

dough mixture and sheeting.

Patented

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Extra bowl, MRC

l Bowl scraper, fixed

l Infrared temperature measure

l PTC temperature probe

l Beater for pastry dough

l Bowl with drain plug

l Touch screen

l Removable bowl scraper

l Stainless steel

l Stronger motors on request

Patented bowl locking and motion system

Touch screen - option

Reliable mixer

drive system

Removable bowl

on trolley as standard

d

c

a B

Technical Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power oF Bowl weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c d

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 300 P 300 kg 185 kg 450 l 11.0 kW/18.0 kW 1.5 kW 1800 kg 2111 1130 1509 2287

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 350 P 350 kg 225 kg 500 l 15.0 kW/22.0 kW 2.2 kW 2210 kg 2411 1256 1774 2287

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 400 P 400 kg 250 kg 600 l 15.0 kW/22.0 kW 2.2 kW 2300 kg 2461 1306 1774 2354

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MR 500 P 500 kg 300 kg 700 l 22.0 kW/30.0 kW 2.2 kW 2400 kg 2561 1356 1774 2421

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

11

Page 12

Removable Bowl

MW - Removable Bowl and Double Tool

Capacity: 160, 240 and 400 kg

The MW-line is a range of mixers with removable bowl

and double mixing tool and the patented taper bowl

locking and motion system. Oil free tool transmission.

Compared to other mixing systems, these machines offer essential advantages

with regard to dough quality. Rapid homogeneous blending of all ingredients

is followed by intensive kneading (dough-friendly). Higher hourly output rates

due to short kneading cycle suitable for all types of doughs (bread / biscuits /

patisserie):

- Wheat flour

- Rye flour

- Wholemeal

- Delicate dough or doughs with fruit

- Cracker or yeast doughs with high levels of fat and sugar

- It is also possible to mix fat creams and other fillings such as chocolate,

nougat and truffle fillings.

locking and motion system

Patented

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Speed control system for tools and bowl (VDS-Vario Drive System)

l Touch screen

Patented bowl and locking system Double tool system

Touch screen (Optional)

Removable bowl

on trolley as standard

d

a B

c

Technical Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power oF Bowl weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c d

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MW 160 160 kg 100 kg 270 l 9.0 kW/18.0 kW 2.2 kW 1900 kg 2001 1027 1500 2051

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MW 240 240 kg 150 kg 380 l 13.0 kW/22.0 kW 2.2 kW 2150 kg 2083 1102 1652 2244

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MW 400 400 kg 250 kg 600 l 26.0 kW/37.0 kW 2.2 kW 3050 kg 2461 1306 1800 2360

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

12

Page 13

Bottom Discharge

MD - Spiral Mixers with Bottom Discharge System

Capacity: 160, 240, 350, 400 and 500 kg

Mixer with a bottom discharge system suitable

for larger bakeries and industrial use. The dough

is unloaded onto a conveyor belt or into a movable

bowl. Mixing system with MD-Line spiral.

This compact system features two or more series of mixers that

feed the dough directlyinto the production lines, while an optional

extension offers a system for letting the dough rest.

The machine was designed with special attention paid to various aspects of hygiene and functionality. In particular, the cleaning of the bowl closing cap was a priority. The bowl transmission

guarantees constant rpm to improve the quality of the dough. The

same transmission was conceived to last longer and requires less

maintenance compared to the classic clutch wheel transmissions

used in this sector.

Options

–––––––––––––––––––––––––––––––––––––––––––––––––––

l Speed control system for tools and bowl

(VDS-Vario Drive System)

Bottom Discharge System

Example of configuration - MD-mixer with transport belt under

d

c

a B

Technical Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power oF Bowl weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c d

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD 160 160 kg 100 kg 270 l 9.0 kW/15.0 kW 1.1 kW 1250 kg 1810 925 1770 2260

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD 240 240 kg 150 kg 380 l 9.0 kW/15.0 kW 1.1 kW 1700 kg 1885 1070 1770 2315

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD 350 350 kg 225 kg 500 l 11.0 kW/18.0 kW 2.2 kW 2410 kg 2240 1100 1920 2510

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD 400 400 kg 250 kg 600 l 13.0 kW/23.0 kW 2.2 kW 2500 kg 2300 1200 1920 2545

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD 500 500 kg 300 kg 700 l 18.5 kW/26.0 kW 2.2 kW 2696 kg 2340 1300 1920 2580

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

13

7

Page 14

Bottom Discharge

MD-W - Mixers with Bottom Discharge System

and Double Mixing Tool

Capacity: 160, 240 and 400 kg

Mixer with a bottom discharge system suitable

for larger bakeries and industrial use. The dough

is unloaded onto a conveyor belt or into a movable

bowl. Mixing system with dual tool (MDW-Line).

This compact system features two or more series of mixers that

feed the dough directlyinto the production lines, while an optional

extension offers a system for letting the dough rest.

The machine was designed with special attention paid to various aspects of hygiene and functionality. In particular, the cleaning of the bowl closing cap was a priority. The bowl transmission

guarantees constant rpm to improve the quality of the dough. The

same transmission was conceived to last longer and requires less

maintenance compared to the classic clutch wheel transmissions

used in this sector.

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––

l Speed control system for tools and bowl

(VDS-Vario Drive System)

Bottom Discharge System

Example of configuration - two MD-mixers with transport belt under

Double Mixing Tool

d

a B

Technical Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

Model doUGH FloUr Bowl Power oF sPiral Power oF Bowl weiGHt diMensions MM

caPacity caPacity volUMe 1:st/2:nd sPeed a B c d

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD-W 160 160 kg 100 kg 270 l 9.0 kW/15.0 kW 2.2 kW 1250 kg 1810 925 1770 2260

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD-W 240 240 kg 150 kg 380 l 9.0 kW/15.0 kW 2.2 kW 1700 kg 1885 1070 1770 2315

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

MD-W 400 400 kg 250 kg 600 l 13.0 kW/23.0 kW 2.2 kW 2500 kg 2300 1200 1920 2545

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– –––––––––––––––––––

c

14

Page 15

15

Page 16

We have the equipment and expertise

you need for your bakery

IllustratIon & InformatIon, Borås

Sveba-Dahlen develops, markets and manufactures bread lines,

rack ovens, deck ovens, tunnel ovens, proving chambers and

fermentation lines. We supply to bakeries, shops and supermarkets,

industrial bakeries, restaurants and catering establishments of all

sizes, all over the world.

Visit our website!

www.sveba-dahlen.com

Sveba-Dahlen AB, 518 32 Fristad

Tel: 033-15 15 00, Fax: 033-15 15 99, mail@sveba-dahlen.se

2013 01 18 / art nr 990020-002

Loading...

Loading...