Page 1

Product Presentation

Intermediate Provers

Page 2

Customer-adapted provers...

All dough need to rest. The Glimek pocket provers and conveyor

provers allows you to adapt resting time and production capacity

to suit your needs. For an even flow in your production our pocket

provers and conveyor provers opens the possibility for both smaller

and larger bakeries to optimize production and regulate resting time

for all doughs.

...and top line step-by-step elevators

Step-by-step elevators for transport of dough pieces i. e. from a

rounder up to a Intermediate Conveyor Prover. Designed for

heavy-duty industrial environments with a capacity range

of up to 3 600 pcs/h.

Find out more on our website www.sveba-dahlen.com

2

Page 3

Product Range

Intermediate Provers

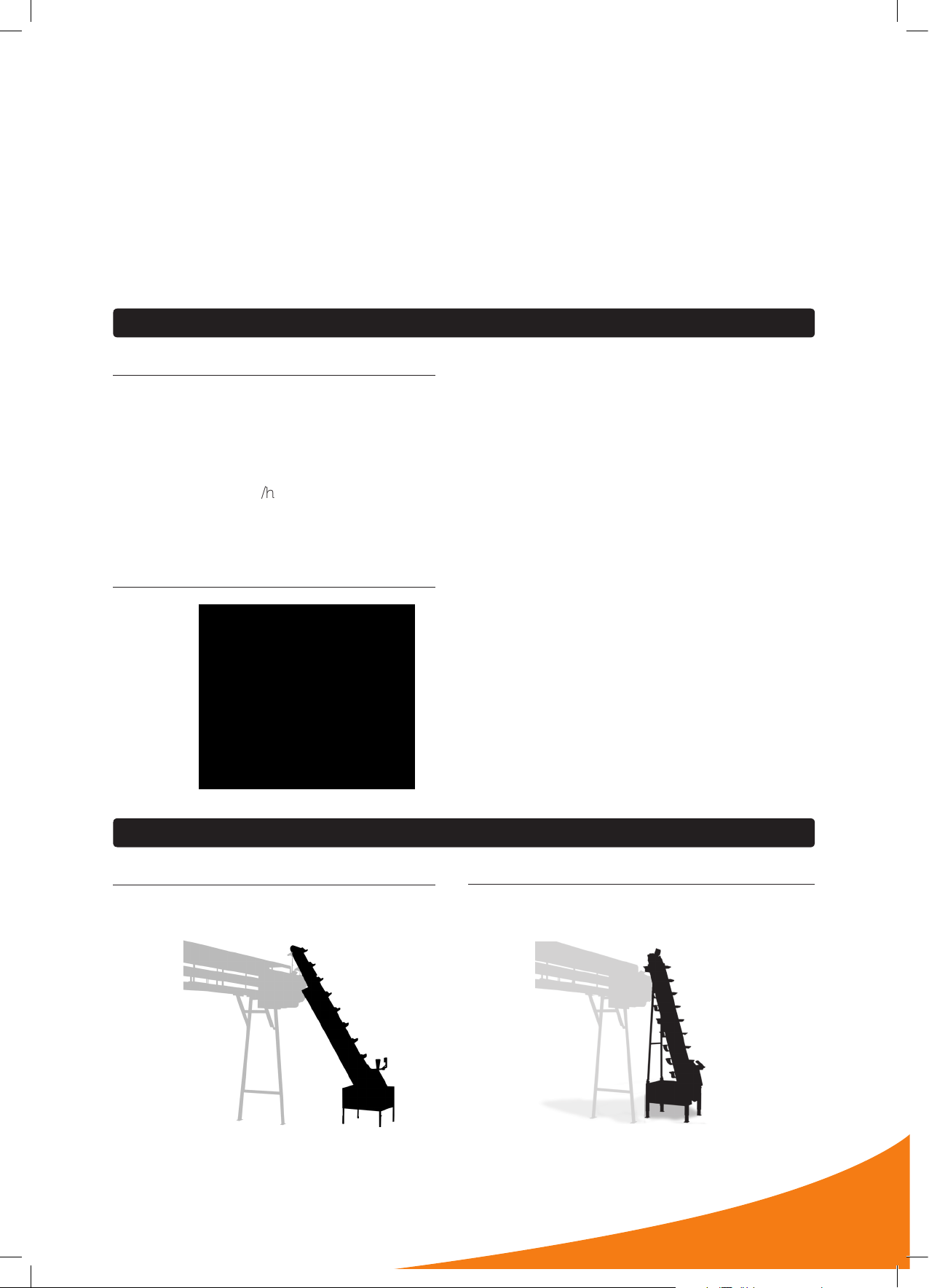

Provers

IPP – Intermediate Pocket Prover

Pocket Prover

Modular system

for 6, 8 or 10 pockets

Capacity:

1200, 1800 or 3000 pcs/h

ICP

Conveyor Prover

1 - 4 decks and

custom adapted lengths

Capacity: up to 3600 pieces/h

Cup Elevators

CE-300 – Cup Elevator

Capacity: up to 2000 pieces/h

CE-500 – Cup Elevator

Capacity: up to 3600 pieces/h

3

Page 4

Intermediate Pocket Prover – IPP

IPP - Pocket Prover

For 6, 8 or 10 pockets

Capacity:

1200, 1800 or 3000 pcs/h

One of the most flexible pocket provers on the

market. Modulated for easy adaption in height and

width, available in standard models from 132 up to

940 eective pockets, larger Provers on request.

Solid construction in stainless steel materials.

Features

––––––––––––––––––––––––––––––––––––––––––––––––––––––

Weight range 100-1500 grams. Capacity in 3 versions, up to 1200,

1800 or 3000 dough pcs /h. Non-stick coated transfer box.

Motor drive directly on shaft (no chains or timing belts). Operation

panel easy accessible under projecting overhang (as standard)

Electrical cabinet in working height position with power supply and

sockets for divider, rounder and moulder. Easy to clean.

Infeed shute, 1 200

V-belt infeed, 1 800

Formula for calculating number of

needed eective pockets:

––––––––––––––––––––––––––––––––––––––––––––––––––––––

Capacity rate / hour

60

X desired proving time in min.

= total Effective Pockets

Options

––––––––––––––––––––––––––––––––––––––––––––––––––––––

l Collection drawers

l UV-lighting

l Synchronized speed with divider (not for 1 200)

l Outfeed cross conveyor (standard on 3 000)

l Outfeed cross conveyor, reversible (additional)

l Guiding plates (not for 1 200)

l Humidification system

l Outlet sliding plate (not for 3 000)

l Piece counter, electronic

l Infeed from back side

Technical

––––––––––––––––––––––––––––––––––––––––––––––––––––––

Capacity range ................................................max 3000 pcs/h

Weight range ...........................................................100-1500 g

El. load ............................................................... 5.95 – 8.63 kW

(depending on connected make-up machines)

Air supply (double infeed) ............................................... 6 bar

Number of eective pockets ....................................... 132-940

Dual infeed, 3 000

Nylon mesh pockets

Non-stick coated transferbox

4

Page 5

Measurements

–––––––––––––––––––––––––––––––––––––––––––

A B C D

–––––––––––––––––––––––––––––––––––––––––––

6 pockets 1955 1930 2040 2600

–––––––––––––––––––––––––––––––––––––––––––

8 pockets 2375 1930 2040 2600

–––––––––––––––––––––––––––––––––––––––––––

10 pockets 2795 1930 2040 2600

–––––––––––––––––––––––––––––––––––––––––––

Extra module – + 590 – –

–––––––––––––––––––––––––––––––––––––––––––

Height ext. module – – + 500 + 500

–––––––––––––––––––––––––––––––––––––––––––

A

B

D

C

Technical

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Max capacit y, pcs/h 1 200

(1)

1 800

NO OF POC KETS I N EACH PROVING PROVIN G PROVIN G

SWING/NUMBER OF

EFFEC TIVE SW INGS *

EFFECTIVE TIME AT EFFEC TIVE TIME AT EFFEC TIVE TIME AT

POCKETS 1200 PCS/H POCKETS 1800 PCS/H POCKETS 3000 PCS/H

Low Provers H=2600 mm**

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/22 132 6,6 132 4,3 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/22 176 8,8 176 5,7 176 3,4

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/22 220 11,0 220 7,1 220 4,3

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/40 – – 240 7,8 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/40 – – 320 10,3 320 6,2

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/40 – – 400 12,9 400 7, 8

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/60 – – 360 11,6 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/60 – – 480 15,5 480 9,3

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/60 – – 600 19,4 600 11, 6

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/78 – – 468 1 5,1 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/78 – – 624 20,2 624 12,1

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/78 – – 78 0 25,2 780 15 ,1

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

High Provers H =3100 mm

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/26 156 7, 8 15 6 5,0 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/26 208 10,4 208 6,7 208 4,0

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/26 260 13 ,0 260 8,4 260 5,0

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/48 –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/48 –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/48 – – 480 15,5 480 9,3

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/72 – – 432 14, 0 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/72 – – 576 18 ,6 576 11,2

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/72 – – 720 23,3 720 14,0

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6/94 – – 564 18 ,2 – –

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

8/94 – – 752 24,3 752 14 ,6

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10/94 – – 940 30,4 940 18,2

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

* Total number of swings is always 4 more than effective number of swings

** Not recommended in combination with MO881 Moulder

– 288 9,3 – –

– 384 12,4 384 7, 4

(2)

3 000

(3)

Infeed

––––––––––––––––––––––––––

(1)

IPP with infeed chute. Photocell controlled. Prover runs

intermittently. Emptying mode.

Control panel under projecting overhang, power supply for

divider, rounder and moulder.

––––––––––––––––––––––––––

(2)

IPP with single infeed V-belt

conveyor L=750 mm. Photocell

controlled, non-stick coated,

infeed conveyor combined with

continuous pocket prover drive.

Variable speed on the prover.

Control panel under projecting overhang, power supply for

divider, rounder and moulder.

––––––––––––––––––––––––––

(3)

IPP with dual infeed conveyor

L=750 mm, centrally placed, photocell controlled, non-stick coated

infeed V-belt conveyors. Flap

system guides the dough pieces

after rounder. Compressed air is

required, 6 bar. Variable speed

on the prover. Control panel

under projecting overhang, power

supply for divider, rounder and

moulder, outfeed cross conveyor.

––––––––––––––––––––––––––

5

Page 6

Intermediate Conveyor Prover – ICP

ICP - 1, 2, 3 or 4 decks conveyor prover

Capacity: up to 3600 pieces/h

A conveyor prover for all types of bakeries and can be

made in 1, 2, 3 or 4 decks and length customized.

Space saving system, can be mounted from ceiling.

Features

––––––––––––––––––––––––––––––––––––––

Removable plastic covers on both sides. Belt

width 350 mm. Made of strong special aluminum

profiles. Drum motors with frequency controlled

drive as standard.

Outlet sliding plate - fixed (option). Outlet sliding

plate - turnable 1500 mm or 2500 mm (option).

Separate stands, ceiling suspensions as option.

Technical drawing needed.

Options

––––––––––––––––––––––––––––––––––––––

l Set of ceiling suspensions – one for drive

end and one for each 2,5 meter

l Outlet sliding plate - Fixed

l Outlet sliding plate - Turnable L=1500

l Outlet sliding plate - Turnable L=2500

l Separate stands

l Straight in-line feeded

l Wall supports

Measurements

––––––––––––––––––––––––––––––––––––––

CEILING

75

min 410

201

220

390

579

768

200

min 570

442

WALL

Formula for calculating conveyor prover length:

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Capacity rate / hour

60

A= 0.25 (meters) for dough pieces over 1 kg

A= 0.20 (meters) for dough pieces up to 1

desired proving time in minutes x A

X

= total length in meters

kg

Technical

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Length of each deck ......................customized, normally 5-12 meter

Capacity range ........................................... up to 3600 dough-pcs/h

Weight range, subject to capacity

and dough characteristics ...............................................100-1500 g

El. load .................................................. 0.22 kW/deck as standard

6

Page 7

Cup Elevator

CE-300 – Cup Elevator

Capacity: up to 2000 pieces/h

A step-by-step elevator for transporting dough

pieces from Rounder up to the Intermediate

Conveyor Prover.

Features

–––––––––––––––––––––––––––––––––––––––––––––––––––

The conveyor belt, 200 mm wide, has riveted cups on every 300

mm. The timing of each dough piece is controlled by a photocell.

The infeed hopper guides the dough piece into an empty cup.

Technical

–––––––––––––––––––––––––––––––––––––––––––––––––––

Capacity range ................................ up to 2000 dough-pcs/h

Weight range*: .................................................... 100-1500 g

Distribution height max ........................................ 3500 mm

El. load ......................................................................0.55 kW

* subject to capacity and dough characteristics

Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––

2572 –3 871

2062–3446

580

600

Cup Elevator

CE-500 – Cup Elevator

Capacity: up to 3600 pieces/h

A step-by-step vertical chain elevator for

transporting the dough piece from the

rounder up to the intermediate conveyor

prover. A heavy duty elevator for use in

industrial bakeries.

Features

–––––––––––––––––––––––––––––––––––––––––––––––––

The timing of each dough piece is controlled by a photocell.

The infeed hopper guides the dough piece into an empty cup.

Additional distributing height (option). The CE-500 is calculated

for max. distributing height 2 806 mm (=24 cups), but can be

made higher, for distributing height up to 3 897 mm.

Technical

–––––––––––––––––––––––––––––––––––––––––––––––––

Capacity range .................................up to 3600 dough-pcs/h

Weight range*: .....................................................100-1500 g

El. load .......................................................................0.75 kW

* subject to capacity and dough characteristics

Measurements

–––––––––––––––––––––––––––––––––––––––––––––––––––

A–DISTRIBUTING B–TOTAL HEIGHT NUMBER

HEIGH T (MM) (MM ) O F CUPS

––––––––––––––––––––––––––––––

1959 - 2070 2519 - 2630 18

––––––––––––––––––––––––––––––

2070 - 2192 2630 - 2752 19

––––––––––––––––––––––––––––––

2192 - 2315 2752 - 2875 20

––––––––––––––––––––––––––––––

2315 - 2438 2875 - 2998 21

––––––––––––––––––––––––––––––

2438 - 2560 2998 - 3120 22

––––––––––––––––––––––––––––––

2560 - 2684 3120 - 3244 23

––––––––––––––––––––––––––––––

2684 - 2806 3244 - 3366 24

––––––––––––––––––––––––––––––

2806 - 2928 3366 - 3488 25

––––––––––––––––––––––––––––––

2928 - 3052 3488 - 3612 26

––––––––––––––––––––––––––––––

3052 - 3174 3612 - 3734 27

––––––––––––––––––––––––––––––

3174 - 3297 3734 - 3857 28

––––––––––––––––––––––––––––––

3297 - 3420 3857 - 3980 29

––––––––––––––––––––––––––––––

3420 - 3543 3980 - 4103 30

––––––––––––––––––––––––––––––

3543 - 3665 4103 - 4225 31

––––––––––––––––––––––––––––––

3665 - 3776 4225 - 4336 32

––––––––––––––––––––––––––––––

3776 - 3897 4336 - 4457 33

––––––––––––––––––––––––––––––

350

350

B

A

7

Page 8

We have the equipment and expertise

you need for your bakery

IllustratIon & InformatIon, Borås

Sveba-Dahlen develops, markets and manufactures bread lines,

rack ovens, deck ovens, tunnel ovens, proving chambers and

fermentation lines. We supply to bakeries, shops and supermarkets,

industrial bakeries, restaurants and catering establishments of all

sizes, all over the world.

Visit our website!

www.sveba-dahlen.com

Sveba-Dahlen AB, SE-518 32 Fristad, Sweden

Tel: +46 33 15 15 00, Fax: +46 33- 15 15 99, mail@sveba-dahlen.se

2013 06 04 / art nr 990026-002

Loading...

Loading...