Service Manual

LCD TV

CHASSIS : SL-115P

MODEL :

TX-17LX2(UK)

TX-17LX2F(EUROPE)

Power Source

“AC 100-240V, 50/60Hz”

Power Consumption

Average use : 50W

Stand-by condition : 3w

“TV set DC 15v, 1.2A max”

LCD

“17-inch(434.38mm), 15:9

aspect ratio LCD panel”

Screen Size

372.48mm(H) * 223.488mm(V)

Sound

Speaker

“5cm * 9cm, 2pcs, 4

”

Audio Output

“5W(2.5W+2.5W), 10%THD”

Headphones

M3(3.5mm) Jack * 1

Receiving Systems / Band name

“PAL B, G, H, SECAM B, G, SECAM L/L”

VHF E2-E12

VHF H1-H2(ITALY)

VHF A-H(ITALY)

UHF E21-E69(UK only)

CATV(S01-S05)

CATV S1-S10 (M1-M10)

CATV S11-S20 (U1-U10)

CATV S21-S41 (Hyperband)

PAL 525/60

Playback of NTSC tape from

some PAL video recorders

(VCR)

M.NTSC

Playback From M.NTSC video

recorders (VCR)

NTSC (AV input only)

Playback From NTSC video

recorders (VCR)

Aerial-ear

UHF(UK only)/VHF

Operating Conditions

Temperature : 5-35°…

Humidity : 5%-90% RH (noncondensing)

Connection Terminals

AV1 (Scart connecter)

“21 Pin socket (Audio/Video

in, Audio/Video out, RGB in)”

AV2

VIDEO

RCA PIN Type * 1

S-VIDEO

Mini DIN 4-pin

AUDIO L-R

RCA PIN Type * 2

Dimensions (W * H * D)

Including TV Stand

532mm * 297mm * 190mm

TV Set Only

532mm * 297mm * 68mm

Weight (Mass)

6.2Kg NET

Note :

DSL115PEF0

2003 Matsushita Electric Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

1. Safety Precautions 2

1.1 General Guidelines 2

1.2 Touch-Current Check 2

2. Prevention of Electro Static Discharge(ESD) to

Electrostatically Sensitive(ES) Devices 3

3. Chasis Board Layout 4

4. Servicing method 5

4.1 Removing the tilt base 5

4.2 Removing the rear cover 5

4.3 Removing the Switch Unit 6

4.4 Removing the C-Board 6

4.5 Removing the E-Board 6

4.6 Removing the F-Board 6

4.7 Removing the D-Board 7

4.8 Removing the Speaker Unit 7

4.9 Removing the BRKT hinge 7

4.10 Removing the Shield pcd assy 7

4.11 Removing the LCD Panel 8

4.12 Removing the A-Board, B-Board 8

5. Service Mode Function 9

5.1 How to enter SERVICE 1 9

1

Design and Specifications are subject to change without notice.

Weight and Dimensions shown are approximate.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

6. Conductor Views 10

6.1 MAIN PCB(TOP) 10

6.2 MAIN PCB(BOTTOM) 11

7. Block and Schematic Diagrams 12

7.1 Schematic Diagram Notes 12

7.2 Power Block Diagram 13

7.3 Power Block Diagram 14

7.4 VCTI Block Diagram 15

7.5 Input Block Diagram 16

7.6 Memory AMP Schematic Diagram 17

7.7 AD9883 Schematic Diagram 18

7.8 Deinterlace Schematic Diagram 19

7.9 SDRAM Schematic Diagram 20

7.10 Image Processor Schematic Diagram 21

7.11 LVDS, KEY Schematic Diagram 22

8. Parts Location & Mechenical Replacement

Parts List 23

8.1 Part Location 23

8.2 Packing Exploded View 24

9. Service Parts List 25

Contents

2

1. Safety Instruction

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all part

which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers,

insulation papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

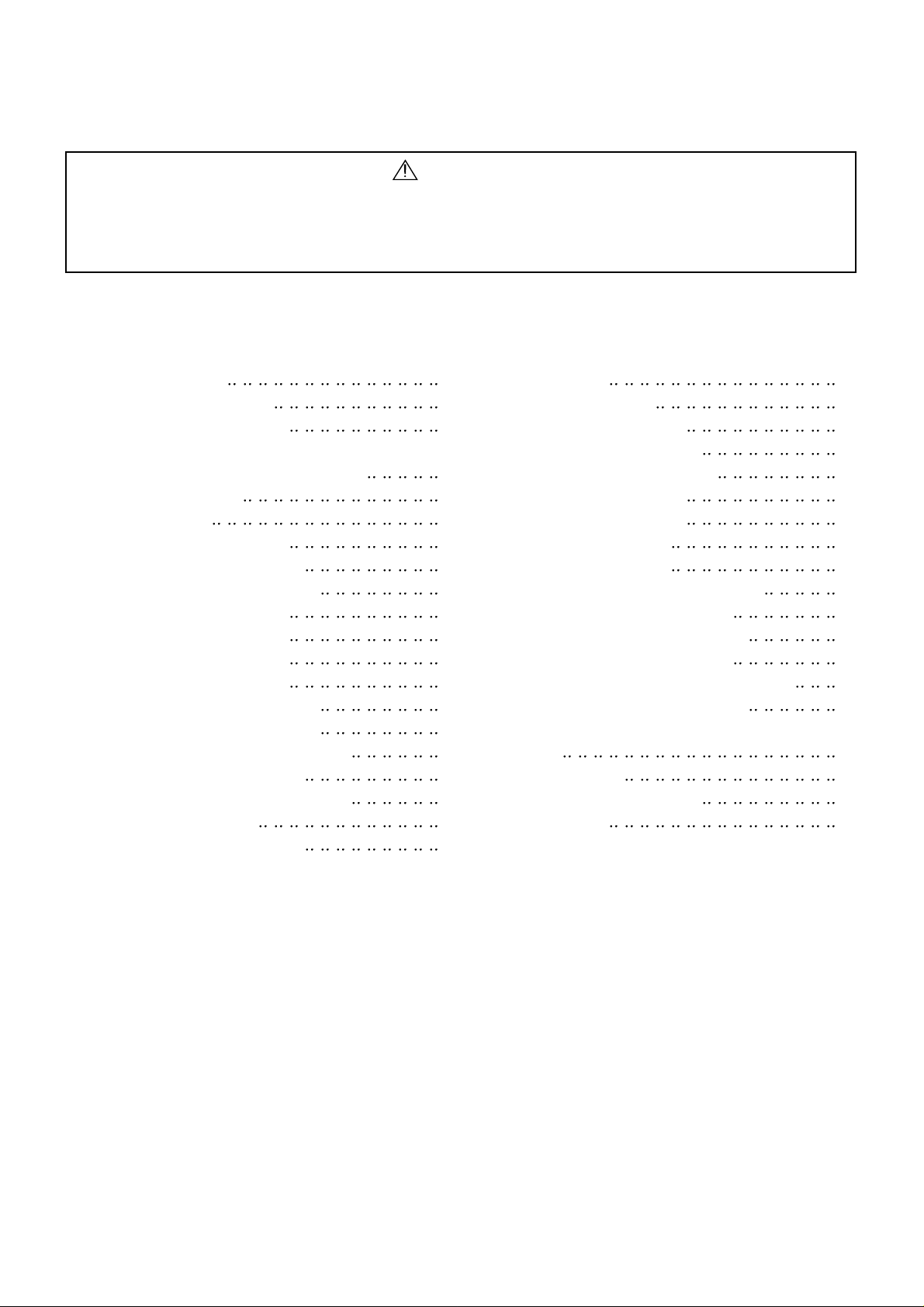

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this chack.

2. Connect a measuring network for touch currents between each exposed matallic part on

the set and a good earth ground such as a water pipe, as shown in Figure1.

3. Use Leakage Current Tester(Simpson 228 or equivalent) to measure the potential across

the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

6. The potential at any point (TOUGH CURRENT) expressed as voltage U1 and U2, does not

exceed the following values:

For a. c.: U1 = 35V(peak) and U2 = 0.35V(peak);

For d. c.: U1 = 1.0V,

Note:

The limit value of U

2 = 0.35V(peak) for a. c. and U1

= 1.0V for d. c. correspond to the

values 0.7 mA (peak) a. c. and 2.0 mA d. c.

The limit value U

1 = 35V(peak) for a. c. correspend to the value 70 mA(peark) a. c. for

frequencies greater than 100kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the

equipment should be repaired and rechecked before it is returned to the customer.

Measuring network for TOUCH CURRENTS

Resistance values in ohms( )

V: Voltmeter or oscilloscope(r.m.s. or peak reading)

Input resistance: 1M

Input capacitance: 200 pF

Frequency range: 15Hz to 1 MHz and d.c. respectively

NOTE - Appropriate measures should be taken to obtain the correct value in case of non-

sinusoidal waveforms.

Figure 1

COLD

WATER PIPE

(EARTH

GROUND

TO

APPLIANCES

EXPOSED

METAL PARTS

3

2 Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive(ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical

ES devices are integrated circuits and some field-effect transistors and semiconductor “chip”

components. The following techniques should be used to help reduce the incidence of

component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped

assembly, drain off any ESD on your body by touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging ESD wrist strap, which should be

removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a

conductive surface such as alminum foil, to prevent electrostatic charge buildup or exposure

of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as

“anti-static(ESD protected)” can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical chages sufficient to

damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before

you are ready to install it.(Most replacement ES devices are packaged with leadse

electrically shorted together by conductive foam, alminum foil or comparable conductive

material).

7. Immediately before removing the protective material from the leads of a replacement ES

device, touch the protective material to the chassis or circuit assembly into which the device

will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise

hamless motion such as the brushing together of your clothes fabric or the lifting of your foot

from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES

device).

There are special components used in this epuipment which are imporant for safety.

These parts are maked by in the schematic diagrams, Exploded Views and replacement parts list. lt is

essential that these critical parts should be replaced with manufacturer’s specified parts to prevent shock,

fire, or other hazards. Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

4

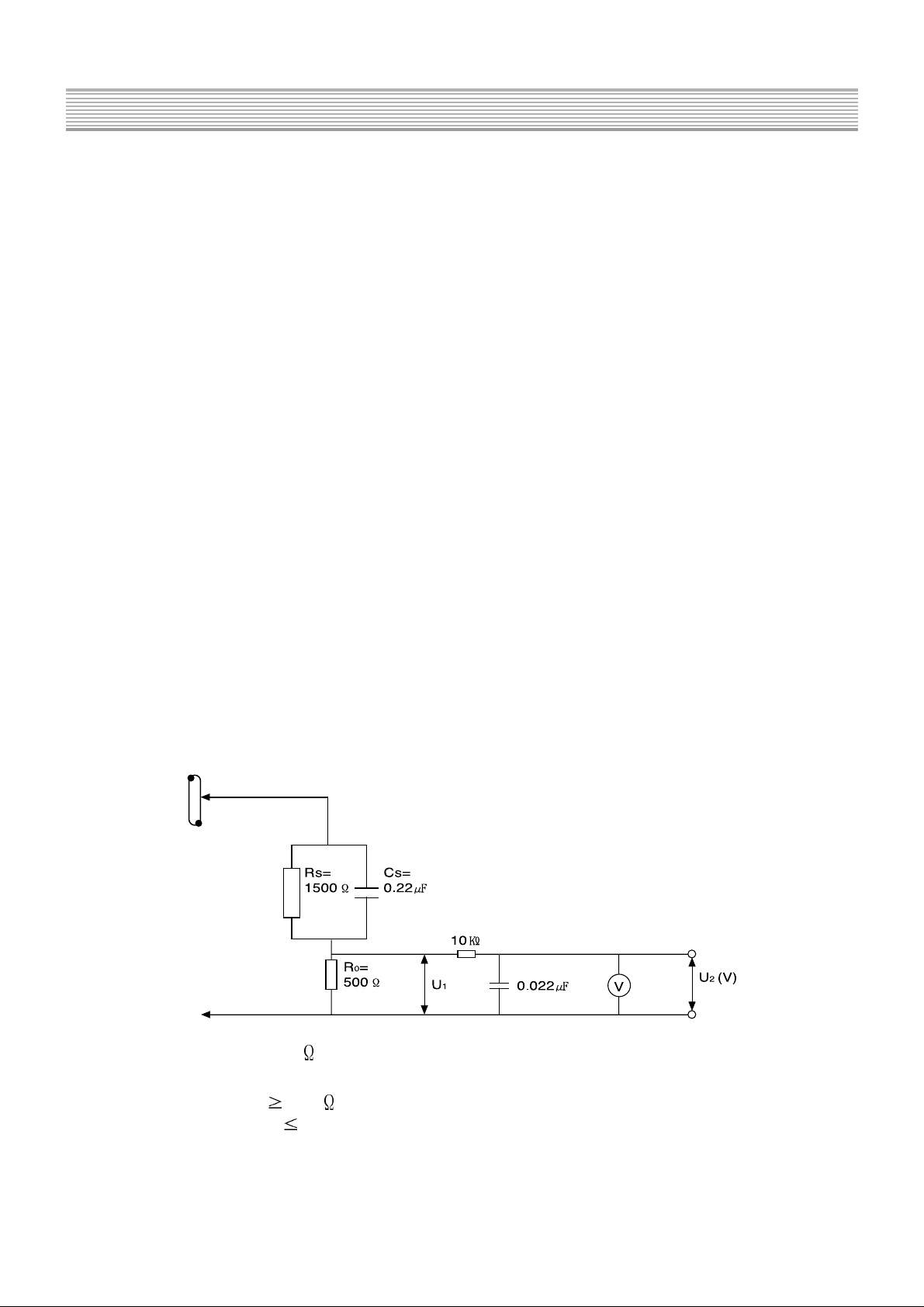

3. Chasis Board Layout

A

C

D

E

F

B

Board Name Function

A-Board MAIN PCB

B-Board INVERTER PCB

C-Board

CONTROL PCB

D-Board AV PCB

E-Board E/PHONE PCB

F-Board IR/LED PCB

5

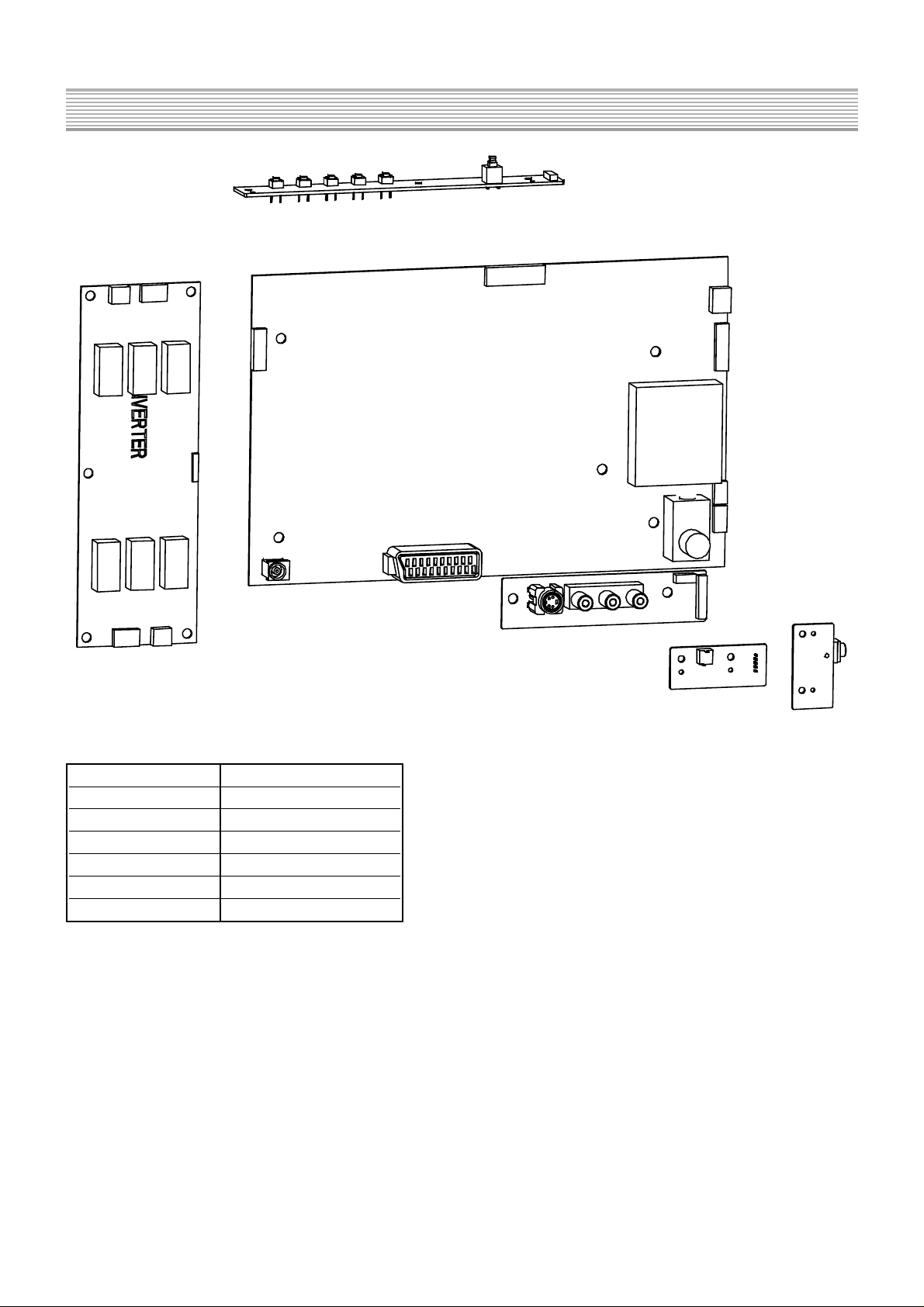

4. Servicing method

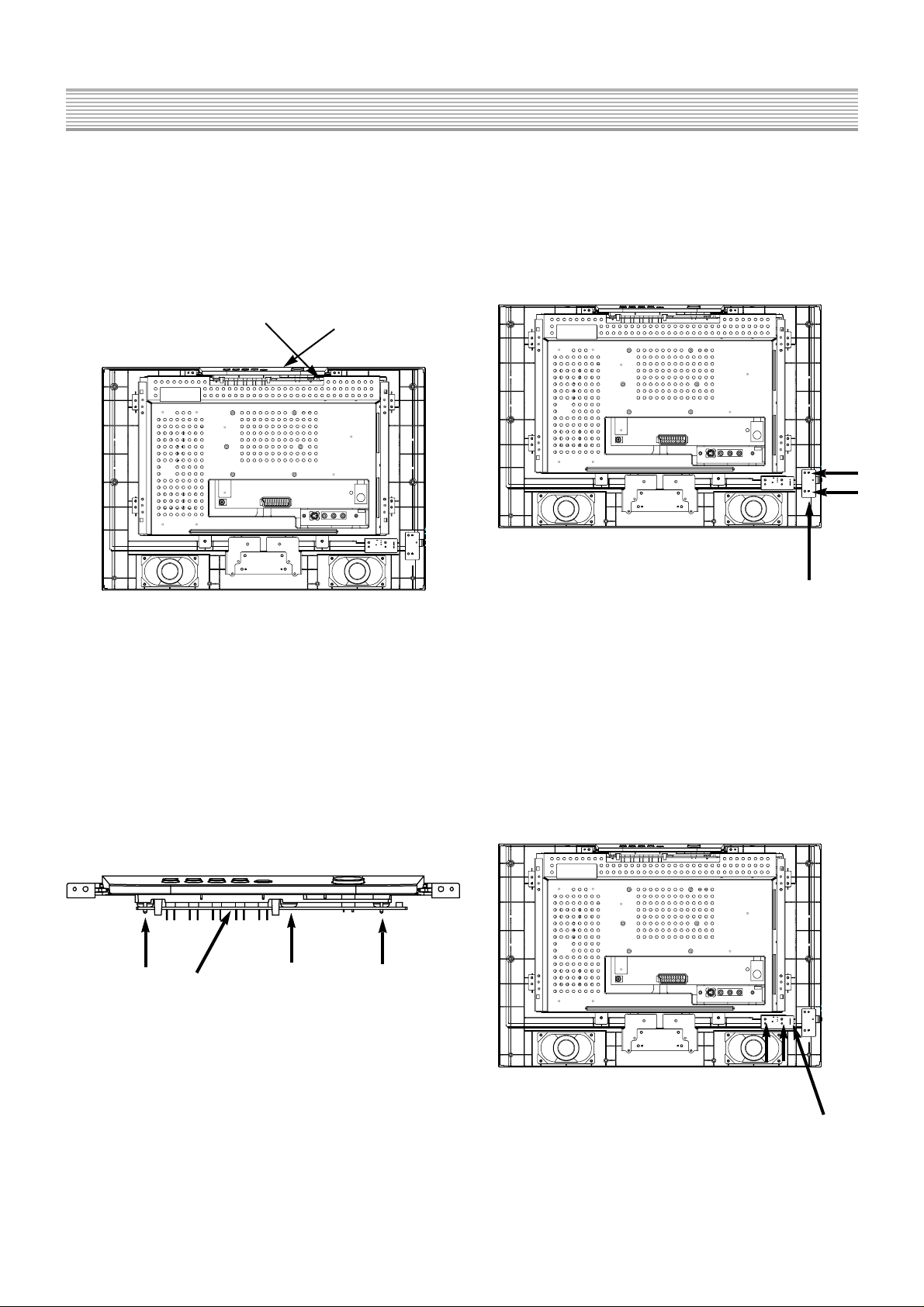

4.1. Removing the tilt base

1. Lay down the main unit so that the rear

cover faces upward.

2. Remove the fixing screw(2pcs).

3. Remove the hinge cover.

4. Remove the fixing screws(4pcs).

5. Remove the tilt base.

4.2. Removing the rear cover

1. Remove the tilt base.(See 5.1.)

2. Remove the fixing screw(10pcs)

3. Remove the rear cover.

Hinge cover

Tilt base

6

Servicing method

4.3. Removing the switch unit

1. Remove the rear cover(See 5.2.)

2. Disconnect the coupler(C1).

3. Remove the fixing screws(2pcs).

4. Remove the switch unit.

4.4. Removing the C-Board

1. Remove the switch unit(See 5.3.)

2. Remove the fixing screws(3pcs)

3. Remove the C-Board.

4.5. Removing the E-Board

1. Remove the rear cover(See 5.2.)

2. Disconnect the coupler(E1).

3. Remove the fixing screws(2pcs).

4. Remove the E-Board.

4.6. Removing the F-Board

1. Remove the rear cover(See 5.2.)

2. Disconnect the coupler(F1).

3. Remove the fixing screws(2pcs).

4. Remove the F-Board.

Swich unita

Coupler(C1)

C-Board

Coupler(E1)

Coupler(F1)

7

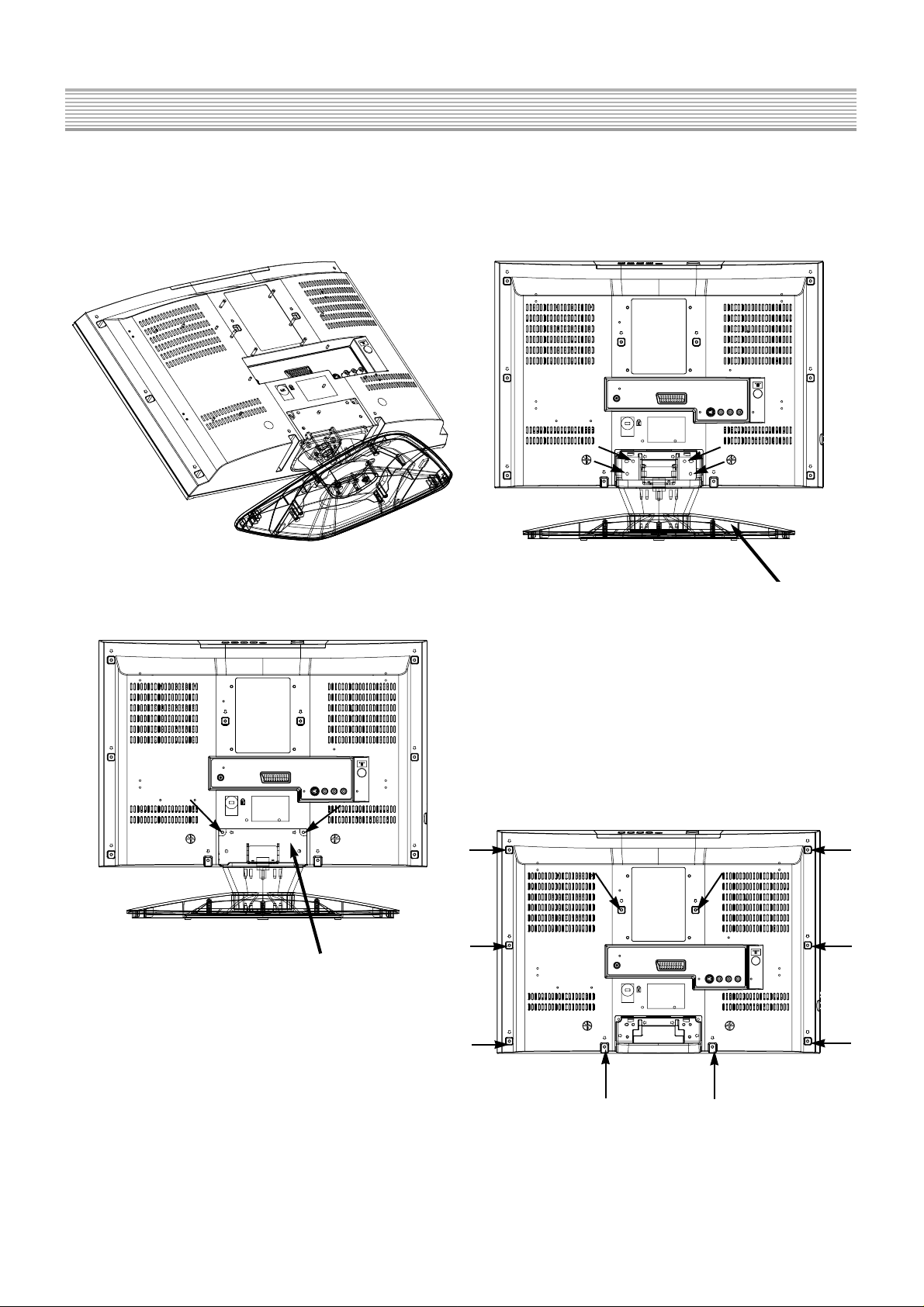

Servicing method

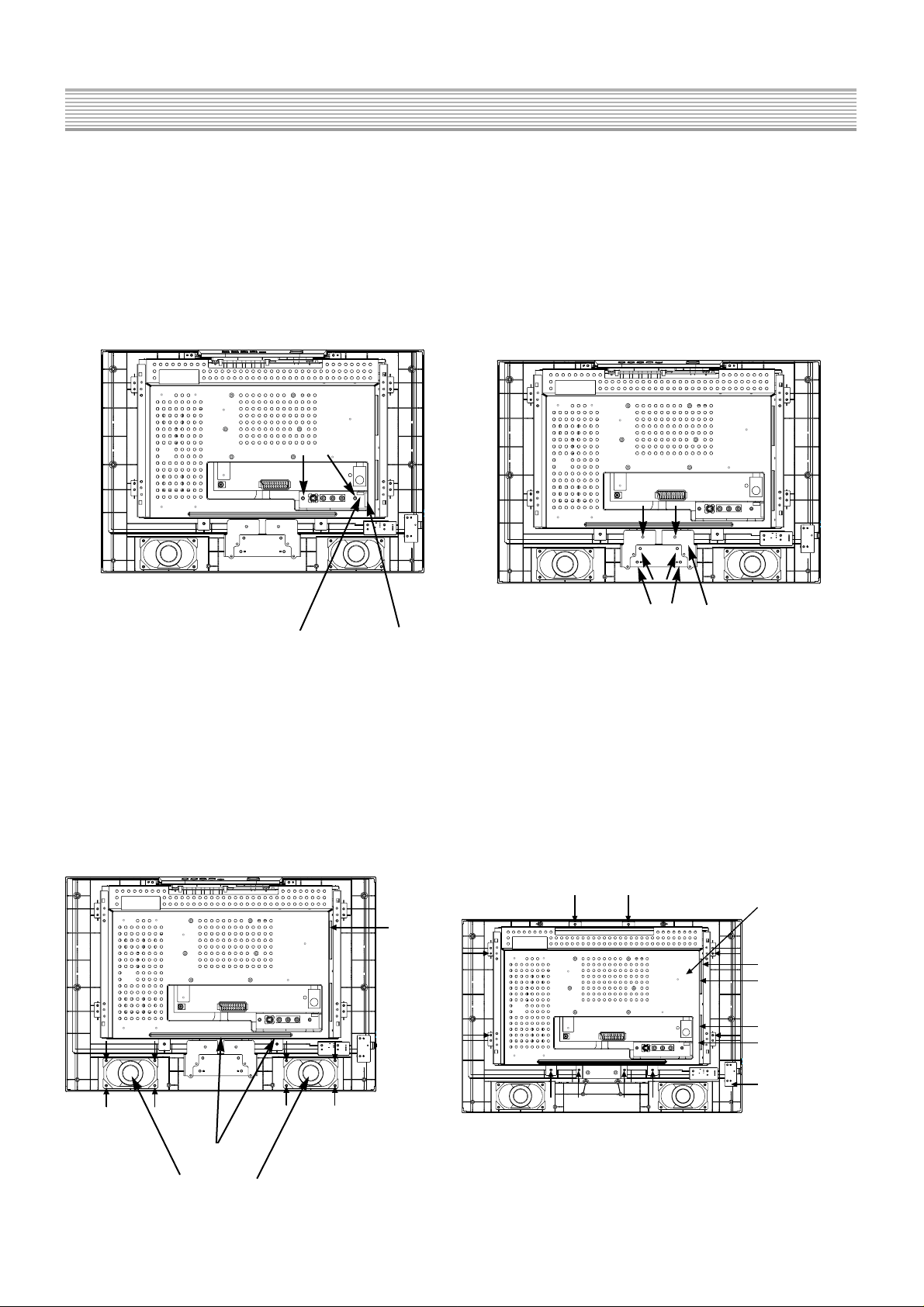

4.7. Removing the D-Board

1. Remove the rear cover(See 5.2.)

2. Disconnect the coupler(D1,D2).

3. Remove the fixing screws(2pcs).

4. Remove the D-Board.

4.8. Removing the Speaker unit

1. Remove the rear cover(See 5.2.)

2. Remove the fixing screws(8pcs).

3. Disconnect the coupler(A1), and unlock the

cable clamper and hook to free the cable.

4. Remove the speaker units.

4.9. Removing the BRKT hinge

1. Remove the rear cover(See 5.2.)

2. Remove the fixing screws(6pcs).

3. Remove the BRKT hinge.

4.10. Removing the Shield pcb assy.

1. Remove the Switch unit(See 5.3.)

2. Remove the BRKT hinge(See 5.9.)

3. Remove the fixing screws(10pcs).

4.Disconnect the coupler (A1), (A2), (A3),

(A4), (E1).

5. Remove the Shield pcb assy.

Coupler(A1)

Shield pcb assy

Coupler(A1)

Coupler(A2)

Coupler(A3)

Coupler(A4)

Coupler(E1)

Coupler(D1)Coupler(D2)

Clamper

Speaker

BRKT hinge

8

Servicing method

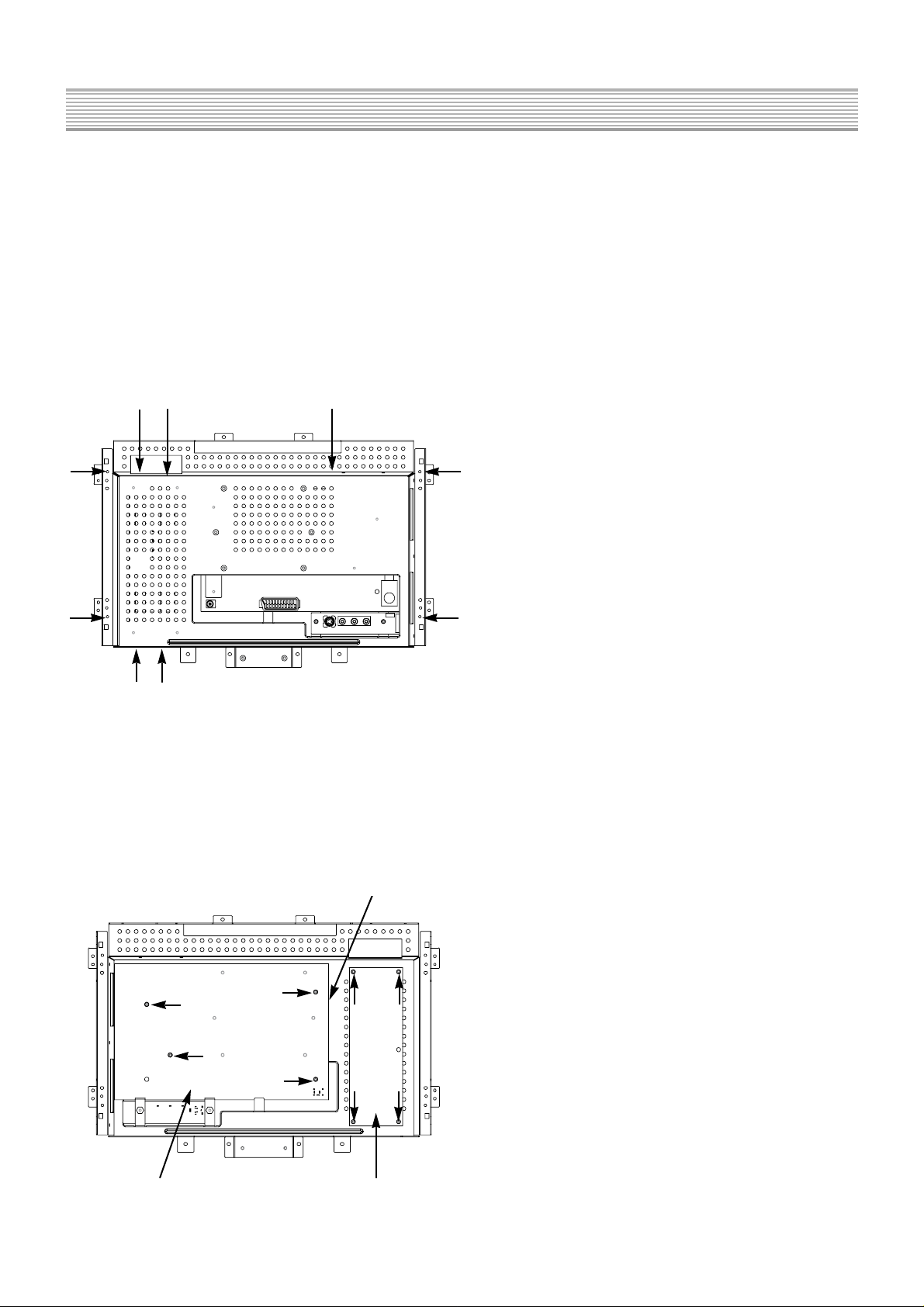

4.11. Removing the LCD panel.

1. Remove the Shield pcb assy.(See 5.10.)

2. Remove the fixing screws(4pcs).

3. Disconnect the coupler (A5), (B1), (B2),

(B3), (B4).

4. Remove the LCD panel.

4.12. Removing the A-board, B-board.

1. Remove the LCD panel.(See 5.11.)

2. Remove the fixing screws(8pcs).

3. Disconnect the coupler(A6).

4. Remove the A-board, B-board.

Coupler(B1),(B2)

Coupler(B3),(B4) Coupler(A5)

Coupler(A6)

B-boardA-board

9

5. Service Mode Function

The following setting and adjustment can be adjusted by remote control in Service Mode.

6.1. How to enter SERVICE 1

1. Set the channel to CH99.

2. Press HOLD button on remote control.

Note: To exit to Service mode, press N or Power button on remote control.

99

Panel R Drive

G Drive

B Drive

Set for UK<Yes>

Key Command

Press the top and bottom key,and

select the functions.

Use left and right key to control the

function values.

6. Conductor Views

10

PART LOCATION

IC TRANSISTOR

IC1 A-2 Q1 F-3

IC2 B-1 Q2 F-3

IC3 E-4 Q3 B-4

IC4 A-3 Q4 D-2

IC5 B-2 Q5 D-3

IC6 A-2 Q6 A-3

IC7 E-3 Q7 A-3

IC8 A-4 Q9 D-2

IC9 B-1 Q10 D-3

IC10 A-4 Q11 B-4

IC11 B-3 Q12 E-1

IC12 F-5 Q14 D-3

IC13 C-3 Q15 D-2

IC14 A-3 Q16 F-4

IC15 B-4 Q17 G-1

IC16 B-2 Q18 G-1

IC17 D-4 Q21 F-1

IC18 A-4 Q23 D-2

IC19 E-3 Q24 F-4

IC20 A-2 Q25 C-2

IC21 F-3 Q26 C-2

IC22 B-3 Q27 F-4

IC23 C-2 Q31 C-2

IC24 A-3 Q32 C-2

IC25 F-3 Q33 C-2

IC26 C-2 Q34 B-2

IC27 F-3 Q35 C-2

IC29 E-3 Q36 D-2

IC30 F-4 Q37 D-2

IC31 C-2 Q38 D-2

IC33 C-1 Q39 C-2

IC34 B-1 Q40 C-2

IC35 E-4 Q41 C-2

IC38 B-3

IC39 B-4

IC40 B-4

6.1. MAIN PCB (TOP)

11

Conductor Views

6.2. MAIN PCB (BOTTOM)

12

7 Block and Schematic Diagrams

Notes:

1. Resistor

All resistors are cabon 1/4W resistor, unless marked as follows:

Unit of resistance is OHM[ ] (K=1,000, M=1,000,000).

: Nonflammable : Metal Oxide

: Solid : Metal Film

: Wire Wound : Fuse

2. Capacitor

All capacitors are ceramic 50V capacitor, unless marked as follows:

Unit of capacitance is

F, unless otherwise noted.

: Temperature Compensation : Electrolytic

: Polyester : Bipolar

: Metalized Polyester : Dipped Tantalum

: Polypropylene : Z-Type

3. Coil

Unit of inductance is

F, unless otherwise noted.

4. Test Point

: Test Point position

5. Earth Symbol

: Chassis Earth (Cold) : Line Earth (Hot)

6. Voltage Meaaurement

Voltage is measured by a DC voltmeter.

Conditions of the measurement are the following:

Power Source AC 100-240V, 50/60Hz

Receiving Signal Colour Bar signal(RF)

All customer’s controls Maximum positions

7. Number in red circle indicates waveform nember.

(See wavefom pattern table.)

8. When arrow mark( ) is found, connection is easily found from the direction of arrow

9. Indicates the major signal flow. : Video Audio

10. This schematic diagram is the latest at the time of printing and subject to change

without notice.

Z

T

m

NP

M

Remarks:

1. The Power Circuit contains a circuit area which uses a separate power supply to

isolate the earth connection.

The circuit is defined by HOT and COLD indications in the schematic diagram. Take

the follwing precautions.

All circuits, except the Power Circuit, are cold.

Precautions

a. Do not touch the hot part or the hot and cold parts at the same time or

you may be shocked.

b. Do not short-circuit the hot and cold circuits or a fuse may blow and

parts may break.

c. Do not connect an instrument, such as an oscilloscope, to the hot and

cold circuits simultaneously or a fuse may blow.

Connect the earth of instruments to the earth connection of the circuit

being measured.

d. Make sure to disconnect the power plug before removing the chassis.

2. Following diodes are interchangeable.

MA150-MA162(Replacement part)

Components identified by mark have special characteristics important for safety.

When replacing any of these components, use only manufacture’s specified parts.

Important Safety Notice

7.1. Schematic Diagram Notes

13

Block and Schematic Diagrams

7.2. Signal Block Diagram

14

Block and Schematic Diagrams

7.3. Power Schematic Diagram

15

Block and Schematic Diagrams

7.4. VCTI Schematic Diagram

16

Block and Schematic Diagrams

7.5. Input Schematic Diagram

17

Block and Schematic Diagrams

7.6. Memory AMP Schematic Diagram

18

Block and Schematic Diagrams

7.7. AD9883 Schematic Diagram

19

Block and Schematic Diagrams

7.8. Deinterlace Schematic Diagram

20

Block and Schematic Diagrams

7.9. SDRAM Schematic Diagram

21

Block and Schematic Diagrams

7.10. Image Processor Schematic Diagram

22

Block and Schematic Diagrams

7.11. LVDS, KEY Schematic Diagram

23

8. Parts Location & Mechanical Replacement Parts List

23

17

16

22

2

20

13

10

6

15

24

5

14

21

19

7

18

12

1

9

4

8

25

3

26

27

11

8.1. Parts Location

24

Parts Location & Mechanical Replacement Parts List

8.2. Packing Exploded View

25

9. Service Part List

ZZ100 48BEUR7636 TRANSMITTER REMOCON EUR7636060

ZZ110 PTACPWA941 ACCESSORY AS DLP-1712LHS

00020 4859000130 PLUG ANT TJB1726400(PANASONIC)

M822 4858219401 BAG INSTRUCTION L.D.P.E T0.05X280X470

ZZ120 PTBCSHA941 COVER BACK AS DLP-1712LHS

M211 4852170710 COVER BACK FR PPE+PS GY

M321 4853221800 BRKT KENSINGTON SECC T=1.0

M591 4855940600 DECO AV PS T=0.3

M781 4857818704 CLOTH BLACK FELT T0.7 L=55 W=15

M782 4857818705 CLOTH BLACK FELT T0.7 L=110 W=15

ZZ130 PTPKCPA941 PACKING AS DLP-1712LHS

0010 6520010100 STAPLE PIN AUTO W65

M801 4858066900 BOX CARTON DW-3

M802 4858067300 BOX ACCESSORY SW-2

M811 485819B700 PAD EPS 1712

M821 4858220001 BAG P.E PE FOAM T0.5X800X800

ZZ140 PTCACAA941 CABINET AS DLP-1712LHS

ADT1 4859000940 ADAPTER N0JZHK000011

JP401 7178301012 SCREW TAPPTITE TT2 WAS 3X10 MFZN BK M201+

HEADPHONE

JACK

M1F1 4851F00800 STAND AS DLP-1712 (PANA)

M1F1A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK M1F1+M211

M211A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK M211+M201

M211B 7002400812 SCREW MACHINE TRS 4X8 MFZN BK M211+M721

M211C 4852170810 COVER FRAME STAND FR PPE+PS GY

M211D 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK M211+M211C

M211E 4855421000 SPEC PLATE PE FILM T=0.05

M231 4852330410 PANEL CTRL FR PPE+PS GY

M231A 7178301011 SCREW TAPPTITE TT2 WAS 3X10 MFZN

M321 4853221700 BRKT HINGE SECC T1.6

M321A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK M321+M201

M321B 7002400812 SCREW MACHINE TRS 4X8 MFZN BK M321+M721

M381 4853822000 FRAME BAR SECC T1.0

M381A 7008300611 SCREW MACHINE WAS 3X6 MFZN M381+PANEL

M381B 7008300611 SCREW MACHINE WAS 3X6 MFZN M381+PANEL

M481 4854868910 BUTTON POWER FR PPE+PS GY

M491 4854960910 BUTTON CH FR PPE+PS GY

M491A 7178301011 SCREW TAPPTITE TT2 WAS 3X10 MFZN

M551 4855553801 DECO SENSOR GPPS SILK PRINT

M551A 7178301011 SCREW TAPPTITE TT2 WAS 3X10 MFZN

M681 4856819000 CLAMP WIRE NYLON 66

M682 4856819100 CLAMP WIRE NYLON 66 BK

M721 4857252700 SHIELD CASE SECC T1.2

M721A 7008300611 SCREW MACHINE WAS 3X6 MFZN M721 +

INVERTER

PCB

M721B 7008300611 SCREW MACHINE WAS 3X6 MFZN M721+MAIN

PCB

M721C 7008300611 SCREW MACHINE WAS 3X6 MFZN M721+M381

M721D 7178301212 SCREW TAPPTITE TT2 WAS 3X12 MFZN BK M721+M201

M731 4857300100 SHIELDRON 88X13X10(T)

M732 4857304001 SHIELDRON 13X40X6.0(T) PLATE INLET FILTER

M791 4857942200 SPONGE SPK POLYETHER POLYURETHANE FOAM 1712

PA11 4859001960 CABLE LVDS AS 12507HS-20+15D3SHS=140

PA11A 2TA00650SV TAPE ALUMINUM T0.06X50 3M(AL35) SILVER

PAV11 4850K01900 CORE FERRITE BNF-1730

PV601 4850K01900 CORE FERRITE BNF-1730

PWC1 4859910110 CORD POWER AS EU KKP-419C KKS-15A 1.8M

V901 485LD02174 LCD PANEL LC171W03-A4K6

V902 4850M011NV MODULE INVERTER DS-1017WDL

ZZ200 PTFMSJA941 MASK FRONT AS DLP-1712LHS

M201 4852089610 MASK FRONT FR PPE+PS GY

M561 4855624700 MARK BRAND PANA LCD 17INCH

ZZ210 PTSPPWA941 SPEAKER AS DLP-1712LHS

P601A 4850704S55 CONNECTOR YH025-04+YRT205+YRT110+ULW=600+600

SP01 4858316910 SPEAKER SP-5090F20

SP01A 7178301011 SCREW TAPPTITE TT2 WAS 3X10 MFZN

LOC PART CODE PART NAME DESCRIPTION REMARK

SP01B 7178301011 SCREW TAPPTITE TT2 WAS 3X10 MFZN

ZZ290 PTMPMSA941 PCB MAIN MANUAL AS DLP-1712LHS

F001 5FWPS1022L FUSE WIDE TL 250V 1A CASE

F002 5FWPS1022L FUSE WIDE TL 250V 1A CASE

IC12 1TS0P34838 IC PREAMP TSOP34838SJ

IC29 149XYFPYCP IC TV PROCESSORS VCT49XYF-PY-C7

IC3 1TDA1517PP IC TDA1517P

IC30 1TDA1517PP IC TDA1517P

IC31 124LC16B1B IC MEMORY 24LC16B1B

J2 4859295420 CONN WAFER 4602-04MV2-1 PLUG 4P ST

J2A 4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

J2B 4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

J3 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP11 4859112950 JACK SCART DSSM-0378 STR

JP2 4859101310 JACK DC DC-037

JP4 4859102130 JACK EARPHONE YSC-1537

JP5 4859105340 JACK S-VHS YKF51-5359

JP8 4859106750 JACK PIN BOARD YSC03P-4120-11S2

L11 58C0000116 COIL BEAD HC-3550R

L46 58C0000116 COIL BEAD HC-3550R

L81 58C0000116 COIL BEAD HC-3550R

LED1 DH1L25RS— LED (RED) HI-L25RS

M722 4857252900 SHIELD COVER SPTH-C T=0.3

P12 4859236120 CONN WAFER YAW025-04

P13 4859231620 CONN WAFER YW025-03

P4 485923172S CONN WAFER YW025-04 (STICK)

PA10 4850706S29 CONNECTOR 12505HS-06+12505HS-06+ULW=200

PA14 4850704S54 CONNECTOR 12505HS-04+12505HS-04+ULW=200

PA3 4850712S01 CONNECTOR 12505HS-12+12505HS-12+ULW=100

PA6 4850714S01 CONNECTOR 12505HS-14+12505HS-14+ULW=180

PA9 4850705S17 CONNECTOR 12505HS-05+12505HS-05+ULW=300

S3 5PX6966D— FILTER SAW X6966D

SW1 5S50101Z90 SW TACT THVV502GDA

SW2 5S50101Z90 SW TACT THVV502GDA

SW3 5S50101Z90 SW TACT THVV502GDA

SW4 5S50101Z90 SW TACT THVV502GDA

SW5 5S40101009 SW PUSH PS-22E06

SW6 5S50101Z90 SW TACT THVV502GDA

TU1 4859725730 TUNER VARACTOR PATBF19D (PAL)

TU2 4850A23840 ANT SHIELD BOX PAXBF01DA (PAL)

X1 5XJ20R25AE CRYSTAL QUARTZ HC-49/S 20.2500MHZ 16PF 30PPM

X4 5XJ14R31AE CRYSTAL QUARTZ HC-49/S 14.31818MHZ 30PPM

X5 5XJ27R00AC CRYSTAL QUARTZ HC-49/S 27.000MHZ 15PF 20PPM

ZZ200 PTMPJ2A941 PCB MAIN CHIP MOUNT B ASDLP-1712LHS

C103 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C104 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C109 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C11 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

C110 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C111 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C112 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C113 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

C117 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C118 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C12 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C120 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C121 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C122 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

C123 HCBK821KBA C CHIP CERA 50V X7R 820PF K 1608

C126 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C127 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C128 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C129 HCBK821KBA C CHIP CERA 50V X7R 820PF K 1608

C13 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C130 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C131 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C134 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C139 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

26

Service Part List

C14 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C144 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C147 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C154 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C157 HCBK822KBA C CHIP CERA 50V X7R 8200PF K 1608

C158 HCBK822KBA C CHIP CERA 50V X7R 8200PF K 1608

C160 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C161 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C162 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C163 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C165 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C166 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C167 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C169 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C17 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C172 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C174 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C175 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C176 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C177 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C183 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C185 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C189 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C19 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C192 HCQK180JBA C CHIP CERA 50V CH 18PF J 1608

C193 HCQK180JBA C CHIP CERA 50V CH 18PF J 1608

C194 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C195 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C196 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C197 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C198 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C199 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C2 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C20 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C200 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C201 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C202 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C207 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C208 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C210 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C211 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C215 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C218 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C221 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C228 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C229 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C230 HCQK100JBA C CHIP CERA 50V CH 10PF J 1608

C236 HCQK100JBA C CHIP CERA 50V CH 10PF J 1608

C237 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C238 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C24 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C240 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C241 HCQK100JBA C CHIP CERA 50V CH 10PF J 1608

C242 HCQK150JBA C CHIP CERA 50V CH 15PF J 1608

C244 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C245 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C246 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C247 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C248 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C249 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C251 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C252 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C257 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C258 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C259 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C26 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C262 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C263 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

C264 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C265 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C266 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C268 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C269 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C27 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C270 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C271 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C272 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C274 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C276 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C278 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C279 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C28 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C280 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C284 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C285 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C286 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C290 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C292 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C293 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C295 HCFF334ZBA C CHIP CERA 16V Y5V 0.33MF Z 1608

C296 HCFF334ZBA C CHIP CERA 16V Y5V 0.33MF Z 1608

C297 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C31 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C311 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C312 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C313 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C32 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C324 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C325 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C326 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C327 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C328 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C329 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C33 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C330 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C333 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

C334 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

C34 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C35 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

C355 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C42 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C43 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C44 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C45 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C46 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C47 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C49 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C50 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C53 HCBK472KBA C CHIP CERA 50V X7R 4700PF K 1608

C54 HCBK472KBA C CHIP CERA 50V X7R 4700PF K 1608

C55 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C56 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C57 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C58 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C59 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C6 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

C60 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C62 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C63 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C64 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C67 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C7 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C70 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C73 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

C74 HCBK393KBA C CHIP CERA 50V X7R 0.039MF K 1608

C75 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

27

Service Part List

C76 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C77 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C79 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C80 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C81 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C82 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C85 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C86 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C87 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C88 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C89 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C90 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C97 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

D1 DZ02W6R2VA DIODE CHIP ZENER Z02W6.2V

D13 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D14 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D17 DBAV70—-B DIODE CHIP BAV70

D2 DBAV70—-B DIODE CHIP BAV70

D21 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D22 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D23 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D3 DZ02W6R2VA DIODE CHIP ZENER Z02W6.2V

D32 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D33 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D38 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D39 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D40 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D41 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D42 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D43 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D45 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

R1 HRFT155JBA R CHIP 1/10 1.5M OHM J 1608

R10 HRFT202JBA R CHIP 1/10 2K OHM J 1608

R100 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R101 HRFT333JBA R CHIP 1/10 33K OHM J 1608

R102 HRFT223JBA R CHIP 1/10 22K OHM J 1608

R107 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R110 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R112 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R121 HRFT241JBA R CHIP 1/10 240 OHM J 1608

R122 HRFT241JBA R CHIP 1/10 240 OHM J 1608

R123 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R128 HRFT123JBA R CHIP 1/10 12K OHM J 1608

R130 HRFT242JBA R CHIP 1/10 2.4K OHM J 1608

R131 HRFT431JBA R CHIP 1/10 430 OHM J 1608

R132 HRFT302JBA R CHIP 1/10 3K OHM J 1608

R14 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R140 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R141 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R153 HRFT000-BA R CHIP 1/10 0 OHM 1608

R156 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R18 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R185 HRFT106JBA R CHIP 1/10 10M OHM J 1608

R186 HRFT000-BA R CHIP 1/10 0 OHM 1608

R189 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R196 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R203 HRFT000-BA R CHIP 1/10 0 OHM 1608

R204 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R205 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R206 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R21 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R210 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R211 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R212 HRFT000-BA R CHIP 1/10 0 OHM 1608

R229 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

R230 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

R234 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R235 HRFT101JBA R CHIP 1/10 100 OHM J 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

R236 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R237 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R238 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R239 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R24 HRFT241JBA R CHIP 1/10 240 OHM J 1608

R243 HRFT000-BA R CHIP 1/10 0 OHM 1608

R244 HRFT000-BA R CHIP 1/10 0 OHM 1608

R245 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R246 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R247 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

R248 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

R249 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R25 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R250 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R254 HRFT000-BA R CHIP 1/10 0 OHM 1608

R257 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R258 HRFT000-BA R CHIP 1/10 0 OHM 1608

R259 HRFT000-BA R CHIP 1/10 0 OHM 1608

R261 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R262 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

R263 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

R264 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R27 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R272 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R273 HRFT000-BA R CHIP 1/10 0 OHM 1608

R277 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R284 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R285 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R288 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R289 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R29 HRFT241JBA R CHIP 1/10 240 OHM J 1608

R291 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R292 HRFT000-BA R CHIP 1/10 0 OHM 1608

R293 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R298 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R30 HRFT202JBA R CHIP 1/10 2K OHM J 1608

R304 HRFT224JBA R CHIP 1/10 220K OHM J 1608

R305 HRFT224JBA R CHIP 1/10 220K OHM J 1608

R31 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R314 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R315 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R316 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R317 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R318 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R32 HRFT202JBA R CHIP 1/10 2K OHM J 1608

R33 HRFT241JBA R CHIP 1/10 240 OHM J 1608

R333 HRFT622JBA R CHIP 1/10 6.2K OHM J 1608

R34 HRFT393JBA R CHIP 1/10 39K OHM J 1608

R37 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R39 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R4 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R40 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R54 HRFT000-BA R CHIP 1/10 0 OHM 1608

R59 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R60 HRFT392JBA R CHIP 1/10 3.9K OHM J 1608

R61 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R63 HRFT000-BA R CHIP 1/10 0 OHM 1608

R65 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R71 HRFT153JBA R CHIP 1/10 15K OHM J 1608

R72 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R78 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R79 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R80 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R82 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R83 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R88 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R90 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R94 HRFT123JBA R CHIP 1/10 12K OHM J 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

28

Service Part List

R96 HRFT750JBA R CHIP 1/10 75 OHM J 1608

ZZ200 PTMPJ0A941 PCB MAIN (RHU) AS DLP-1712LHS

ZZ200 PTMPJBA941 PCB MAIN M-10 AS DLP-1712LHS

ZZ200 PTMPJRA941 PCB MAIN RADIAL AS DLP-1712LHS

ZZ200 PTMPJAA941 PCB MAIN AXIAL AS DLP-1712LHS

A001 4859810793 PCB MAIN 270X234 G4V

ZZ200 PTMPJ1A941 PCB MAIN CHIP MOUNT A AS DLP-1712LHS

C1 HCELH471MD C CHIP ELECTRO 25V 470MF CM 1010

C10 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C100 HCELH471MD C CHIP ELECTRO 25V 470MF CM 1010

C102 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C105 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C108 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C114 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C115 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C116 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C119 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C124 HCELH221ME C CHIP ELECTRO 25V 220MF CM 8010

C125 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C132 HCELK220MC C CHIP ELECTRO 50V 22MF CM 6353

C133 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C138 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

C140 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

C141 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C145 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C146 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C15 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C155 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C156 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C16 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C164 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

C168 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C170 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C173 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C178 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C179 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C18 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C180 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C181 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C182 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C184 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C186 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

C187 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C188 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C203 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

C204 HCELH471MD C CHIP ELECTRO 25V 470MF CM 1010

C206 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C209 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C21 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C212 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C213 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C214 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C216 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C217 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C219 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C22 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C220 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C226 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C227 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C23 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C231 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C239 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C25 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C250 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C253 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C256 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C260 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C261 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

C267 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C273 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C275 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C281 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C282 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C283 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C287 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C288 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C289 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C29 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C291 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C294 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C298 HCELH221ME C CHIP ELECTRO 25V 220MF CM 8010

C299 HCELH221ME C CHIP ELECTRO 25V 220MF CM 8010

C3 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C30 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C300 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C301 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C303 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C304 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C305 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C306 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C307 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C309 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C314 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

C315 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C316 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C317 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C319 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C320 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C321 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C322 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C323 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C331 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C332 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C335 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C336 HCELF220MC C CHIP ELECTRO MV 16V 22MF 5.0DX5.2H

C337 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C338 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C339 HCELK220MC C CHIP ELECTRO 50V 22MF CM 6353

C349 HCELF470MC C CHIP ELECTRO 16V 47MF CM 5053

C353 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C356 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C36 HCELH221ME C CHIP ELECTRO 25V 220MF CM 8010

C37 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

C38 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

C39 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C4 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C40 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C41 HCELH101MD C CHIP ELECTRO 25V 100MF CM 8063

C48 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C5 HCELH471MD C CHIP ELECTRO 25V 470MF CM 1010

C51 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C52 HCELH221ME C CHIP ELECTRO 25V 220MF CM 8010

C61 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

C65 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C66 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

C68 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C69 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C71 HCELC102ME C CHIP ELECTRO 6.3V 1000MF CM 8010

C78 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C83 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C84 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C9 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C92 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C93 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C94 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C95 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

LOC PART CODE PART NAME DESCRIPTION REMARK

29

Service Part List

C96 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C98 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C99 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

D10 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D15 DM2FM3—-C DIODE CHIP SCHOTTKY M2FM3 M2F TYPE

D16 DBAV99L—B DIODE CHIP BAV99L

D24 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D25 DBAV99L—B DIODE CHIP BAV99L

D26 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D27 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D28 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D29 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D30 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D31 DZ02W5R6VA DIODE CHIP ZENER Z02W5.6V

D34 DBAV99L—B DIODE CHIP BAV99L

D50 DM2FM3—-C DIODE CHIP SCHOTTKY M2FM3 M2F TYPE

IC1 1A1117E33D IC CHIP REGULATOR AP1117E33A 3.3V 2% SOT-223

IC10 1A1117E33D IC CHIP REGULATOR AP1117E33A 3.3V 2% SOT-223

IC11 1VF800A70Q IC CHIP FLASH SST39VF800A-70 4C-EK TRAY

IC13 1PW11310QQ IC CHIP IMAGE PROCESSOR PW113-10Q

IC14 1S18033SDE IC CHIP SW REG SI-8033SD 3.0A 3.3V 60KHZ 5PIN

IC15 1A1117E18D IC CHIP REGULATOR AP1117E18A 1.8V 2% SOT-223

IC16 19883C110Q IC CHIP ADC MST9883CR-110 MSPS

IC17 1ELLV385-E IC CHIP EL-LV385

IC18 1LM317BD2E IC CHIP REGULATOR LM317BD2T ADJ 1.2V 37V 1.5A D2PAK

IC19 1A1117EA-D IC CHIP REGULATOR AP1117EA ADJ 2% SOT-223

IC2 1CD74HC52D IC CHIP LOGIC CD74HC4052M SOIC 16 REEL

IC20 1S18050SDE IC CHIP SW REG SI-8050SD 3.0A 5.0V 60KHZ 5PIN

IC21 1A1117E18D IC CHIP REGULATOR AP1117E18A 1.8V 2% SOT-223

IC22 1MD1N150-Q IC CHIP HD DEINTERLACER MDIN-150

IC23 12S32200BQ IC CHIP IS42S32200B-6T

IC24 1LM317BD2E IC CHIP REGULATOR LM317BD2T ADJ 1.2V 37V 1.5A D2PAK

IC25 1LM317BD2E IC CHIP REGULATOR LM317BD2T ADJ 1.2V 37V 1.5A D2PAK

IC26 1CXA1315MD IC CHIP D/A CXA1315M

IC27 1LM317BD2E IC CHIP REGULATOR LM317BD2T ADJ 1.2V 37V 1.5A D2PAK

IC33 1CD74HC52D IC CHIP LOGIC CD74HC4052M SOIC 16 REEL

IC34 1P15V330-D IC CHIP VIDEO SWITCH PI5V330

IC35 1BA6161F-C IC CHIP SW REG BA6161F 30~35V 100KHZ SOP8 REEL

IC38 124LC16BTC IC CHIP EEPROM 24LC16BT-I/SN 16K 8 PIN SOIC REEL

IC39 TFDS4953-C FET CHIP FDS4953 SO-8 -30V -5A REEL

IC4 1K1A358F-C IC CHIP OP AMP KIA358F DUAL OP AMP FLP-8

IC40 1V273APWRD IC CHIP LOGIC SN74LV273APWR

IC5 1P15V330-D IC CHIP VIDEO SWITCH PI5V330

IC6 1A1117E33D IC CHIP REGULATOR AP1117E33A 3.3V 2% SOT-223

IC7 1K1A7027TB IC CHIP RESET KIA7027AT 2.7V TSM TYPE

IC8 TFDS4953-C FET CHIP FDS4953 SO-8 -30V -5A REEL

IC9 1P15V330-D IC CHIP VIDEO SWITCH PI5V330

L1 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L10 HLC100K02A L CHIP COIL 10UH MLF 2012

L14 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L15 HLC472M01D L CHIP COIL 4.7MH M SLF7045

L16 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L17 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L18 HLC339M00B L CHIP COIL 3.3UH M NLCV25T-PF

L19 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L2 HLC101K01C L CHIP COIL 100UH K NLC5650T

L22 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L23 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L24 HLC100K02A L CHIP COIL 10UH MLF 2012

L25 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L26 HLC479J00A L CHIP COIL 4.7UH MLF2012

L27 HLC151K01E L CHIP COIL 150UH K 120120

L28 HLC100K02A L CHIP COIL 10UH MLF 2012

L3 HLC100K03B L CHIP COIL 10UH K NLCV25T-PF

L30 HLC100K03B L CHIP COIL 10UH K NLCV25T-PF

L31 HLC479J00A L CHIP COIL 4.7UH MLF2012

L32 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

L33 HLC100K03B L CHIP COIL 10UH K NLCV25T-PF

LOC PART CODE PART NAME DESCRIPTION REMARK

L36 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L37 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L38 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L39 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L4 HLC339M00B L CHIP COIL 3.3UH M NLCV25T-PF

L40 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L41 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L45 HLC569K00A L CHIP COIL 5.6UH MLF2012E

L47 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L49 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L5 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L50 HFFMMZ301A F CHIP FERRITE BEAD 300 OHM MMZ 2012Y

L51 HFFMMZ301A F CHIP FERRITE BEAD 300 OHM MMZ 2012Y

L52 HFFMMZ301A F CHIP FERRITE BEAD 300 OHM MMZ 2012Y

L53 HFFMMZ301A F CHIP FERRITE BEAD 300 OHM MMZ 2012Y

L54 HLC151K01E L CHIP COIL 150UH K 120120

L55 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L56 HFEACF470B F CHIP EMI ACF321825 47P

L57 HFEACF470B F CHIP EMI ACF321825 47P

L58 HFEACF470B F CHIP EMI ACF321825 47P

L6 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L61 HFEACF470B F CHIP EMI ACF321825 47P

L62 HFEACF470B F CHIP EMI ACF321825 47P

L63 HFZACF471C F CHIP LC ACF321825-471

L64 HFZACF471C F CHIP LC ACF321825-471

L65 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L66 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L67 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L7 HFEACF470B F CHIP EMI ACF321825 47P

L71 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L72 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

L73 HLC100K03B L CHIP COIL 10UH K NLCV25T-PF

L74 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L75 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L76 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L77 HLC479M02D L CHIP COIL 4.7UH M SLF0628

L82 HLB300M04A L CHIP BEAD 30 OHM MPZ 2012

L83 HLB300M04A L CHIP BEAD 30 OHM MPZ 2012

L9 HFFMMZ202A F CHIP FERRITE BEAD 2000 OHM MMZ 2012Y

LP1 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

LP2 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

LP3 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

LP4 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

LP5 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

LP6 HFRMZA600A F CHIP BEAD ARRARY 60 OHM MZA 3216Y

P10 49590001S0 CONN WAFER 12505WR-06A00

P10A 49590001S0 CONN WAFER 12505WR-06A00

P11 4859294220 CONN WAFER 12507WR-20(SMD)

P11A 4859296720 CONN WAFER 12505WR-04A00

P14 4859296720 CONN WAFER 12505WR-04A00

P3 49590004S0 CONN WAFER 12505WR-12(SMD)

P6 4859294420 CONN WAFER 12505WR-14(SMD)

P6A 4859294420 CONN WAFER 12505WR-14(SMD)

P9 49590009S0 CONN WAFER 12505WR-05A00

P9A 49590009S0 CONN WAFER 12505WR-05A00

Q1 T2N7002M-B FET CHIP 2N7002MTF SOT-23 60V 0.2A

Q10 T2SA1037KB TR CHIP 2SA1037AKT146-R

Q11 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q12 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q14 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q15 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q16 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q17 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q18 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q2 T2N7002M-B FET CHIP 2N7002MTF SOT-23 60V 0.2A

Q21 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q23 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q24 T2SC2412KB TR CHIP 2SC2412K-T146-BR

LOC PART CODE PART NAME DESCRIPTION REMARK

30

Service Part List

Q25 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q26 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q27 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q3 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q31 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q32 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q33 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q34 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q35 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q36 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q37 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q38 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q39 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q4 T2SA1037KB TR CHIP 2SA1037AKT146-R

Q40 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q41 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q5 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q6 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q7 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q9 T2SA1037KB TR CHIP 2SA1037AKT146-R

R103 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R104 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R106 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R11 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R111 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R114 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R115 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R116 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R117 HRFT000-BA R CHIP 1/10 0 OHM 1608

R118 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R119 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R12 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R124 HRFT000-BA R CHIP 1/10 0 OHM 1608

R125 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R126 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R127 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R133 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R134 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R135 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

R143 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R144 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R145 HRFT331JBA R CHIP 1/10 330 OHM J 1608

R147 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R149 HRFT331JBA R CHIP 1/10 330 OHM J 1608

R15 HRFT330JBA R CHIP 1/10 33 OHM J 1608

R150 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R151 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R152 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R155 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R157 HRFT331JBA R CHIP 1/10 330 OHM J 1608

R16 HRFT151JBA R CHIP 1/10 150 OHM J 1608

R160 HRFT000-BA R CHIP 1/10 0 OHM 1608

R161 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R163 HRFT000-BA R CHIP 1/10 0 OHM 1608

R165 HRFT000-BA R CHIP 1/10 0 OHM 1608

R166 HRFT331JBA R CHIP 1/10 330 OHM J 1608

R168 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R169 HRFT000-BA R CHIP 1/10 0 OHM 1608

R17 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R170 HRFT000-BA R CHIP 1/10 0 OHM 1608

R171 HRFT752JBA R CHIP 1/10 7.5K OHM J 1608

R172 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R173 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R174 HRFT752JBA R CHIP 1/10 7.5K OHM J 1608

R175 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R176 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R177 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R178 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

R179 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R180 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R181 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R182 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R183 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R184 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R187 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R188 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R19 HRFT272JBA R CHIP 1/10 2.7K OHM J 1608

R190 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R191 HRFT331JBA R CHIP 1/10 330 OHM J 1608

R192 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R193 HRFT000-BA R CHIP 1/10 0 OHM 1608

R194 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R195 HRFT000-BA R CHIP 1/10 0 OHM 1608

R197 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R199 HRFT000-BA R CHIP 1/10 0 OHM 1608

R2 HRFT000-BA R CHIP 1/10 0 OHM 1608

R20 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R200 HRFT000-BA R CHIP 1/10 0 OHM 1608

R207 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R208 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R209 HRFT000-BA R CHIP 1/10 0 OHM 1608

R214 HRFT220JBA R CHIP 1/10 22 OHM J 1608

R215 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R216 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R217 HRFT220JBA R CHIP 1/10 22 OHM J 1608

R219 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R22 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R220 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R224 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R225 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R227 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R23 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R231 HRFT201JBA R CHIP 1/10 200 OHM J 1608

R232 HRFT201JBA R CHIP 1/10 200 OHM J 1608

R233 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R240 HRFT222JBA R CHIP 1/10 2.2K OHM J 1608

R255 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R26 HRFT220JBA R CHIP 1/10 22 OHM J 1608

R260 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R265 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R266 HRFT220JBA R CHIP 1/10 22 OHM J 1608

R268 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R269 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R270 HRFT750JBA R CHIP 1/10 75 OHM J 1608

R271 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R275 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R276 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R278 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R28 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R280 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R281 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R282 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R290 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R294 HRFT123JBA R CHIP 1/10 12K OHM J 1608

R295 HRFT272JBA R CHIP 1/10 2.7K OHM J 1608

R296 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

R297 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R299 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R3 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R300 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R302 HRFT224JBA R CHIP 1/10 220K OHM J 1608

R303 HRFT224JBA R CHIP 1/10 220K OHM J 1608

R313 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R319 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R320 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R321 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

LOC PART CODE PART NAME DESCRIPTION REMARK

31

Service Part List

R322 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R323 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R324 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R325 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R326 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R327 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R328 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R329 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R38 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R43 HRFT151JBA R CHIP 1/10 150 OHM J 1608

R44 HRFT330JBA R CHIP 1/10 33 OHM J 1608

R45 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R46 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R47 HRFT752JBA R CHIP 1/10 7.5K OHM J 1608

R48 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R50 HRFT151JBA R CHIP 1/10 150 OHM J 1608

R51 HRFT330JBA R CHIP 1/10 33 OHM J 1608

R52 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R53 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R6 HRFT000-BA R CHIP 1/10 0 OHM 1608

R62 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R64 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R66 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R7 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R70 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R73 HRFT272JBA R CHIP 1/10 2.7K OHM J 1608

R74 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R75 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R76 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R77 HRFT470JBA R CHIP 1/10 47 OHM J 1608

R8 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R81 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

R84 HRFT391JBA R CHIP 1/10 390 OHM J 1608

R85 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R86 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R87 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

R9 HRFT271JBA R CHIP 1/10 270 OHM J 1608

R92 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R93 HRFT752JBA R CHIP 1/10 7.5K OHM J 1608

R97 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R98 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R99 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RP1 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP17 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP18 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP19 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP2 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP20 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP21 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP22 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP23 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP24 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP25 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP26 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP27 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP28 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP29 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP3 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP30 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP31 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP32 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP33 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP34 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP35 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP36 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP37 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RP4 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

LOC PART CODE PART NAME DESCRIPTION REMARK

Loading...

Loading...