DAEWOO T011-21 Service Manual

DAEWOO(T011-21”)

COLOUR TELEVISION

SERVICE MANUAL

1

CONTENTS

1. Safety Precautions…………………………………………………………………………………

2. MCU and signal Processor for a PAL/NTSC TV……………………………………………………

3. Definition of A8899CPCNG6VU9 Pin……………………………………………………………

4. Remote Control Circuit Diagram and Function……………………………………………………

1)User Remote………………………………………………………………………………………

2)Service Remote……………………………………………………………………………………

5. Service Controlled Function…………………………………………………………………………

1)White balance adjustment…………………………………………………………………………

2)Pictureand AGC adjustment……………………………………………………………………

3)Option set…………………………………………………………………………………………

6. Service and Design Data……………………………………………………………………………

7. ICs Functional Description…………………………………………………………………………

8. Test Point Waveforms………………………………………………………………………………

9. IC Voltages…………………………………………………………………………………………

10. Other……………………………………………………………………………………………

3

4

5

6

6

7

8

8

8

9

15

16

16

17

17

2

1. SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manufacturer’s warranty and will further relieve the manufacturer

of responsibility for personal injury or property damage resulting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are identified

in the parts list of Service manual. Electrical components having

such features are identified by shading on the schematics and by

( ! ) on the parts list in Service manual. The use of a substitute

replacement which does not have the same safety characteristics

as the recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards

4. Don’t short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when repairing.

Some model’s power circuit is partly different in the GND. The

difference of the GND is shown by the LIVE: ( ) side GND,

ISOLATED (NEUTRAL) : ( ) side GND and EARTH : ( )

side GND. Don’t short between the LIVE side GND and

ISOLATED (NEUTRAL) side GND or EARTH side GND and

never measure with a measuring apparatus (oscilloscope etc.) the

LIVE side GND and ISOLATED (NEUTRAL) side GND or

EARTH side GND at the same time. If above note will not be kept,

a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See ADJUSTMENT

OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform with

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect installation, cracked or melted high voltage harness,

poor soldering, etc.). To maintain the proper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting a

clip lead to the ground frame and connecting the other end of the

lead through a 10kΩ 2W resitor to the anode button.

8. When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those

components that indicate evidence of overheating should be

replaced. Always use the

9. manufacturer’s replacement components.

10. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna terminals,

video/audio input and output terminals, Control knobs, metal

cabinet, screwheads, earphone jack, control shafts, etc.) to be sure

the product is safe to operate without danger of electrical shock.

11. The surface of the TV screen is coated with a thin film which can

easily be damaged. Be very careful with it when handle the TV.

Should the TV screen become soiled, wipe it with a soft dry cloth.

Never rub it forcefully. Never use any cleaner or detergent on it.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 3000V AC

(r.m.s.) for a period of one second.

(…Withstand a voltage of 1100V AC (r.m.s.) to an appliance rated

up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V or

more, for a periode of one second.)

This method of test requires a test equipment not generally found

in the service trade.

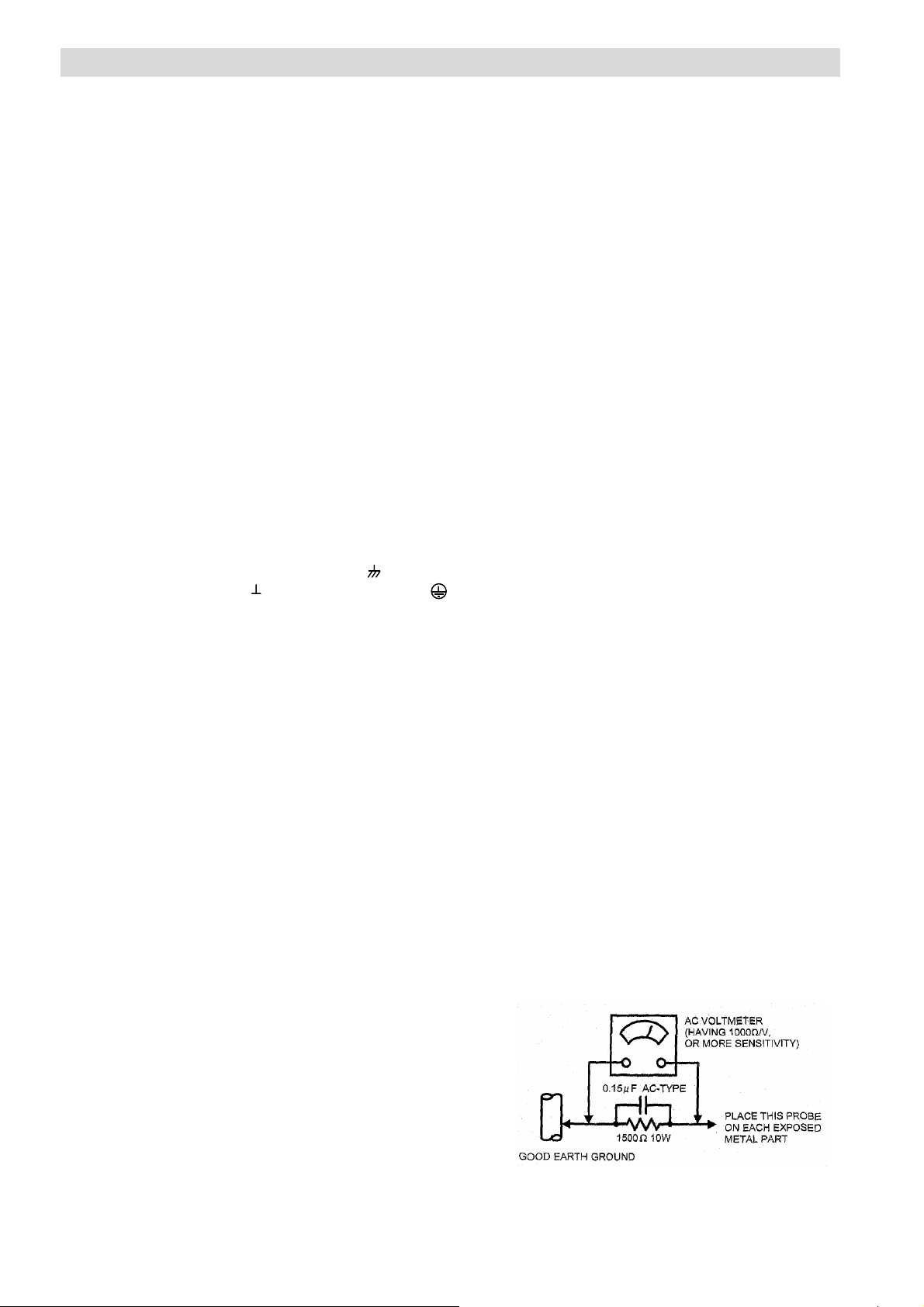

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a “Leakage

Current Tester”, measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground

(water pipe, etc.). Any leakage current must not exceed 0.5mA AC

(r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

●Alternate Check Method

Plug the AC line cord directly into the AC outlet ( do not use a

line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled by a

0.15µF AC-type capacitor between an exposed metal part and a

known good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part, particularly any

exposed metal part having a return path to the chassis, and

measure the AC voltage across the resistor. Now, reverse the plug

in the AC outlet and repeat each measurement. Any voltage

measured must not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.)

3

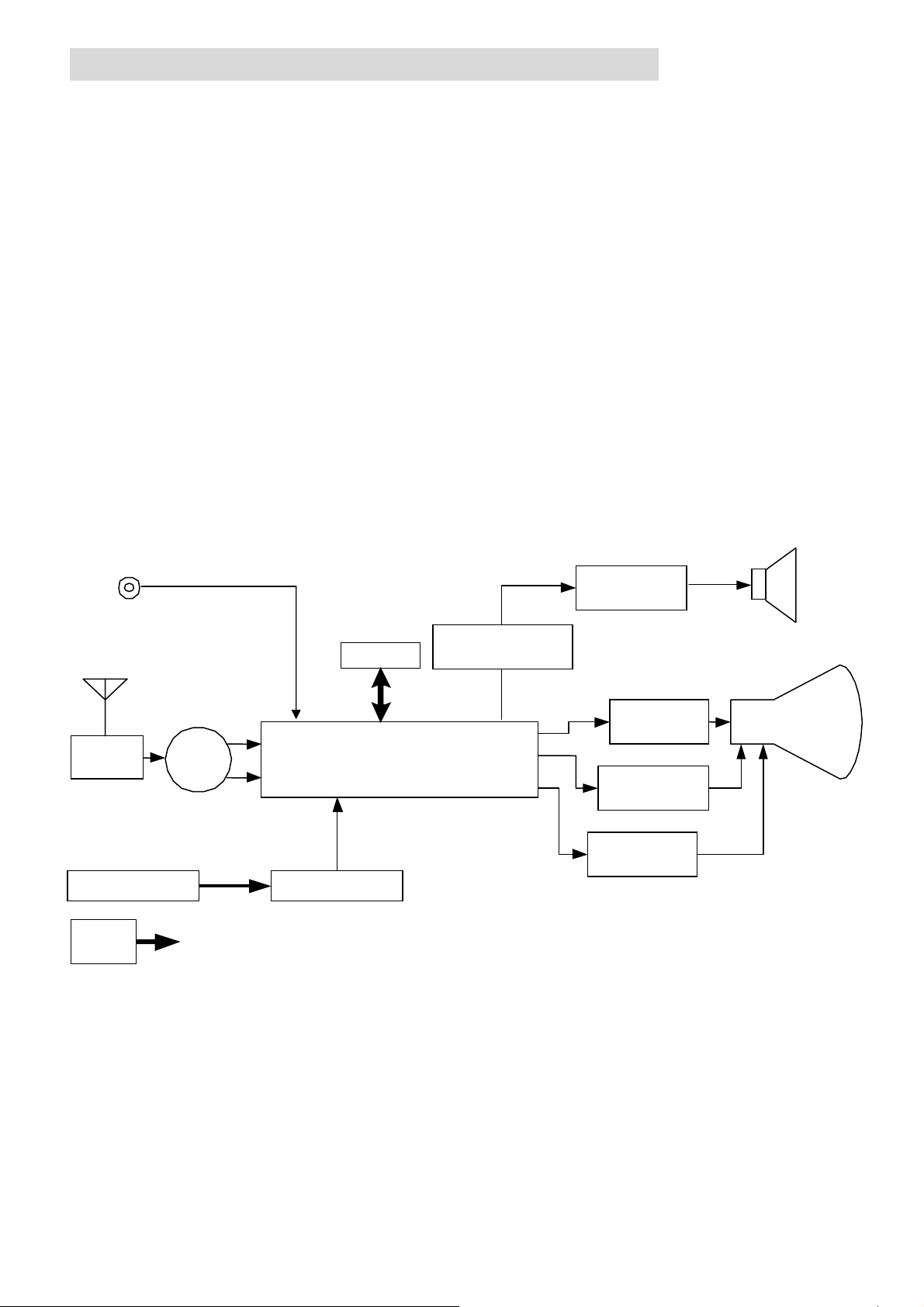

2.MCU and signal processor for a PAL/NTSC TV

r

r

The A8899CPCNG6VU9 is an integrated circuit for a PAL/NTSC TV. A MCU and a TV

signal processor are integrated in a 64-pin shrink DIP package. The MCU contains 8-bit

CPU, ROM, RAM, I/O ports, timer/counters, A/D converters, an on-screen display

controller, remote control interfaces, IIC bus interfaces and the Closed Caption decoder. The

TV signal processor contains PIF, SIF, Video, multi-standard chroma, Sync, RGB

processors.

◆ A8899CPCNG6VU9 MCU+OSD+CCD+ TV Processor controller with Software inside.

◆ 24C08 Non Volatile memory(EEPROM)

◆ STV9325 Vertical deflection system output circuit.

◆ TDA7263 Audio Output

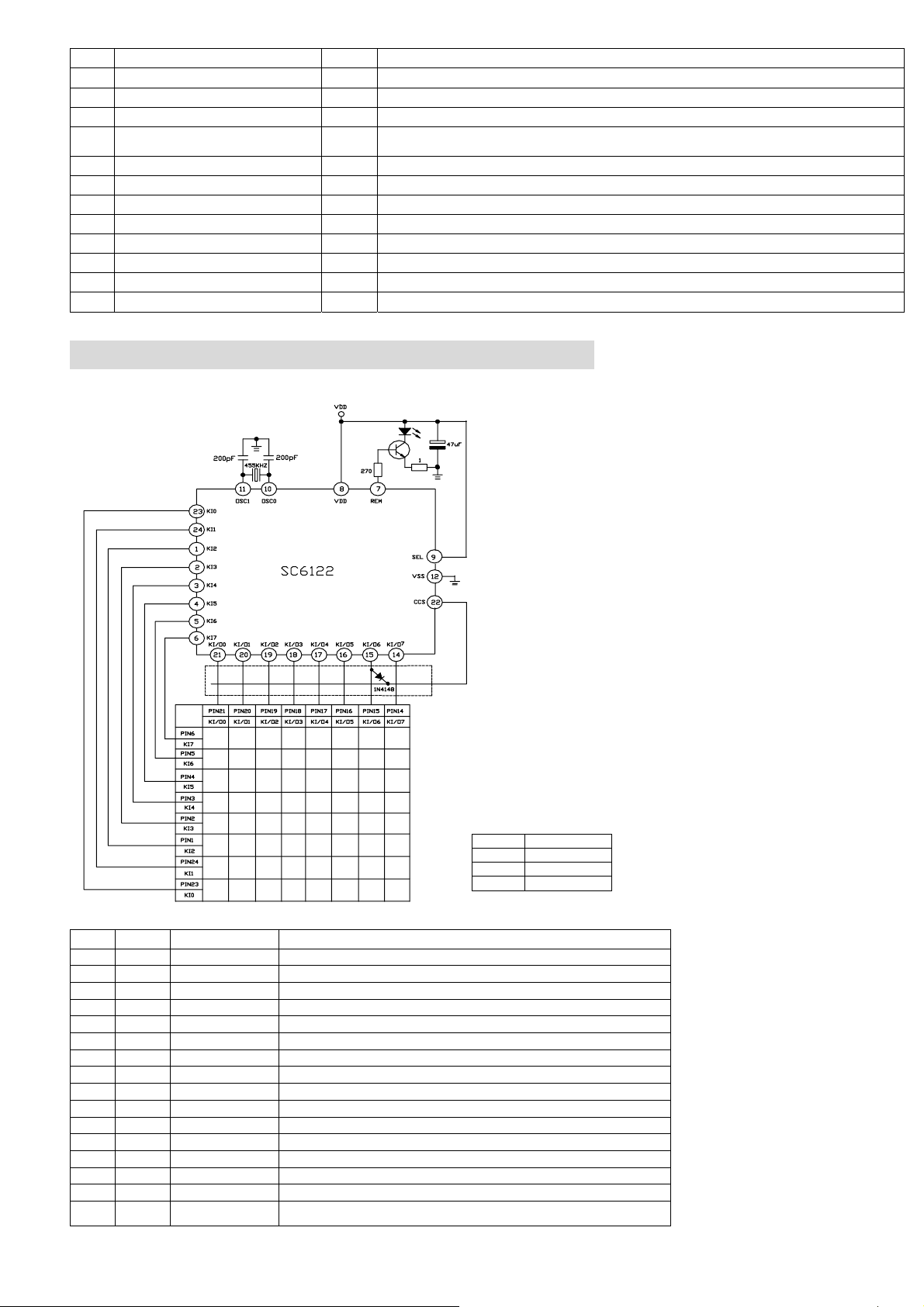

◆ SC6122 Remote Controlled Transmitter.

TOSHIBA G8 chassis color TV block diagram

AV I nput/Output

Tune

IR transmit

Power

Supply

MEMORY

MCU , PIF/SIF, Video ,Chroma,

Sync, RGB processors,

H./V. driving pulse

IR receive

Sound Process

Speake

Audio Out

CRT Drive

V. O U T

H.OUT

4

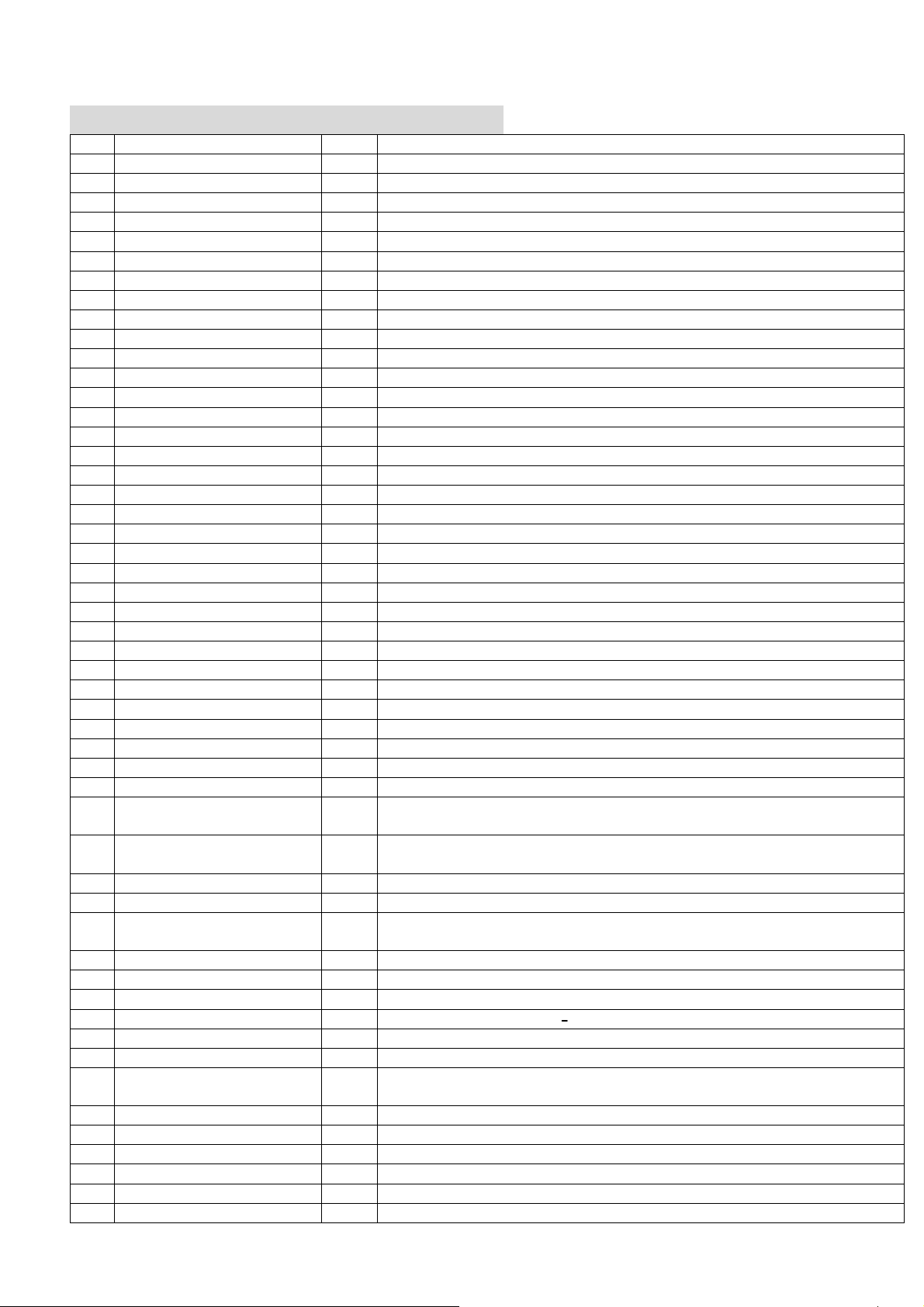

3. Definition of A8899CPCNG6VU9 Pin

NO.

Pin name I/O Function

1 X-ray I/O X-ray

2 Thermal resistance Out Thermal resistance

3 KEY I/O Key input

4 VSS - GND connection

5 RESET I/O Reset signal input

6 XOUT Out 8 MHz oscillator connecting

7 XIN In 8 MHz oscillator connecting

8 TEST In GND connection

9 VDD - 5V power supply

10 VSS - GND connection

11 TV DEF AGND - GND yerminal for TV DEF block

12 FBP in In Input terminal for FBP

13 H out Out Output terminal for Horizontal driving pulse

14 HAFC 1 - Terminal to be connected capacitor for H AFC filter

15 V saw - Terminal to be connected capacitor to generate Vsaw signal

16 V out Out Output terminal for Vertical driving pulse

17 AVcc(8V) - Vcc terminal for DEF,RGB,Audio out and PIF out circuit

18 TV A GND - GND terminal for TV block

19 Cb in In Input terminal for Cb signal

20 EW out Out output terminal for EWsignal

21 Cr in In Input terminal for Cr signal

22 Ext AU1 in In Input terminal for Audio1 signal 1

23 C/V3 in In Input terminal for Chroma or Video signal

24 Y/V2 in In Input terminal for Video signal2 or Y signal

25 ALC Filter In Terminal to be connected capacitor for ALC(Audio Level Control)

26 V1 in In Input terminal for Video signal.(Input leave = 1 Vp-p)

27 ABCL In Input terminal for ABL/ACL control

28 AU out1(ATT) Out Output terminal 1 for Audio signal

29 AU out2(ATT) Out Output terminal 2 for Audio signal

30 TV out/FM radio Out Output terminal for detected PIF signal or FM radio

31 SIF out Out Output terminal for 1bit DAC, detected SIF signal or audio monitor out 2.

32 Ext AU2 in In Input terminal for External Audio signal 1

33 H correct/SIF in In Input terminal for H correction and 2nd SIF

34 DC NF Out Terminal to be connected capacitor for DC Negative Feedback from SIF Det

output

35 PIF PLL - Terminal to be connected with loop filter for PIF PLL.This terminal voltage is

controlled PIF VCO frequency.

36 IF Vcc 5V - Vcc terminal for IF circuit. Supply 5V.

37 Reg Fil - Terminal to be connected capacitor for stabilizing internal bias.

38 AU monitor out1 Output terminal for External Audio signal or TV audio signal selected by

BUS(Audio SW)

39 IF AGC - Terminal to be connected with IF AGC filter.

40 IF GND - GND terminal for IF circuit.

41 IF in In Input terminals for IF signals.

42 IF in In Input terminals for IF signals.

43 RF AGC Output terminal for RF AGC control level.

44 Black Det - Terminal to be connected with Black Det filter for black stretch.

45 SVM/Monitor Output terminal for monitor function. Also output terminal for SVM signal

selectable through IIC bus.

46 APC Filter Terminal to be connected with APC filter for chroma demodulation.

47 YC Vcc 5V Vcc terminal for Y/C circuit

48 EHT in In EHT input

49 DVCC Vcc terminal for digital block

50 R out Out Output terminal for R signal.

51 G out Out Output terminal for G signal.

5

52 B out Out Output terminal for B signal.

53 TV DGND - GND terminal for digital block.

54 up AGND - GND for Oscillator circuit

55 up AVDD - Vdd for Oscillator circuit Supply 5V

56 VIDEO1/2 Out

57 SDA1 I/O IIC-BUS SDA1

58 SCL1 I/O IIC-BUS SCL1

59 50/60Hz control I/O 50/60Hz

60 PWM I/O PWM

61 MUTE I/O MUTE

62 H.SYNC I/O Horizontal sync signal input

63 REMOTE I/O Remote controller signal input

64 POWER I/O Power control & Check, On=Hi-Z(input),Off=L(output)

TV=0,AV1=OPEN,AV 2 = 5 V

4. Remote Control Circuit Diagram and Function

A.User Remote

OPTION

12

11

10

56

16

14

1B

1A

1F

1E

User Remote

CUSL 40

CUSH BF

Diode Pin15

40

03

02

01

00

45

07

06

05

04

49

0B

0A

09

08

4D

4C

0F

0E

0D

0C

NO. Code Name TV Mode

01 00 0 0

02 01 1 1

03 02 2 2

04 03 3 3

05 04 4 4

06 05 5 5

07 06 6 6

08 07 7 7

09 08 8 8

10 09 9 9

11 0A CCD CCD

12 0B -/-- 1-13 0C MENU Menu switch

14 0D SYS System

15 0E QV Quick View

16 0F

→∣ P∣←

Video PP

6

Loading...

Loading...