Daewoo RC-7004F, rc-700, RC-8002B, RC-7004B, RC-7005S Service Manual

...

S/M No. : C7000KUEF0

Service Manual

VACCUM CLEANER

Model: RC-7004F

RC-7004B

RC-7005S

DAEWOO ELECTRONICS CO., LTD.

SPECIFICATIONS............................................................................................................................... 2

EXTERNAL VIEWS ............................................................................................................................. 3

1. ASSEMBLY...... ....... ... ....... ... ........ .. ........ .. ........ .. ........ ... ....... ... ....... ... ....... ... ............... ... . ............... 3

2. MODEL (RC-7004F, RC-7004B, RC-7005S)........... . .. .............................. .............. .. .. . .. .. ............. 4

DIAGRAM ............................................................................................................................................ 5

1. WIRING DI AG RAM .... .. ........ ... ....... ... ....... ... ....... ... ........ .. ........ .. ........ .. ........ ... ....... ... ....... ... .. ......... 5

2. CIRCUIT DIAGRAM...................................................................................................................... 6

TROUBLE SHOOTING GUIDE . ... ......... ... ... ......... ... ......... ... ......... ... ... ........ ... ......... ... ......... ... ... ......... .. 7

DISASSEMBLING AND TREATMENT ....................................................................... ......... ......... ...... 9

1. CLEANE R ASSEMBLY........ ... ............... .. ........ .. ........ ... ....... ... ....... ... ....... ... ........ .. ........ .. ........ ...... 9

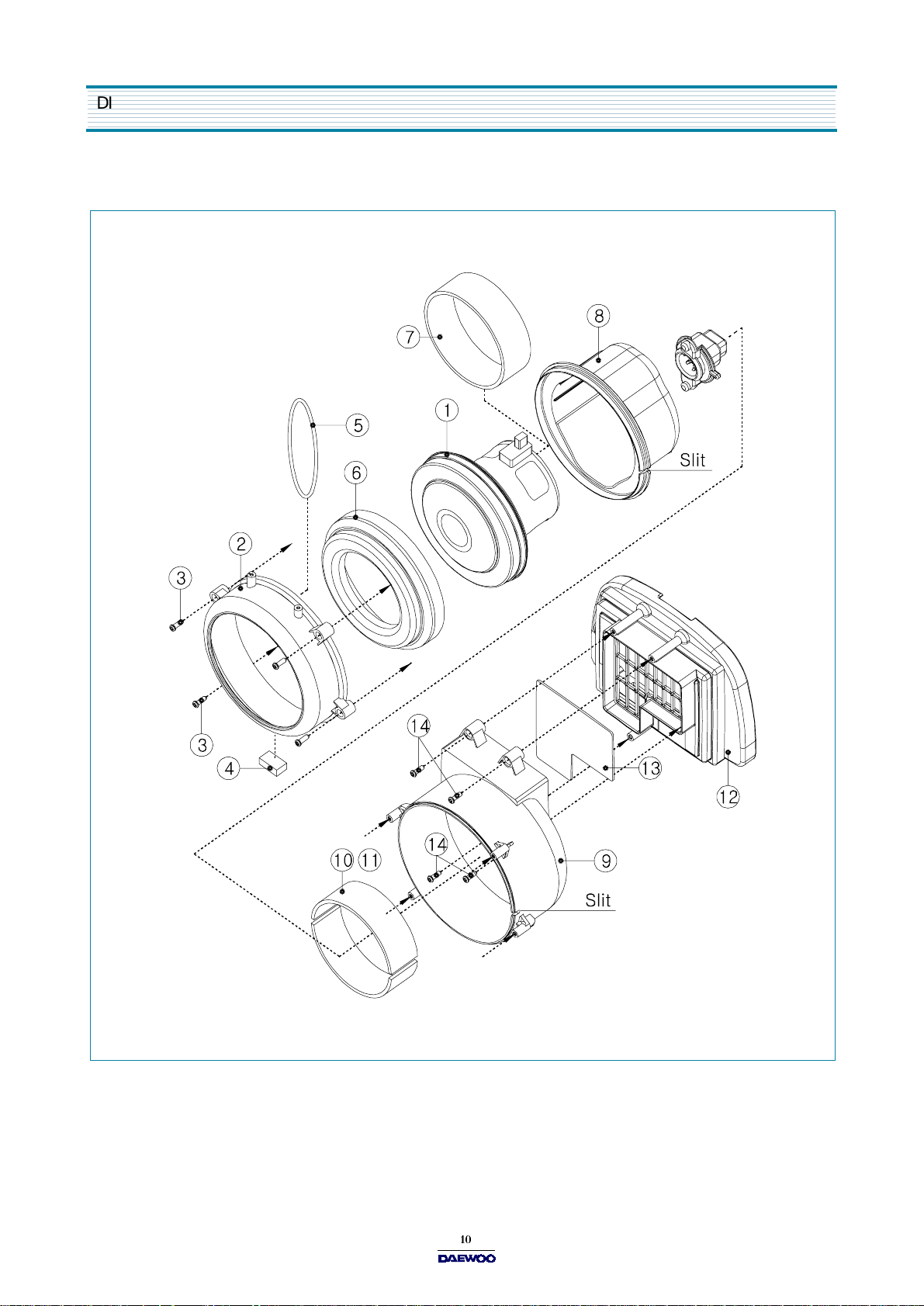

2. MOTOR ASS EMBL Y...................... ... ....... ... ....... ... ........ .. ........ .. ........ .. ........ ... ............... .. .............. 10

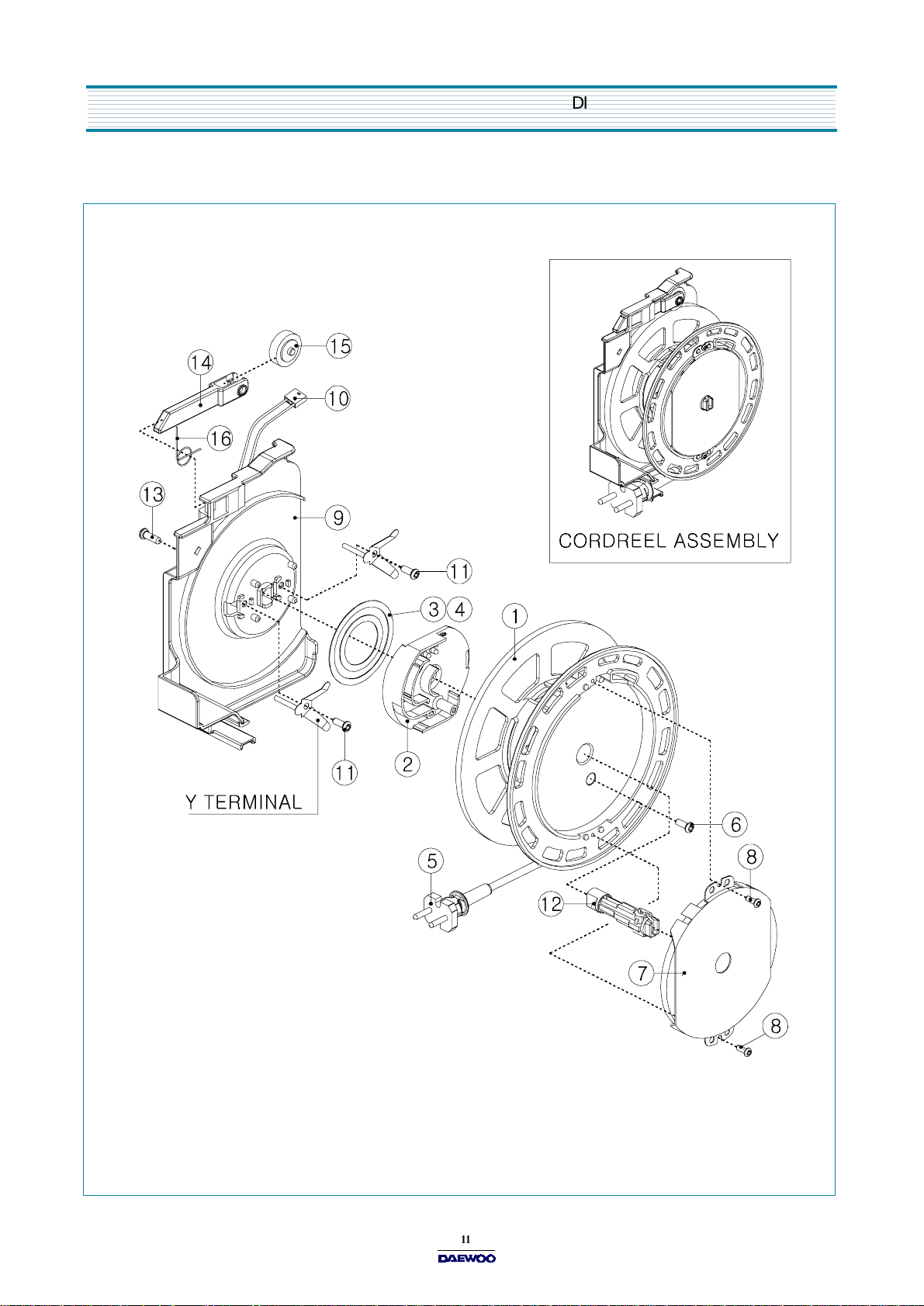

3. CORD REEL ASSEMBLY ............................................................................................................. 11

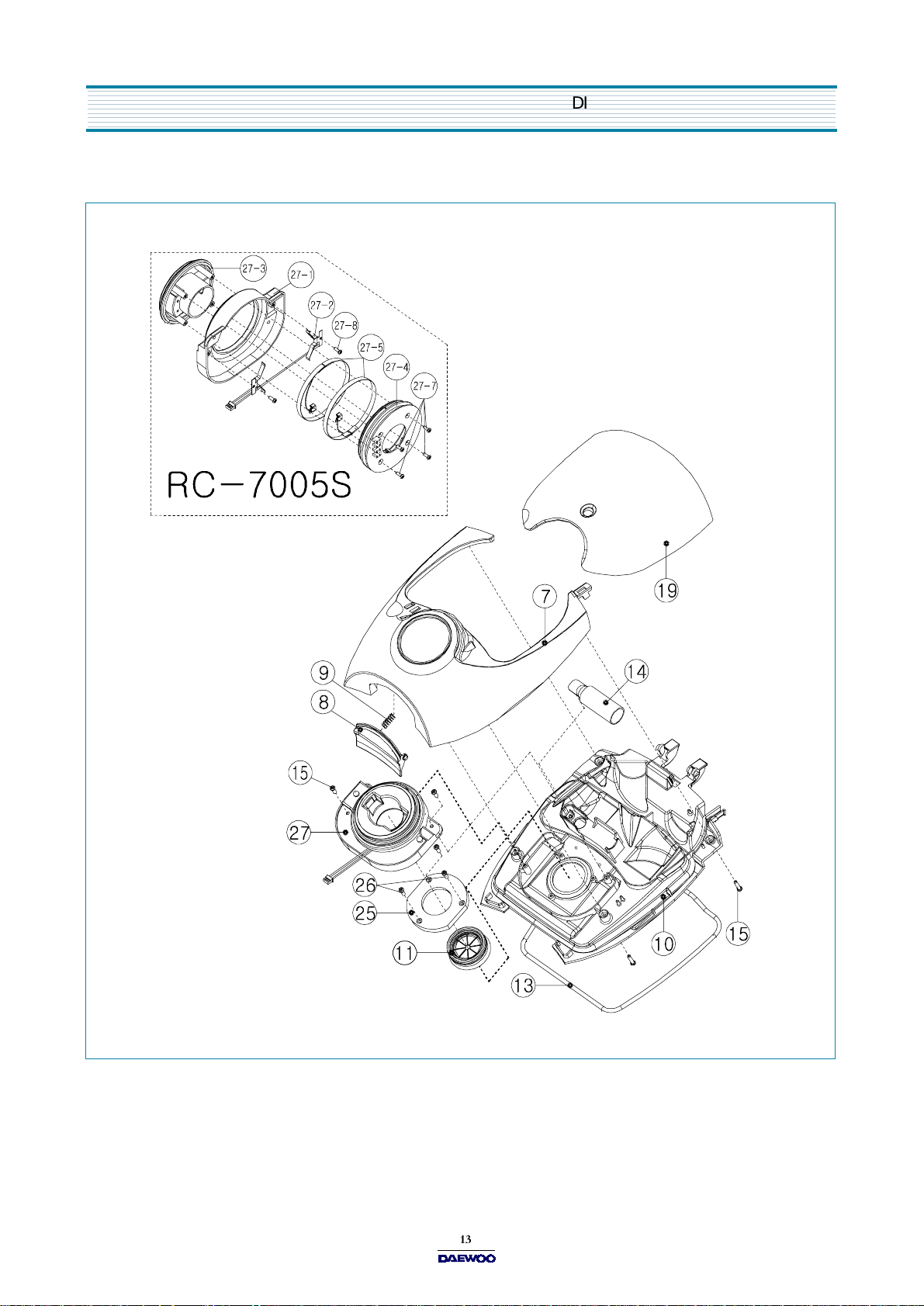

4. COVER DU ST ASSEMBLY....... ... ............... .. ........ .. ........ ... ....... ... ....... ... ........ .. ........ .. ........ .. ......... 13

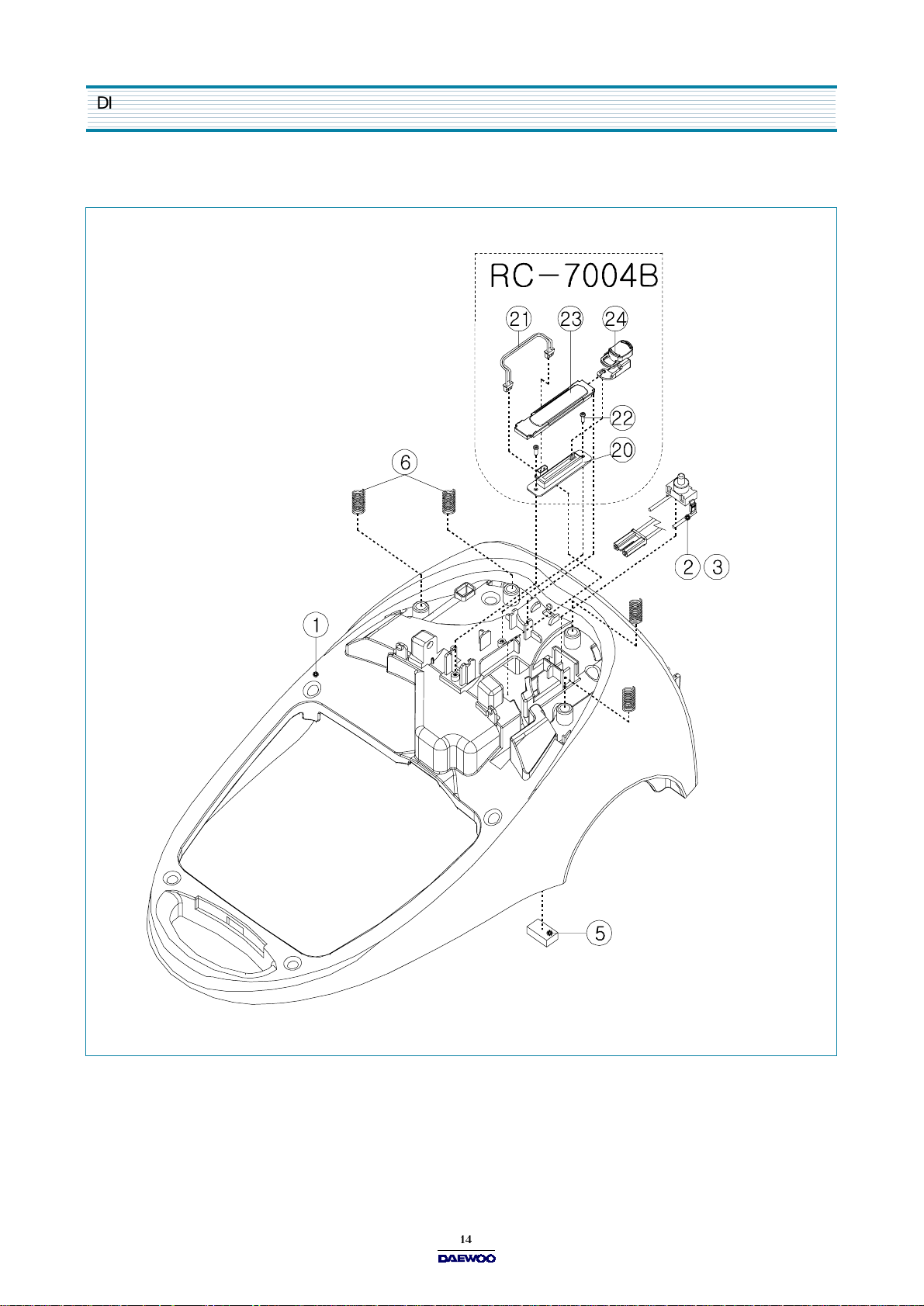

5. COVER BODY ASSEMBLY .......................................................................................................... 1 4

6. HOSE ASSEMBLY........................................................................................................................ 15

7. BRUSH ASSEMBLY (PEDAL BRUSH)......................................................................................... 16

EXPLODED VIEW AND PARTS LIST................................................................................................. 17

1. CLEANE R ASSEMBLY........ ... ............... .. ........ .. ........ ... ....... ... ....... ... ....... ... ........ .. ........ .. ........ ...... 17

2. BODY ASSEMBLY........................................................................................................................ 23

3. COVER ASS EMBLY ................. ... ....... ... ....... ... ....... ... ........ .. ........ .. ........ .. ................ .. ........ .. .. ....... 25

4. MOTOR ASS EMBL Y...................... ... ....... ... ....... ... ........ .. ........ .. ........ .. ........ ... ............... .. .............. 34

5. CORD REEL ASSEMBLY ............................................................................................................. 38

6. HOSE ASSEMBLY........................................................................................................................ 40

7. BRUSH ASSEMBLY...................................................................................................................... 44

8. PIPE ASSEMBLY.......................................................................................................................... 47

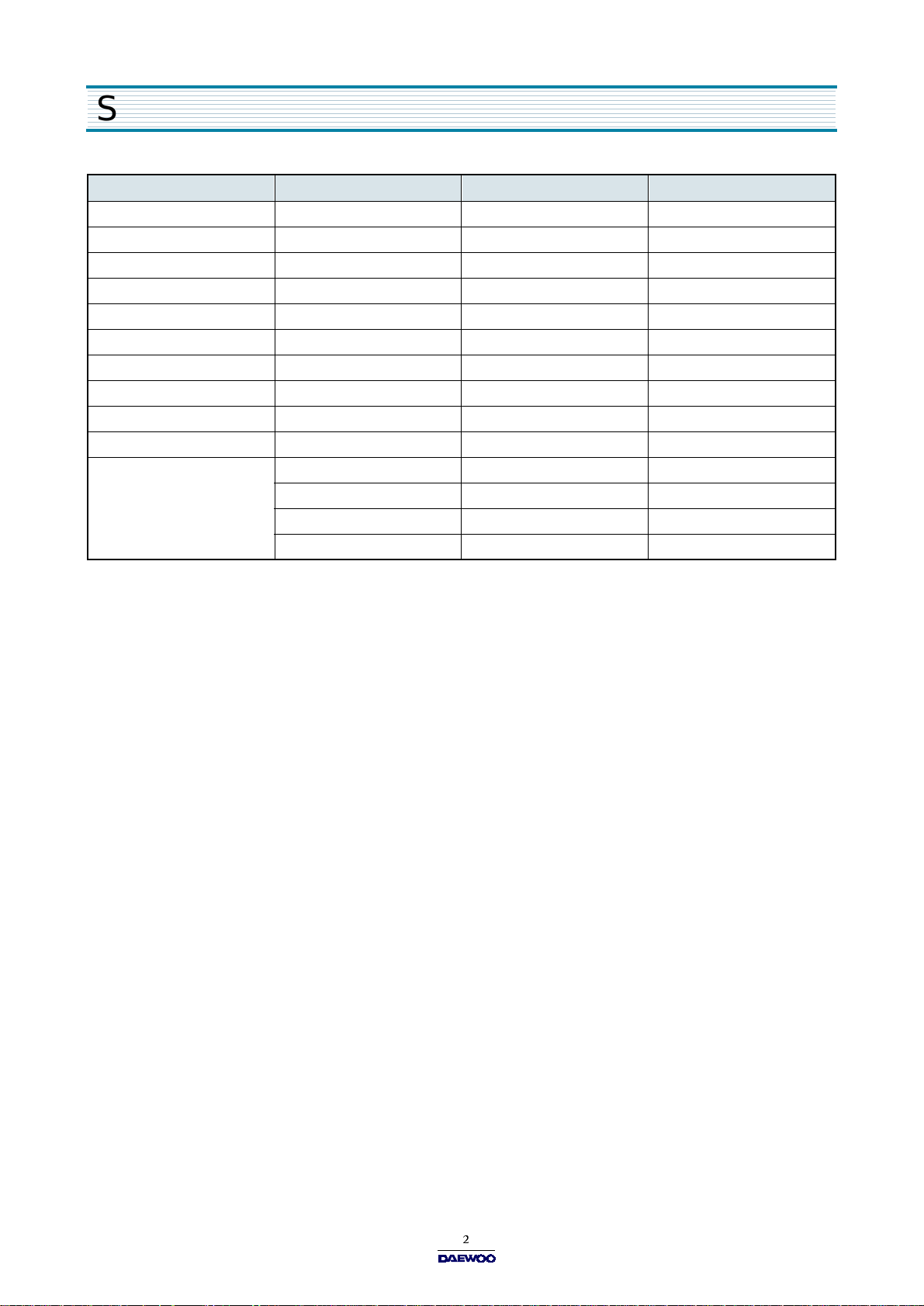

SPECIFICATIONS

MODEL RC-7004F RC-7004B RC-7005S

Rated Voltage AC 230V AC 230V AC 230V

Frequency 50/60Hz 50/60Hz 50/60Hz

Input Watt MAX 1400W (CEE 1200W ) MAX 1400W (CEE 1200W ) MAX 1500W(CEE 1300W)

Weight(Body) 5.3Kg 5.3Kg 5.5Kg

DImension(LXHXD) 486X240X319mm 486X240X319mm 486X240X319mm

Cord Length 6m 6m 6m

Power Control Body ON/OFF Body Variable H ose Variable

Dust Meter Mechanical Mechanical Mechanecal

Hose Non-Current 1.6m Non-Current 1.6m Current 1.6m

Extension Pipe 2 Pieces Steels 2 Pieces Steels Telescopic Steel

Nozzle Clean Brush Pedal Brush Pedal Brush

Crevice Tool Crevice Tool Crevice Tool

Upholstery nozzle Upholstery nozzle Upholstery nozzle

Dusting Brush Dusting Brush Dusting Brush

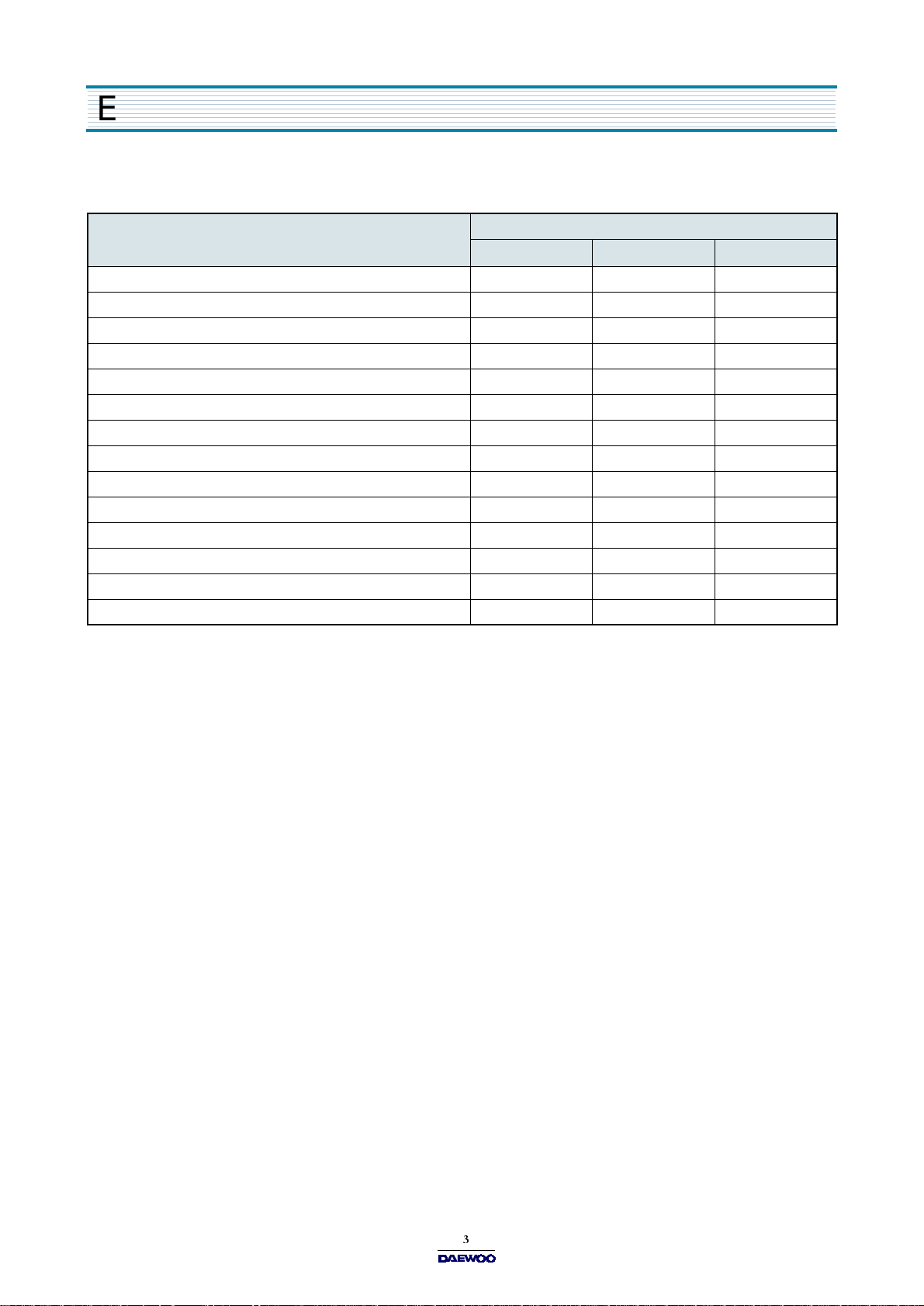

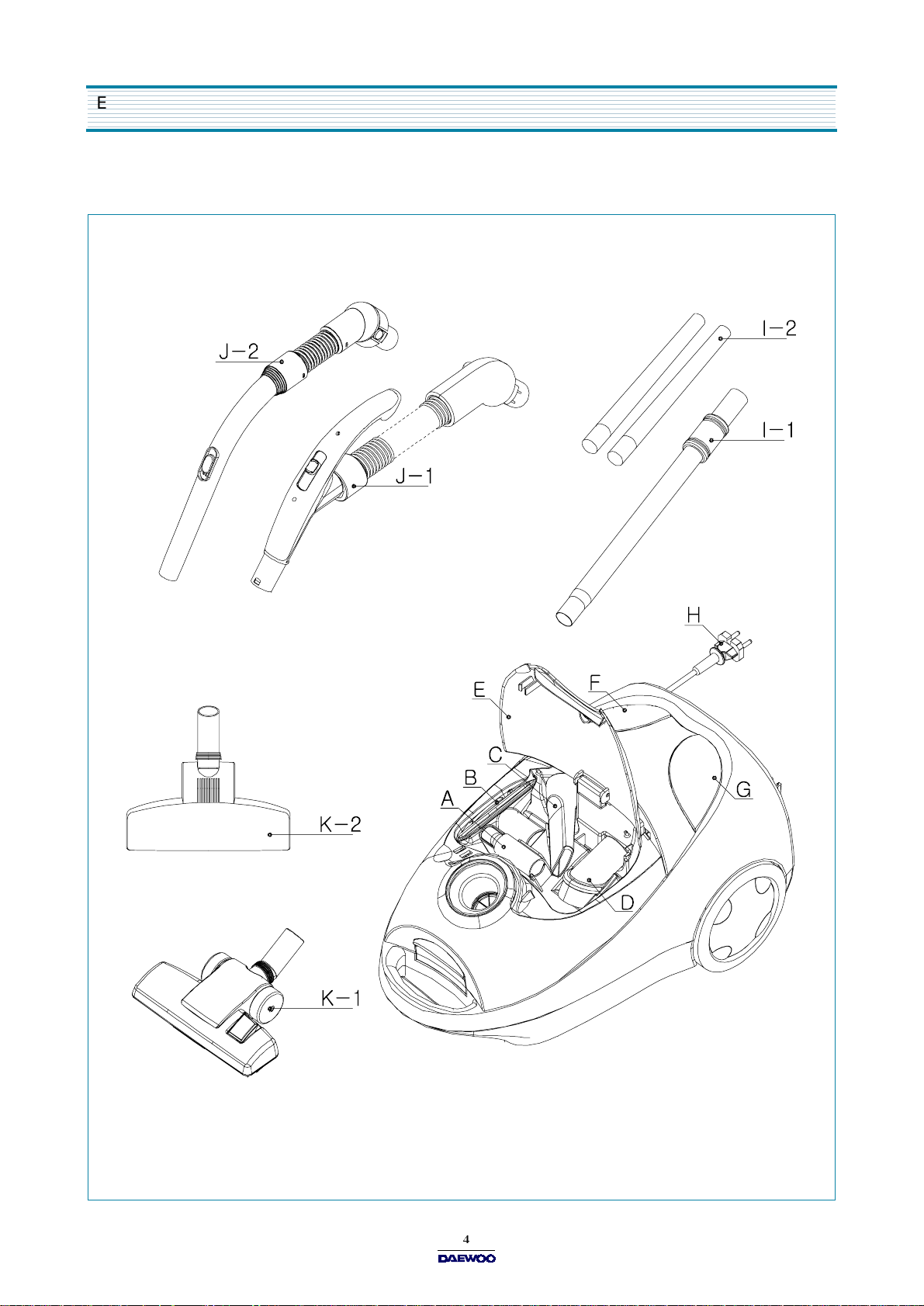

EXTERNAL VIEWS

1. ASSEM BLY

PART NAME

RC-7004F RC-7004B RC-7005S

A - DUST METER O O O

B - CLEANING TOO LS (Upholstery) O O O

C - CLEANING TOOLS (Crevice Tool) O O O

D - CLEANING TOOLS(Dusting Brush) O O O

E - COVER NOZZLE O O O

F - CORD REWIND BUTTON O O O

G - SWITCH BUTTON O O O

H - POWER CORD O O O

I-1 - EXTENSION PIPE (Steel Telescopic Tube) - - O

I-2 - EXTENSION PIPE (2 Steel Tubes) O O J-1 - HOSE HANDLE - - O

J-2 - HOSE HANDLE O O K-1 - PEDAL BRUSH - O O

K-2 - CLEAN BRUSH O - -

MODEL

EXTERNAL VIEWS

2. MODEL (RC- 700 4F, R C-7 004B , RC-70 05S )

DIAGRAM

1. WIRING DIAGRAM (RC-7004F)

WIRING DIAGRAM (RC-7004B, RC-70 05S)

DIAGRAM

2. CIRCUIT DIAGRAM (RC-7004F)

CIRCUIT DIAGRAM (RC-7004B, RC-7005S)

TROUBLE SHOOTING GUIDE

TROUBLE CAUSE COUNTERMEA

SUCTION POWER IS WEAK FILTER BAG(PAPER OR CLOTH)

IS FULL WITH DUST

CLOGGING OR TEAR IN HOSE REMOVE OBSCTACLE

DEFECTIVE M OTOR REPLACE THE MOTOR

CLEANER DOES NOT WORK BREAKING IN POW ER CORD

(AT BLAD E TIP O R R O OT O F PLU G )

BREAKING OF CONNECTIONS IN HOSE

ASSEMBLY

DEFECTIVE SLIDE VOLUME

LOCATED IN HOSE HANDLE

OR COVER BODY

DEFECTIVE PCB ASSEMBLY REPLACE IT (SEE 6-1)

CHANGE IT WITH NEW ONE(PAPER)

REMOVE THE DUST(CLOTH)

OR REPLACE THE HOSE

(SEE 5-2)

REPLACE THE POWER COR D

(SEE 5-3)

REPA IR ( SEE 5 - 6)

REPLACE IT (SEE 5-6)

REPLACE IT (SEE 5-5)

MOTOR DOES NOT STOP

EVEN IF SWITCH

BREAKING OF CONNECTIONS

O R P OOR CON TA CTS IN CORD

REEL ASSEMBLY

DEFECTIVE M OTOR REPLACE IT (SEE 5-2)

BREAKING OF CONNECTIONS IN COVER

BODY ASSEMBLY

OR COVER DUST ASSEMBLY

BREAKING OF ZENER DIODE(ZD) IN PCB REPLACE IT (SEE 6-1)

DEFECTIVE SW ITCH REPLACE IT (SEE 5-5)

DEFECTIVE PCB ASSEMBLY REPLACE IT (SEE 6-1)

REPA IR ( SEE 5 - 3)

REPA IR ( SEE 5 - 4)

REPA IR ( SEE 5 - 5)

TROUBLE SHOOTING GUIDE

TROUBLE CAUSE COUNTERMEA

POWER CORD IS

NOT WOUND UP

BROKEN REEL SPRING

OF CORD REEL

POWER CORD BRO KE AWAY

FROM THE BOBBIN

REPLACE IT (SEE 5-3)

REPA IR ( SEE 5 - 3)

CAUTION

BE CAREFUL WH EN BREAKING UP THE CO RD REEL, THE REEL SPRING MAY SPRING OUT OF THE

SPRING COVER

POWER CORD DOES

NOT STOP AT AN

ARBITRARY POSITION

ABRASION OF THE ROLLER

BRAKE OF CORD REEL

LEVER SPRIN G BROKE AWAY

FROM THE CORD REEL BRACKET

REPLACE THE ROLLER

BRAKE (SEE 5-3)

REPA IR ( SEE 5 - 3)

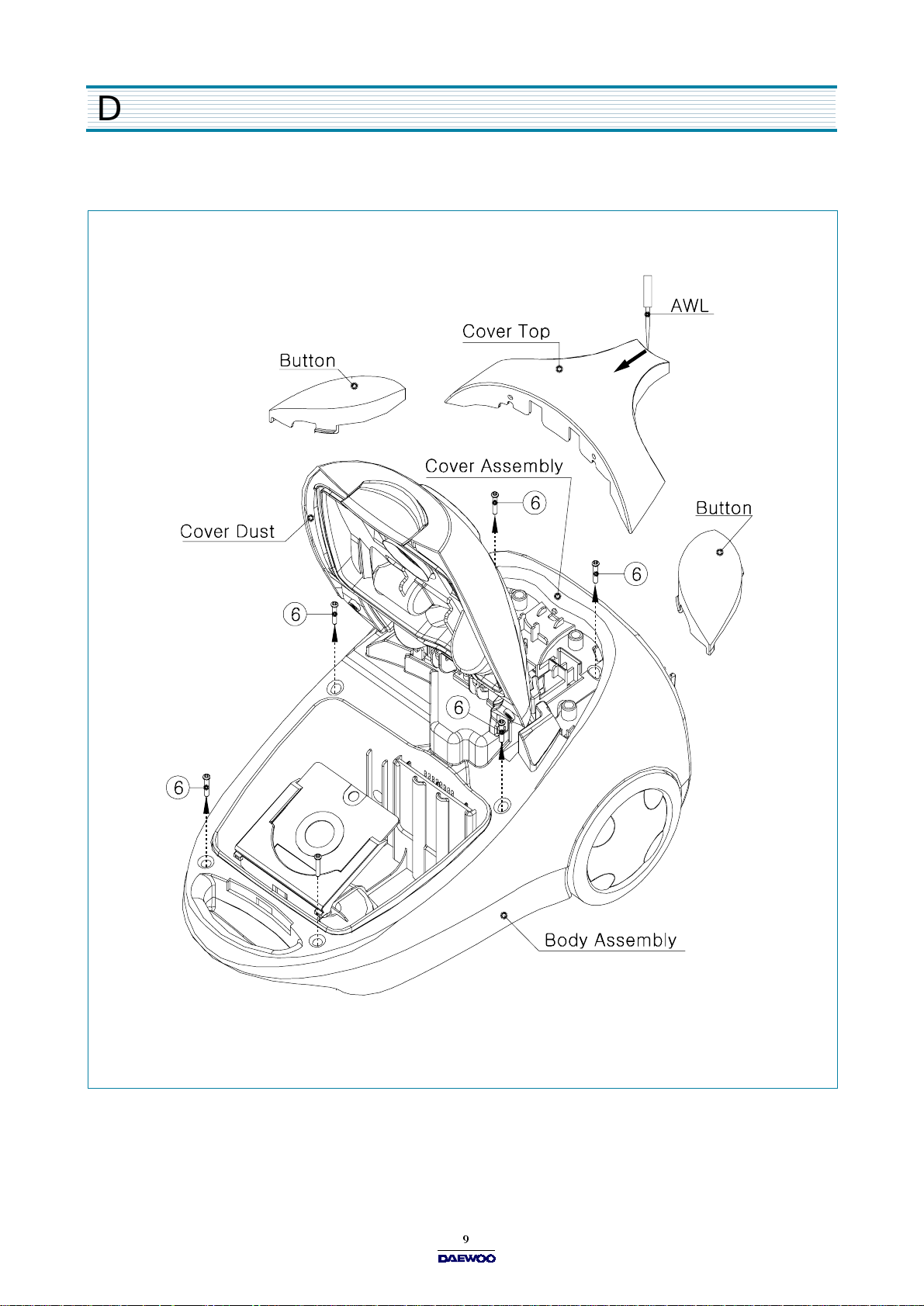

D ISASSEMBLING AND TREATMENT

1. CLEANER ASSEMBLY

1) OPEN THE C OVER D US T AND TAKE THE COVER TO P O UT OF THE C OVER ASSE M BLY BY USING AN AWL.

2) SEPARATE THE TWO BUTTONS FR OM THE CO VER ASSEM BLY.

3) UNSCR EW THE 6 SCREW S(6) THEN LIFT THE CO VER ASSEMBLY UP FROM THE BODY ASSEM BLY.

D ISASSEMBLING AND TREATME NT

2. MOTOR ASSEMBLY

1) TAKE THE MOTOR ASSEMBLY OUT OF THE BODY.

2) UNSCREW THE 4 SCREWS(3).

3) CHECK THE MOTOR(1) (W HETHER THE MOTOR IS BURNT OUT OR NOT).

4) WH EN ASSEMBLING, INSERT THE LEADS INTO THE SLIT.

3. CORD REEL ASSEMBLY

D ISASSEMBLING AND TREATMENT

D ISASSEMBLING AND TREATME NT

1) TAKE THE CORD REEL OUT OF THE BODY.

2) UNSCR EW THE SCR EW (13) AND SEPARATE THE BOBBIN(1) FROM THE BRACKET(9) AND CHECK THE

CONTACTS BETWEEN THE Y TYPE TERM INALS AND THE RING TYPE TERMINALS(3, 4).

4) CHECK THE LEVER SPRING(16).

5) IF THE ROLLER BRAKE(15) IS WORN OUT AND SEPARATE THE LEVER(14) FROM THE BRACKET(9), THEN

REPLACE THE ROLLER BRAKE(15).

AT THIS TIME, THE BOBBIN(1) IS ROTATED COU NTER CLOC KWISE DUE TO THE PR ESERVED W INDING.

6) IF THE REEL SPRING(7) IS BROKEN, UNSCREW THE 2 SCR EW S(8) AND REPLACE IT.

CAUTION

WHEN DISASSEMBLING, THE REEL SPRING MAY SPRING OUT OF THE COVER.

7) UNSCR EW THE SCR EW (6) AND SEPARATE THE HO LDER TERM INAL(2) FROM THE BOBBIN(1).

8) CHECK THE C ON N ECTIONS BE TW EEN THE PO WER COR D(5) AND THE RING TERMINALS(3,4).

9) W H EN AS SEM BLING, MAKE THE R ESERVED W INDING 5 REVO LUTIONS OF THE BO BBIN CLOCKWISE.

4. COVER DUST ASSEMBLY

D ISASSEMBLING AND TREATMENT

1) UNSCR EW THE 6 SCREW S(15) AND SEPARATE THE COVER DUST(7) FROM THE PLATE(10).

2) UNSCR EW THE 2 SCREW S(15) AND SEPARATE THE FRAME TERMINAL AS(27) FROM THE PLATE(10).

3) CHECK THE CON TACTS BETWEEN THE V TYPE TERMINALS(27-2) AND THE RING TYPE TERMINALS(27-5)

4) CHEC K THE CONNECTIONS BETW EEN THE 2 TERM INALS(27-5).

5) CHECK THE CON NECTIONS BETW EEN THE TERMINAL(27-2) AND THE PCB ASSEMBLY.

D ISASSEMBLING AND TREATME NT

5. COVER BODY ASSEMBLY

1) CHEC K THE CONNEC TIONS BETWEEN THE PCB ASSY(20) AND THE WIRE(21).

2) CHECK THE PCB ASSY(20)

3) CHECK THE SWITCH(2, 3).

4) CHECK WHETHER THE KNOB(24) IS BROKEN OR NOT.

Loading...

Loading...