Page 1

Service Manual

Vacuum Cleaner

Model : RC-407

D AEWOO ELECTRONICS CO., LTD.

O VERSEAS SER VICE DEPT.

Page 2

CONTENTS

1. SPECIFICATIONS 1

2. CIRCUIT DIAGRAM 2

3. CAUSE OF TROUBLE AND COUNTERMEASURE 3

¡

4.

DESCRIPTION 4

¡

DISCRIPTION LIST 5

5. EXPLODED VIEW AND PARTS LIST 6

¡

BODY (DOWN) ASS’Y 6

¡

BODY (DOWN) PARTS LIST 7

¡

COVER ASS’Y 8

¡

COVER PARTS LIST 9

¡

HOSE LINE ASS’Y 10

¡

HOSE LINE PARTS LIST 11

¡

SUCTION BRUSH ASS’Y 12

¡

SUCTION BRUSH PARTS LIST 13

¡

BOX FILTER ASS’Y 14

¡

BOX FILTER PARTS LIST 14

¡

ACCESSORY NOZZLES 15

¡

ACCESSORY NOZZLES PARTS LIST 15

1. SPECIFICATIONS

RATED VOLTAGE AND RATED FREQUENCY AC 220V / 50Hz

AC 230V / 50Hz

AC 230V / 50, 60Hz

AC 240V / 50 Hz

RATED INPUT 1200W

DIMENSION (W¡¿L¡¿H) 270¡¿482¡¿234(mm)

NET WEIGHT 7.3kg

CORD LENGTH 5m / 6m

1

Page 3

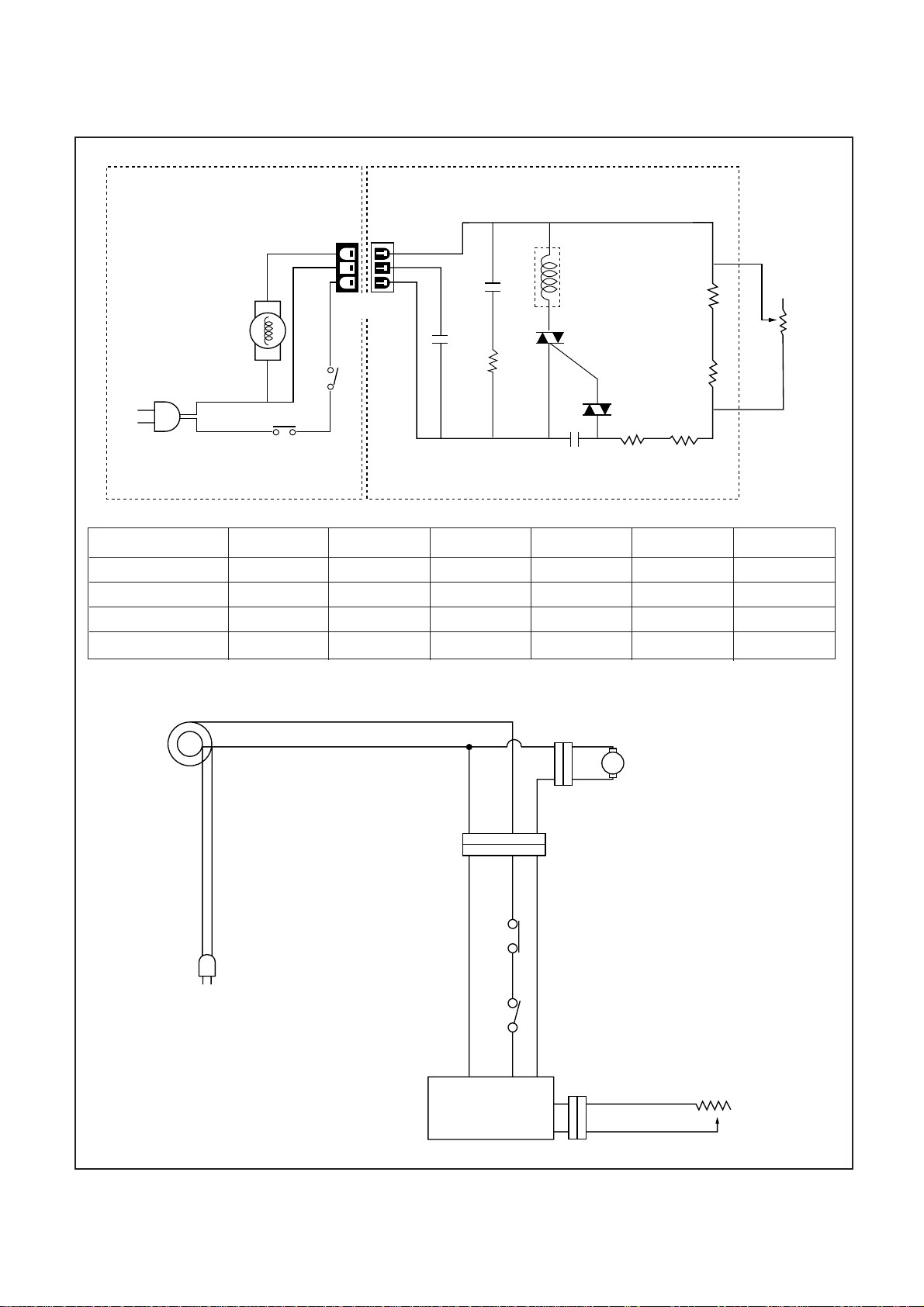

2. CIRCUIT DIAGRAM

BLUE

BLACK

WHITE

BLUE

BLACK

WHITE

MOTOR

THERMOSTAT

250V 7.5A, 85˚C

SWITCH

250V 10A

POWER CORD

AC 250V, 7A

POWER

C3

104K

C2

104K

FILTER COIL

120µH, 12A

TRIAC

SM16JZ47

R5

100 1W

R4

R3

P.C.B

C1

104K

DIAC

DB4

YELLOW

YELLOW

S/V

R1 R2

LR-03 LP-03

HARNESS ASS'Y

WIRING DIAGRAM

M

WHWH

BK

CR

BK BK

BL

BK WH

WH

YW

SLIDE

VOLUME

T1 T2

PCB ASS'Y

YW

BL

AC 220V/50HZ 10KΩ 1/2W 10KΩ 1/2W 180KΩ 1/2W 240KΩ 1/2W 500KΩ 85˚C

AC 220V/60HZ 10KΩ 1/2W 10KΩ 1/2W 150KΩ 1/2W 160KΩ 1/2W 500KΩ 85˚C

AC 230V/50,60HZ 10KΩ 1/2W 10KΩ 1/2W 180KΩ 1/2W 180KΩ 1/2W 500KΩ 85˚C

AC 110V/50, 60HZ 1KΩ 1/2W 1KΩ 1/2W 91KΩ 1/2W 91KΩ 1/2W 200KΩ 85˚C

VOLTAGE R1 R2 R3 R4

SLIDE VOLUME THERMOSTA T

2

Page 4

3. CAUSE OF TROUBLE AND COUNTERMEASURE

TROUBLE CAUSE

MOTOR DOSE NOT

ROTATE

COUNTERMEASURE

BREAK POWER CORD (AT

BLADE TIP OR ROOT OF PLUG)

DEFECTIVE PCB

BREAK THE LEAD WIRE

DEFECTIVE SWITCH REPLACE THE SWITCH

ABRASION CARBON

OF THE MOTOR

BREAK IN OTHER CONNECTION

DEFECTIVE SWITCH REPLACE

REPLACE THE POWER

CORD

REPLACE

REPAIR (SOLDER OR USE

CLOSED END TERMINAL)

REPLACE OR REPAIR

REPAIR

MOTOR DOSE NOT STOP

EVEN IF THE SWITCH IS

SET “OFF”

CORD IS NOT

WOUND UP AT ALL

CORD DOESN’T STOP AT

ARBITRARY POSITION

*Be careful when breaking up the cordreel. The reel spring can spring out of the cover .

SUCTION POWER IS LOW

DEFECTIVE PCB

THE CORD IS DRIVEN OR

TWISTED

INSUFFICIENT RESERVED

WINDING

BROKEN THE SPRING OF

CORD REEL

ABRASION OF THE BRAKE

ROLLER

DUST IS SUCKED EXCESSIVELY

INTO THE PAPER BAG

CLOGGING OR BREAK OF THE

HOSE OR EXTENSION PIPE

REPLACE

REPAIR

REPAIR

REPAIR

REPLACE

REPLACE THE PAPER BAG

REMOVE THE OBSTACLE

OR REPLACE HOSE/E.P.

THE FILTER BOX IS FILLED

WITH DUST

DEFECTIVE MOTOR REPLACE

REMOVE DUST OF THE

FILTER BOX

3

Page 5

4. DESCRIPTION

9

5

6

1

13

12

2

8

7

4

3

10 11

4

Page 6

Description List

NO PART NAME PART CODE SPECS. Q

1 BODY ASS’Y 3620401500 2 COVER ASS’Y 3621404800 220V 50HZ

COVER ASS’Y 3621404810 230V 50HZ

3 HOSE ASS’Y 3623200900 1.3m E.V.A

HOSE ASS’Y 3623204500 1.8m E.V.A

4 PIPE AS 3624404500 STEEL

PIPE AS 3624404600 BLOWER

5 BRUSH ASS’Y 3629301600 6 UP HOLSTERY NOZZLE 4569A68000 PP

7 DURSTING BRUSH 3629301500 ABS

8 NOZZLE CREVICE 3628100300 PP

9 DUST BO X 3621901000 PE NON WOVEN MAT

10 DUST BAG HOLDER 3623001700 11 DUST BAG 4560A57001 PAPER

DUST BAG 3621901610 CLOTH

12 MOTOR ASS’Y 3662511400 230V/50Hz 1100W(F)

¡¡flfl

TY

3962110810 240V/50Hz 1100W(F)

3962230300 110V/60Hz 1200W(E)

3962330510 220V/50Hz 1200W(E)

3962510230 230V/50Hz 1200W(E)

13 CORD REEL ASS’Y 3629500800 250V/7A 5m KS

3629501000 250V/7A 6m KS

3629504200 250V 10/16A 6m

3629501005 250V 7A 5m ISRAEL

3629504210 250V 7A 6m U. K

3629504500 250V 7A

ARENTINA

5

Page 7

5. EXPLODED VIEW AND PARTS LIST

8

8

1

6

2

5

18

17 19

16

9

10

11

12 7 13 14 15

4

21

22

31

32

33

30

24

23

22

21

28

29

27

26

25

3

BODY (DOWN) ASS’Y

6

Page 8

BODY (DOWN) PARTS LIST

NO PART NAME PART CODE SPECS. Q

1 TERMINAL AS 3628701900 TERMINAL£«WIRE (WH) 1

2 TERMINAL AS 3628703100 TERMINAL£«WIRE (BK) 1

3 HARNESS 3622705600 1

4 CEC 4505A63030 ST CE-230 1

5 SCREW TAPPING 7121401011 T2S PAN 4¡¿10 MFZN 2

6 BRACKET CR 3620600300 ABS 1

3620600310 PC

7 SCREW TAPPING 7121401411 T2S PAN 4¡¿14 MFZN 4

8 TERMINAL OB 3628700100 C2600P 1

9 TERMINAL OA 3628700200 C2600P 1

10 BOBBIN 3629200200 ABS 1

11 POWER CORD WKH14N7811 ISRAEL 1

3621301000 KS

4568F38022 CHILE

4569A36010 SEMKO

12 BOBBIN 3629200100 ABS 1

13 REEL SHAFT 4569C35050 ABS 1

14 SPRING REEL AS 3625102000 SUS 301 EH 1

15 SCREW TAPPING 7121300811 T2S PAN 3¡¿8 MFZN 2

16 LEVER CR 3623700700 ABS 1

17 STOPPER CR 4569C35082 NBR 1

18 SPRING CR LEVER 3625102300 HSW3 1

19 STOPPER FRAME 4565A35070 POM 1

20 WAX VASELINE 2291140301

21 COVER BACK CASTER 4569C20070 ABS 2

22 CASTER FRAME BACK 4569C20020 PP 2

23 BRACKET FRONT CASTER 4569C20040 PP 1

24 CASTER FRONT 4568A45020 PP 1

25 CAP MOTOR BACK 4569C10040 NR 1

26 MOTOR SPONGE 4569C10070 POLY URETHANE FOAM 1

27 V/C MOTOR 3962330330 220V, 1200W O/S 1

3962510230 230V , 1200W E-class

3962511300 230V , 1200W F-class

3962610600 240V , 1200W

28 CAP MOTOR FRONT 4569A20040 NR 1

29 BODY EXAUST FILTER 4569C20060 POLYESTER 1

30 SCREW TAPPING 7121402011 T2S PAN 4¡¿20 MFZN 6

31 DA PACKING-R 4569R20080 NR 1

32 PRO TECTOR 4569C20030 PVC-S 1

33 BODY 4569C20010 ABS 1

¡¡flfl

TY

7

Page 9

COVER PARTS LIST

NO PART NAME PART CODE SPECS. Q

1 LATCH PUSH 4519F35000 1

2 COVER NOZZLE 3621405100 ABS 1

3 COVER DM 4560F30040 ABS 1

4 SCREW TAPPING 7121301211 T2S PAN 3X12 MFZN 2

5 VALVE 3625400100 LDPE 1

6 PACKING 3624000400 PVC-S 1

7 HOUSING 4560F23010 SAN 1

8 DUST METER 4560F23030 ABS (RED) 1

9 DUST METER 4560F23060 ABS (GREEN) 1

10 SPRING 3625102500 SUS 1

11 ELBOW DM 4569C23050 PVC-S 1

12 COVER DUST 3621405000 ABS 1

13 CLAMP COVER 3621201000 ABS 1

14 SPRING 3625102400 HSW3 1

15 SOCKET 3629800900 ABS 1

16 PACKING SOCKET 3624000700 TPE 1

17 PLATE 3624500500 ABS 1

18 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 7

19 COVER BODY 3621404900 ABS 1

20 PCB AS 3624302100 220~240V/50HZ 1

3624302130 230V/50HZ (SEMKO)

3624302150 230V/50, 60HZ

21 SCREW TAPPING 7121401011 T2S PAN 4X10 MFZN 2

22 VR SLIDE 5V2504001B 500K 1

23 LABEL CONTROL 3623505700 PC FILM 1

24 SCREW TAPPING 7121402011 T2S PAN 4X20 MFZN 2

25 SPRING 4569A24030 HSW3 3

26 BUTTON CR 3626601100 ABS 1

27 FRAME BUTTON 3622200300 ABS 1

28 BUTTON SWITCH 3626601200 ABS 1

29 KNOB 3623400300 ABS 1

30 GUIDE KNOB 3622501100 ABS 1

31 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 4

32 COVER TOP 3621405300 ABS 1

33 SW PUSH 4569A37000 AC 250V/10A 1

34 THERMOSTAT 3629000600 65˚C 250V 7.5V 1

35 HARNESS 3622706200 1

36 SCREW TAPPING 7121301211 T2S PAN 3X12 MFZN 1

¡¡flfl

TY

9

Page 10

HOSE LINE PARTS LIST

NO PART NAME PART CODE SPECS. Q

1 PIPE HOSE 3624402100 ABC 1

2 VALVE 3625400200 ABS 1

3 COVER PIPE 3621405600 ABS 1

4 SCREW TAPPING 7121301211 T2S PAN 3X12 MFZN 2

5 HOSE 3623201100 EVA 1

6 CUFF HOSE 3626800200 LDPE 2

7 HOUSING 4560F23010 SAN 1

8 ADAPTER 3629100200 ABS 1

9 CLAMP ADAPTER 3621200700 P A 1

10 BUTTON ADAPTER 3626601300 ABS 1

11 ELBOW DM 4569C23050 PVC-S 1

12 SCREW TAPPING 7188401011 WASHER ATTACHED 2

13 HOOK HOSE 4560F77000 PP 1

¡¡flfl

TY

11

Page 11

SUCTION BRUSH PARTS LIST

NO PART NAME PART CODE SPECS. Q

1 PIPE BRUSH 3624402400 PP 1

2 NECK 3628000700 PP 1

3 HOOK 3623100100 PA 2

4 COVER BRUSH 3621405400 PP 1

5 COVER AIR 3621406200 PP 1

6 SHAFT 3624900400 SWRM + MFZN 2

7 ROLLER 3624701000 P A + TPE 2

8 RING E 7402004011 ER-4 MFZN 2

9 CAP ROLLER 3620901500 PA 2

10 LEVER BRUSH 3623700800 ABS 1

11 PLATE BRUSH AS 3624500800 ASSY 1

12 SPRING 3625102600 HSW3 2

13 ROLLER 3624700600 P A + TPE 2

14 PIN 3628200200 SWRM MFZN 2

15 PLATE BRUSH 3624500600 SUS T=0.5 1

16 PICKER LITTER 3627000100 ABS + NYLON 2

17 SCREW TAPPING 7121401411 T2S PAN 4 X 14 MFZN 4

¡¡flfl

TY

13

Page 12

ACCESSORY NOZZLES

1

2

3

ACCESSORY NOZZLES PARTS LIST

NO. PART NAME CODE SPECS. Q’TY

1 NOZZLE CREVICE 3628100300 PP 1

2 DUSTING BRUSH 3629301500 ABS + NYLON 1

3 NOZZLE UPHOLSTER Y 4569A68000 PP 1

15

Loading...

Loading...