Page 1

Service Manual

Vacuum Cleaner

Model: RC-406

(RC-190)

DAEWOO ELECTRONICS CO., LTD.

Page 2

VACUUM CLEANER

Contents

1. SPECIFICATIONS

...................................................................................................................

1

2. CIRCUIT DIAGRAM

SLIDE VOLUME TYPE

........................................................................................................

2

3. CAUSE OF TR OUBLE AND COUNTERMEASURE

.............................................................

3

4. EXPLODED VIEWS AND PARTS LIST

BODY(DOWN) ASS’Y

.........................................................................................................

5

BODY(DOWN) PARTS LIST

................................................................................................

6

BODY(UP) ASS’Y

..............................................................................................................

7

BODY(UP) PARTS LIST

......................................................................................................

8

HOSE LINE ASS’Y (I)

.........................................................................................................

9

HOSE LINE PARTS LIST (I)

...............................................................................................

10

HOSE LINE ASS’Y (II)

.......................................................................................................

11

HOSE LINE PARTS LIST (II)

..............................................................................................

12

SUCTION BRUSH ASS’Y

..................................................................................................

13

SUCTION BRUSH PARTS LIST

.........................................................................................

14

Page 3

1. SPECIFICATIONS

1

SPECIFICATIONS

ITEM RC-406 (RC-109)

POWER SOURCE 100V/50-60Hz, 120/60Hz, 220V/50-60Hz, 230V/50-60Hz,

240V/50-60Hz

POWER CONSUMPTION 1,000W, 1,200W

DIMENSION (WXLXH) BODY : 270X482X234 (MM)

WITH PARTS CASE : 270X482X430 (MM)

NOISE BELOW 65dB

CORD LENGTH 5M

NET WEIGHT 8.8Kg

Page 4

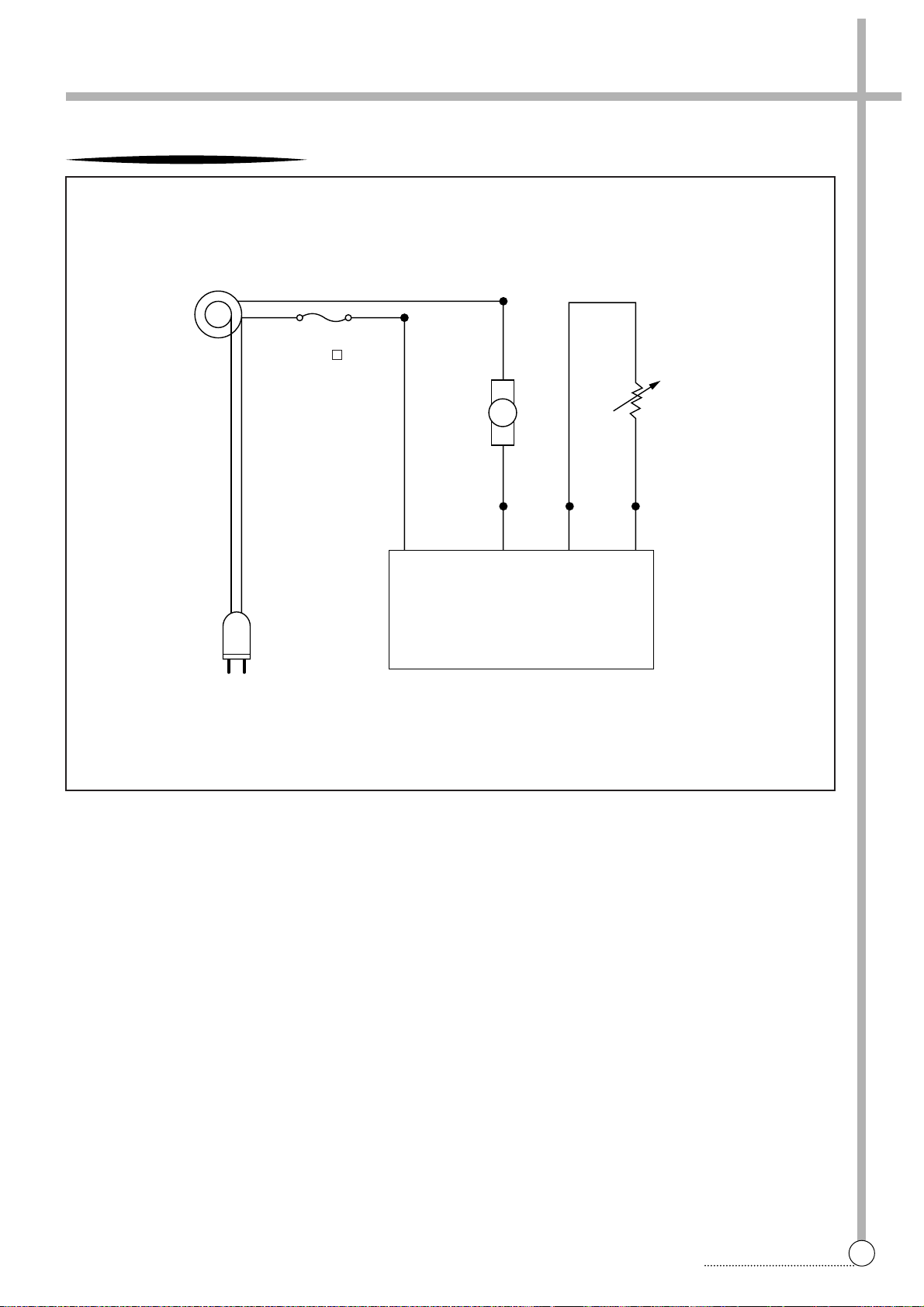

2. CIRCUIT DIAGRAM

2

CIRCUIT DIAGRAM

SLIDE VOLUME

YELLOWYELLOW

YELLOWWHITEBLACK

PLUG

CORD REEL

ASS'Y

BLUE

THERMOSTAT

PCB ASS'Y FOR POWER

CONTROL

M

BLACK

SLID VOLUME TYPE

85

Page 5

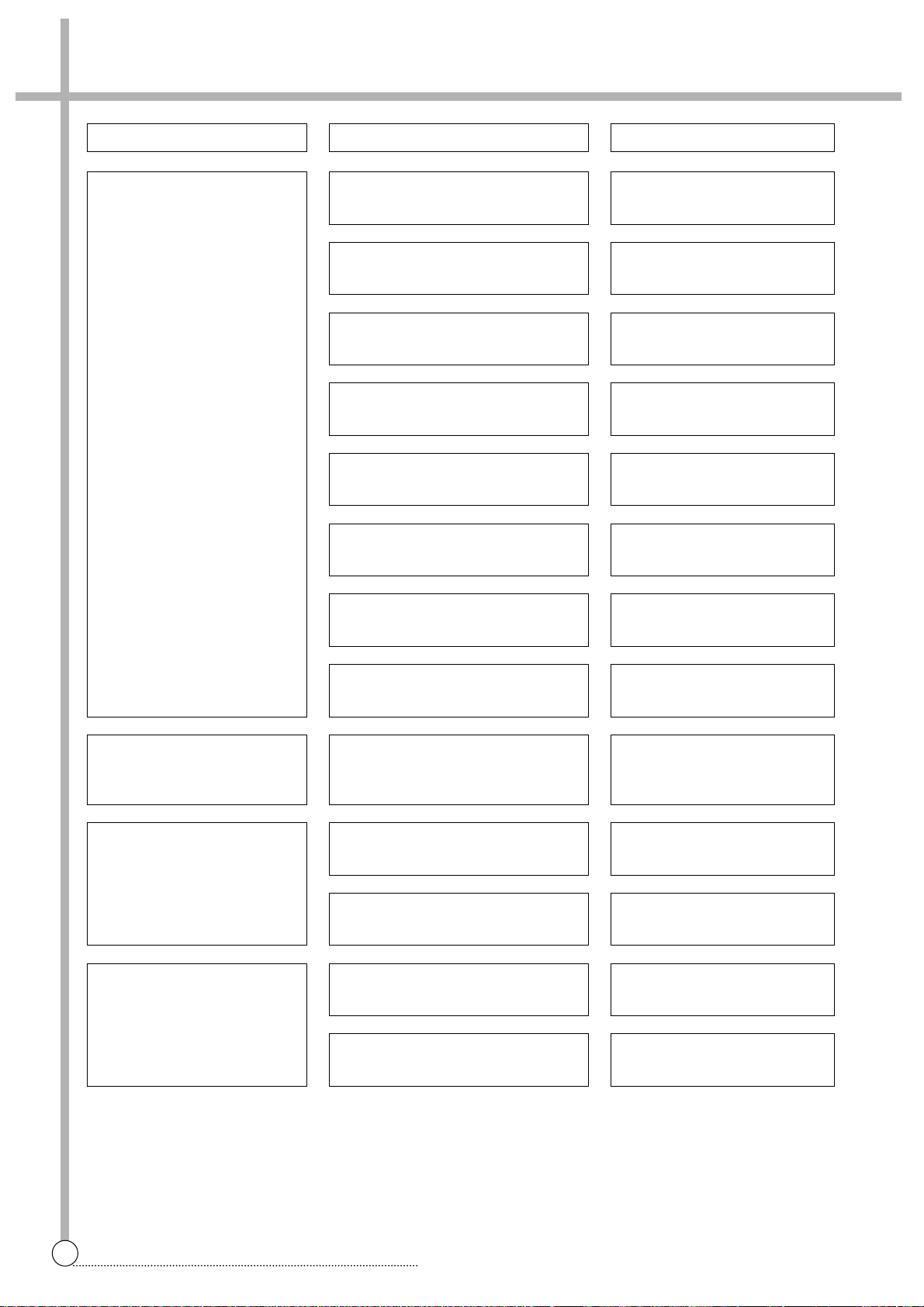

3. CAUSE OF TROUBLE AND COUNTERMEASURE

3

CAUSE OF TROUBLE AND COUNTERMEASURE

TROUBLE CAUSE

BREAK POWER CORD (AT

BLADE TIP OR ROOT OF PLUG)

MOTOR DOSE NOT

ROTATE

DEFECTIVE PCB

BREAK THE LEAD WIRE

REPLACE THE POWER

CORD

REPLACE

REPAIR (SOLDER OR USE

CLOSED END TERMINAL)

DEFECTIVE SWITCH REPLACE THE SWITCH

ABRASION CARBON BRUSH REPLACE OR REPAIR

BLOW OF FUSE REPLACE

DEFECTIVE SWITCH REPLACE

BREAK IN OTHER CONNECTION REPAIR

DEFECTIVE SWITCH OR PCB

MOTOR DOSE NOT STOP

EVEN IF THE SWITCH IS

SET “OFF”

REPLACE

THE CORD IS DRIVEN OR

TWISTED

CORD IS NOT WOUND UP

AT ALL

REPAIR

INSUFFICIENT RESERVED

WINDING

ADD PROPER

RESERVED WINDING

ABRASION OF THE BRAKE

ROLLER

CORD DOESN’T STOP AT

ARBITRARY POSITION

REPLACE

BROKEN THE SPRING OF CORD

REEL

REPLACE OR REPAIR

COUNTERMEASURE

Page 6

4

CAUSE OF TROUBLE AND COUNTERMEASURE

TROUBLE CAUSE

DUST IS SUCKED EXCESSIVELY

INTO THE PAPER BAG

SUCTION POWER IS LOW

REPLACE THE PAPER BAG

CLOGGING OR BREAK OF THE

HOSE OR EXTENSION PIPE

REMOVE THE OBSTACLE

OR REPLACE HOSE/E.P.

THE FILTER BOX IS FILLED

WITH DUST

REMOVE DUST OF THE

FILTER BOX

DEFECTIVE MOTOR REPLACE

ELONGATION OR BREAK OF

GEAR BELT

TURBO BRUSH DOSE NOT

ROTATE

REPLACE

THERE IS MUCK ON THE

ROTATING BRUSH

REMOVE MUCK

SUCTION POWER IS LOW REFERENCE ABOVE

CLOGGING OF THE OPENING REMOVE THE OBSTACLE

COUNTERMEASURE

Page 7

4. EXPLODED VIEW AND PARTS LIST

5

EXPLODED VIEW

4

8

16

16

15

14

13

38

5

1 38

6

9

2

8

621

8

10 11

24

26

27

28

29

31

23

22

32

22

23

33

34

36

35

37

12

20191817

25

30

BODY (DOWN) ASS’Y

Page 8

6

PARTS LIST

BODY (DOWN) PARTS LIST

NO. PARTS NAME CODE NO. REFERENCE Q’TY

1 TERMINAL Y-B AS. 4568A43000 1

2 TERMINAL Y-A AS. 4568A42000 1

4 P. C. B AS 4569G27000 POWER CONTROL 1

5 TMERMOS TAT 4569B47002 PW-2 T85 1

6 BRACKET CR 4569C35020 1

8 SCREW TAPPING 7121401211 3

9 TERMINAL OB 4565A36034 1

10 TERMINAL OA 4565A36024 1

11 SUPPORTER TERMINAL 4565A36010 1

12 PLUG CORD 4569C38000 1

13 BOBBIN 4569C35010 1

14 FEEL SHAFT 4569C35050 1

15 SPRING REEL AS. 4568A41000 1

16 SCREW TAPPING 7121300811 2

17 BUTTON CR 4569C35030 1

18 LEVER CORD REEL 4568A35060 1

19 SPRING CR LEVER 4568A35090 1

20 STOPPER CORD REEL 4565A35070 1

21 TIRE C.R. STOPPER 4568A35080 1

22 COVER BACK CASTER 4569C20070 2

23 CASTER FRAME BACK 4569C20020 2

24 BODY FELT 4569C20050 1

25 MB SUPPORTER 4569C20090 3

26 CAP MOTOR BACK 4569C10040 1

27 MOTOR SPONGE 4569C10070 1

28 V/C MOTOR 3962330530 220V / 50Hz 1000W 1

3962510240 230V / 50Hz 1000W

3962610300 240V / 50Hz 1000W

3962330310 220V / 50Hz 1100W

3962510210 230V / 50Hz 1100W

29 CAP MOTOR FR ONT 4569A20040 1

30 BODY EXHAUST FILTER 4569C20060 1

31 RIB CUSHION-A 4569C10020 1

32 DA PACKING-R 4569C20080 1

33 PROTECT OR 4569C20030 1

34 BODY 4569C20010 1

35 BRACKET FRONT CASTER 4569C20040 1

36 SCREW TAPPING 7121401211 6

37 CASTER FRONT 4568A54020 1

38 SCREW TAPPING 7121400811 2

Page 9

7

EXPLODED VIEW

1

2

3

4

6

7

8

9

0

q

w

e

r

t

y

u

i

o

p

a

s

d

f

g

h

j

k

l

;

z x

c

e

v

b

e

BODY (UP) ASS’Y

Page 10

8

PARTS LIST

BODY (UP) PARTS LIST

NO. PARTS NAME CODE NO. REFERENCE Q’TY

1 PIPE DA 4569C49060 1

2 PRAGMENT-R 4569C49080 1

3 PRAGMENT-P 4569C49090 1

4 COVER NOZZLE 4569C52020 1

6 COVER MIDDLE 4569C24020 1

7 HOUSING DA 4569C49010 1

8 PACKING DA 4569C49020 1

9 WASHER D A 4569C49070 1

10 SUPPORTER DA 4569C49050 1

11 SPRING DA 4569C49040 1

12 PLUNGER DA 4569C49030 1

13 SCREW TAPPING 7121401211 1

14 PLATE CONTROL 4569C24050 1

15 BRUSH DUSTING 3629300110 1

4569A67100

3629301500

16 PIPE NOEELE 3628100300 1

4568A24020

17 DUST COVER 4569C52010 1

18 BAG HOLDER 4569C22010 1

19 COVER DUST CLAMP 4569C52150 1

20 COVER HOSE HOLE 4569C52130 1

21 SCREW TAPPING 7121301411 4

22 HOSE ADAPTER 4569C52060 1

23 BOX FILTER AS. 4569C21000 1

24 BAG CLAMP 4569C22030 1

25 HANDLE B.H 4569C22020 1

26 SCREW TAPPING 7121300811 3

27 ADAPTER SUPPORTER 4569C52070 1

28 FRAME PACKING 4569C52120 1

29 V TERMINAL-A 4569C52080 1

30 V TERMINAL-B 4569C52160 1

31 TERMINAL FRAME 4569C52090 1

32 DC TERMINAL AS. 4569C52170 2

33 PLT SEALING 4569C52030 1

34 SPRING DC CLAMP 4569C52030 1

35 SP PACKING 4569C52140 1

Page 11

9

EXPLODED VIEW

1

2

5

6

u

y

t

o

p

3

4

i

9

5

9

5

9

5

7

8

0

q

w

5

r

e

HOSE LINE ASS’Y ( I )

Page 12

10

PARTS LIST

HOSE LINE PARTS LIST ( I )

NO. PARTS NAME CODE NO. REFERENCE Q’TY

1 SCREW TAPPING 7121300811 1

2 COVER HANDLE 4569C70120 1

3 VOLUME SLIDE 5V2254000B 1

4 COVER HOSE 4565A70040 1

5 HOLDER BRUSH 4569A65060 3

6 PIPE HANDLE 4569C70130 1

7 CAP ELBOW-LEFT 4569C70010 1

8 ELBOW 4569C70030 1

9 PIPE EXTENTION 4569C65010 3

10 SPRING HOSE CLAMP 4569C70050 1

11 CLAMP HOSE 4569C70040 1

12 CAP ELBOW-RIGHT 4569C70020 1

13 HOSE 4565A71001 1

14 HOLDER L TERMINAL 4569C70080 1

15 KNOB CONTROL 4569G70150 1

16 PLATE CONTROL 4569G70090 1

17 PLATE P.C. 4569G70170 1

18 SCREW TAPPING 7121300811 2

19 SCREW MACHINE 7001200511 2

20 PLATE SLINE VOLUME 4569G25050 1

Page 13

11

EXPLODED VIEW

o

r

y

t

e

u

w

i

0

0

2

3

5

4

1

p

8

7

6

q

d

s

a

9

HOSE LINE ASS’Y ( II )

Page 14

12

PARTS LIST

HOSE LINE PARTS LIST ( II )

NO. PARTS NAME CODE NO. REFERENCE Q’TY

1 COVER HOSE 3621401100 ABS 1

2 COVER HOSE 3621401200 ABS 1

3 ELBOW 3627100100 ABS 1

4 BUTTON 3626600400 ABS 1

5 SPRING 4569C70051 HSW3 1

6 L TERMINAL-L AS 4569C70060 TERMINAL+WIRE 1

7 L TERMINAL-R AS 4569C70070 TERMINAL+WIRE 1

8 HOLDER TERMINAL 4569C70080 ABS 1

9 HOSE 4565A71001 PVC+SWRS 1.3M 1

10 TAPE VINYL 2TU00019BK 19mm BLACK 1

11 SCREW TAPPING 7121301211 T2S PAN 3X12 2

12 PIPE 3624406200 ABS 1

13 PCB SLIDE VOLUME AS 3624304800 500K 1

14 SCREW TAPPING 7121300811 T2S P AN 3X8 2

15 PLATE 3624500200 ABS 1

16 KNOB 3623400100 PC, S-3000 1

17 COVER 3621413200 ABS 1

18 COVER HOSE 4565A70040 PP 1

19 SCREW TAPPING 7121301211 T2S PAN 3X12 2

20 PIPE 3624403600 PP T=2.5 2

21 SPACER 3625000400 EVA POAM T=1.5 1

22 HOLDER PIPE 3623001900 ABS 1

23 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 1

Page 15

13

EXPLODED VIEW

1

2

2

3

4

5

6

0

9

7

8

7

8

SUCTION BRUSH ASS’Y

Page 16

14

PARTS LIST

SUCTION BRUSH PARTS LIST

NO. PARTS NAME CODE NO. REFERENCE Q’TY

1 CONNECTOR 4569C90060 ABS 1

3624405500 BLOWER

2 SPRING BRUSH 4568B90050 2

3 COVER BR USH 4569C90070 1

4 GASKET BRUSH 4568B90080 1

5 LEVER CHANGE 4568B90040 1

6 SB BOD Y 4569C90010 1

7 PIN ROLLER 4568B90030 2

8 ROLLER BRUSH 4568B90020 2

9 HOLDER BRUSH AS. 4569C90090 1

10 SCREW TAPPING 7121401411 4

Page 17

S/M NO. : RC406EV020

DAEWOO ELECTRONICS CO., LTD.

686, AHYEON-DONG, MAPO-GU, SEOUL,KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 360-8184

TEL: 02) 360-8182~3/8178~9

http://www.dwe.daewoo.co.kr

Printed Date : JUNE, 1997

Loading...

Loading...