Page 1

S/M No. : RC3714F010

Service Manual

Vacuum Cleaner

Model: RC-3714F/RC-3714B

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

D AEW OO ELECTR ONICS CO., LTD .

http : //svc.dwe .co.kr OCTOBER. 2002

Page 2

CONTENTS

1. SPECIFICATIONS ------------------------------------------------------------------------------------------

2. EXTERNAL VIEWS ---------------------------------------------------------------------------------------------

2-1. ASSEMBLY ---------------------------------------------------------------------------------------

3. DIAGRAM ------------------------------------------------------------------------------

3-1. WIRING DIAGRAM ---------------------------------------------------------------

3-2. CIRCUIT DIAGRAM -------------------------------------------------------------------

4. TROUBLE SHOOTING GUIDE --------------------------------------------------------------

5. DISASSEMBLING AND TREATMENT -----------------------------------------------------------

5-1. CLEANER ASSEMBLY ----------------------------------------------

5-2. BODY ASSEMBLY ------------------------------------------------------------

5-3. MOTOR ASSEMBLY ----------------------------------------------------------------

5-4. CORDREEL ASSEMBLY ------------------------------------------------

5-5. PCB ASSEMBLY --------------------------------------------------------------

5-6. HOSE ASSEMBLY ----------------------------------------------------------------

5-7. BRUSH ASSEMBLY --------------------------------------------------------------

6. EXPLODED VIEW AND PARTS LIST ------------------------------------------------

6-1. CLEANER ASSEMBLY ----------------------------------------------

6-2. BODY ASSEMBLY -----------------------------------------------

6-3. COVER ASSEMBLY -----------------------------------------------------

6-4. MOTOR ASSEMBLY ----------------------------------------------------------------

6-5. CORDREEL ASSEMBLY ------------------------------------------------------

6-6. PCB ASSEMBLY --------------------------------------------------------------

6-7. HOSE ASSEMBLY --------------------------------------------------------

6-8. PIPE ASSEMBLY -------------------------------------

6-9. BRUSH ASSEMBLY --------------------------------------------------------

Page

2

3

3

4

4

5

6

8

8

10

11

12

14

16

17

18

18

22

24

28

29

31

34

36

38

Page 3

1. SPECIFICATIONS

MODEL

Rated Voltage/Frequency

Input Watt

Suction Power

Weight (Body)

Dimension (LXHXD)

Cord Length

Nozzle

RC-3714F, RC-3714B

AC 230V, 50Hz

1400W

250W

3.5Kg

376 X 278 X 257 mm

5.4m

Crevice Nozzle

2

Page 4

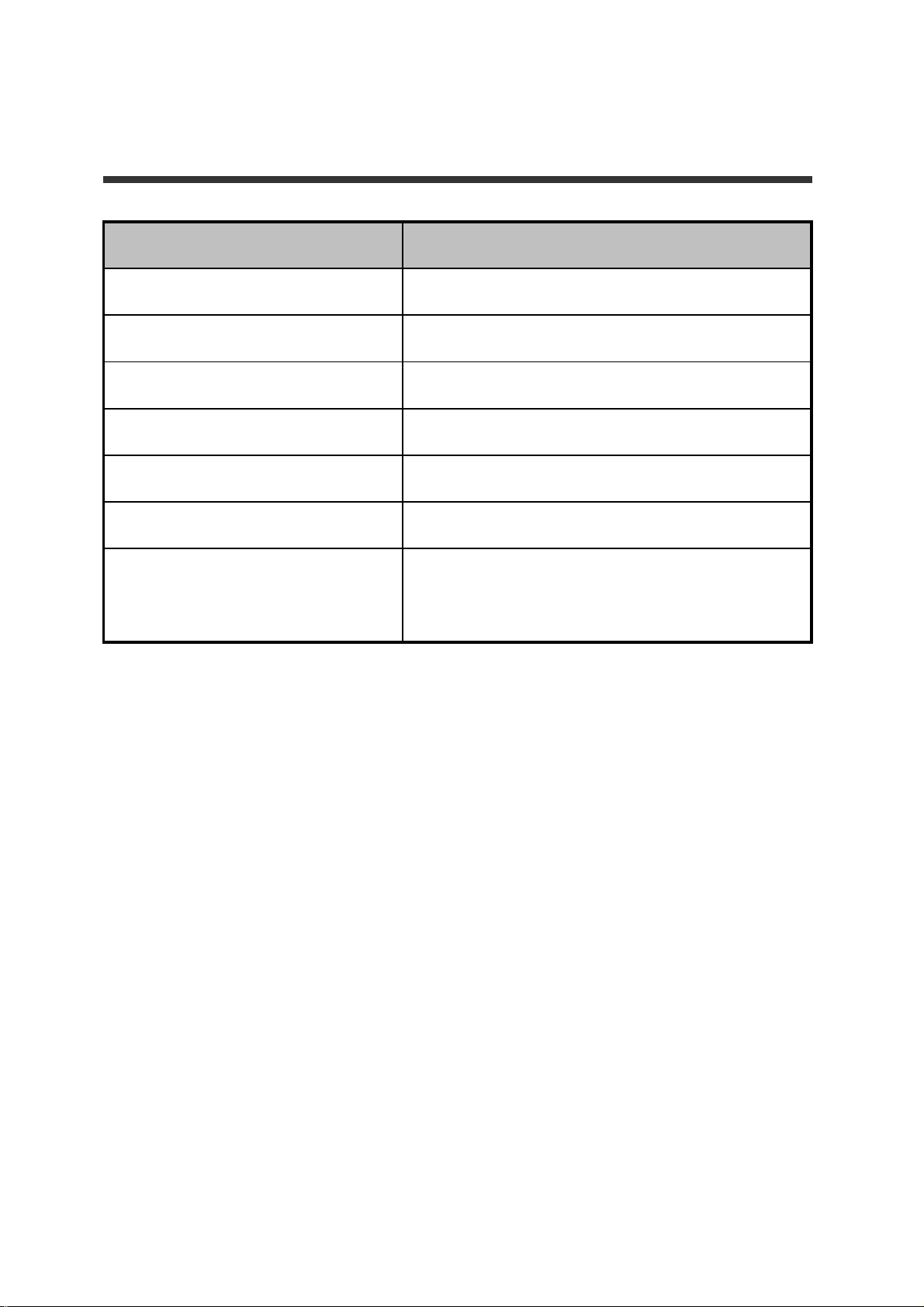

2. EXTERNAL VIEWS

2-1. ASSEMBLY

PART NAME MODEL

A

- HOSE HANDLE RC-3714F, RC-3714B

B

- BODY HANDLE RC-3714F, RC-3714B

C

- CORD REWIND BUTTON RC-3714F, RC-3714B

D

- SWITCH BUTTON RC-3714F, RC-3714B

E

- DUST COVER RC-3714F, RC-3714B

F

- DUST METER RC-3714F, RC-3714B

G - ADAPTER RC-3714F, RC-3714B

H - HOSE RC-3714F, RC-3714B

I - POWER CORD RC-3714F, RC-3714B

J - BRUSH RC-3714F, RC-3714B

A

B

C

D

E

F

G

H

I

J

3

Page 5

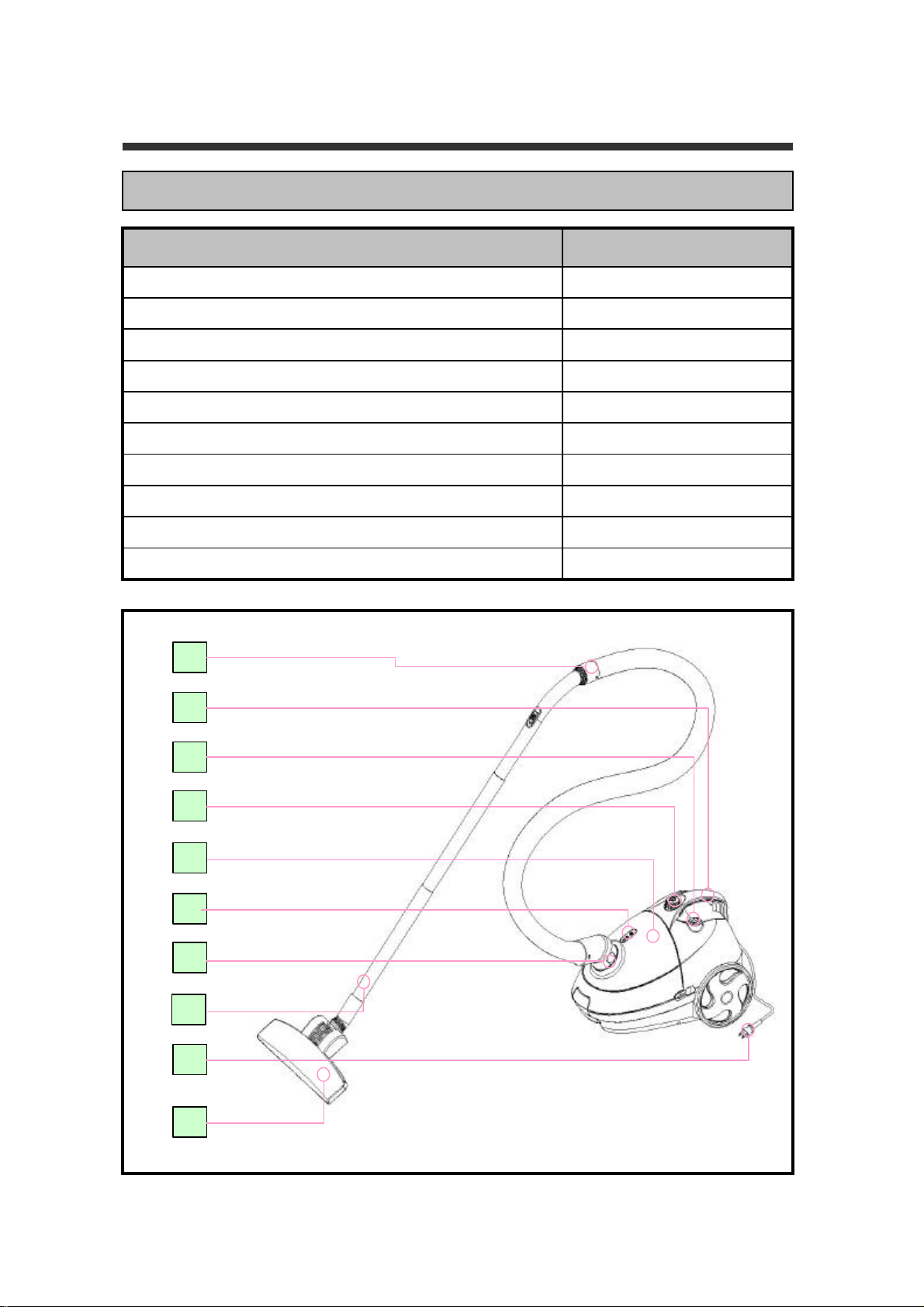

3. DIAGRAM

3-1. WIRING DIAGRAM

1) MODEL RC-3714F

PCB

Switch

Motor

CordReel

2) MODEL RC-3714B

Volume PCB

Motor

PCB

Switch

CordReel

4

Page 6

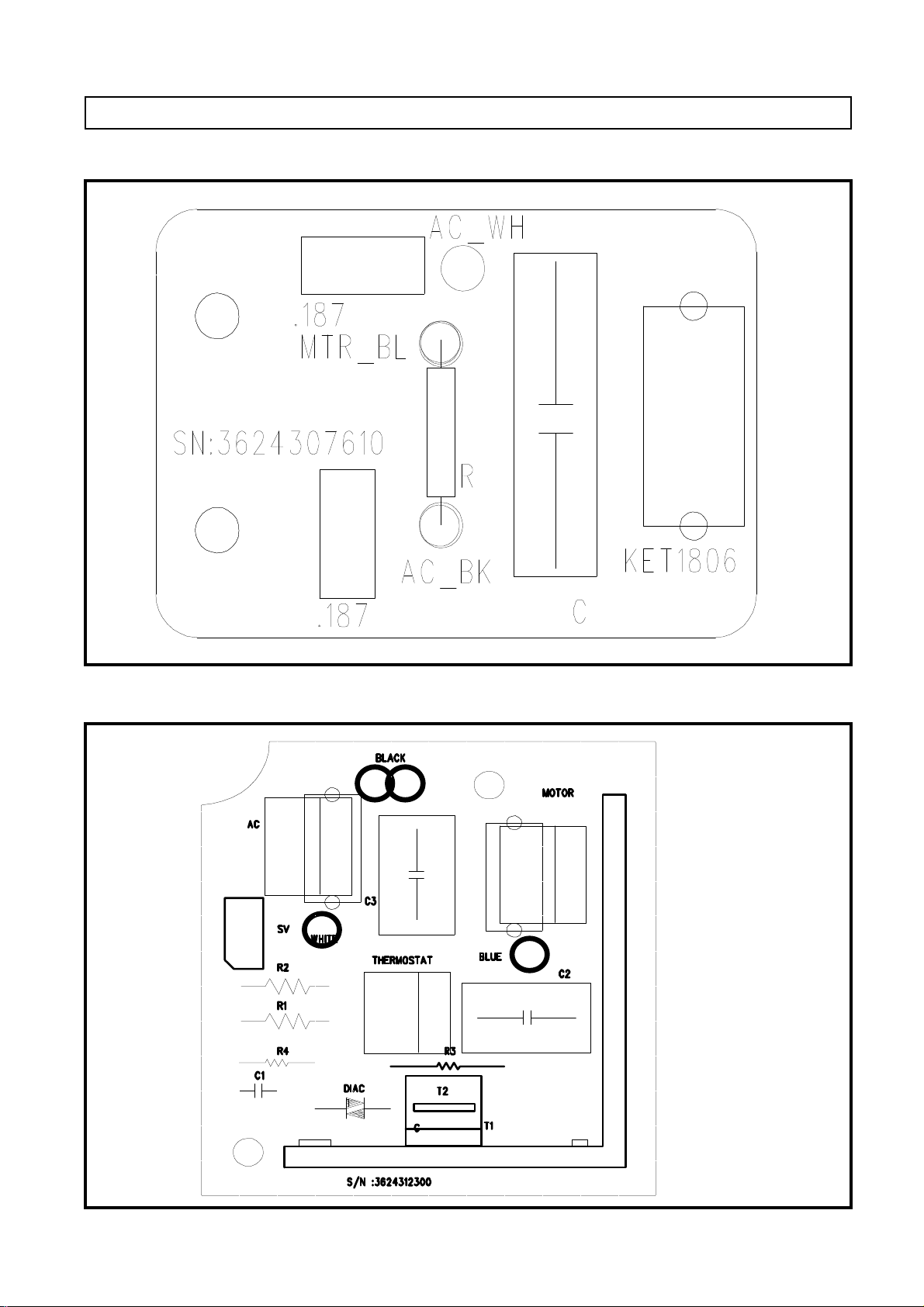

3-2. CIRCUIT DIAGRAM

SWITCH

180k¥Ø1/2W

0.1uF 100VDC

16A 600V

125VAC 15A 80¡É

2k¥Ø 1/2W

0.1uF 100VDC

16A 600V

1) MODEL RC-3714F

FUSE

15A 250V

AC

0.22uF 275VAC

C3

TRIAC

R2

ON/OFF

DIAC

R4

47¥Ø 1/4W

THERMOSTAT

2) MODEL RC-3714B

FUSE

15A 250V

AC

MOTOR

TRIAC

C3

0.22uF 275VAC

C1

DIAC

R1

2k¥Ø 1/2W

MOTOR

R4

47¥Ø 1/4W

C1

5

R1

Page 7

4. TROUBLE SHOOTING GUIDE

TROUBLE CAUSE COUNTERMEASURE

SUCTION POWER FILTER BAG(PAPER) IS FULL CHANGE IT WITH NEW ONE (See 5-2)

IS WEAK WITH DUST

FILTER PRE IS CLOGGY WITH DUST REMOVE THE DUST (See 5-2)

CLOGGING OR TEAR IN HOSE REMOVE OBSCTACLE

OR REPLACE THE HOSE (See 5-6)

DEFECTIVE MOTOR REPLACE THE MOTOR (See 5-3)

THE OPENING IN BRUSH IS CLOGGY REMOVE THE DUST (See 5-7)

WITH DUST

CLEANER DOES BREAKING IN POWER CORD REPLACE THE POWER CORD (See5-4)

NOT WORK (AT BLADE TIP OR ROOT OF PLUG)

BREAKING OF CONNECTIONS REPAIR (See 5-6)

IN HOSE ASSEMBLY

DEFECTIVE SLIDE VOLUME REPLACE IT (See 5-6)

LOCATED IN HOSE HANDLE

DEFECTIVE PCB ASSEMBLY REPLACE IT (See 5-5)

BREAKING OF CONNECTIONS REPAIR (See 5-4)

OR POOR CONTACTS IN

CORD REEL ASSEMBLY

DEFECTIVE MOTOR REPLACE IT (See 5-3)

BREAKING OF CONNECTIONS REPAIR (See 5-2)

IN BODY ASSEMBLY

BREAKING IN A FUSE REPLACE IT (See 5-5)

MOTOR DOES NOT DEFECTIVE PCB ASSEMBLY REPLACE IT (See 5-5)

STOP EVEN IF

SWITCH

6

Page 8

TROUBLE CAUSE COUNTERMEASURE

POWER CORD IS

NOT WOUND UP

BROKEN REEL SPRING REPLACE IT (See 5-4)

OF CORD REEL

POWER CORD BROKE AWAY REPAIR (See 5-4)

FROM THE BOBBIN

CAUTION

POWER CORD DOES

NOT STOP AT AN

ARBITRARY POSITION

BE CAREFUL WHEN BREAKING UP THE CORD REEL, THE REELSPRING

MAY SPRING OUT OF THE SPRING COVER.

ABRASION OF THE ROLLER BRAKE REPLACE THE ROLLER

OF CORD REEL BRAKE (See 5-4)

LEVER SPRING BROKE AWAY REPAIR (See 5-4)

FROM THE CORD REEL BRACKET

7

Page 9

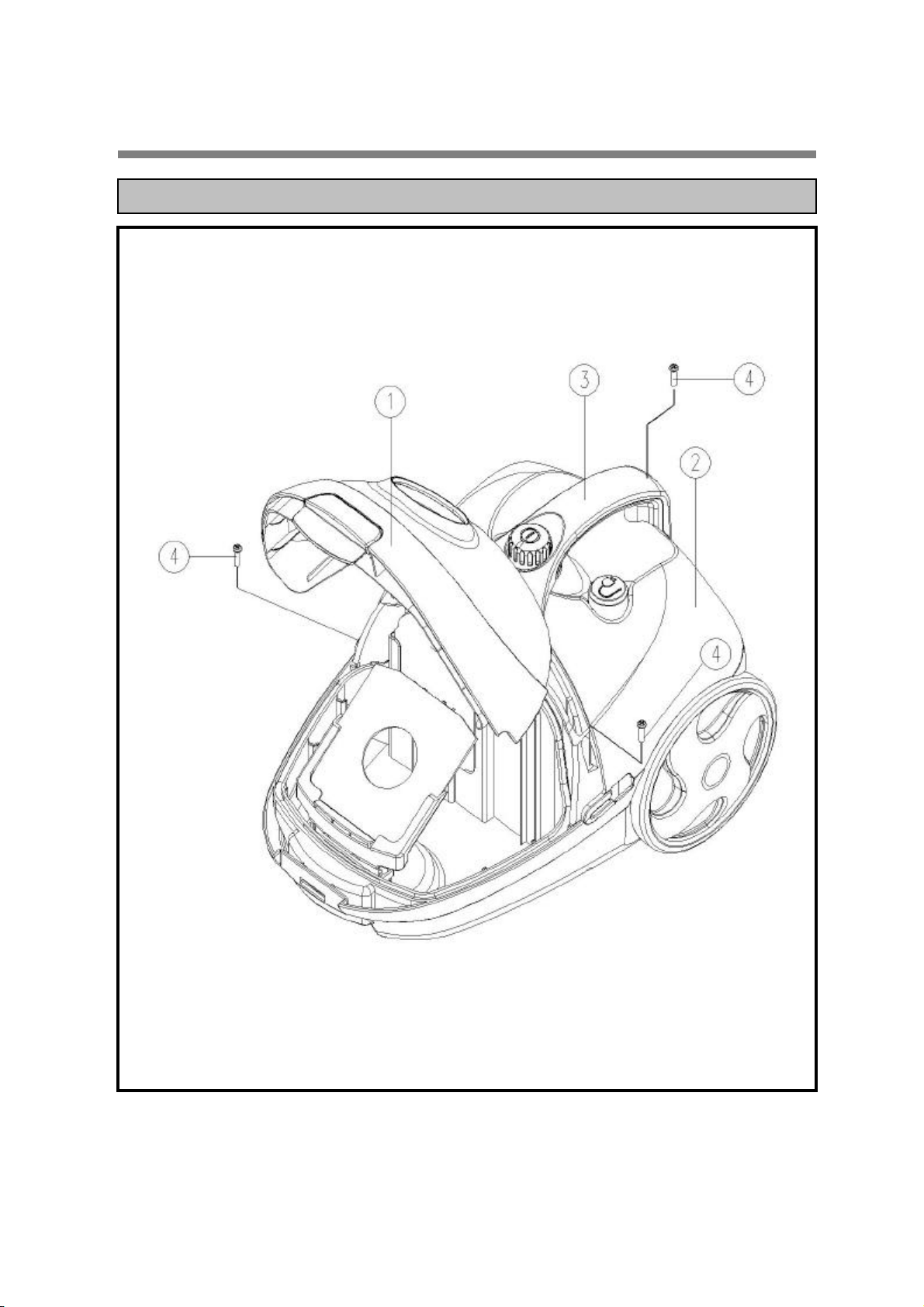

5. DISASSEMBLING AND TREATMENT

5-1. CLEANER ASSEMBLY

1) OPEN THE DUST COVER(1) AND UNSCREW THE 3 SCREWS(4) THEN LIFT

THE COVER ASSEMBLY(2) UP FROM THE BODY ASSEMBLY.

8

Page 10

2) LIFT THE MOTOR ASSEMBLY(2), PCB ASSEMBLY(3), CORDREEL ASSEMBLY(4) UP

FROM THE BODY ASSEMBLY(1).

9

Page 11

5-2. BODY ASSEMBLY

1) CHECK THE FILTER (7,9).

2) CHECK THE GASKET (6).

10

Page 12

5-3. MOTOR ASSEMBLY

1) TAKE THE MOTOR ASSEMBLY OUT OF THE BODY.

3) CHECK THE MOTOR(1) (WHETHER THE MOTOR IS BURNT OUT OR NOT).

4) CHECK THE CONNECTION BETWEEN MOTOR TERMINAL AND THE LEADS.

11

Page 13

5-4. CORDREEL ASSEMBLY

12

Page 14

1) TAKE THE CORD REEL ASSEMBLY OUT OF THE COVER ASSEMBLY.

2) UNSCREW THE SCREW(13).

3) SEPARATE THE BOBBIN(1) FROM THE BRACKET(10) AND CHECK

THE CONTACTS BETWEEN THE Y TYPE TERMINALS(12) AND

THE RING TYPE TERMINALS(2,3).

4) CHECK THE LEVER SPRING(16).

5) IF THE ROLLER BRAKE(15) IS WORN OUT AND SEPARATE THE LEVER(14) FROM

THE BRACKET(10), THEN REPLACE THE ROLLER BRAKE(15).

AT THIS TIME, THE BOBBIN(1) IS ROTATED COUNTERCLOCKWISE DUE TO

THE PRESERVED WINDING.

6) IF THE REEL SPRING(8) IS BROKEN, UNSCREW THE 2 SCREWS(9) AND

REPLACE IT.

WHEN DISASSEMBLING, THE REEL SPRING MAY SPRING

CAUTION

OUT OF THE COVER.

7) UNSCREW THE SCREW (6) AND SEPARATE THE HOLDER TERMINAL(5) FROM

THE BOBBIN(1).

8) CHECK THE CONNECTIONS BETWEEN THE POWER CORD(4) AND THE RING

TERMINALS(2,3).

9) WHEN ASSEMBLING, MAKE THE RESERVED WINDING 5 REVOLUTIONS OF

THE BOBBIN CLOCKWISE.

13

Page 15

5-5. PCB ASSEMBLY

1) MODEL RC-3714F

1) CHECK THE TERMINAL(5).

14

Page 16

1) MODEL RC-3714B

1) CHECK THE TERMINAL(12).

15

Page 17

5-6. HOSE ASSEMBLY

1) CHECK THE CONNECTIONS THE ADAPTER(1) AND THE HOSE(2).

2) CHECK THE PACKING(7)

16

Page 18

5-7. BRUSH ASSEMBLY

1) UNSCREW THE 4 SCREWS(13) AND SEPARATE THE COVER BRUSH(12) FROM

THE BODY BRUSH(1).

2) CHECK THE OPENING OF THE NECK BRUSH(6) AND THE PIPE BRUSH(5).

17

Page 19

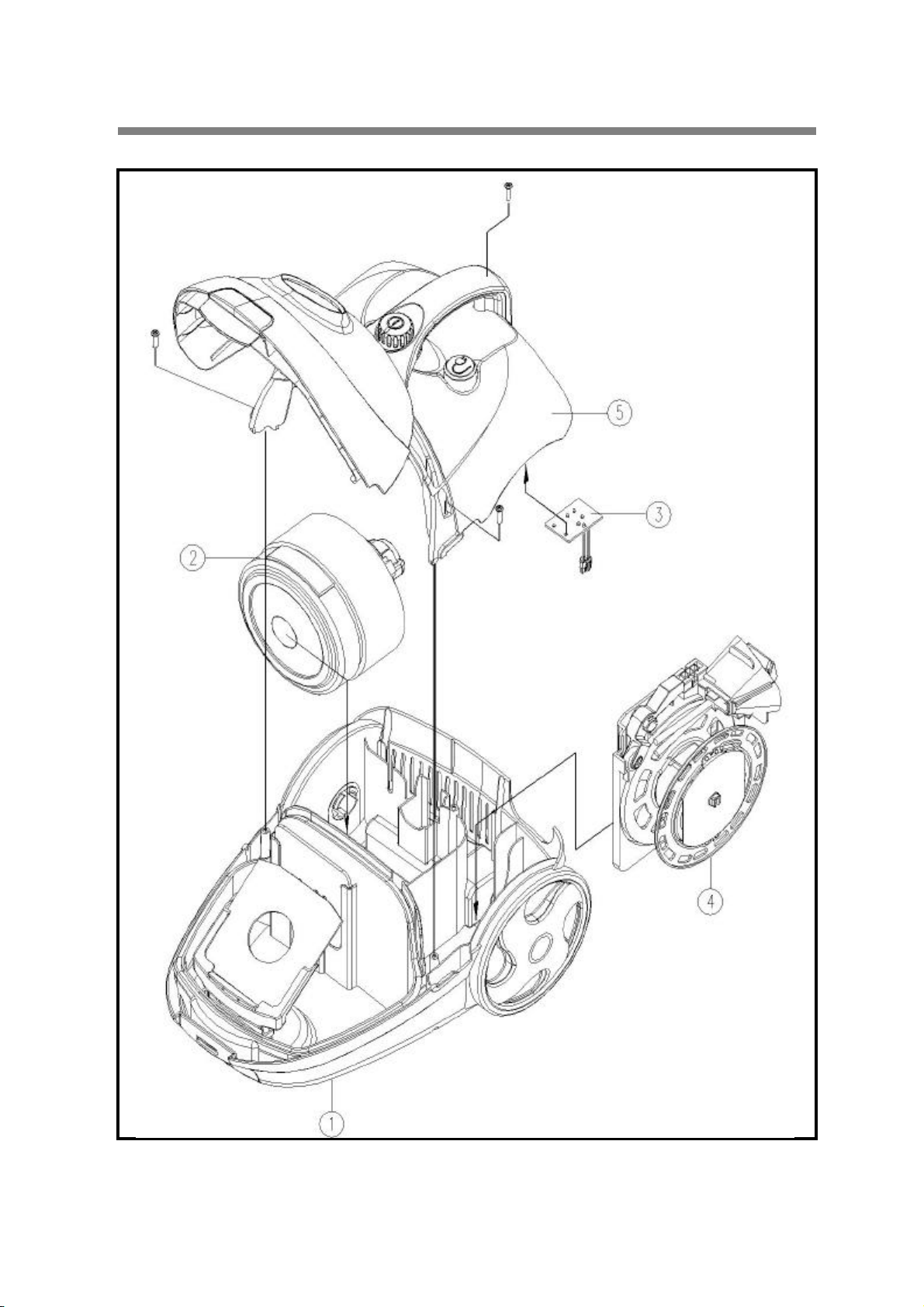

6.EXPLODED VIEW AND PARTS LIST

6-1. CLEANER ASSEMBLY

1) MODEL RC-3714F

18

Page 20

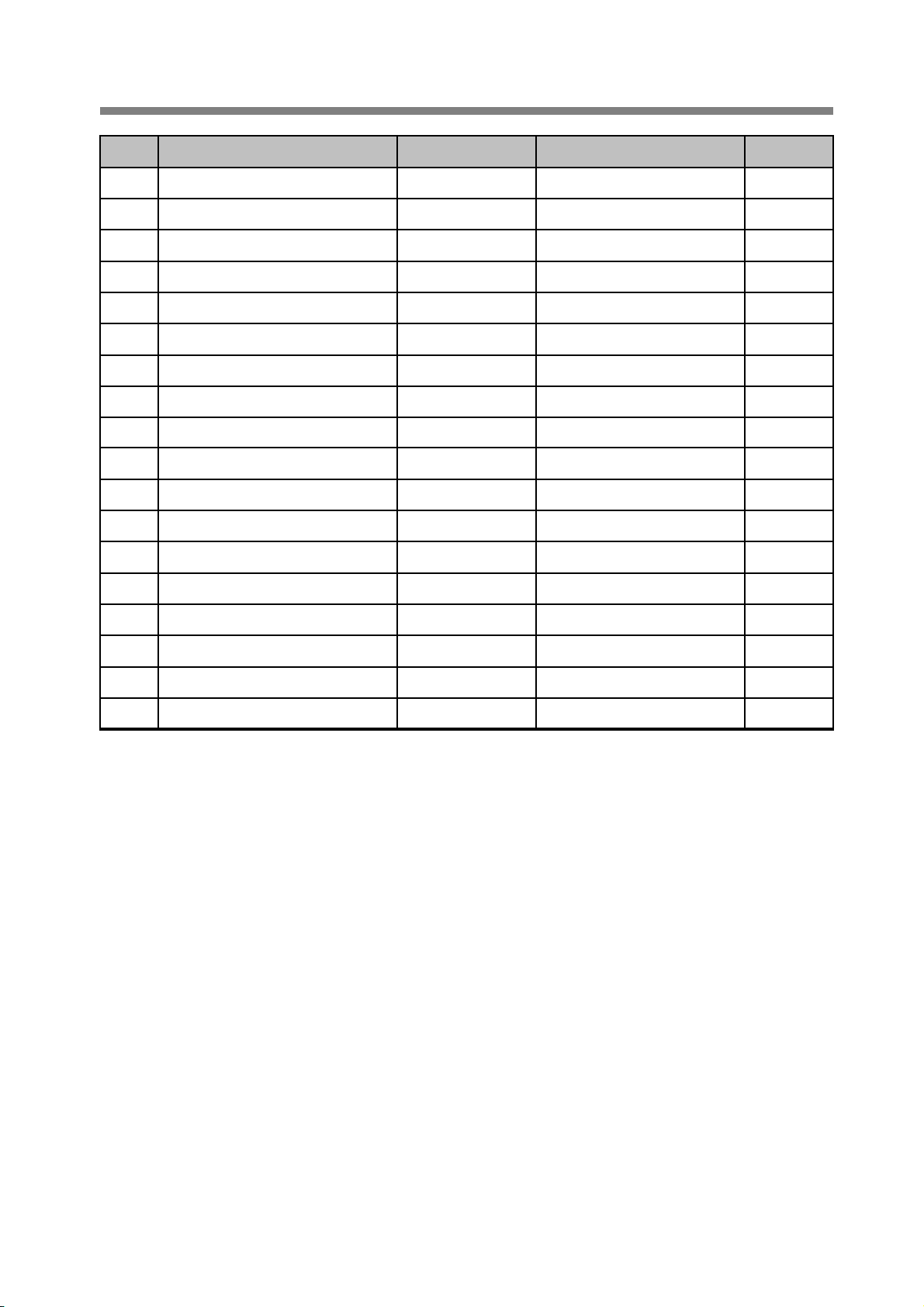

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY ASSY 3620411300 ASSY 1

2 MOTOR UNIVERSAL 3962511450 230V 1100W DMI 1

3 PCB POWER CONTROL AS 3624307640 ASSY(230V,50/60Hz)) 1

4 CORD REEL ASSY 3629508100 ASSY(5m) 1

5 COVER ASSY 3621435600 ASSY 1

6 PIPE EXTENSION 3624408500 ASSY(PP) 2

7 NOZZLE CREVICE 3628100600 PP 1

8 HOSE ASSY 3623206200 ASSY(EVA) 1

9 BRUSH ASSY 3629304920 ASSY(NO STAMPING) 1

19

Page 21

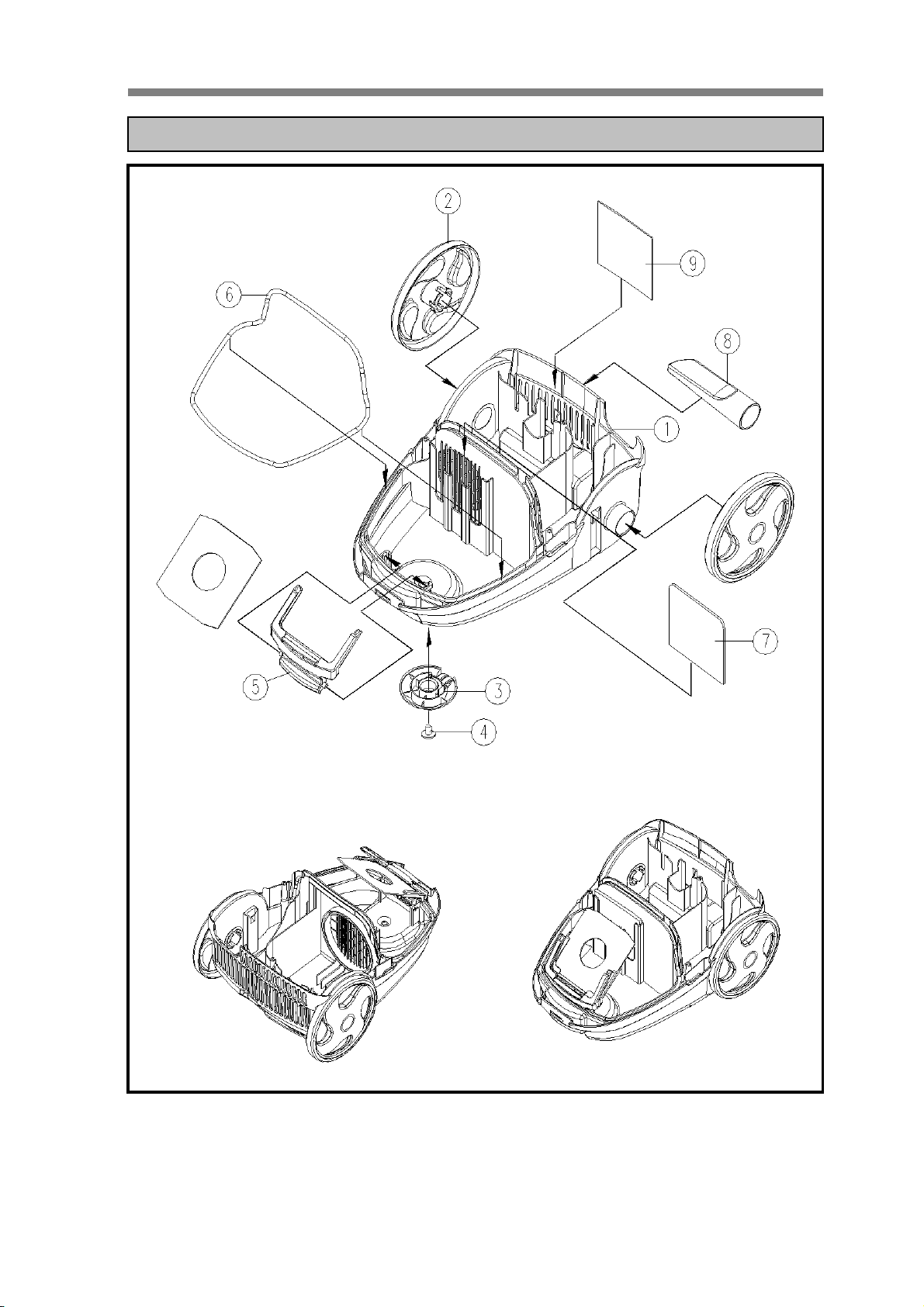

2) MODEL RC-3714B

20

Page 22

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY ASSY 3620411300 ASSY 1

2 MOTOR UNIVERSAL 3962511450 230V 1100W DMI 1

3 PCB POWER CONTROL AS 3624313000 ASSY(230V,50/60Hz)) 1

4 CORD REEL ASSY 3629508100 ASSY(5m) 1

5 COVER ASSY 3621435700 ASSY 1

6 PIPE STEEL 3624403510 SPC T=0.7/32-CR 2

7 NOZZLE CREVICE 3628100600 PP 1

8 HOSE ASSY 3623206300 ASSY(EVA, 1.5M) 1

9 BRUSH ASSY 3629304920 ASSY(NO STAMPING) 1

21

Page 23

6-2. BODY ASSEMBLY

22

Page 24

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY 3620410200 PP 1

2 ROLLER BACK 3624705000 PP 2

BRACKET ROLLER 3620601500 PP 1

3

ROLLER FRONT 3624703600 PP 1

SHAFT ROLLER 3624901000 SWRM 1

4 SCREW TAPPING 7128401212 T2S WAS 4X12 MFZN BK 1

5 HOLDER FILTER 3623006700 PP 1

6 GASKET 3622301800 NR FOAM , 750mm 1

7 FILTER IN 362190420T POLYESTER 1

8 NOZZLE CREVICE 3628100600 PP 1

9 FILTER EXHUAST 3621908200 PE+TAPE 1

23

Page 25

6-3. COVER ASSEMBLY

1) MODEL RC-3714F

(3621435600)

24

Page 26

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 COVER BODY 3621433500 ABS 1

2 SPRING BUTTON CR 3625107400 HSW3 1

3 BUTTON CR 3626606700 ABS 1

4 SCREW TAPPTITE 7171402011 3

5 HANDLE DOWN 3622603300 PP 1

6 HANDLE UP 3622603200 ABS 1

7 BUTTON SW 3626606200 ABS 1

8 CAP KNOB 3620904400 ABS 1

9 SPRING BUTTON SW 3625110200 HSW3 1

10 SWITCH PUSH 3629002000 7A/250V, SKT 1

11 COVER DUST 3621429100 ABS 1

12 SPRING CLAMP 362510640S HSW3 1

13 CLAMP COVER 3621202800 ABS 1

14 SOCKET 3629801800 PP 1

15 HOUSING DM 3626100800 GPPS 1

16 SPRING DM 3625109600 SUS 1

17 DUST METER 3629703900 ABS 1

25

Page 27

2) MODEL RC-3714B

(3621435700)

26

Page 28

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 COVER BODY 3621433500 ABS 1

2 SPRING BUTTON CR 3625107400 HSW3 1

3 BUTTON CR 3626606700 ABS 1

4 SCREW TAPPTITE 7171402011 3

5 HANDLE DOWN 3622603300 PP 1

6 HANDLE UP 3622603200 ABS 1

7 BUTTON SW 3626606200 ABS 1

8 CAP KNOB 3620904400 ABS 1

9 SPRING BUTTON SW 3625110200 HSW3 1

10 PCB S/V AS 3624304510 1

11 SWITCH PUSH 3629002000 7A/250V, SKT 1

12 COVER DUST 3621429100 ABS 1

13 SPRING CLAMP 362510640S HSW3 1

14 CLAMP COVER 3621202800 ABS 1

15 SOCKET 3629801800 PP 1

16 HOUSING DM 3626100800 GPPS 1

17 SPRING DM 3625109600 SUS 1

18 DUST METER 3629703900 ABS 1

27

Page 29

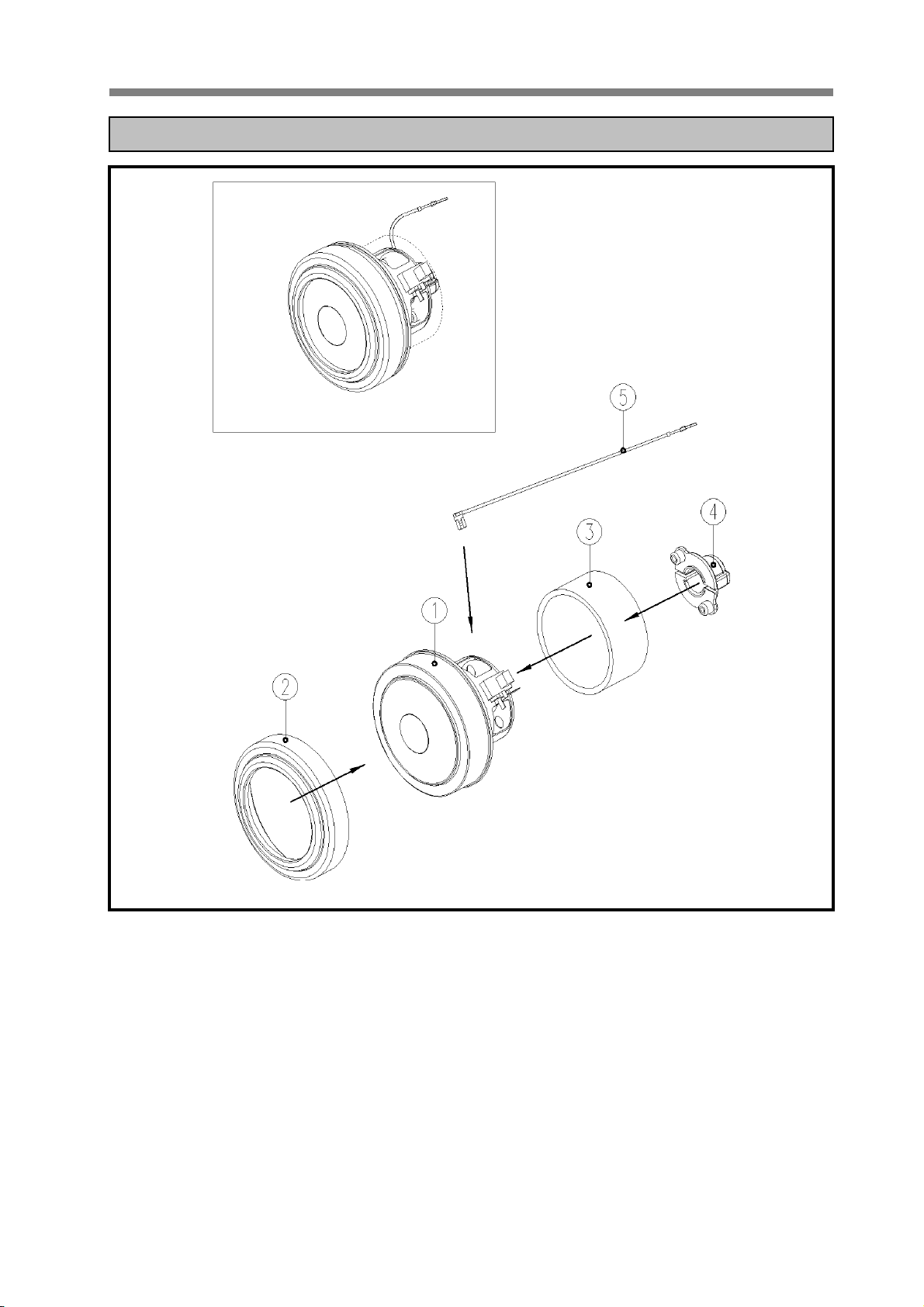

6-4. MOTOR ASSEMBLY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1) MODEL RC-3714F, RC-3714B

NO PART NAME PART CODE SPECS. Q'YT

1 MOTOR UNIVERSAL 3962511450

2 PACKING MOTOR 4560M20101 NR 1

3 ABSORBER SOUND 4569C10071 PU FOAM (T=10) 1

4 MOUNT MOTOR 3627900900 PVC 1

230V 1100W DMI

1

28

Page 30

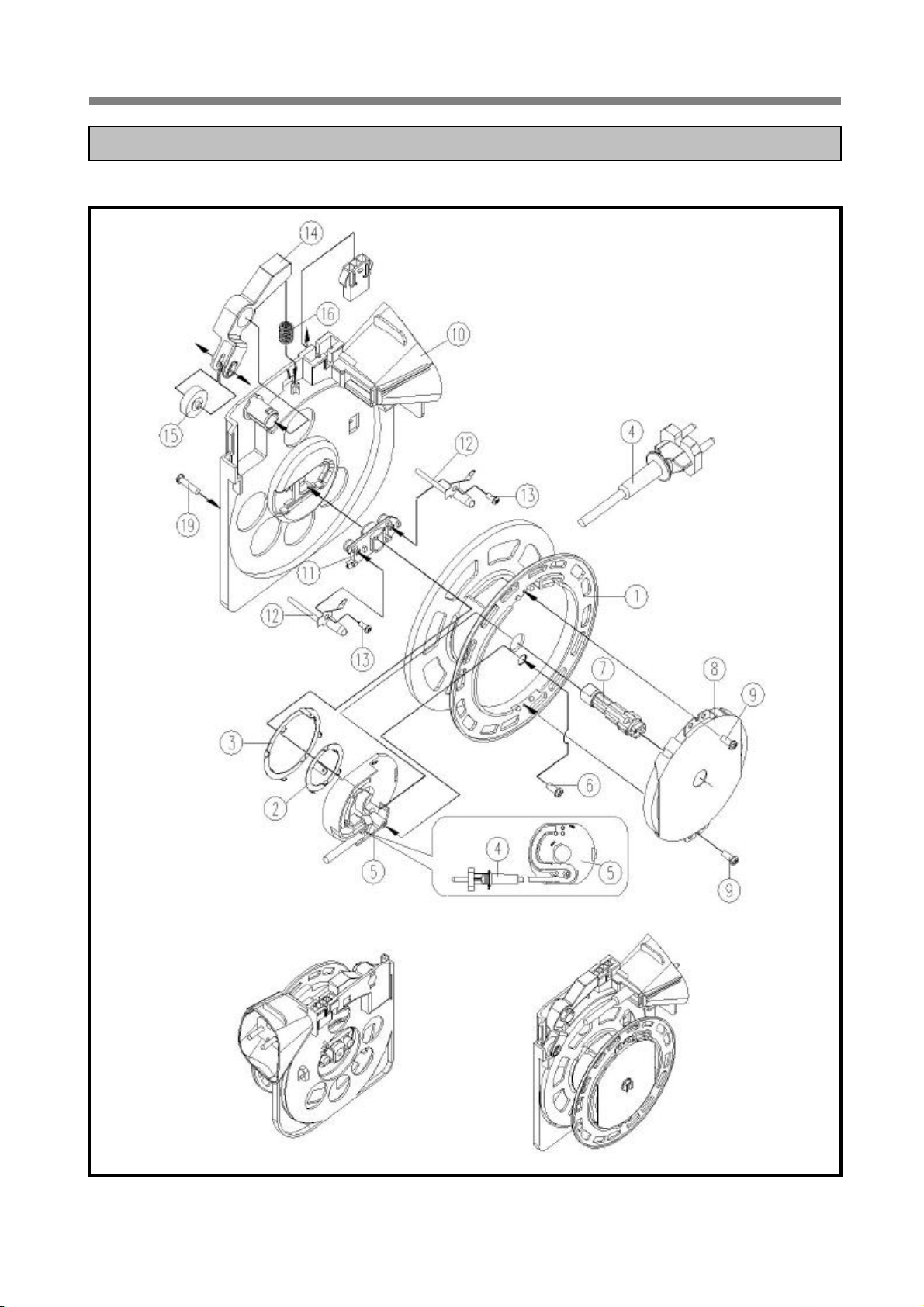

6-5. CORDREEL ASSEMBLY

1) MODEL RC-3714F, RC-3714B

29

Page 31

NO PART NAME PART CODE SPECS. Q'YT

SUS301£«COVER,3500mm

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BOBBIN 3629200600 PP 1

2 TERMINAL OA 4565A36024 C2600P-1/2H, T=0.3 1

3 TERMINAL OB 4565A36034 C2600P-1/2H, T=0.3 1

4 CORD POWER 3621302550 250V16A H05VVH2F 5.4M 1

5 HOLDER TERMINAL 4565A36010 PP(5101SW, V-0) 1

6 SCREW TAPPING 7121401211 T2S PAN 4X12 MFZN 1

7 SHAFT REEL 3624900510 PC 1

8 SPRING ASSY 3625102000

1

9 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 2

10 BRACKET CR 3620602800 PP 1

11 SUPPORTER TERMINAL 3625300500 PP(5101SW) 1

3622714200 Y TER+WIRE 1

3622714300 Y TER+WIRE 1

12 HARNESS CR

3622714400 HOUS+WIRE 1

3622714500 WIRE+REP 1

13 SCREW TAPPING 7121400611 T2S PAN 4X6 MFZN 2

14 LEVER CR 3623703000 ABS 1

15 STOPPER ASSY 3625200200 ASSY 1

16 SPRING LEVER 3625104300 HSW3 1

17 SCREW TAPPING 7122401011 T2S TRS 4X10 MFZN 1

18 WAX VASELINE 2291140301 VASELINE 0.002

19 SCREW TAPPING 7121401611 T2S PAN 4X16 MFZN 1

30

Page 32

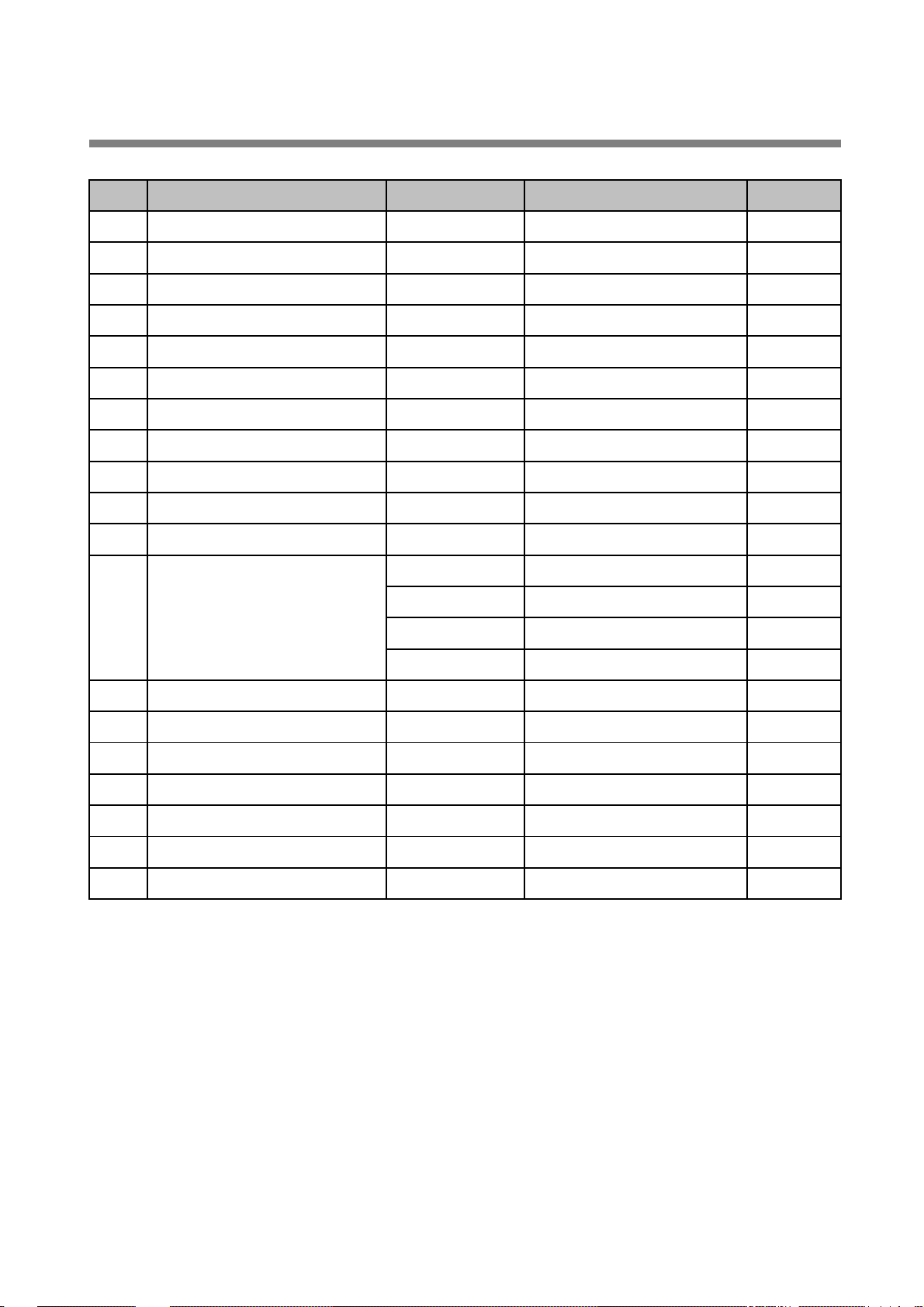

6-6. PCB ASSEMBLY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1) MODEL RC-3714F

NO PART NAME PART CODE SPECS. Q'YT

1 PCB Board 3624307610

2 CAPACITOR CL1DB3224K

3 HOUSING

~

4 INTERNAL WIRE ~

5 SLEEVE ~

Type 1, 105¡É, UL 94V-0

0.22uF 275VAC

~ 1

90¡É, 300V

105¡É, 600V

1

1

1

1

31

Page 33

2) MODEL RC-3714B

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

NO PART NAME PART CODE SPECS. Q'YT

1 PCB Board 3624307610

2 TRIAC TBTA12600B

Type 1, 105¡É, UL 94V-0

~

1

1

3 CAPACITOR CL1DB3154K AC 275V 0.15MF K 1

4 CONNECTOR 485923242Y ~ 1

5 RESISTER RD-2Z103J- ~ 1

6 RESISTER RD-2Z204J- ~ 1

7 RESISTER RD-4Z470J- ~ 1

8 CONDENSER CMXV1J224J

9 DIAC DDB4------

10 HEAT SINK 3627400200

11 HOUSING ~

DC 63V, 0.22MF J

DB4

45*70, 3T

~

1

1

1

1

12 SLEEVE ~ ~ 1

32

Page 34

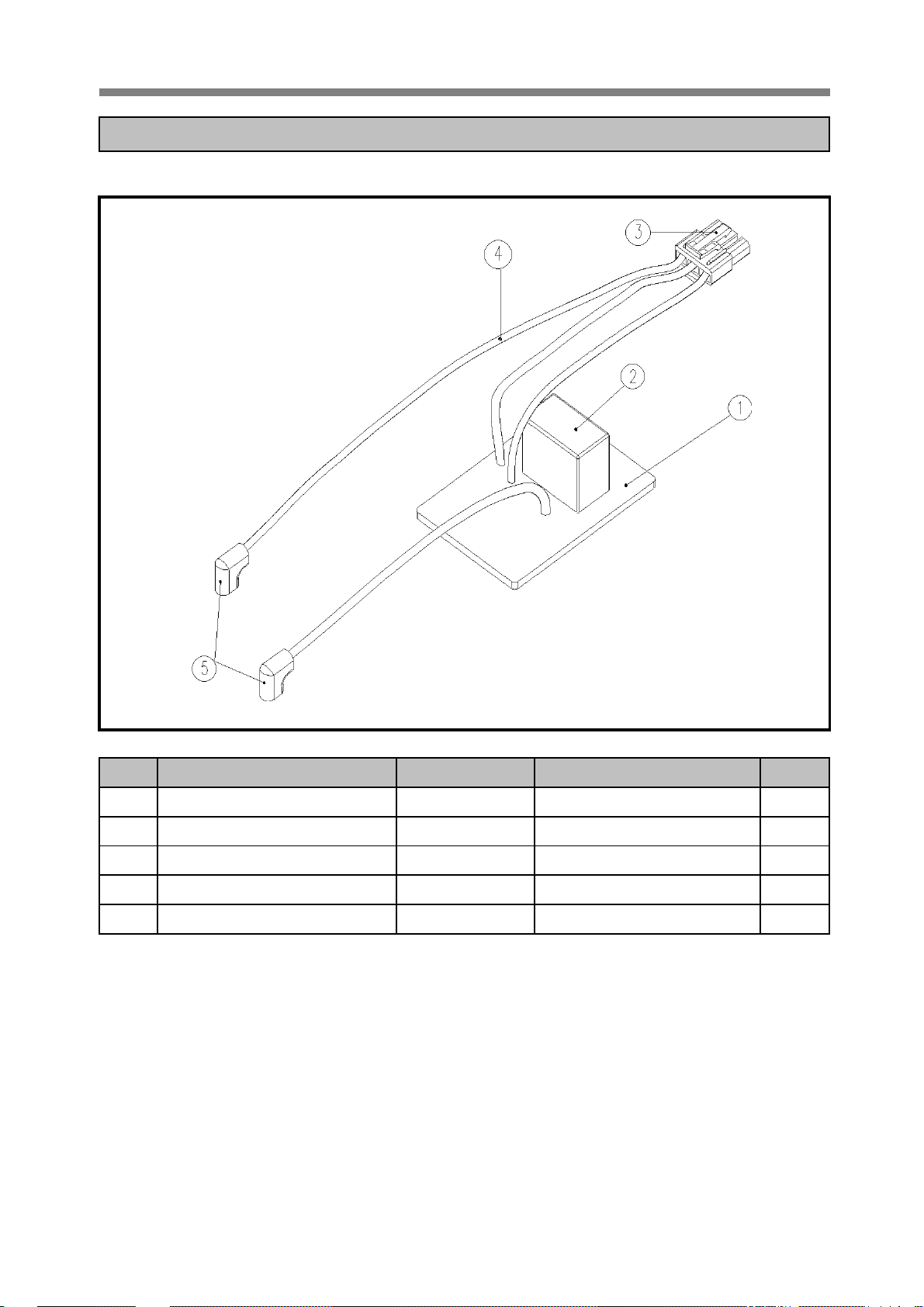

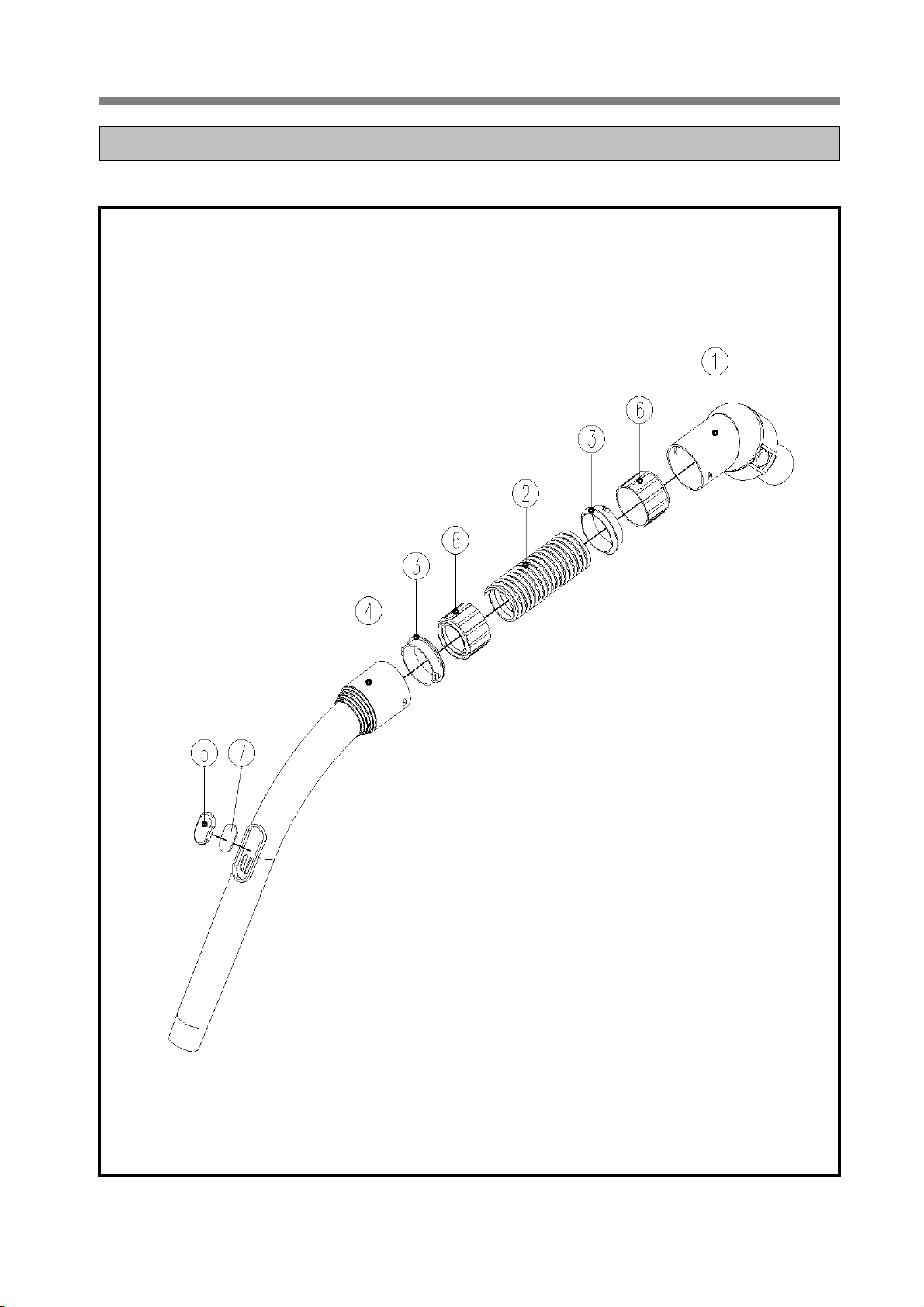

6-7. HOSE ASSEMBLY

1) MODEL RC-3714F, RC-3714B (3623206200)

33

Page 35

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 PIPE ADAPTER 3629101700 PP 1

2 HOSE 3623206300 EVA 1,6m(Non-Current) 1

3 HOLDER HOSE 4569A71021 PP 1

4 PIPE HOSE 3624408200 PP 1

5 VALVE AIR 3625400400 PP 1

6 CUFF HOSE 3626800200 LDPE 1

7 PACKING HOSE 3624005900 SPONGE 1

34

Page 36

6-8. PIPE ASSEMBLY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1) MODEL RC-3714F (3624408500)

NO PART NAME PART CODE SPECS. Q'YT

1 PIPE 3624408500 PP 2

35

Page 37

1) MODEL RC-3714B (3624403510)

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

NO PART NAME PART CODE SPECS. Q'YT

1 PIPE STEEL 3624403510 SPC T=0.7/32 - CR 2

36

Page 38

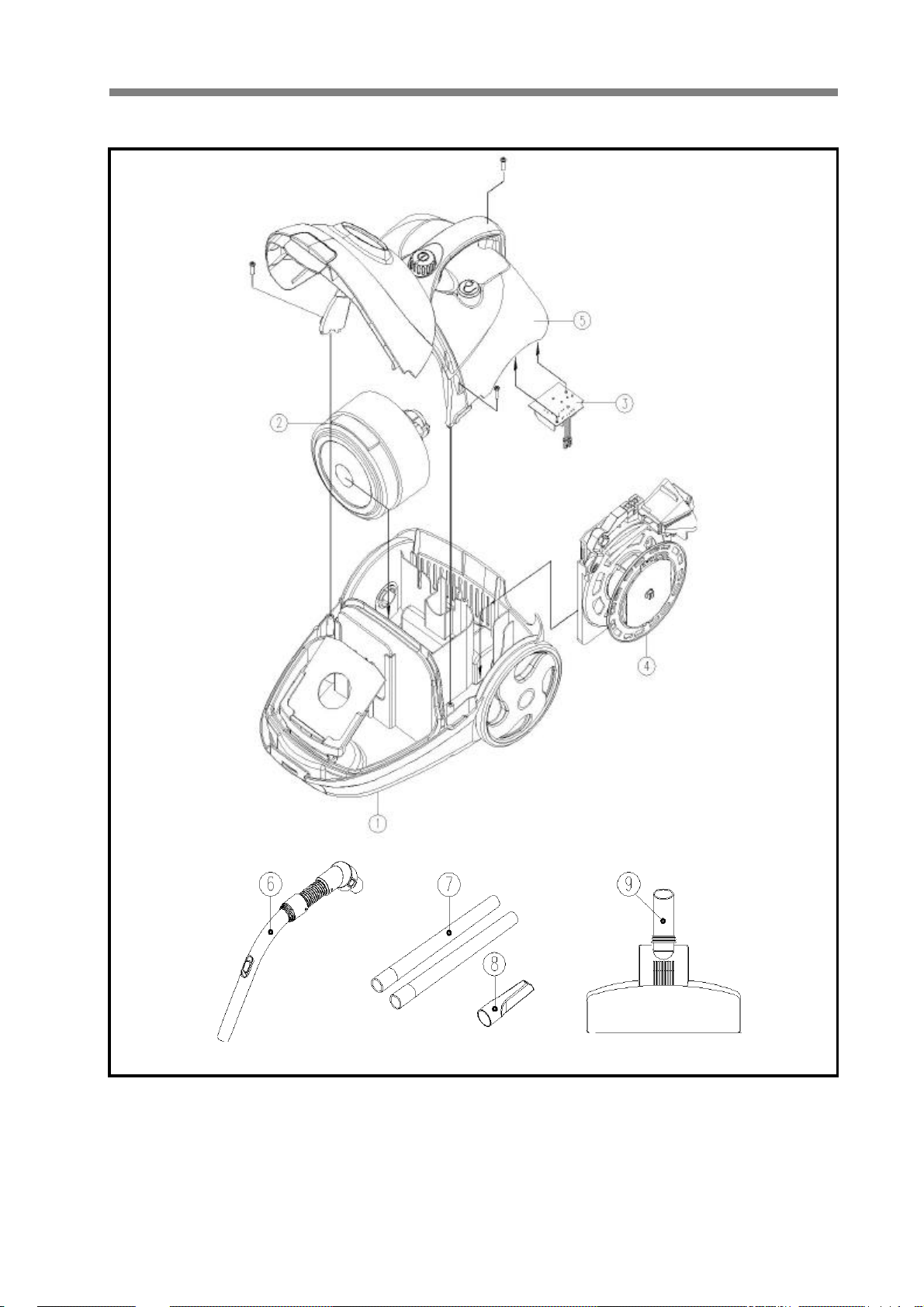

6-9. BRUSH ASSEMBLY

1) MODEL RC-3714F, RC-3714B (3629304920)

37

Page 39

NO PART NAME PART CODE SPECS. Q'YT

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY BRUSH 3620406400 PP 1

2 ROLLER-F BRUSH 3624703100 PP 2

3 SHAFT ROLLER 3624900900 PA 2

4 PICKER LITTER 3622700700 PA 2

5 PIPE BRUSH 3624408300 PP 1

6 NECK BRUSH 3628001600 PP 1

7 ROLLER-B BRUSH 3624703000 PP 2

8 COVER BRUSH 3621417200 PP 1

13 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN BK 4

38

Loading...

Loading...