Page 1

S/M No. : C3500KVEF0

Service Manual

Vacuum Cleaner

Model: RC-350

DAEWOO ELECTRONICS CO., LTD.

Page 2

SPECIFICATIONS............................................................................................................................... 2

DIAGRAM ............................................................................................................................................ 3

1. WIRING DIAGRAM...................................................................................................................................... 3

2. CIRCUIT DIAGRAM..................................................................................................................................... 3

TROUBLE SHOOTING GUIDE . ... ......... ... ... ......... ... ......... ... ......... ... ... ........ ... ......... ... ......... ... ... ......... .. 4

DISASSEMBLING AND TREATMENT ....................................................................... ......... ......... ...... 5

1. CLEANER ASSEMBLY............................................................................................................................... 5

2. CORD REEL ASSEMBLY............................................................................................................................ 6

EXPLODED VIEW AND PARTS LIST................................................................................................. 7

1. BODY ASSEMBLY....................................................................................................................................... 7

2. BODY COVER ASSEMBLY......................................................................................................................... 8

3. CORD POWER ASSEMBLY........................................................................................................................ 9

4. DUST COVER AQSSEMBLY ............. .. .. ............ ......................... ......................... .. ............ ......................... 10

5. HOSE ASSEMBLY....................................................................................................................................... 11

6. WIDE SUCTION BRUSH ASSEMBLY......................................................................................................... 12

7. EXTENSION PIPE AND NOZZLES............................................................................................................. 13

Page 3

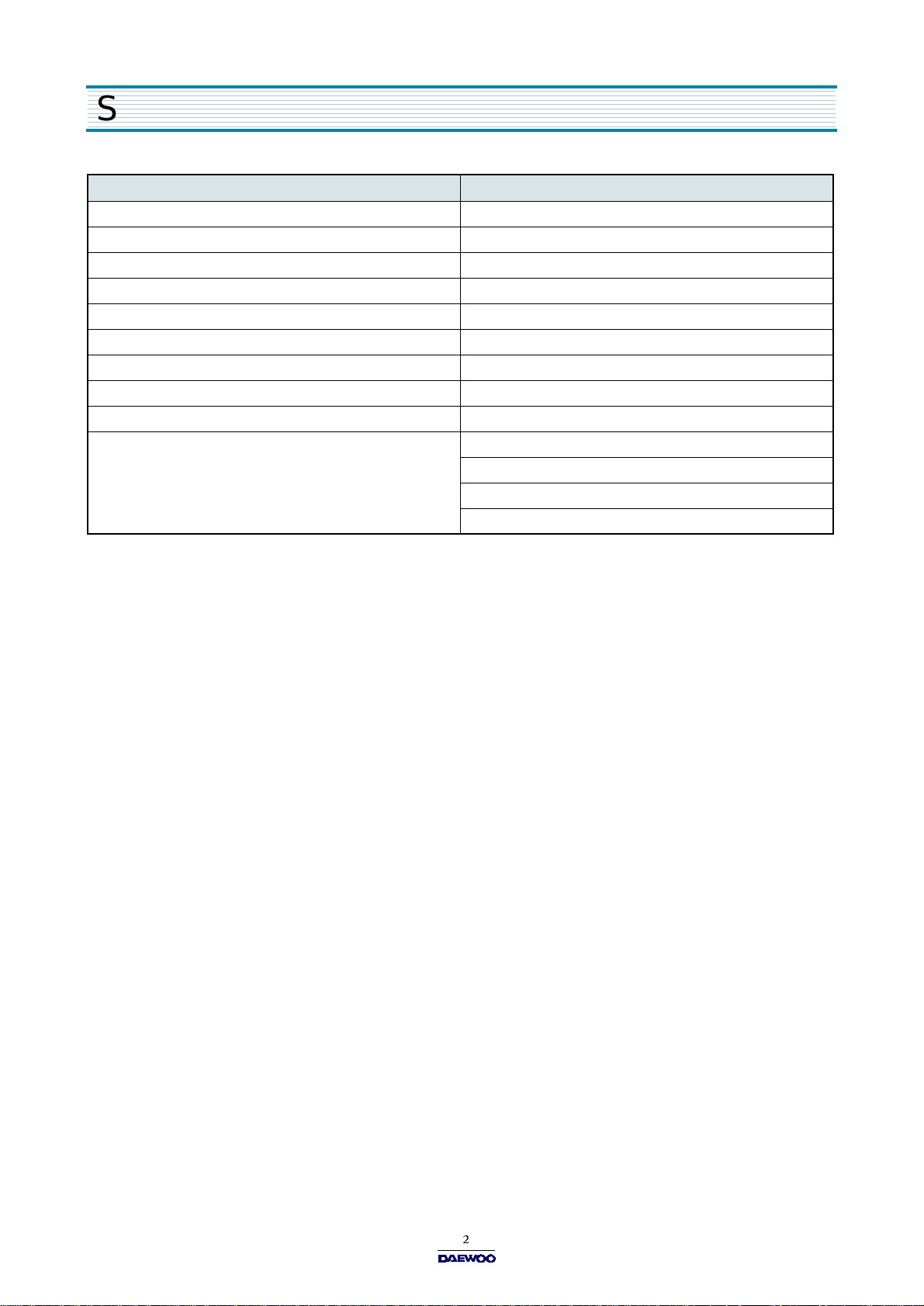

SPECIFICATIONS

MODEL RC-350

RATED VOLTAGE/FREQUENCY 230V/50Hz

INPUT WATT 1300W(MAX)

WEIGHT(BODY) 3.7kg

DIMENS IION(LHD) 354 X 240X 262mm

CORD LENGTH 6m

POWER CONTROL ELECTRONIC VARIABLE

DUST METER MECHANICAL

HOSE NON-CURRENT 1.8m

EXTENSION PIPE 2 PLASTICS

WIDE SUCTIO N BRUSH

NOZZLE

DUSTING BRUSH

CREVICE NOZZLE

UPHOLSTERY NOZZLE

Page 4

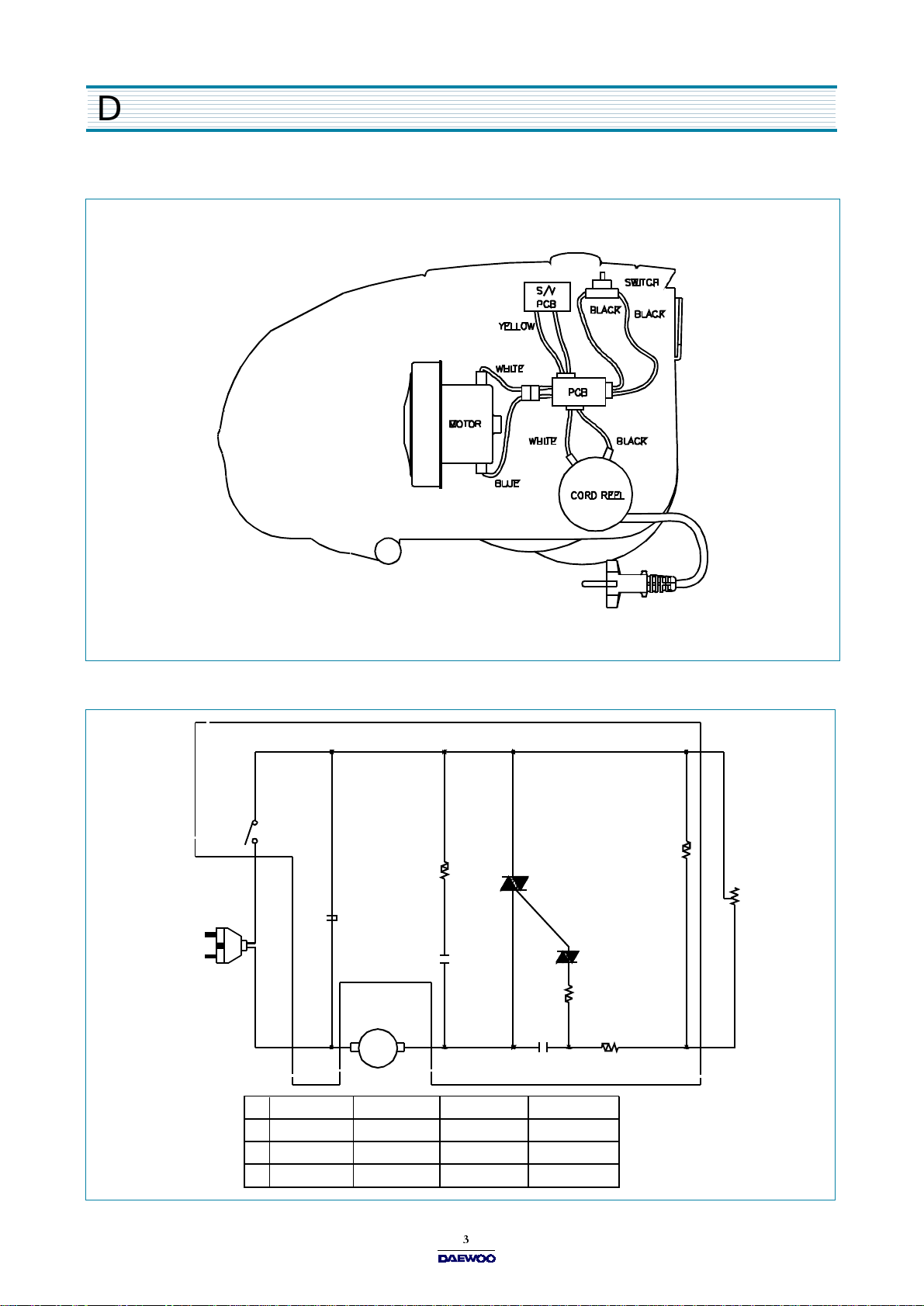

DIAGRAM

1. WIRING DIAGRAM

2. CIRCUIT DIAGRAM

S/W

100~110V

C1

0.1uP 100V

R1

1K OH M 1/2W

R2

180K OH M 1/2W

C3

0.15uP

275V

MOTOR

BLUE

120~127V

0.1uP 100V

1K OHM 1 /2W

240K OH M 1/2W

R3

100 OH M

1W

C2

0.1uP

275VAC

220~240V/50Hz

0.22uP 100V

10K OHM 1/2W

200K OH M 1/2W

T2

TRIAC

G

T1

R4

47 OH M

1/4W

C1

220~230V/60Hz

0.22uP 100V

10K OHM 1/2W

150K OH M 1/2W

DIAC

R1

PCB

R2

YELLOW

S/V R

200K OH M

Page 5

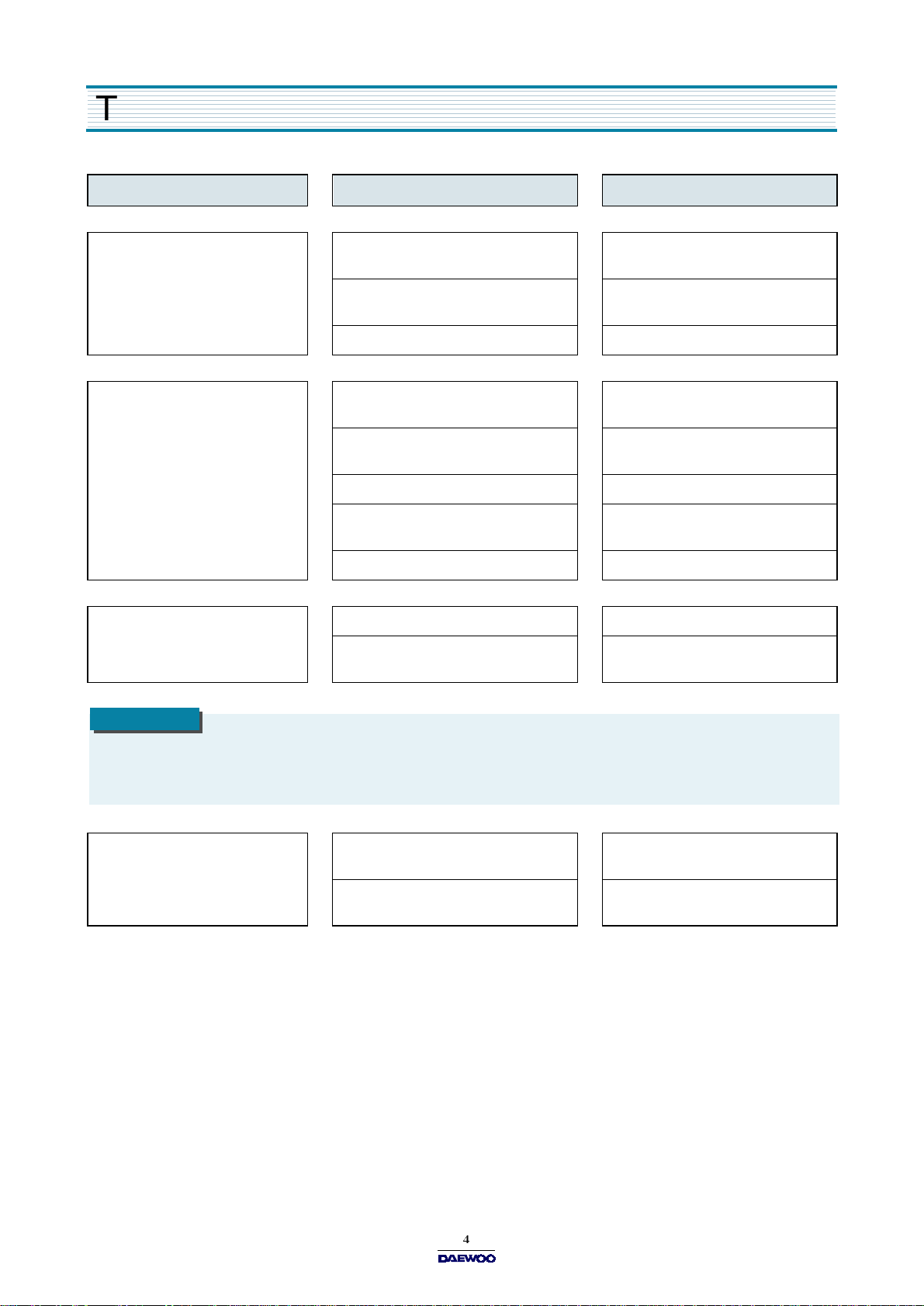

TROUBLE SHOOTING GUIDE

TROUBLE CAUSE COUNTERMEASURE

SUCTION POWER IS WEEK

CLEANER DOES NOT WORK

POWER CORD IS NOT WOUND UP

FILTER BAG(PAPER OR CLOT H ) IS

FULL WITH DUSH

CLOGGING OR TEAR IN HOSE

DEFECTIVE MOTOR REPLACE THE MOTOR

BREAKING IN POWER CORD

(AT BLADE TIP OR ROOT OF CORD)

BREAKING OF CONNECTIONS OR POOR

CONTACTS IN CORD REEL ASSEMBLY

DEFECTIVE MOTOR REPLACE IT

BREAKING OF CONNECTIONS IN

BODY AS SEMBLY

DEFECT IV E SW ITCH REPLAC E IT

BROKEN REEL SPRING REPLAC E IT

POWE R CORD BROKE AWAY FROM

THE BOBBIN

CHANGE IT WITH NEW ONE

REMOV E OB STACL E O R

REPLAC E T H E HO SE

REPAIR

REPAIR

REPAIR

REPAIR

CAUTION

BE CAREFUL WHEN BREAKING UP THE CORD REEL. THE REEL SPRING MAY SPRING OUT OF THE SPRING COVER.

POWER CORD DOES NOT STOP

A T AN ARBITRARY POS ITION

ABRASION OF THE ROLLER BRAKE

(STOPPER CR) OF CORD REEL

LEVER SPRING BROKE AWAY FROM THE

CORD REEL BRACKET

REPLAC E T H E RO L L E R BR AK E

(STOPPER CR )

REPAIR

Page 6

D ISASSEMBLING AND TREATMENT

1. CLEANER ASSEMBLY

1) While standing the handle(1), unscrew the 2(+) screw.

Lift the dust cover assembly(2).

2) Seperate the case filter. Unscrew the 4(+) screw.

3) Rotate and lift the body cover assembly(4).

Page 7

D ISASSEMBLING AND TREATMENT

2. CORD REEL ASSEMBLY

1) Take the cord reel out of the body cover.

2) Unscrew the screw and separate the bobbin from the bracket and check the contacts between the Y terminals.

At this time, the bobbin is rotated counterclockwise due to the preserved winding.

3) If the reel spring is broken, unscrew the 2 screws and replace it.

CAUTION

WHEN DISASSEMBLING, THE REEL SPRIN G MAY SPRING OUT OF THE COVER.

4) Unscrew the screw and part bobbin.

5) Check the connections between the power cord and the terminals.

6) When assem bling, make the reserved winding 4 revolutions of the bobbin clockwise.

Page 8

EXPLODED VIEW AND PARTS LIST

1. BODY ASSEMBLY

No PART NAME CODE SPEC Q’TY

1 BODY 3620406300 PP 11

2 ROLLER B ACK 3624703410 PP 2

3 ROLLE R FR ON T 3624703600 PP 1

4 SHAF T RO LLER 3624901000 SW RM 1

5 BRACK ET R OLLER 3620601500 PP 1

6 HOLD ER FILTER 3623004000 PP 1

7 SPRING HO LDE R 362510600 SK-5 1

8 GASK ET 3624004800 RUBBER FOAM 1

9 FILTER-IN 3621904200 POLYESTER 1

10 BAG FILTER 3620202500 2-LAYER, 3L 1

11 SCREW TAPPING 7128401212 T2S WAS 4X12 1

Page 9

EXPLODED VIEW AND PARTS LIST

2. BODY COVER ASSEMBLY

No PART NAME CODE SPEC Q’TY

1 COVER BOD Y 3621416950 PP 1

2 LEVER CR 3623702000 P C 1

3 SPRING LEVER 3625104300 HSW3 1

4 FRAME STOPPER 4565A35070 P OLY ACETAL 1

5 S TOPP ER C R 4569C35082 NBR 1

6 SCREW TAPPING 7121301211 T2S PAN 3X12 1

7 PC B 3624304501 RO TARY PCB 1

8 H ARN ESS 3622710100 HOUSING+W IRE(YW)+WIRE(YW) 1

9 VR RO TARY 5V2204009B B200K 1

10 SW ITCH PUS H 3629002000 7A/250V(SKT) 1

11 HARN ESS 3622710200 RECEP+W IRE(BK) 1

12 FILTER 3621905600 P O LYESTER 1

13 PACKING M OTOR 3624004900 SBR 1

14 MOT OR U NIVERSA L 3962511400 230V 110W(F) DMI 1

15 M OU N T MO TO R 3627900900 TPE 1

16 FILTER EXHA US T 3621904300 POLYESTER 1

17 CASE F ILTER 3621103000 P P 1

18 PCB A S 3624308520 RC-350 230-240V/50Hz 1

19 S CRE W TAPPING 7171402011 TT2 PAN 4X20 4

Page 10

3. CORD POWER ASSEMBLY

EXPLODED VIEW AND PARTS LIST

No PART NAME CODE SPEC Q’TY

1 B O BBIN 3629200600 PP 1

2 H O LDER TERM INAL 4565A36020 PC(V-0) 1

3 TER MINAL 4565A36024 C2600P-1/2H T0.3 1

4 TER MINAL 4565A36034 C2600P-1/2H T0.3 1

5 CORD PO W ER 3621302500 250V16A H05VVH2F TA-17 1

6 SC REW TAPPING 7121301411 T2S PAN 3X14 MFZN 1

7 SP RING AS 3625102005 S US-301EH+ CO VER 3800 1

8 SC REW TAPPING 7121301411 T2S PAN 3X8 MFZN 1

9 BR AC KET C R 3620601600 PC 1

10 TERM INAL AS 3628709800 Y-TERM INAL+HOU SING 1

11 SC REW TAPPING 7121400611 T2S PAN 4X6 MFZN 2

12 SHAFT REEL 3624900510 PC 1

13 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 1

Page 11

EXPLODED VIEW AND PARTS LIST

4. DUST COVER AQSSEMBLY

No PART N AM E CODE SPEC Q’TY

1 CO V ER D US T 3621417000 ABS K R-2870 1

2 SO CK ET 3629800600 AB S KR -2870 1

3 CLAM P CO V ER 3621202000 AB S KR -2870 1

4 SPR ING CLA MP 3625106400 HSW 3 1

5 H O SING DM 3626100300 G PP S 1

6 DUST METE R 3629702100 A BS 1

7 C AP D M 3620903500 LD PE 1

8 SPRING D M 3625106300 SUS 1

9 SCRE W TAPPING 7121401411 T 2S PAN 4X14 MFZN 1

10 COVER TO P 3621417150 PP 1

11 BUTTON PO W ER 3626603650 ABS 1

12 BUTTON CR 3626603750 ABS 1

13 SPRING 3625103400 HSW 3 C R BU TTON 2

14 H AND LE 3622601400 P P 1

15 S CRE W TAPPING 7121402011 T 2S PAN 4X20 MFZN 2

16 KNO B C OLNT ROL 3623401000 AB S 1

17 CAP KNO B 3620903800 AB S 1

Page 12

5. HOSE ASSEMBLY

EXPLODED VIEW AND PARTS LIST

No PART NAME CODE SPEC Q’TY

1 ADAPT ER PIPE 3629101700 PP 1

2 HOLD ER HOSE 4569A71021 P P 2

3 RING HOS E 3624600200 PP 1

4 HO SE 3623206300 EVA 1.8M 1

5 CU FF HO SE 3626800200 LDPE 1

6 PIPE HO SE 3624408200 P P 1

7 PACKING HOLE 3624005900 EVA SPONG E 1

8 VALVE AIR 3625400400 PP 1

Page 13

EXPLODED VIEW AND PARTS LIST

6. WIDE SUCTION BRUSH ASSEMBLY

No P ART NAM E CODE SPEC Q’TY

1 BODY BR USH 3620406400 PP 1

2 C O VER B RUS H 3621417200 PP 1

3 NE CK BR USH 3628001600 PP 1

4 P IPE BRUSH 3624408300 PP 1

5 R O LLER-B BRU SH 3624703000 SBS 2

6 ROLLER -F BRUS H 3624703100 SBS 2

7 SHAFT ROLLER 3624900900 PA 2

8 PICKER LITTER 3627000700 PA 2

9 SCREW TAPPING 7171401411 TT2 PAN 4X14 MFZN 4

Page 14

7. EXTENSION PIPE AND NOZZLES

EXPLODED VIEW AND PARTS LIST

No PART NAME CODE SPEC Q’TY

1 P IPE EXTEN SION 3624408500 PP 2

2 BRU SH D USTING 3629305000 PP+NYLON 1

3 HO LD ER N OZZLE 3623004200 PP 1

4 PICKER LITTER 3627000700 PA 2

5 NOZZLE UPH O LSTERY 3628100700 PP 1

6 NOZZLE CR EVICE 3628100600 PP 1

Page 15

DAEWOO ELECTRONICS CO., LTD

686, AHYEON-DONG MAPO-GU

SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX : DWELEC K28177-8

CABLE : “DAEW OOELEC”

E-mail : G7F00E@web.dwe.co.kr

FAX : 02) 360-8184

TEL: 02) 360-8179~8180

PRINTED DATE : NOV. 1998

Loading...

Loading...