Page 1

1

CONTENTS

1. SPECIFICATION

.......................................................................

2

2. DIAGRAM

..................................................................................

3

1) WIRING DIAGRAM

................................................................

3

2) CIRCUIT DIAGRAM

..............................................................

3

3. CAUSE OF TROUBLE AND COUNTERMEASURE

................

4

4. COUNTERMEASURE DETAIL

.................................................

5

5. EXPLODED VIEW AND PARTS LIST

......................................

9

1) BODY ASSEMBLY

................................................................

9

2) COVER ASSEMBLY

...........................................................

11

3) HOSE LINE ASSEMBLY

.....................................................

13

4) BRUSH ASSEMBLY

............................................................

15

Page 2

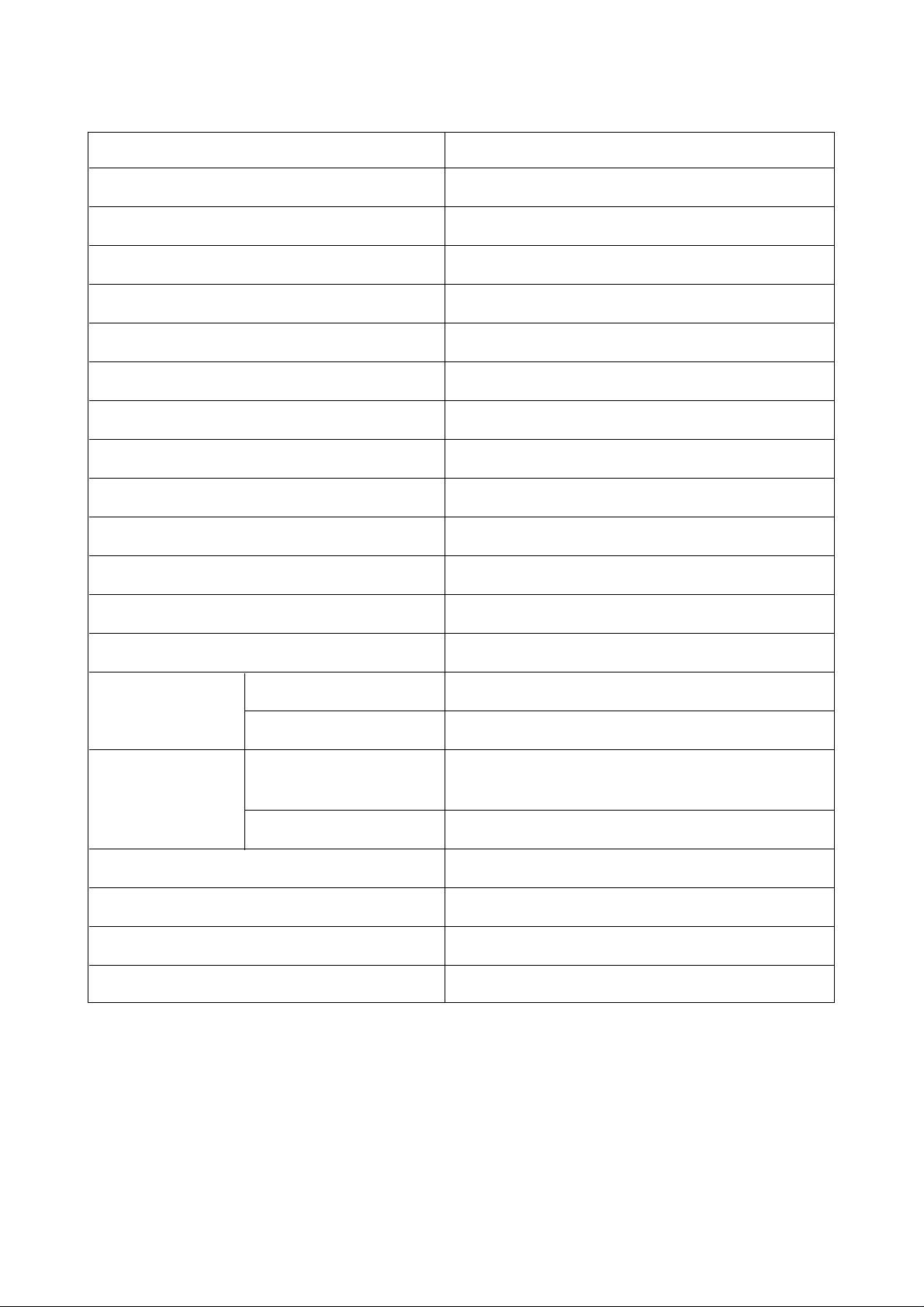

1. SPECIFICATION

2

RATING 220V, 50~60Hz

INPUT 1010W

AIR WATT 330W

VACUUM 1,050 mmAq.

AIR FLOW 1.11 m/min.

NOISE 65 dB

DIMENSION (L X H X W) 356 X 221 X 246mm

POWER CORD RETRACTABLE 5m

SUCTION CONTROL ELECTRIC SLIDE

DUST METER MECHANICAL

PARTS KEEPING STAND KEEPING

DUST BAG CAPACITY 2.2 Liter

POWER SWITCH ON HOSE HANDLE

FUSE RATING 250V, 6A

WEIGHT

BODY 3.8Kg

NET 4.9Kg

DUST CAVITY

2-LAYER PAPER BAG

FILTER

NON-WOVEN FABRIC MAT

MOTOR CAVITY NON-WOVEN FABRIC MAT

HOSE CURRENT 1.3m

EXTENTION PIPE PLASTIC 2 EA

BRUSH CLEAN

SPARE PAPER BAG 2 EA

Page 3

2. DIAGRAM

3

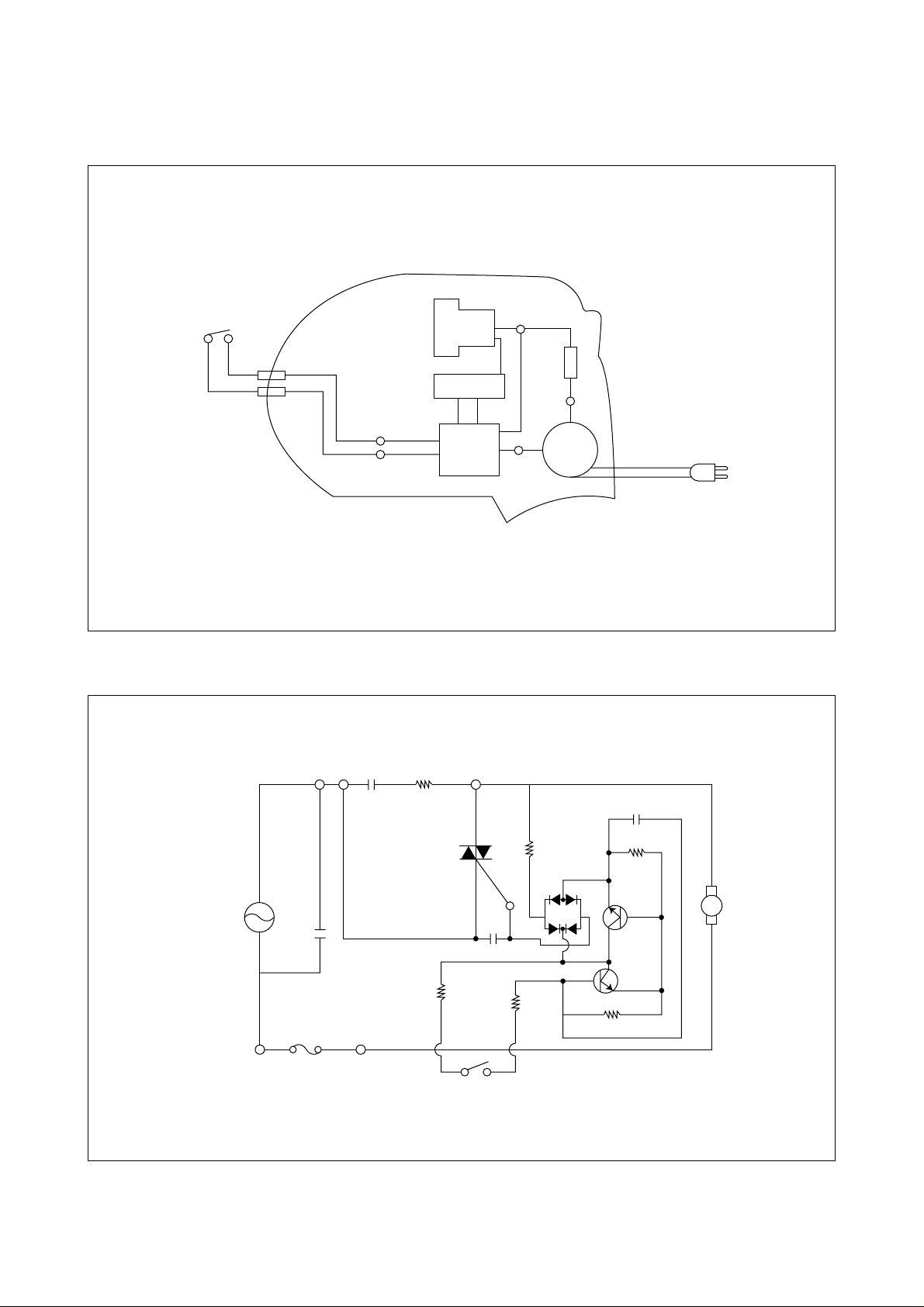

1) WIRING DIAGRAM

BK

RED

ORANGE

BK

MOTOR

BL

FILTER COIL

SWITCH

YL

YL

P.C.B

CORD

REEL

WH

FUSE

2) CIRCUIT DIAGRAM

220V

50~60Hz

C1

FUSE

220V, 6A

R5

R6

S/W

R4

Q2

Q1

M

R3

R2

C3

DIODE

T2

T1

TRIAC

R1C2

C4

Page 4

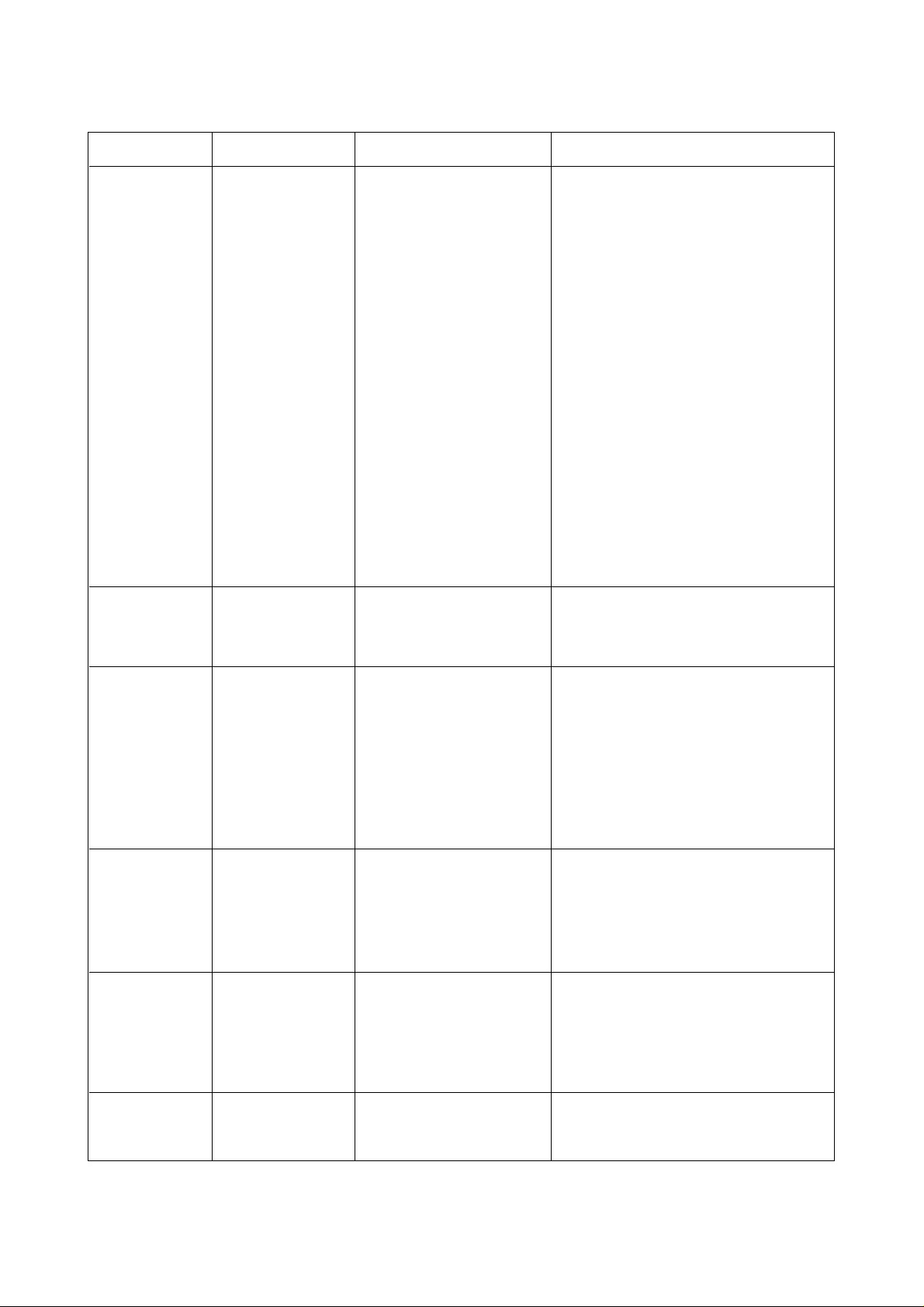

3. CAUSE OF TROUBLE AND COUNTERMEASURE

4

TROUBLE

Motor does not

rotate.

Motor does not

stop even if the

switch is set

"OFF".

Suction power

is low.

Dust is

excessively

discharged from

exhaust grill

during operation.

Cord can not be

wound up.

Cord does not

stop at arbitrary

position.

CHECK POINT

Power cord

Fuse

Terminal in body

Cord reel

Motor

Hose switch

Connections

PCB assembly

Hose switch

PCB assembly

Paper bag

Hose, brush, and

pipe

Filter

Motor

Paper bag and

filter

Cord reel

Power cord

Reserved winding

Tire

Bobbin

CAUSE

Break of power cord (at

blade tip or root of plug)

Fuse cut-out

Deflection or break in

connections

Deflection of terminal or

break in connections

Abrasion of carbon brushes

Break in motor winding

Deflection of terminal

Break

Defective TRIAC

Deflection of terminal

Defective TRIAC

Full bag with dust

Blocked or break

Clogged

Defective Motor

Damaged or torn

Break of the spring for

winding cord.

Entanglement of cord

Insufficient reserved

winding

Abrasion of the tire

Sticking dust on the surface

of the bobbin

COUNTERMEASURE

Replace the power cord.

Replace the fuse. (Detail 1)

Repair. (Detail 2)

Repair. (Detail 3)

Replace the carbon brushes. (Detail 4)

Replace the motor.

Repair.

Repair. (solder or use connectors)

Replace the PCB assembly.

Repair.

Replace the PCB assembly.

Replace the paper bag. (CP-11)

Remove the obstacle or replace.

Clean the filter.

Replace the motor.

Replace the paper bag or the filter.

Replace the bobbin assembly.

Draw out the cord 40-50 Cm and wind

up again.

Add proper reserved winding. (6 turns)

Replace the tire.

Clean.

Page 5

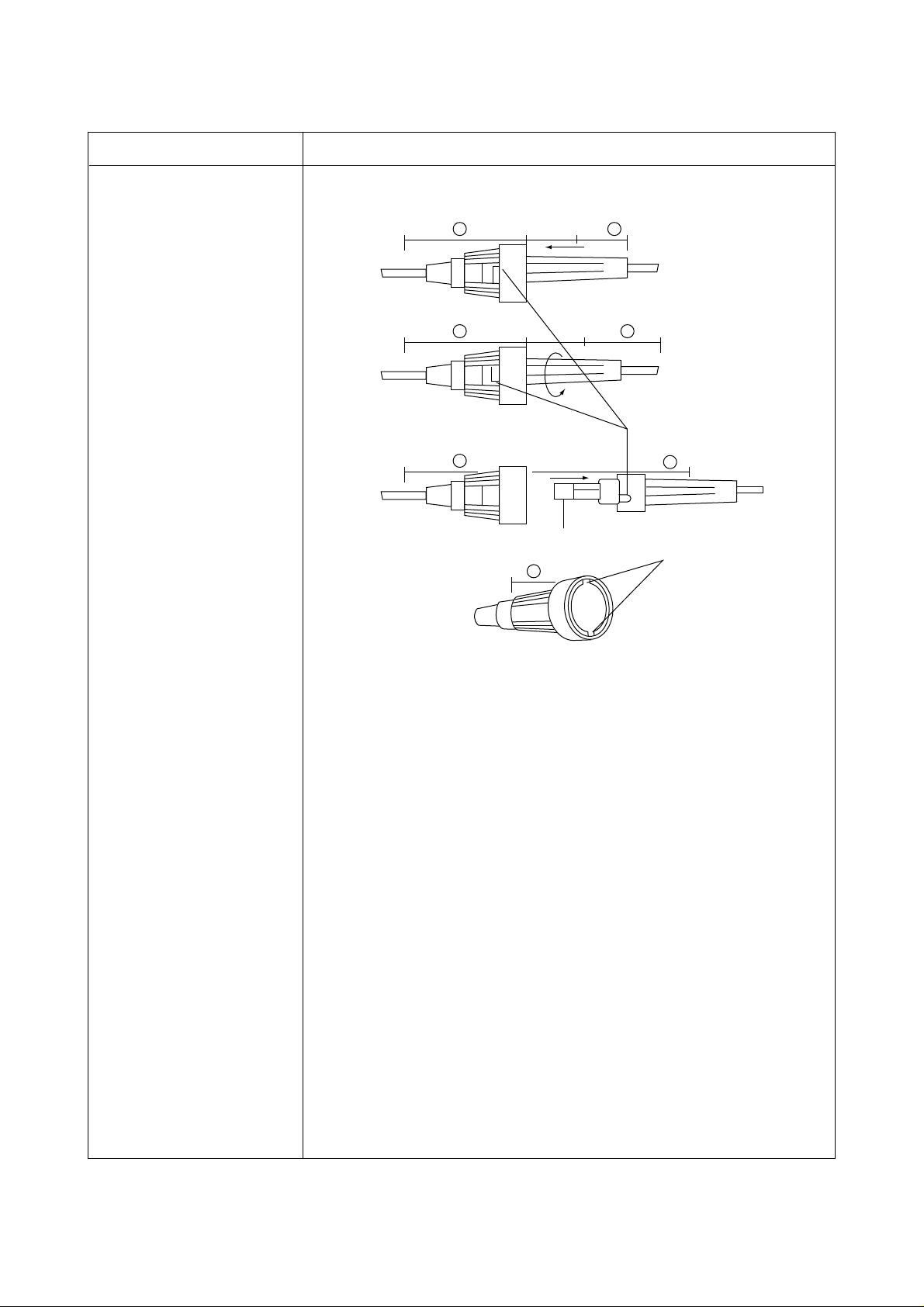

4. COUNTERMEASURE DETAIL

5

COUNTERMEASURE COUNTERMEASURE PROCEDURE

1. Replacing a fuse

1. Remove 3 screws (41) of the bottom of the body (1), so the

cover assembly can be separated from the body.

2. Take out the fuse assembly from the body.

3. Rotate B part with pushing in the directions as shown the above

figure.

4. Separate B part from A part, and then replace the fuse (250V,

6A)

5. When assembling, rotate B part in the opposite direction of

separating after inserting the projection of the B part into the

groove of the A part.

*CAUTION

Take care not to damage the internal wires on assembling.

A B

A

A

Fuse

A

B

Projection

B

Groove

Page 6

6

COUNTERMEASURE COUNTERMEASURE PROCEDURE

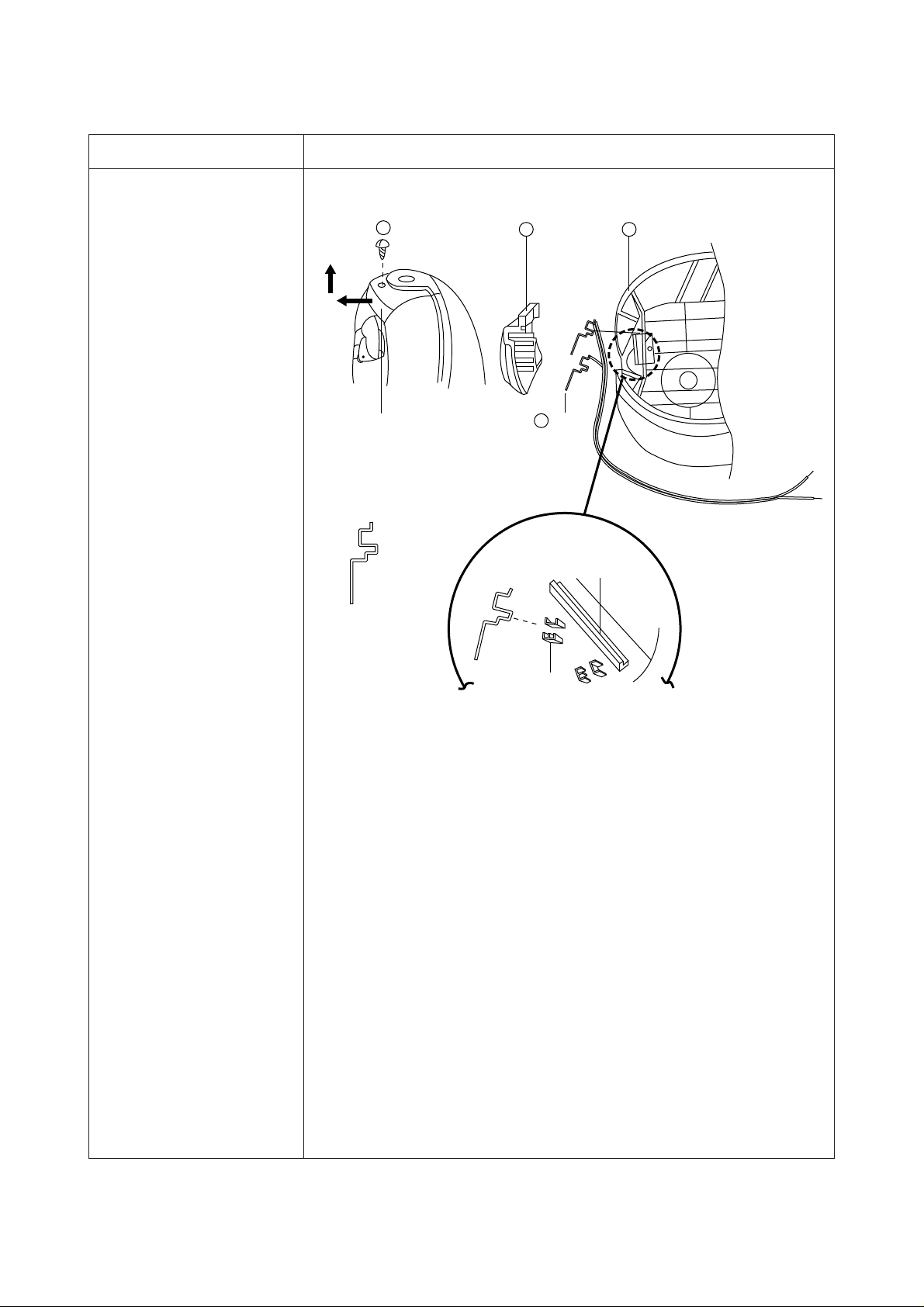

2. Repairing the terminal

in the body

1. After removing the screw (4), pull out the frame in the directions

as shown the above figure from the body.

2. Check the terminals (3).

-They are bent or deflected other than standard shape. ➪➪

Repair the terminals as shown the standard shape in the

above figure.

-Break of a wire. ➪ ➪ Soldering.

3. When assembling, first of all, fix the terminals into the grooves

of the body, and then push the frame top down, so the upper

part of the frame can be hung on the frame supporter of the

body.

4

Groove for carrying

Standard shape

2 Frame

3 Terminal

1 Body

Frame supporter

Groove

Page 7

7

COUNTERMEASURE COUNTERMEASURE PROCEDURE

3. Repairing the cord

reel assembly

1. Separate the cover assembly, and then take out the cord reel

assembly from the body.

2. After removing the screws (1), separate the PCB assembly.

3. Rotate the bobbin 6 turns in the opposite direction indicated by

the arrow mark on the cover (12).

4. After removing the screw (3), separate the bobbin from the

bracket (4).

5. Check the state of the contacts between the terminals (5, 6, 17).

-Deflection or break of the terminals (5, 6). ➪➪Repairing or

replacing them.

6. When assembling, after putting the bobbin and the bracket

toqether with the screw (3), make a reserved wind of 6 turns.

*CAUTION

Take care not to separate the spring (13) from the cover (12).

It is very dangerous.

2 84 0 u y t r e w q9

1 5 6 3 7 i

Page 8

8

COUNTERMEASURE COUNTERMEASURE PROCEDURE

4. Replacing carbon

brushes

1. Separate the cover assembly, and then take out the motor from

the body.

2. Check whether the brush cap is separated from the brush

bolder.

-Separation of the brush cap. ➪ ➪ Fix it.

3. Check whether the carbon brush is worn out.

- In case that the length of the carbon brush is less than 5 mm.

➪

➪ Replace the carbon brush assembly in pair.

Motor

A

Brush cap

Brush holder

32mm

Carbon brush

5mm

Page 9

5. EXPLODED VIEW AND PARTS LIST

9

1) BODY ASSEMBLY (3620400800)

18

363534333231302928

40

38

2726252423222120

1091

171615

14

13

3 4242

19

11

12

250V 6A

5

41

6

7

8

37

✱

250V 8A

Page 10

PARTS LIST OF BODY ASSEMBLY

✱ REPLACEMENT PART LIST (Applied model: RC-209)

-BUTTON CR (4560F35020) ➞ BUTTON CR (3626601500)

10

NO. PART NAME PART CODE Q’TY DESCRIPTION

1 BODY 4560F20010 1 ABS

2 SOCKET 4560F20030 1 ABS

3 PACKING SOCKET 4560F20040 1 NATURAL RUBBER

4 TERMINAL 4565A37002 2 C5210P-EH

5 BRACKET ROLLER 4569C20041 1 PP

6 CASTER ROLLER 4568A54020 1 PP

7 LABEL 4560F10010 1 STICKER

8 ROLLER 4560F20020 2 PP

9 FUSE ASSEMBLY 4560A39002

1

250V, 8A

10 LABEL FUSE 4568F39010 1 STICKER

11 HOLDER FILTER 4560F25010 1 ABS

12 SPRING 4560F25080 1 HSW3

13 BAG FILTER 4560A57001 1 2-LAYER

14 FILTER 4560F24020 1 NON WOVEN FABRIC MAT

15 CAP MOTOR *F 4560M20101 1 NR

16 MOTOR UNIVERSAL 3962230200 1 220V, 1000W, O/S H

17 ABSORBER MOTOR 4569C10071 1 PU FORM

18 CAP MOTOR *L 3620900600 1 NR

19 GASKET COVER 4560F20060 1 PVC-S

20 SCREW TAPPING 7121400811 2 T2S PAN 4X8 MFZN

21 POWER CONTROL PCB AS 3624301101 1 RC-205 220V/60HZ

22 SCREW TAPPING 7121401211 1 T2S PAN 4X12 MFZN

23 BRACKET CR 4560F35010 1 ABS

24 SPRING 4560F35030 1 HSW3

25 BUTTON CR 3626601500 1 ABS(RC-209)

26 STOPPER CR 4569C35081 1 NBR

27 FRAME STOPPER 4565A35070 1 POLY ACETAL

28 TERMINAL 4565A36024 1 C2600P-1/2H

29 TERMINAL 4565A36034 1 C2600P-1/2H

30 HOLDER TERMINAL 4565A36010 1 ABS

31 BOBBIN 4565C35010 1 ABS

32 SCREW TAPPING 7121401211 1 T2S PAN 4X12 MFZN

33 SHAFT CR 4569C35051 1 PC LEAXAN 500

34 SPRING AS 3625102000 1 SUS301-EH-COVER,35

35 COVER 4565A35041 1 SPG

36 SCREW 7121300811 2 T2S PAN 3X8

37 TERMINAL AS 4560F42000 1 Y TERMINAL&LEAD

38 TERMINAL AS 4560F42000 1 Y TERMINAL&LEAD

39 CORD POWER 4560A38010 1 250V,7A

40 SCREW 7121400811 2 T2S PAN 4X8

41 SCREW 7121401411 3 T2S PAN 4X14

42 SCREW 7121301011 1 T2S PAN 3X10

✱

Page 11

11

2) COVER ASSEMBLY

16

8

15

9

10

11

12

13

14

7

6

4

3

2

1

5

✱

✱

✱

✱

Page 12

12

PARTS LIST OF COVER ASSEMBL Y

NO. PART NAME PART CODE Q’TY DESCRIPTION

1 COVER BODY 3621406600 1 ABS (RC-209)

2 FILTER 4560F24020 1 NON-WOVEN FABRIC MAT

3 PACKING 4560F24030 1 POLYETHILENE FOAM

4 COVER DUST 3621406700 1 ABS (RC-209)

5 HANDLE BODY 3622600300 1 ABS (RC-209)

6 BRUSH MULTI AS 4560A67000 1 ASSY

7 ELBOW DM 4560F23050 1 PVC-S

8 HOUSING DM 4560F23010 1 SAN

9 SPRING 3625100700 1 SUS

10 DUST METER 4560F23030 1 ABS GREEN

11 DUST METER 4560F23060 1 ABS RED

12 PACKING DM 3624000400 1 S-PVC

13 VALVE DM 3625400100 1 LDPE

14 SCREW TAPPING 7121300811 2 T2S PAN 3X8 MFZN

15 SCREW TAPPING 7121300811 2 T2S APN 3X8 MFZN

16 COVER NOZZLE 3621406500 1 ABS (RC-209)

✱ REPLACEMENT PART LIST (Applied model: RC-209)

- COVER BODY (4560F24010) ➞ COVER BODY (3621406600)

- COVER DUST (4560F52010) ➞ COVER DUST (3621406700)

- HANDLE BODY (4560F52010) ➞ HANDLE BODY (3622600300)

- COVER NOZZLE (4560F52020) ➞ COVER NOZZLE (3621406500)

✱

✱

✱

✱

Page 13

13

3) HOSE LINE ASSEMBLY

23

6

24

16

17

18

6

19

20

10

21

22

7

9

11

12

10

15

1413

25

7

1

8

2

3

4

5

6

Page 14

14

PARTS LIST OF HOSE LINE ASSEMBL Y

NO. PART NAME PART CODE Q’TY DESCRIPTION

1 ADAPTER HOSE 4565A70010 1 ABS

2 SPRING 4565A70050 1 SWPB D0.5

3 PIN TERMINAL 4568A70020 2 C2800W-H

4 BUTTON ADAPTER 4565A70061 1 ABS

5 HOLDER BUTTON 4565A70070 1 ABS-380/750

6 SCREW TAPPING 7121300812 4 T2S PAN 3X8 MFZN

7 COVER HOSE 4565A70040 2 PP

8 WIRE CONNECTION 4565A70030 0.15M STEEL WIRE 0.7D

9 TAPE VINYL 2TU00019BK 0.30M 19mm BLACK

10 WIRE BIND 8860108WH 0.70M AWG 21

11 HOSE 4565A71001 1 PVC-S/SWRS 1.32M

12 FRAME 4565A70080 1 ABS

13 RING 4560F70150 1 PP

14 PIPE 4560F70130 1 PP

15 RING 4560F70120 1 ABS

16 COVER PIPE 3621401300 1 ABS

17 KNOB 3623400100 1 PC

18 PLATE 3624500200 1 ABS

19 SCREW MACHINE 7001200310 2 PAN M 2X3

20 PLATE VOLUME 4569G25050 1 SPG

21 VR SLIDE 5V2504007B 1 CSSPN-3006-1B500K

22 WIRE LEAD 8YS12018YW 0.15M VSF 12/0.18

23 PIPE 4560F75030 2 PP

24 HOLDER PIPE 4560F76000 1 ACETAL

25 HOOK HOSE 4560F77000 1 PP

Page 15

15

4) BRUSH ASSEMBLY

2

5

3

1

1

4

2

14

10

11

9

6

8

7

12

13

Page 16

16

PARTS LIST OF BRUSH ASSEMBL Y

NO. PART NAME PART CODE Q’TY DESCRIPTION

1 ROLLER BRUSH 4560F90020 4 PP£«PVC

2 PIN ROLLER 4560F90120 4 SWRM MFZN

3 SCREW TAPPING 7121401411 4 T2S PAN 4X14

4 BODY BRUSH 4560F90010 1 ABS

5 HOLDER BRUSH ASS’Y 4568B91001 3 ABS£«NYLON

6 PACKING 3624000500 1 NBR FOAM

7 NECK 4560F90070 1 ABS

8 COVER PIPE 3621401000 1 ABS

9 HOOK 3623100100 2 POM

10 COVER SCREW 4560A65080 1 FILM, T=0.5

11 SCREW TAPPING 7121300812 1 T2S PAN 3X8

12 COVER PIPE 3621400800 1 ABS

13 PIPE 3624401700 1 ABS

14 COVER BRUSH 4560F90080 1 ABS

Page 17

DAEWOO ELECTRONICS CO., L TD.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 360-8184

TEL: 02) 360-8179~8180

http://G7F00E@web.dwe.co.kr

PRINTED DATE: JAN.1999

Page 18

Service Manual

Vacuum Cleaner

Model: RC-205

DAEWOO ELECTRONICS CO., LTD.

S/M NO.:C2050KVEF1

Page 19

Loading...

Loading...