Page 1

S/M No. : RC-200-EF1

Service Manual

VACCUM CLEANER

MODEL : RC-200

RC-2006GD

RC-2006SV

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CO., LTD

http : //svc.dwe.co.kr

AUG. 2002

Page 2

CONTENTS

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

Page

1. SPECIFICATIONS ………………………………… 2

2. EXTERNAL VIEW ………………………………… 3

2-1. ASSEMBLY ………………………………………….

2-2. MODEL …………………………………………………

3. DIAGRAM ………………………………………

3-1. WIRING DIAGRAM ………………………………

3-2. CIRCUIT DIAGRAM ………………………………

4. TROUBLE SHOOTING GUIDE …………………

5. DISASSEMBLING AND TREATMENT …………

5-1. CLEANER ASSEMBLY …………………………...

5-2. CORDREEL ASSEMBLY ……………………………

5-3. HOSE ASSEMBLY …………………………………

5-4. BRUSH ASSEMBLY ………………………………… 11

3

4

5

5

5

6

8

8

9

10

6. EXPLODED VIEW AND PARTS LIST …………

6-1. CLEANER ASSEMBLY ……………………………

6-2. BODY ASSEMBLY …………………………………

6-3. COVER ASSEMBLY …………………………………

6-4. CORD REEL ASSEMBLY …………………………

6-5. HOSE ASSEMBLY …………………………………

6-6. BRUSH ASSEMBLY …………………………………

6-7. PIPE ASSEMBLY …………………………………..

1

12

12

14

16

18

20

22

6

2

Page 3

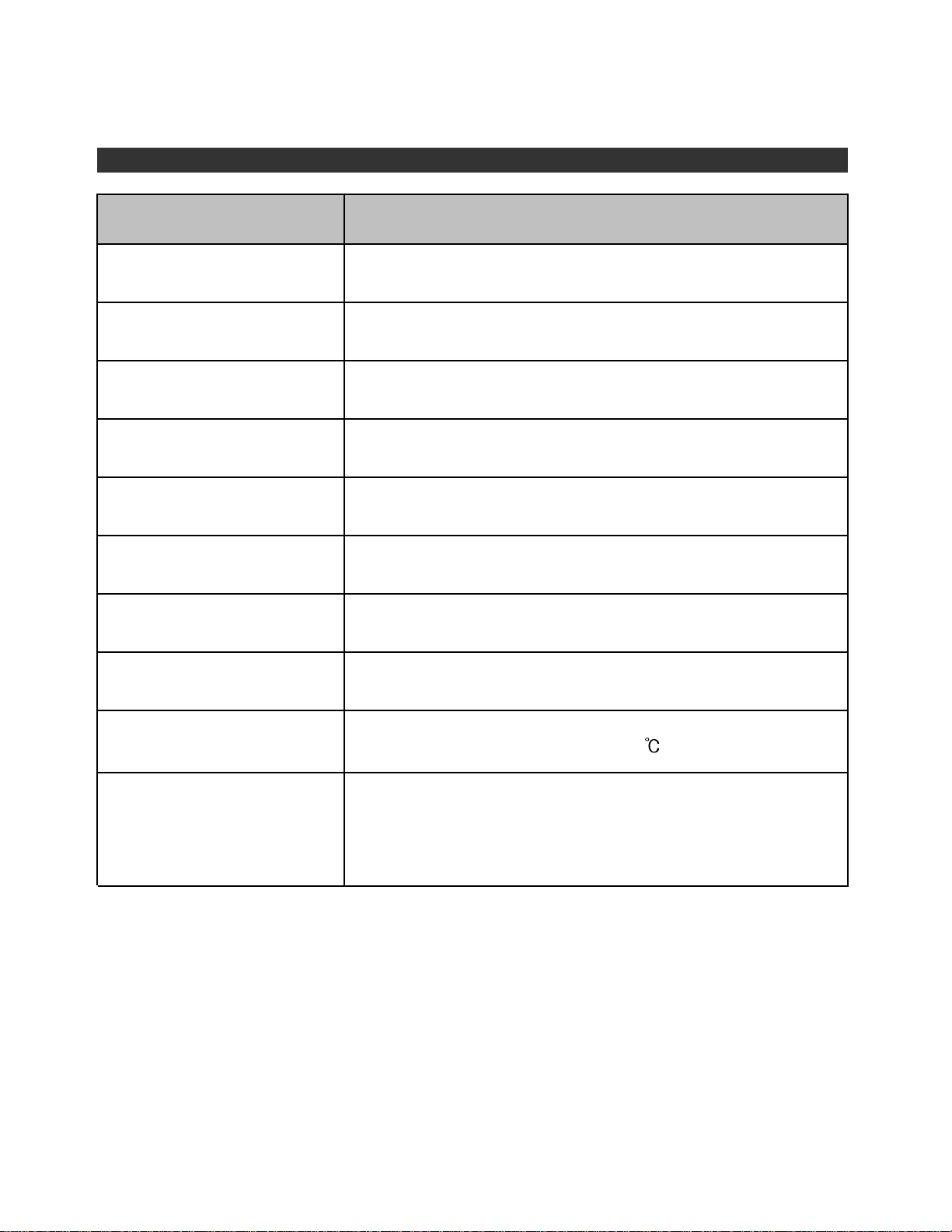

1. SPECIFICATIONS

Model

Rated Voltage

Frequency

Input Watt

Weight(Body)

Dimension(LXHXD)

Cord Lenth

Power Control

RC-200

AC 230V

50Hz

1400W

3.7Kg

300 X 215 X 270 mm

6m

Slide volume

Dust Meter

Safety Device

Nozzle

Mechanical

Thermostat(N85:85 OFF)

Dusting Brush

Crevice Tool

2

Page 4

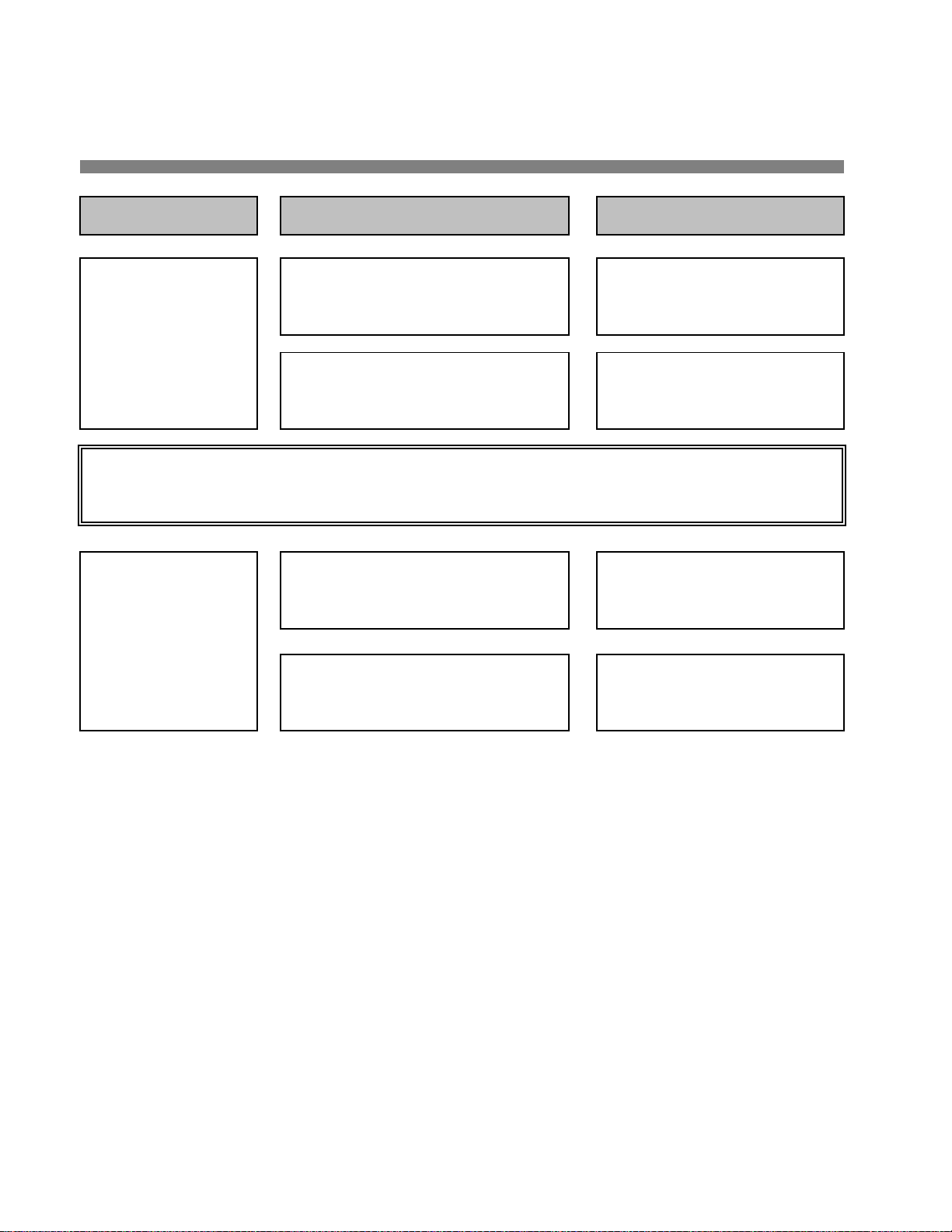

2. EXTERNAL VIEW

2-1. ASSEMBLY

A - DUST METER

B - HOSE HANDLE

C - CORD REWIND BUTTON

D - POWER CORD

PART NAME

E - CLEANING TOOLS(CREVICE TOOL)

E' - CLEANING TOOLS(DUSTING BRUSH)

F - NOZZLE( PEDAL BRUSH )

G - EXTENSION PIPE (PLASTIC TELESCOPIC)

F - HANDLE ADAPTER

3

Page 5

2-2. MODEL RC-200

4

Page 6

3. DIAGRAM

3-1. WIRING DIAGRAM

3-2. CIRCUIT DIAGRAM

Page 7

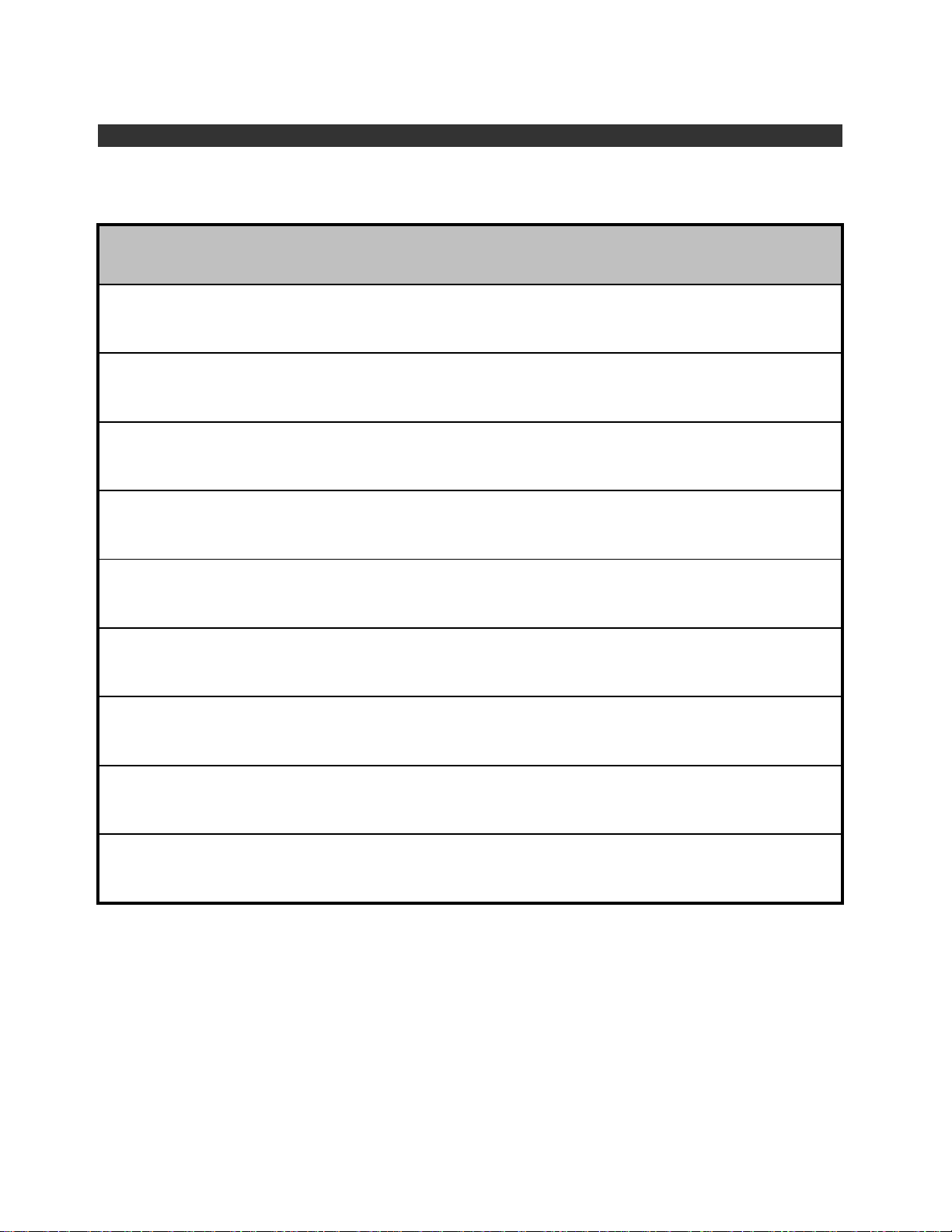

4. TROUBLE SHOOTING GUIDE

TROUBLE CAUSE COUNTERMEASURE

SUCTION POWER FILTER BAG(PAPER OR CLOTH) CHANGE IT WITH NEW ONE

IS WEAK IS FULL WITH DUST OR REMOVE THE DUST

CLOGGING OR TEAR IN HOSE REMOVE OBSCTACLE

OR REPLACE THE HOSE

DEFECTIVE MOTOR REPLACE THE MOTOR

(SEE 5-2)

CLEANER DOES BREAKING IN POWER CORD REPLACE THE POWER

NOT WORK (AT BLADE TIP OR ROOT OF PLUG) CORD (SEE 5-3)

DEFECTIVE SLIDE VOLUME

LOCATED IN COVER BODY REPLACE IT (SEE 5-5)

DEFECTIVE PCB ASSEMBLY REPLACE IT (SEE 5-5)

BREAKING OF CONNECTIONS REPAIR (SEE 5-3)

OR POOR CONTACTS IN

CORD REEL ASSEMBLY

DEFECTIVE MOTOR REPLACE IT (SEE 5-2)

BREAKING OF CONNECTIONS

IN COVER BODY ASSEMBLY REPAIR (SEE 5-5)

DEFECTIVE SWITCH REPLACE IT (SEE 5-5)

MOTOR DOES NOT DEFECTIVE PCB ASSEMBLY REPLACE IT (SEE 5-5)

STOP EVEN IF

SWITCH

6

Page 8

TROUBLE CAUSE COUNTERMEASURE

POWER CORD IS BROKEN REEL SPRING REPLACE IT (SEE 5-3)

NOT WOUND UP OF CORD REEL

POWER CORD BROKE AWAY REPAIR (SEE 5-3)

FROM THE BOBBIN

※ CAUTION : BE CAREFUL WHEN BREAKING UP THE CORD REEL, THE REEL

SPRING MAY SPRING OUT OF THE SPRING COVER.

POWER CORD DOES ABRASION OF THE ROLLER REPLACE THE ROLLER

NOT STOP AT AN BRAKE OF CORD REEL BRAKE (SEE 5-3)

ARBITRARY

POSITION LEVER SPRING BROKE AWAY REPAIR (SEE 5-3)

FROM THE CORD REEL BRACKET

7

Page 9

5. DISASSEMBLING AND TREATMENT

5-1. CLEANER ASSEMBLY

1) OPEN THE DUST COVER(1) AND HANDLE(2).

2) UNSCREW THE 5 SCREWS(4x20)(3).

3) SEPARATE THE COVER DUST ASSEMBLY FROM THE COVER BODY.

4) THEN LIFT THE COVER BODY UP FROM THE BODY ASSEMBLY.

8

Page 10

5-2. CORD REEL ASSEMBLY

1) TAKE THE CORD REEL OUT OF THE BODY.

9

Page 11

O

5-3. HOSE ASSEMBLY

1) UNSCREW THE 2 SCREWS(26) AND CHECK WHETHER THE KNOB(16) IS BROKEN OR N

2) CHECK THE SLIDE VOLUME(13).

3) UNSCREW THE SCREW(23) AND CHECK THE CONNCTIONS THE TERMINALS(20)

AND THE RING TERMINAL(21).

10

Page 12

5-4. BRUSH ASSEMBLY

1) TO SEPARATE THE COVER BRUSH(1) FROM THE BODY BRUSH(14),UNSCREW THE

4 SCREWS(15).

11

Page 13

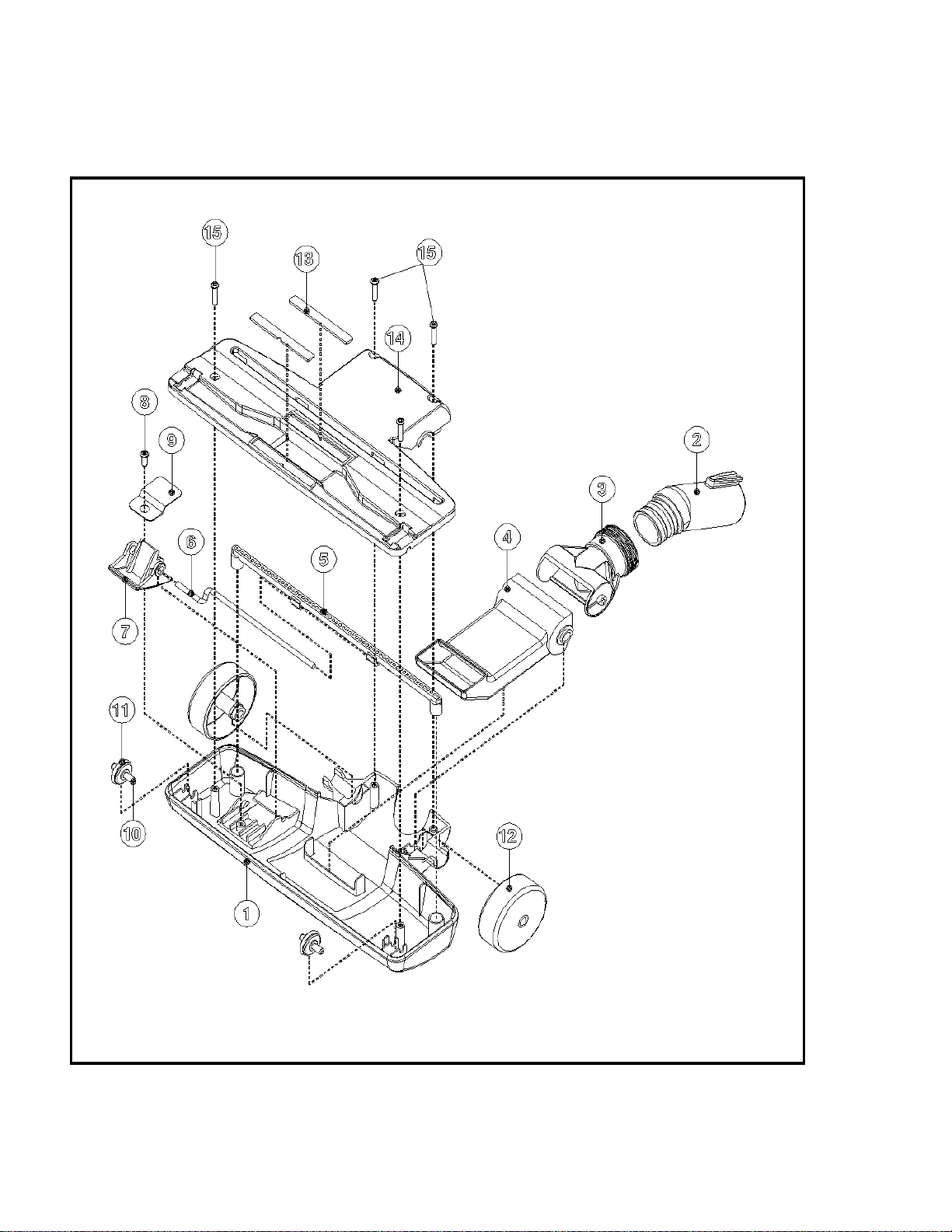

6. EXPLODED VIEW AND PARTS LIST

6-1. CLEANER ASSEMBLY

12

13

Page 14

N0. PART NAME PART CODE SPECS. Q'TY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY AS 3620409300 ASSY 1

2 MOTOR UNIVERSAL 3962511560 230V 1

3 PACKING MOTOR 3624006200 NR FORM 1

4 CORD REEL ASSY 3629507620 ASSY 1

5 COVER MIDDLE AS 3621427100 PP+FELT 1

6 PCB POWER CONTROL AS 3624311930 ASSY 1

7 SCREW TAPPTITE 7121401011 T2S PAN 4X10 1

8 COVER AS 3621427070 ASSY 1

9 SCREW TAPPTITE 7171402011 TT2 PAN 4X20 5

10 BAG FILTER 4561A57000 PAPER BAG 1

3621901630 CLOTH BAG 1

11 HOSE AS 3623207800 EVA,1.5M BUTTON(HANDLE) 1

12 PIPE AS 3624411910 STEEL, TELTSCOPIC 1

3624410200 PLASTIC, TELESCOPIC 1

13 BRUSH AS 3629308450 SWING BRUSH 1

3629306630 PEDAL BRUSH 1

14 BRUSH DUSTING 3629306000 PP+PA 1

15 NOZZLE CREVICE 3628100900 PP 1

13

Page 15

6-2. BODY ASSEMBLY(3620409300)

14

Page 16

N0. PART NAME PART CODE SPECS. Q'TY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BODY 3620409100 PP 1

2 BRACKET ROLLER ASSY 3620601900 ASSY 1

3 SCREW TAPPING 7128401212 T2S WAS 4X12, BK 1

4 ROLLER BACK 3624705300 ASSY(PP + SBS) 2

5 TERMINAL CASE AS 3628712450 TER+WIRE+REC 1

6 PROTECTOR 3628301200 PVC-S 1

7 PACKING SOCKET 3624007400 NR 1

8 SOCKET 3629801300 PP 1

9 SCREW TAPPTITE 7171401412 TT2 PAN 4X14, BK 2

10 HOLDER FILTER 3623002000 PP 1

11 SPRING 3625102700 HSW3 1

12 FILTER INLET 3621907000 POLYESTER 1

13 CASE FILTER 3621105000 PP 1

14 ABSORBER SOUND 3620110400 FELT T=3.0 1

15 SCREW TAPPING

7121401011 T2S PAN 4X10 1

15

Page 17

6-3. COVER ASSEMBLY(3621427070)

16

Page 18

N0. PART NAME PART CODE SPECS. Q'TY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 COVER DUST 3621424950 ABS+PAINTING 1

2 DUST METER AS 3629702400 ASSY 1

3 COVER DM 3621425050 ABS+MFCR 1

4 COVER BODY 3621424800 PP 1

5 FILTER EXHUAST 3621907110 POLYESTER 1

6 HANDLE 3622602850 ABS+PAINTING 1

7 BUTTON CR 3626605450 ABS+PAINTING 1

8 SPRING BUTTON 3625107000 HSW3 1

9 COVER TOP 3621425250 ABS+PAINTING 1

17

Page 19

6-4. CORD REEL ASSEMBLY(3629507620)

18

Page 20

N0. PART NAME PART CODE SPECS. Q'TY

C

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 BOBBIN 3629200600 PP 1

2 HOLDER TERMINAL 4565A36020 PC(V-0) 1

3 TERMINAL OA 4565A36024 C2600P-1/2H T0.3 1

4 TERMINAL OB 4565A36034 C2600P-1/2H T0.3 1

5 CORD POWER 3621302500 HO5VVF 1

6 SCREW TAPPING 7128401011 T2S WAS 4X10 MFZN 1

7 SHAFT REEL 3624900510 PC 1

8 SPRING AS 3625102005

SUS301 COVER,3800mm

9 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 2

10 BRACKET CR 36206024 00 PP(5212MF4) 1

11 HARNESS 3622712500 Y TER+WIRE(BK)+187RE

12 HARNESS 3622712600 Y TER+WIRE(WH)+TER 1

13 SCREW TAPPING 7121400811 T2S PAN 4X8 MFZN 2

14 HARNESS 3622712700 WIRE(WH)+187REC+HOUSE

15 THERMOSTAT 3629001400 KI T85 1

16 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 1

17 LEVER CR 3623702600 ABS( LG XR-409H ) 1

18 SPRING LEVER 3625104300 HSW3 1

19 SCREW TAPPING 7128401011 T2S WAS 4X10 MFZN 1

20 STOPPER CR 4569C35082 NBR 1

21 FRAME STOPPER 4565A35070 POM 1

22 SCREW TAPPING 7121401011 T2S PAN 4X10 MFZN 1

1

1

1

19

Page 21

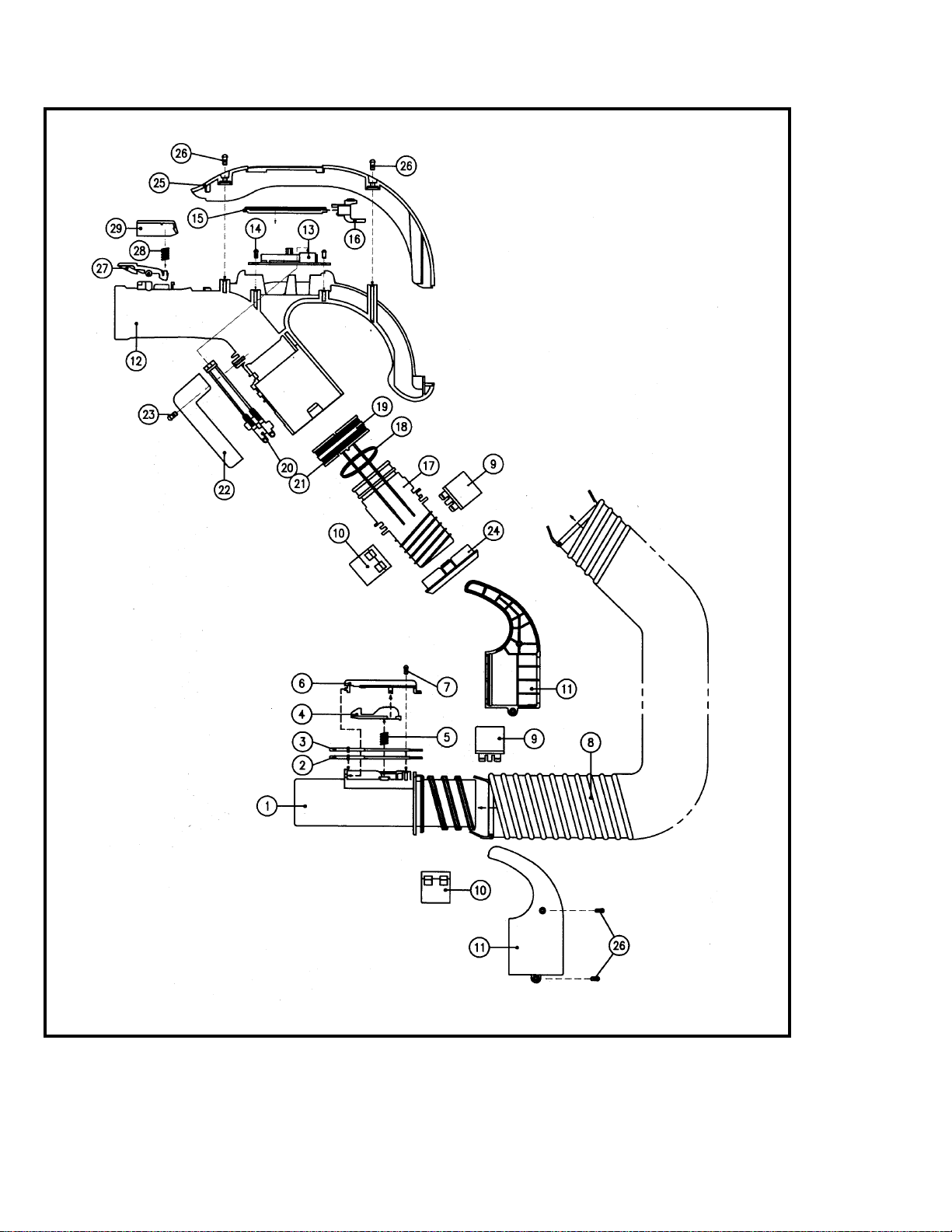

6-5. HOSE ASSEMBLY(3623207800)

20

Page 22

N0. PART NAME PART CODE SPECS. Q'TY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 ADAPTER 3629101900 ABS 1

2 TERMINAL AS 3628710200 TERMINAL+WIRE(YL) 1

3 TERMINAL AS 3628710400 TERMINAL+WIRE(BR) 1

4 CLAMP ADAPTER 3621200900 ABS 1

5 SPRING 3625102900 HSW3 1

6 COVER ADAPTER 3621405900 ABS 1

7 SCREW TAPPING 7121301012 T2S PAN 3X10,BK 1

8 HOSE 3623206700 EVA 1.5M 1

9 CLAMP HOSE A 3623004500 ABS 1

10 CLAMP HOSE B 3623004600 EVA 1.5M 1

HANDLE ADAPTER L 3622302000 ABS 1

11

HANDLE ADAPTER R 3622602100 ABS 1

12 PIPE HOSE 3624410100 ABS 1

13 PCB SLIDE VOLUME AS 3624303900 ASS'Y(200K) 1

14 SCREW TAPPING 7121300811 T2S PAN 3X8 2

15 PLATE 3624501600 ABS 1

16 KNOB 3623401400 PC 1

17 ADAPTER PIPE 3629101800 ABS 1

18 PACKING PIPE 3624002400 NBR 1

19 FRAME TERMINAL 3622200600 ABS 1

20 TERMINAL AS 3628704620 TER+WIRE+RECEP 1

21 TERMINAL 3628704500 C2801S-H 2

22 COVER TERMINAL 3621419300 ABS 1

23 SCREW TAPPING 7121301012 T2S PAN 3X10,BK 1

24 HOLDER HOSE 3623004700 PP 1

25 COVER PIPE 3621419600 ABS 1

26 SCREW TAPPING 7121301212 T2S PAN 3X12,BK 4

27 BUTTON 3626603800 PC 1

28 SPRING PIPE 3625106700 HSW3 1

29 COVER BUTTON 3621418500 PC 1

21

Page 23

6-6. BRUSH ASSEMBLY

SWING BRUSH (3629308450)

22

Page 24

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

NO. PART NAME PART CODE Q’ TY SPECS.

1 PIPE BRUSH 3624411500 1 PP

2 NECK BRUSH 3628002300 1 PP

3 FRAME NECK 3622201900 1 ABS

4 ROLLE-F BRUSH 3624703100 3 PP

5 SHAFT ROLLER 3624900900 4 PA

6 ABSORBER SOUND 3620110100 2 PU FOAM T = 14

7 SPRING RUBBER 3625107700 2 SILICON RUBBER

8 COVER NECK 3621421450 1 ABS+MFCR

9 SCREW TAPPING 7121401412 8 T2S PAN 4X14BK

10 BODY BRUSH 3620408200 1 PP

11 SCREW TAPPING 7128400811 2 T2S WAS 4X8

12 SCREW TAPPING 7128401011 1 T2S WAS 4X10 BK

13 COVER BRUSH 3621421500 1 ABS

14 COVER WING L 3621421600 1 PP

15 COVER WING R 3621421700 1 PP

16 PICKER LITTER 3627000700 2 PA

17 BRUSH FRONT 3629306800 2 ABS+PA

18 BRUSH 3629306500 2 ABS+PA

23

Page 25

PEDAL BRUSH (3629306630)

24

Page 26

N0. PART NAME PART CODE SPECS. Q'TY

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 COVER BRUSH 3621420800 PP 1

2 PIPE BRUSH 3624412800 PP 1

3 NECK BRUSH 3628002100 PP 1

4 DUCT BRUSH 3629306300 PP 1

5 SWEEPER BRUSH 3629306400 ABS 1

6 SHAFT SWEEPER 3624901400 HSW3 1

7 BUTTON BRUSH 3626604400 ABS 1

8 SCREW TAPPING 7128408011 T2S 4x8 1

9 SPRING BUTTON 3625107300 SK-5, T=0.3 1

10 SHAFT ROLLER 3624900900 PA 2

11 ROLLER F BRUSH 3624704300 PP 2

12 ROLLER BACK 3624704400 PP 2

13 PICKER LITTER 3627000700

PA

2

14 BODY BRUSH 3620407800 PP 1

15 SCREW TAPPING 7121401411 T2S 4x14 4

25

Page 27

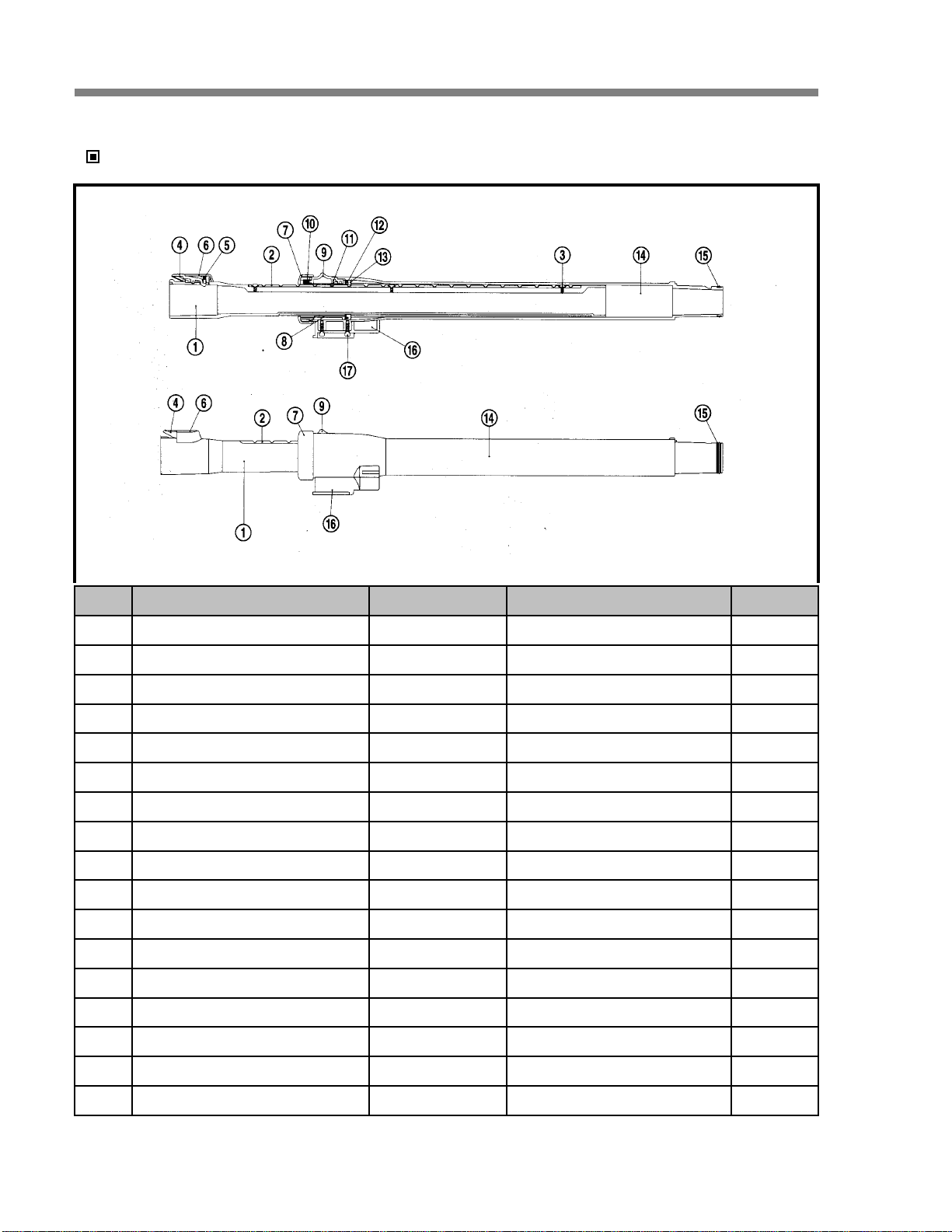

6-7. PIPE ASSEMBLY

STEEL TELESCOPIC

26

Page 28

NO. PART NAME PART CODE Q’ TY SPECS.

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

1 PIPE STEEL IN 3624411220 1 SPC T = 0.7

2 PIPE STEEL OUT 3624411320 1 SPC T = 0.7

3 GUIDE PIPE 3622503800 1 ABS

4 COVER UP 3621422500 1 ABS

5 COVER DOWN 3621422600 1 ABS

6 SHAFT PIPE 3624900810 1 STS 304-B

7 SPRING PIPE 3625105200 2 HSWR

8 PACKING PIPE 3624003910 1 PE

9 COVER SIDE-A 3621422700 1 ABS

10 COVER SIDE-B 3621422800 1 ABS

11 CUFF 3626800700 1 PP

12 COVER BUTTON 3621418100 1 PC

13 BUTTON 3626603800 1 PP

14 SPRING 3625100500 1 HSW3

15 HOLDER 3623004800 1 ABS

16 SCREW TAPPING 7121401411 1 T2S PAN 4X14

27

Page 29

PLASTIC TELESCOPIC (3624410200)

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

N0. PART NAME PART CODE SPECS. Q'TY

1 PIPE IN 3624409100 ABS 1

2 PLATE PIPE 3624501500 SPC 1

3 SCREW TAPPING 7171300612 M3X6 PAN MFZN BK+B 3

4 BUTTON 3626603800 PC 1

5 SPRING PIPE 3625106700 HSW3 1

6 COVER BUTTON 3621418500 PC 1

7 CAP PIPE 3620903700 PC 1

8 GUIDE PIPE 3622502500 POM 1

9 KNOB 3623401200 PC 1

10 SPRING BUTTON 3625107100 HSW3 1

11 SHAFT 3624901200 STS 1

12 PACKING PIPE 3624005500 NBR 1

13 STOPPER 3625000500 POM 1

14 PIPE OUT 3624410000 ABS 1

15 PACKING PIPE 3624002600 NBR 1

16 HOLDER PIPE 3623004900 ABS 1

17 SCREW TAPPING 7121401412 T2S PAN 4X14 MFZN BK 2

28

Page 30

DAEWOO ELECTRONICS CO., LTD

686, AHYEON-DONG MAPO-GU

SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX : DWELEC K28177-8

CABLE : “ DAEWOOELEC”

Loading...

Loading...