Trouble Shooting Guide

Washing Mchine

Model :DWM-7510,S

◆

◆

◆

◆

◆

◆

◆

SPIN MOTOR

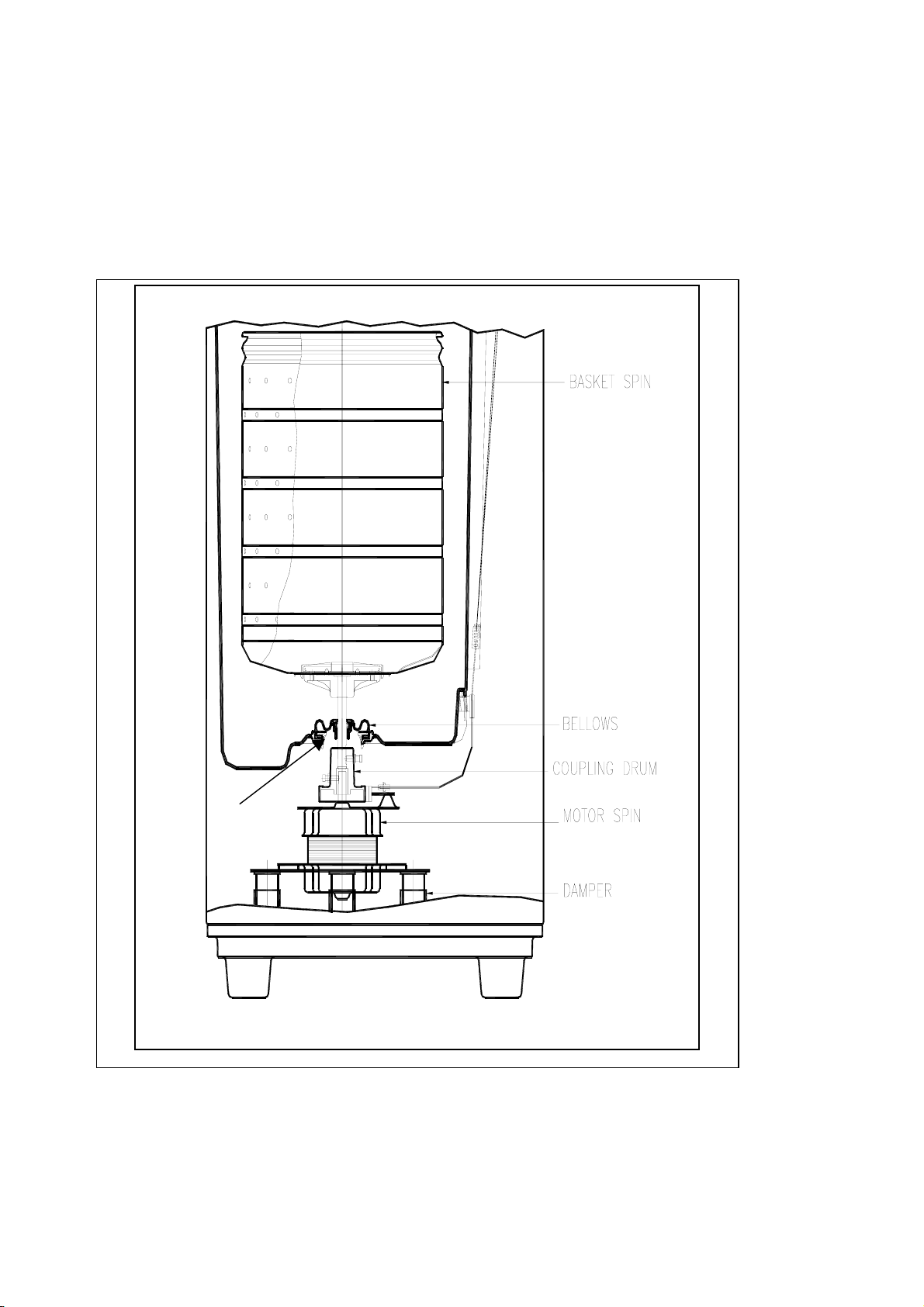

BASKET SPIN

BELLOWS

WATER LEAKAGE

COUPLING DRUM

WASH TIMER

HOW TO REPLACE

THE EACH COMPONENT

1. STRUCTURE OF SPIN PART

IN ORDER TO HELP YOUR UNDERSTANDING OF 2-TUB WASHING MACHINE.

WE PREPARE SIMPLE STRUCTURE. IF YOU WANT TO KNOW MORE IMFORMATION,

PLEASE REFER TO SERVICE MAUNAL.

FIXTURE

BELLOWS

2. TROUBLE SHOOTING FOR EACH PROBLEM

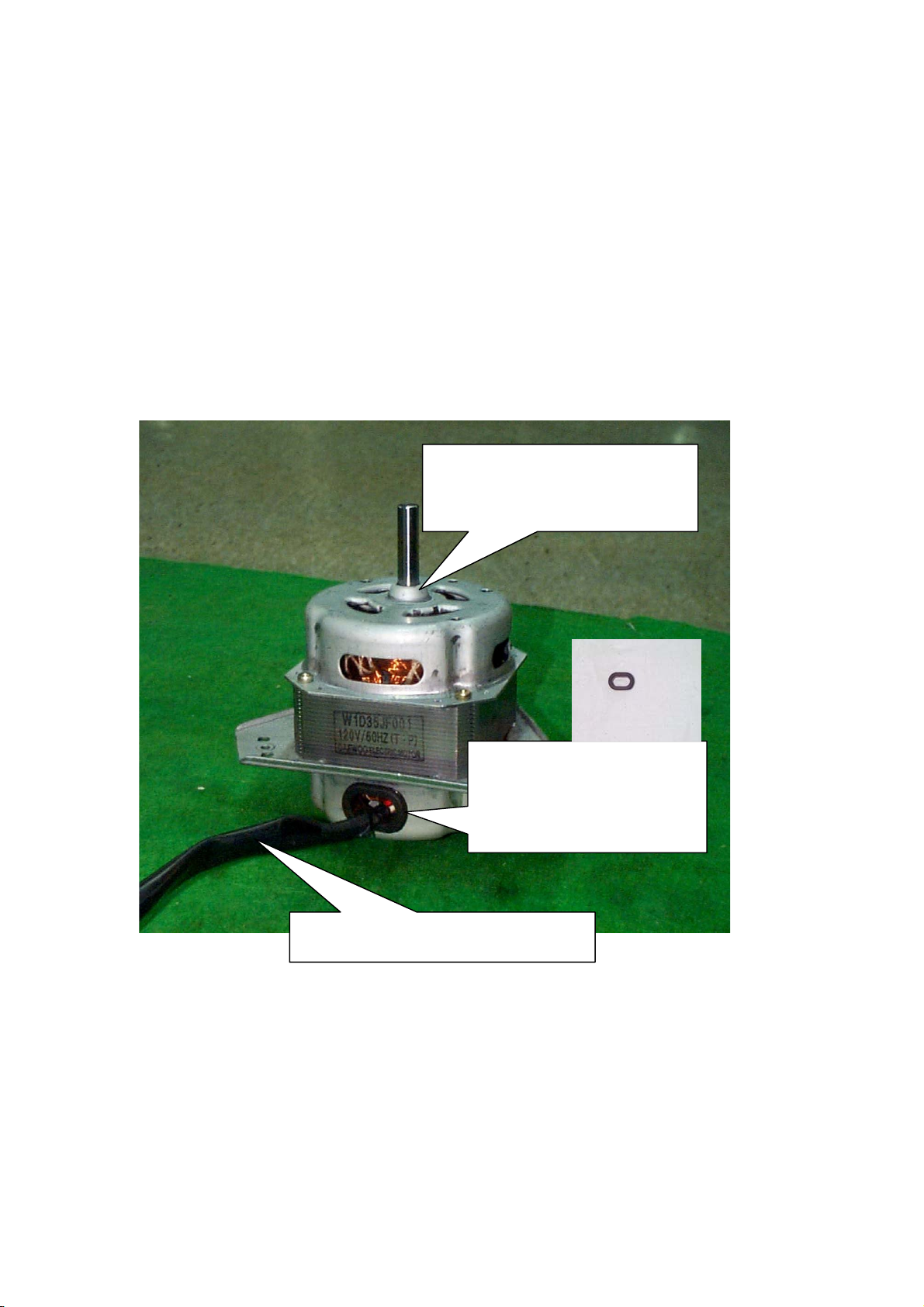

2-1. SPIN MOTOR

1) PROBLEM AND CAUSE

① STICKING MOTOR SHAFT AND OILLESS METAL BEARINGS WHICH ARE IN

THE MOTOR INSIDE.

② COIL DAMAGE DUE TO THE WATER LEAKAGE, BECAUSE OF BELLOWS BROKEN.

③ LEAD WIRE SHORT, BECAUSE OF SHARP EDGE OF MOTOR CASE

2) IMPROVEMENT POINT

RELATED NUMBER ① AND ③

- Change the Oilless metal

bearing from Fe to

Cu.

These are inside of Motor

- ADAPT NEW PART MADE

BY RUBBER IN ORDER TO

PROTECT THE WIRE FROM

SHARP EDGE

ADAPTING DATE : 98.09

- ADAPT TUBE AND CHANGE THE

WIRE FROM NORMAL GRADE TO UL

FOR ②

CHANGE THE STRUCTURE OF BELLOWS

- HEIGHT FROM 23mm TO 31mm

- CHANGE DATE : 98.08 LOT

- REMAKE THE FIXTURE BELLOWS

BELLOWS

FIXTURE

AFTER

BELLOWS

BEFORE

3) REMARKS

IF THIS KIND OF PROBLEM HAPPENED, YOU'D BETTER REPLACE

IMPROVED SPIN MOTOR AND BELLOWS TOGETHER.

IN ORDER TO PREVENT THIS KIND OF PROBLEM OCCURING AGAIN.

4) CODE NUMBER FOR NEW PARTS

REFER TO SERVICE MANUAL.

2-2. BASKET SPIN

1) PROBLEM

① DEFORMATION AND FRICTION NOISE

② DISMATCHING OF CENTER LINE(LEAN OF BASKET SPIN)

2) CAUSE

① LACK OF BELLOWS FUNCTION

② MAL-MANUFACTURING OF COUPLING DRUM

③ INSUFFICIENT OF BASKET SPIN STRENGTH

3) IMPROVEMENT POINT

FOR ①

BE SAME OF ② WITH SPIN MOTOR AND CHANGE THE MATERIAL OF DAMPER

FOR ②, ③

DAMPE

- CHANGE THE DAMPER MATERIAL

FROM CR TO NBR

- CHANGING DATE : 98.07 LOT

- CHANGE THE BASKET SPIN ROUND

FROM R2.5 TO R3.0

- CHANGING DATE : 98.08 LOT

- REMAKE THE COUPLING DRUM

- ADAPTED DATE : 98.08 LOT

4) REMARKS

IF THIS KIND OF PROBLEM HAPPENED, YOU'D BETTER REPLACE

IMPROVED SPIN BASKET, BELLOWS, DAMPER,

COUPLING DRUM ALLTOGETHER. IN ORDER TO PREVENT

THIS KIND OF PROBLEMOCCURING AGAIN.

2-3. BELLOWS

1) PROBLEM AND CAUSE

BROKEN BECAUSE OF FRICTION BETWEEN BELLOWS AND FIXTURE BELLOWS

2) IMPROVEMENT POINT

ALREADY MENTIONED ABOVE, PLEASE REFER TO SPIN MOTOR AND BASKET SPIN

2-4. WATER LEAKAGE

1) CAUSE

DUE TO BELLOWS BROKEN

2) IMPROVED POINT

ALREADY MENTIONED ABOVE, PLEASE REFER TO SPIN MOTOR AND BASKET SPIN

2-5. COUPLING DRUM

1) PROBLEM AND CAUSE

IT'S NOT ALIGN WITH MOTOR SHAFT AND BASKET SPIN, BECAUSE OF WORN OUT

DIE CASTING TOOL

2) IMPROVED POINT

REMAKE THE DIE CASTING TOOL AND CONTROL THE MANUFACTURING ALLOWANCE

2-6. WASH TIMER

1) PROBLEM AND CAUSE

IT'S NOT WORKING BECAUSE OF FRICTION OF PANEL AND KNOB,

AND MAL-FUNCTION OF WASH TIMER

2) IMPROVED POINT

PANEL

FRICTION OF PANEL AND KNOB

UPWARD

KNOB

MOVE THE PIN 1.5mm UPWARD

* REFERENCE*

WE HAD ALREADY FINISHED ENDURANCE TEST REGARDING TO ABOVE PROBLEM

DEPEND ON DAEWOO INTRA-STANDARD. THEREFORE WE HAVE CONFIDENCE FOR

RELIABILITY ABOUT THESE KINDS OF PROBLEM

3. HOW TO REPLACE THE EACH COMPONENT

X

P

S

3-1. BELLOWS ASS'Y AND BASKET SPIN

DISASSEMBLE

THE SCREW 5

DISASSEMBLE

THE SCREW 4

1) DISASSEMBLE THE SCREW AND THEN 2) THE STATE AFTER DOING 1)

GET RID OF PLATE T

3) DISASSEMBLE THE BOLT HEX USED FI

THE COUPLING DRUM FOLLOWING UPWARD

5) DISASSEMBLING STATE OF BASKET S

AND THEN DISASSEMBLE THE BELLOW

BY PURSING THE SNAP FIT OF FIXTURE

BELLOWS.

* ASSEMBLING IS REVERSING OF THE DISASSEMBLING

4) DISASSEMBLE THE BASKET SPIN

6) ASSEMBLE THE NEW BELLOWS ASS'Y

WITH BOND

3-2. SPIN MOTOR, COUPLING DRUM, DAMPER

DISASSEMBLE

THE SCREW 5

DISASSEMBLE

THE SCREW 4

1) DISASSEMBLE THE SCREW AND THEN 2) THE STATE AFTER DOING 1)

GET RID OF PLATE T

LINK

WIRE

3) DISCONNECTING THE HARNESS 4) DISASSEMBLE THE BOLT HEX USED FIX

AND THEN DISASSEMBLE LINK WIRE THE COUPLING DRUM AND V-BELT

COUPLIN

G

DRUM FIX

SPIN MOTOR

FIX BOLT

3 EACH

5) AND THEN, AFTER STATE WITHOUT 6) AFTER DISASSEMBLING TUB

BASKET SPIN NEXT DISASSEMBLE THE COUPLING

DRUM FROM MOTOR

AND THEN DISASSEMBLE SPIN MOTOR

T

SCREW OF FIXING

BRACKET SPIN

MOTOR 4 EACH

DAMPER ASS'Y

4 EACH

7) AFTER DISASSEMBLING SPIN MOTOR 8) NEXT STATE AFTER DISASSEMBLING

AND THEN DISASSEMBLIE THE BRACKE

SPIN MOTOR AND THEN DISASSEMBLE DAMPER

BRACKET SPIN MOTOR

ASS'Y

* ASSEMBLING IS REVERSING OF

THE DISASSEMBLING

9) THE STATE OF ALL COMPONENT DISASSEMBLED

Loading...

Loading...