Daewoo DWM-7510 User Manual

Service Manual

Washing Machine

Model: DWM-7510

DAEWOO ELECTRONICS CO., LTD.

TABLE OF CONTENTS

1. SPECIFICATIONS.................. ........ ........ ........ ....... ................................ ........ ........ ....... ......................... 1

2. EXTERNAL VIEW .......................................... ....... ........ ................................ ........ ....... ......................... 2

3. PRINCIPLES OF OPERATION AND EXPLANATION OF FUNCTIONS ............................................. 3

4. DIRECTION FOR DISASSEMBLY AND ASSEMBLY ......................................................................... 7

5. TROUBLESHOOTING GUIDE ............................................................................................................. 10

6. EXPLODED VIEW AND PARTS LIST ................................................................................................. . 15

7. WIRING DIAGRAM................................. ........ ....... ........ ................................ ........ ....... ....... .................. 23

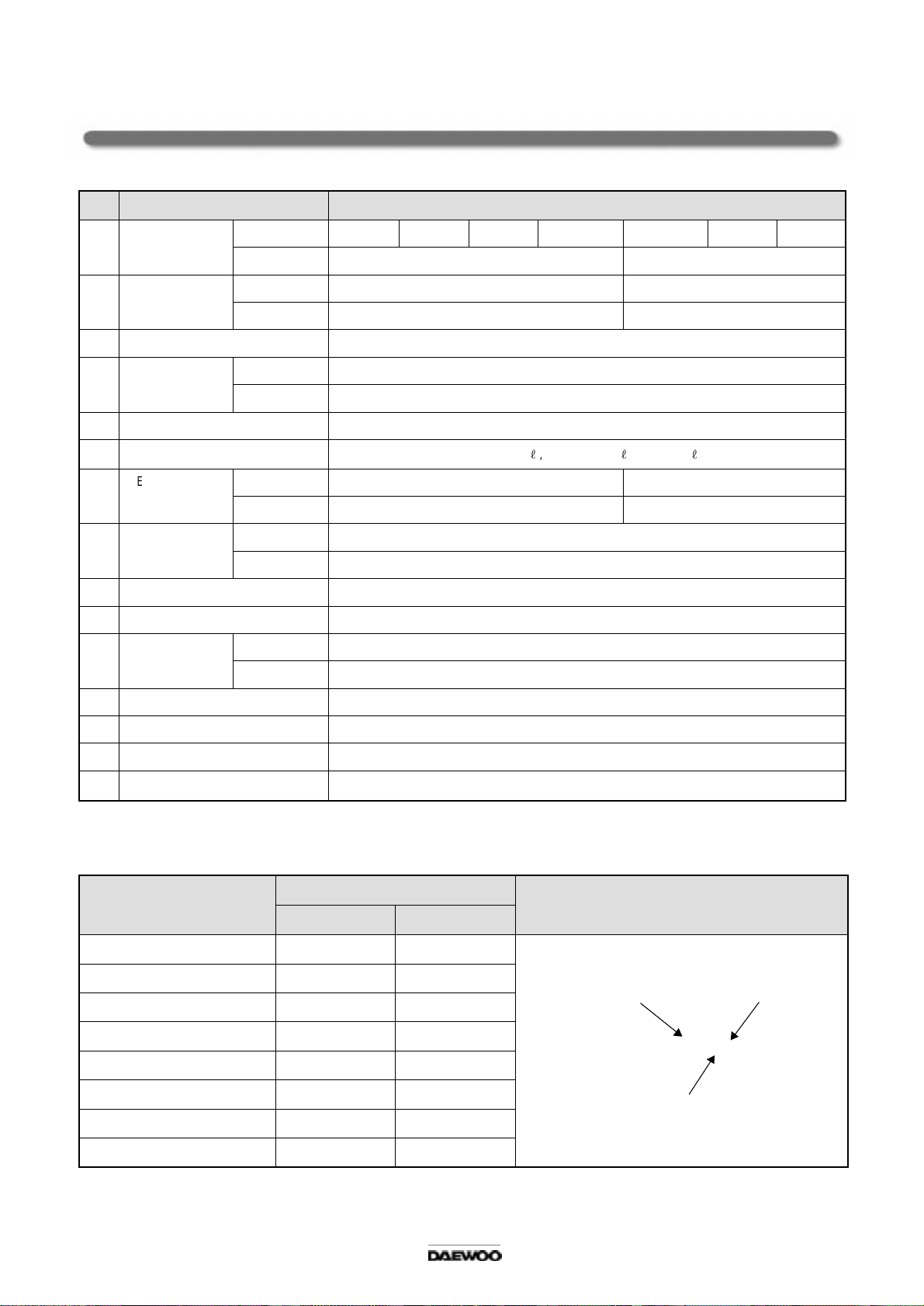

1. SPECIFICATIONS

NO ITEM SPECIFICATIONS

1POWER

SOURCE

2POWER

CONSUMPTION

3 DIMENSION NET : 874 X 532 X 989, PACKED UP : 898 X 558 X 1015 (WXDXH)

4 MACHINE

WEIGHT

5 WASHING COURSE STRONG, NORMAL

6WATER LEVEL

7 REVOLUTION

PER MINUTE

8 TIMER WASH MAX. 15 min., Manual operation

9 WASHER TYPE PULSATOR TYPE

10 SPIN TYPE CENTRIFUGALLY SEPARATED TYPE

11 MAXIMUM MASS

OF TEXTILE

VOLTAGE

FREQUENC Y 60Hz 50Hz

PUMP

NON PUMP

PU MP NE T : 4 0 kg , PAC KED UP : 44 k g

NON PUMP NET : 38kg, PACKED UP : 42kg

WASH 100 rpm 100 rpm

SPIN 1700 rpm 1400 rpm

SPIN MAX. 5 min., Manual operation

WASH 7.5kg

SPIN 7.0kg

AC 110V AC 1 20V AC 220V AC 127/220V AC 110/220V AC 220V AC 240V

640W 610W

580W 550W

HIG H : 72

, MEDIUM : 61, LOW : 52

12 WATER SUPPLY MANUAL

13 SPIN RINSE O

14 OUTLET OF DRAIN HOSE REAR

15

LINT FILTER

O

NO TE : Explanation table for suffix of names.

SUFFIX

POWER SOURCE

AC 100V 50/60Hz J -

AC 110V 60Hz T TP

AC 120V 60H z A AP

AC 220V 50H z N NP

AC 220V 60H z L LP

AC 240V 50H z M MP

AC 110/220V 50Hz D DP

NON PUMP PUMP

Model Name Pump

EXPLANATION

DWM - XXXX N P

Power Source

AC 127/220V 60Hz S -

2

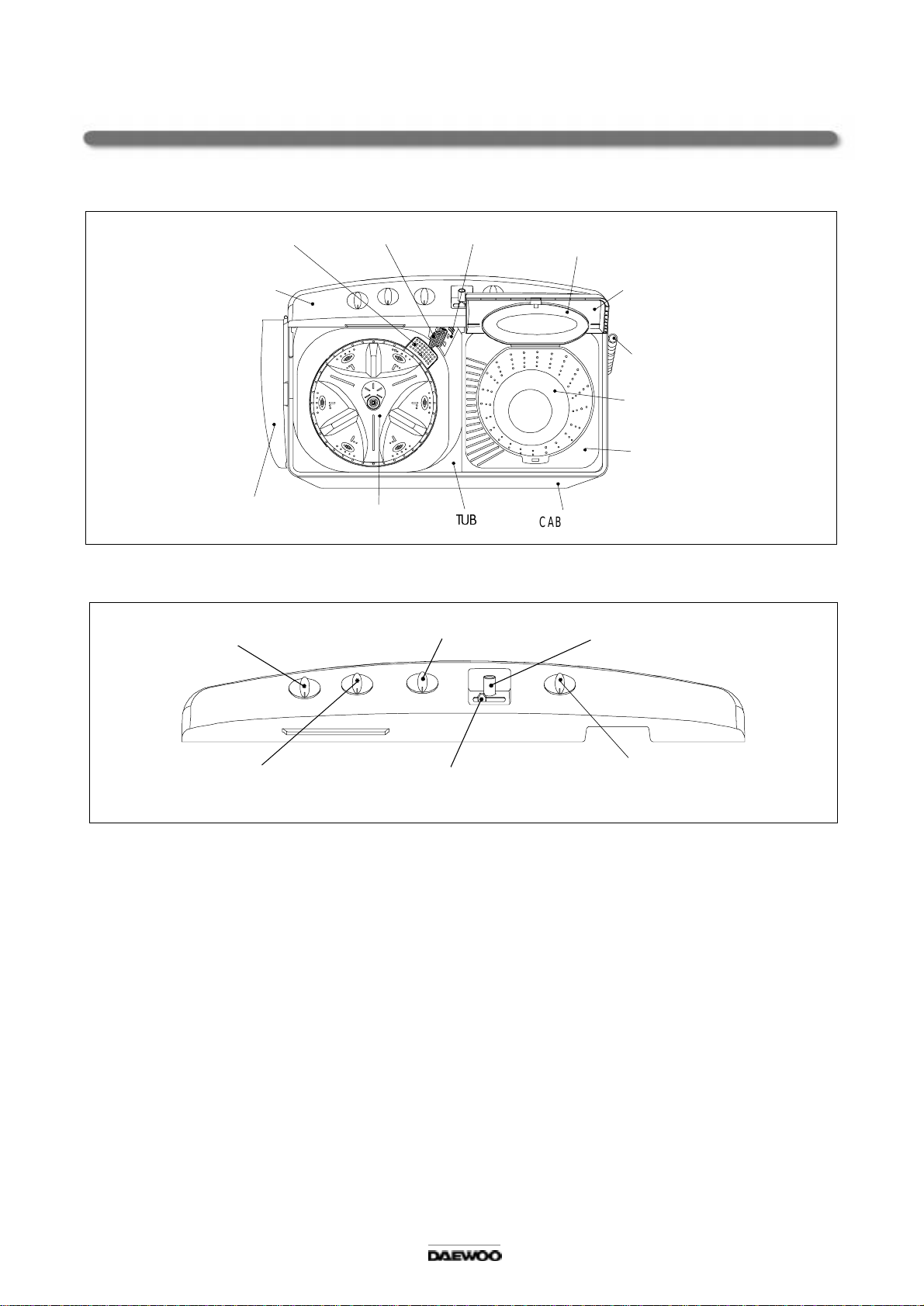

2. EXTERNAL VI EW

2-1. STRUCTURE OF THE WASH MACHINE

DRAIN STRAINER

PANEL B

DOOR W ASH

FILTER AS

PULSATOR

GUIDE FILTER

2-2. CONTROL PANEL(PANEL B ASS'Y)

WASH TIMER

VALVE SELECTO R

COVER SAFETY

DOOR SPIN

DRAIN HOSE

BASKET SPIN

PLATE T

CABINET

IN L E T W AT E R

SPIN T IMER

WASH TIMER

WASH ACTION

LEVER W ATER

SUPPLY SELECTOR

Use to select the desired time for washing or rinsing.

WASH ACTION

Use to select wash action. (“STR ON G ”, “NO RM AL”)

VALVE SELECTOR

Select “WASH.RINSE” for washing and rinsing, and “DRAIN” to drain the water.

(In case PU MP M O DE L turn on the drain pump.)

“OFF” to turn off the drain pump. (Only PUM P MO DEL)

LEVER WATER SUPPLY SELECTOR

Left : water supply in the WASH TU B

Right: : water supply in the BASKET SP IN.

INLET WATER

Connect inlet hose to supply water in the WA SH TU B or BAS KE T S PIN.

SPIN TIMER

Use to select the desired time for spinning.

3

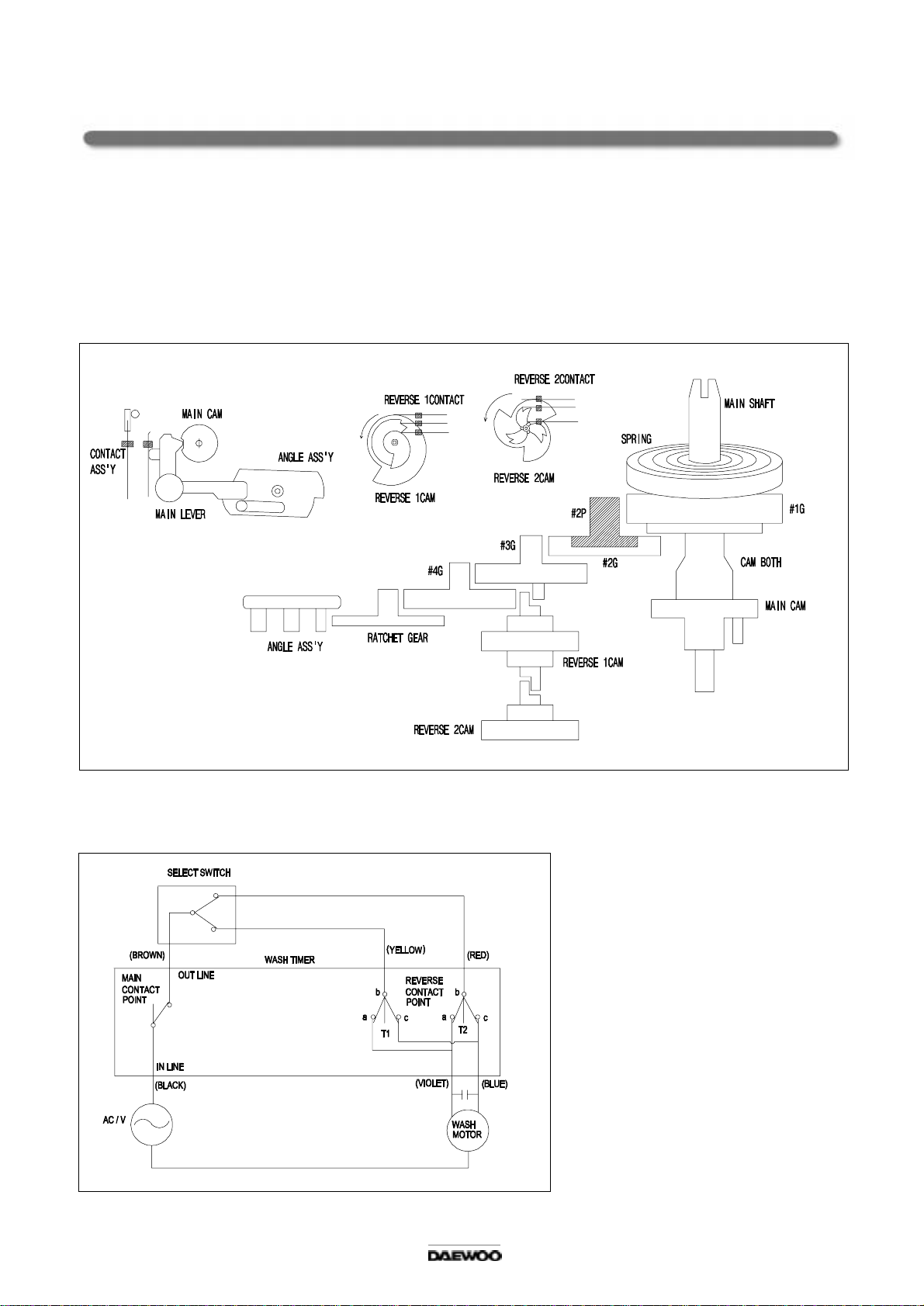

3. PRINCIPLES OF OPERATION AND EXPLANATION OF FUNCTIONS

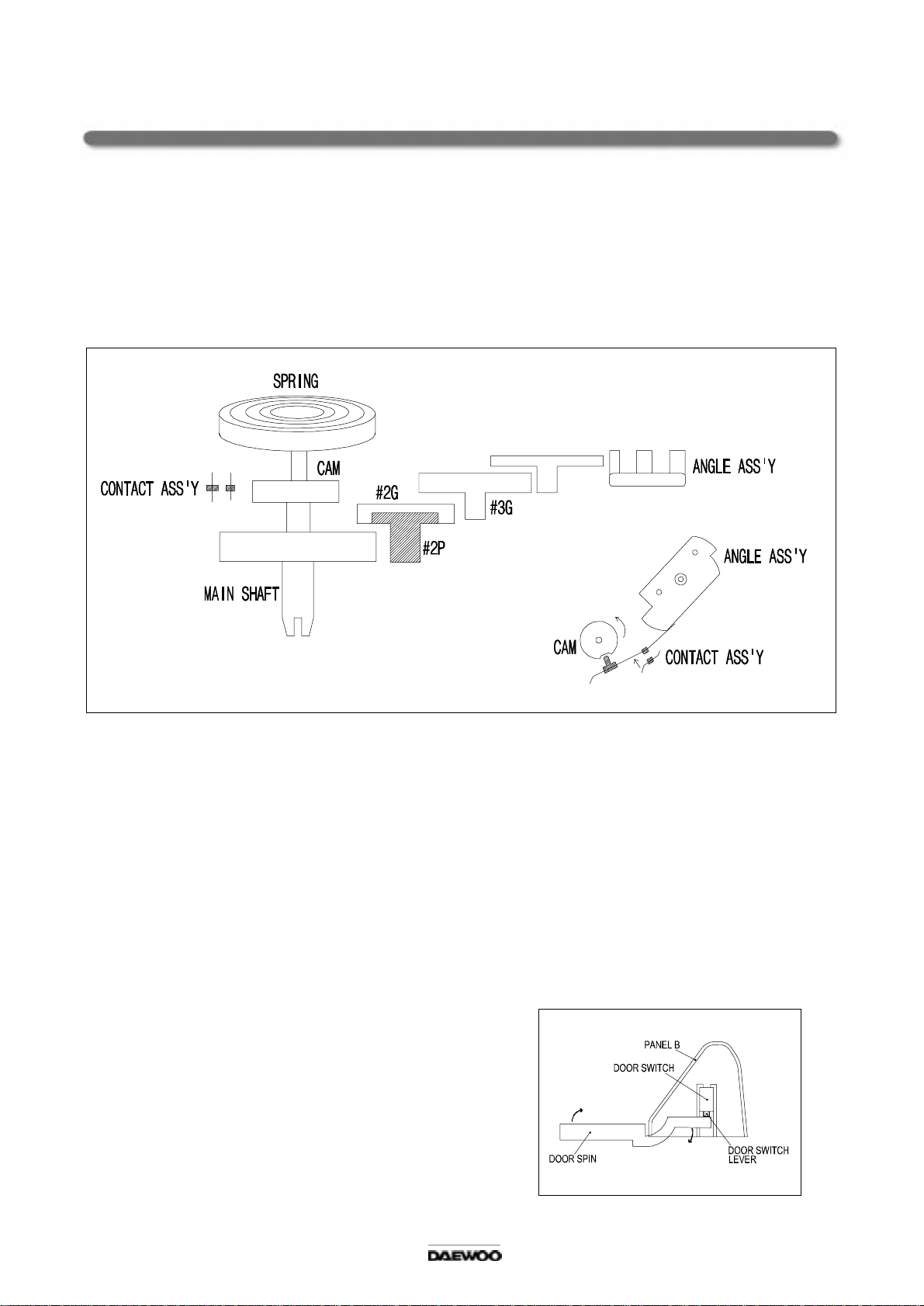

WASH TIMER

FUNCTION

The m ain switch remains ON during the washing time set by turning the timer knob.

At the same time, the internal switch T1 and T2 which provide power to WASH MOTOR alternately at assigned Intervals.

Select switch knob sets the wash type by means of controlling the interval of internal switch contact.

STRUCTURE AND PRINCIPLE OF ACTIVATION

CIRCUIT DIAGRAM

4

SPIN TIMER

FUNCTION

The spin timer is the switch providing power to the SPIN MOTOR (DRAIN PUM P M O TO R) during the set spin

dry time, and is a spring-type time switch comes on upon turning and those contact points comes off after the

set time.

STRUCTURE AND PRINCIPLE OF ACTIVATION

1) The main shaft turns due to the unwinding force when the spin timer is turned, the spring wound with that

force being delivered through each gear and the spring slowly unwinding at a speed finally

controlled by the angle assembly.

2) The contact point turns ON and the assembly angle is set in motion, which is in the CAM groove in the

OF F state, comes off the groove when the main shaft is turned to wind the spring. The contact point

turns OFF, return to CAM groove when the spring unwind com pletely.

SAFETY D E VICE F O R B AS K ET SP IN

The BASKET SPIN is an apparatus which eliminates the water from the laundry through centrifugal separation

generated by rapid revolution(approximately 1,600rpm for 60Hz). Accordingly, there are a DO O R SWITCH

to cut off the power going into the DO O R SP IN is opened and a brake system to stop the rotating BASK ET S PIN.

DOO R S WIT C H

W hen the DO OR S PIN is opened during spinning,

the D O O R SWITCH LEV ER w hich sites atop the DOOR

SPIN falls off the contact, and cuts off the power going

into the S P IN MO TOR .

5

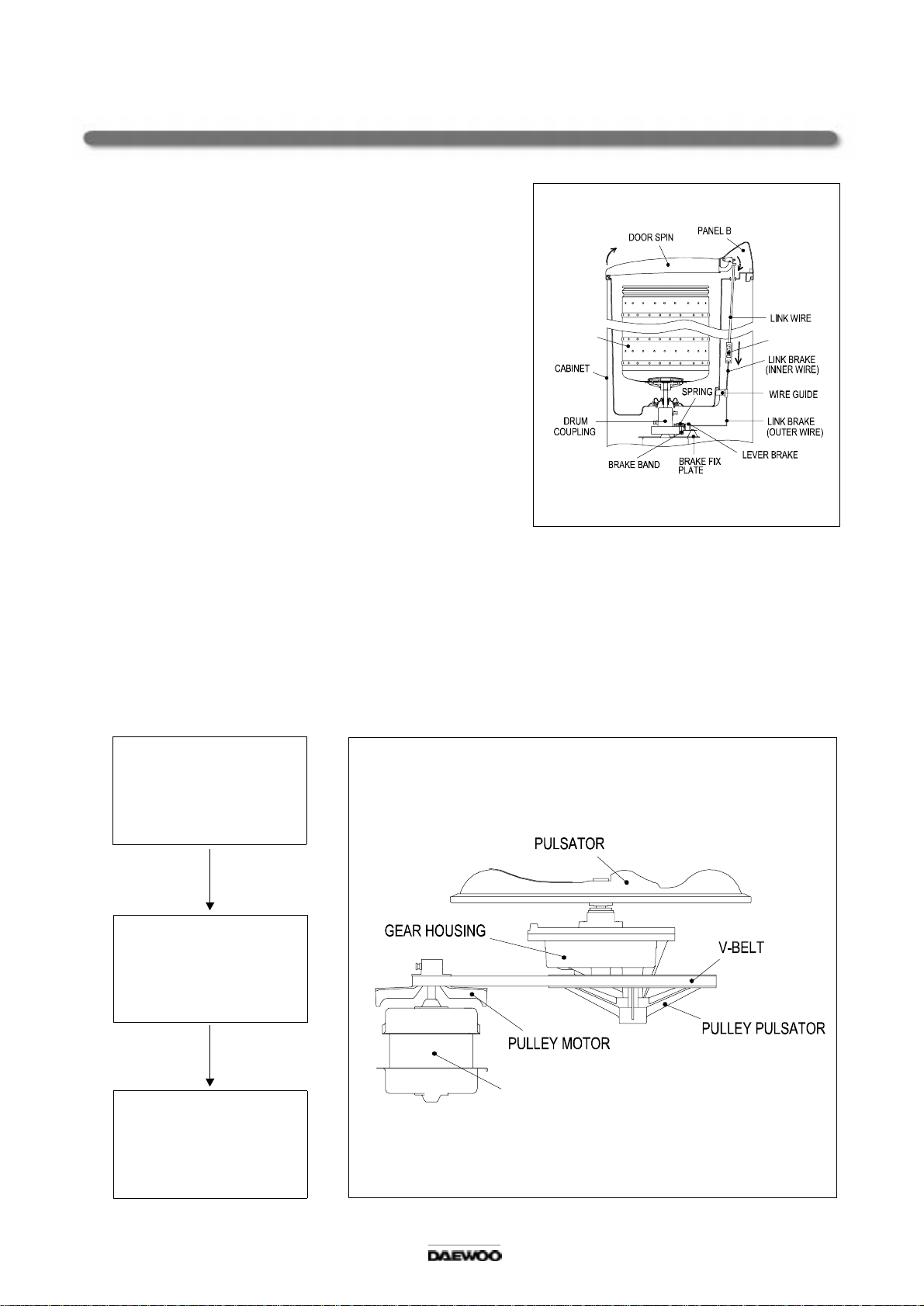

BRAKE SYSTEM

W hen the DO OR S PIN is opened, LINK W IRE

which connect to DOOR SPIN loosens. And then

the BRAKE BAND touches the DRUM COUPLING

assembly and stops the SPIN DRY ER as it is pulled

by the SPR ING in the BRAKE FIX PLATE assembly.

PLATE

CONTROL WIRE

BRAKE BAND GAP CONTROL METHOD

BASKET SPIN

The BAND BRA KE works best when the gap between

it and the DRUM COUPLING is about 2mm w hen the

DO OR SPIN is closed. The SPIN DR YER stops slow ly if

the gap between the two is too narrow, the SPIN DRY ER

revolution is affected and the PLATE C O N TR O L W IRE m ay

be adjusted to maintain the BR A KE B AN D gap adequately.

WA SH DE CELE RAT OR A SSEM BL Y

The initial deceleration following the activation of the W AS H M O TO R takes place through the PULLEY

MO TOR and PULLEY PULS ATOR , and the secondary deceleration is done by the gear in the GEAR

HO U SING which also increases their revolution strength. This revolution speed and strength is delivered to

the PU LS ATOR, which is then able to cause water current that is strong yet soft so that wash loads are not

damaged.

MOTOR WASH

About 1,700rpm(60Hz)

1,400rpm (50Hz)

PULLE Y PULS ATOR

About 330rpm (60Hz)

330rpm (50Hz)

PULSATOR

About 100rpm (60Hz)

100rpm (50Hz)

WASH MOTOR

6

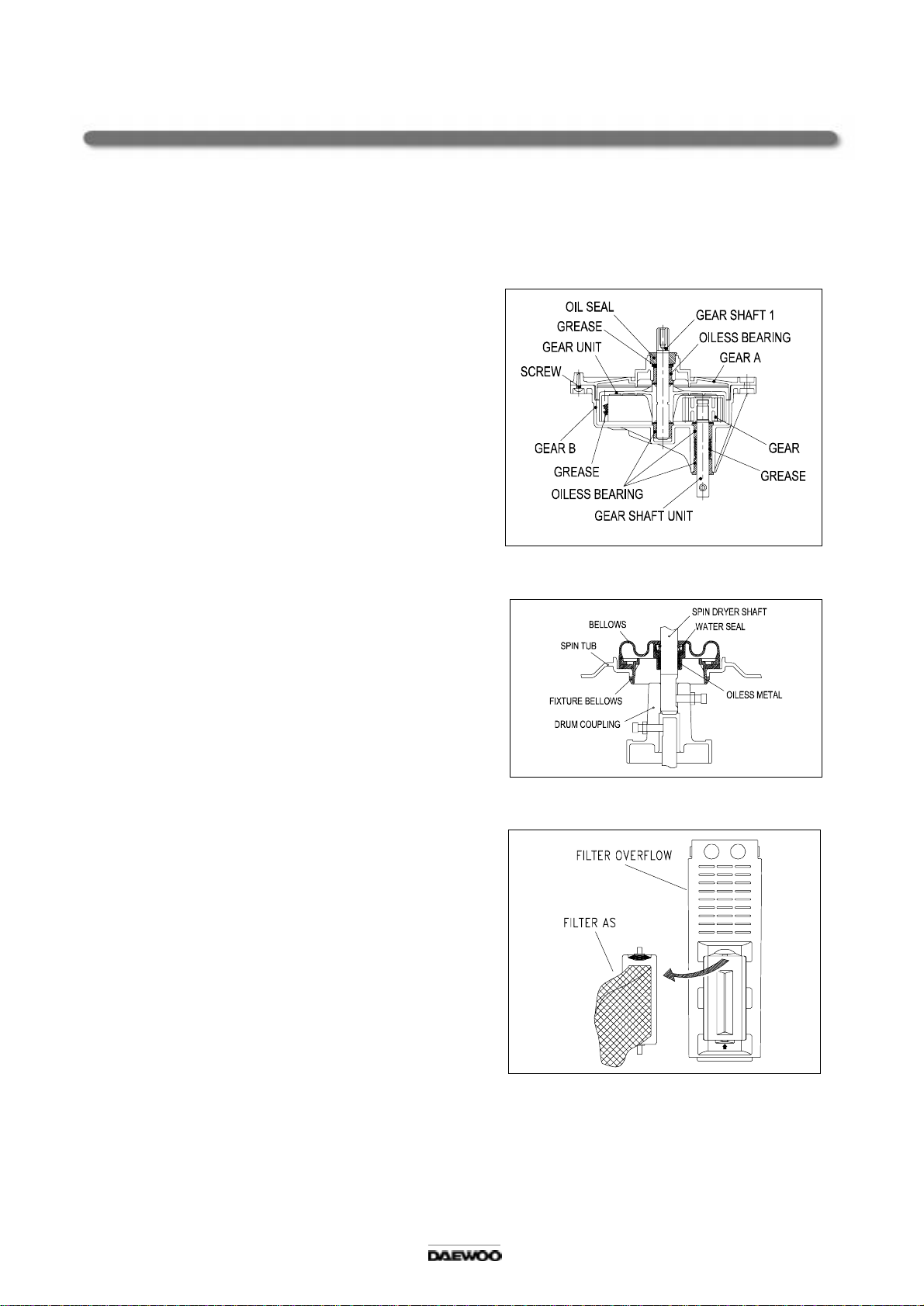

GEA R HO USING AS S'Y

The GEA R HO U SING ASSE M BLY is a transmission device which turns the P ULS ATOR at 3.3 : 1 lowered

speed through the gear unit assembly which receives power at the GEAR S HA FT UNIT.

STRUCTURE

1) The two sides of the GEAR S HA FT UNIT

are supported by the O ILLESS BE AR ING

in the GEAR HOUSING ASSEMBLY.

2) The GE AR U NIT ASSEM BLY is connected

to the GE AR S HA FT 1 and GEA R S HA FT

UN IT by the G EA R and G E AR U N IT respectively.

3) The two sides of GE AR S H AFT 1 are

supported by the OIL SEA L and O ILLESS

BEARING in the GEAR HOUSING ASSEMBLY.

SPIN BELLOWS ASS'Y

The wrinkled rubber device on the bottom of the

BASKET SPIN is called SPIN BELLOWS ASSEMBLY.

It has a waterseal and a oilless metal inside

to prevent leakage and so that the BASKE T S PIN

may work smoothly.

FILTER

Much lint may be obtained depending upon the kind of

clothes to be washed and sam e of the lint m ay also be

suck to the clothes.

To m inim ize this possibility, a lint filter is provided

on the upper part of the FILT ER O V ER FLO W to filter the

wash water.

Use of the lint filter during every wash is

recom m end.

CLEAN ING THE LINT FILTER

1) Remove the FILTER AS from the FILTER OV ER FLO W by pressing it dow nw ards.

2) Turn the FILTE R A S inside out, and wash the lint off w ith water.

3) Return the FILTE R AS it was, and fix the F ILTE R AS to the FILTER O VE R FLO W.

7

4. DIRECTION FOR DISASSEMBLY AND ASSEMBLY

ASSY PANEL BACK

1. Remove 5 screws on the PANEL B . 2. Rem ove KN OB and 2 screw s on the PANEL B.

(Sp in Tim e r)

3. Remove C O N TR OL LE VE R and W AS H

TIM ER.

BASKET SPIN

4. Remove 5 screws on the COV ER B AC K . 5. R em ove LINK BR A KE and A SS EM B LY

BRAKE WIRE.

8

Loading...

Loading...