Page 1

1

TABLE OF CONTENTS

1. PRECAUTION...............................................................................................................................................2

2. GENERAL SPECIFICATIONS.....................................................................................................................3

3. NAMES OF MAJOR COMPONENTS ........................................................................................................4

4. FUNCTION OF MAIN COMPONENTS.......................................................................................................5

5. GENERAL INFORMATIONS.......................................................................................................................6

6. CARE AND MAINTENANCE.......................................................................................................................7

7. TROUBLE SHOO TING GUIDE...................................................................................................................8

8. HOW TO DISASSEMBLE..........................................................................................................................10

9. WIRING DIAGRAM.....................................................................................................................................11

10. REFRIGERANT CYCLE ..........................................................................................................................12

11. EXPLODED DIAGRAM AND PARTS LIST...........................................................................................13

Page 2

2

1. PRECA UTION

Please observe the following instructions.

1. Turn off unit.

Make sure the unit is OFF and the AC cord is unplugged before repairing or servicing.

2. In case of checking the circuit una v oidab l y while the unit is connected with po wer sour ce, be careful

not to connect with the part of electric charge.

You may cause electric shock.

3. Use of proper part if you need to replace the part, be sure to use genuine part of servicing model.

Do not repair or replace the electric contact part.

Consumer must not repair the unit, because it is dangerous.

4. Use of proper tool.

You must use the proper tool to repair the unit, and use the measuring appliance adjusted accurately.

5. Damage of electric wire and power cord when servicing.

Check electric wire and a surely replace a damage electric wire and a damage power cord.

6. Never use connecting the middle of wire, after cutting the middle of wire.

It may cause a fire and trouble.

7. Checking the insulation resistance.

After you complete the assembly of unit, surely check the insulation resistance.

Confirm that the insulation resistance of the power line and the ground terminal is over 30MΩ by measuring insulation

resistance.

8. Checking the ground.

After checking the ground, servicing it completely.

9. Checking the installation.

After checking the installation, servicing it completely.

10. Care children.

When servicing, do not make the children approach the air-conditioner.

Page 3

3

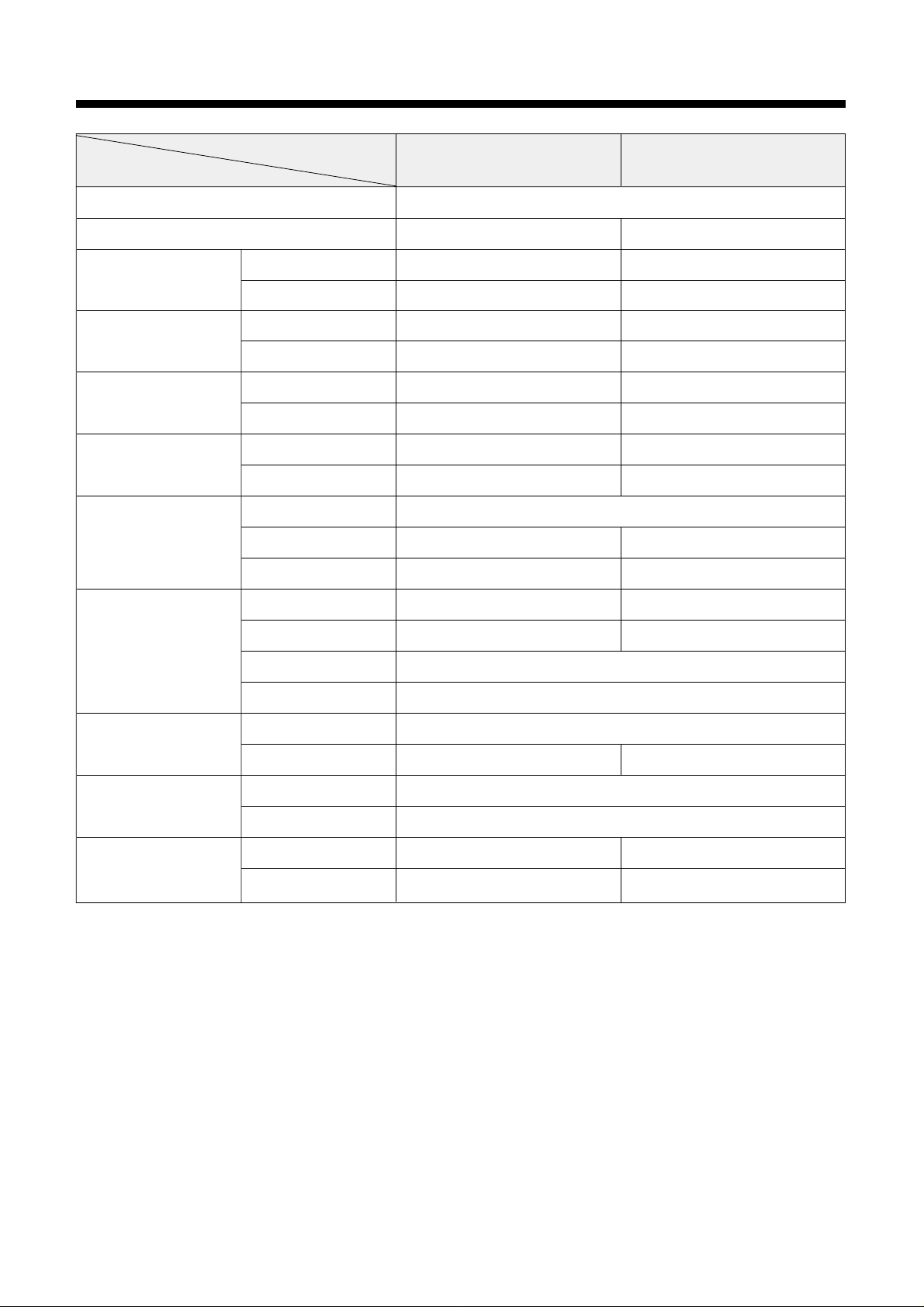

2. GENERAL SPECIFICATIONS

ITEM

MODEL

DWC-052C DWB-052C

Function Cooling only

Power source AC 115V / 60Hz AC 220-240V / 50Hz

Cooling Capacity

Btu/h 5,340 Btu/h 5,350 Btu/h

Kcal/h 1,346 Kcal/h 1,348 Kcal/h

Energy Efficiency Ratio

Btu/Wh 10.2 Btu/Wh 10.3 Btu/Wh

Kcal/Wh 2.57 Kcal/Wh 2.59 Kcal/Wh

Dehumidification

Pts/h 1.73 Pts/h 1.46 Pts/h

g/h 787 g/h 662 g/h

Electrical Data

Power Input (W) 525 W 520 W

Running Current (A) 4.6 A 2.4 A

Compressor

Type Rotary

Model RM5455GQ87 KH-091VFHC

Capacitor 40µF / 370VAC 13µF / 400VAC

Model A9520KC030 A9520CC020

Fan Motor

Capacitor 4µF / 370VAC 2µF / 400VAC

Indoor-Fan Blower-Fan

Outdoor-Fan Propeller-Fan

Refrigerant(R-22)

Control Capillary

Charge Amount(g) 13.3oz (380g) 14.7oz (420g)

Dimensions

Unit(W x H x D)

PACKING(W x H x D)

Weight

Net Weight 45.4 lbs (20.6Kg) 46.3 lbs (21Kg)

Gross Weight 48.5 lbs (22kg) 48.5 lbs (22kg)

17.3(W) x 12.3(H) x 15.2(D) inch (440(W ) x 313(H) x 385(D) mm)

19.2(W) x 15.4(H) x 17.4(D) inch (488(W ) x 390(H) x 443(D) mm)

Page 4

4

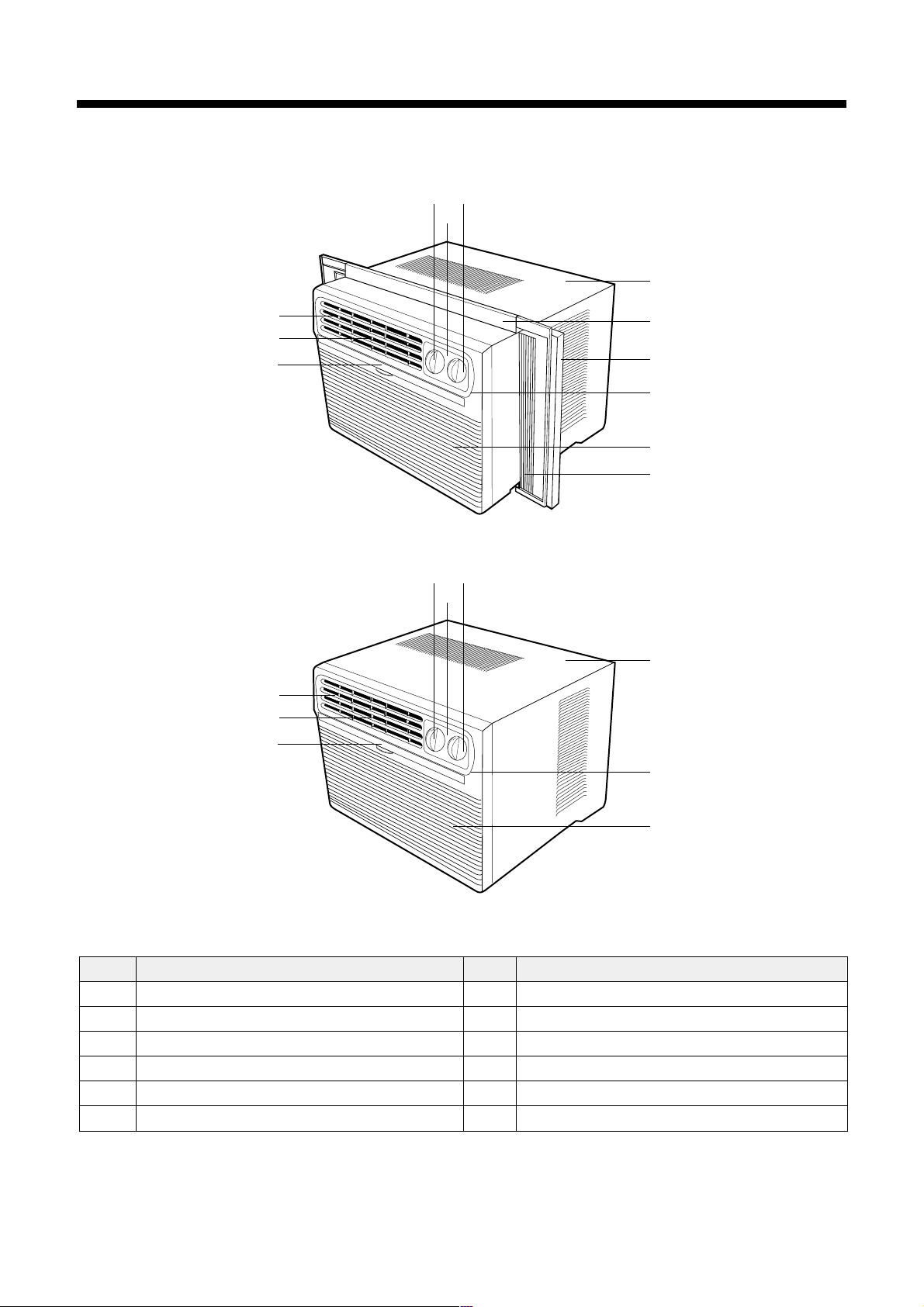

3.NAMES OF MAJOR COMPONENTS

NO PART NAME

1 CABINET

2 BLADE VERTICAL

3 COOL AIR DISCHARGE

4 GRILLE FRONT

5 KNOB THERMOSTAT

6 KNOB SELECTOR

NO PART NAME

7 AIR INTAKE

8 AIR FILTER

9 CONTROL PANEL

10 PLATE WINDOW TOP

11 FRAME WINDOW KIT

12 SHUTTER WINDOW

2

3

8

6

5

1

4

7

0

q

w

9

2

3

8

65

1

4

7

9

* Window kits are optional.

(Item No. 10, 11, 12)

Page 5

5

4. FUNCTION OF MAIN COMPONENTS

1. ROTARY SWITCH (SELECT OR)

Please refer to the part of selector in the chapter 9 (Wiring Diagram).

The rotary switch (selector) controls the fan motor’s rotation speed, and has five positions.

The function of the five position is as follow.

• OFF: This position stops all operations of the air conditioner.

• HIGH COOL: This position provides the maximum air flow for rapid

cooling, dehumidifying and dust removing operations.

(Use this position on sultry summer days.)

• LOW COOL: This position provides the minimum air flow for quiet

cooling, dehumidifying operations.

(Use this position on suitable for night-time.)

• HIGH FAN: This position provides the maximum air fiow alone fan

operation without cooling operation.

• LOW FAN: This position provides the minimum air flow air flow alone

fan operation without cooling operation.

2. THERMOSTAT (TEMPERA TURE CONTR OL)

• The Thermostat automatically starts and stops operation in order to keep

the room temperature at a proper level, and this results in efficient use of

power and economical cooling.

• Turn clockwise for a cooler room temperature.

• Turn counter-clockwise for a warmer room temperature.

3. MOT OR

The motor is used to rotate the indoor and outdoor fan so that the room air can be recirculated.

4. F AN

• BLOWER FAN: The Blower draws hot air from the room through the Evaporator and then discharges it back into the

cool air. It circulates the room air.

• PROPELLER FAN: The propeller draws outdoor air through louvering and cools Condenser, and then blows the hot air

out.

5. CAPACITOR

The Capacitor enlarges the difference of phase between main coil and sub coil so that the Compressor and Fan Motor

starts well.

6. ACCUMULATOR

The Accumulator blocks the unflow of liquid refrigerant and impurities into the Compressor.

Selector

Off

Low

Cool

Low

Fan

High

Cool

High

Fan

Thermostat

Cooler

Page 6

6

5. GENERAL INFORMATIONS

1. CHANGING AIR FLOW DIRECTION

Air flow deflectors divert air from center flow to left or right.

Adjust deflectors for desired air flow pattern.

2. AIR FLOW AR OUND UNIT

Check in door grill and outdoor louvers for air flow obstructions. Do not block air flow to and from unit. The outdoor coil

should be checked and periodically cleaned for debris that may collect and block unit air flow. If air flow is obstructed

or deflected back into unit, the compressor may cycle on and off rapidly, causing early compressor failure.

3. Electrical Grounding Instructions.

This appliance is equipped with a three-prong(grounding) plug for protection against possible shock hazards. If a twoprong wall receptacle is encountered, the customer is required to contact a qualified electrician and have the twoprong wall receptacle replaced with a properly grounded three-prong wall receptacle in accordance with the National

Electrical Code.

4. USE OF EXTENSION CORDS

Because of potential safety hazards under certain conditions we strongly recommend against the use of an extension

cord. However, if you still elect to use an extension cord, it is absolutely necessary that it is earthed and the marked

rating of the extension cord should be 250V 10A or more for Model DWB-052C.

Also, it is absolutely necessary that it be a UL listed 3-wire grounding type appliance extension cord rated has a 3blade grounding and 3-slot receptacle that will plug into appliance. The marked rating of the extension cord should be

125V 13A or more, for Model DWC-052C.

5. DRAIN HOLE AND W ATER DRIPPING OUTSIDE

Locate drain hole at the rear of unit. Water in base pan is picked up by the fan blade and thrown onto the warm

outdoor coil where it evaporates. The air conditioner must be installed level or tited or slightly to the outside for proper

water disposal. On exceptionally hot and humid days the air conditioner may permit excess water to pass thru rear

drain hole or overflow. This should be considered normal.

Page 7

7

6. CARE AND MAINTENANCE

1. AIR FILTER

Clean the air filter, which removes dust inside the room.

It should be washed at least once every week during operation.

1. Remove the Air Filter from the front grill by pulling up.

2. Clean Air Filter with a vacuum cleaner or lukewarm, soapy water.

3. Shake it when clean to remove moisture completely. Replace it.

2. CLEANING THE AIR CONDITIONER

1. At least once a year, remove cabinet and thoroughly clean air conditioner. Have the unit inspected by an authorized

servicer to ensure unit is functioning properly.

2. Wash air conditioner with lukewarm, soapy water as needed. Rinse and dry thoroughly.

3. If using concentrated liquid detergent, dilute in warm water first.

4. Front grill may be wiped off with a cloth dampened in a mild detergent solution.

5. Cabinet may be washed with mild soap or detergent and lukewarm water, then polished with liquid wax for

appliances.

6. Condenser and Evaporator coils should be cleaned at the beginning of each cooling season. Use a soft brush or

vacuum cleaner to clean them, making sure that the Condenser and Evaporator coils are not damaged.

7. Do not use abrasive cleaners. These items scratch, crack and discolor surfaces.

Page 8

8

7. TROUBLE SHOO TING GUIDE

TROUBLE SITUATION ANALYSIS CAUSE REMED Y

Fan motor and

compressor do not

run

Switch is in “cool”

position but the

compressor does not

run

1. Power failure

2. Power is supplied,

but the equipment

does not run

1. Not operating at all

2. Compressor

3. Frequent start and

stop

1) Power plug

2) Circuit breaker

1) receptacle

2) Operation switch

3) Cord or lead wire to

the switch

1) Compressor

2) Thermostat

3) Selector switch

4) O.L.P

5) Capacitor

1) Electricity

2) Room temperature

and outside

temperature

3) Compressor

4) O.L.P

5) Capacitor

1) Thermostat

2) Capacitor

3) O.L.P

1) Power failure

2) Circuit breaker is tripped

3) Power plug is not contacting

• Disconnection

• Mechanical failure of switch

1) Disconnection

2) Malfunction of contact

• Disconnection or burned-out

1) Failure

2) Malfunction

3) Knob is not set to the proper

setting

• Failure of malfunction of proper

setting

1) Disconnection

2) Malfunction of contact

• Lack of capacity

• Disconnection

1) The voltage exceeded allowed

range

2) Capacity of wire is not

sufficient

• Extremely high

• Burned-out

• Malfunction

• Lack of capacity

• Malfunction

• Lack of capacity

• Malfunction

• Consult your electric company

• In case of a breaker, turn it on

and off a few times

• Replace the power plug

• Repair or replace the

receptacle

• Replace the cord or lead wire

• Replace the compressor or

connection wire

• Replace

• Repair or replace

• Turn knob for cooler setting

• Repair or replace the swtting

• Repair

• Repair or replace

• Replace

• Repair

• Consult your electric company

• Check the capacity of wire

• Ventilate well and remove the

heat source

• Replace

• Replace

• Replace

• Replace

• Replace

• Replace

Page 9

9

TROUBLE SITUATION ANALYSIS CAUSE REMED Y

The compressor runs

but the motor doesn’t

run

Both fan motor and

compressor are

running but cooling is

bad

Vibration & Noise

Water leakage into

room

Electric shock

(Leakage of current)

Not cooling at all

Insufficient cooling

1) Fan

2) Fan motor

3) Capacitor

4) Fan motor circuit

Refrigerant system

1) Refrigerant system

2) Filter

3) Heat exchanger of

condenser

1) Installation place

2) Fan

3) Fixing screws

4) Electric

components

• Installation condition

• Insulation of

components

• Blocked by others

• Disconnection or burned-out

electric cord

• Failure malfunction of contact

• Disconnection of malfunction of

contact

1) Refrigerant system is choked

2) Compressor failure

3) Leakage of refrigerant gas

1) Refrigerant system is choked

2) Compressor failure

3) Leakage of refrigerant gas

4) Refrigerant charge is too high

• Clogged up with dust

1) Fin is cogged up with dust

2) The ventilation is not good

3) The unit is exposed to the

sunlight

4) Other heat source is added in

the room

• Installation of the unit is

imperfectly done

1) Fan is contacted with

obstacles

2) Fixing bolt

• Have a screw loose

• Electrical noise

• The front is lower than rear side

1)Insulation defect of wiring and

lead wire

2) Leakgae of current due to the

dew or rust

• Repair

• Replace the fan motor

• Replace

• Check the circuit

• Repair

• Repair

• Recharge refrigerant gas

• Check and repair refrigerant

system

• Replace

• Check a part of Leakage and

repair

• Repair and recharge

• Clean the air fiter

• Clean the unit

• Shade the unit from the

sunlight

• Remove the added heat source

• Install the unit perfectly

• Remove obstacles

• Tighten the bolt

• Tighten the screw

• Exchange the components

• Make rear side of the unit lower

than the front

• Check the unit’s Leakage of

current.

• Replace the defective parts or

components

Page 10

10

8. HO W T O DISASSEMBLE

1 Before service of 1. Stop the unit, remove the power cord from the receptacles.

any part. 2. Move the unit to the safe location for the suitable work.

2 Ass’y Fan Motor 1. Remove Front Grill

- Fan Motor - Remove Filter Pre.

- Propeller Fan - Remove screw(1 point) in Front Grill.

- Blower Fan 2. Remove Cabinet from the unit.

- Remove screws (8 point) from the unit’s sides.

3. Remove Screw (1 point) from Panel Housing’s Side and Remove Holder EVA.

4. Remove Ass’y Control Box

- Remove screws (5 point).

- Remove wires in the each components.

5. Remove Plate Scroll

6. Remove wires in the Panel Housing.

7. Remove screws (7 point) from Ass’y Fan Motor’s sides.

- Ass’y Fan Motor is assembly of Fan Motor, Propeller and Blower Fan, Orifice

and Panel Housing.

8. Lift the Ass’y Fan Motor from the unit.

9. Remove Clip Fan (2 point) from the shaft of Fan Motor.

10. Remove Propeller Fan from the shaft of Fan Motor.

11. Remove Blower Fan from the shaft of Fan Motor.

12. Remove Scroll

13. Remove Fan Motor from Panel Housing.

- Remove screws (4 point).

3 Ass’y Control Box 1. Same as the procedure 1 to 4 in the Item 2.

-

Rotary Switch (selector)

- Thermostat

- Capacitor

- Power Cord

4 O.L.P 1. Same as the procedure 1 to 2 in the Item 2.

2. Remove Terminal Cover from Compressor.

- Remove hex-nut (1 point).

Please refer to the chapter 11 (Exploded diagram and parts list).

Page 11

11

9. WIRING DIA GRAM

Page 12

Condenser

Propeller fan

Capillary tube

Compressor

Accumulator

Blower fan

Evaporator

M MOTOR

12

10. REFRIGERANT CYCLE

Page 13

13

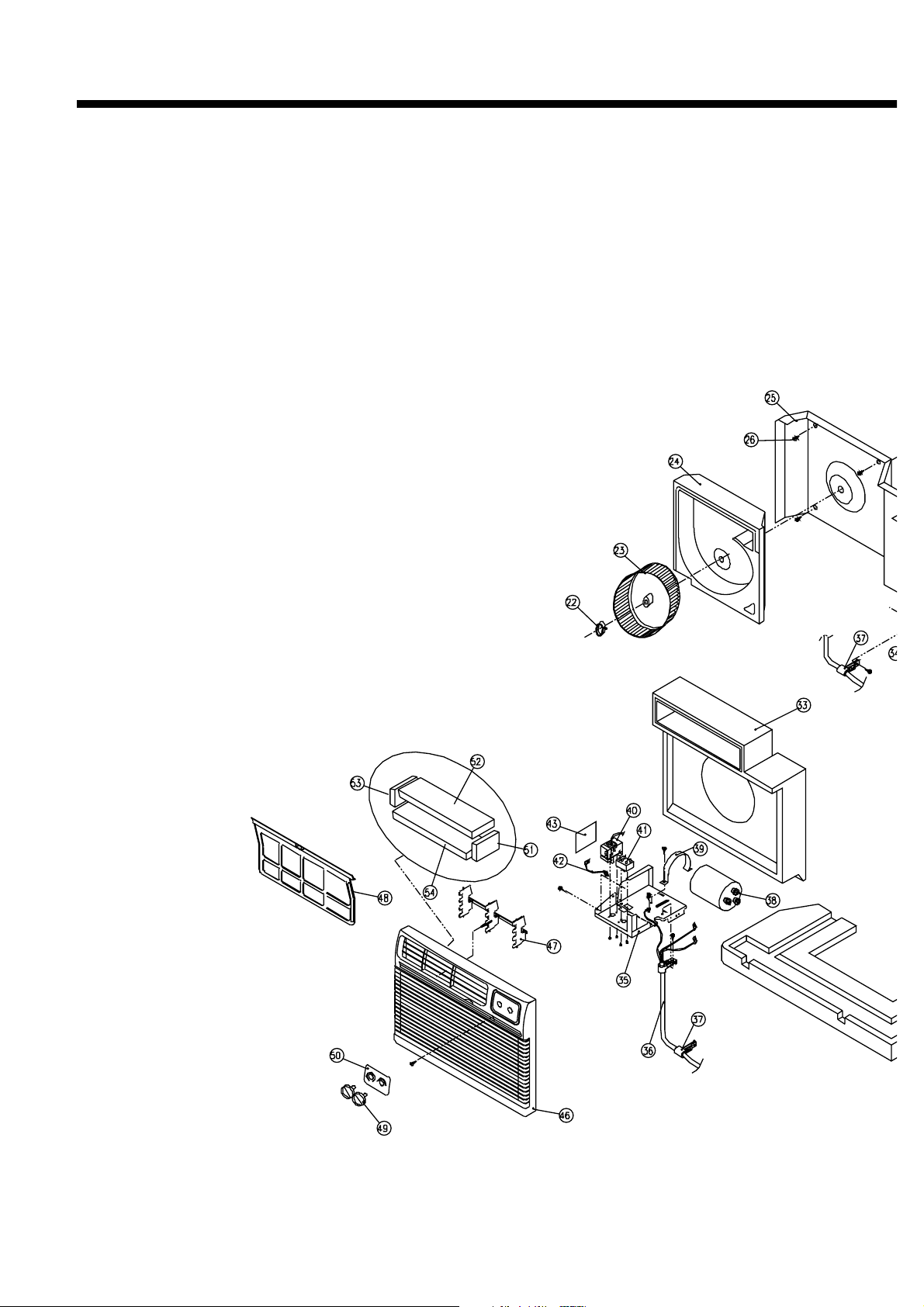

11. EXPLODED DIA GRAM AND PAR TS LIST.

■ DWC-052C,D WB-052C PARTS LIST

NO CODE COMPONENTS Q'TY SPECIFICATION REMARK

1 3110300100 PAN BASE 1 SGCC T1.0

2 3116000100 COMP BOLT 3 M8 DWC-052C

3116000400 COMP BOLT 3 M8 DWB-052C

3 3112500100 GUIDE WIN LOWER 1 SGCC T0.8 DWC-052C

4 3118100100 PAN DRAIN 1 EPS

5 3110000200 AS EVA 1 2R1C, 330X209X25

6 3114400300 PIPE EVA IN 1 C1220T-OL, OD7.0XT0.7

7 3110001900 AS PIPE SUCTION 1 C1220T-OL, OD7.94XT0.7 DWC-052C

3110005600 AS PIPE SUCTION 1 C1220T-OL, OD7.94XT0.7 DWB-052C

8 3117100100 AS COMPRESSER 1 RM5455GQ87 DWC-052C

3117100800 AS COMPRESSER 1 KH091VFHC DWB-052C

9 - GASKET 1

10 - TERMINAL COVER 1

11 - GASKET NUT 1

12 - NUT FLANGE 1

13 (AHT941C003) GROMMET 3 EPDM DWC-052C

3116000300 GROMMET 3 EPDM DWB-052C

14 - WASHER 3

15 - NUT 3

16 - SPRING 1

17 - OVERLOAD PROTECTOR 1

18 3112700300 HARNESS COMP 1 UL1015 3*16AWG

19 3110000300 ASSY CONDENSER 1 2R1C, 380X304X25

20 3114400100 PIPE DISCHARGE 1 C1220T-OL, OD6.35 DWC-052C

3114401600 PIPE DISCHARGE 1 C1220T-OL, OD6.35 DWB-052C

21 3110002000 AS PIPE CAPILLARY 1 ID1.0, OD3.2X1000

22 3101202800 CLIP FAN 2 SK5

23 3111800100 FAN BLOWER 1 ABS730

24 3116600100 SCROLL 1 EPS

25 3114200100 PANEL HOUSING 1 SGCC T0.8

26 7122401211 SCREW 3 T2S 4X12

27 3118000100 MOTOR FAN 1 A9520KC030(DMI) DWC-052C

3118000400 MOTOR FAN 1 (S.W) DWC-052C

3118000500 MOTOR FAN 1 (O.S) DWC-052C

3118000800 MOTOR FAN 1 A9520CC020(DMI) DWB-052C

28 7S432X2081 SCREW TAPTITE 4 TT3 TRS 3X8 MFZN

29 3113800400 LOCK TWIST STANDOFF 1 DASTL-3NA

30 3110700100 BUSHING 1 DACB-012(73MM)

31 3111400100 COVER ORIFICE 1 PP(M540)

32 3111800200 FAN PROPELLER 1 ABS+GF

33 3114500300 PLATE SCROLL 1 EPS

34 3113000100 HOLDER EVA 1 SGCC T0.6

35 3110500100 BOX CONTROL 1 SGCC T0.6

36 3111300100 CORD POWER 1 125V, 13A, SJT3*16AWG DWC-052C

3111300300 CORD POWER 1 250V, 16A DWB-052C

37 3111200300 CLAMP POWER CORD 2 PP

38 3116900100 CAPACITOR 1 4/40µF 370V DWC-052C

3116900200 CAPACITOR 1 4/40µF 370V DWC-052C

3116900800 CAPACITOR 1 2/13µF 400V DWB-052C

39 3111200100 CLAMP CAPACITOR 1 SGCC T0.6 DWC-052C

3101200600 CLAMP CAPACITOR 1 SGCC T1.0 DWB-052C

40 3118500100 THERMOSTAT 1 125/250VAC,20/80A,16~31°C

3118500200 THERMOSTAT 1 125/250VAC,20/80A,16~31°C

41 3118500300 ROTARY S/W 1 SRB-315-4-10D

42 3112700200 HARNESS ROTARY 1 UL1015 16AWG 105¢™

43 3113500400 LABEL CIRCUIT 1 ART PAPER

44 3110800100 CABINET 1 SGCC T0.6

45 3112500200 GUIDE WINDOW TOP 1 SGCC T0.8 DWC-052C

46 3112400200 GRILLE FRONT 1 HIPS

47 3116500100 BLADE VERTICAL 1 PP

48 3111900200 FILTER 1 HIPS

49 3110001400 AS KNOB 2 ABS720

50 3111600100 DECO FRONT 1 PC FILM

51 3118400100 SEAL G/FRONT(1) 1 F-PE DWB-052C

52 3110012400 ASS'Y SEAL G/FRONT(2) 1 F-PE DWB-052C

53 3110012500 ASS'Y SEAL G/FRONT(3) 1 F-PE DWB-052C

54 3118400200 SEAL G/FRONT(4) 1 F-PE DWB-052C

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 14

■ DWB-052C, D WC-052C EXPLODED DIAGRAM

Page 15

Page 16

S/M NO.: DWC052C020

DAEW OO ELECTRONICS CO ., LTD.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 590-6291

TEL: 02) 360-7114/590-6151~5

http://www.dwe. daewoo.co.kr

PRINTED DATE: JAN. 2001

Page 17

Service Manual

Window Type

Room Air Conditioner

Model: D WB-052C

D WC-052C

DAEW OO ELECTR ONICS CO., LTD.

S/M No. : DWC052C020

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

Loading...

Loading...