Page 1

TABLE OF CONTENTS

1. PRECAUTION...............................................................................2

2. GENERAL SPECIFICATIONS ................................................................3

3. NAMES OF MAJOR COMPONENTS .........................................................4

4. FUNCTION OF MAIN COMPONENTS ........................................................5

5. GENERAL INFORMATIONS .................................................................7

6. CARE AND MAINTENANCE .................................................................9

7. ELECTRICAL REQUIREMENTS ............................................................10

8. DESCRIPTION OF FUNCTIONS ............................................................11

9. WIRING DIAGRAM.........................................................................12

10. REFRIGERANT CYCLE ...................................................................13

11. PCB DRIVING DESCRIPTION .............................................................14

12. TROUBLE SHOO TING GUIDE.............................................................16

13. HOW TO DISASSEMBLE..................................................................19

14. EXPLODED DIAGRAM AND PARTS LIST ..................................................20

1

Page 2

1. PRECA UTION

Please observe the following instructions.

1. Turn off unit.

Make sure the unit is OFF and the AC cord is unplugged before repairing or servicing.

2. In case of checking the circuit una v oidab l y while the unit is connected with po wer sour ce, be careful

not to connect with the part of electric charge.

You may cause electric shock.

3. Use of proper part if you need to replace the part, be sure to use genuine part of servicing model.

Do not repair or replace the electric contact part.

Consumer must not repair the unit, because it is dangerous.

4. Use of proper tool.

You must use the proper tool to repair the unit, and use the measuring appliance adjusted accurately.

5. Damage of electric wire and power cord when servicing.

Check electric wire and a surely replace a damage electric wire and a damage power cord.

6. Never use connecting the middle of wire, after cutting the middle of wire.

It may cause a fire and trouble.

7. Checking the insulation resistance.

After you complete the assembly of unit, surely check the insulation resistance.

Confirm that the insulation resistance of the power line and the ground terminal is over 30MΩ by measuring insulation

resistance.

8. Checking the ground.

After checking the ground, servicing it completely.

9. Checking the installation.

After checking the installation, servicing it completely.

10. Care children.

When servicing, do not make the children approach the air-conditioner.

2

Page 3

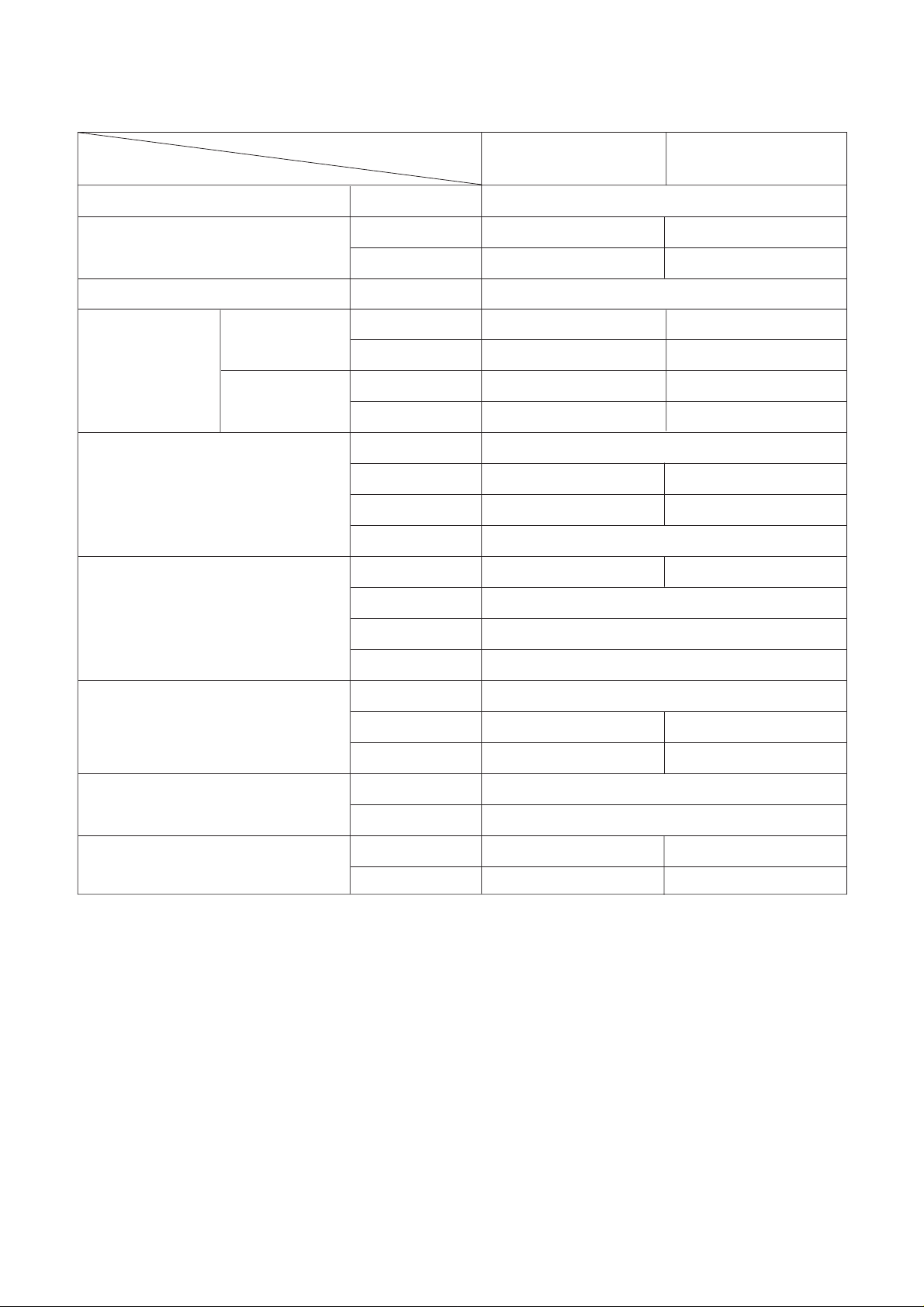

2. GENERAL SPECIFICATIONS

MODEL

ITEM

Power Source V/Hz AC 220-240V/50Hz

Capacity

(Cooling & Heating)

Dehumidification L/h 2.1

Electrical Data Power Input(W)

Running Current(A)

Compressor

Fan Motor

Btu/h 18,000 24,000

Kcal/h 4,530 6,050

Cooling 2,240 2,750

Heating 1,880 2,350

Cooling 10.4 13.1

Heating 8.8 11.4

Type Recipro

Model AWG-5524EXC AWG-5530EXC

Capacitor 35µF/400VAC 45µF/400VAC

Overload Protector Internal Type

Model AM12DWD08 A2945CA011

Capacitor 7.5µF / AC 400V

Indoor-Fan Blower Fan

DWB-180CH-R DWB-240CH-R

Outdoor-Fan Propeller Fan

Control Capillary

Refrigerant(R-22)

Capillary Tube ID ø1.4 x L800 x 2 ID ø 1.6 x L800 x 2

Charge Amount (g) 1,230g 1,030g

Dimensions Unit (W x H x D) 660 x 430 x 705 (mm)

Packing (W x H x D) 711 x 525 x 757 (mm)

Weight Net Weight (Kg) 65.0 66.0

Gross Weight (kg) 69.0 70.0

3

Page 4

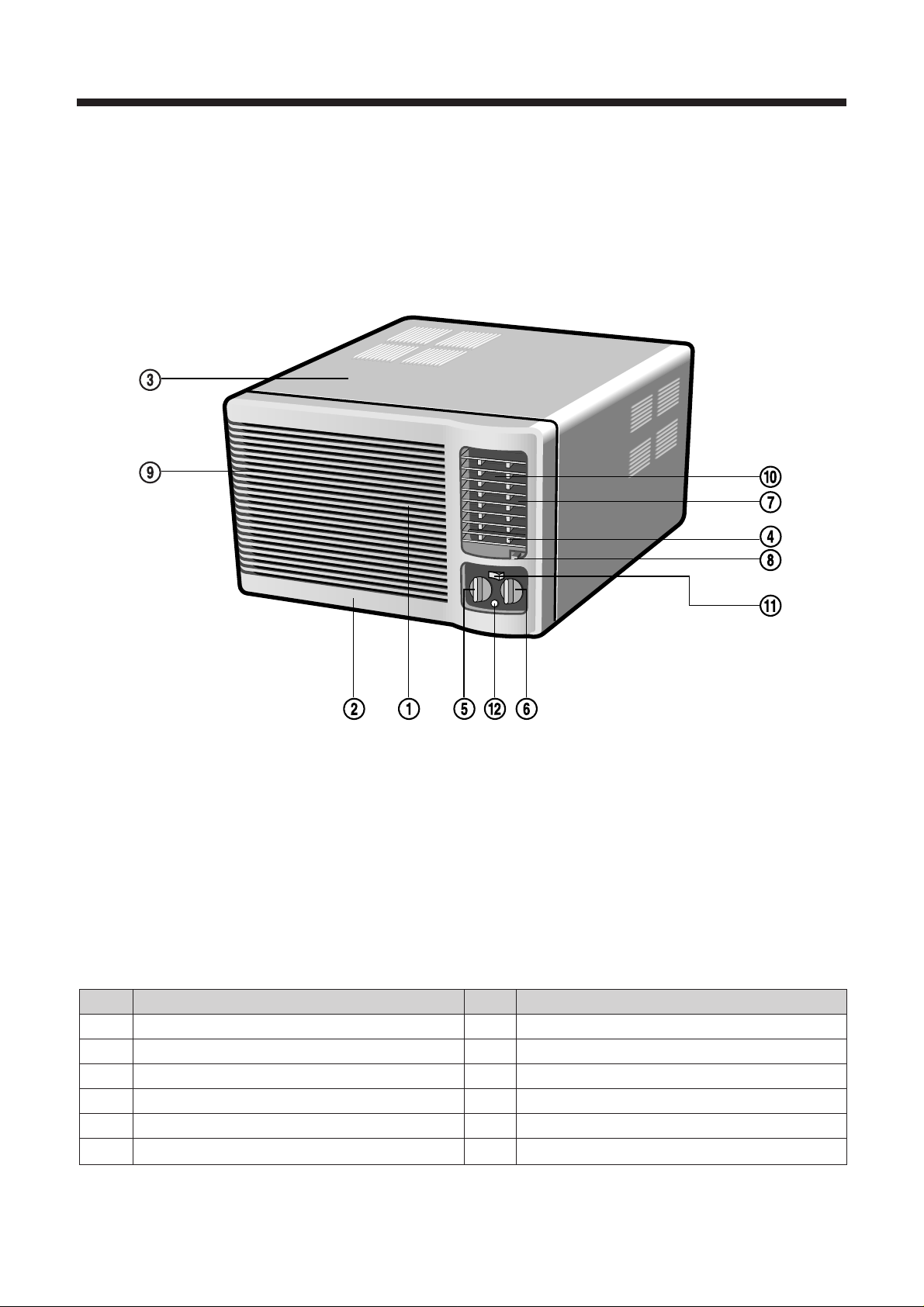

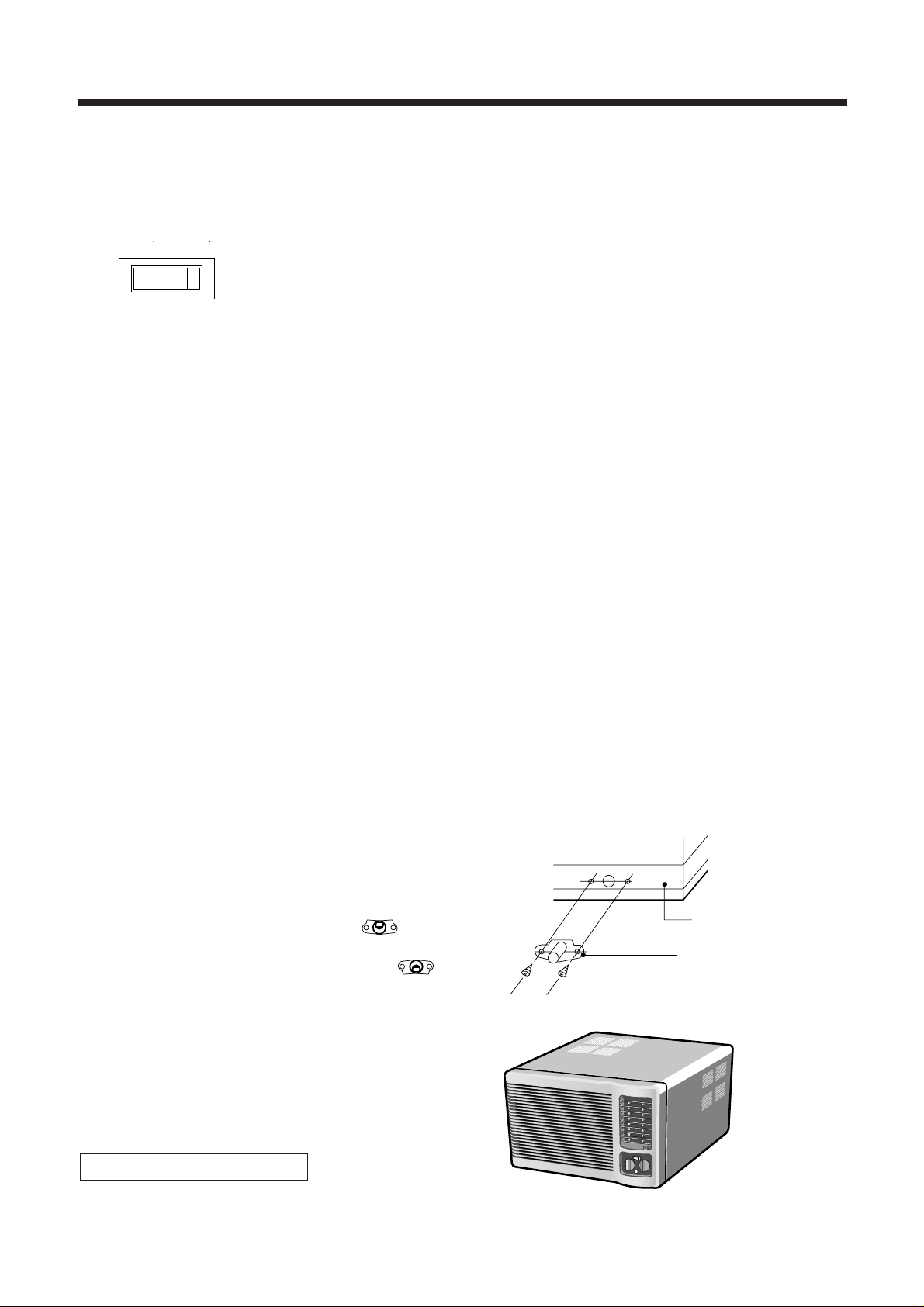

3.NAMES OF MAJOR COMPONENTS

NO PART NAME

1 AIR FILTER

2 GRILLE FRONT

3 CABINET

4 BLADE VERTICAL

5 KNOB THERMOSTAT

6 KNOB SELECTOR

NO PART NAME

7 BLADE HORIZONTAL

8 AIR VENT

9 AIR INTAKE

10 AIR DISCHARGE

11 AUTO SWING SWITCH

12 HEATER LAMP

4

Page 5

4. FUNCTION OF MAIN COMPONENTS

NOTE

• ECONOMICAL AND COMFORTABLE USE

1. Properly control the room temperature.

2. Avoid being exposed to direct sunlight.

3. Prevent the wind from entering the room.

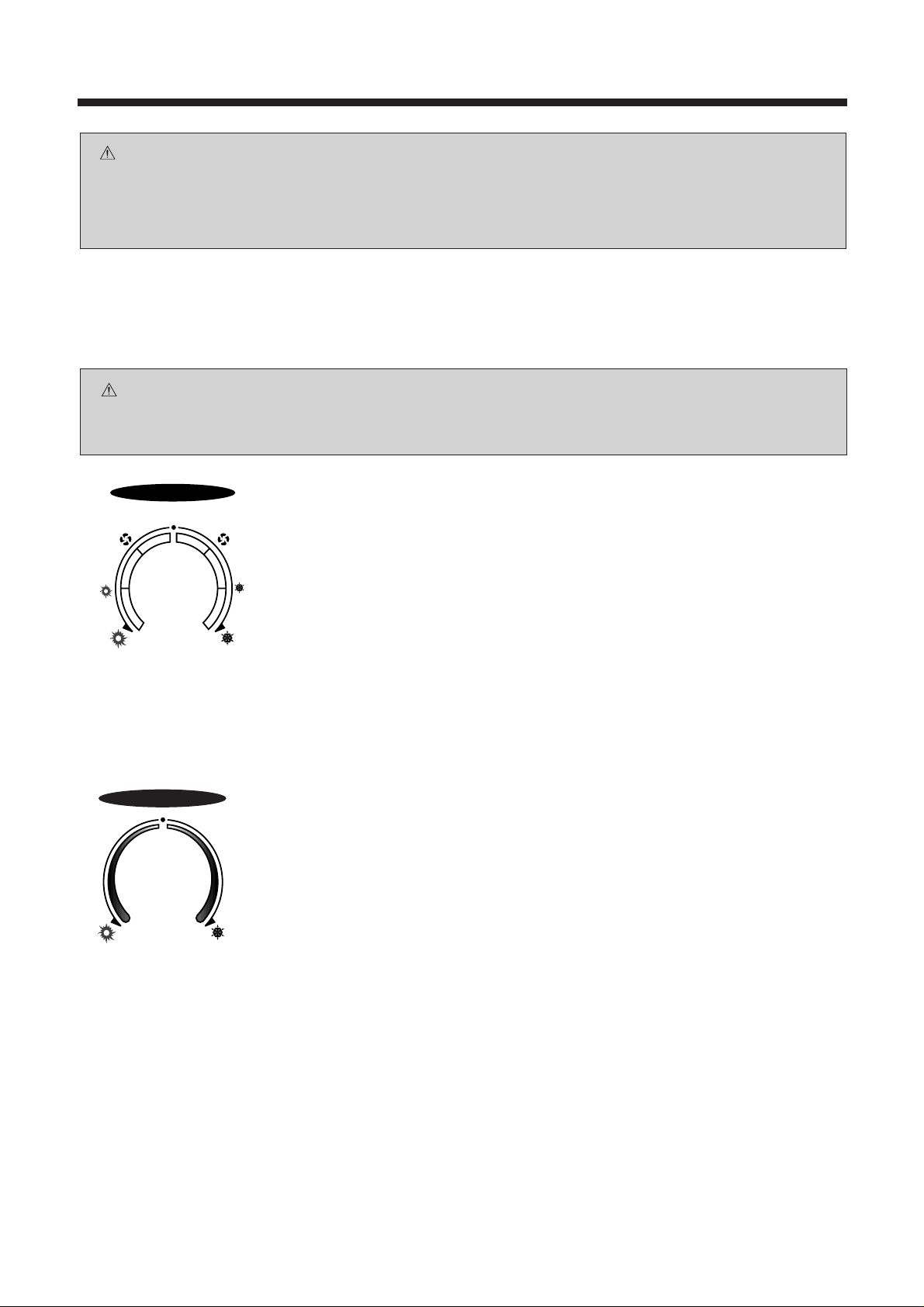

• FAN & COOLING CONTROL

The Fan Control Selector Switch has six positions.

Choose one of the speed settings by rotating the fan control Selector Switch to the appropriate position

CAUTION

When the air conditioner has been performing its cooling operation and is turned “OFF” or set to the ‘FAN”

position, wait at least 3 minutes before resetting to the cooling operation.

OFF Select this setting for stop all operation of air conditioner

FAN Select this setting for low speed air circulation without cooling and

heating.

LOW COOL Select this setting for cooling operation with LOW FAN.

LOW

HEAT

SELECTOR

OFF

FANFAN

LOW

COOL

HIGH COOL Select this setting for cooling operation with HIGH FAN.

HIGH

HEAT

WARMER COOLER

HIGH

COOL

LOW HEAT Select this setting for Heating operation with LOW FAN.

HIGH HEAT Select this setting for Heating operation with HIGH FAN.

• TEMPERATURE CONTROL

Choose a temperature settings by rotating the knob of thermostat to the appropriate position

THERMOSTAT

• The Thermostat automatically starts and stops operation in order to keep the room

temperature at a proper level, and this results in efficient use of power and economical

cooling.

• Turn clockwise for a cooler room temperature.

• Turn counter-clockwise for a warmer room temperature.

WARMER COOLER

• HEATER LAMP

When the unit sets heating operation condition, the red lamp is lighted.

When the frost settles on the heat exchanger of the outside, defrosting is made automatically and the red lamp is turned

off.

The unit may give a hiss and the fan motor stops for 1 to 10 minutes.

This should not be regarded as a problem.

After defrosting, the heating operation begins again.

5

Page 6

• MOTOR

The motor is used to rotate the indoor and outdoor fan so that the room air can be recirculated.

CAUTION

In order to After Service convenience that the motor is common parts with DWB-180(240)C-R model, (This part

is not use of medium speed function so that the lead wire’s receptacle is taping)

Because of the motor supplies of having a lead wire’s receptacle when Pump model’s After Service that it is

necessary to taping of lead-wire.

• FAN MOTOR

– BLOWER FAN : The Blower draws hot air from the room through the Evaporator and then discharges it back into the

cool air. It circulates the room air.

– PROPELLER FAN: The Propeller draws outdoor air through louvering and cools Condenser, and then blows the hot air out.

* Heating condition is in opposition.

• CAPACITOR

The Capacitor enlarges the difference of phase between main coil so that the Compressor and Fan Motor starts well.

• ACCUMULATOR

The Accumulator blocks the unflow of liquid refrigerant and impurities into the Compressor.

6

Page 7

5. GENERAL INFORMATIONS

DEFLECCIÓN AUTOMÁTICA

ENCEN./APAG.

The rear side of the unit

Drain Cap

Door Vent

• CHANGING AIR FLOW DIRECTION

Air flow deflectors divert air from center flow to left or right and up or down.

Adjust deflectors for desired air flow pattern.

AUTO SWING

AUTO SWING

ON/OFF

• AUTO SWING

The switch of auto swing operating is linked with the power source.

ON: Air swing is operated while SELECTOR knob is set the COOL/HEAT or FAN position.

OFF: Stop the operation of air swing.

• AIR FLOW AR OUND UNIT

When the auto louver switch is turned to “ON” position, the vertical louvers

automatically move right and left.

Thus, you can obtain comfortable cooling.

The vertical louvers may be stopped at any position when the auto louver switch is turned off.

Check indoor grille and outdoor louvers for air flow obstructions. Do not block air flow to and from unit. The outdoor coil

should be checked and periodically cleaned for debris that may collect and block unit air flow. If air flow is obstructed or

deflected back into unit, the compressor may cycle on and off rapidly, causing early compressor failure.

• DRAIN HOLE AND W ATER DRIPPING OUTSIDE

Locate drain hole at the rear or on the bottom of unit. Water in base pan is picked up by the fan blade and thrown onto the

warm outdoor coil where it evaporates. The air conditioner must be installed level or tilted slightly to the outside for proper

water disposal. On exceptionally hot and humid days the air conditioner may permit excess water to pass thru rear drain hole

or overflow. This should be considered normal.

• HOW TO INSTALL THE DRAIN CAP

This drain cap is not attached the rear the unit at the factory.

If you want to install the drain cap, please install the drain

cap like Fig. of the drain cap.

There are two kinds of method to install the drain cap.

The first method is that the shape of hole like

It is good for the household.

The second method is that the shape of hole is like

It is good for the shop.

• DOOR VENT

The door vent for the room air ventilation is lever type.

If the door vent lever moves to the left, then close the

vent and moves to the rght, then open the vent.

CLOSE VENT → OPEN

→

7

Page 8

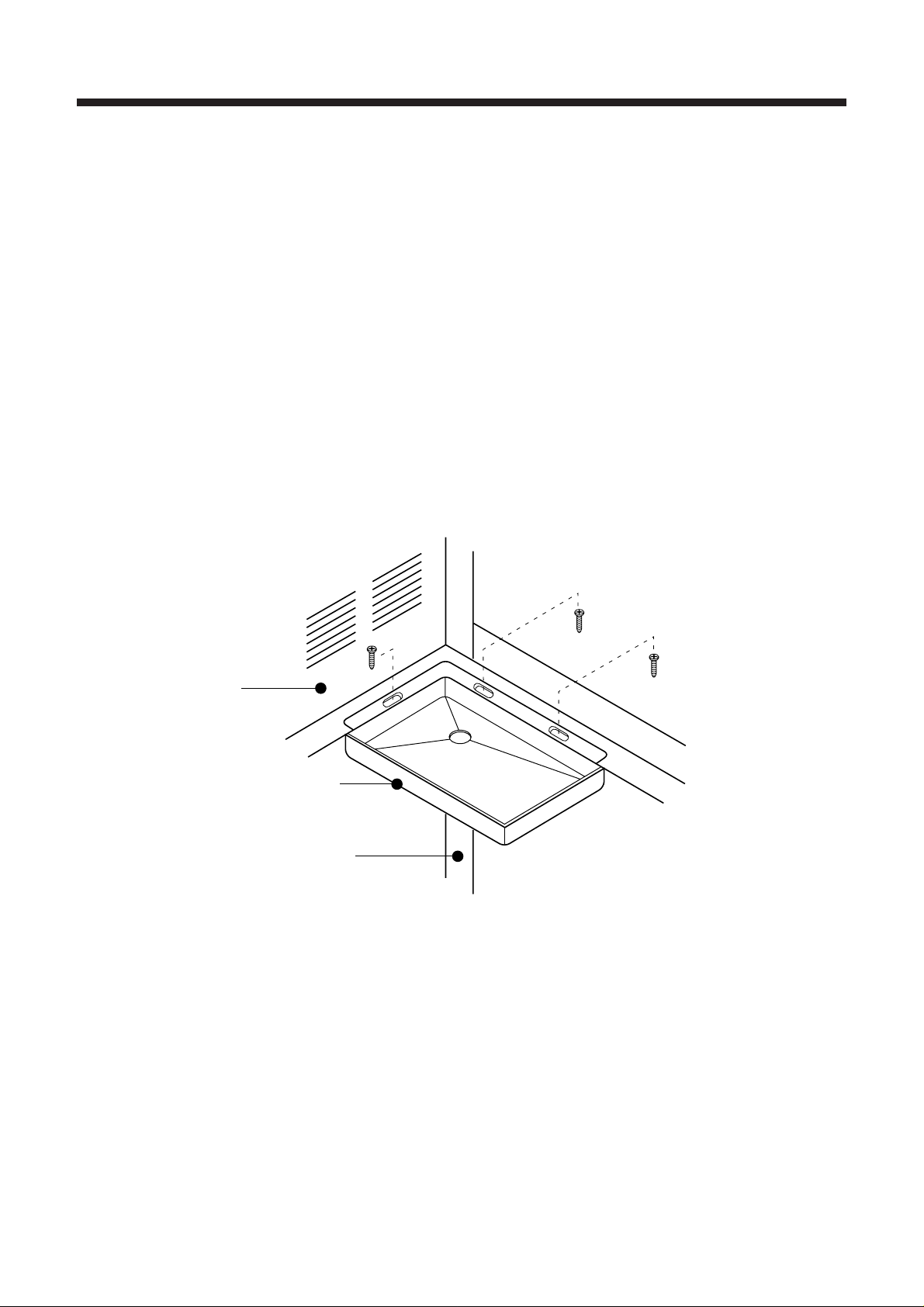

• HOW TO ATTACH CABINET DRAIN

CABINET

SCREW

CABINET

DRAIN

DRAIN HOSE

The air conditioner employs a proper drain method whereby the condensed water (moisture removed from the air) is

drained to the outside.

In very humid weather, excessive condensate water removed from the air may cause some water to collect. To remove

this excess water you can install the cabinet drain as detailed below.

1. Take the cabinet drain which is located in the upper styrofoam pad.

2. Remove the hole rubber from the base pan bottom hole.

3. Install the cabinet drain to the left corner of the cabinet with 3 screws.

4. Connect the drain hose to the outlet located at the bottom of the cabinet drain.

You can purchase the drain hose or tubing locally to satisfy your particular needs.

(Drain hose is not supplied)

8

Page 9

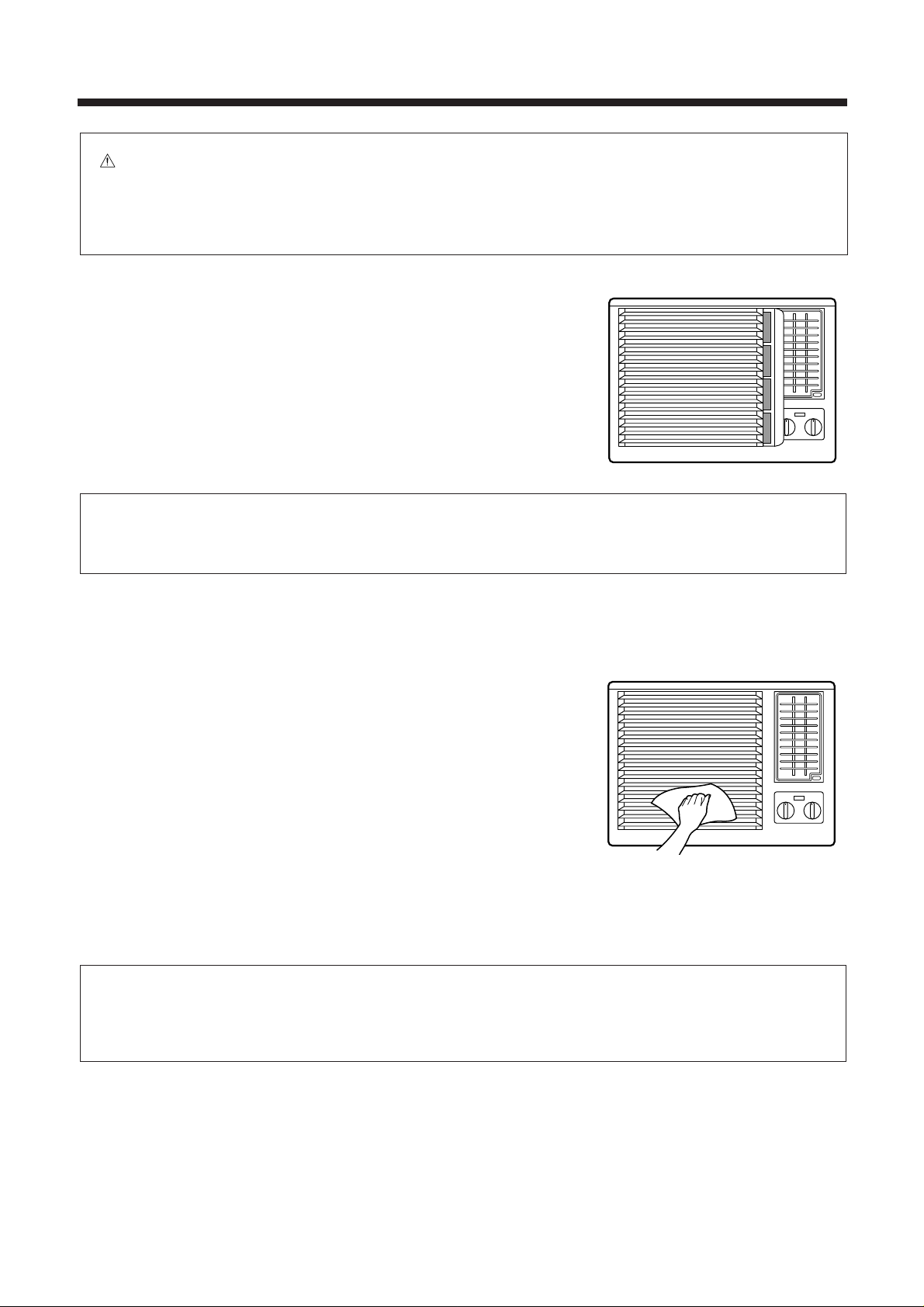

6. CARE AND MAINTENANCE

CAUTION

To avoid death of personal injury due to electrical shock, turn fan control OFF and unplug

power cord before cleaning or performing maintenance. After cleaning or performing

maintenance, reconnect power.

• AIR FILTER

Clean the air filter, which removes dust inside the room.

It should be washed at least once every week during operation.

1. Remove the Air Filter from the front grille by pulling up.

2. Clean Air Filter with a vacuum cleaner or lukewarm, soapy water.

3. Shake it when clean to remove moisture completely. Replace it.

NOTE

A dirty Air Filter reduces air flow and the cooling capacity.

Do not operate unit without Air Filter.

• CLEANING THE AIR CONDITIONER

1. At least once a year, remove cabinet and thoroughly clean air conditioner.

Have the unit inspected by an authorized service man to ensure unit is

functioning properly.

2. Wash air conditioner with lukewarm, soapy water as needed.

Rinse and dry thoroghly.

3. If using concentrated liquid detergent, dilute in warm water first.

4. Front grille may be wiped off with a cloth dampened in a mild detergent

solution.

5. Cabinet may be washed with mild soap or detergent and lukewarm water,

then polished with liquid wax for appliances.

6. Condenser and Evaporator coils should be cleaned at the beginning of each cooling season. Use a soft brush or

vacuum cleaner to clean them, making sure that the Condenser and Evaporator coils are not damaged.

7. Do not use abrasive cleaners. These items scrach, crack and discolor surfaces.

NOTE

To assure continued peak efficiency, condenser coils (weather side of unit) should be checked periodically and

cleaned if clogged with soot or dirt from the atmosphere.

9

Page 10

7. ELECTRICAL REQUIREMENTS

• ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong(grounding) plug for protection against possible shock hazards. If a two-prong

wall receptacle is encountered, the customer is required to contact a qualified electrician and have the two-prong wall

receptacle replaced with a properly grounded three-prong wall receptacle in accordance with the National Electrical Code.

WARNING :

To avoid death, personal injury or properly damage due to electrical shock, this unit must be

grounded.

Do not under any circumstances cut or remove the round grounding prong from the plug.

Do not use a two prong adapter.

• USE OF EXTENSION CORD

Because of potential safety hazards under a certain condition we strongly recommend against the use of an extension

cord. However, if you still elect to use an extension cord, it is absolutely necessary that it is earthed and the marked

rating of the extension cord should be AWG #12

The socket-outlet shall be installed near the equipment and shall be easily accessible.

WARNING :

To avoid death, personal injury or properly damage due to electrical shock, do not use an

extension cord or pinch the power cord.

Do not remove the warning tag from the power cord.

• REPLACEMENT OF SUPPLY FLEXIBLE CORD.

It the supply flexible cord is damaged, it must be replaced by the manufacturer or its service agent or similarly qualified

person in order to avoid a hazard.

10

Page 11

8. DESCRITION OF FUNCTIONS

ON

Time

50minutes 10minutes

Sensing

Temperature

Compressor

(Heater sump)

Fan motor

(Reversing valve)

(Lamp)

ON

(-4°C) (15°C)

ON

OFF

• COOLING OPERATION

If the rotary switch is turned to “COOL”, the unit starts to cooling operation.

The power is not supplied to the de-ice controller P.C.B(Deicer PCB) in this mode.

The fan motor is “ON” when rotary switch is turned to “COOL” because RL1(on the P.C.B) is normally close.

• HEATING OPERATION

If the rotary switch is turned to “HEAT”, the unit starts to heating operation.

The power is supplied to the de-ice controller P.C.B in this mode.

Fan motor, Reversing valve, Lamp, Heater, these parts go on just turnning the rotary switch to “HEAT” because RL1 is

normally close.

The de-ice mode of heating operation is follows below.

• DE-ICE OPERATION

When the power is supplied by the turnning rotary switch to “HEAT”, the micro-computer chip(on the P.C.B) starts to

check the time and temperature.

Entering de-ice operation(to turn cooling cycle).

1. The micro-computer chip is check the temperature of condensor, After 50 minutes since the units starts on heating

mode.

2. If the Temperature is below -4˚C, RL1 goes on.

3. Then, all parts of concerning with RL1 go off also, such as Fan motor, Lamp, Reversing valve.

4. Now, the unit turned to cooling operation but fan motor is off.

Back to heat mode.

1. On the de-ice operation if the temperature is going over 15˚C, RL1 goes off.

2. Or 10minutes passed on the de-ice operation, RL1 goes off also.

3. Now the unit turned to heating mode because RL1 off means all parts turned on also.

such as Fan motor, Reversing valve, Lamp.

Remark : This de-ice operation is always repeat in heating mode when satisfying of the condition to enter the de-ice

operation.

11

Page 12

9. WIRING DIA GRAM

(Lo)

BL

YW

18

6

4

2

OR

OR

WH

BR (WH)

BL

OR

RD RD

BR (WH)

WH

ROCKER

SWITCH

HEATER

T2

T1

HL

SC

LC

R

C

BR

BR RD

WH

OR

F

C

H

OR

WH (BR)BK (BL)

OR

WH

TH

L2

L3 L1

BK OR

WH

WH

WH BL

GRN

GRN

RD

7

SELECTOR

SWITCH

SWING

MOTOR

REVERSING-VALVE

LAMP

COMP

THERMOSTAT

3103528820

CAPACITOR

FAN

MOTOR

DEICER

CAPACITOR

(HI)

12

Page 13

10. REFRIGERANT CYCLE

Evaporator

Blower fan

MOTOR

Reversing

Valve

Accumulator

Propeller fan

Condenser

Refrigerant flow(COOLING)

Refrigerant flow(HEATING)

Capillary Tube

M

Compressor

13

Page 14

11. PCB DRIVING DESCRIPTION

14

Page 15

1. DC POWER SUPPLY

1(VDD)

2

3

4(RESET)

VDD

no use

no use

Reset input

VSS(GND)

Sensor input

VREF

Relay control output

(VSS)8

7

(VREF)6

5

PIC12C671

Refer to “C” (DC Power) in the circuit diagram

DC Voltages is needs +12[V] and +5[V].

DC +12[V] is used for relay control, and DC +5[V] is used for the micro-computer. and the peripheral hardware in the P.C.B.

DC +5[V] is regulated y IC2(7805S).

CE1, CE2, CC6, CC5 designed for voltage regulation or noise filtering.

2. RESET

Refer to “A” (reset) in the circuit diagram.

Number 4 (IC1) is used for reset the micro-computer when the power is on or off.

3. SENSOR V ALUE INPUT

Refer to “B” (Sensor) in the circuit diagram.

Number 7 (IC1) is used for reading the value of the sensor.

Temperature is read on voltage instead of the resistance of the sensor.

4. AC LOAD CONTROL

Refer to “D” (AC Load) in the circuit diagram.

Nuber 5 (IC1) is used for control the relay(RL1).

RL1 controls Reversing valve, Lamp or Fan motor.

MICOM PIN ASSIGNMENT

15

Page 16

12. TROUBLE SHOO TING GUIDE

TROUBLE SITUATION ANALYSIS CA USE REMED Y

Fan motor and

compressor do not run

Switch is in “cool”

position but the

compressor does not

run

1. Power failure

2. Power is supplied,

but the equipment

does not run

1. Not operating at all

1) Power plug

2) Circuit breaker

1) receptacle

2) Operation switch

3) Cord or lead wire to

the switch

1) Compressor

2) Thermostat

1) Power failure

2) Circuit breaker is tripped

3) Power plug is not contacting

●

Disconnection

●

Mechanical failure of switch

1) Disconnection

2) Malfunction of contact

●

Disconnection or burned-out

1) Failure

2) Malfunction

3) Knob is not set to the proper

setting

●

Consult your electric company

●

In case of a breaker, turn it on

and off a few times

●

Replace the power plug

●

Repair or replace the

receptacle

●

Replace the cord or lead wire

●

Replace the compressor or

connection wire

●

Replace

●

Repair or replace

●

Turn knob for cooler setting

●

2. Compressor

3) Selector switch

4) O.L.P

5) Capacitor

1) Electricity

2) Room temperature

and outside

temperature

3) Compressor

4) O.L.P

5) Capacitor

●

Failure of malfunction of proper

●

Repair or replace the swtting

setting

●

1) Turn over

●

Lack of capacity

●

Disconnection

1) The voltage exceeded allowed

Wait until return it.

●

Replace

●

Repair

●

Consult your electric company

range

●

Check the capacity of wire

2) Capacity of wire is not

●

sufficient

Ventilate well and remove the

heat source

●

Extremely high

●

Burned-out

●

Malfunction

●

Lack of capacity

●

Replace

●

Replace

●

Replace

3. Frequent start and

stop

1) Thermostat

2) Capacitor

3) O.L.P

●

Malfunction

●

Lack of capacity

●

Turn over

16

●

Replace

●

Replace

●

Wait until return it.

Page 17

TROUBLE SITUATION ANALYSIS CA USE REMED Y

The compressor runs

but the motor doesn’t

run

Both fan motor and

compressor are

running but cooling is

bad

Not cooling at all

Insufficient cooling

1) Fan

2) Fan motor

3) Capacitor

4) Fan motor circuit

Refrigerant system

1) Refrigerant system

2) Filter

3) Heat exchanger of

condenser

●

Blocked by others

●

Disconnection or burned-out

●

●

electric cord

●

Failure malfunction of contact

●

Disconnection of malfunction of

●

●

contact

1) Refrigerant system is choked

2) Compressor failure

3) Leakage of refrigerant gas

1) Refrigerant system is choked

2) Compressor failure

3) Leakage of refrigerant gas

●

●

●

●

●

●

4) Refrigerant charge is too high

●

●

Clogged up with dust

●

1) Fin is cogged up with dust

●

2) The ventilation is not good

●

3) The unit is exposed to the

sunlight

●

Repair

Replace the fan motor

Replace

Check the circuit

Repair

Repair

Recharge refrigerant gas

Check and repair refrigerant

system

Replace

Check a part of Leakage and

repair

Repair and recharge

Clean the air fiter

Clean the unit

Shade the unit from the

sunlight

Remove the added heat source

Vibration & Noise

Water leakage into

room

Electric shock

(Leakage of current)

1) Installation place

2) Fan

3) Fixing screws

4) Electric

components

●

Installation condition

●

Insulation of

components

4) Other heat source is added in

the room

●

Installation of the unit is

●

imperfectly done

1) Fan is contacted with

●

obstacles

2) Fixing bolt

●

Have a screw loose

●

Electrical noise

●

The front is lower than rear side

1)Insulation defect of wiring and

●

●

●

●

●

lead wire

2) Leakgae of current due to the

●

dew or rust

Install the unit perfectly

Remove obstacles

Tighten the bolt

Tighten the screw

Exchange the components

Make rear side of the unit lower

than the front

Check the unit’s Leakage of

current.

Replace the defective parts or

components

17

Page 18

TROUBLE SHOO TING

If you find the ice on the outdoor side, please check the P.C.B as following.

1) P.C. B test function.

1) Remove the sensor connector from the P.C.B.

2) Supply the power

3) Short the sensor connector (pin 1 and 3 of CN1) for 3 seconds over.

4) If the relay(RL1) is on and off just one time, the P.C.B. is regard of correct.

5) Connect the sensor to the P.C.B. again.

2) R-T TABLE OF SENSOR.

TEMP(°C)

-5

-4

-3

-2

-1

0

1

2

3

4

5

3) RELAY CHECK

If the resistance is “zero” between the two pin L1 and L3, the relay(RL1) is O.K.

(The check must be conducted after the power supply cord is removed.)

4) If the P.C.B, Sensor, Relay are correct all, please check the other parts.

R(KOhm)

43.67

41.35

39.18

37.13

35.21

33.4

31.69

30.08

28.57

27.14

25.79

Voltage(V)

1.117

1.165

1.213

1.264

1.315

1.368

1.421

1.474

1.529

1.584

1.641

TEMP(°C)

6

7

8

9

10

11

12

13

14

15

16

R(KOhm)

24.52

23.31

22.18

21.11

20.11

19.14

18.23

17.38

16.56

15.81

15.07

Voltage(V)

1.696

1.753

1.811

1.868

1.926

1.984

2.043

2.101

2.16

2.218

2.277

18

Page 19

13. HO W T O DISASSEMBLE

Please refer to the chapter 14 (Exploded diagram and parts list).

1 Before service of 1. Stop the unit, remove the power cord from the receptacles.

any part. 2. Move the unit to the safe location for the suitable work.

2 Ass’y Fan Motor 1. Remove Front Grille

- Fan Motor - Remove Filter Pre.

- Propeller Fan - Remove screw(2 point) in Front Grille.

- Blower Fan 2. Remove Cabinet from the unit.

- Remove screws (4 point) from the unit’s sides.

3. Remove Holder Scroll.

4. Remove Scroll upper

5. Remove Ass’y Control Box

- Remove screws (4 point).

- Remove wires in the each components.

6. Remove wires in the Panel Housing.

7. Remove screws (4 point) from Ass’y Fan Motor’s sides.

- Ass’y Fan Motor is assembly of Fan Motor, Propeller and Blower Fan, Orifice

and Panel Housing.

8. Lift the Ass’y Fan Motor from the unit.

- Remove screws (7 point)

9. Remove Clip Fan (2 point) from the shaft of Fan Motor.

10. Remove Propeller Fan from the shaft of Fan Motor.

11. Remove Blower Fan from the shaft of Fan Motor.

12. Remove Fan Motor from Panel Housing.

- Remove screws (4 point).

3 Ass’y Control Box 1. Same as the procedure 1 to 5 in the Item 2.

-

Rotary Switch (selector)

- Auto Louver Switch.

- Thermostat

- Capacitor

- Power Cord

19

Page 20

14. EXPLODED DIA GRAM AND PAR TS LIST.

■ DWB-180CH-R PARTS LIST

No. CODE COMPONENTS Q’TY SPECIFICATION REMARK

1 3100066220 ASS’Y PAN BASE 1 ASS’Y

2 COMP BOLT 3 M8

3 3100002900 ASS’Y SEAL CAP DRAIN 1 ASS’Y

4 3106600910 SCROLL LOWER 1 EPS

5 3106700400 CAM 1 POM

6 3104600110 RING VENT 1 NBR P6

7 3101700300 LEVER VENT 1 PP(M-540)

8 3100066510 AS EVA 1 FPI 1.8, 4R-4C

9 3100074000 AS PIPE EVA OUT 1 ASSY(C1220T)

10 3100074101 AS PIPE EVA IN 1 ASSY(C1220T)

11 3100073001 AS PIPE CAPILLARY 1 ASSY(C1220T)

12 3100073900 AS PIPE 4-WAY 1 ASSY(C1220T)

13 3106600810 SCROLL UPPER 1 ESP

14 3100068001 COMPRESSOR 1 AWG-5524EXC(TECUMSEH)

15 WASHER PLAIN 3 M8

16 NUT LOCK 3 M8

17 GROMMET 3 EPDM

18 GASKET 1 SILICON

19 COVER TERMINAL 1

20 3102708000 HARNESS COMP ASS’Y 1 AWG-14x3(UL)

21 3107000500 FAN CLIP 2 SK5

22 3101802800 FAN BLOWER 1 ABS(ABS-730)

23 3104202301 PANEL HOUSING 1 SGCC T1.0

24 3108506500 SEAL HOUSING 1 F-PE +US

25 3100701600 BUSHING P.H 1 MASS

26 3104409400 RUBBER PIPE BUTTYL 2 4 MASS

27 3108005400 MOTOR FAN 1 DMI (AM12DWD08)

28 3100701500 BUSHING GUIDE 1 NBR

29 7S432X5121 SPECIAL SCREW 4 TT3/HEX 5x12

30 3101405402 COVER ORIFICE 1 PP (M-540)

31 3100066700 LOCK WIRE STANDOFF 2

32 3101802900 FAN PROPELLER 1 ABS+GF20%

33 3100058231 AS CABINET WL 1 ASSY

34 3108505300 SEAL CABINET TOP 1 F-PE+US

35 3108505400 SEAL CABINET SIDE(L) 1 F-US

36 3108505500 SEAL CABINET SIDE(R) 1 F-US

37 3108505600 SEAL COND TOP 1 F-US

38 3100066310 ASS’Y CONDENSOR 1 3R-2C(P2.0)

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

20

Page 21

No. CODE COMPONENTS Q’TY SPECIFICATION REMARK

39 3100070811 AS PIPE COND IN 1 ASSY(C1220T)

40 3100070911 AS PIPE COND OUT 1 ASSY(C1220T)

41 3104431300 PIPE 4-WAY EVA 1 C1220T-0D 12.7

42 3100074601 AS PIPE DISCHARGE 1 ASSY

43 3100074501 AS PIPE SUCTION 1 ASSY

44 3100067900 ASS’Y GRILLE FRONT 1 ASSY

3108505200 SEALGRILLE FRONT 1 F-US

3100072500 AS SEAL GRILLE FRONT(2) 1 DWA-240C-R

3108505240 SEALGRILLE FRONT(D) 1 F-PE

3108505250 SEALGRILLE FRONT(E) 1 F-PE

45 3108505230 SEAL GRILLE FRONT(3) F-PE

46 3106502202 BLADE VERTICAL 1 HIPS

48 3101902201 FILTER PRE 1 HIPS+MESH

49 7112401011 SCREW TAPPING 1 T1 TRS 4x10

50 3101600840 DECO FRONT 1 PC T0.2

51 3100509220 BOX CONTROL 1 SGCC T0.8

52 5S10405110 S/W ROTARY 1 DAESUNG SRB 417-2D

53 7001400611 SCREW MACHINE 2 PAN 4x6 MFZN

54 5SM0101810 THERMOSTAT 1 PFA606D(PCC)

55 7001400611 SCREW MACHINE 2 PAN 4x6 MFZN

56 3966031000 MOTOR SYNCRO 1 MN73SHBJ

57 7122300611 SCREW TAPPING 2 T2S PAN 3x6

58 3109500400 CAPACITOR 1 7.5+35µF, 400 VAC

59 3101201500 CLAMP CAPACITOR 1 SGCC T0.8

60 7122401011 SCREW TAPTITE 1 T1 TRS 4x10

61 3101300400 POWER CORD 1 AWG12

62 3101203100 CLAMP POWER CORD 1 DA-6N

63 7122401011 SCREW TAPTITE 1 T1 TRS 4x10

64 3108505800 SEAL COTROL BOX 1 F-PE

65 3105000100 SPACER LOCKING 4 DABS-8R

66 3104303100 DEICER PCB ASSY 1 ASSY

67 3102708210 HARNESS SELECTOR 1

68 3102708150 HARNESS LAMP 2

69 3102708450 HARNESS DEICER 1

70 3102708320 HARNESS SWING MOTOR(C) 1

71 3102708100 HARNESS THERMOSTAT 1 UL 1015-14

72 3102708200 HARNESS S/W ROTARY 1 UL 1015-18

73 3102708300 HARNESS SWING MOTOR 1 UL 1015-18

74 3103600400 LAMP HEATER 1 BN-6(RED)

75 3108912700 TERMINAL BLOCK 1 DA-TB1(DONG-A)

76 3103534100 LABEL SPEC 1

77 3103905900 MANUAL OWNER’S 1

21

Page 22

■ DWB-240CH-R PARTS LIST

No. CODE COMPONENTS Q’TY SPECIFICATION REMARK

1 3100066220 ASS’Y PAN BASE 1 ASS’Y

2 COMP BOLT 3 M8

3 3100002900 ASS’Y SEAL CAP DRAIN 3 M8

4 3106600910 SCROLL LOWER 1 EPS

5 3106700400 CAM 1 POM

6 3104600110 RING VENT 1 NBR P6

7 3101700300 LEVER VENT 1 PP(M-540)

8 3100066510 AS EVA 1 FPI 1.8, 4R-4C

9 3100074000 AS PIPE EVA OUT 1 ASSY(C1220T)

10 3100074101 AS PIPE EVA IN 1 ASSY(C1220T)

11 3100073010

12 3100073900 AS PIPE 4-WAY 1 ASSY(C1220T)

13 3106600810 SCROLL UPPER 1 EPS

14 3100068201 COMPRESSOR 1 AWG-5530EXC(TECUMSEH)

15 WASHER PLAIN 3 M8

16 NUT LOCK 3 M8

17 GROMMET 3 EPDM

18 GASKET 1 SILICON

19 COVER TERMINAL 1

20 3102708000 HARNESS COMP ASS’Y 1 AWG-14x3(UL)

21 3107000500 FAN CLIP 2 SK5

22 3101802800 FAN BLOWER 1 ABS(ABS-730)

23 3104202301 PANEL HOUSING 1 SGCC T1.0

24 3108506500 SEAL HOUSING 1 F-PE + US

25 3100701600 BUSHING P.H 1 MASS

26 3104409400 RUBBER PIPE BUTTYL 2 MASS

27 3108005500 MOTOR FAN 1 DMI (A2945CA010)

28 3100701500 BUSHING GUIDE 1 NBR

29 7S432X5121 SPECIAL SCREW 4 TT3/HEX 5x12

30 3101405402 COVER ORIFICE 1 PP (M540)

31 3100066700 LOCK WIRE STANDOFF 2

32 3101802900 FAN PROPELLER 1 ABS+GF20%

33 3100058231 AS CABINET WL 1 ASSY

34 3108505300 SEAL CABINET TOP 1 F-PE+US

35 3108505400 SEAL CABINET SIDE(L) 1 F-US

36 3108505500 SEAL CABINET SIDE(R) 1 F-US

37 3108505600 SEAL COND TOP 1 F-US

38 3100066310 ASS’Y CONDENSOR 1 3R-2C(P2.0)

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

COMP ACCESSORY PART

22

Page 23

No. CODE COMPONENTS Q’TY SPECIFICATION REMARK

39 3100070811 AS PIPE COND IN 1 ASSY(C1220T)

40 3100070911 AS PIPE COND OUT ASSY(C1220T)

41 3104431300 PIPE 4-WAY EVA 1 C1220T-0D 12.7

42 3100074601 AS PIPE DISCHARGE 1 ASSY

43 310074501 AS PIPE SUCTION 1 ASSY

44 3100067900 ASS’Y GRILLE FRONT 1 ASSY

3108505200 SEAL GRILLE FRONT 1 F-US

3100072500 AS SEAL GRILLE FRONT(2) 1 DWA-240C-R

3108505240 SEAL GRILLE FRONT(D) 1 F-PE

3108505250 SEAL GRILLE FRONT(E) 1 F-PE

45 3108505230 SEAL GRILLE FRONT(3) ASSY

46 3106502202 BLADE VERTICAL 1 HIPS

47 3106502100 BLADE HORIZONTAL 2 PP

48 3101902201 FILTER PRE 1 HIPS+MESH

49 7112401011 SCREW TAPPING 1 T1 TRS 4x10

50 3101600840 DECO FRONT 1 PC T0.2

51 3100509220 BOX CONTROL 1 SGCC T0.8

52 5S10405110 S/W ROTARY 1 DAESUNG SRB 417-2D

53 7001400611 SCREW MACHINE 2 PAN 4x6 MFZN

54 5SM0101810 THERMOSTAT 1 PFA606D(PCC)

55 7001400611 SCREW MACHINE 2 PAN 4x6 MFZN

56 3966031000 MOTOR SYNCRO 1 MN73SHBJ

57 7122300611 SCREW TAPPING 2 T2S PAN 3x6

58 3109504700 CAPACITOR 1 7.5+µF, 400 VAC

59 3101201500 CLAMP CAPACITOR 1 SGCC T0.8

60 7122401011 SCREW TAPTITE 1 T1 TRS 4x10

61 3101300400 POWER CORD 1 AWG12

62 3101203100 CLAMP POWER CORD 1 DA-6N

63 7122401011 SCREW TAPTITE 1 T1 TRS 4x10

64 3108505800 SEAL COTROL BOX 1 F-PE

65 3105000100 SPACER COCKING 4 DABS-8R

66 3104303100 DEICER PCB ASSY 1 ASSY

67 3102708210 HARNESS SELECTOR 1

68 3102708150 HARNESS LAMP 2

69 3102708450 HARNESS DEICER 1

70 3102708320 HARNESS SWING MOTOR(C) 1

71 3102708100 HARNESS THERMOSTAT 1 UL 1015-14

72 3102708200 HARNESS S/W ROTARY 1 UL 1015-18

73 3102708300 HARNESS SWING MOTOR 1 UL 1015-18

74 3103600400 LAMP HEATER 1 BN-6(RED)

75 3108912700 TERMINAL BLOCK 1 DA-TB1(DONG-A)

76 3103538400 LABEL SPEC 1

77 3103905900 MANUL OWNER’S 1

23

Page 24

■ DEICER PCB ASS’Y (3104303100)

CODE COMPONENTS Q’TY SPECIFICATION REMARK

3108803500 PIN 3 GP881206-2(250)

D15G561K– – VARISTOR 1 15G1561K

3108806100 WAFER 1 SMW250-03 SENSOR

DZN4004A– – DIODE 4 1N4004 TAPE

DZN4148FBT DIODE 2 1N4148 TAPE

CCXE1H103M C-CERA 4 103Z, 50VDC

CCXE1H104M C-CERA 2 104Z, 50VDC

CEXE1V108C C-ELEC 1 1000µF 35V SD

CEXE1C107C C-ELEC 1 100µF 16V SD

RN-4K1272F RESISTOR 1 1/4W-12.7KF

RD-4K103J- RESISTOR 1 1/4W-10KJ

RD-4K102J- RESISTOR 2 1/4W-1KJ

RD-4K331J- RESISTOR 1 1/4W-330J

1K1A78S05P IC REGULATOR 1 KIA78S05P DC5V

3104303200 DEICER PCB 1 86X55X1.6T

5EPW035000 TRANS PCB 1 MOUNT

5SC0102100 RELAY 1 UT205-12SC

14HLP12C67 IC MICOM 1 PIC12C671 8P

TZTC3198Y TR 1 KRC3198Y

24

Page 25

2

Page 26

5

Page 27

DAEW OO ELECTRONICS CO., LTD.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 590-6291

TEL: 02) 360-7114/590-6151~5

http://www.dwe. daewoo.co.kr

S/M NO.: DWC121C010

PRINTED DATE: OCT.1999

Page 28

Service Manual

Window Type

Room Air Conditioner

Model: DWB-180CH-R

DWB-240CH-R

DAEWOO ELECTRONICS CO., LTD.

Loading...

Loading...