Daewoo DTQ-29U9FS-FSOFC-FSA, CN-789 S/M Schematic

S/M No. : TCP789SEF0

Service Manual

68 Cm STEREO Color Television

MODEL

DTQ-29U9FS

DTQ-29U9FSO

DTQ-29U9FSA

DTQ-34Z9FC

DTH-29U9FSA

CHASSIS

CN-789S

CN-789S

CN-789S

CN-789S

CN-789M

Model DTQ-29U9FS DTQ-29U9FSO DTQ-29U9FSA DTQ-34Z9FC DTH-29U9FSO DTH-29U9FSA

Chassis CN-789S CN-789M

System NTSC NTSC/PAL-M/PAL-N

Input voltage AC110 ~ 220V

Power consumption 140W 130W 158W 140W 130W

Speaker impedance 8 OHM

MTS system Zenith

Sound output power

(100% modulation)

Receiving channels

(181ch)

RF impedance 75 OHM

Screen size 68 Cm

Remote control R-37C04 R-37C05 R-37C04 R-37C05

Screen aspect

Dimension

Weight 56kg

WOOFER : 10W X WOOFER : 10W X

R : 7.5W

L : 7.5W

VHF : 2 ~ 13

UHF : 14 ~ 69

A5-A1, A-W, W+1-W+84, 5A

4 : 3

16 : 9

Width : 843mm

Height : 592mm

Depth : 504mm

DAEWOO ELECTRONICS CO., LTD

http : //svc.dwe.co.kr

MAY. 2000

TABLE OF CONTENTS

1. Important Service Notes ............................................................................................................. 2

2. Specifications .............................................................................................................................. 4

3. Alignment Instructions ............................................................................................................... 5

4. Block Diagram ............................................................................................................................. 7

5. IC Descriptions ............................................................................................................................ 14

6. Exploded View ............................................................................................................................. 18

7. Service parts list .......................................................................................................................... 20

1

1. Improtant Service Notes

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO - VIDEO PRODUCTS

CAUTION :

DO NOT ATTEMPT TO MOOIFY THIS PROOUCT IN AHY WAY.

NEVER PERFORM CUSTOMIZED INSTALLATI0NS WITHOUT MANUFACTURER" S

APPROVAL. UNAUTHORIZED MOOIFICATI0NS WILL NOT ONLY VOID THE WARRANTY,

BUT MAY LEAD TO YOUR BEING LIABLE FOR ANT RESULTING PROPERTY DAMAGE OR

USER INJURY. SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS AND

SERVICING GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF POTENTIAL

HAZARDS AND INJURY TO THE USER.WHILE SERVICING, USE AN ISOLATION

TRANSFORMER FOR PROTECTION FROM A.C LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK SHOULD

BE MADE OF THE FOLLOWING :

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS TO AVOID

POSSIBILITY OF ADJACENT COMPONENT SHORTS THIS IS ESPECIALLY IMPORTANT

ON THOSE NODULES WHICH ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER SUPPLY

CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER ORIGINAL

DESIGN. BE SURE, THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG

HAS NOT BEEN DEFECTED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS,

SOLDER SPLASHES OF SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL

LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORANN TO PARTS AND

COMPONENTS, FOR FRAYED LEADS, DAMAGED INSULATION (INCLUDING A.C.

CORD), AND REPLACE IF NECESSARY. FOLLOW ORIGINAL LAYOUT, LEAD LENGTH

AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A RESISTOR

RATED AT 1 WATT OR MORE. LEAD TENSION AROUND PROTRUDING METAL

SURFACES MUST BE AVOIDED.

6. ALL CRlTICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF RESISTOR,

CAPACITORS, ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES. DO NOT

USE REPLACEMENT COMPONENTS OTHER THAN THOSE SPECIAL OR MAKE

UNRECOMMENDED CIRCUIT MODIFICATIONS.

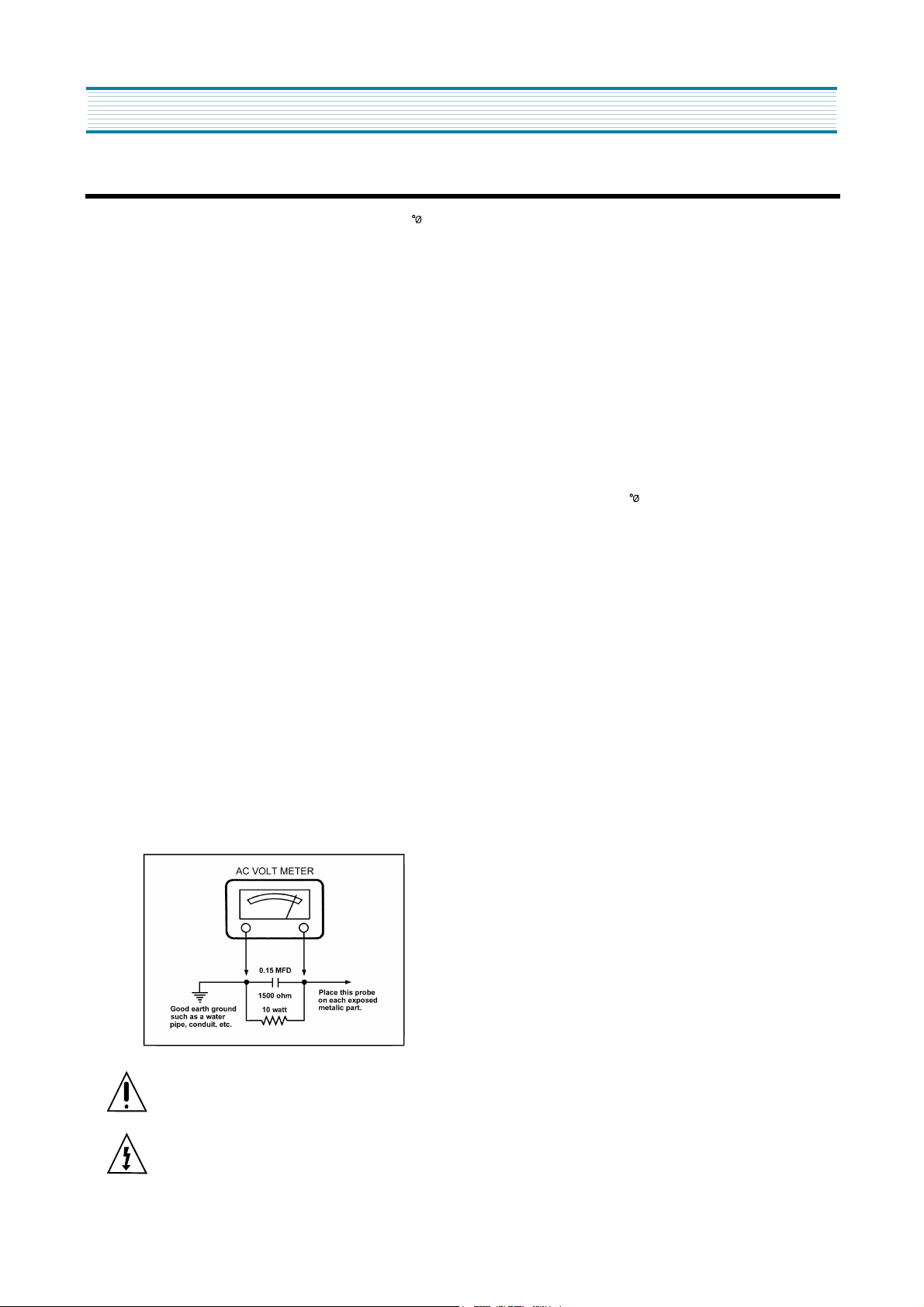

7. AFTER RE-ASSEMBLY OF THE STE ALWAYS PERFORM AN A.C. LEAKAGE TEST ON

ALL EXPOSED METALLIC PARTS OF THE CABINET. (THE CHANEL SELECTOR KNOB,

ANTENNA TERMINALS, HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANCER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING

5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER :

CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .75 MFD. 150V A.C.

TYPE CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND (WATER POPE,

CONDUIT, ETC) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME. MEASURE

THE A.C VOLTAGE ACROSS THE COMBINATION OF 1500 OHM RESISTOR AND .15

MFD CAPACITOR. REVERSE THE A.C. PLUG AND REPEAT A.C. VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASUREMENTS

MUST NOT EXCEED .75 VOLTS R.M.S THIS CORRESPONDS TO 0.5 MILLIAMP A.C.

NAY VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED IMMEDIATELY

SUBJECT : GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF UNINSULATED

"DANGEROUS VOLTAGE" THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQULATERAL TRIANGLE

IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE

PRESENCE OF IMPORTANT SAFETY INFORMATION ON SERVICE

LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND AND INSTRUCTIONS TO ALL SERVICE PERSONNEL

COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENIAL SOURCE OF X-RAYS

IN CURRENT TV RECEIVERS IS THE PICTURE TUBE HOWEVER, THIS TUBE DOES

NOT EMIT X-RAYS WHEN THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIEDLEVEL

THE PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC OPERATION AT

HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH

VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, AMY PRODUCE

RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED.

DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN COLOR SETS.

AIWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND

RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE

CHECKED PERIODICALLY AGAINST A REFERENCE STANDARD. SUCH AS THE ONE

AVAlLABLE AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE IS NO

POSSIBLITY OF AN X-RADIATION PROBLEM. EVERY TIME A COLOR CHASSIS IS

SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND DOWN WHILE MONITORING

THE HIGH VOLTAGE WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING CORRECTLY. WE

SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST

PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A

STANDARD SERVICING PROCEDURE, AND THAT THE HIGH VOLTAGE READING BE

RECORDED ON EACH CUSTOMER S INVOICE

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A PROOUCT

WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID BEING UNNECESSARILY

CLOSE TO THE PICTURE TUBE AND THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE

THE PRODUCT LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF

EXCESSIVE VOLTAGE.

6. REFER TO HV, B+ AND SHUTDOWN ADJUSTMENT PROCEDURES DESCRIBED IN

THE APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE USED).

SUBJECT : IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRA

IMPLOSION PROTECTION SYSTEM BUT CARE SHOULD BE TAKEN TO AVOID

IAMAGE DURING INSTALLATION. AVOID SCRATCHING THE TUBE. OF SCRATCHED

REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-lN RECESS, CUBBYHOLE OR

CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN THE PATH

OF HEAIED AIR FLOW.

2. AVOID CONDlTIONS OF HIGH HUMIDITY SUCH AS : OUTDOOR PAT10 INSTALLAIONS

WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A

FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING.

THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR

OTHER COVERINGS WHICH MIGHT OBSTRUCTS VENTILATION

4. WALL AHD SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING

KIT, MUST FOLLOW THE FACTORY APPROVED MOUNTING INSTRUCTIONS. A

PRODUCT MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS ORIGINAL FEET

(OR THE EQUIVALENT THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS MUST NOT

TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED

INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON SLOPING

SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO

THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A

CART WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH HAS NOT

BEEN LISTED BY UNDERWRITERS LABORATORIES. INC. FOR USE WITH THEIR

SPECIFIC MODEL OF TELEVISTION RECEIVER OR GENERICALLY APPROVED FOR

USE WITH TV.S OF THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS, EXPLAIN THAT A

FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

2

Improtant Service Notes

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO - VIDEO PRODUCTS

CAUTION :

Do not attempt to modify this product in any way Unauthorized modifications will

not only void the warranty, but may lead to your being liable for any resulting property damage

or user Injury. Service work should be performed only afters you are thoroughly familiar with all

of the following safety checks and servicing guidelines. To do otherwise, increases the risk of

potential hazards injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check should be made of the

following :

SUBJECT FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a way as to avoid possibility of adjacent

component shorts. This is especially important on those chassis which are transported to

and from the repair shop.

2. Never release a repair unless all protective devices such as Insulators, barriers, covers,

shields, strein reliefs, and other hardware have been reinstalled per original design.

3. Soldering must be inspected to discover possible cold solder joints frayed leads, damaged

insulation (Including A.C. cord), solder splashes or sharp solder points. Be certain to

remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration to parts and components, and

replace if necessary follow original layout, lead length and dress.

5. No leads or components should touch a receiving tube or a resistor rated at 1 watt or more.

Lead tension around protruding metalsurfaces must be avoided.

6. All critical components such as fuses, flameproof resistors, capacitor, etc must be replaced

with exact factory types. Do not use replacement components other than those specified or

make unrecommended circuit modifications.

7. After re-assembly of the set always perform an A.C. leakage test on all exposed metallic

parts of the cabinet, (the channel selector knob, antenna terminals, handle and screws) to

be sure the set is safe to operate without danger of electrical shock. Do not use a line

Isolation transformer during this test. Use an A.C voltmeter, having 5000 ohms per volt or

more sensitivity, in the following manner : connect a 1500 ohm 10 watt resistor, paralleled

by a 15 mfd. 150V A.C. type capacitor between a known good earth ground ( 9 water pipe,

conduit, etc ) and the exposed metallic parts, one at a time. Measure the A.C. voltage across

the combination of 1500 ohm resistor and 0.15 MFD capacitor. Reverse the A.C plug and

repeat A.C. voltage measurements for each exposed metallic part. Voltage measured must

not exceed 0.75 volts R.M.S. This corresponds to 0.5 milliamp A.C. Any value exceeding

this limit constitutes a potential shock hazard and must be corrected immediately

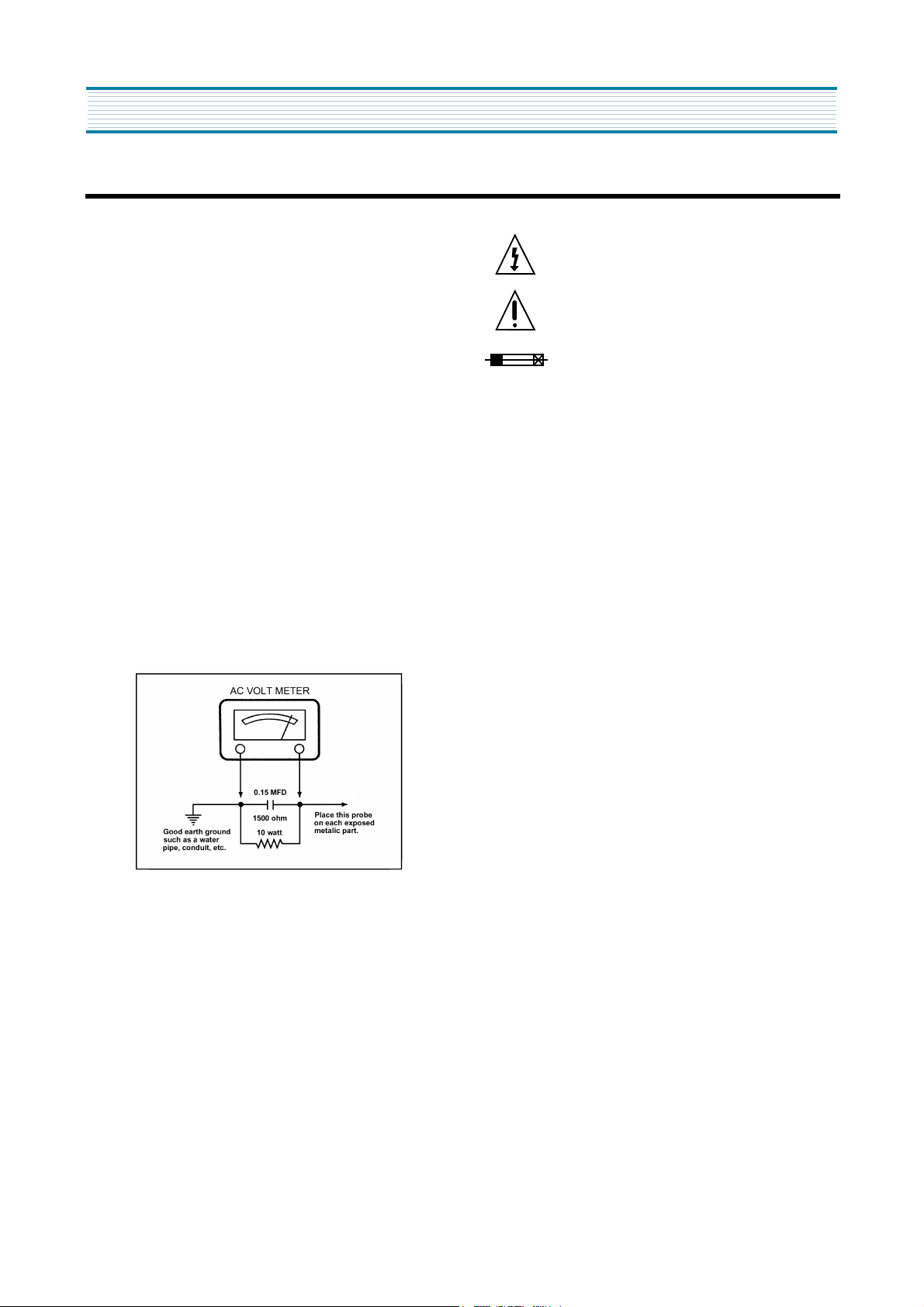

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to alert

the service personnel to the presence of uninsulated "dangerous

voltage" that may be of sufficienty magnitude to constitute a risk of

electric shock.

The exclamation point within an equilateral triangle is intended to alert

the service personnel to the presence of important safety information

in service literature.

Fuse symbol is printed on pcb adjacent to the fuse, with "RISK OF FIRE

REPLACE FUSE AS MARKED". The symbol is explained in the service

manual with the following wording or equivalent.

"

CAUTION :

WITH SAME TYPE (6.3A, 250V)" and "ATTENTION : AFIN D'ASSU UNE PROTECTION

PERMANENTE CONTRE LES RISQUES D'INCENDIE, REMPLACER UNIQUEMENT PAR

UN FUSIBLE DE MEME TYPE ET DE "6.3A, 250V".

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the subject of X-rays in

current T.V receivers is the picture tube.

However, this tube does not emit X-rays when the high voltage is at the factory specified

level. The proper value is given in the applicable schematic.

Operation at higher voltages may cause a failure of the picture tube or high voltage supply

and, under certain circumstances, may produce radiation in excess of desirable levels.

2. Only factory specified C.R.T anode connectors must be used.

Degaussing shields also serve as X-ray shield in color sets. Always re-install them.

3. It is essential that the serviceman has available an accurate and reliable high voltage meter.

The calibration of the meter should be checked perio - dically against a reference standard.

Such as the one available at your distributor.

4. When the high voltage circuitry is operating properly there is no possibility of an X-radiation

problem. Every time a color chassis is serviced, the brightness should be run up and down

while monitoring the high voltage with a meter to be certain that the high voltage does not

exceed the specified value and that it is regulating correctly. We suggest that you and your

service organization review test procedures so that voltage regulation is always checked as

a standard servicing procedure. And that the high voltage reading be recorded on each

customer's invoice.

5. When troubleshooting and making test measurements in a receiver with a problem of

excessive high voltage, avoid being unnecessarily close to the picture tube and the high

voltage compartment.

Do not operate the chassis longer than is necessary to locate the cause of excessive

voltage.

6. Refer to HV, B+ and Shutdown adjustment procedures described in the appropriate

schematic and diagrams(where used).

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY

SUBJECT : IMPLOSION

1. All direct viewed picture tubes are equipped with an integeral implosion protection system,

but care should be taken to avoid damage during installation. Avoid scratching the tube. If

scratched, replace it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER INSTALLATION

1. Never install any receiver in closed-in recess, cubbyhole or closely fitting shelf space over, or

close to heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as : Outdoor patio installations where dew is a factor.

Near steam radiators where steam leakage is factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The customer should also

avoid the use of decorative scarves or other coverings which might obstruct ventilation.

4. Wall and shelf mounted installations using a commercial mounting kit, must follow the

factoryapproved mounting instructions. A receiver mounted to a shelf or platform must retain

its original feet (or the equivalent thickness in spacers) to provide adequate are flow across

the bottom, bolts or screws used for fasteners must not touch and parts or wiring. Perform

leakage test on customized installations.

5. Caution customers against the mounting of a receiver on sloping shelf or a tilted position,

unless the receiver is properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to the cart. Caution the

customer on the harzards of trying to roll a cart with small casters across thresholds or deep

pile carpets.

7. Caution customers against the use of a cart or stand which has not been listed by

underwriters laboratories, inc. For use with their specific model of television receiver or

generically approved for use with T.V.’s of the same or larger screen size.

3

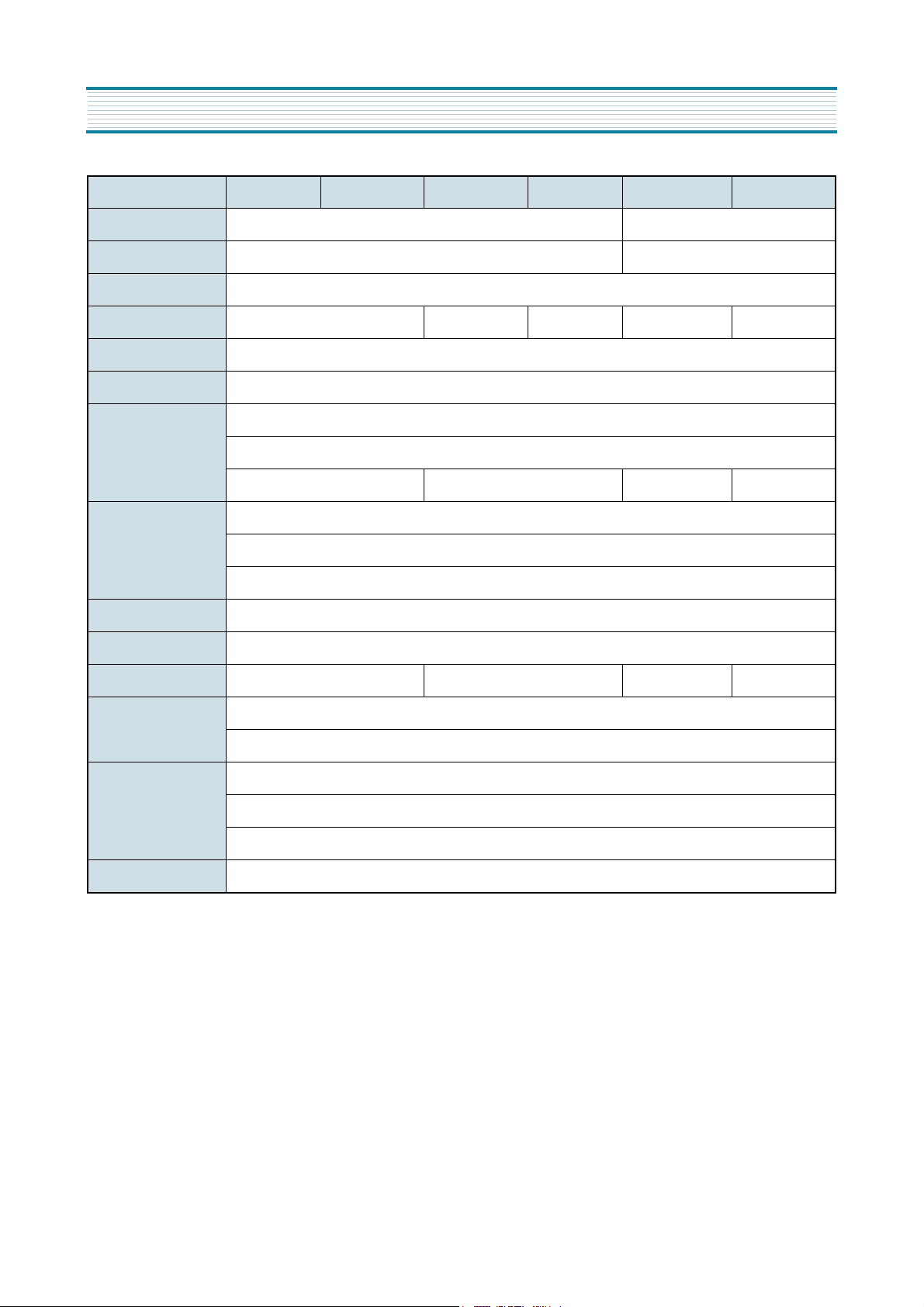

2. Specifications

Model DTQ-29U9FS DTQ-29U9FSO DTQ-29U9FSA DTQ-34Z9FC DTH-29U9FSO DTH-29U9FSA

Chassis CN-789S CN-789M

System NTSC NTSC/PAL-M/PAL-N

Input voltage AC110 ~ 220V

Power consumption 140W 130W 158W 140W 130W

Speaker impedance 8 OHM

MTS system Zenith

R : 7.5W

Sound output power

(100% modulation)

WOOFER : 10W X WOOFER : 10W X

Receiving channels

(181ch)

A5-A1, A-W, W+1-W+84, 5A

L : 7.5W

VHF : 2 ~ 13

UHF : 14 ~ 69

RF impedance 75 OHM

Screen size 68 Cm

Remote control R-37C04 R-37C05 R-37C04 R-37C05

4 : 3

Screen aspect

16 : 9

Width : 843mm

Dimension

Weight 56kg

Height : 592mm

Depth : 504mm

4

3. Alignment Instructions

POWER

MUTE

TV/VIDEO

ADD/ERASE

How to enter into Service Mode

1

RECALL

STOP

P

A

R

E

W

O

P

R

C

V

W

E

R

100

MTS

U

S

E

PLAY

F

F

W

SLEEP

/

S

T

I

L

L

Direct the remote control to the reception window of TV

2

Push buttons of remote control in sequece.

1 MUTE RECALL MUTE

3

then, the screen will appear as followws.

* Service Mode *

1 - HEAT RUN 7 - PIP CON

2 - SCREEN 8 - WHT BAL

3 - VOL CHK 9 - D.P. CON

4 - PIC CHK 0 - FUN CHK

5 - PIC CON 100 - ABL

6 - GEOMETR * - EX FACT

CHANNEL

MENU

SOUND

SURROUND

CHANNEL

SOUND

DIGITAL

SENSOR

R-37C04

How to memorize the adjusted settings in service mode

: Must press “RECALL” button the state which the screen is displaying

each of service menus after all adjustments are completed each of all

service menu.

5

Alignment Instructions

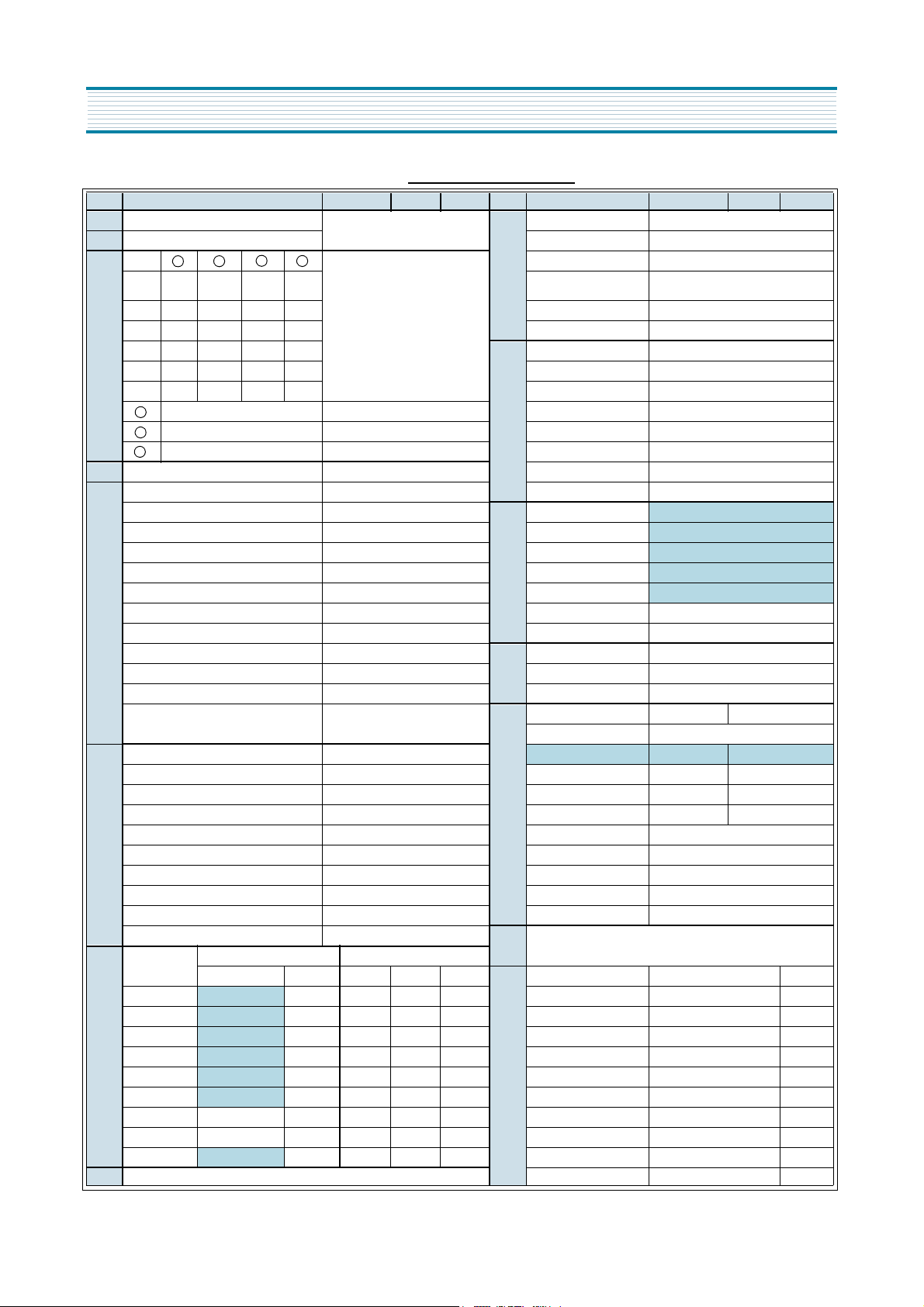

CN-789S EEPROM DATA

KEY CONTENTS 29U9FSO 29U9FS 29U9FSA KEY CONTENTS 29U9FSO 29U9FS 29U9FSA

S1 HEAT-RUN=>AUTO ON=>NORMAL S7-1 TWIN ON/OFF

S2 HORIZENTAL LINE => NORMAL P1 PIP A H-POS 7

3

S3 P2 MAIN A-POS 7

S4 CON/BRI/SHA/TIN MIN-MAX-CENTER PIP-CONT 6

S5-1 FLESHTONE OFF PIP SHARP 6

S5-26P-ACL OFF BRIGHTNESS 90 70

S6 4:3 / WIDE

EXT VOL:50, CAPTION:C1, AUTO ON CAPTION ON ON

1 2

OFF MUSIC MOVIE NEW

100Hz 21 19 15 7 P6 MAIN V-POS 2

300Hz 14 17 15 15 P7 PIP A V-POS 3

1K 9 13 13 14 S7-2 Y-GAIN 9

3K 14 17 15 12 PIP COLOR 8

10 21 18 11 8 PIP TINT 6

VOLUME MIN PEDEST U 4

5

VOLUME MAX PEDEST V 6

6

7

VOLUME CENTER DC TRAN 0

S-TRAC OFF S8-1 G-DRIVE 63

WHITE PEAK ON B-DRIVE 63

COLOR R 0 R-BIAS 127

COLOR LIMIT ON G-BIAS 70

Y R ON B-BIAS 70

GP-PHASE OFF C SYSTEM ON

R-Y PHASE 1 OSD 7

R-Y AMPLI 1 S8-2 V-DLY 2

Y DELAY OFF H-DLY 64

VM GAIN 0 H-POS 6

B-STRET LIM O CONTRAST 26 24

B-POINT1 1 SHARPNESS 0 3

B-POINT2 2 TINT 0 0

W-PEAK CUR 0 MAIN PRE 90

D-ABL PO 7 STEREO ID 10

D-ABL GA 0 VIDEO PRE 46

ABL POINT 2 MONOTOR VOL 21

ABL GAIN 3 LNA 6

WIDE MUTE ON S10 CLOCK - AVC - WIDE -3S SURROUND - DIG. SENSOR - CAPTION - WOOFER

29U9FS 29U9FSO TWIN MULTI(4) MULTI(7) S11 AUTO OFF ON ON

V-DC 4/M+2 4/M+2 WIDE ON ON

H-CENTER 13/M 15/M 0 0 0 3S SURROUND OFF OFF

CUTION1 14/M+2 19/M M+1 M+1 M+1 LNA OFF OFF

H-WIDTH 47/M 41/M DIG. SENSOR ON ON

V-WIDTH 46/M-31 64/M-34 AUTO EQ ON OFF

V-LIN 11/M 4/M PIP ON OFF

V-S 2/0 6/5 PIP PAL OFF OFF

PIN-CONER 8/M-3 6/3 WOOFER ON OFF

TRAPEZE 44/M 35/M NTSC ON ON

* W / BALANCE : 263 / 268 ( H : 140 / L : 15 )

4

S

P5 MAIN H-POS 19

S9 CNR U V 17 22

COLOR 20

6

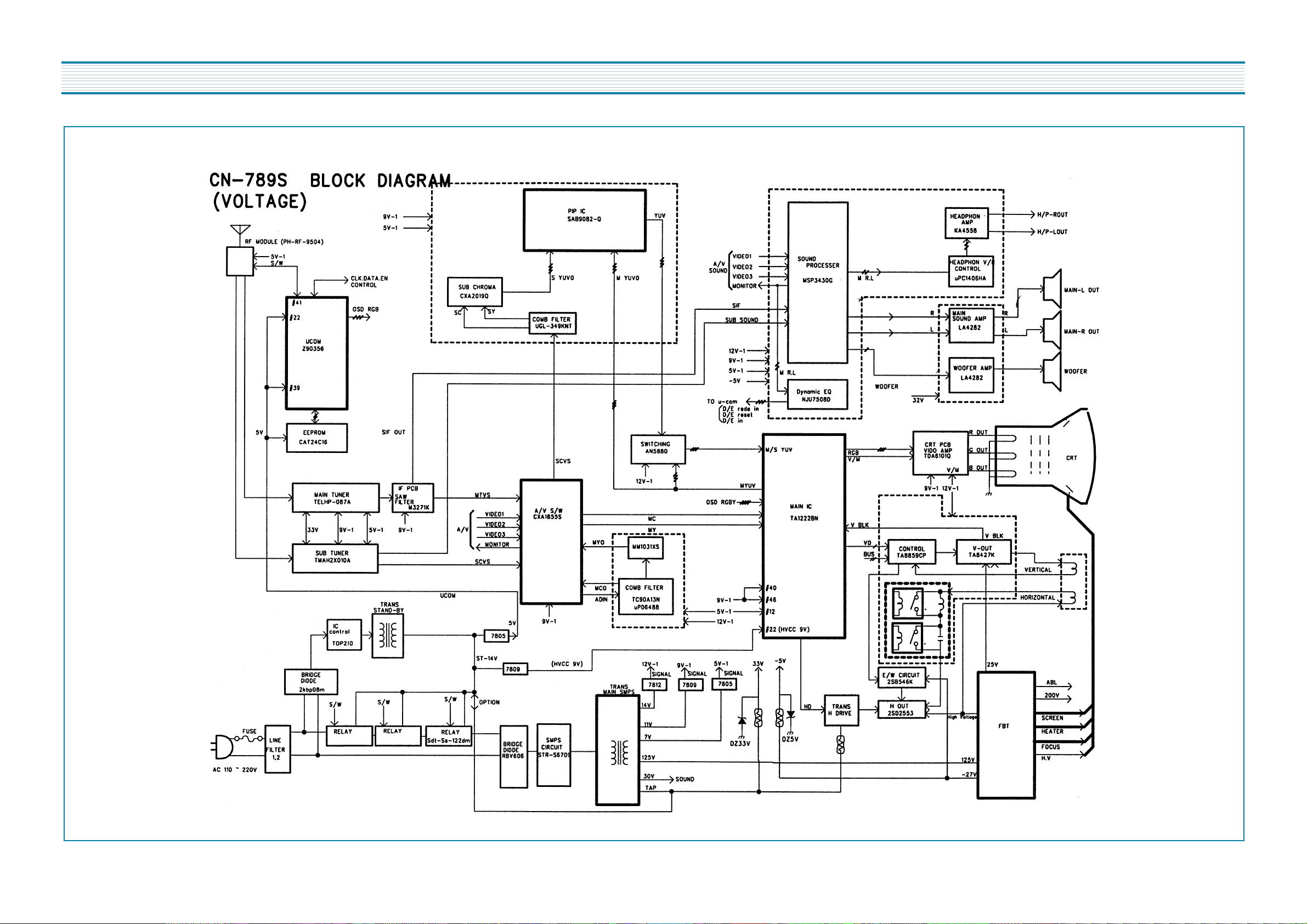

4. BLOCK DIAGRAM

7

4. Block Diagram

1) DTQ-29U9FS/FSO/FSA-MICOM

8

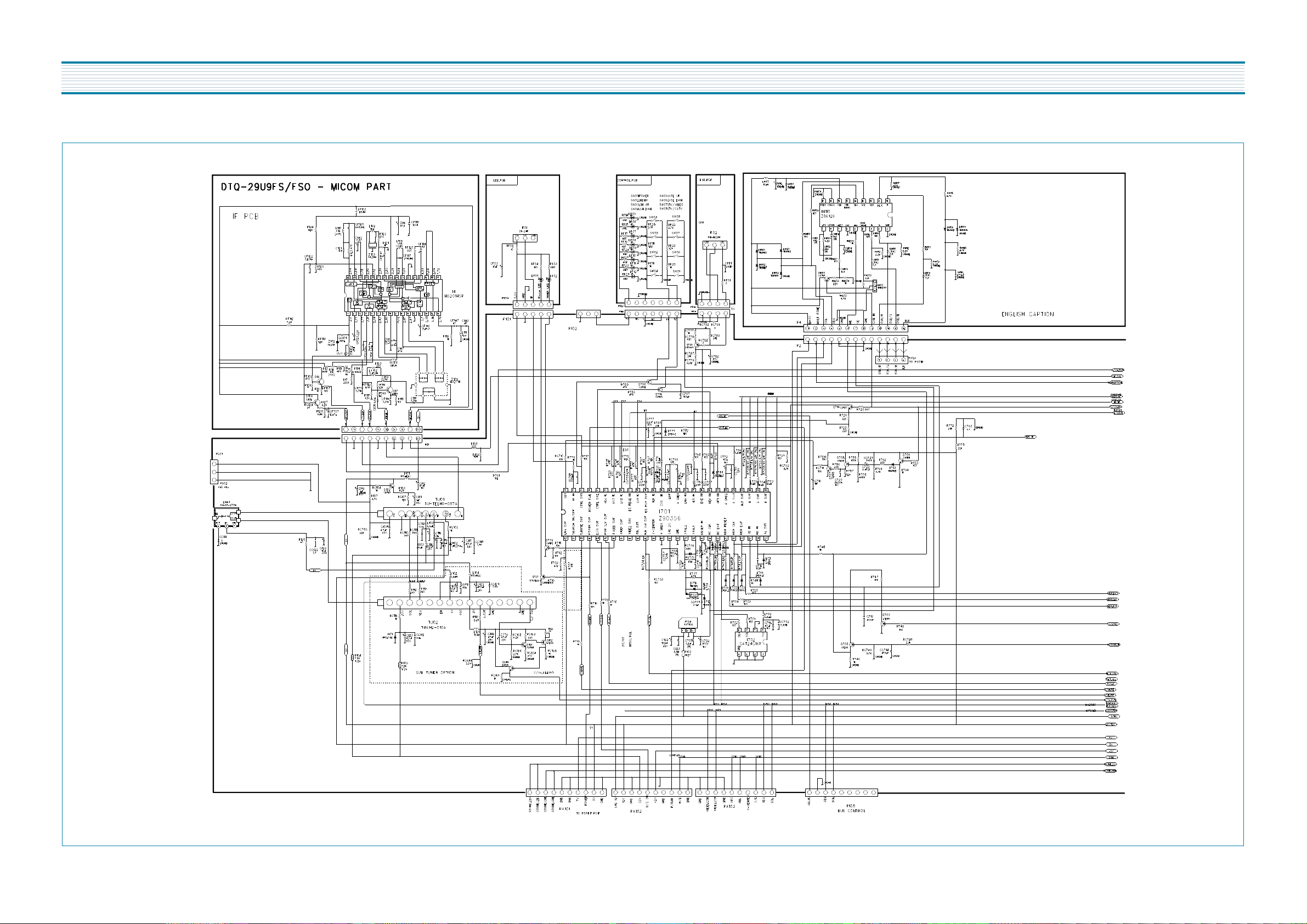

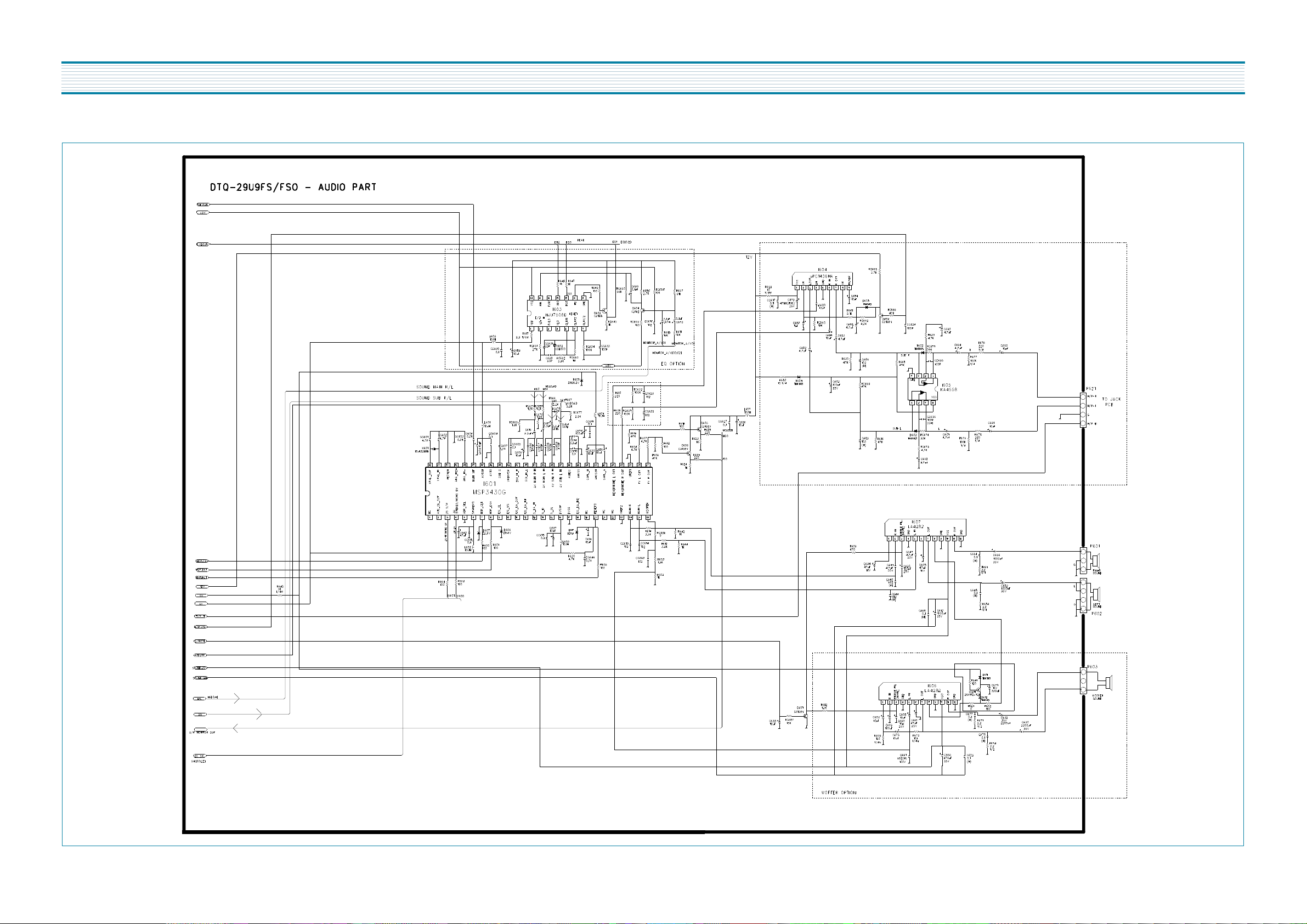

4. Block Diagram

2) DTQ-29U9FS/FSO/FSA-AUDIO

9

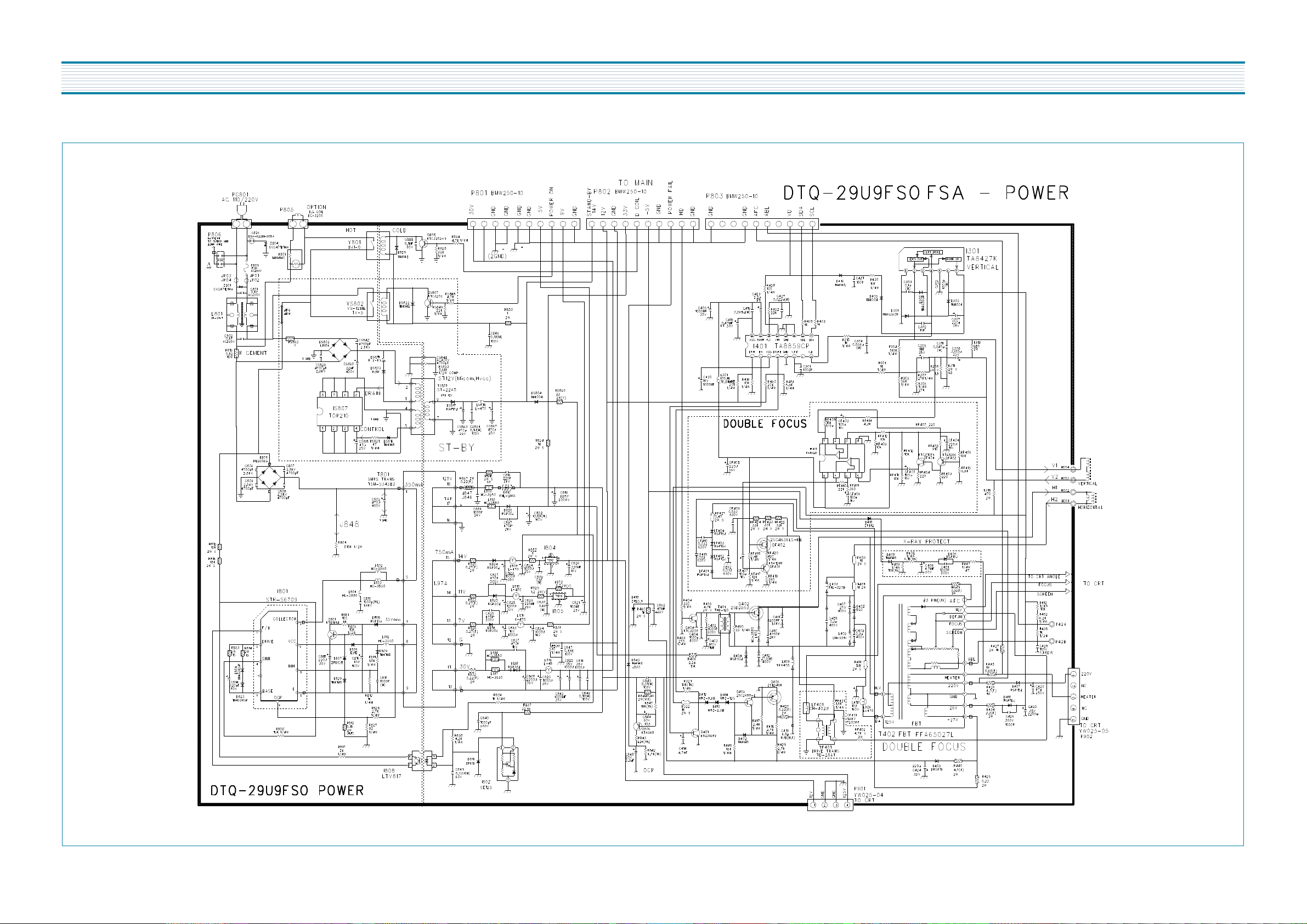

4. Block Diagram

3) DTQ-29U9FSO/FSA-POWER

10

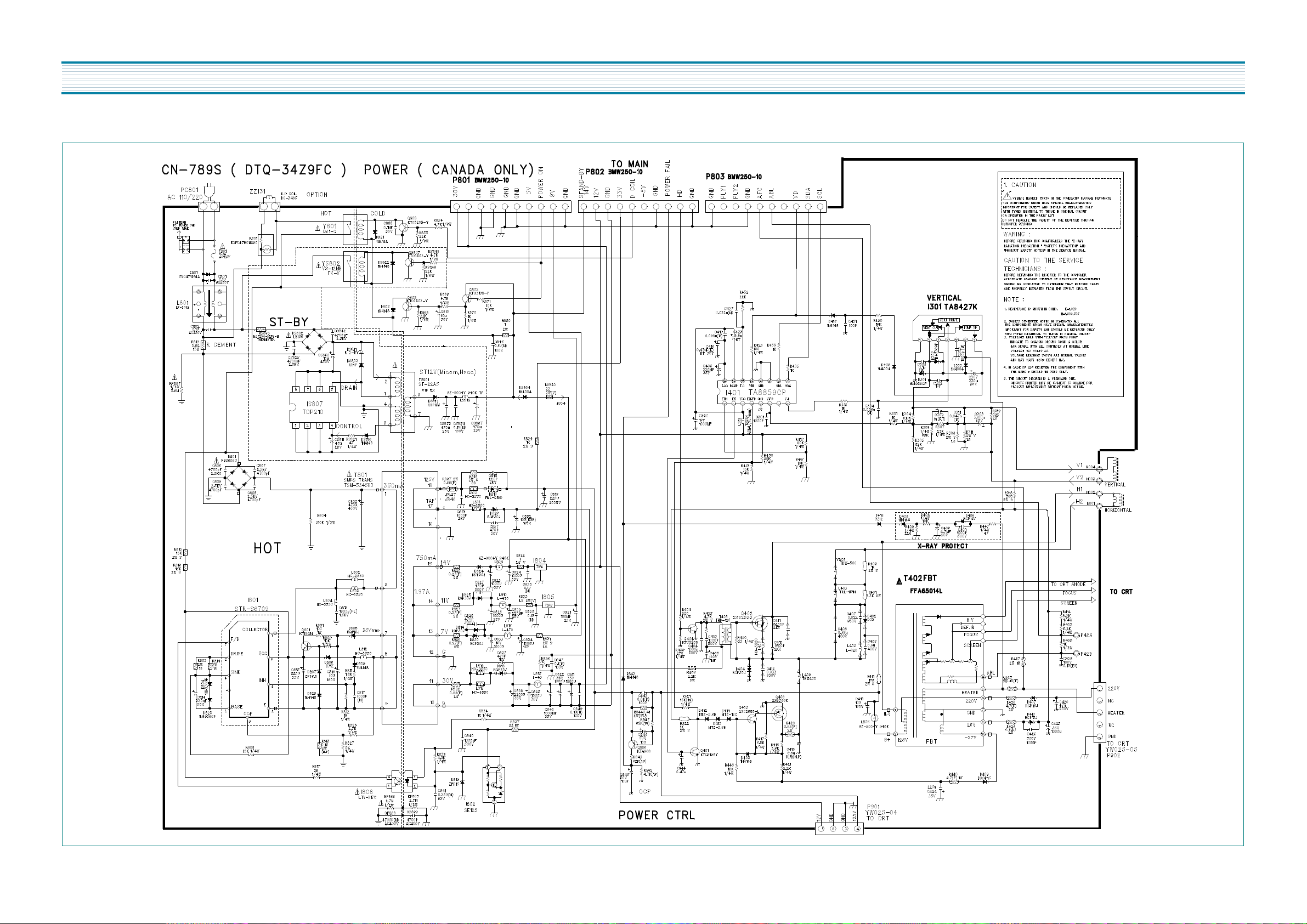

4. Block Diagram

4) DTQ-34Z9FC-POWER

11

Loading...

Loading...