Page 1

Service Manual

Color Television

CN-200I/A

CHASSIS

NTSC-M SYSTEM

:

MODEL

DTQ-26S1FC/FS/FSP(CN-200I)

:

DTQ-29S1FCN/FSN/FSP(CN-200I)

DTQ-26S1HC/HS/HSP(CN-200A)

DTQ-29S1HC/HS/HSP(CN-200A)

DAEWOO ELECTRONICS CO., LTD.

OVERSEAS SERVICE DEPT.

Page 2

FEATURES

FS (Frequency Synthesizer) Tuning System

CATV Ready

Monitor Look Design

A/V IN. (Stereo)

Stereo/Mono Function

ELECTRICAL SPECIFICATIONS

POWER INPUT

FC SERIES AC 120V 60Hz

FS SERIES AC 85V ~ AC 150V 60Hz

FSP SERIES AC 220V 50Hz/60Hz

POWER RATING

26” MODELS 100W

29” MODELS 105W

INTERMEDIATE FREQUENCIES

PICTURE IF CARRIER FREQUENCY 45.75MHz

SOUND IF CARRIER FREQUENCY 41.25MHz

COLOR SUB CARRIER FREQUENCY 42.17MHz

AUDIO OUTPUT RATING 1.2W 2

SPEAKER 2W 8 ohm 2

ANTENNA INPUT IMPEDANCE VHF/UHF 75 ohm UNBALANCED

TUNING RANGES

VHF 2 THRU 13

UHF 14 THRU 69

CATV 1 THRU 125

CONTENTS

Safety Precautions 3

Control View 5

Important Service Notes 7

Block Diagram 8

General Adjustments 10

Trouble Shooting Charts 12

Description of Semiconductors 20

Printed Boards 21

Exploded View 23

Schematic Diagram 25

Parts List 27

Option List 36

2

Page 3

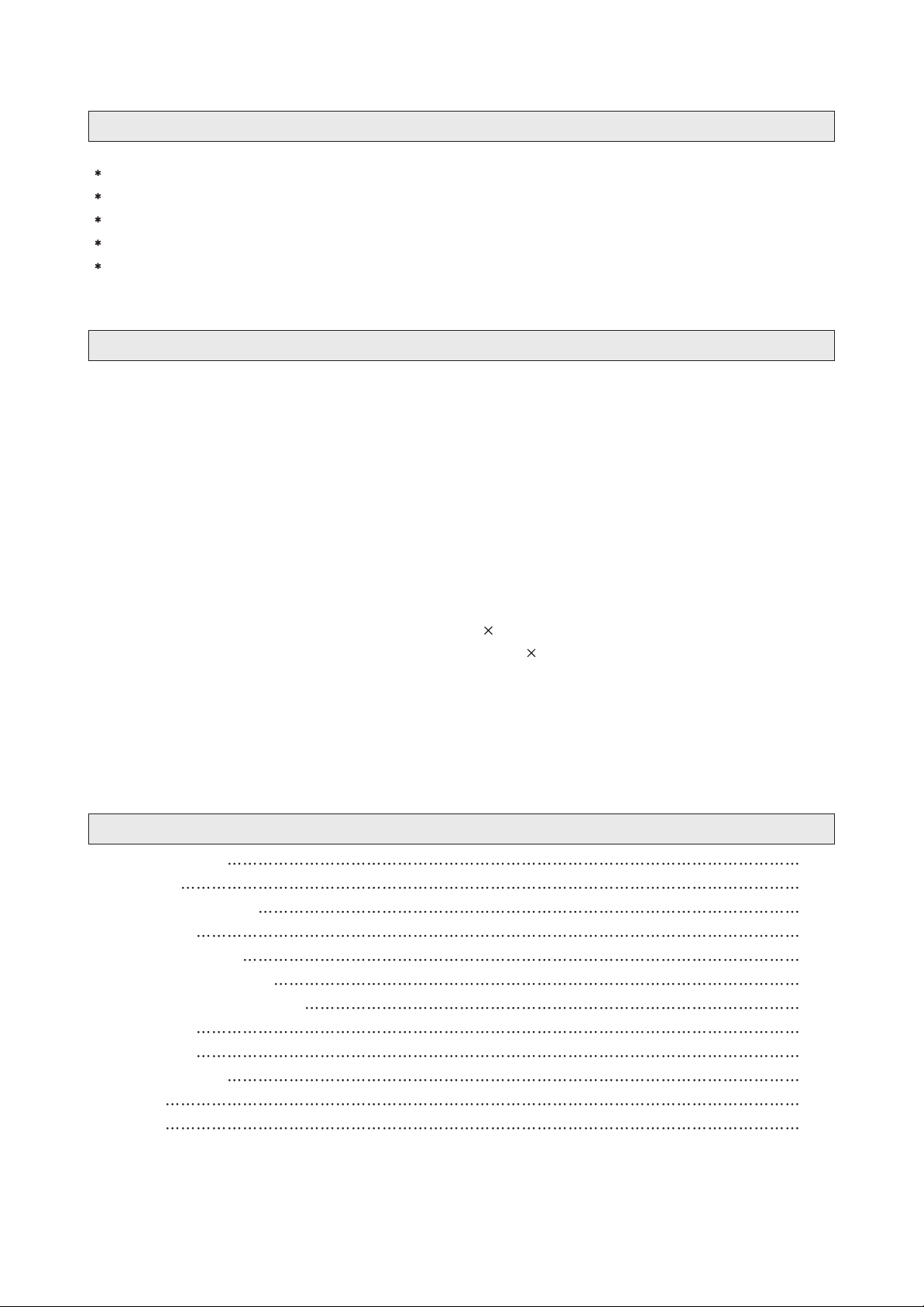

CONTROL VIEW

F-CONNECTOR

300 OHM-75 OHM

COUPLING

TRANSFORMER

VHF

75Ω

FROM 75 OHM

VHF ANTENNA WITH

CABLE OR CABLE

TV SYSTEM

5

Page 4

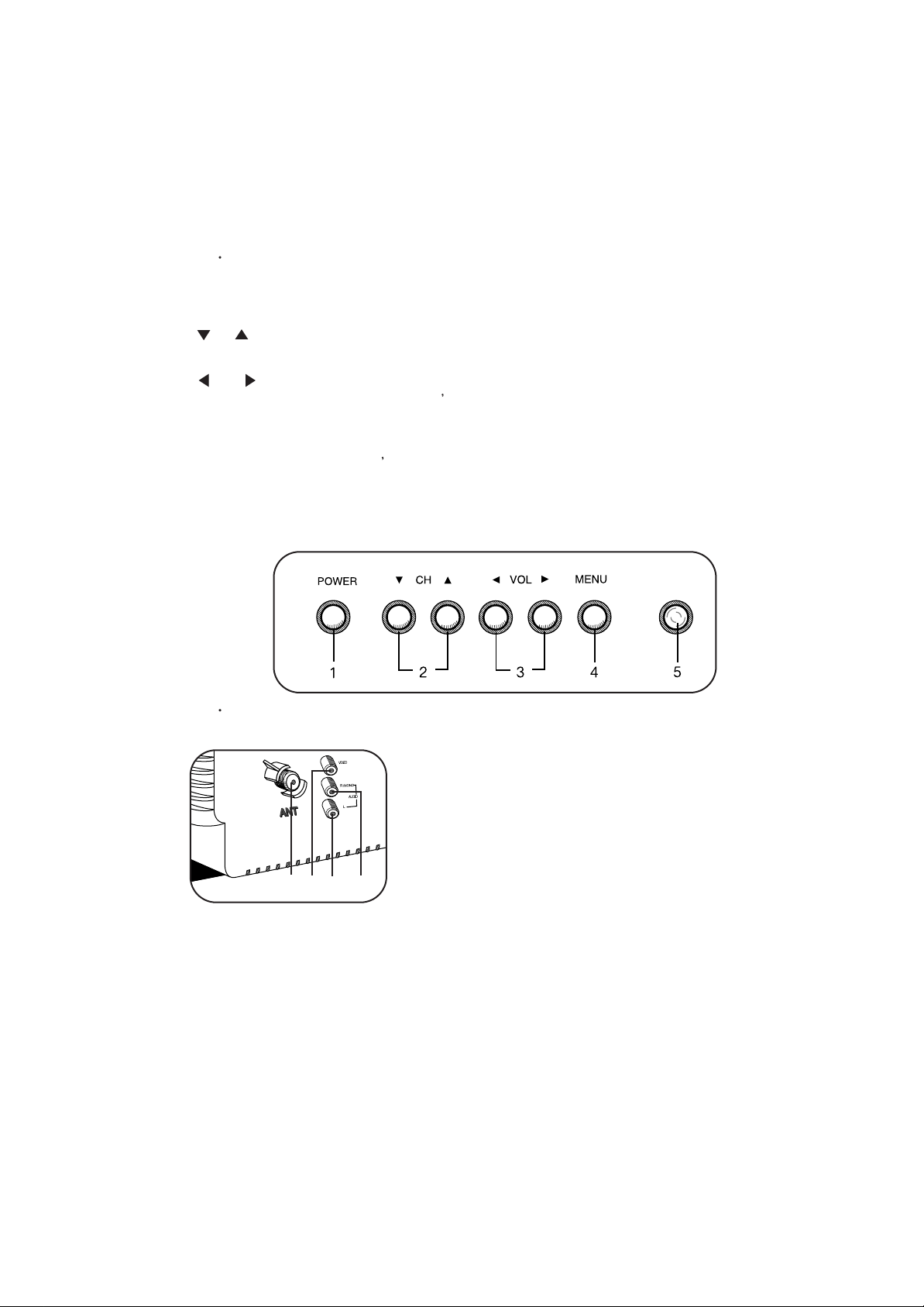

1. Overview of Your Equipment

Your TV comes with a remote control. The section below summarizes the buttons,controls, and terminals

that you will use with your TV.

2. Your TV' s Front Panel

1. POWER

Use this buttom to turn your TV on or off.

2. CH

Use these buttom to change channels on your TV, or to select items in the menu system.

3. VOL

Use these buttom to change your TV s volume, to activate selections in the menu system, or to

change audio and video settings.

4. MENU

Use this buttom to turn the TV s menu system on and off.

5. Remote control receiver

This receiver receives a signal from your remote control. Do not block it.

3. Your TV' s Back Panel

1

24

1. Antenna terminal

Use this terminal to attach an antenna or cable

system to your TV.

2. VIDEO IN

This terminal allows the TV to receive a video

signal from another components, such as a VCR.

3. AUDIO R/MONO IN

3

This terminal allows the TV to receive an audio

R/MONO signal from another components, such as

a VCR.

4. AUDIO L IN

This terminal allows the TV to receive an audio L

signal from another components, such as a VCR.

6

Page 5

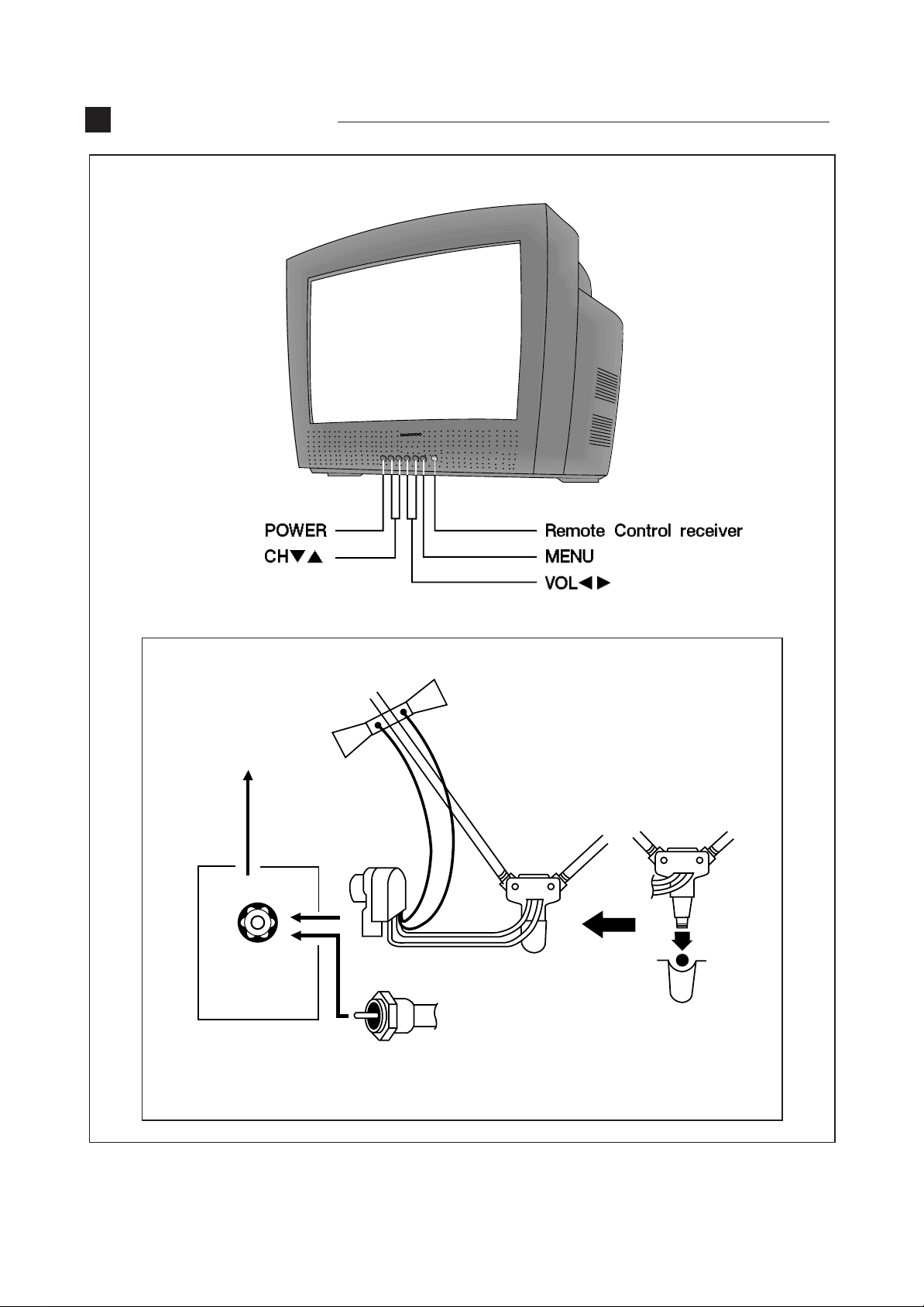

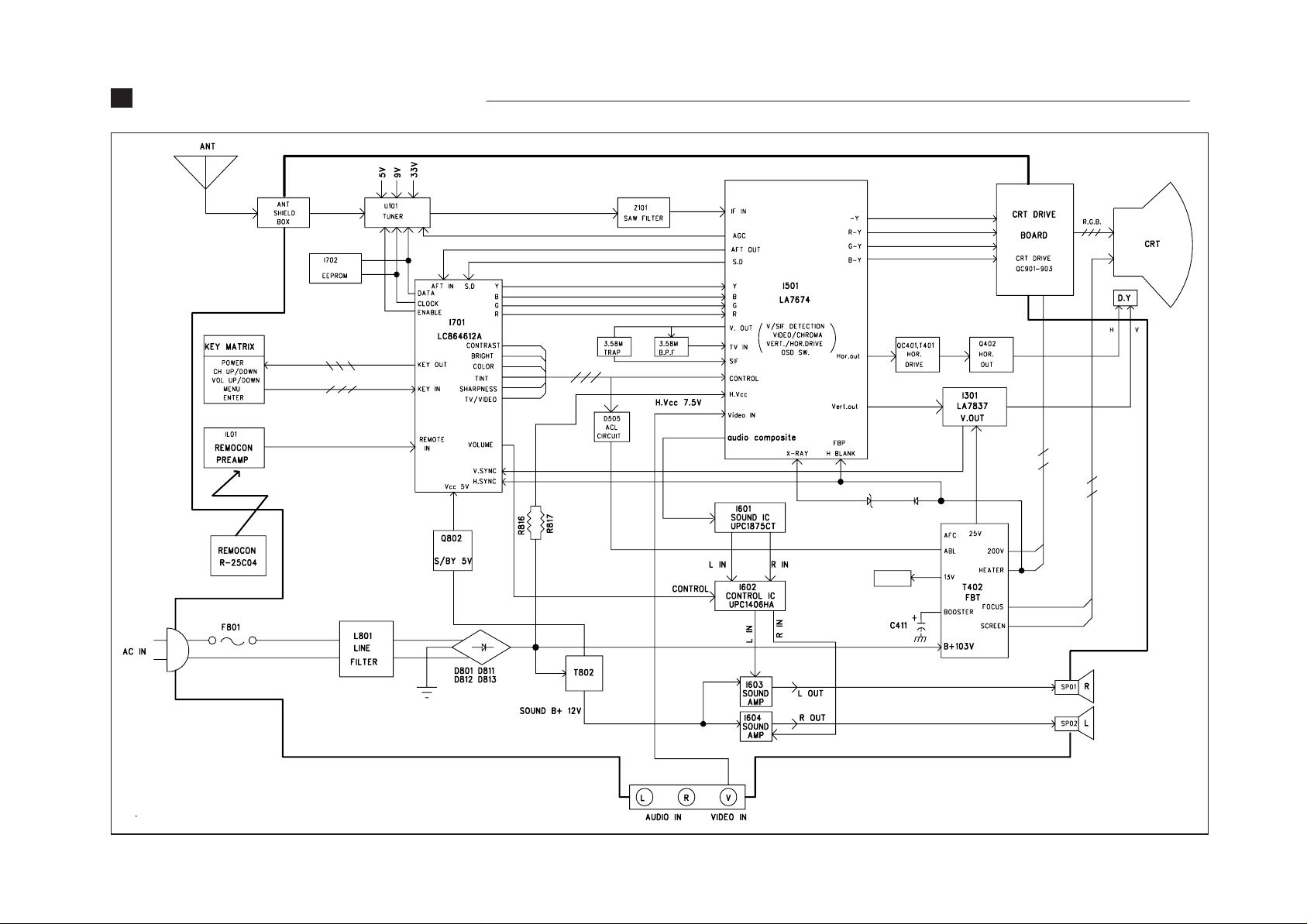

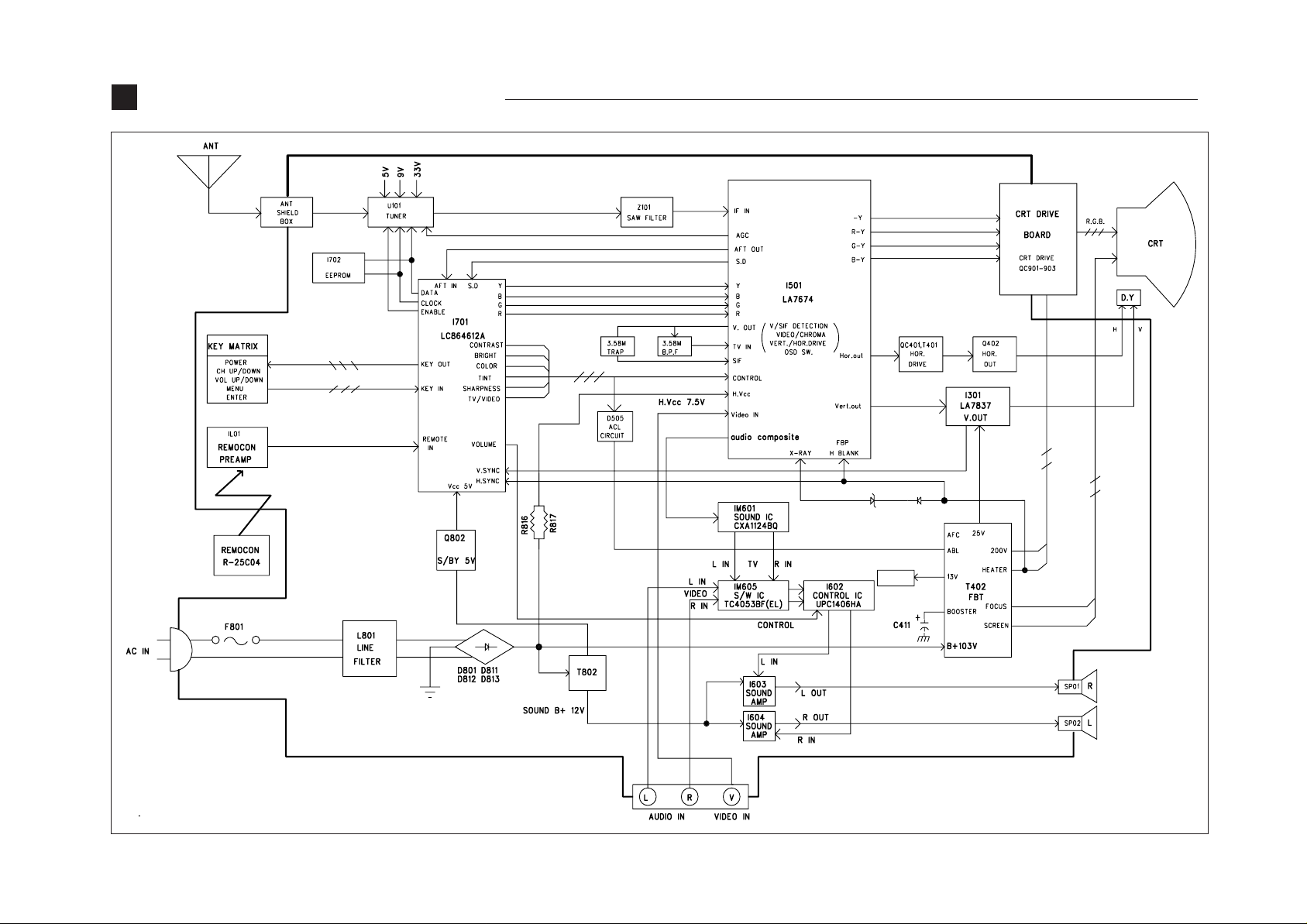

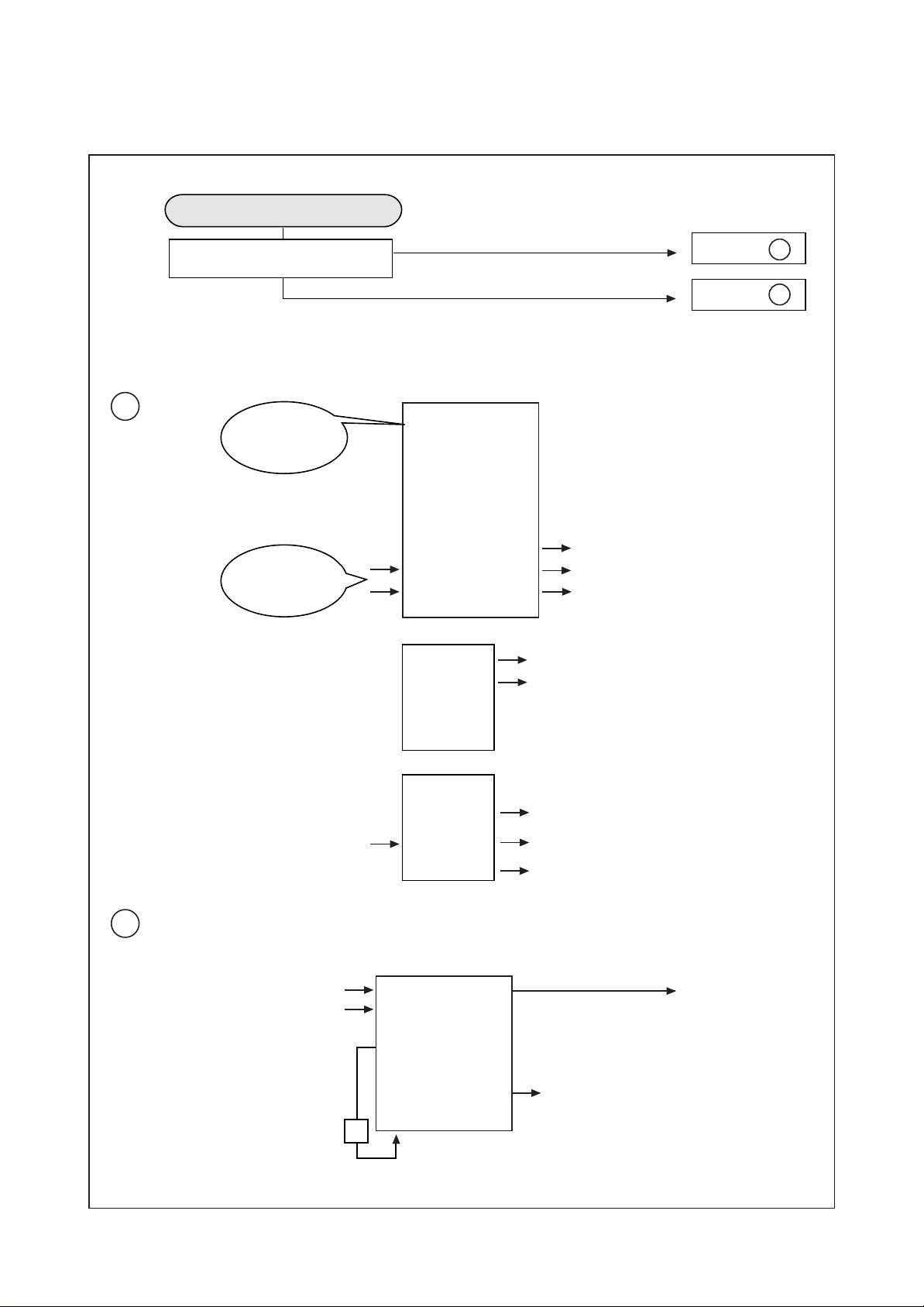

BLOCK DIAGRAM (CN-200I)

8

Page 6

BLOCK DIAGRAM (CN-200A)

9

Page 7

GENERAL ADJUSTMENTS

1. GENERAL

In the majority of cases, all color televisions will need only

slight touch-up adjustment upon installation. Check the basic

characteristics such as height, focus and sub- basic

characteristics such as height, focus and sub- bright. Observe

the picture for good black and white details without

objectionable color shading.

2. VERTICAL HEIGHT ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness and contrast controls for a good picture.

3) Adjust vertical height control (R305) for approximately one

half inch over scan at top and bottom of picture screen.

4) Vertical centering adjustment R310

Horizontal centering adjustment R516.

3. FOCUS ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness, sharpness and contrast controls for a

good picture.

3) Adjust focus control (part of T402) for sharp scanning lines

and/or sharp picture.

4. RF AGC ADJUSTMENT

1) Tune in an active channel.

2) Using the attenuator, apply the signal of 60dBm to the

antenna input terminal.

3) Turn RF AGC control (R113) full clockwise until snow

or/and noise appears in the picture, then slowly turn control

counter clockwise until snow or/and noise disappears.

5. HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked to verify

that the receiver is operating within safe and efficient design

limitations as specified:

1) Operate Receiver for at least 15 minutes at 120V AC line.

2) Set brightness sharpness, contrast and color control to

minumum position (Zero beam).

3) Connect accurate high voltage meter to CRT anode. The

reading should be 26kv~28kv

clockwise.)

4) Rotate the RED, GREEN and BLUE BIAS controls (R917,

R918, R919) counterclock wise from the maximum, set

them to the position where notches in the knobs become

parallel to the surface of P.C. Board.

5) Set the GREEN and BLUE DRIVE controls (R920, R921)

to the mid position.

6) Turn the service switch SW901 (Service Position) on the

CRT board.

7) Rotate the SCREEN control (on T402) gradually

clockwise until the second horizontl line following the first

line appears slightly on the screen. Then turn fully

counterclockwise the two BIAS controls corresponding to

the colors of the first and the second horizontal lines to

eliminated the lines.

8) Set the SCREEN control to the position where the third

horizontal line lights slightly on the screen.

9) Adjust the two BIAS control set to the minimum in item 7)

above to obtain the slightly lighted horizontal line in the

same levels of three (red, green, blue) colors. (The line

should be white if the BIAS controls are adjusted

properly.)

10) Turn the service switch SW901 again (Normal position on

the CRT board.)

11) Press PICTURE-SEL, P-UP and set the brightness and

contrast controls to the maximum.

12) Adjust the BLUE and GREEN DRIVE control to obtain

proper white-blanced picture in high light areas.

13) Using P-SEL, P-DN key, set the brightness and contrast

controls to obtain dark gray raster. Then check the white

balance in low brightness. Of the white balance is not

proper, retouch the BIAS controls and DRIVE controls to

obtain a good white balance in both low and high light

areas.

8. MAIN B+(103V) ADJUSTMENT

1) Tune in an active channel

2) Check TP10 (DC 103V Line) using D.V.M

3) Adjust voltage control (R809) for main B+(DC 103V)

If a correct reading cannot be obtained, check circuity for

malfunctioning components.

6. X-RADIATION PROTECTION CIRCUIT TEST

When service has been performed on the horizontal

deflection system, high voltage system or B+system, the XRADIATION protection circuit must be tested for proper

operation as follows:

1) Operate receiver for at least 15 minutes at 120V AC line.

2) Adjust all customer controls for normal picture and sound.

3) Short R414(X-RAY Short test), and remove short clip.

4) If the operation of horizontal osc. does not stop in step

The circuit must be repaired, before the set is returned to

the customer.

7. CRT GRAY SCALE ADJUSTMENT

1) Tune in an active channel.

2) Set the COLOR control to minimum.

3) Turn the SCREEN control (on T402 fully counter-

9. SUB-BRIGHTNESS ADJUSTMENT

1) Tune in a color program.

2) Set the CONTRAST control to maximum and the

BRIGHTNESS control to maximum and the

SHARPNESS control to the center position.

3) Set the COLOR and TINT controls to center.

4) Set the SUB-BRIGHT control R522 to center and

leave the receiver on five minutes in this state.

5) Watching the picture carefully, adjust the SUB-

BRIGHT control in the position where the picture does

not show evidence of blooming in high brightness area

and not appear too dark in low bright area.

6) Check for BRIGHTNESS controls at both extremes.

7) If the picture does not appear dark with the

CONTRAST and BRIGHTNESS control turned to

minimum, or not appear bright with the controls turned to

maximum, adjust the SUB-BRIGHT control again for an

acceptable picture.

10

Page 8

10. PICTURE IF/AFT ADJUSTMENTS

NOTE

: THIS RECEIVER IS TRANSISTORIZED AND SPECIAL CARE MUST BE TAKEN WHEN SERVICING. READ

THE FOLLOWING (NOTES BEFORE ATTEMPTING ALIGNMENT)

Alignment requires an exacting procedure and should be undertaken only when necessary.

Isolation transformer must be used to prevent shock hazard.

The test equipment specified or its equivalent is required to perform the alignment properly. Use of equipment which

does not meet these requirements may result in improper alignment.

Accurate equipment is essential to obtain proper alignment of this receiver.

Use of excessive signal from a sweep generator can cause overloading of receiver circuit Overloading should be

avoided to obtain a true response curve. Insertion of markers from the marker generator should not cause distortion of

the response curve.

The AC Power line voltage should be kept 120 volts while alignment is being performed.

Do not attempt to disconnect any components while the receiver is in operation.

Make sure the power cord is disconnected before replacing any parts in the receiver.

TEST EQUIPMENT

Digital voltmeter National Model VP-2600A or equivalent

Oscilloscope

Direct/Low-capacity probe

Tektronix Model 2215A or equivalent.

Tektronix Model P6120 or equivalent

(Accessory of oscilloscope)

Color-Bar/Dot/Crosshatch generator

PIF sweep marker generator

Power supply

Isolation transformer

Tektronix Model 146 or equivalent.

Nihon Tsushinki Model 4723 or equivalent

Academy Model 150A or equivalent

Voltage adjustable type having capacity of

at least 150 watts

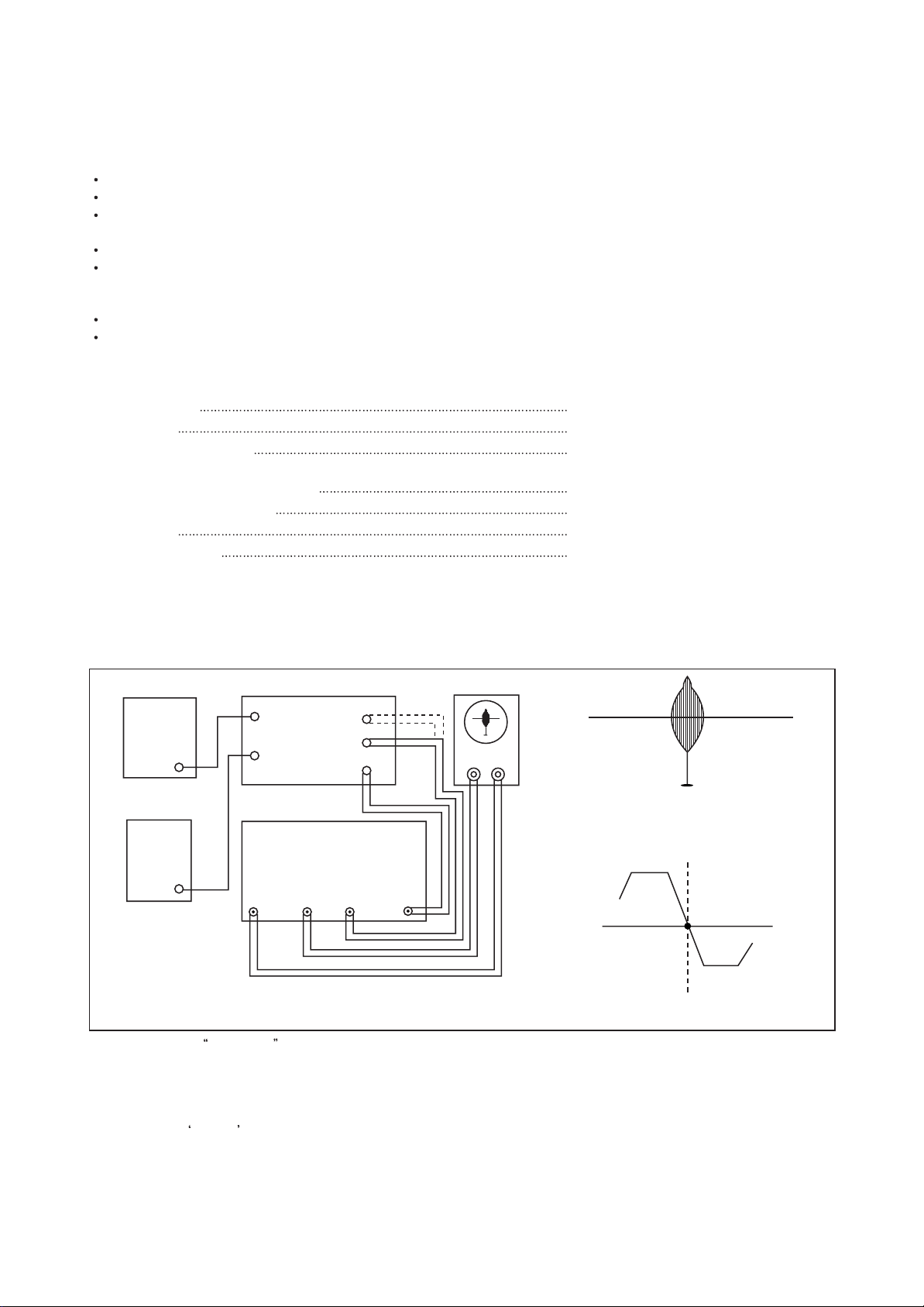

BLOCK DIAGRAM

OUT

OSCILLOSCOPE

Y

X

45.75MHz

Fig. 6 PIF Response

P

45.75MHz

Fig. 7 AFT Response Curve

B+

BIAS

POWER

SUPPLY

A

(12V)

AGC

BIAS

POWER

SUPPLY

B

(4-5V)

1) Disconnect the

MAIN BOARD

TP3

TP5

PIF SWEEP/MARKER GEN.

VH

Fig. 5 Picture IF Sweep Alignment

TP7

TP6

DETIN

TUNER IF output from TP6 and connect equipment as shown above.

2) Set the sweep/marker generator for 30 Vrms.

3) Observe 1 Vp-p on scope by adjusting power supply B (4~5V).

4) Adjust PIF coil L505 for according beat signal with 45.75 MHz marker on scope (See Fig. 6).

5) Connect the

DET IN to TP7.

6) Adjust AFT coil L504 for center display at 45.75 MHz on scope (See Fig. 7).

7) After completing the above steps, disconnect equipment and adjust the AGC delay circuit as explained in the General

Adjustments section of this manual.

11

Page 9

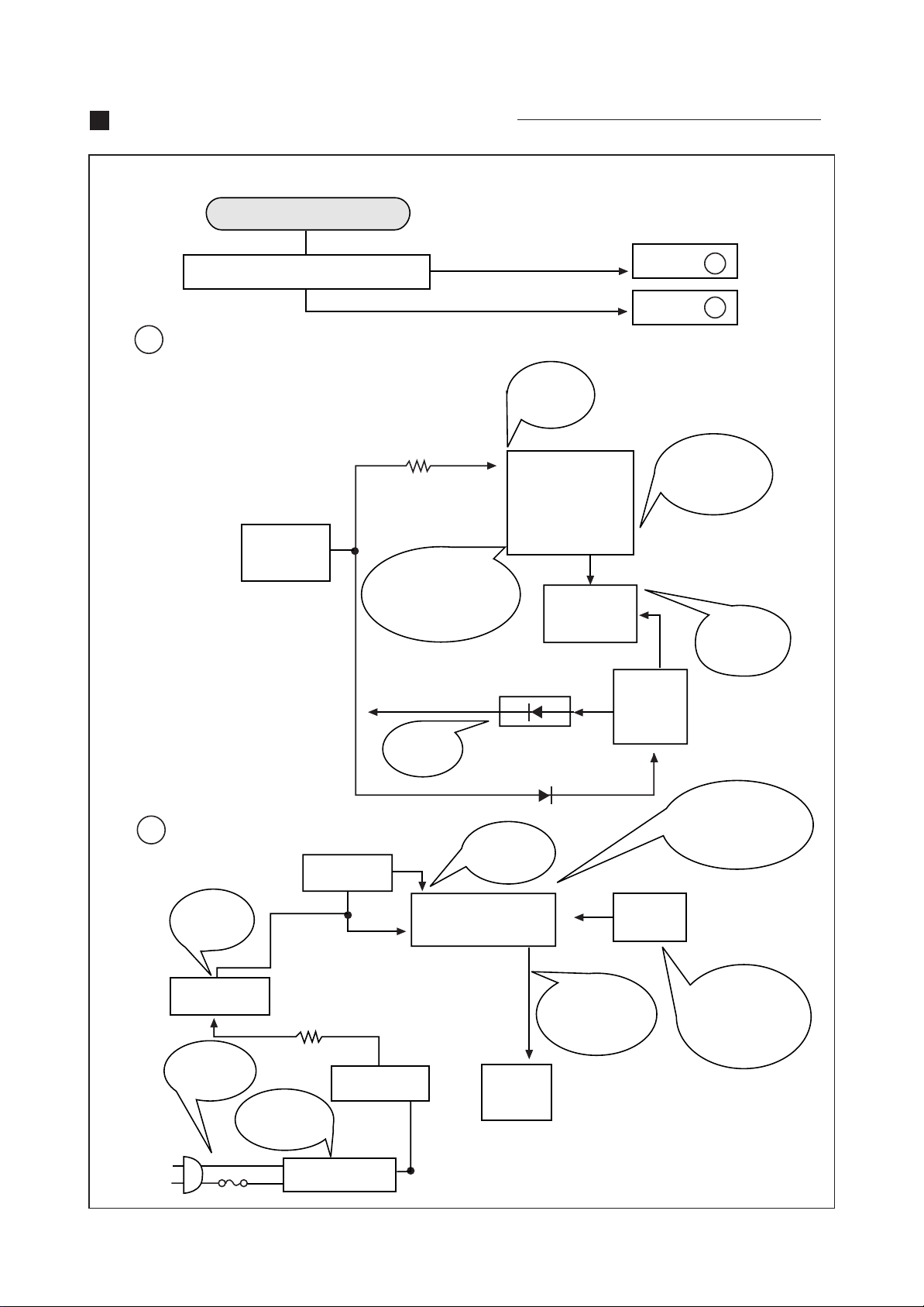

TROUBLE SHOOTING CHARTS

NO POWER

A

DOES QC701(POWER ON/OFF TR)

OPERATE?

CHECK TP10

(MAIN B+

LINE)

R816 15K

2WATT

103V

DC

IF #26 NORMAL

& NO OUTPUT AT

#23 THEN

CHANGE I501

YES

NO

CHECK

#30

(7.5V

DC

)

30

I501

26

Q402

H. OUTPUT

12V 12V

D406

24

GO TO

GO TO

T402

F.B.T

A

B

DOES

SHUT DOWN

CIRCUIT

OPERATE?

CHECK

Q402

COLLECTOR

B

5V

SHOULD

BE

4.3V-5.2V

Q802

REGULATOR

CHECK

F801

125V 5A

CHECK

LEAD

SOLDERING

QC706

RESET

R808

T801

L801

LINE FILTER

CHECK

12V LINE

16

12

NORMAL: 5V

RESET: 0V

I701

LC864616A

QC701

POWER

CONTROL

D403

36

42

OPEN LOAD

THEN CHECK

#42 ON STATE

4 ~5V

103V(B+)

CHECK

ALL THE POINTS

THEN CHANGE

I701

PWR

CONTROL

KEY

KEY OPERATE?

CHECK DIODE

D701 & SWITCH

KEY BOARD

12

Page 10

NO PICTURE

C

CHECK

CONTROL

(NORMAL)

VOLTAGES

#39: 5.0V

#31: 3.9V

CHECK THE WAVE FORM OF

I501 #44 (2Vp-p)

FC

QC201

CONTRAST

BRIGHT

D505

ABL

COMPOSITE

VIDEO INPUT

H

R522

SUB-BRIGHT

C506

OK

NG

FS

42

39

31

CHECK

9V LINES

#11,14

I501

LA 7674

11 14

CHECK

ABL

Ib = 1.2mA

21

GO TO

GO TO

Y-OUT

H. BLANKING

T402

FBT

ABL H.T

C

D

H

QC501

VIDEO

DRIVE

CHECK

210V

KINE

D404

R413

R412

D

ENA

I701

LC864616A

CHECK

CSB503E

DATA

1110

CLK

U101 TUNER

IF

Z101

SAW FILTER

CHECK

IF AGC

VTG.

5V

DC

TP2

AGC

5V

9V

V

8

9

T

(33V)

ADJUST

RF-AGC

R113

I501

LA7674

10

DETECTOR

OUTPUT

44

14112

CHECK

9V LINE

#11, 14

CHECK

HEATER

6.3Vrms

TO QC201

H

13

Page 11

NO SOUND(CN-200I)

E

CHECK FOR SIGNAL

AT I501 #1

CHECK

MONO 100% MOD

-> 0.424 Vp-p

CHECK

EXT SOUND

SIGNAL OFF:L

#1

(B+)

#2 9V

#12

#13

#1 9V

(B+)

#2(0~5V)

I602

I601

(MUTE)

#4

#6

#19

#18

#17

CHECK 1Vp-p

CHECK 1Vp-p

MUTE ON: 5V

OFF: 0V

GO TO

GO TO

E

F

F

CHECK SOUND INPUT

CHECK 9V

Z201

CHECK SOUNDIF INPUT

#11

#14

#44

#48

#8(0~5V)

I604/I603

#3

I501

LA7674

#7

#6

#5

CHECK 12VDC

CHECK SOUND OUTPUT

COMPOSITE SIGNAL

#1

#4

CHECK FM DET

CIRCUIT

I601 #1

14

Page 12

NO SOUND(CN-200A)

E

CHECK FOR SIGNAL

AT I501 #1

CHECK

MONO 100% MOD

-> 0.693 Vp-p

CHECK 4.5V

#38

(B+)

#30 9V

#2(9VDC)

IM601

#39

#40

#1 9V

(B+)

#2 (0~5V)

I602

(MUTE)

#4

#6

#22

#21

#20

L OUT

#15

R OUT

#13

#8

CHECK 1Vp-p

CHECK 4.5V

CHECK R/L OUTPUT

MUTE ON: 5V

OFF: 0V

GO TO

GO TO

E

F

F

CHECK SOUND INPUT

CHECK 9V

Z201

CHECK SOUND IF INPUT

#11

#14

#44

#48

#8 (0~5V)

I604/I603

#3

I501

LA7674

#7

#6

#5

CHECK 12VDC

CHECK SOUND OUTPUT

COMPOSITE SIGNAL

#1

#4

CHECK FM DET

CIRCUIT

I601 #1

15

Page 13

CH DON'T STOP

G

CHECK INPUT SIGNAL

CONDITIONS

U101

TUNER

2 3

I701

LC864616A

4

13

33

IF OUTPUT

CHECK

AFT WINDOW

VTG.

1.6V ~ 3.4V

ADJUST

RF AGC

R113

L: NO SIGNAL

H: SIGNAL

GOOD

BAD

8, 9

10

47

I501

LA7674

GO TO

LOSS OF SIGNAL OR

WEAK SIGNAL

45

46

9

8

AFT

PIF

ADJUST

PIF & AFT

REFER TO GENERAL

ADJUSTMENTS

G

S.D SIGNAL

DETECTION

16

44

Page 14

NO COLOR

CENTER

3.5V

TINT

41

CHECK

DC

9V

11

COMPOSITE

VIDEO

COLOR

C506

CENTER

4V

36

42

FS

QC201

Emitter

FC

NO VERTICAL DEFLECTION

CHECK 9V

DC

I501

LA7674

12

X502

APC FILTER

13

CHECK

CRYSTAL

CHECK

9V

DC

3.579545MHZ

14

18

19

20

21

CHECK 9V

R-Y

G-Y

B-Y

LUMINANCE (-Y) VIDEO B (210V)

CHECK

CONNECTOR

P901

CC

Q901

Q902

Q903

R

G

B

+

I501

LA7674

14

28

CHECK

VERT.OUT

R301

VR305 V,HEIGHT

R311

1

I301

LA7837

2

48

12

R304

R305

C307

+

V.D.Y.

17

CHECK 25V

D402 R417

C413

C417

CHECK THE WAVEFORM

I301 #12 NO OUTPUT:

CHANGE IC301

DC

Page 15

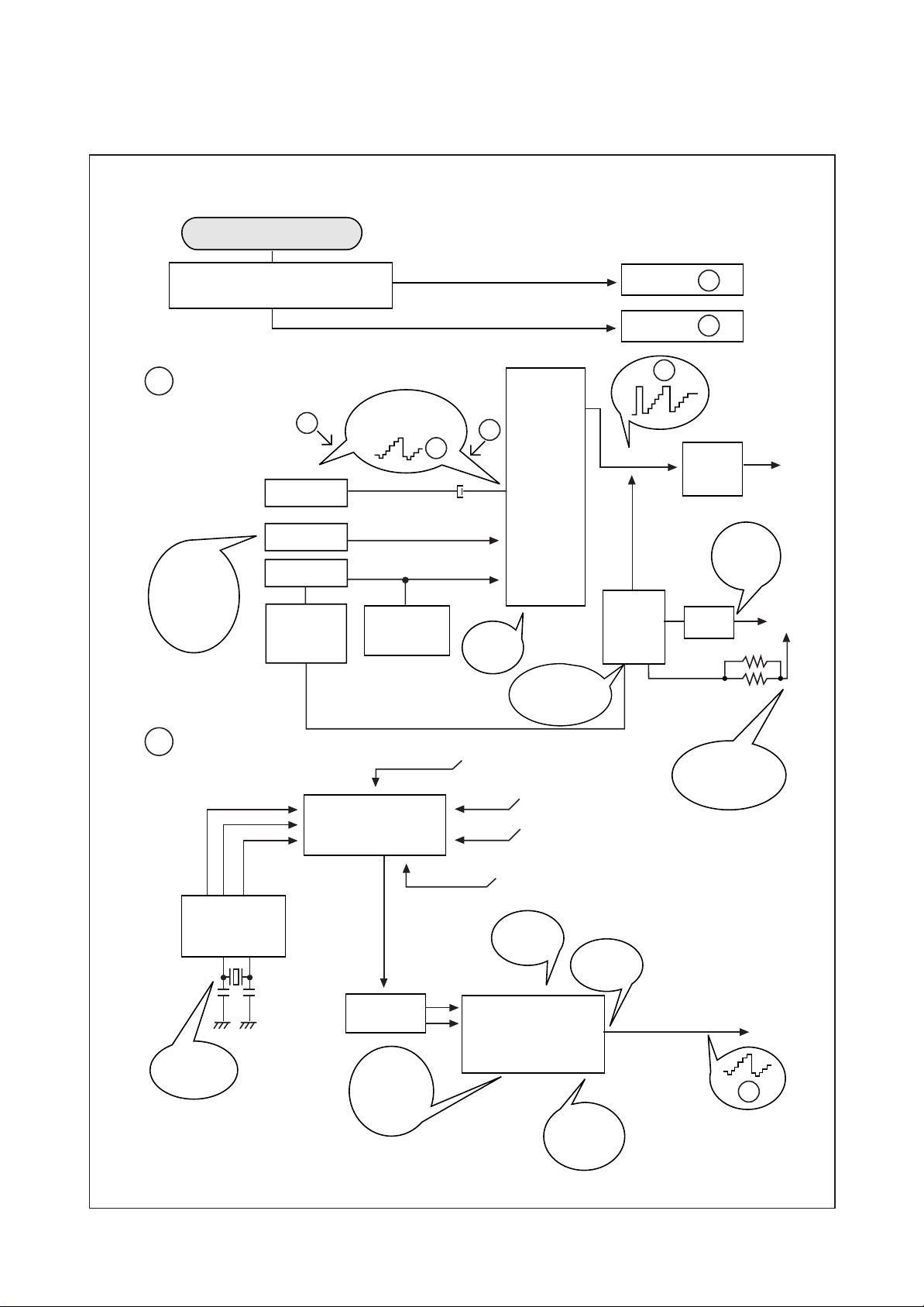

ON SCREEN DISPLAY DOES NOT OPERATE

CHECK

FOR,60Hz

/ VS

19

21

22

/ HS

20

I701

23

24

10

CHECK

FOR, 15, 734Hz

11

OSC CHECK

REMOTE CONTROL DOES NOT OPERATE

IL01

REMOCON

SENSOR

GND 5V OUT

R

G

B

BL

R, G, B, BL

CHANGE

IF OSD DOES NOT

OPERATE, CHANGE

I701

I701 LC864616A

CHECK

WAVEFORM

34

18

Page 16

PIN ASSIGN OF IC LC864616A(I701)

VIDEO MUTE(O)

DATA(O)

CLOCK(O)

ENABLE(O)

SOUND MUTE(O)

TV/VIDEO(O)

MPX1(O)

MPX2(O)

1 P10

2 P11

3 P12

4 P13

5 P14

6 P15

7 P16

8 P17

9 DVss

10 CF1

11 CF2

P07 42 POWER(O)

KEY OUT

41P06

KEY OUT

40P05

KEY OUT

39P04

KEY IN

38P03

KEY IN

37P02

KEY IN

36P01

KEY IN

35P00

34P73/INT3/TOIN REMOCON(IN)

33P72/INT2/TOIN SD(IN)

32P71/INT1 X-Ray IN

3-LAN

MN/ST

CH UP

SAP TV/VID

EEPROM

VOL + POWER

VOL -CH DN

MENU

:

Switch

:

Option

Diode

AFC IN

N. C

N. C

1Vpp IN

12 DVdd

13 P90/AN0

14 P91/AN1

15 P92/AN2

16 /RESET

17 FILT

18 CVIN

19 /VS

20 /HS

21 R 22G

NOTE) CF is used 503KHz RESONATOR

31P70/INT0 AC 60Hz IN

30PWM5 CONTRAST

29PWM4 BRIGHTNESS

28PWM3 COLOR

27PWM2 TINT

26PWM1 SHARPNESS

25PWM0 VOLUME

24BL

23B

19

Page 17

TROUBLE SHOOTING CHARTS

NO POWER

A

DOES QC701(POWER ON/OFF TR)

OPERATE?

CHECK TP10

(MAIN B+

LINE)

R816 15K

2WATT

103V

DC

IF #26 NORMAL

& NO OUTPUT AT

#23 THEN

CHANGE I501

YES

NO

CHECK

#30

(7.5V

DC

)

30

I501

26

Q402

H. OUTPUT

12V 12V

D406

24

GO TO

GO TO

T402

F.B.T

A

B

DOES

SHUT DOWN

CIRCUIT

OPERATE?

CHECK

Q402

COLLECTOR

B

5V

SHOULD

BE

4.3V-5.2V

Q802

REGULATOR

CHECK

F801

125V 5A

CHECK

LEAD

SOLDERING

QC706

RESET

R808

T801

L801

LINE FILTER

CHECK

12V LINE

16

12

NORMAL: 5V

RESET: 0V

I701

LC864616A

QC701

POWER

CONTROL

D403

36

42

OPEN LOAD

THEN CHECK

#42 ON STATE

4 ~5V

103V(B+)

CHECK

ALL THE POINTS

THEN CHANGE

I701

PWR

CONTROL

KEY

KEY OPERATE?

CHECK DIODE

D701 & SWITCH

KEY BOARD

12

Page 18

NO PICTURE

C

CHECK

CONTROL

(NORMAL)

VOLTAGES

#39: 5.0V

#31: 3.9V

CHECK THE WAVE FORM OF

I501 #44 (2Vp-p)

FC

QC201

CONTRAST

BRIGHT

D505

ABL

COMPOSITE

VIDEO INPUT

H

R522

SUB-BRIGHT

C506

OK

NG

FS

39

31

CHECK

9V LINES

#11,14

I501

LA 7674

42

11 14

CHECK

ABL

Ib = 1.2mA

21

GO TO

GO TO

Y-OUT

H. BLANKING

T402

FBT

ABL H.T

C

D

H

QC501

VIDEO

DRIVE

CHECK

210V

KINE

D404

R413

R412

D

ENA

I701

LC864616A

CHECK

CSB503E

DATA

1110

CLK

U101 TUNER

IF

Z101

SAW FILTER

CHECK

IF AGC

VTG.

5V

DC

TP2

AGC

5V

9V

V

8

9

T

(33V)

ADJUST

RF-AGC

R113

I501

LA7674

10

DETECTOR

OUTPUT

44

14112

CHECK

9V LINE

#11, 14

CHECK

HEATER

6.3Vrms

TO QC201

H

13

Page 19

NO SOUND(CN-200I)

E

CHECK FOR SIGNAL

AT I501 #1

CHECK

MONO 100% MOD

-> 0.424 Vp-p

CHECK

EXT SOUND

SIGNAL OFF:L

#1

(B+)

#2 9V

#12

#13

#1 9V

(B+)

#2(0~5V)

I602

I601

(MUTE)

#4

#6

#19

#18

#17

CHECK 1Vp-p

CHECK 1Vp-p

MUTE ON: 5V

OFF: 0V

GO TO

GO TO

E

F

F

CHECK SOUND INPUT

CHECK 9V

Z201

CHECK SOUNDIF INPUT

#11

#14

#44

#48

#8(0~5V)

I604/I603

#3

I501

LA7674

#7

#6

#5

CHECK 12VDC

CHECK SOUND OUTPUT

COMPOSITE SIGNAL

#1

#4

CHECK FM DET

CIRCUIT

I601 #1

14

Page 20

NO SOUND(CN-200A)

E

CHECK FOR SIGNAL

AT I501 #1

CHECK

MONO 100% MOD

-> 0.693 Vp-p

CHECK 4.5V

#38

(B+)

#30 9V

#2(9VDC)

IM601

#39

#40

#1 9V

(B+)

#2 (0~5V)

I602

(MUTE)

#4

#6

#22

#21

#20

L OUT

#15

R OUT

#13

#8

CHECK 1Vp-p

CHECK 4.5V

CHECK R/L OUTPUT

MUTE ON: 5V

OFF: 0V

GO TO

GO TO

E

F

F

CHECK SOUND INPUT

CHECK 9V

Z201

CHECK SOUND IF INPUT

#11

#14

#44

#48

#8 (0~5V)

I604/I603

#3

I501

LA7674

#7

#6

#5

CHECK 12VDC

CHECK SOUND OUTPUT

COMPOSITE SIGNAL

#1

#4

CHECK FM DET

CIRCUIT

I601 #1

15

Page 21

CH DON'T STOP

G

CHECK INPUT SIGNAL

CONDITIONS

U101

TUNER

2 3

I701

LC864616A

4

13

33

IF OUTPUT

CHECK

AFT WINDOW

VTG.

1.6V ~ 3.4V

ADJUST

RF AGC

R113

L: NO SIGNAL

H: SIGNAL

GOOD

BAD

8, 9

10

47

I501

LA7674

GO TO

LOSS OF SIGNAL OR

WEAK SIGNAL

45

46

9

8

AFT

PIF

ADJUST

PIF & AFT

REFER TO GENERAL

ADJUSTMENTS

G

S.D SIGNAL

DETECTION

16

44

Page 22

NO COLOR

CENTER

3.5V

TINT

41

CHECK

DC

9V

11

COMPOSITE

VIDEO

COLOR

C506

CENTER

4V

36

42

FS

QC201

Emitter

FC

NO VERTICAL DEFLECTION

CHECK 9V

DC

I501

LA7674

12

X502

APC FILTER

13

CHECK

CRYSTAL

CHECK

9V

DC

3.579545MHZ

14

18

19

20

21

CHECK 9V

R-Y

G-Y

B-Y

LUMINANCE (-Y) VIDEO B (210V)

CHECK

CONNECTOR

P901

CC

Q901

Q902

Q903

R

G

B

+

I501

LA7674

14

28

CHECK

VERT.OUT

R301

VR305 V,HEIGHT

R311

1

I301

LA7837

2

48

12

R304

R305

C307

+

V.D.Y.

17

CHECK 25V

D402 R417

C413

C417

CHECK THE WAVEFORM

I301 #12 NO OUTPUT:

CHANGE IC301

DC

Page 23

ON SCREEN DISPLAY DOES NOT OPERATE

CHECK

FOR,60Hz

/ VS

19

21

22

/ HS

20

I701

23

24

10

CHECK

FOR, 15, 734Hz

11

OSC CHECK

REMOTE CONTROL DOES NOT OPERATE

IL01

REMOCON

SENSOR

GND 5V OUT

R

G

B

BL

R, G, B, BL

CHANGE

IF OSD DOES NOT

OPERATE, CHANGE

I701

I701 LC864616A

CHECK

WAVEFORM

34

18

Page 24

PIN ASSIGN OF IC LC864616A(I701)

VIDEO MUTE(O)

DATA(O)

CLOCK(O)

ENABLE(O)

SOUND MUTE(O)

TV/VIDEO(O)

MPX1(O)

MPX2(O)

1 P10

2 P11

3 P12

4 P13

5 P14

6 P15

7 P16

8 P17

9 DVss

10 CF1

11 CF2

P07 42 POWER(O)

KEY OUT

41P06

KEY OUT

40P05

KEY OUT

39P04

KEY IN

38P03

KEY IN

37P02

KEY IN

36P01

KEY IN

35P00

34P73/INT3/TOIN REMOCON(IN)

33P72/INT2/TOIN SD(IN)

32P71/INT1 X-Ray IN

3-LAN

MN/ST

CH UP

SAP TV/VID

EEPROM

VOL + POWER

VOL -CH DN

MENU

:

Switch

:

Option

Diode

AFC IN

N. C

N. C

1Vpp IN

12 DVdd

13 P90/AN0

14 P91/AN1

15 P92/AN2

16 /RESET

17 FILT

18 CVIN

19 /VS

20 /HS

21 R 22G

NOTE) CF is used 503KHz RESONATOR

31P70/INT0 AC 60Hz IN

30PWM5 CONTRAST

29PWM4 BRIGHTNESS

28PWM3 COLOR

27PWM2 TINT

26PWM1 SHARPNESS

25PWM0 VOLUME

24BL

23B

19

Page 25

DESCRIPTION OF SEMICONDUCTORS

LA7674 (VIF/SIF/VIDEO/CHROMA/DEFLECTION)

1. Case Outline : SDIP 52P

2. Pin Connections/Block Diagram

IC501 LA7674

IF/VIDEO/CHROMA/DEF

FM DET

IF AGC

EX AIN

FM DET

NFB

A

OUT

GND

IF

IF IN

RF AGC

VCC

APC

VXO

VCC

R

1

LOCK

DET

2

3

4

5

ATT

FM-

DET

FM-

6

DET

7

8

IN

VIF

AMP

9

RF-

10

AGC

11

12

13

14

15

IN

VCO

AGC

TINT

IF-

APC

ACC

KILL-

ER

VIDEO

DET

LIM

AMP

APC

DET

VCO

VIDEO

AMP

AFT

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

IFAPC

VCD

VCO

RF AGC

SIF

IN

AFT OUT

AFT

AFT

V

DET

AV S.W

IN V

IN

TINT

EX. VIN

CONT

VIDEO

R-Y

G-Y

B-Y

FBP

HOUT

HOD

HOSC

HAFC

GIN

BIN

-Y

OSD

16

17

18

19

20

OSD-SWITCH

CARRIER-F

FBT-DET

-Y OUT

COLOR

DEMO

2NA

BPA

SOFT

IST

BPA

BLACK

EXPAND

CONTRAST

SHARP

21

DRIVER

HOR

FBTDET

FBT-DET

-Y OUT

AFC

2

CLAMP

BRIGHT

D.L

22

IN

23

24

25

26

OSC

HOR

AFC

1

HOR

C/D

SYNC/

SEP

VER

SYNC-

SEP

VER

C/D

HOR

COIN

37

36

35

34

33

32

31

30

29

28

27

GND

COLOR

BDET

Y

IN

SHARP

CLAMP

BRIGHT

V

CCH

S. SEP

V. OUT

H.DET

20

Page 26

DTQ-26S1FC/FS/FSP/HC/HS/HSP

EXPLODED VIEW

23

Page 27

DTQ-29S1FCN/FSN/FSP/HC/HS/HSP

EXPLODED VIEW

24

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Loading...

Loading...