Service Manual

Color Television

CN-115I

CHASSIS

NTSC-M SYSTEM

:

MODEL

DTQ-14N2FC/FS/FSP

:

DTQ-20N2FC/FS/FSP

DTQ-14J2FC/FS/FSP

DTQ-20J2FC/FS/FSP

DTQ-14N3FC/FS/FSP

DTQ-20N3FC/FS/FSP

DAEWOO ELECTRONICS CO., LTD.

FEATURES

FS (Frequency Synthesizer) Tuning System

CATV Ready

Monitor Look Design

High Focus Minineck CRT

ELECTRICAL SPECIFICATIONS

POWER INPUT

FC SERIES AC 120V 60Hz

FS SERIES AC 85V - AC 150V 60Hz

FSP SERIES AC 220V 50Hz/60Hz

POWER RATING

14” MODELS 60W

20” MODELS 70W

INTERMEDIATE FREQUENCIES

PICTURE IF CARRIER FREQUENCY 45.75MHz

SOUND IF CARRIER FREQUENCY 41.25MHz

COLOR SUB CARRIER FREQUENCY 42.17MHz

AUDIO OUTPUT RATING 1.3W

SPEAKER 2W 8 ohm

ANTENNA INPUT IMPEDANCE VHF/UHF 75 ohm UNBALANCED

TUNING RANGES

VHF 2 THRU 13

UHF 14 THRU 69

CATV 1 THRU 125

CONTENTS

Safety Precautions 3

Control View 6

Important Service Notes 8

Block Diagram 9

General Adjustments 10

Trouble Shooting Charts 14

Description of Semiconductors 20

Printed Circuit Board Diagram 22

Exploded Views 23

Schematic Diagram with Waveforms 29

Parts List 30

Option List 40

2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO VIDEO PRODUCTS

DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY. NEVER

CAUTION

PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER S APPROVAL.

UNAUTHORIZED MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT MAY

LEAD TO YOUR BEING LIABLE FOR ANT RESULTING PROPERTY DAMAGE OR USER

INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE THOROUGHLY

FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS AND SERVICING

GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS AND

INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C.

LINE SHOCK.

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK SHOULD

BE MADE OF THE FOLLOWING:

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS TO AVOID

POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER SUPPLY

CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER ORIGINAL DESIGN.

BE SURE, THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT

BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS,

SOLDER SPLASHES OF SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL

LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION TO PARTS AND

COMPONENTS, FOR FRAYED LEADS, DAMAGED INSULATION (INCLUDING A.C. CORD),

AND REPLACE IF NECESSARY. FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND

DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A RESISTOR

RATED AT 1 WATT OR MORE. LEAD TENSION AROUND PROTRUDING METAL

SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF RESISTOR,

CAPACITORS, ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES. DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE SPECIFIED OR MAKE

UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE STE ALWAYS PERFORM AN A.C. LEAKAGE TEST ON

ALL EXPOSED METALLIC PARTS OF THE CABINET. (THE CHANNEL SELECTOR KNOB,

ANTENNA TERMINALS, HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL SHOCK.

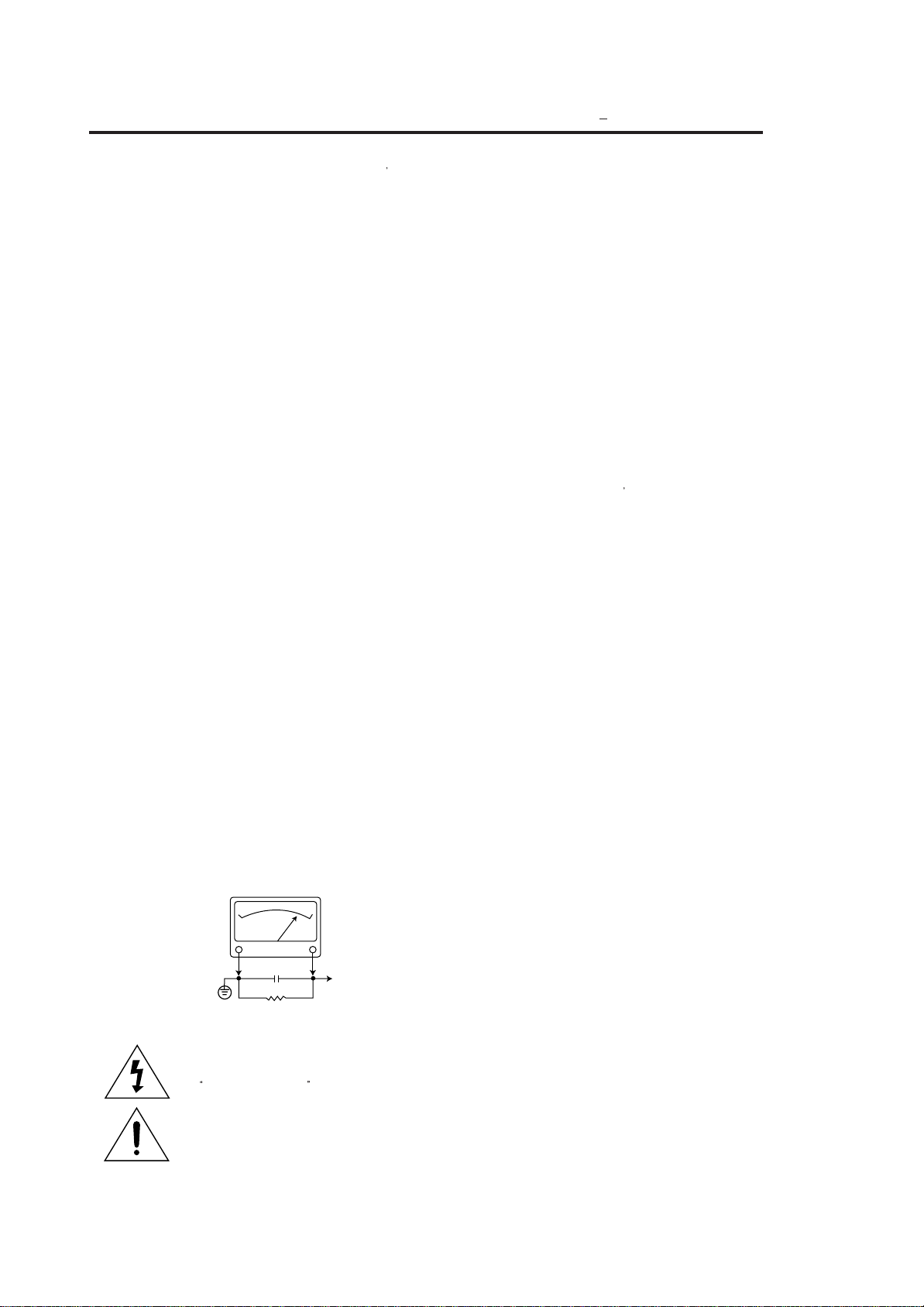

ISOLATION TRANSFORMER DURING THIS TEST

HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER :

CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150V A.C.

TYPE CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND (WATER POPE,

CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME. MEASURE

THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500 OHM RESISTOR AND .15

MFD CAPACITOR. REVERSE THE A.C. PLUG AND REPEAT A.C. VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST

NOT EXCEED .75 VOLTS R.M.S THIS CORRESPONDS TO 0.5 MILLIAMP A.C. NAY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK HAZARD AND MUST BE

CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

:

SAFETY CHECKS

SUBJECT:FIRE & SHOCK HAZARD

A.C. VOLTMETER

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE, CONDUIT, ETC.

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

DANGEROUS VOLTAGE THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL

TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION ON SERVICE LITERATURE.

0.15µF

1500 OHM

10WATT

DO NOT USE A LINE

USE AN A.C. VOLTMETER,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER

2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE IS NO

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A PRODUCT WITH

6. REFER TO HV, B + AND SHUTDOWN ADJUSTMENT PROCEDURES DESCRIBED IN THE

SUBJECT : IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRAL IMPLOSION

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO INSTALLATIONS

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING. THE

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT,

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON SLOPING SHELF

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO THE

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH HAS NOT

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS, EXPLAIN THAT A

950ART94

1009

THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN

CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT

EMIT X-RAYS WHEN THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER

VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE

SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, AMY PRODUCE RADIATION IN

EXCESS OF DESIRABLE LEVELS.

DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN COLOR SETS. ALWAYS REINSTALL THEM.

RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE

CHECKED PERIODICALLY AGAINST A REFERENCE STANDARD. SUCH AS THE ONE

AVAILABLE AT YOUR DISTRIBUTOR.

POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY TIME A COLOR CHASSIS IS

SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND DOWN WHILE MONITORING

THE HIGH VOLTAGE WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING CORRECTLY. WE

SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST

PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A

STANDARD SERVICING PROCEDURE, AND THAT THE HIGH VOLTAGE READING BE

RECORDED ON EACH CUSTOMER

A PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID BEING UNNECESSARILY CLOSE

TO THE PICTURE TUBE AND THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE

PRODUCT LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCESSIVE

VOLTAGE.

APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE USED).

PROTECTION SYSTEM. BUT CARE SHOULD BE TAKEN TO AVOID DAMAGE DURING

INSTALLATION. AVOID SCRATCHING THE TUBE. OF SCRATCHED REPLACE IT.

FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN THE PATH OF

HEATED AIR FLOW.

WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A

FACTOR, ETC.

CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER

COVERINGS WHICH MIGHT OBSTRUCT VENTILATION.

MUST FOLLOW THE FACTORY APPROVED MOUNTING INSTRUCTIONS. A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE

EQUIVALENT THICKNESS IN SPACERS)TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS MUST NOT TOUCH ANY

PARTS OR WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

OR A TILTED POSITION, UNLESS THE PRODUCT IS PROPERLY SECURED.

CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP PILE CARPETS.

BEEN LISTED BY UNDERWRITERS LABORATORIES. INC. FOR USE WITH THEIR

SPECIFIC MODEL OF TELEVISION RECEIVER OR GENERICALLY APPROVED FOR USE

WITH T.V.S OF THE SAME OR LARGER SCREEN SIZE.

FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

S INVOICE.

3

Product safety servicing guidelines for color

television receivers

A.C. VOLTMETER

CAUTION :

way. Unauthorized modifications will not only void the

warranty, but may lead to your being liable for any

resulting property damage or user injury.

Service work should be performed only after you are

thoroughly familiar with all of the following safety checks

and servicing guidelines. To do otherwise, increases the

risk of potential hazards and injury to the user.

Do not attempt to modify this product in any

SAFETY CHECKS

After the original service problem has been corrected, a

check should be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a

way as to avoid possibility of adjacent component

shorts. This is especially important on those chassis

which are transported to and from the repair shop.

2. Never release a repair unless all protective devices

such as insulators, barriers, covers, shields, strain

reliefs, and other hardware have been reinstalled per

original design.

3. Soldering must be inspected to discover possible cold

solder joints, frayed leads, damaged insulation

(including A.C. cord), solder splashes or sharp solder

points. Be certain to remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration

to parts and components, and replace if necessary

follow original layout, lead length and dress.

5. No leads or components should touch a receiving tube

or a resistor rated at 1 watt or more. Lead tension

around protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof

resistors, capacitors, etc. must be replaced with exact

factory types. Do not use replacement components

other than those specified or make unrecommended

circuit modifications.

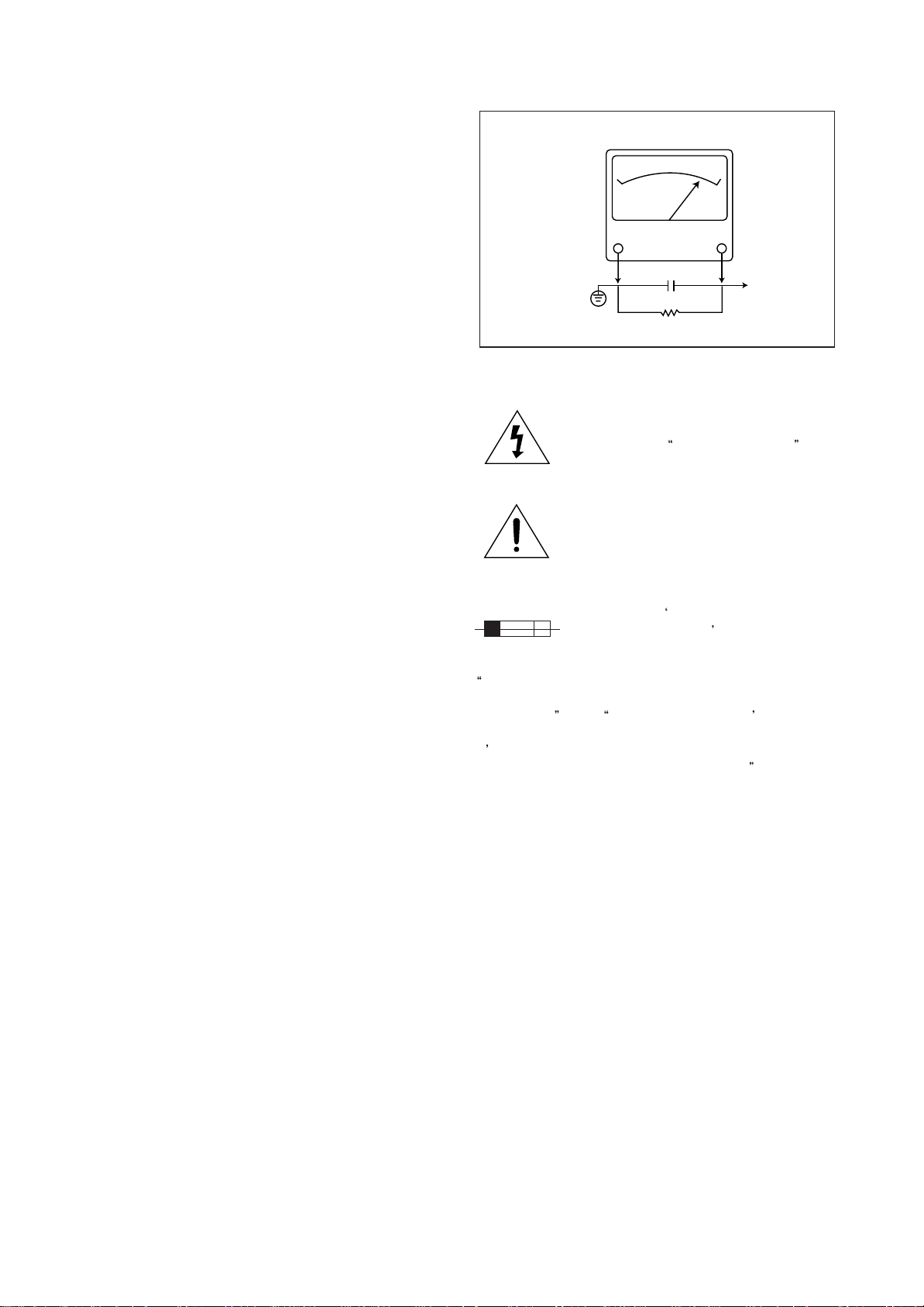

7. After re-assembly of the set always perform an A.C.

leakage test on all exposed metallic parts of the

cabinet, (the channel selector knob, antenna terminals,

handle and screws) to be sure the set is safe to operate

without danger of electrical shock. Do not use a line

isolation transformer during this test. Use an A.C.

voltmeter, having 5000 ohms per volt or more

sensitivity, in the following manner : connect a 1500

ohm 10 watt resistor, paralleled by a 15 mfd. 150V A.C.

type capacitor between a known good earth ground

9water pipe, conduit, etc.) and the exposed metalic

parts, one at a time. Measure the A.C. voltage across

the combination of 1500 ohm resistor and 0.15 MFD

capacitor. Reverse the A.C. plug and repeat A.C.

voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.75 volts R.M.S.

This corresponds to 0.5 milliamp A.C. Any value

exceeding this limit constitutes a potential shock hazard

and must be corrected immediately.

Good earth ground,

such as the water

pipe, conduit, etc.

0.15µF

••

1500 OHM

10WATT

Place this probe

on each exposed

metal part.

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the service personnel to the presence

of uninsulated

may be of sufficienty magnitude to

constitute a risk of electric shock.

The exclamation point within an equilateral

triangle is intended to alert the service

personnel to the presence of important

safety information in service literature.

Fuse symbol is printed on pcb adjacent to

the fuse, with

FUSE AS MARKED

explained in the service manual with the

following wording or equivalent.

CAUTION : FOR CONTINUED PROTECTION AGAINST

FIRE HAZARD, REPLACE ONLY WITH SAME TYPE 4A,

125V FUSE

PROTECTION PERMANENTE CONTRE LES RISQUES

D

INCENDIE, REMPLACER UNIQUEMENT PAR UN

FUSIBLE DE MEME TYPE ET DE 4A, 125V

and ATTENTION: AFIN D ASSU UNE

dangerous voltage that

RISK OF FIRE REPLACE

. The symbol is

.

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service

personnel cover the subject of X-rays in current T.V.

receivers is the picture tube. However, this tube does

not emit X-rays when the high voltage is at the factory

specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may

cause a failure of the picture tube or high voltage

supply and, under certain circumstances, may produce

radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must

be used. Degaussing shields also serve as X-ray shield

in color sets. Always re-install them.

3. It is essential that the serviceman has available an

accurate and reliable high voltage meter. The

calibration of the meter should be checked perio dically against a reference standard. Such as the one

available at your distributor.

4. When the high voltage circuitry is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be run up and down while monitoring the high voltage

4

with a meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly. We suggest that you and your service

orgainzation review test procedures so that voltage

regulation is always checked as a standard servicing

procedure. And that the high voltage reading be recorded

on each customer

5. When troubleshooting and making test measurements

in a receiver with a problem of excessive high voltage,

avoid being unnecessarily close to the picture tobe and

the high voltage compartment.

Do not operate the chassis longer than is necessary to

locate the cause of excessive voltage.

6. Refer to HV, B+and Shutdown adjustment procedures

described in the appropriate schematic and

diagrams(where used).

s invoice.

SUBJECT : IMPLOSION

1. All direct viewed picture tubes are equipped with an

integral implosion protection system, but care should be

taken to avoid damage during installation. Avoid

scratching the tube. If scratched, replace it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER

INSTALLATION

1. Never install any receiver in closed-in recess,

cubbyhole or closely fitting shelf space over, or close to

heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as : Outdoor

patio installations where dew is a factor. Near steam

radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear

venting. The customer should also avoid the use of

decorative scarves or other coverings which might

obstruct ventilation.

4. Wall and shelf mounted installations using a

commercial mounting kit, must follow the factory

approved mounting instructions. A receiver mounted to

a shelf or platform must retain its original feet(or the

equivalent thickness in spacers) to provide adequate

are flow across the bottom, blots or screws used for

fasteners must not touch and parts or wiring. Perform

leakage test on customized installations.

5. Caution customers against the mounting of a receiver

on sloping shelf or a tilted position, unless the receiver

is properly secured.

6. A receiver on a roll-about cart should be stable on its

mounting to the cart. Caution the customer on the

hazards of trying to roll a cart with small casters across

thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand

which has not been listed by underwriters laboratories,

inc. For use with their specific model of television

receiver or generically approved for use with T.V.

the same or larger screen size.

s of

5

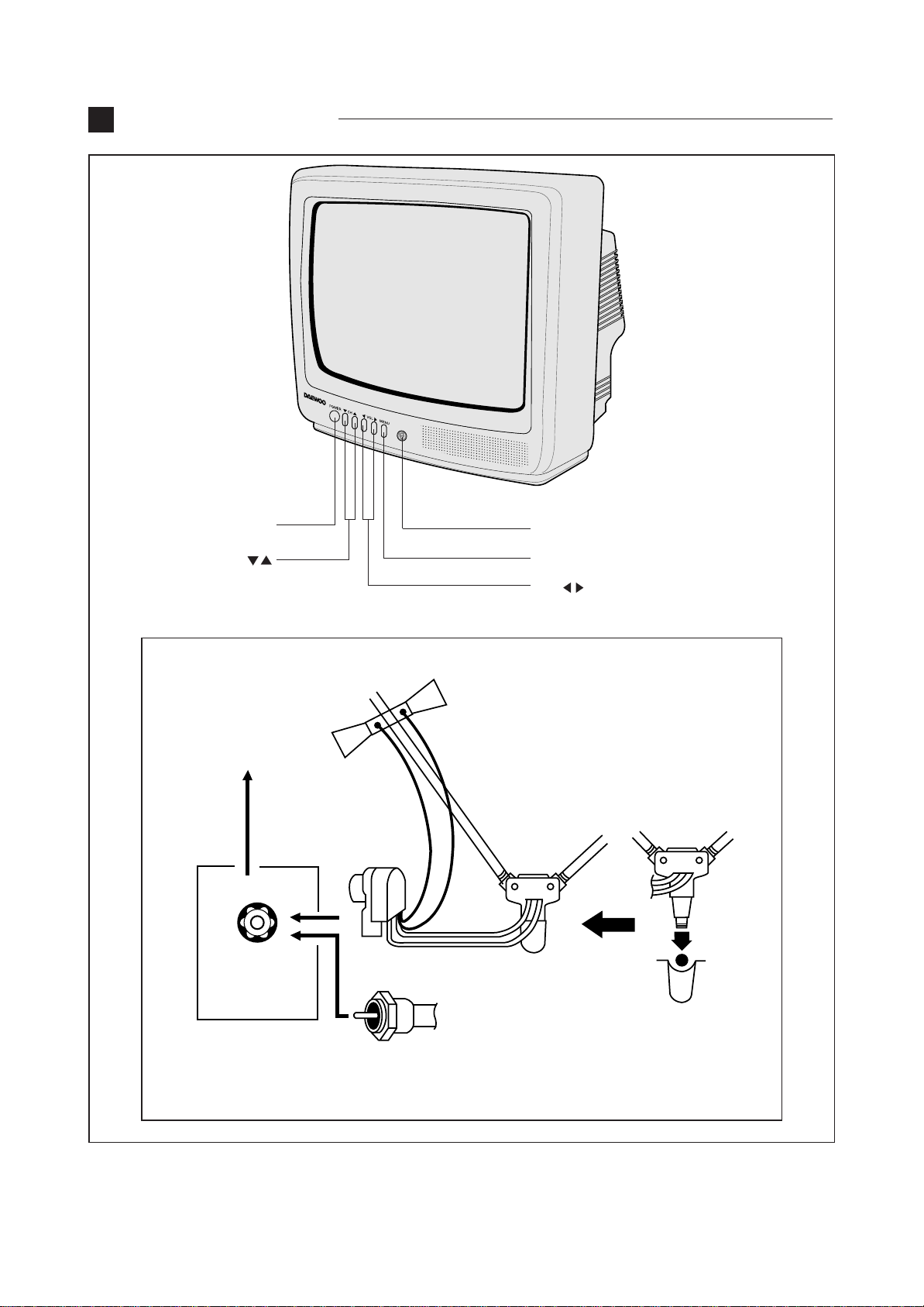

CONTROL VIEW

POWER

CH

F-CONNECTOR

300 OHM-75 OHM

COUPLING

TRANSFORMER

VHF

75Ω

Remote Control receiver

MENU

VOL

FROM 75 OHM

VHF ANTENNA WITH

CABLE OR CABLE

TV SYSTEM

6

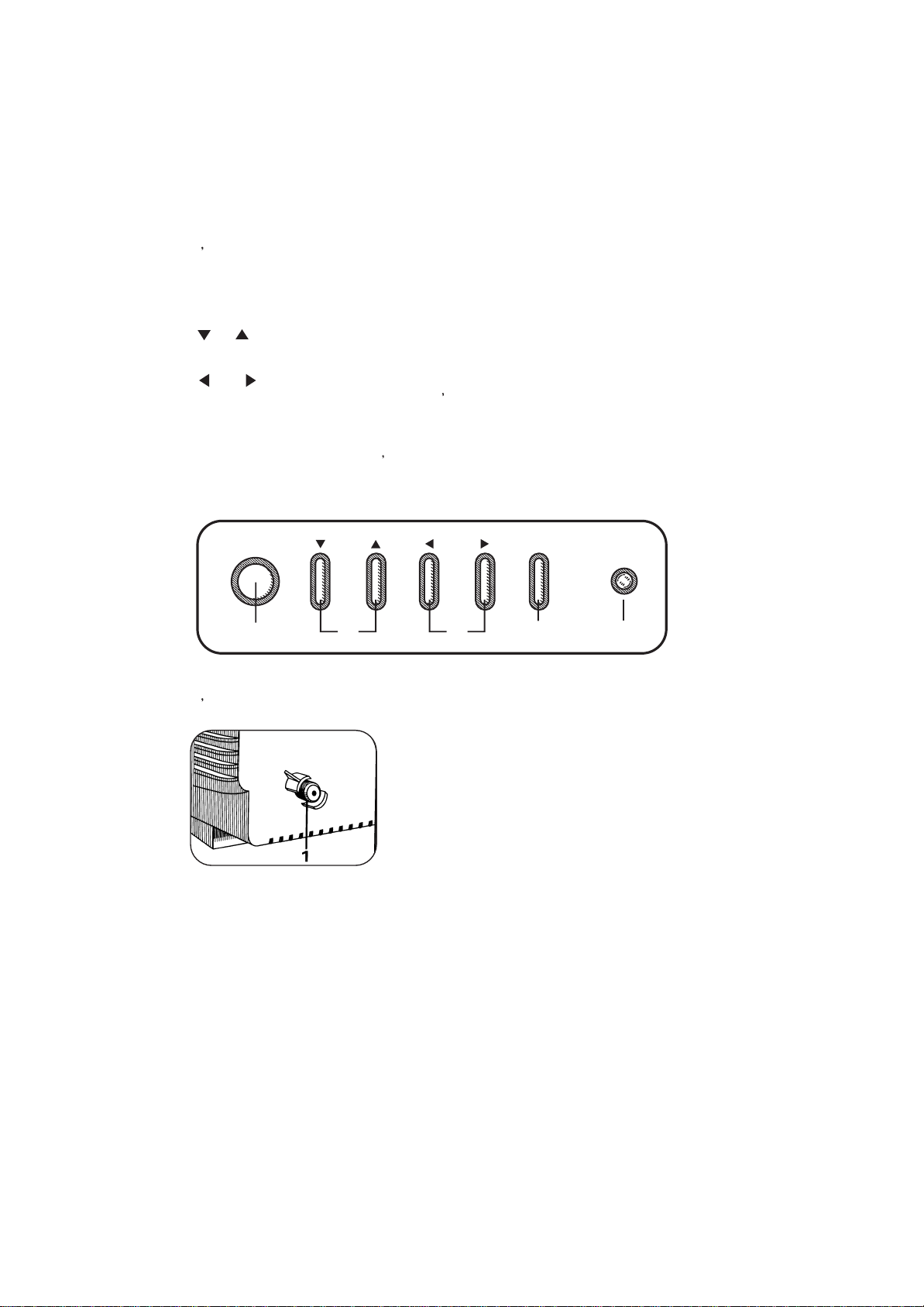

1. Overview of Your Equipment

POWER

1

CH VOL MENU

2 3 4 5

Your TV comes with a remote control. The section below summarizes the buttons,controls, and terminals

that you will use with your TV.

2. Your TV s Front Panel

1. POWER

Use this buttom to turn your TV on or off.

2. CH

Use these buttom to change channels on your TV, or to select items in the menu system.

3. VOL

Use these buttom to change your TV s volume, to activate selections in the menu system, or to

change audio and video settings.

4. MENU

Use this buttom to turn the TV s menu system on and off.

5. Remote control receiver

This receiver receives a signal from your remote control. Do not block it.

3. Your TV s Back Panel

1. Antenna terminal

Use this terminal to attach an antenna or cable

system to your TV.

7

IMPORTANT SERVICE NOTES

1. X-RAY RADIATION PRECAUTION

1) Excessive high voltage can produce potentially

hazardous X-RAY RADIATION. To avoid such

hazards, the high voltage must not be above the

specified limit. The nominal value of the high voltage

of this receiver is 24.4kv at zero beam current

(minimum brightness) under a 120V AC power source.

The high voltage must not, under any circumstances,

exceed 27kv (28.5kw). Each time a receiver requires

servicing, the high voltage should be checked following

the HIGH VOLTAGE CHECK procedure on page 6 of

this manual. It is recommended as a parts of the

service record. It is important to use an accurate and

reliable high voltage meter.

2) This receiver is equipped with X-RADIATION

PROTECTION circuit which prevents the receiver from

producing an excessively high voltage even if the

B+voltage increases abnormally. Each time the

receiver is serviced, X-RADIATION PROTECTION

circuit must be checked to determine that the circuit is

properly functioning, following the X-RADIATION

PROTECTION CIRCUIT CHECK procedure on page 6

of this manual.

3) The only source of X-RAY RADIATION in this TV

receiver is the picture tube. For continued X-RAY

RADIATION protection, the replacement tube must be

exactly the same type tube as specified in the parts list.

4) Some parts in this receiver have special safety-related

characteristics for X-RAY RADIATION protection. For

continued safety, parts replacement should be

undertaken only after referring to the PRODUCT

SAFETY NOTICE below.

2. SAFETY PRECAUTION

WARNING

: Service should not be attempted by anyone

unfamiliar with the necessary precaution on this receiver.

The following are the necessary precaution to be

observed before servicing.

1) Since the chassis of this receiver has hazardous

potential to ground whenever the receiver is plugged in

(floating chassis), an isolation transformer must be

used during servicing to avoid shock hazard.

2) Always discharge the picture tube anode to the CRT

conductive coating the picture tube. The picture tube is

highly evacuated and if broken, glass fragments will be

violently expelled. Use shatterproof goggles and keep

picture tube away from the body while handling.

3) When placing chassis in the cabinet, always be certain

that all the protective devices are put back in place,

such as; nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4) Before returning the set to the customer, always

perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas,

terminals, screw-heads, metal overlays, control shafts

etc. to be sure the set is safe to operate without

danger of electrical shock. Plug the AC line cord

directly into a 120V AC outlet (do not use a line isola-

Minimum brightness

tion transformer during this check). Use an AC

voltmeter having 5000 ohms per volt or more sensitivity in the following manner.

Connect at 1500 ohm 10 watt resistor, paralleled by a

0.15 mfd. AC type capacitor, between a known good

earth ground (water pipe, conduit etc.) and the

exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500 ohm resistor

and 0.15 mfd capacitor. Voltage measured must not

exceed 0.3 volts RMS. This corresponds to 0.2

millliamp. AC. Any value exceeding the limit constitutes

a potential shock hazard and must be corrected

immediately.

AC VOLT METER

0.15MFD

Place this probe

on each exposed

metallic part.

Good earth ground

such as d water

pipe, conduit, etc.

1500 ohm

10watt

3. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have

special safety-related characteristics. These

characteristics are often passed unnoticed by a visual

inspection and the protection afforded by them cannot

necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual and its

supplements; electrical components having such features

are identified by shading on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute

replacement parts which do not have the same safety

characteristics as specified in the parts list may create Xray radiation or other hazards.

4. SERVICE NOTES

1) When replacing parts or circuit boards, clamp or bend

the lead wires to terminals before soldering.

2) When replacing a high wattage resistor (metal oxide

film resistor) in the circuit board, keep the resistor min

1/2 inch away form circuit board.

3) Keep wires away from high voltage or high

temperature components.

8

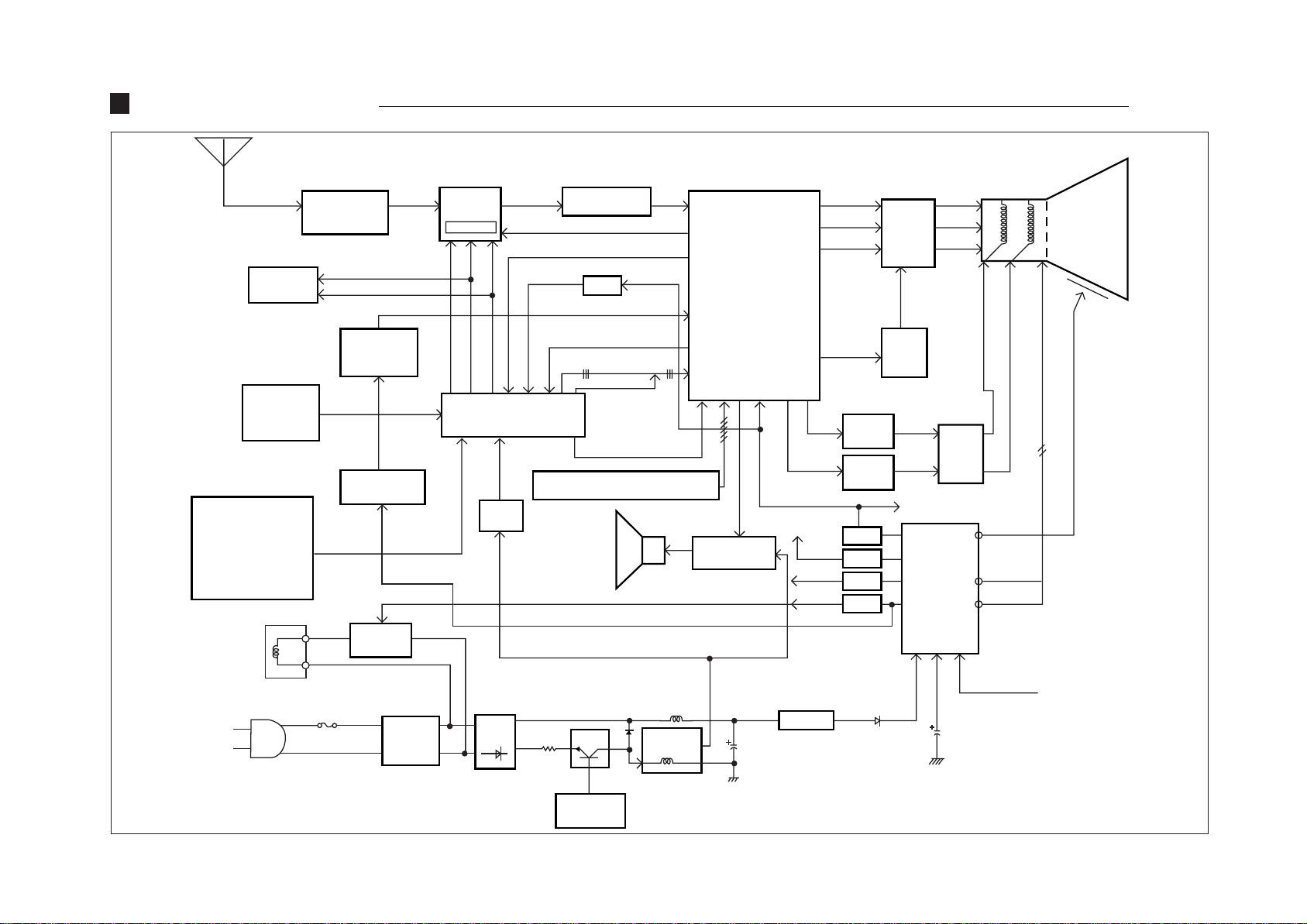

BLOCK DIAGRAM

96. 5. 30

1702

EEPROM

IL701

SENSOR

REMOCON

CONTROL KEY

POWER

CH UP/DOWN

VOL UP/ DOWN

MENU

L900

D/COIL

ASB1

ANT S/BOX

S-90

JA01

VIDEO IN

AUDEO IN

TA01

TRANS A/V

RL801

RELAY

F801

4A 125V

L801

LINE

FILTER

U101

TUNER

PLL IC

ED

I701

C

MICOM

LC864612A

5V

CONT.BRI COLOR. TINT. SHARP

Q802

REG

RELAY ON/OFF

D801

R818

FUSIBLE

Z101

SAW FILTER

RF-AGC

Q705

R.G.B OSD

YS

VOL. CONTROL

USER CONTROL

SPEAKER

D804

Q804

AFT

H.SYNC

V.SYNC

L802

T801

2519A1

I501 (LA 7674)

IF/V/C/DEF

PIF SIF AGC AFT

SOUND DEC

VIDEO AMP

VIDEO AUDIO IN.

CHROMA AMP

OSD INPUT

DEF,AFC,H.V OUT

AFC

I601

AUDIO AMP

12V

C808

180V

26.5V

B 103V

R-Y R.K

G-Y

B-Y

12V

–Y

I301

V.OUT

Q402

M.OUT

R412

D404

D407

D406

D403

Q901

COLOR

AMP

Q501

VIDEO

DRIVE

Q903

G.K

B.K

OUT

P401

DEF

YOKE

HEATER

T402

FBT

1401SPND

2001SPND

C419

BOOSTER

V901

14”

20”

CRT

H.V

9

H.V

FOCUS

SCREEN

ABL

Q801

PWM CTL

GENERAL ADJUSTMENTS

GENERAL ADJUSTMENTS

1. GENERAL

In the majority of cases, all color televisions will need only

slight touch-up adjustment upon installation. Check the

basic characteristics such as height, focus and sub- basic

characteristics such as height, focus and sub- bright.

Observe the picture for good black and white details

without objectionable color shading. If color shading is

evident, demagnetize the receiver. If color shading still

persists, perform purity and convergence adjustments.

This should be all that is necessary to achieve Optimum

receiver performance.

2. VERTICAL HEIGHT ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness and contrast controls for a good

picture.

3) Adjust vertical height control (R305) for approximately

one half inch over scan at top and bottom of picture

screen.

4) Vertical centering adjustment VR316

Horizontal centering adjustment VR556.

3. FOCUS ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness, sharpness and contrast controls for a

good picture.

3) Adjust focus control (part of T402) for sharp scanning

lines and/or sharp picture.

4. RF AGC ADJUSTMENT

1) Tune in an active channel.

2) Using the attenuator, apply the signal of 60dBm to the

antenna input terminal.

3) Turn RF AGC control (R113) full clockwise until snow

or/and noise appears in the picture, then slowly turn

control counter clockwise until snow or/and noise

disappears.

5. HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked to

verify that the receiver is operating within safe and

efficient design limitations as specified:

1) Operate Receiver for at least 15 minutes at 120V AC

line.

2) Set brightness sharpness, contrast and color control to

minumum position (Zero beam).

3) Connect accurate high voltage meter to CRT anode.

The reading should be 24kv~26kv

If a correct reading cannot be obtained, check circuity for

malfunctioning components.

6. X-RADIATION PROTECTION

CIRCUIT TEST

When service has been performed on the horizontal

deflection system, high voltage system or B+system, the

X-RADIATION protection circuit must be tested for proper

operation as follows:

1) Operate receiver for at least 15 minutes at 120V AC

line.

2) Adjust all customer controls for normal picture and

sound.

3) Short R414(X-RAY Short test), and remove short clip.

4) If the operation of horizontal osc. does not stop in step

The circuit must be repaired, before the set is returned

to the customer.

7. CRT GRAY SCALE ADJUSTMENT

1) Tune in an active channel.

2) Set the COLOR control to minimum.

3) Turn the SCREEN control (on T402 fully counterclockwise.)

4) Rotate the RED, GREEN and BLUE BIAS controls

(R906, R913, R920) counterclock wise from the

maximum, set them to the position where notches in

the knobs become parallel to the surface of P.C.

Board.

5) Set the GREEN and BLUE DRIVE controls (R911,

R918) to the mid position.

6) Turn the service switch SW901 (Service Position) on

the CRT board.

7) Rotate the SCREEN control (on T402) gradually

clockwise until the second horizontl line following the

first line appears slightly on the screen. Then turn fully

counterclockwise the two BIAS controls corresponding

to the colors of the first and the second horizontal

lines to eliminated the lines.

8) Set the SCREEN control to the position where the

third horizontal line lights slightly on the screen.

9) Adjust the two BIAS control set to the minimum in item

7) above to obtain the slightly lighted horizontal line in

the same levels of three (red, green, blue) colors. (The

line should be white if the BIAS controls are adjusted

properly.)

10) Turn the service switch SW901 again (Normal position

on the CRT board.)

11) Press PICTURE-SEL, P-UP and set the brightness

and contrast controls to the maximum.

12) Adjust the BLUE and GREEN DRIVE control to obtain

proper white-blanced picture in high light areas.

13) Using P-SEL, P-DN key, set the brightness and

contrast controls to obtain dark gray raster. Then

check the white balance in low brightness. Of the

white balance is not proper, retouch the BIAS controls

and DRIVE controls to obtain a good white balance in

both low and high light areas.

8. MAIN B+(103V) ADJUSTMENT

1) Tune in an active channel

2) Check TP7 (DC 103V Line) using D.V.M

3) Adjust voltage control (R820) for main B+(DC 103V)

10

9. SUB-BRIGHTNESS ADJUSTMENT

1) Tune in a color program.

2) Set the CONTRAST control to maximum and the BRIGHTNESS control to maximum and the SHARPNESS

control to the center position.

3) Set the COLOR and TINT controls to center.

4) Set the SUB-BRIGHT control R554 to center and leave

the receiver on five minutes in this state.

5) Watching the picture carefully, adjust the SUB-BRIGHT

control in the position where the picture does not show

evidence of blooming in high brightness area and not

appear too dark in low bright area.

6) Check for BRIGHTNESS controls at both extremes.

7) If the picture does not appear dark with the

CONTRAST and BRIGHTNESS control turned to

minimum, or not appear bright with the controls turned

to maximum, adjust the SUB-BRIGHT control again for

an acceptable picture.

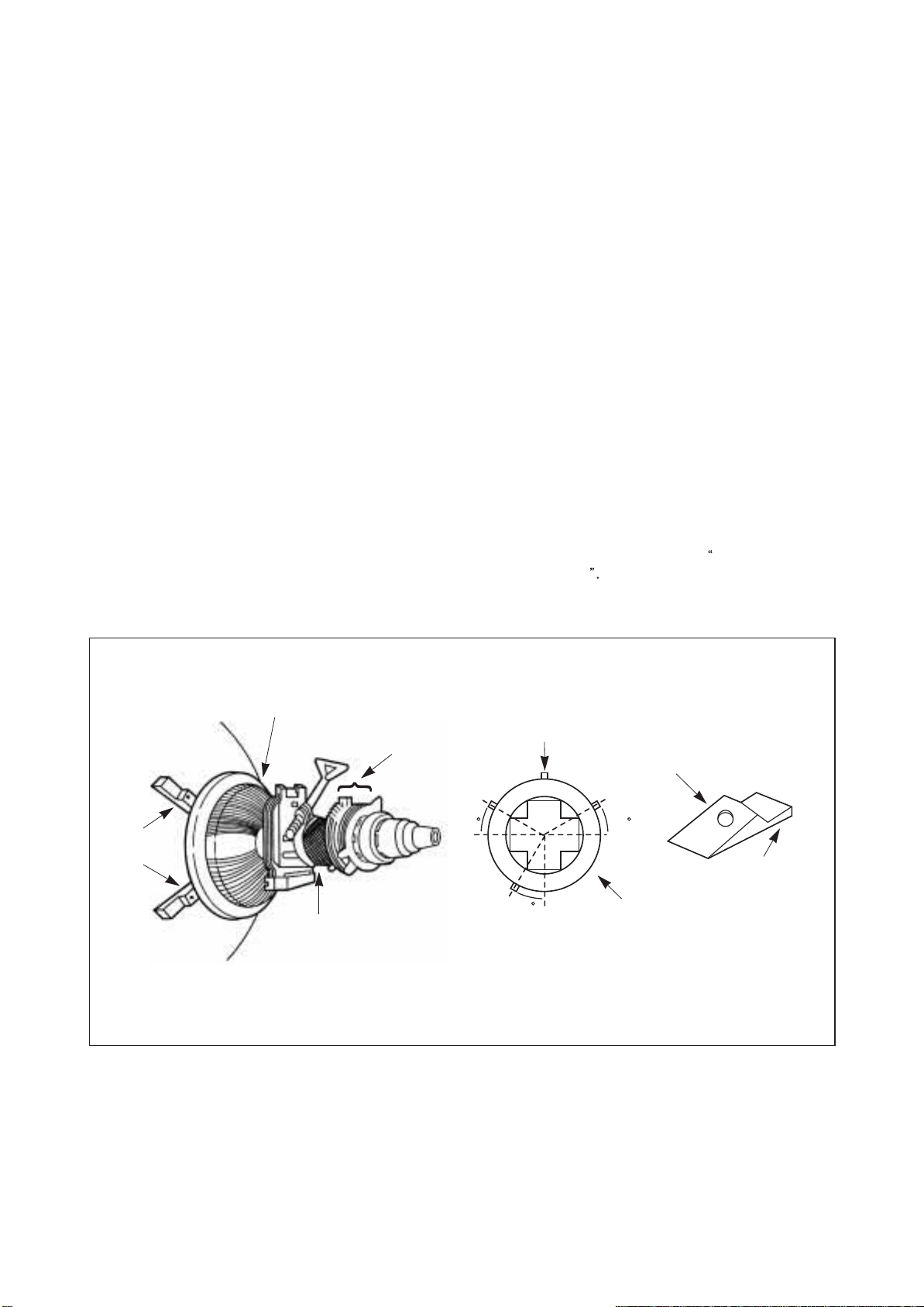

10. CONVERGENCE MAGNET ASSEMBLY

POSITIONING

If Convergence magnet assembly and rubber wedges

need mechanical positioning follow figure 2.

10-1. COLOR PURITY ADJUSTMENT

NOTE

1) Demagnetize the picture tube with a degaussing coil.

2) Adjust the CONTRAST and BRIGHTNESS controls to

3) Adjust RED and BLUE Bias controls (R971 and R973)

4) Loosen the clamp screw holding the yoke, and slide

5) Remove the Rubber Wedges.

6) Rotate and spread the tabs of the purity magnet (See

7) Move the yoke slowly forward until a uniform green

8) Check the purity of the red and blue raster by adjusting

9) Obtain a white raster, referring to

10) Proceed with covergence adjustment.

: Before attempting any purity adjustments, the

receiver should be operated for at least 15

minutes.

maximum

to provide only a green raster. Adjust the GREEN BIAS

control (R972) if necessary.

the yoke backward th provide vertical green

belt(zone)in the picture screen.

figure 2) around the neck of the picture tube until the

green belt is in the center of the screen. At the same

time, center the raster vertically.

screen is obtained. Tighten the clamp screw of the

yoke temporarily.

the BIAS controls.

CRT GRAY SCALE

ADJUSTMENT

RUBBER

WEDGES

PICTURE TUBE

DEFLECTION

YOKE

GLASS CLOTH

TAPE

CONVERGENCE

MAGNET ASS'Y

TEMPORARY

MOUNTING

30 30

30

Fig. 2 Rubber Wedges Location

RUBBER

WEDGES

ADHESIVE

DEF.

YOKE

11

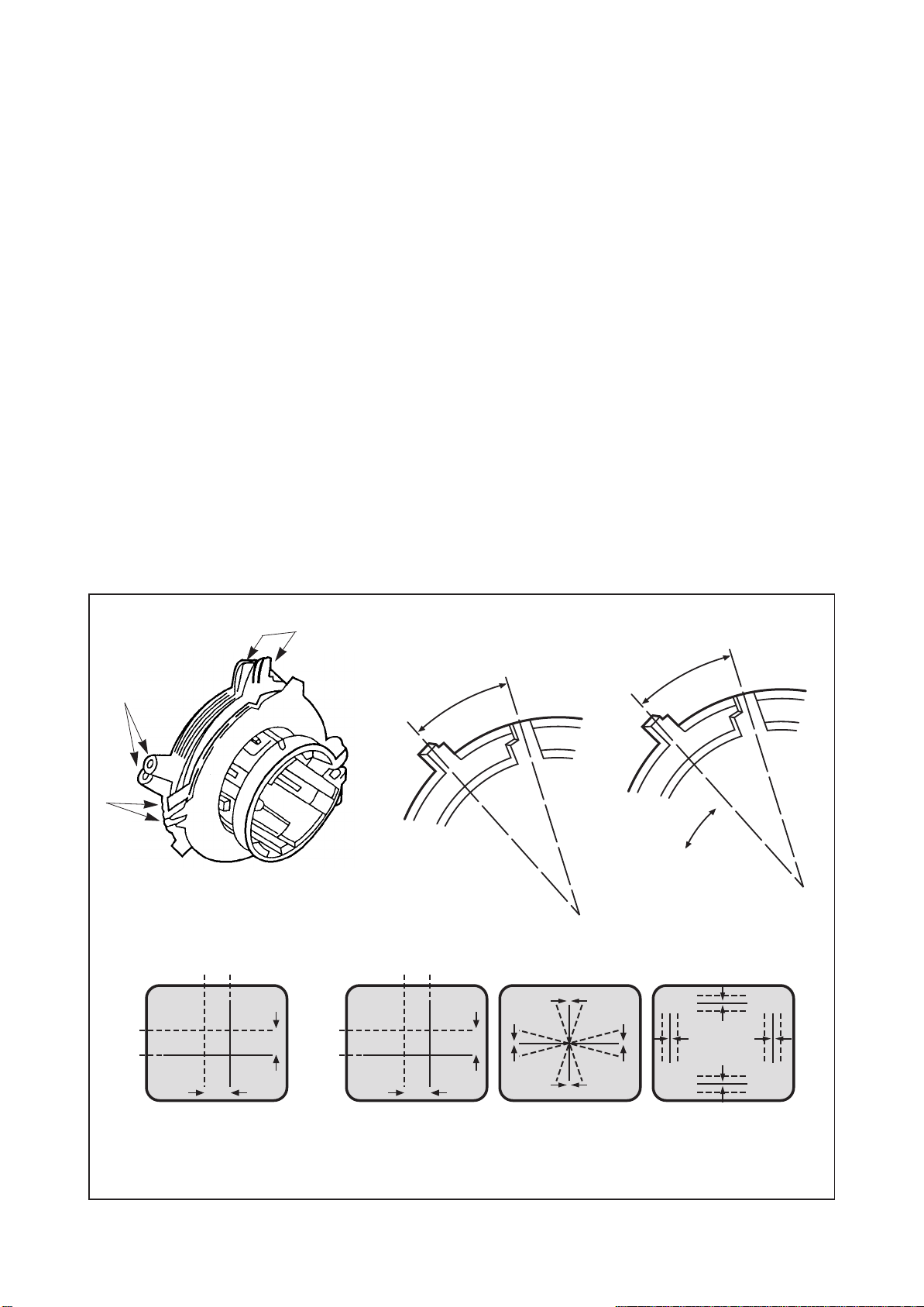

10-2. CONVERGENCE ADJUSTMENTS

NOTE

: Before attempting any purity adjustments, the

receiver should be operated for at least 15

minutes.

A. CENTER CONVERGENCE ADJUSTMENT

1) Receive crosshatch pattern with a crosshatch signal

generator.

2) Adjust the BRIGHTNESS and CONTRAST Controls for

a good picture.

3) Adjust two tabs of the 4-Pole Magnets to change the

angle between them (See Fig. 3) and superimpose red

and blue vertical lines in the center area of the picture

screen. (See Fig. 4)

4) Turn both tabs at the same time keeping their angles

constant to superimpose red and blue horizontal lines

at the center of the screen. (See Fig. 4)

5) Adjust two tabs of 6-Pole Magnets to superimpose

red/blue line with green on top of each other. Adjusting

the angle affects the vertical lines and rotating both

magnets affects the horizontal lines.

6) Repeat adjustments 3), 4), 5) keeping in mind red,

green and blue movement, because 4-Pole Magnets

and 6-Pole Magnets interact and make dot movement

complex.

B. CIRCUMFERENCE CONVERGENCE ADJUSTMENT

NOTE

: This adjustment requires Rubber Wedge Kit.

1) Loosen the clamping screw on deflection yoke to allow

the yoke to tilt.

2) Place a wedge as shown in figure 2 temporarily. (Do

not remove cover paper on adhesive part of the

wedge.)

3) Tilt front of the deflection yoke up or down to obtain

better convergence in circumference. (See Fig. 4) Push

the mounting wedge into the space between picture

and the yoke to hold the yoke temporarily.

4) Place other wedge into bottom space and remove the

cover paper to stick.

5) Tilt front of the yoke right or left to obtain better

convergence in cicumference. (See Fig. 4)

6) Hold the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to hold the yoke.

7) Detach the temporarily mounted wedge and put it in

another upper space. Stick it on picture tube to fix the

yoke.

8) After placing three wedges, re-check overall

convergence. Tighten the screw firmly to hold the yoke

tightly in place.

9) Stick 3 adhesive tapes on wedges as shown in figur32.

4-POLE

PURITY

MAGNETS

MAGNETS

4DJUST THE

ANGLE

(VERTICAL

CONSTANT

LINES)

ROTATE TWO TABS AT

THE SAME TIME

CONVERGENCE MAGNET ASSEMBLY

BLUE

BLUE

RED

RED

RED/BLUE

GRN

RED/BLUE

Fig. 3

GRN

B G R

R

G

B

R G B

(HORIZONTAL LINES)

ADJUSTMENT OF MAGNET

B

G

R

B

G

R

BGR

4-Pole Magnets Movement 6-Pole Magnets Movement Incline the Yoke up(or down) Incline the Yoke right(or left)

Center Convergence by Convergence Magnets Circumference Convergence by DEF. Yoke

BGR

R

G

B

Fig. 4 Dot Movement Pattern

12

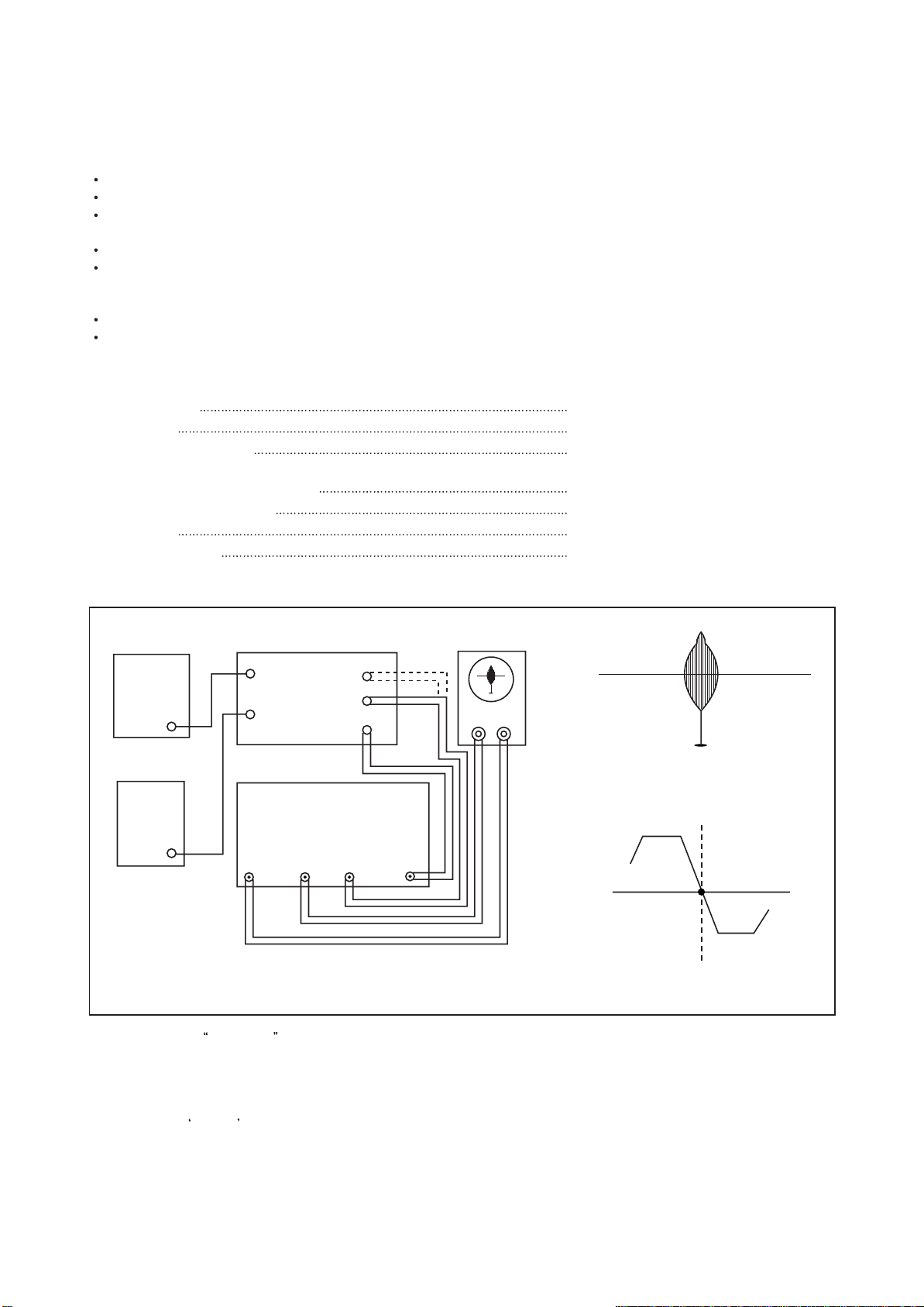

11. PICTURE IF/AFT ADJUSTMENTS

NOTE

: THIS RECEIVER IS TRANSISTORIZED AND SPECIAL CARE MUST BE TAKEN WHEN SERVICING. READ

THE FOLLOWING (NOTES BEFORE ATTEMPTING ALIGNMENT)

Alignment requires an exacting procedure and should be undertaken only when necessary.

Isolation transformer must be used to prevent shock hazard.

The test equipment specified or its equivalent is required to perform the alignment properly. Use of equipment which

does not meet these requirements may result in improper alignment.

Accurate equipment is essential to obtain proper alignment of this receiver.

Use of excessive signal from a sweep generator can cause overloading of receiver circuit Overloading should be

avoided to obtain a true response curve. Insertion of markers from the marker generator should not cause distortion of

the response curve.

The AC Power line voltage should be kept 120 volts while alignment is being performed.

Do not attempt to disconnect any components while the receiver is in operation.

Make sure the power cord is disconnected before replacing any parts in the receiver.

TEST EQUIPMENT

Digital voltmeter National Model VP-2600A or equivalent

Oscilloscope

Direct/Low-capacity probe

Tektronix Model 2215A or equivalent.

Tektronix Model P6120 or equivalent

(Accessory of oscilloscope)

Color-Bar/Dot/Crosshatch generator

PIF sweep marker generator

Power supply

Isolation transformer

Tektronix Model 146 or equivalent.

Nihon Tsushinki Model 4723 or equivalent

Academy Model 150A or equivalent

Voltage adjustable type having capacity of

at least 150 watts

BLOCK DIAGRAM

B+

BIAS

POWER

SUPPLY

A

(16.5V)

AGC

BIAS

POWER

SUPPLY

B

(4-5V)

1) Disconnect the

MAIN BOARD

TP3

TP5

PIF SWEEP/MARKER GEN.

VH

Fig. 5 Picture IF Sweep Alignment

TP6

TP1

TP4

DETIN

OUT

TUNER IF output from TP1 and connect equipment as shown above.

OSCILLOSCOPE

Y

X

45.75MHz

Fig. 6 PIF Response

P

45.75MHz

Fig. 7 AFT Response Curve

2) Set the sweep/marker generator for 30 Vrms.

3) Observe 1 Vp-p on scope by adjusting power supply B (4~5V).

4) Adjust PIF coil L505 for according beat signal with 45.75 MHz marker on scope (See Fig. 6).

5) Connect the

DET IN to TP6.

6) Adjust AFT coil L504 for center display at 45.75 MHz on scope (See Fig. 7).

7) After completing the above steps, disconnect equipment and adjust the AGC delay circuit as explained in the General

Adjustments section of this manual.

13

Loading...

Loading...