Daewoo DSB-240LH Schematic

Contents

CONTENTS

1. Specifications..........................................................................................................2

2. Outline and Dimensions.........................................................................................6

3. Operation ..............................................................................................................12

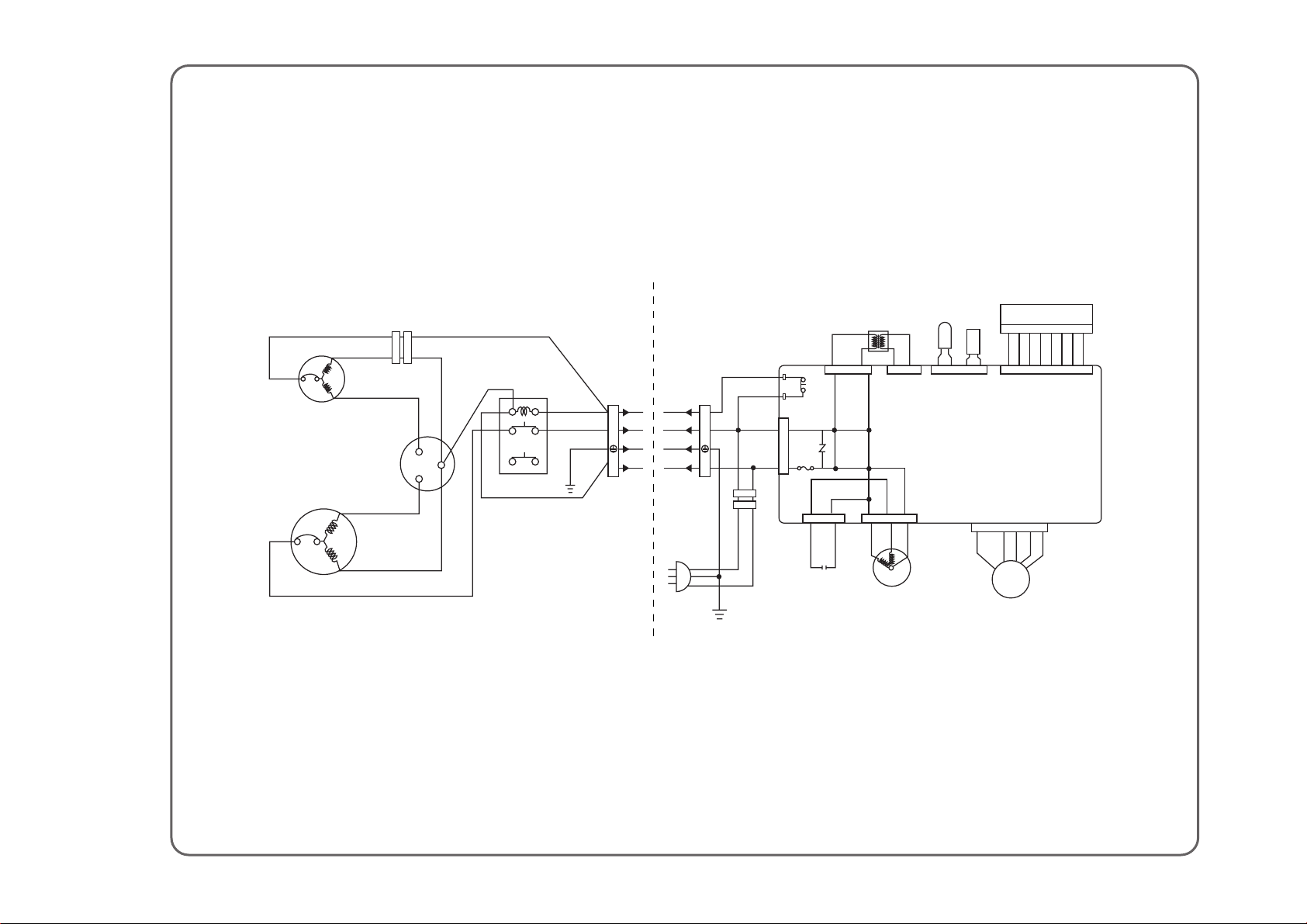

4. Wiring Diagram.....................................................................................................28

5. Refrigerant Cycle..................................................................................................32

6. Control Block Diagram.........................................................................................33

7. Electric Circuit Diagram........................................................................................34

8. Trouble Shooting...................................................................................................36

9. Key Components of Electronic Circuit.................................................................62

10. Disassembly Instructions .....................................................................................65

1) Indoor Unit........................................................................................................65

2) Outdoor Unit.....................................................................................................68

3) Exploded Diagram (Indoor Unit)......................................................................71

4) Exploded Diagram (Outdoor Unit)...................................................................79

5) Control Box Assembly......................................................................................87

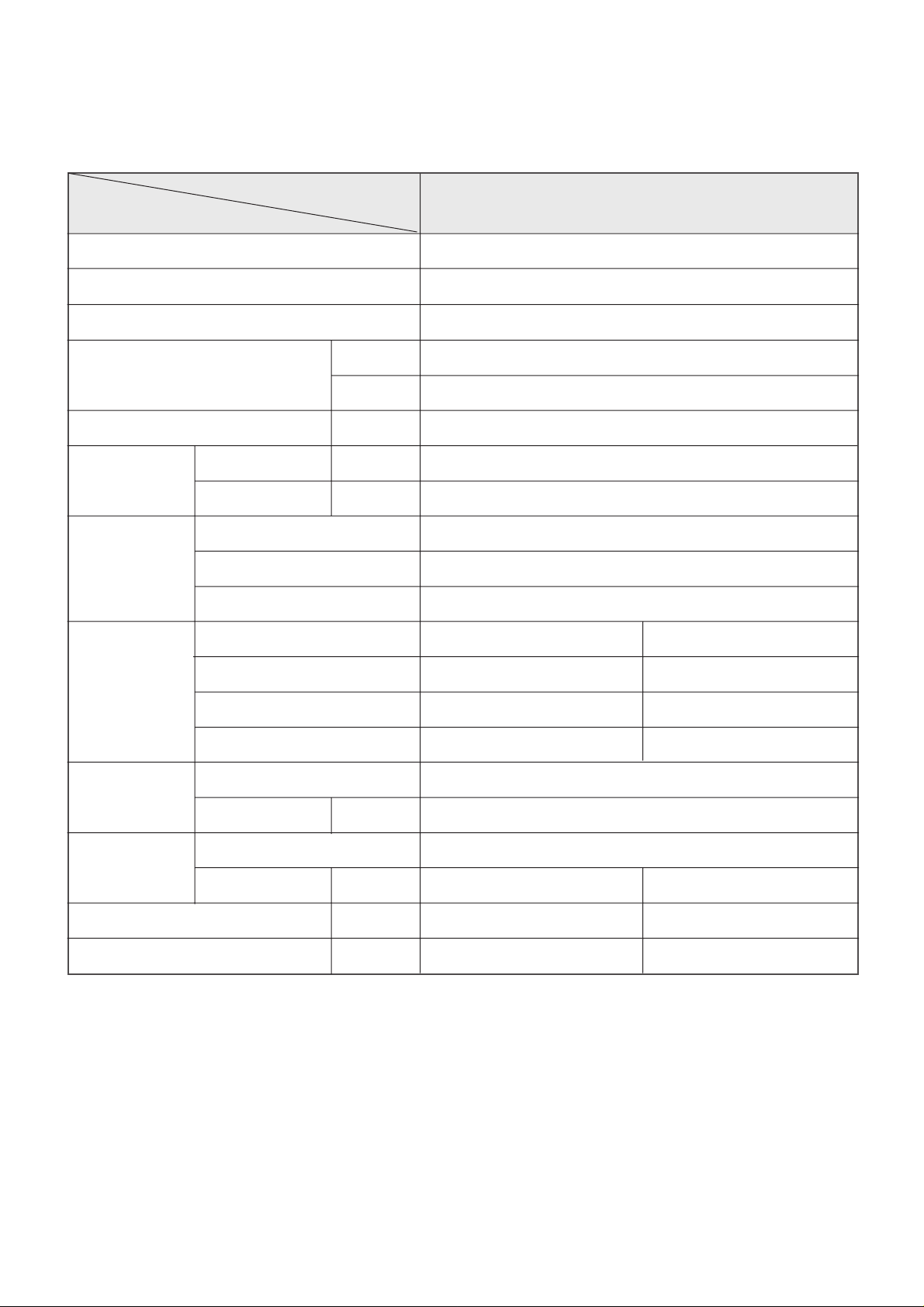

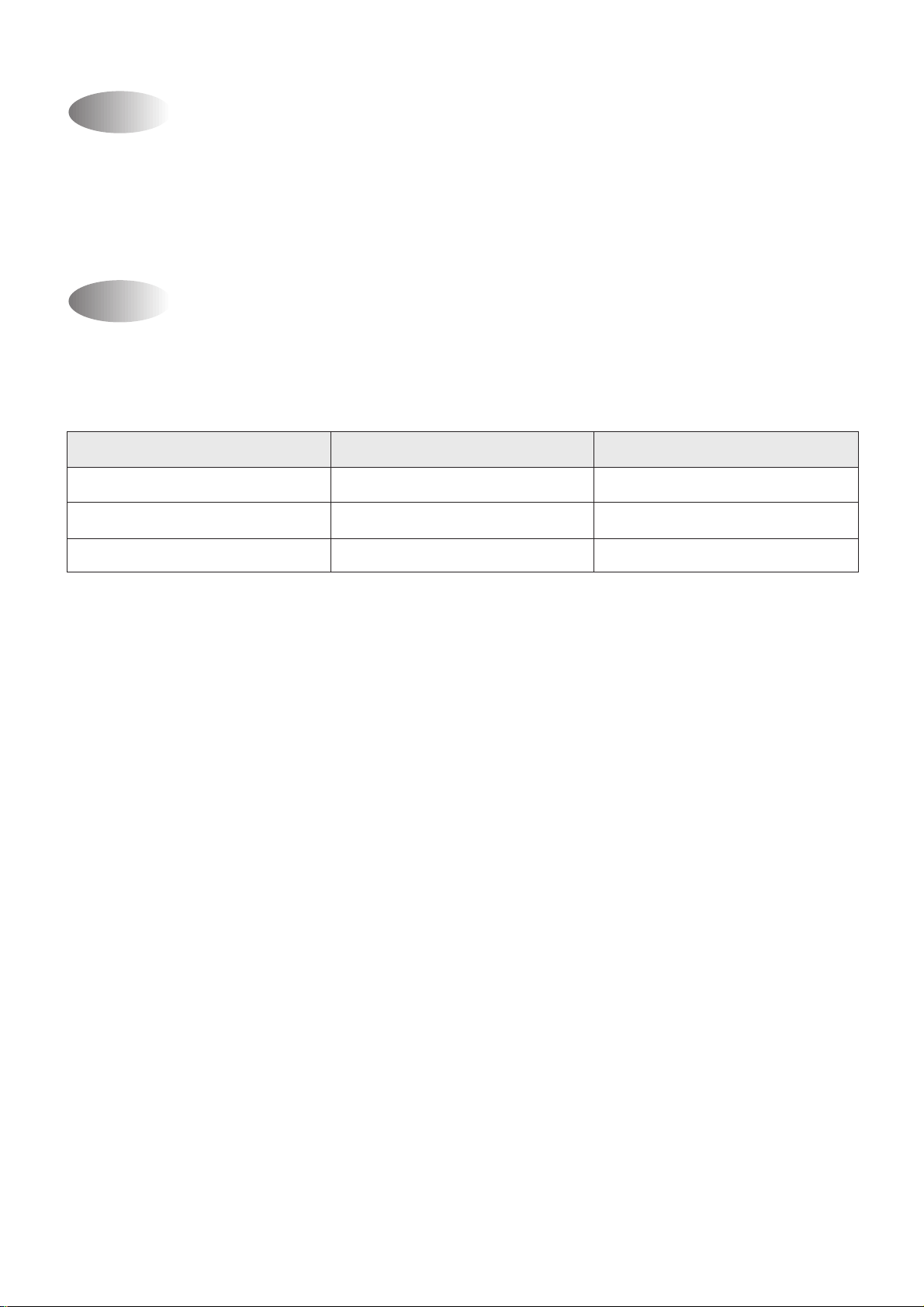

1. SPECIFICATIONS

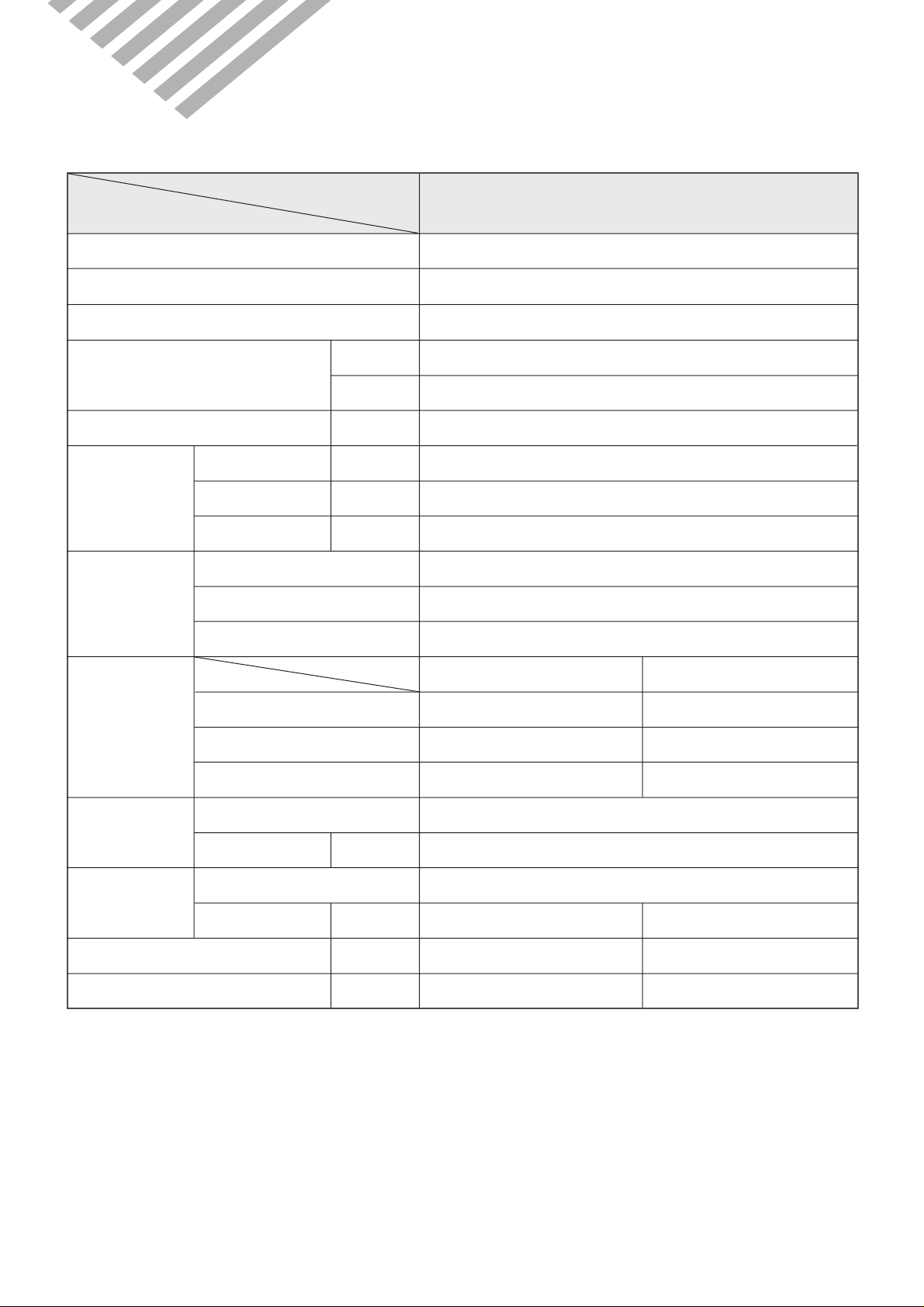

¡ DSB-070L

MODEL

ITEM

Function Cooling

Class T

Power AC 220~ 240V/ 50Hz

Capacity W 2,051

Btu/h 7,000

Dehumidification l/h 0.89

Running Current A 2.9

Electrical

Data

Compressor

Power Input W 680

Starting Current A 18

Type Rotary

Model QB 125PL 12B

Capacitor 25µF/370VAC

DSB-070L

Indoor Unit Outdoor Unit

Fan

Motor

Refrigerant

(R-22)

Connection

Dimensions (W x H x D) mm 750 x 245 x 174 654 x 549 x 256

Net Weight kg 7.0 34

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 1.8µF 400V

Motor Model Number IC-8417DWKF5A IC-9625DWLF5A

Control Capillary

Charge Q'ty g 800

Type Flare

OD

(Liquid/Suction)

in(mm) 1/4 (6.35) 1/2 (12.7)

2

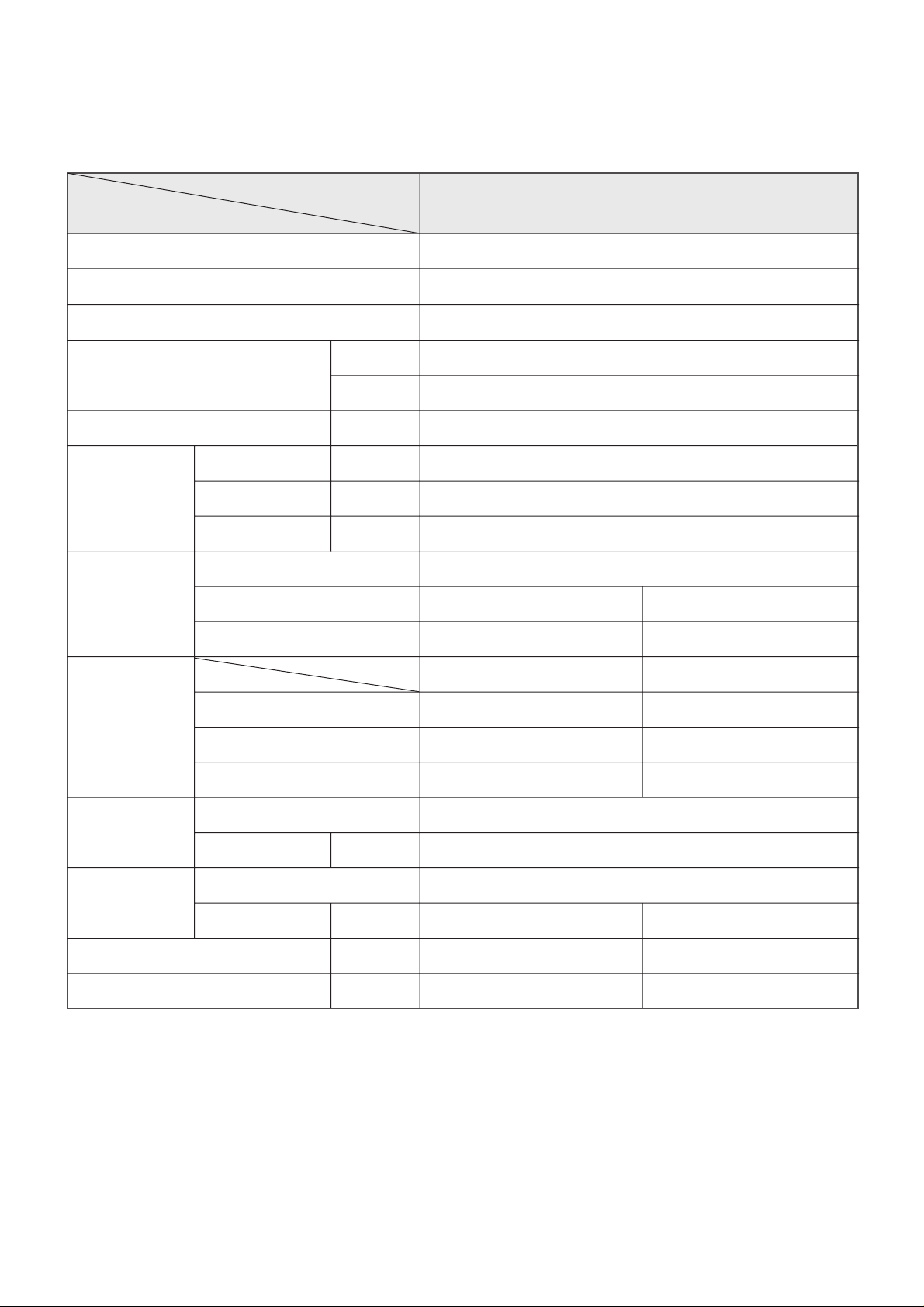

¡ DSB-091L

MODEL

ITEM

Function Cooling

Class T

Power AC 220~240V/ 50Hz

Capacity W 2,637

Btu/h 9,000

Dehumidification l/h 1.15

Running Current A 4.2

Electrical

Data

Compressor

Power Input W 920

Starting Current A 21

Type Rotary

Model RBB090A001 QK 164PN12F

Capacitor 25µF / 370VAC 30µF / 370VAC

DSB-091L

Indoor Unit Outdoor Unit

Fan

Motor

Refrigerant

(R-22)

Connection

Dimensions (W x H x D) mm 750 x 245 x 174 654 x 549 x 256

Net Weight kg 7.0 34

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 1.8µF 400V

Motor Model Number IC-8417DWKF5A IC-9630DWLF5A

Control Capillary

Charge Q'ty g 1,000

Type Flare

OD

(Liquid/Suction)

in(mm) 1/4 (6.35) 1/2 (12.7)

3

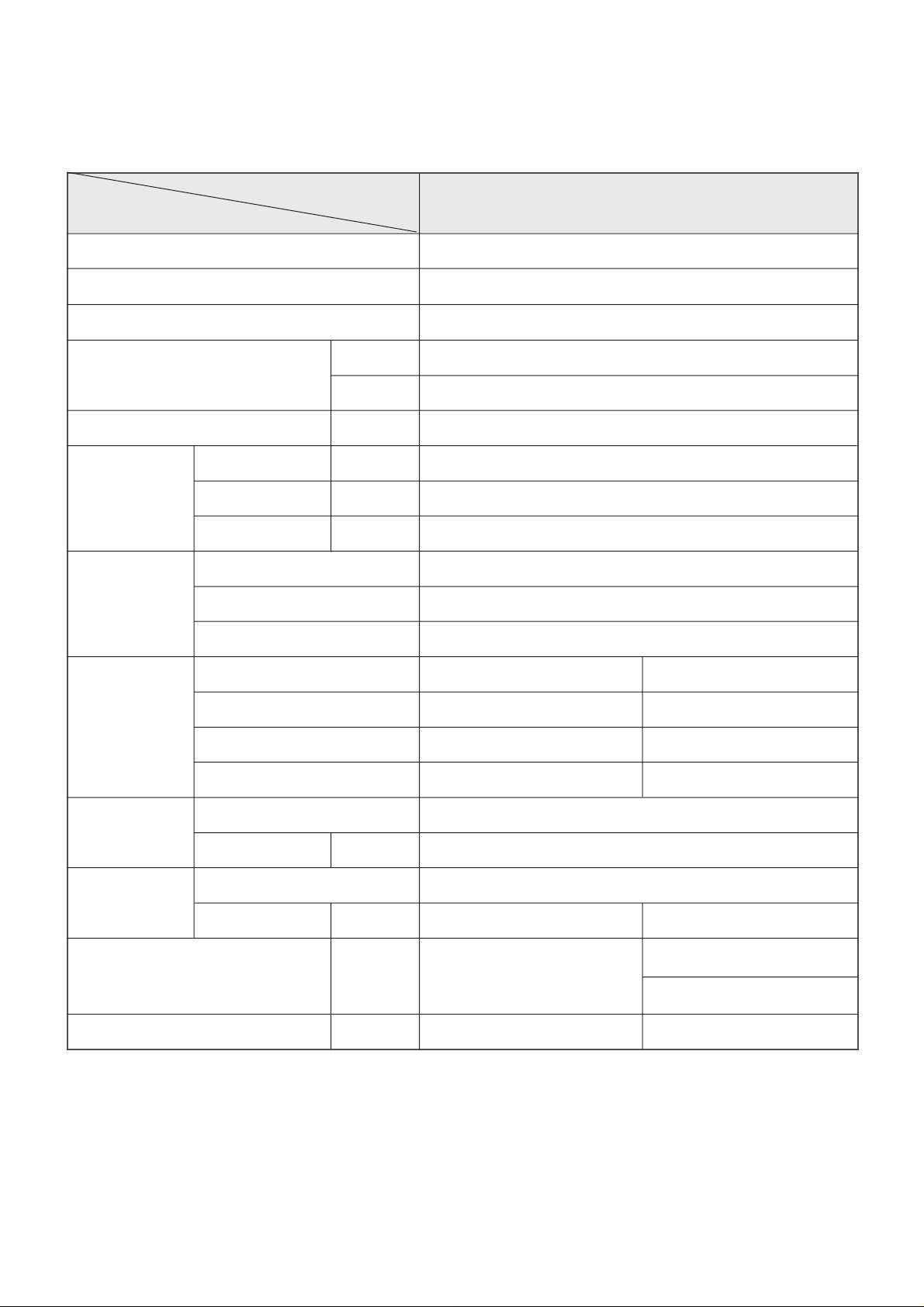

¡ DSB-121L/122L

MODEL

ITEM

Function Cooling

Class T

Power AC 220~240V/ 50Hz

Capacity W 3,507

Btu/h 12,000

Dehumidification l/h 1.53

Running Current A 5.7

Electrical

Data

Compressor

Power Input W 1,250

Starting Current A 34

Type Rotary

Model RCB 120A001

Capacitor 25µF/ 400VAC

DSB-121L/122L

Division Indoor Unit Outdoor Unit

Fan

Motor

Refrigerant

(R-22)

Connection

Dimensions (W x H x D) mm 925 x 285 x 194

Net Weight kg 9.7 34

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 3.5µF 400VAC

Motor Model Number IC-8428DWKG7C IC-9430DWLC5B

Control Capillary

Charge Q'ty g 1,300

Type Flare

OD

(Liquid/Suction)

in(mm) 1/4 (6.35) 1/2 (12.7)

666 x 552 x 264(Before)

654 x 549 x 256(After)

4

¡ DSB-240L

MODEL

ITEM

Function Cooling

Class T

Power AC 220~240V/ 50Hz

Capacity W 7,030

Btu/h 24,000

Dehumidification l/h 3.2

Electrical

Data

Compressor

Running Current A 13.4

Power Input W 2,400

Type Recipro

Model AWG5530EXC

Capacitor 45µF/ 400VAC

Division Indoor Unit Outdoor Unit

DSB-240L

Fan

Motor

Refrigerant

(R-22)

Connection

Dimensions (W x H x D) mm 1080 x 298 x 200 872 x 675 x 325

Net Weight kg 14.7 64

Type Cross flow fan Propeller fan

Capacitor 2µF 400VAC 5µF 400VAC

Motor Model Number IC9430DWKG7A 05ME986DERC

Control Capillary

Charge Q'ty g 2,050

Type Flare

OD

(Liquid/Suction)

in(mm) 3/8 (9.52) 5/8 (15.9)

5

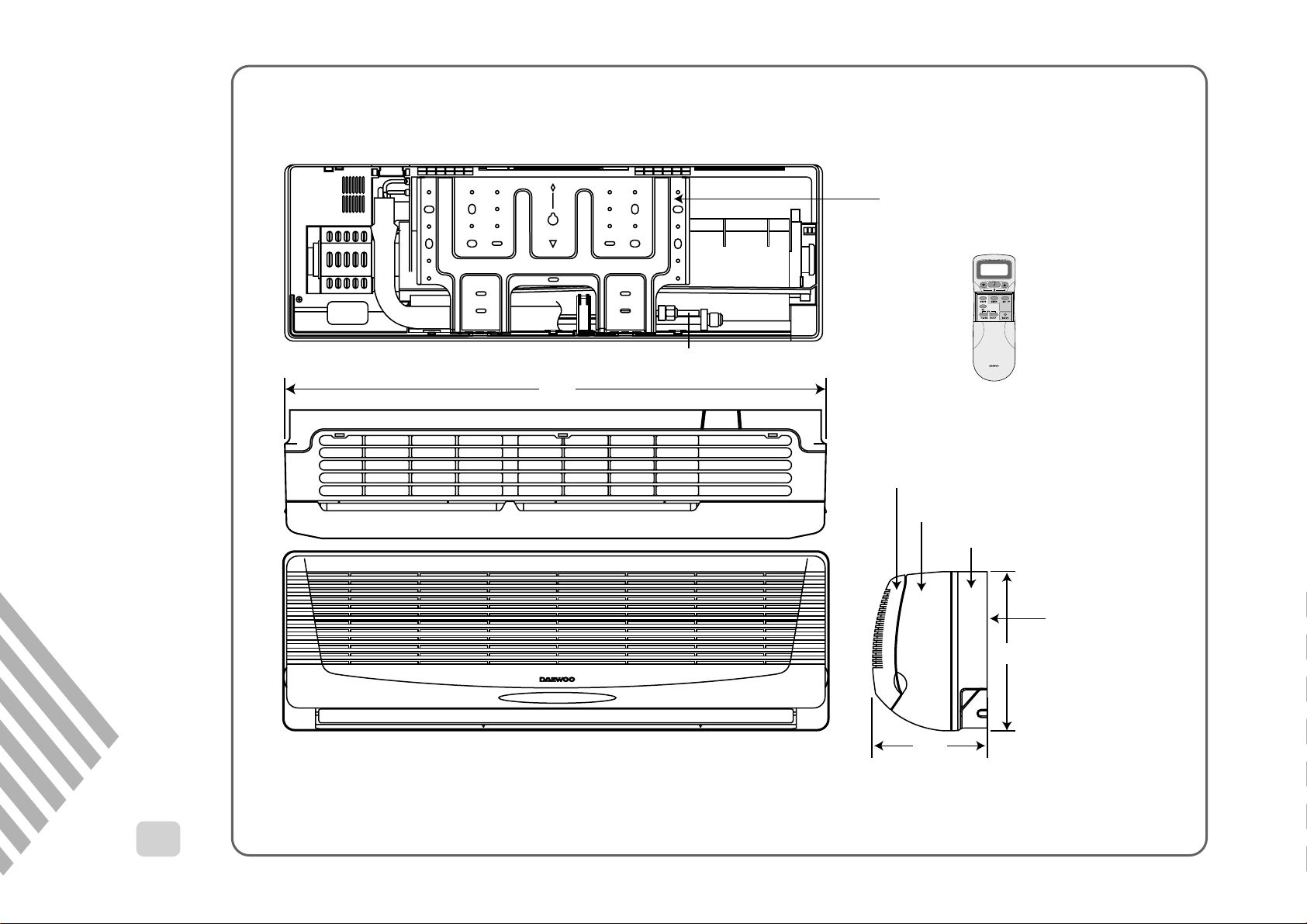

750

Plate Mounting

REMOCON

Connecting Pipe

Grille Insert

174

245

REMOTE CONTROLLER

Frame Grille

Body

Plate Mounting

INDOOR UNIT

2. OUTLINE AND DIMENSIONS

1

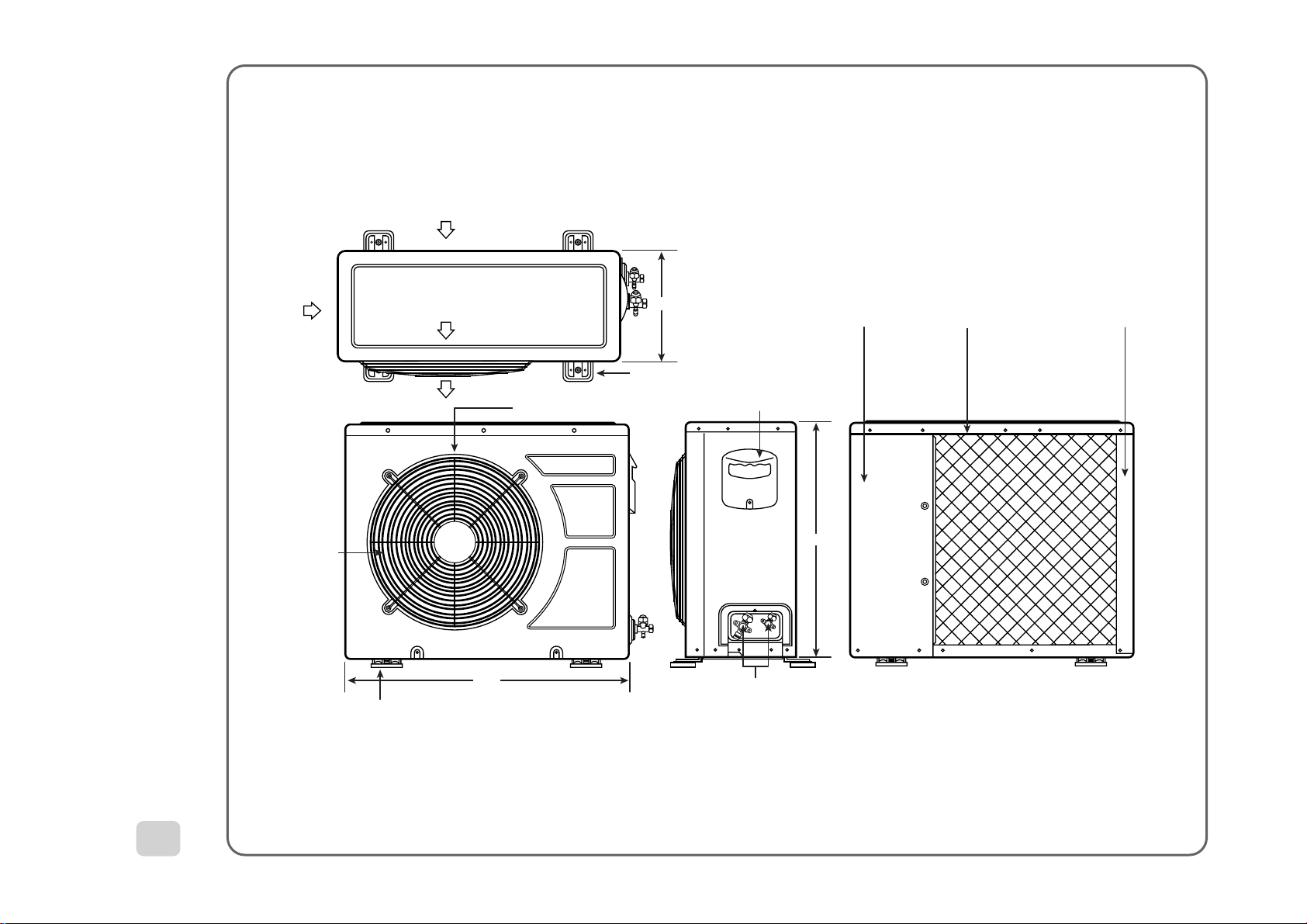

¡ DSB-070L/DSB-091L

6

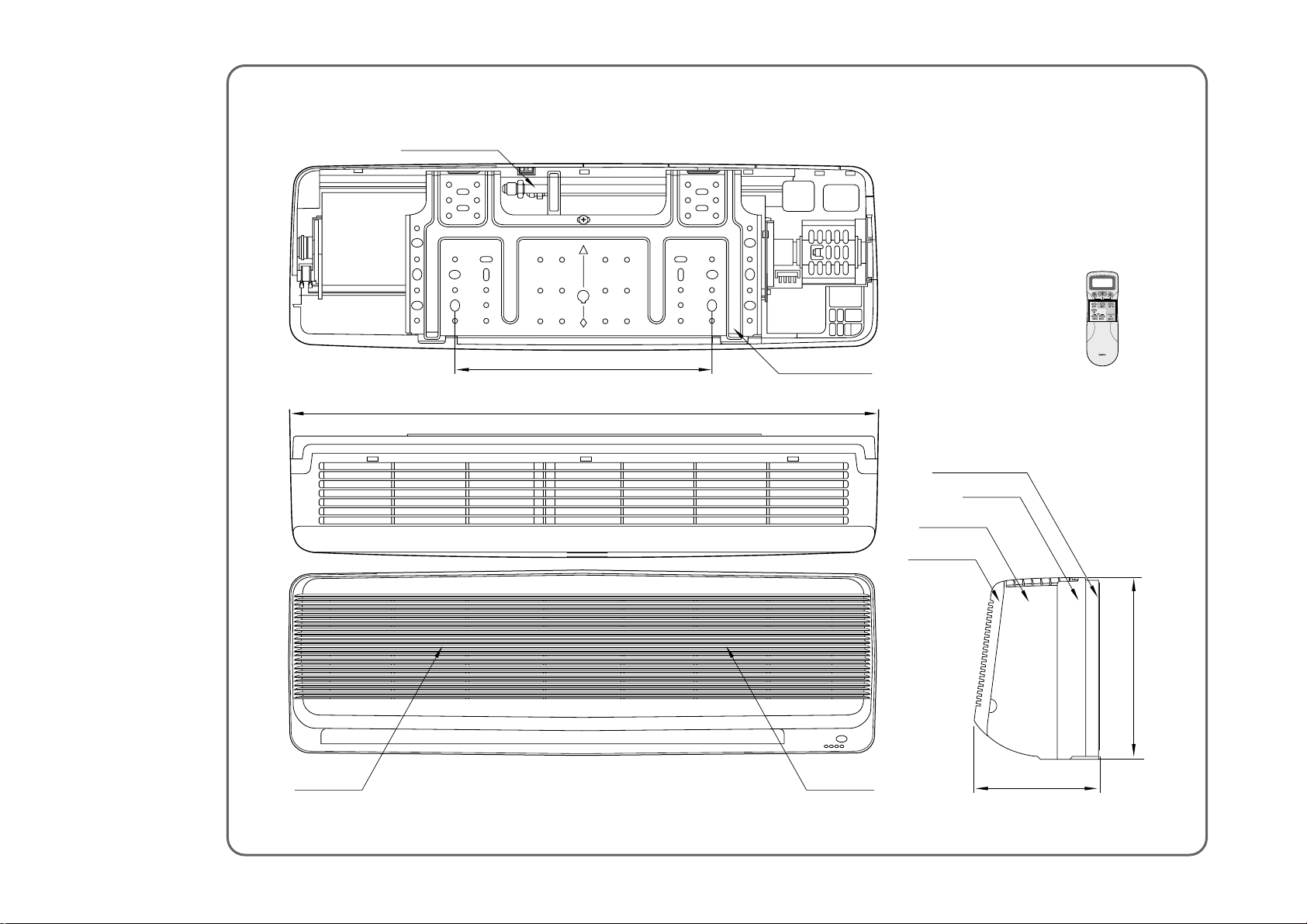

REMOCON

Filter - L Filter - R

Grille Insert

Frame Grille

Body

Plate Mounting

Connecting Pipe

Plate Mounting

406

194

285

925

REMOTE CONTROLLER

¡ DSB-121L/122L

7

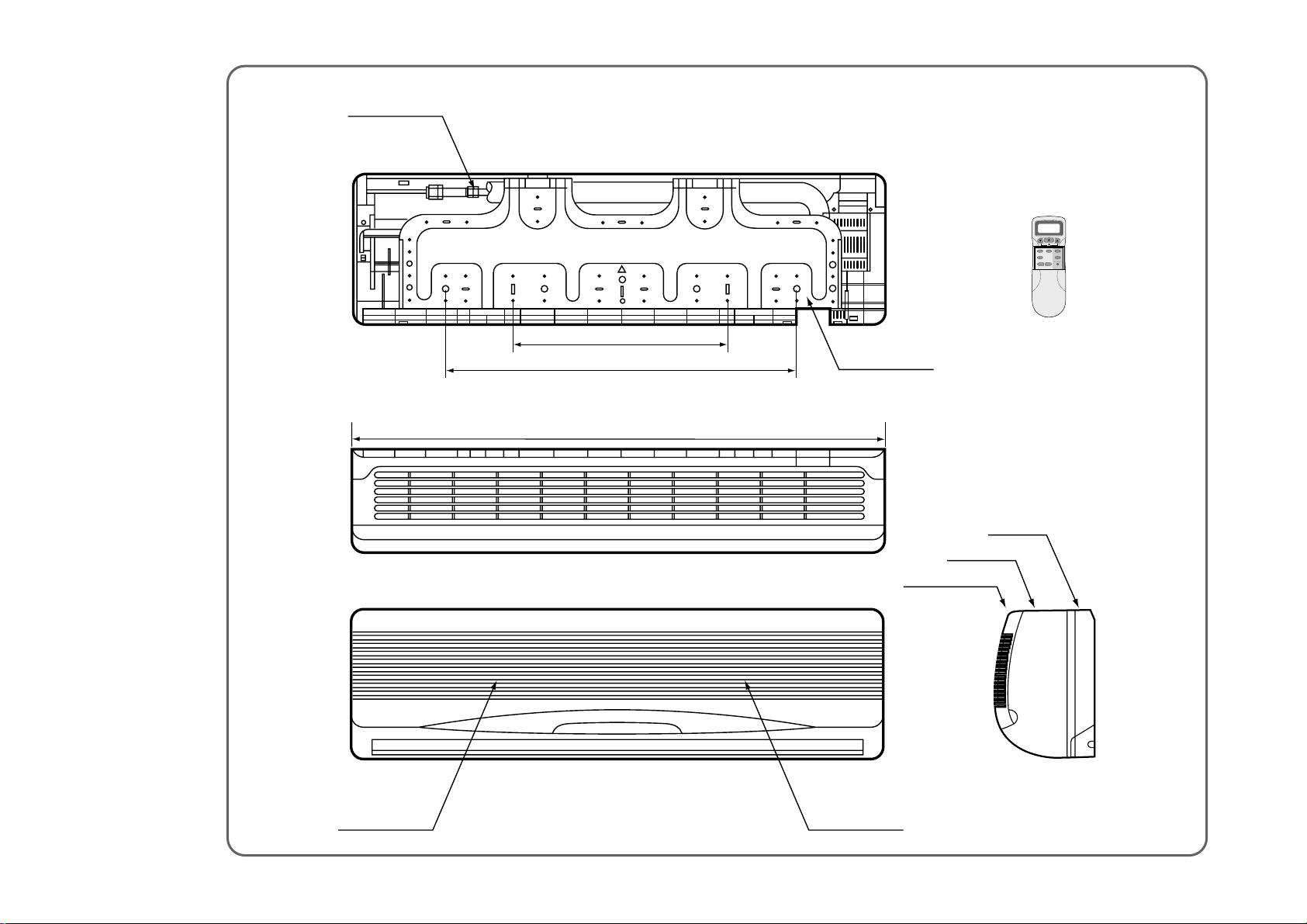

Connecting Pipe

Body

Frame Grille

Grille Insert

Plate Mounting

430

710

1080

Filter-L Filter-R

REMOCON

8

¡ DSB-240L

256

549

654

Inlet

Inlet

Cabinet Side

Panel Top

Guide Support

Outlet

Foot Cushion

OUTDOOR UNIT

Outlet

Cabinet Front

Foot

Handle

9

Service Valve

2

¡ DSB-070L/DSB-091L/DSB-121L/DSB-122L(After)

Cabinet SideHandleCabinet Front Foot

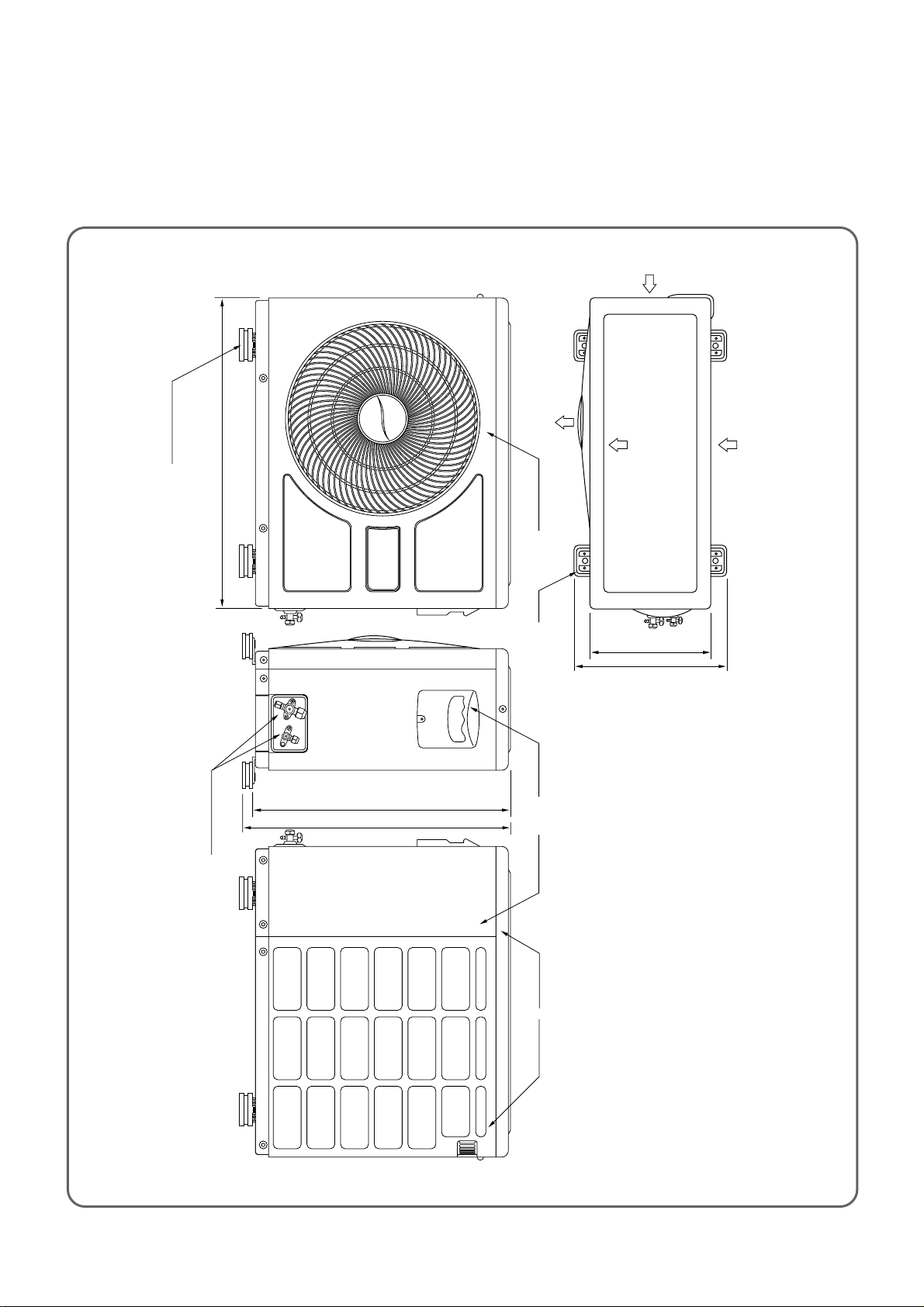

264

334

Panel Top

Cabinet Back

552

572

Inlet

AIR

Inlet

Outlet

Foot Cushion

Service Valve

666

¡ DSB-121L/122L(Before)

10

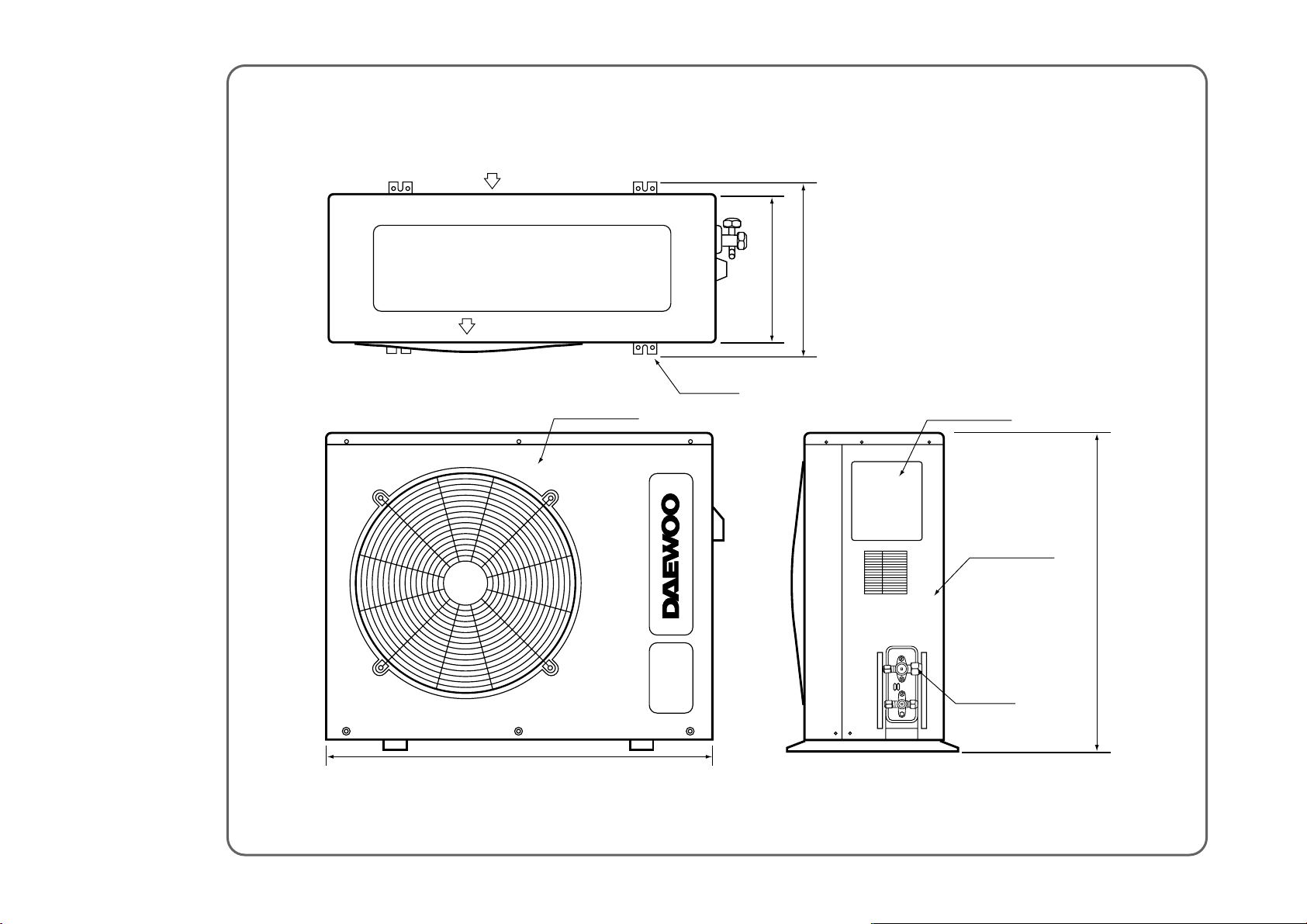

Inlet

380

699

323

foot

Service valve

873

Cabinet front

Service Cover

Cabinet Side

¡ DSB-240L

11

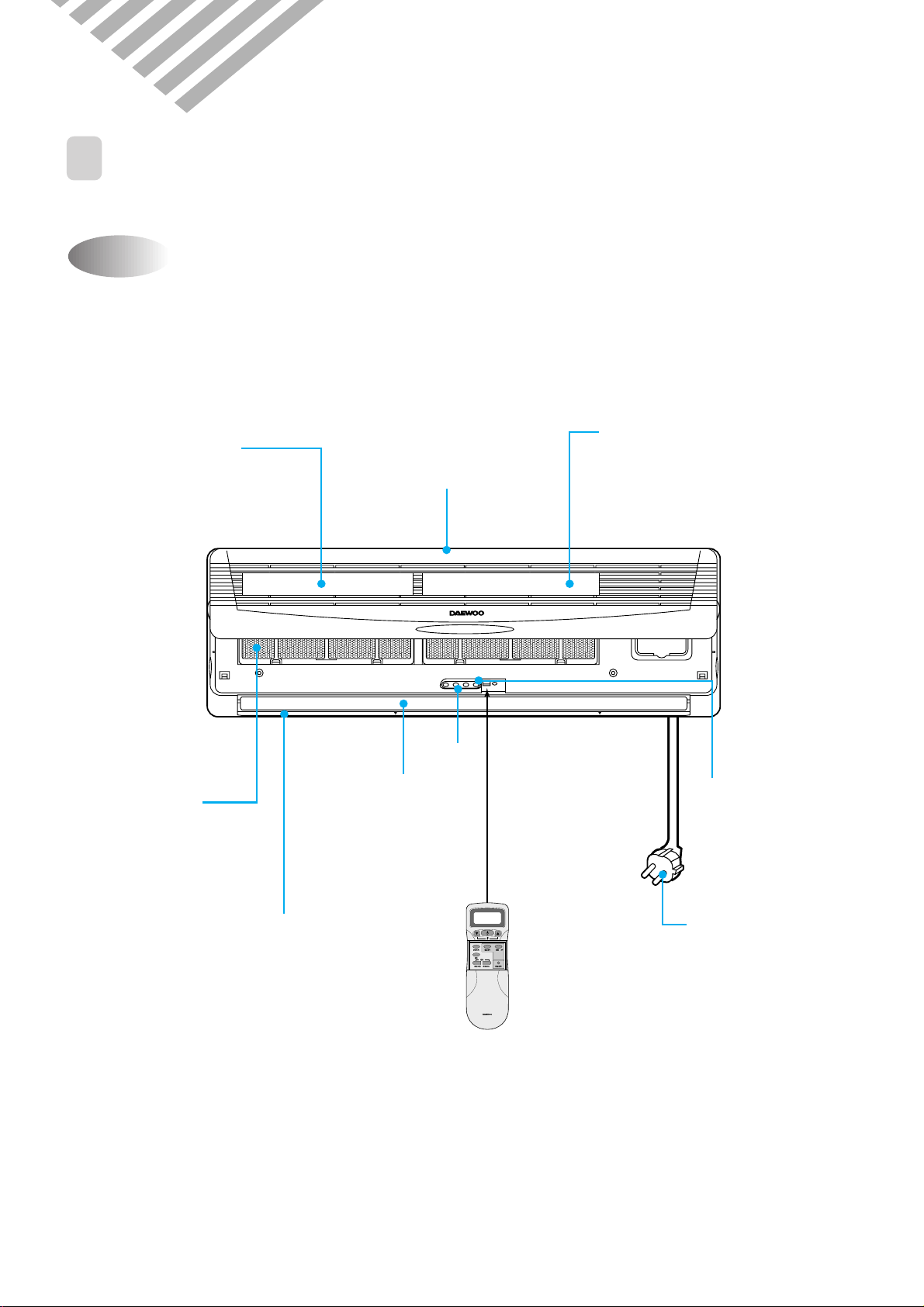

3. OPERATION

REMOTE CONTROLLER

PARTS OF NAME AND FUNCTION

1

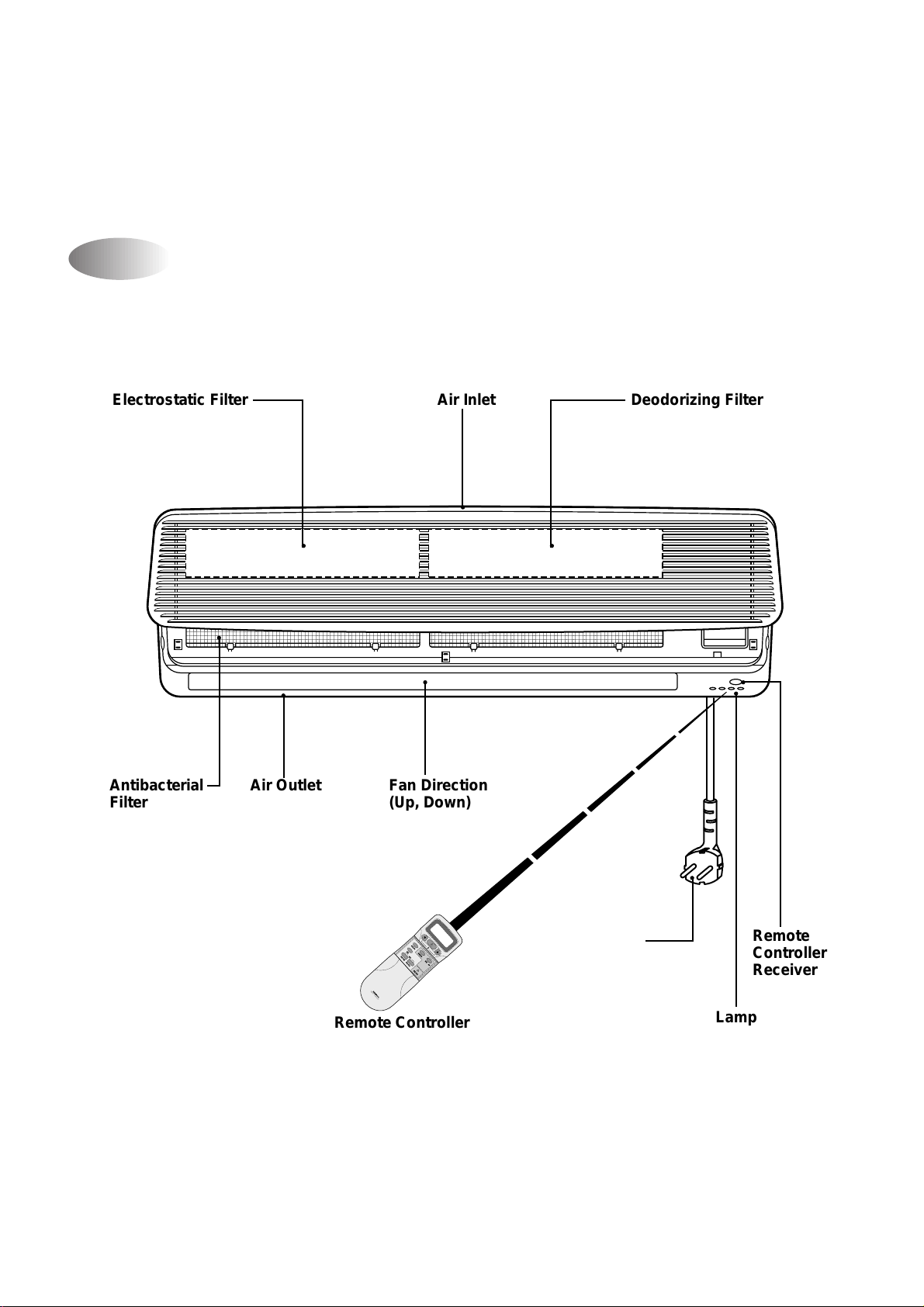

¡ DSB-070L/DSB-091L

Indoor Unit

Electrostatic Filter

(option)

Deodorizing Filter

(option)

Air Inlet

Antibacterial

Filter

Fan Direction

(Up, Down)

Air Outlet

Lamp

Remote

Controller

Receiver

Power Plug

Remote Controller

12

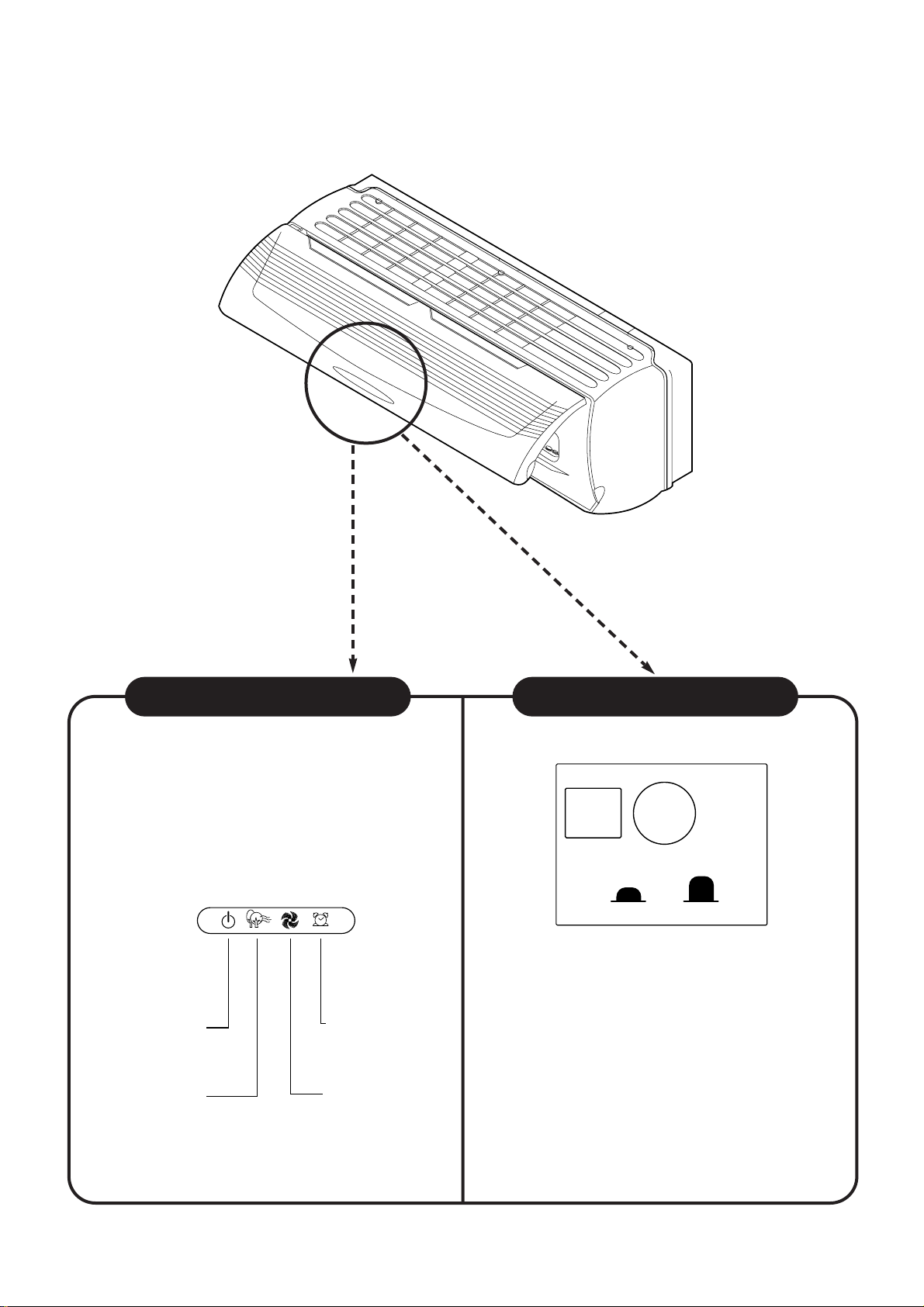

¡ DSB-121L/122L

Power Plug

Electrostatic Filter Deodorizing FilterAir Inlet

Antibacterial

Filter

Air Outlet Fan Direction

(Up, Down)

Remote Controller

Remote

Controller

Receiver

Lamp

REMOTE CONTROLLER

Indoor Unit

13

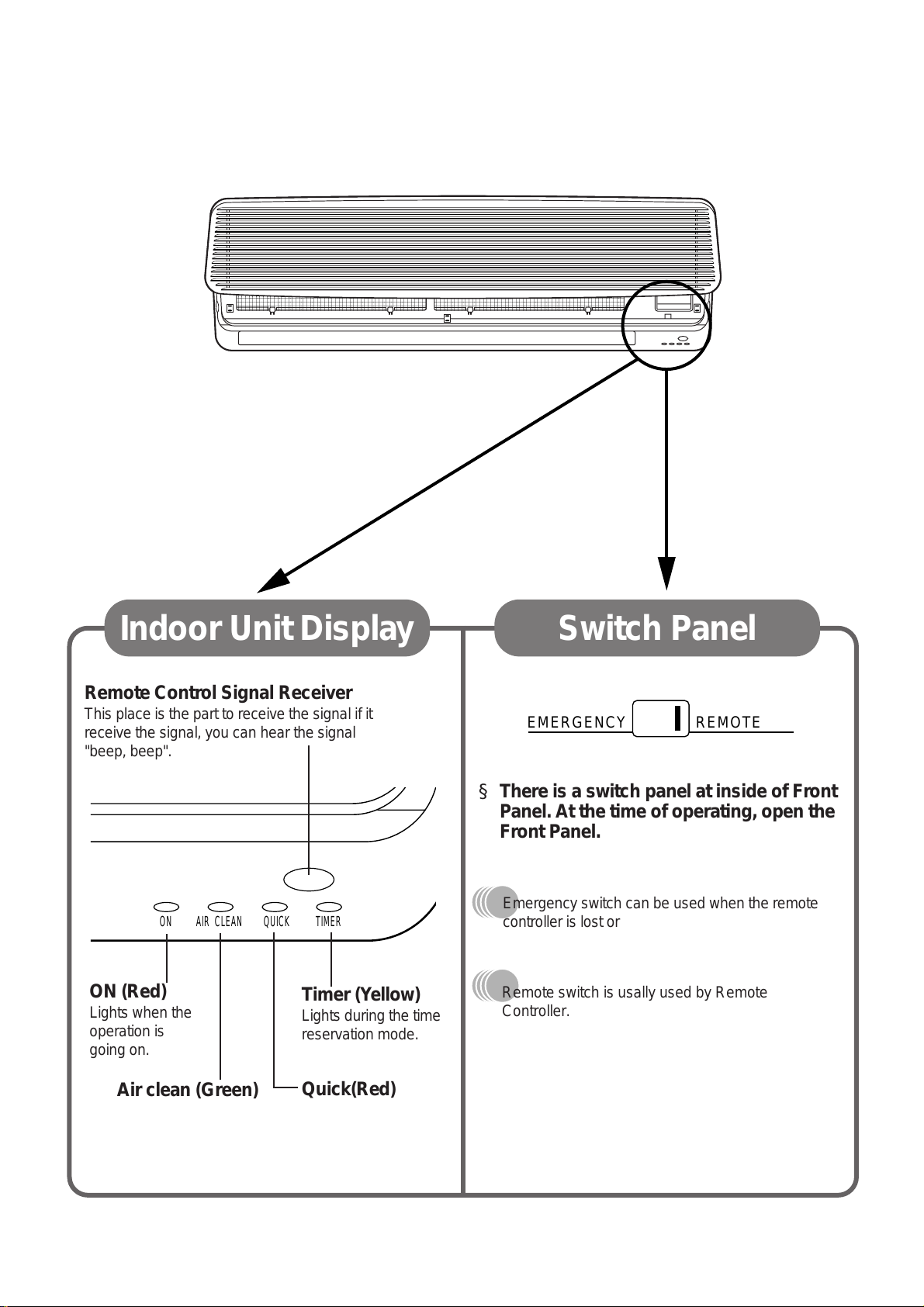

¡ DSB-070L/DSB-091L

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

ON (Red)

Lights when the

operation is going on.

Air clean (Green)

EMR. REMOCON

Indoor Unit Display Switch Panel

■

Remote Control Signal Receiver

This place is the part to receive the signal if it

receive the signal, you can hear the signal “beep.

“beep. beep .”

■

There is a switch panel at inside of Front

Panel. At the time of operating, open the

Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote

controller.

14

EMERGENCY REMOTE

ON AIR CLEAN QUICK TIMER

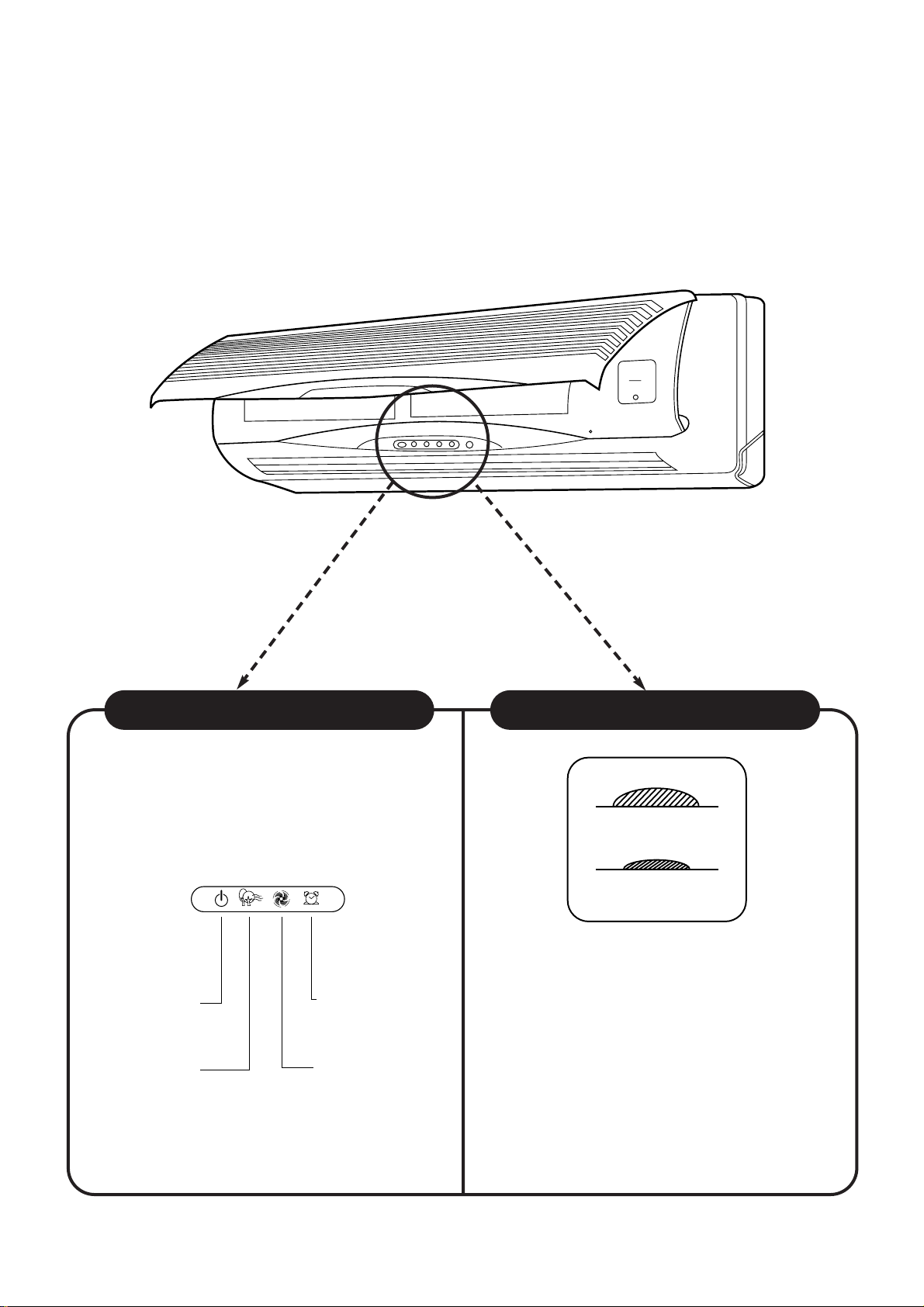

¡ DSB-121L/122L

Indoor Unit Display Switch P anel

Remote Control Signal Receiver

This place is the part to receive the signal if it

receive the signal, you can hear the signal

"beep, beep".

§ There is a switch panel at inside of Front

Panel. At the time of operating, open the

Front Panel.

Emergency switch can be used when the remote

controller is lost or testing.

ON (Red)

Lights when the

operation is

going on.

Timer (Y ello w)

Lights during the time

reservation mode.

Remote switch is usally used by Remote

Controller.

Air clean (Green)

Quick(Red)

15

¡ DSB-240L

Timer (Yellow)

Lights-on during the time

of reservation mode.

Quick (Red)

Lights-on during the time

of Quick Mode.

ON (Red)

Lights-on

during the operation

Air clean (Green)

Lights-on

during the operation

EMERGENCY

REMOCON

Indoor Unit Display Switch Panel

■

Remote Control Signal Receiver

This place is the part to receive the signal if it

receive the signal, you can hear the signal “beep.

“beep, beep .”

REMOCON

EMERGENCY

■

There is a switch panel at inside of

Front Panel. At the time of operating,

open the Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote

controller.

16

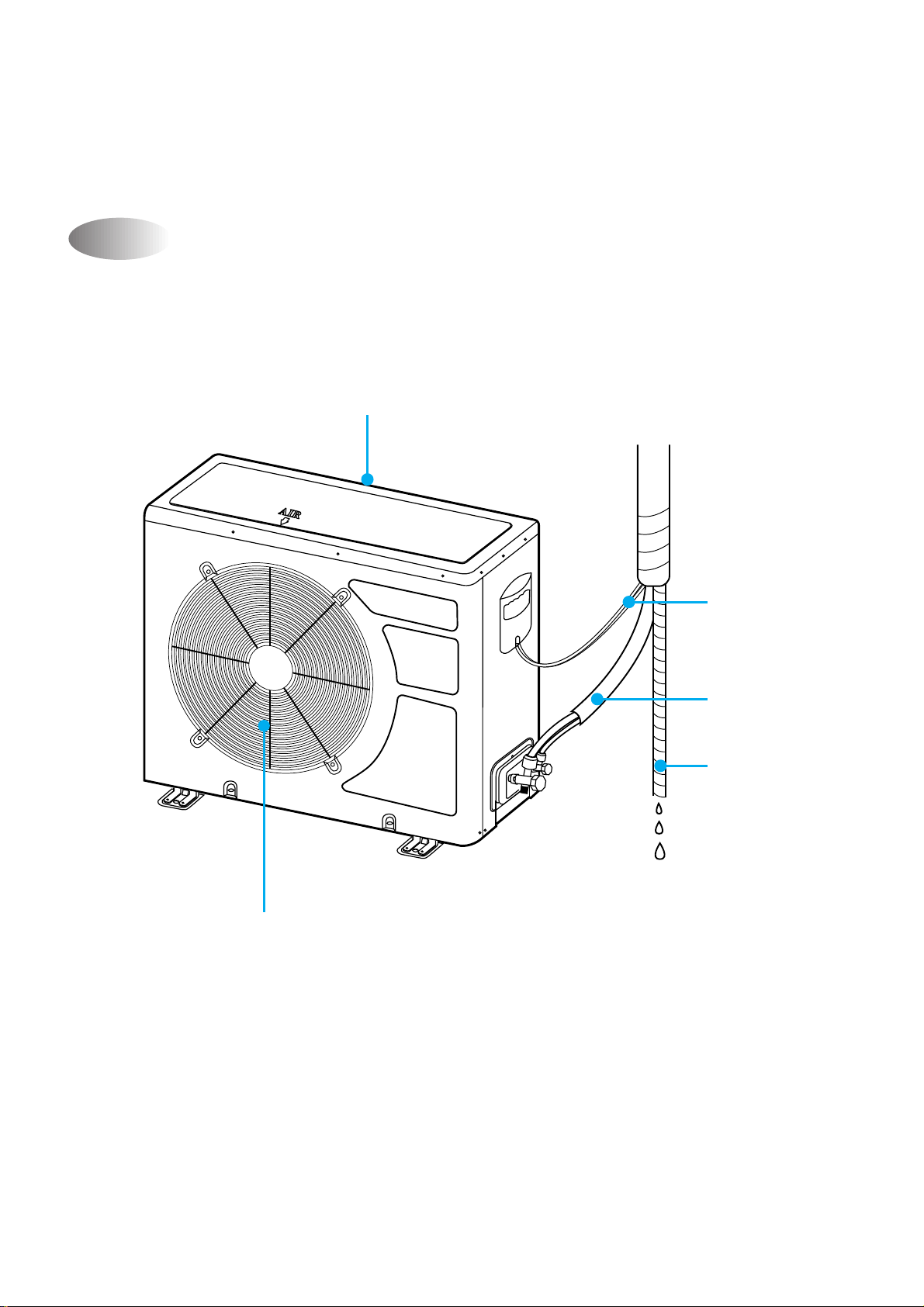

¡ DSB-070L/DSB-091L/DSB-121L/DSB-122L(After)

Outdoor Unit

Air Inlet (Side Back)

Connection Wire

Air Outlet

Connecting Pipe

Drain Hose

17

AIR

Air Inlet (side Back)

Air Outlet

Connection

Wire

Connecting

Pipe

Drain Hose

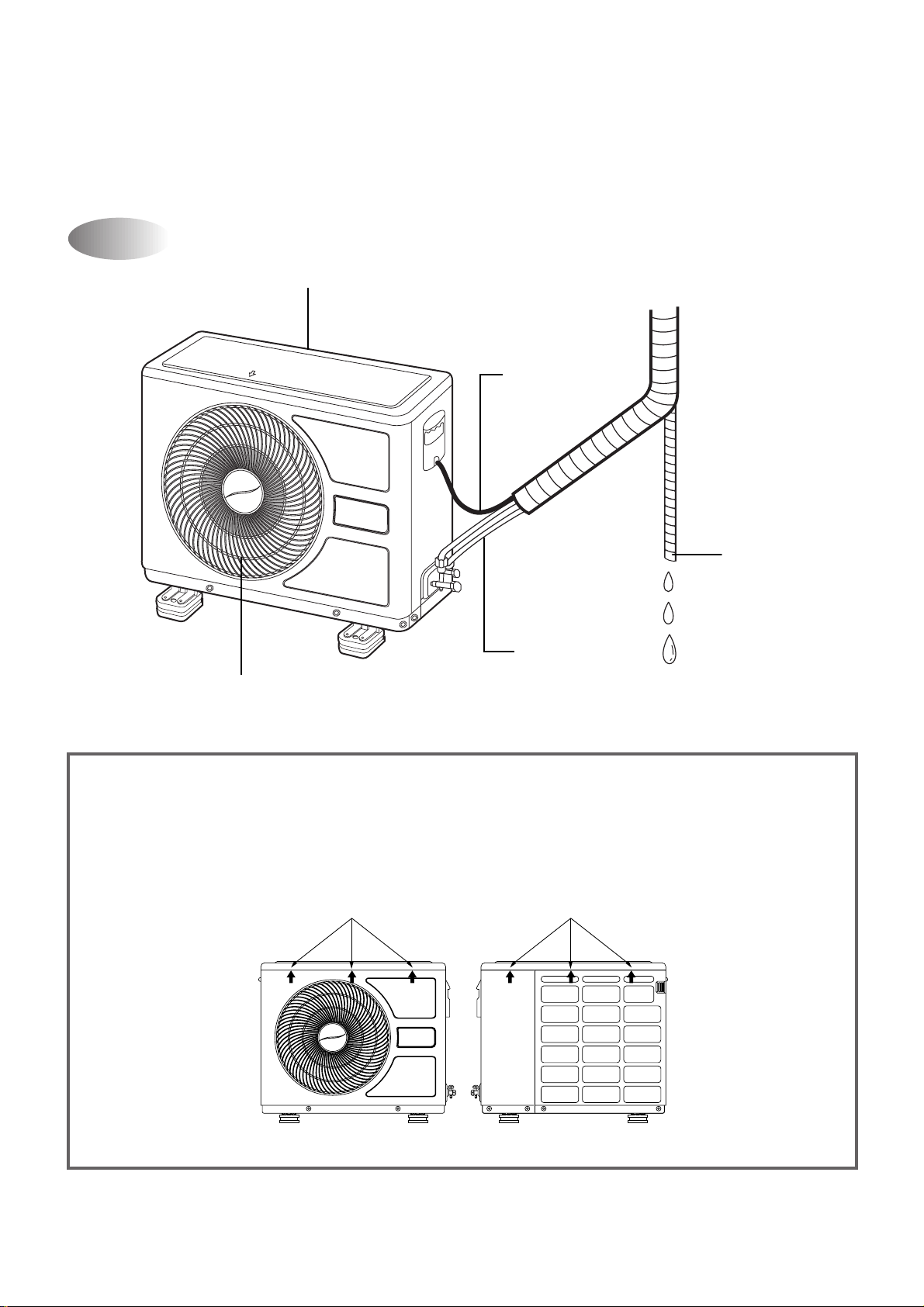

¡ DSB-121L/DSB-122L(Before)

Outdoor Unit

NOTE:

How to remove Top Panel

1. Loosen the screw at left and right side.

2. Push the three parts op Front and Back sides like figure orderly.

3. Unhook the locking parts of T op Panel.

The front locking parts

FRONT SIDE BACK SIDE

The back locking parts

18

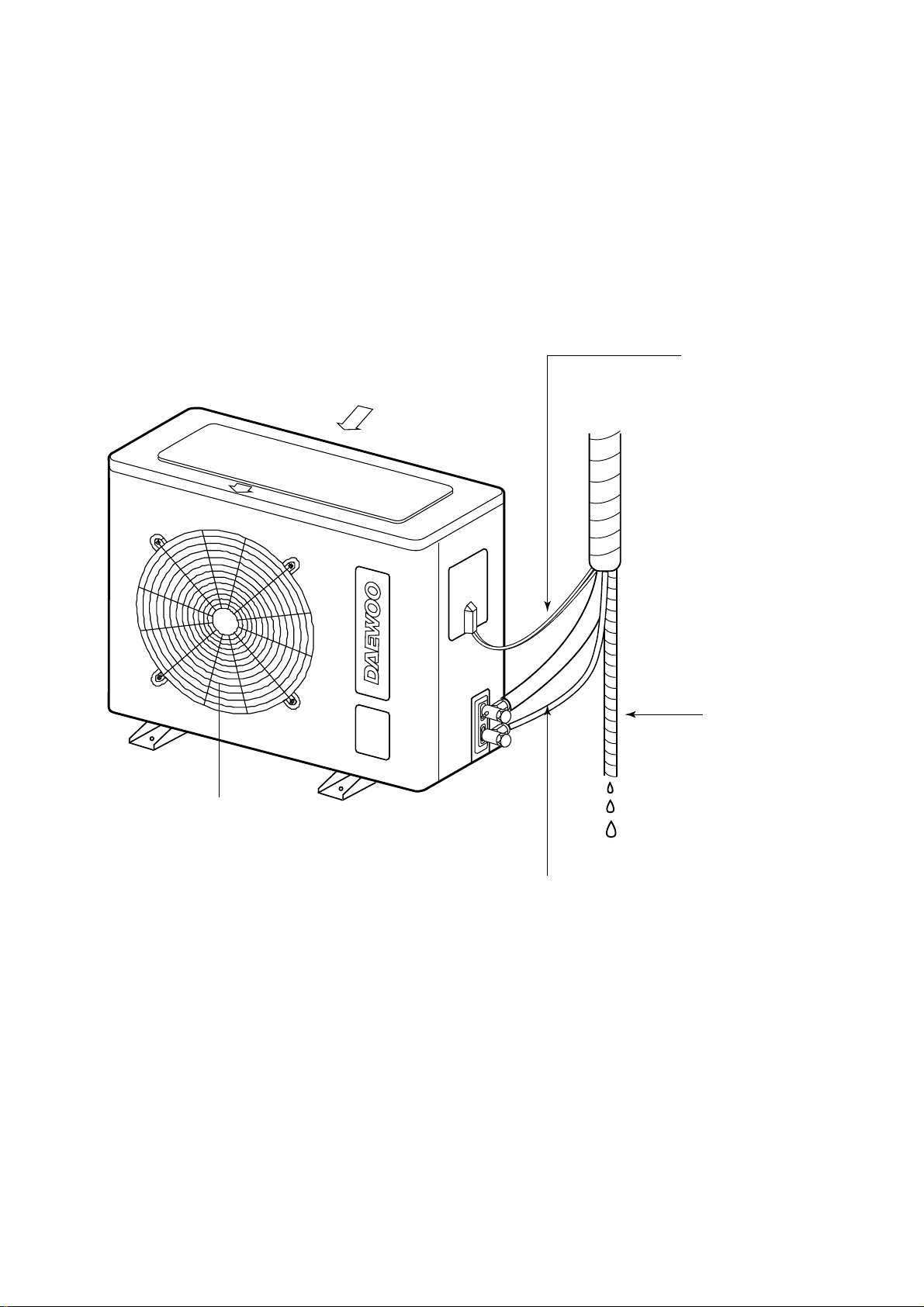

¡ DSB-240L

Air Inlet

Air Outlet

Connection Pipe

Connection wire

Drain Hose

19

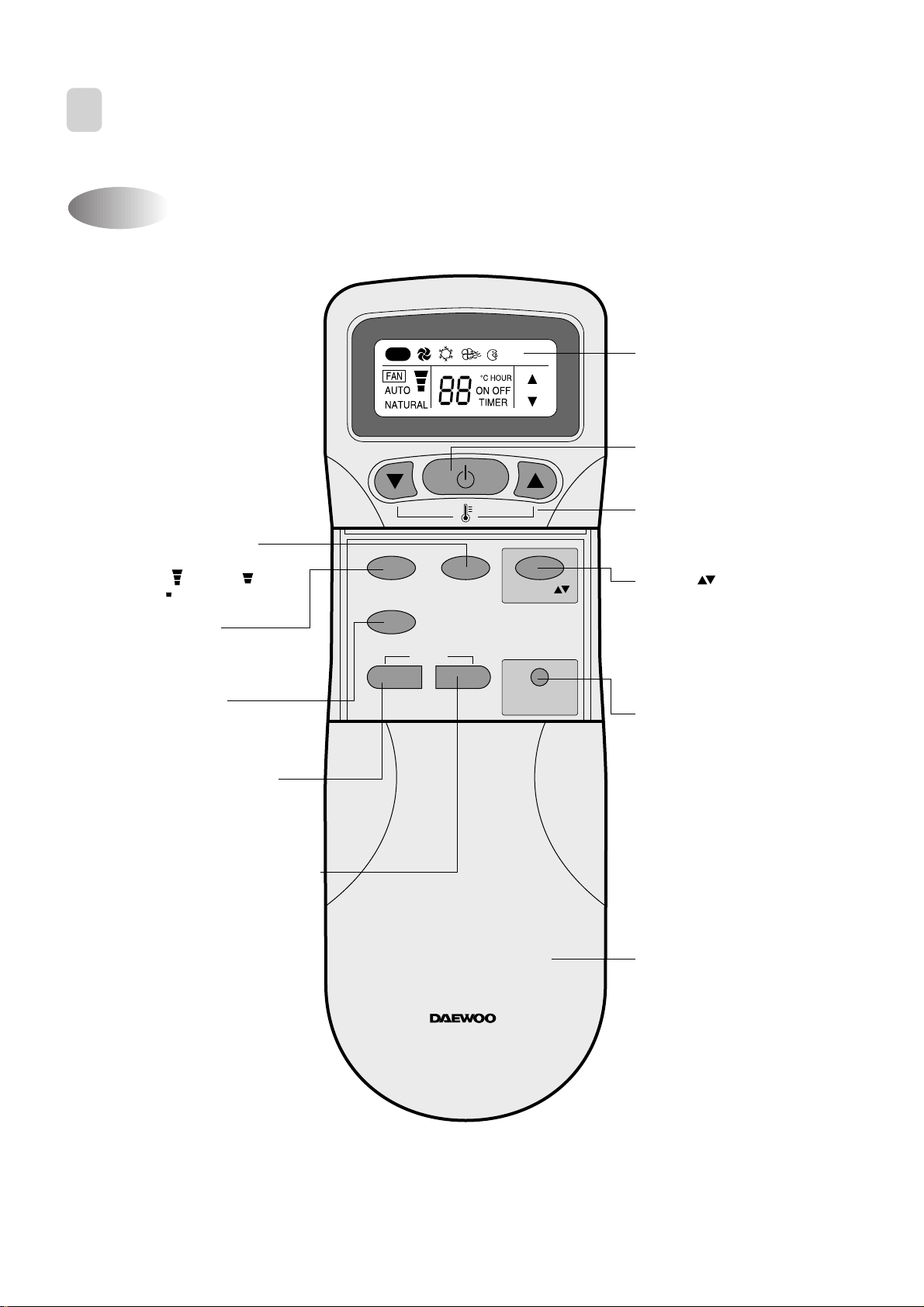

REMOTE CONTROLLER

MODE

SLEEP

ON/OFF

TIMER

ENTER/

CANCEL

FAN SPEED

TURBO/MILD

Display

Displays information

pertaining to unit.

TURBO/MILD

Press to be colder the unit.

TIMER ENTER/CANCEL Button

Press to enter a timer setting or

to cancel timer setting

TIMER ON/OFF Button

Press to set the unit of or on time.

(0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8,

10, 12, 16, 20, 24hr)

MODE Button

Press to cycle through the modes

(Auto/Quick/Cooling/Fan/Dry)

SLEEP Button

Press to set the unit for

the sleep mode.

FAN DIR.

FAN DIR. Button

Press to select up/down

direction for fan.

ON/OFF Button

Press to turn the unit

on or off.

TEMPERATURE Buttons

Press to raise or lower

the desired temperature.

FAN SPEED Button

Press to select the fan speed

(High " ", Middle " ",

Low " ").

COVER

Slide down to access most

of the remote buttons.

Slide down further to

access the battery

compartment.

AUTO

REMOTE CONTROLLER

2

¡ DSB-070L/DSB-091L/DSB-121L/DSB-122L/DSB-240L

Name of Each Button

20

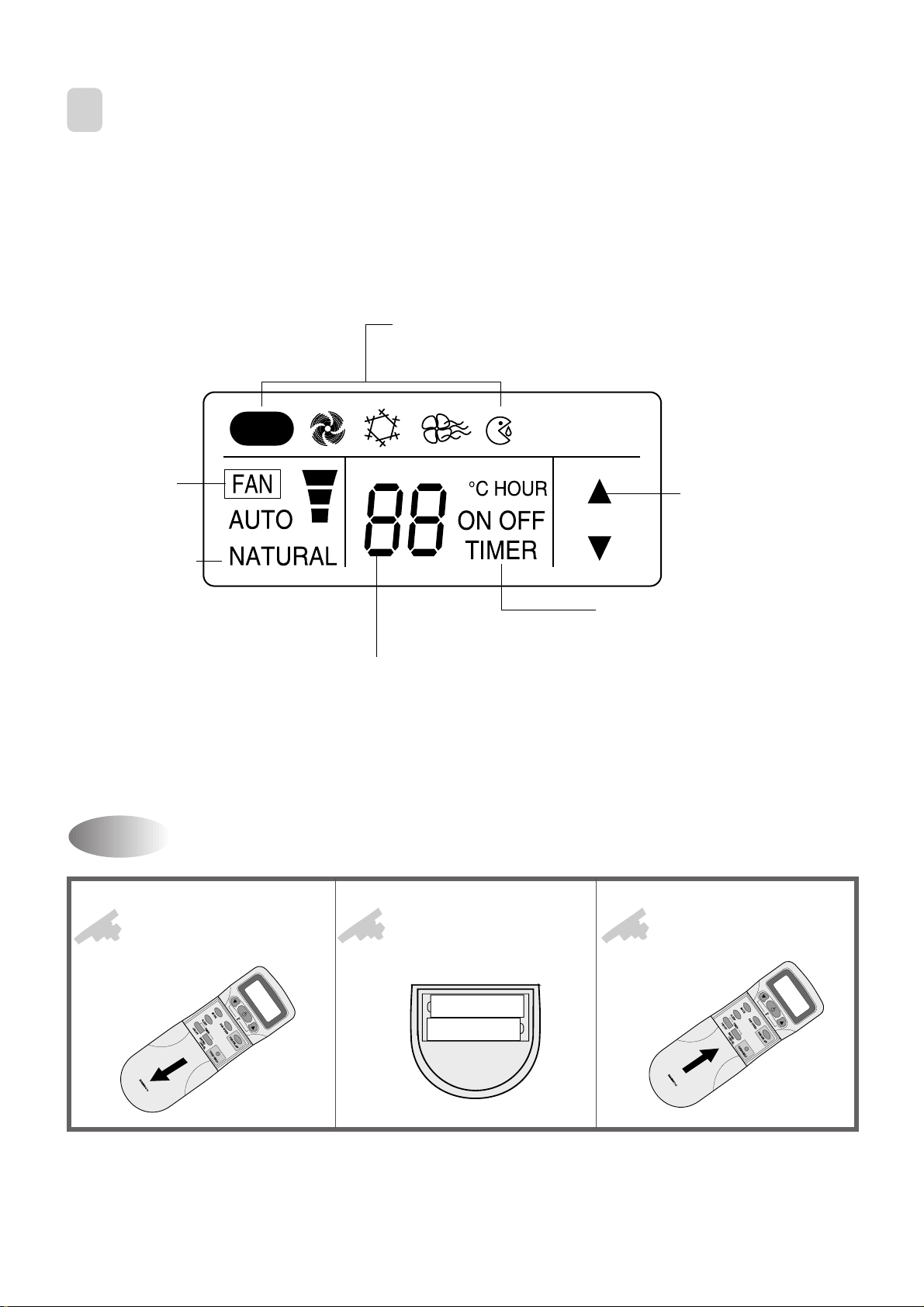

REMOTE CONTROLLER DISPLAY

REMOTE CONTROLLER

+–

+–

REMOTE CONTROLLER

MODE Indicators (Auto/Quick/Cool/Fan/Dehumidifier)

Lights to indicate the mode selected.

TIMER Indicators (Include sleep)

Lights to indicate the timer function mode.

TEMPERATURE & RESERVATION TIME lndicator

Lights to indicate the temperature or time.

FAN DIRECTION Indicators

Lights to indicate the

fan direction.

NATURAL Indicator

Lights to indicate the

speeds simulating a loreeze.

FAN Indicators

Lights to indicate

the fan speed.

AUTO

3

¡ DSB-070L/DSB-091L/DSB-121L/DSB-122L/DSB-240L

Replacing Batteries

Open the cover after

pressing the arrow

1

direction and pulling out.

Put the drycell by §]§^

2

direction.

21

3

Close the cover after

pushing into arrow

direction.

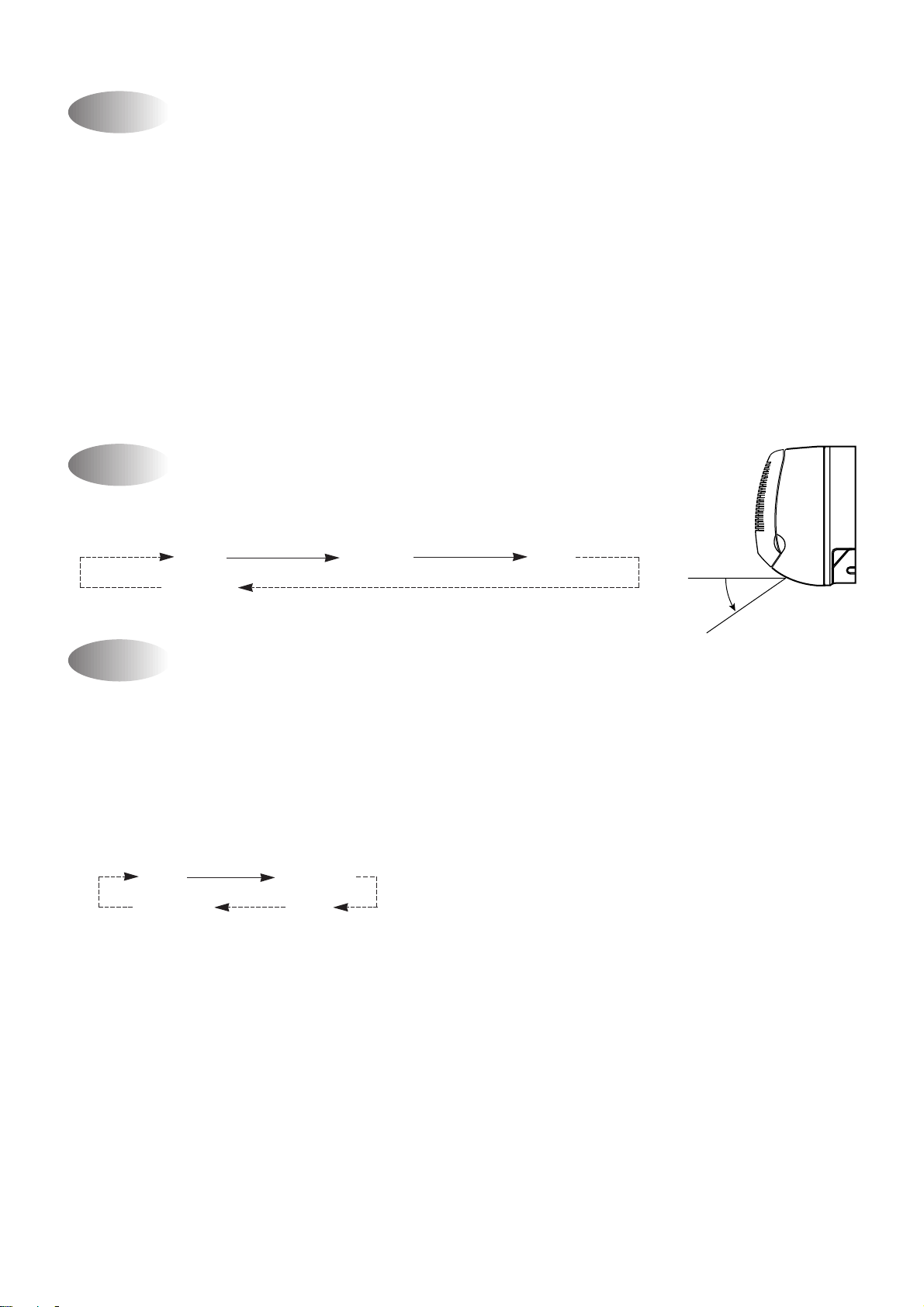

DESCRIPTION OF FUNCTIONS

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

COMP (ON)

*RT: ROOM TEMPERATURE

DT: DESIRED TEMPERATURE

COMP (OFF)

-1°C0°C

(COOLING)

(RT-DT)

4

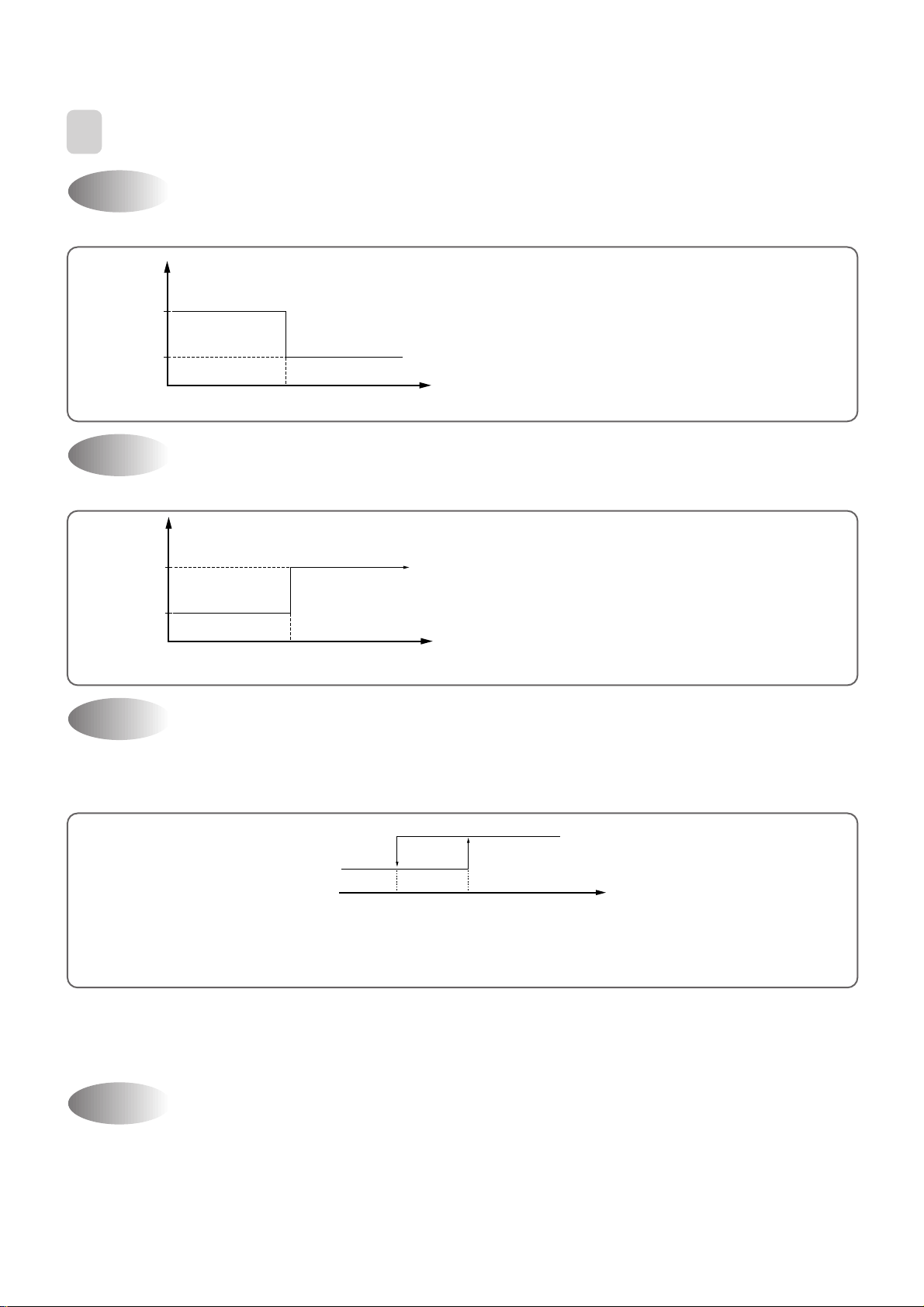

OFF-Timer

If you set time in OFF-Timer Mode, the unit will stop at the set time.

ON-Timer

If you set time in ON-Timer Mode, the unit will run at the set time.

Control of Room Temperature

(1) Range of setting temperature: 18~32°C

(2) Setting temperature: Operating temperature of compressor

+1°C

(3) During the time of test operating, Fan (Indoor , Outdoor) and Compressor is running regardless of room

temperature.

Buzzer

If the Indoor Unit Display receive the signal of Remote Controller , y ou can hear the signal "beep –" or "beep ,

beep".

(1) In the case of receiving ON/OFF signal-"beep" "beep"

(2) And so on-"beep"

22

Fan Speed (Indoor Unit)

0°C

L

M

H

1°C2°C

(R.T-D.T)

(D.T)

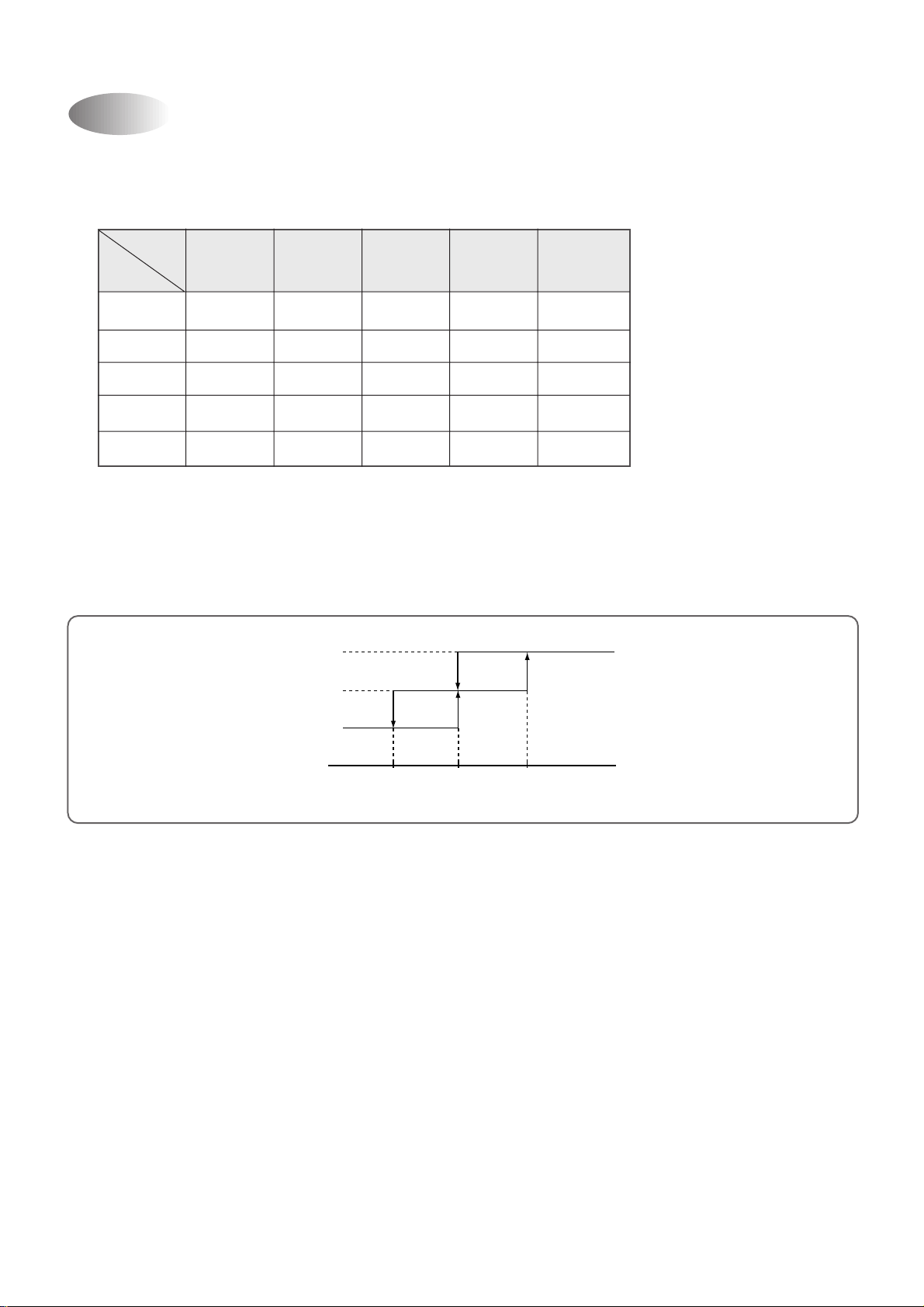

(1) Motor speed (Super high speed, high speed, normal speed, low speed, ultra low speed).

(2) Remote controller setting fan speed. (Auto , L, M, H, Natural)

(3) Relation of operating mode between fan speed. (legned: X-no relation)

FAN ONLY COOL

H HHLHH

MMMLMH

LLLLLH

Auto Auto L Auto H

Natural Natural Natural L Natural H

DEHUMI-

DIFICATION

AUTO QUICK

(4) Automatic Operation

If the unit is set in 'AUT O' mode , the unit operates automatically according to the room temperature to keep the

room temperature comfortable.

(COOLING)

23

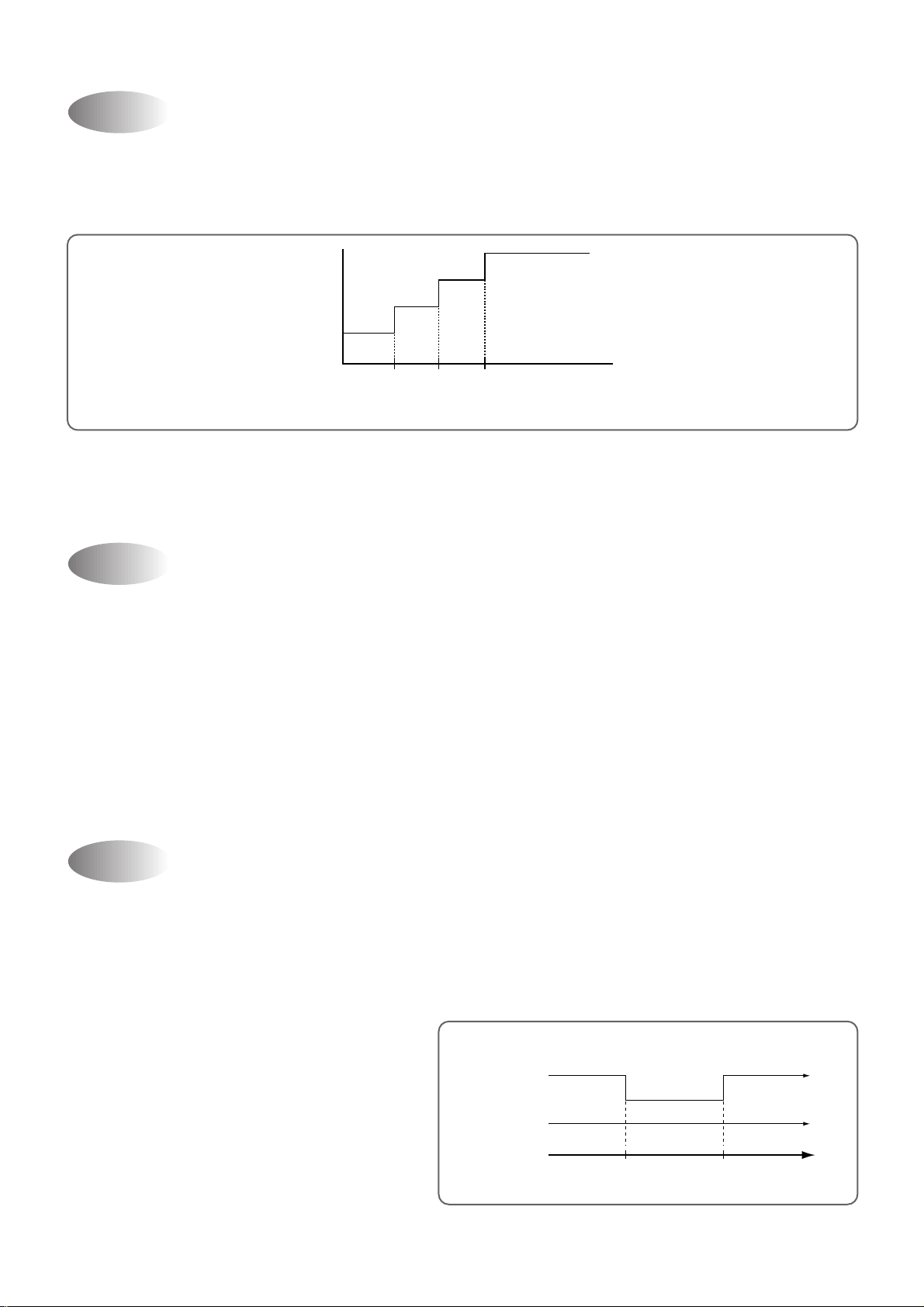

Sleep Mode

0 0.5 1.0 HOUR

(COOLING CYCLE)

DT

+0.5°C

+0.5°C

+0.5°C

-1°C+7°C

Compressor and

Outdoor Fan

ON ON

OFF

Indoor Fan

Set speed

(1) When you are going to sleep , select sleep s witch and the unit controls the room to the desired temper ature.

(The unit will not operate after 4 hour)

(2) For changing the temperature.

(3) To cancel sleep mode, press the SLEEP button again or press the MODE button once.: the SLEEP

indicator will disappear in the display.

Emergency Operation

(1) When the remote controller is lost, damaged or the battery is discharged, the Emergency operation can be

used to run the unit.

(2) The setting conditions of Emergency operation are as follows.

• Operation mode: Quick

• Preset temperature:18°C: Cooling

• Fan speed: High

¡You cannot operate with remote controller.

Frost Prevention of Indoor Unit

When the unit operates at low ambient temperature, frost may appear on the Ev aporator. When the indoor coil

temperature is lower than 0°C at the end of 10 minutes of continuous compressor operation from the start, the

microcomputer of the unit stops the compressor to protect the unit from the frost. The control procedure for

indoor coil freeze protection.

1) The compressor and outdoor fan turn off.

2) Indoor fan operates according to user set speed.

3) The normal operation returns when the indoor coil

temperature is higher than 7°C or equal to 7°C.

(Indoor coil temperature)

24

3 min. Time Delay of Compressor

In normal operation, there is a time delay of three minutes between turn off and turning back on including initial

power up.

Auto Mode

(1) In Auto Mode

After the indoor fan is operated f or 20 seconds in the Auto Mode the unit will operate automatically b y selecting

operating Mode according to the room temperature

(RT: Room temperature)

ROOM TEMPERATURE

DT-2°C RT

DT-2°C

DT+3°C RT

(2) Selecting Operating Mode Again

Room temperature meets desired temperature and the compressor stops running over 30 minutes, then the unit

selects operating Mode again.

>

RT ≤DT+3°C

≤

<

OPERA TING MODE

Cooling

Dehumidifier

Cooling

FLAP POSITION

Cooling Position

Cooling Position

Cooling Position

25

Dehumidification Mode

1Desired temperature < Room temperature

Outdoor Fan, Compressor : ON

Indoor Fan : Low speed

2Desired temperature ¡ˆRoom temperature

Compressor : 3 min/ON, 5 min/OFF

Fan Speed : low speed

3Room temperature ¡´18°C

Compressor : OFF

Fan speed : Low speed

Air Discharge Direction(only remocon operation)

The air discharge direction procedure is below.

Fixed Up/Down Fixed

Up/Down

Quick Mode(Powerful Cooling)

1) Cooling Mode

* When the room temperature is higher than 22°C

1Fan Speed: Super high speed

2Air discharge direction: Fixed

3Set temperature: 18°C (Fixed)

4Compressor and Outdoor Fan

The air discharge direction procedure is below

Fixed Up/Down

Up/Down Fixed

* The option is LEFT/RIGHT direction.

COOLING POSITION

26

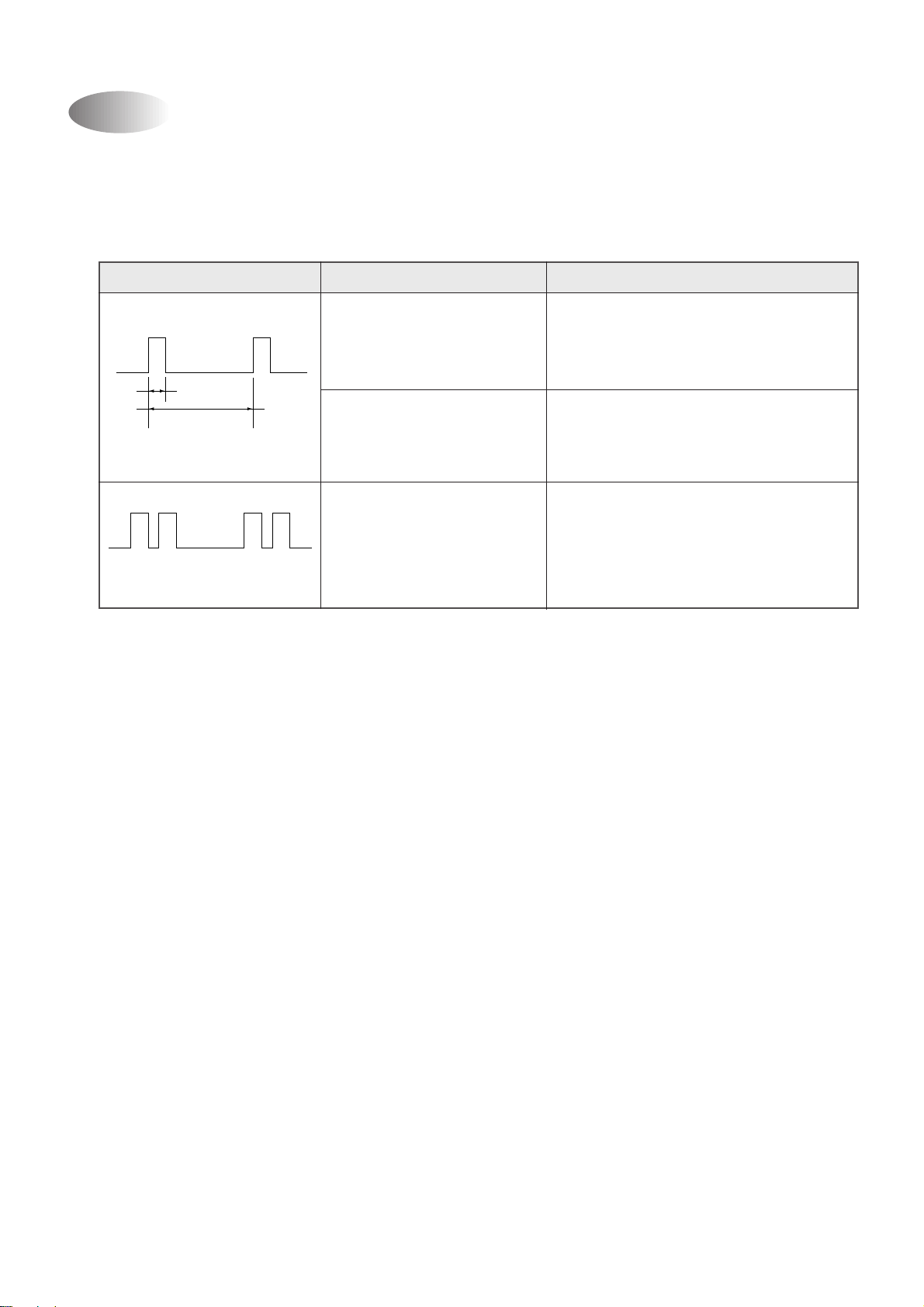

Self-Diagnostic Function

The control will contain diagnostic test to verify the integrity of the system.

(1)Error Code Display P attern

1 ON LAMP: Blink

LED BLINK PATTERN CASE NOTE

Room Sensor open or Short • Continuously woorking to fix room

0.5s

temperature 32°C in cooling mode

8s

1 times blink • O/D coil sensor open or short

2 times blink • Gas leak

• I/D coil sensor open or short Do not woorking

• Compressor or electrical parts Continuously workiug

of compressor error.

27

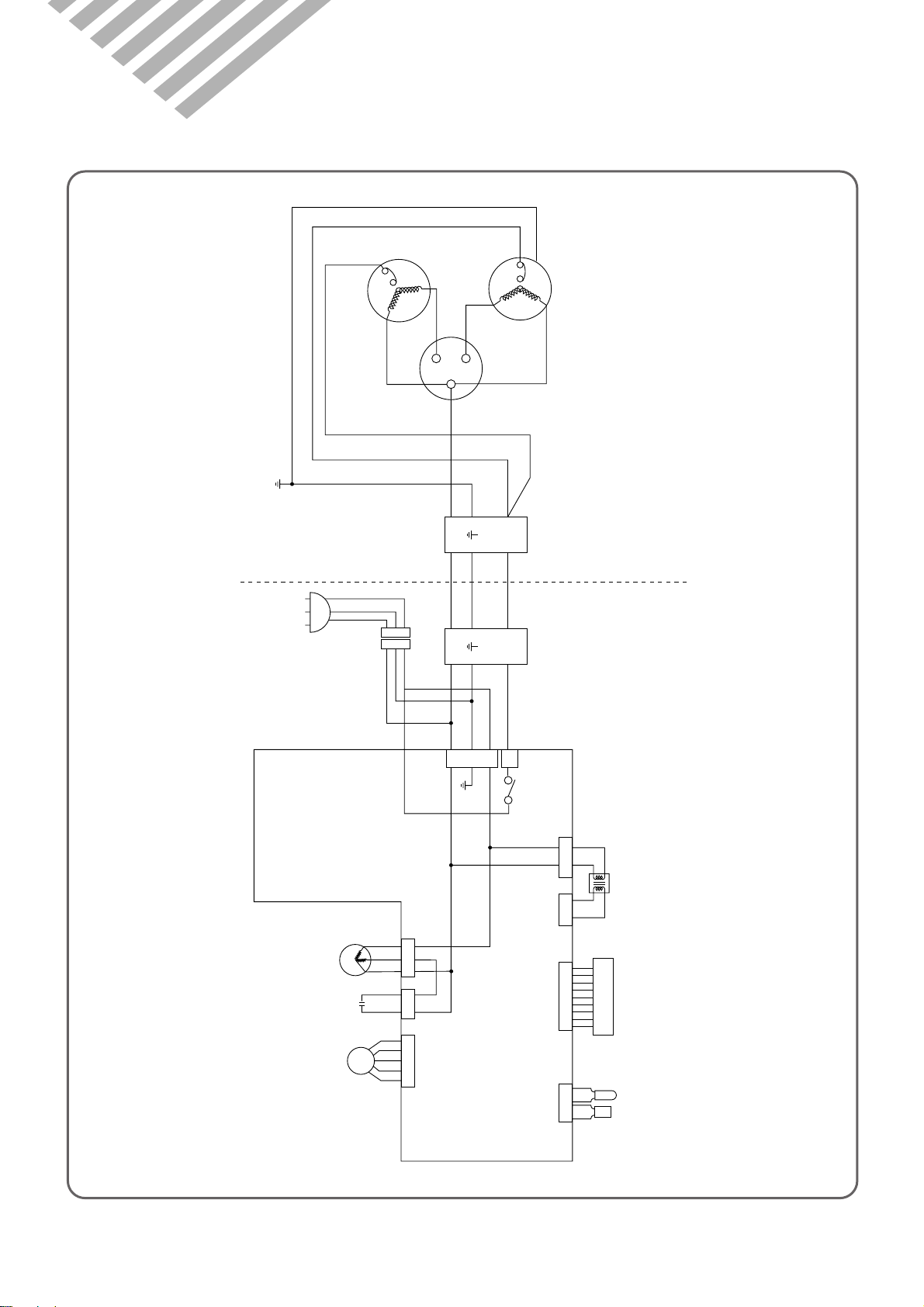

4. WIRING DIAGRAM

OUTDOOR UNIT INDOOR UNIT

FAN MOTOR

BRN

BLUE

BLU

BLU

COMP

BLU

BRN

BRN

YEL/GRN

YEL/GRN

BROWN

YELLOW/GREEN

BRN

BRN

BLU

POWER CORD

BLK

YEL/GRN

CAPACITOR

OUTDOOR

TERMINAL

BLOCK

YEL

RED

S

C

R

COMPRESSOR

FAN

HERM

C

1

1

BLK

BLK

RED

RED

BLU

ORG

RED

BLK

RED

PINK

BLU

ORG

YEL

YEL

WHT

BLU

RED

GRN

YEL

GRY

BRN

BLK

BLK

BLK

BLK

BLK

2

TRANS

1 12345678 1 23 4

I/D SENSOR

LED PCB

2

123

S

C

R

INDOOR

FAN MOTOR

FAN MOTOR

CAPACITOR

SWING

MOTOR

12

12345

Y

L

Y

L

1

2

3

¡ DSB-070L/DSB-091L/DSB-121L/DSB-122L

28

Y

N

L

Y

N

L

FAN MO T OR

BLK

RED

ORG

H

S

S

R

C

C

CAP A CIT OR DUAL

FAN

HERM

RED

BRN

BRN

OUTDOOR INDOOR

RED

POWER RELA Y

RA TH. : R OOM AIR THERMISTOR

IDC TH. : INDOOR COIL THERMISTOR

RA TH. : R OOM AIR THERMISTOR

IDC TH. : INDOOR COIL THERMISTOR

FAN MO T OR

CAP A CIT OR

INDOOR

FAN MO T OR

SWING MOTOR

BLU

WHT

YEL/GRN

RED

BLU

YEL/GRN

BRN

RED

BLU

BLU

YEL/GRN

YEL

RED

WHT

RED

RED

RA

TH.

IDC

LED PCB

11234567

TH.

BLK

PCB TRANS

BLU

RL1

CN1

BLU

BRN

FUSE

BLK

RED

CN4 CN3

CN2 CN6 CN9 CN1

CN13

R

C

S

ORG BLU

RED

ORG

YEL

PNK

BLU

BRN

BRN

YEL/GRN

CONTROL PCB

POWER

CORD

1

8

4

0

6

2

BLU

COMPRESSOR

29

¡ DSB-240L

Loading...

Loading...