Daewoo DPA-380R, DPA-380RH, DPB-500R, DPB-500RH Service Manual

CONTENTS

1. Installation Guide...........................................................................................2

2. Specification..................................................................................................6

3. Outline..........................................................................................................8

4. Operation...................................................................................................10

5. Circuit Diagram...........................................................................................20

6. Refrigerant Cycle.........................................................................................31

7. Trouble Shooting..........................................................................................32

8. Exploded Diagram ......................................................................................38

Contents

2

1. INST ALLATION GUIDE

1

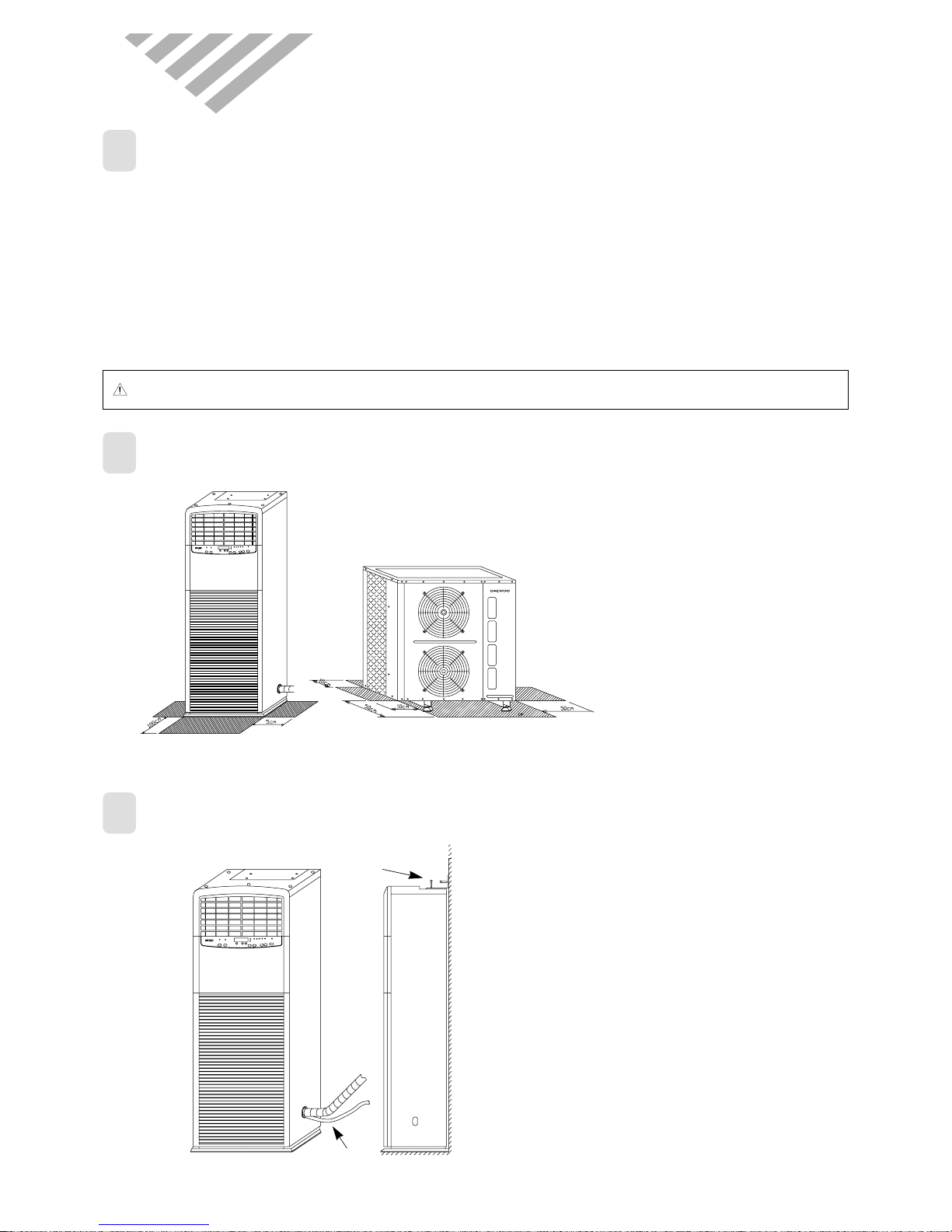

INSTALLATION PLACE

◆Indoor unit ◆Outdoor unit

Secure enough space from the neighboring

objects as shown below.

This is required to operate the unit

efficiently.

• Flat and strong place in the room

• No obstacles in front of air in/out grille

• Easy place to connect drain hose to outside of room

• Easy place to connect copper tube with outdoor unit

• Secure enough distance from neighboring objects as

shown below.

• Secure enough distance from neighboring objects as

shown below.

• A place no reach of direct ray of sun (if necessary, shield the

light)

• No obstacles in front of air in/out grille

• A place having a drain out-let

• Easy place to connect copper tube with indoor unit

• Secure enough distance from neighboring objects as shown

below.

(Indoor unit) (Outdoor unit)

CAUTION : Do not hang the outdoor unit on the wall of building, in case of falling, it may cause a serious trouble and damage.

2

SPACE TO INSTALL

3

INSTALLATION OF INDOOR UNIT

1) Drain hose should maintain downward

slope to outside of room.

2) Indoor unit should be fixed firmly with the

bracket to avoid falling down. The bracket

has several holes to fix the unit any

direction needed (fore/back/right/left)

2

1

3

4

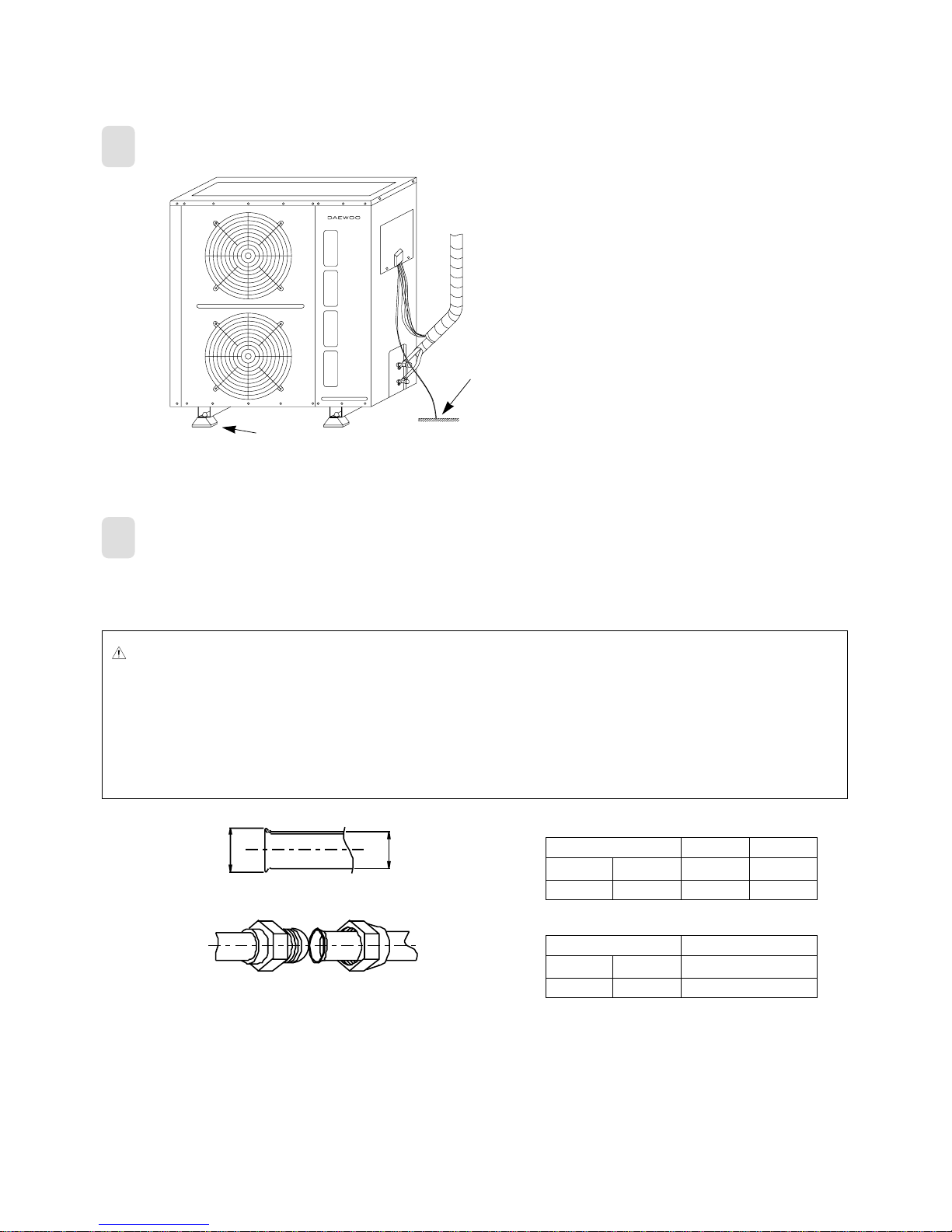

INSTALLATION OF OUTDOOR UNIT

5

REFRIGERANT TUBE CONNECTION

1) Cushion rubbers absorb vibration of

outdoor unit

2) The unit must be grounded for safety in

accordance with local electrical codes.

(Grounding resistance should be under

100 ohms

■ Specification and method of copper tube

• Connection method of copper tube is to make connection with flare nut at the end of the copper tube with a flare tool.

1

2

CAUTION

• Use designated diameter and thickness of tube.

• Connect all tube as short as possible and fix firmly.

• Less than 3M of the difference of height between indoor and outdoor unit is desirable.

• Fill up more refrigerant if the connection tube is longer than 5M (130g/M).

(The refrigerant volume filled from the factory is suitable for 5M connection)

• Be careful not to let in any dust or motes into the tube when the tube passes the wall.

• When insulating the connection, use foam rubber or equivalent.

D

A

Lquid

Gas

3/8”

5/8”

A

12.0~12.4

18.6~19.0

D

9.52

15.88

Unit: mm

Nominal diameter

Flare specification

Lquid

Gas

3/8”

5/8”

Unit: mm

Nominal diameter

Torque

300Kg • cm

500Kg • cm

Torque

4

6

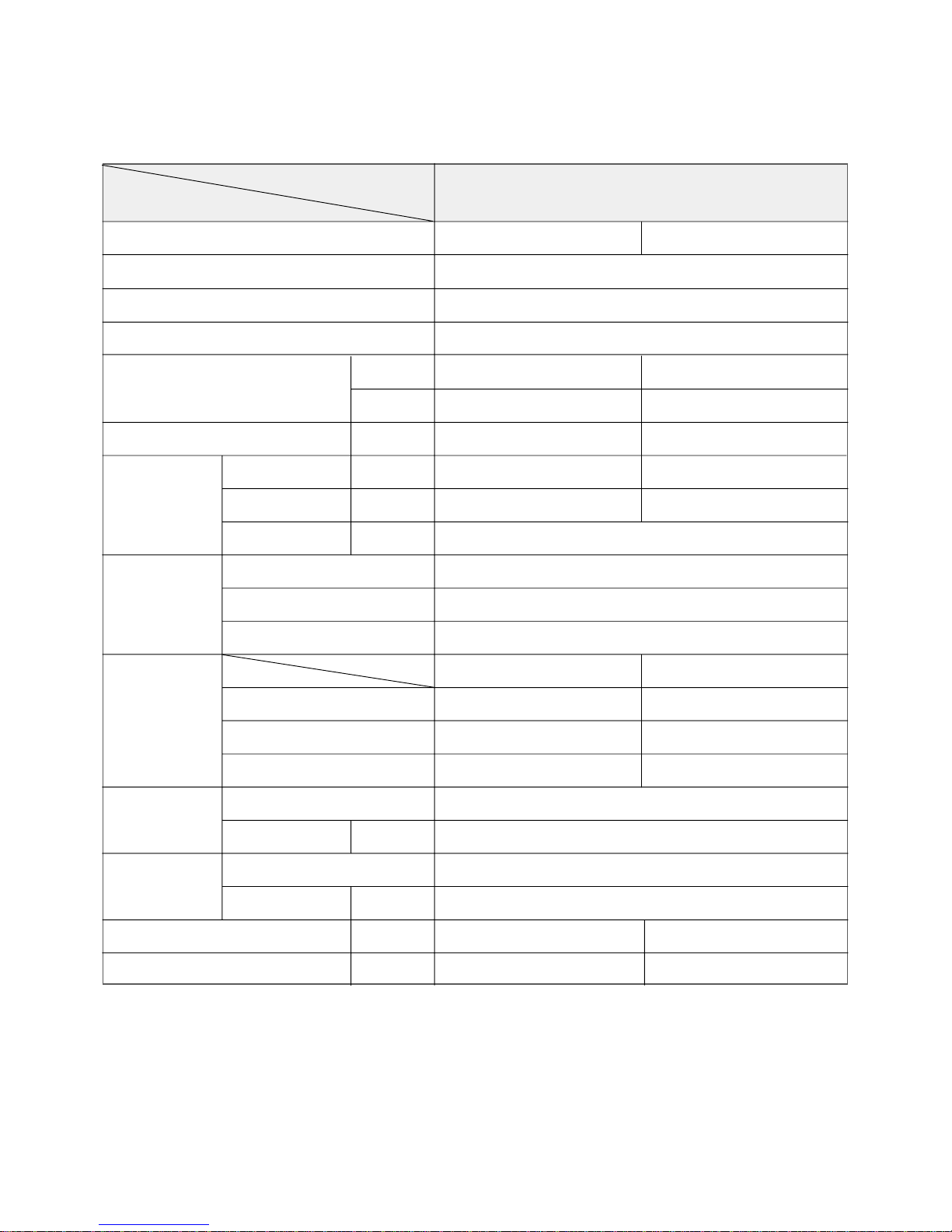

ELECTRICAL WIRING

CAUTION

• Be sure to use designated wires and make it as short as possible

• Use an exclusive power supply for the air conditioner

• Use an electricity leakage interrupter having suitable capacity.

• Grounding resistance should be under 100 ohms and the grounding wire should be connected firmly to the

terminal of out door unit.

■ Wire connection of indoor and outdoor unit

• When connecting wires of indoor and outdoor unit, the numbers of terminal block and terminals of connecting wires should

match exactly as shown below.

• Terminals of connecting wires should be fixed firmly using wire fixing tool to the same direction of terminal board.

5

(MODEL: DPA-300RH)(MODEL: DPA-300R)

CONNECTING METHOD

SPECIFICATION OF WIRES

(MODEL: DPA-300R)

(MODEL: DPA-300RH)

No. of Terminal Block

Y

N

L

N1

L1

Spec

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 6.0mm

2

H07RN-F, 6.0mm

2

H07RN-F, 6.0mm

2

Name of Cord

CONNECTION CORD

CONNECTION CORD

CONNECTION CORD

CONNECTION CORD

POWER CORD

POWER CORD

POWER CORD

No. of Terminal Block

3

2

Y

N

L

N1

L1

Spec

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 1.0mm

2

H07RN-F, 6.0mm

2

H07RN-F, 6.0mm

2

H07RN-F, 6.0mm

2

Name of Cord

SIGNAL LINE

SIGNAL LINE

CONNECTION CORD

CONNECTION CORD

CONNECTION CORD

CONNECTION CORD

POWER CORD

POWER CORD

POWER CORD

6

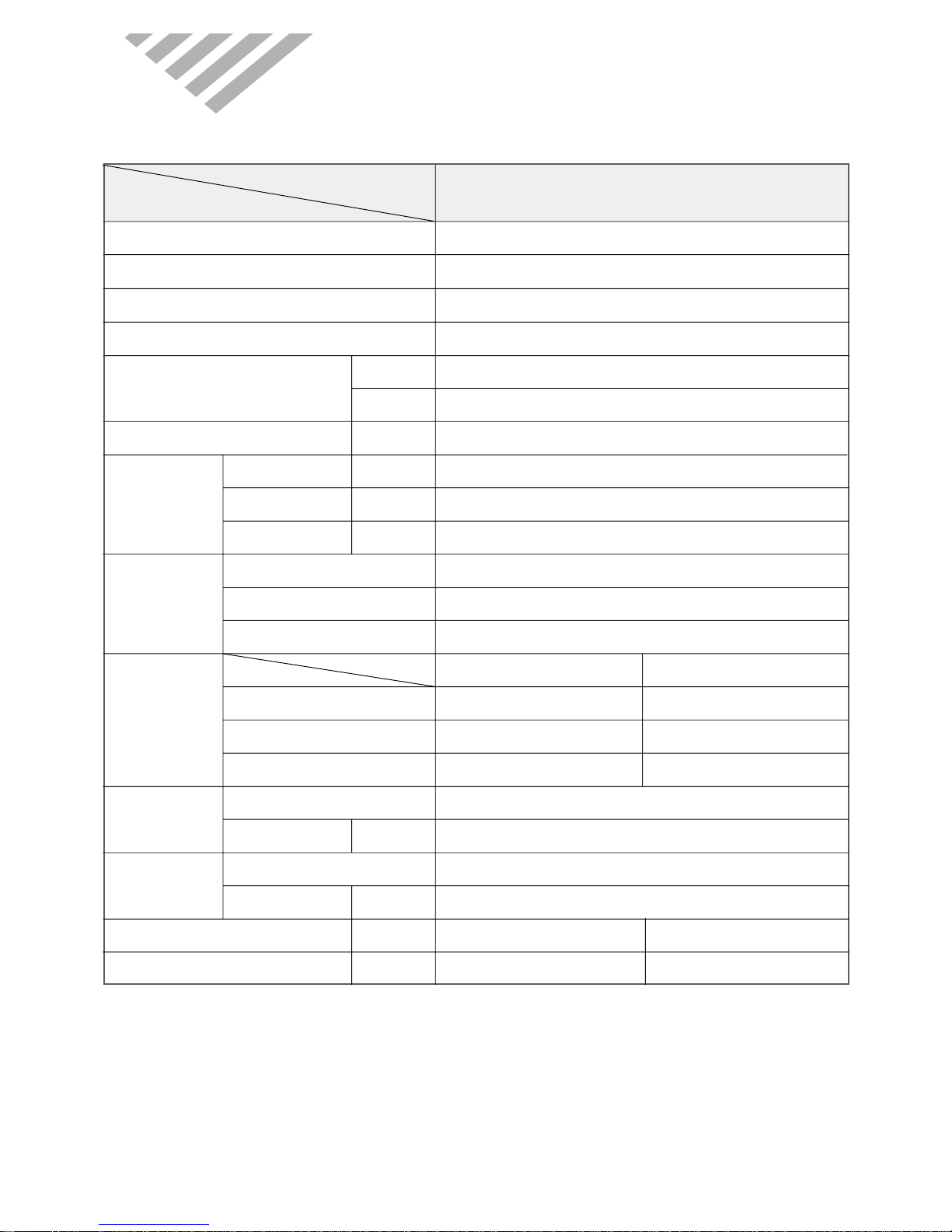

2. SPECIFIC A TIONS

MODEL

DPA-300R

ITEM

Function COOLING

Class T

Power AC 220V, 60Hz

Conditions By JIS C9812

Capacity W 11,134

Btu/h 38,000

Dehumidification l/h –

Running Current A 17.0

Power Input W 3,600

Starting Current A –

Type Recipro

Model CR38K6-PFV

Capacitor 40µF / 450 VAC

Indoor Unit Outdoor Unit

Type Sirocco Propeller fan

Capacitor 6µF/400V AC 4µF/400V AC

Motor Model Number IC-13840DWKF6B OBM-3012BI

Control Capillary

Charge Q'ty g 2,600

Type Flare

OD

(Liquid/Suction)

in(mm) 3/8” (9.52mm) / 5/8” (15.88mm)

Dimensions (W x H x D) mm 650x1,830x430 1,000x1,065x370

Net Weight kg 75 93

Electrical

Data

Compressor

Fan

Refrigerant

(R-22)

Connection

◆DPA-300R

7

MODEL

DPA-300RH

ITEM

Function COOLING HEATING

Class T

Power AC 220V, 60Hz

Conditions By JIS C9812

Capacity W 11,134 11,134

Btu/h 38,000 38,000

Dehumidification l/h ––

Running Current A 19.0 18.0

Power Input W 4,000 3,800

Starting Current A –

Type Recipro

Model CR41KQ-PFV

Capacitor 50µF / 400 VAC

Indoor Unit Outdoor Unit

Type Sirocco Propeller fan

Capacitor 6µF/400V AC 4µF/400V AC

Motor Model Number IC-13840DWKF6B OBM-3012BI

Control Capillary

Charge Q'ty g 2,600

Type Flare

OD

(Liquid/Suction)

in(mm) 3/8” (9.52mm) / 5/8 (15.88mm)

Dimensions (W x H x D) mm 650x1,830x430 1,000x1,065x370

Net Weight kg 75 94

Electrical

Data

Compressor

Fan

Refrigerant

(R-22)

Connection

◆DPA-300RH

8

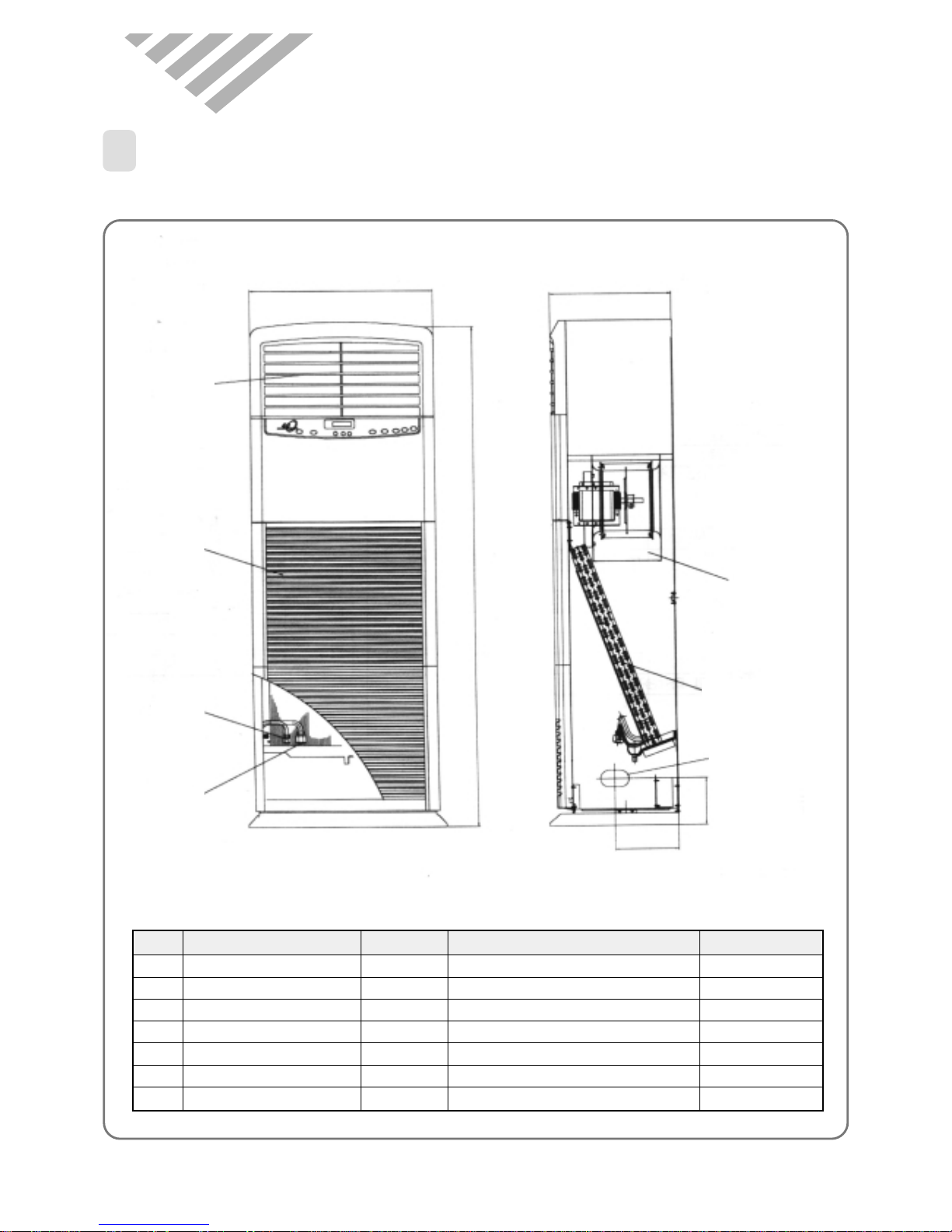

3. OUTLINE

1

INDOOR UNIT

◆DP A-300R/RH

No Part Name Quantity Description Remarks

1 Connecting Hole 3 ø60X100 (Left, Right, Back)

2 Evaporator 1 Heat Exchanger

3 Suction Grille 1 Air Inlet

4 Discharge Grille 1 Air outlet

5 Fan Blower 1 Sirocco Type

6 Joint (Gas) 1 OD ø15.88mm

7 Joint (Liquid) 1 OD ø9.52mm

4

3

5

2

1

7

6

650

1830

22

430

225

9

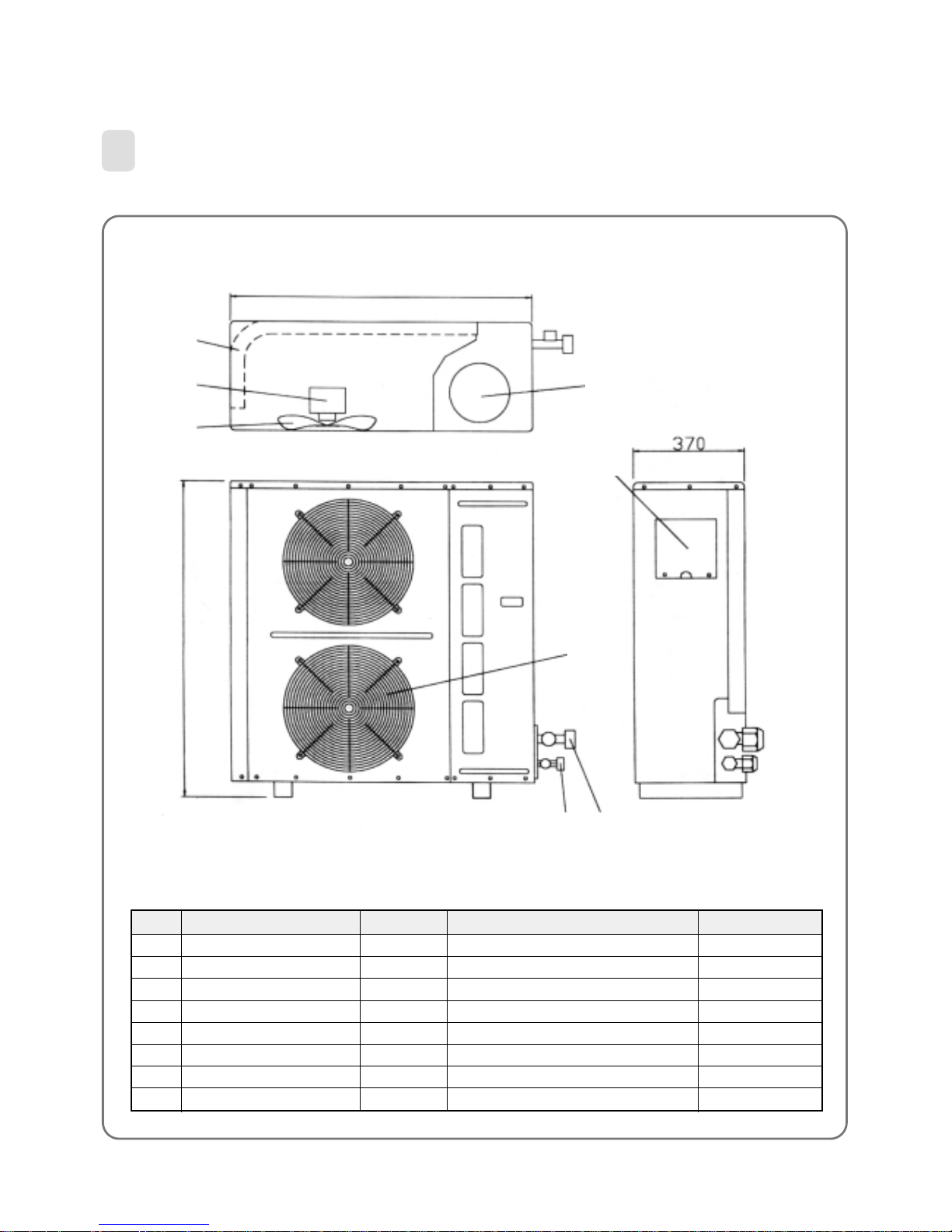

2

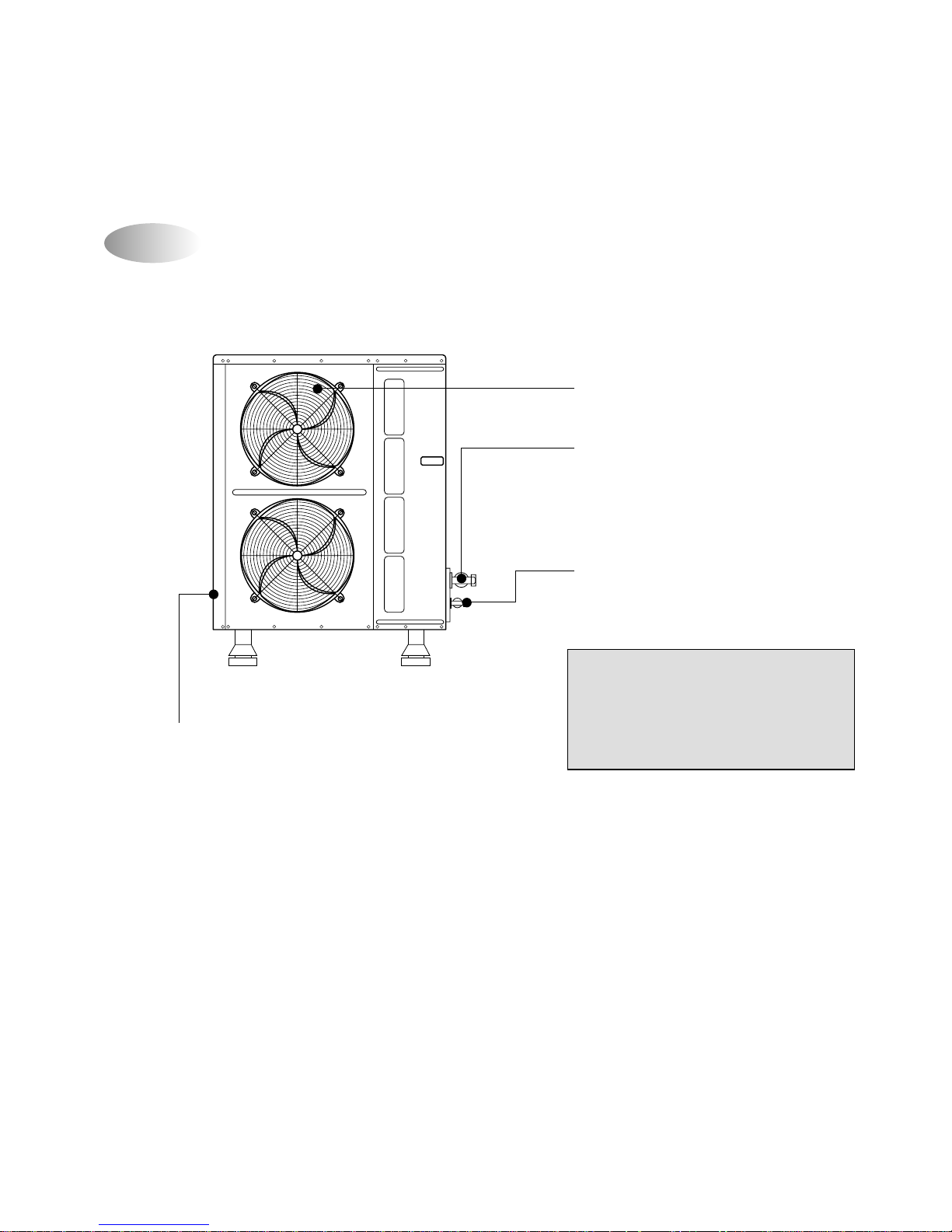

OUTDOOR UNIT

◆DP A-300R/RH

No Part Name Quantity Description Remarks

1 Service Valve (Liquid) 1 OD ø9.52mm Flare Type

2 Service Valve (Gas) 1 OD ø15.88mm Flare Type

3 Service Door 1

4 Fan Guard 1 Fan Protector

5 Fan Blower 1 Propeller type

6 Condenser 1 Heat Exchanger

7 Fan motor 1 Foor propeller fan

8 Compressor 1 Depend on Models

1000

4

1 2

6

7

5

1065

8

3

10

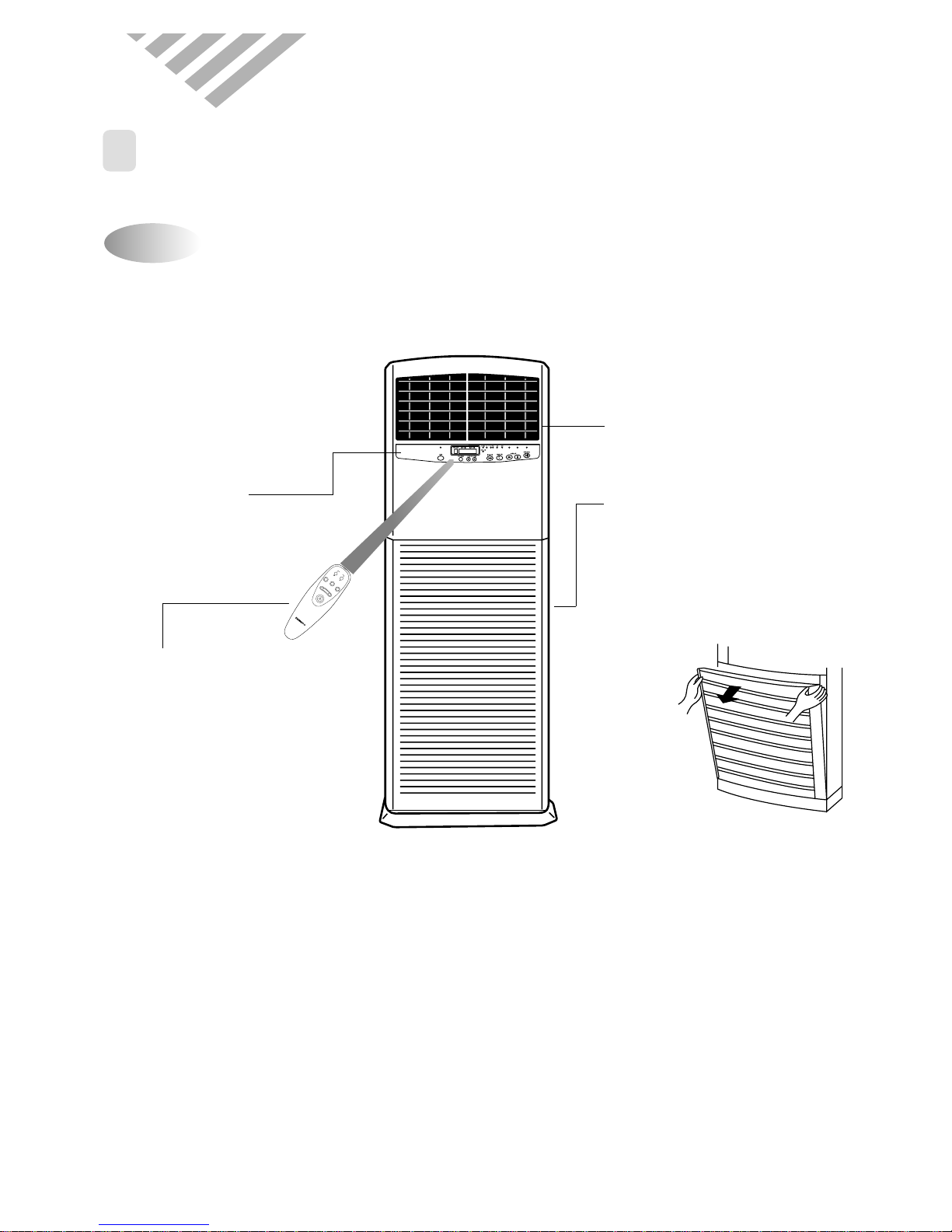

1

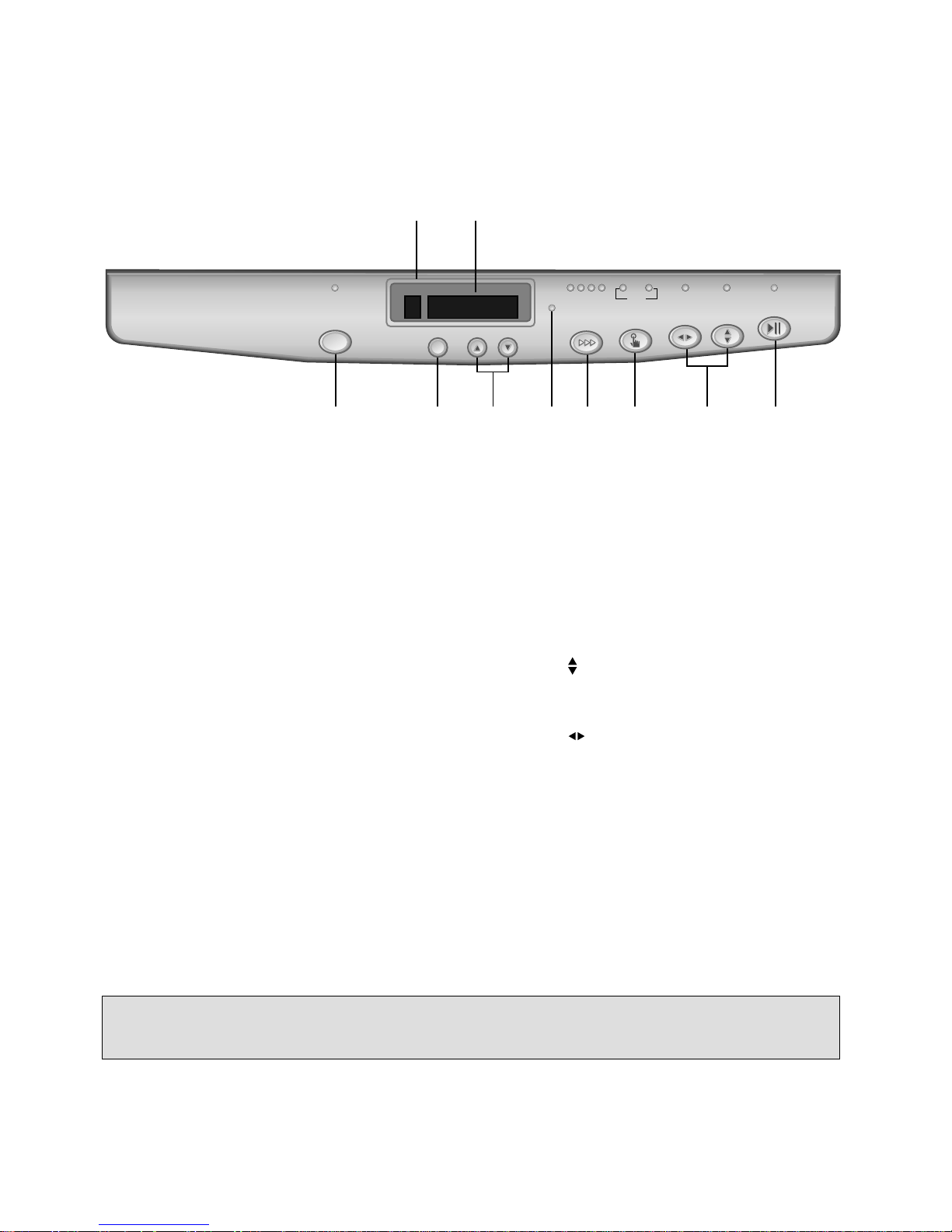

PARTS OF NAME AND FUNCTION

Indoor Unit

4. OPERA TION

MAIN CONTROLS/

REMOTE SENSOR

REMOTE CONTROLLER

- Operative distance is within 7m

from the indoor unit.

- Use toward to the remote sensor

AIR OUT

AIR IN

- There is an air filter inside this

grille.

* The method to open the air

suction grille

Pull the upper side of grille with

both hands.

FA

N

D

IR

.

L

O

C

K

M

O

D

E

F

A

N

S

P

E

E

D

T

E

M

P

F

A

N

D

IR

.

A

U

T

O

S

W

I

N

G

11

SAVE Mode Button and Indicator

TIMER ON/OFF Button

Press to set the unit off or on time.

(1, 2, 3......24hr)

TEMPERATURE & RESERVATION TIME

Button

Press to raise or lower the desired

temperature and time.

OUTDOOR UNIT OPERATION Indicator

Lights to indicate the outdoor unit operation.

FAN SPEED Button and Indicator

Press to select the fan speed

(High / Middle / Low / Auto)

MODE Button and Indicator

Press to cycle through the modes

(Cool / Fan / Heat)

FAN DIR. Button and Indicator

Press to select up/down direction for fan.

FAN DIR. Button and Indicator

Press to select left/right direction for fan.

ON/OFF Button and Indicator

Press to turn the unit on or off

Remote Sensor

TEMPERATURE & RESERVATION TIME

Indicator

1

2

3

4

5

6

7

8

9

10

1 2

9 0

3 4 5 6 7

8

REMOCON

SAVE

TIMER UP DOWN

FAN SPEED MODE

FAN DIR.

ON/OFF

CURRENT TEMP DESIRED TEMP

COMP

COOL FAN

HEAT

LO. MI. HI. AUTO

NOTE:

• Heat mode is available on the only heat pump model.

12

Outdoor Unit

CAUTION

• Do not install the outdoor unit on

unstable place like outside wall of

building or outside of balcony. In case of

falling, it may cause serious trouble and

damage.

OUTDOOR UNIT AIR IN

- If there is any obstacle in front of

the grille, the efficiency of the unit

can be lowered.

SERVICE VALVE(GAS TUBE)

SERVICE VALVE(LIQUID TUBE)

OUTDOOR UNIT AIR OUT

13

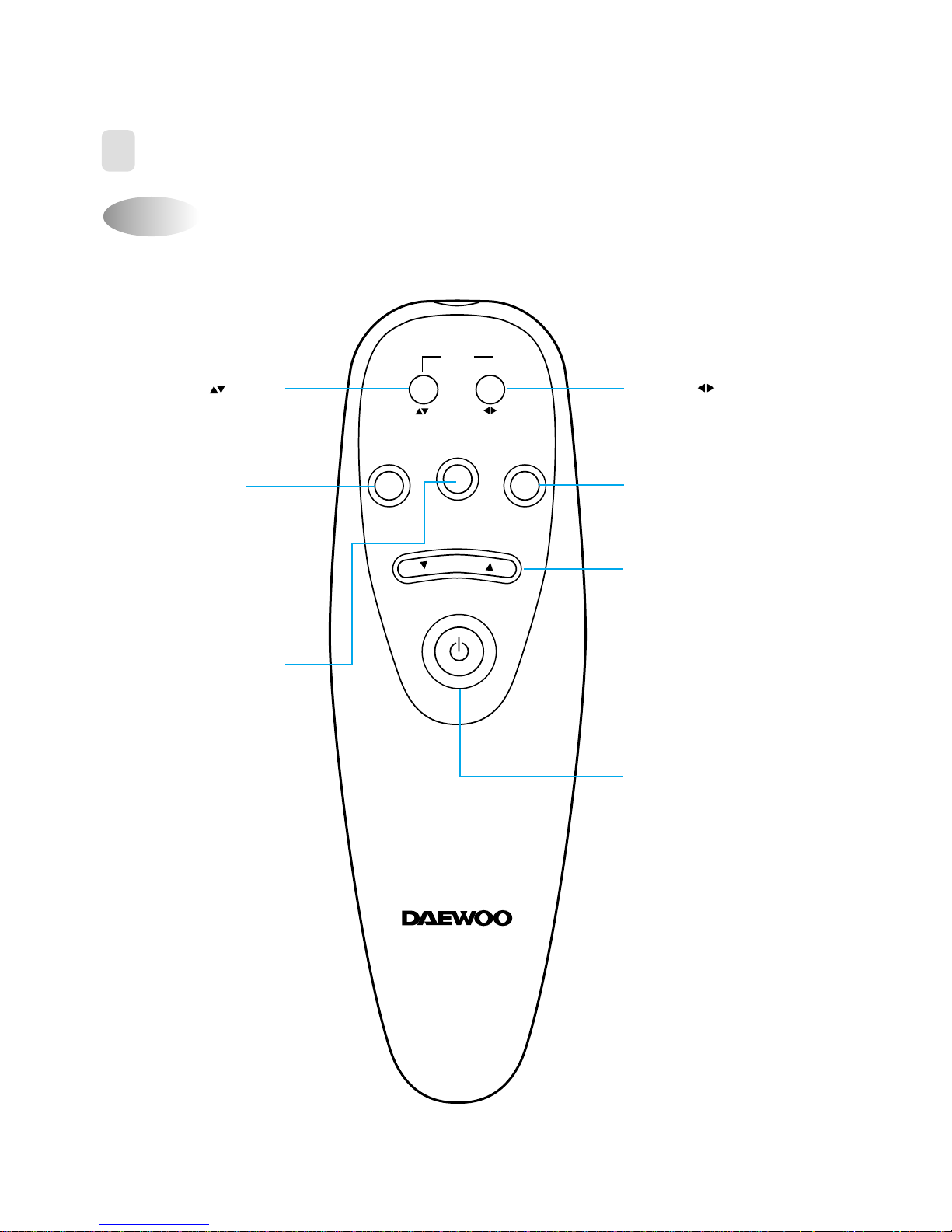

Name of Each Button

2

REMOTE CONTROLLER

FAN DIR.

LOCK MODE

FAN

SPEED

TEMP

FAN DIR.

AUTO

SWING

FAN DIR. Button

Press to select left/right

direction for fan.

TEMPERATURE Button

Press to raise or lower the

desired temperature and

time.

MODE Button

Press to cycle through

the modes

(Cool/Fan/Heat)

LOCK Button

In case that the Lock

option is applied, other

buttons on the indoor unit

don’t work.

To cancel the Lock option,

press any botton on the

remote controller.

FAN SPEED Button

Press to select the fan

speed

(High/Middle/Low/Auto)

FAN DIR. Button

Press to select up/down

direction for fan.

ON/OFF Button

Press to turn the unit on

or off

14

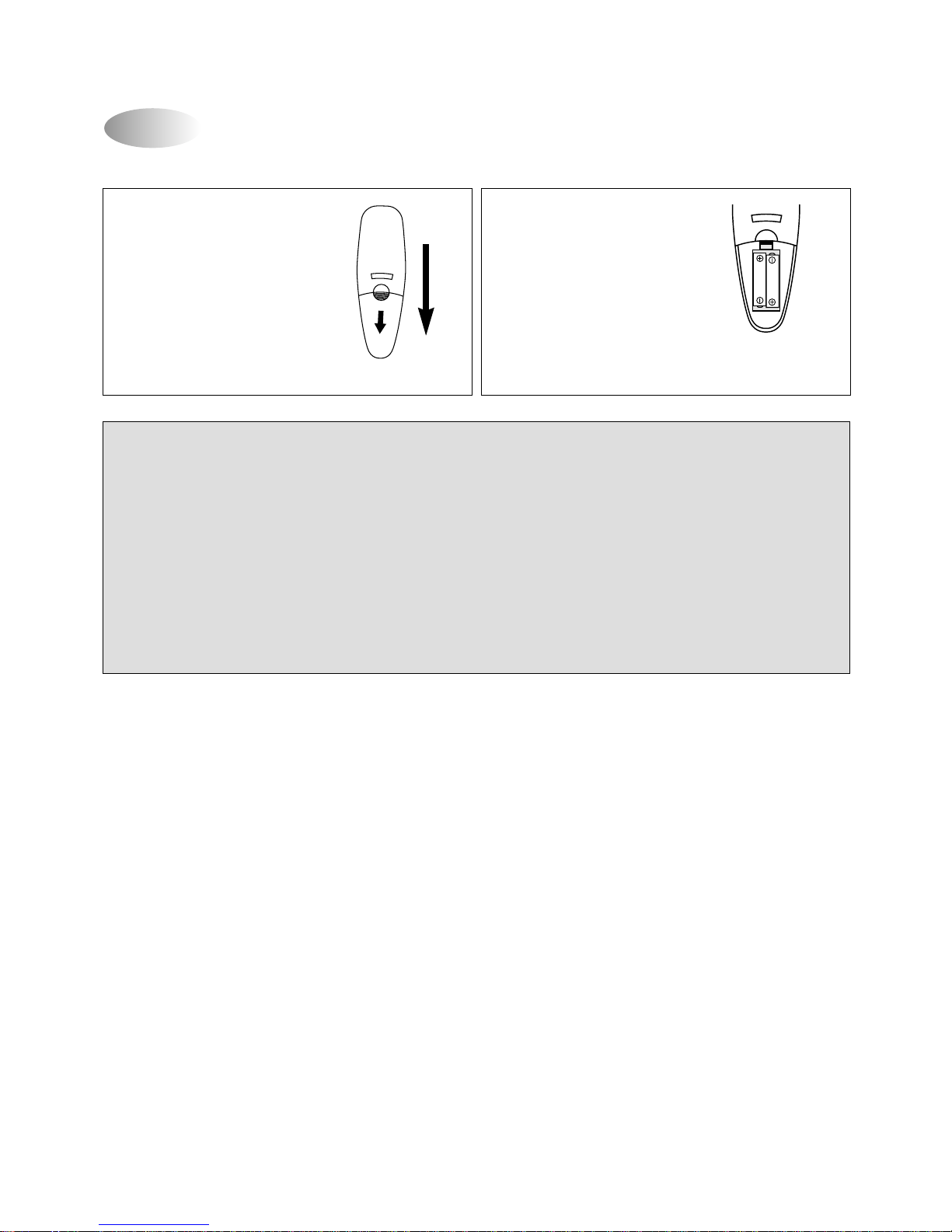

Replacing Batteries

1. Slide down further to access

the battery compartment.

2. Insert two “AAA” size

Alkaline batteries

following the polarity

diagram below.

BATTERY PRECAUTIONS

The precautions below should be followed when using batteries in this device:

1. Use only the size and type of batteries specified.

2. Be sure to follow the correct polarity when installing the batteries as indicated in the batter y compartment.

Reversed batteries maycause damage to the device.

3. Do not mix different types of batteries together (e.g. Alkaline and Carbon-zinc) or old batteries with fresh.

4. If the device is not to be used for a long period of time, remove the batteries to prevent damage or injury

from possible battery leakage.

5. Do not try to recharge batteries not intended to be recharged; they can overheat and rupture. (Follow battery

manufacturer’s directions).

Loading...

Loading...