Page 1

(FOR NEC MODULE)

Page 2

CONTENTS

1. COMMENTS

2. SAFETY PRECAUTION

3. PRODUCT SPECIFICATION

4. BLOCK DIAGRAM

5. AV BLOCK DESCRIPTION

6. LVDS SPECIFICATIONS

7. SERVICE MODE (VIDEO PCB INITIAL DATA)

8. SOFTWARE UPGRADE METHOD

9. POWER ADJUSTMENTS

10.ASSEMBLY LIST

11.PDP MODULE CHECK POINT

11-1. Flow Chart

11-2. Serial Number

11-3. Panel Crack

11-4. Flexible Cable

11-5. Connectors

11-6. Tester Checking

11-7. Strip Defect

11-8. Vertical Line

11-9. Horizontal Line

12. EXPLODED VIEW

1

Page 3

1. COMMENTS

This paper is the additional service manual for the

DP-42SM/WM/GM using the NEC panel.

Other service contents with the exception of this

manual are same as the existing service manual

(DP-42SM/WM/GM). The existing service manual

was made for ORION panel.

2

Page 4

2. Safety Precautions

(1) When moving or laying down a PDP Set, at least two people must be working.

Avoid any impact towards the PDP Set.

(2) Do not leave the broken PDP Set on for a long time. To prevent any further

damages, after check the broken Set’s condition, make sure to turn the power

(AC) off.

(3) When opening the BACK COVER, turn off the power (AC) to prevent electric

shock. When a PDP is on, high voltage and high current exist inside the Set.

(4) When loosening screws, check the connecting position and type of the

screw. Sort out the screws and store them separately. Because screws holding

PCB are working as electric circuit GROUNDING, make sure to check if any

screw is missing when assembling.

(5) If you open the BACK COVER, you will see a Panel Gas Exhaust Tube.If this

part is damaged, entire PDP PANEL must be replaced. Therefore, when working,

be careful not to damage this part.

(6) A PDP Set contains different kind of connector cables. When connecting or

disconnecting connector cables, check the direction and position of the cable

beforehand.

(7) When disconnecting connectors, unplug the connectors slowly with care.

Especially when connecting/disconnecting FFC (film) cables or FPC cables, do

not unplug the connectors too much instantaneously or strongly, and always

handle the cables with care.

(8) Connectors are designed so that if the number of pins or the direction does

not match, connectors will not fit. When having problem in plugging the

connectors, make sure to check their kind, position, and direction.

3

Page 5

3. Product Specification

1. GENERAL

1-1. MODEL NO

1-2. CHASSIS NO

1-3. SCREEN SIZE

1-4. COUNTRY

1-5. RESOLUTION

1-6. REMOCON TYPE

1-7. SAFETY STANDARD

2. MECHANICAL

2-1. APPEARANCE

1) WITHOUT STAN D

2) WITH STAND

3) CARTON BOX

2-2. WEIGHT

1) WITHOUT STAN D

2) WITH STAND

DSP-4280NVS

SP-115

42”(16:9)

WORLD WIDE

853(H) X 480(V)

R-V28A (E)

UL, C-UL, CE, CB, FCC(CLASS B),

CE(CLASS B)

WxHxD=1,039 x 628 x 80 mm

WxHxD=1,039 x 725 x 320 mm

WxHxD=1,256 x 800 x 327 mm

29.9 Kg

36.8 Kg

REMARKS P E C I F I C A T I O NI T E M

3. ELECTR ICAL

3-1. VIDEO INPUT

3-2. DTV/DVD INPUT

3-3. PC INPUT

3-4. SOUND INPUT

3-4. SPEAKER OUTPUT

3-5. POWER REQUIREMENT

3-6. POWER CONSUMPTION

3-8. RS-232 CONTROL

3-9. FUNCTION

1) SCALING

2) ZOOM

3) OSD

4) OTHERS

COMPOSITE(NTSC, PAL, SECAM,

PAL-M/N, NTSC4.43) &

S-VHS(50/60Hz Y/C) 2SETS

1080 i, 720P, 480P , 480i

(Y, Pb/Cb, Pr/Cr COMPONENT

SIGNAL) 2SETS

VGA ~ UXGA (15 PIN D-SUB) 1SET

VIDEO 2SETS, DTV/DVD 2SETS,

PC 1SET

8W(R) + 8W(L)

AC 100V~240V, 50/60Hz

320W

RS-232(FOR SOFTWARE UPGRADE)

PC: H/V SIZE & POSITION ADJUST

VIDEO/DTV/DVD:NOMAL,16:9,

PANORAMA,ENLARGE LB,ENLARGE

LBS

20 SCALE ZOOM & PANING

SUPPORT 11 LANGUAGES

STILL, SLEEP MODE,SOUND MODE

4

Page 6

4. OPTICAL

4-1. SCREEN SIZE

4-2. ASPECT RATIO

4-3. NUMBER OF PIXELS

4-4. DISPLAY COLOR

4-5. PIXEL PITCH

4-6. PEAK LUMINANCE

4-7. CONTRAST RATIO

4-8. VIEWING ANGLE

5. USERCONTROL & ACCESSORY

5-1 CONTROL BUTTON(SET)

REMARKS P E C I F I C A T I O NI T E M

42”(106Cm) DIAGONAL

16:9

853(H)X480(V)

16.77 MILLION COLOR (8BIT RGB)

1.08(H)X1.08(V)

300cd/㎡(WITH FILTER GLASS)

1500:1

160

DEGREE(VERTICAL/HORIZONTAL)

AC POWER BUTTON(PUSH-P ULL

S/W)

MENU, SELECT, UP, DOWN, LEFT,

RIGHT(SOFT S/W)

5-2. REMOTE CONTROL(R-V28)

5-3. ACCESSORIES

POWER,INPUT

SELECT,DISPLAY,ZOOM-,

ZOOM+, MENU, UP,

DOWN,VOLUME UP,

VOLUME DOWN,FREEZE,SCREEN

MODE,

SOUND MODE,SLEEP

REMOCON,

BATTERY,INSTRUCTION MANUAL

A/V CABLE,STAND,

WALL HANGER,

SPEAKER R/L

5

Page 7

4. BLOCK DIAGRAM

6

Page 8

5. A/V BLOCK DESCRIPTION

5-1. A/V BLOCK DIAGRAM

7

Page 9

5-2.VIDEO PCB

- PROCESS Various Signal (PC, COMPONENT, COMPOSITE ) to produce 24BIT DIGITAL output

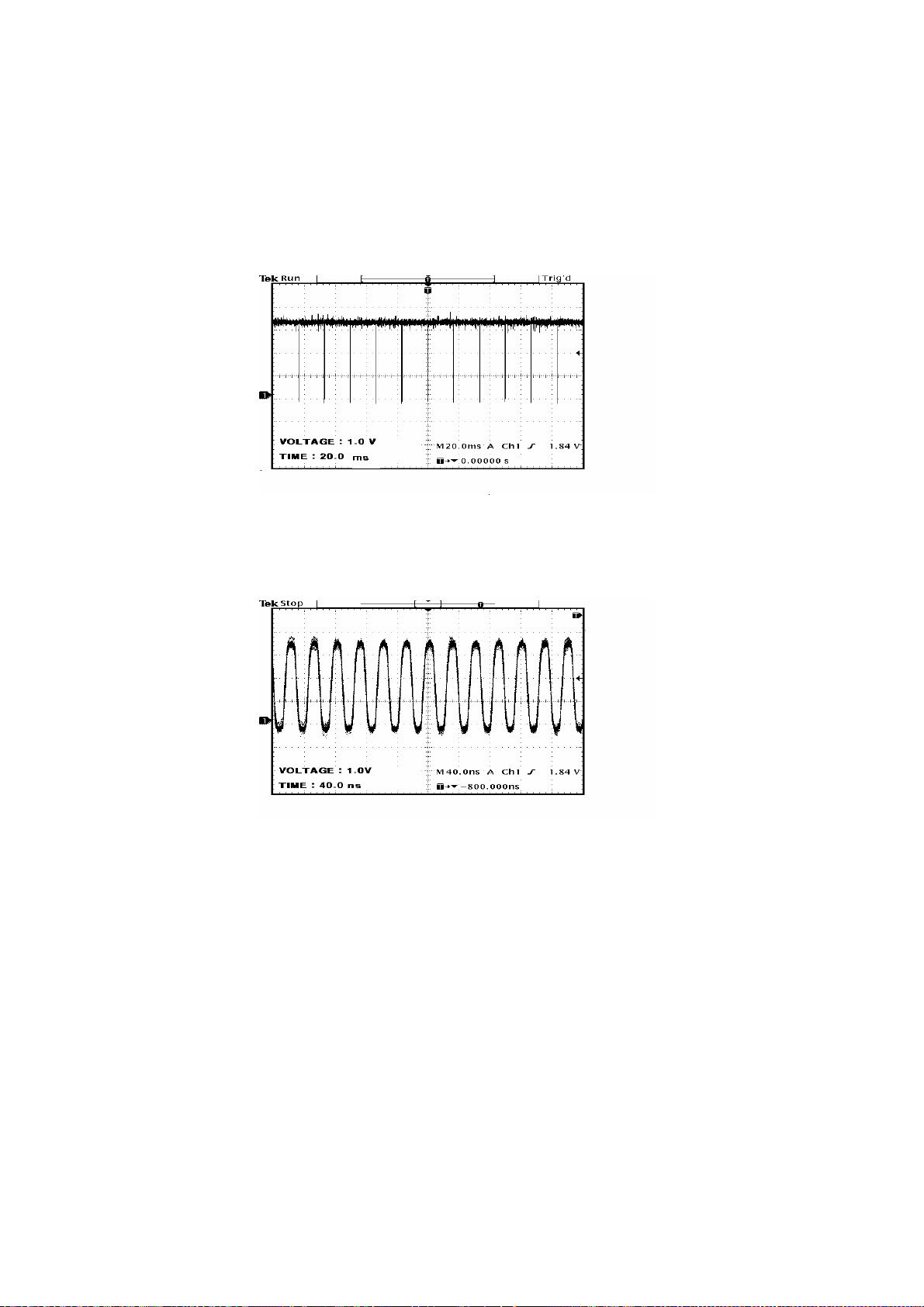

1) IC and TP

(1) IC400(UPD64083)

-Using 3D COMBFILTER to separate COMPOSITE signal to Brightness Signal(Y) and Color

Signal(C)

*TP ( Input : COLOR BAR PATTERN )

A. YCOMP : Brightness Signal(Y)

B. CCOMP : Color Signal (C)

(2) IC401 (SAA7118E)

-Receive NTSC, SECAM, PAL VIDEO by COMPOSITE(V) , S-VHS(Y.C) COMPONEN T (Y Cb Cr)

and process signal

*TP

A. DECOE : CHIP ENABLE part. When signal process is done by IC401, output 3.3V DC LEVEL

8

Page 10

(3) IC406 (DPTV-MVS)

-A Scan Rate Converter which converts Interlace signal into Progressive signal

*TP

A. VVS : VERTICAL SYNC (output by DPTV-MVS)

B. VHS : HORIZONTAL SYNC (output by DPTV-MVS)

C. VCLK : CLOCK (output by DPTV-MVS)

9

Page 11

(4) IC500 (CXA3516R)

-3-channel 8-bit 165MSPS A/D converter which process PC , DTV signal

* TP

A. GCOAST : COAST CONTOL Signal for PLL (input by CXA3516)

B .GHS : HORIZONTAL SYNC for GRAPHIC (output by CXA3516)

C. GCLK : CLOCK for CLOCK (output by CXA3516)

10

Page 12

D. GFBK : SYNC for PLL

(5) IC600 (PW171) - Image processor IC

*TP

A. DEN : DATA ENABLE (output by PW171)

B. DHS : HORIZONTAL SYNC (output by PW171)

11

Page 13

C.DVS : VERTICAL SYNC for DISPLAY (output by PW171)

D. DCLKB : CLOCK for DISPLAY (output by PW17 1)

5-3. JACK PCB

- Separate and process various VIDEO and AUDIO signal

(1) IC706(VIDE O / S YNC SELECTOR)

- This chooses Y Cb/Pb Cr/Pr or RGB signal to output Y Cb/Pb Cr/Pr, to separate SYN C, and to

perform SYNC COUNTER.

(2) IC704(7_INPUT 3_OUTPUT AUDIO/VIDEO SWITCH)

- The IC perform AUDIO or VIDEO SWITCHING

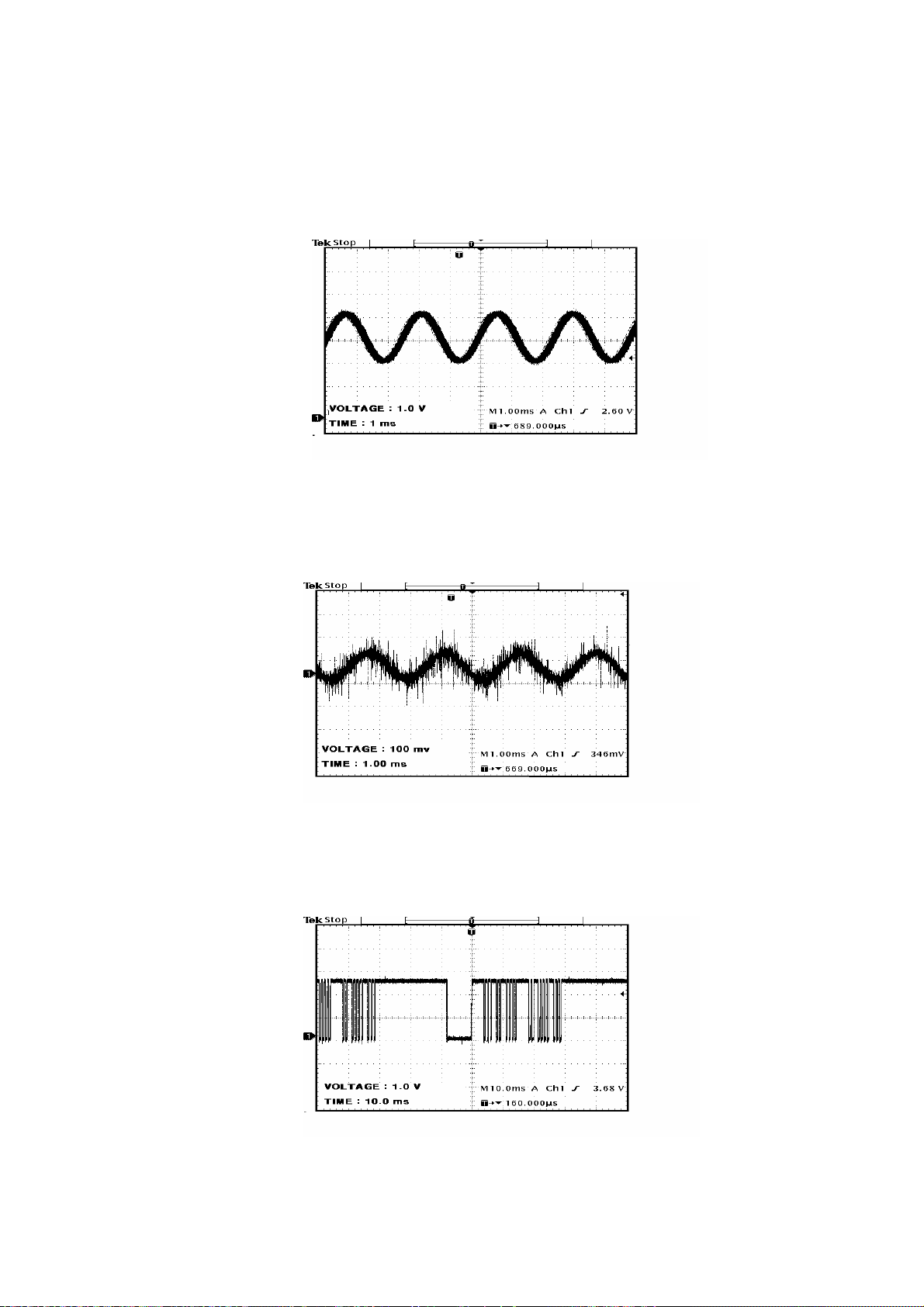

(3) IC700( MULTI STANDARD SOUND PROCDSSOR)

-AUDIO SINGNAL VOLUME control, EQUALIZER control

12

Page 14

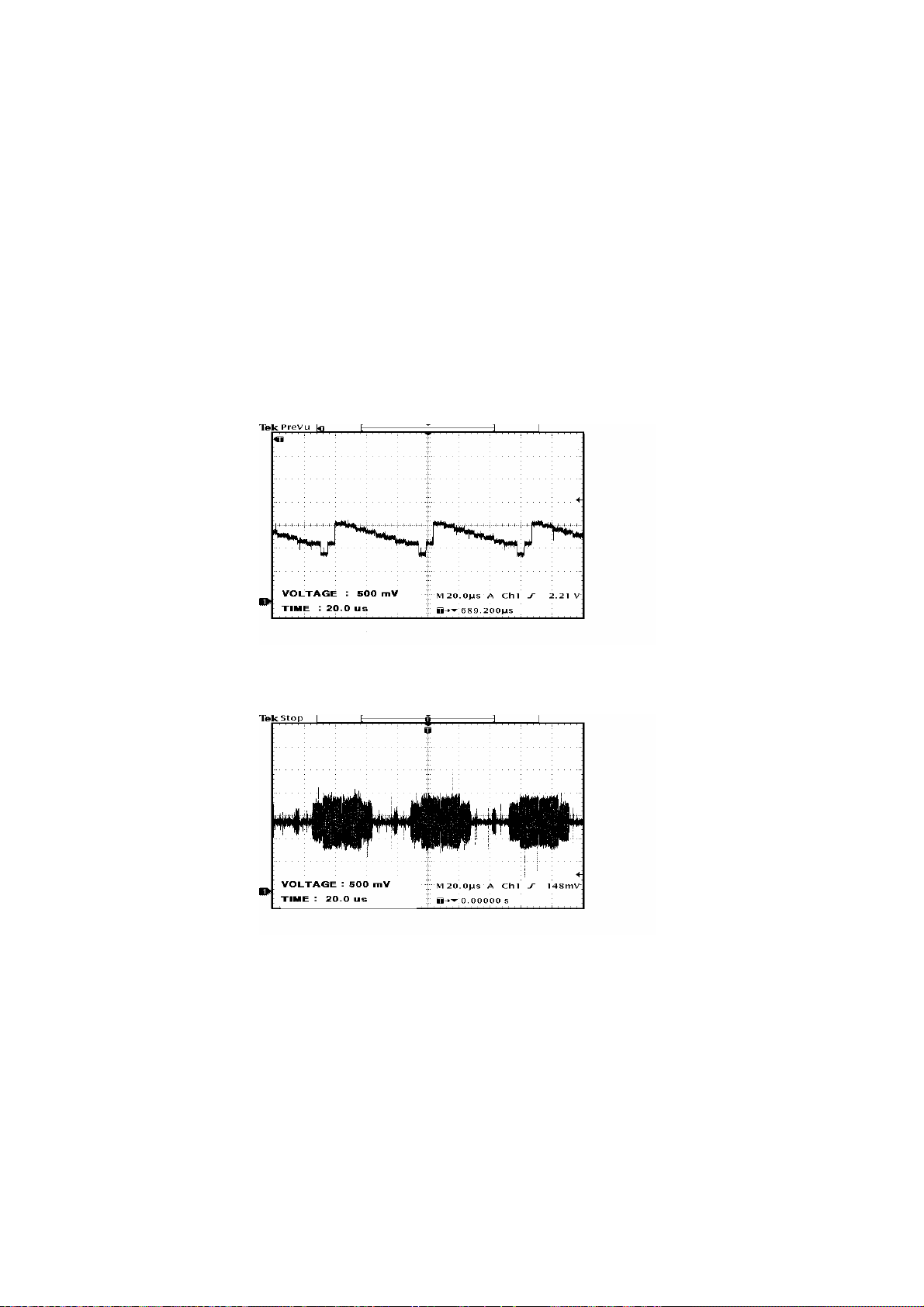

*TP

R_OUT(L_OUT) : AUDIO SIGNAL that goes into MSP3420 before AUDIO PROCESSING

(4) IC701 .IC700 (TDA 7480)

*TP

A. RIGHT(LEFT) :AMP input signal before 30dB amplification

4-1-4.KEY PCB

-Input PCB using KEY

4-1-5.LED PCB

- PCB for REMOCON CONTROL

13

Page 15

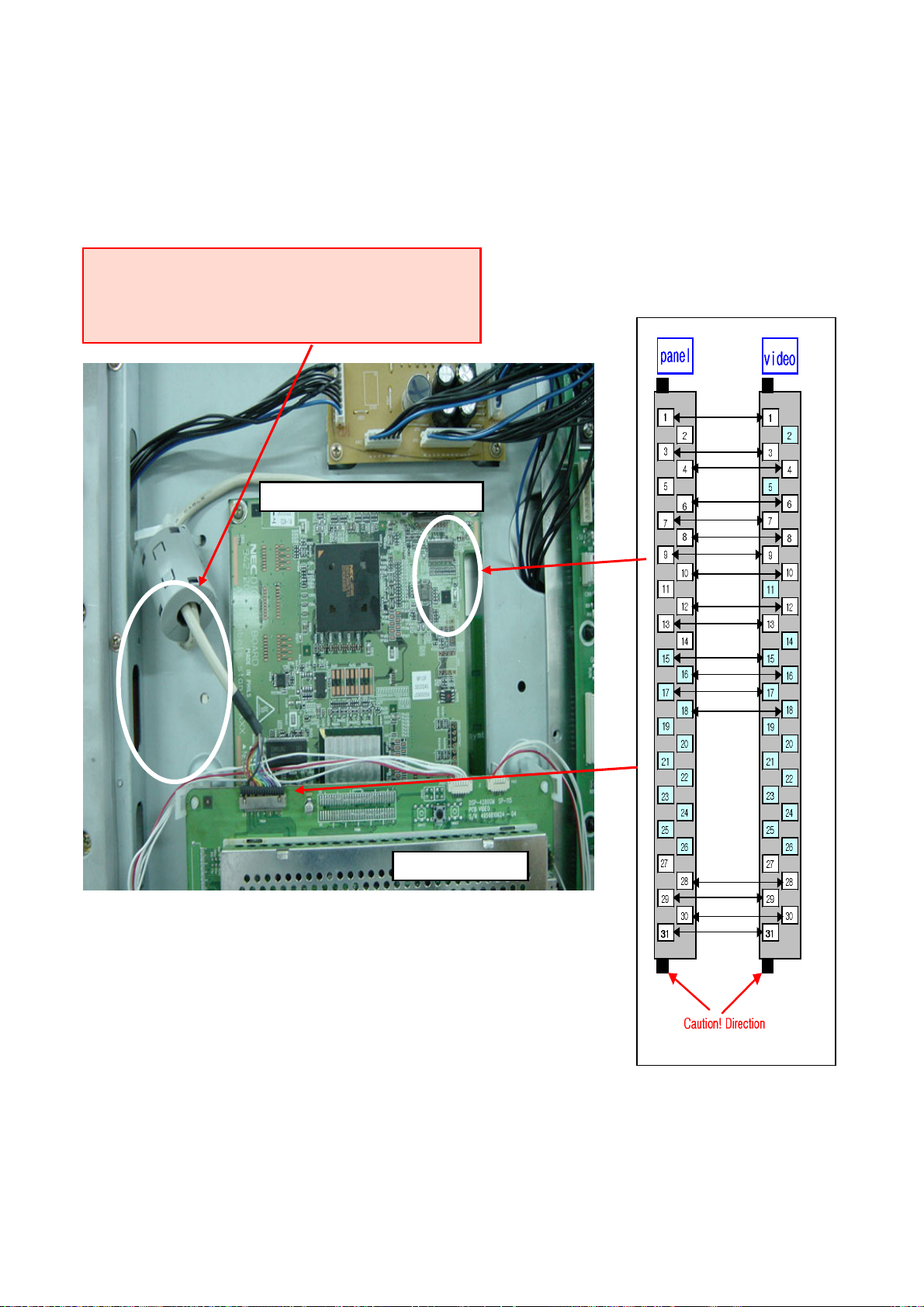

6. LVDS CABLE

CAUTION!

After servicing, you must check

if ring core is coupled with LVDS cable.

Otherwise, PDP may not display.

DIGITAL BOARD (PANEL)

VIDEO BOARD

14

Page 16

7. SERVICE MODE (VIDEO PCB INITIAL DATA)

(1) Input Selection : VIDEO

(2) USER CONTROL INITIAL VALUE

BRIGHTNESS : 35, CONTRAST : 47, COLOR : 32, TINT : 0 (CENTER)

SHARPNESS : 4

(3) SERVICE MODE INITIAL VALUE

1) PW171

SUB-BRIGHTNESS : 28, SUB-CONTRAST : 40

R-BIAS : 64, G-BIAS : 64, B-BIAS : 64

R-GAIN : 64, G-GAIN : 64, B-GAIN : 64

2) SAA7118

SUB BRT : 128, SUB CONT : 50, SUB CLR : 55, SUB TNT : 0

SUB SRP : 10

3) DPTV

SUB BRT : 61, SUB CONT : 16,

4) CXA3516

SUB CONT : 58, Cb OFFSET : 39, Cr OFFSET : 37, HYS : 3,

THRSLD : 14

5) MSP34X0

PRESCALE : 22

6) PANEL

MOVING : Video60STD

STILL : Video60RFC

15

Page 17

8. SOFTWARE UPGRADE Method

1.Connect the JACK PCB to the Vid eo PCB.

2.Connect 9 PIN serial cable to the comput er’s serial port.

3.Connect seri al cable’s opposite end to Ja ck PCB’s RS-232C port.

4.Run PC’s Flashupgrader.exe and then push “Next(N) >” button.

1.Select current Upg r ad e fil e

-Copy files sent by research center to a folder you wish to copy.

-Browse and Select pw SDK.inf f rom the folder.

-Push “Next(N) >” button.

16

Page 18

1. Select as above and push “Next(N ) > ” button. Select Comm port and Boud rate and push

“Next(N) >” button

1.Upgrade process will be displayed. Power the AC o n will initiate the download.

17

Page 19

1.When all files Upgrade ar e co mpl ete , a window (b elo w) will ope n. Push “Finish” button to

complete the p rocess.

18

Page 20

9. POWER ADJUSTMENTS

1. Vsus (SUSTAIN Voltage) : Discharge Sustain Voltage

▪ METER used : DIGITAL MULTIMETER (DC Voltage Measure Mode)

▪ Adjusting TP : TP204 (refer to PAGE 11)

▪ Adjusting VOLUME : RV203 (refer to PAGE 11)

▪ Standard Voltage : 170V (This value could be different from the optimum

adjusting voltage)

▪ Optimum adjusting Voltage : Stated in the LABEL

(See voltage adjustment label in the top of Panel Back Plate - PAGE 11)

2. Vadd (ADDRESS voltage) : DATA Input Voltage

▪ METER used : DIGITAL MULTIMETER (DC Voltage Measure Mode)

▪ Adjusting TP : TP206 (refer to PAGE 11)

▪ Adjusting VOLUME : RV204 (refer to PAGE 11)

▪ Standard Voltage : 60V (This value could be different from the optimum

adjusting voltage)

▪ Optimum adjusting Voltage : Stated in the LABEL

(See voltage adjustment label in the top of Panel Back Plate - PAGE 11)

*. As NEC Panel doesn’t apply Vyer, it is unnecessary to adjust.

19

Page 21

POWER ⇒ Y-SUS

( Vsus, Vyer, 15V )

POWER ⇒ X-SUS

( Vsus, Vadd, 15V )

POWER ⇒ JACK

( AUDIO PWR : ± 15 V )

POWER ⇒ VIDEO

( 5V, 12V )

HIGH

VOLTAGE

SWITCH

POWER ⇔ VIDEO

( STB 5V, PWR_CTL )

AC POWER

INPUT LINE

20

Page 22

Vsus ‘s TP ( TP204 ) Vadd ‘s TP ( TP206 )

VOLUME for adjusting

Vsus ( RV203 )

VOLUME for adjusting Vadd ( RV204 )

GND

Ï ON

HIGH VOLTAGE SWITCH

*HIGH VOLTAGE : Vsus, Vyer, Vadd

21

Page 23

10. ASSEMBLY LIST

ASS'Y DESCRIPTIONASS'Y CORDPCB ASS'Y NAMENo.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CONN CENTER AS

CONN LEFT AS

CONN RIGHT AS

PCB VIDEO MANUAL ASPTVDMSG009VIDEO PCB AS

PCB JACK MANUAL ASPTJAMSG009JACK PCB AS

PCB SUB MANUAL ASPTSBMSG0095V SUB PCB AS

NP42B2MF024850M06110MODULE PDP

X-SUS PCB AS (NP42B2M F02 NEC)485AS00290X-SUS PCB AS

Y-SUS PCB AS (NP42B2MF02 NEC)485AS00390Y-SUS PCB AS

DIGITAL PCB AS (NP42B2MF02 NEC)485AS00490DIGITAL PCB AS

CONN CENTER AS (NP42B2MF02 NEC)485AS00790

CONN LEFT AS (NP42B2MF02 NEC)485AS00590

CONN RIGHT AS (NP42B2MF02 NEC)485AS00690

PANEL GLASS (NP42B2MF0 2 NEC)485AS00190PANEL GLASS

PDF-6PH024952400200GLASS FILTER

PDD-4214850M05910MODULE POWER

YMH025-11R+YMH025-11R+ULW=2304850711N04CONNECTOR

YMH025-07R+YMH025-07R+ULW=2204850707N11CONNECTOR

16

17

18

19

20

21

22

23

24

25

26

27

28

29

YMH025-09R+YH396-09V+ULW=4004850709N06CONNECTOR

YMH025-10R+YH396-10V+ULW=3104850710N09CONNECTOR

A2501H02-4P+440133-4+ULW=4104850704N29CONNECTOR

YMH025-10R+YMT025R+ULW=5004850710N08CONNECTOR

YMH025-05R+YMT025R+ULW=5004850705N27CONNECTOR

12505HS-06+12505TS+ULW=7504950706025CONNECTOR

12505HS-05+12505TS+ULW=9004850705N28CONNECTOR

YMH025-04R+YMT025R+ULW=4004850704N28CONNECTOR

0.5-R-50P-320MM 6X4-6X4485900038LCABLE FFC

0.5-K-50P-400MM 6X4-6X4485900018LCABLE FFC

0.5-K-50P-360MM 6X4-6X4485900028LCABLE FFC

ZCAT3035-13305PZCAT3035FILTER EMI

SECC T1.04853954100BRKT MAIN

PCBEHE2-25M-014957300400SUPPORT CIRCUIT C

22

Page 24

11. PDP MODULE CHECK POINT

11-1. Flow Chart

Check process

Type, Serial Number

Panel Crack

Flexible Cable

Connectors

Tester Checking

Phenomenon

Take pictures (Module and shipment box)

Take pictures

Take pictures

If you can confirm visual malfunction,

take pictures

Input it in your line again

Each

Strip Defect

Vertical Line

Horizontal Line No Display Writing Issues

Page 38-39 Page 41-44 Page 45

Judgment (Mak e C-PDP Failure De scription sheet)

23

Page 25

11-2. Serial Number

Module Number and Panel ID

Serial No.

Type

SERIAL NO.

302200129

Vd=60V

Vs=168.4V

CODE CA-01

Panel ID

222301242941

24

Page 26

11-3. Panel Crack

Panel Crack

Check the surface of glass whether crack or not

This issue may be caused by transportation or treatment after shipment.

We would like you to take some pictures, the broken module, the outside box,

and inform the shipment data

If you do not the pictures, we can dispose the broken modules on our responsibility.

25

Page 27

11-4. Flexible cable

Flexible Cable

Check the Flexible Cables whether scratched, broken, or not.

Cutting cable or broken

In this case, it caused by handling them at customer line.

We would like you to be careful to handle the modules.

26

Page 28

11-5. Connectors

Connectors Condition

Check the Cable or Connectors whether connected and locked, o r not

NEC MODULE ONLY (with the exception of video, power and jack board)

DIGITAL BOARD

5 connectors

SCAN BOARD

11 connectors

COMMON BOARD

7 connectors

DATA RELAY BOARD 2 connectors

DATA RELAY BOARD 2 connectors

We would like you to be careful to handle the modules at assembling

27

Page 29

Each Connectors Condition

LOCKED

Data HIC

-DATA RELAY BOARD

DIGITAL BOARD DIGITAL BOARD SCAN BOARD

-DATA RELAY BOARD -DATA R ELAY BOARD

-SACN DRIVING BOARD

UNLOCKED

28

Page 30

Each Connectors Condition

COMMON BOARD DIGITAL BOARD

- FLEXIBLE CALBLE - FLEXIBLE CALBLE

LOCKED

UNLOCKED

CONNECTED

UNCONNECTED

29

Page 31

11-6. Tester Checking

Fuse Checking

Glass fuse

(F1 and F2)

on Common Board

Fuse resistance

(R101)

on Common Board

OK :

Shortage

NG :

Opened

Glass fuse

(F1 and F2)

on Scan Board

OK :

Shortage

NG :

Opened

Fuse resistance

(R12 R29)

on Scan Board

OK : 2.2

ohms

NG :

Opened

R12 OK : 2.2

ohms

R29 OK : 4.7

ohms

30

Page 32

Alarm Line

Checking

Glass Alarm

At #50 pin on CN8

On Data Relay Board

(Right-Down)

Glass Alarm

between pins on CN3

On Scan Board

OK :

Shortage

NG :

Opened

OK :

Shortage

NG :

Opened

31

Page 33

Data HIC line

Checking

F2 fuse and GND on scan board

F2 fuse and GND on scan board

Between F2 fuse and GND

OK :

Opened

NG :Short

age

Between F2 fuse and GND

Check between F2 fuse and GND at scan or common board.

If it is shortage,

Remove the heatsink over the data HIC,

And Check the surface of data HIC, the take a picture

OK : Opened

NG :Shortage

32

Page 34

Parts Location

COMMON Board

PH2101

COMMON Board

PH2101

33

PH2102

Page 35

Power HIC Checking

PH2101 on Common board

Check the following

cases.

PH2101 on common board

PH2101

A

B

C

D

E

F

G

H

PH2101

Between A and G

Between B and H

Between C and D

Between E and F

34

OK : More than

K ohm

NG : Shortage

Page 36

Power HIC Checking

PH2101 on Scan board

PH2101 on scan board

Check the following cases.

F

E

D

PH2101

PH2101

H

G

Between A and G

Between B and H

Between C and D

Between E and F

C

B

A

OK : More than

K ohm

NG : Shortage

35

Page 37

Power HIC Checking

PH2102 on Scan

board

Check the following

cases.

PH2101 on common board

PH2102

PH2102

A

B

C

D

E

F

G

H

I

J

Between A and B

Between B and C

Between D and E

Between F and G

Between H and I

Between J and K

36

K

OK : More than

K ohm

NG : Shortage

Page 38

SCAN IC Driver Checking

Scan IC

Scan

IC

NEGA

POSI

NEGA

POSI

Check the following cases.

Between NEGA and POSI

OK : More than K ohm

NG : Shortage

37

Page 39

11-7. Strip Defect

Strip Defect

Compare with specification

1 Strip

2 Strip 2 Strip

38

Page 40

Strip Defect

3 Strip 3 Strip 3 Strip

39

Page 41

11-8. Vertical Line

Vertical Line

Open Mode

ALL Red

Pattern

Single line

ALL Green

Pattern

ALL Blue

Pattern

ALL Black

Pattern

Black 1 Line Red 1 Line Red1 Line No

Appearance

Red 1 Line Open

Mode

[Check Point]

a) The broken data flexible cable.

If OK, Data IC Broken.

40

Page 42

Vertical Line

Shortage Mode

Two line

ALL Red

Pattern

Blue 1 Line Red1 Line No

a) This phenomen on is caused by panel issues.[Check Point]

ALL Green

Pattern

No

Appearance

Shortage between Red and

Blue

ALL Blue

Pattern

ALL Black

Pattern

Appearance

41

Page 43

Vertical Line

Block

1/2 data IC Block (width

30mm)

[Check Point]

a) The broken surface IC on data IC.

b) The broken data flex ibl e cable.

42

Page 44

Vertical Line

Block

1 data IC Block

[Check Point]

a) Lacking connector between Data Relay board and Data IC.

b) The broken data flex ibl e cable.

43

Page 45

Vertical Line

[Check Point]

Block

Many data IC Block

a) Lacking connec tor between Data Relay board and Scan or Common board

b) The broken data flex ibl e cable

c) Shortage between leads in connector.

Foreign Material etc.

44

Page 46

11-9. Horizontal Line

Horizontal Line

Single

Single line, two lines or block

Two Line Block Block

NEGA

POSI

NEGA

[Check Point]

a)The broken surface IC on scan IC driver.

Check the resistance between NEGA and POSI on scan

IC board. (Normal : K ohm Level)

b) The broken data flex ibl e cable.

c) Lacking connector between scan IC and scan board.

45

Page 47

Loading...

Loading...