Daewoo C-WD1112AHX, D-WD1112AHXS Service Manual

S/M No. : WD1112A001

Service Manual

Drum Washing Machine

Model: C-WD1112AHX

D-WD1112AHXS

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

Jul. 2007

DRUM WASHING MACHINE

SERVICE GUIDE

1. WHAT IS DRUM?...............................................................2

2. SPECIFICATION OF DRUM WASHING MACHINE ......................6

3. VERIFICATION OF DRUM ASSY............................................7

4. PARTS LIST FOR EACH ASSY...............................................9

5. SEQUENCE CHART OF PCB...............................................21

6. SPECIFICATION OF ELECTRONIC PARTS..............................31

7. WIRING DIAGRAM........................................................... 50

8. TROUBLESHOOTING REGARDING DRAIN .............................51

9. INSTALLATION GUIDE ......................................................52

10. ATTENTION POINT WITH SERVICE .....................................54

2

One of the famous washers in the globe which uses laundry falling energy.

1. WHAT IS DRUM ?

1. WHAT IS DRUM WASHER?

◈ The biggest capacity with compact size

◈ No damage and entanglement but excellent washability

◈ 4way savings-noise, vibration, washing times, energy

◈ Self-cleaning course of Drum

◈ Good washing performance with heating system

◈ Condensing dry system with saving energy

◈ Big door glass with easy laundry take-in/out

◈ The higest spin speed

2. Sales point of our washer

3

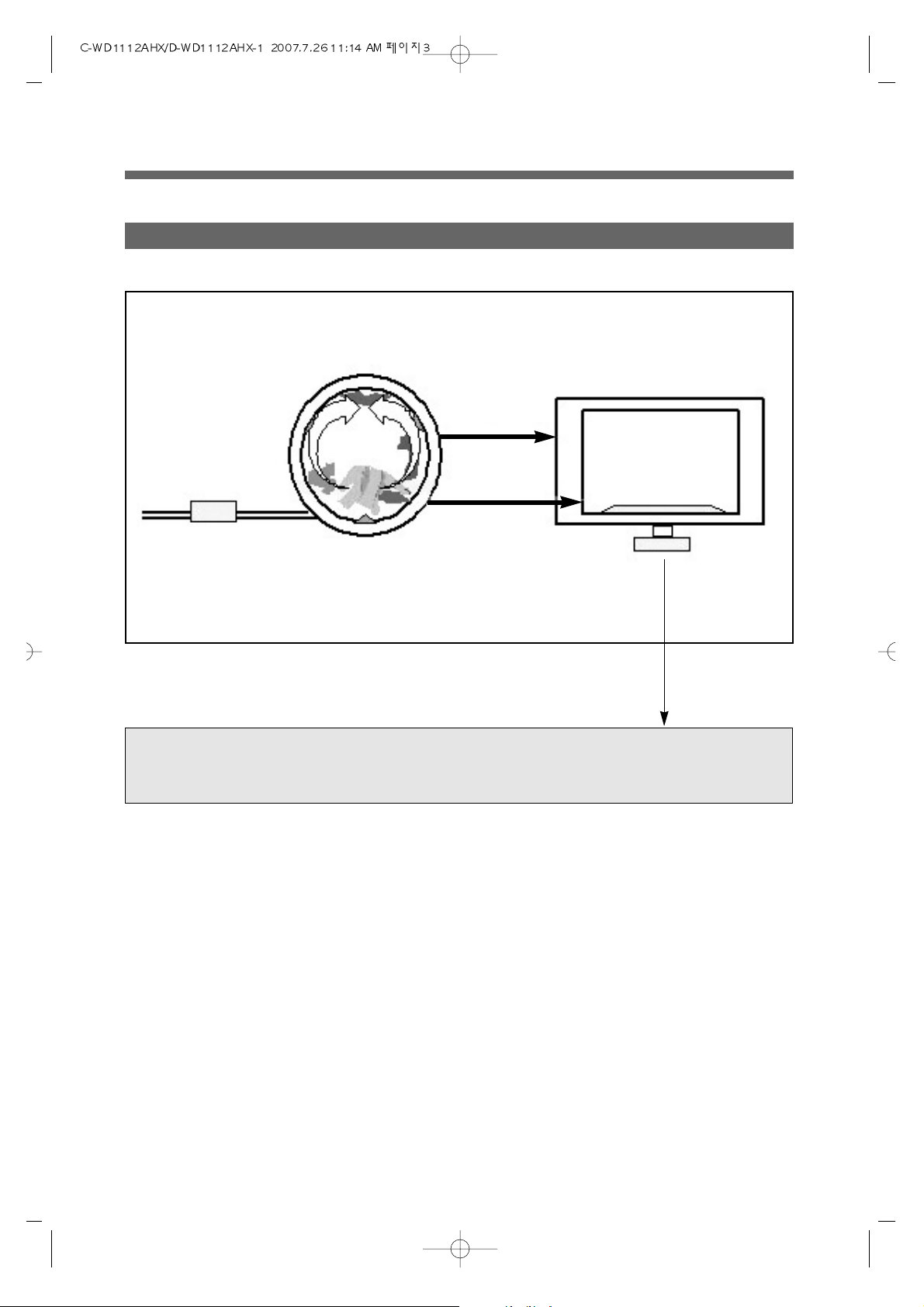

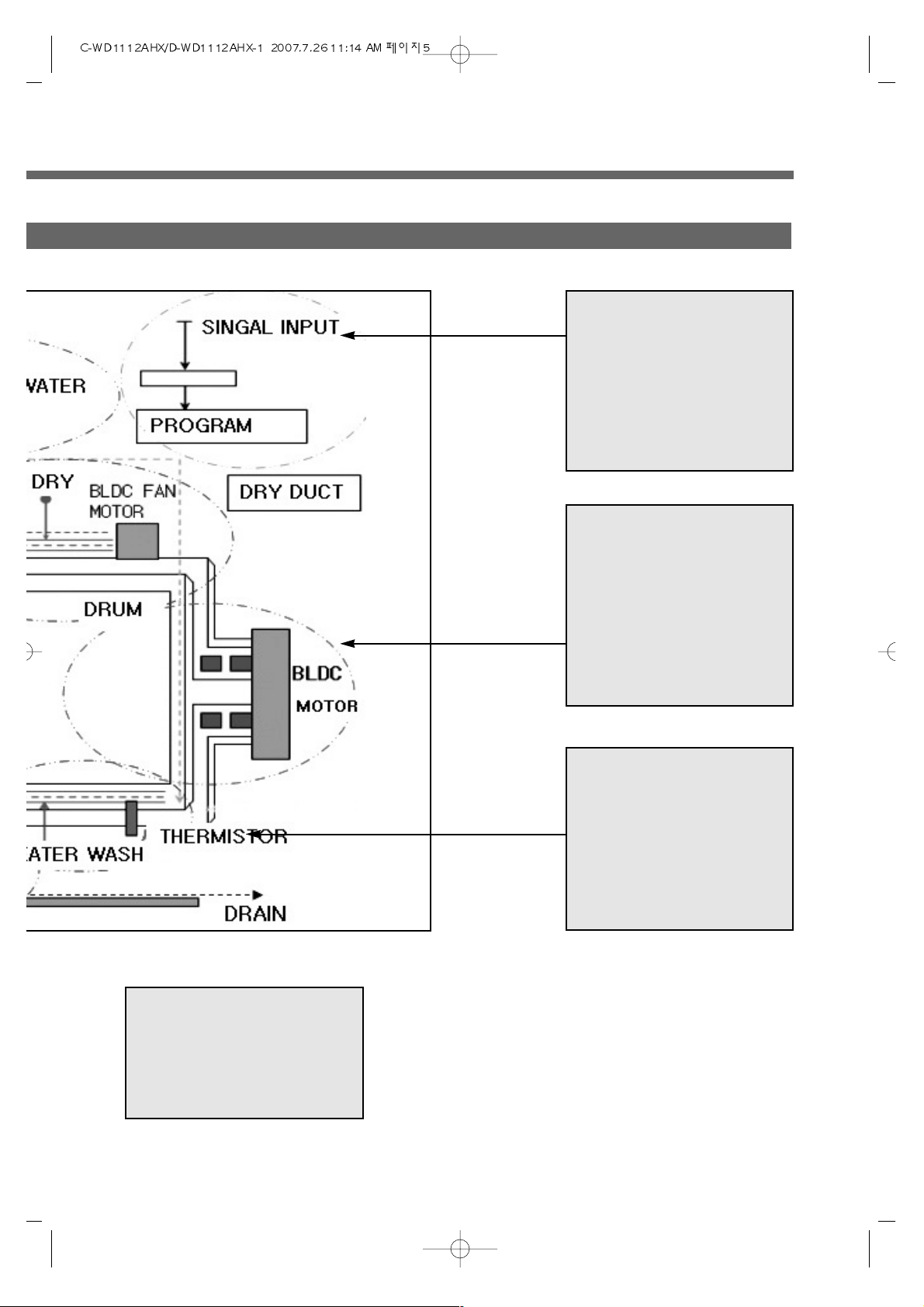

• DD CONTROL : DIRECT DRIVE TYPE

• BLDC MOTOR

3. THE DRIVE SYSTEM OF DRUM WASHING MACHINE

TUB

DRUM

LIFTER

WASH

BLDC

DRAIN

PUMP

4. DRIVE SYSTEM

4

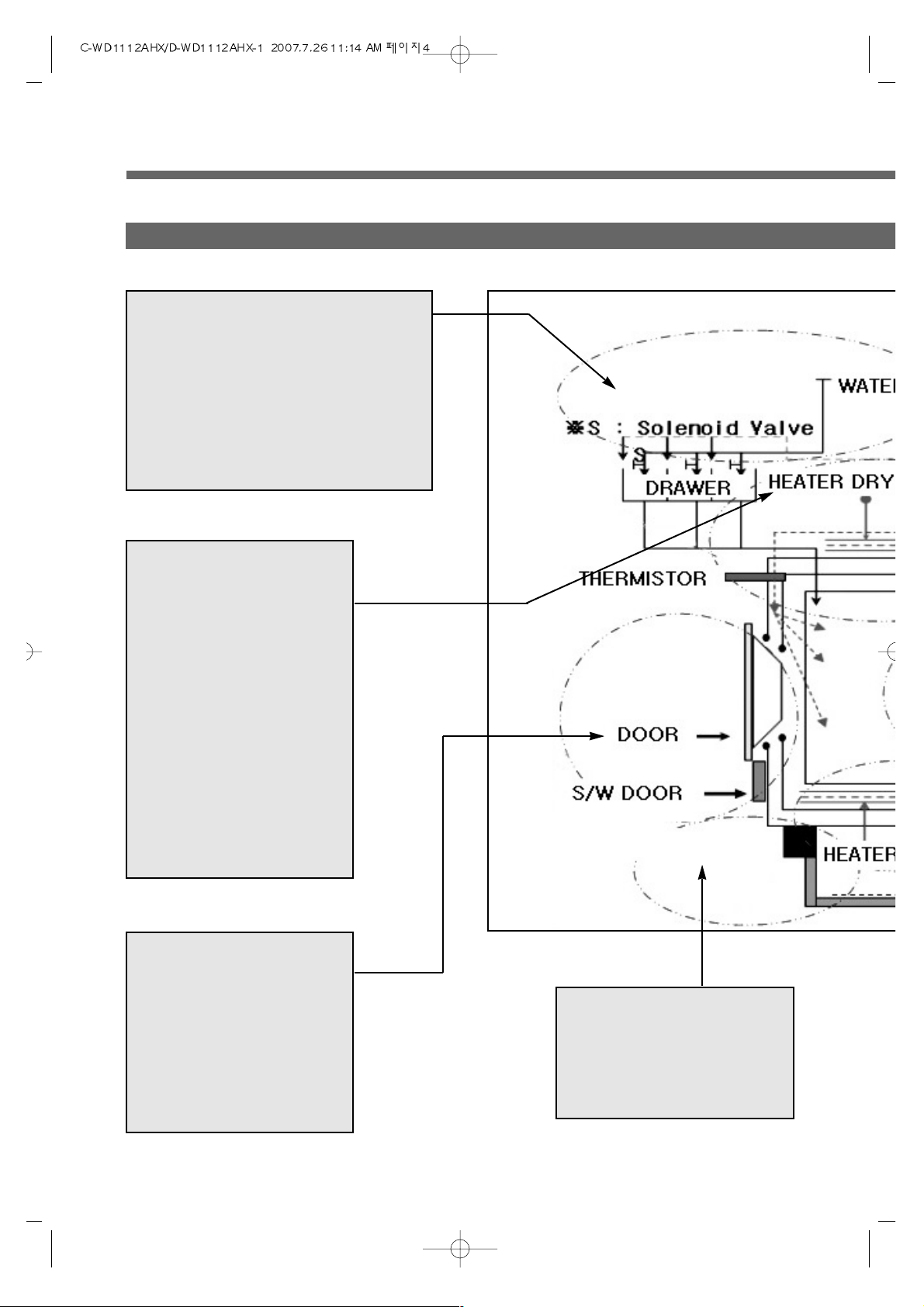

3. INLET PARTS

•COMBO

- COLD : 3-WAY (COLD, PREWASH, DRY)

- HOT : 1-WAY

•WASHER

- COLD : 2-WAY (COLD, PREWASH)

- HOT : 1-WAY

5. DOOR부

•DOOR LOCK S/W

: WATER ADDING

FUNCTION

•LOCK HINGE

•DOOR AS : GLASS

•GASKET

7. DRAIN PARTS

•DRAIN PUMP

•VALVE HOUSING

•DRAIN HOSE I

6. DRY PARTS

• HEATER DRY : 1300W

• BLOWER FAN

• FAN MOTOR : BLDC

• THERMISTOR

• THERMOSTAT

: FUSE, BI-METAL

• CONDENSING SYSTEM

• DRY FAN DRIVE

-` GENERATION OF

HEATER’S HEAT

-` TEMP. SENSOR

DRAIN PARTS

5

1. CONTROLLER

•MAIN PCB

•FRONT PCB

•HARNESS

•NOISE FILTER

•POWER CORD : 13A

2. DRIVE PARTS

•BLDC MOTOR

•DRUM

•BEARING

•SPIDER/SHAFT

•TUB

•WEIGHT BALANCER

4. WASH HEATING

•WASH HEATER : 1000W

•THERMISTOR

8. SUPPORTER

•BASE

•DAMPER AS : 4(70N)

6

2. SPECIFICATION OF DRUM WASHING MACHINE

1. PANEL TYPE 1

DIMENSION(WxDxH) 686mm(W) x 807mm(D) x 1020mm(H)

MACHINE WEIGHT 96 ㎏

POWER SOURCE 120V / 60Hz

POWER WASHING 10 A

CONSUMPTION DRY 11.5 A

WASHING TYPE DRUM TYPE

DRY TYPE Digital condensing dry system

OPERATION WATER PRESSURE 29kPa ~ 784kPa(0.3㎏f/cm2~8㎏f/cm2)

7

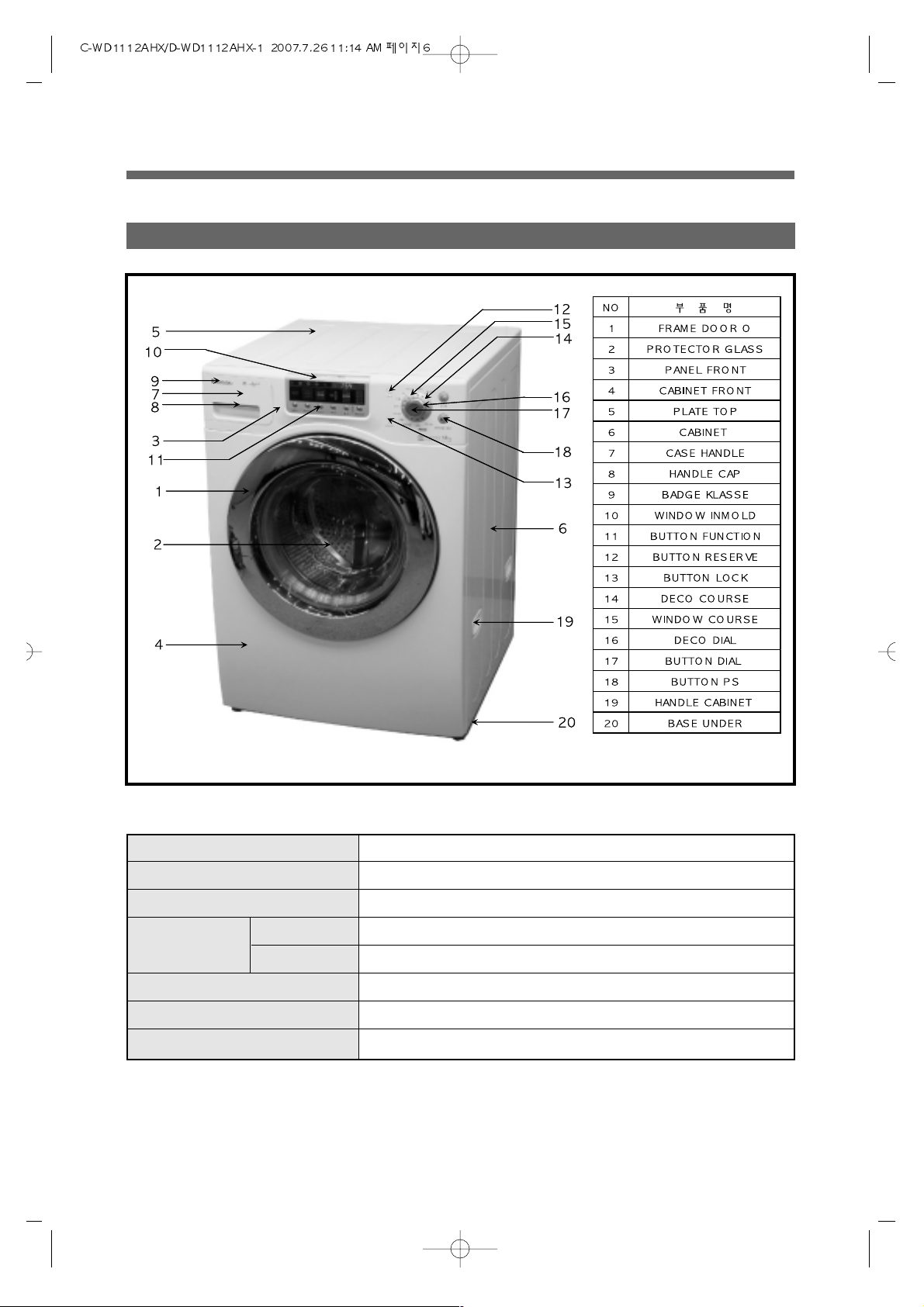

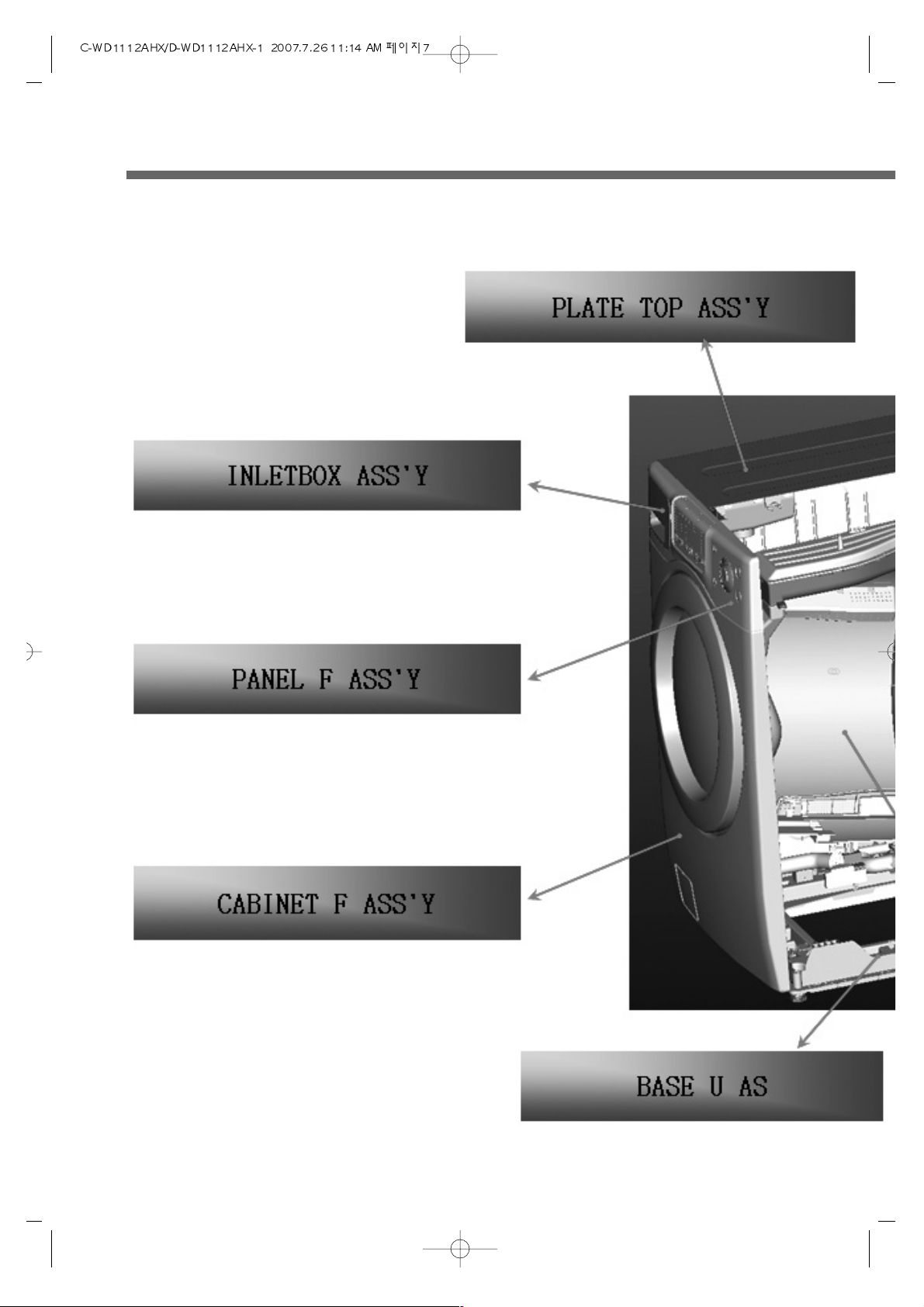

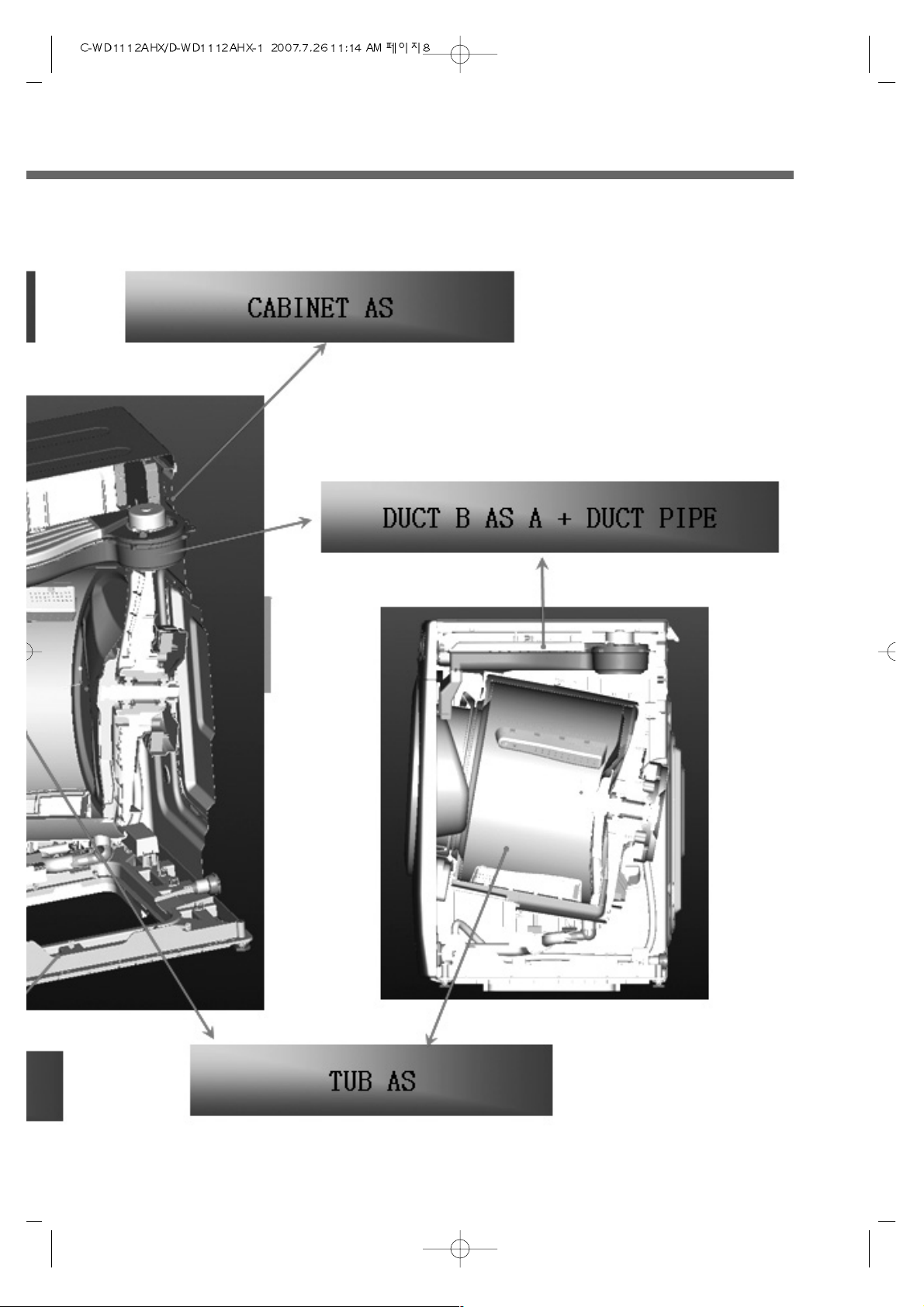

3. VERIFICATION OF DRUM ASSY

8

9

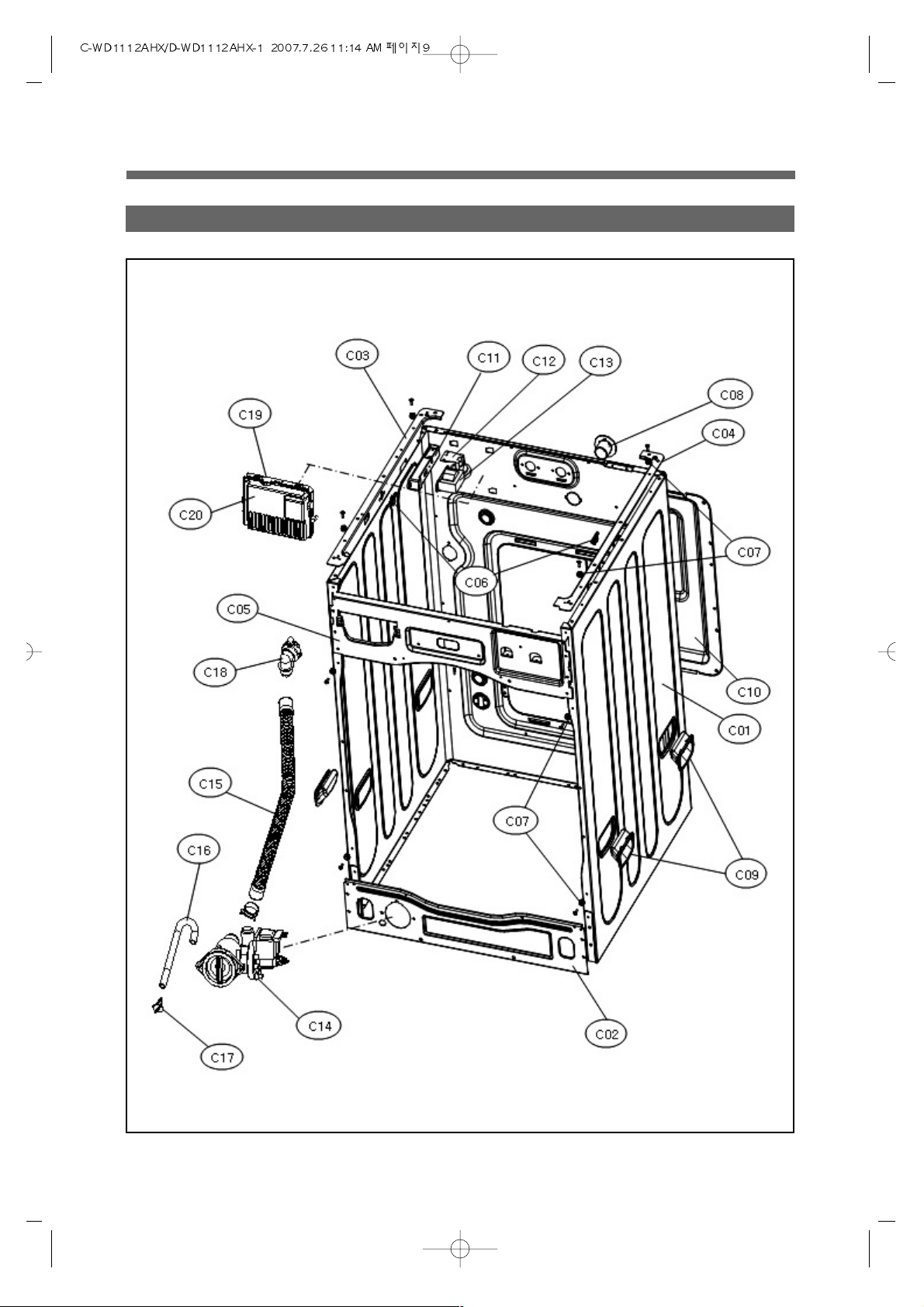

1. THE EXPLODED VIEW OF CABINET ASSEMBLY

4. PARTS LIST FOR EACH ASSY

10

No. PARTS NAME PARTS CODE DESCRIPTION UNITS REMARK

C01 CABINET 3610811730 SGCC 0.8T, PUMP COMBO 1

C02 FRAME LOWER 3612206700 SBHG 1.2T 1

C03 FRAME TOP L 3612206500 SGCC 1.6T 1

C04 FRAME TOP R 3612206600 SGCC 1.6T 1

C05 FRAME UPPER 3612206400 SBHG 1.2T 1

C06 STOPPER SPRING 3615202200 POM 2

C07

FIXTURE PLATE 3612008000 POM 8

SCREW TAPPING 7121401211 T2S PAN 4X12 MFZN 8

C08 NOZZLE AIR 3618103110 PP 1

C09 HANDLE CABINET 3612608100 PP 2

C10 COVER BACK AS 3611425510 COVER B + PAD CABINET 1

C11

C12 SENSOR PRESSURE 3614825220 DWD-130RP 1

C13 REACTOR 52G043A110 UL L=150MM 1 BASE U

C14 UNIT DRAIN PUMP AS 36189L5600 PUMP+FILTER 1

C15 HOSE DRAIN I AS 3613271200 PUMP HOSE 1

C16 HOSE WATER REMAIN 3613271400 EPDM 1

C17 CAP WATER REMAIN 3610916800 PP 1

C18 GUIDE DRAIN HOSE 3612510400 PP 1

C19 PCB AS

PRPSSWAD02 USA COMBI, UL 1 COMBO

PRPSSWAD03 USA WASHER, UL 1 WASHER

C20 COVER PCB M 3611427700 UL,ABS VE-0856, MAIN PCB 1

11

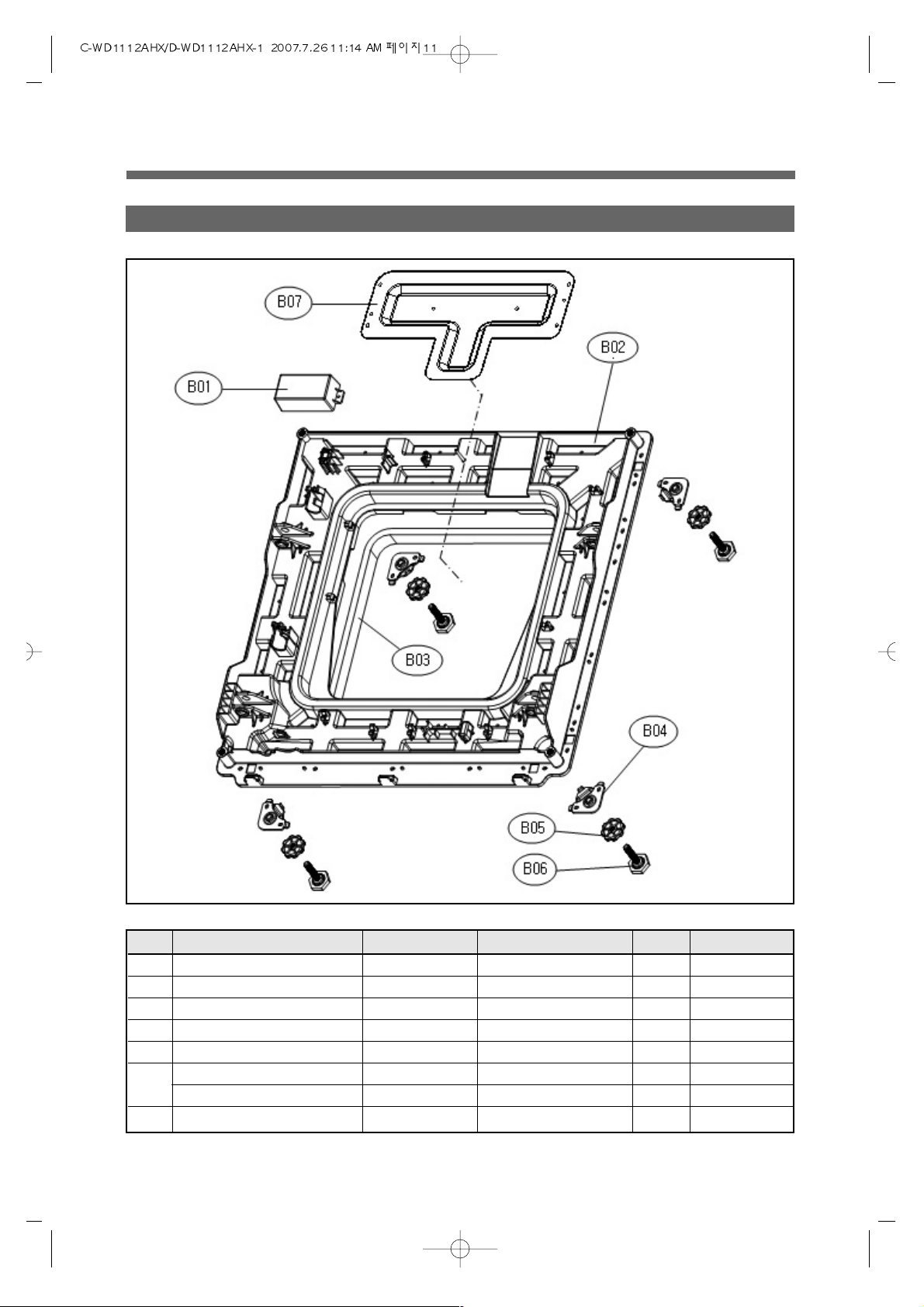

2. THE EXPLODED VIEW OF BASE U ASSEMBLY

No. PARTS NAME PARTS CODE DESCRIPTION UNITS REMARK

B01 EMI FILTER 3611908700 DWLF-K23 1

B02 BASE U 3610392700 PP 1

B03 ABSORBER BASE 3610115400 PEM, 12X1500, 25T 1

B04 SUPPORTER LEG 3615303600 3.0T 4

B05 FIXTURE LEG 3612006400 ABS, DWD-100DR 4

B06

FOOT 3612100600 BUTYL, DWD-100DR 4

SPECIAL BOLT 3616029000 10 X 1.25, 51MM 4

B07 PROTECTOR HEATER 3618304600 SECC 0.35T 1

12

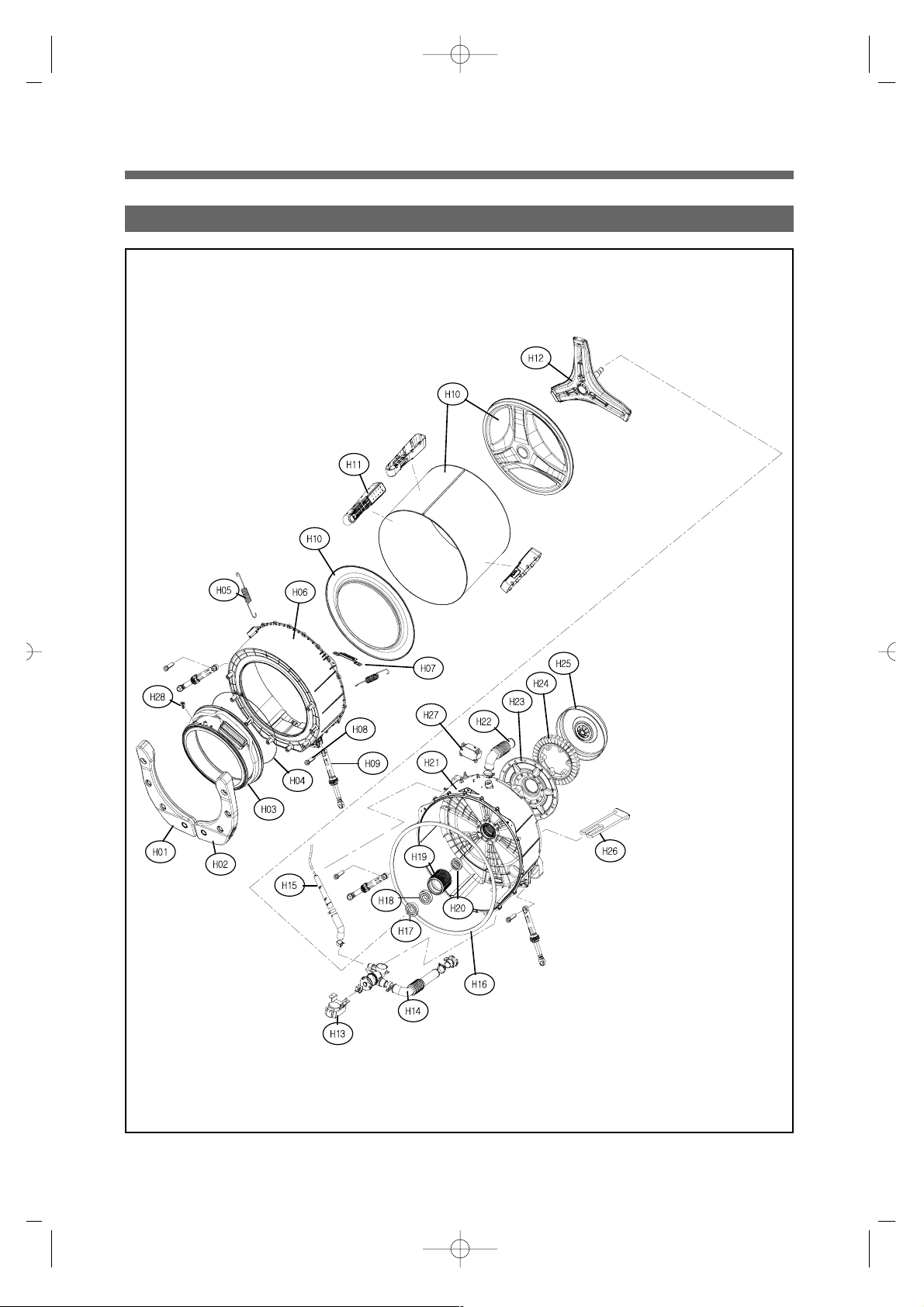

3. THE EXPLODED VIEW OF TUB ASSEMBLY

13

No. PARTS NAME PARTS CODE DESCRIPTION UNITS REMARK

H01

BALANCER WEIGHT AS(L)

3616106900 13KG DRUM 1

H02

BALANCER WEIGHT AS(R)

3616106800 13KG DRUM 1

H03 GASKET

3612321900 EPDM 1 COMBO

3612322000 EPDM 1 WASHER

H04 CLAMP GASKET AS 3611205300 WIRE 1

H05 SPRING SUSPENSION 3615114800 13KG DRUM 2

H06 TUB FRONT 3618828Y00 FRPP 1

H07 FIXTURE HEATER 3612006700 SUS 1

H08 DAMPER PIN 361A700200 AKS D=14.5 4

H09 DAMPER FRICTION 361A700110 70N AKS ST=170-260 DL=197.5 4

H10 DRUM AS 3617008X00 SUS 1

H11 LIFT AS 361A400510 NON-NANO, SUS FILTER 3

H12 SPIDER AS 361A300600 ALDC+S45C 1

H13 - - - -

H14 HOSE DRAIN 3613269000 EPDM,PUMP 1

H15 AIR TRAP AS 3610AAR600 HOSE+TRAP 1

H16 GASKET TUB 3612321100 EPDR FORM 1

H17 WATER SEAL 361A600200 NBR 1

H18 BEARING INNER 3616303800 6306DD 1

H19 BEARING HOUSING 3616303700 ALDC 1

H20 BEARING OUTER 3616303900 6305DD 1

H21 HOSE AIR 3613266300 EPDM 1

H22 BASE 3610392600 SESEN 1

H23 UNIT STATOR BLDC 36189L4840 Φ265X30H,36SLOT,2SNESOR,WS2A30G001 1

H24 UNIT ROTOR BLDC 36189L4900 MAGNET24,SERRATION,WR1238F001 1

H25 HEATER WASH 3612801740

UL.120V1.0KW6.7W/SQ.SUS.1R3A515003.L/W.

1

H26 - - - -

14

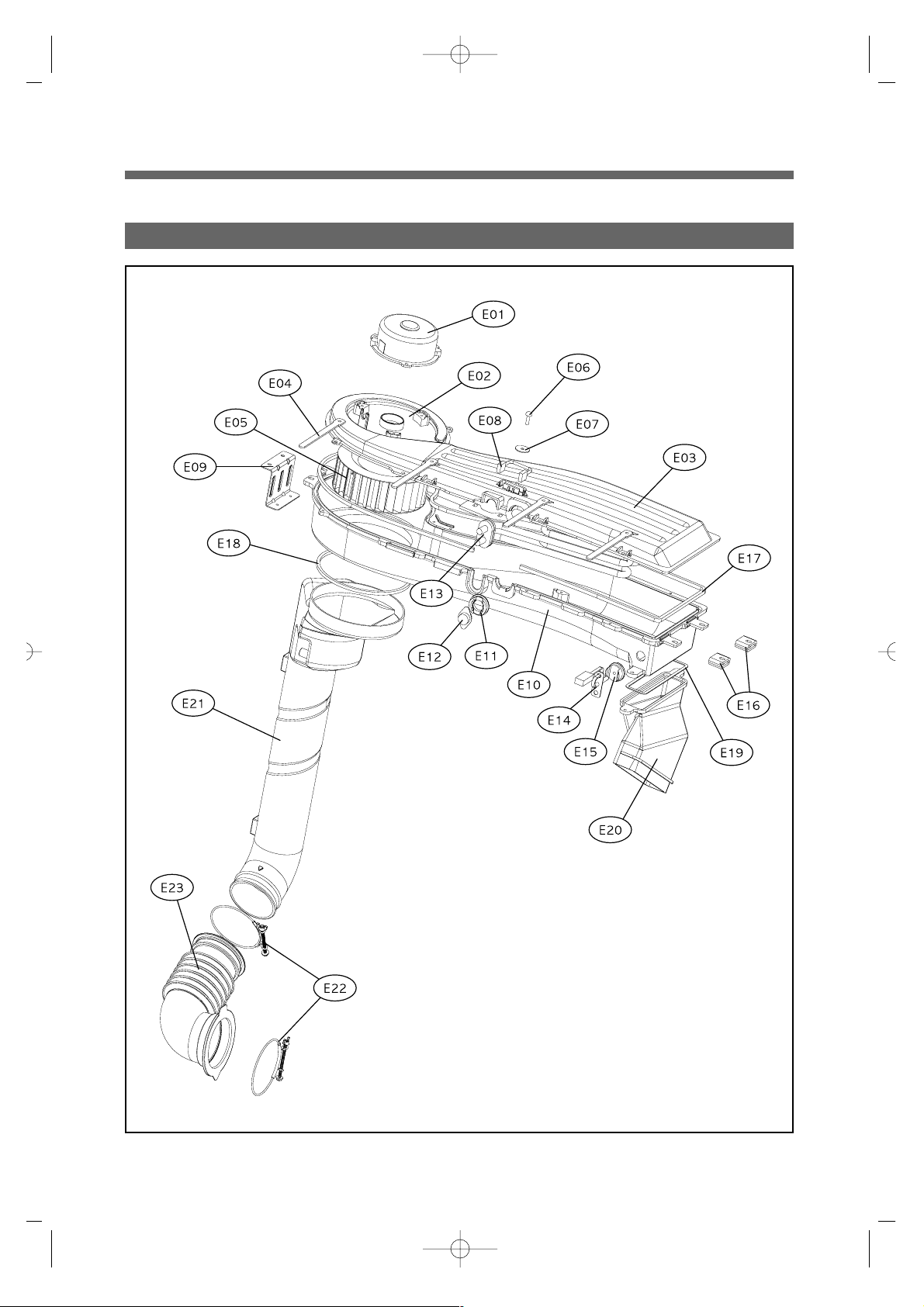

4. THE EXPLODED VIEW OF DUCT B AS AND DUCT PIPE ASSEMBLY

15

No. PARTS NAME PARTS CODE DESCRIPTION UNITS REMARK

E01 UNIT FAN MOTOR 36189L3Z10 ISM-77806DWWA 24V CW 8P 14W 1

E02 DUCT COVER 361A200400 AL, 2.5T 1

E03 DUCT B UPPER AS 361A200670 ALCOSTA UPPER, NON-COATING 1

E04 CLAMP CORD 3611203330 DABE-2 A=9 B=5.3 L=105 4

E05 FAN AS 3611885900 D133 FAN, GFPP30% _- NYLON66 1

E06 SCREW TAPPING 7122400811 T2S TRS 4x8 MFZN 1

E07 WASHER PLAIN 7400432011 PW 4.3*20*1T 1

E08 FUSE TEMPERATURE 361A800170 128℃,DF-128S,15A,250V,VDE 1

E09

FRAME HEATER FRANGE

3612206200 SBHG 1

E10 DUCT B LOWER 361A200101 AL, 3T 1

E11 PACKING THERMOSTAT 3614009900 SILICON 1

E12 SWITCH THERMOSTAT 3619047400 UL,150ON-120OFF,125V/15A,250V/10A 1

E13 HEATER DRY 3612802200

120V/1.3KW_12OHM3.5W/SQ.INCOLOY800.RA8.1R3A034008

1

E14 THERMISTOR DRY 361AAAAC10 UL APPROVED.R40=26.065K.R90=4.4278K 1

E15 PACKING RUBBER 3614009800 SILICON 1

E16 CUSHION DRY 3611562800 NBR 2

E17 GASKET SEAL B 3612320810 EPDM FOAM, L=412, 4.9*4.4*4.8 1

E18 GASKET SEAL A 3612320820 Φ5,L=1385 1

E19 GASKET INLET 3612320900 DWD-100DR 1

E20 DUCT GUIDE 361A201700 ALDC 1

E21 DUCT PIPE AS 361A201400 13KG 1

E22 CLAMP AS(DUCT) 3611203700 DUCT 1

E23 BELLOWS DUCT 3616403000 EPDM 1

16

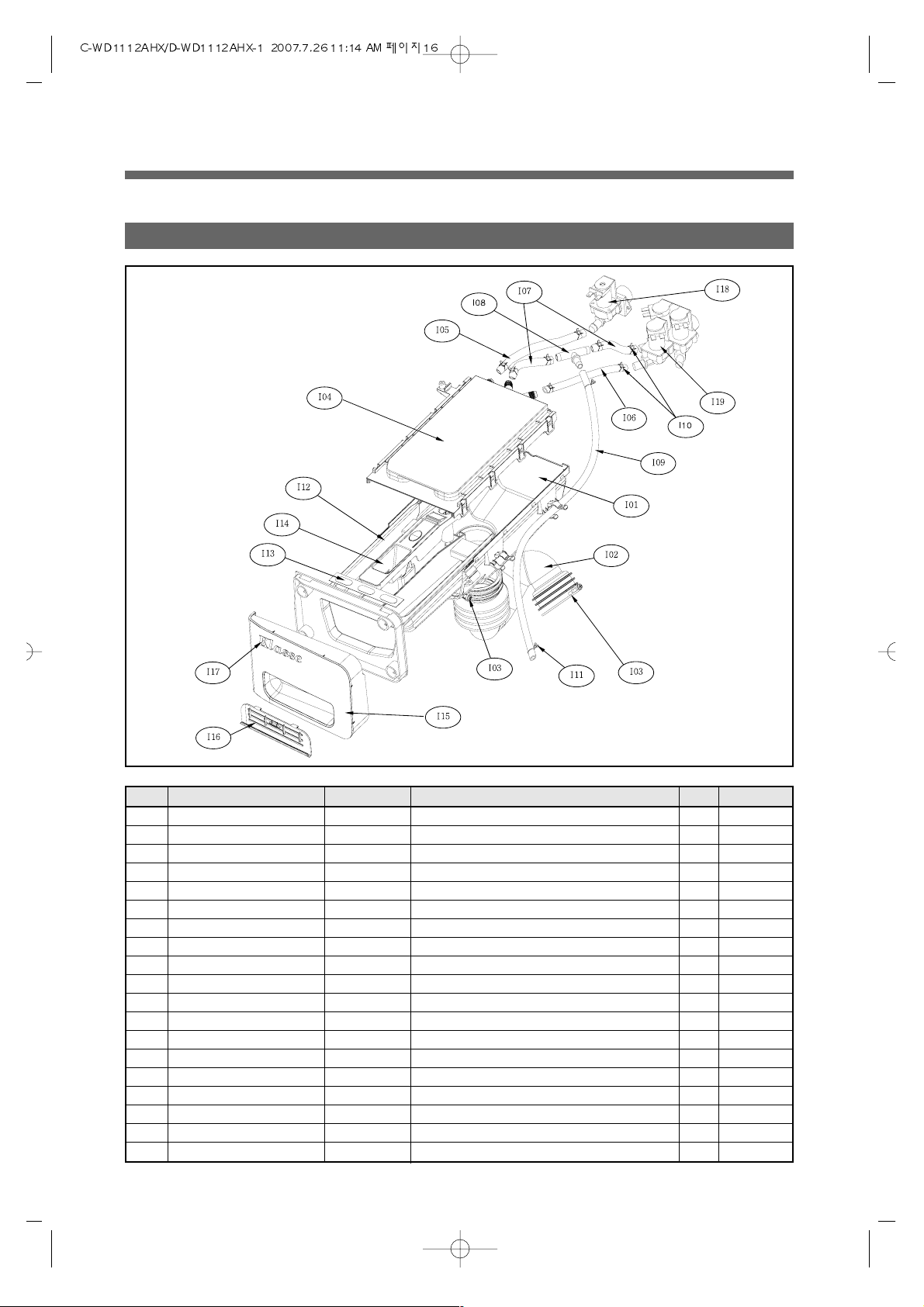

5. THE EXPLODED VIEW OF INLET BOX ASSEMBLY

No. PARTS NAME PARTS CODE DESCRIPTION UNITS REMARK

I01 INLET BOX 3617505800 ABS 1

I02 HOSE INLET 3613270300 EPDM 1

I03 CLAMP AS 3611203200 ID=60, WIRE+GUIDE+BOLT+NUT 2

I04 NOZZLE AS 3618103500 PP 1

I05 HOSE HOT 3613270400 EPDM, ID=10, OD=16, L=460mm 1

I06 HOSE MAIN 3613270500 EPDM, ID=10, OD=16, L=410mm 1

I07 HOSE C 3613267020 EPDM, ID=10, OD=16, L=230mm 2

I08

PIPE JOINT(HOSE INLET)

3614413300 PP 1

I09 HOSE SHOWER 3613270110 EPDM, L=590mm 1

I10 CLAMP SPRING 3611203800 ID=15.5, T=0.6, B=10 8

I11 CLAMP 4507D08152 HOSE ID=7 2

I12 CASE DETERGENT 3611141800 ABS 1

I13

I14 CAP SOFTENER 3610917200 PP 1

I15 CASE HANDLE 3611141700 ABS 1

I16 HANDLE CAP 3612609100 ABS 1

I17

I18 VALVE INLET 3615416700 UL.120V60HZ.BITRON.1WAY 1

I19 VALVE INLET 3615416900 UL.120V60HZ.BITRON.3WAY 1

Loading...

Loading...