Daewoo C-ED1212LHS, C-ED1212SHS Service Manual

S/M No. : ED12120001

Service Manual

Washing Machine

Model :

C-ED1212LHS, C-ED1212SHS (BRAZIL ELECTROLUX ONLY)

Caution

:In this Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service Information Center (http://svc.dwe.co.kr).

Mar. 2011

DRUMWASHINGMACHINE

SERVICEMANUAL

1. WHAT IS DRUM?.......................................................................... |

2 |

2. SPECIFICATION OF DRUM WASHING MACHINE .................... |

6 |

3. VERIFICATION OF DRUM ASSY ................................................ |

7 |

4. PARTS LIST FOR EACH ASSY.................................................... |

8 |

5. SEQUENCE CHART OF PCB..................................................... |

21 |

6. TROUBLE SHOOTING ............................................................... |

32 |

7. WIRING DIAGRAM .................................................................... |

48 |

8. TROUBLESHOOTING REGARDING DRAIN ............................. |

50 |

9. INSTALLATION GUIDE............................................................... |

51 |

10. ATTENTION POINT WITH SERVICE ....................................... |

53 |

1.WHAT IS DRUM ?

1.WHAT IS DRUM WASHER?

One of the famous washers in the globe which uses laundry falling energy.

2.Sales point of our washer

The biggest capacity with compact size

Environmently friendly washer with NANO technology

• Sterilizing up to 99.9%

No damage and entanglement but excellent washability

4way savings-noise, vibration, washing times, energy

Self-cleaning course of Drum

Good washing performance with heating system

Condensing dry system with saving energy

Sunshine dry effects with infrared x-ray

Big door glass with easy laundry take-in/out

The higest spin speed - 1200rpm

2

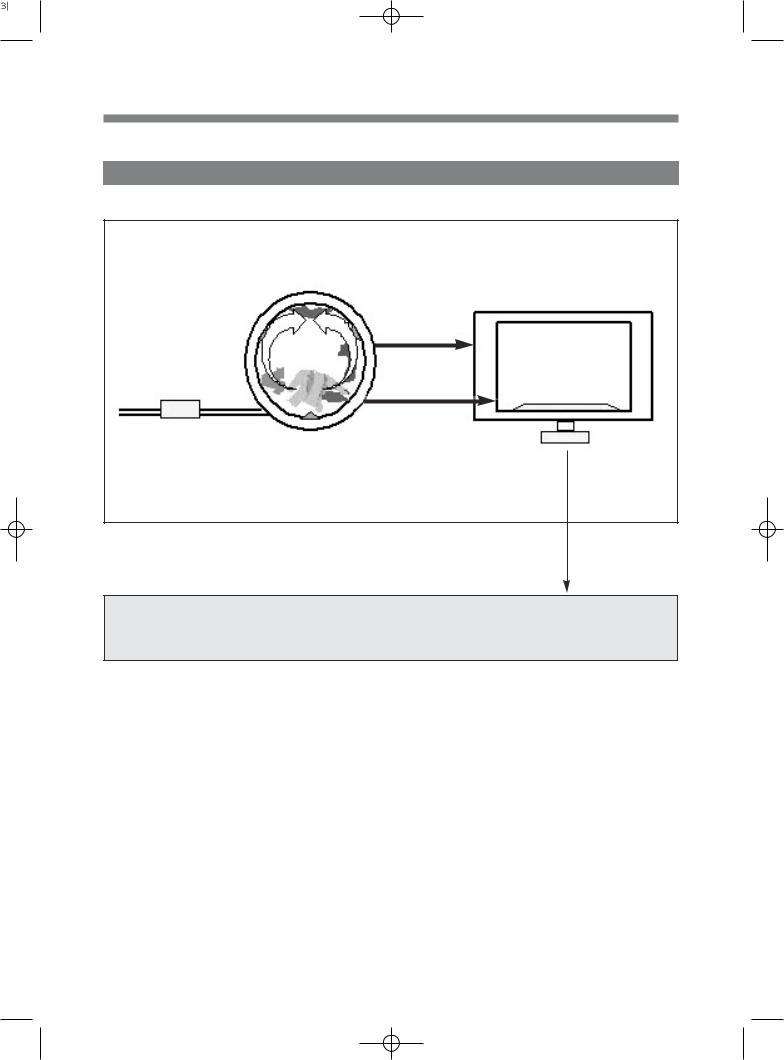

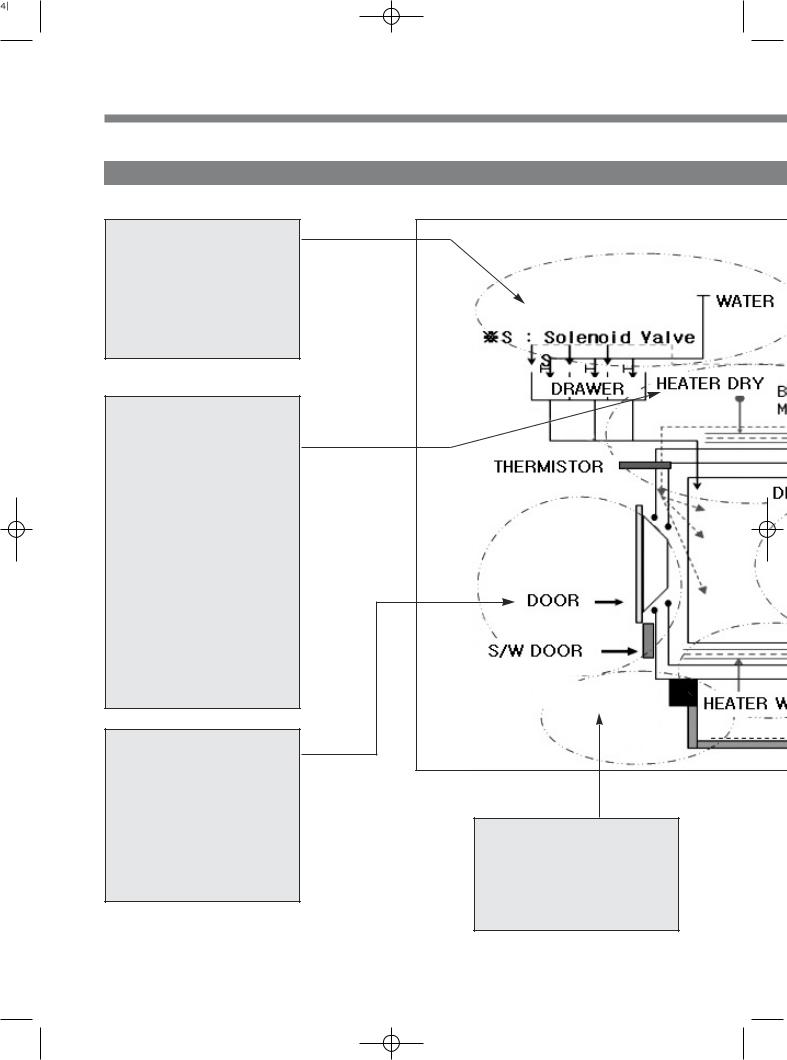

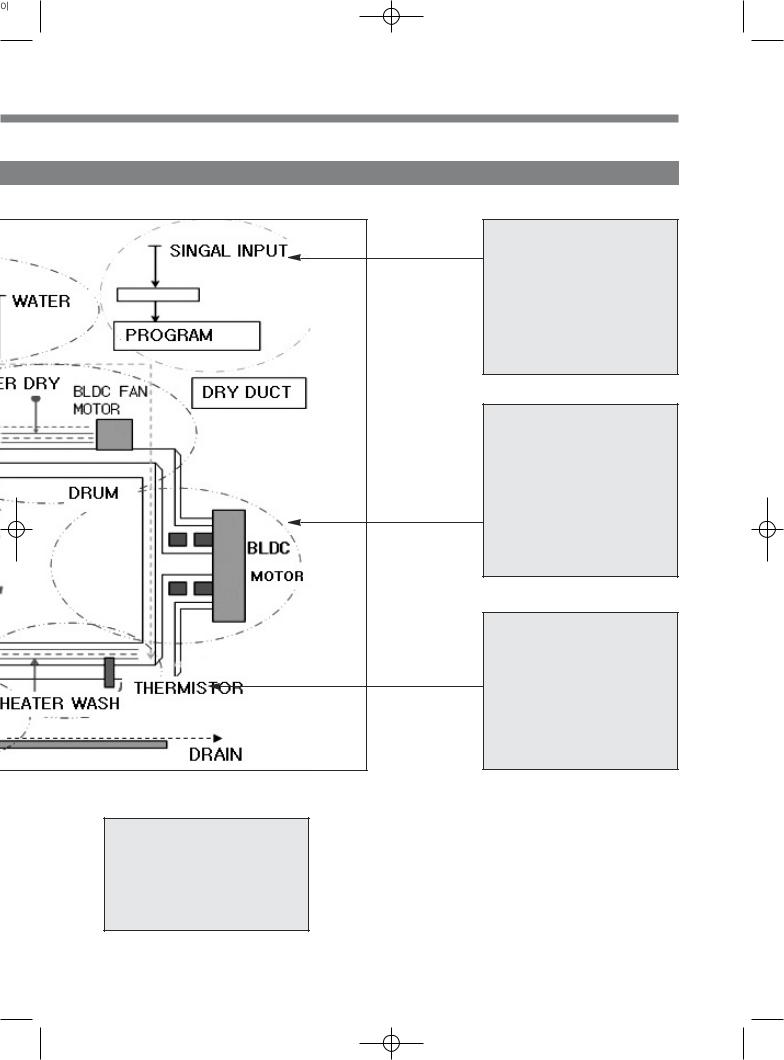

3. THE DIRECT DRIVE SYSTEM OF DRUM WASHING MACHINE

TUB

WASH

DRUM

DRAIN

PUMP LIFTER BLDC (MOTOR)

•DD CONTROL : DIRECT DRIVE SYSTEM

•BLDC MOTOR

3

4.DRIVE SYSTEM

3.INLET PARTS

• COLD : 3-WAY

-COLD, PREWASH, DRY

• COLD : 2-WAY

-COLD, PREWASH

6.DRY PARTS

•HEATER DRY : OPTION

•BLOWER FAN

•FAN MOTOR : BLDC

•THERMISTOR

•THERMOSTAT

: FUSE, BI-METAL

•CONDENSING SYSTEM

•DRY FAN DRIVE

→ GENERATION OF HEATER’S HEAT

→TEMP. SENSOR

→100°C OFF 90°C ON : OPTION

5.DOOR PARTS

•DOOR LOCK S/W

: ADDING CLOTHES

•LOCK HINGE

•DOOR AS : GLASS

•GASKET

DRAIN PARTS

7.DRAIN PARTS

•DRAIN PUMP(MOTOR)

•VALVE HOUSING

•DRAIN HOSE I

4

8.SUPPORTER

•BASE

•DAMPERAS:3(70N)

1.CONTROLLER

•MAIN PCB

•FRONT PCB

•HARNESS

•NOISE FILTER

•POWER CORD : 15A

2.DRIVE PARTS

•BLDC MOTOR

•DRUM

•BEARING

•SPIDER/SHAFT

•TUB

•WEIGHT BALANCER

4.WASH HEATING

•WASH HEATER : OPTION

•THERMISTOR

•40°C FIXED TEMP. CONTROL : OPTION

•60°C, 90°C BOIL

4

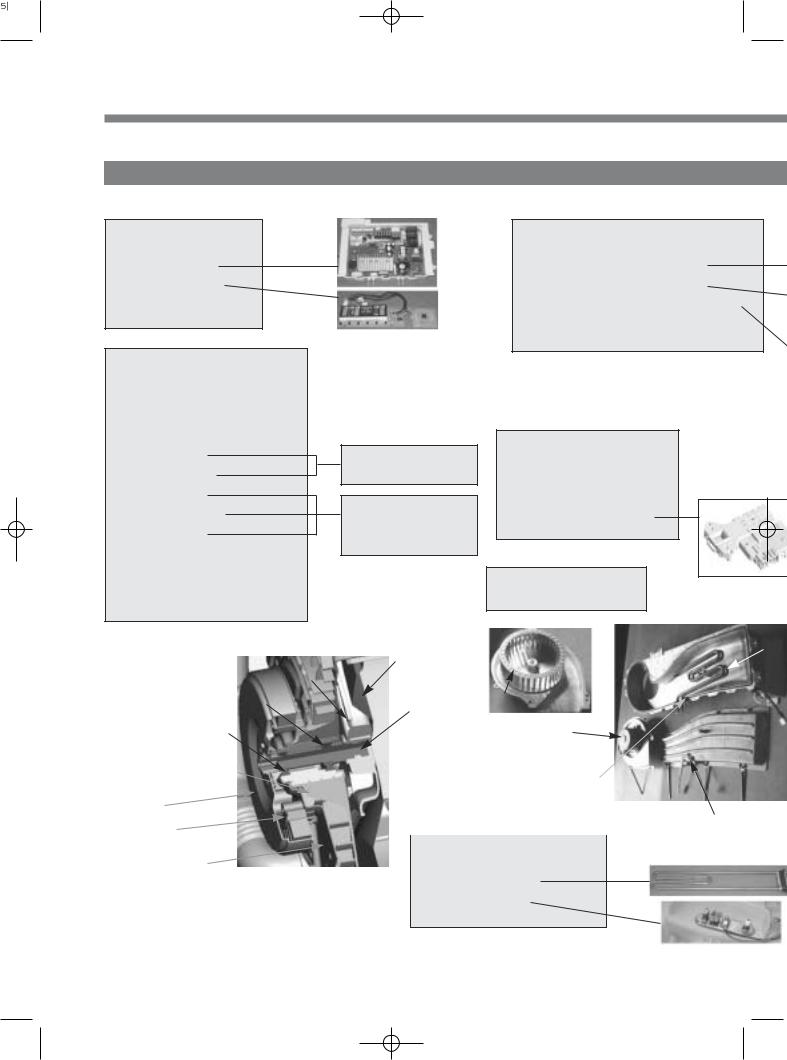

5.FUNCTION

1.CONTROLLER

(1-1) MAIN PCB (1-2) FRONT PCB (1-3) NOISE FILTER

2. PARTS for DRIVING

(2-1) LIFTER AS

(2-2) GASKET

(2-3) WEIGHT BALANCER (2-4) ROTOR

(2-5) STATOR

(2-6) SHAFT (2-7) BEARING (2-8) SPIDER (2-9) DRUM (2-10) TUB (2-11) BASE

BLDC MOTOR

PARTS for TRANMITTING

3. INLET PARTS

(3-1) 3-WAY INLET VALVE (3-1) 2-WAY INLET VALVE

(3-2) 1-WAY INLET VALVE (HOT) (3-3) INLET BOX AS

4. DOOR AS

(4-1) GLASS DOOR (4-2) HINGE DOOR (4-3)DOOR LOCK S/W

5. DRY : DUCT B AS

|

|

(2-9) |

|

• HEATER DRY |

|

|

|

|

|

||

|

|

(2-8) |

|

|

|

|

(2-7) |

(2-6) |

• FAN |

|

|

|

|

|

|||

|

|

|

|

||

(2-7) |

|

|

|

• FAN |

|

|

|

|

|

MOTOR |

|

(2-10) |

|

|

|

• BI-METAL |

• TEMP. |

|

|

|

|

SENSOR |

|

(2-4) |

|

|

|

S/W |

|

(2-5) |

|

|

|

|

• TEMP. FUSE |

(2-11) |

|

|

6. WASH HEATING |

|

|

•WASH HEATER

•THERMISTOR

5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. DRAIN |

|

8. SUPPORTER |

|

|

|

(7-1) PUMP AS |

|

(8-1) BASE U |

|

|

|

(7-2) HOSE DRAIN I |

|

(8-2) DAMPER AS : 3(70N) |

|

(HOT) |

|

(7-3) HOSE DRAIN |

|

(8-3) SPRING : |

|

|

|

|

|

FRONT - 2 (BLACK) |

|

|

|

|

|

REAR - 2 (YELLOW) |

|

|

|

|

|

|

|

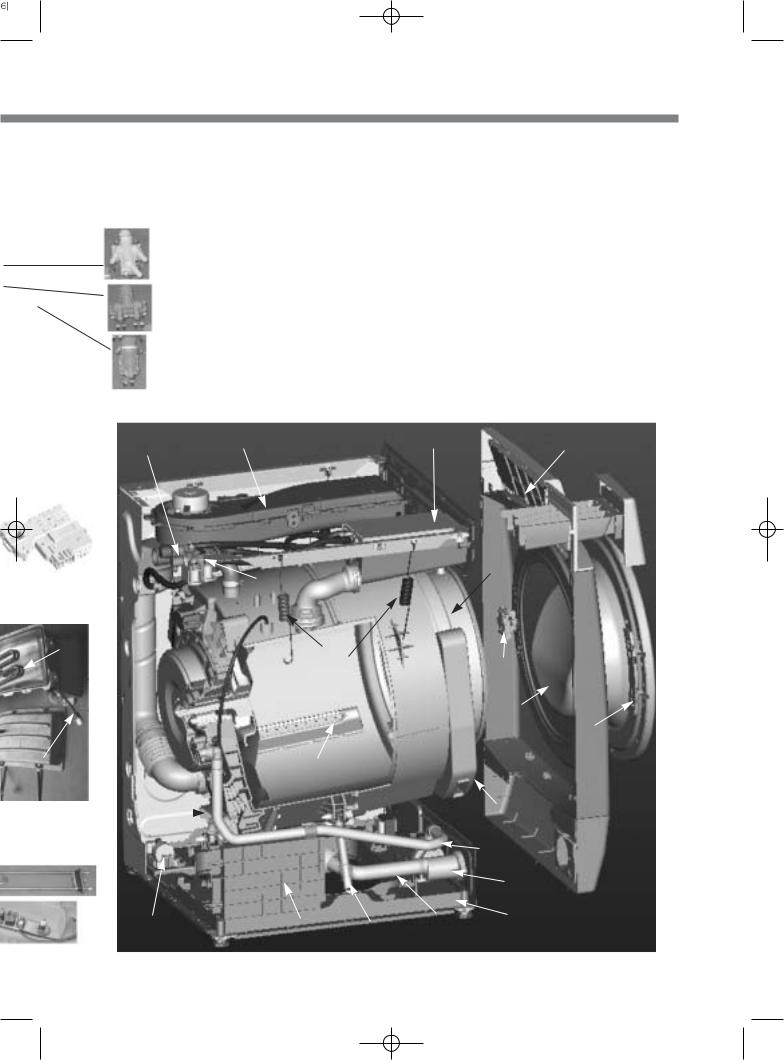

(3-2) |

(5) |

(3-3) |

(1-2) |

|

|

(3-1) |

|

(2-2) |

|

|

|

|

|

||

ATER DRY |

|

|

|||

(8-3) |

|

|

|||

|

|

|

(4-3) |

||

|

|

|

|

|

|

|

|

|

|

|

(4-1) |

|

|

|

|

|

(4-2) |

• TEMP. |

(2-1) |

|

|

||

SENSOR |

|

|

|

|

|

(6) |

|

|

|

(2-3) |

|

|

|

|

|||

MP. FUSE |

|

|

|

|

|

|

|

|

|

|

(7-2) |

|

|

|

|

|

(7-1) |

(1-3) |

(1-1) |

(8-2) |

(8-1) |

||

(7-3) |

|||||

5

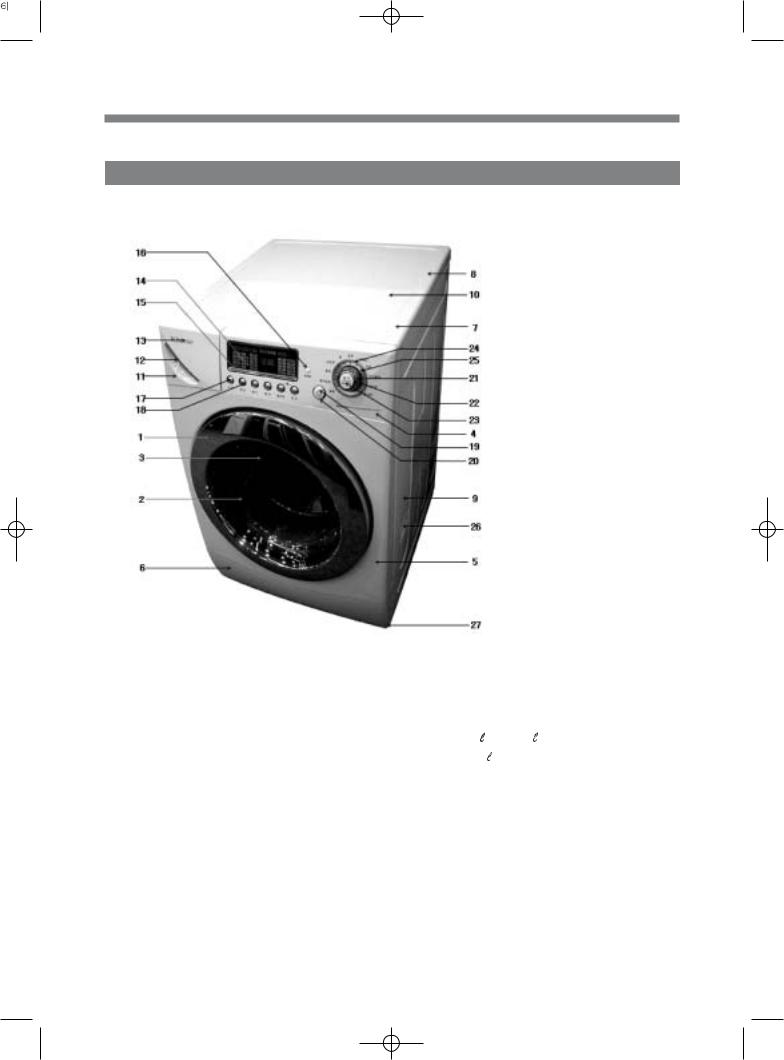

2.DRUM WASHING SPECIFICATION OF MACHINE

1.PANEL TYPE 1

|

|

|

|

|

|

|

|

|

|

|

NO |

PARTS NAME |

|

|

|

|

|

1 |

FRME DOOR O |

|

|

|

|

|

2 |

DOOR WINDOW |

|

|

|

|

|

3 |

DCD STICKER |

|

|

|

|

|

4 |

PANEL LOWER |

|

|

|

|

|

5 |

CABINET FRONT |

|

|

|

|

|

6 |

PANEL LOWER |

|

|

|

|

|

7 |

FRAME TOP F |

|

|

|

|

|

8 |

FRAME TOP R |

|

|

|

|

|

9 |

CABINET |

|

|

|

|

|

10 |

PLATE TOP |

|

|

|

|

|

11 |

CASE HANDLE |

|

|

|

|

|

12 |

HANDLE CAP |

|

|

|

|

|

13 |

BADGE |

|

|

|

|

|

14 |

WINDOW DISPLAY |

|

|

|

|

|

15 |

DECO. WINDOW |

|

|

|

|

|

16 |

BUTTON DOOR UNLOCK |

|

|

|

|

|

17 |

BUTTON FUNCTION |

|

|

|

|

|

18 |

DECO. FUNCTION |

|

|

|

|

|

19 |

PLATE DISPENSER |

|

|

|

|

|

20 |

BUTTON POWER |

|

|

|

|

|

21 |

BUTTON DIAL OUT |

|

|

|

|

|

22 |

BUTTON DIAL IN |

|

|

|

|

|

23 |

BUTTON DIAL IN |

|

|

|

|

|

24 |

HOLDER COURSE IN |

|

|

|

|

|

25 |

HOLDER COURSE OUT |

|

|

|

|

|

26 |

HANDLE CABINET |

|

|

|

|

|

27 |

BASE UNDER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIMENSION(WxDxH) |

|

630mm(W) x 755mm(D) x 950mm(H) |

|

|||

MACHINE WEIGHT |

|

90 / 85kg |

|

|

||

WATER CONSUMPTION |

WASH 130 / DRY 28 |

|

|

|||

WASHING CONSUMPTION |

32 |

|

|

|

||

POWER SOURCE |

|

Option |

|

|

||

POWER |

|

WASHING |

1100W (Heating ) ~ 2400W : Option |

|

||

CONSUMPTION |

|

DRY |

1250W ~2400W : Option |

|

|

|

|

|

WASHING |

11 kg (Domestic) |

|

|

|

CAPACITY |

|

SPIN |

11 kg (Domestic) |

|

|

|

|

|

DRY |

6.5 kg (Domestic) |

|

|

|

WASHING TYPE |

|

DRUM TYPE |

|

|

||

DRY TYPE |

|

Digital condensing dry system |

|

|

||

OPERATION WATER PRESSURE |

29kPa ~ 784kPa(0.3kgf/cm2~8kgf/cm2) |

|

||||

|

|

|

|

|

|

|

6

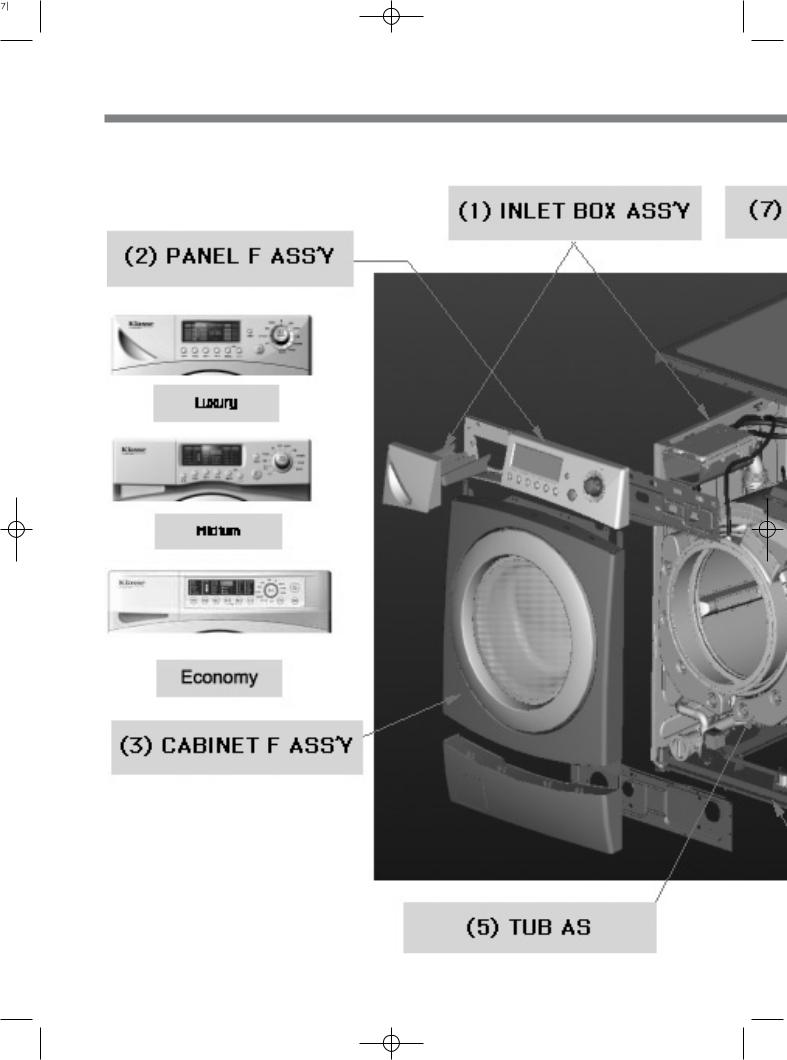

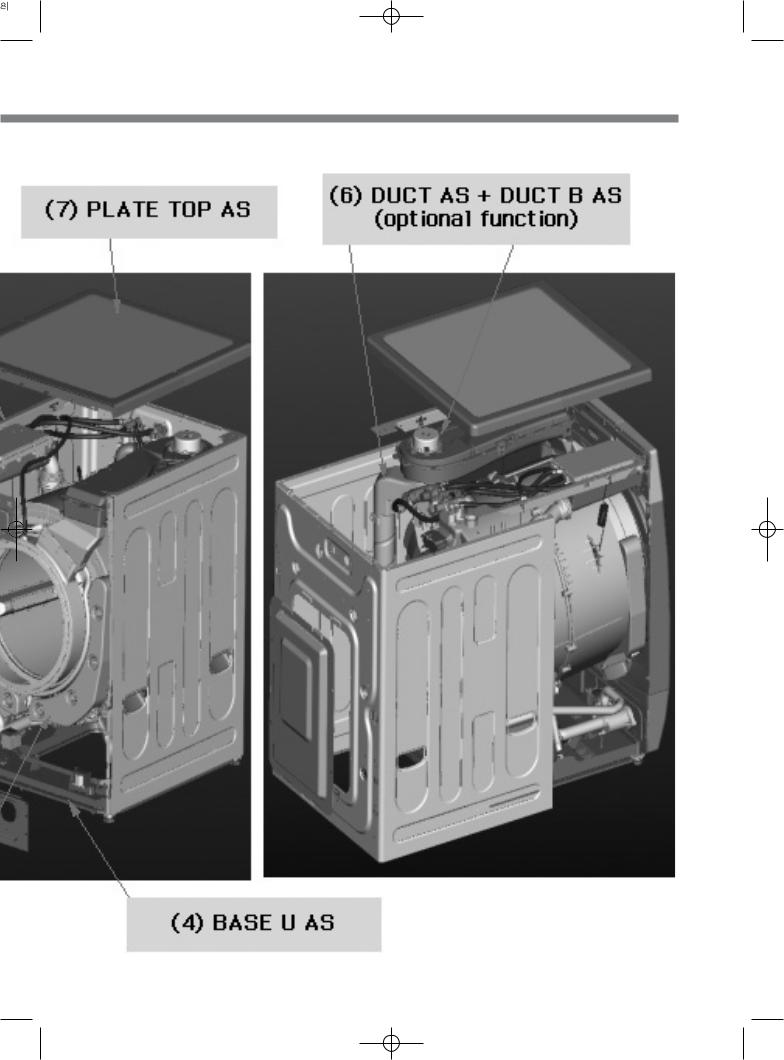

3. VERIFICATION OF DRUM ASSY

7

7

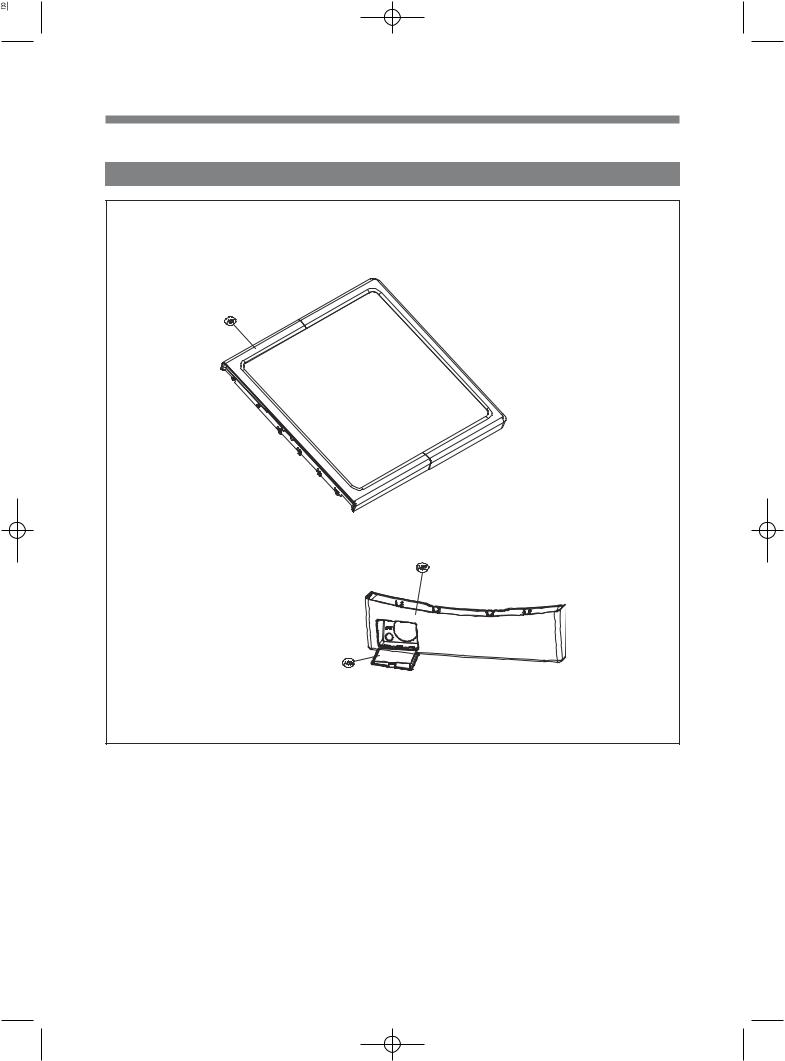

4.PARTS LIST FOR EACH ASSY

1.PLATE T, PANEL LOWER AS

PLATE T, PANEL LOW AS

No. |

PARTS NAME |

PARTS CODE |

DESCRIPTION |

Q’TY |

REMARK |

A01 |

PLATE TOP AS |

3614531820 |

DRUM 11KG |

1 |

|

|

|

|

|

|

|

A02 |

PANEL LOWER |

3614284200 |

HIPS,PUMP |

1 |

|

|

|

|

|

|

|

A03 |

COVER PUMP |

3611426400 |

HIPS,PUMP |

1 |

|

8

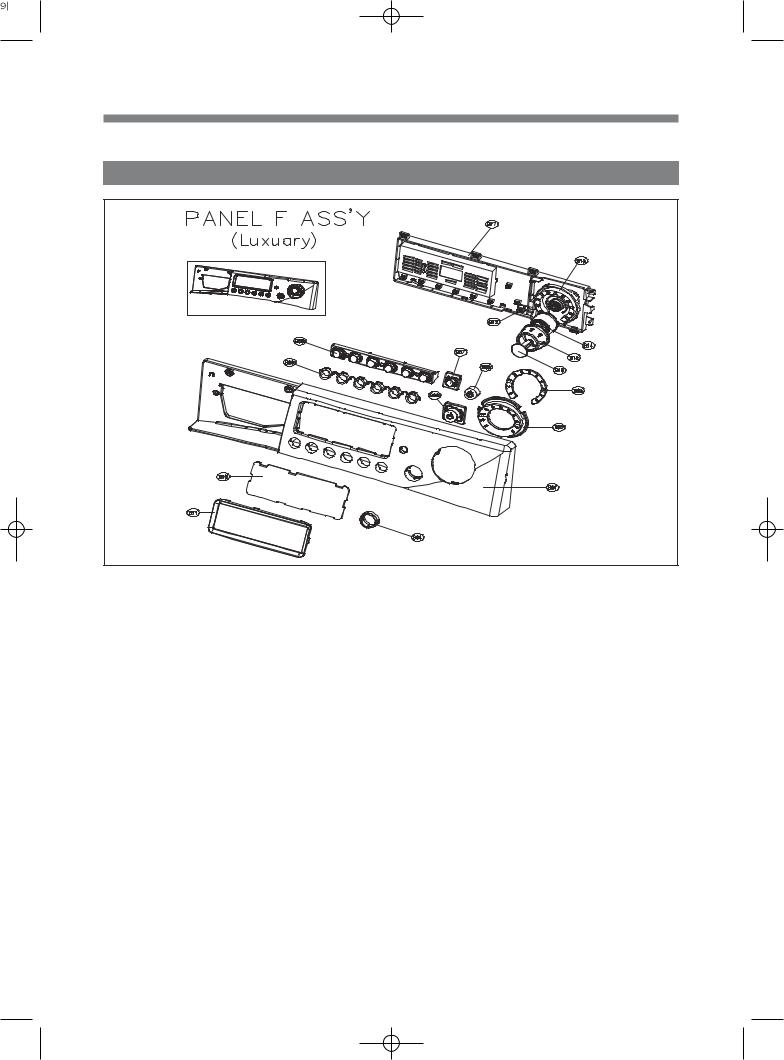

2. PANEL F AS(Luxury)

No. |

PARTS NAME |

PARTS CODE |

DESCRIPTION |

Q’TY |

REMARK |

B01 |

PANEL F |

3614282200 |

ABS |

1 |

|

|

|

|

|

|

|

B02 |

HOLDER COURSE OUT |

3613049000 |

ABS, GUILDING_BASE |

1 |

|

|

|

|

|

|

|

B03 |

HOLDER COURSE IN |

3613048900 |

ABS(TR558) |

1 |

|

|

|

|

|

|

|

B04 |

DECORATOR POWER |

3611631000 |

ABS, UV_BASE |

1 |

|

|

|

|

|

|

|

B05 |

BUTTON POWER IN |

3616602800 |

ABS |

1 |

|

|

|

|

|

|

|

B06 |

BUTTON POWER OUT |

3616602900 |

ABS(TR558) |

1 |

|

|

|

|

|

|

|

B07 |

BUTTON DOOR LOCK |

3616602600 |

ABS |

1 |

|

|

|

|

|

|

|

B08 |

DECORATOR FUNCTION |

3611630900 |

ABS, GILDING_BASE |

1 |

|

|

|

|

|

|

|

B09 |

BUTTON FUNCTION |

3616602700 |

ABS, UV_BASE |

1 |

|

|

|

|

|

|

|

B10 |

WINDOW DISPLAY |

3615502700 |

ABS(TR558) |

1 |

|

|

|

|

|

|

|

B11 |

DECORATOR WINDOW |

3611630800 |

ABS, GILDING_BASE |

1 |

|

|

|

|

|

|

|

B12 |

HOLDER |

3613048800 |

ABS(TR558) |

1 |

|

|

|

|

|

|

|

B13 |

HOLDER COURSE MAIN |

3613049100 |

ABS |

1 |

|

|

|

|

|

|

|

B14 |

BUTTON DIAL MIDDLE |

3616602400 |

ABS, GILDING_BASE |

1 |

|

|

|

|

|

|

|

B15 |

BUTTON DIAL OUT |

3616602500 |

ABS(TR558) |

1 |

|

|

|

|

|

|

|

B16 |

BUTTON DIAL IN |

3616602300 |

ABS, GILDING_BASE |

1 |

|

|

|

|

|

|

|

B17 |

PCB AS |

PRPSSW1D15 |

PUMP E1211 DRY |

1 |

220V |

|

|

|

|

|

|

|

|

PRPSSW1D18 |

HIGH, PUMP, DRY |

1 |

127V |

|

|

|

|

|

|

9

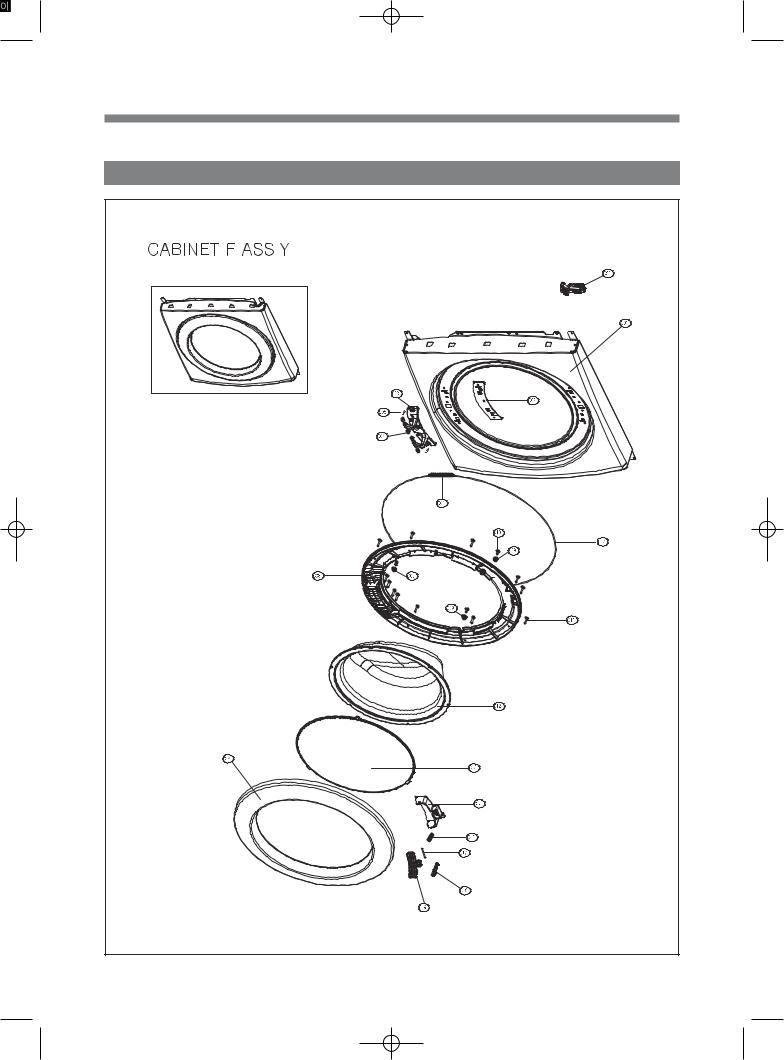

3. CABINET F AS

10 |

No. |

PARTS NAME |

PARTS CODE |

DESCRIPTION |

Q’TY |

REMARK |

C01 |

CABINET F |

3610811000 |

SECD, 0.8t |

1 |

|

|

|

|

|

|

|

C02 |

PLATE HINGE SUPPORT |

3614531550 |

1.2t |

1 |

|

|

|

|

|

|

|

C03 |

HINGE DOOR |

3612902700 |

ALDC |

1 |

|

|

|

|

|

|

|

C04 |

CAP HINGE DOOR |

3610916500 |

POM |

4 |

|

|

|

|

|

|

|

C05 |

SCREW TAPPING |

3616051229 |

STS430, F/L BOLT(SE) 5x12 |

3 |

|

|

|

|

|

|

|

C06 |

CLAMP DOOR AS |

3611203100 |

HWSR D1.8 |

1 |

|

|

|

|

|

|

|

C07 |

HOOK DOOR |

3613100700 |

Zn-DC |

1 |

|

|

|

|

|

|

|

C08 |

FLAME DOOR I |

3611204700 |

PP |

1 |

|

|

|

|

|

|

|

C09 |

STOPPER DOOR |

3615202300 |

PP |

3 |

|

|

|

|

|

|

|

C10 |

HANDLE DOOR |

3612608200 |

ABS |

1 |

|

|

|

|

|

|

|

C11 |

SCREW TAPPING |

7115402029 |

T1S FLT 4x20 SUS430 NATURAL |

15 |

|

|

|

|

|

|

|

C12 |

DOOR GLASS |

361A110600 |

GLASS(DWD-100DR) |

1 |

|

|

|

|

|

|

|

C13 |

PROTECTOR GLASS |

3618304201 |

ABS TRANSPATENT |

1 |

|

|

|

|

|

|

|

C14 |

FRAME DOOR O |

3612204600 |

ABS |

1 |

CR |

|

|

|

|

|

|

C15 |

COVER HANDLE |

3611425620 |

ABS |

1 |

CR |

|

|

|

|

|

|

C16 |

SPRING HOOK |

3615113700 |

SUS, ID=3, NI=7, D=ø0.9 |

2 |

|

|

|

|

|

|

|

C17 |

PIN HANDLE |

3618200100 |

SUS, D=3.0, L=39 |

1 |

|

|

|

|

|

|

|

C18 |

SWITCH DOOR LOCK |

3619046400 |

DF F01 007 220V 16A |

1 |

|

|

|

|

|

|

|

|

|

3619046410 |

DF F11 110 125V 16A |

1 |

|

|

|

|

|

|

|

11

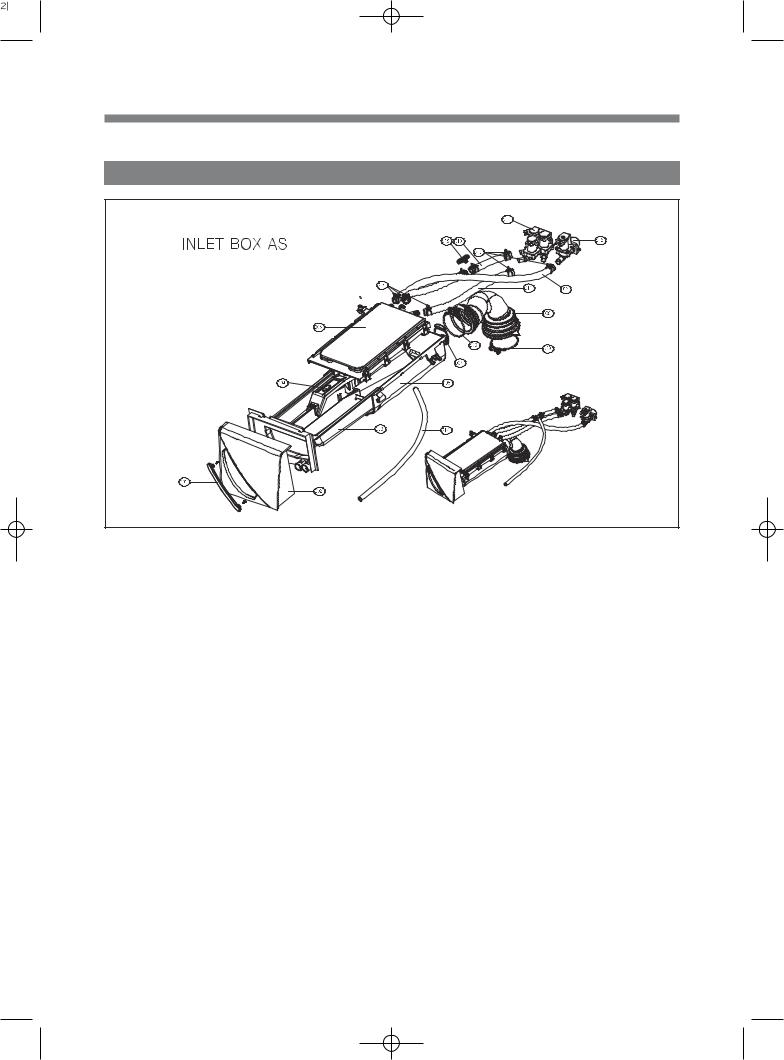

4. INLET BOX AS

No. |

PARTS NAME |

PARTS CODE |

DESCRIPTION |

Q’TY |

REMARK |

D01 |

HANDLE CAP |

3612608300 |

ABS |

1 |

Luxury |

|

|

|

|

|

|

D02 |

CASE HANDLE |

3611139400 |

ABS |

1 |

Luxury |

|

|

|

|

|

|

|

SCREW TAPPING |

9121301208 |

T/S-2S PH(SUS) 3*12 |

2 |

HANDLE CAP |

|

|

|

|

|

|

D03 |

CASE DETERGENT |

3611139500 |

PP |

1 |

|

|

|

|

|

|

|

D04 |

CAP SOFTENER |

3610916600 |

PP |

1 |

|

|

|

|

|

|

|

D05 |

INLETBOX |

3617505310 |

PP |

1 |

|

|

|

|

|

|

|

D06 |

NOZZLE AS |

3618103500 |

PP, DWD-100DR |

1 |

TOP+UNDER |

|

|

|

|

|

|

D07 |

PACKING |

3614010000 |

EPDM |

1 |

|

|

|

|

|

|

|

D08 |

HOSE INLET |

3613266400 |

EPDM |

1 |

|

|

|

|

|

|

|

D09 |

CLAMP AS |

3611203200 |

ID=60, WIRE+GUIDE+BOLT+NUT |

2 |

INLETBOX/TUBR |

|

|

|

|

|

|

D10 |

HOSE WATER SUPPLY |

3613270900 |

EPDM, ID=9.5, OD=14.5, L=165mm |

2 |

PRE WASH |

|

|

|

|

|

|

D11 |

HOSE WATER SUPPLY |

3613270900 |

EPDM, ID=9.5, OD=14.5, L=335mm |

1 |

MAIN WASH |

|

|

|

|

|

|

D12 |

HOSE WATER SUPPLY |

3613270900 |

EPDM, ID=9.5, OD=14.5, L=420mm |

1 |

HOT |

|

|

|

|

|

|

D13 |

CLAMP HOSE |

3611205800 |

100H, ID=13.8, W=10, 0.9T |

8 |

|

|

|

|

|

|

|

D14 |

VALVE INLET |

3615415050 |

220-240V,3WAY,PP/BRACKET |

1 |

COLD |

|

|

|

|

|

|

|

|

3615415070 |

110-130V,3WAY,PP/BRACKET |

1 |

COLD |

|

|

|

|

|

|

D15 |

VALVE INLET |

3615414800 |

220-240V,1WAY,PP/BRACKET |

1 |

HOT |

|

|

|

|

|

|

|

|

3615415700 |

100-130V,1WAY,PP/BRACKET |

1 |

HOT |

|

|

|

|

|

|

D16 |

PIPE JOINT |

3614413300 |

PP |

1 |

|

|

|

|

|

|

|

D17 |

HOSE WATER SUPPLY |

3613270900 |

EPDM, ID=9.5, OD=14.5, L=620 |

1 |

|

|

|

|

|

|

|

12

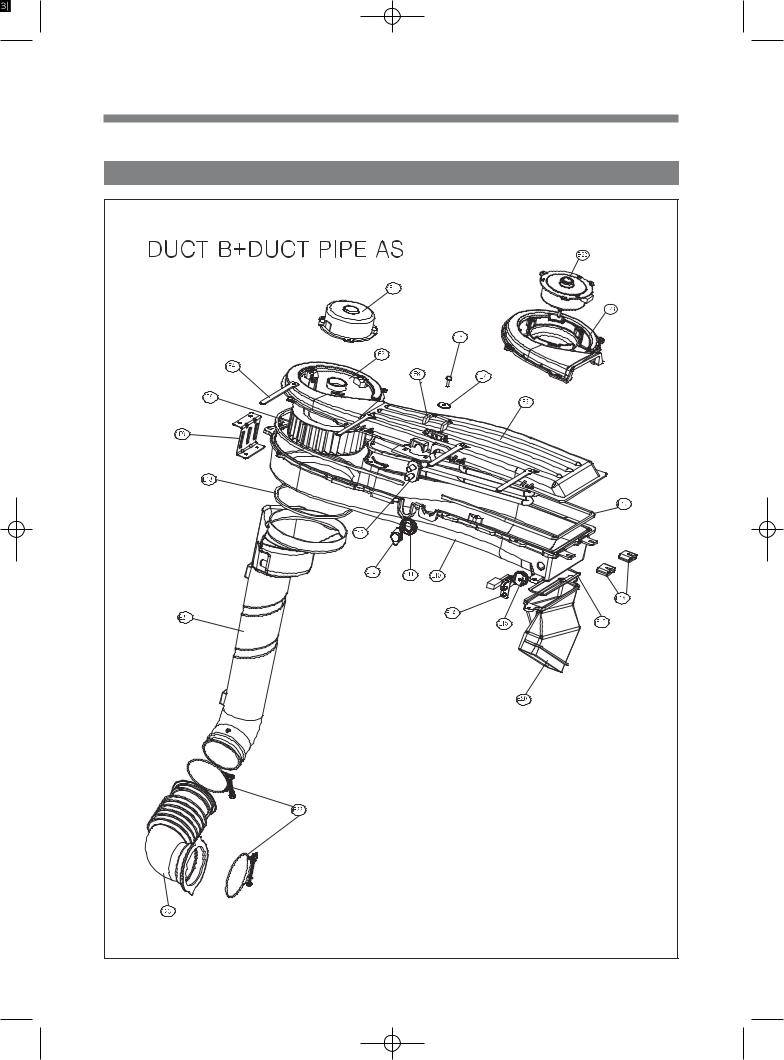

5. DUCT + DUCT PIPE AS

13 |

■ Duct + Duct pipe as

No. |

PARTS NAME |

PARTS CODE |

DESCRIPTION |

Q’TY |

REMARK |

E01 |

UNIT FAN MOTOR |

36189L3Z20 |

ISM-77806DWWA, 24V CW 8P 14W |

1 |

~Feb 2011 |

|

|

|

|

|

|

E22 |

UNIT FAN MOTOR |

36189M2Q00 |

17.5V VDC C.W |

1 |

Feb 2011 ~ |

|

|

|

|

|

|

E02 |

DUCT COVER |

361A200400 |

AL, 2.5T, DWD-100DR |

1 |

~Feb 2011 |

|

|

|

|

|

|

E23 |

COVER DUCT |

3611432600 |

C-ED, GFPP 30% |

1 |

Feb 2011 ~ |

|

|

|

|

|

|

E03 |

DUCT B UPPER AS |

361A200670 |

ALCOSTA UPPER, NON-COATING |

1 |

|

|

|

|

|

|

|

E04 |

CLAMP CORD |

3611203350 |

L=94,W=5.6,A=8.0,LH-94 |

4 |

|

|

|

|

|

|

|

E05 |

FAN AS |

3611885900 |

D133 FAN, GFPP30%<-NYLON66 |

1 |

~Feb 2011 |

|

|

|

|

|

|

|

|

3611886400 |

17.5V VDC C.W |

1 |

Feb 2011 ~ |

|

|

|

|

|

|

E06 |

FUSE TEMPERATURE |

361A800120 |

128°C DF-128S 15A 250V |

|

|

|

|

|

|

|

|

E07 |

FRAME HEATER FRANGE |

3612204100 |

SBHG 1.2T, DWD-100DR |

1 |

|

|

|

|

|

|

|

E08 |

DUCT B LOWER |

361A200101 |

AL, 3T, DWD-100RP |

1 |

|

|

|

|

|

|

|

E09 |

PACKING THERMOSTAT |

3614009900 |

SILICON, DWD-100DR |

1 |

|

|

|

|

|

|

|

E10 |

SWITCH THERMOSTAT |

3619046500 |

ON120°C OFF150°C 230V 15A |

1 |

|

|

|

|

|

|

|

E11 |

HEATER DRY |

3612800900 |

220V 2100W 23.05OHM |

1 |

220V |

|

|

|

|

|

|

|

|

3612802100 |

UL120V/2.1kW 12OHM |

1 |

127V |

|

|

|

|

|

|

E12 |

THERMISTOR DRY |

361AAAAC00 |

R40=26.065kΩ,R90=4.4278kΩ |

1 |

|

|

|

|

|

|

|

E13 |

PACKING RUBBER |

3614009800 |

SILICON, DWD-100DR |

1 |

|

|

|

|

|

|

|

E14 |

CUSHION DRY |

3611562800 |

NBR, DWD-100DR |

2 |

|

|

|

|

|

|

|

E15 |

GASKET SEAL A |

3612320820 |

DWD-110RP, ø5, L=1385 |

1 |

|

|

|

|

|

|

|

E16 |

GASKET SEAL B |

3612320810 |

EPDM FOAM, L=412, 4.9x4.4x4.8 |

1 |

|

|

|

|

|

|

|

E17 |

GASKET INLET |

3612320910 |

NON ASBESTOS, 1Tx33x135 |

1 |

|

|

|

|

|

|

|

E18 |

DUCT GUIDE |

361A201000 |

DWD-110RP,3T,ALDC |

1 |

|

|

|

|

|

|

|

E19 |

DUCT PIPE AS |

361A200700 |

11KG |

1 |

|

|

|

|

|

|

|

E20 |

CLAMP AS |

3611203700 |

DUCT |

2 |

|

|

|

|

|

|

|

E21 |

BELLOWS DUCT |

3616403000 |

EPDM |

1 |

|

|

|

|

|

|

|

14

Loading...

Loading...