Training Manual

PRODUCT : COLOR - TV

DAEWOO ELECTRONICS CO., LTD.

http : //svc.dwe.co.kr

Jun . 2002

Table of contents

-

-

-

-

-

-

-

Chapter 1. TV Standards

1. Introduction----------------------------------------------------2

2. Trend of Trouble--------------------------------------------

3. How to Progress The Diagnosis of Trouble---------- 5

4. Understanding of Trouble Symptom-------------------

5. Diagnosis of Trouble---------------------------------------

6. Notes-----------------------------------------------------------

7. Color Television Circuit System------------------------- 10

Chapter 2. Trouble Shooting Charts

1. CN-001N CHASSIS-----------------------------------------11

4

5

7

9

2. CP-185 CHASSIS------------------------------------------

3. CP-385 CHASSIS------------------------------------------

4. CP-785 CHASSIS------------------------------------------

1

17

22

27

Chapter 1. TV Standards

1. Introduction

The first, color television system to be used for a public broadcast service was the

CBS(Columbia Broadcasting System) field sequential system which was adopted in

the United States in 1951.

The CBS system was subsequently replaced by the NTSC(National Television

System Committee) system which transmits all three primary signals simultaneously.

The NTSC system has been used for public broadcasting on the USA since

December 1953.

The NTSC system, which operates on a 60HZ field and 525 Scanning lines, is designed

to be compatible with the monochrome TV system in the US. The width of the video zone

is 4.5MHz and the width of the channels is 6MHz.

This system has been adopted in the USA, KOREA,CANADA,JAPAN and other countries,

and particularly where the utility electricity mains supply frequency is 60Hz.

The PAL system was proposed by W.Bruch of Germany, PAL is stand for "Phase

Alternation by Line". This system was adopted by many European Countries and

public broadcasting began in 1967 in Germany. This system is almost the same as

the NTSC system for the color TV signals, but differs in the fact that the signal are

inversed by 180 at every horizontal scanning line, therefore using a 1H delay line in the

color receiver, suing a 625 line, 50 field.

The SECAM system broadcast service began in FRANCE in 1967 which was officially

adopted by France, USSR and other countries.

The SECAM is stand for "Sequential couleurs A Memoire" This system operates on a 625

lines, 50 fields, was based on the two distinguishing features of the system,

the use of segmental color signals a memory device, the memory device took the from

of a 1H delay line in the receiver.

This system has disadvantages in the parts of phase divergence and cross talk(leakage

of signals) because of the way that the color signals,divided into two,are simultaneously

transmitted.

2

FEATURE

TV SYSTEMS STANDARD

FORMAT

NTSC PAL SECAM

SCAN LINES (H)

H-FREQ (KHZ)

V-FREQ (HZ)

PICTURE PER SEC

INTERLACED SCANING

ASPECT RATIO

VIDEO MODULATION

SOUND MODULATION (KHZ)

VIDEO BAND (MHZ)

SOUND CARRIER (MHZ)

525 625 625

15.734 15.625 15.625

59.94 50 50

29.97 25 25

2 : 1 2 : 1 2 : 1

4 : 3 4 : 3 4 : 3

AM - AM - AM +

FM±25 FM±50 AM 60%

4.2 5 6

4.5 5.5 6.5

CHANNEL BAND (MHZ)

COLOR CARRIER (MHZ)

COUNTRY

STANDARD SPEC

67 8

3.579545 4.433618 R=4.40625,B=4.25

USA, GERMANY, FRANCE,

JAPAN, W-EUROPE E-EUROPE,

KOREA CHINA, CIS

FCC CCIR CCIR

3

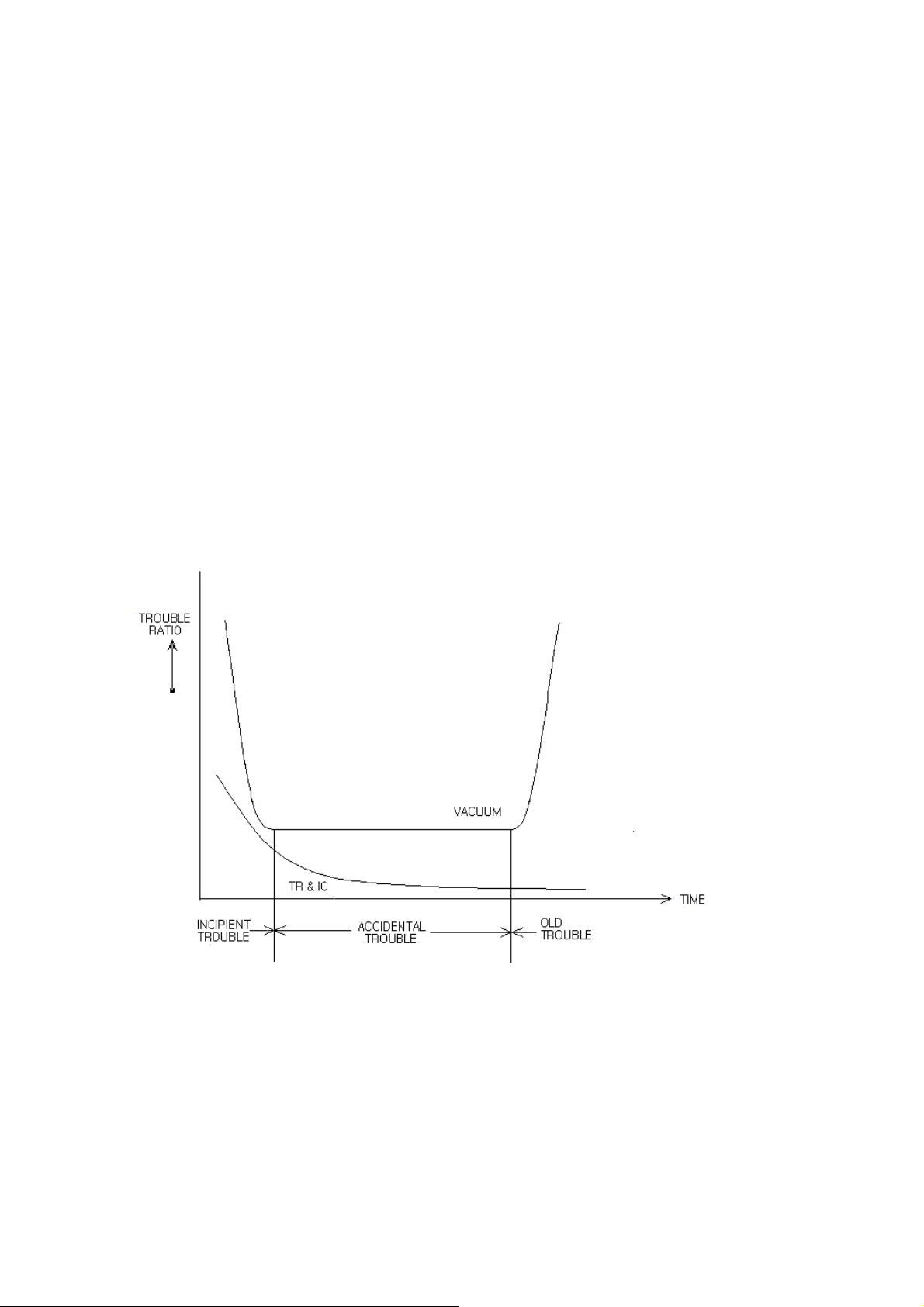

2. TREND OF TROUBLE

TV receiver is composed of a great many components and the number of which

can be different in accordance with each model. But even that only one of its

composed components is trouble, the TV receiver doesn't operate normally.

The lower the ratio of generating the trouble and the less the number of composed

components are used, the higher the reliability of the receiver is assured.

When using a receiver mode of vacuum tube the trend of trouble increases as time

goes by, but as transistor and IC make an appearance and the used components

decrease considerably be means of employing the integrated circuits,considerable

decreasing of trouble is resulted.

Recently,trouble-shooting which is required of exchanging the whole PCB as well

as the troubled components serves as the assurance of reliability and the satisfaction

of customer.

- BATH TUBE CURVE (TREND of TROUBLE) -

4

3. HOW TO PROGRESS THE DIAGNOSIS OF TROUBLE

It is not easy to repair the TV sets with prompt and accurate by clarifying

the reason of trouble out of a great many components unless the composition of

each circuit and the flow of signal should be understood systematically.

The diagnosis of trouble in TV receiver usually can be localized a major

section by observing the symptom of it. That is, an efficient order of

diagnosis, first divide the total into the two blocks and find the block in which the

trouble occurs, and again divide the block into two more in detail, by this repeat

procedures, localize to narrow section, and detect the component caused to be trouble.

The order of diagnosis is progressed as follows.

1) Observe the symptom of trouble

2) Presume the troubled circuit from the symptoms

3) Localize the trouble to a narrow section(circuit break down)

4) Find the troubled component and check

5) Replace it by a good part of the same specification.

6) Make sure the set is operated normally.

4. UNDERSTANDING OF TROUBLE SYMPTOM

It's said that the troubleshooting is started from the feeling of the strange of

picture of sound,ended to check the normal operation. Therefore understanding of

symptom is the source of shooting and short way of able to repair with efficient

and sure and also it is very important to obtain the further more information from it.

If you wish to presume the circuit of troubled, you should know the flow of signals

and each operation ,and understand the situations for the troubled circuit corresponding

to its symptom.

While as above mentioned, the diagnosis of trouble in TV receiver can be localized

to narrow section by observing the raster and picture and by listening to sound.

TV receivers exhibit the specific signs for some definite troubles, For instance no high

voltage with normal sound means no brightness on the screen.

5

Localizing the trouble to one stage and a specific component generally should be

required of test equipment such as the multimeter, oscilloscope, and pattern

generator etc.. Just with a simple ohm-meter, test of opened-resistor and

short-capacitor is possible once the trouble has been narrowed down a suspected

component. It's summarized the relation of the symptom of trouble and its circuit.

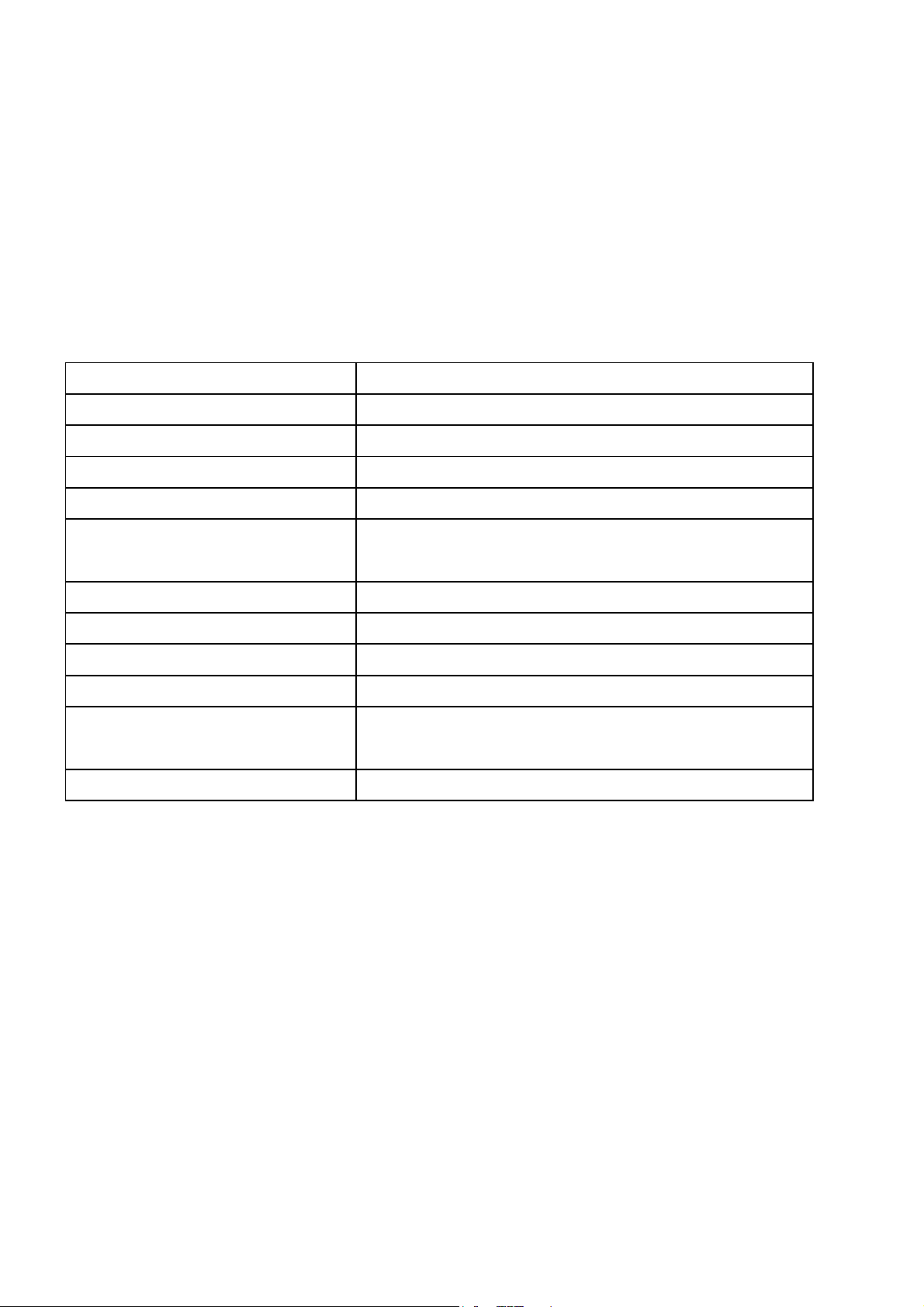

[ TABLE 1] RELATION OF SYMPTOM AND CIRCUIT

SYMPTOM OF TROUBLE RELATED CIRCUIT

NO RASTER AND NO SOUND POWER, H-DEFLECTION, u-COM,FBT

NO RASTER AND NORMAL SOUND HV,CRT,FBT

NO PICTURE AND NO SOUND LOW B+ LINE,TUNER,IF AMP,AGC,u-COM

NO PICTURE AND NORMAL SOUND VIDEO DETECTOR,VIDEO AMP,VIDEO SWITCHING

NO COLOR

INCORRECT COLOR COLOR DEMODULATOR,COLOR MATRIX,CRT DRIVE

SINGLE HORIZONTAL LINE V-DEFLECTION

CONVERGENCE DY AND PC MAGNET,CRT

NO HOLD SYNC. SYNC SEPARATOR,AFC,H-OSCILLATOR,AGC,APC

NO SOUND

SINGLE VERTICAL LINE H-DEFLECTION

CHROMA BPF,AGC,BURST AMP,CHROMA,OSCILLATOR

COLOR KILLER,CHROMA SWITCHING,COLOR CONTROL

SOUND BPF,SOUND DEMODULATOR AND AMP

VOLUME CONTROL,MUTE,SPEAKER

6

5. DIAGNOSIS OF TROUBLE

Generally because the TV circuits are composed of so many components it's

not easy to cover the wide range of total parts. Therefore you should presume the

location of trouble by dividing the circuit into the narrow section.

When trouble-shooting is carried out, the multimeter and oscilloscope are mainly

used and by checking the voltage and waveform of each terminal the troubled

component can be detected.

Above all it's very important to accumulate the experience of repair through trial

and error understanding the flow path of signals.

5.1 DIAGNOSIS OF PASSIVE COMPONENTS (RLC)

Opening, short of R,L and C or reduction of capacitance value can be checked

with a simple tester, and only opening test can be also achieved by connecting a

good part with parallel. Poor insulation and short test should be done with a

tester after turning the power off.

While, It is required of alternative testing, which measures the value alternativery by

changing the probe direction of tester, because low value may be read due to the influence

of short components. In this case the larger one is selected out of measured values.

In case that it is difficult to determine whether the part is poor or not due to the effect

of other parts, check it after opening the lead.

7

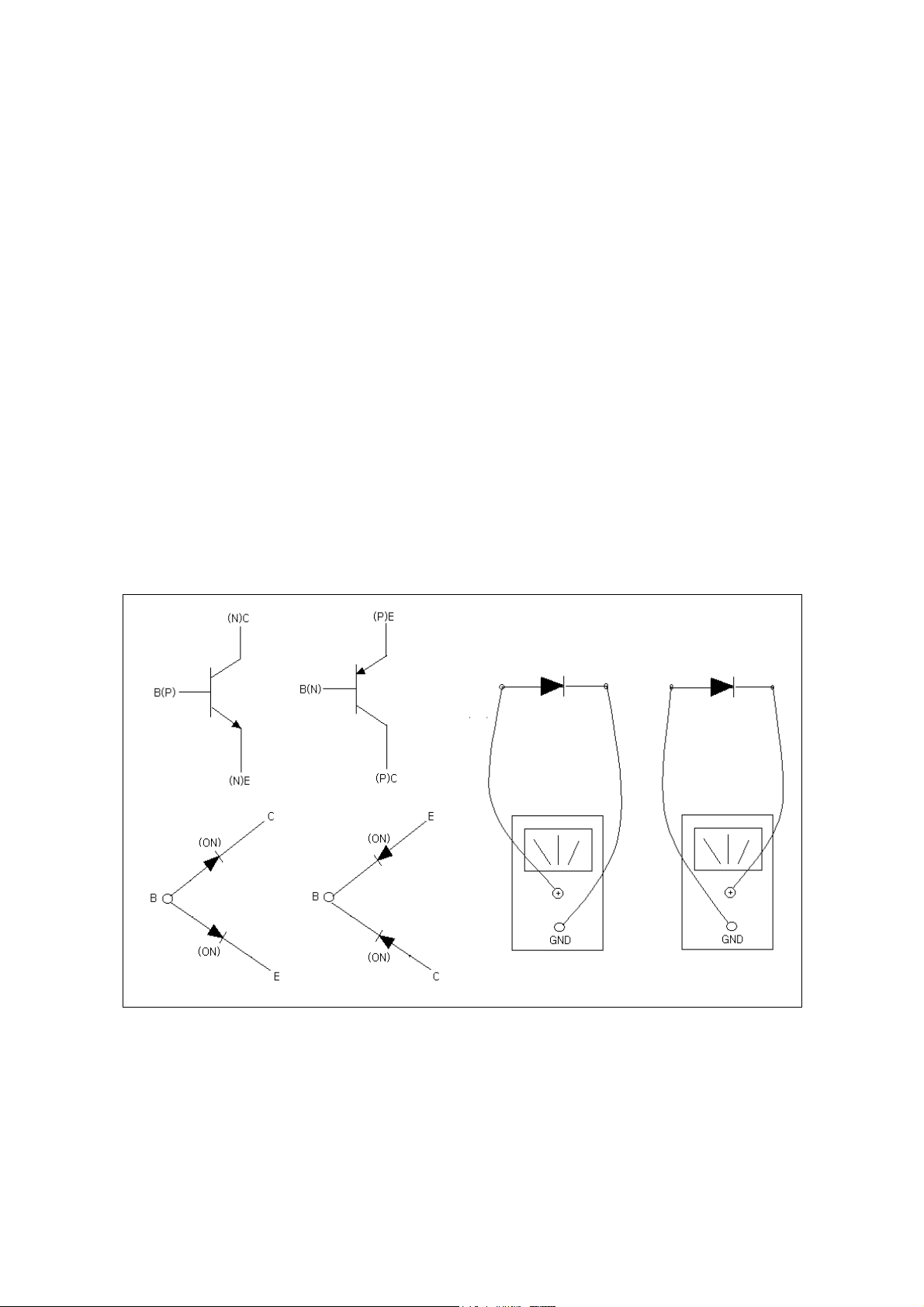

5.2 DIAGNOSIS OF TRANSISTOR CIRCUIT

In the transistor amplifier circuit, forward bias current, forward bias current flow across base and

emitter, its forward voltage is, regardless of the type of transistor, about 0.7V in silicon TR and 0.2V

in germanium TR.

After measuring VB,VE,VC AND VBE, consider it as a normal if the following conditions are satisfied

1) VBE is about 0.6V(or 0.2V), that is, forward biased.

2) VB, VE and VC are within ±20% of the value specified in circuit.

Determination of trouble is also done by checking the resistance across the base and emiter,

base and collector, emitter and collector.

That is, after measuring the forward and reverse resistance, if its difference is large it is a normal.

If its difference is small, on the contrary, if its difference is large it is a possible to check it by

the short test with a digital multimeter.

5.3 DIAGNOSIS OF IC CIRCUIT

In case the troubled circuit contains IC the reason of trouble can be IC itself or surrounding

parts. For diagnosis, first compare the voltage of each terminal with the specification, if it

appears to be the difference of ±20% it can becaused to be the reason of trouble.

While as the reason of trouble, there is a case that the supply voltage is wrong and each

terminal voltage of IC is wrong regardless of the normal supply voltage.

In this case try to exchange IC after checking the surrounding components.

As above mentioned troubleshooting is completed by only charging the poor component

for a good one, but in accordance with the circuit there can be a case which is required of

readjustment of bias or frequency etc..

In a way of preventing the recurrence of trouble, knowledge of troubled reason is important.

8

6. NOTES

Remarkable items are described in below on troubleshooting, especially special

attention should be paid to dealing with TR and IC as they are very weak to heat

such as overcurrent and static electricity.

1) Turn the power off when soldering the component.

2) Don't short the circuit during operation as TR or IC can be destroyed.

3) Solder certainly the parts dealing with large power.

4) Use the specified components when changing.

5) Return the wire originally after troubleshooting.

6) Use the soldering iron grounded at the shim of it.

7) Have on the earth ring when dealing with IC or TR.

8) Don't touch the back side of PCB with a bare hand, especially take care for

the part of high voltage.

9

Loading...

Loading...