DAEWOO CML-710 Service Manual

LCD COLOR MONITOR

Model : CML-710

http://www.lucoms.com 2004

Service Manual

DAEWOO LUCOMS CO., LTD.

SAFETY PRECAUTIONS 2

GENERAL SAFETY INFORMATION 3

SERVICING PRECAUTIONS 4

TECHNICAL INFORMATION 8

GENERAL INFORMATION 9

PIN CONNECTOR 9

CAUTIONS FOR ADJUSTMENT AND REPAIR 9

OPERATION & ADJUSTMENT 10

ALIGNMENT PROCEDURE 16

TROUBLESHOOTING HINTS 17

BLOCK DIAGRAM 24

SCHEMATIC DIAGRAM 25

PCB PATTERN 30

INFORMATION OF PART DESCRIPTION 34

ELECTRICAL PARTS LIST 35

CONTENTS

1

2

SAFETY PRECAUTIONS

◆ Safety Check

Care should be taken while servicing the inverter that generates the high voltage to lighten CCFL of the

LCD panel.

◆ Fire & Shock Hazard

• Insert an isolation transformer between the analog color display and AC power line before servicing the

chassis.

• When servicing, pay close attention to the original lead dress especially in the high voltage circuit area;

if a short circuit is found, replace all parts which have been overheated as a result of the short circuit.

• All the protective devices must be reinstalled per original design.

• Soldering must be inspected for possible cold solder points, frayed leads, damaged insulation, solder

splashes or sharp solder points. Be certain to remove all foreign materials.

CAUTION: No modifications of any circuits should be attempted. Service work should be performed

only after you are thoroughly familiar with all of the following safety checks and servicing

guidelines.

3

GENERAL SAFETY INFORMATION

◆ Terms in the manual

CAUTION Statements identify conditions or practices that could result in damage to the equipment or

other property.

WARNING Statements identify conditions or practices that could result in personal injury or loss of

life.

◆ Terms as marked on equipment

CAUTION Statements indicate a personal injury hazard not immediately accessible as one reads the

marking or a hazard which is properly included on the equipment itself.

WARNING Statements are clearly concerning indicated personal injury hazards.

◆ Symbols in the manual

The symbols indicate where applicable cautionary or other information is to be found.

◆ Symbols as marked on equipment

Protective GROUND terminal

◆ High Voltage Warning And Critical Component Warning Label

The following warning label is on the inverter isolation case.

4

SERVICING PRECAUTIONS

◆ General Servicing Precautions

1. Always unplug the AC power cord from the AC power source before:

a. Removing or reinstalling any component, circuit board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the instrument.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM. etc.) equipped with a suitable high voltage probe. Do not test high

voltage by “drawing an arc”.

3. Do not any spray chemicals on or near this instrument, or any of its assemblies.

4. Unless otherwise specified in this service manual, only clean electrical contacts by applying the

following mixture to the contacts with a pipe cleaner, cotton-tipped stick, or comparable nonabrasive

applicator: 10% (by volume) Aceton and 90% (by volume) isopropyl alchohol (90%-99% strength).

5. Do not apply AC power to this instrument and/or any other of its electrical assemblies unless all the

solid-state device heat sinks are correctly installed.

6. Always connect the test instrument ground lead to the appropriate instrument chassis ground before

connecting the test instrument positive lead. Always remove the test instrument ground lead last.

7. Only use the test fixtures specified in this service manual with this instrument.

CAUTION: Before servicing instruments covered by this service manual, its supplements, and

addendum, please read and follow the SAFETY PRECAUTIONS of this manual.

NOTE: If unforeseen circumstances create conflict between the following servicing precautions and any

of the safety precautions on page 1 of this manual, always follow the safety precautions.

Remember: Safety First.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic capacitors

may result in a explosion.

CAUTION: This is a flammable mixture. Unless specified in this service manual, lubrication of

contacts is not required.

5

SERVICING PRECAUTIONS

◆ Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components are commonly called Electrostatically Sensitive (ES) Devices.

The typical examples of ES devices are integrated circuits, some field-effect transistors, and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence

of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly,

wipe off any electrostatic charge on your body by touching any known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device which should be removed for

potential shock reasons prior to applying power to the unit under testing conditions.

2. After removing the electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil to prevent electrostatic charge buildup or exposure to the assembly.

3. Only use a grounded-tip soldering iron to solder or unsolder ES devices.

4. Only use an anti-static type solder removal device. Some solder removal devices not classified as “antistatic” can generate enough electrical charges to damage ES devices.

5.

Do not use freon-propelled chemicals. These can generate enough electrical charges to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from the leads of replacement ES devices, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Minimize bodily movements when handling unpackaged replacement ES devices. (Otherwise harmful

motion such as the brushing together clothes fabric or the lifting your foot from a carpeted floor can

generate enough static electricity to damage ES devices).

◆ General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron with appropriate tip size and shape that will maintain

tip temperature between a 550°F-660°F (288°C-316°C) range.

2. Use an appropriate gauge of RMA resin-core solder composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean.

4. Throughly clean the surface to be soldered. Use a small wire-bristle (0.5 inch or 1.25cm) brush with a

metal handle. Do not use freon-propelled spray-on cleaners.

5. Use the following soldering technique:

a. Allow the soldering iron tip to reach normal temperature (550°F to 660°F or 288°C to 316°C)

b. Hold the soldering iron tip and solder strand against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the component lead and the printed circuit foil,

and hold it there until the solder flows onto and around both the component lead and the foil.

d.

Closely inspect the solder area and remove any excess or splashed solder with a small wire-bristle brush.

CAUTION:

Be sure that no power is applied to the chassis or circuit, and observe all other safety

precautions.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

6

SERVICING PRECAUTIONS

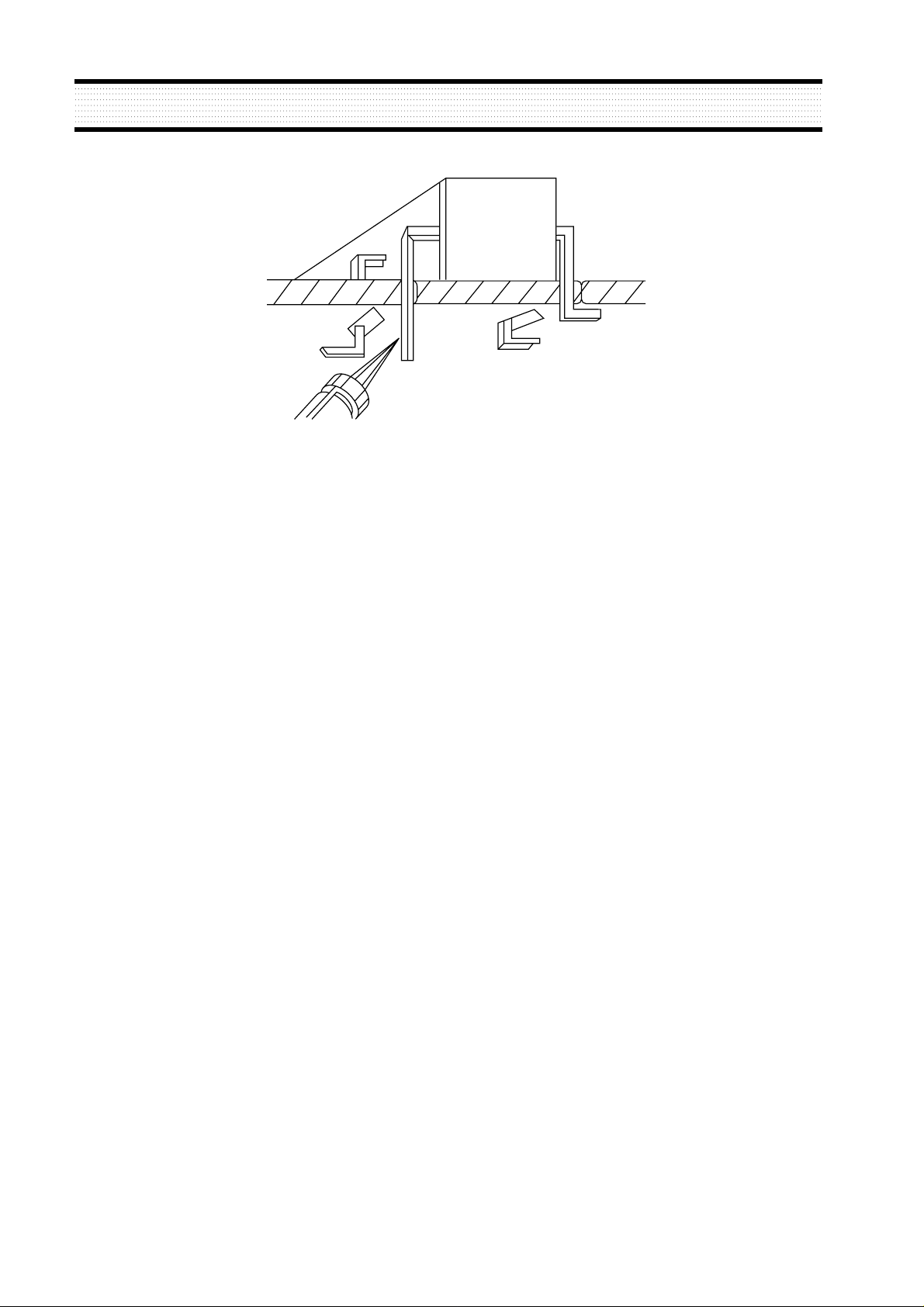

FIGURE 1. USE SOLDERING IRON TO PRY LEADS

◆ IC Removal/Replacement

Some utilized chassis circuit boards have slotted (oblong) holes through which the IC leads are inserted

and then bent flat against the circuit foil. When holes are slotted, the following technique should be used

to remove and replace the IC. When working with boards using the familiar round hole, use the standard

technique as outlined in paragraphs 5 on the page under the title of general soldering guidelines.

◆ Removal

1. Desolder and straighten each IC lead in one operation by gently prying up on the lead with the

soldering iron tip as the solder melts.

2. Draw away the melted solder with an anti-static suction-type solder removal device (or with

desoldering braid before removing the IC.

◆ Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and solder it.

3. Clean the soldered areas with a small wire-bristle brush. (lt is not necessary to reapply acrylic coating

to the area).

◆ “Small-Signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as possible to the component body.

2. Bend the ends of each of three leads remaining on the circuit board into a “U” shape.

3. Bend the replacement transistor leads into a “U” shape.

4. Connect the replacement transistor leads to the corresponding leads extending from the circuit board

and crimp the “U” with long nose pliers to ensure metal-to-metal contact, then solder each connection.

◆ Power IC, Transistor or Devices Removal/Replacement

1. Heat and remove all solders from the device leads.

2. Remove the heatsink mounting screw (if applicable).

3. Carefully remove the device from the circuit board.

4. Insert new device in circuit board.

5. Solder each device lead and then clip off excess lead.

6. Replace heatsink.

7

◆ Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicularly to the circuit board.

3. Observing diode polarity, wrap each lead out of the new diode around the corresponding lead on the

circuit board.

4. Securely crimp each connection and solder it.

5. Inspect the solder joints of the two “original” leads on the circuit board copper side. If they are not

shiny, reheat them and apply additional solder if necessary.

SERVICING PRECAUTIONS

8

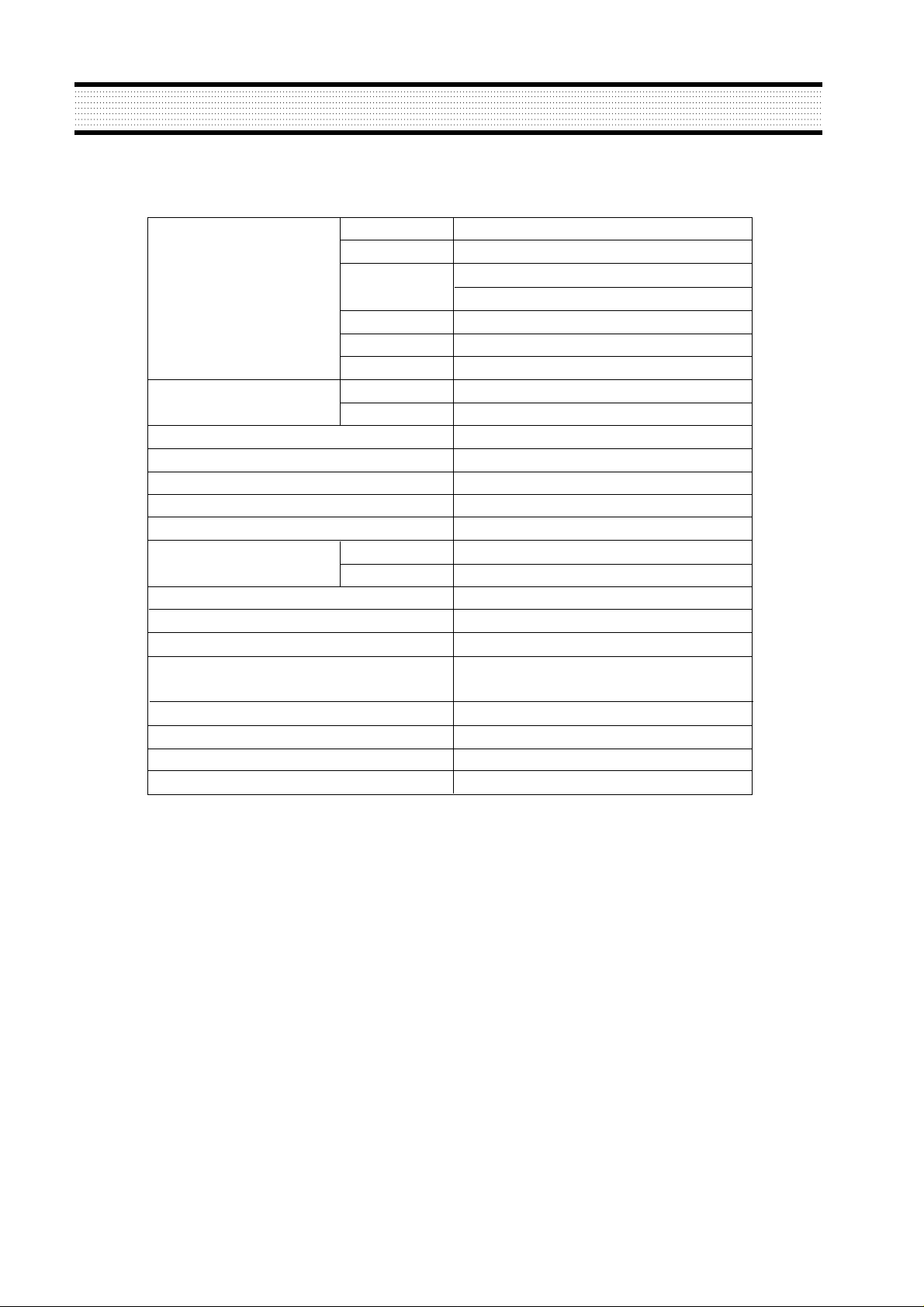

TECHNICAL INFORMATION

Panel Size 17-inch (43.2cm) diagonal

Pixel Pitch 0.264 x 0.264mm

Viewing Angle 70°(Right/Left)

60°(up), 60°(down)

Contrast Ratio 400:1 contrast ratio (typ)

Brightness 250cd/m

2

brightness (typ)

Color Filter RGB vertical stripe

Synchronization Horizontal 30 - 80KHz

Vertical 56 - 77Hz

Video Bandwidth 135MHz

Max Resolution 1280 x 1024@75Hz

Optimal Resolution 1280 x 1024@75Hz

Colors 8bit (16M Colors)

Display Area 337.9mm x 270.3mm

PC Input Signal Sync H/V separate (TTL)

Video 15 pin mini D-sub(Analog RGB)

Plug and Play VESA DDC Compatible

Power Source 100-240Vac, 50/60Hz (Free Voltage)

Power Consumption 40W

Dimension-W x H x D 386 x 398 x 190mm (with stand)

(without speaker) 386 x 346 x 60 mm (without stand)

Weight-net/gross 6.2/7.6Kg(13.6/16.7lbs)

Power Saving EPA, VESA DPMS, Nutek Compliant

Tilt Range 5° forward, 30° backward

Operating Temperature 10 ~ 40°C /50 ~ 104°F

9

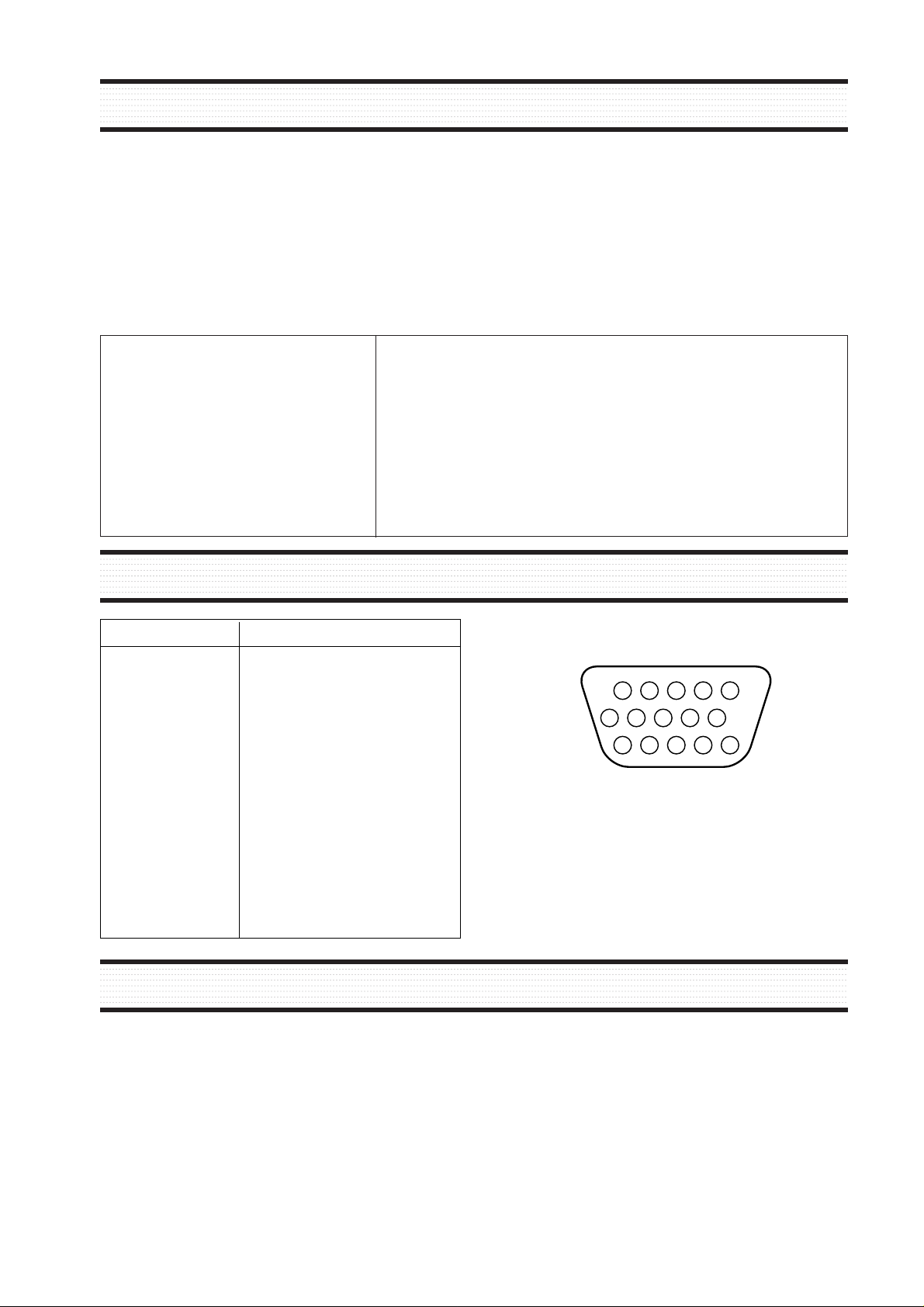

Arrangement of 15-pin D-sub connector

Pin Signal

1 Red

2 Green

3 Blue

4 GND

5 GND

6 GND - Red

7 GND - Green

8 GND - Blue

9 +5Vdc

10 GND - H.Sync

11 GND - V.Sync

12 Bi-directional Data (SDA)

13 Horizontal Sync

14 Vertical Sync (VCLK)

15 Data Clock (SCL)

1

610

15

PIN CONNECTOR

• The white balance adjustment has been done by a color analyzer in factroy. The adjustment procedure, described in

the service manual is made by a visual check.

• Allow 20 minutes warm-up time for the display before checking or adjusting only electrical specification or

function.

• Reform the leadwire after any repair work.

◆ Caution For Servicing

•

In case of servicing or replacing inverter, high voltage sometimes remains in the output of the inverter. Completely

discharge high voltage before servicing or replacing inverter to prevent a shock to the serviceman.

CAUTIONS FOR ADJUSTMENT AND REPAIR

This TFT LCD monitor automatically scans all horizontal frequencies from 30KHz to 80KHz, and all vertical frequencies

from 56Hz to 77Hz(15”- 50KHz to 75KHz). This TFT LCD monitor supports IBM PC, PC/XT, PC/AT, personal System/2

(PS/2), Apple Macintosh, and compatible users crisp text and vivid color graphics display when using the following graphics

adapters : (VGA, Super VGA, VESA, XGA, SXGA and Apple Macintosh Video Card). And so, this TFT LCD monitor has a

maximum horizontal resolution of 1280 dots and a maximum vertical resolution of 1024 lines for superior clarity of display.

By accepting analog signal inputs which level is zero to 0.7 Volts. This TFT LCD monitor can display 16.7M colors

depending on the graphics adapter and software being used.

◆ Abbreviations

ADJ Adjustment

AFC Automatic Frequency Control

TFT-LCD Thin Film Transistor Liquid Crystal Diplay

CCFL Cold Cathode Fluorescent Lamp

H.SYNC Horizontal Synchronization

OSC Oscillator

P.S.U Power Supply Unit

PWA Printed Circuit Board Wiring Assembly

R.G.B Red, Green, Blue

V.Sync Vertical Synchronization

ADC Analog Digital Converter

GENERAL INFORMATION

10

<< L710 >>

OPERATION AND ADJUSTMENT

POWER LIGHT

MENU/EXIT

Swithes the monitor on and

off.

Shows both normal operation

and power management status

with power indicator light.

POWER Indicator

POWER

1

3

4

5

7

2

Moves cursor to the right or

low window in the OSD

window and increases the

value of any selected function.

Moves cursor to the left or

high window in the OSD

window and decreases value

of any selected function.

While the OSD screen is off,

you can adjust the screen

brightness according to each

situation.

SELECT

6

Moves from top menu to sub

menu in the OSD window and

opens the function window for

the selected icon.

Turns the OSD window on.

Turns the OSD (On-Screen

Display) window off and moves

from sub menu to top menu in

the OSD window.

AUTO

8

Launches the AUTO

TRACKING function directly.

*

( )

*

( )

*

( )

*

( )

: Hot Key

3

1

2

6

7

8

45

11

OPERATION AND ADJUSTMENT

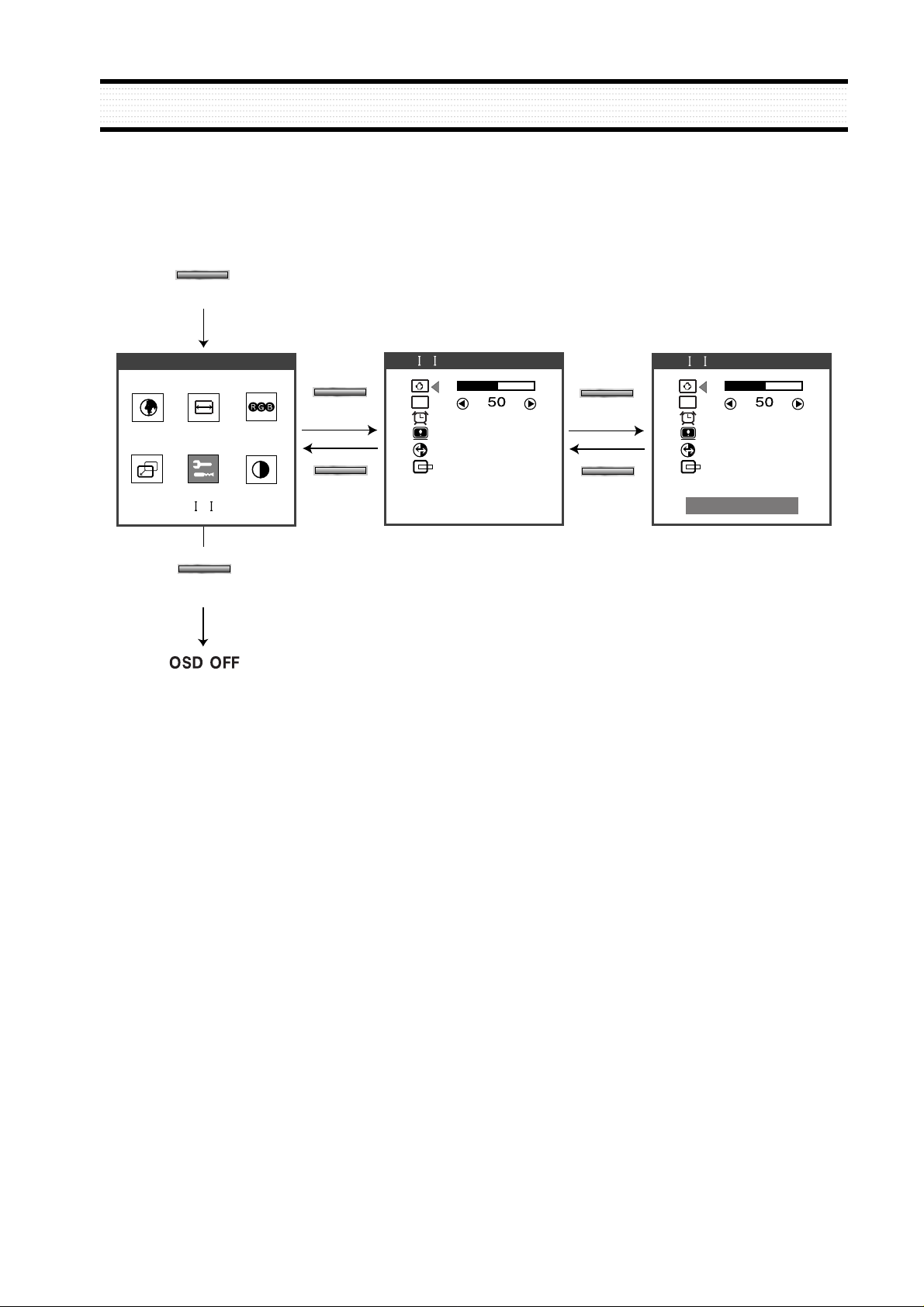

Key Process

MENU

EXIT

EXIT

EXIT

OSD

OSD

SHARPNESS

SHARPNESS

UT L TY

UT L TY

UT L TY

1280X1024 80K 75

SELECT

SELECT

When there is no OSD, if you press this

BRIGHTNESS button, you can adjust

the brightness directly.

: decreases brightness

: increases brightness

12

When there is no OSD, if you press this

AUTO button, you can use the best

display performance fit for a current

mode.

AUTO TRACKING

AUTO

The screen will be brightened progressively

by 10%. If you carry out general PC works

such as document edition on the Movie

mode,you may shorten the life span of LCD

panel. Thus,it is recommended to verify the

selected mode before use.

POWER LIGHT

PC MODE

GAME MODE

MOVIE MODE

POWER LIGHT

HOT KEY

OPERATION AND ADJUSTMENT

BRIGHTNESS /

Loading...

Loading...