Page 1

SECTION 1

ENGINE CIELO EURO III

SECTION 1A

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Diagnosis 1A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Test 1A-1. . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Test 1A-2. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Leak Diagnosis 1A-3. . . . . . . . . . . . . . . . . . . . . . . .

Knock Diagnosis 1A-4. . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

COMPRESSION TEST

Important: Disconnect the Crankshaft Position (CKP)

Sensor connector to disable the fuel and the ignition

systems.

Test the compression pressure for each cylinder. Low

compression pressure may be the fault of the valves or

the pistons. The following conditions should be considered when you check the cylinder compression:

D The engine should be at normal operating tempera-

ture.

D The throttle must be wide open.

D All the spark plugs should be removed.

D The battery must be at or near full charge.

1. Place approximately three squirts of oil from a plunger-type oiler into each spark plug port.

2. Insert the engine compression gauge into each spark

plug port.

3. Crank test each cylinder with four to five compression

strokes using the starter motor.

Noise Diagnosis 1A-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1A-11. . . . . . . . . . . . . . . . . . . . . . .

Cleanliness and Care 1A-11. . . . . . . . . . . . . . . . . . . . .

On-Engine Service 1A-11. . . . . . . . . . . . . . . . . . . . . . .

4. The lowest reading should not be less than 70% of

the highest reading. The compression gauge reading

should not be less than 689 kPa (100 psi) for any of

the cylinders.

5. Examine the gauge readings obtained after the four

‘‘puffs’’ per cylinder are obtained from cranking the

starter motor. The readings are explained in the following descriptions:

D Normal Condition – Compression builds up quickly

and evenly to the specified compression on each cylinder.

D Piston Rings Faulty – Compression is low on the first

stroke and tends to build up on following strokes, but

the compression pressure does not reach normal. The

compression pressure improves considerably with the

addition of oil into the cylinder.

D Valves Faulty – Low compression pressure on the

first stroke. The compression pressure does not tend

to build up on the following strokes. The compression

pressure does not improve much with the addition of

oil into the cylinder.

DAEWOO T-154 BL2,3

Page 2

1A – 2 GENERAL ENGINE INFORMATION

OIL PRESSURE TEST

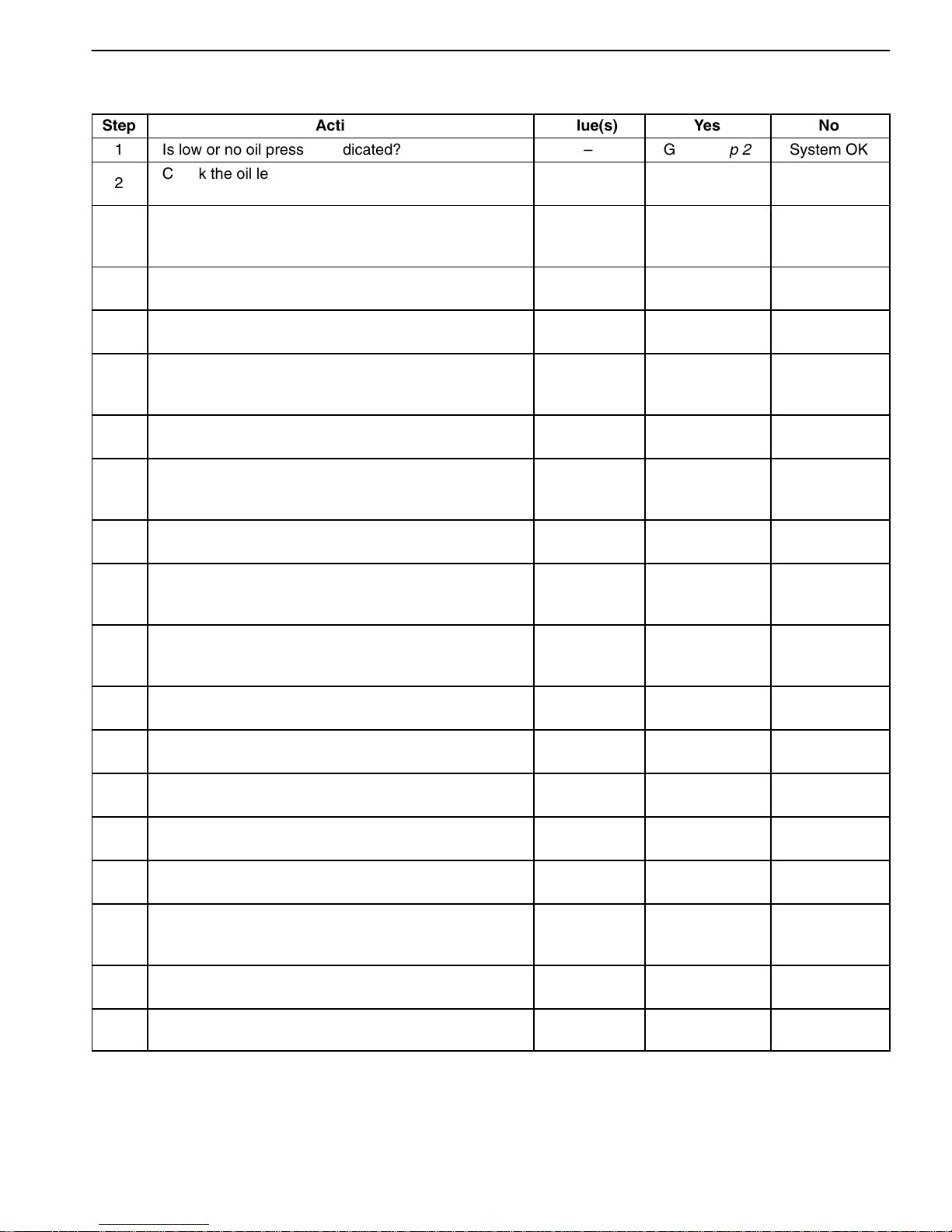

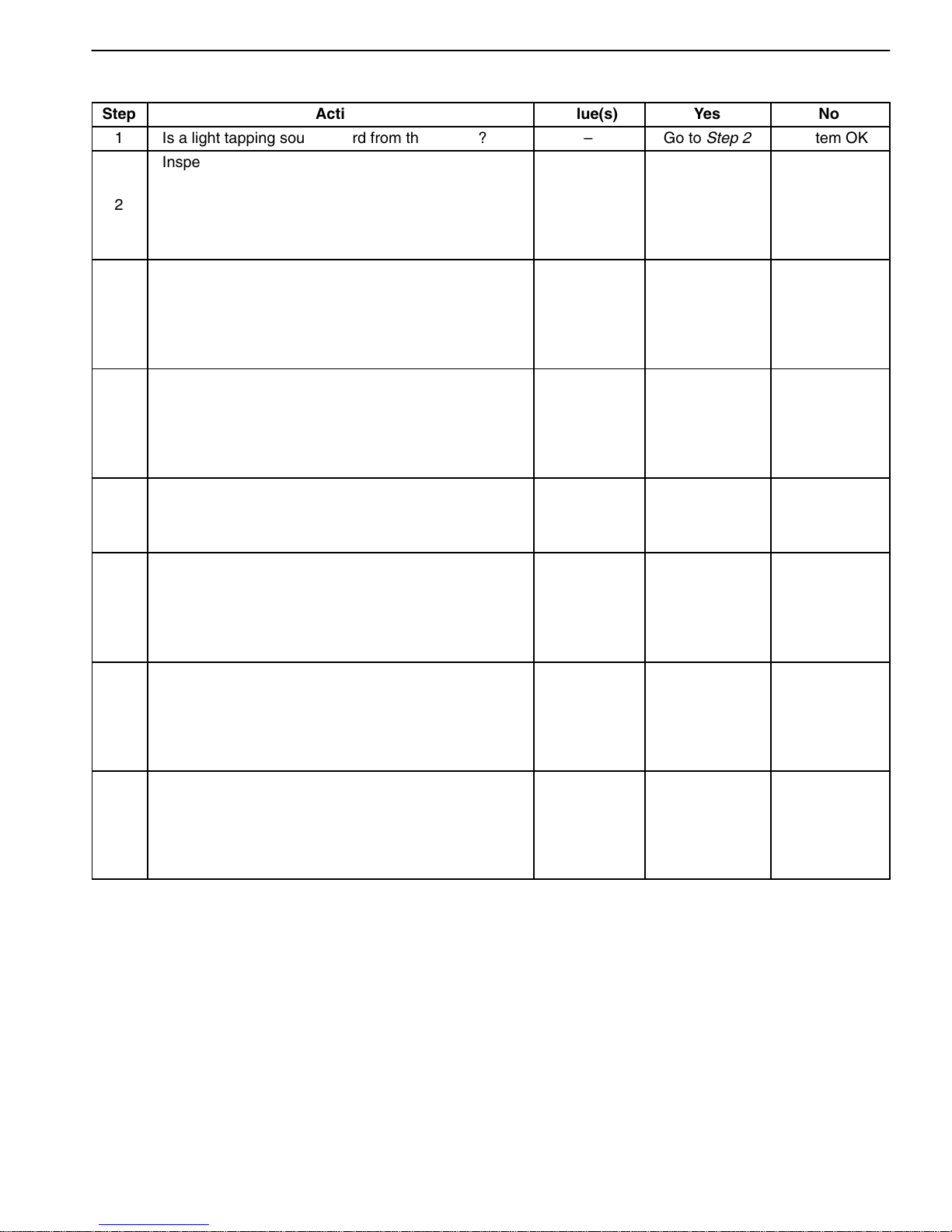

Step

Action

Value(s)

Yes

No

1 Is low or no oil pressure indicated? – Go to Step 2 System OK

2

Check the oil level in the crankcase.

Is the level low?

– Go to Step 3 Go to Step 4

Add oil so that the oil level is up to the full mark on

3

4

5

the indicator.

Is the repair complete?

–

–

Go to Step 1

Check the idle speed.

Is the idle speed below the specified value? 825 rpm Go to Step 5 Go to Step 6

Increase the idle speed.

Is the speed increased?

– Go to Step 1 –

Inspect the oil pressure switch.

6

7

Is the oil pressure switch incorrect or

malfunctioning?

–

Go to Step 7 Go to Step 8

Install a new oil pressure switch.

Is the repair complete? – Go to Step 1 –

Inspect the oil pressure gauge.

8

9

Is the oil pressure gauge incorrect or

malfunctioning?

–

Go to Step 9 Go to Step 10

Install a new oil pressure gauge.

Is the repair complete? – Go to Step 1 –

Inspect the engine oil.

10

Is the engine oil in the crankcase diluted or of the

improper viscosity?

–

Go to Step 11 Go to Step 12

Install new engine oil of the proper viscosity for the

11

12

13

14

15

16

expected temperatures.

Is the repair complete?

–

Go to Step 1

Inspect the oil pump.

Is the pump worn or dirty?

– Go to Step 13 Go to Step 14

Replace the oil pump.

Is the repair complete? – Go to Step 1 –

Inspect the oil filter.

Is the oil filter plugged?

– Go to Step 15 Go to Step 16

Install a new oil filter.

Is the repair complete? – Go to Step 1 –

Inspect the oil pickup screen.

Is the oil pickup screen loose or plugged?

– Go to Step 17 Go to Step 18

–

Tighten or replace the oil pickup screen, as

17

18

19

necessary.

Is the repair complete?

–

–

Go to Step 1

Inspect the oil pickup tube.

Are there any holes in the oil pickup tube? – Go to Step 19 Go to Step 20

Replace the oil pickup tube.

Is the repair complete?

– Go to Step 1 –

DAEWOO T-154 BL2,3

Page 3

GENERAL ENGINE INFORMATION 1A – 3

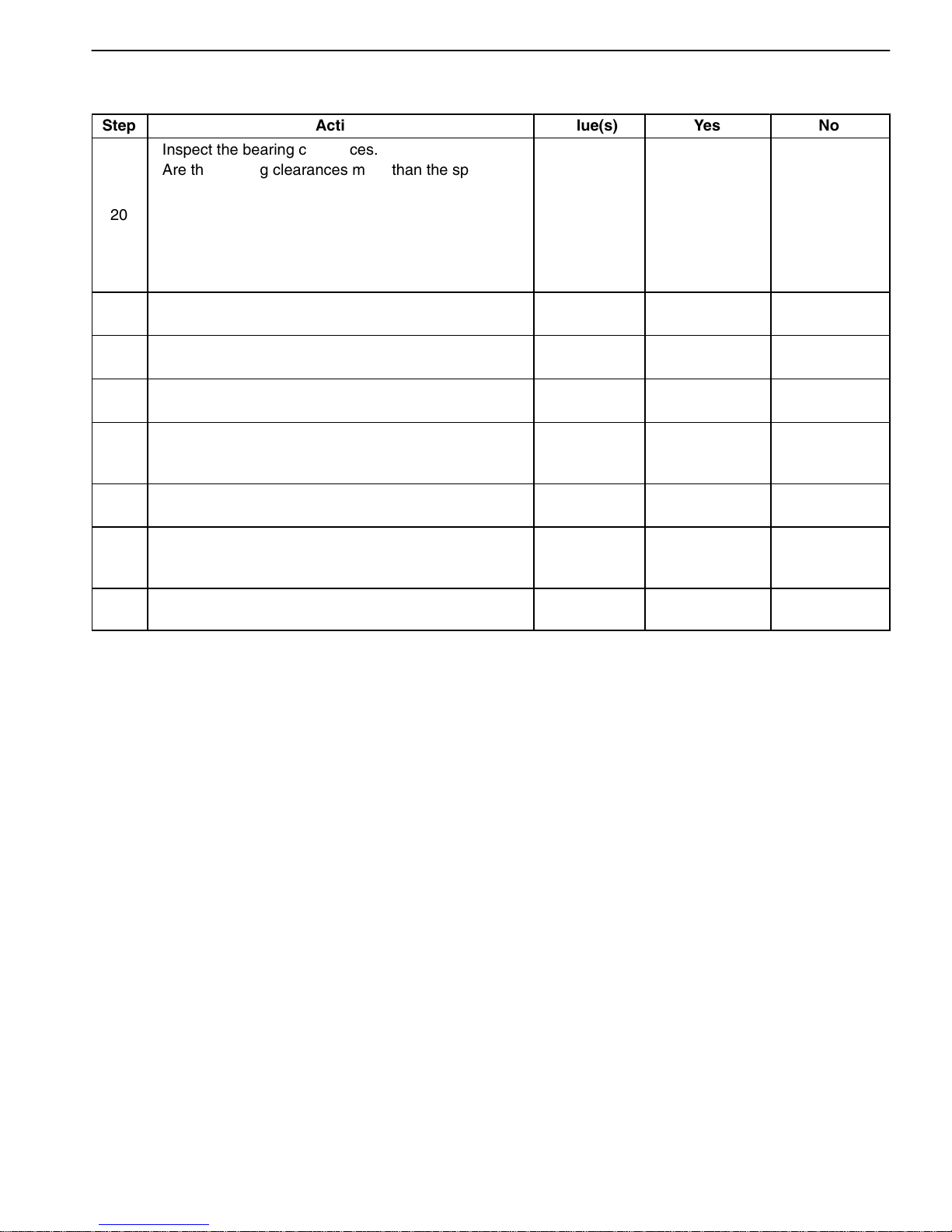

OIL PRESSURE TEST (CONT’D)

Step

20

21

22

23

24

25

26

27

Action

Inspect the bearing clearances.

Are the bearing clearances more than the specified

values?

Replace the bearing, if necessary.

Is the repair complete? – Go to Step 1 –

Inspect the oil galleries.

Are the oil galleries cracked, porous or plugged?

Repair or replace the engine block.

Is the repair complete? – Go to Step 1 –

Inspect the gallery plugs.

Are any of the gallery plugs missing or installed

improperly?

Install the plugs or repair them, as necessary.

Is the repair complete?

Inspect the camshaft.

Is the camshaft worn or is there evidence of poor

machining?

Replace the camshaft.

Is the repair complete? – Go to Step 1 –

Value(s)

Crankshaft

0.005 mm

(0.002 in.)

Connecting

Rod

0.019 X

0.070 mm

(0.0007 X

0.0027 in.)

– Go to Step 23 Go to Step 24

–

– Go to Step 1 –

–

Yes

Go to Step 21 Go to Step 22

Go to Step 25 Go to Step 26

Go to Step 27 System OK

No

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions, a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak:

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1. After running the vehicle at normal operating

temperature, park the vehicle over a large

sheet of paper.

2.2. Wait a few minutes.

2.3. Find the approximate location of the leak by

the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary to

clean the suspected area with a degreaser, steam, or

spray solvent.

4.1. Thoroughly clean the area.

4.2. Dry the area.

4.3. Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4. After operating the vehicle, visually check the

suspected component.

4.5. If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method:

1. Clean the suspected area.

2. Apply an aerosol-type powder, (such as foot powder),

to the suspected area.

3. Operate the vehicle under normal operating conditions.

4. Visually inspect the suspected component. Trace the

leak path over the white powder surface to the source.

Black Light and Dye Method:

A dye and light kit is available for finding leaks. Refer to

the manufacturer’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil fill

tube.

2. Operate the vehicle under normal operating conditions as directed in the kit.

DAEWOO T-154 BL2,3

Page 4

1A – 4 GENERAL ENGINE INFORMATION

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined in order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets:

D The fluid level/pressure is too high.

D The crankcase ventilation system is malfunctioning.

D The fasteners are improperly tightened or the threads

are dirty or damaged.

KNOCK DIAGNOSIS

Definition for Knock

Engine knock refers to various types of engine noise.

Heavy knock is usually very loud and the result of broken

or excessively worn internal engine components. Light

D The flanges or the sealing surface is warped.

D There are scratches, burrs or other damage to the

sealing surface.

D The gasket is damaged or worn.

D There is cracking or porosity of the component.

D An improper seal was used, (where applicable).

Seals:

D The fluid level/pressure is too high.

D The crankcase ventilation system is malfunctioning.

D The seal bore is damaged, scratched, burred or

nicked.

D The seal is damaged or worn.

D Improper installation is evident.

D There are cracks in the component.

D The shaft surface is scratched, nicked or damaged.

D A loose or worn bearing is causing excess seal wear.

knock is a noticeable noise, but not as loud. Light knock

can be caused by worn internal engine components.

Loose or broken external engine components can also

cause heavy or light knock.

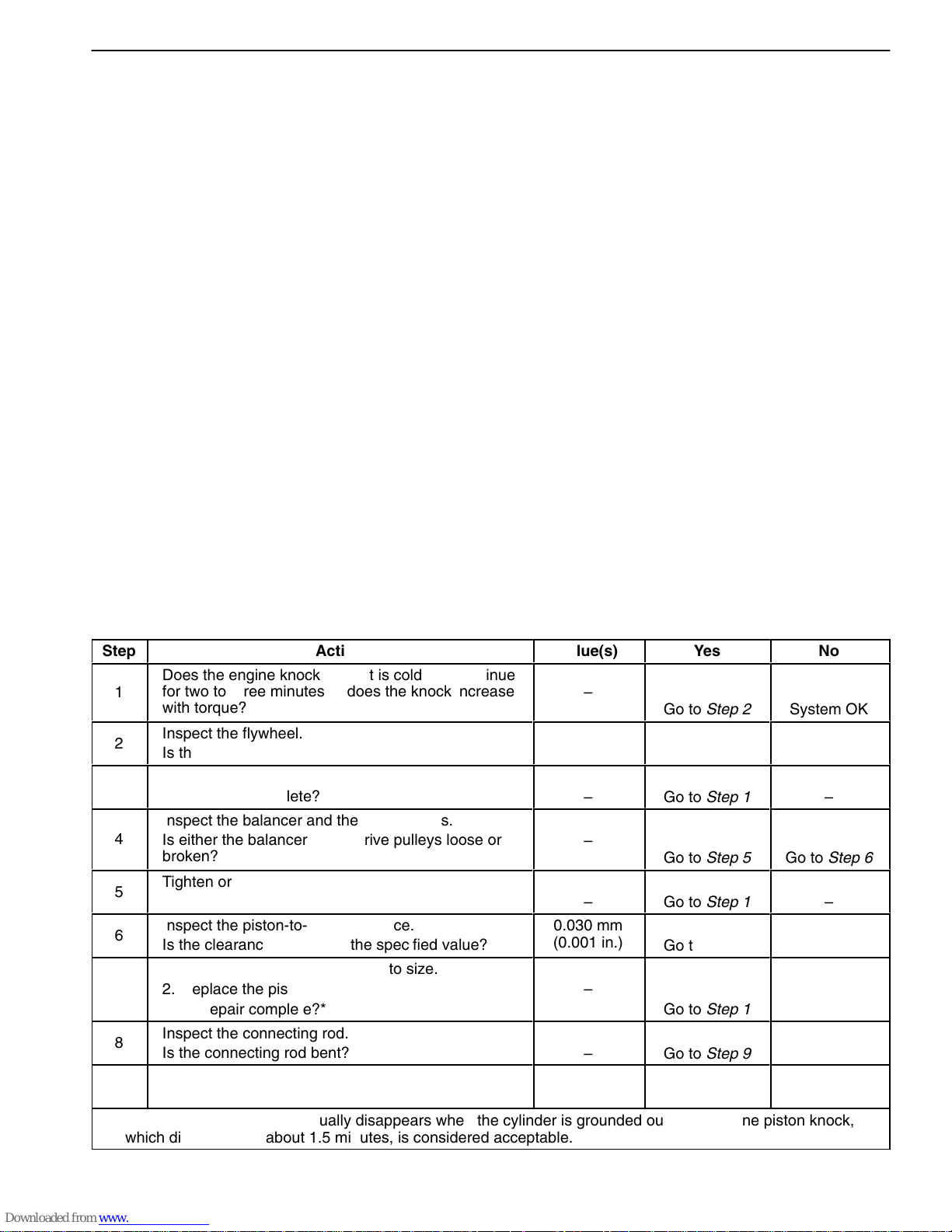

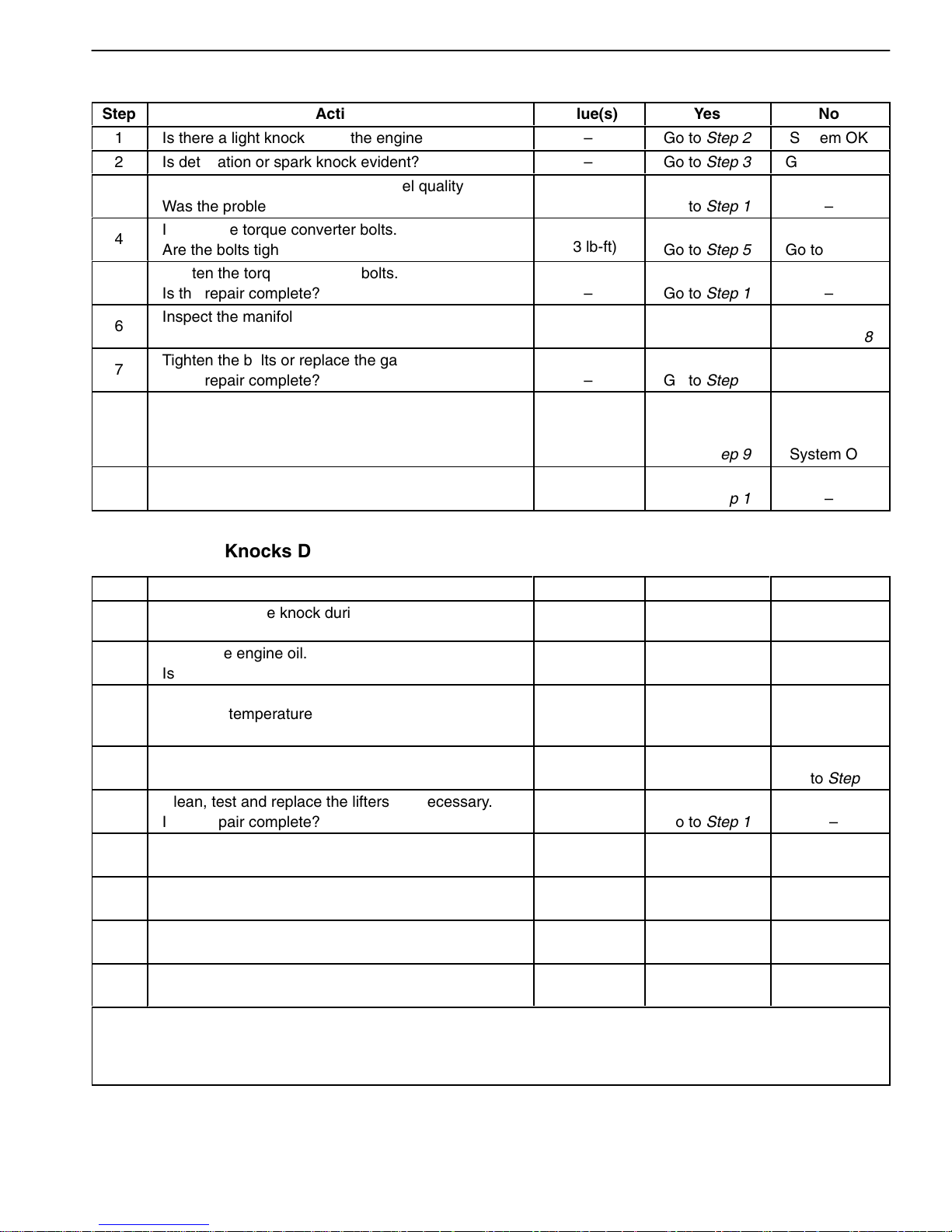

Engine Knocks Cold and Continues for Two-Three Minutes

and/or Knock Increases with Engine Torque

Step

ÜÜ

1

ÜÜ

2

ÜÜ

3

ÜÜ

4

ÜÜ

5

ÜÜ

6

ÜÜ

Does the engine knock when it is cold and continue

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

for two to three minutes or does the knock increase

with torque?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Inspect the flywheel.

Is the flywheel contacting the splash shield?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Reposition the splash shield.

Is the repair complete?

Inspect the balancer and the drive pulleys.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is either the balancer or the drive pulleys loose or

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

broken?

Tighten or replace the balancer or the drive pulleys.

Is the repair complete?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Inspect the piston-to-bore clearance.

Is the clearance more than the specified value?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

1. Rebore the cylinder and hone to size.

7

ÜÜ

8

ÜÜ

9

ÜÜ

2. Replace the piston.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?*

Inspect the connecting rod.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the connecting rod bent?

Replace the connecting rod.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

* Cold engine piston knock usually disappears when the cylinder is grounded out. Cold engine piston knock,

which disappears in about 1.5 minutes, is considered acceptable.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Action

Value(s)

ÜÜÜ

–

ÜÜÜ

–

ÜÜÜ

–

ÜÜÜ

–

ÜÜÜ

ÜÜÜ

–

0.030 mm

(0.001 in.)

ÜÜÜ

–

ÜÜÜ

ÜÜÜ

–

ÜÜÜ

–

Yes

ЬЬЬЬЬ

Go to Step 2

ЬЬЬЬЬ

Go to Step 3

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

ЬЬЬЬЬ

Go to Step 5

ЬЬЬЬЬ

Go to Step 1

Go to Step 7

ЬЬЬЬЬ

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

Go to Step 9

ЬЬЬЬЬ

Go to Step 1

No

ÜÜÜÜ

System OK

ÜÜÜÜ

Go to Step 4

ÜÜÜÜ

–

ÜÜÜÜ

ÜÜÜÜ

Go to Step 6

ÜÜÜÜ

–

Go to Step 8

ÜÜÜÜ

–

ÜÜÜÜ

ÜÜÜÜ

System OK

ÜÜÜÜ

–

DAEWOO T-154 BL2,3

Page 5

GENERAL ENGINE INFORMATION 1A – 5

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

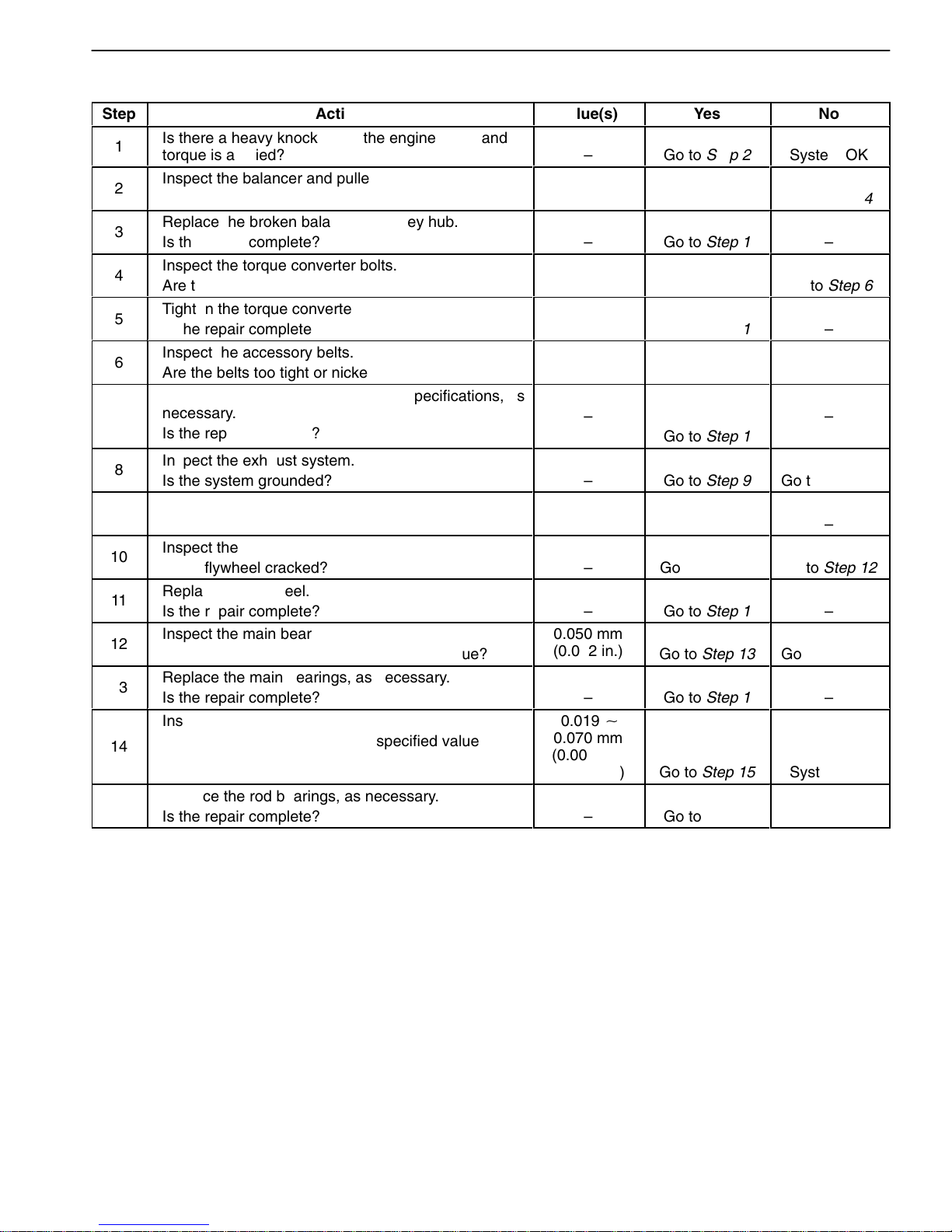

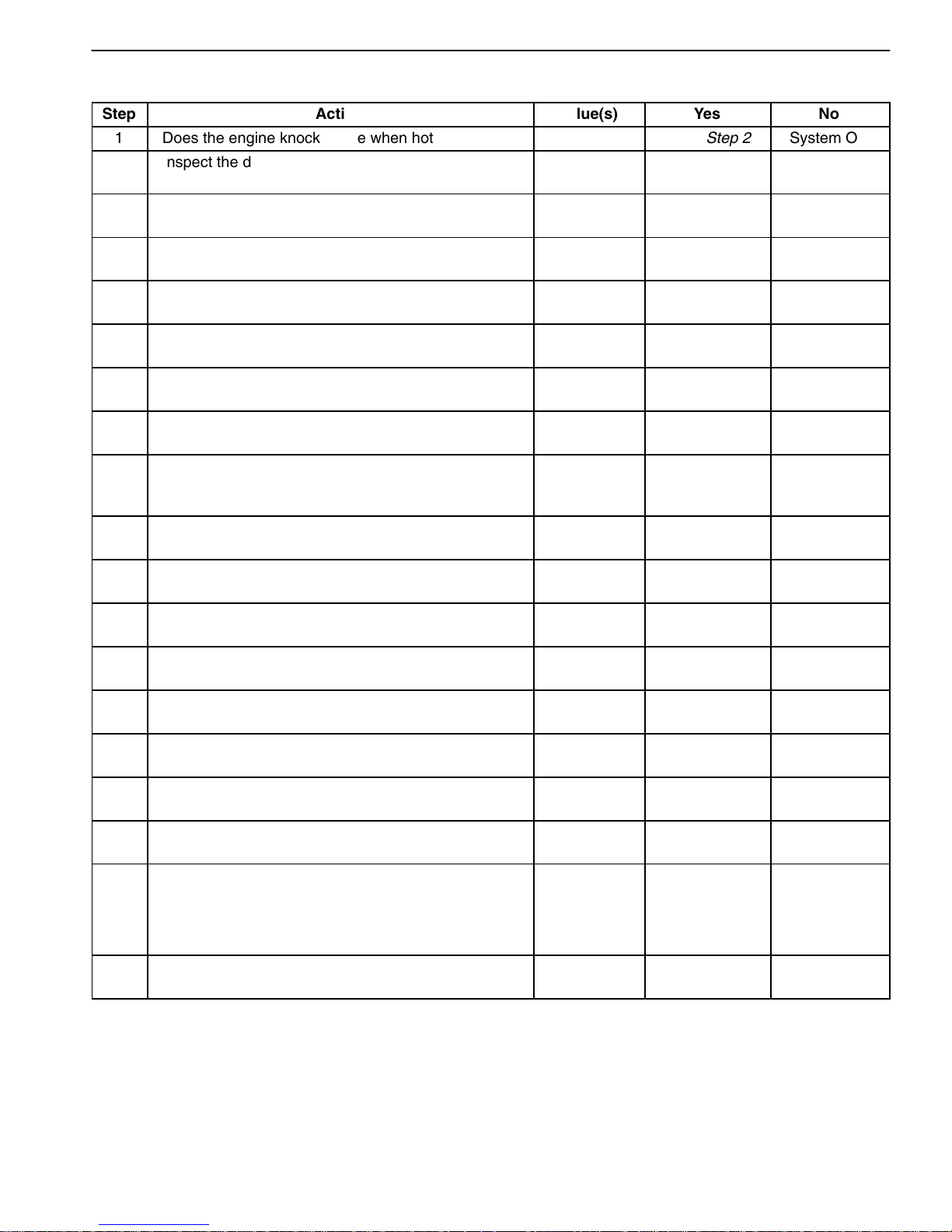

Heavy Knock Hot with Torque Applied

Step

1

ÜÜ

2

3

ÜÜ

4

ÜÜ

5

ÜÜ

6

ÜÜ

7

ÜÜ

8

ÜÜ

9

ÜÜ

10

ÜÜ

11

ÜÜ

12

ÜÜ

13

ÜÜ

14

ÜÜ

15

ÜÜ

Action

Is there a heavy knock when the engine is hot and

torque is applied?

Inspect the balancer and pulley hub.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the balancer or pulley hub broken?

Replace the broken balancer or pulley hub.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Inspect the torque converter bolts.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Are the bolts tightened to the specified value?

Tighten the torque converter bolts.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Inspect the accessory belts.

Are the belts too tight or nicked?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Replace and/or tension the belts to specifications, as

necessary.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Inspect the exhaust system.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the system grounded?

Reposition the system, as necessary.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Inspect the flywheel.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the flywheel cracked?

Replace the flywheel.

Is the repair complete?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Inspect the main bearing clearance.

Is the clearance more than the specified value?

Replace the main bearings, as necessary.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Inspect the rod bearing clearance.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the clearance more than the specified value?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Replace the rod bearings, as necessary.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Is the repair complete?

Value(s)

–

ÜÜÜ

–

ÜÜÜ

–

45 NSm

ÜÜÜ

(33 lb-ft)

ÜÜÜ

–

–

ÜÜÜ

–

ÜÜÜ

ÜÜÜ

–

ÜÜÜ

–

ÜÜÜ

–

–

ÜÜÜ

0.050 mm

(0.002 in.)

ÜÜÜ

–

0.019 X

ÜÜÜ

0.070 mm

(0.0007 X

ÜÜÜ

0.0028 in.)

ÜÜÜ

–

Yes

Go to Step 2

ЬЬЬЬЬ

Go to Step 3

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

Go to Step 5

ЬЬЬЬЬ

Go to Step 1

Go to Step 7

ЬЬЬЬЬ

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

Go to Step 9

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

Go to Step 11

Go to Step 1

ЬЬЬЬЬ

Go to Step 13

ЬЬЬЬЬ

Go to Step 1

ЬЬЬЬЬ

ЬЬЬЬЬ

Go to Step 15

ЬЬЬЬЬ

Go to Step 1

No

System OK

ÜÜÜÜ

Go to Step 4

ÜÜÜÜ

–

ÜÜÜÜ

Go to Step 6

ÜÜÜÜ

–

Go to Step 8

ÜÜÜÜ

–

ÜÜÜÜ

ÜÜÜÜ

Go to Step 10

ÜÜÜÜ

–

ÜÜÜÜ

Go to Step 12

–

ÜÜÜÜ

Go to Step 14

ÜÜÜÜ

–

ÜÜÜÜ

ÜÜÜÜ

System OK

ÜÜÜÜ

–

DAEWOO T-154 BL2,3

Page 6

1A – 6 GENERAL ENGINE INFORMATION

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Light Knock Hot

Step

1

2

3

ÜÜ

4

ÜÜ

5

6

ÜÜ

7

ÜÜ

ÜÜ

8

ÜÜ

9

ÜÜ

Action

Is there a light knock when the engine is hot?

Is detonation or spark knock evident?

Value(s)

–

–

Yes

Go to Step 2

Go to Step 3

No

System OK

Go to Step 4

Check the engine timing and the fuel quality.

Was the problem found?

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

Inspect the torque converter bolts.

Are the bolts tightened to the specified value?

–

ÜÜÜ

45 NSm

(33 lb-ft)

Go to Step 1

ЬЬЬЬЬ

ÜÜÜÜ

Go to Step 5 Go to Step 6

–

Tighten the torque converter bolts.

Is the repair complete?

– Go to Step 1 –

Inspect the manifold.

Is there an exhaust leak at the manifold? – Go to Step 7 Go to Step 8

Tighten the bolts or replace the gasket.

Is the repair complete? – Go to Step 1 –

Check the rod bearing clearance.

Is the clearance within the specified value?

0.019 X

0.070 mm

(0.0007 X

0.0028 in.) Go to Step 9 System OK

Replace the rod bearings as necessary.

Is the repair complete? – Go to Step 1 –

Knocks During Initial Start-Up But Last Only a Few Seconds

Step

1

2

Does the engine knock during initial start-up but last

only a few seconds?

Check the engine oil.

Is the proper viscosity oil used in the crankcase? – Go to Step 4 Go to Step 3

Action

Value(s)

Yes

– Go to Step 2 System OK

No

Install oil of the proper viscosity for the expected

3

seasonal temperatures.

Is the repair complete?

4

5

6

7

8

9

Inspect the hydraulic lifters.

Is there evidence of hydraulic lifter bleed-down? – Go to Step 5 Go to Step 6

Clean, test and replace the lifters, as necessary.

Is the repair complete?*

Inspect the crankshaft end clearance.

Is the clearance more than specified value?

Replace the crankshaft thrust bearing.

Is the repair complete? – Go to Step 1 –

Inspect the front main bearing clearance.

Is the clearance more than the specified value?

Replace the worn parts of the front main bearing.

Is the repair complete?

–

Go to Step 1

– Go to Step 1 –

0.1 mm

(0.0039 in.)

Go to Step 7 Go to Step 8

0.005 mm

(0.0001 in.)

Go to Step 9 System OK

– Go to Step 1 –

–

* When the engine is stopped, some valves will be open. Spring pressure against the lifters will tend to bleed

lifter down. Attempts to repair this should be made only if the problem is consistent.

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

An engine that is only operated for short periods between start-ups may have lifter noise that lasts for a few

ЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬЬ

minutes. This is a normal condition.

DAEWOO T-154 BL2,3

Page 7

GENERAL ENGINE INFORMATION 1A – 7

Knocks at Idle Hot

Step

Action

Value(s)

Yes

No

1 Does the engine knock at idle when hot? – Go to Step 2 System OK

2

3

4

5

6

7

8

Inspect the drive belts.

Are the belts loose or worn? – Go to Step 3 Go to Step 4

Tension or replace the belts, as necessary.

Is the repair complete?

– Go to Step 1 –

Inspect the A/C compressor and the generator.

Is either the compressor or the generator faulty? – Go to Step 5 Go to Step 6

Replace the faulty A/C compressor or the generator.

Is the repair complete?

– Go to Step 1 –

Inspect the valve train.

Are valve train components faulty? – Go to Step 7 Go to Step 8

Replace faulty valve train components.

Is the repair complete?

Check the engine oil.

Is the proper viscosity oil used in the crankcase?

– Go to Step 1 –

–

Go to Step 10 Go to Step 9

Install oil of the proper viscosity for the expected

9

10

11

12

13

14

15

16

17

18

seasonal temperatures.

Is the repair complete?

Inspect the piston pin clearance.

Is the clearance more than the specified value?

–

0.020 mm

(0.0008 in.)

Go to Step 1

Go to Step 11 Go to Step 12

Replace the piston and the pin.

Is the repair complete? – Go to Step 1 –

Check the connecting rod alignment.

Is the alignment faulty?

– Go to Step 13 Go to Step 14

Check and replace the rods, as necessary.

Is the repair complete? – Go to Step 1 –

Inspect the piston-to-bore clearance.

Is the clearance within the specified value?

0.030 mm

(0.0012 in.) Go to Step 16 Go to Step 15

Hone the bore and fit a new piston.

Is the repair complete?

– Go to Step 1 –

Inspect the crankshaft balancer.

Is the balancer loose?

– Go to Step 17 Go to Step 18

Torque or replace worn parts.

Is the repair complete? – Go to Step 1 –

Check the piston pin offset.

Is the offset at the specified value?

0.5 X 0.7

mm (0.020 X

0.028 in.)

–

Toward Thrust

Side Go to Step 19 System OK

19

Install the correct piston.

Is the repair complete? – Go to Step 1 –

DAEWOO T-154 BL2,3

Page 8

1A – 8 GENERAL ENGINE INFORMATION

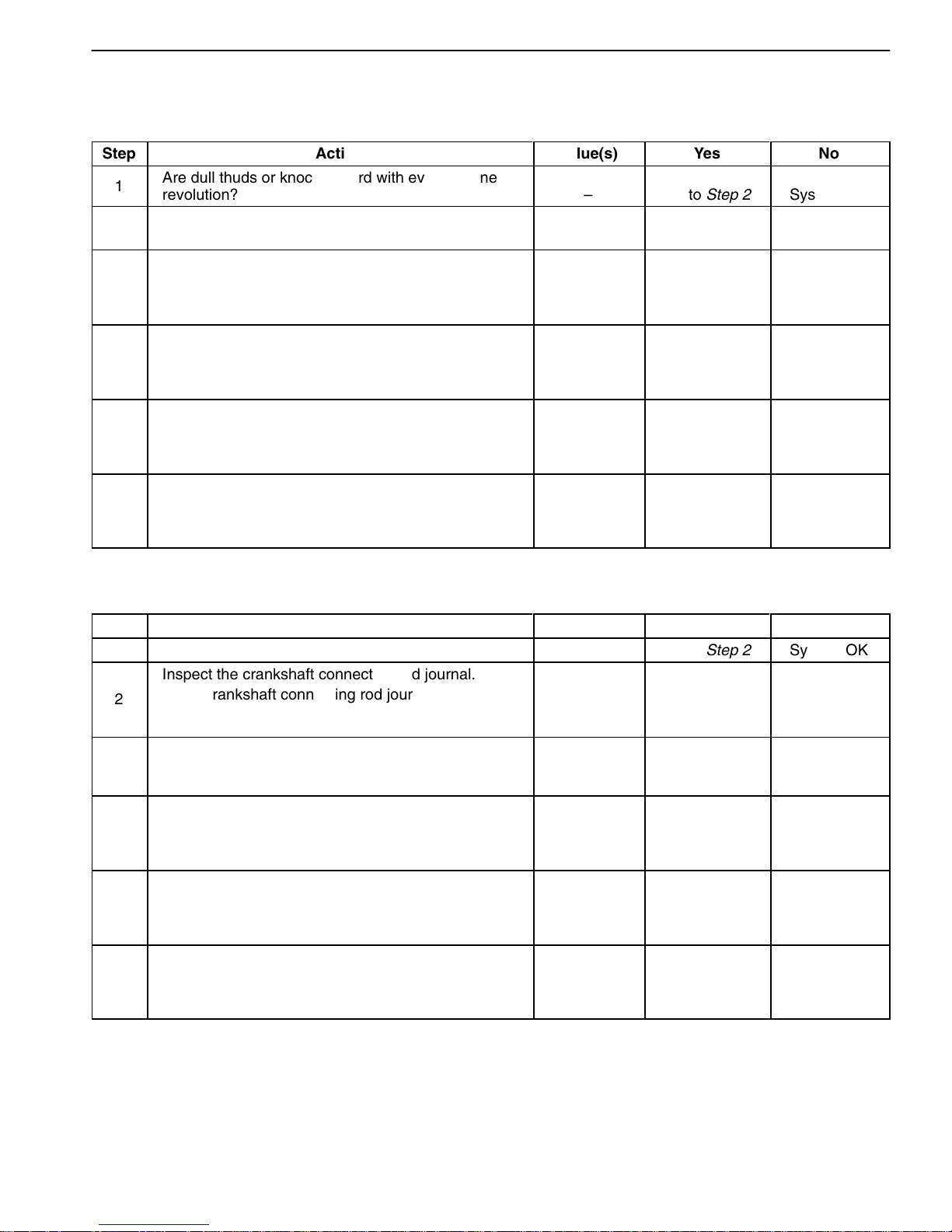

NOISE DIAGNOSIS

Main Bearing Noise

Step

1

2

3

4

5

6

Action

Are dull thuds or knocks heard with every engine

revolution? – Go to Step 2 System OK

Check the oil pump pressure.

Is the oil pump pressure low?

Inspect the crankshaft end play.

Does the crankshaft end play exceed the specified

value?

Inspect the crankshaft journals.

Are the crankshaft journals out-of-round?

Inspect the belt tension.

Does the belt tension exceed the specified value?

Inspect the crankshaft pulley.

Is the crankshaft pulley loose?

Value(s)

–

0.1 mm

(0.0039 in.)

0.004 mm

(0.0002 in.)

max.

–

–

Yes

Go to Oil

Pressure Test

Go to

Crankshaft

Replacement

Procedure

Go to

Crankshaft

Replacement

Procedure

Go to

Timing Belt

Replacement

Procedure Go to Step 6

Go to

Crankshaft

Replacement

Procedure

No

Go to Step 3

Go to Step 4

Go to Step 5

System OK

Connecting Rod Bearing Noise Symptom

Step

1 Is a knock noise heard under all engine speeds? – Go to Step 2 System OK

Inspect the crankshaft connecting rod journal.

2

3

4

5

6

Is the crankshaft connecting rod journal worn?

Check the oil pump pressure.

Is the oil pump pressure low?

Inspect the crankshaft connecting rod journals.

Are the journals out of round?

Inspect the connecting rods.

Is there a misaligned connecting rod?

Inspect the connecting rod bolts.

Are the connecting rod bolts torqued properly?

Action

Value(s)

–

–

–

–

–

Yes

Go to

Crankshaft

Replacement

Procedure Go to Step 3

Go to

Oil Pressure

Test Go to Step 4

Go to

Crankshaft

Replacement

Procedure Go to Step 5

Go to Pistons

and Rods

Replacement

Procedure Go to Step 6

System OK

No

Go to Pistons

and Rods

Replacement

Procedure

DAEWOO T-154 BL2,3

Page 9

GENERAL ENGINE INFORMATION 1A – 9

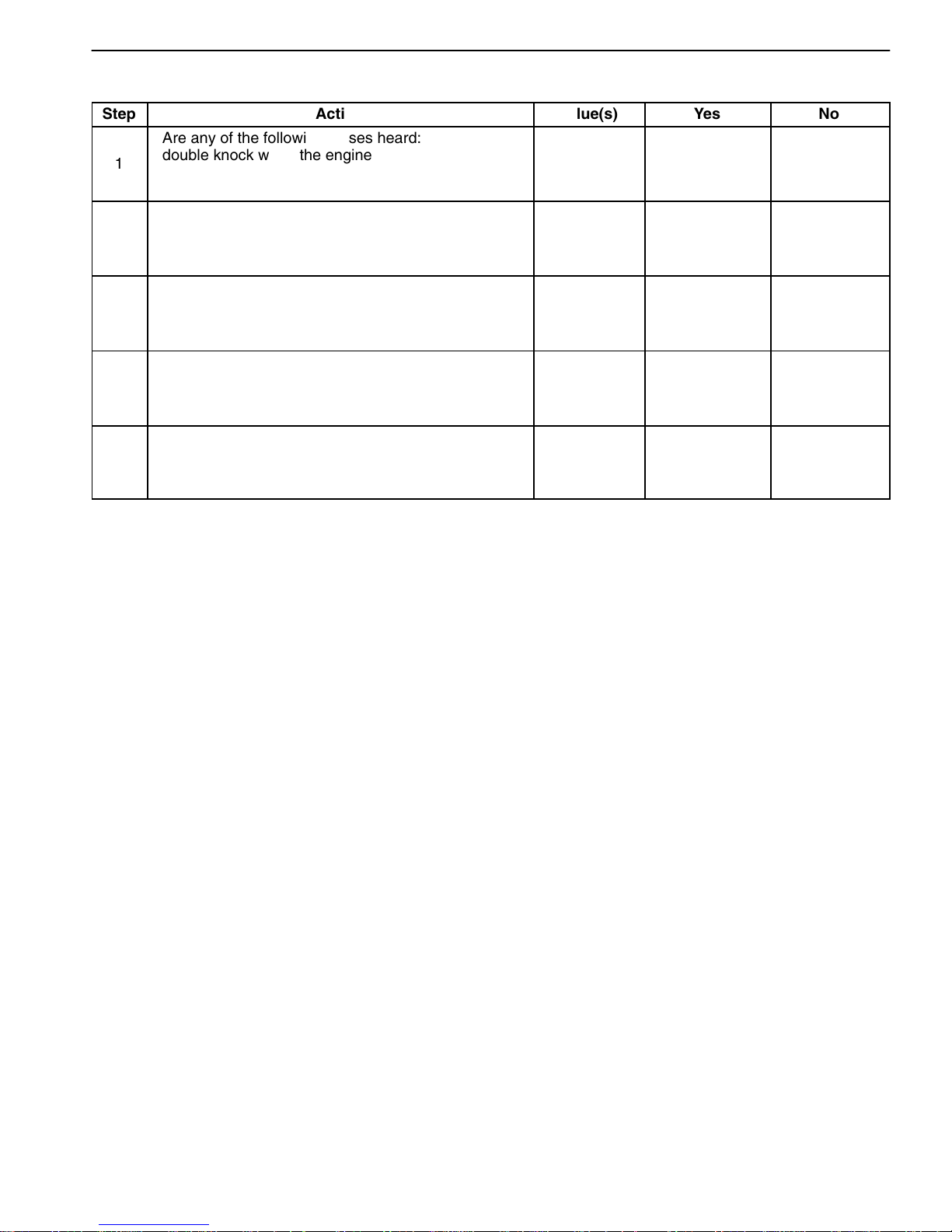

Piston Noises

Step

1

2

3

4

5

Action

Are any of the following noises heard: a sharp

double knock when the engine is idling, a light

ticking with no load on the engine or a ‘‘slapping’’

noise when the engine is cold?

Inspect the piston pin and the bushing.

Is the piston pin or the bushing worn or loose?

Inspect the piston.

Is the piston broken or cracked?

Inspect the connecting rods.

Is there a misaligned connecting rod?

Inspect the piston position.

Is the piston 180_ out of position?

Value(s)

–

–

–

–

–

Yes

No

Go to Step 2 System OK

Go to Pistons

and Rods

Replacement

Procedure Go to Step 3

Go to Pistons

and Rods

Replacement

Procedure Go to Step 4

Go to Pistons

and Rods

Replacement

Procedure Go to Step 5

Go to Pistons

and Rods

Replacement

Procedure System OK

DAEWOO T-154 BL2,3

Page 10

1A – 10 GENERAL ENGINE INFORMATION

Valve Mechanism or Valve Train Noises

Step

Action

Value(s)

Yes

No

1 Is a light tapping sound heard from the engine? – Go to Step 2 System OK

Inspect the valve springs.

Are the springs weak or broken?

2

–

Go to

Cylinder Head

and Valve Train

Components

Replacement

Procedure Go to Step 3

Inspect the valves.

Are the valves sticking or warped?

3

–

Go to

Cylinder Head

and Valve Train

Components

Replacement

Procedure

Inspect the valve lifters.

Are the valve lifters dirty, stuck or worn?

4

–

Go to

Cylinder Head

and Valve Train

Components

Go to Step 4

Replacement

Procedure Go to Step 5

Inspect the camshaft lobes.

5

Are the camshaft lobes damaged or improperly

machined?

–

Check the oil supply to the valve train.

Is the oil supply insufficient or poor?

6

–

Go to

Camshaft

Replacement

Procedure Go to Step 6

Go to

Cylinder Head

and Valve Train

Components

Replacement

Procedure Go to Step 7

Inspect the valve guides.

Are the valve guides worn?

7

–

Go to

Cylinder Head

and Valve Train

Components

Replacement

Procedure

Inspect the valve spring seat.

Is the valve spring seat incorrect?

8

–

Go to

Cylinder Head

and Valve Train

Components

Go to Step 8

Replacement

Procedure System OK

DAEWOO T-154 BL2,3

Page 11

GENERAL ENGINE INFORMATION 1A – 11

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the ten-thousandths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

engine oil should be applied to friction areas during assembly, to protect and lubricate the surfaces on initial

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair procedure. This is considered standard shop practice even if

not specifically stated.

Whenever valve train components are removed for service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable before removing or installing any electrical unit, or

when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against accidental entrance of foreign material, which could follow

the intake passage into the cylinder and cause extensive

damage when the engine is started.

DAEWOO T-154 BL2,3

Page 12

BLANK

DAEWOO T-154 BL2,3

Page 13

.

SECTION 1B

SOHC ENGINE MECHANI CAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Specifications 1B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Specifications 1B-2. . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 1B-4. . . . . . . . . . .

Special Tools 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 1B-5. . . . . . . . . . . . . . . . . . . . . . . .

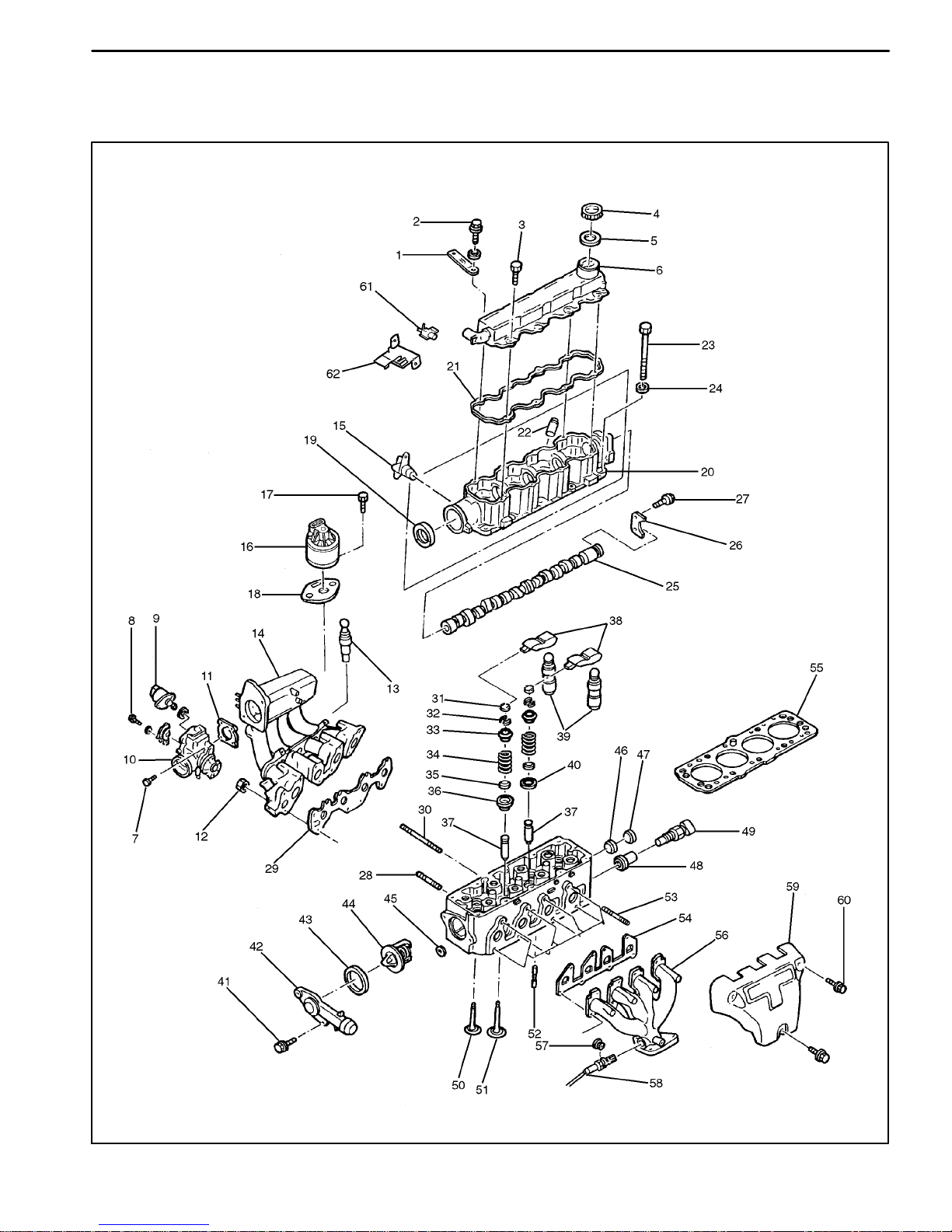

Component Locator 1B-8. . . . . . . . . . . . . . . . . . . . . . . .

Upper End 1B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

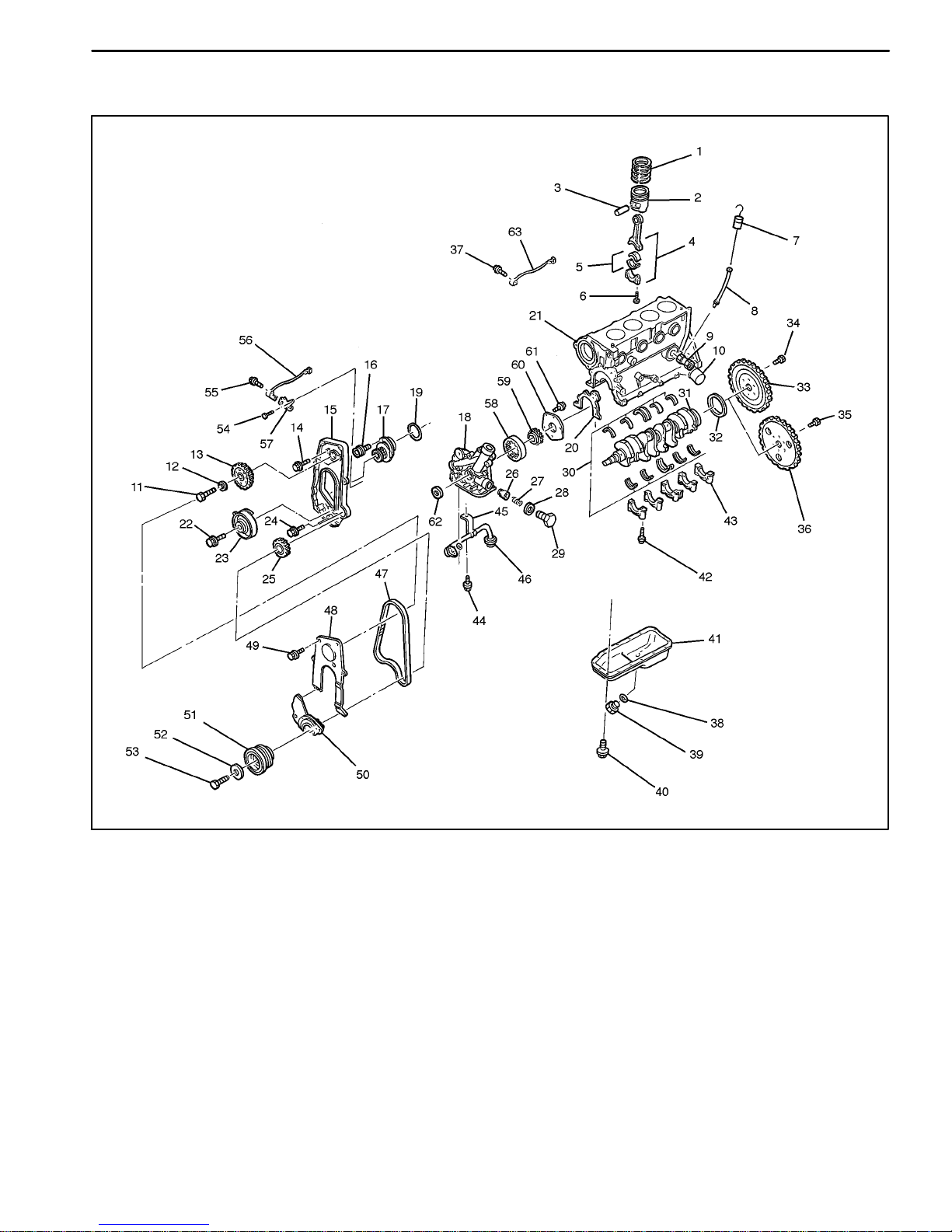

Lower End 1B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance and Repair 1B-12. . . . . . . . . . . . . . . . . . .

On-Vehicle Service 1B-12. . . . . . . . . . . . . . . . . . . . . . . . .

Valve Cover 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1B-13. . . . . . . . . . . . . . . . .

Camshaft 1B-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt Check and Adjust 1B-31. . . . . . . . . . . . . .

Timing Belt 1B-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1B-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1B-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Mount 1B-50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1B-52. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold 1B-57. . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Gear 1B-58. . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Timing Belt Cover 1B-60. . . . . . . . . . . . . . . . . . .

Engine 1B-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistons and Rods 1B-71. . . . . . . . . . . . . . . . . . . . . . . .

Unit Repair 1B-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Valve Train

Components 1B-77. . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 1B-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Bearings and Connecting Rod

Bearings – Gauging Plastic 1B-93. . . . . . . . . . . . . .

General Description and System

Operation 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1B-96. . . . . . . . . . . . . . . . .

Crankshaft 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold 1B-96. . . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 1B-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation Valve 1B-96. . . . . . . . . . .

DAEWOO T-154 BL2,3

Page 14

1B–2 SOHC ENGINE MECHANICAL

SPECIFICATIONS

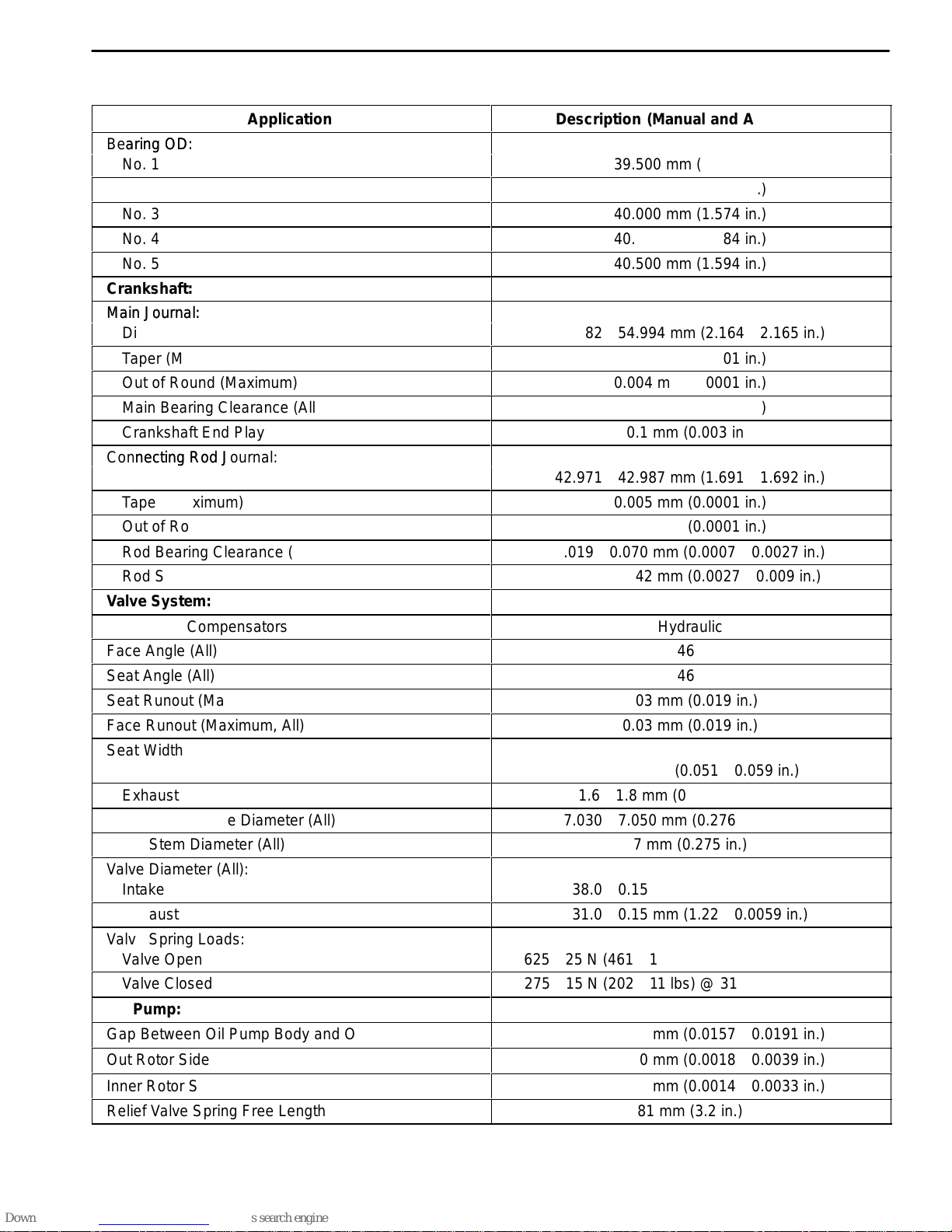

ENGINE SPECIFICATIONS

Application Description (Manual and Automatic)

General Data:

Engine Type 4 Cylinder (In-Line)

Displacement:

1.5 SOHC 1 498 cm3 (91.44 in3)

Bore Stroke:

1.5 SOHC 76.5 X 81.5 mm (3.01 in. X 3.21 in.)

Compression Ratio 9.5 0.2:1

Firing Order 1–3–4–2

Cylinder Bore:

Diameter 76.5 mm (3.01 in.)

Out of Round (Maximum) 0.0065 mm (0.00025 in.)

Taper (Maximum):

1.5 SOHC 0.0065 mm (0.00025 in.)

Piston:

Diameter 76.470 mm (3.01 in.)

Clearance to Bore 0.030 mm (0.0012 in.)

Piston Rings:

Ring, End Gap:Ring, End Gap:

Top Compression 0.3 mm (0.019 in.)

2nd Compression 0.3 mm (0.019 in.)

Groove Clearance:Groove Clearance:

Top Impression 0.02 mm (0.0008 in)

2nd Impression 0.02 mm (0.0008 in.)

Piston Pin:

Diameter 18.000 mm (0.708 in.)

Pin Off-Set 0.5 0.7 mm (0.019 0.027 in.)

Camshaft:

Lift Intake:

1.5 SOHC 6.12 mm (0.240 in.)

Lift Exhaust 6.12 mm (0.240 in.)

End Play 0.09 0.21 mm (0.0035 0.0082 in.)

Journal OD:Journal OD:

No. 1 39.445 mm (1.552 in.)

No. 2 39.700 mm (1.562 in.)

No. 3 39.945 mm (1.572 in.)

No. 4 40.200 mm (1.582 in.)

No. 5 40.445 mm (1.592 in.)

DAEWOO T-154 BL2,3

Page 15

SOHC ENGINE MECHANICAL 1B–3

Á

Á

ENGINE SPECIFICATIONS (Cont’d)

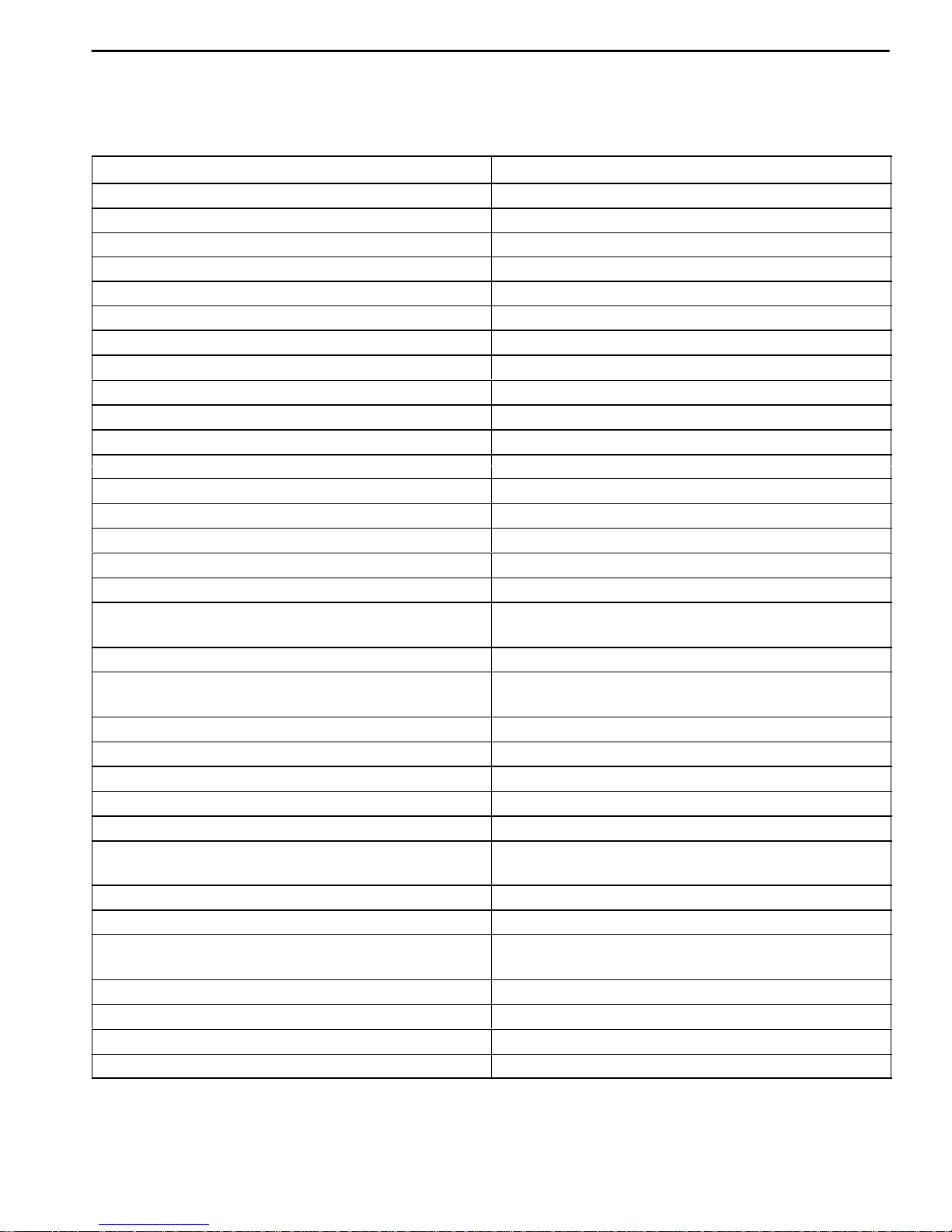

Application

Bearing OD:

Bearing OD:

No. 1

No. 2

No. 3

No. 4

No. 5

Crankshaft:

Main Journal:

Main Journal:

Diameter (All)

Taper (Maximum)

Out of Round (Maximum)

Main Bearing Clearance (All)

Crankshaft End Play

Connecting Rod Journal:

Connecting Rod Journal:

Diameter (All)

Taper (Maximum)

Out of Round (Maximum)

Rod Bearing Clearance (All)

Rod Side Clearance

Valve System:

Valve Lash Compensators

Face Angle (All)

Seat Angle (All)

Seat Runout (Maximum, All)

Face Runout (Maximum, All)

Seat Width:

Seat Width:

Intake

Exhaust

Valve Guide Inside Diameter (All)

Valve Stem Diameter (All)

Valve Diameter (All):

Valve Diameter (All):

Intake

Exhaust

Valve Spring Loads:

Valve Spring Loads:

Valve Open

Valve Closed

Oil Pump:

Gap Between Oil Pump Body and Out Rotor

Out Rotor Side Clearance

Inner Rotor Side Clearance

ББББББББББББББББ

Relief Valve Spring Free Length

Description (Manual and Automatic)

39.500 mm (1.555 in.)

39.750 mm (1.564 in.)

40.000 mm (1.574 in.)

40.250 mm (1.584 in.)

40.500 mm (1.594 in.)

54.982 54.994 mm (2.164 2.165 in.)

0.005 mm (0.0001 in.)

0.004 mm (0.0001 in.)

0.005 mm (0.0001 in.)

0.1 mm (0.003 in.)

42.971 42.987 mm (1.691 1.692 in.)

0.005 mm (0.0001 in.)

0.004 mm (0.0001 in.)

0.019 0.070 mm (0.0007 0.0027 in.)

0.070 0.242 mm (0.0027 0.009 in.)

Hydraulic

46

46

0.03 mm (0.019 in.)

0.03 mm (0.019 in.)

1.3 1.5 mm (0.051 0.059 in.)

1.6 1.8 mm (0.063 0.071 in. )

7.030 7.050 mm (0.276 0.277 in.)

7 mm (0.275 in.)

38.0 0.15 mm (1.49 0.0059 in.)

31.0 0.15 mm (1.22 0.0059 in.)

625 25 N (461 18 lbs) @ 21.5 mm (0.846 in.)

275 15 N (202 11 lbs) @ 31.5 mm (1.240 in.)

0.400 0.484 mm (0.0157 0.0191 in.)

0.045 0.100 mm (0.0018 0.0039 in.)

ББББББББББББББББ

0.035 0.085 mm (0.0014 0.0033 in.)

81 mm (3.2 in.)

DAEWOO T-154 BL2,3

Page 16

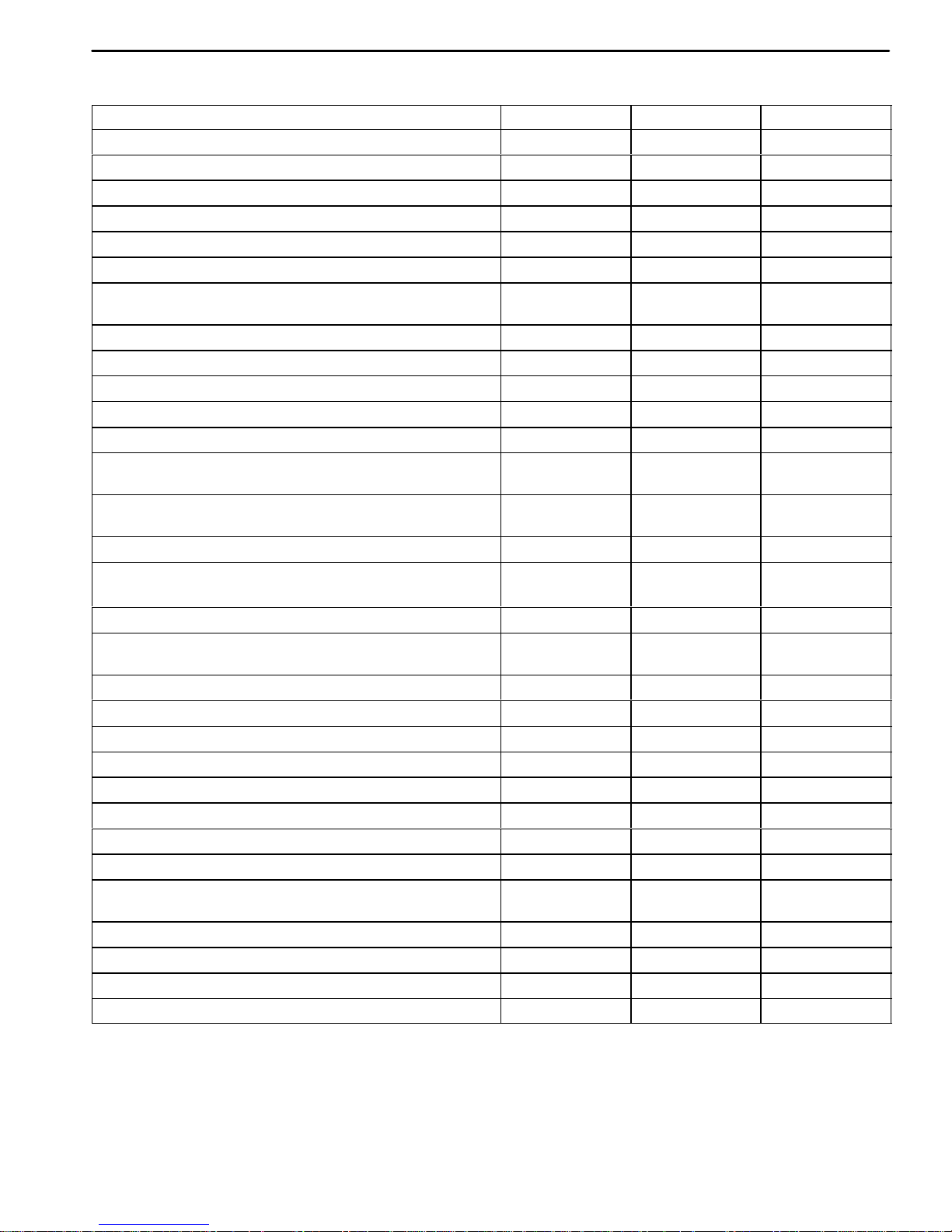

1B–4 SOHC ENGINE MECHANICAL

FASTENER TIGHTENING SPECIFICATIONS

Application Nm Lb-Ft Lb-In

A/C Compressor Hose Assembly Retaining Bolt 33 24 –

A/C Compressor Mounting Bolts 27 20 –

A/C Compressor Mounting Bracket Bolts 50 37 –

Air Filter Housing Bolts 8 – 71

Alternator Adjusting Bolt 25 18 –

Alternator Adjusting Bracket Retaining Bolt 25 18 –

Auxiliary Catalytic Converter-to-Exhaust Manifold Nuts

and Bracket Bolts

Camshaft Gear Bolt 45 33 –

Camshaft Pressure Plate Bolts 10 – 89

Connecting Rod Bearing Cap Bolts 25 + 30 18 + 30 –

Coolant Pump Retaining Bolts 10 – 89

Coolant Temperature Sensor 20 15 –

Crankshaft Bearing Cap Bolts 50

Crankshaft Pulley Bolt 95

Crankshaft Position Sensor Retaining Bolt 10 – 89

Cylinder Head Bolts (Camshaft Support Housing &

Cylinder Head Mounting Bolts)

Electronic Ignition System Ignition Coil Mounting Bolts 10 – 89

Electronic Ignition System Ignition Coil Mounting Plate

Bolts 10

Engine Lift Bracket Bolt 25 18 –

Engine Mount Attaching Nuts 40 30 –

Engine Mount Bracket Retaining Bolts 60 44 –

Engine Mount Bracket-to-Engine Mount Retaining Bolts 60 44 –

Exhaust Manifold Heat Shield Bolts 15 11 –

Exhaust Manifold Nuts 25 18 –

Flexible Plate Bolts 60 44 –

Flexible Plate Inspection Cover Bolts 10 – 89

Flywheel Bolts 35

Flywheel Inspection Cover Bolts 12 – 106

Front Muffler-to-Main Catalytic Converter Nuts 30 22 –

Fuel Rail Retaining Bolts 25 18 –

Intake Manifold Retaining Nuts 25 18 –

40 30 –

37

+ 45 + 15

+ 45 + 15 –

70

+ 30 + 15

25 + 70

+ 70 + 30

+ 30 + 15 –

18 + 70

+ 70 + 30

–

26

+ 30 + 15

+ 30 + 15 –

–

89

DAEWOO T-154 BL2,3

Page 17

SOHC ENGINE MECHANICAL 1B–5

FASTENER TIGHTENING SPECIFICATIONS (Con t ’d)

Application Nm Lb-Ft Lb-In

Intake Manifold Support Bracket Retaining Bolts 22 16 –

Lower Timing Belt Cover Bolts 10 – 89

Oil Pan Retaining Bolts 10 – 89

Oil Pan Drain Plug 55 41 –

Oil Pressure Switch 40 30 –

Oil Pump Retaining Bolts 10 – 89

Oil Pump/Pickup Tube and Support Bracket Bolts 10 – 89

Oil Pump Safety Relief Valve Bolt 30 22 –

Oil Pump Rear Cover Bolts 6 – 53

Power Steering Pump Mounting Bolts 25 18 –

Power Steering Pump Pulley Bolts 25 18 –

Rear Timing Belt Cover Bolts 10 – 89

Right Transaxle Brace Bolts 60 44 –

Spark Plugs 25 18 –

Thermostat Housing Mounting Bolts 20 15 –

Throttle Cable Bracket Bolts 8 – 71

Timing Belt Automatic Tensioner Bolt 20 15 –

Transaxle Bell Housing Bolts 75 55 –

Transaxle Torque Converter Bolts 65 48 –

Upper Timing Belt Cover Bolts 10 – 89

Valve Cover Bolts 9 – 80

A102B150

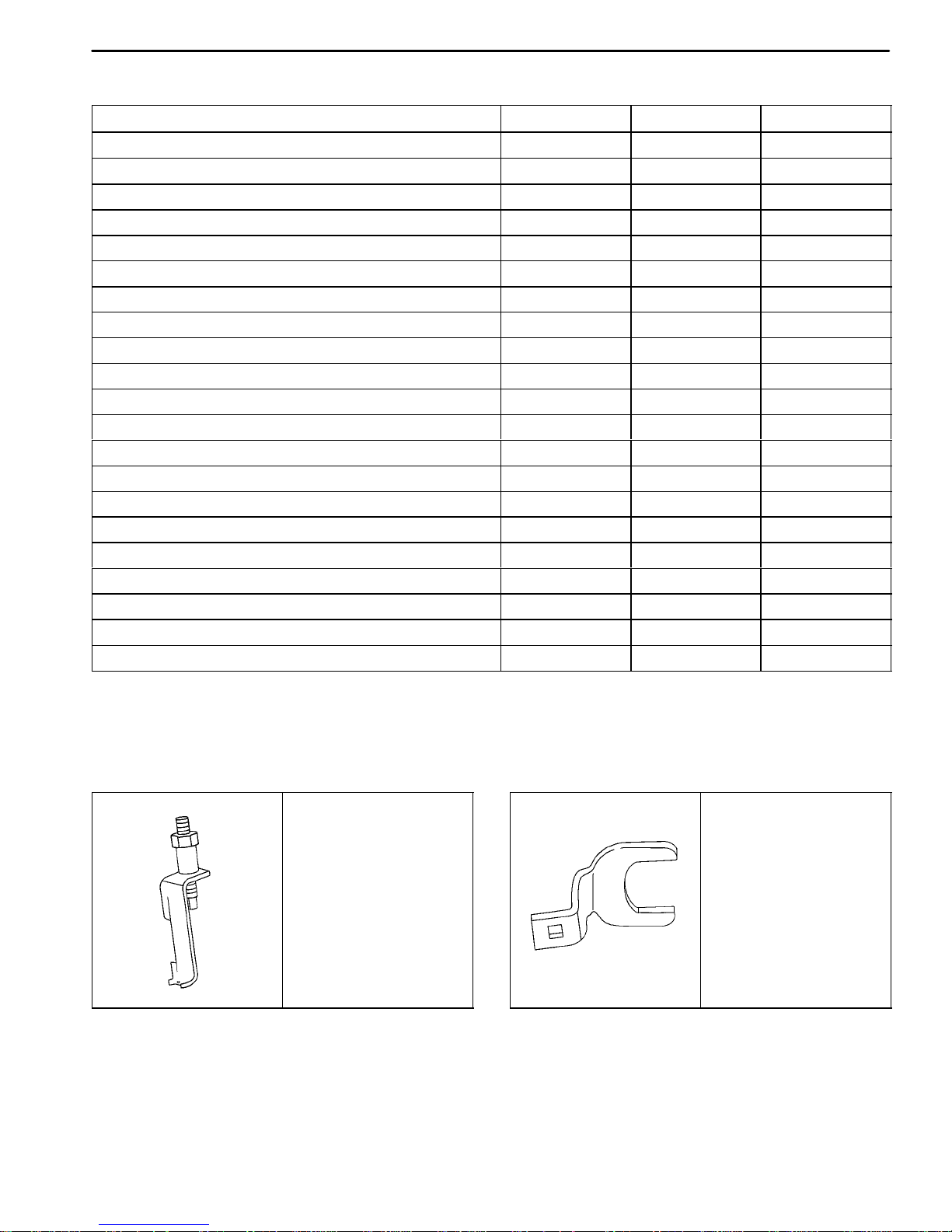

SPECIAL TOOLS

SPECIAL TOOL S TABLE

KM-565-A

Valve Spring

Compressor

J-42492

Timing Belt Adjuster

A102B151

DAEWOO T-154 BL2,3

Page 18

1B–6 SOHC ENGINE MECHANICAL

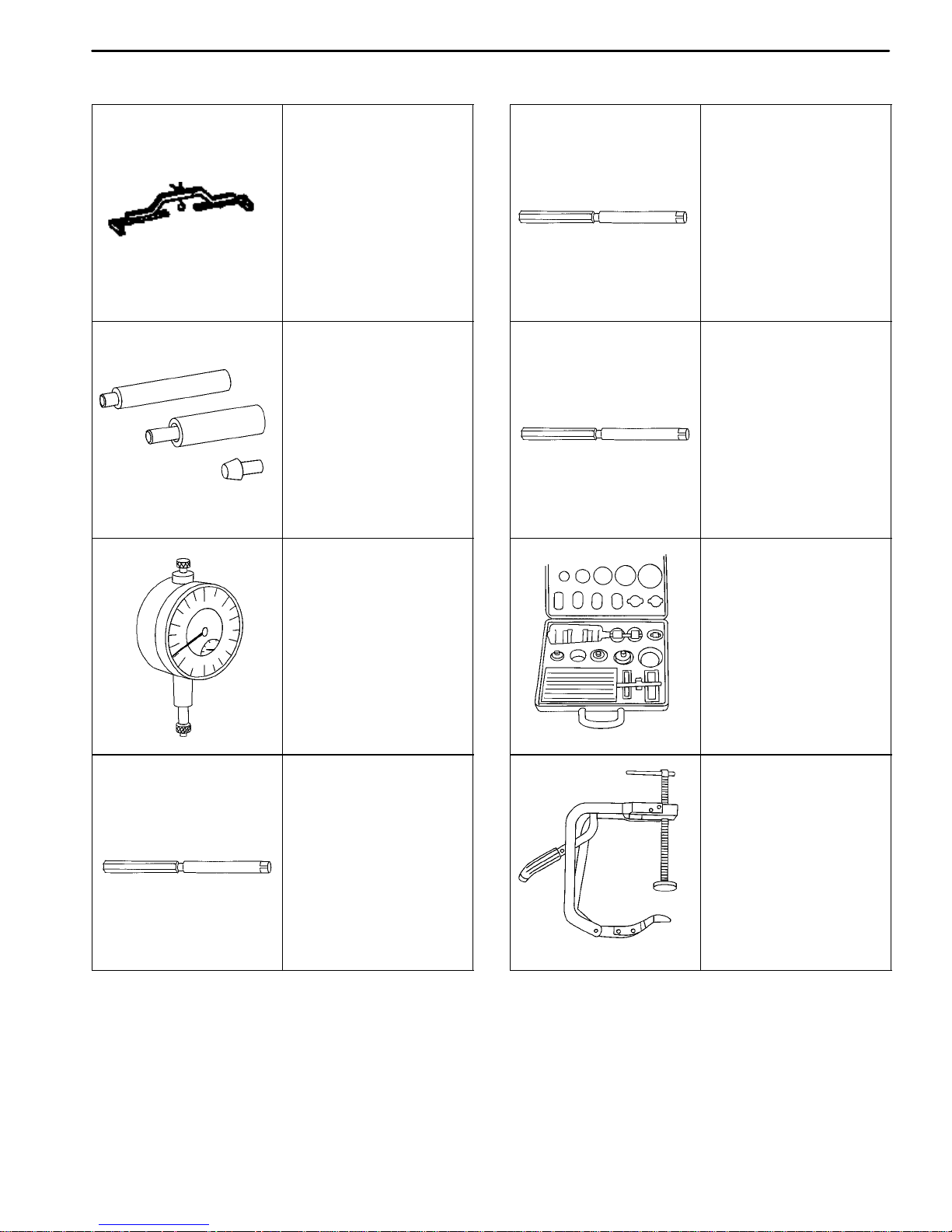

SPECIAL TOOLS TABLE (Cont’d)

A102B152

A102B153

KM -263-B

Engine Assembly

Support Fixture

KM-427

Piston Pin Service Set

MKM-571-B

Gauge

KM-254

Valve Guide Reamer

A102B155

KM-255

Valve Guide Reamer

A102B155

KM-340-0

Cutter Set

Includes: KM-340-7

Includes: KM-340-13

Includes: KM-340-26

A102B154

A102B155

KM-253

Valve Guide Reamer

A102B156

KM-348

Valve Spring

Compressor

A102B157

DAEWOO T-154 BL2,3

Page 19

SOHC ENGINE MECHANICAL 1B–7

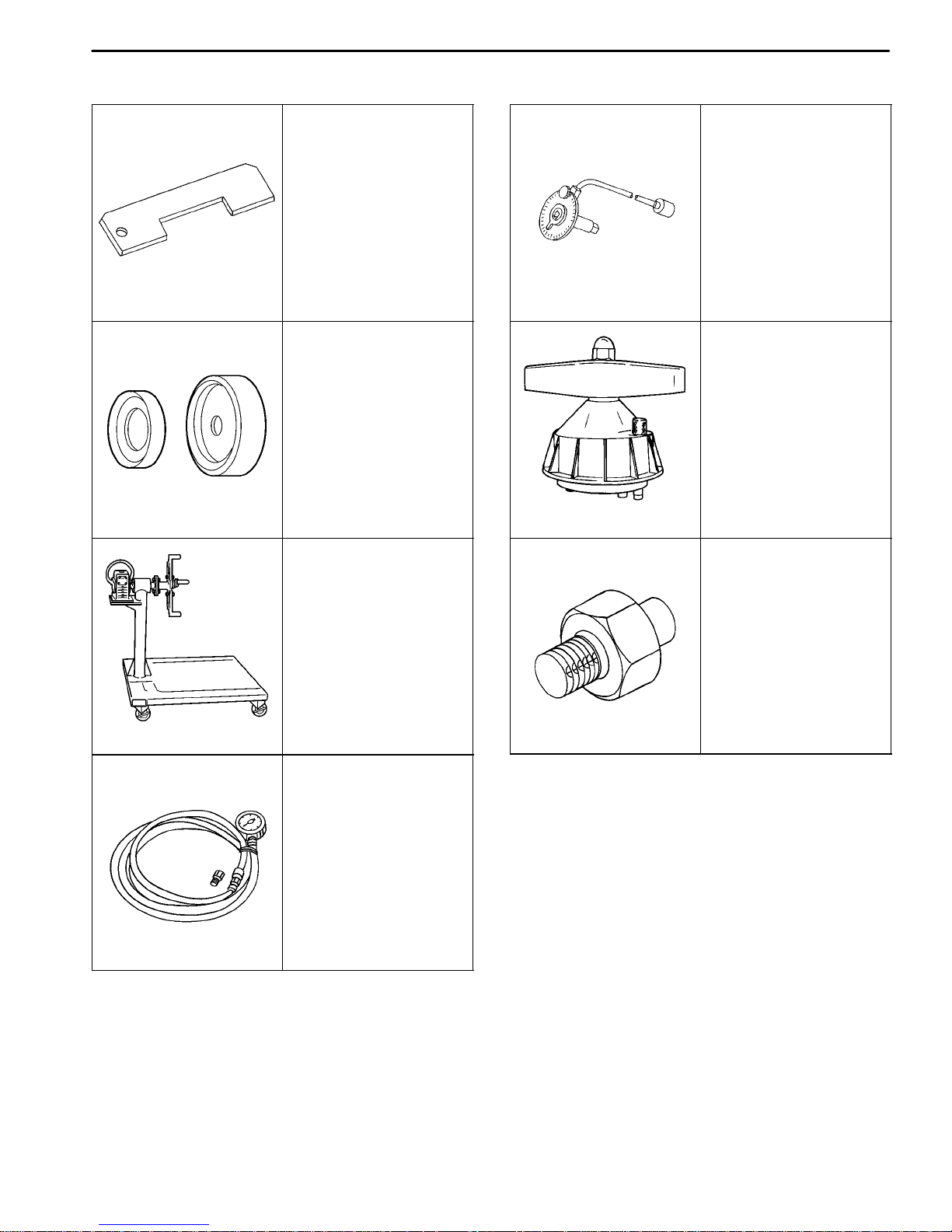

SPECIAL TOOLS TABLE (Cont’d)

A102B158

A102B160

KM-419

Distance Gauge

KM-635

Crankshaft Rear Oil

Seal Installer

MKM-412

Engine Overhaul Stand

KM-470-B

Angular Torque Gauge

A102B161

J-36972

Crankshaft Rear Oil

Seal Installer

A102C155

KM-135

Adapter

A102B159

A202B005

B102C044

KM-498-B

Pressure Gauge

DAEWOO T-154 BL2,3

Page 20

1B–8 SOHC ENGINE MECHANICAL

COMPONENT LOCATOR

UPPER END

A402B001

DAEWOO T-154 BL2,3

Page 21

SOHC ENGINE MECHANICAL 1B–9

1 Wiring Bracket

2 Bolt

3 Bolt

4 Cap, Bayonet Joint

5 Seal, Bayonet Cap

6 Valve Cover

7 Bolt

8 Throttle Position Sensor

9 Idle Air Control Valve

10 Throttle Body

11 Throttle Body Gasket

12 Nut

13 Engine Coolant Temperature Sensor

14 Intake Manifold

15 Camshaft Position Sensor

16 EGR Valve

17 Bolt

18 EGR Gasket

19 Shaft Seal Ring

20 Camshaft Support

21 Valve Cover Gasket

22 Tube

23 Cylinder Head Bolt

24 Washer

25 Camshaft

26 Camshaft Pressure Plate

27 Bolt

28 Bolt-Stud

29 Intake Manifold Gasket

30 Bolt-Stud

31 Valve Thrust Piece

32 Valve Key

33 Valve Spring Plate

34 Valve Spring

35 Valve Stem Seal

36 Exhaust Valve Spring Seat

37 Valve Guide

38 Cam Follower

39 Cam Follower Lifter

40 Intake Valve Spring Seat

41 Bolt

42 Thermostat Housing

43 Thermostat Housing Seal Ring

44 Thermostat

45 Screw Plug

46 Oil Duct Cap

47 Oil Duct Cap

48 Adapter

49 Coolant Temperature Sensor

50 Exhaust Valve

51 Intake Valve

52 Cylinder Head Oil Duct Sleeve

53 Bolt-Stud

54 Exhaust Manifold Gasket

55 Cylinder Head Gasket

56 Exhaust Manifold

57 Nut

58 Exhaust Oxygen Sensor

59 Exhaust Manifold Heat Shield

60 Bolt

61 EGR Solenoid

62 Bracket

DAEWOO T-154 BL2,3

Page 22

1B–10 SOHC ENGINE MECHANICAL

LOWER END

A202B006

DAEWOO T-154 BL2,3

Page 23

SOHC ENGINE MECHANICAL 1B–11

1 Piston Ring Seat

2 Piston

3 Piston Pin

4 Connecting Rod

5 Connecting Rod Bearing Set

6 Connecting Rod Bolt

7 Oil Level Gauge Stick

8 Gauge Stick Tube

9 Connecting Piece

10 Oil Filter

11 Camshaft Pulley Bolt

12 Washer

13 Camshaft Gear

14 Rear Cover Bolt

15 Rear Timing Belt Cover

16 Bolt

17 Coolant Pump

18 Oil Pump

19 Seal Ring

20 Oil Pump Body Gasket

21 Engine Block

22 Bolt

23 Auto Tensioner

24 Bolt

25 Crankshaft Gear

26 Pressure Relief Valve Plunger

27 Spring

28 Oil Pump Seal Ring

29 Bolt Plug

30 Crankshaft Bearing Set

31 Crankshaft

32 Shaft Seal Ring

33 Flywheel (Manual Transaxle)

34 Bolt (Manual Transaxle)

35 Bolt (Automatic Transaxle)

36 Flex Plate (Automatic Transaxle)

37 Bolt

38 Threaded Ring

39 Drain Plug

40 Bolt

41 Oil Pan

42 Main Bearing Cap Bolt

43 Main Bearing

44 Bolt

45 Bracket

46 Oil Pickup Tube

47 Timing Belt

48 Upper Timing Belt Front Cover

49 Bolt

50 Lower Timing Belt Front Cover

51 Crankshaft Pulley

52 Washer

53 Bolt

54 Bolt

55 Bolt

56 Crankshaft Position Sensor

57 Bracket

58 Gear

59 Gear

60 Cover

61 Bolt

62 Seal

63 Knock Sensor

DAEWOO T-154 BL2,3

Page 24

1B–12 SOHC ENGINE MECHANICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

VALVE COVER

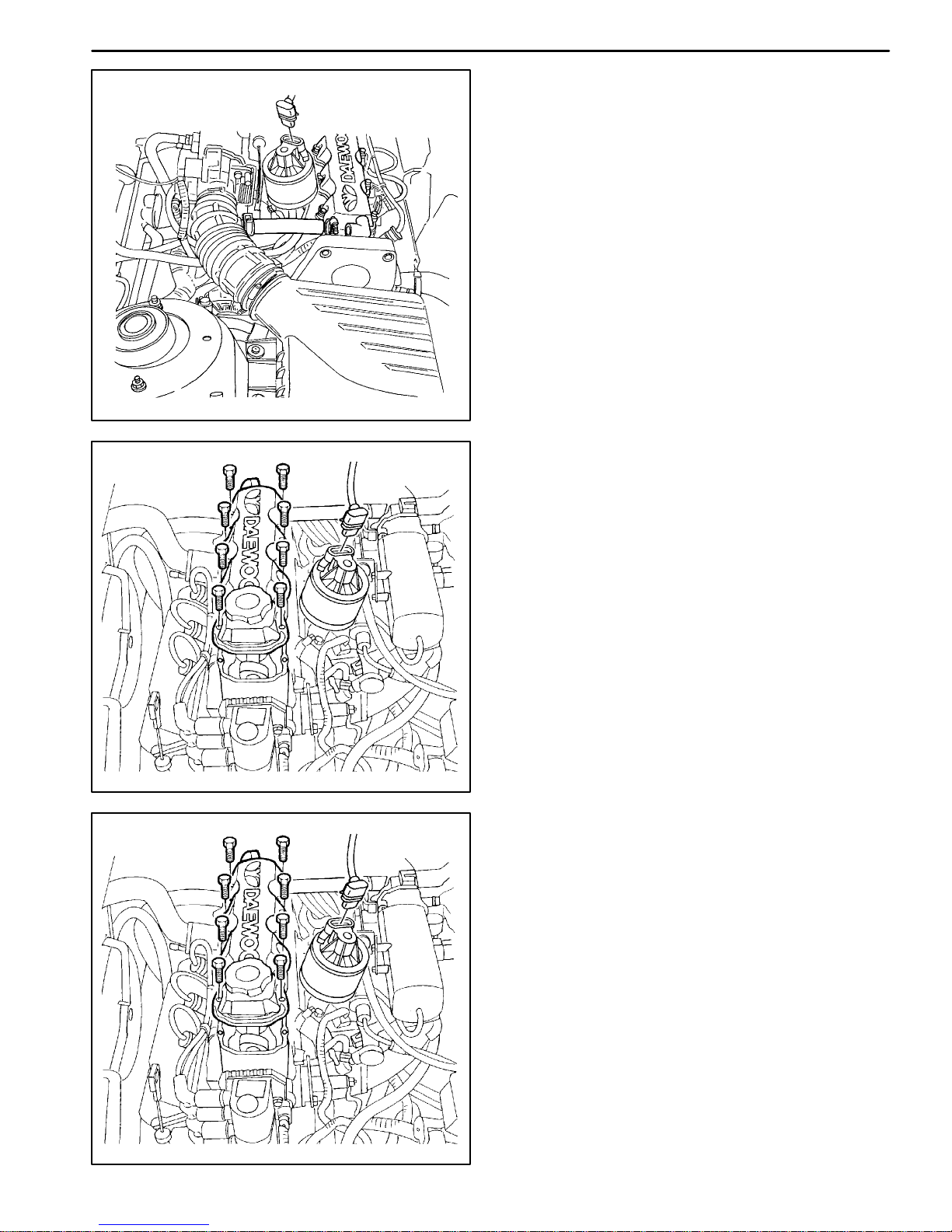

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the breather tube from the valve cover.

A402B002

3. Remove the eight bolts from the valve cover.

4. Remove the valve cover.

5. Remove the valve cover gasket.

6. Clean the sealing surfaces of the valve cover and the

camshaft housing.

A402B003

Installation Procedure

1. Install the new valve cover gasket and the valve cover.

2. Install the eight bolts to the valve cover.

Tighten

Tighten the valve cover bolts to 9 N m (80 lb-in).

A402B003

DAEWOO T-154 BL2,3

Page 25

A402B002

d

SOHC ENGINE MECHANICAL 1B–13

3. Connect the breather tube to the valve cover.

4. Connect the negative battery cable.

CYLINDER HEAD AND GASKET

Tools Required

J-42492 Timing Belt Adjuster

KM-470-B Angular Torque Gauge

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for 10

seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the engine control module (ECM) groun

terminal from the intake manifold.

A102B001

5. Drain the engine coolant. Refer to Section 1D, Engine

Cooling.

6. Disconnect the intake air temperature (IAT) sensor

connector.

7. Disconnect the breather tube from the valve cover.

8. Disconnect the air intake tube from the throttle body.

DAEWOO T-154 BL2,3

Page 26

1B–14 SOHC ENGINE MECHANICAL

A102B092

9. Disconnect the electronic ignition (EI) system ignition coil connector.

10. Disconnect the oxygen (O

) sensor connector.

2

11. Disconnect the fuel injector harness connectors.

12. Disconnect the idle air control (IAC) valve connector.

13. Disconnect the throttle position (TP) sensor connector.

14. Disconnect the engine coolant temperature (ECT)

sensor connector.

15. Disconnect the coolant temperature sensor (CTS)

connector.

16. Remove the camshaft position (CMP) sensor.

A102B016

17. Remove the air cleaner housing bolts.

18. Remove the air cleaner housing.

A102B002

DAEWOO T-154 BL2,3

Page 27

A102B003

SOHC ENGINE MECHANICAL 1B–15

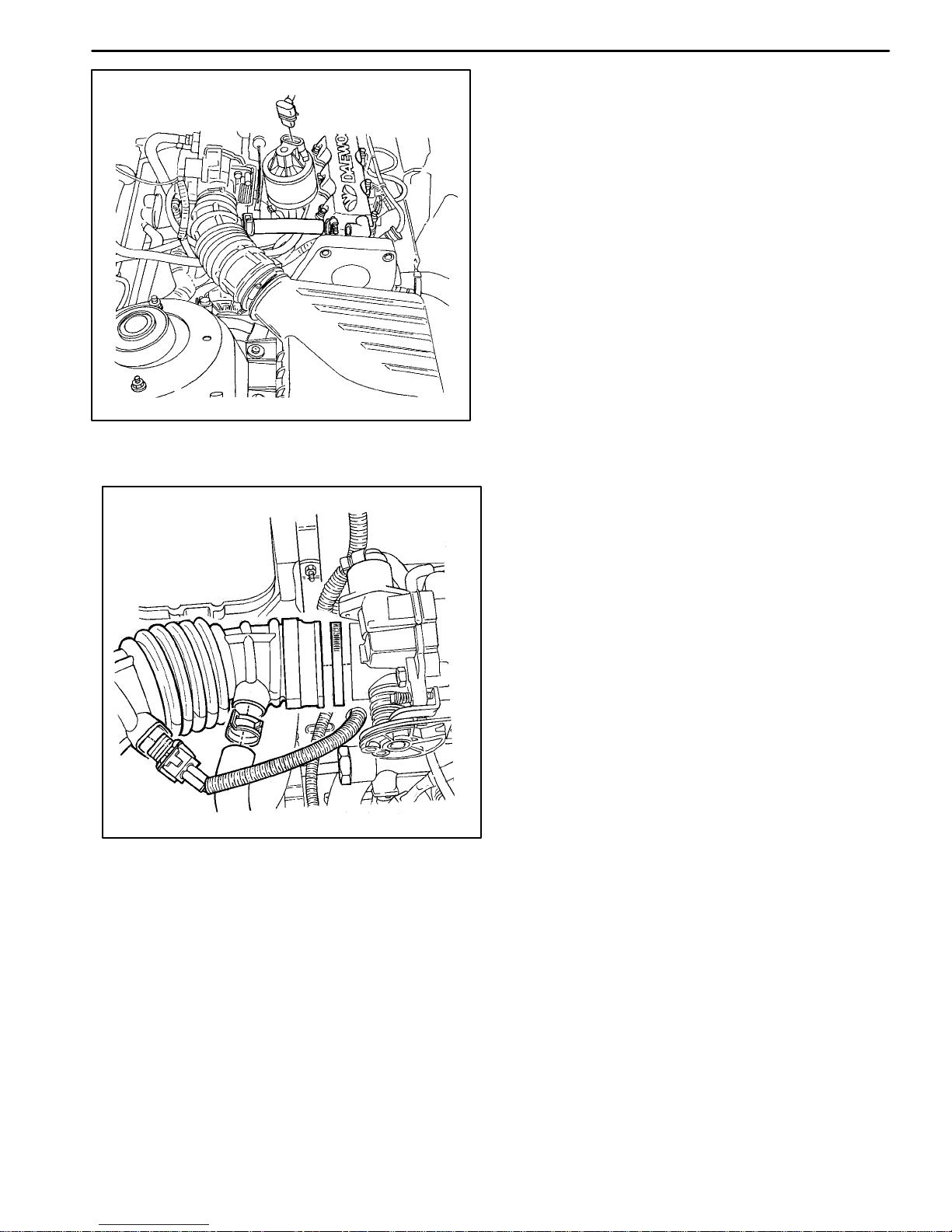

19. Remove the upper timing belt cover bolts.

20. Remove the upper timing belt cover.

21. Align the camshaft gear timing mark to the notch in

the rear timing belt cover.

DAEWOO T-154 BL2,3

A102B004

22. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

23. Remove the right front wheel well splash shield.

24. Remove the A/C compressor drive belt, if equipped.

A102B006

Page 28

1B–16 SOHC ENGINE MECHANICAL

25. Remove the alternator drive belt.

26. Remove the power steering pump pulley bolts, if

equipped.

27. Remove the power steering pump pulley, if

equipped.

A102B005

28. Disconnect the fuel return line at the fuel pressure

regulator.

29. Disconnect the fuel feed line at the fuel rail.

A402B009

30. Remove the alternator adjusting bolt.

31. Remove the alternator adjusting bracket retaining

bolt.

32. Remove the alternator adjusting bracket.

A102B118

DAEWOO T-154 BL2,3

Page 29

A102B114

SOHC ENGINE MECHANICAL 1B–17

33. Disconnect the upper radiator hose at the thermostat housing.

34. Disconnect the brake booster vacuum hose at the

intake manifold.

35. Disconnect all of the necessary vacuum hoses.

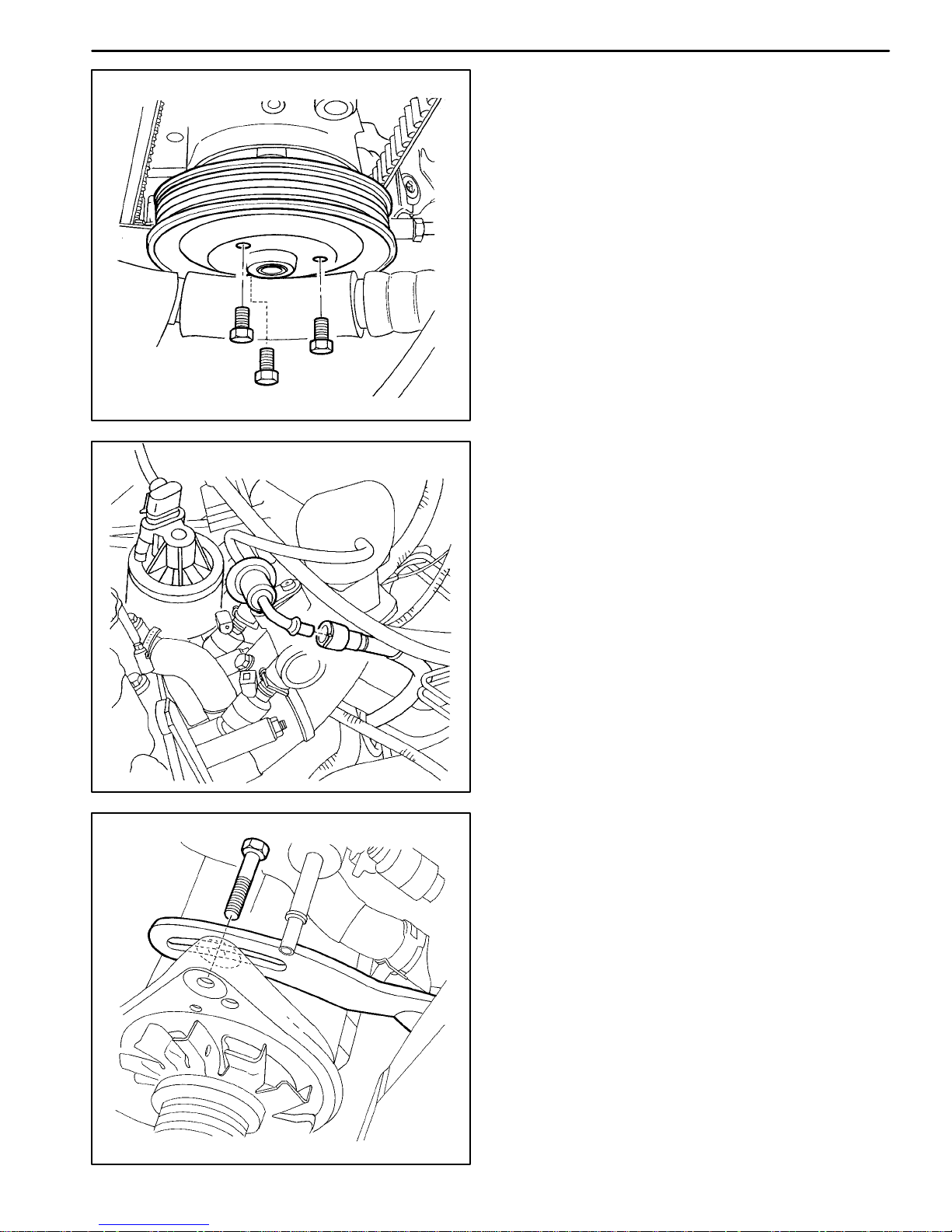

36. Remove the crankshaft pulley bolt.

37. Remove the crankshaft pulley.

38. Remove the power steering pump, if equipped. Refer to Section 6B, Power Steering Pump.

39. Install the engine mount bracket-to-engine mount

retaining bolt s and tighten the bolts to secure the engine, if the power steering pump was removed.

40. Remove the lower timing belt cover bolts.

41. Remove the lower timing belt cover.

DAEWOO T-154 BL2,3

A102B008

42. Slightly loosen the coolant pump retaining bolts.

43. Rotate the coolant pump counterclockwise using the

timing belt adjuster J-42492 to relieve the timing belt

tension.

44. Remove the timing belt. Refer to “Timing Belt” in this

section.

A102B040

Page 30

1B–18 SOHC ENGINE MECHANICAL

45. Disconnect the crankcase ventilation tube at the

camshaft housing.

A402B004

46. Remove the valve cover bolts.

47. Remove the valve cover and the valve cover gasket.

A102B111

Notice: Take care to prevent any scratches, nicks or

damage to the camshaft.

48. While holding the camshaft firmly in place, remove

the camshaft gear bolt.

49. Remove the camshaft gear.

50. Remove the timing belt automatic tensioner bolt.

51. Remove the timing belt automatic tensioner.

52. Remove the rear timing belt cover bolts.

53. Remove the rear timing belt cover.

A102B046

DAEWOO T-154 BL2,3

Page 31

TAA1F480

SOHC ENGINE MECHANICAL 1B–19

54. Disconnect the ignition wires at the spark plugs.

55. Remove the retaining nuts from the auxiliary catalytic converter at the exhaust manifold flange.

56. Disconnect the heater inlet hose at the coolant distributor.

57. Disconnect the surge tank coolant hose at the

throttle body.

DAEWOO T-154 BL2,3

A102B119

58. Remove the intake manifold support bracket retaining bolts from the coolant distributor.

59. Disconnect the throttle cable at the throttle body and

the intake manifold.

A402B005

Page 32

1B–20 SOHC ENGINE MECHANICAL

60. Gradually loosen all of the cylinder head bolts in the

sequence shown.

61. Remove the cylinder head bolts.

62. Remove the camshaft carrier assembly.

Notice: Prevent any engine oil or coolant from entering

the cylinders when removing the cylinder head. Damage

to the engine could result.

63. Remove the cylinder head with the intake manifold

and the exhaust manifold attached.

64. Remove the cylinder head gasket.

A402B006

Cleaning Procedure

1. Clean the gasket surfaces of the cylinder head and

the engine block.

2. Make sure the gasket surfaces of the cylinder head

and the engine block are free of nicks and heavy

scratches.

3. Clean the cylinder head bolts.

4. Inspect the cylinder head for warpage. Refer to “Cyl-

inder Head and Valve Train Components” in this section.

A102B122

Installation Procedure

1. Apply a continuous 3 mm (0.12 inch) bead of gasket

maker to the sealing surface of the camshaft carrier.

2. Install the cylinder head gasket.

3. Install the cylinder head with the intake manifold and

the exhaust manifold attached.

4. Install the camshaft carrier assembly.

A402B007

DAEWOO T-154 BL2,3

Page 33

A402B008

SOHC ENGINE MECHANICAL 1B–21

5. Install the cylinder head bolts in the sequence shown.

Tighten

Tighten the cylinder head bolts in the sequence previously shown to 25 N m (18 lb-ft) using a torque

wrench. Use the angular torque gauge KM-470-B

to tighten the cylinder head bolts another 70 degrees

plus 70 degrees plus 30 degrees.

DAEWOO T-154 BL2,3

A102B172

6. Connect the throttle cable at the throttle body and at

the intake manifold.

7. Install the intake manifold support bracket retaining

bolt to the coolant distributor.

Tighten

Tighten the intake manifold support bracket retaining

bolts to 22 N m (16 lb-ft).

A102B029

Page 34

1B–22 SOHC ENGINE MECHANICAL

8. Connect the surge tank coolant hose at the throttle

body.

9. Connect the heater inlet hose to the coolant distributor.

A102B119

10. Install the auxiliary catalytic converter nuts at the exhaust manifold flange.

TAA1F480

Tighten

Tighten the auxiliary catalytic converter-to-exhaust

manifold nuts to 40 N m (30 lb-ft).

11. Connect the ignition wires at the spark plugs.

12. Install the rear timing belt cover.

13. Install the rear timing belt cover bolts.

Tighten

Tighten the rear timing belt cover bolts to 10 N m

(89 lb-in).

14. Install the timing belt automatic tensioner.

15. Install the timing belt automatic tensioner bolt.

Tighten

Tighten the timing belt automatic tensioner bolt to

20 N m (15 lb-ft).

A102B046

DAEWOO T-154 BL2,3

Page 35

A102B111

SOHC ENGINE MECHANICAL 1B–23

Notice: Take extreme care to prevent any scratches,

nicks, or damage to the camshaft. Such damage can impair vehicle operation.

16. Install the camshaft gear.

17. While holding the camshaft firmly in place, install the

camshaft gear bolt.

Tighten

Tighten the camshaft gear bolt to 45 N m (33 lb-ft ).

18. Install the valve cover and the valve cover gasket.

19. Install the valve cover bolts.

A402B004

Tighten

Tighten the valve cover bolts to 9 N m (80 lb-in).

20. Connect the crankcase ventilation tube to the camshaft housing.

21. Align the mark on the camshaft gear to the notch at

the top of the rear timing belt cover.

DAEWOO T-154 BL2,3

A102B004

Page 36

1B–24 SOHC ENGINE MECHANICAL

A102B030

A102B020

22. Align the mark on t h e crankshaft gear to the notch at

the bottom of the rear timing belt cover.

23. Install the timing belt. Refer to “Timing Belt” in this

section.

24. Check the timing belt tension. Refer to “Timing Belt

Check and Adjust” in this section.

25. Install the lower timing belt cover.

26. Install the lower timing belt cover bolts.

Tighten

Tighten the lower timing belt cover bolts to 10 N m

(89 lb-in).

27. Install the power steering pump and the bolts, if

equipped. Refer to Section 6B, Power Steering

Pump.

28. Install the engine mount bracket-to-engine mount retaining bolt s if the power steering pump was installed.

Tighten

Tighten the engine mount bracket-to-engine mount

retaining bolts to 60 N m (44 lb-ft).

29. Install the crankshaft pulley.

30. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 N m (70 lb-ft)

using a torque wrench. Use the angular torque gauge

KM-470-B to tighten the crankshaft pulley bolt another 30 degrees plus 15 degrees.

31. Install the power steering pump pulley, if equipped.

32. Install the power steering pump pulley bolts, if

equipped.

Tighten

Tighten the power steering pump pulley bolts to

25 N m (18 lb-ft).

A102B005

DAEWOO T-154 BL2,3

Page 37

A102B114

SOHC ENGINE MECHANICAL 1B–25

33. Connect all of the vacuum hoses.

34. Connect the brake booster hose at the intake manifold.

35. Connect the upper radiator hose at the thermostat

housing.

36. Install the alternator adjusting bracket.

37. Install the alternator adjusting bracket retaining bolt.

A102B118

Tighten

Tighten the alternator adjusting bracket retaining bolt

to 25 N m (18 lb-ft).

38. Install the alternator adjusting bolt. Do not tighten.

39. Connect the fuel feed line at the fuel rail.

40. Connect the fuel return line at the fuel pressure regulator.

DAEWOO T-154 BL2,3

A402B009

Page 38

1B–26 SOHC ENGINE MECHANICAL

41. Install the alternator drive belt.

Tighten

Tighten the alternator adjusting bolt to 20 N m (15 lb-ft).

42. Install the upper timing belt cover.

43. Install the upper timing belt cover bolts.

Tighten

Tighten the upper timing belt cover bolts to 10 N m

(89 lb-in).

44. Install the A/C compressor drive belt, as necessary.

45. Install the right front wheel well splash shield.

46. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

A102B003

47. Install the air filter housing.

48. Install the air filter housing bolts.

A102B001

Tighten

Tighten the air filter housing bolts to 8 N m (71 lb-in).

49. Connect the air intake tube to the throttle body.

50. Connect the breather tube to the valve cover.

51. Connect the IAT sensor connector.

52. Install the CMP sensor.

53. Connect the CTS connector.

54. Connect the ECT sensor connector.

55. Connect the IAC valve connector.

56. Connect the TP sensor connector.

57. Connect the EI system ignition coil connector.

58. Connect the fuel injector harness connectors.

59. Connect the O2sensor connector.

60. Connect the ECM ground terminal at the intake manifold.

61. Connect the negative battery cable.

62. Install the fuel pump fuse.

63. Refill the engine cooling system. Refer to Section

1D, Engine Cooling.

A102B016

DAEWOO T-154 BL2,3

Page 39

A402B003

SOHC ENGINE MECHANICAL 1B–27

CAMSHAFT

Tools Required

KM-565-A Valve Spring Compressor

Removal Procedure

1. Remove the timing belt. Refer to “Timing Belt” in this

section.

2. Disconnect the air breather tube at the valve cover.

3. Remove the valve cover bolts.

4. Remove the valve cover.

5. Remove the valve cover gasket.

6. Install the valve spring compressor KM-565-A.

Notice: Take extreme care to prevent any scratches,

nicks, or damage to the camshaft. Such damage can impair vehicle operation.

A102B074

7. Remove the camshaft followers using the valve

spring compressor KM-565-A.

8. While holding the camshaft firmly in place, remove

the camshaft gear bolt.

9. Remove the camshaft gear.

DAEWOO T-154 BL2,3

A102B111

Page 40

1B–28 SOHC ENGINE MECHANICAL

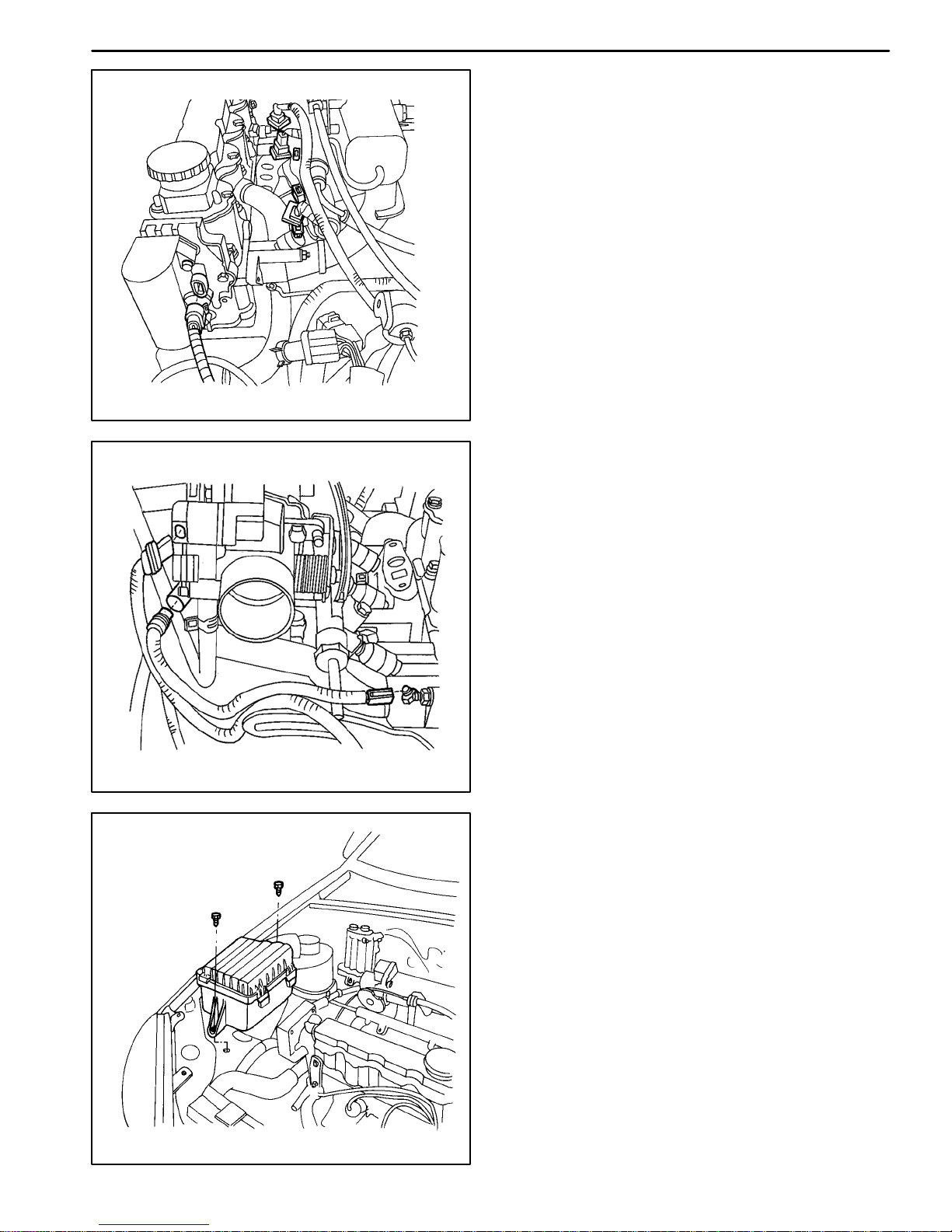

10. Disconnect the positive battery cable from the battery.

11. Remove the battery and the battery tray. Refer to

Section 1E, Engine Electrical.

A102C034

12. Disconnect the electronic ignition (EI) system ignition coil connector.

13. Disconnect the EI system ignition wires at the ignition coil.

14. Remove the EI system ignition coil mounting bolts.

15. Remove the EI system ignition coil.

A102B075

16. Remove the EI system ignition coil mounting plate

bolts.

17. Remove the EI system ignition coil mounting plate.

18. Remove the camshaft pressure plate bolts.

19. Remove the camshaft pressure plate.

A102B076

DAEWOO T-154 BL2,3

Page 41

A102B077

SOHC ENGINE MECHANICAL 1B–29

20. Remove the camshaft.

Installation Procedure

1. Install the camshaft.

2. Install the camshaft pressure plate.

3. Install the camshaft pressure plate bolts.

A102B076

Tighten

Tighten the camshaft pressure plate bolts to 10 N m

(89 lb-in).

4. Measure camshaft end play. Camshaft end play

should be 0.04 to 0.16 mm (.016 to 0.64 inch).

5. Install the EI system ignition coil mounting plate.

6. Install the EI system ignition coil mounting plate

bolts.

Tighten

Tighten the EI system ignition coil mounting plate

bolts to 10 N m (89 lb-in).

7. Install the EI system ignition coil.

8. Install the EI system ignition coil mounting bolts.

DAEWOO T-154 BL2,3

A102B075

Tighten

Tighten the EI system ignition coil mounting bolts to

10 N m (89 lb-in).

9. Connect the ignition wires at the EI system ignition

coil.

10. Connect the EI system ignition coil connector.

Page 42

1B–30 SOHC ENGINE MECHANICAL

11. Install the battery and the battery tray. Refer to Sec-

tion 1E, Engine Electrical.

12. Connect the positive battery cable to the battery.

A102C034

Notice: Take extreme care to prevent any scratches,

nicks, or damage to the camshaft. Such damage can impair vehicle operation.

A102B111

13. Install the camshaft gear.

14. While holding the camshaft firmly in place, install the

camshaft gear bolt.

Tighten

Tighten the camshaft gear bolt to 45 N m (33 lb-ft).

15. Install the camshaft followers using the valve spring

compressor KM-565-A.

16. Remove the tool KM-565-A.

A102B074

DAEWOO T-154 BL2,3

Page 43

A402B003

SOHC ENGINE MECHANICAL 1B–31

17. Install the valve cover gasket.

18. Install the valve cover.

19. Install the valve cover bolts.

Tighten

Tighten the valve cover bolts to 9 N m (80 lb-in).

20. Connect the air breather tube to the valve cover.

21. Install the timing belt. Refer to “Timing Belt” in this

section.

TIMING BELT CHECK AND ADJUST

Tools Required

J-42492 Timing Belt Adjuster

KM-470-B Angular Torque Gauge

A102B001

Adjustment Procedure

1. Disconnect the negative battery cable.

2. Disconnect the intake air temperature (IAT) sensor

connector.

3. Disconnect the air intake tube from the throttle body.

4. Disconnect the breather tube from the valve cover.

5. Remove the air cleaner housing bolts.

6. Remove the air cleaner housing.

7. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

8. Remove the right front wheel well splash shield.

DAEWOO T-154 BL2,3

A102B002

Page 44

1B–32 SOHC ENGINE MECHANICAL

9. Remove the A/C compressor drive belt, if equipped.

10. Remove the alternator drive belt.

11. Remove the power steering pump pulley bolts, if

equipped.

12. Remove the power steering pump pulley, if

equipped.

13. Remove the power steering pump mounting bolts,

if equipped.

14. Remove the upper timing belt cover bolts.

15. Remove the upper timing belt cover.

A102B003

16. Remove the crankshaft pulley bolt.

17. Remove the crankshaft pulley.

A102B018

18. Remove the lower timing belt cover bolts.

19. Remove the lower timing belt cover.

A102B008

DAEWOO T-154 BL2,3

Page 45

A102B030

SOHC ENGINE MECHANICAL 1B–33

20. Install the crankshaft pulley bolt.

21. Rotate the crankshaft at least one full turn clockwise

using the crankshaft pulley bolt.

22. Align the dot on the crankshaft gear to the notch at

the bottom of the rear timing belt cover.

23. Align the camshaft gear timing mark to the notch at

the top of the rear timing belt cover.

DAEWOO T-154 BL2,3

A102B004

24. Slightly loosen the three coolant pump retaining

bolts.

25. Using the timing belt adjuster J-42492, rotate the

coolant pump clockwise to add the highest tension

to the timing belt.

26. Tighten the coolant pump retaining bolts loosely.

A102B040

Page 46

1B–34 SOHC ENGINE MECHANICAL

27. Align the adjust arm hole of the timing belt automatic

tensioner to the hole in the timing belt automatic tensioner bracket.

28. Insert a 4.5 mm driver through the adjust arm hole

and the tensioner bracket hole.

29. Rotate the crankshaft two full turns clockwise using

the crankshaft pulley bolt.

30. Rotate the crankshaft at least one full turn clockwise

using the crankshaft pulley bolt.

31. Remove the driver from the timing belt automatic

tensioner.

32. Loosen the coolant pump retaining bolts.

A102B039

33. Rotate the coolant pump until the adjust arm pointer

of the timing belt automatic tensioner is aligned with

the notch in the timing belt automatic tensioner

bracket.

34. Tighten the coolant pump retaining bolts.

A102B041

Tighten

Tighten the coolant pump retaining bolts to 10 N m

(89 lb-in).

35. Remove the crankshaft pulley bolt.

36. Install the lower timing belt cover.

37. Install the lower timing belt cover bolts.

Tighten

Tighten the lower timing belt cover bolts to 10 N m

(89 lb-in).

A102B008

DAEWOO T-154 BL2,3

Page 47

A102B018

A102B005

SOHC ENGINE MECHANICAL 1B–35

38. Install the crankshaft pulley.

39. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 N m (70 lb-ft)

using a torque wrench. Use the angular torque gauge

KM-470-B to tighten the crankshaft pulley bolt another 30 degrees plus 15 degrees.

40. Install the upper timing belt cover.

41. Install the upper timing belt cover bolts.

Tighten

Tighten the upper timing belt cover bolts to 10 N m

(89 lb-in).

42. Install the power steering pump mounting bolts, if

equipped.

Tighten

Tighten the power steering pump mounting bolts to

25 N m (18 lb-ft).

43. Install the power steering pump pulley, if equipped.

44. Install the power steering pump pulley bolts, if

equipped.

Tighten

Tighten the power steering pump pulley bolts to

25 N m (18 lb-ft).

DAEWOO T-154 BL2,3

45. Install the alternator drive belt.

Tighten

Tighten the alternator adjusting bolt to 25 N m (18 lbft).

46. Install the A/C compressor drive belt, if equipped.

47. Install the right front wheel well splash shield.

48. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

49. Install the air cleaner housing.

50. Install the air cleaner housing bolts.

Tighten

Tighten the air filter housing bolts to 8 N m (71 lb-in).

A102B002

Page 48

1B–36 SOHC ENGINE MECHANICAL

51. Connect the air intake tube to the throttle body.

52. Connect the breather tube to the valve cover.

53. Connect the IAT sensor connector.

54. Connect the negative battery cable.

A102B001

TIMING BELT

Tools Required

J-42492 Timing Belt Adjuster

KM-470-B Angular Torque Gauge

A102B001

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the intake air temperature (IAT) sensor

connector.

3. Disconnect the air intake tube from the throttle body.

4. Disconnect the breather tube from the valve cover.

5. Remove the air cleaner housing bolts.

6. Remove the air cleaner housing.

7. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

8. Remove the right front wheel well splash shield.

A102B002

DAEWOO T-154 BL2,3

Page 49

A102B003

SOHC ENGINE MECHANICAL 1B–37

9. Remove the A/C compressor drive belt, if equipped.

10. Remove the alternator drive belt.

11. Remove the power steering pump, if equipped. Refer to Section 6B, Power Steering Pump.

12. Remove the upper timing belt cover bolts.

13. Remove the upper timing belt cover.

14. Remove the crankshaft pulley bolt.

15. Remove the crankshaft pulley.

16. Remove the lower timing belt cover bolts.

17. Remove the lower timing belt cover.

DAEWOO T-154 BL2,3

A102B008

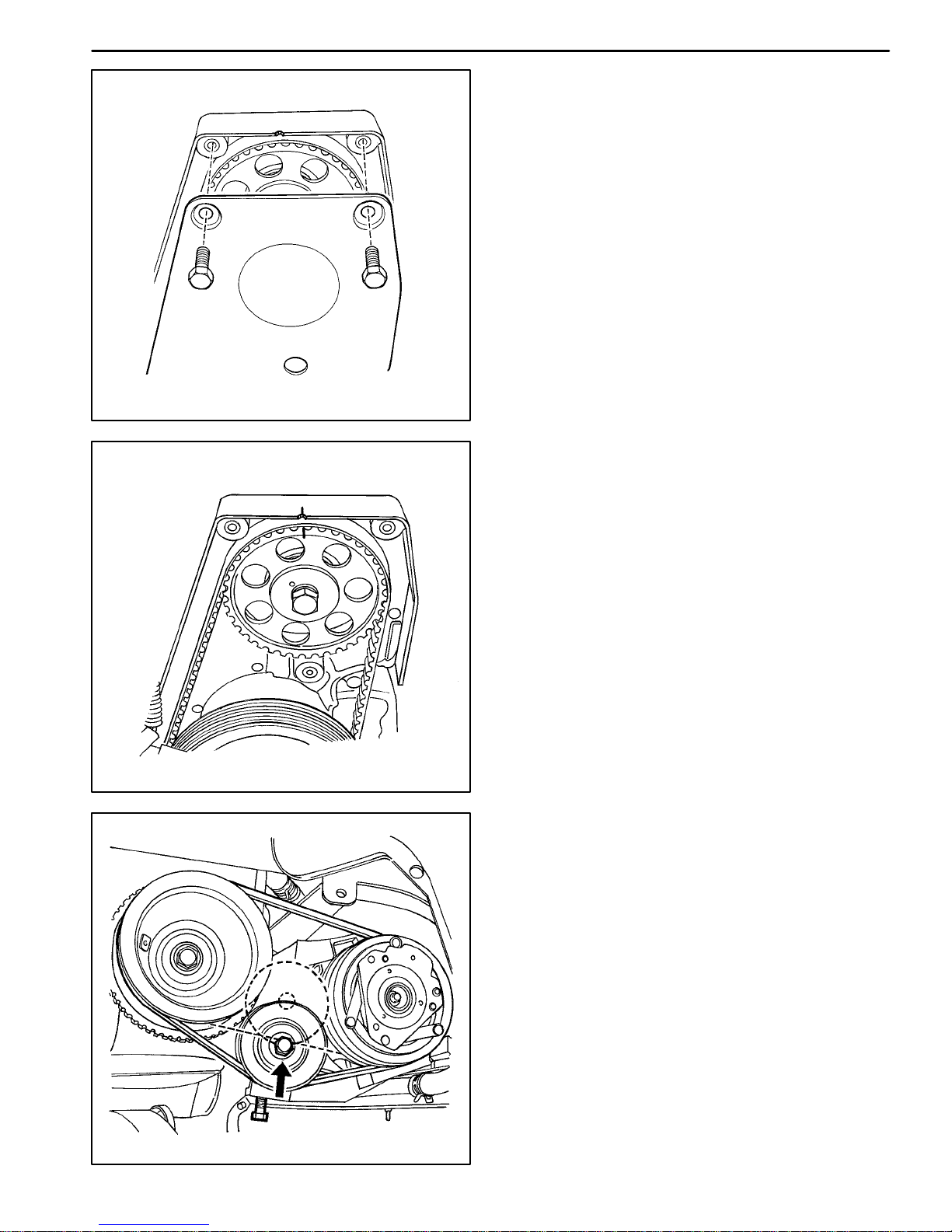

18. Install the crankshaft pulley bolt.

19. Using the crankshaft pulley bolt, rotate the crankshaft clockwise until the mark on the crankshaft

gear is aligned with the notch at the bottom of the

rear timing belt cover.

A102B030

Page 50

1B–38 SOHC ENGINE MECHANICAL

20. Slightly loosen the coolant pump retaining bolts.

21. Using the timing belt adjuster J-42492, rotate the

coolant pump counterclockwise to release the tension on the timing belt.

22. Remove the timing belt.

A102B040

Installation Procedure

1. Align the mark on the crankshaft gear to the notch on

the bottom of the rear timing belt cover.

2. Align the mark on the camshaft gear to the notch on

the top of the rear timing belt cover.

3. Install the timing belt.

A102B042

4. Using the timing belt adjuster J-42492, rotate the

coolant pump clockwise to add the highest tension to

the timing belt.

5. Tighten the coolant pump retaining bolts loosely.

A102B040

DAEWOO T-154 BL2,3

Page 51

A102B039

SOHC ENGINE MECHANICAL 1B–39

6. Align the adjust arm hole of the timing belt automatic

tensioner to the hole in the timing belt automatic tensioner bracket.

7. Insert a 4.5 mm driver through the adjust arm hole

and the tensioner bracket hole.

8. Rotate the crankshaft two full turns clockwise using

the crankshaft pulley bolt.

9. Align the mark on th e crankshaft gear to the notch at

the bottom of the rear timing belt cover.

DAEWOO T-154 BL2,3

A102B030

10. Remove the driver from the timing belt automatic

tensioner.

11. Slightly loosen the three coolant pump retaining

bolts.

12. Using the timing belt adjuster J-42492, rotate the

coolant pump.

A102B040

Page 52

1B–40 SOHC ENGINE MECHANICAL

13. Rotate the coolant pump until the adjust arm pointer

of the timing belt automatic tensioner is aligned with

the notch in the timing belt automatic tensioner

bracket.

14. Tighten the coolant pump retaining bolts.

Tighten

Tighten the coolant pump retaining bolts to 10 N m

(89 lb-in).

A102B041

15. Remove the crankshaft pulley bolt.

16. Install the lower timing belt cover.

17. Install the lower timing belt cover bolts.

A102B008

Tighten

Tighten the lower timing belt cover bolts to 10 N m

(89 lb-in).

18. Install the crankshaft pulley.

19. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 N m (70 lb-ft)

using a torque wrench. Using the angular torque

gauge KM-470-B, tighten the crankshaft pulley bolt

another 30 degrees plus 15 degrees.

A102B018

DAEWOO T-154 BL2,3

Page 53

A102B003

SOHC ENGINE MECHANICAL 1B–41

20. Install the upper timing belt cover.

21. Install the upper timing belt cover bolts.

Tighten

Tighten the upper timing belt cover bolts to 10 N m

(89 lb-in).

22. Install the power steering pump, if equipped. Refer

to Section 6B, Power Steering Pump.

23. Install the alternator drive belt.

24. Install the A/C compressor drive belt, if equipped.

DAEWOO T-154 BL2,3

A102B006

25. Install the right front wheel well splash shield.

26. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

27. Install the air filter housing.

28. Install the air filter housing bolts.

Tighten

Tighten the air filter housing b olts to 8 N m (71 lb-in).

A102B002

Page 54

1B–42 SOHC ENGINE MECHANICAL

29. Connect the air intake tube to the throttle body.

30. Connect the breather tube to the valve cover.

31. Connect the IAT sensor connector.

32. Connect the negative battery cable.

A102B001

OIL PUMP

Tools Required

KM-498-B Pressure Gauge

KM-135 Adapter

A102B019

Engine Oil Pressure Inspection Procedure

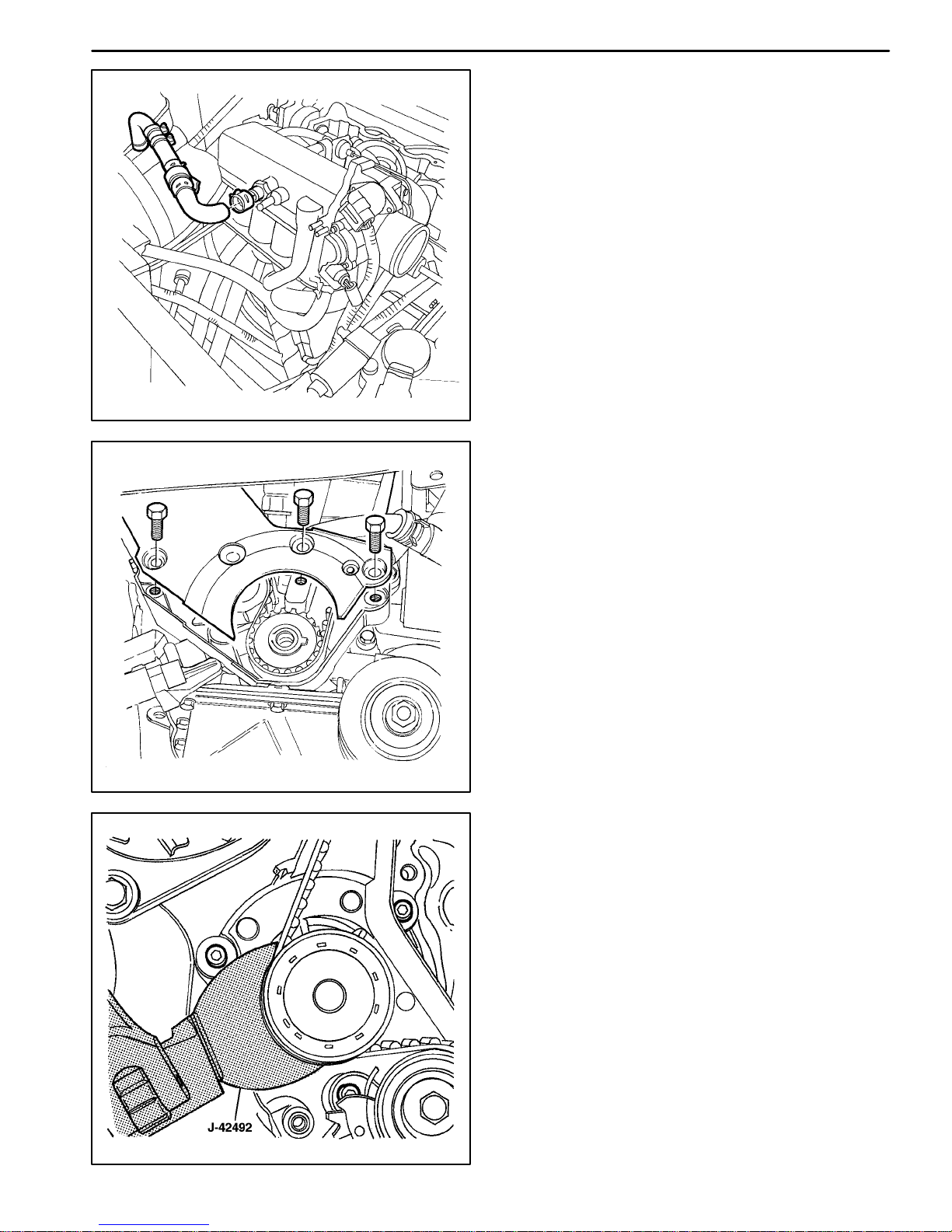

1. Remove the right-hand wheel well splash shield.

2. Remove the oil pressure switch connector.

3. Install the adapter KM-135 in place of the oil pressure

switch.

4. Connect the pressure gauge KM-498-B to the adapt-

er.

5. Start the engine and check the oil pressure at idle

speed and an engine temperature of 80 C (176 F).

Important: The minimum oil pressure should be 30 kPa

(8.88 psi).

6. Stop the engine and remove the oil pressure gauge

and the adapter.

A202B003

DAEWOO T-154 BL2,3

Page 55

A102B019

SOHC ENGINE MECHANICAL 1B–43

7. Install the oil pressure switch.

Tighten

Tighten the oil pressure switch to 40 N m (30 lb-ft).

8. Connect the electrical connector to the oil pressure

switch.

9. Install the right-hand wheel well splash shield.

10. Check the oil level and fill the oil to the FULL mark.

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the power steering pump, if equipped. Refer to Section 6A, Power Steering System.

3. Remove the timing belt. Refer to “Timing Belt” in this

section.

4. Remove the rear timing belt cover. Refer to “Rear

Timing Belt Cover” in this section.

5. Disconnect the oil pressure switch connector.

DAEWOO T-154 BL2,3

A102B019

6. Remove the crankshaft position (CKP) sensor bolt.

7. Remove the CKP sensor.

8. Remove the oil pan. Refer to “Oil Pan” in this section.

9. Remove the oil pump pickup tube and the support

bracket bolts.

10. Remove the oil pump pickup tube.

A102B064

Page 56

1B–44 SOHC ENGINE MECHANICAL

11. Remove the oil pump retaining bolts.

12. Carefully separate the oil pump and the gasket from

the engine block and the oil pan.

13. Remove the oil pump.

A102B065

Inspection Procedure

1. Clean the oil pump and the engine block gasket mat-

ing surfaces.

2. Remove the safety relief valve bolt.

3. Remove the safety relief valve and the spring.

4. Remove the oil pump-to-crankshaft seal.

A202B002

5. Remove the oil pump rear cover bolts.

6. Remove the rear cover.

A202B001

DAEWOO T-154 BL2,3

Page 57

SOHC ENGINE MECHANICAL 1B–45

7. Clean the oil pump housing and all of the parts.

8. Inspect all of the parts for signs of wear. Refer to

“Engine Specifications” in this section.

9. Coat all of the oil pump parts with clean engine oil.

10. Reinstall all of the oil pump parts.

Notice: Pack the oil pump gear cavity with petroleum

jelly to ensure an oil pump prime. Failure to do this can

damage the engine.

11. Install the oil pump rear cover and the bolts.

Tighten

Tighten the oil pump rear cover bolts to 6 N m (53 lbin).

12. Install the safety relief valve, the spring, the washer,

and the bolt.

A202B001

Tighten

Tighten the oil pump safety relief valve bolt to 30 N m

(22 lb-ft).

Installation Procedure

1. Apply a bead of room temperature vulcanizing (RTV)

sealer to the oil pump gasket.

2. Install a new oil pump gasket to the oil pump.

3. Coat the threads of the oil pump bolts with Loctite

573.

4. Install the oil pump to the engine block with the bolts.

DAEWOO T-154 BL2,3

Tighten

Tighten the oil pump retaining bolts to 10 N m (89 lbin).

A102B065

Page 58

1B–46 SOHC ENGINE MECHANICAL

5. Install a new oil pump to the crankshaft shaft seal.

6. Coat the lip of the seal with a thin coat of grease.

A202B002

7. Coat the threads of the oil pump pickup tube and the

support bracket bolts with Loctite 573.

8. Install the oil pump pickup tube and the bolts.

A102B064

Tighten

Tighten the oil pump pickup tube and the support

bracket bolts to 10 N m (89 lb-in).

9. Install the oil pan. Refer to “Oil Pan” in this section.

10. Install the CKP sensor and the bolt.

Tighten

Tighten the crankshaft position sensor retaining bolt

to 10 N m (89 lb-in).

11. Connect the oil pressure switch connector.

12. Install the rear timing belt cover. Refer to “Rear Timing Belt Cover” in this section.

13. Install the timing belt. Refer to “Timing Belt” In this

section.

14. Install the power steering pump, if equipped. Refer

to Section 6A, Power Steering System.

15. Connect the negative battery cable.

A102B019

DAEWOO T-154 BL2,3

Page 59

TAA1F480

SOHC ENGINE MECHANICAL 1B–47

OIL PAN

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the engine oil from the engine crankcase.

3. Disconnect the post-converter heated oxygen (O2)

sensor.

4. Remove the auxiliary catalytic converter upper flange

nuts from the exhaust manifold and the bolts from the

bracket.

5. Remove the nuts from the front muffler pipe to the

main catalytic converter.

6. Remove both catalytic converters as a unit.

DAEWOO T-154 BL2,3

B102G003

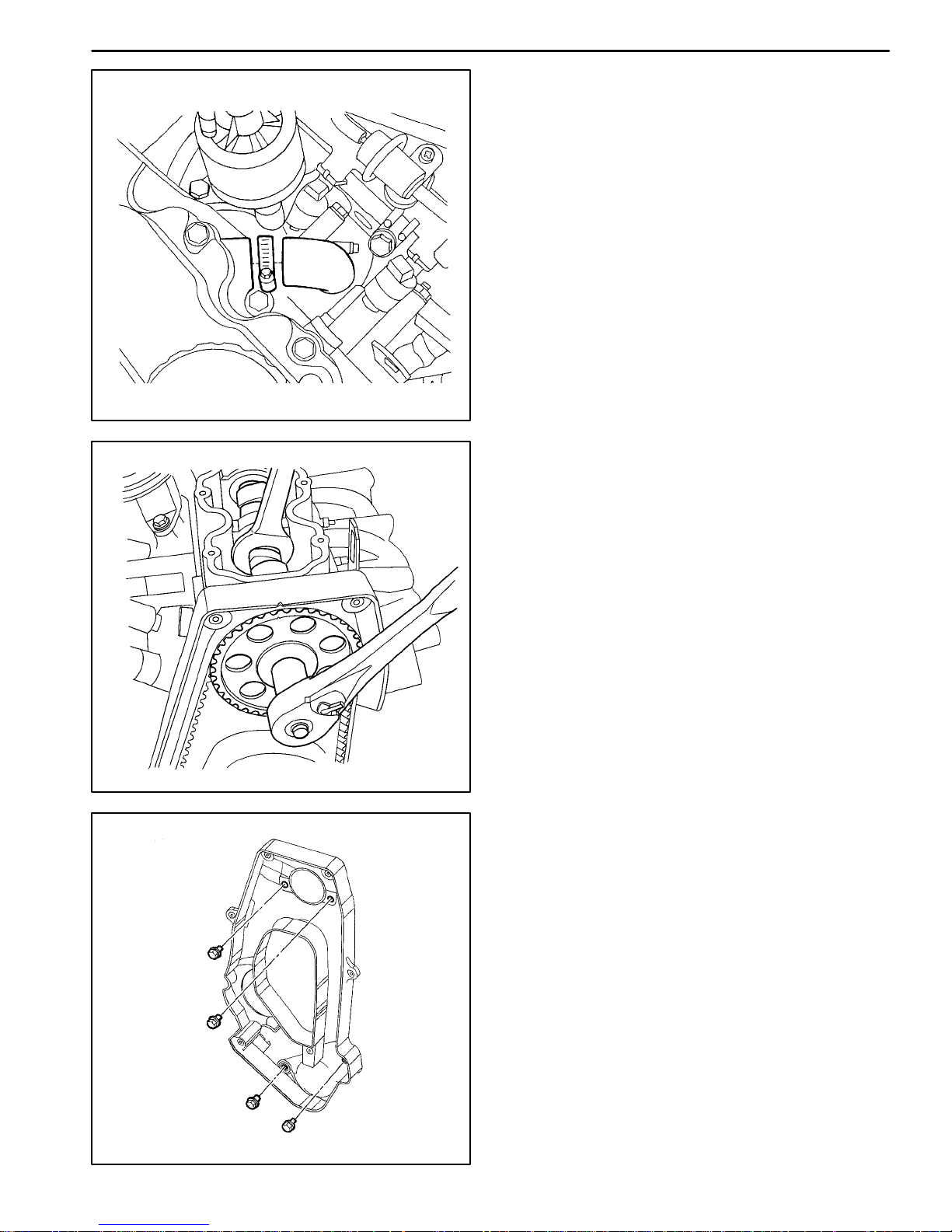

7. Remove the flywheel or flexible plate inspection cover

bolts.

8. Remove the flywheel or flexible plate inspection cov-

er.

A102B021

Page 60

1B–48 SOHC ENGINE MECHANICAL

9. Remove the oil pan retaining bolts.

10. Remove the oil pan from the engine block.

A102B043