Page 1

Service Manual

Drum Washing Machine

Model: C-ED124X/D-ED124X

C-ED125X/D-ED125X

May. 2008

Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

S/M No. : CED124X001

Page 2

DRUM WASHING MACHINE

SERVICE MANUAL

1. WHAT IS DRUM?..........................................................................1

2. WASHER SPECIFICATION..........................................................4

3. OPERATING MECHANISM DIAGRAM.........................................6

4. EACH PART OF DRUM WASHING MACHINE ............................8

5. PARTS LIST BY ASS'Y...............................................................10

6. CONTROL PART FUNCTION SPECIFICATION ........................25

7. ELECTRONIC FIELD SPECIFICATION......................................42

8. WIRING DIAGRAM .....................................................................64

9. TROUBLE SHOOTING REGARDING DRAIN ............................66

10. INSTALLATION.........................................................................67

11. ATTENTION POINT WITH SERVICING ...................................69

Page 3

1

Water consumption is reduced by using the power of the laundry falling (free-fall) created when rotating

the drum. With temperature control system, this drum washing machine saves energy and improves

washing performance at the same time.

1. WHA T IS DRUM W ASHING MACHINE?

1. Drum Washing Machine

" The biggest capacity with compact size

11Kg Capacity enable to wash bigger laundry.

" Sumultaneous supply of cold and hot water

As cold and hot water is supplied at the same time

heating time and energy is saved.

" Luxury Audio Dial

Using the advanced Audio Dial is luxury design of

exterior.

" DD inverter motor

The direct-drive type of which motor is directly

connected to drum without an interim chuth,

significantly reduces noise and vibration.

" Self-Cleaning Course of Drum.

Enable to Self-Cleaning of Drum.

" Digital Condensing Dry System.

Condensing Dry System with saveing energy .

" For pump drainage, the powerful pump speeds up

drainage process.

2. Key Features

Page 4

2

#DD Control: Direct drive type of direct connection between drum and motor

#Rotation by powerful high-performance BLDC motor

#Pump drainage type for built-in installation and Natural drainage

3. Power System

$%&'!()*+,*-.

/*0%)*1!()*+,*-.

234567

82(9

2:;/(7< 2:;/(7<

Page 5

3

4. Major Functions

# Washing

When rotating drum after putting in the laundry and detergent into the drum, the laundry are rotated by

protrusions (lifters) attached inside the drum.

Washing is carried out with bending and impact actions generated by falling of the laundry to the

bottom part of drum.

$ Rinsing

Rinsing cleanly washes out detergent and dirt removed from the laundry after washing cycle.

% Spin-drying

Weak, standard and strong spin cycle can be selected according to types of fabrics to be washed. spinwringing is carried out by rotation (the centrifugal force) of drum according to the designated speed.

& Drainage

Pump Drainage: Powerful pump for built-in installation and application of filter to remove foreign

substances

Natural Drainage: Applied Natural Drainage as the same pullsator.

Page 6

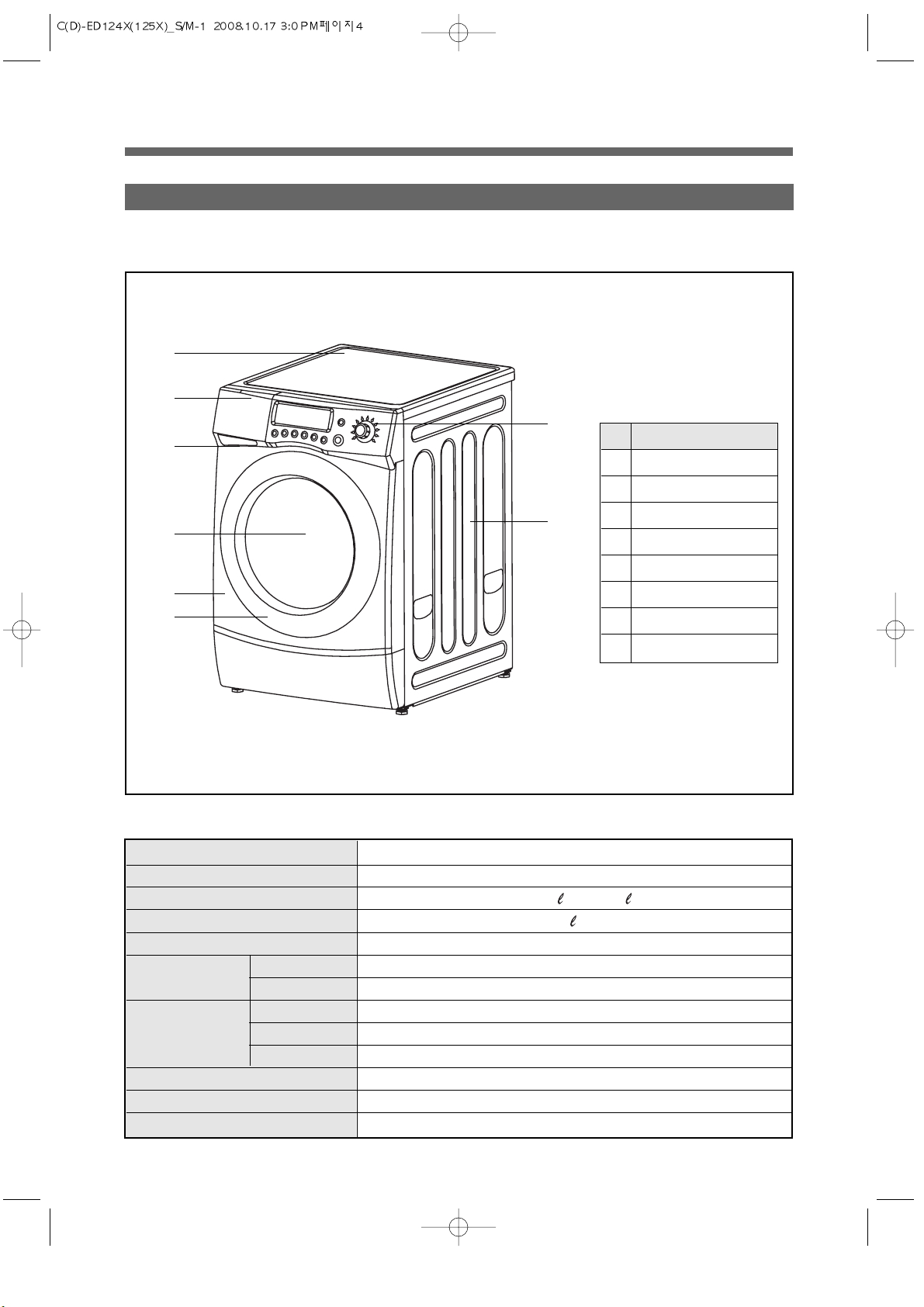

4

== //>>))&&**11

2.WASHER SPECIFICATION

1. Product Specification

NO PARTS NAME

1CABINET F

2 FRAME DOOR O

3 PROTECT GLASS

4 PANEL F

5 CASE DETERGENT

6PLATE TOP

7 CABINET

8 BUTTON DIAL

?

@

A

B

C

D

E

F

DIMENSION(WxDxH) 630mm(W) x 755mm(D) x 950mm(H)

MACHINE WEIGHT 85 kg

WATER CONSUMPTION WASH 94 / DRY 28

WASHING CONSUMPTION 28

POWER SOURCE 220V/60Hz

POWER WASHING 200W (Heating ) ~ 2000W

CONSUMPTION DRY 2100W

WASHING 11 kg

CAPACITY SPIN 11 kg

DRY 6.5 kg

WASHING TYPE DRUM TYPE

DRY TYPE Digital condensing dry system

OPERATION WATER PRESSURE 29kPa ~ 784kPa(0.3kgf/cm

2

~8kgf/cm2)

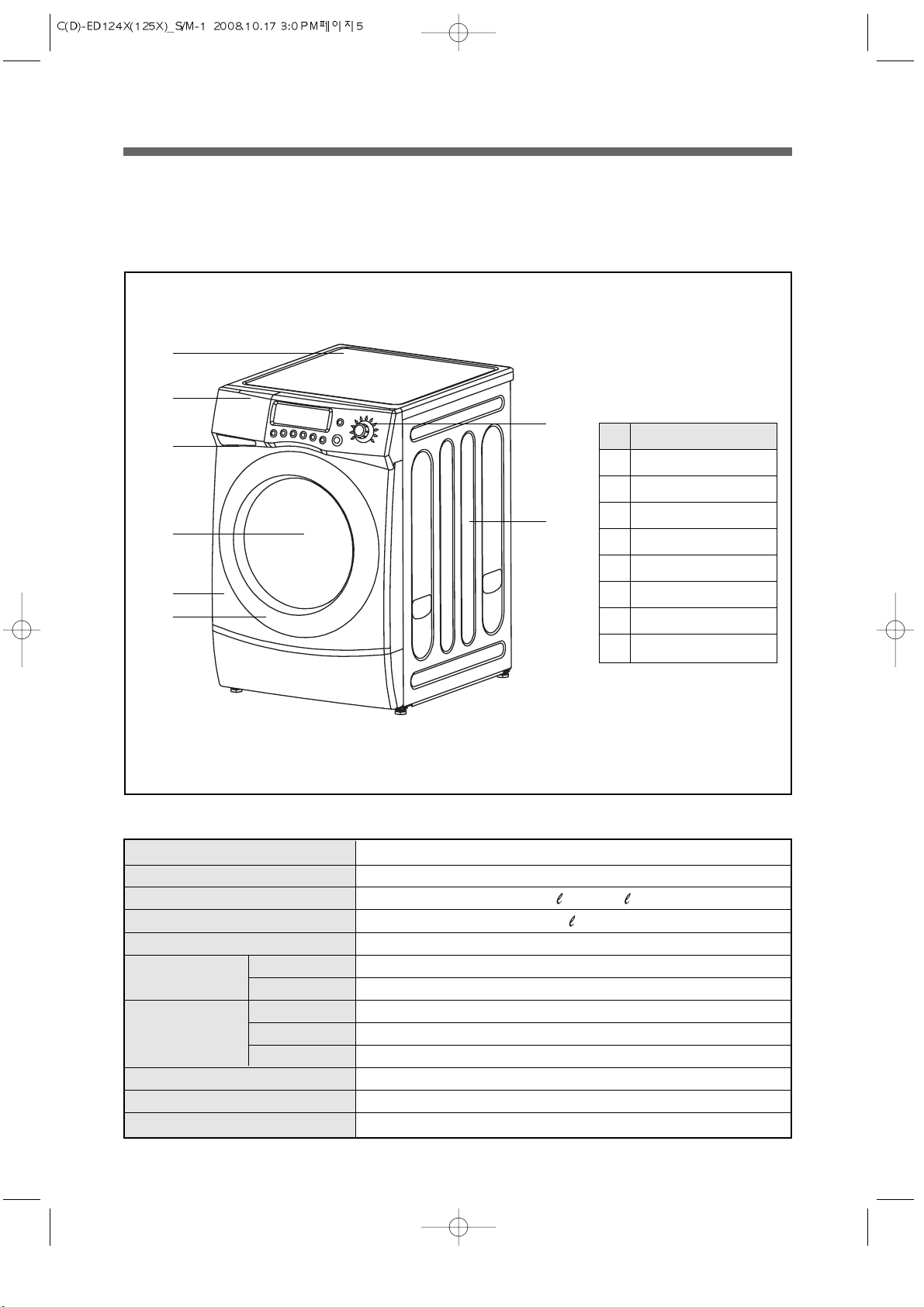

Page 7

5

GG $$))..&&++%%&&

NO PARTS NAME

1 CABINET F

2 FRAME DOOR O

3 PROTECT GLASS

4 PANEL F

5 CASE DETERGENT

6PLATE TOP

7 CABINET

8 BUTTON DIAL

DIMENSION(WxDxH) 630mm(W) x 755mm(D) x 950mm(H)

MACHINE WEIGHT 85 kg

WATER CONSUMPTION WASH 94 / DRY 28

WASHING CONSUMPTION 28

POWER SOURCE 220V/60Hz

POWER WASHING 200W (Heating ) ~ 2000W

CONSUMPTION DRY 2100W

WASHING 11 kg

CAPACITY SPIN 11 kg

DRY 6.5 kg

WASHING TYPE DRUM TYPE

DRY TYPE Digital condensing dry system

OPERATION WATER PRESSURE 29kPa ~ 784kPa(0.3kgf/cm

2

~8kgf/cm2)

?

@

A

B

C

D

E

F

Page 8

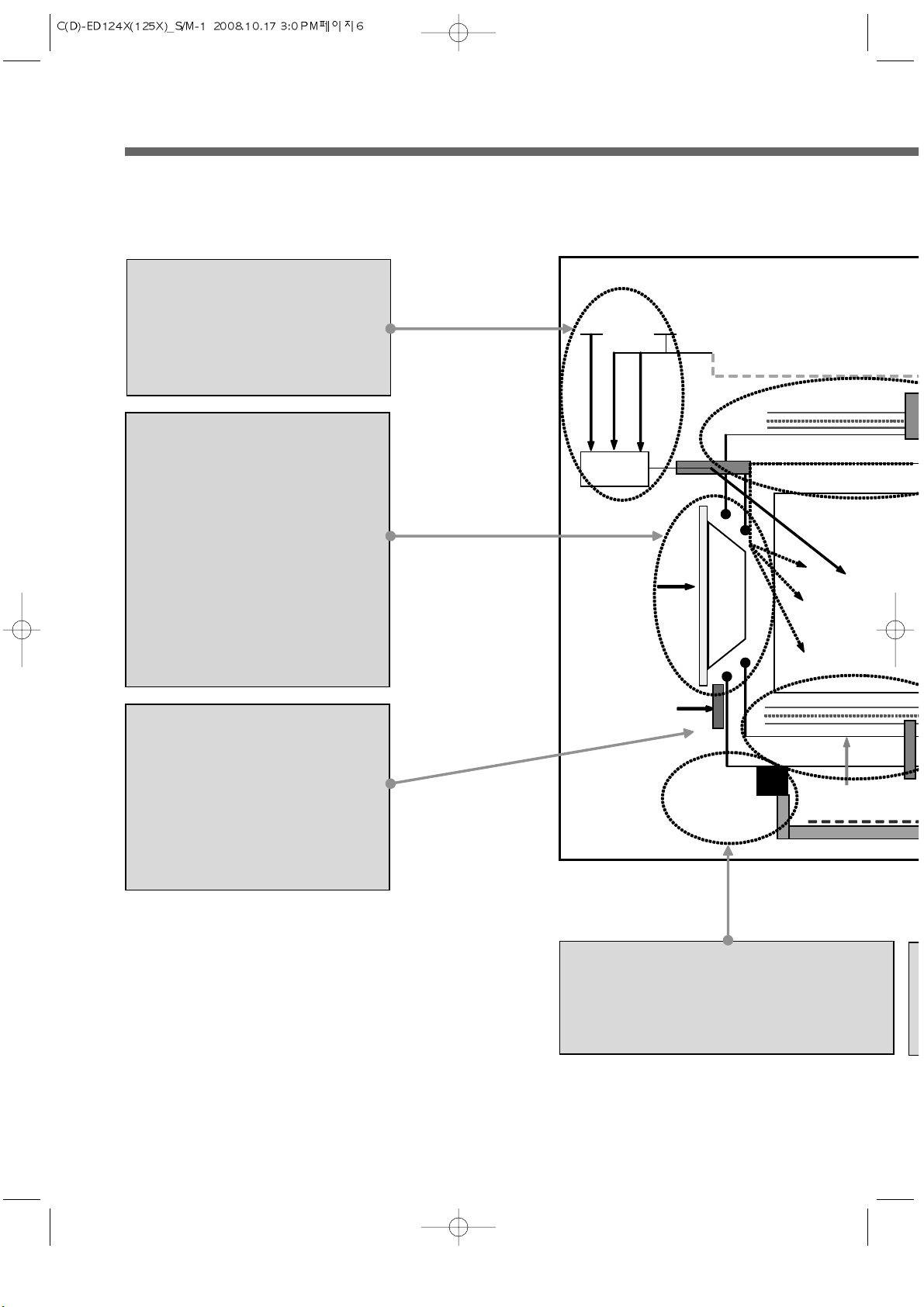

3. OPERA TING MECHANISM DIAGRAM

6

4. WATER SUPPLY PART

• Cold Water: 3 holes

Cold water, pre-washing

• Hot Water: 1 hole

• Water supply box, hose

Water

Supply

Detergent

Container

Thermister

Door

Door

Switch

Drainage

Pump

Washing

Heater

5. DOOR

• Door lock S/W

• Lock hinge

• Door AS: Glass

• Gasket

6. DRY PARTS

• HEATER DRY : OPTION

• BLOWER FAN

• FAN MOTOR : BLDC

• THERMISTOR

• THERMOSTAT

: FUSE, BI-METAL

• CONDENSING SYSTEM

• DRY FAN DRIVE

→ GENERATION OF HEATER’S

HEAT

→ TEMP. SENSOR

→ 110°C Off 100°C On : OPTION

7. DRAINAGE PART

• Drainage pump

• Valve housing

• Hose

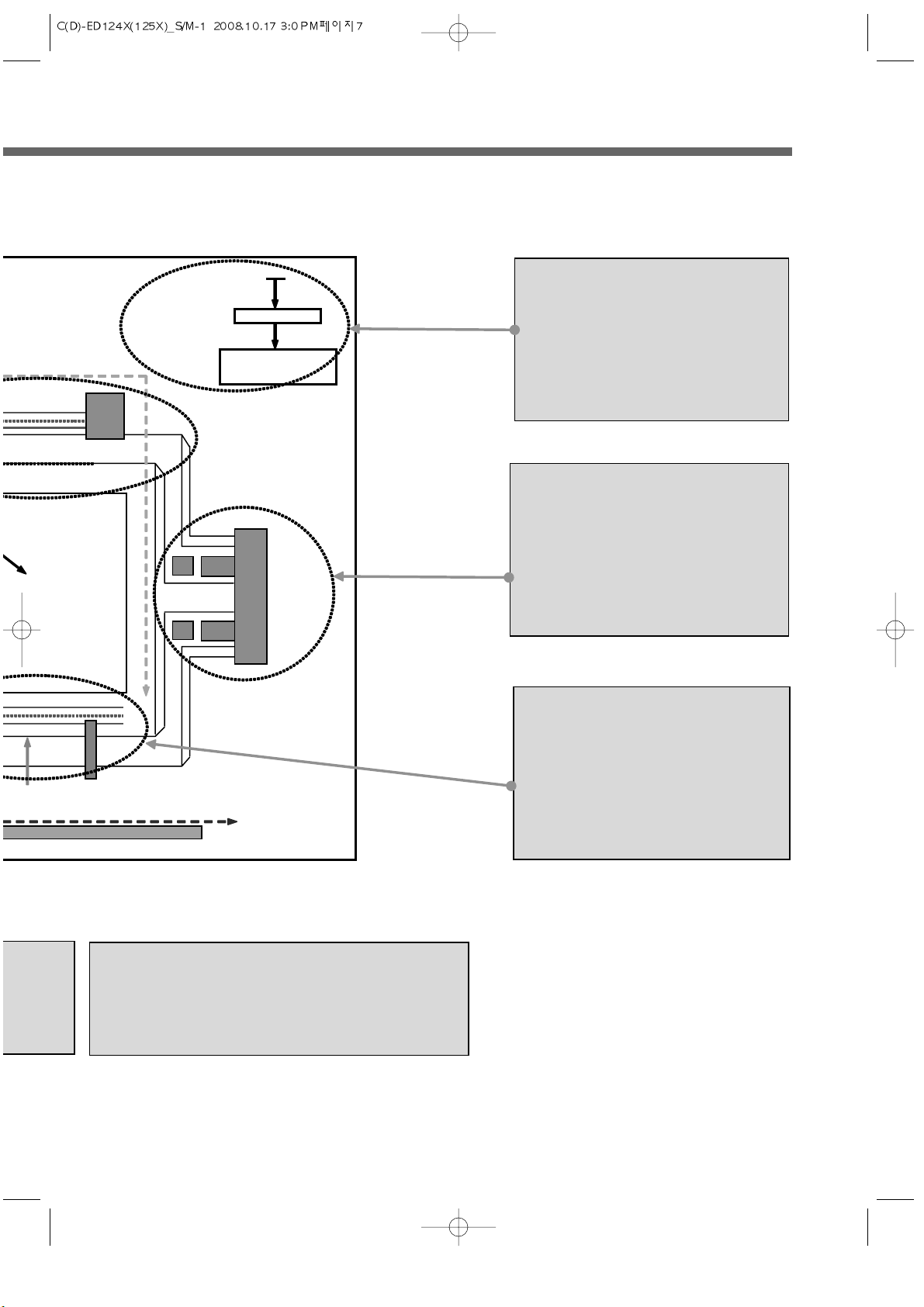

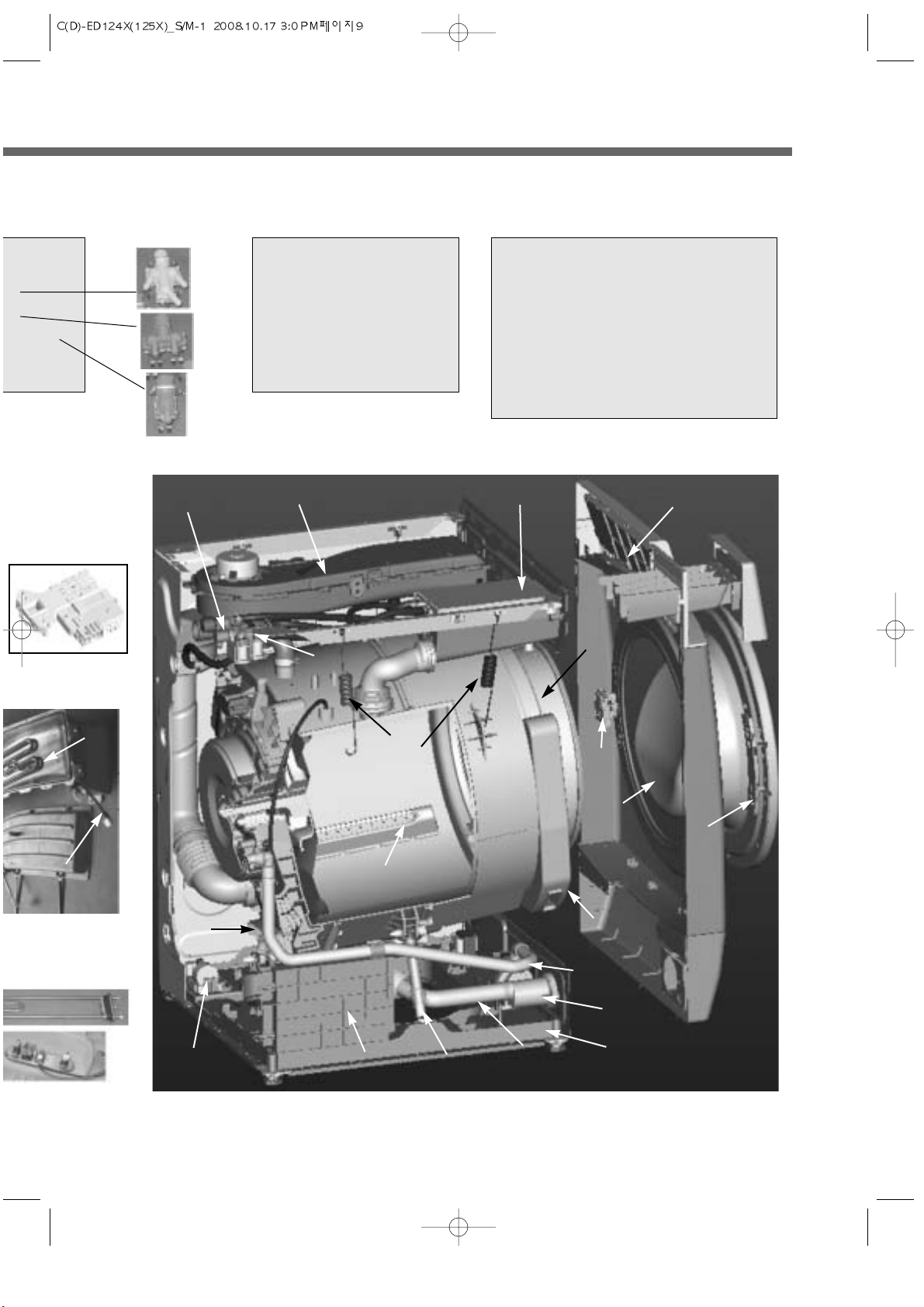

Page 9

7

Thermister

BLD

C

Motor

Drum

Program

Electricity Input

Noise Filter

8. SUPPORTER

• DAMPER AS : Front 2(70) / Rear 2(110N)

• Spring : 2

3. HEATING PART

• Water Heater: 1000W

• Washing temperature sensor

2. DRIVING PART

• BLDC motor

• Drum

• Bearing

• Spider/ shaft

• Tub

• Weight balancer

1. CONTROL PART

• Main PCB

• Front PCB

• Harness

• Noise filter

• Power Cord: 15A

Page 10

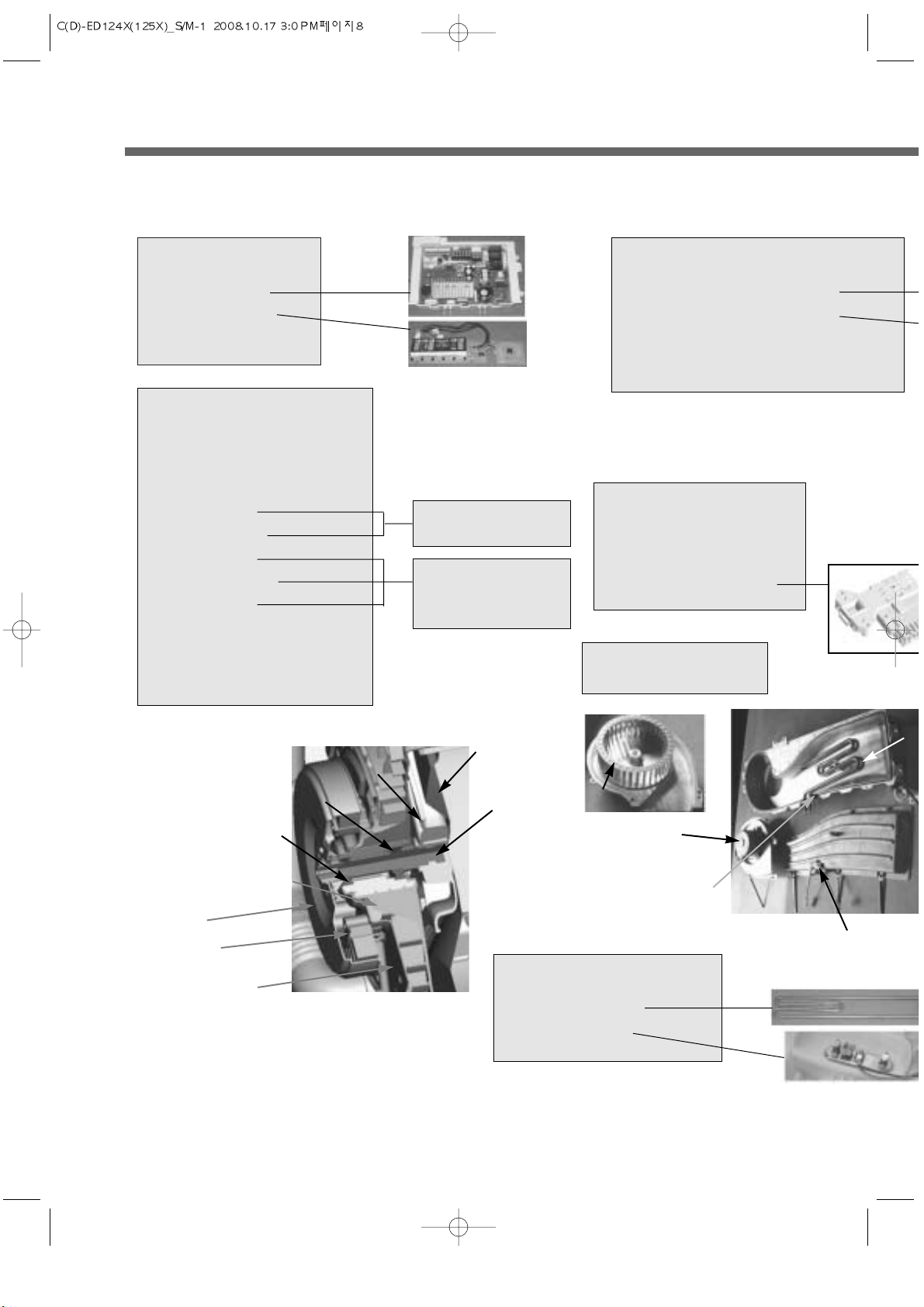

8

4. EACH P ART OF DRUM WASHING MACHINE

1. CONTROLLER

(1-1) MAIN PCB

(1-2) FRONT PCB

(1-3) NOISE FILTER

3. INLET PARTS

(3-1) 3-WAY INLET VALVE

(3-1) 2-WAY INLET VALVE

(3-2) 1-WAY INLET VALVE (HOT)

(3-3) INLET BOX AS

4. DOOR AS

(4-1) GLASS DOOR

(4-2) HINGE DOOR

(4-3)DOOR LOCK S/W

6. WASH HEATING

• WASH HEATER

• THERMISTOR

5. DRY : DUCT B AS

2. PARTS for DRIVING

(2-1) LIFTER AS

(2-2) GASKET

(2-3) WEIGHT BALANCER

(2-4) ROTOR

(2-5) STATOR

(2-6) SHAFT

(2-7) BEARING

(2-8) SPIDER

(2-9) DRUM

(2-10) TUB

(2-11) BASE

BLDC MOTOR

PARTS for

TRANMITTING

• FAN

MOTOR

(2-9)

(2-6)

(2-7)

(2-4)

(2-5)

(2-11)

(2-10)

• TEMP. FUSE

• BI-METAL

S/W

• HEATER DRY

• TEMP.

SENSOR

(2-7)

(2-8)

• FAN

Page 11

9

7. DRAIN

(7-1) PUMP AS

(7-2) HOSE DRAIN I

(7-3) HOSE DRAIN

8. SUPPORTER

(8-1) BASE U

(8-2) DAMPER AS : 3(70N)

(8-3) SPRING :

FRONT - 2 (BLACK)

REAR - 2 (YELLOW)

(5) (3-3)(3-2) (1-2)

(2-2)

(4-3)

(4-1)

(4-2)

(2-3)

(7-2)

(7-1)

(8-1)

(7-3)(8-2)(1-1)(1-3)

(2-1)

(6)

(8-3)

(3-1)

• TEMP.

SENSOR

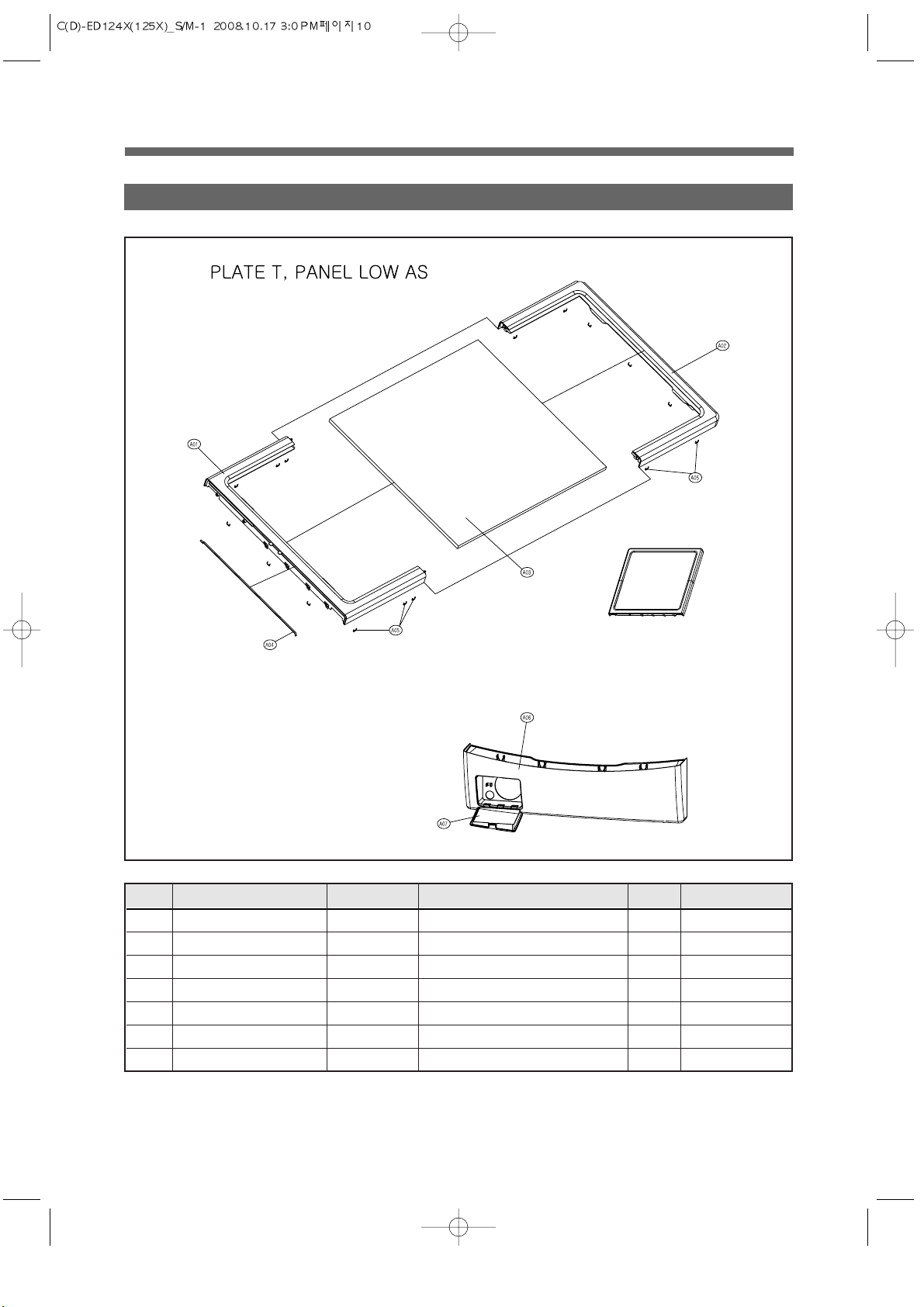

Page 12

10

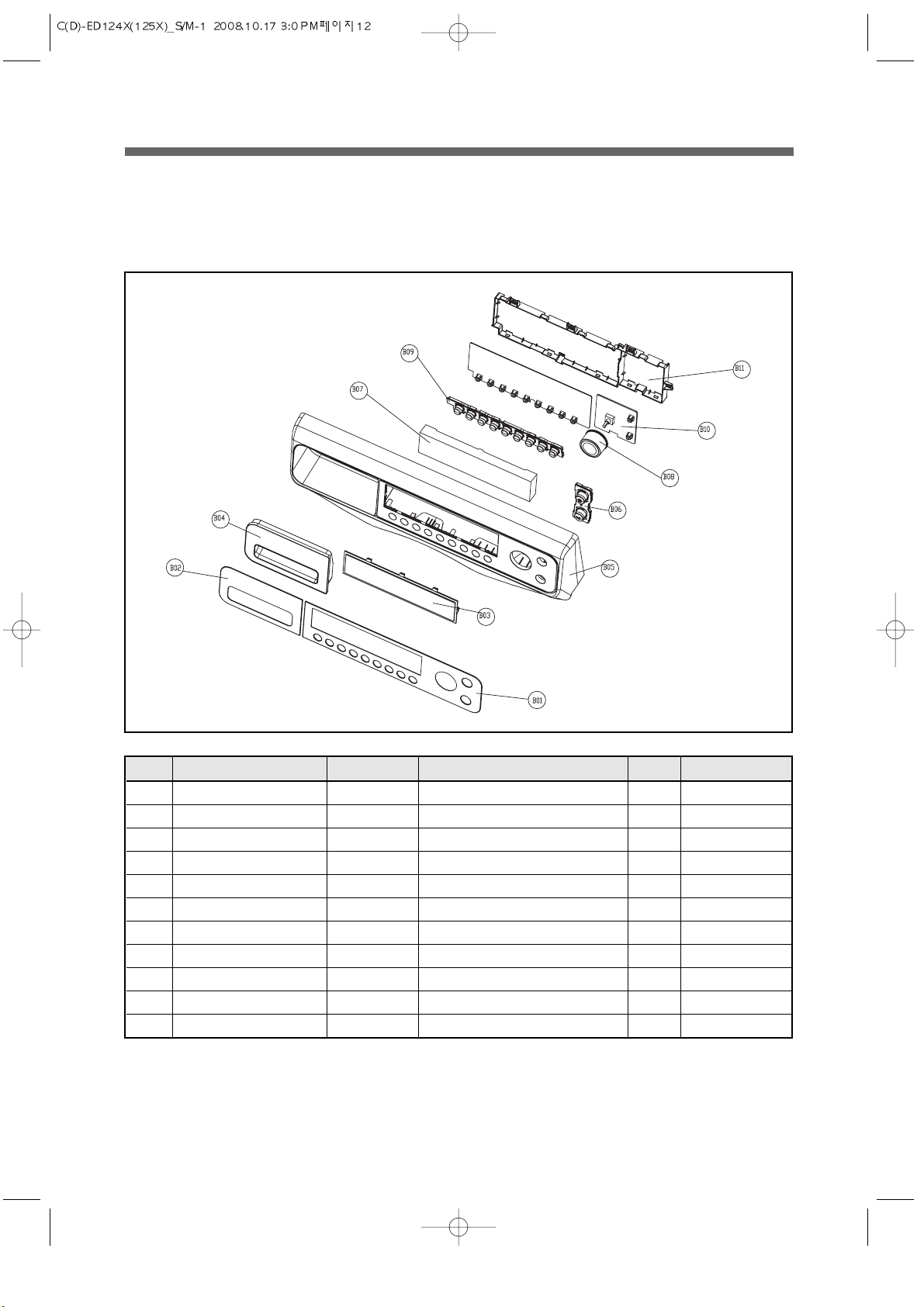

1. PLATE T, PANEL LOWER AS

5. P ARTS LIST BY ASS’Y

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

:HE 47:I6!$2:56!4 D?EFFH@@HE J3$K E

:HF 47:I6!$2:56!76:7 D?EFFH@AHE J3$K E

:HD $2:56!5L$ D?E@ADE?HH MLL( E

:H@ N:KO65!$2:56!5 D?EFDFEDHH

(M(PEHH(7Q!6$(IQ!@R@FAIIQ!5SFTH

E

:HA 43R5;76!$2:56!5 D?EFHHCEHH

K5:$26UBREHVQ!MLL(!43R5;76Q!(M(PEHH(7

E

:H? $:/62!2LM67 D?E@FB@FHH J3$KQ$;I$ E

:HC 9LW67!$;I$ D?EE@F?@HH J3$KQ$;I$ E

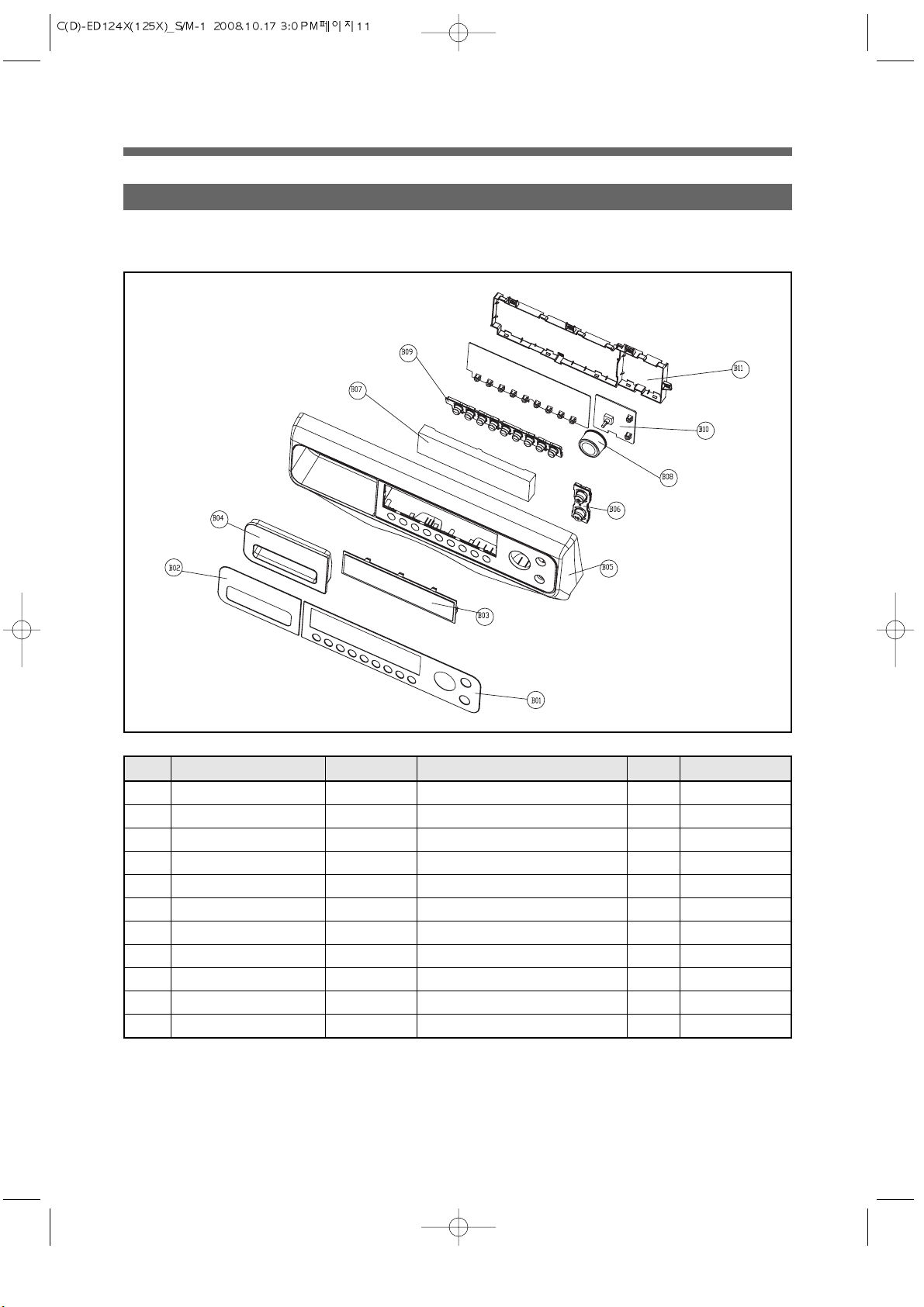

Page 13

11

2. PANEL F AS

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

8HE (69L7:5L7!$:/62!4 D?EE?BDDHH :2;I3/;I E

8HF

(69L7:5L7!J:/(26!9:K6

D?EE?BD@HH :2;I3/;I E

8HD M3/(LM!(3K$2:< D?EAAHDCHH :8K E

8H@ J:/(26!9:K6 D?EF?HXFHH :8K E

8HA $:/62!4 D?E@FB@XEH :EEH7Q!:8K E

8H? 8;55L/!$YK D?E??H@XHH :8K E

8HC 9;K5LI!26( D?EDHAEHH (M(P:EEH7 E

8HB 8;55L/!(3:2!:K D?E??D@CHH EDH7$ZK!8;55L/!(3:2!:K E

8HX 8;55L/!4;/953L/ D?E??H@BHH :8K E

8EH $98!:K $7$KKM:(EH

(M(P:EEH7!47L/5!$98!:KK<

E

8EE 9:K6!4P$98 D?EEE@FHHH J3$K E

[[ $$))..&&++%%&&

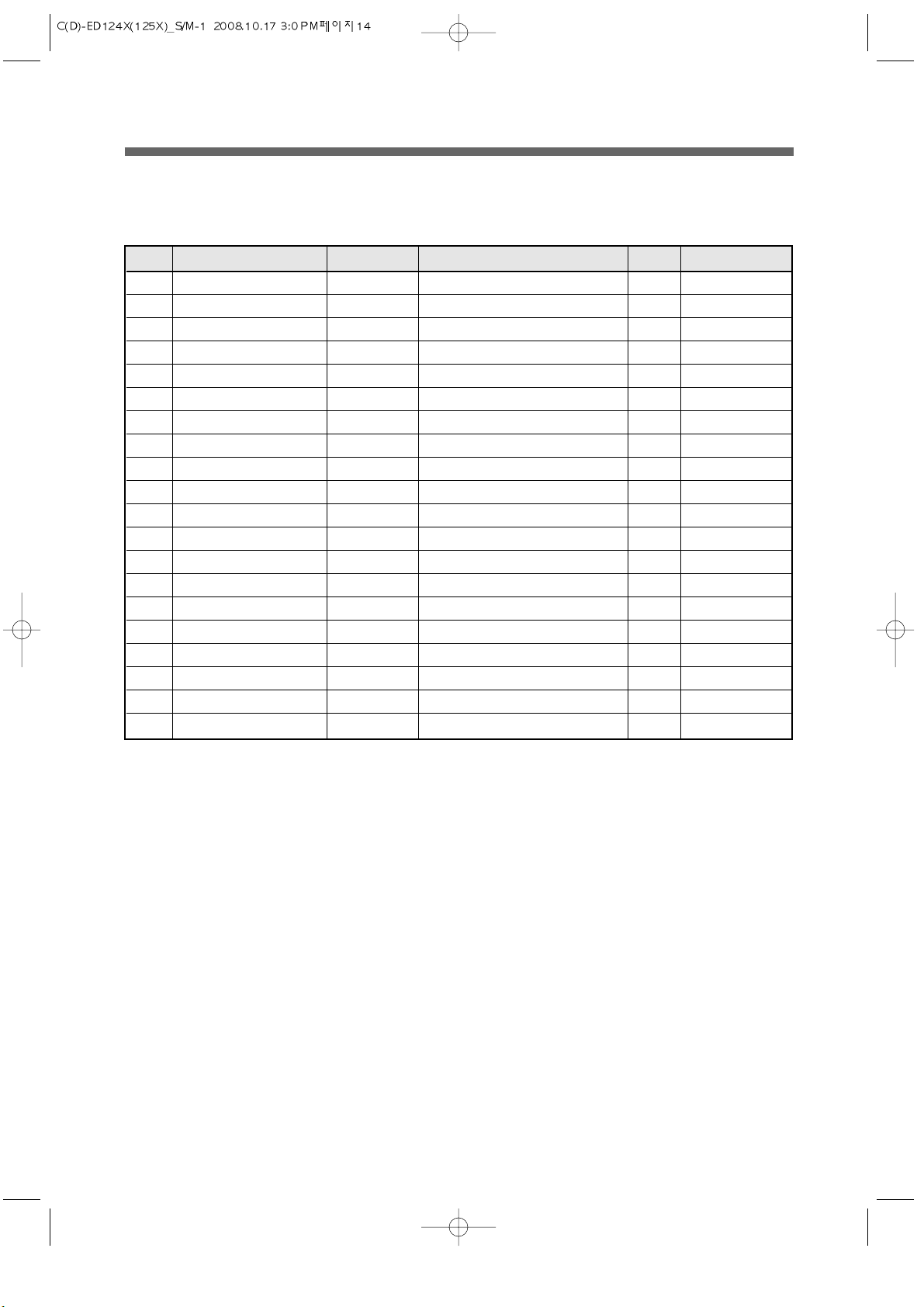

Page 14

12

[[ //>>))&&**11

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

8HE (69L7:5L7!$:/62!4 D?EE?BDAHH $9!432I E

8HF

(69L7:5L7!J:/(26!9:K6

D?EE?BD?HH $9!432I E

8HD M3/(LM!(3K$2:< D?EAAHDCHH :8K E

8H@ J:/(26!9:K6 D?EF?HXFHH :8K E

8HA $:/62!4 D?E@FB@XEH :EEH7Q!:8K E

8H? 8;55L/!$YK D?E??H@XHH :8K E

8HC 9;K5LI!26( D?EDHAEHH (M(P:EEH7 E

8HB 8;55L/!(3:2!:K D?E??D@CHH EDH7$ZK!8;55L/!(3:2!:K E

8HX 8;55L/!4;/953L/ D?E??H@BHH :8K E

8EH $98!:K $7$KKM:(EH

(M(P:EEH7!47L/5!$98!:KK<

E

8EE 9:K6!4P$98 D?EEE@FHHH J3$K E

Page 15

13

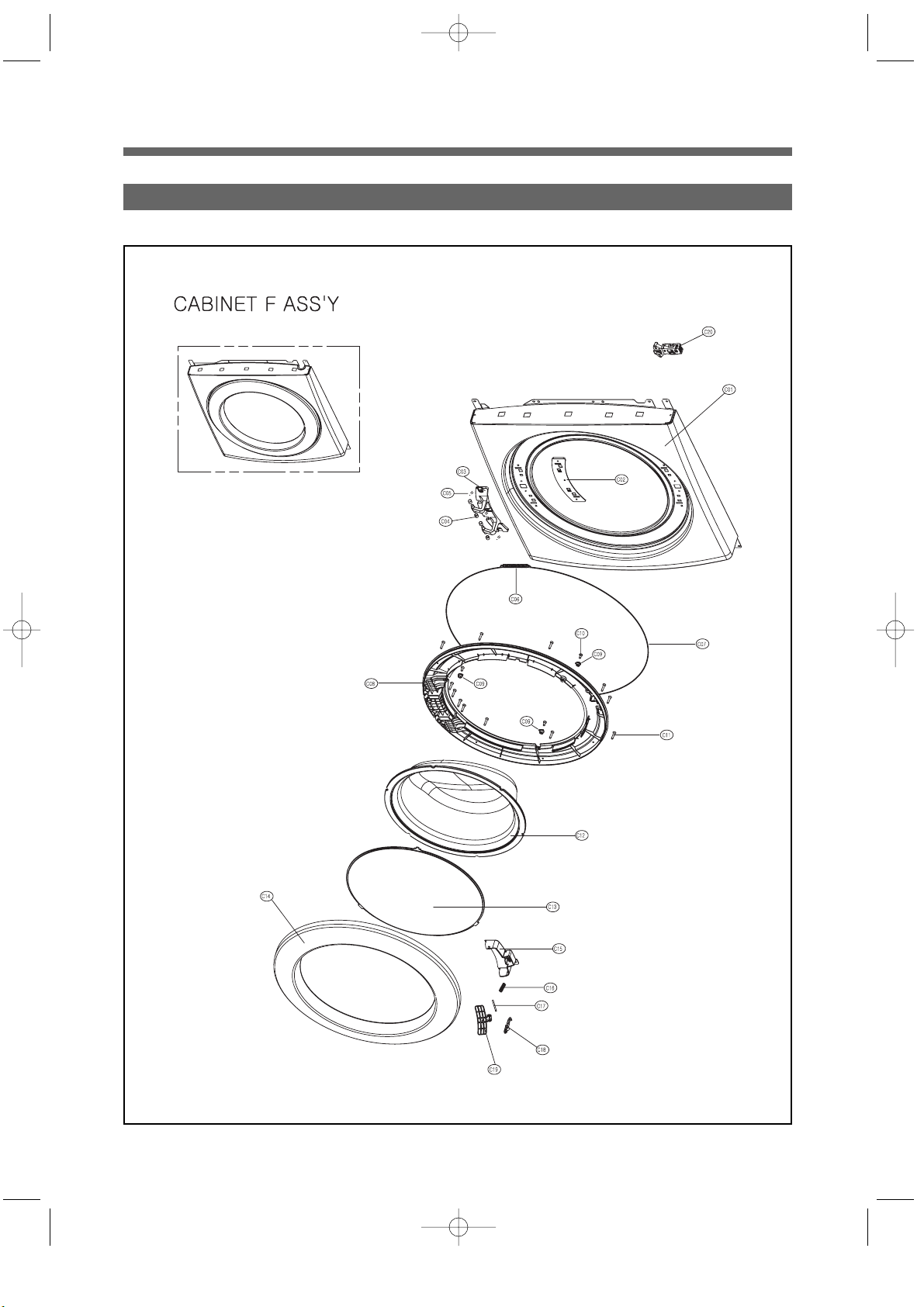

3. CABINET F ASSY

Page 16

14

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

9HE 9:83/65!4 D?EHBEEHHH K69(!HTB5 E

9HF $2:56!J3/N6!K;$T D?E@ADEAHH K$N!ET?5 E

9HD J3/N6!(LL7 D?EFXHFCHH \/(9 E

9H@ 9:$!J3/N6!(LL7 D?EHXE?AHH $LI E

9HA K976M!5:$$3/N D?E?HAEFFX K5K@DH!4]2!8L25UK6V!A^EF D

9H? K$73/N!(LL7 D?EAEEDBHH (SETH E

9HC 92:I$!(LL7 D?EEFH@FHH JMK7!(SET@ E

9HB 47:I6!(LL7!3 D?EFFH@CHH $$ E

9HX K5L$$67!(LL7 D?EAFHFDHH $$ D

9EH K976M!5:$$3/N CEFF@HE?HB 5FK!57K!@RE?!K;K!@DH F

9EE K976M!5:$$3/N CEEA@HFHFX 5EK!425!@^FH!K5K@DH!/:5;7:2 EA

9EF (LL7!N2:KK D?E:EEH?HH N2:KK!U(M(PEHH(7V E

9ED $7L5695L7!N2:KK D?EBDH@FHE N$$K E

9E@ 47:I6!(LL7!L D?EFFH@?HH :8KQ97 E

9EA 9LW67!J:/(26 D?EE@FA?FH :8KQ!97 E

9E? K$73/N!JLLO D?EAEEDCHH K;K!3(S@TDQ/3SCQ(S_HTX F

9EC $3/!J:/(26 D?EBFHHEHH K;KQ!(DTH E

9EB JLLO!(LL7 D?EDEHHCHH \/(9 E

9EX J:/(26!(LL7 D?EF?HBFHH :8K E

9FH KM359J!(LL7!2L9O D?EXH@?@HH

(4!4HE!HHC!FFHW!E?:!$59PKL26/L3(

E

Page 17

15

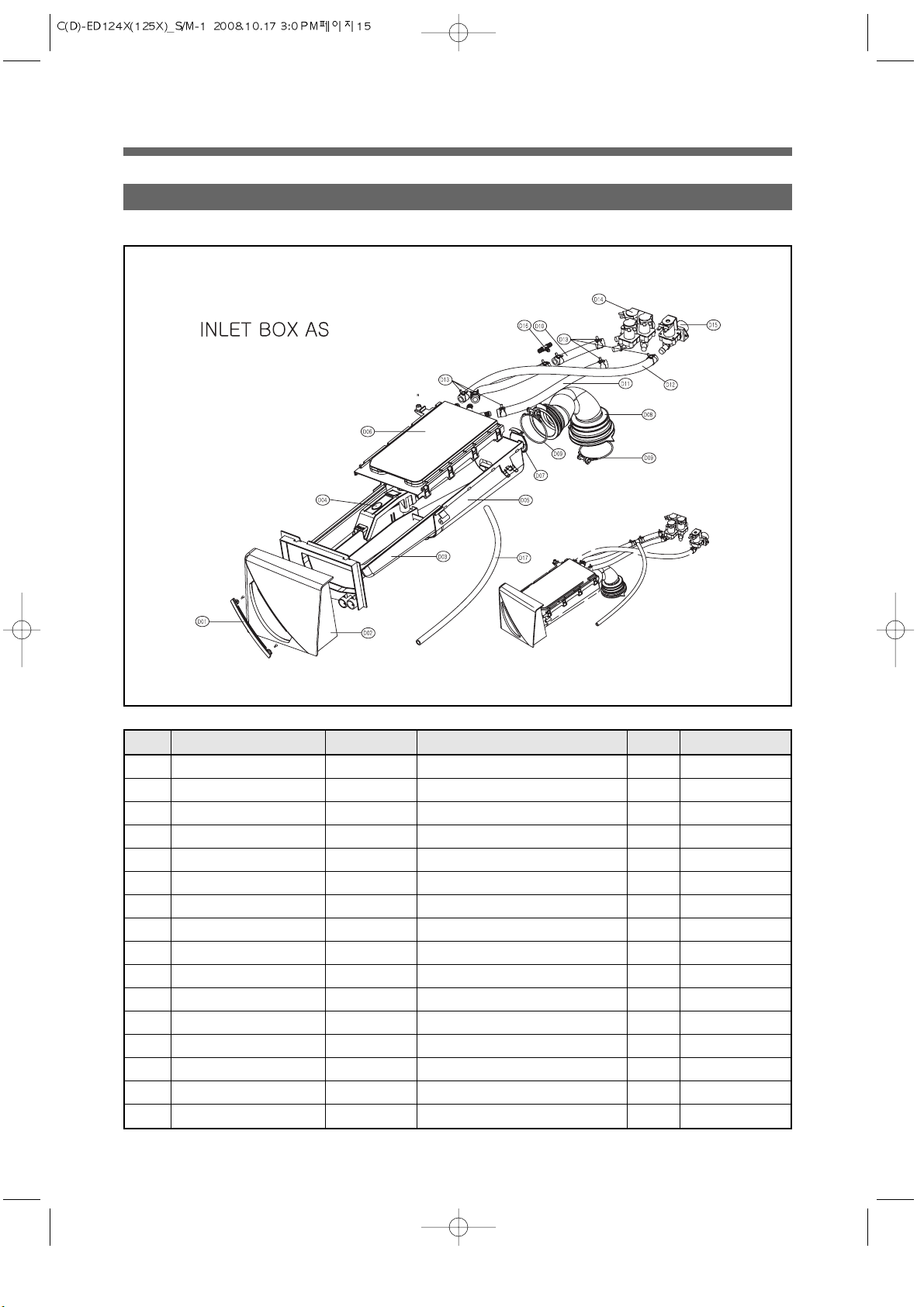

4. INLET BOX AS

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

(HF J:/(26!9:K6 D?EF?HXFHH :8K E

(HD 9:K6!(6567N6/5 D?EEE@EXHH $$ E

(H@ 9:$!KL456/67 D?EHXE??HH $$ E

(HA 3/2658LR D?ECAHADEH $$ E

(H? /L\\26!:K D?EBEHDAHH $$Q!(M(PEHH(7 E

(HC $:9O3/N D?E@HEHHHH 6$(I E

(HB JLK6!3/265 D?EDF??@HH 6$(I E

(HX 92:I$!:K D?EEFHDFHH

3(S?HQ!M376`N;3(6`8L25`/;5

E

(EH JLK6!M:567!K;$$2< D?EDFCHXHH 6$(I!3(XTA!L(E@TA HTDDA I*+,

(EE JLK6!M:567!K;$$2< D?EDFCHXHH 6$(I!3(XTA!L(E@TA HT@F J>0

(EF JLK6!M:567!K;$$2< D?EDFCHXHH 6$(I!3(XTA!L(E@TA HTDD $).

(ED 92:I$!K$73/N D?EEFHDBHH 3(SEATAQ!5SHT?Q!8SEH B

(E@ W:2W6!3/265 D?EA@EAHAH

FFHaF@HWQDM:<Q73/K6!N;3(6Q$$]87:9O65

E

(EA W:2W6!3/265 D?EA@E@BHH

FFHPF@HW!EPM:<!JL5!$$P87:9O65

E

(E?

$3$6!bL3/5UJLK6!3/265V

D?E@@EDDHH $$ E

(EC JLK6!M:567!K;$$2< D?EDFCHXHH 6$(I!3(XTA!L(E@TA HT?F KJLM67!JLK6

Page 18

16

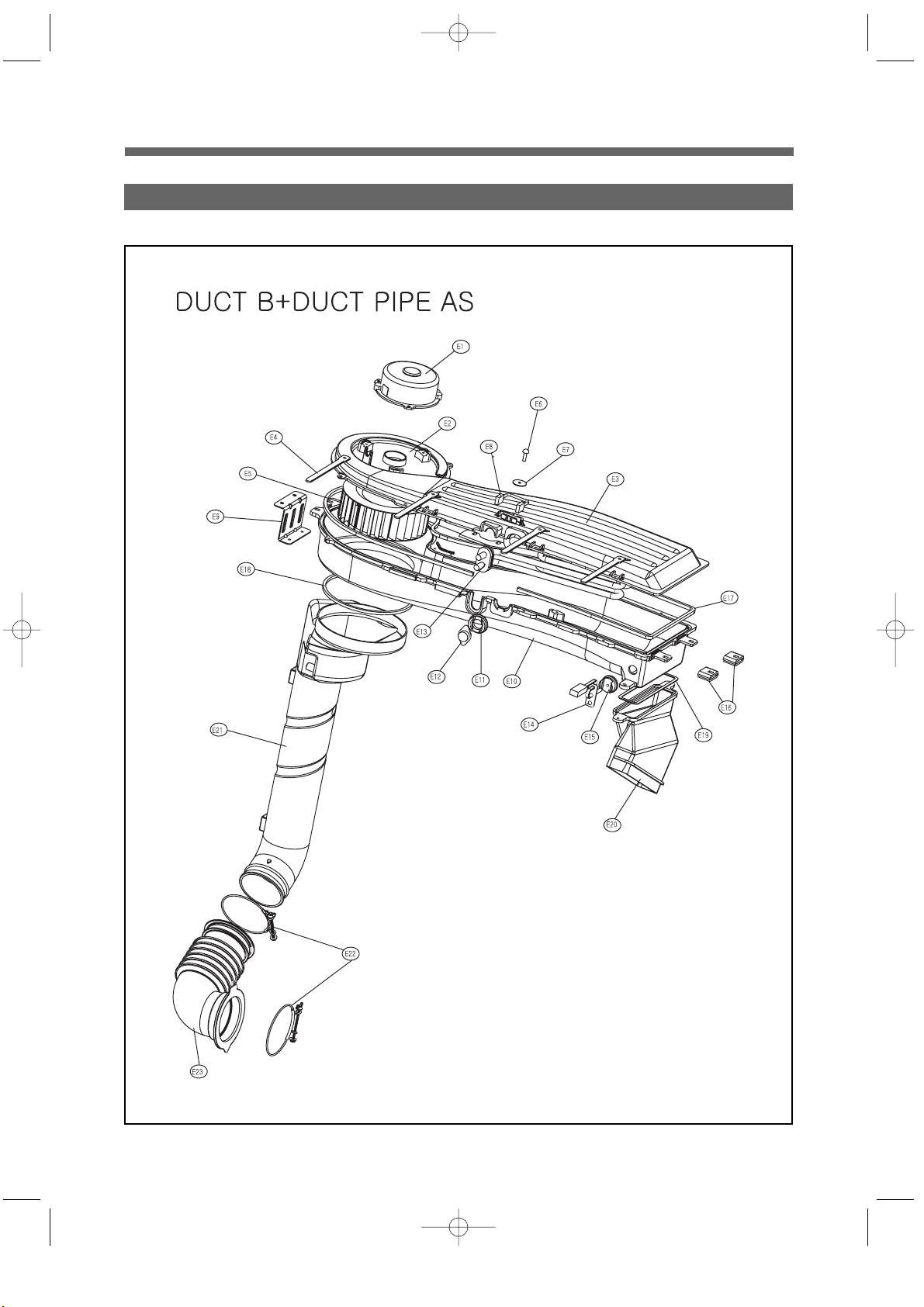

5. DUCT + DUCT PIPE AS

Page 19

17

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

6HE ;/35!4:/!IL5L7 D?EBX2D\FH

3KIPCCBH?(MM:!F@WQ9MQB$QE@M

E

6HF

6HD (;95!8!;$$67 D?E:FHEFHH :29LK5:!HTA5^FFB^@@X E

6H@ 92:I$!9L7( D?EEFHDDAH 2SX@Q!MSAT?Q:SBTHQ!2JPX@ @

6HA 4:/!:K D?EEBBAXHH

(EDD!4:/Q!N4$$DHc!dP!/<2L/??

E

6H? K976M!5:$$3/N CEFF@HE@EE 5FK!57K!@RE@!I4\/ D

6HC K$693:2!K976M!:K D?E?HDH?HH 5:$5356!$Q!57K@^E?Q!M:KJ67 E

6HB 4;K6!56I$67:5;76 D?E:BHHEFH EFBe (4PEFBK!EA:!FAHW!W(6 E

6HX

47:I6!J6:567!47:/N6

D?EFFH@EHH K8JN!ETF5Q!(M(PEHH(7 E

6EH (;95!8!2LM67 D?E:FHHEHE :2Q!D5Q!(M(PEEH7$ E

6EE

$:9O3/N!5J67ILK5:5

D?E@HHXXHH K3239L/Q!(M(PEHH(7 E

6EF

KM359J!5J67ILK5:5

D?EXH@?AHH

L/EFHe L44EAHe FDHW!EA:!W(6

E

6ED J6:567!(7< D?EFBHHXHH FFHW!FEHHM!FDTHA!LJI!?TEM E

]Kf!3/9L2L<BHH!E7E:HD@HHE

D?EFBHE@HH FDHW!FEHHM!FDTEX!LJI!?TEM E

]Kf!3/9L2L<BHH!E7E:H@HHF

6E@ 5J67I3K5L7!(7< D?E::::9HH 7@HSF?TH?AgQ7XHS@T@FCBg E

6EA $:9O3/N!7;8867 D?E@HHXBHH K3239L/Q!(M(PEHH(7 E

6E? 9;KJ3L/!(7< D?EEA?FBHH /87Q!(M(PEHH(7 F

6EC N:KO65!K6:2!8 D?EFDFHBEH

6$(I!4L:IQ!2S@EFQ!@TX^@T@^@TB

E

6EB N:KO65!K6:2!: D?EFDFHBFH (M(PEEH7$Q!_AQ2SEDBA E

6EX N:KO65!3/265 D?EFDFHXHH (M(PEHH(7 E

6FH (;95!N;3(6 D?E:FHEHHH (M(PEEH7$QD5Q:2(9 E

6FE (;95!$3$6!:K D?E:FHHCHH EEON E

Page 20

18

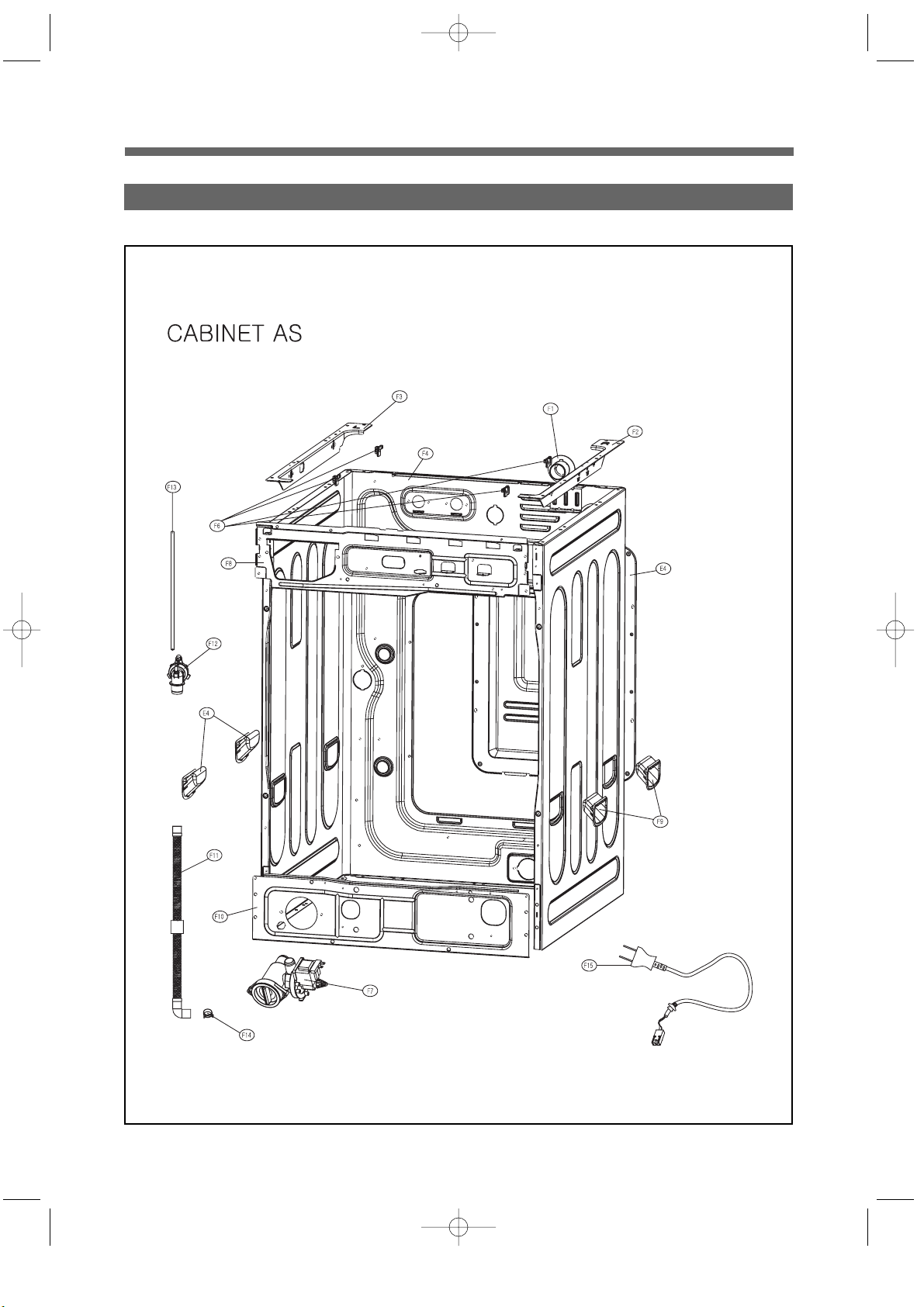

6. CABINET AS

Page 21

19

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

4HE /L\\26!:37 D?EBEHDEEH $$Q!(M(PEHH(7 E

4HF 47:I6!5L$!7 D?EFFH@DHH N3Q!ET?5Q!(M(PEHH(7 E

4HD 47:I6!5L$!2 D?EFFH@XHH ET?5Q!N3Q!(M(PEHH(7 E

4H@ 9:83/65 D?EHBEHXHH

KN9(EQHTB^XFATC^EXFFQ$:3/53/NQ(M(PEEH7$

E

4HA 9LW67!8:9O!:K D?EE@FAAEH

9LW67!8:9O!`!$:(!9:83/65!:K

E

4H? K5L$$67!K$73/N D?EAFHFFHH $LIQ!(M(PEHH(7 @

4HC ;/35!(7:3/!$;I$!:K D?EBX2AODH

:2TFFHPF@H]AH!8FHP?!DHM!EEON

E

4HB 47:I6!;$$67 D?EFFH@HHH K8JNQ!ETF5Q!(M(PEHH(7 E

4HX J:/(26!9:83/65 D?EF?HBEHH $$Q!(M(PEHH(7 E

4EH 47:I6!2LM67 D?EFFH@FHH K8JNQ!ETF5Q!(M(PEHH(7 E

4EE JLK6!(7:3/!3 D?EDF??EHH 6$(I E

4EF 9;44!JLK6!(7:3/ D?E?BHF@HH $$Q!(M(PEHH(7 E

4ED JLK6!K3$JL/ D?EDF?X?HH 6$(I E

4E@ 92:I$!JLK6 D?EEFH@CHH (F? E

4EA 9L7(!$LM67!:K D?EEDDXD@H

JHAWWP4!ETAKf!FAHWE?:!4677356

E

D?EEDDXDHE

JHAWWP4!ETAKfRD9!FAHWE?:!FTDI!N<!OK!2L/NM622

E

D?EEDDXXDH

JHAWWP4!ETAKf!FAHWE?:!6;PF$!4677356

E

Page 22

20

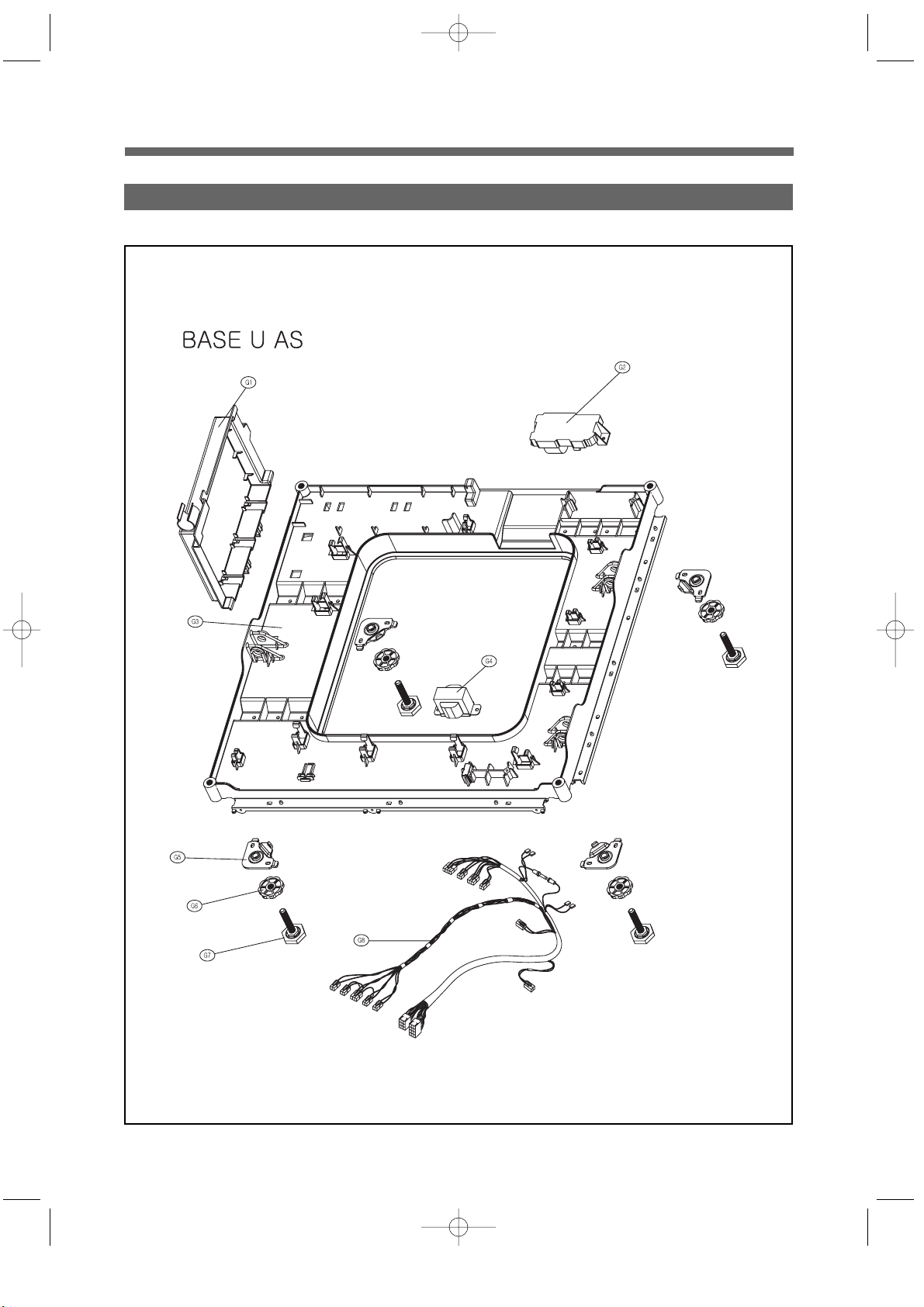

7. BASE U AS

Page 23

21

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

NHE $98!:K

NHF 6I3!432567UOEXV D?EEXHBHHH

(M24POEXQRHT@C;T<EHHH$TW:7@CEOT4;K6FH:

E

NHD 8:K6!; D?EHDXEXEH $$Q!(M(PEHH(7 E

NH@ 76:95L7 AFNH@DbHHF (M(PEHH(7Q!@: E

NHA K;$$L7567!26N D?EADHD?HH $LQ!DTH5 @

NH? 43R5;76!26N D?EFHH?@HH :8KQ!(M(PEHH(7 @

NHC 4LL5 D?EFEHH?HH 8;5<2Q!(M(PEHH(7 @

K$693:2!8L25 D?E?HFXHHH EH!R!ETFAQ!AEII @

NHB J:7/6KK!:K D?EFCX?4HH

(7;IPEEONT(7<P4;22

E

D?EFCX?4?H

(7;IPEEONT$;I$Q!(7<

E

Page 24

22

8. TUB AS

Page 25

23

"#$ %&'()!"&*+ %&'()!,#-+ .+)/'01(0#2 34(5 6+*&'7$

JHE

8:2:/96!M63NJ5!7]2!:K

D?E?EHC?HH

EEONQ?TAONU7]2VQ:N35:53L/!2LM

E

JHF $3$6!bL3/5 D?E@@H@XHH $$ E

JHD 92:I$!UJLK6!$3$6V D?EEFH@DHH _E@Q!I\4/ E

JH@ JLK6!bL3/5 D?EDF??AHH 6$(I E

JHA N:KO65 D?EFDFHCHH 6$(I E

JH? 92:I$!N:KO65!:K D?EEFHD?HH N:KO65 E

JHC K$73/N!K;K$6/K3L/!4 D?EAEEDAHH FTX F

JHB 5;8!47L/5 D?EBBFH@HE 47$$!4JCDHHNI E

JHX 43R5;76!J6:567 D?EFHH?CHH K;K E

JEH (:I$67!$3/ D?E:CHHFHH :OK!(SE@TA D

JEE (:I$67!473953L/ D?E:CHHEFH

EFH/!:OK!K5SECHPF?H!(2SEXCTA!2LM!/L3K6

D

JEF (7;I!K;8!:K D?ECHHDDHE EEON!HTA5 E

JED 234567!:K D?E:@HHDAH

(M(P:EE^KQ2345!8L(<`432567!:K

E

JE@ K$3(67!:K D?E:DHHFHH EEON E

JEA (7:3/!JL;K3/N!3 D?EX?5:IHH $$Q$;I$ E

JE? JLK6!(7:3/ D?EDF?XHHH 6$(IQ$;I$ E

JEC :37!57:$!:K D?EH::7EHE EEH7$Q!JLK6`57:$ E

JEB

K$73/N!K;K$6/K3L/!7

D?EAEED?HH FTX F

JEX N:KO65!5;8 D?EFDFEEHH 6$(I!4L7I E

JFH M:567!K6:2 D?E:?HHEHH /87 E

JFE 86:73/N!3//67 D?E?DHDEHH ?FH?\!4:8 E

JFF 86:73/N!JL;K3/N D?E?DH@?HH :2(9Q!(M(P5EFH7 E

JFD 86:73/N!L;567 D?E?DHDFHH ?FHA\!4:N E

JF@ JLK6!:37 D?EDF??DHH 6$(IQ!(M(PEHH(7 E

JFA ;/35!8;8826!$;I$ D?EBX2@EHH

FFHPF@HW!(8OPF@H(:!CHHaEFHH99

E

JF? ;/35!K5:5L7!82(9 D?EBX2@BHH

_F?ARFBJQD?K2L5QFK/6KL7QDFA@(HFHHH

E

JFC ;/35!7L5L7!82(9 D?EBX2@XHH

I:N/65F@QK677:53L/QM7EFDB4HHE

E

JFB J6:567!M:KJ D?EFBHF@HH

FFHW!FOMTE7H:CFEHHET7MB54T379:

E

D?EFBHF@EH

FDHW!FOMTE7H:CFEHHFT7MB54T379:

E

JFX /L\\26!KJLM67 D?EBEH@HHH $$ E

JDH 92:I$!JLK6 D?EEFHD@EH KOAQ!(SDD E

Page 26

24

6. CONTROL P ART FUNCTION SPECIFICA TION

1. SEQUENCE CHART

((++hh++ii++>>,, 55++&&..

K&*11 I+jj1. I+jj1. K&*11 I+jj1. K&*11 I+jj1.

K.,i+,- FHi.k

M*0.)!K%''1l F&+, ■

$).T!M*im EH&+,

B&+,

()*+, E&+, ■

8*1*,k+,-!K'+,

F&+, ■

I+jT!K'+, D&+, ■

K.,i+,- FHi.k ■■ ■■■■

M*0.)!K%''1l F&+, ■■■■■■■

XH&+,

M*im+,-E BH&+,

UJ.*0+,-V DA&+,

DH&+,

FA&+, ■

M*im+,-F

FA&+,

FH&+,

EA&+,

()*+, E&+, ■■■■■■■

8*1*,k+,-!K'+,

F&+, ■■■■■■■

I+jT!K'+, D&+, ■■■■■■■

M*0.)!K%''1l F&+, ■■■■■■■

7+,i.!E D&+, ■■■■■■■

()*+, E&+, ■■■■■■■

8*1*,k+,-!K'+,

F&+, ■■■■■■■

I+jT!K'+, D&+, ■■■■■■■

M*0.)!K%''1l F&+, ■■■■■■■

7+,i.!F D&+, ■■■■■■■

()*+, E&+, ■■■■■

8*1*,k+,-!K'+,

F&+, ■■■■■

I+jT!K'+, D&+, ■■■■■

M*0.)!K%''1l F&+, ■■■■■

7+,i.!D D&+, ■■■■■

()*+, E&+, ■■■■■■■

8*1*,k+,-!K'+,

E&+, ■■■■■■■

C&+,

I*+,!K'+, A&+,

D&+,

9).*i.!k*). ?Hi.k ■■■■■■■

6,j EHi.k ■■■■■■■

77..&&**++,,!!55++&&..!!((++ii''11**ll

EnFH EnFA EnAX FnF? FnD? @n@E EnA?

/L56

$$

77

66TT

MM

::

KK

JJ

M

:

K

J

3

/

N

7

3

/

K

6

K

$

3

/

6/(

//>>))&&**11

J.*hl!!K0*+,

MMmm++00..ii 66kk>>PPMMmm++00..ii

ET3,!0m.!J.*hl!K0*+,!9>%)i.Q!$).o*im!+i!+,k1%j.j!*i!(.p*%10T

FT(.p*%10!K.00+,-!5+&.i!>p!7+,i.!+,!0m.!/>)&*1!9>%)i.i!*).!0o>!0+&.iT

FH&+,

CA&+,

DH&+,

@A&+,

BA&+,

Page 27

25

((++hh++ii++>>,, 55++&&..

K&*11 K&*11 I+jj1. I+jj1. J+-m

K>*q DH&+, ■

M*0.)!K%''1l F&+, ■■■■■

?H&+,

M*im+,-E AH&+,

UJ.*0+,-V DA&+,

DH&+,

EA&+, ■

FA&+,

M*im+,-F FH&+,

EA&+, ■■ ■

()*+, E&+, ■■■■■

8*1*,k+,-!K'+,

E&+, ■■■■■

I+jT!K'+, D&+, ■■■■■

M*0.)!K%''1l F&+, ■■■■■

7+,i.!E D&+, ■■■■■

()*+, E&+, ■■■

8*1*,k+,-!K'+,

E&+, ■■■

I+jT!K'+, D&+, ■■■

M*0.)!K%''1l F&+, ■■■

7+,i.!F D&+, ■■■

()*+, E&+, ■

8*1*,k+,-!K'+,

E&+, ■

I+jT!K'+, D&+, ■

M*0.)!K%''1l F&+, ■

7+,i.!D D&+, ■

()*+, E&+, ■■■■■

8*1*,k+,-!K'+,

E&+, ■■■■■

C&+,

I*+,!K'+, A&+,

D&+,

9).*i.!k*). ?Hi.k ■

()l EHH&+,

DH&+, ■

9>>1+,- A&+, ■

6,j EHi.k ■

9).*i.!k*). DH&+, ■

9).*i.!k*). ?Hi.k ■

6,j EHi.k ■■■

77..&&**++,,!!55++&&..!!((++ii''11**ll

@X DF EnEE EnHX EnAE

/L56

M

:

K

J

3

/

N

7

3

/

K

6

K

$

3

/

(

7

<

6/(

ET!3,!0m.!5%r!91.*,!9>%)i.!()l!+i!+,k1%j.j!*i!(.p*%10T

FT!9).*i.!9*).!9>%)i.!)%,i!%,0+1!'%11!>%0!0m.!1*%,j)lT

FH&+,

B&+, EH&+,

MM>>>>11

f%+kq!!DH

8811**,,qq..00 FF!!OO--

5%r!!91.*,i

Page 28

26

((++hh++ii++>>,, 55++&&..

K&*11 K&*11 I+jj1.

K.,i+,- FHi.k ■■■■

K0.*&!M*0.)!K%''1l

E&+, ■■■■

K0.*&!J.*0+,-

EA&+, ■■■■

K0).*&!M*im+,-

EA&+,

EH&+,

C&+, ■■

4+,+im+,-!M*0.)!K%''1l

E&+, ■■■■

4+,+im+,-!M*im+,-

FA&+, ■■■■

K>*q DH&+,

M*0.)!K%''1l F&+,

?H&+,

M*im+,-E AH&+,

UJ.*0+,-V DA&+,

DH&+,

EA&+,

FA&+,

M*im+,-F FH&+,

EA&+,

()*+, E&+,

8*1*,k+,-!K'+,

F&+,

I+jT!K'+, D&+,

M*0.)!K%''1l F&+,

7+,i.!E D&+,

()*+, E&+,

8*1*,k+,-!K'+,

F&+,

I+jT!K'+, D&+,

M*0.)!K%''1l F&+,

7+,i.!F D&+,

()*+, E&+,

8*1*,k+,-!K'+, F&+, ■■■■

C&+,

I*+,!K'+, A&+,

D&+,

9).*i.!9*). ?Hi.k ■■

6,j EHi.k ■■■■

77..&&**++,,!!55++&&..!!((++ii''11**ll

EnDF EnDA En@H En@D

/L56

K

5

6

:

I

M

:

K

J

3

/

N

7

3

/

K

6

K

$

3

/

6/(

ET!I.&>)l!k>%)i.!+i!*i!i*&.!*i!*jj!>,.!)+,i.!0>!.k>!i0.*&!k>%)i.T

6k>PK0.*& K0.*& K0)>,-!!K0.*& I.&>)l

`!*jjE

)+,i.

Page 29

27

''(())**!

!

++,,--..//0011!!2233445533006633

)7!+,-./01!23453063!8,9:

# ;93<,-.!,0=!2>,?!<>9?/01!893@/>5-!A,/0!<,-./01*

$ B36/-/>0!C3@3DE!=36/=3!+,:39!C3@3D!,0=!F/A3!:>!C>,=!230-/01!/0!G>9A,DH+./:3HI6>(+./:3!J>59-3

% 2>,?!6>0-/-:!>K!<,:39!-588DL!,0=!<,-./01H!,K:39!:./-H!-:,9:!A,/0!<,-./01*

&M3,:39!=>3-!0>:!<>9?/01!/0!893<,-.!,0=!->,?!6>59-3*

'7!+,-./01!F/A3

# +,-./01!M3,:39!/-0E:!93<>9?/01!,K:39!93,6.!=36/-/>0!:3A839,:593*

$ G>9A,D!J>59-3!N!OPQ /06D5=3!R!A/0!:.,:!.3,:39!=>3-!0>:!<>9?/01*

% SK!23:!58!G>9A,D!N!OPQ :.30!A,/0!<,-./01!:/A3!/-!OP!A/0*

& SK!C2!@,D53!/-!A>93!:.,0!TUPH!)!.>59!,==!/0!+,-./01!F/A3*

2. Skill of each Sequence

8,9:!

J>59-3

V,/0

;93

2>,?

CWXB!2IG2SGY

W

W

W

+,:39!C3@3D

B36/-/>0!C3@3D

B36/-/>0!C3@3D

M/1.

MIXFSGY

B36/-/>0!C3@3D

Z

Z

+,-./01

B36/-/>0!C3@3D

[!>9!)P!A/0

TPA/0

F/A3

J>59-3

8,9:

+,:39!C3@3D MIXFSGY!F/A3 +,-./01!F/A3 F>:,D!+,-./01!F/A3

TPQ

2A,DD 'PA/0 '\A/0 O\A/0

V/==D3 '\A/0 '\A/0 \PA/0

G>9A,D

OPQ

2A,DD 'PA/0!]NR7 OPA/0 URA/0

V/==D3 '\A/0!]NR7 OPA/0 R'A/0

UPQ

2A,DD TPA/0 '\A/0 \\A/0

V/==D3 O\A/0 '\A/0 RPA/0

2A,DD R\A/0 '\A/0 )PPA/0

V/==D3 [\A/0 '\A/0 ))PA/0

TPHOPQ

2A,DD '\A/0 '\A/0 \PA/0

V/==D3 '\A/0 '\A/0 \PA/0

2:3,A!+,-.

UPQ

2A,DD TPA/0 '\A/0 \\A/0

V/==D3 TPA/0 '\A/0 \\A/0

^PQ

2A,DD \PA/0 '\A/0 R\A/0

V/==D3 \PA/0 '\A/0 R\A/0

M3,@L!2:,/0_ TPHOPQ V/==D3 TPA/0 '\A/0 \\A/0

UPQ V/==D3 \PA/0 '\A/0 R\A/0

2A,DD Z )\A/0 )\A/0

2A,DD Z [A/0 [A/0

V/==D3 Z '\A/0 '\A/0

V/==D3 )\A/0 'PA/0 T\A/0

+./:3-

+>>D

`5/6?

aD,0?3:

'!b1

Page 30

28

T7!ID36:9/6!J59930:!F/A3!>K!+,-./01!V>:>9

# S:!<>9?-!=36/-/>0!6L6D3

$ SK!V>:>9!c3-:9/6:/>0!>6659!dL!>@39D>,=H!V>:>9!:9L!:>!93<>9?!>88>-/:3!=/936:/>0*

% +./D3!+,:39!2588DLH!V>:>9!2:/9!89>633=!WG!K/9-:*

& J93,-3!J,93!/-!89>63--!>K!93A>@,D!D,50=9L!:.,:!-:/6?!:>!=95A*!S:!<>9?-!,K:39!28/0!23453063*

O7!c3(+,:39!2588DL

# S:!<>9?-!/K!<,:39!D3@3D!/-!D><39!:.,0!=36/-/>0!D3@3D

$ V>:>9!-:>883=!<./D3!c3(+,:39!2588DL

% +./D3!+,-.!23453063!c3(+,:39!2588DL!<>9?-!)\!:/A3-*

& SK!+,:39!C3@3D!/-!D><39!:.,0!cI2IF!C3@3DH!B/-8D,L!SI!,0=!M3,:39!>KK*

G>9A,D

+./:3-

2:3,A!+,-.

M3,@L!2:,/0

+>>D

`5/6?

aD,0?3:

'!b1

+,:39

F3A839,:593

PeOPQ

UPQ

^\Q

TPeOPQ

UPQ

^\Q

PeOPQ

UPQ

J>D=

J>D=

J>D=

PeOPQ

UPQ

+,:39

2588DL

\f)P

\f)P

\f)P

\f)P

\f)P

\f)P

\f)P

\f)P

Z

\f)P

\f)P

\f)P

\f)P

M3,:/01

)Pf)P

)Pf)P

)Pf)\

)Pf)P

)Pf)P

)Pf)\

)[fR

)[fR

Z

Z

)Pf)P

)Pf)P

)Pf)P

V,/0!+,-./01

)[fU

)Pf)P

Rf)\

)Pf)P

)Pf)P

Rf)\

)Pf\

)PfR

'f)\

)[fU

)PfR

)[fU

)Pf)P

2>,?

)\f)[P

)\f)[P

)\f)[P

)\f)[P

)\f)[P

)\f)[P

)\f)[P

)\f)[P

Z

Z

Z

)\f)[P

)\f)[P

J93,-3

J,93

)Pf\

)Pf\

)Pf\

)Pf\

)Pf\

)Pf\

)Pf\

)Pf\

Z

)Pf\

)Pf\

)Pf\

)Pf\

2833=

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

J>59-3

8,9:

VWFWc!FSVI!W0fWgg!]-367

+,-./01

Page 31

29

# W0DL!6>D=!<,:39!-588DL!/0!c/0-3!23453063*

$ S0!D,-:!c/0-3!23453063H!5-3!K,d9/6!6>0=/:/>039!dL!>830!<,:39!@,D@3-*

'7!c3(+,:39!2588DL

# XK:39!)!A/0!/0!c/0-3!23453063H!6.36?!<,:39!D3@3D!,0=!<>9?!c3(+,:39!2588DL*

T7!c/0-3!23453063

''((''**!!cc//00--33!!2233445533006633

)7!+,:39!2588DL!23453063

G>9A,D

+./:32:3,A!+,-.

M3,@L!2:,/0

'!b1

+>>D

`5/6?

aD,0?3:

F5d!JD3,0

+,:39

F3A8

J>D=

J>D=

J>D=

J>D=

J>D=

J>D=

J>D=

J>D=

J>D=

c/0-3

F/A3

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

V/=*!28/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

TA/0

V/=*!28/0

9*8*A

A/=

<3,?

<3,?

A/=

A/=

<3,?

A/=

<3,?

<3,?

98A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

O\!9*8*A

<,:39!-588DL

\f)P

\f)P

\f)P

\f)P

\f)P

Z

\f)P

\f)P

\f)P

9/0-3

)Pf\

)Pf\

)Pf\

)Pf\

)Pf\

'f'P

)Pf\

)Pf\

)Pf\

VWFWc!W0fWgg!]-367

B/-8D,L bMh 3:6

M/1. \BR 'T*^' X==!c/0-3!<,:39!D3@3D

V/= \XO 'T*) c/0-3!<,:39!D3@3D

8,9:

+,:39!C3@3D

+,:39

C3@3D

8,9:

Page 32

30

''((TT**!!2288//00!!2233445533006633

)7!B9,/0

# S:!K>DD><-!B9,/0,13!23453063*

'7!a,D,063!28/0

# SK!i0d,D,063!J.36?!8,--H!2:,9:!c(28/0*

$ a(28/0!/-!i0:/D!i0d,D,063!6.36?!-36:/>0H!T\P!9*8*A

T7!c]c3,D7!28/0

# g9>A!30=!>K!a(28/0!:>!30=!>K!28/0!23453063!/-!c!28/0*

$ 9*8*A!/-!,KK36:3=!dL!-3453063

O7!2.>3-!28/0

# a,D,63!28/0!=>3-!0>:!<>9?/01*

''((OO**!!II00==

)7!J93,-3!J,93

# J93,-3!J,93!/-!89>63--!>K!93A>@,D!D,50=9L!:.,:!-:/6?!:>!=95A*!S:!<>9?-!TP-36!H,K:39!28/0!23453063*

$ +>>D!,0=!2.>3-!6>59-3!=>0E:!<>9?!693,-3!6,93

'7!I0=

# XK:39!)P!-36!8><39!>KK!H,D,A3=!IGB*

$ SK!=9L/01!-3453063!,==3=H!<>9?!=9L/01!-3453063*

% XK:39!IGB!H!=>>9!50D>6?*

Page 33

31

''((\\**!!BB99LL//0011!!2233445533006633

)7!6>0-/-:!>K!=9L/01!-3453063*

3j7!-3D36:!0>9A,D!=9L/01!]F>:,D!-830=!:/A3!'kTU7

'7!B9L/01!28/0

# XDD!6>59-3!839K>9A,063!V,j!-8/0*

T7!J93,-3!J,93

# J93,-3!J,93!89>633=!UP!-36*

O7!ID36:9/6!J59930:!F/A3!>K!B9L!23453063*

\7!B9L/01!lfl!<>9?/01

# S:!<>9?!K9>A!:.3!,K:39!'P-36H!S0!B9L/01!23453063!:>!I0=!>K!B9L/01!23453063*

U7!JWWCSGY

# g,0!A>:>9!,0=!V,/0!A>:>9!<>9?!,:!>063!=59/01!J>>D/01!23453063*

$ F3A8*!>K!B95A!/-!D3--!:.,0!\PQ K/0/-.!J>>D/01!23453063*

% J>>D/01!:/A3!/-!:>:,D!\!A/0*

B9,/0])A/07

B9L/01])PPA/07 JWWCSGY]\A/077 I0=])P-367

➞➞ ➞➞ ➞➞

J93,-3!J,93]TPA/07

(m!G>:!B/-8D,L3=

➞➞

J>59-3

G>9A,D

+./:3

2:3,A!+./:3

M3,@L!2:,/0

`5/6?

B9L/01!28/0

VXZ

VXZ

VXZ

VXZ

VXZ

I:6

XDD!6>59-3!839K>9A,063!V,j

-8/0*

J93,-3!J,93 B9L/01 JWWCSGY +9/0?D3!g933 F/A3

M3,:39!WKKfW0!F3A839:593]Q7

C>< )Pf\ )\f\ )Pf)P )Pf\P ))P RPfUP

S9>0 )Pf\ )\f\ )Pf)P )Pf\P UP )P\f^\

G>9A,D )Pf\ )\f\ )Pf)P )Pf\P )\P )P\f^\

2:9>01 )Pf\ )\f\ )Pf)P )Pf\P 'PP )P\f^\

Page 34

32

R7!B9L/01!M3,:39!<>9?/01

# B9L/01!M3,:39!<>9?!50:/D!I0=!>K!B9L/01!23453063*

[7!J93,-3!J,93

# J93,-3!J,93!839K>9A,063!,K:39!B9L/01!23453063!K>9!TP!A/0*

$ W0DL!V>:>9!<>9?!=59/01!+9/0?D3!g933

''((UU**!!22::33,,AA!!2233445533006633

)7!2:3,A!<,:39!-588DL

# +,:39!2588DL!:/A3!/-!)!A/0*H!'!:/A3-H!/0!2:3,A!23453063*

'7!2:3,A!M3,:/01

# S0!>9=39!:>!/0693,-3!<,:39!:3A8*!H!.3,:39!<>9?*

$ 2:3,A!M3,:/01!F3A839:593*

T7!2:3,A!+,-./01

# F./-!-3453063!/-!30,dD3!:>!A,j/A5A!3KK36:!>K!-:3,A!,0=!A,/0:,/0!<,:39!:3A839:593*

$ 2:3,A!+,-./01!F/A3

O7!g/0/-./01!2:3,A!+,:39!2588DL

# 2,A3!:.3!0>9A,D!<,:39!-588DL*

$ +,:39!2588DL!-830=!)!A/0*

\7!g/0/-./01!2:3,A!+,-.

# S:!<>9?-!/K!6,0E:!93,6.!=36/-/>0!:3A8*!>K!V,/0!+,-./01

$ -830=!)P!A/05:3-*

U7!V,/0!+,-./01

# 2,A3!:.3!0>9A,D!<,-./01

J>59-3

I6>

G>9A,D

2:9>01

F3A839:593

\\Q

UPQ

UPQ

F/A3

)\A/0

)\A/0

)\A/0

J>59-3

I6>

G>9A,D

2:9>01

F/A3

RA/0

)PA/0

)\A/0

M3,:39!W0fWKK!:3A839,:593

\\QfU\Q

UPQfRPQ

UPQfRPQ

Page 35

33

TT(())**!!CCWWXXBB!!22IIGG22SSGGYY

)7!B36/=/01!:.3!<,:39!D3@3D

# G>9A,DH!+./:3H!I6>(+./:3!J>59-3!</DD!d3!K>DD><3=!dL!:./-!89>63--*

$ J.36?!:.3!<,:39!D3@3D!</:.!=9L!D,50=9L!,:!:.3!-:,9:/01!<,-.*

% J.36?!:.3!<,:39!D3@3D!dL!5-/01!A>:>9!>5:85:!=,:,!=59/01!'P!-36H!U\98A*

'7!B36/=/01!28/0!2:,9:/01!2:38*

# J.36?!,K:39!K/0/-./01!<,-./01!-:38!</:.!<3:!D,50=9L*

$ J.36?/01!dL!5-/01!A>:>9!>5:85:!=,:,!=59/01!'P!-36H!U\!98A*

% F.3!B36/=3=!=,:,!/-!=/KK3930:!=3830=/01!>0!D>,=/01!6>0=/:/>0*

TT((''**!!aa,,DD,,006633!!2288//00

)7!V>:>9!9500/01!=59/01!d,D,063!-8/0

# 2893,=/01!:.3!D,50=9L!k!c>:,:/01!:.3!-,A3!O\!98A!</:.!D3K:!,0=!9/1.:!=/936:/>0!,D:390,:/@3DL*

$ i0d,D,063!6.36?/01!8>/0:!k!K/9-:!-:38H!-.36?!:.3!i*a!,:!^\!98AH!)UP!98A!-36>0=!-:38H!6.36?!:.3!i*a

,:!^\!98A!T\P!98A*

F./9=!-:38!,:!TPP!98A*!SK!:.3!50d,D,063!=,:,!/-!>@39!:.3!69/:39/>0

F./-!89>63--!</DD!d3!9383,:3=*

% XK:39!=9,/0H!6.36?!:.3!50d,D,063!=,:,!,1,/0*!F./-!/-!->(6,DD3=!d,D,063!-8/0!-:38*

'7!;9>839:L!>K!d,D,063!-8/0

# J>0=56:/01!'P!:/A3-!A,j/A5A*

$ SK!:.3!<,-.39!6,0!0>:!8,--!d,D,063!-8/0!-:38!=59/01!'P!:/A3-H!:.30!<,:39!</DD!d3!-588D/3=*

% SK!:.3!<,-.39!6,0!0>:!8,--!'P!:/A3-!>K!d,D,063!-8/0H!iI!399>9!A>=3!</DD!d3!=/-8D,L3=!>0!E)[k[[E

TT((TT**!!BBWWWWcc!!22ff++

)7!F.3!<>9?/01!89/06/8D3!>K!B>>9!2f+

# B>>9!C>6?/01

a/A3:,D!>0!]T!-367!((m!->D30>/=!]-588DL!'PA-36!85D-3!'!:/A3-7

$ B>>9!i0D>6?/01

a/A3:,D!>KK!((m!->D30>/=]-588DL!'PA-36!85D-3H!50:/D!D>6?7

% XK:39!=>>9!D>6?/01!,DD!8,9:-!6,0!<>9?!0>A,DDL*

& XK:39!893--/01!8><39!d5::>0H!/K!:.3!:3A839,:593!>K!<,-.!:.39A/-:>9!/-!>@39!\\Q >9!:.3!<,:39

D3@3D!/-!>@39!:.3!-,K3:L!D3@3DH!:.3!=>>9!</DD!d3!D>6?3=*

n F.3!=>>9!</DD!d3!50D>6?3=!/AA3=/,:3DL!,K:39!,DD!89>63--3-!,93!K/0/-.3=*

o F.3!=>>9!6,0!d3!>8303=!=59/01!89>63--/01!/K!:.393!/-!0>!89>dD3A!:>!50D>6?*

3. Main Function of PCB Program

Page 36

34

'7!BWWc!W;IG!2p2FIV

# SK!,==!:.3!D,50=9L!=59/01!<,-./01H!893--!:.3!=>>9!50D>6?!d5::>0*

$ B>>9!>830!-3453063!,:!,d0>9A,D!6>0=/:/>0*

TT((OO**!!JJ..//DD==!!CC>>66??

# ;93--!:.3!_F3A8_!,0=!_J>0=30-/01!B9L_!d5::>0!-/A5D:,03>5-DL!=59/01!89>63--/01*

$ i0=39!:.3!J./D=!C>6?!K506:/>0H!>0DL!8><39!d5::>0!/-!<>9?/01*

% B59/01!J./D=!C>6?!K506:/>0H!JMC!</DD!d3!=/-8D,L3=!>0!E)[k[[E

& S0!>9=39!:>!50D>6?!J./D=!C>6?!A>=3H!893--!_28/0_!,0=!_J>0=30-/01!B9L_!-/A5D:,03>5-DL*

TT((\\**!!FF..33!!--33445533006633!!>>KK!!==99,,//00

# SK!:.3!6.36?/01!:/A3!:>!93-3:!8>/0:!/-!d3D><!)!A/0H!:.3!93A,/0/01!=9,/0!:/A3!/-!TP!-36*

$ SK!:.3!6.36?/01!:/A3!:>!93-3:!8>/0:!/-!>@39!)!A/0H!:.3!93A,/0/01!=9,/0!:/A3!/-!'!A/0*

% SK!:.3!6.36?/01!:/A3!:>!93-3:!8>/0:!/-!>@39!)P!A/0H!WI!-/10,D!</DD!d3!,883,93=!>0!;Ja*

& SK!:.3!:3A839,:593!/-!>@39!\PQ H!:.3!<,:39!</DD! d3! -588D/3=! :>!./1.!<,:39!D3@3DH!:.30!:.3!=9,/0! </DD

-:,9:*

Page 37

35

"#

"#

$%&

$%&

Start/Hold

Door unlock button,

2sec ON

DISPLAY

‘LOCK’ OFF

Door Open

Cold water

supply

Drainage

Water level is less than

safety level?

Temperature is less

than 50e?

Page 38

36

5-1. Testing Mode

PCB and other electronic parts will be tested without water supply whether they are normal or not.

1) Process

press power button --> press "SPIN" button 3 times with pressing "WASH" button --> 'L d' will be shown on LED -->

Whenever pressing "TEMP" button 1 time, below process will be occurred.

MICOM V er. --> L C (Lock Closed) --> run (count) ---> b1, b2, b3, b4, b5, b6, b7

-> F (Fan Motor) -> H (Hot V/V)

-> C (Cold V/V) -> P (prewashing V/V) -> d ( dry V/V) -> bb (bubble)

-> dr (drain motor) -> L O(Lock S/W Open)

2) More details

1 When turn on 'LOCK' signal, all process is conducting normaly .

2 When working starts, the PCB displays all the sensor conditions.

3 In this case, BLDC Motor is not tested. In order to test it, select spin or rinse.

5-2. Continous testing mode

1) Process

after pressing "WASH", "RINSE", "SPIN" button simultaniously , press "POWER" button.

ALL LED On --> SPIN button ---> ALL LED off

--> L C (Lock Close) ---> r (Motor right) --> L (Motor Left)

--> F ( Fan Motor) ---> H (Hot V/V) --> C (Cold V/V) --> b (Pre whsh V/V) --> d ( dry V/V)

--> bb (bubble) --> h1 (W ash heater)--> h2(Dry heater) --> dr (Drain motor On)

-->L O(Lock S/W Open)

2) More tails

1 LED test can be done with all LED On.

2 All sensor conditions will be shown on PCB during processing.

5. TEST MODE

Page 39

37

6-1. IE (Input Error) - Error in water supply

1) Conditions of Occurrence

# In case the designated water level is not reached in 5 minutes during water supply or re-supply

2) All LEDs are turned off and 'IE' blinks in18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-2. OE (Output Error) - Error in drainage

1) Conditions of Occurrence

# In case water level does not reach reset point in 10 minutes after drainage starts

2) All LEDs are turned off and 'OE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-3. UE (Unbalance Error)

1) Conditions of Occurrence

# In case main spin-drying is not reached within 20 cycles of balance spin-drying

$ In case balance spin-drying fails during interim spin-drying, UE occurs as the cycle moves to the next

process.

2) All LEDs are turned off and 'UE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error mode is cleared by opening door and organizing the laundry in spin-dry chamber, closing door and

pressing start/ temporary stop button. Then, spin-drying begins again.

6-1. Error Display

Page 40

38

6-4. LE (Lock Error) - Door opening error

1) Conditions of Occurrence

# When intending to begin cycle by pressing start/ temporary stop button while door is opened

2) All LEDs are turned off and 'LE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-5. E1 - Water level detection error

1) Conditions of Occurrence

# In case water level is below reset or overflow is detected in line test mode

2) Water supply motor is kept on until water level falls below reset.

3) All LEDs are turned off and 'E1' blinks in 18:88 display.

4) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

5) Error display is cleared when turning off/ on power.

6-6. E2 - Overflow error

1) Conditions of Occurrence

# In case water level in water tank is above overflow level due to continuous operation of water supply

valve

2) Water supply motor is kept on until water level falls below reset.

3) All LEDs are turned off and 'E2' blinks in 18:88 display.

4) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

5) Error display is cleared when turning off/ on power.

Page 41

39

6-7. E4 - Water leakage during washing

1) Conditions of Occurrence

# In case water level falls below re-supply even after 15 times of re-supply prior to finishing of water

heating

2) All LEDs are turned off and 'E4' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-8. E9 - Abnormalities in water level sensor

1) Conditions of Occurrence

# In case water level frequency is of 15KHz or lower and 30KHz or higher during cycle due to

abnormalities in water level sensor, etc.

2) All LEDs are turned off and 'E9' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

Page 42

40

6-9. Motor-related Error

1) E5 (DC-Link High Voltage) Error

# In case DC-link voltage to IPM increases to 450V or higher

$ Motor operation is stopped and 'E5' is shown in display window.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

2) E6 (EMG) Error

# In case current detected with EMG port is of 20A or higher

$ Motor operation is stopped and 'E6' is shown in display window.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

3) E7 (Direction) Error

# In case signal of Hall IC is different from the predicted signal according to direction of rotation

$ Motor operation is stopped and 'E7' is shown in display window.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

4) E8 (Initial Operation Fail) Error

# In case input signal of Hall IC is abnormal due to problems in motor connection, etc.

$ Motor operation is stopped and 'E8' is shown in display window.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

6-10. Error in Temperature Sensor

1) H2 Error - Washing temperature sensor open/ short

# In case washing temperature sensor is defective or not connected

$ Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

% Error display is cleared when turning off/ on power.

2) H4 Error - Washing temperature sensor overheating

# In case temperature detected by washing temperature sensor is 95Q or higher

$ Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

% Error display is cleared when turning off/ on power.

Page 43

41

3) H5 Error - Water temperature error in wool/ delicate course

# In case water temperature in wool/ delicate course is 45Q or higher

$ Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

% Error display is cleared when turning off/ on power.

4) H6 Error - Abnormality in washing heater

# Within 15 minutes after heater operation begins;

In case standard temperature is of 42Q or lower: If temperature does not increase by 2Q or more In

case standard temperature is higher than 42Q: If temperature does not increase by1Q or more

$ If temperature falls below standard temperature by 2Q or more due to re-supply of water, etc.,

standard temperature is reset as the current temperature and error check time of15 minutes is reset.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

5) H8 Error - Washing heater overheating

# In case washing heater temperature increases by 5Q or more within 30 seconds when there is no

water in tank, etc.

$ Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

% Error display is cleared when turning off/ on power.

Page 44

42

7. ELECTRONIC FIELD P ARTS LIST AND SPECIFICA TION

"#$%&!'()*+

,-./ 0%1%2,345

"#$%&

'6#%3#5!()*+

LOCK 1

(gray)

LOCK 2

(purple)

Ha

(brown)

Hb

(purple)

Hc

(gray)

5V

(red)

U

(yellow)

V

(blue)

W

(white)

GNC

(black)

GND1

(black)

Vdd1

(purple)

L/F

(white)

GND2

(gray)

Vdd2

(pink)

Ha

(yellow)

T2

(orange)

T1

(brown)

COLD

(green)

PRE

(orange)

DRY

(yellow)

L/CHCK

(blue)

HOT

(brown)

D/M

(black)

B/B

(white)

red

red

red

brown

3:P/CORD(blue)

4:W/HEATER(blue)

RELAY

W

(blue)

V

(purple)

U

(pink)

"#$%&!'()*+,'

1. PCB PIN

Page 45

43

2. VALVE INLET

Rre-washing Water

Input Valve

Washing Water Input

Valve

Hot Water Input Valve

M4-4

: CABINET 4

Bleach Input

Valve

Classification

Code

Color

Coil Resistance

Use

Appearance

Structure

3-hole Valve and Hot Water Valve

3-hole: 3615416940, Hot Water: 3615416700

Gray

4320 ~ 5280 .

Supplying water for washing/ pre-washing and bleach

Water not

supplied

Water supply not

carried, only noise

is heard

Water supply not

carried out without

noise

Water tap not opened

Coil short

Excessive foreign

substances in SUS filter

Foreign substances in

valve

Connector loosened

Coil short

Wiring short

Defect in water level

sensor

Defect in pressure hose

Defect in water supply

valve

Defect in water supply

valve assembly, etc.

Check for tap opening.

Check if resistance between water supply valve terminals is

within 4320~5280..

Remove water supply hose and check for foreign substances in

filter.

Visually check connector connection status.

Check if resistance between water supply valve terminals is

within 4320~5280..

Wiring short -> Conduction test

Refer to water level sensor defect check method.

Check for blocking of holes in pressure hose.

-

Floater restraint, loosening -> S/W not working

Check for leakage through the sides of water supply valve.

Continuous water

supply in power

'on' state

Continuous water

supply in power 'off'

state

Water leakage

through sides

Others

Water is

continuously

supplied

(inside tub)

PCB Error

Mode

"IE"

"IE"

"IE"

"IE"

"IE"

"IE"

"IE"

"E2"

"E2"

-

-

Symptoms of

Breakdown

Detailed

Symptoms

Cause Diagnosis of Defect

Open water tap.

Clean out foreign substances

from inside the filter.

Replace water supply

valve.

Administer re-insertion.

Replace water supply

valve.

Replace water level

sensor.

Replace defect parts.

Replace water supply

valve.

Replace water supply

valve.

Solution

Page 46

44

Defect in

Water

Supply

Water supply not

carried out (IE)

Continuous water

supply (IE)

Immediate water

supply when power

is turned on

Water supply

continued when

power is turned off

• Defect in water supply valve

• Defect in PCB • Water supply relay short

• Suspension of water supply

• Tap frozen

• Tap closed

• Hot & cold water hose switched for connection

• Low water pressure (0.2kgf/cm or less)

• Blocking of water supply valve filter by foreign substances

• Defect in cold & hot water valve

• Defect in connection of water supply terminal (not connected)

• Defect in pressure switch

• Defect in PCB

• Defect in water supply valve

• Leakage in air hose (air leakage from pressure switch hose)

• Air trip blocked, damaged

• Defect in pressure switch

• Defect in drainage valve: Continuous water supply

• Blocking by foreign substances in drainage bellows

• Defect in PCB

• Defect in water supply relay drive circuit

• Water supply relay open

• Water supply relay short

Page 47

45

Symptoms of

Breakdown

Water

supply not

carried out

Water

supply not

carried out

Continuous

water supply

Inspection Result

- Cold/ hot water hose switched

-Large amount of rust, sand and

dust, etc.

-5.3kW or higher

-Connector loosened/ not

inserted

-Electric wire short

-Sound and defect in water

supply due to foreign

substances in bellows

-E9

Electric wire easily loosened

when tugged

PCB water supply circuit open,

damaged (water supply relay

operation not carried out)

PCB water supply circuit or

relay short (continuous

conduction to valve)

Water supply bellows

blocked/ deformed

-Not closed due to foreign

substances inside drainage

housing

-Wire caught by foreign

substances outside drive

motor

-Forced restoration not possible

Problem Identified

-Defect in cold/ hot water

hose assembly

-Defect in cleaning of water

supply filter (blocked)

-Coil short

-Connection defect

-Electric wire short

-Structural defect in water

supply valve

-Loosening of pressure S/W

terminal or electric wire

short

-Defect in pressure S/W

Pin connector housing not

inserted

Defect in water supply circuit

Water supply relay short

Defect in water supply valve

-Foreign substances in valve

housing

-Foreign substances

-Defect in drive motor

restoration

Repair Method

-Assemble cold/ hot

water hose correctly.

-Clean water supply filter.

-Replace water supply

valve.

-Try reconnection or

remove elements of

connection defect.

-Try reconnection or

remove elements of

connection defect.

-Replace water supply

valve.

-Connect terminal of

pressure S/W.

-Connect terminal of

PCB.

-Replace pressure S/W.

Completely insert

connector housing.

Replace PCB.

Replace PCB.

Replace water supply

valve.

-Remove foreign

substances.

-Remove foreign

substance.

-Replace drive motor.

Inspection

Spot

Water

supply valve

Pressure

Switch

PCB

PCB

Water

supply valve

Drainage

drive motor

(valve

housing)

Inspection Method

1) Suspension of water supply

2) Water tap locked

3) Cold-hot water hose incorrectly

connected

4) If no defect is found, dismantle water

supply hose and check water supply

valve filter.

1) Measure coil resistance in water

supply valve.

2) Remove top cover and visually

check for separation of water supply

valve terminal connector and wiring

short/ connection status.

3) In case water valve operation sound

is heard, but water supply is not

carried out, check for blocking of

water supply valve or restraint on

plunger.

1) Check for ‘E9’ in display window.

1. Check PCB pin connector insertion

status.

2. Power is supplied to water supply

valve terminal, but water supply is

not administered.

1. Immediate supply when power is

turned on

1. Check if water supply is continuously

carried out even if power is not on.

1. Check for normal operation of water

supply valve/ water supply status.

2. Check if water is drained through

drainage hose.

3. Check for foreign substances inside

valve housing.

4. Check for foreign substances in drive

motor wire.

5. Forcefully restore SUS wire.

Page 48

46

3. Water Level Sensor

1) Spec. of Water Level Sensor

(kHz)

HEATER SAFETY

24.55

STEAM

24.736

RESET

25.2

LOW

23.2

MID

23.75

RINSE

23.18

ADD WATER

22.96

OVERFLOW

22.6

Symptoms Detailed Symptoms Cause Diagnosis Solution

PCB Error

Mode

2) Breakdown Analysis

O/F: Forced drainage is

necessary as water

level is high. When

this level is reached,

water supply must be

stopped and drainage

must be forcefully

administered.

RESET :

1. Spin-drying begins

30sec after drainage

level reset is reached.

2. Heater operation level

Low: Small load of laundry , therefore considered to be

water level of 'low'

Medium: Large load of laundry

Medium High: W ater level for rinsing

Safety: Door open possible

Door opened only when water level is below

safety level

Continuous

water

supply

"E9"

Water valve normal

Occurrence in water level

sensor

30kHz or higher

Defect in pressure sensor

hose

Blocking of pressure sensor

hose

Connector loosened

Wiring short

Check for holes.

Visual checking

Visually check connector

connection status.

Wiring short ->

conduction test

Replace hose.

Remove foreign substances.

Administer re-insertion.

"E2"

"E2"

"E9"

"E9"

Page 49

47

1) Specificafion

4. POWER CORD

Classification Rated

Cord Thickness

Color Code Type Length Remarks

3611339340

DEC 250V/15A 1.5sq Gray 3611339301 EU-2P 2.3m -

3611339930

2) Assembly

4 embossed parts in cabinet

-> To prevent loosening after assembly

-> SS: 2 special screws

-> LG: Forced indentation

. CONNECTOR

-> #1806 Housing 3P Used: Using both ends only and not the hole in the middle (materials highly

resistant to flame)

-> To prevent fire caused by high current

[Before] [After]

Page 50

48

5. DOOR LOCK SWITCH

1) DOOR LOCK S/W

78"/!09:; :;(0"<7/<9=

>?@ABC?CBB :99"!D90E!!:DF(@!GHBI!7/0F(9D;=9<:!/J7;

Page 51

49

4) Diagnosis of Defect

Symptoms Detailed Symptoms Cause Diagnosis of Defect Solution

Error

Mode

Ticking

noise

LE'

Door does

not open.

Tick' during initial

operation and 'tick-tick'

during temoprary

suspension: 'DF' type

only

Continuous occurrence

of 'tick' noise

and 'LE': 'DF' type only

1. 'LE' occurrence

without 'tick' noise in

'DF' type

Power failure, forced

power off during

operation

No power failure and

power on

Others

Normal noise

Connector loosened

Terminal loosened from

connector

Door not completed

closed

Abnormality in hook of

door

Defect in catch CAM

operation

Connector loosened

Terminal loosened from

connector

Breaking of solenoid coil

Water in drum

Inside the drum hot

Insert connector.

Insert connector.

S/W 4 or 5 terminal

Completely close

door.

Replace door AS.

Replace door S/W.

Insert connector.

Insert terminal. S/W

2 or 3 terminal

Replace door S/W.

Door opens after

drainage.

–

"LE"

"LE"

"LE"

"LE"

"LE"

"LE"

"LE"

"LE"

–

Normal sound generated during solenoid operation when

'sliding CAM' is locked/ unlocked to close or open door.

PCB MICOM' cannot open door in case of power failure or forced power S/W off during operation.

Door can be opened in the max. of 5min.

Prevention of door opening to prevent burn caused by hot laundry after

drying

Door does not open normally in case of loosening of connector/ terminal and breaking of solenoid

coil during operation. Administer measures after test according to the following method.

Visually checking connector connection

status

Referring to door lock S/W dismantling

and checking methods below

-

-

Occurrence of continuous 'tick' noise

unlike normal sound

Visually checking connector connection

status

Referring to door lock S/W dismantling

and checking methods below

Referring to picture below

Checking if water level is higher than

safety level

Page 52

50

1) Spec of Heater of Washing Machine

Classification

Parts name

A DUCT COVER

B FAN MOTOR

C HEATER DRY

D DUCT B LOWER

E VALVE INLET(DRY)

F THERMOSTAT

G THERMISTOR

H DUCT B UPPER

I FAN AS

J FUSE TEMPERATURE

E

C

D

B

A

IJFH

G

1. Heater

Page 53

51

2) Dry Function Diagram

3) Temp- Time Graph During Dry Cycle

While rotating DRUM, DRY HEATER applice heat to air and FAN blows it into DRUM evaporating water in the laundry.

• Evaporated water is sucked into CONDENSING DUCT, and condensed in DUCT contacting WATER SUPPLY (condensed water

is extracted through DRAIN HOUSING).

• Dry function is performed by continuous repetition of evaporating and condensing circulation as above.

DRY DUCT

T : Thermistor

(CONTROL

HEATER’S

TEMPERATURE )

HEATER

FAN MOTOR

CONDENSING

DUCT

DRUM

DRAIN

HOUSING

T

WATER SUPPLY

INSIDE TEMPERATURE

OF DRUM

TIME

DRYING PROCESS

ZONE

TEMP.

PRE HEATING

ZONE

123456

/0

78

56

9':;!

<=/0

>6

Page 54

52

4) Dry Course

In order to check the drying temperature during process going on : --> press the "DRY" button, the display shows as below.

UPPER LED:

Temperature for DRY

The current temperature is 98

P

LOWER LED:

Temperature for WASH

REMAIN TIME

min

COURSE DRY COURSE

LOW TEMP.

Heater control temperature is 60°C On/70°C Off

Drying Time is 110min according to Load Sensing Data

IRON

Heater control temperature is 95°C On/105°C Off, with good condition for ironing

Drying Time is 60min according to Load Sensing Data

Cupboard Heater control temperature is 95°C On/105°C Off, drying time is 150 min

STRONG Heater control temperature is 95°C On/105°C Off, drying time is 200 min

SELECTING TIME

Heater control temperature is 95°C On/105°C Off, customer can select the drying time

out of 1:00, 1:30, 2:00

KLMN

O

Page 55

53

5) TROUBLE SHOOTING OF DRY SYSTEM

✦

HEATER DRY

Function : heating the air during dry

• FAILURE MODE : * "H7" - The air cannot be heated to 10°C during 2 min.

• CHECKING METHOD : * Check the resistance of heater coil and replace with new one.

✦

Thermistor

Function : sensing the air temperature.

• FAILURE MODE : * The air cannot be heated even though water is supplied.

* "H1" - shot or cut-off

* "H3" - air temp. is reached over 150°C

• CHECKING METHOD : * Check the resistance of thermistor, replace with new one.

✦

FUSE TEMPERATURE

function : protecting from the fire hazard or overheating, if the temp., rises over 128°C, power supply will be cut-off.

• Pictures

• FAILURE MODE : Dry is not performed.

• CHECKING METHOD : Check if fuse is short, and replace with new one.

FIXED BY

WASHER

+SCREW

Page 56

54

✦

SWITCH THERMOSTAT(BIMETAL)

function : control the duct temperature, if the temp reached over 150°C, all power supply will be cut. and if the temp go down

120°C the power will be ON.

protecting overheating by cutting off heater power supply if the temperature rises over 150°C, and reoperating heater

by connecting heater power supply if the temperature falls under 120°C.

• OPERATING TEMPERATURE • PICTURE

✦

UNIT FAN MOTOR

function : circulating the inside air during dry process.

• SPEC • PICTURE

• FAILURE MODE : * E3 shown : FAN MOTOR cannot work.

• CHECKING METHOD : Check the FAN MOTOR is short, and replace with new one.

OPEN TEMPERATURE(OFF) 150°C ± 5°C

CLOSE TEMPERATURE(ON) 120°C ± 5°C

ITEMS SPEC

RATING VOLTAGE 24V

RPM

MOTOR 3700 ± 10%

DUCT FAN AS 1900 ± 10%

ROTAING DIRECTION CW

Page 57

55

6) LACK OF DRY PERFORMANCE

• Situation : after drying, the clothes still get wet.

cause) ☞The laurdry amount is more than the recommendation capacity 7.0kg.

☞Condensing cold water is not supplied.

☞Clogging Bellows Duct results in poor air circulation.

checking method)

• Situation after drying, the clothes was soaked and hot.

cause) ☞ The dry is done from bad spin performance because of unbalance.

☞no spin was done before the dry had started.

• Situation : PCB shows "H1" or "H3".

cause) ☞Thermistor is broken.

☞Thermistor is short or cut-off.

countermeasures) ☞replace the Thermistor.

part name checking point checking results jurge repair method

BELLOWS

DUCT

VALVE INLET

+Condensing

HOSE

clogging

bellows duct

no water supply

from inlet valve

heater was

overheated

owing to poor air

circulation

VALVE INLET

connector slipped

out

VALVE INLET

broken

ill-connection of

condensing hose to

duct pipe

clean the bellow

duct

connect normally

replace valve inlet

connect normally

BELLOW

DUCT

VALVE INLET

CONDENSING

HOSE

Page 58

56

• Situation : PCB shows "H7".

cause) ☛ Dry heater is cut-off.

☛ Fuse temp. is cut-off.

repaire method) ☛ replace the Dry heater.

☛ replace the Fuse temp.

checking point part name checking results repaire method

HEATER

SENSOR TEMP.

FUSE TEMP.

dry Heater is short or cut-off.

Thermistor is short or cut-off.

FUSE TEMPERATURE is cut-off.

replace the

dry Heater.

replace the

Thermistor.

replace the

FUSE

TEMPERATURE.

THERMISTOR

HEATER DRY

FUSE

TEMPERATURE

Page 59

57

• situation : PCB shows "E3".

cause) ☞FAN MOTOR can not work.

countermeasures) ☞Replace the Fan Motor.

part name checking results repair method disassemble process of Fan Motor

FAN MOTOR fan motor failure replace

fan motor

1Disassemble Duct Cover As from Duct B As

(Screw 4EA)

2Disassemble FAN AS From Duct Cover As

(Fixed by 8mm NUT)

3Disassemble the FAN MOTOR(SCREW 3EA)

parts Control time

MOTOR 15 sec On, 5sec Off

DRAIN MOTOR Continous working

FAN MOTOR Continous working

DRY HEATER 95°C On, 105°C Off

INLET VALVE 30sec On, 5sec Off

Remarks) control times of each parts during dry process

DUCT COVER AS

Fixed By 8mm NUT

Page 60

58

Washing Heater Temp. Sensor Table

"GH!Q!@@RAS@ET U CRBCV

"SB!Q!@RWBCET U >V

.GH)@BB!Q!>W?BE!U @V

/;X7 X<=

=9"X8D

X8Y /;X7 X<=

=9"X8D

X8Y /;X7 X<=

=9"X8D

X8Y /;X7 X<=

=9"X8D

X8Y

?@.@.@.?@.@. @. ? @. @. @. ? @. @. @.

AB$ CDCEFGB CFDEH%$ IGBEIDJ $ IBEI%C I%EFJ% IJE%FF B$ HEB$I HEH%I HEF$I DG GEH$I GEH%I GEJ$I

AIF CHHEHBC CDGEBGH CFHEGFG G ICEJJH IBEIGD I%EDHG BG HEGHF HEB$F HEHBD DC GE%%% GEH$I GEH%C

AID C%GEBIC CH%EIGG CJFEGF$ C IGECDB ICEJBF IBECGB BC %EFBH HEGJH HEB$% DI GE%$D GE%%H GEH$I

AIJ CIJEC$D C%$EC%C CHIECFH I CFEDHF IGECHC ICEH%% BI %EJIC %EF%C HEGJC DB GEBHI GE%G$ GE%%H

AIH CCIEF$$ CIHEGH% CBDEBI$ B CDE%CD CFED%C IGEGJJ BB %E%CJ %EJID %EFBF D% GEBGF GEBHB GE%$F

AI% CGGEBB$ CCCEFJD CIBE%GH % CJEC%H CDE%GH CFEJJH B% %EIC$ %E%CI %EJC% DH GEIJJ GEBCG GEBH%

AIB GFFEHDI CG$E%IJ CCGEIFC H CHE$BB CJECBC CDEBB$ BH %EGIG %EIC% %E%GD DJ GEIIH GEIJF GEBCC

AII GDDEHHF GFDEDD% C$FEG$G J CBEDFI CHE$II CJEGJB BJ BEFBF %EGI% %EICG DD GECFJ GEIIF GEIDG

AIC GJDEIBJ GDJEFHJ GFJE%DJ D CIED$G CBEDDJ C%EFJC BD BEJJB BEF%I %EGIG DF GEC%F GEI$$ GEIBC

AIG GHDEHHD GJJEJIG GDHEJFI F CCEJHB CIEJFD CBEDIG BF BEH$J BEJJD BEF%$ F$ GECCC GECHC GEI$C

AI$ G%FE%DD GHDEGCF GJHEHJ$ G$ CGEJD$ CCEJHB CIEJBD %$ BEBBI BEH$D BEJJC FG GEGDH GECCH GECH%

ACF G%$EFFF G%FE$BF GHJE$FF GG C$EDIH CGEJJI CCEJG$ %G BECDF BEBBJ BEH$% FC GEG%C GEGFG GECCF

ACD GBCEFIJ G%$E%CJ G%DEGGJ GC GFEFIF C$EDIC CGEJC% %C BEGBG BECFC BEBBB FI GEGGF GEG%J GEGFB

ACJ GI%EIHH GBCE%CH GBFEHD% GI GFE$DJ GFEFID C$EJDD %I IEFFF BEGBB BECF$ FB GE$DJ GEGCB GEGHG

ACH GCDEC%I GI%E$$F GBGEJHH GB GDECJJ GFE$DD GFEDFF %B IEDHC BE$$C BEGBC F% GE$%J GE$FI GEGCF

AC% GCGE%HH GCJEFB% GIBEICB G% GJE%$H GDECJF GFE$%C %% IEJCC IED%H IEFF$ FH GE$CJ GE$HI GE$FD

ACB GG%ECI$ GCGEC%C GCJECJB GH GHEJJ$ GJE%$J GDECBB %H IE%F% IEJCI IED%C FJ $EFFF GE$II GE$HJ

ACI G$FECJG GGBEF%F GC$EHBJ GJ GHE$HF GHEJJC GJEBJ% %J IEBJI IE%FH IEJC$ FD $EFJG GE$$% GE$ID

ACC G$IEHH% G$FE$IF GGBEBGI GD G%EB$C GHE$JC GHEJBI %D IEI%% IEBJB IE%FI FF $EFBB $EFJJ GE$G$

ACG FDEIDJ G$IEBHJ G$DE%BJ GF GBEJHJ G%EB$J GHE$BH %F IECBI IEI%J IEBJG G$$ $EFGD $EF%$ $EFDC

AC$ FIEBGH FDECC$ G$IE$CB C$ GBEGHC GBEJJI G%EIDI H$ IEGII IECBI IEI%I G$G $EDFI $EFCB $EF%%

AGF DDEH$I FIEGBG FJEHJF CG GIE%JH GBEG%D GBEJBG HG IE$CF IEGI% IECB$ G$C $EDHD $EDFF $EFI$

AGD DBE$JC DDEIHG FCEHBF CC GIE$GD GIE%JB GBEGI$ HC CEFCF IE$I$ IEGIC G$I $EDB% $EDJ% $EF$%

AGJ JFED$H DIEDH$ DJEFGB CI GCEBDH GIE$GJ GIE%BD HI CEDII CEFI$ IE$CD G$B $EDCC $ED%G $EDDG

AGH J%EJDD JFEHCC DIEB%H CB GGEFD$ GCEBDJ GCEFFI HB CEJB$ CEDIB CEFCD G$% $EJFF $EDCJ $ED%H

AG% JCE$$$ J%EHCD JFEC%% C% GGEBFJ GGEFDG GCEBH% H% CEH%B CEJBB CEDI% G$H $EJJJ $ED$% $EDII

AGB HDEB$D JGEDB$ J%ECJC CH GGE$IJ GGEBFF GGEFHC HH CE%HF CEH%H CEJBI G$J $EJ%H $EJDB $EDGG

AGI H%E$CG HDECJ$ JGE%GD CJ G$E%FD GGE$B$ GGEBDC HJ CEBDJ CE%JG CEH%B G$D $EJIH $EJHI $EJF$

AGC HGEDC% HBEF$C HJEFJD CD G$EGJF G$EH$G GGE$CB HD CEB$D CEBDF CE%HF G$F $EJGH $EJBI $EJHF

AGG %DEDG$ HGEJCB HBEHIJ CF FEJD$ G$EGDI G$E%DJ HF CEIII CEBG$ CEBDJ GG$ $EHFJ $EJCI $EJBF

AG$ %%EFHI %DEJCB HGEBD% I$ FEB$$ FEJDH G$EGJC J$ CEC%D CEIIC CEB$J GGG $EHJF $EJ$B $EJCF

AF %IECGB %%EDCF %DEBBI IG FE$IH FEB$% FEJJ% JG CEGDJ CEC%F CEIIG GGC $EHHG $EHDH $EJG$

AD %$EHC$ %IE$FJ %%E%JI IC DEHDD FE$BC FEIF% JC CEGGF CEGDD CEC%J GGI $EHBB $EHHD $EHFC

AJ BDEGJG %$E%GJ %CEDHB II DEI%H DEHF% FE$II JI CE$%B CEGC$ CEGDJ GGB $EHCJ $EH%G $EHJB

AH B%ED%J BDE$DG %$EI$% IB DE$IF DEIHI DEHDH JB GEFFG CE$%% CEGGF GG% $EHG$ $EHIB $EH%J

A% BIEHJ$ B%EJJF BJEDDF I% JEJIJ DE$BJ DEI%J J% GEFCD GEFF$ CE$%G GGH $E%F% $EHGJ $EHB$

AB BGE%FB BIE%FB B%E%FB IH JEBBD JEJBB DE$BG JH GEDHF GEFCD GEFDD GGJ $E%JF $EH$C $EHCB

AI IFEHI$ BGE%CD BIEBC% IJ JEGJ$ JEB%% JEJIF JJ GEDGC GEDHF GEFCJ GGD $E%H% $E%DH $EH$D

AC IJEJJI IFE%JB BGEIJ% ID HEF$% JEGJD JEB%$ JD GEJ%D GEDGI GEDHD GGF $E%%$ $E%JC $E%FI

AG IHE$GH IJEJC% IFEBI% IF HEH%C HEFGC JEGJI JF GEJ$% GEJ%D GEDGG GC$ $E%IH $E%%J $E%JD

Page 61

59

Day Heater Temp. Sensor Table

"CB!Q!G?RB?HET U >V

"@BB!Q!>R>ET U @@R@V

.CB)@BB!Q!CBGHE!U GV

/'P+ "Z,[ "2#[3 "Z%\ /'P+ "Z,[ "2#[3 "Z%\ /'P+ "Z,[ "2#[3 "Z%\

$ GBCE%% GHCECG GDBEGC %H GCEFD$ GBE$HH G%EC$I GGC CECGG CEIBI CEBJJ

G GI%E%% G%BE$F GJBEJC %J GCE%C$ GIE%%J GBEHBI GGI CEGBF CECJF CEBGG

C GCDEFI GBHEBG GH%ED% %D GCE$JD GIE$HF GBEG$% GGB CE$F$ CECGJ CEIBJ

I GCCEHD GIFEGJ G%JEBD %F GGEH%% GCEH$G GIE%FG GG% CE$IC CEG%D CECD%

B GGHEJH GICEIC GBFE%F H$ GGECBD GCEG%I GIE$FJ GGH GEFJJ CEG$$ CECC%

% GGGEGJ GC%EDH GBCEGI HG G$ED%J GGEJCC GCEHCB GGJ GEFCI CE$BI CEGHH

H G$%EDJ GGFEJB GI%E$F HC G$EBDI GGEI$F GCEGJG GGD GEDJ$ GEFDF CEGG$

J G$$EDH GGIEFH GCDEB% HI G$EGCI G$EFGI GGEJIH GGF GEDC$ GEFIH CE$%%

D FHEGC G$DE%$ GCCEGH HB FEJJJ G$E%II GGEIGF GC$ GEJJG GEDD% CE$$C

F FGEHC G$IEIC GGHECC H% FEBB% G$EGHD G$EFGF GCG GEJCI GEDIH GEF%$

G$ DJEIJ FDEBI GG$EHG HH FEGC% FEDGJ G$E%I% GCC GEHJD GEJDD GEF$$

GG DIEII FIEJF G$%EI$ HJ DEDGD FEBDG G$EGHJ GCI GEHII GEJBG GED%C

GC JFE%G DFEB$ G$$ECJ HD DE%CB FEG%J FEDGI GCB GE%F$ GEHFH GED$%

GI J%EDD D%ECB F%E%G HF DECB$ DEDBH FEBJB GC% GE%BD GEH%C GEJ%F

GB JCEBB DGEI$ FGE$G J$ JEFHJ DE%BD FEGBD GCH GE%$D GEHG$ GEJG%

G% HFEGJ JJE%H DHEJB JG JEJ$% DECHG DEDIB GCJ GEBHD GE%HF GEHJC

GH HHE$J JBE$G DCEJ$ JC JEB%C JEFD% DE%II GCD GEBI$ GE%CF GEHI$

GJ HIEGI J$EH% JDEDJ JI JECG$ JEJGF DECBB GCF GEIFI GEBF$ GE%F$

GD H$EIB HJEBH J%ECB JB HEFJH JEBHB JEFHH GI$ GEI%J GEB%I GE%%$

GF %JEHD HBEBI JGED$ J% HEJ%G JECGD JEHFF GIG GEICI GEBGH GE%GC

C$ %%EGH HGE%H HDE%I JH HE%IB HEFDC JEBBC GIC GECDF GEIDG GEBJ%

CG %CEJH %DEDI H%EBI JJ HEICH HEJ%% JEGF% GII GEC%H GEIBH GEBIF

CC %$EBD %HECB HCEBF JD HEGC% HE%IH HEF%J GIB GECC% GEIGI GEB$B

CI BDEIG %IEJJ %FEJ$ JF %EFIG HEIC% HEJCF GI% GEGFB GECDG GEIJ$

CB BHEC% %GEBI %JE$% D$ %EJB% HEGCI HE%$F GIH GEGHB GECBF GEIIJ

C% BBECD BFEC$ %BE%I DG %E%H% %EFCJ HECFJ GIJ GEGI% GECGF GEI$%

CH BCEBG BJE$D %CEGI DC %EIFC %EJIF HE$FI GID GEG$J GEGDF GECJB

CJ B$EHI B%E$J BFEDH DI %ECC% %E%%D %EDFJ GIF GE$D$ GEGH$ GECBB

CD IDEFB BIEG% BJEHF DB %E$HB %EIDI %EJ$D GB$ GE$%I GEGIC GECG%

CF IJEIC BGEIC B%EHB D% BEF$F %ECG% %E%CH GBG GE$CJ GEG$% GEGDH

I$ I%EJD IFE%D BIEHD DH BEJ%F %E$%I %EI%G GBC GE$$C GE$JF GEG%D

IG IBEIG IJEFI BGEDC DJ BEHG% BEDFH %EGDC GBI $EFJD GE$%I GEGIG

IC ICEFG IHEI% B$E$B DD BEBJH BEJBH %E$GF GBB $EF%B GE$CD GEG$%

II IGE%D IBED% IDEIH DF BEIBG BEH$$ BEDHC GB% $EFIG GE$$B GE$D$

IB I$EIG IIEBG IHEJ% F$ BECGC BEBH$ BEJGG GBH $EF$F $EFD$ GE$%%

I% CFE$F ICE$% I%ECC FG BE$DH BEIC% BE%HH GBJ $EDDJ $EF%D GE$IG

IH CJEFI I$EJ% IIEJH FC IEFH% BEGFB BEBC% GBD $EDHH $EFI% GE$$J

IJ CHEDI CFE%$ ICEIJ FI IEDBF BE$HD BECDF GBF $EDBH $EFGB $EFDB

ID C%EJJ CDEIC IGE$B FB IEJIH IEFBJ BEG%F G%$ $EDCH $EDFI $EFHC

IF CBEJH CJEGF CFEJJ F% IEHCJ IEDCF BE$II

B$ CIED$ CHEGG CDE%J FH IE%CC IEJGH IEFGG

BG CCEDJ C%E$J CJEBC FJ IEBC$ IEH$H IEJFI

BC CGEFF CBE$F CHEIC FD IEICC IE%$G IEHD$

BI CGEG% CIEG% C%ECJ FF IECCJ IEIFF IE%JG

BB C$EIB CCEC% CBECJ G$$ IEGI% IEI$$ IEBH%

B% GFE%J CGEIF CIEIG G$G IE$BI IEC$% IEIHJ

BH GDEDB C$E%J CCEB$ G$C CEF%B IEGGI IECJC

BJ GDEGI GFEJD CGE%I G$I CEDHJ IE$CB IEGD$

BD GJEBH GFE$I C$EHF G$B CEJDB CEFIJ IE$FC

BF GHEDG GDEIG GFEF$ G$% CEJ$B CED%B IE$$H

%$ GHEGF GJEHC GFEGI G$H CEHCH CEJJB CEFCI

%G G%EH$ GHEFH GDEB$ G$J CE%%G CEHFH CEDBC

%C G%E$I GHEII GJEJG G$D CEBJD CEHCG CEJHB

%I GBEBD G%EJI GJE$B G$F CEB$D CE%BD CEHDF

%B GIEFH G%EG% GHEB$ GG$ CEIB$ CEBJJ CEHGH

%% GIEBH GBEH$ G%EJF GGG CECJB CEB$F CE%BH

Page 62

60

1) Spec of Heater of Washing Machine

;)@('

'KLMN

*OPQRSTLUOP!VOWMX

'MQUQLKPYM

*RXXMPL!9MPQULZ

+MSTE!#RQM

+[(';\]+,'

;KLMXUK^

;K_E!+MSTE

VKXL!*ONM

*8(6

\'*)

CC$`a!CI$`

C$$$"b%c

CBECOdS

DEF

GHJ?

[MKLMX!eRU^LAUP

]:]BI$

")+('

IHGCD$CB$$

IHGCD$CBG$

:"J;"

\'*)

CC$`a!CI$`

CG$$"b%c

CIE$%OdS

HEG

GCD?fgRU^LAORLh

fgRU^LAORLh

\i*,jkD$$

H$$?

IHGCD$GB$$

Temp. Fuse of Washing Heater (184°C CUT OFF TYPE)

: Located inside heater to prevent fire, etc. caused by

heating without water due to breakdown of water

level sensor, etc.

: Cut-off in app. 1min in case of overheating, heater temp. of

app. 270°C

: Washing heater must be used under water.

Washing

Temp. Sensor

Drying Temp.

Sensor

Dry Heater

Wash Heater

7. HEATER

""

Wash Heater

""

Dry Heater

Page 63

61

Heater Replacement

2) Breakdown Diagnosis

Breakdown

Cause Diagnosis Solution

PCB

Symptoms Error Mode

Washing

water

not heated

(common for

drum)

Overheating of

washing water

Wiring short

Washing heater or

temp. fuse short

Connector/ terminal

loosening

Defect in washing

heater temp. sensor

Defect in washing

heater temp. sensor

Connect the cut-off part.

Replace washing

heater.

Insert terminal.

Replace temp. sensor.

Replace temp. sensor.

"H6"

"H6"

"H6"

"H2"

"H2" or "H4"

Check for short

Check for short: Normal if 23.3~25.7ohm between both

terminals of washing heater

Check for loosening: Common for drum

Measuring resistance between both terminals of sensor:

Measuring resistance between both terminals of sensor:

* How to Replace Washing Heater and Temp. Sensor

1. Dismantling Connector 2. Loosening Earth and Heater Nuts

3. Replacing Heater and Temp. Sensor

4. Administer assembly in reverse order and make sure to fasten heater nuts first before the earth nuts.

Page 64

62

1) Structure of BLDC Motor

7. HEATER

gj9*!;,+,'

2) Power Transmission System of BLDC Motor

Page 65

63

3) Specification

Classification Item BLDC : DD Motor

1. General

2. Performance

3. Structure

Rated Voltage

Insulating Structure

External Appearance

No. of Poles

Consumption Power

RPM

Output

Characteristics

Stator

Resistance

Rotor

Hall IC

Vm = 310 [Vdc], Hall IC Voltage 5 [Vdc]

Type B, insulator method

Shaft connection and stator connection

structure, Air-gap : 1mm

24 poles, Core: 36 slots, Layer: [30mm]

390[W]±10[%], during washing

(picked value)

During Washing: 45RPM,

During Spin-drying:1300RPM

Torque: 300Kgf.cm (washing: 45rpm)

Current: 1.5A (washing: 45rpm),

2.5A (spin-drying: 800rpm)

AC Input Terminal - Washing: 250Wo,

Spin-drying: 380Wo

ø265x30H

U(blue) - V(purple) : 13.8Ω[at 75°C]

V(purple) - W(pink) : 13.8Ω[at 75°C]

W(pink) - U(blue) : 13.8Ω[at 75°C]

cf) Motor resistance at ambient temp. of

0 ~ 35°C

7.04 ~ 8.1Ω

Magnet : 24 segments, bracket, serration

2-sensor Control Type, Top Central Angle:

7.5 degrees

Signal Error Angle (phase difference):

90±5 degrees (based on electric angle)

Page 66

64

8. WIRING DIAGRAM

C-124X/125X: DOUBLE VALVE, BUBBLE

C-124X/125X: DOUBLE VALVE, N/BUBBLE

Page 67

65

D-124X/125X: DOUBLE VALVE, BUBBLE

D-124X/125X: DOUBLE VALVE, N/BUBBLE

Page 68

66

9. TROUBLE SHOOTING REGARDING DRAIN

1) Structure of Dran Parts by TUB

[,](!9')\i!\

[,:]\il!`)j`(

9')\i!;,+,'

`)j`(!)\'!)]

2) Checking Methods

• Situation : * "OE" is shown on PCB.

* Not finishing drain during 10 min.

* The water level can not reach to RESET POINT during 10 min of drain.

Checking Methods

* Check the hose drain O condition; twisted or frozen.

* Check the hose drain O condition, blocked.

* DRAIN MOTOR is broken.

Replacing methods

* replace HOSE DRAIN O

* clean the inside of Filter.

* replace DRAIN MOTOR

Page 69

67

10. INST ALLA TION GUIDE

1) Related Parts and Configuration

PARTS NAME

FIXTURE UP/DOWN AS

UNIT SERVICE WRENCH

LEG ADJUST AS

REMARKS

FIXTURE UP AS

(3612008200)

: L= 109mm

FIXTURE DOWN AS

(3612008300)

: L=143mm

m Remove Fixture

UP/DOWN AS

n Adjust Leg

FIGURES

]V(*\)j

]*'("!:V

#\o+:'(!:V #\o+:'(

9,"i

#,,+

#\o+:'(

j(l

]V(*\)j

]*'("

9,"i

2) INSTALLATION PROCESS

1Remove the FIXTURE UP/DOWN AS

2Insert CAP HOLDER(4EA) after removing FIXTURE UP/DOWN AS.

Removal Method Remarks

☞Disassemble the FIXTURE UP/DOWN AS by

turning CCW direction.

☞Please keep FIXTURE UP/DOWN AS for later use.

☞When fixing FIXTURE UP/DOWN AS, turn it CW

direction.

CAP HOLDER

Page 70

68

3Please install the DRUM W ASHING MACHINE properly on even and hard floor as below .

4Adjust the level of washer using LEG ADJUSTAS.

Adjusting Method Remarks

☞If turned CW, the LEG ADJUST AS moves the

washer upward.

☞If turned CCW, the LEG ADJUST AS moves the

washer downward.

5After adjusting level, fix SPECIAL BOL T.

Adjusting Method Remarks

✰ Please fix the SPECIAL BOLT by rotating it CCW

in order to prevent washer vibration.

Page 71

69

11. A TTENTION POINT WITH SERVICING

No Item Part Name Checking Point

1 Replacing Thermistor Thermistor Dry Keep the Packing from seperating (Hold Packing when replacing)

Dry Keep the Packing from folding

2 Replacing Duct B As DUCT B AS & Check the sealing between Duct Pipe & Duct B AS

& Duct Pipe DUCT PIPE

3 Replacing & Inlet Valve Use only screw M4*8 for fixing Inlet Valve

Repairing Inlet Valve

4 Replacing Hose Drain Hose Drain Keep the sealing condition of Tub O tightly

5 Replacing HOSE HOSE A,B,C Check the assembling order between INLET BOX & Hose A,C :

A,B,C Pre Wash-Cold

6 Replacing Heater Wash Unfastening the nut for fixing earth first then unfasten

Heater Wash the nut for fixing heater

At assembling the heater dry, check if the assembling condition between

fixture heater is tight.(little gap on left & right)

At fastening the nut for fixing the heater wash, keep the protrusion length

of bolt to 10~12mm.

(if under 10mm, water can leak, and if over 12mm, fixture heater can

deform)

7 Replacing Thermistor Wash Unfasten the Nut for fixing heater, replace the thermistor, and

“Thermistor Wash” fasten the nut for fixing heater

8 Assembling Hinge Door

At fastening screw for fixing Door AS, be careful so that scratching at

“Hinge Door” the related parts does not happen

: If the scratching happens, it is possible to be claimed about

appearance damage

9 (Dis)assembling Door As Be careful about the up/down direction of Door Glass : Keep the

“Door AS” indication point of the part code downward.

10 (Dis)assembling MOTOR AS To avoid the injury on the hand, grip the rim of the rotor

“Motor AS” At initiating the assembling operation of the stator, grip the

stator and fasten the screw; at unfastening the screw, grip the stator so

that it does not fall.

11 Damper AS Damper AS Fixed 4 Dampers with spring when assemble.

Page 72

S/M NO. :

DAEWOO ELECTRONICS CORP.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

PRINTED DATE: May. 2008

Page 73

p q

rst u

+(j!!!!!

!

;,9(j

*A(9GCBov9A(9GCBov*A(9GC%ov9A(9GC%of]v;hwxyz{|}