Page 1

D1146

Primary filter:clean at every 5,000km,change at every 15,000km there

Change at every 20,000km.

166Page

Valve clearance Adjust at end of first 1,000km and every 20,000km there after. 171 Page

Air cleaner Clean at every 4,000km, change at every 12,000km there after. 176 Page

Transmission oil Change at end of first 5,000km and every 20,000km there after. 178 Page

Rear axle oil Change at end of first 5,000km and every 20,000km there after. 179 Page

Power steering oil Change at end of first 1,000km and every 24,000km there after. 180 Page

Power steering filter Change at end of first 1,000km and every 24,000km there after. 182 Page

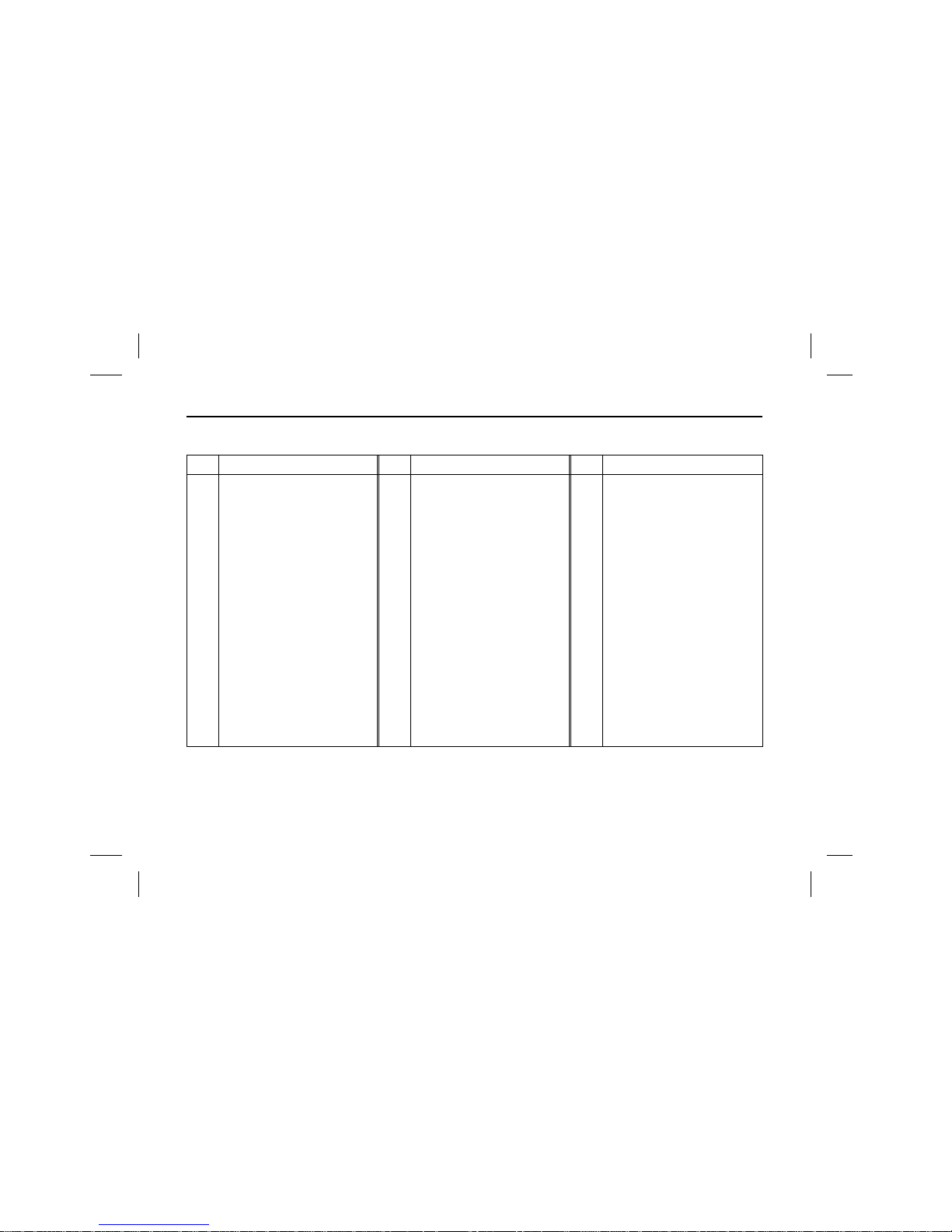

IMPORTANT SERVICE ACTIVITIES

ҧAny failure resulting from a lack of normal maintenance as the maintenance service chart in this manual is not covered

by warranty.

CHECK ITEMS CHECK AND SERVICE INTERVALS PAGE

Engine oil 163 Page

Change : At end of first 1,000km,

long distance : every 30,000km

short distance : every 20,000km

D1146Ti

DE08TiS

DE12/T/Ti/TiS

Fuel filter

D1146

D1146Ti

DE12

DE12T

DE12Ti

Primary filter : clean at every 5,000km,

change at every 15,000km there after.

secondary filter : change at every 5,000km.

Engine oil filter Change with engine oil 164Page

DE08TiS

DE12TiS

Change : At end of first 1,000km,

High-speed, long distance : every 15,000km

In city, short distance : every 10,000km

Page 2

This manual has been prepared to acquaint you with the operation and maintenance of your DAEWOO

BUSES and the provide important safety information. We urge you to read it carefully and follow the

recommendations to help assure the most enjoyable, safe and troublefree operation of your vehicle.

When it comes to service, remember that your DAEWOO dealer knows your vehicle best and is

interested in your complete satisfaction.

We would like to take this opportunity to thank you for choosing a DAEWOO product and assure

you of our continuing interest in your motoring pleasure and satisfaction.

This manual should be considered as a permanent part of your vehicle, and must remain with the

vehicle at the time of resale.

All information, illustrations and specifications contained in this manual are based on the latest product

information available at time of publication.

The right is reserved to make changes at any time without notice.

FOREWORD

Page 3

1

1. IMPORTANT INFORMATIONŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 2

2. OPERATION AND CARE OF NEW VEHICLE

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 4

3. GETTING ON AND OFF, DRIVER’S SEAT AND BELT

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 6

4. INSTRUMENT, SWITCHES AND CONTROLS

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 14

5. DRIVING

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 135

6. INSPECTION AND MAINTENANCE

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 162

7. LUBRICATION

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 213

8. SCHEDULED MAINTENANCE SERVICE

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 221

9. TROUBLESHOOTING

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 225

10. MAIN DATA AND SPECIFICATION

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 234

11. BODY DIMENSION

ŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋŋ 253

TABLE OF CONTENTS

Page 4

2

IMPORTANT INFORMATION

LOCATION OF ENGINE NUMBER AND CHASSIS NUMBER

It is advisable to keep note of the engine number and chassis number as they are required when contacting your dealer for repair services and parts order.

V.I.N plate

V.I.N(Vehicle identification Number)

plate is attached to the inner panel

above the front door.

Type A : Applicable for vehicles in

all countries except GCC

members.

V.I.N plate

V.I.N(Vehicle identification Number)

plate is attached to the inner panel

above the front door.

Type B : Applicable for vehicles in

GCC members.

Chassis number

The chassis number is stamped on

the upper face of the chassis frame

within the engine compartment.

Page 5

3

Engine number Key

There are three types of key for the

bus ;

• Engine starting

• Mechanical locking for entrance

door (OPTION)

• Doors

– Entrance door operating

– Luggage doors (OPTION)

– Rear engine door (OPTION)

– Side engine doors (OPTION)

– Battery inspection door (OPTION)

–

Fuel tank inspection door (OPTION)

– Fuel inlet flap door (OPTION)

The keys are not interchangeable, but

door lock keys are interchangeable.

The code number of each key is

stamped on the key.

Record the key number and keep it

in a safe place.

In the event that the original key is

lost, duplicating can be done using

the key code information.

Engine No.

1378

Page 6

4

OPERATION AND CARE OF NEW VEHICLE

It is important to observe the following precautions as operation and care

of the vehicle, particularly during the

break–in period have a strong influence over the performance and service life of the vehicle.

1. Start and let the engine idle until

it becomes thoroughly warmed up

and coolant temperature increases

beyond 50°C (or 125°F) before

starting off.

2. Avoid racing the engine, abrupt

starts and hard stops.

3. Avoid over loading the vehicle during and after the break–in period.

Over loading

Over loading not only shortens the

service life of your vehicle but also

create serious potential safety hazards.

The weight of payload must be limited within the GVW rating and distributed over the front and rear axles so

as not to exceed the axle capacities.

Refer to “MAIN DATA AND SPECIFICATION” for GVW and Axle capacity.

Maintenance

In order to maintain safe and dependable vehicle operation, inspection and

adjustment should be performed as

outlined in “INSPECTION AND MAINTENANCE”.

Your DAEWOO dealer is willing to

perform regular maintenance operation on your vehicle.

Page 7

5

Engine oil change

Change engine oil filter catridge to new one at the

same time with engine oil.

Maximum engine speed

During the initial milage(Break–in period : 2,000km),

confine engine speed to 70% of the maximum and

scan the tachometer as you drive to prevent engine

over–running.

After the break–in period, increase the engine speed

gradually to complete running–in of the vital parts.

Engine Model Change Interval

D1146

At end of first 1,000km

D1146Ti

High–speed, long distance :

DE12Ti every 15,000km

DE12Ti In city, short distance :

DE12Ti every 10,000km

DE08TiS

At end of first 1,000Km

Long distance : every 30,000km

DE12TiS

short distance : every 20,000km

Page 8

6

GETTING ON AND OFF, DRIVER’S SEAT AND BELT

DOOR OPENING AND CLOSING

(Applicable for vehicles in all

entrance door with mechanical key)

When opening the front door to get

in, first unlock the mechanical key on

the entrance door and operate the

entrance key on the right side of the

front middle panel.

When closing the front door to get

off, open the front door by operating

the door control switch and get off.

In the outside of bus, close the door

with the key and look the mechanical

key on the entrance door not to be

opened in case of air leaking.

(Applicable for vehicles in all

entrance door except mechanical key)

When opening the front door to get

in, operate the entrance key on the

right side of the froot middle panel.

When closing the front door to get

off, open the front door by operating

the door control switch and get off.

In the outside of bus, close the door

with the key.

I

D

L

I

N

G

H

.

.

L

Before operating entrance key, unlock

mechanical key on door frame.

NOTICE

When opening front entrance door for a long time, setting emergency valve

at manual position and put control switch in close position. When returning

to automatic condition, putting control switch and door in same condition

and set emergency valve at automatic position.

CAUTION

(Type A : Toggle switch) (Type B : One touch switch)

Page 9

7

MANUAL OPENING AND

CLOSING

Type A : Select type

As setting the “Auto–Manual” change

lever installed right, lower inner side

of front panel(beside of driver’s right

leg), the door can be opened and

closed by hands.

Type B :

Push/Pull or rotary type (OPTION)

As setting the "Auto-Manual" change

knobs are installed two types. One of

the types installed inner upper panel

the entrance door operated by air.

Other installed outer mid panel on left

side of door operated by electric push

button. the door can be opened and

closed by hands.

I

D

L

I

N

G

H

.

.

L

(Push/Pull type) (Rotary type)

Page 10

8

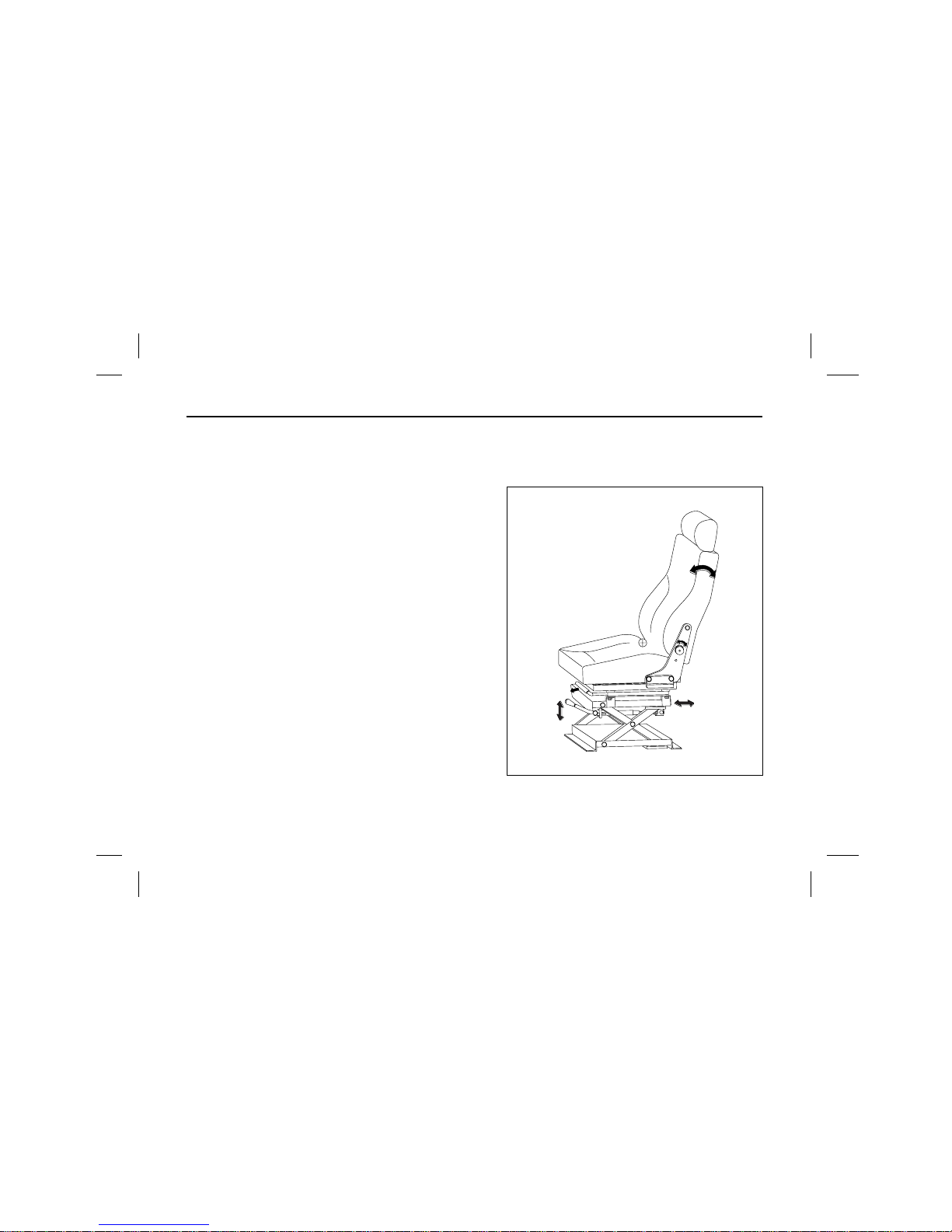

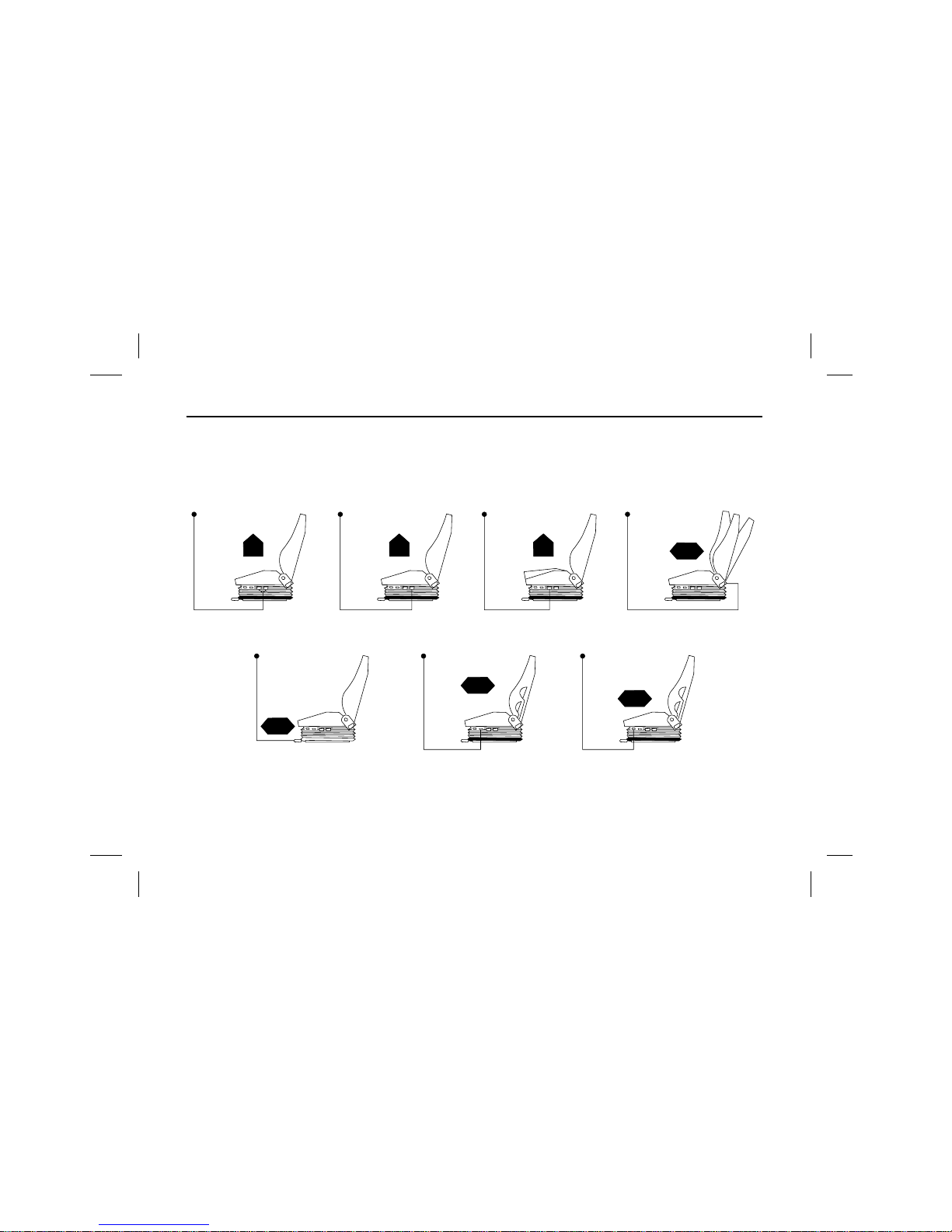

Adjustment of Fixed type (S-104H) (BM090, BS090)

1. Back angle adjustment

To adjust the seat back, turn No. 1 handle, and lean

backwards and foreward until desired angle is

achieved.

2. Slide adjustment

To move the seat forward and backward.

Pull No. 2 lever, forward and slide the seat.

3. Height (Tilting) adjustment

Desired the seal height can be achieved by puling

No. 3 lever upward and downward.

2

1

2

3

1

DRIVER’S SEAT AND BELT

Page 11

9

How to use non suspension seat

Semi suspension seat can be infinitly adjusted to suit the weight of the driver.

Height Adjustment

Back Angle

Slide Adjustment

Page 12

10

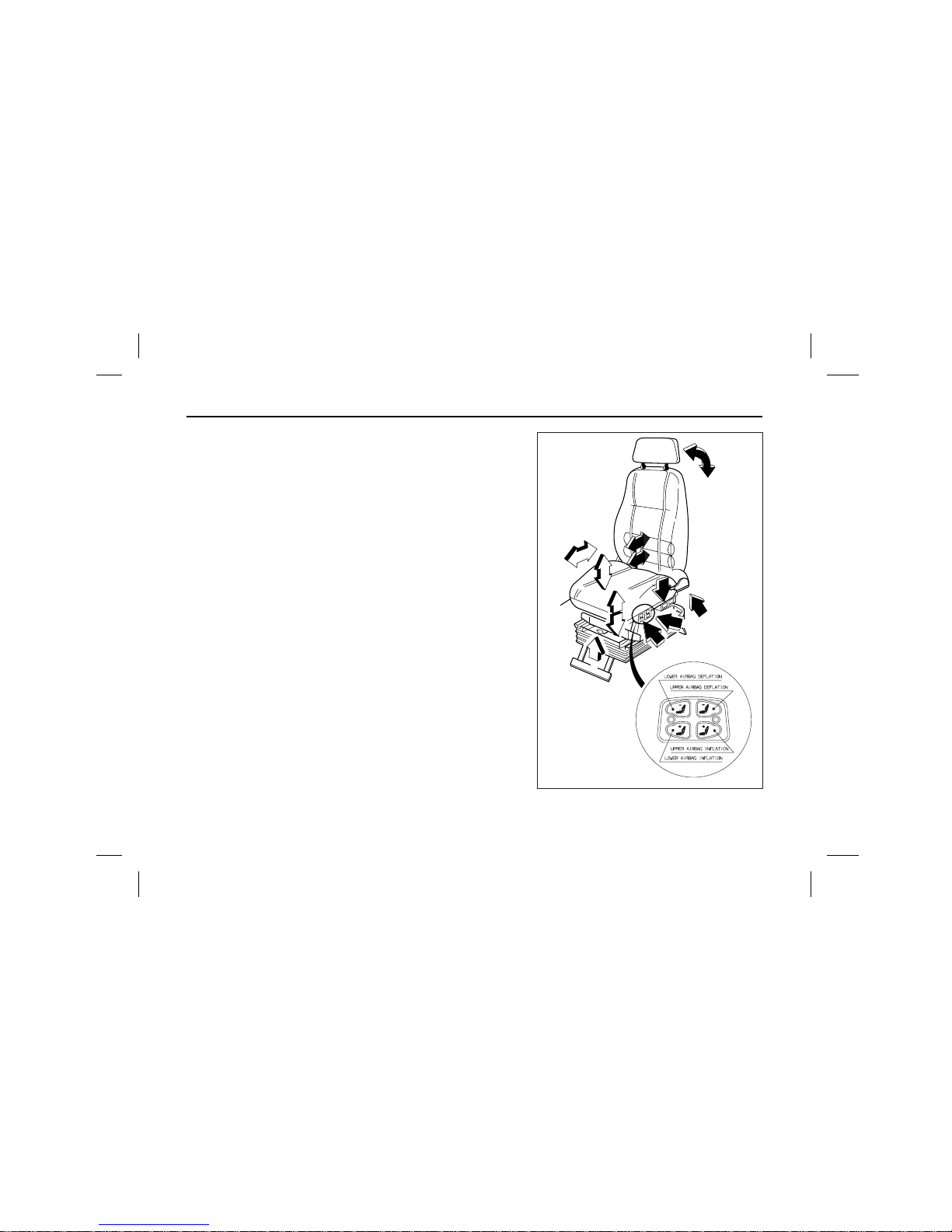

Adjustment of Air suspension type driver’s

seat (S-110A) (BS106, BH113/115/120E, BV120)

1. Slide adjustment

To move the seat forward or rearward, pull No. 1 lever

upwards and the slide the seat.

2. Back angle adjustment

To adjust the seat back, pull No. 2 lever and lean

backwards or forewards until the desired angle is

achieved.

3. Height and slope adjustment

Desired seat height can be achieved by pulling No. 3

lever.

4. Upper lumbar support air cushion adjustment.

4. Lower button is for inflation, upper button is for defl-

4. ation

5. Lower lumbar support air cushion adjustment.

Push the lumbar support air cushion adjustment button to suit seating position.

4. Lower button is for inflation, upper button is for defl-

4. ation

6. Air suspension stroke support air undercushion adjustment

ř

Do not adjust the driver’s seat while driving.

Ś

2

2

4

4

5

3

3

6

1

5

4

1

Adjustment of Air suspension type driver’s seat (S-110A)

(BH090, BS106, BH115E, BH120E) (BM090/BS090 : OPTION)

Page 13

11

How to use air suspension seat

Air suspension seat can be infinitly adjusted to suit the weight of the driver.

Height Adjustment Tilt Adjustment(RR) Tilt Adjustment(FRT) Back Angle

Lumbar Support(Lower)Lumbar Support(Upper)Slide Adjustment

Page 14

12

The vehicle is equipped with three point type(driver’s)

and reel type(passenger’s)

Every person who drives or rides in this vehicle

should wear a seat belt at all time.

The buzzer will sound, if the driver’s seat belt is not

fastened when the ignition switch is turned to the

“ON” position.

1) Pull the belt evenly out of the retractor and guide

it across the body making certain that it is not

twisted.

The seatback should not be in a reclining position

anymore than needed for comfort.

2) Insert the metal latch plate ڹ into the buckle ں.

3) To remove the belt, depress the red push button

on the buckle.

And the belt wil roll up automatically.

4) When the driver’s seat belt is not in use, adjust

the latch plate ڹ within 10

cm

from the seat loop.

The belt must not be twisted when fitted.

Do not wear the shoulder belt across the neck or

under your outer arm.

Seat Belts

1

2

Page 15

13

Seat belt warning lamp

The seat belt warning lamp comes on

when the ignition switch is placed in

the “ON” position unless the driver’s

seat belt is securely fastened.

Pilot indicator lamps

1. Never use the belt for more

than one person at a time.

2. Never wear the belts twisted.

3. Make sure seat belts or their

attachments not to be thrusted

in metal parts of the seat or

the door.

4. Seat belts should be adjusted

as firmly as possible.

5. Do not wear seat belts low

under your shoulder.

6. If you replace your seat belts

incorrectly, you may by injured

by hardware of the belts at

sudden stops.

7. Do not wear your seat belts

with hard or breakable objects

such as glasses, pens, etc. put

into the pocket of your upper

garment.

NOTICE

1. Periodically inspect all parts of

the belts and replace any damaged parts.

2. Make sure that the belts are

not to be damaged by sharp

edged objects.

3. The belts should be changed if

webbing has become frayed or

damaged.

4. Check if fixing bolts have been

firmly installed to the floor.

5. Always keep the seat belts

clean and dry.

6. Clean only with tepid soapy

water.

7. Do not bleach or dye seat

belts.

CAUTION

Page 16

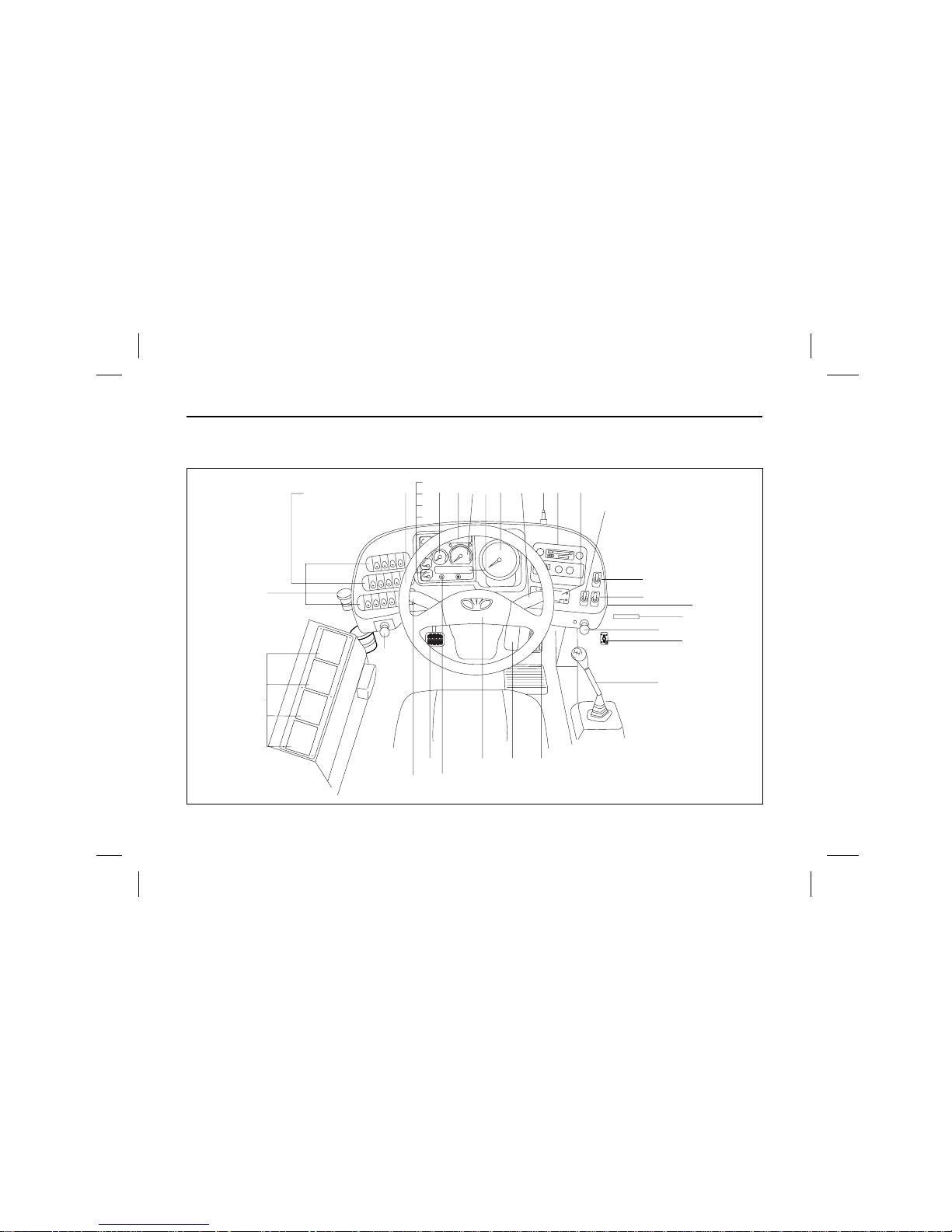

14

INSTRUMENTS, SWITCHES AND CONTROLS

11

18

202223

24

27

26

30

29

25

56798

21

13 17

10

1

2

3

4

14

19

15

32

12

31

28

Page 17

15

ҧThe quantities or locations of switches could be different from the figure, because the switches could be added or

omitted, or locations could be changed by the requirements of customers.

LEGEND OF INSTRUMENT PANEL AND OTHER DEVICES

No. Description No. Description No. Description

1 Voltage meter

2

Engine coolant temperature gauge

3 Fuel gauge–Engine

4 Engine oil pressure

5 Air pressure gauge

6 Upper pilot lamps

7 Engine RPM gauge

8 Lower pilot lamps

9 Tachograph (OPTION)

Speedometer (OPTION)

10 Door opening switch (FRT)

11 Door opening switch(MID) (OPT)

12 Microphone stand

13 Radio & Cassette player

14 Switches

15 Door opening switch(RR) (OPT)

17 Defroster controller

18 Engine idling knob

19 Shift lever

(Except auto transmission)

20 Accelerator pedal

21 Wiper control and exhaust

brake lever

22 Brake pedal

23 Horn switch

24 Bulb check

25 Steering wheel

26 Head & Direction lamp lever

27 Clutch pedal

28 Valve–cab control

29 Clutch oil reservoir

30 Control panel (OPTION)

31 Door controller

32 Cup holder (BM090, BS106)

Page 18

16

ATTACHMENTS OF STEERING COLUMN

Steering wheel and horn button

The steering wheel should not be

turned while the vehicle is stationary

as it adversely affects the tires and

steering system.

Horn button is equipped on the middle of steering wheel.

Steering wheel adjustment

Type A : Tilt & Telescopic

(BH115E,BH120E)

(BM090/BS090/BS106 : OPTION)

Adjust the steering wheel to the

desired position after pulling lock

lever.

Adjusting angle : 8°

Travel : 40mm

Type B : Fixed (BM090, BS106)

Starter switch

Starter switch operates in the 4

stages as follows :

ҮLOCK : The key can be inserted or

removed only when the switch is in

this position.

ҮACC : This position turns on the

radio, digital clock, cigarette lighter

and consent.

unlock

3°

5°

lock

20mm

20mm

Page 19

17

ҮON : This position turns on the

electrical equipment. During the

vehicle operation, hold the key in

this position.

ҧWhen the key is in “ON” position,

the engine is automatically preheated according to outdoor temperature. Pre–heater warning

lamp blinks for 0.3 second at a

higher temperature(coolant temp. :

above 25°

C

) and for 18 seconds

at a lower temperature(coolant

temp

.: below 25°

C

), during

which the engine is preheated for

20 seconds.

ҮSTART : Once the engine is start-

ed, it is preheated automatically

according to outdoor temperature

(until coolant temperature becomes

25°

C

or up to 6 minutes). This

improves the engine condition.

Turn signal switch

Move this combination switch lever in

the desired direction so that the corresponding turn signal lamp operates

and causes the turn signal indicator

lamp on the instrument panel to flash.

The switch lever returns automatically to the neutral position when the

steering wheel is returned to the

reverse direction. When head lamp

switch is in 2nd stage simultaneously

with turn signal lamp “ON”, cornering

lamp also comes on.

LOCK

ACC

ON

START

Pilot indicator lamps

Ү

Once the engine started,

release the key immediately.

Ү

Do not exceed 10 seconds for

the operation of starter.

Ү

Gearshift lever should be in

neutral position when attempting

to start the engine.

CAUTION

Page 20

18

High beam switch

When the head lamps are on, pulling

the lever down lights up not only the

head lamps with high beam but also

the high beam indicator lamp. When

pulling it up, head lamps with low

beam are on.

Passing lamp switch

To light up passing lamps at any

time, pull up the lever towards the

steering wheel.

The lever will return to the OFF position when released.

Lamp switch(turn type)

Lamp switch operates in two stages

as follows :

1st stage : tail lamp, license plate

lamp, instrument panel

lamp, clearance lamp

2nd stage:tail lamp, license plate

lamp, instrument panel

lamp, clearance lamp,

head lamp, cornering

lamp(simultaneously with

turn signal lamp “ON”)

Windshield wiper switch

The windshield wiper switch has 3

positions to control the windshield

wiper.

1. OFF ˞ Off

2. INT ˞ Intermittent wipe

3. LO ˞ Continuous wipe, slow speed

4. HI ˞ Continuous wipe, fast speed

high beam

(passing)

high beam

low beam

2nd stage

1st stage

OFF

1

2

3

4

Do not operate the wipers when the

windshield remains dry. They may

scratch the windshield glass. Do not

operate the wipers if they are covered with snow or ice as this may

damage the wiper system.

NOTICE

Page 21

19

Wiper speed control switch

The desired intermittent operation

time can be controlled by turning the

knob when the wiper switch is in

“INT” position.

Windshield washer switch

To let washer fluid spray on the windshield, press and hold the center button of switch.

And the windshield wipers are simultaneously operated for 2–3 cycles.

Exhaust brake switch

The exhaust brake system is

designed to shut off exhaust pipe

when the engine brake is applied,

resulting in assisting brake action.

When the switch lever is pushed

downward, and clutch and accelerator

pedals are released, the indicator

lamp comes on showing that the

exhaust brake is in operation. When

the clutch and accelerator pedals are

depressed, the exhaust brake stops

working.

Hazard warning flasher switch

When the right–hand lever is pushed

upward, all the turn signal lamps are

made to flash regardless of the turn

signal switch position.

The hazard warning flasher switch is

to be used when your vehicle gets in

a traffic hazard or is parked in the

darkness.

Page 22

20

PERIPHERAL DEVICES OF STEERING COLUMN

Idle control knob

(Except MT643 auto T/M)

Turning the knob clockwise after cold

starting of the engine will increase

idling speed and thus facilitate quick

normalization of the engine coolant

temperature.

Always drive with the knob turned

back home.

Idle control valve

(For MT643 auto T/M)

Valve position

• FAST IDLE (UP) : 900~1000rpm.

• IDLE (DOWN) : 550~650rpm.

Battery switch

It controls the entire electrical circuits with the exception of parking

lamps, hazard warning flashers. The

electrical circuits are energized when

the battery main switch is pressed.

I

D

L

I

N

G

H

.

.

L

ascending

position

IDLE

FAST

IDLE

Do not use this knob to stop the

engine.

NOTICE

Page 23

21

Door opening switch

The entrance door is operated by the

air cylinders as the door opening

switches on.

Manual door opening switch

When the manual door opening

switch is placed at “auto” position, the

doors are operated by the door opening switches, or when the switch is

placed at “manual” position, the doors

are not operated by the door opening

switch and can be opened or closed

by the hands.

Air parking brake switch

When the switch is pushed, the parking brake is actuated and the indicator lamp comes on. pushed one more

the switch, releases the brake. Make

sure that the indicator lamp is off

before driving off.

I

D

L

I

N

G

H

.

.

L

(Toggle switch type)

I

D

L

I

N

G

H

.

.

L

Type A : Cab control valve

Type B : Gradual control

Page 24

22

ABS/ASR check switch(OPTION)

The switch used for self Diagnosis of

ABS/ASR system.

It needs for a car mechanics, but not

used for a driver usually, push the

button about 3 seconds, self diagnosis started and the ABS/ASR warning

lamp blinker on instrument panel.

ABS ARS

ABS

ABS ARS

ASR

POWER

POWE

R

A

I

R

C

O

ND

I

TI

O

N

ER

POWER

A

UT

O

V

E

N

T

IL

A

T

O

R

A

I

RC

OND

I

T

I

O

N

E

R

1

2

3

4

Page 25

23

Engine check / clear switch

(For DE12TiS ENG.)

When engine malfunction pilot lamp

comes on, follow the below procedure

to solve the problem.

1. To check error type pressing

engine check switch.

With pressing this switch, engine

malfunction lamp blinkers according to the error types.

(Example)

Error code 12 : prestroke control error

ҮError code

1. Engine check switch (Blue color)

2. Engine clear switch (Black color)

2. After repairing defects according to

the engine maintenance manual,

press the engine clear switch for

5seconds to remove the errors on

ECU.

Pilot indicator lamps

CHECK

ENGINE

CHECK

ENGINE

CLEAR

1 2

ON

OFF

Malfunction

Pilot lamp

No. Defects

01 Normal

12 Prestroke control error

13 Prestroke sensor error

14 Prestroke offset error

15 Prestroke actuater power error

16 Engine rpm sensor error

21 Coolant temp. sensor error

22 Fuel rack sensor error

23 Air heater relay error

Page 26

24

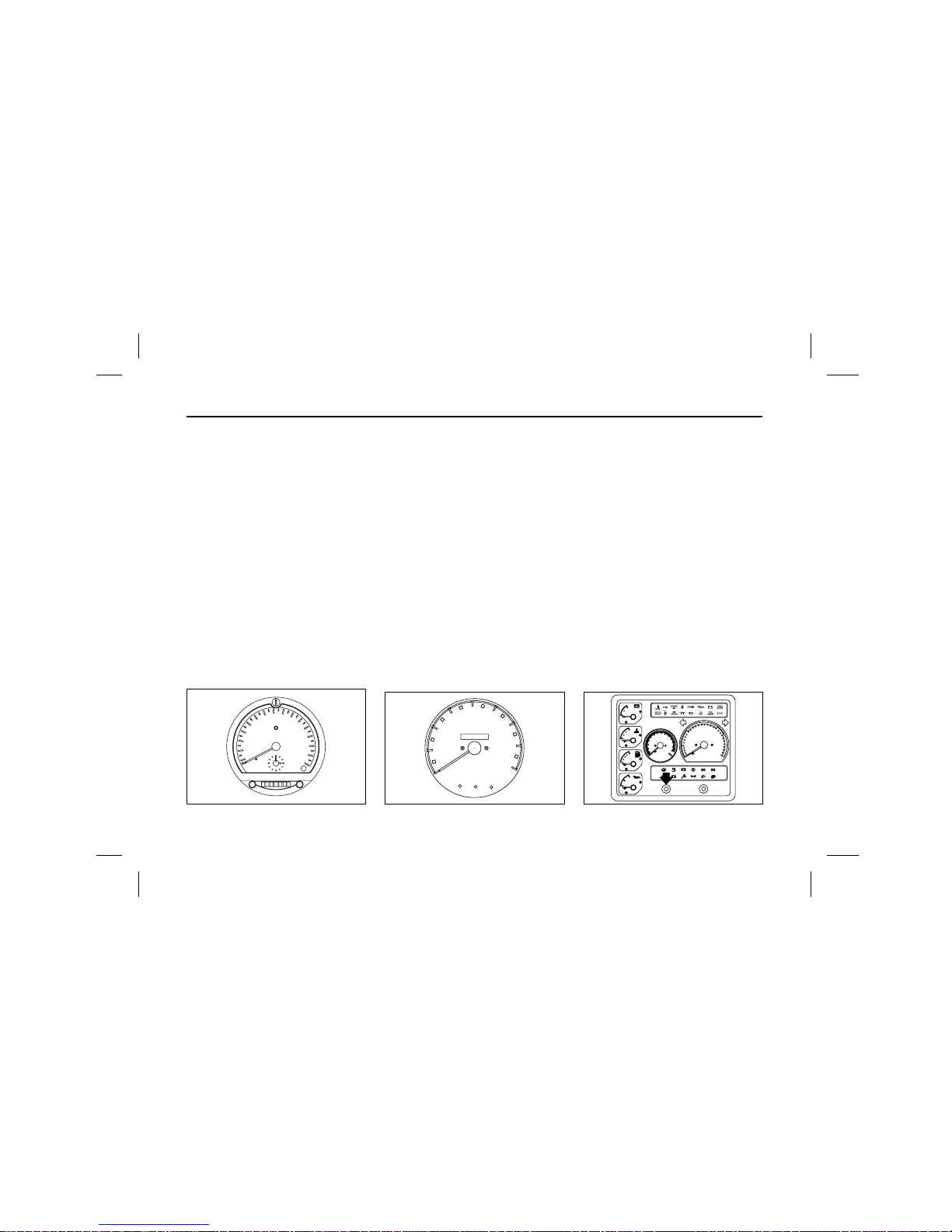

INSTRUMENTS AND INDICATOR LAMPS

1. Voltmeter

2. Engine coolant temperature gauge

3. Fuel gauge

4. Engine oil pressure gauge

5. Air pressure gauge

6. Engine tachometer

(If the engine RPM indicating function is included in tachograph, this

gauge is substituted to blank cover.)

7. Tachograph

(BH115E, BH120E)

(BM090/BS106 : OPT)

Speedometer (BM090, BS106)

8. Bulb check switch

9. Cover

10. Turn signal/hazard warning indicator

11. Upper pilot indicator lamps

12. Lower pilot indicator lamps

32

24

16

0

0

4

8

C

H

E

F

0

1

2

3

x1000rpm

0

3

6

9

12

15

kg/cm

A I R

2

7101112

3458129 6

7

0

20

40

60

80

100

120

140

160

Km/h

0000000

Tachograph

Speedometer

0

80

000000

km/h

60

40

20

160

140

120

100

Page 27

25

Voltmeter

The voltmeter indicates the battery

condition. Check the voltmeter reading with the engine running. The

gauge needle should stand between

the reading of 24 and 28.

Temperature gauge

The gauge indicates the engine

coolant temperature. If the gauge

needle stands below the red colored

zone, it means that engine coolant

temperature is normal.

If the needle stands in “H”(overheating), stop the vehicle and run the

engine at a moderately fast idle

speed or put the gear in lower position to reduce engine load. If the

vehicle is operated in abnormal condition, engine performance will be

reduced and fuel consumption will be

increased.

Fuel gauge

This gauge indicates fuel level of the

fuel tank all the time regardless of the

starter switch position.

The capital letter “E” represents

almost “empty”. Top–up the fuel tank

before the gauge indicates “E”.

32

24

16

0

C

H

E

F

Page 28

26

Oil pressure gauge

This gauge indicates oil pressure in

the engine lubricating system. The

indication of the gauge should be 1–3

kg/cm2when the engine is at idle ; it

should be 3–6.5

kg/cm2when the

engine is running at medium speed.

When the gauge needle does not

move upward at all or hydraulic pressure changes abruptly, check the oil

level in the engine crankcase. If the

oil level is found normal, have the

hydraulic system checked by your

nearest Daewoo dealer.

Do not run the engine with low oil

pressure indication.

Air pressure gauge

Air pressure gauge indicates air pressure in the air tanks. While driving,

the gauge needle must be within the

range of 5.3–8.2

kg/cm2.

Be habitual of watching the gauge,

while driving, to make sure the gauge

needle indicates the normal conditions.

Engine tachometer

The tachometer indicates the engine

speed in revolutions per minute(rpm)

and red colored zone represents

critical engine speed.

Excessively high engine rpm(red colored zone) may cause damage to the

engine.

To drive economically, keep the

engine within 1,000Ŕ2,000rpm.

Maximum allowable engine speed :

D1146 ENG : 2,500rpm.

D1146Ti/DE12/DE12T ENG.

: 2,200rpm.

DE08TiS ENG : 2,300rpm.

DE12Ti/DE12TiS ENG.:2,100rpm

1

4

8

0

3

6

9

12

15

kg/cm

A I R

A

O

H

A

I

R

F

U

L

L

A

I

R

2

0

1

2

3

x1000rpm

If the gauge needle stands in the

red zone, warning lamp comes on

and alarm buzzer sounds. Immediately stop the vehicle, check for

unusual conditions, run the engine

at a moderately fast idle speed to

increase air pressure, then drive off.

NOTICE

Page 29

27

Tachograph

(BH115E, BH120E)

(BM090/BS090/BS106 : OPT)

The tachograph is consisted of odometer and clock. The vehicle speed

and running distances are registered

in a single chart. The speedmeter

indicates the vehicle speed in kilometer per hour(

km/h

). The odometer indicates individual trip distances. The

odometer records the total distance in

km

. The unit of registered distance is

loom.

For further information refer to

“TACHOGRAPH” on page.

Speedometer (BM090, BS106)

The speedometer is consisted of

odometer and clock. The vehicle

speed and running distances are registered in a single chart. The speedmeter indicates the vehicle speed in

kilometer per hour(

km/h

). The odometer indicates individual trip distances.

The odometer records the total distance in

km

. The unit of registered

distance is loom.

For further information refer to

“SPEEDOMETER” on page.

Bulb check switch

When bulb check switch is pressed,

warning lamp on instrument panel

comes on.

And also the warning buzzer sounds.

Before driving, use this switch to

check that all warning lamps including speed indicator lamps and their

circuits are operating normally.

7

0

20

40

60

80

100

120

140

160

Km/h

0000000

0

80

000000

km/h

0-80 101-160

81-100

60

40

20

160

140

120

100

32

24

16

0

0

4

8

C

H

E

F

0

1

2

3

x1000rpm

0

3

6

9

12

15

kg/cm

A I R

2

SPEED

T/M

SAFETY

ABS ASR

E

Page 30

28

Turn signal indicator lamp

When the turn signal switch or hazard warning flasher switch is turned

on, the turn signal indicator lamp

flashes to indicate the operation of

the external turn signal lamps or hazard warning flashers.

Page 31

29

UPPER PILOT INDICATOR LAMPS

Type A

9 10 11 12 13 14 15 16

12 4

5 6783

1. Engine coolant temperature (high)

2. Air tank pressure (low)

3. Brake oil level (low) (OPT : AOH Brake)

4. Seat belt (Unfastened)

5. Parking lamp (on)

6. Engine oil pressure (low)

7. Battery charging

8. Engine door (open)

9. Emergency door (open) (OPTION)

10. Mirror defroster (on) (OPTION)

11. Air dryer operation (on) (OPTION)

12. Engine preheat (on)

13. High beam (on)

14. Transmission neutral position

15. Entrance door (open)

16. Passenger’s stop order (OPTION)

Page 32

30

Type B

9 10 11 12 13 14 15 16

12 4 5

6783

321

1. Engine coolant temperature (high)

2. Air tank pressure (low, Front)

3. Air tank pressure (low, MID.)

4. Air tank pressure (low, Rear EMER.)

5. Brake oil level (low) (OPT : AOH Brake)

6. Engine oil pressure (low)

7. Battery charging

8. Engine preheat (on)

9. Seat belt (Unfastened)

10. Engine door (open)

11. Air dryer operation (on) (OPTION)

12. Engine room fire warning (OPTION)

13. High beam (on)

14. Transmission neutral position

15. Entrance door (open)

16. Passenger’s stop order (OPTION)

Page 33

31

Type C

9 10 11 12 13 14 15 16

1234

5 6 78

321

1. Engine coolant temperature (high)

2. Air tank pressure (low, Front)

3. Air tank pressure (low, MID.)

4. Air tank pressure (low, Rear EMER)

5. Brake oil level (low) (OPT : AOH Brake)

6. Engine oil pressure (low)

7. Battery charging

8. Engine room fire warning (OPT)

9. Seat belt (Unfastened)

10. Engine door (open)

11. Air dryer operation (on) (OPTION)

12. Engine preheat (on)

13. High beam (on)

14. Transmission neutral position

15. Entrance door (open)

16. Passenger’s stop order (OPTION)

Page 34

32

Type D

9 10 11 12 13 14 15 16

12 4

5 678

1. Engine coolant temperature (high)

2. Air tank pressure (low)

3. Brake oil level (low) (OPT : AOH Brake)

4. Seat belt (Unfastened)

5. Parking lamp (on)

6. Engine oil pressure (low)

7. Battery charging

8. Engine door (open)

9. Emergency door warning (open) (OPTION)

10. Mirror defroster (on) (OPTION)

11. Air dryer operation (on) (OPTION)

12. Engine preheat (on)

13. High beam (on)

14. Transmission neutral position

15. Entrance door (open)

16. Passenger’s stop order (OPTION)

Page 35

33

Type E

9 10 11 12 13 14 15 16

12 4

6783 5

3

2

1

1. Engine coolant temperature (high)

2. Air tank pressure (low, Front)

3. Air tank pressure (low, MID.)

4. Air tank pressure (low, Rear EMER)

5. Brake oil level (low) (OPT : AOH Brake)

6. Engine oil pressure (low)

7. Battery charging

8. Engine room fire warning (OPT)

9. Seat belt (Unfastened)

10. Engine door (open)

11. Air dryer operation (on) (OPTION)

12. Engine preheat (on)

13. High beam (on)

14. Transmission neutral position

15. Retarder warning (OPTION)

16. Passenger’s stop order (OPTION)

Page 36

34

Engine coolant temperature (high)

When the temperatue of engine coolant

becomes near 100°C (210°F) the warning

lamp turns on.

Air tank pressure (low)

(Type A) (Type B, C, E) (Type D)

The indicator lamp comes on and the warning buzzer is

operated simultaneously, when air pressure within the air

tank is lowered to 5.3kg/cm

2

.

If the air pressure indicator lamp comes on while driving,

stop the vehicle and check to locate the cause of trouble

and avioc driving with the indicator lamp turned on.

Repeated application of service brakes could cause temporary lowering of air pressure. In such an instance, keep

the engine running as fast idle until the indicator lamp

goes out.

Seat belt (Unfastened)

The seat belt warning lamp comes on when

the ignition switch is placed in the “ON”

position unless the driver's seat belt is

securely fastened.

Parking lamp (on)

(Type A)

The parking brake indicator lamp comes

on when the parking brake lever is pulled

with the starter switch “ON”. The parking

brake indicator lamp does not indicate the

action of the parking brake. Make sure to

pull the parking brake lever fully when parking the vehicle.

Before moving the vehicle, be sure to check that the parking brake indicator lamp is off.

PARKING

AIR

321

(Type D)

Page 37

Engine oil pressure (low)

The lamp comes on when the battery main

switch is operated and goes out as the

engine is started and pressure of oil in the

engine is increased.

If the lamp comes on while driving, stop the engine immediately and check the level of oil in the engine crank-case.

If the oil level is normal, restrictions in the oil filter or a

trouble in the lubricating system may be indicated and the

system should be checked at your nearest service station.

Do not run the engine with the lamp illuminated.

Battery charging

The indicator lamp comes on when the battery main switch is operated and goes out

as the engine is started and alternator circuit is brought into normal function.

The indicator lamp comes on while the engine is running,

it indicates that the alternator circuit is malfunctioning, then

immediately stop the vehicle and have the alternator ciruit

checked by your nearest service shop.

Engine door (open)

(Type A, B, C, E) (Type D)

The indicator lamp comes on when the engine room door

is opened. If the lamp turns on even after closing the door,

check the door lock and lock the door firmly

Emergency door (open)

(Type A) (Type D)

The indicator lamp comes on when the emergency door

is opened. If the lamp comes on even after closing the

door, check the door lock and lock the door firmly..

35

ENG.

DOOR

EMER.

DOOR

Page 38

Mirror defroster (on) (OPTION)

Pressing the side mirror defroster switch, the

indicator lamp “ON” and the defrosting coil

in the mirror starts actuating.

Air dryer operation (on) (OPTION)

(Type A,B,C,E) (Type D)

The indicator lamp comes on when the air dryer is operating. (Air dryer heating system on)

Engine preheat (on)

This lamp is designed to indicate preheating

of the engine. It comes on when starter

switch is positioned “ON”, while it goes out

when the preheating is completed.

High beam (on)

The high beam indicator lamp comes on

when head lamps with high beam are in

use.

Transmission neutral position

The indicator lamp comes on when the gear

shift lever locates in neutral position.

Entrance door (open)

(Type A,B,C,E) (Type D)

The lamp comes on while the entrance door is opened.

Passenger's stop order (OPTION)

(Type A,B,C,E) (Type D)

When the passenger push the button between windows,

the buzzer sounds and this lamp comes on.

36

AIR

DRYER

STOP

ENT.

DOOR

Page 39

Engine room fire warning (OPTION)

The indicator lamp comes on when the

engien room is fired.

Retarder system warning (OPTION)

At the case that additional retarding system

is applied, while the retarder is operating,

the indicator lamp comes on.

37

ENG.

ROOM

Page 40

38

LOWER PILOT INDICATOR LAMPS

Type A

9 10 11 12 13 14 15

1234

5 6 7 8

E

ABS

ASR

CHECK

1. Safety equipment operation

2. Retarder system operation (OPTION)

3. Retarder system warning (OPTION)

4. Exhaust brake operation

5. Speed 3 indication (OPTION)

6. Electronically controlled air

Suspension operation (OPTION)

7. Air condition warning (OPTION)

8. MIL

9. Brake pad wear warning

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Speed limiter operation (OPTION)

14. Speed 1 indication (OPTION)

15. Speed 2 indication (OPTION)

Page 41

39

Type B

10 11 12 13 14 15

1234

5 6 7 8

RTD RTD

E

ABS

ASR

1. Safety equipment operation

2. Retarder system operation (OPTION)

3. Retarder system warning (OPTION)

4. Exhaust brake operation

5. Speed 3 indication (OPTION)

6. Electronically controlled air

Suspension operation (OPTION)

7. Transmission temperature

8. Do not shift

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Speed limiter operation (OPTION)

14. Speed 1 indication (OPTION)

15. Speed 2 indication (OPTION)

Page 42

40

Type C

9 10 11 12 13 14 15

12345678

ABS

ASR

E

1. Safety equipment operation

2. Defroster operation

3. Fuel empty warning

4. Exhaust brake operation

5. Battery main S/W operation

6. Retarder operation (OPTION)

7. T/M temperature warning

8. Air condition warning (OPTION)

9. Over speed warning (OPTION)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Light 1 step operation

14. Head lamp low beam (on)

15. Front fog lamp operation

Page 43

41

Type D

10 11 12 13 14 15

12 34

5 678

E

ABS

ASR

FRONT

DOOR

MID.

DOOR

REAR

DOOR

EMER.

V/ V-F

ENG.

ROOM

EMER.

V/ V-M

EMER.

V/ V-R

1. Safety equipment operation

2. Exhaust brake operation

3. Front door opened

4. Middle door opened (OPTION)

5. Rear door opened (OPTION)

6. Front emergency valve operation (OPT)

7. Middle emergency valve operation (OPT)

8. Rear emergency valve operation (OPT)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Engine room fire warning (OPTION)

14. Front fog lamp operation

15. Rear fog lamp operation (OPTION)

Page 44

42

Type E

109 11 12 13 14 15

12 34

5 678

E

P

ABS

ASR

FRONT

DOOR

MID.

DOOR

REAR

DOOR

EMER.

V/ V-F

EMER.

V/ V-M

EMER.

V/ V-R

CHECK

1. Safety equipment operation

2. Exhaust brake operation

3. Front door opened

4. Middle door opened (OPTION)

5. Rear door opened (OPTION)

6. Front emergency valve operation (OPT)

7. Middle emergency valve operation (OPT)

8. Rear emergency valve operation (OPT)

9. MIL

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Parking lamp (ON)

14. Front fog lamp operation

15. Rear fog lamp operation (OPTION)

Page 45

43

Type F

10 11 12 13 14 15

12 34

5 678

E

P

ABS

ASR

FRONT

DOOR

MID.

DOOR

REAR

DOOR

EMER.

V/ V-F

EMER.

V/ V-M

EMER.

V/ V-R

1. Safety equipment operation

2. Exhaust brake operation

3. Front door opened

4. Middle door opened (OPTION)

5. Rear door opened (OPTION)

6. Front emergency valve operation (OPT)

7. Middle emergency valve operation (OPT)

8. Rear emergency valve operation (OPT)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Parking lamp (ON)

14. Front fog lamp operation

15. Rear fog lamp operation (OPTION)

Page 46

44

Type G

109 11 12 13 14 15

12 34

5 678

E

P

ABS

ASR

1. Safety equipment operation

2. Exhaust brake operation

3. Speed 1 indication (OPTION)

4. Speed 3 indication (OPTION)

5. Speed 2 indication (OPTION)

6. Parking lamp (ON)

7. Mirror heater (OPTION)

8. Air condition warning (OPTION)

9. Emergency door (OPEN) (OPTION)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Speed limiter operation (OPTION)

14. Front fog lamp operation

15. Rear fog lamp operation (OPTION)

Page 47

45

Type H

7 8 9 10 11 12

12 34

56

E

ABS

ASR

1. Safety equipment operation

2. Retarder system operation (OPTION)

3. Retarder system warning (OPTION)

4. Exhaust brake operation

5. Speed 3 indication (OPTION)

6. T/M temperature warning

7. ABS system warning (OPTION)

8. ASR system warning (OPTION)

9. Auto greaser operation (OPTION)

10. MIL

11. Speed 1 indication (OPTION)

12. Speed 2 indication (OPTION)

Page 48

46

Type I

1091112131415

1234

5 678

E

FRONT

DOOR

MID.

DOOR

REAR

DOOR

EMER.

V/ V-F

EMER.

V/ V-M

EMER.

V/ V-R

ABS

ASR

P

1. Safety equipment operation

2. Exhaust brake operation

3. Front door opened

4. Middle door opened (OPTION)

5. Rear door opened (OPTION)

6. Front emergency valve operation (OPT)

7. Middle emergency valve operation (OPT)

8. Rear emergency valve operation (OPT)

9. Auto greaser operation (OPTION)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Retarder system operation (OPTION)

13. Parking lamp (ON)

14. Front fog lamp operation

15. Rear fog lamp operation (OPTION)

Page 49

47

Type J

9 10 11 12 13 14 15

12345678

E

ABS

ASR

1. Safety equipment operation

2. Defroster operation

3. Fuel empty warning

4. Exhaust brake operation

5. Battery main S/W operation

6. Retarder operation (OPTION)

7. T/M temperature warning

8. Do not shift

9. Over speed warning (OPTION)

10. ABS system warning (OPTION)

11. ASR system warning (OPTION)

12. Auto greaser operation (OPTION)

13. Light 1 step operation

14. Head lamp low beam (on)

15. Front fog lamp (on)

Page 50

Safety equipment operation

(Type A-G, I, J) (Type H)

When the passenger stands at entrance step, the rear

door is not closed, this lamp comes on.

Retarder system operation (OPTION)

(Type A, C, H-J) (Type B)

For automatic transmission, while the retarder is operating,

the indicator lamp comes on.

Retarder system warning (OPTION)

(Type A, H) (Type B)

At the case that additional retarding system is applied,

while the retarder is operating, the indicator lamp comes

on.

Exhaust brake operation

The indicator lamp comes on while the

exhaust brake is operating.

Electronically controlled air suspension operation (OPTION)

The height of the body is controlled automatically in accordance with the weight and

speed of the vehicle, the lamps comes on

when the system is operating.

48

SAFETY

E

ECS

RTD

RTD

Page 51

49

Speed 1 indication (OPTION)

(Type A, B, G) (Type H)

At the vehicle speed in 0~5km/H the lamp comes on, also

the left Yellow-Green marker lamp on the roof at the front

of the vehicle, lights on.

Speed 3 indication (OPTION)

(Type A, B, G) (Type H)

At the vehicle speed in 0~5km/H the lamp comes on, also

the left Yellow-Green marker lamp on the roof at the front

of the vehicle, lights on.

Speed 2 indication (OPTION)

(Type A, B, G) (Type H)

At the vehicle speed in 80km/H the lamp comes on, also

the middle red marker lamp on the roof at the front of the

vehicle, lights on.

Brake pad wear warning

The indicator lamp comes on when the

brake limning is too much worn out.

Over speed warning (OPTION)

At the vehicle speed in 80km/H the lamp

comes on, also the middle red marker lamp

on the roof at the front of the vehicle, lights

on.

SPEED 1

SPEED 2

SPEED 3

SPEED

Page 52

ABS system warning (OPTION)

As the battery relay and the starter switches are turned on, the indicator lamp comes

on and goes put when the vehicle speed

reach to 5~10km/H. If the lamp keeps lighting while driving, the ABS/ARS system is out

of order and should be checked.

ASR system warning (OPTION)

As the battery relay and the starter switches are turned on, the indicator lamp comes

on and goes out in a short time. If the lamp

keeps lighting while driving, the ASR system

is out of order and should be checked.

Auto greaser operation (OPTION)

The indicator lamp comes on while the auto

greasing system is operating or the main

pressure of the system drops below

25kg/mm

2

.

Speed limiter operation (OPTION)

The lamp comes on while the speed limiter

system is operating.

Air conditioner warning (OPTION)

The lamp comes on when the high/low voltage is flowing or the compressor clutch is

disconnected, etc.

Head lamp low beam (ON)

The high beam indicator lamp comes on

when head lamps with high beam are in

use.

Engine malfunction lamp

Check the state of engine operating when

starter key on.

This lamp flashes at engine cranking in

normal of engine operating.

Otherwise, on abnormal of Engine operating, lamp come

on continuously and come on during of engine running.

50

ASR

CHECK

SPEED

LIMITER

ABS

When the ABS/ASR system is out of order, the brake

system works as if ABS system is not applied.

NOTICE

Page 53

51

Transmission temperature

(Type B) (Type C, J) (Type H)

The lamp comes on when the oil temperature of automatic

transmission is overheated beyond the specified value.

Shift

(Type B) (Type J)

The lamp comes on when the engine RPM rises beyond

shifting point.

Defroster operation

For automatic transmission, while the

retarder is operating, the indicator lamp

comes on.

When the defroster in operating for refuse frost, the indicator lamp comes on.

Fuel empty warning

When fuel indiator needle located around

Empty state, (Red line) indicator lamp come

on.

Battery main S/W operating

The indicator lamp comes on when the bat-

tery relay switch is operated and goes out

as the engine is started and alternator cir-

cuit is btought into normal function.

The indicator lamp comes on while the engine is running,

it indicates that the alternator circuit is malfuncitioning, then

immediately stop the vehicle and have the alternator circuit checked by your nearest service shop.

Light 1 step operating

At the vehicle speed in 0~5km/H the lamp

comes on, also the Yellow-Green marker

lamp on the roof at the front of the vehicle,

lights on.

At the tail lamps come on, indicator lamp come on.

T/M

TEMP.

SHIFT T/M

Page 54

52

Front fog lamp operation

The lamp comes on when the front fog lamp

switch is turned “ON”.

Rear fog lamp operation (OPTION)

The lamp comes on when the tail lamp is

“ON” and it light off while tail lamp come

off.

Against rear fog lamp keep up “OFF” while tail lamp is

comes on.

Parking lamp (On)

The parking brake indicator lamp comes on

when the parking brake lever is pulled with

the starter switch “ON”.

The parking brake indicator lamp does not indicate the

action of the parking brake. Make sure to pull the parking brake lever fully when parking the vehicle.

Before moving the vehicle, be sure to check that the parking brake indicator lamp is off.

Front door operation

When the front door is opened, this indica-

tor lamp comes on.

Middle door operation (OPTION)

The indicator lamp comes on when the mid-

dle door is opened.

Rear door operation (OPTION)

The indicator lamp comes on when rear

door is opened.

Front emergency valve operation (OPTION)

The indicator lamp comes on while the mid-

dle emergency valve operation.

FRONT

DOOR

MID.

DOOR

REAR

DOOR

EMER

V/V-F

P

Page 55

53

Middle emergency valve operation (OPTION)

The indicator lamp comes on while the

Mid. emergency vlave operation.

Rear emergency valve operation (OPTION)

The indicator lamp comes on while the

rear emergency valve operation.

Engine room fire warning (OPTION)

The indicator lamp comes on when the

engien room is fired.

Mirror defroster (ON) (OPTION)

Pressing the side mirror defroster switch, the

indicator lamp “ON” and the defrosting coil

in the mirror starts actuating.

Emergency door (open) (OPTION)

The indicator lamp comes on when the

emergency door is opened. If the lamp

coems on even after closing the door, check

the door lock and lock the door firmly.

EMER

V/V-M

EMER.

DOOR

EMER

V/V-R

ENG.

ROOM

Page 56

54

SWITCHES

Ɓ The quantities or locations of switches could be different from the figure, because the switches could be added or

omitted, and locations could be changed by the requirement of customers.

Page 57

55

Room lamp switch (Floor 1)

Push the switch to light on the first

room lamp (incandescent) from the

entrance door (Front).

Room lamp switch (Floor 2)

(Apply for vehicles with lamp

rack)

Push the switch, light come on the all

room lamp (incandescent) but except

first room lamp at the entrance door

(Front).

Mood lamp switch 1 (OPTION)

(Apply for vehicles with lamp

rack)

Pressing the switch to light on the

mood lamp come on in order odd.

F

F F

Page 58

56

Mood lamp switch 2 (OPTION)

(Apply for vehicles with lamp

rack)

Pressing the switch to light on the

mood lamp in order even.

Room lamp switch (Bulb)

Push the switch to light on the fluorescent room lamps at the passenger’s compartment.

Driver lamp switch

Pressing the switch, the driver’s compartment lamp comes on.

F

B

Page 59

57

Luggage lamp switch (OPTION)

Pressing the switch, the luggage compartment lamps come on. The switch

operates when the light switch is on.

Reading lamp switch (OPTION)

Pressing the switch, reading lamps

below the air–conditioner grill come

on.

Fog lamp switch (Front)

Pressing the switch, the fog lamps

come on to improve your Foreward/

backward vision in fog or snow.

Page 60

58

Fog lamp switch(Rear) (OPTION)

Pressing the switch, the fog lamps

come on to improve your Backward

vision in fog or snow.

Battery main switch

Pressing the switch to light on the

battery lamp come on.

Parking lamp switch (OPTION)

Pressing the switch to light on the

parking lamp lamp come on.

P

Page 61

59

Front ent. door switch (OPTION)

Pressing the switch, front ent. door

lamps upper the front door come on.

Mid. ent. door switch (OPTION)

Pushing the switch, Mid. ent. door

lamps come on.

When Mid door opened.

Rear ent. door switch (OPTION)

Pressubg the switch, rear ent. doorr

lamps comes on when rear ent. door

opened.

Page 62

60

TV/VCR power switch (OPTION)

Pressing the switch, electric power to

TV/VCR is supplied.

Electric fan switch (OPTION)

Pressing the switch, electric fan

power supplied for driver's and passengeeer's fan.

Step lamp switch (OPTION)

Push the switch to light on the search

lamp from the front/middle/rear door.

Page 63

61

Destination board switch (OPT)

Push the switch to light on the destination boards front and rear.

Door rack lamp switch (OPTION)

Pressing the switch, door rack lamps

come on.3

Heater mirror switch (OPTION)

Pressing the switch, provide heater in

mirror.

Page 64

62

ҮPower on by pressing the switch(ڹ),

the indicator lamp(ں) light comes on

Automatically(power off by pressing

the switch(ڹ) again).

ҮTurn to right the contrast switch(ڻ),

the scene state is kept distinctly,

the turning to the bright control

switch(ڼ ) left/right, the bright of

scene is controlled darkly and

brightly.

ҮSelet(ڽ) the camera C1/C2 in case

of two camera installed. C1 is inner

watching camera by pressing the

upper button and other is outer

watching.

ҮSelect the Auto/Manual switch(ھ).

–Auto : Rear situation is displayed

the monitor with operation

on camera in state of shifted reward gear of vehicle.

–Manual : Camera operated by

power on.

ҮPress the light of scene controller

button(ڿ) the scene is drak in night,

othewise in daytime, it’s brighted.

òCAMERAó

1. LENS :It’s possible inputing the a

picture and veiwing 130°

degrees of an angle.

2. COVER : Profected the camera on

water proof stuff.

3. DIN PLUG : Connect the monitor

and camera.

THE CAR VISION SYSTEM FOR VEHICLE (OPTION)

1

234

5

6 7

2

1

3

Page 65

63

HEATING AND DEFROSTING

Heating and defrosting of

driver’s compartment

Move the upper control lever from the

left end of right side, the blower fan

starts to operate and the incoming air

flow increases gradually.

When the middle control lever to the

right side end, in the blower is cycled

in inner.

Otherwise, the lever to the left side end,

the blower is inhaled from outer for circulation.

Heating and defrosting of

driver’s compartment

When the lower control lever is

placed at the left and, the air comes

by two directions, one is to the driver’s foot side and another is to the

windshield glass side.

By moving the control lever to the right

side, the air coming into the foot side

decreases and to the wind shield glass

side increases gradually.

When the lever reaches to the right

end, the air comes in by the windshield

glass side only.

OFF 3OFF 12

OFF 1 2

3

Page 66

64

Heating of passenger's compartment (OPTION)

Power switch

Power on by turning the end of left

side (Light Red color part) to side of

center (Red color) or Right (Dark

color).

HEATER

Controller operator switch

Before press the units controller button, must be operated power switch

(ڹ ), and push the button for unit

selector (ں).

Select the unit No. by pressing the

buttons are ordinary order from unit

No.1 to No.5.

After, the selection fan by turning the

Rotary selector (ڹ) to right side (Dark

Red).

It’s increase highly.

21

HEATER

1

2

321

HEATER

1

2

321 4

HEATER

1

2

(Heater–2EA) (Heater–3EA) (Heater–4EA)

Page 67

65

AIR–CONDITIONING

COOLER (ROOF–ON TYPE) (OPTION)

Temperature controller

(Type A : Rotary type control

panel)

Turning the end of left side(Dark

blue), the temperature of indoor is

decrease lowerly otherwise, turning

the right side(Light blue) it’s increase

highly.

Power switch

The cooler power switch is operated

by pressing the button (2), then cooler blower fan is operated as each

step of fan speed switch (4, 5, 6).

While the cooling operator switch is

not pressed, room air only cirrculates.

Cooling operator switch (3)

Before press the button, must be

operated power switch(1).

Press the switch (3) and cooler starts

operation.

Blower fan operator switch

(4, 5, 6)

Swithc (4) : 60% of max. capacity.

Swithc (5) : 80% of max. capacity.

Swithc (6) : 100% of max. capacity.

Warning indicator (7)

When the refrigerant is flowing the

high/low pressure or the disconnected

of compressor clutch, etc., then the

indicator lamp come on.

POWER

AIRCONDITIONER

1

23456

POWER

AIRCONDITIONER

1

23457

Type ы Type ь

Page 68

66

(Type B : Seesaw type control

panel)

Cooling

ҮFirst start engine and set the room

temperature with the control knob.

ҮPush the cooling/vent switch to

“cooling” side.

ҮPush “ON” the power switch, the all

systems like the compressor, condenser fan and evaporator blower

start operation for cooling.

(The “cooling” indicating lamp

comes on).

ҮWhen the room temperature drops

below the set temperature, the system does air blowing operattion

only, and the room temperature

rises beyond the set temperature,

the system returns to cooling operation automatically.

Ventilation

ҮPush the cooling/vent switch to

“VENT” side.

ҮPush “ON” the power switch, to

maintain adequate room temperature by blowing in the fresh and

cool outdoor air.

ҮAt this time the compressor and

condenser fan do not operate, but

the blowers in the evaporator operate.

Stop

ҮNormal stopping

First push “cooling/vent” switch to

“vent” side, then cooling stops and

the system operates only for ventilation, Push power switch “OFF”,

then all systems stop operation.

ҮEmergency self stopping.

- When refrigerant pressure rises

abnormally high (over 22kg/cm

2

),

the electric clutch of compressor is

disengaged, so the compressor

stops working.

(The “Trouble” indicating lamp

comes on).

In the case that any troubles are

checked in operation, the emergency self stop occurs, this means

the stop of compressor, the condenser and evaporator fan do not

stop and continue operating.

AIR-CONDITIONER

VENT COOLING

COOLINGON

OFF VENT

HIGH

LOW

TEMP

TROUBLE

15 30

Page 69

67

- When refrigerant pressure goes

down abnormally low(below

0.5kg/cm

2

), the electric clutch of

compressor is disengaged, so the

compressor stops working.

(The “trouble” indicating lamp

comes on).

High/low switch operation

By pushing the High/low switch, high

or low ventilation in ventilation operation and high or low cooling in cooling operation could be selected. This

switch enhances the performance of

temperature control.

As the time goes by(about 10

minutes), the refrigerant pressure

rises and the cooling can start

again without any special actions.

If emergency self stops by the

abnormal low pressure occur frequently, stop the vehicle operation

and have service for the ait–conditioner system.

NOTICE

Page 70

68

Refrigerant amount

No or few bubbles are seen on the

sight glass under engine idling, when

the refrigerant is sufficient. When the

refrigerant is not sufficient, not a few

bubbles are seen.

If the refrigerant is overcharged, it

shows high pressure than normal.

In this case, purse the refrigerant a little to the specified amount.

Season check

1. Before season–off

Do not separate the air conditioner

in season–off.

Keep the air conditioner under

installation during season–off.

Keeping refrigerant is helpful for

protection of rust and oil consumption for long service life.

2. Season–off

Operate once in a month and check

for cooling performance.(Operate

approx. 5 minutes)

Not being operated by thermostat

when inside–temperature is below

15°C.

Do operate again after the temperature rises over 15°C by heating.

3. Season–in

Closely check as the check lists.

Naturally the refrigerant escapes as

time passing.

Refill refrigerant to the sufficient

amount.

insufficiency sufficiency

Sufficient amount is approx. 12ť0.5kg

Page 71

69

Regular check & maintenance

Maintenance schedule

Maintenance items Method Standard

Periodic check Change

Day Week Month Season period

Standard

Refriger

ant

cycle

Control

device

Drive

cycle

Compressor

Compressor oil

Gas leak of

connection &

pipe

Refrigerant amount

Refrigerating hose

Condenser

Evaporator

Air fillter

Fusible link

Drier

Control panel

Pressure switch

Lamp

Clutch bearing

Condenser fan

Evaporator fan

V–belt

Pulley

Overhaul

Check and refill

Check with

leak–tester

Check through sight glass

Check

Wash, clean or replace

Check or replace

Clean with compressed air or water

Check

Replace desiccant

Check

Check

Check

Replace

Check and replace

Check and replace

Replace

Replace

Normal operating air–con.

Sufficient

No gas–leaks

No damage

Keep tighten clamp

No bubbles

No leak

No damage

Keep clean fin & tube

Keep clean

Keep clean

Operation

Operation

Operation

Operation

Operation

No damage

Noiseless

Noiseless

No damage

Keep reasonable belt tension

No damage

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

ƃ

1,500HR

2Years

5Years

5Years

5Years

5Years

5Years

5Years

1,000HR

3Years

3Years

5Years

Every

season

2 Years

3Years (high side)

5Years (low side)

Page 72

70

Check points (operation)

Items Procedure & check point

Before operation

During operation

Stop

1. Check for V–belt tension and damage.

2. Check for fixing position of crank pulley, tension pully and clutch pully.

3. Check for clogged inlet of cooling–air and filter mat.

4. Keep compressor clean without dust or oil. If not, clean it with compressed air.

5. Check for fixing condition of bolts and nuts. If not, retighten them.

6. Check for gas–leak of connected position with leak–tester and retighten.

1. Check for operation when turning on the main switch after starting engine.

2. Check for operation of vent, cooling and unloading by using the temperature volume.

3. Check for capacity of cooling air from ducts.

4. Check for operation of high–low pressure switch.

Low pressure set : 0.5kg/cm

2

(warning light turn “on” and compressor clutch is disconnected)

High pressure set : 0.5kg/cm2(warning light and buzzer turn “on” and compressor clutch is disconnected)

1. Check for stopping of cooler when pushing button switch to turn off.

2. Check for stopping when turning off the main switch.

Page 73

7171

Check points (cycle)

Refrigerant cycle

Engine

Control devices

Items

Compressor

Condenser

Evaporator fan

Hi, low pressure switch

Drier

Receiver tank

Others

V–belt

Magnetic clutch

Control panel

Cooling unit

Condenser fan

Evaporator fan

Magnetic clutch

Check point

1. Check for operation.

2. Check for oil level and keep sufficient amount.

1. Clean fin and tube.

2. Check for gas leak and damages.

ҮCheck for operation.

ҮCheck for operation.

ҮReplace desiccant and filters.

ҮCheck for operation.

1. Check for clamping of connected parts.

2. Check for gas leak of connected parts.

3. Check for air filter mat, drain hose and keep clean.

ҮCheck for the tension of V–belt.

ҮCheck for compressor pulley.

1. Check for switch

2. Check for lamps.

3. Check wirings for loosened condition and clamping condition.

4. Check for attaching condition.

ҮCheck for the damages and looseness.

ҮCheck wiring frame for looseness.

ҮCheck terminal for fixing condition.

ҮCheck covered wire for damage.

Page 74

72

Trouble shooting

If show abnormal symptoms during operation, check the cause as followings.

This chapter describes the details of troubleshooting.

Defect

High pressure is

operating at higher

than standard

High pressure is

operating at lower

than standard

Low pressure is

operating at higher

than standard

Cause

1. Air is mixed into the cycle.

2. Overcharged refrigerant

3. Choked and clogged condenser with dust and dirt.

4. Defective condenser fan.

5. Too high ambient temperature when parking.

1. Liquid back symptom: Refrigerant gas, which

enter compressor, contain liqued refrigerant.

2. The expansion valve worn–out

3. Broken discharge valve of compressor.

4. Clogged inlet strainer of compressor.

1. Liqued refrigerant enters compressor.

2. The expansion valve worn–out.

3. Broken suction or discharge valve of compressor.

4. Too much refrigerant in the cycle.

5. Air is mixed into refrigerating cycle.

Measures

1. Discharge the refrigerant completely, charge

refrigerant again to specified amount after

check vacuum.

2. Discharge the refrigerant to specified

amount.(12ť0.5kg)

3. Clean with water or compressed air.

4. Repair or exchange.

5. Reduce the temperature in the shade.

1. Check the sensible bulb to the suction pipe.

2. Replace

3. Replace

4. Check and clean clogged part.

1. Check the sensible bulb sticked to the suction pipe.

2. Replace

3. Replace

4. Discharge refrigerant to the standard level.

5. Charge refrigerant again to specified amount,

after discharging the refrigerant

Page 75

73

Defect

Low pressure is

operating at lower

than standard

Cause

1. Clogged pipe, drier and expansion valve

2. Lack of refrigerant.

3. The evaporator is frosted or insufficient inlet

air for evaporator.

4. Air–inlet side clogged.

5. Air filter clogged with dust and dirt.

6. Evaporator clogged with dust and dirt.

7. The sensible bulb or pipe of expansion valve.

8. Frosted liquid refrigerant in refrigerating cycle.

9. The expansion valve worn–out.

Measures

1. Disconnect them and check.

2. Check leaking part, then charge refrigerant up

that the no–bubbles are seen on the sight

glass.

3. Stop operation temporarily.

4. Check for clogged part and clean up.

5. Keep the air filter clean with water or compressed.

6. Check for clogged part and clean.

7. Replace

8. Discharge the refrigerant completely, and

charge the refrigerant again to the specified

amount without liquid refrigerant.

9. Replace

Page 76

74

Air–conditioning cycle

10 10

9

8

7

6

5

4

12

13

2

1

11

33

I. Comp.

1. Compressor

2. Discharge shut–off valve

3. Condenser

4. Receiver tank

5. Service shut–off valve

6. Dryer

7. Sight glass

8. Expansion valve

9. Distributor

10. Evaporator

11. Suction shut–off valve

12. High pressure switch

13. Low pressure switch

Page 77

75

Installation of components

Condenser unit

1. Condenser(LEFT)

2. Condenser(RIGHT)

3. Receiver tank

4. Dryer

5. Motor(DC24V)

6. Fan

7. Motor mount

8. High pressurized gas line(hose)

9. High pressurized liqued pipe(left)

10. High pressurized liqued pipe(right)

11. High pressurized liqued line(hose)

12. Housing

13. Sealing

14. Locking

15. Air intake duct

14

15

2

13

12

1

9

6

5

7

4

3

11 10

8

Page 78

76

1. Evaporator(left)

2. Evaporator(right)

3. Expansion valve

4. Sight glass

5. Motor(DC24V)

6. Fan

7. Fan case

8. High pressurized liqued pipe

9. High pressurized gas pipe

10. Low pressurized gas pipe

11. Pressure equalizing pipe

12. Air filter

13. Drainage prevention filter

14. Operating panel

15. Temperature sensor

16. Wiring

17. Drain hose

18. Panel support

19. Pipe support

20. Housing

21. Sealing

22. Locking

23. Air intake

17

21

13

19

4

1

16

23

3

11

10

18

8

9

12

2

14

15

5

7

6

22

20

Evaporator unit

Page 79

77

Part name & Treatment for each device

1. Control panel

1. Operation & Pre-heater switch

2. Blower air control switch

3. Indoor TEMP. setting switch

4. Power operation lamp

5. Oil buzzer lamp

6. COMP. Buzzer lamp

7. Battery charging lamp

8. Cold water buzzer lamp

2. Function of each switch

1) Operation & Pre-heater switch

The organization of switch is dumbuler switch as

2 stage, heat ON is using for pre-heating to glow

plug, start ON is using for engine operation of AIR

-CON.

(Do not use it for more than 10 sec. At pre-heater

& for more than 3 sec. at operating)

2) Blower air control switch

The switch is used at air control of AIR-CON blower & engine stop as 5 stages.

1 OFF : at AIR-CON stop.

2 LOW : The air of AIR-CON blower is operated at

LOW.(60% of total air)

3 MID : The air of AIR-CON blower is operated at

MID.(80% of total air)

4 HIGH : The air of AIR-CON blower is operated

at HIGH.(100% of total air)

5 AUTO :Blower AIR-CON is controlled automati-

cally depending on INDOOR & SETTING

TEMP.(3 stage control of auto air)

OIL

COMP

15 30

HIGH

AUTO

MID

LOW

OFF

HEAT

(10sec)

START

(3sec)

ROOM TEMP(¡C)

POWER

BAT

WATER

1 2 3 75

4

6

8

COOLER (ROOF-ON TYPE W/POWER PACK) (OPTION)

Page 80

78

3) Indoor TEMP. settimg switch

It is designed that the INDOOR

TEMP can be kept regularly by

user’s setted temp(15~30°C) in

order to keep fresh condition into

the indoor cabine and indoor temp

can be automaticalley controlled at

auto driving.

Therefore, unnecessary action

would not be need and be contributed to safe driving.

4) Power operation lamp

The lamp can be on and signed

the control status at air con operation & blower air control switch

on.

5) Oil buzzer lamp

The buzzer lamp can be on if the

E/G <less than 0.3Kg/cm

2

G> and

simultaneously, E/G would be

stopped with occurance of buzzer.

6) COMP. Buzzer lamp

The lamp for pressure rejected

buzzer would be on to compressor

high <more than 24Kg/cm

2

G> & com-

pressor low<less than 0.5Kg/cm

2

G>

due to system failure at air con operation. At this time, E/G would be

automatically stopped with buzzer.

7) Battery charging lamp

The lamp would be on at the

charging failure of battery due to

over currency after E/G operation

& alternator operation.(When BLOWER S/W is on at E/G operation, lamp on is not failure)

8) Cold water lamp

The lamp would be on if temperature of cold water is high(100

±2°C) after E/G operation. At this

time, E/G would be automatically

stopped with buzzer.

3. Operation turn of AIR-CON