Daewoo B20S-2, B25S-2, B30S-2, BC20S-2, BC25S-2 Specifications Systems Operation Testing & Adjusting Disassembly & Assembly

...Page 1

Specifications

Systems Operation

Testing & Adjusting

Disassembly & Assembly

Lift Trucks Power Train

B20S-2, B25S-2, B30S-2

BC20S-2, BC25S-2, BC30S-2

SB2025E01

Aug. 1999

Page 2

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the ÒSafetyÓ section of the Service or Technical Manual. Additional safety

precautions are listed in the ÒSafetyÓ section of the owner/operation/maintenance publication.

Specific safety warnings for all these publications are provided in the description of operations where hazards

exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. Warnings in

this publication and on the product labels are identified by the following symbol.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read

and understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in

this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you

and others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete

and most current information before starting any job. DAEWOO dealers have the most current information available.

WARNING

1

Page 3

Page 4

Power Train Index

Index

Systems Operation

Drive Motor............................................................... 6

Final Drive ................................................................ 8

General Information.................................................. 5

Power Transfer Group.............................................. 7

Testing And Adjusting

Drive Motor..............................................................14

Armature Terminal Test ......................................19

Armature Tests ...................................................15

Brush Holder Test ..............................................19

Brush Life Estimate............................................20

Commutator Inspection......................................17

Field Coil And Terminal Tests.............................18

Motor Brushes....................................................14

Thermal Switch Tests.........................................20

Final Drive ...............................................................27

Wheel Bearing Adjustment.................................27

Power Transfer Group Adjustments ........................21

Pinion Bearing Adjustment.................................24

Pinion Depth Check ...........................................24

Pinion Installation...............................................22

Power Transfer Group........................................21

Power Transfer Group Bearing And Gear

Clearance (Backlash) Adjustments...............25

Troubleshooting........................................................ 9

Checks During Operation ................................... 9

Drive Motor .................................................... 9

Power Transfer Group And Final Drive ........13

Visual Checks ..................................................... 9

Specifications

Drive Axle Mounting Group .....................................33

Drive Motor..............................................................30

Drive Tire Installation...............................................33

Final Drive ...............................................................32

General Tightening Torque......................................28

Power Transfer Group.............................................31

Disassembly & Assembly

Brakes, Brake Adjuster And Wheel Cylinder...........36

Final Drives And Hubs.............................................45

Oil Cooled Disc Type Brake....................................48

Power Transfer Group.............................................39

3

Page 5

Page 6

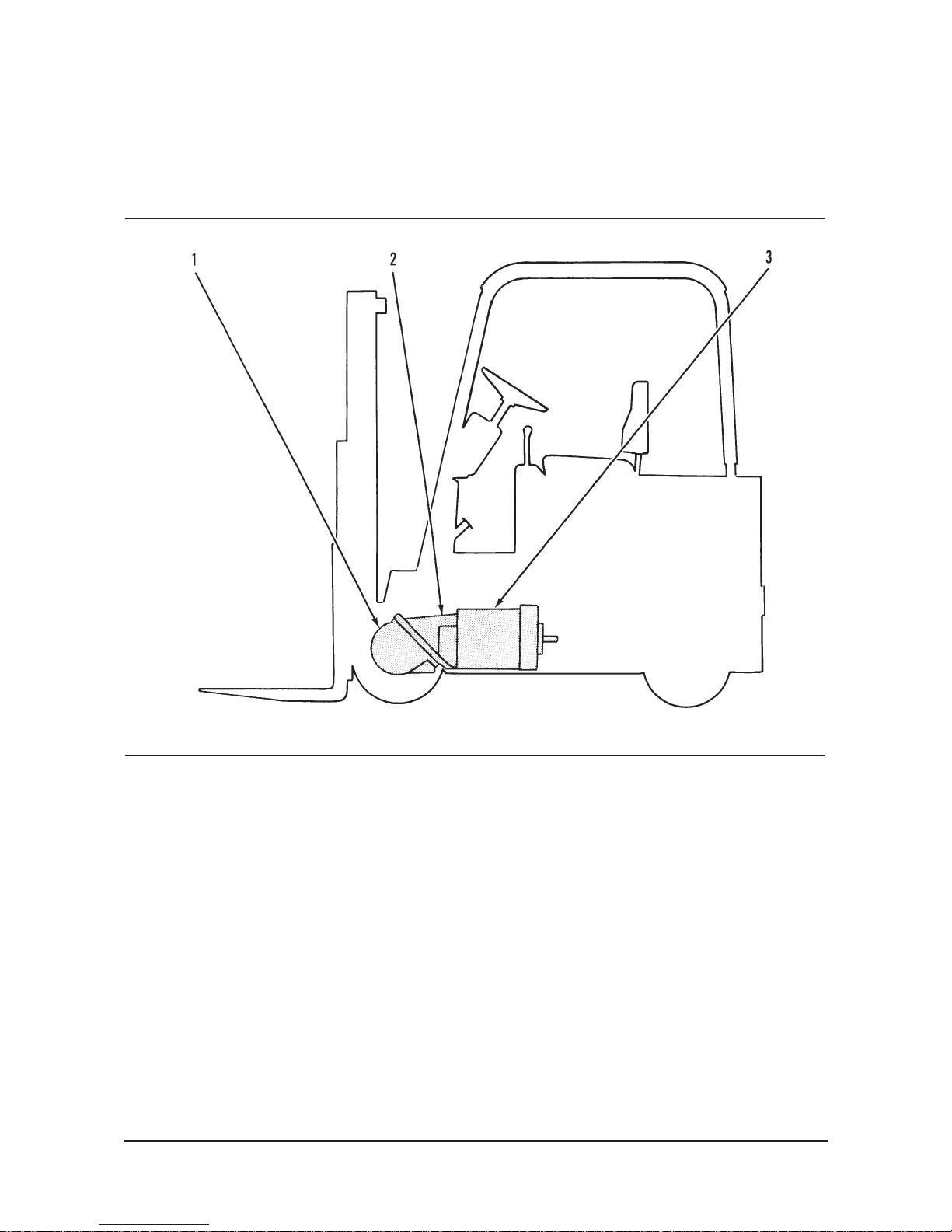

Power Train Systems Operation

Systems Operation

General Information

Power Flow

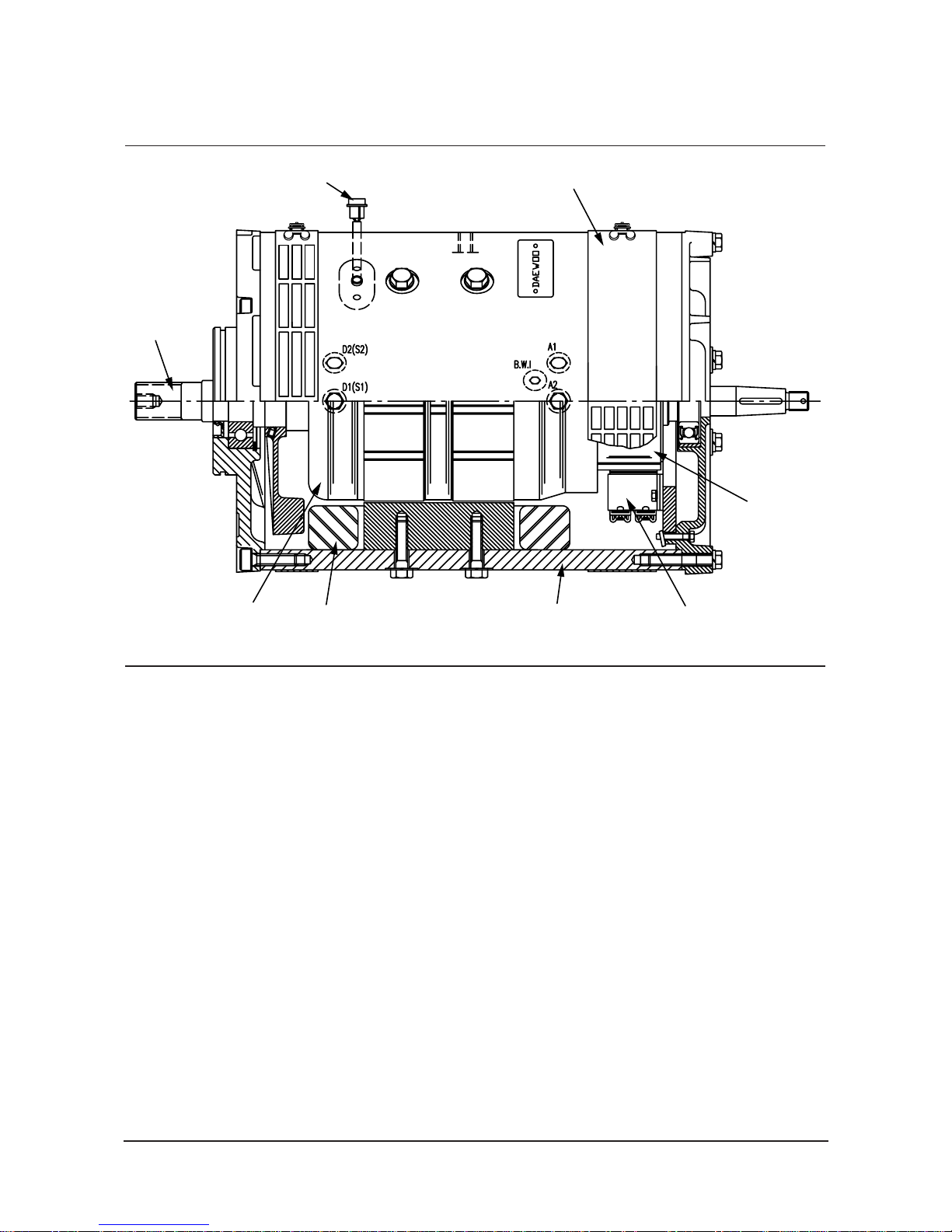

(1) Final drive (2) Power transfer group (3) Drive motor

5

The power train for the B, BC MODEL Lift Trucks

consists of three main components: drive motor (3),

power transfer group (2) and final drive (1).

Electric storage batteries are used as a power source

for drive motor (3). The drive motor turns power

transfer group (2). The power is sent through the

power transfer group to the axles. The axle turns final

drive (1), which is part of the drive wheels.

Page 7

Power Train Systems Operation6

Drive Motor

Drive Motor

(1) Shaft. (2) Cover. (3) Thermal switch (thermostat). (4) Commutator. (5) Armature assembly. (6) Field coils. (7) Frame.

(8) Brush holder.

1

32

4

8765

The drive system is operated by a direct current (DC)

motor. Electric storage batteries are the source of

power for the DC motor.

The drive motor is a series wound motor and uses a

high temperature insulation. A series wound motor is

a commutator motor. The field and armature circuits

are a series, which provides a single path for the current. Armature (5) is mounted with single row ball

bearings at each end. The ball bearings are permanently lubricated with a high temperature lubricant.

The electrical connections to the motor are made at

corrosion resistant terminals on motor frame (7). On

the outside of the motor frame is cover (2) that can

be removed for easy access to the brushes and the

commutator. Field coils (6) are fastened to the inside

of the motor frame.

The four motor brushes are held in four brush holders (8). A spring holds each of the brushes against

commutator (4) as the brushes wear.

The Optional Superior (S) function equipped lift

truckÕs drive motor is protected from overheating by a

thermal switch (thermostat) (3). The thermal switch

opens at 150

L 6¡C (302 L 11¡F). It closes at 130 L 7¡C

(266 L 13¡F). When the normally closed thermal

switch is open, the amount of current through the

motor is limited to allow the motor to cool. The motor

has a fan for cooling.

The drive motor is activated when the parking brake

is released, the key and seat switch are closed, a

direction is selected and the accelerator pedal is

depressed.

The drive motor powers the power transfer group

through shaft (1).

Page 8

Power Train Systems Operation7

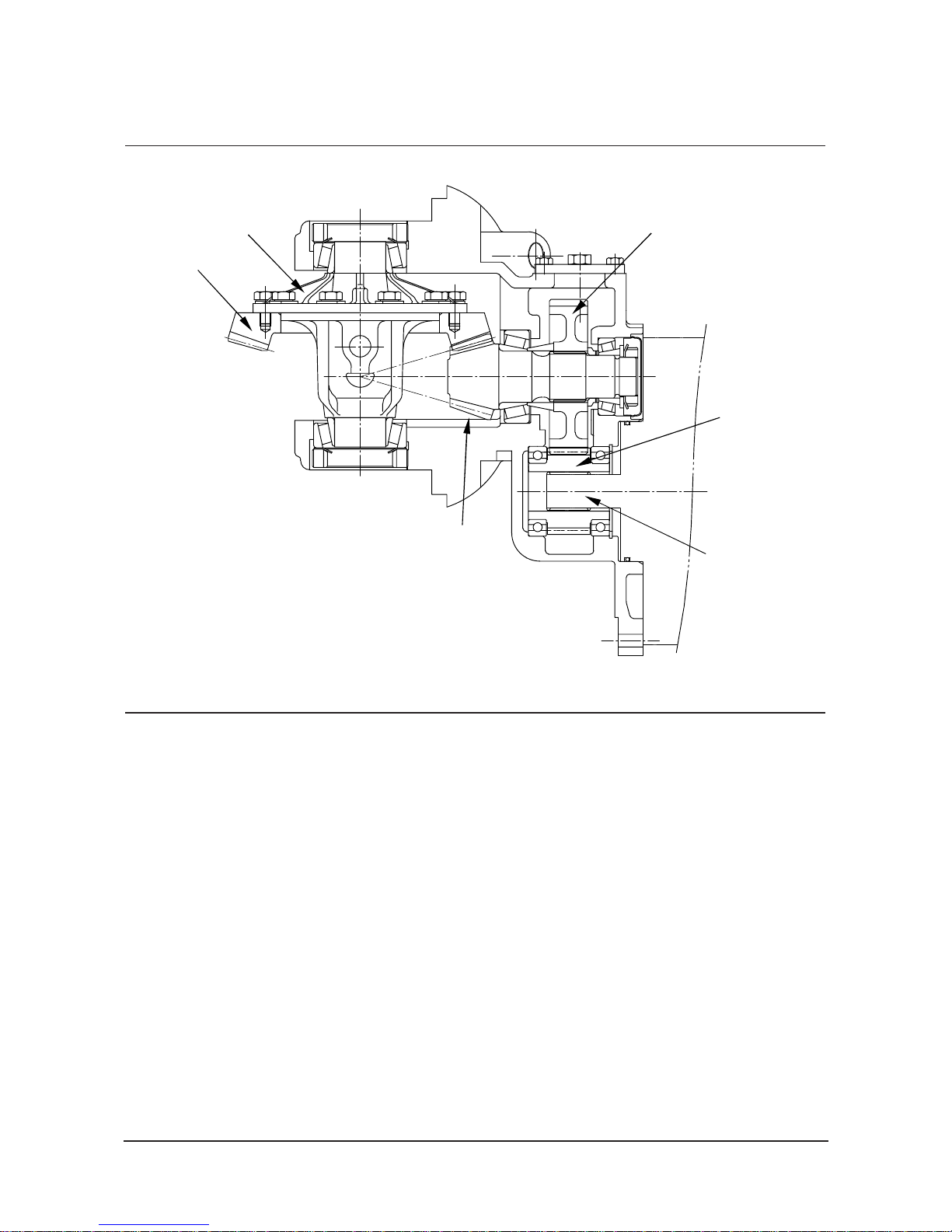

Power Transfer Group

Power Transfer Group

(1) Bevel gear (2) Differential case (3) Helical gear (4) Spiral hypoid pinion (5) Input Gear (6) Drive Motor Shaft

1

2

3

5

6

4

The power transfer group is mounted under the

frame in the front of the lift truck. ItÕs a double reduction unit with the final reduction through spiral hypoid

pinion (4) and bevel gear (1).

Power for the transfer group comes from the electric

drive motor through the input gear connected with

the Drive Motor Shaft (6) through the spline . The

input gear (5) turns helical gear (3) that is mounted

on the shaft of the hypoid pinion (4).

The hypoid pinion is engaged with bevel gear (1)

which is mounted to differential case (2).

Differential case (2) has two pinion gears that are

engaged with two side gears. The side gears turn the

axle shafts.

The power transfer group is used to send the power

from the electric drive motor to the wheels. When

one wheel turns slower than the other, the power

transfer group lets the inside wheel stop or turn slower in relation to the outside wheel.

When the truck is moving straight in a forward direction with the same traction under each wheel, there is

equal torque on each axle. This holds (stops) differential pinion gears which give the same effect as if

both wheels were on the same axle. During a turn,

the force (traction) that is on the drive wheels is different. These different forces are also felt on opposite

sides of the power transfer group and cause differential pinion gears to turn. The rotation of differential

pinion gears stops or slows the inside wheel and lets

the outside wheel go faster. This moves the machine

through a turn under full power.

The power transfer group gets lubrication from oil

thrown about inside the housing, by the rotating

gears.

Page 9

Power Train Systems Operation8

Final Drive

Final Drive

(1) Axle shaft (2) Hub (3) Drive wheel (4) spindle

The power transfer group turns axle shaft (1). The

gear teeth on the end of axle shaft (1) engage the

gear teeth of hub (2). The gear teeth of hub (2) are

on the inside diameter of the hub, which causes the

rotation of the hub to be the same as the axle shafts.

The reduction in size between the axle shaft and the

hub causes the hub to turn at a slower speed.

Spindle (4) is fastened to the truck frame and is used

as a support for hub (2).

Drive wheel (3) is fastened to hub (2) and turns with

the hub.

The final drive is a grease lubricated unit.

Page 10

Power Train Testing And Adjusting

Troubleshooting

Visual Checks

Make a visual inspection of the truck to check for

problems. Operate the truck in each direction.

Make a note of the noises that are not normal and

find their source. If the operation is not correct, make

reference to the Check List During Operation for

ÒProblemsÓ and ÒProbable CausesÓ.

Checks During Operation

Drive Motor

Before an analysis is made of any electric drive

motor problem, always make reference to the

Troubleshooting section of the MicroController

System Operation module.

The lift truck can move suddenly. Battery voltage

and high amperage are present. Injury to

personnel or damage to the lift truck is possible.

Safely lift both drive wheels off the floor. Put wood

blocks or jack stands of the correct capacity under

the frame so the drive wheels are free to turn.

During any test or operation check, keep away

from the drive wheels. The head capacitor (HEAD

CAP) will have to be discharged before any

contact with the control panel is made. Disconnect

the battery and discharge the HEAD CAP. Rings,

watches and other metallic objects should be

removed from hands and arms when

troubleshooting the MicroController control

system.

To prevent personal injury, never use air pressure

that is more than 205 kPa (30 psi), and wear

protective clothing and a face shield.

NOTICE

To prevent damage to electrical components, make

sure the air line is equipped with a water filter when

they are cleaned with air.

If an electrical failure or an overload of the motor

is present, personnel must not breathe the toxic

fumes which are a product of the burnt insulation.

All power must be disconnected from the motor

before any inspection is made to find the failure.

The area around the motor must be well ventilated

(air flow) and the motor is to be cooled before any

repair work is done. Water must not be used on

any electric equipment because of the danger of

electrical shock. If fire is present, disconnect the

electrical power and use a carbon dioxide

extinguisher to put the flame out.

Do not operate the drive motors without a load,

as too much speed may cause damage to the

motor and injury to personnel.

Problem 1: Drive Motor Will Not Operate.

Probable Cause:

1. Switch not closed (battery connector, key switch,

seat switch, direction switch or parking brake

switch):

Close the switch. If it still does not operate, test

for power to the control panel and power flow

through each switch with a voltmeter.

2. Bad connection. Fuse bad:

Check battery connections. Check connections

at battery connector. Check fuses, drive and

logics.

Replace fuse if bad.

Check the Drive motor and control panel for

possible reasons for a bad fuse. Some causes

are:

a. Operate during too heavy transistor load, too

high current limit (C/L).

b. Operate in stall conditions.

c. Possible short circuit in drive motor, see

Probable Causes 5, 6 and 7.

3. Low battery voltage:

Check battery terminal voltage. If too low,

charge the battery.

Check all the cells for one or more that have

defects.

Check the specific gravity of each cell. The

maximum density difference from the highest to

the lowest cell must not be more than. 020 SG

(specific gravity).

WARNING

WARNING

9

Page 11

Power Train Testing And Adjusting

4. Control panel operation not correct:

See the MicroController System Operation

module.

5. Brushes are worn:

Inspect the drive motor commutator for burnt

marks or scoring (scratches). Make corrections

or make a repair of the armature commutator

and replace the brushes as necessary.

See Armature Commutator Inspection and

Brush Inspection in Testing And Adjusting.

Make reference to Problem: Sparks At The

Commutator And/Or Rapid Brush Wear.

6. Check for opens in the field coils:

Test coils according to procedures in Testing

And Adjusting. If there are opens, make a

replacement of the field assembly.

7. Check for a short circuit in the armature windings:

Loose field winding pole pieces, make the

necessary corrections.

Field armature bar insulation.

Repair or rebuild the insulation or make a

replacement of the armature.

8. Static return to off circuit actuated:

If the static return to off is actuated, the control

will not start again until the accelerator is

released and the directional control lever is

returned to neutral.

Problem 2: Traction will not operate through a

normal work period, but hydraulic operation is

normal.

Probable Cause:

1. Brakes have a defect, cause a resistance (lack of

free movement). Heat increases, which causes the

motor to stall:

Check the brake adjustment according to the

procedures in Testing And Adjusting in the

Vehicle Systems module.

2. Too much heat in MicroController control panel

because:

a. Extra heavy traction loads.

Decrease the duty cycle load.

b. Faulty thermal switch.

See the MicroController System Operation

module.

c. Too high current limit (C/L) setting.

Lower the setting on the C/L adjustments.

These can cause transistors to become defective,

control panel failure or drive fuse to go bad.

Problem 3: Neither traction or hydraulic will last

through a complete normal work period.

Probable Cause:

1. Too small a battery equipped in the lift truck:

Use a larger battery for the complete work cycle

and normal work period.

2. Battery not being fully charged or equalized during

the battery charging operation:

Check the battery cells for an equalization

charge (a charge to make the specific gravity

the same in all cells). Check the battery charger

for defects.

3. Battery change interval is too long or changed

battery cooling time is too short. This decreases

the capacity and the ability of the battery:

Decrease the battery work duration before a

change. Increase the battery cooling time after

a charge before it is put to use.

4. Battery has one or more defective cells which

results in less than the rated capacity and ability of

the battery:

Replace the battery.

5. Traction system draws (make a consumption of)

too much battery power because of traction

system faults. Operation of the duty cycle

(complete working cycle) condition is not correct:

Check the brake adjustment according to the

procedures in Testing And Adjusting in the

Vehicle Systems module, Check the mechanical

components such as wheel bearings, axles,

etc., for corrections to eliminate the faults.

Change to a tire with less friction.

6. Hydraulic system draws too much battery power

because of lifting and tilting arrangements, or

hydraulic conditions are not correct for the duty

cycle:

Decrease hydraulic relief valve setting to the

capacity that only will be used.

Change to a smaller hydraulic pump.

Check the mast for restriction during operation.

7. Lift truck working more than the capacity of its

design with no available power after one work

shift:

Have available an extra (exchange) battery.

Decrease the speed and work load required to

complete the work shift.

10

Page 12

Power Train Testing And Adjusting

Problem 4: Sparks at the commutator and/or

rapid brush wear.

Probable Cause:

1. Worn brushes:

Make a replacement of the brushes. See New

Brush Installation And Brush Inspection in

Testing And Adjusting.

2. Overheating (too much heat) of the traction motor:

Check for an overload motor or a motor with

defects. See Armature Commutator Inspection

in Testing And Adjusting.

Decrease the current limit (C/L) adjustments if

set too high. See the MicroController System

Operation module.

Test the plugging rate, if set too short it will

cause arcing and wear at the brushes.

The duty cycle is too heavy, change the duty

cycle.

3. Defective drive motor:

See Armature Commutator Inspection in Testing

And Adjusting.

a. Commutator bars burnt in two or more positions at

180¡ apart because:

(1) Armature bars open.

Make a replacement of the armature.

(2) Motor was stalled against a heavy load while

power discharged and caused the two bars, in

contact with the brushes, to burn.

NOTICE

Too heavy a load can stall the motor, and result in a

failure to the drive motor.

(3) Short circuit in the armature.

See Armature Tests in Testing And Adjusting.

(4) Armature not in balance, out of round, off center

or with high commutator bars. This causes the

brushes to bounce (move up and down).

Make sure the diameter is the same all the way

around and is in center line with the shaft. See

Specifications.

b. Dirty motor that has a metallic or carbon dust. this

dust is a conductor which causes electrical shorts,

increase amp draw and decrease drive motor

output:

Remove any dirt with air pressure.

c. Brush movement causes arcing and brush wear:

Check the brush springs for cracks, and

overheat signs (blue).

Compare spring force with a new brush spring.

Check the brush holder for oversize (larger size

than for brush).

Replace the brush spring if necessary.

d. Loose brush leads or motor bus bar connections.

Loose cable connections at motor terminals.

Results are:

(1) High resistance and heating.

(2) Faster brush wear.

Check brushes for tight-connections.

Replace the brushes if leads are loose in

brush material. Check all cable and wire

connections for tightness.

e. Wrong grade of brushes installed that are not

adaptable to the motor:

Make sure all the brushes are of DAEWOO

standards. Do not use other brands of brushes.

f. Possibly heavy working condition that causes too

much motor heat and rapid brush wear:

Make a replacement of the brushes and make

sure the brushes are seated. See New Brush

Installation and Brush Inspection in Testing And

Adjusting.

Check the brush springs for the correct

installation and for the correct spring usage. Too

strong a spring rate will increase amperage

draw and brush wear rate.

Prevent operation in stall condition. Excessive

(too much) duty cycle which increases motor

temperatures and rapid brush wear.

4. Overload of the drive motor such as: towing loads,

constant ramp operation, chiseling (hydraulic

actions that are not practical) loads and dragging

(pull or push loads on the ground) loads:

Operator training for better working practices.

Add an auxiliary cooling to the drive motors.

5. Current limit (C/L) set too high that causes too

much current consumption through motors in the

transistor range:

Decrease the current limit (C/L) adjustment to

the correct setting, see the MicroController

System Operation module.

6. Drive motor, armature or field windings have a

defect that results in high current draw at low

torque output:

See Armature Tests and Field Coil and Terminal

Tests in Testing And Adjusting.

11

Page 13

Power Train Testing And Adjusting

7. Restriction caused by components:

Correct and make adjustments to wheel brakes

and parking brakes that drag.

Make changes to tires with less restriction.

Check and correct wheel bearing torques.

Problem 5: Low resistance to ground [battery

polarity either positive (+) or negative (-) or a

medium voltage is in direct contact with truck

frame (body) or drive motor body].

Probable Cause:

1. Dirty battery, electrolyte on top of cells and is in

contact with the frame. Current flows through

battery box, which places a voltage on the truck

frame:

Clean the battery with baking soda and water

solution.

2. Battery or control panel wire connections in

contact with truck frame:

Make a continuity test and move the wire from

contact.

Remove wires in sequence until the fault is

cleared.

The fault will be in the wire last disconnected.

3. Dirty motor:

Remove metallic or carbon dust with air

pressure.

4. Wet motor:

To dry the motor, heat it to 90¡C (194¡F).

Problem: 6. Commutator surface has groove or

extra wear.

Probable Cause:

1. Brushes are worn too low, brush wires caused

arcing on the commutator:

Replace the brushes. See Brush Inspection in

Testing And Adjusting and the method to make

the Brush Lift Estimate in Testing And Adjusting.

2. Dirty motor; and possibly salt water got inside:

Disassemble motor, remove the debris with air

pressure. If necessary, dry the motor with heat

to 90¡C (194¡F)

3. Grades of brushes mixed:

Make sure all the brushes are of DAEWOO

standards. Do not use other brands of brushes.

Problem 7: Lift truck moves faster in one

direction than the other direction with the same

amount of accelerator pedal movement in Bypass

mode (speed).

Probable Cause:

1. Motor brushes not located in the correct electrical

position (brush neutral settings):

If the holes in the brush holder are not

extended, make them longer so that brush

holder can have a little rotation. When the

holder is in the correct position, lift truck speed

will be the same in both directions.

2. One directional contactor worn more than the

other or loose connection on one contactor:

Check contactor for wear and tighten any loose

connections.

Problem 8: Lift truck will not get to top speed.

Probable Cause:

1. Battery not fully charged or battery has bad cells:

Charge the battery. Check for bad cells.

Replace battery if necessary.

2. A fault either in the drive motor, control panel or

drive train:

Check lift truck speed in both directions. If the

MicroController panel needs tuned up, make

adjustments as shown in the respective

MicroController System Operation module. If

the drive motor is at fault, make the tests of the

motor components in Testing And Adjusting.

Problem 9: Lift truck does not have enough

power to position itself under a load. Lift truck

does not have enough power on ramps or towing

trailers.

Probable Cause:

1. Current limit (C/L) set too low:

Set current limit (C/L) to specification in the

MicroController System Operation module.

12

Page 14

Power Train Testing And Adjusting

2. Current limit (C/L) circuit has a defect:

Make test to the MicroController control panel as

stated in the respective service module. Repair or

replace components as necessary.

3. Unpolished or improperly positioned forks:

Install tapered and polished forks. Position forks

correctly for load being lifted.

4. Lift truck equipped with tires that have poor

traction:

Install tires that have good traction per

recommendation from DAEWOO Inc.

5. Lift truck work load is too heavy or the duty cycle

too long:

Decrease the work load and/or duty cycle.

Problem 10: Lift truck has slow acceleration:

Probable Cause:

1. Drive control overheated and the thermal switch

opens:

NOTE: The lift truck will still go into the bypass

mode, but current limit will be cut back in the

transistor mode if the thermal switch opens.

Allow the MicroController control panel to become

cool so the thermal switch will close.

NOTE: The thermal switch will open circuit if the

temperature is 150 L 6¡C (302 L 11¡F) and reclose

(short circuit) at 130 L 7¡C (266 L 13¡F).

Power Transfer Group and Final Drive

Problem 1: Constant noise in drive axle housing.

Probable Cause:

1. Lubricant not to the specified level.

2. Wrong type of lubricant.

3. Wheel bearings out of adjustment or have a defect.

4. Bevel gear and pinion not in adjustment for correct

tooth contact.

5. Teeth of bevel gear and pinion have damage or

wear.

6. Too much or too little pinion to bevel gear

clearance (backlash).

7. Loose or worn drive motor bearings.

8. Loose or worn side bearings.

9. Noise in the drive wheel reduction components.

Problem 2: Noise at different intervals.

Probable Cause:

1. Bevel gear does not run evenly.

a. Nut on drive gear not tightened correctly.

b. Drive gears have a defect (warped).

2. Loose or broken bearings.

3. Failure of or not enough lubricant on the drive

wheel reduction components.

Problem 3: One drive wheel does not turn (motor

operates).

Probable Cause:

1. Broken axle shaft.

a. Loose wheel bearings.

b. Loose flange studs or nuts.

c. Bent housing.

2. Pinion gear teeth have damage.

3. Bevel gear, pinion or gears broken.

Problem 4: Leakage of lubricant.

Probable Cause:

1. Loss through axle shafts.

a. Lubricant above specified level.

b. Wrong kind of lubricant.

c. Restriction of axle housing breather.

d. Axle shaft oil seal installed wrong or has

damage.

2. Loss at pinion.

a. Lubricant above specified level.

b. Wrong kind of lubricant.

c. Restriction of axle housing breather.

d. Drive motor seal worn or not installed correctly.

13

Page 15

Power Train Testing And Adjusting

Drive Motor

Motor Brushes

Brush Inspection

1. Measure the brush material on the longest side.

Brush Measurement

2. If the brush length is less than 19 mm (.75 in) on

the longest side, replace the brushes.

New Brush Installation

NOTE : Installation of new brushes is a two person

operation.

1. Disconnect the batteries and remove them from

the lift truck. Put the batteries close enough to the

truck that the battery connector can be plugged in.

2. Lift the truck and put blocks under it so that the

drive wheels are off the ground. Put blocks in front

and in back of the steering wheels.

3. Discharge the head capacitor.

4. Remove the commutator screen cover remove old

brushes.

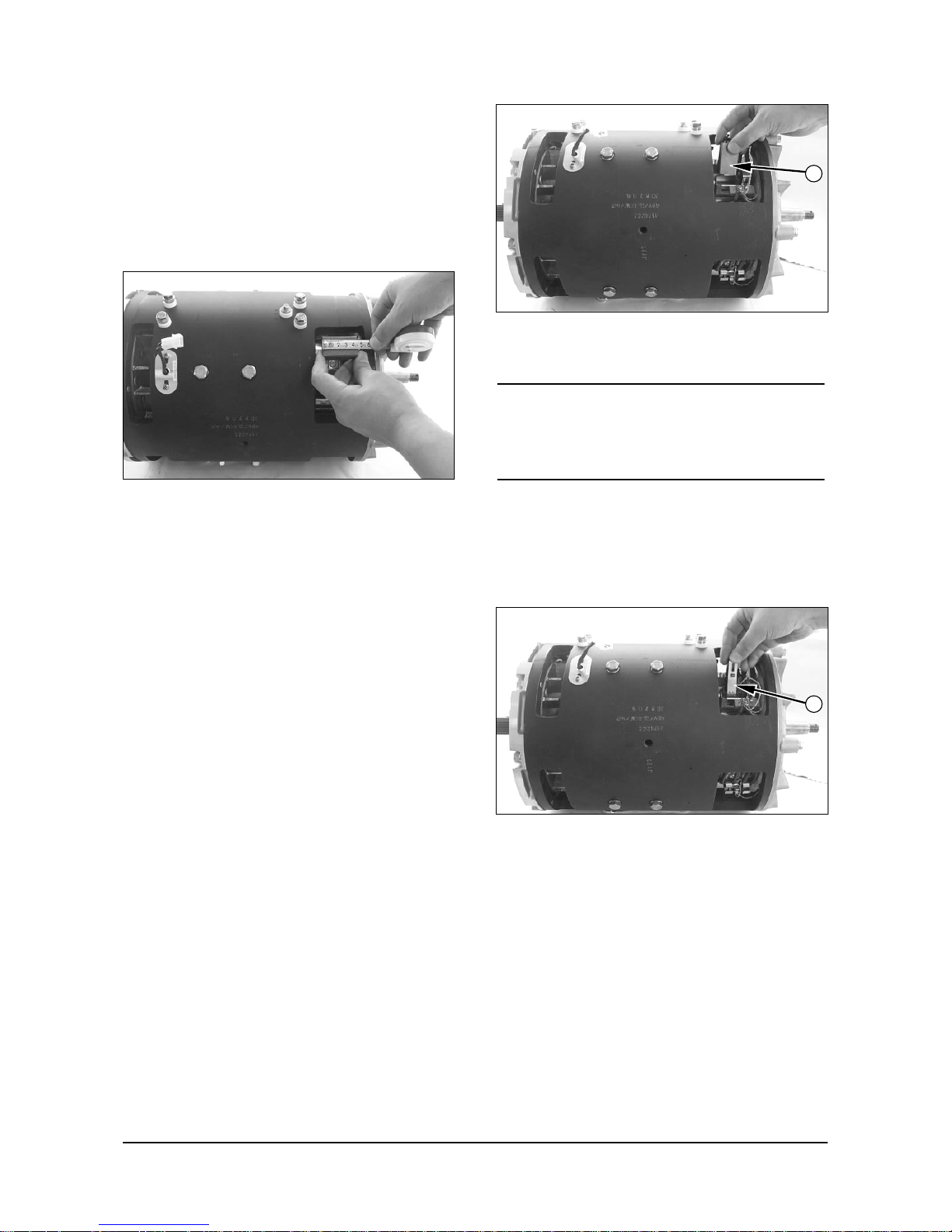

Install Brushes

(1) Brushes.

NOTICE

Installation of the wrong brushes can cause early

motor failure. Always make sure the correct DAEWOO

brushes are installed.

5. Install new brushes(1). Make sure the brushes

move freely in the brush holders. Use a piece of

plain bond paper to remove brush material if there

is a restriction of brush movement.

Install Springs

(2) Spring.

6. Place carefully the brush spring(2) on the top of

brush and make sure they fasten into the brush

holder box.

7. Pull up on the two wires of each brush until the

contact end of the brush moves away from the

commutator. Release the wires to see if the brush

moves smoothly back into contact with the

commutator. If it is too difficult to pull out, or it does

not move smoothly in the brush holder box,

remove the spring and brush. Make an inspection

to find and correct the cause of the problem.

8. Connect the batteries to the battery connector.

14

1

2

Page 16

Power Train Testing And Adjusting

Wear eye protection when seating, polishing or

cleaning the motor with air pressure. During the

seating and polishing procedure, keep fingers

away from components in rotation. For prevention

of injury to fingers, do not use a commutator

cleaner or brush seater stone that is shorter than

63.5 mm (2.50 in.).

Brush Seating

(3) ZLX Ð0036 Brush seater stone.

9. Put ZLXÐ0036 Brush Seater Stone (3) on the

commutator and operate the motor at a slow

speed.

NOTICE

Do not let stone (3) stay in contact with the commutator

bar too long. This causes more wear than is necessary

to the brushes and the commutator.

10. Move stone (3) across the commutator at the

backe edge of the brushes for a short time. This

will take the shiny finish off the commutator and

seat the new brushes.

11. Turn the key switch to the OFF position and

disconnect the batteries. Check the contact

surface of each brush. At least 85% of the brush

contact surface of each brush must show wear. If

necessary, do Steps 8 through 11 again until the

correct wear can be seen on the brush contact

surface.

NOTICE

Never use air pressure that is more than 205 kPa (30

psi). Make sure the line is equipped with a water filter.

12. After the brushes have the correct seat contact

surface, operate the motor at slow speed. Use

compressed (pressure) air to remove all dust and

abrasive grit.

Armature Tests

Test For Short Circuit

Short Circuit Test

(1) Growler. (2) Armature. (3) Hacksaw blade.

(4) Green light. (5) Red light.

1. Put armature windings (2) in the jaws of growler.

(3).

2. Turn the growler (1) on. Slowly turn the growler on

the armature (2) while a hacksaw blade (3) is held

over the windings.

3. If the windings are shorted, the green light (4) will

be on. The red light (5) will be on if the windings

do not have a short.

The odor of burned insulation from the drive motor

while it is in operation is an indication of a short in

the armature.

Tools Needed

Digital Multimeter Or Equivalent 1

Growler Tester 1

WARNING

15

3

5

3

2

4

1

Page 17

Power Train Testing And Adjusting

Ground Test

Ground Test.

A digital multimeter can also be used to test for

grounds. Put the Function/Range Switch on the 2M

resistance (½) scale. When the test probes are put

on the commutator and the shaft, the meter must

give an indication of over load (OL). This means that

the resistance is more than 2 megohms.

NOTICE

Never use air pressure that is more than 205 kPa (30

psi). Make sure the air line has a water filter.

If there is an indication of a ground in the above test,

remove any dirt or debris form the armature with

compressed (pressure) air.

Do the test for grounds again. If there is still an

indication of a ground, make a replacement of the

armature.

Open Circuit Test

Open Circuit Test

1. Put the digital multimeter Function / Range Switch

on the 200 ohm resistance (½) scale.

2. Put one test lead on one commutator bar. Put the

other test lead on an adjacent (next to) bar and

there must be less than one ohm resistance.

This test can also be done with an instrument,

such as a Kelvin Double Bridge, that can make a

measurement of very low resistance. Do the test

the same as above and make a comparison of the

resistance measurements.

Two burned areas on opposite sides of the

commutator are indications of an open armature

winding. These burned areas can cause very rapid

brush wear.

16

Page 18

Power Train Testing And Adjusting

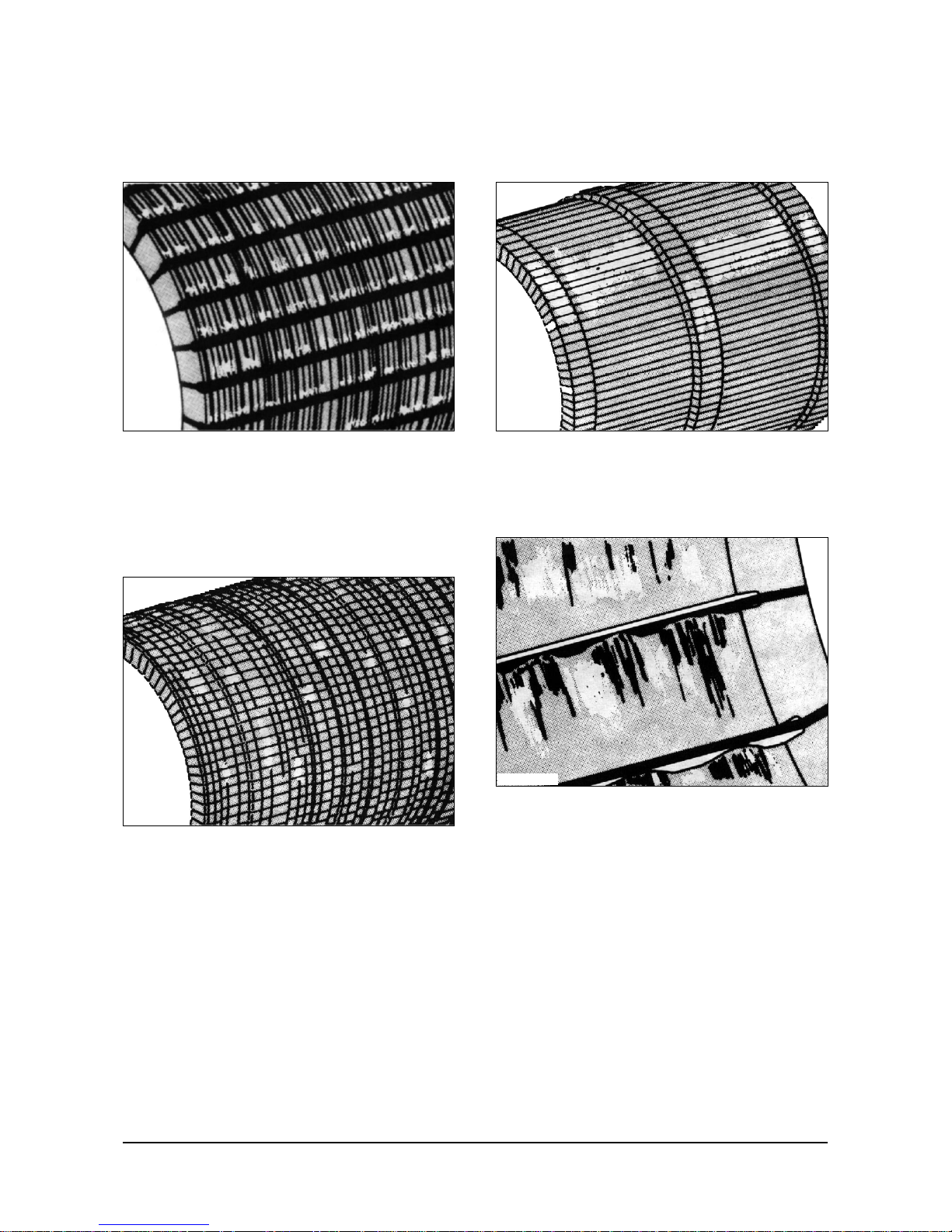

Commutator Inspection

Surfaces of Commutators that need Replacement

Marks on the Commutator Surface

Marks on the commutator surface are an indication

that metal has moved from the commutator surface

to the carbon brushes. Marks will cause fast brush

wear.

Threads on the Commutator Surface

Threads (grooves that look like threads) on the

commutator surface, will also cause fast brush wear.

Grooves on the Commutator Surface

Grooves on the commutators surface are caused by

a cutting material in the brush or atmosphere.

Copper Drag on the Commutator Surface

Copper drag is an extra amount of commutator

material at the back edge of the commutator bars.

17

EHPS009B

EHPS010B

EHPS012B

EHPS011B

Page 19

Power Train Testing And Adjusting

Pitch BarÐMarks on the Commutator Surface

Pitch barÐmarks cause low or burnt marks on the

commutator surface.

Field Coil and Terminal Tests

Open Circuit Test

Open Circuit Test

1. Put the digital multimeter Function/Range Switch

on the 200 ohm resistance (½) scale.

2. Put one test probe to each outer field terminal

(S1,S2).

3. The resistance must be less than one ohm. If the

resistance is too high, it is an indication of

corrosion on the terminals or an open field coil.

Ground Test

Ground Test

(1) Field Terminal. (2) Motor housing.

1. Put the digital multimeter Function/Range Switch

on the 20M resistance (½) scale.

2. Put one test lead to either outer field terminal (1)

and the other test lead to the motor housing (2).

There must be more than one megohm resistance.

3. If there is a measurement of less than one

megohm, it can be caused by wet insulation on the

field windings or excessive brush dust in housing.

Heat the motor at 88°C (190°F) until the resistance

goes above one megohm. If the resistance does

not go above one megohm, the shell and field

assembly must be replaced.

Tools Needed

Digital Multimeter Or Equivalent 1

18

EHPS013B

1

2

Page 20

Power Train Testing And Adjusting

Armature Terminal Test

Test for Continuity

Brush Test

1. Put the digital multimeter Function/Range Switch

on the 200 ohm resistance (½) scale.

2. Put one test lead to an outer armature terminal

and the other test lead to each brush lead that

connects to that terminal. There must be less than

one ohm resistance.

3. Do Step 2 again with the other outer armature

terminal and brush leads.

4. Too much resistance is an indication of corrosion

at the connection to the terminal.

Ground Test

Ground Test

(1) Armature Terminal. (2) Motor Housing.

1. Put the digital multimeter Function/Range Switch

on the 20M resistance (½) scale.

2. Put one test lead to an outer brush terminal (1)

and the other test lead to the motor housing (2).

There must be more than one megohm resistance.

3. Do the test again with one test lead on the other

outer brush terminal.

Brush Holder Test

Brush Holder Test

(1) Brush Holder. (2) End Bell.

1. The brush holders are mounted on the rocker at

the commutator end of the motor. Make a visual

inspection of the brush holders and the rocker.

2. Put digital multimeter Function/Range Switch on

the 200 ohm resistance (½) scale. Put one test

lead to a brush holder (1) and the other test lead

to the end bell (2). The meter must show overload

(OL).

3. Check each brush holder. If meter reading is low,

the brush holder is grounded. Replace the rocker.

Tools Needed

Digital Multimeter Or Equivalent 1

Tools Needed

Digital Multimeter Or Equivalent 1

19

2

1

2

1

Page 21

Power Train Testing And Adjusting

Thermal Switch Tests

Open Circuits Test

Open Circuit Test

1. Put the digital multimeter Function/Range Switch

on the 200 ohm resistance (½) scale.

2. Put one test lead to each side of the thermal

switch harness.

3. The resistance must be less than one ohm.

Ground Test

Ground Test

1. Put the digital multimeter Function/Range Switch

on the 20M resistance (½) scale.

2. Put one test lead to either of the plug prongs. The

other test lead must be grounded to the motor

housing.

There must be more than one megohm resistance.

Brush Life Estimate

1. Before installation of new brushes, make an

inspection of the armature commutator, see

Armature Commutator Inspection in Testing and

Adjusting.

2. Do the steps and procedures for New Brush

Installation in Testing and Adjusting.

3. Make the initial (first) inspection of brush wear

between 250 smh and 500 smh. The reason for

this initial inspection is to see if the brush wear

rate is normal and not too fast. The measurement

will help make an estimate of the length of brush

life to be expected.

NOTE : If there is an indication that brush wear is too

fast, see Troubleshooting, Problem: Sparks

at the commutator and/or rapid brush wear;

for probable causes of this problem.

4. Inspect all brushes in the motors. Measure and

record each brush length (see Specification for

each new brush length and minimum brush length).

5. Estimate expected brush life (hours). Use the

shortest measurement from Step 4 and the

following Sample Procedure:

Length of new brush ................45.8 mm (1.803 in.)

Minimum length of brush...............19 mm (0.75 in.)

New brush length [45.8 mm (1.803 in.)] - Minimum

brush length [19 mm(0.75 in.)] = Total amount of

usable brush wear [26.8 mm(1.055 in.)].

Length of shortest brush at 500 smh is 43.3 mm

(1.703 in.).

New brush length [45.8 mm (1.803 in.)] - Length of

shortest brush at 500 smh [43.3 mm (1.703 in.)] =

Amount of brush wear at 500 smh [2.5 mm (.10 in.)].

Amount of brush wear at 500 smh [2.5 mm (.10

in.)]

Ö Total amount of usable brush wear [26.8

mm (1.055 in.)] = Portion of brush used at 500

smh (.1).

Service Meter Hours (smh) at brush wear

measurement (500 smh)

Ö Portion of brush

used (.1) = Approximate total brush life of a new

brush (5000 smh).

Approximate total brush life of a new brush

(5000smh)ÐAmount of smh at brush life estimate

(500 smh) = Remainder of usable brush life

(4500 smh).

Tools Needed

Digital Multimeter Or Equivalent 1

20

Page 22

Power Train Testing And Adjusting

6. The smh estimate of brush life can be used if the

machine is to work at the same rate (duty cycle),

the battery is not discharged too much or the

battery cells have not become damaged. If the

machine is made to work harder, the battery is

discharged too much, or the battery cells become

damaged, the motor temperature will get hot very

fast. This will cause rapid wear of the brush.

7. It is important to check brush length and brush

condition at a specific time, such as during the

preventive maintenance check. If an inspection

shows that brush life will not extend to the next

preventive maintenance check, install new

brushes.

Power Transfer Group

Adjustments

Power Transfer Group

Power Transfer Group

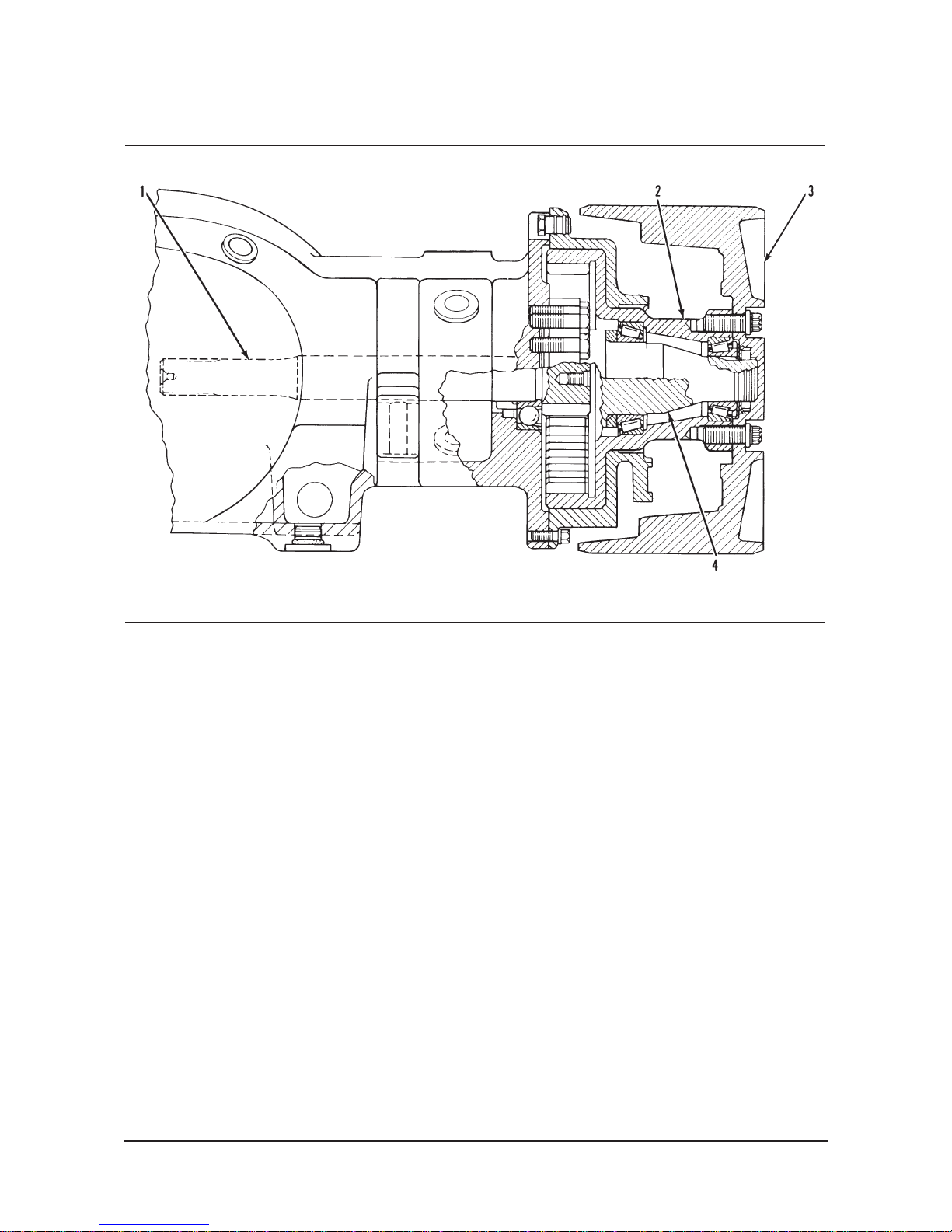

(1) Bevel gear. (2) Pinion gear. (3) Shim pack. (4) Bearing

cup.

Bevel gears and pinions are available in sets that are

machined for each other and must never be installed

separately. The same identification mark of letters

and numbers is put on both the pinion and bevel

gear. Make sure they have the same identification

mark before going to the procedures that follow.

The distance from the centerline of bevel gear (1) to

the flat end of pinion (2) is 78.0 mm (3.071 in.). The

end of each pinion has a mark of either a plus (+)

number, a minus (-) number, or zero (0). These

numbers indicate the position where each gear set

runs best. The dimension is controlled by shim pack

(3) behind inner bearing cup (4).

If a pinion has a mark of (+.10), it needs 0.10 mm

(0.004 in.) less shims than a pinion with a mark of (0).

This increases the distance from the centerline of the

bevel gear to the end of the pinion to 78.1 mm (3.075

in.). This increase of 0.10 mm (0.004 in.) is the

meaning of a (+.10) mark on the pinion. If the pinion

has a mark of (-.10), it needs 0.10 mm (0.004 in.)

more shims than a pinion with a (0) mark. This

reduces the dimension from the centerline of the

bevel gear to the end of the pinion to 77.9 mm (3.067

in.).

1

2

4

3

ID MARKS

21

Page 23

Power Train Testing And Adjusting

Pinion Installation

Pinion Configuration

(2) Shim pack. (3) Bearing cup. (4) Bearing cup.

(5) Bearing cone. (6) Pinion gear. (7) Bearing cone.

(8) Locknut. (9) Ring. (10) Gear. (11) Ring.

NOTE: The adjustment procedures that follow only

cover the shim set configuration. Look for additional

service publications to provide more detailed

information on the change.

22

Page 24

Power Train Testing And Adjusting

1. If the original bevel gear and pinion set is to be

used again, measure old shim pack (2) and make

a new shim pack the same thickness. If a new

bevel gear and pinion set is used, refer to the

Pinion Shim Chart for the amount that the original

shim pack should be changed.

If three or more shims are used, the smaller shims

are to be put in the center of the shim pack.

EXAMPLE: If the old pinion has a mark of (+.06) and

the new pinion has a mark of (-.08) add 0.14 mm

(0.006 in.) shims to the original shim thickness.

2. Install bearing cups (3) and (4) with new shim

pack (2) behind bearing cup (3). Install bearing

cone (5) on pinion shaft (6).

3. Put the pinion shaft assembly into the housing and

install bearing cone (7) and nut (8). Tighten nut (8)

to a torque of 15 to 34 N¥m (11 to 25 lb¥ft) while

rotating the pinion.

4. Measure the distance from the centerline of the

differential bearing bores to the end of the pinion

and determine the amount of shims needed

behind bearing cup (3). See Pinion Depth Check.

5. Remove bearing cup (3) and add or remove the

required shims. Reinstall bearing cup (3).

6. Recheck pinion depth. The measured pinion depth

must be within 0.03 mm (0.001 in.) of the required

pinion depth.

7. After the pinion depth is correct, remove

Pinion Depth Gauge and the pinion shaft. Put ring

(9) on the pinion shaft and put gear (10) in position

in the housing. [NOTE: Side of gear (10) with

recessed hub must be installed next to ring (9)].

Put the pinion shaft in the housing and through

gear (10). Install ring (11) on pinion shaft (6).

8. Set pinion bearing preload. See Pinion Bearing

Adjustment.

9. Recheck pinion depth.

10. After pinion bearing preload and pinion depth are

correct, bend a tab on the lockwasher into a slot

of nut (8) to lock it in position.

23

PINION SHIM CHART

New Pinion Marking

+.10 +.08 +.06 +.04 +.02 0 -.02 -.04 -.06 -.08 -.10

+.10 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm +0.12mm +0.14mm +0.16mm +0.18mm +0.20mm

(0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.) (0.005 in.) (0.006 in.) (0.006 in.) (0.007 in.) (0.008 in.)

+.08 -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm +0.12mm +0.14mm +0.16mm +0.18mm

(0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.) (0.005 in.) (0.006 in.) (0.006 in.) (0.007 in.)

+.06 -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm +0.12mm +0.14mm +0.16mm

(0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.) (0.005 in.) (0.006 in.) (0.006 in.)

+.04 -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm +0.12mm +0.14mm

(0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.) (0.005 in.) (0.006 in.)

+.02 -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm +0.12mm

(0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.) (0.005 in.)

0 -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm +0.10mm

(0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.) (0.004 in.)

-.02 -.0.12mm -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm +0.08mm

(0.005 in.) (0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.) (0.003 in.)

-.04 -0.14mm -0.12mm -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm +0.06mm

(0.006 in.) (0.005 in.) (0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.) (0.002 in.)

-.06 -0.16mm -0.14mm -0.12mm -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm +0.04mm

(0.006 in.) (0.006 in.) (0.005 in.) (0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.) (0.002 in.)

-.08 -0.18mm -0.16mm -0.14mm -0.12mm -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0 +0.02mm

(0.007 in.) (0.006 in.) (0.006 in.) (0.005 in.) (0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.) (0.001 in.)

-.10 -0.20mm -0.18mm -0.16mm -0.14mm -0.12mm -0.10mm -0.08mm -0.06mm -0.04mm -0.02mm 0

(0.008 in.) (0.007 in.) (0.006 in.) (0.006 in.) (0.005 in.) (0.004 in.) (0.003 in.) (0.002 in.) (0.002 in.) (0.001 in.)

Old

Pinion

Marking

Page 25

Power Train Testing And Adjusting

Pinion Depth Check

Tools Needed:

Pinion Depth Gauge (A).

Pinion Depth check

(1) Bearing cap (A) Pinion Depth Gauge

1. Put the bar and discs of tool (A) in the bearing

bores of the housing assembly as shown. Install

bearing caps (1) and tighten the bolts.

2. Measure the distance from the end of the pinion

shaft to the bottom of the bar with an inside

micrometer. Record this measurement.

3. Measure the outside diameter of the bar with an

outside micrometer. Divide this measurement by 2

and add it to the recorded measurement from Step

2. Record this total measurement. This is the

actual mounting distance.

4. Calculate the required shim thickness to add or

remove as follows: the nominal mounting

distance+deviation from nominal (as marked on the

end of the pinion, either + or - number, in

millimeters) = required mounting distance. The

actual mounting distance (from Step 3) - the

required mounting distance = required shim

thickness to add or remove (added if difference is +,

removed if difference is -).

Example:

78.00 mm (3.071 in.) - nominal mounting distance

- 0.08 mm (0.003 in.) - deviation from nominal

(marked on end of pinion)

77.92 mm (3.068 in.) - required mounting distance

78.10 mm (3.075 in.) - actual mounting distance

from Step 3

-77.92 mm (3.068 in.) - required mounting distance

0.18 mm (0.007 in.) - thickness of shims to be

added or removed

Pinion Bearing Adjustment

Tools Needed:

Pinion Bearing Preload Gauge (A)

Dial Indicator Group (B).

Pinion Bearing Preload Adjustment

(1) Shim pack (2) Bearing cone (3) Locknut (4) Pinion gear

1. Install tool (A) [or 4.0 mm (.16 in.) of shims] in

place of shim pack (1). Install bearing cone (2), the

washer, lockwasher, and nut (3). Tighten nut (3) to

a torque of 15 to 34 N¥m (11 to 25 lb¥ft.). (NOTE:

See Preload Shim Chart for shim numbers.)

2. Use tooling (B) to measure the end play of pinion

shaft (4). Record this measurement. Remove nut

(3), the lockwasher, washer, and bearing cone (2).

3. Remove tool (A) (or shims). Measure the thickness

of tool (A) with an outside micrometer (if shims

were used, measure each shim individually and

add the measurements together). subtract from

this thickness the recorded end play from Step 2.

This is the thickness of shims (1) that are needed

with no bearing preload.

24

Preload Shim Chart

Part No. Thickness

Part No. Thickness

924760 0.04 mm (.002 in.)

924761 0.08 mm (.003 in.)

924762 0.12 mm (.005 in.)

924763 0.25 mm (.010 in.)

924764 0.8 mm (.03 in.)

924765 1.6 mm (.06 in.)

Page 26

Power Train Testing And Adjusting

4. In order to get bearing preload, subtract 0.05 mm

(.002 in.) from the shim pack thickness found in

Step 3. This is the shim pack thickness that needs

to be installed.

5. Install the correct thickness of shims (1), bearing

cone (2), the washer, lockwasher, and nut (3).

Tighten nut (3) to a torque of 180 L 25 N¥m

(135 L 18 lb¥ft).

Rolling Torque Check

6. Check the rolling torque of the pinion as shown. It

must be 0.85 to 1.70 N¥m (7.5 to 15.0 lb¥in). If the

torque is not correct, add or remove shims (1) until

it is correct. Removal of shims (1) increases the

rolling torque. Adding shims (1) decreases the

rolling torque. Record the actual rolling torque after

the shims have been added or removed.

Power Transfer Group Bearing and

Gear Clearance (Backlash)

Adjustments

Tools Needed:

Dial Indicator Group (A)

Backlash Adjustment

(1) Bearing Cone. (2) Bevel Gear. (3) Bolt. (4) Bearing Cup.

(5) Bearing Cap. (7) Lockwasher. (8) Locknut.

(9) Pinion Gear.

1. Install bearing cones (1) on the differential case.

2. Put bevel gear (2) on the differential case and

tighten ten bolts (3) to a torque of 70 L 15 N¥m

(50 L 11 lb¥ft). Put bearing cups (4) on bearing

cones (1).

2

3

4

1

9

8

7

5

25

Page 27

Power Train Testing And Adjusting

Install Carrier Assembly

(5) Bearing cap (6) Bolts

3. Put the carrier assembly in position in the housing

assembly. Install bearing caps (5) and four bolts

(6).

Tighten bolts (6) to a torque of 220 L 25 N¥m

(160 L 18 lb¥ft).

4. Install lockwashers (7) and locknuts (8). Use

tooling (A) to check gear clearance (backlash)

between bevel gear (2) and pinion (9). Adjust

locknuts (8) until the clearance is 0.15 to 0.20 mm

(0.006 to 0.008 in.).

Adjust the clearance by turning one locknut (8) in

and the other locknut out an equal amount.

5. Check the rolling torque again as shown in Pinion

Bearing Adjustment, Step 6. Tighten locknuts (8)

equally to preload the differential case bearings.

Proper bearing preload will increase the rolling

torque at the pinion (recorded in Pinion Bearing

Adjustment, Step 6) by 0.63 to 0.88 N¥m (5.6 to

7.8 lb¥in).

6. Measure backlash again. After backlash and

preload are correct, bend a tab on each

lockwasher (7) into a slot in locknuts (8) to hold

them in position.

Correct Tooth Contact Setting

7. Check the tooth contact pattern as follows. Check

the tooth contact setting between the bevel gear

and pinion after the gear clearance (backlash) and

bearing preload adjustments have been made as

follows.

a. Put a small amount of Prussian blue, red lead or

paint on the bevel gear teeth. Turn the pinion in

both directions and check the marks made on the

bevel gear teeth.

Short Toe Contact Setting

b. With no load, correct tooth contact setting will be

as shown. The area of contact starts near the toe

of the gear and goes 30 to 50% up the length of

the tooth.

With this setting, when a load is put on the gear,

the load will be over the correct area of the teeth.

26

Page 28

Power Train Testing And Adjusting

Short Heel Contact Setting

c. If bevel pinion shaft is too far away from bevel

gear, short toe contact will be the result as shown.

The teeth of pinion will be in contact with toe ends

of convex faces (part that makes a curve toward

the outside), and top edge of heel end of concave

faces (part that makes a curve toward the inside).

To correct this, add shims under pinion bearing

cup. After this is done, check gear clearance

(backlash) and tooth contact again.

d. If bevel pinion shaft is too near to center of bevel

gear, short heel contact will be the result as

shown. The teeth of pinion will be in contact with

the toe ends of concave faces (part that makes a

curve toward the inside) and the heel ends of

convex faces (part that makes a curve toward the

outside). To correct this, remove shims from under

pinion bearing cup. After this is done, check gear

clearance (backlash)and tooth contact again.

NOTE: Several adjustments of both pinion and bevel

gear can be needed before correct tooth contact and

gear clearance (backlash) is made. Always

remember that a change to gear clearance

(backlash) will also change the tooth contact.

Therefore, be sure gear clearance (backlash) is in

correct adjustment before tooth contact is checked.

e. After gear clearance (backlash) and tooth contact

are correct, remove extra Prussian blue, red lead

or paint from bevel gear and pinion.

Final Drive

Wheel Bearing Adjustment

Wheel Bearing Adjustment

(1) Hub. (2) Washer. (3) Nut.

1. Tighten nut (3) slowly to 135 N¥m (100 lb¥ft) while

hub (1) is turned to put the bearings in position.

Wheel Bearings

(2) Washer. (3) Nut.

2. Loosen nut (3) completely and tighten it again to

50 L 5 N¥m (37 L 4 lb¥ft).

3. Bend washer (2) to hold the nut in position.

27

3

2

Page 29

Power Train Specifications28

*1 newton meter (N¥m) is approximately the same as 0.1 kg¥m.

General tightening torque

for bolts, nuts and taperlock studs

The following charts give the standard

torque values for bolts, nuts and taperlock

studs of SAE Grade 5 or better quality.

Exceptions are given in other sections of

the Service Manual where needed.

Use these torques for bolts and nuts with

standard threads (conversions are

approximate).

Standard thread

taperlock Stud

Use these torque for bolts and nuts

on hydraulic valve bodies.

Use these torques for studs with

taperlock threads.

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

5/16

3/8

7/16

1/2

5/8

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

9 L 3

18 L 5

32 L 5

50 L 10

75 L 10

110 L 15

150 L 20

265 L 35

420 L 60

640 L 80

800 L 100

1000 L 120

1200 L 150

1500 L 200

13 L 2

24 L 2

39 L 2

60 L 3

118 L 4

5 L 2

10 L 3

20 L 3

30 L 5

40 L 5

60 L 10

75 L 10

110 L 15

170 L 20

260 L 30

320 L 30

400 L 40

480 L 40

550 L 50

12 L 4

25 L 7

45 L 7

70 L 15

100 L 15

150 L 20

200 L 25

360 L 50

570 L 80

875 L 100

1100 L 150

1350 L 175

1600 L 200

2000 L 275

20 L 3

35 L 3

50 L 3

80 L 4

160 L 6

7 L 3

15 L 5

30 L 5

40 L 10

55 L 10

80 L 15

100 L 15

150 L 20

230 L 30

350 L 40

400 L 40

550 L 50

650 L 50

750 L 70

inches

thread size Standard torque

lb¥ft N¥m*

standard thread

Page 30

Power Train Specifications29

*1 newton meter (N¥m) is approximately the same as 0.1 kg¥m.

Metric fasteners

Hose clamps - worm drive band type

Ground engaging and cutting edge bolts and nuts

[Usually, material strength identification on bolt

head is with numbers (i.e., 8.8, 10.9, etc.)]

The chart on the right gives the torque for

bolts and nuts with Grade 8.8.

NOTICE: Caution must be taken to avoid

mixing metric and standard (customary)

fasteners. Mismatched or incorrect fasteners

can result in vehicle damage or malfunction, or

possible personal injury.

Original fasteners removed from the vehicle

should be saved for assembly when possible.

If new ones are required, caution must be

taken to replace with one that is of same part

no. and grade or better.

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

12L4

25L7

55L10

95L15

150L20

220L30

325L50

450L70

600L90

775L100

1150L150

1610L200

2000L275

2700L400

9L3

18L5

40L7

70L10

110L15

160L20

240L35

330L50

440L65

570L75

840L110

1175L150

1450L200

200L300

inches

5/8

3/4

7/8

1

1-1/4

lb. ft.

195L20

350L50

565L85

900L110

1500L185

N•m*

265L25

475L70

765L115

1220L150

2000

L 250

Metric ISO thread

torque

(N¥m)* (lb¥ft)

thread size (mm)

ISO Ð International Standard Organization

clamp width

15.9 mm (.625 inch)

13.5 mm (.531 inch)

7.9 mm (.312 inch)

initial assembly

torque on new hose

reassembly or

retightening torque

N¥m*

7.5L0.5

4.5L0.5

0.9L0.2

lb¥in

65L5

40L5

8L2

N¥m*

4.5L0.5

3.0L0.5

0.7L0.2

lb¥in

40L5

25L5

6L2

-Round dome shaped headProof load - 120,00 psi min.

Tensile strength - 150,000 psi min.

Hardness - Rockwell C 33 to 39

Size - 5/8

-Seven radial dashesRound dome shaped head

Proof load - 135,000 psi min.

Tensile strength - 160,000 psi min.

Hardness - Rockwell C 36 to 42

Sizes 3/4 thru 1-1/4

Torque requirements for plow bolts

standard torquethread diam.

Page 31

Power Train Specifications30

Drive Motor

Machine chamfer on the commutator bars ...0.40 mm

(.016 in.)

Torque for the terminal bolts (not shown) that hold

cable connections ...............................12 N¥m (9 lb¥ft)

Depth of the insulation below commutator

bars ....................................................1.0 mm (.04 in.)

Width of the insulation below commutator

bars ................................................0.76 mm (.030 in.)

Maximum difference between commutator high and

low point (out of round) ...........0.03 mm (.001 in.) TIR

Maximum difference between bar to

bar .......................................0.005 mm (.0002 in.) TIR

Thermal switch (not shown) [Superior (S) Option.

only]:

Opening temperature ...........150 L 6¡C (302 L 11¡F)

Closing temperature ...........130 L 7¡C (266 L 13¡F)

Thermal switch (Not Shown)[Standard only]

Opening Temperature ............135 L 4¡ (275 L 10¡F)

Closing Temperature ..............118 L 6¡ (244 L 11¡F)

Drive Motors

Model Voltage

(1)

New Brush Size Minimum

(2)

New Commutator Minimum

Thickness Bwidth Blength

Brush Length*

Diameter

Commutator Diameter**

B20S-2, B25S-2

36/48

12.5 mm B 25.0 mm B 45.8 mm 19.0 mm 117.4 mm

111.0 mm (4.37 in.)

B30S-2 (.49 in. B 0.98 in. B 1.8 in.) (.75 in.) (4.62 in.)

BC20S-2,

16.0 mm B 28.0 mm B 45.8 mm 19.0 mm 119.0 mm

BC25S-2, 36/48

(.63 in. B 1.10 in. B 1.80 in.) (.75 in.) (4.69 in.) 111.0 mm (4.37 in.)

BC30S-2

B20S, B25S

12.5 mm B40.0 mm B45.8 mm

19.0 mm

117.4 mm

B30S, BC20S 72/80

(.49 in. B1.57 in. B1.8 in.)

(.75 in.)

(4.62 in.)

111.0 mm (4.37 in.)

BC25S, BC30S

*As measured manually on standard trucks. As measured by the Brush Wear Indicator (BWI) on Superior (S) option trucks.

**All rough edges (burrs) must be removed after the commutator is machined.

Page 32

Power Train Specifications

Power Transfer Group

(1) Torque for bolts (1) that hold ring gear to

differential case assembly ................70 L 15 N¥m

(50 L 11 lb¥ft)

(2) Adjust differential bearings with locknut (2) to a

rolling torque of ...........................2.12 to 2.97 N¥m

(19 to 27 lb¥in)

(3) Amount of free play (backlash) between bevel

gear and pinion (3) ......................0.15 to 0.20 mm

(.006 to .008 in.)

(4) Tighten nut (4) to 180 L 25 N¥m (135 L 18 lb.ft.).

Install shims (6) as needed to obtain rolling torque

of 0.85 to 1.70 N¥m (7.5 to 15.0 lb¥in) at the

pinion without the differential case assembly.

(5) Apply LOCTITE NO.609 Sealant to outside

diameter of cap (5) prior to assembly.

(6) Install shims (7) as needed. See Power Transfer

Group Adjustments in Testing and Adjusting.

(8) Apply Loctite No. 242 to six bolts (10).

(9) Apply 6V1541 Primer and Loctite No. 17430 to

cover (9) and housing assembly (8) prior to

assembly.

(10) Torque for differential bearing cap bolts (11).

............................220 L 25 N¥m (160 L 18 lb¥ft)

NOTE: The marks on the bearing caps and gear

carrier must be in correct alignment.

1

2

3

4

5

6

7

2

31

Page 33

Power Train Specifications

Final Drive

(1) Apply Loctite No.242 Thread Lock to thread of

bolt (1) and tighten to a torque of

........................................................115 L 14 N¥m

(2) Torque for wheel mounting bolts (2)

..............................270 L 25 N¥m (200 L 18 lb¥ft)

(3) Torque for bolts (3) holding service brake

....................................55 L 10 N¥m (41 L 7 lb¥ft)

(4) Heat retainer (4) to a temperature of 371 to

427¡C (700 to 801¡F) for no more than four hours

and install on axle shaft.

32

Page 34

Power Train Specifications33

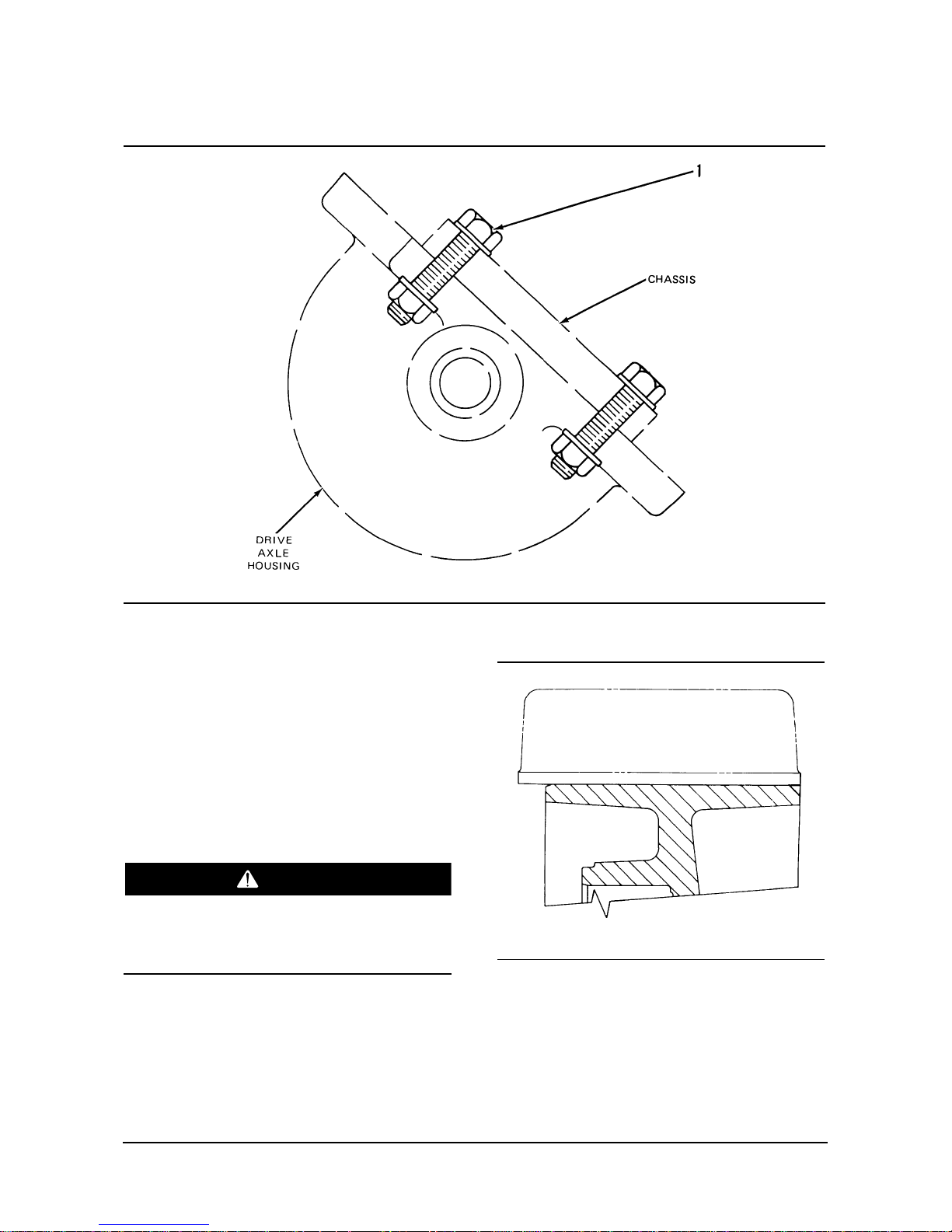

Drive Axle Mounting Group

(1) Install four bolts (1) that fasten drive axle housing

to the chassis frame. Tighten bolts (1) to a torque

of ...........................488 L 27 N¥m (360 L 20 lb¥ft)

Drive Tire Installation

B Series

The optional cushion drive tire must be installed

as shown. failure to do so will decrease machine

stability and cause possible personal injury.

Cushion Tire

Install the cushion tire so that the edge of the tire is

even with the outside edge of the wheel.

WARNING

Page 35

Power Train Specifications

Cushion Tire Mounting

Tighten the cushion tire wheel mounting bolts (1) to

a torque of ..................270 L 25 N¥m (200 L 18 lb¥ft)

Pneumatic Tire Mounting

Tighten the pneumatic tire wheel nuts (2) to a torque

of ................................644 L 34 N¥m (475 L 25 lb¥ft)

Use ÒcrisscrossÓ procedure to tighten the nuts.

BC Series

BC20S-2, BC25S-2

The drive tire must be installed as shown below.

Failure to do so will decrease the stability of the lift

truck and can cause injury to the operator.

Install the tire so that the edge of the tire is even with

the outside edge of the wheel.

WARNING

34

Page 36

Power Train Specifications

BC30S-2-Narrow Axle

BC30S Models-Narrow Axle

Install the tire so there is distance (X) between the

edge of the tire and the outside edge of the wheel.

Distance (X) is .............21.4 L 0.8 mm (.84 L .03 in.)

BC30S-2 wide Axle

BC30S Models-Wide Axle

Install the tire so there is distance (Y) between the

edge of the tire and the outside edge of the wheel.

Distance (Y) is......25.4 L 0.8 mm (1.00 L .03 in.)

35

Page 37

Power Train Disassembly & Assembly

Disassembly & Assembly

Brakes, Brake Adjuster And

Wheel Cylinder

Remove Brakes, Brake Adjuster

And Wheel Cylinder

1. Put the lift truck in position on tooling (A), and

remove the drive wheels. On B20/25/30S models,

remove the brake drum also.

2. Remove brake return springs (1), (2) and (3) with

a suitable brake shoe spring tool.

3. Remove brake retainer springs (4). Remove the

brake shoes.

4. Remove bolts (6) to remove wheel cylinder cover

(5).

5. Disconnect brake lines (7). Remove plungers (8)

from the wheel cylinder.

6. Remove bolts (9) to remove wheel cylinder (10).

Tools Needed A

Jack Stand 1

36

2

3

1

4

5

6

7

9

10

8

Page 38

Power Train Disassembly & Assembly

7. Remove bolt (11) to remove brake adjuster (12).

8. Disassemble the brake adjuster. Remove springs

(15) from the adjuster. Remove bolt (14), wheel

(16) and shims (13). Do the same for the other

side of the brake adjuster.

9. Disassemble the wheel cylinder. Remove dust

caps (20) from each end of the wheel cylinder.

10. Remove pistons (18) with seals (19) and spring

(17) from the wheel cylinder.

Install Brakes, Brake Adjuster And

Wheel Cylinder

1. Install spring (17) in the wheel cylinder.

NOTE: Put clean brake fluid on the seals and inside

of the wheel cylinder before assembly.

2. Install pistons (18) with seals (19) in the wheel

cylinder.

3. Install dust caps (20).

4. Install shims (13) on wheel (16). Install wheel (16)

in the brake adjuster with bolt (14). Do the same

for the other side of the brake adjuster. Install

springs (15) on the arms of the brake adjuster.

37

11

12

15

19

17

20

18

19

17

20

18

16

13

14

15

16

13

14

Page 39

Power Train Disassembly & Assembly

5. Install brake adjuster (12) and bolt (11) that holds

it. Tighten the bolt to a torque of 72 L 5 NIm (55 L

4 lbIft). See Brake Adjuster Installation in Testing

And Adjusting for further adjustments.

6. Install wheel cylinder (10) and bolts (9). Tighten

the bolts to a torque of 15 L 2 NIm (11 L 1 lbIft).

7. Install plungers (8). Connect brake lines (7), and

tighten the nuts to a torque of 14 L 2 NIm

(10 L 1 lbIft).

8. Install wheel cylinder cover (5) and bolts (6).

9. Install the brake shoes and brake retainer springs

(4).

10. Install brake return springs (1), (2) and (3) with a

suitable brake spring tool.

11. Install the brake drums on B20/25/30S

models. Install the drive wheels.

38

11

12

4

5

6

7

9

10

8

2

3

1

Page 40

Power Train Disassembly & Assembly

Power Transfer Group

Remove And Install Power Transfer

Group

Start By:

a. Remove transaxle

b. Remove final drives and hubs

1. The weight of power transfer group (1) is 50 kg

(110 lb). Install tool (A) on the power transfer

group, and attach a hoist.

2. Remove four bolts (2) and the power transfer

group. Remove the O-ring seal if it is necessary.

NOTE: The following steps are for installation of the

power transfer group.

3. Put the O-ring seal on the power transfer group if

it was removed. Put clean SAE 10W oil on the

seal.

4. Put the power transfer group in position on the

drive axle housing. Install the four bolts.

End By:

a. Install final drives and hubs.

b. Install transaxle.

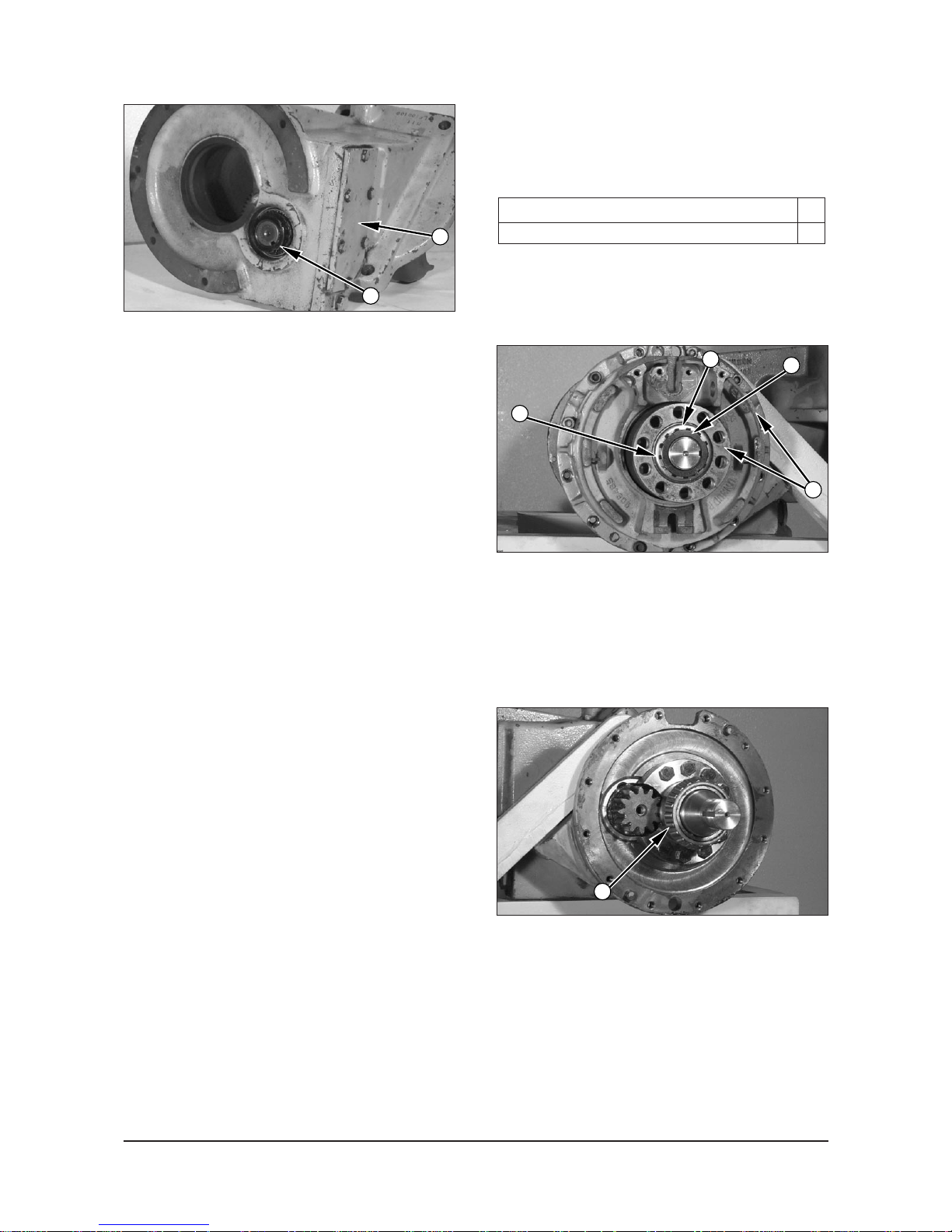

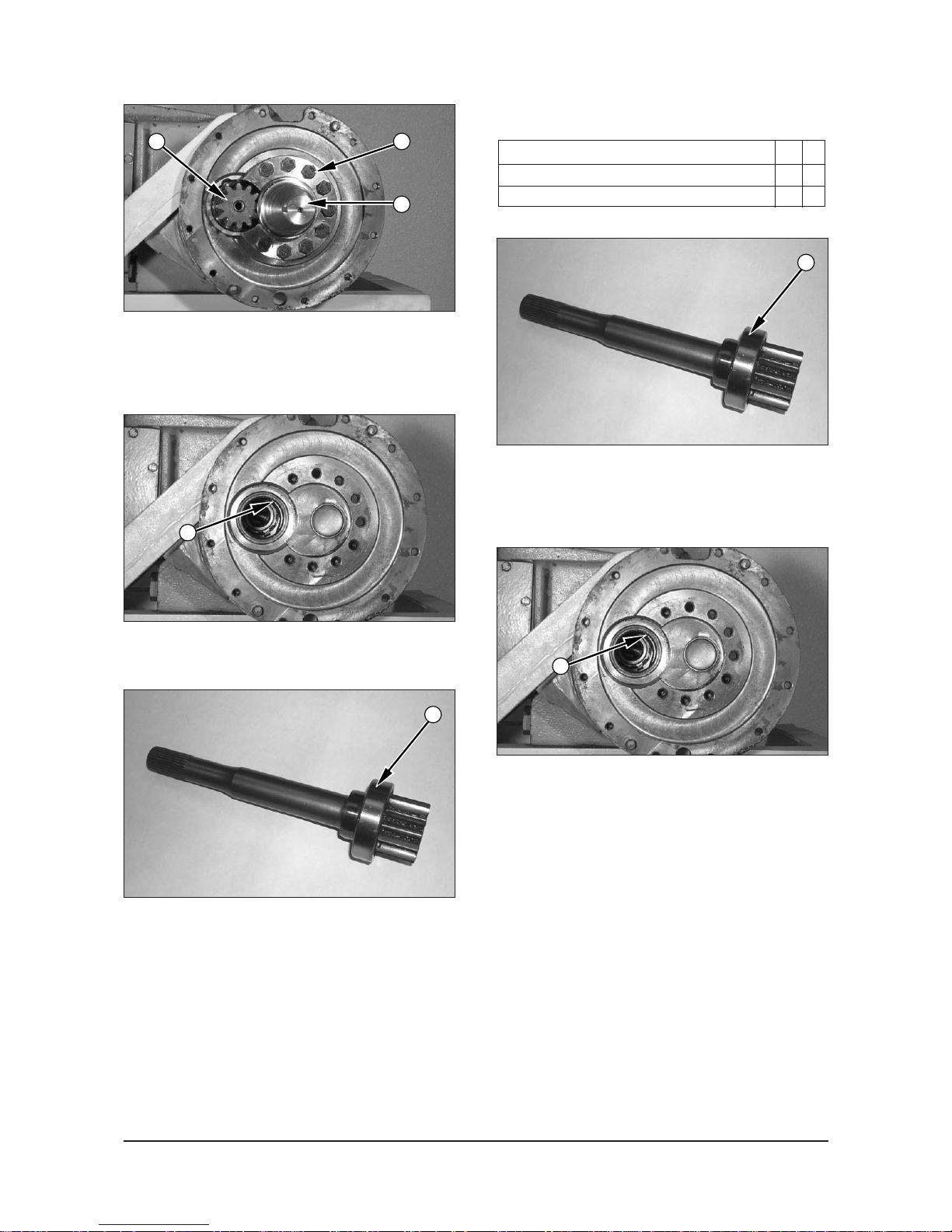

Disassemble Power Transfer Group

Start By:

a. Remove power transfer group.

1. Mark the bearing caps and locknuts for proper

installation. Bend the tab on the lockwasher back.

Remove locknuts (2) with tooling (A) and the

lockwashers. Remove bearing caps (1). The

weight of the carrier assembly with the bevel gear

is 50 kg (110 lb). Attach a hoist, and remove the

carrier assembly.

2. Remove two bearing cups (3). Remove the 10

bolts and bevel gear (4).

Tools Needed A B C

Spanner Wrench 1

Handle 1

Bearing Puller 1

Spanner Wrench 1

Tools Needed A

Link Bracket 1

39

2

1

1

2

3

4

Page 41

Power Train Disassembly & Assembly

3. Use a hammer and punch to remove roll pin (6)

from the carrier. Remove pin (8), side gears (7)

and the thrust washers.

4. Remove axle gears (9) and the thrust washers. If

bearing cones (5) need to be replaced, use tool

(B) and a press to remove them from the carrier.

5. Remove cover (10) from the housing assembly.

Remove the cap from over pinion nut (11). Bend

the lockwasher away from nut (11). Remove nut

(11) with tool (C). Remove the lockwasher and

washer.

6. Remove outer bearing cone (17), shims (23) and

ring (22) from the pinion shaft. Pull pinion shaft

(12) out of gear (15) and the housing assembly.

Remove ring (21) from the pinion shaft. Remove

the gear from the side of the housing assembly

that cover (10) was removed from.

7. If necessary, remove inner bearing cone (13) from

the pinion shaft with a press.

8. If necessary, remove bearing cups (18) and (20)

and shim (19) from the housing assembly.

9. Remove the snap ring (24) from the gear shaft

(26).

10. If necessary, remove the bearings (25) from the

gear shaft (26) with a bearing puller.

24

25

26

40

5

6

8

7

9

10

11

IDCD356S

12

13

21

15

22 17

11

20

23

19

18

Page 42

Power Train Disassembly & Assembly

Assemble Power Transfer Group

1. Install bearing cups (18) and (20) without shims

(19) behind cup (18) in the housing assembly.

Press bearing cone (13) on the pinion shaft.

2. Position pinion shaft (12) into the housing

assembly. Install outer bearing (17) and nut (11)

on the pinion shaft. Tighten the nut to a torque of

15 to 34 NIm (11 to 25 lbIft) while rotating the

pinion.

3. Put the bar and discs of tool (D) in the bearing

bores of the housing assembly as shown. Install

bearing caps (1), and tighten the bolts.

4. Measure the distance from the end of the pinion

shaft to the bottom of the bar with an inside

micrometer. Record this measurement.

5. Measure the outside diameter of the bar with an

outside micrometer. Divide this measurement by 2,

and add it to the recorded measurement of Step 4.

Record this total measurement.

24

20

26

23

25

19

18

12

11

17

10

15

2113

532

1

4

TOOLS NEEDED A C D E F

Spanner Wrench 1

Handle 1

Spanner Wrench 1

Pinion Depth Gauge 1

Shim Pack, 4.0 mm (.16Ó)

1

Dial Indicator Set 1

41

IDCD356S

12

13

21

15

22 17

11

20

23

19

18

IDCD359S

Page 43

Power Train Disassembly & Assembly

6. Calculate the required shim thickness as follows:

the nominal mounting distance L deviation from

nominal (as marked on the end of the pinion in

millimeters, either + or - number) = required

mounting distance. The measured distance (from

Step 5) - the required mounting distance =

required shim thickness. The measured distance

must be within 0.03 mm (.001 in) of the required

mounting distance. If it is, the correct thickness of

shims have been installed. If the required

mounting distance is greater than the measured

distance, remove some shims (19). If the required

mounting distance is less than the measured

distance, add some shims (19).

EXAMPLE 1:

78.00 mm (3.071 in) - nominal mounting distance

- 0.09 mm (.004 in) - deviation from nominal

(marked on end of pinion)

77.91 mm (3.067 in) - required mounting distance

78.10 mm (3.074 in) - actual mounting distance

from Step 5

- 77.91 mm (3.067 in) - required mounting distance

0.19 mm (.007 in) - thickness of shims

to be installed under cup (18)

EXAMPLE 2:

78.00 mm (3.071 in) - nominal mounting distance

- 0.09 mm (.004 in) - deviation from nominal

(marked on end of pinion)

77.91 mm (3.067 in) - required mounting distance

77.91 mm (3.067 in) - actual mounting distance

- 77.91 mm (3.067 in) - required mounting distance

0 mm (0 in) - thickness of shims that need

to be added or removed

from under cup (18)

7. If the original bearings and ring gear and pinion

set are used, install bearing cups (18) and (20)

with original amount of shims (19) behind bearing

cup (18) in the housing assembly. Press bearing