Page 1

Service Manual

MINI COMPONENT SYSTEM

Model :

AMI-722/AMI-822M

DAEWOO ELECTRONICS CO., LTD.

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS ................................................................................................. 2

ADJUSTMENTS............................................................................................................. 4

EXPLODED VIEW AND PARTS LIST ................................................................................. 7

WIRING DIAGRAM ...................................................................................................... 9

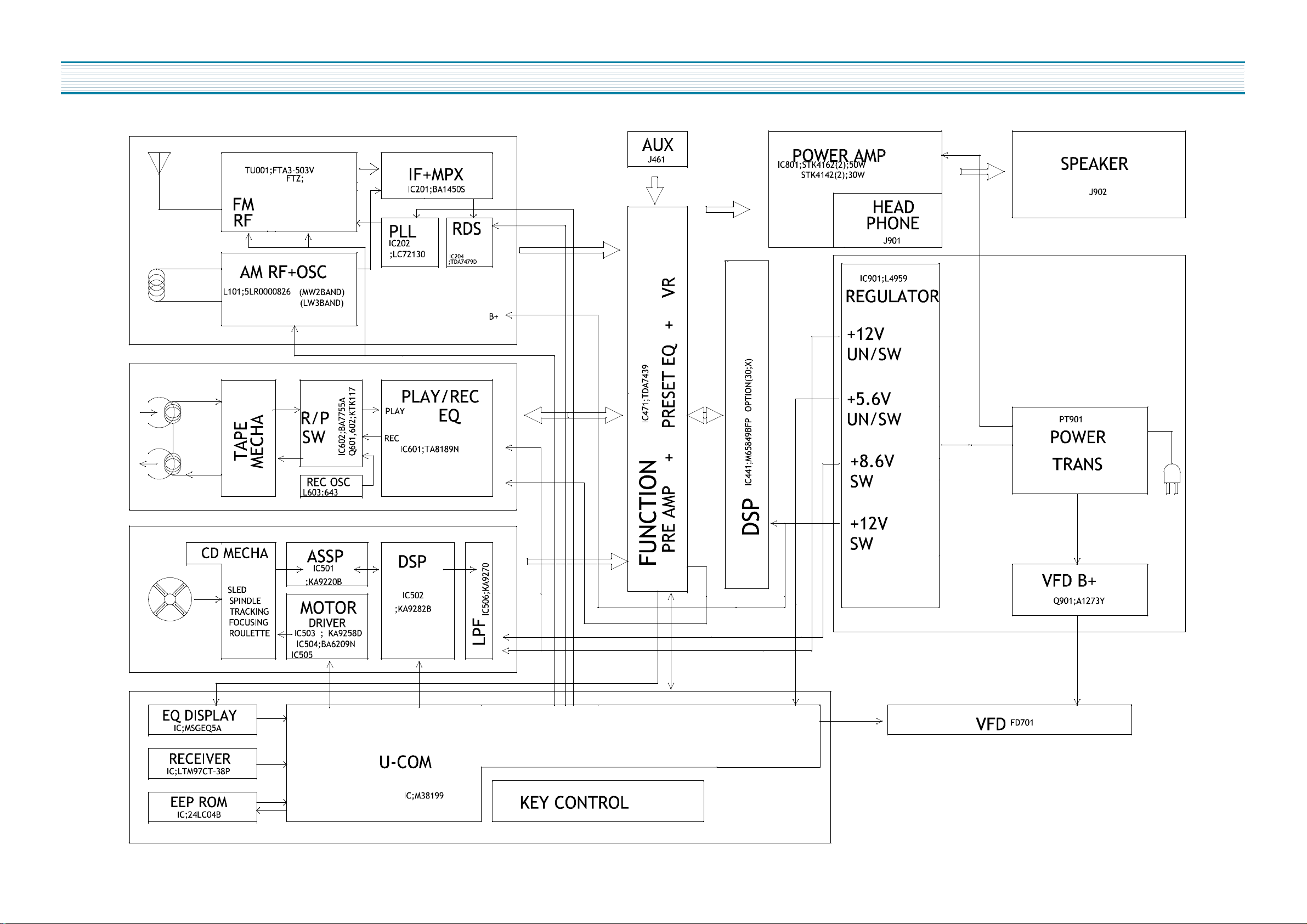

BLOCK DIAGRAM ....................................................................................................... 10

SCHEMATIC DIAGRAM................................................................................................ 11

POWER / AMP ................................................................................................................................... 11

CD.................................................................................................................................................... 12

TUNER ............................................................................................................................................... 13

TUNER-FTZ (OPTIONAL) ....................................................................................................................... 14

TAPE ................................................................................................................................................. 15

CONTROL.......................................................................................................................................... 16

PCB PATTERN LAYOUT.................................................................................................. 17

ELECTRICAL PARTS LIST................................................................................................ 19

1

Page 3

SAFETY PRECAUTIONS

WARNING

THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION :

TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS POLARIZED AC

PLUG WITH AN EXTENSION CORD, RECEPTACLE OR OTHER OUTLET

UNLESS THE BLADES CAN BE FULLY INSERTED TO PREVENT BLADE

EXPOSURE.

THIS UNIT EMPLOYS A LASER. ONLY QUALIFIED SERVICE PERSONNEL

SHOULD REMOVE THE COVER OR ATTEMPT TO SERVICE THIS DEVICE

DUE TO POSSIBLE EYE INJURY.

CAUTION :

OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

CAUTION :

PLUG TO WIDE SLOT, FULLY INSERT.

ATTENTION :

LA LAME LA PLUS LARGE DE LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER JUSQU'AU FOND.

: TO PREVENT FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

CAUTION

RISK OF ELECTRIC SHOCKS

DO NOT OPEN

TO REDUCE THE RISK IF ELECTRIC SHOCK, DO NOT

REMOVE COVER (OR BACK). NO USER SERVICEABLE PARTS

INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULTED "DANGEROUS VOLTAGE"

WITHIN THE PRODUCT'S ENCLOSURE THAT MAY BE

SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK TO PERSONS.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF IMPORTANT OPERATING AND MAINTENANCE

(SERVICING) INSTRUCTIONS IN THE LITERATURE

ACCOMPANYING THE APPLIANCE.

CAUTION

LASER SAFETY

USE OF ANY CONTROLS, ADJUSTMENTS, OR PROCEDURES

TO PREVENT ELECTRIC SHOCK, MATCH WIDE BLADE OF

POUR EVITER LES CHOCS ELECTRIQUES, INTRODUIRE

Important Safety Instructions

- All the safety and operating instructions should be read before

the appliance is operated.

- The safety and operating instructions should be retained for

future reference.

- All warnings on the appliance and in the operating instructions

should be adhered to.

- All operating and use instructions should be followed.

1. Water and Moisture - The appliance should not be

water - for example, near a bathtub, washbowl, kitchen sink,

used near

laundry tub, in a wet basement, or near a swimming pool,

and the like.

PORTABLE CART

Figure 2

ceiling only as recommended by the manufacturer.

5. Ventilation - The appliance should be situated so

location or position does not interfere with

ventilation. For example, the appliance

on a bed, sofa, rug, or similar surface that may block the

ventilation openings; or, placed in a built-in installation, such

as a bookcase or cabinet that may impede the flow

through the ventilation openings.

6. Heat - The appliance should be situated away from

sources such as radiators, heat registers,

appliances (including amplifiers) that

7. Power Sources - The appliance should be

power supply only of the type described in the operating

instructions or as marked on the appliance.

8. Grounding or Polarization - The precautions that

taken so that the grounding or polarization means of an

appliance is not defeated.

9. Power - Cord Protection - Power-supply cords

routed so that they are not likely to be

by items placed upon or against them, paying particular

attention to cords at plugs, convenience receptacles, and the

point where they exit from the appliance.

10.Protective Attachment Plug - The appliance is equipped with

an attachment plug having overload

safety feature. See Instruction Manual for replacement or

resetting of protective device. If replacement of the plug is

required, be sure the service technician has used a

replacement plug specified by the manufacturer that has the

same overload protection as the original plug.

11.Cleaning - The appliance should be cleaned only as

recommended by the manufacturer.

12.Power Lines - An outdoor antenna should be located

from power lines.

2. Carts and Stands - The appliance

should be used only with a cart or

stand that is recommended by th

manufacturer.

3. An appliance and cart combination

should be moved with care. Quick

stops, excessive force, and uneven

surfaces may cause the appliance

and cart combination to overturn.

4. Wall or Ceiling Mounting - The appli-

ance should be mounted to a wall or

that its

its proper

should not be situated

stoves, or other

produce heat.

connected to a

should be

should be

walked on or pinched

protection. This is a

of air

heat

away

2

Page 4

SAFETY PRECAUTIONS

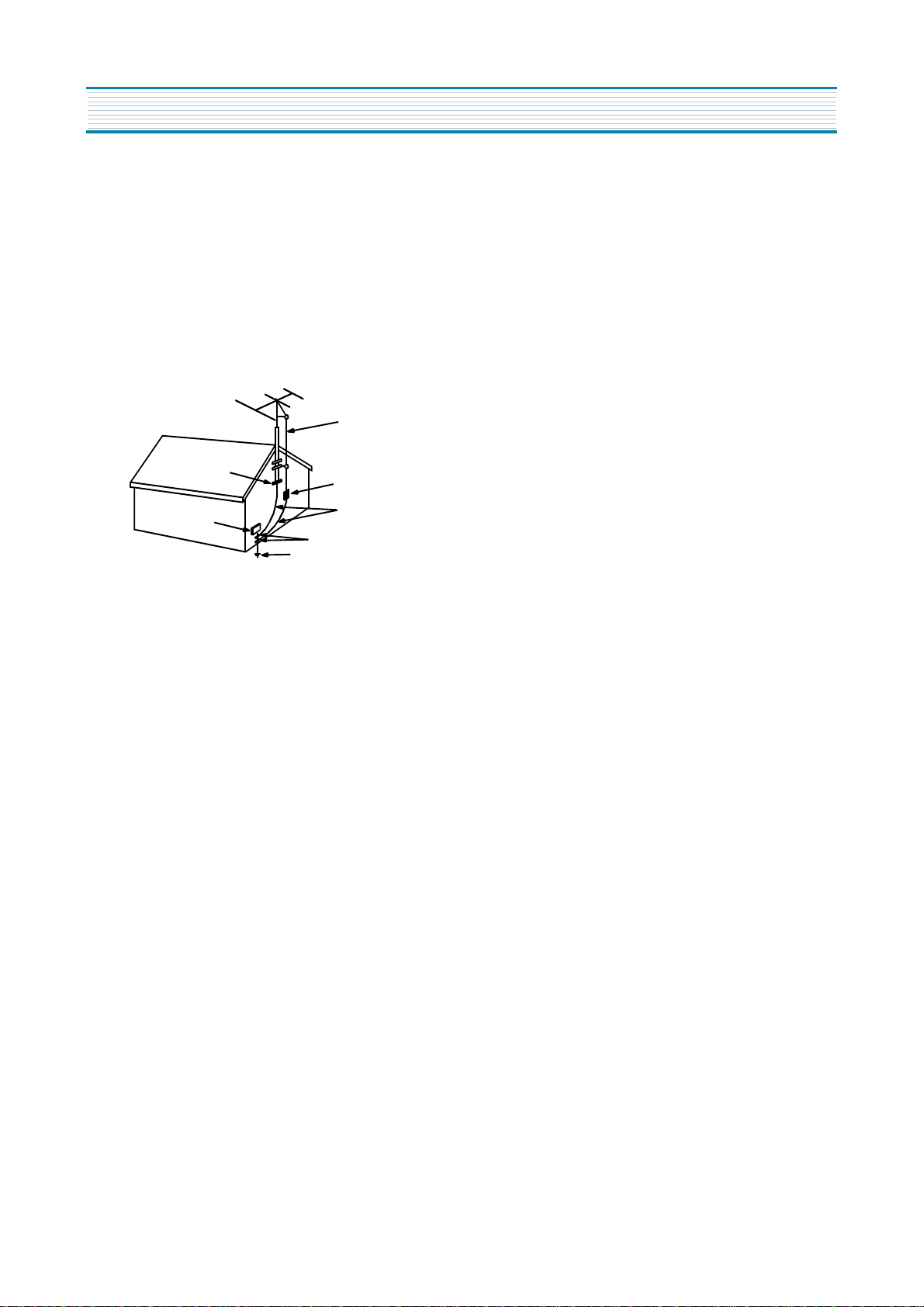

13.Outdoor Antenna Grounding - If an outside antenna

connected to the receiver be sure the antenna

system is

grounded so as to provide some protection against voltage

surges and built-up static charges. Article 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with

regard to proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna-dis

charge unit, size of grounding conductors,location of antennadischarge unit, connection to grounding electrodes and

requirements for the grounding electrode. See Figure 1.

EXAMPLE OF ANTENNA

GROUNDING

GROUND CLAMP

ELECTRIC

SERVICE

EQUIPMENT

NEC - NATIONAL ELECTRICAL CODE

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250 PART H)

ANTENNA LEAD

IN WIRE

ANTENNA DISCHARGE UNIT

(NEC SECTION 810-20)

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

14.Non-use Periods - The power cord of the appliance should be

unplugged from the outlet when left

unused for a long period

of time.

is

15.Object and Liquid Entry - Care should be taken so

that objects

do not fall and liquids are not spilled into the enclosure through

openings.

16.Damage Requiring Service - The appliance should

be

serviced by qualified service personnel when:

a) The power-supply cord or the plug has been

b) Objects have fallen, or liquid has been spilled

damaged; or

into the

appliance; or

c) The appliance has been exposed to rain; or

d) The appliance does not appear to operate

normally or

exhibits a marked change in performance; or

e) The appliance has been dropped, or the

enclosure

damaged.

17.Servicing - The user should not attempt to service the

appliance beyond that described in the operating instructions.

All other servicing should be referred to qualified service

personnel.

3

Page 5

ADJUSTMENTS

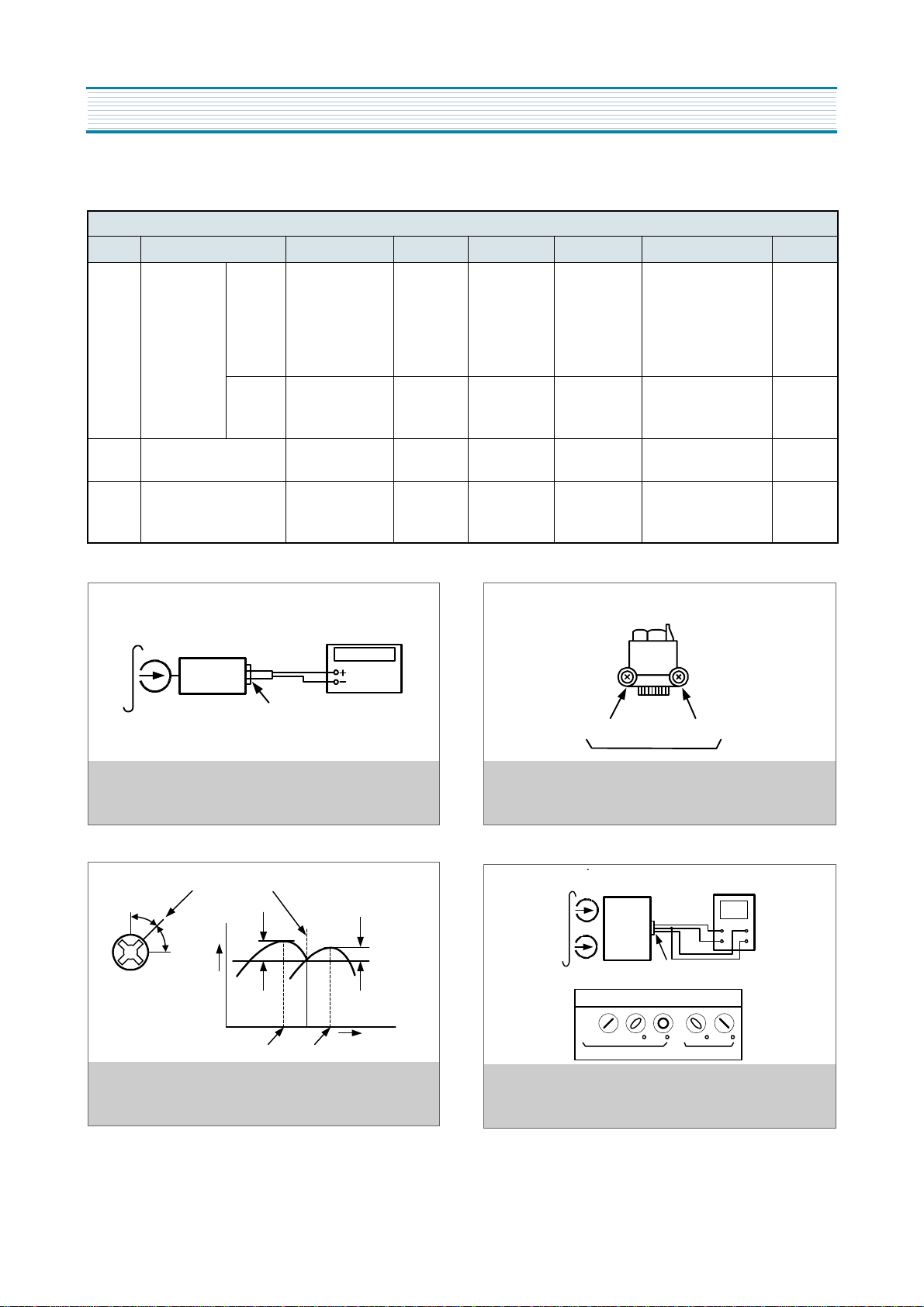

1. TUNER SECTION

TEST EQUIPMENT

FM RF SSG

75 ohm Coaxal

FM Antenna

Terminal(75 ohm)

1. Signal Generator with a frequency range of FM broadcast.

2. Oscilloscope with a side amplifier of approximately 100 KHz.

3. FM 75/50Ω dummy antenna.

4. VTVM

Carrier Frequency : 98MHz

Output Level : 26dBuV

Modulation:Audio 1kHZ, 75kHz Deviation

SET

FM 75/50Ω

Dummy

FM ALIGNMENT

1. Turn on the FM signal generator and the VTVM allowing 15 minutes warming-up period.

2. Connect the VTVM across the headphone jack or speaker terminal.

3. Set signal generator frequency as listed in ALIGNMENT CHART and maintain a sufficient output level to provide an

indication on VTVM.

NOTE

1. Use a screwdriver with plastic or ceramic grip for all adjustments.

2. Standard test frequency 1 KHz and deviation 75 KHz for FM.

- FM RF, IF ALIGNMENT CHART -

Step Item Input Circuit Setup Output Circuit Setup Tuner Setting Adjust Point Adjustment

1

2

FM IF

Adjustment

Auto Stop

Sensitivity

Connect stereo signal

generator to FM ANT

terminal (J001)

Connect stereo signal

generator to FM ANT

terminal (J001)

Connect DC voltme-

ter across R201

Connect DC voltme-

ter across RV201

FM98MHz75KHz

Dev. 26dB

FM 98MHz

75KHz Dev.

26dB

µ

µ

L203

RV201

Adjust forDC 0V±0.1V

Adjust for DC

1.17V±0.02V

Confirm stereo indica-

tor is lighted and L/R

channel is separated.

Unless other specified set being switched FM mode, adjust generator's frequency to center of the FM band where no FM broadcast exists

Otherwise adjustment of FM usable sensitivity, frequency range for FM band are not needed, but confirm these data are satisfied with specification.

CAUTION : When realigning the FM receiving frequency the highest end of the frequency range should not be more than 108 MHz and the

lowest end of the frequency range should not be less than 87.5 MHz, in order to comply with FTZ regulation in West Germany.

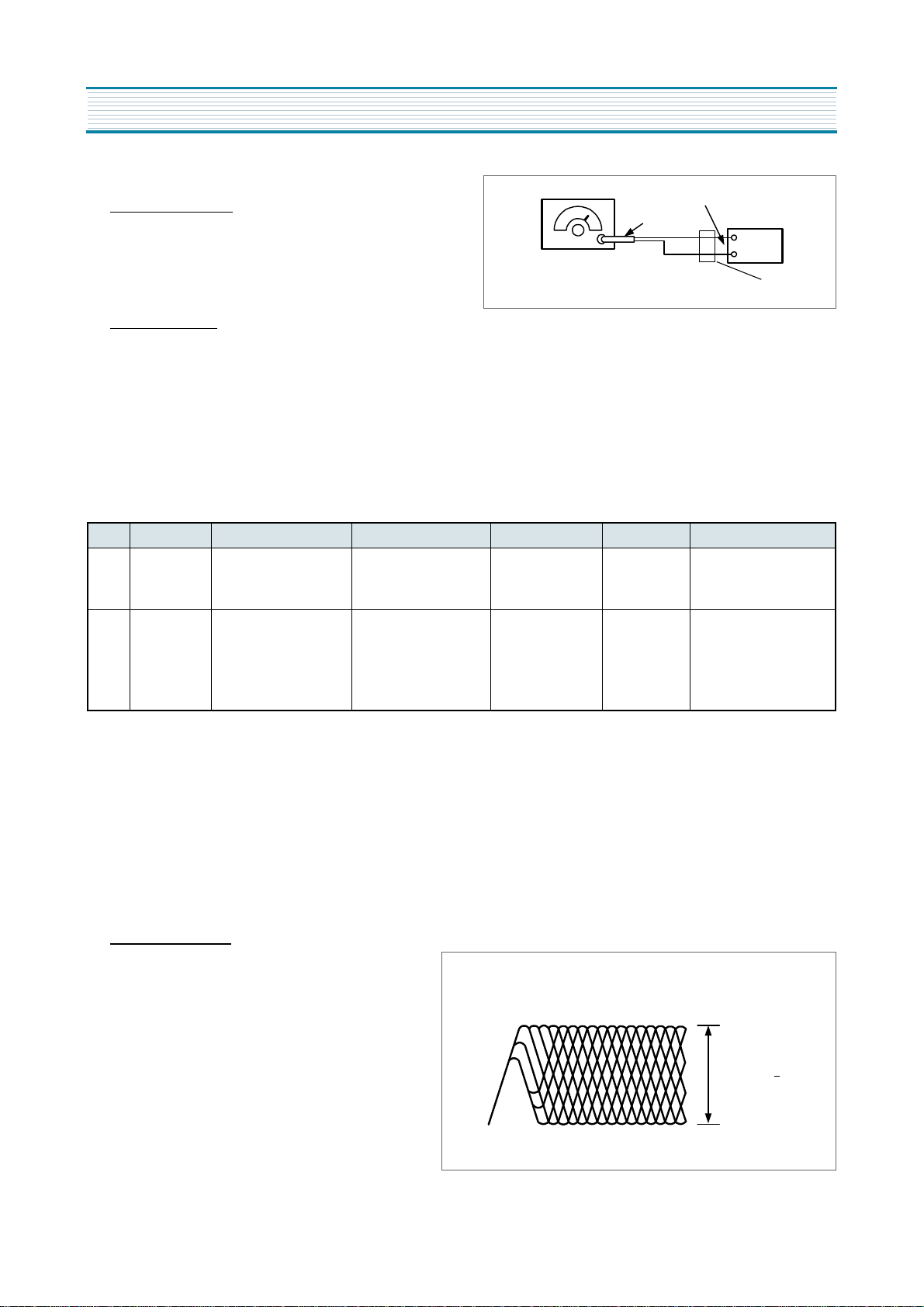

2. CD SECTION

Note:

1. Use the oscilloscope with more than 10M

2. Clean the laser object lens using natural detergent and a soft applicator when the signal level is lower than the value as indicated in

the following checks.

RF LEVEL CHECK

1. Connect oscilloscope to test point TP502 and IC502

Pin66 on CD PCB.

2. Press power switch on.

3. Put test disc(TCD-781) in and press play button then

pause button.

4. Confirm that oscilloscope waveform is clear. Clear

RF signal waveform means that the shape"#"can be

clearly distinguished at the center of waveform.

5. Adjust RV501 to get a clear waveform and maximum

amplitude.

Ω

impedance.

RF Signal Waveform

VOLT/DIV : 200mV

TIME/DIV : 50ns

Level : 1.2+0.3Vp-p

4

Page 6

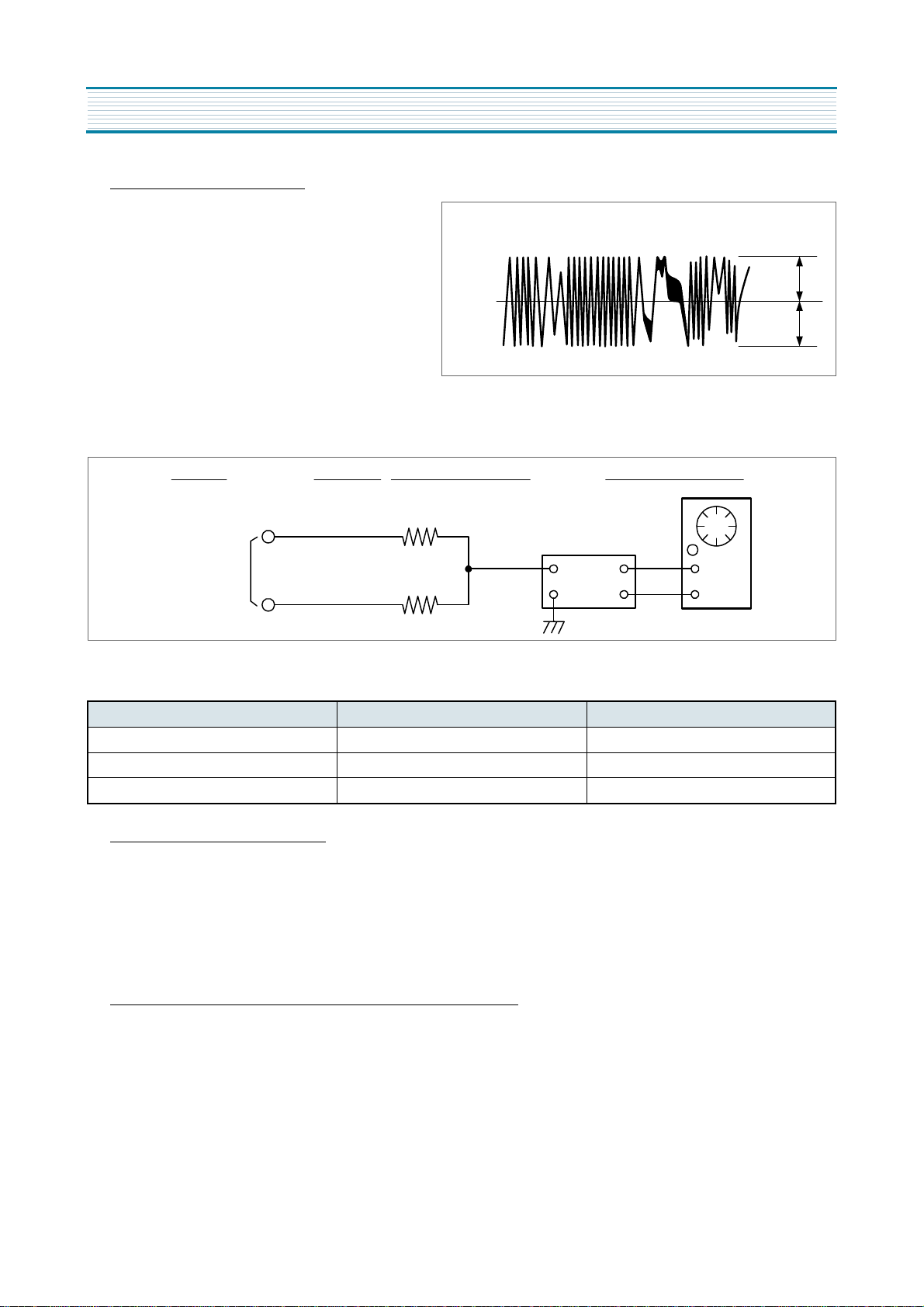

E-F BALANCE ADJUSTMENT

Output Level

1. Connect oscilloscope to test point TP502 and TP503

on CD PCB.

2. Press power switch on.

3. Put test disc(TCD-781) in and press play button then

pause button.

4. Press Fast Forward button and adjust RV502 for a

symmetrical waveform on the oscilloscope in relation

to 0V.

* Design and specifications may be subject to change without notice.

3. TAPE SECTION

ADJUSTMENTS

Traverse Waveform

A

0V

B

Measurement

Input Level

Measurement

Point

Point

R-CH

L-CH

47 kohm

47 kohm

Input Point

VTVM

Test Tape be used

Tape Contents Use

MTT-111N 3 KHz Tape Speed Adjustment

MTT-114N 10 KHz Head Azimuth Adjustment

MTT-5511 Blank Record Frequency Property

HEAD ADJUSTMENT (AZIMUTH)

1. 10KHz test tape(example: MTT-114N) must be used for this adjustment.

2. Connect to a VTVM or oscilloscope to the headphone jack or speaker terminal.

3. Press the play button.

4. Adjust the azimuth by using a screwdriver to maintain the max. L&R output voltage.

5. Adjust tape A(1), tape B(2) respectively, Please secure the azimuth position by using locking paint.

Scope

RECORDING BIAS OSCILLATOR FREQUENCY ADJUSTMENT

1. Connect the frequency counter to TP603, GND.

2. Press the REC button.

3. Adjust L603 to obtain 80 KHz±100Hz

5

Page 7

ADJUSTMENTS

Frequency Counter

Test Tape

TAPE ALIGNMENT CHART

Step Item Reference Value Test Tape Adjust Point Test Point Note FIG.

Be sure Wow & Flutter is within 0.35%

Normal 3,000~3,010Hz MTT-111N RV601

1

Tape Speed

Adjustment

High 5,820~6,180Hz MTT-111N - - - - - -

2 Azimuth Adjustment

Recording Bias Oscilla-

3

tor Frequency Adjustment

Maximum Level

Phase:Within90°

80 KHz±0.5

Line Out L/R

Channel

Shorted

TP601,

TP602

MTT-114N Head Screw

Line Out L/R

Channel

MTT-5511 L603 TP603,GND

Adjust Tape Speed of

end position after

adjustment at tape

start position

Confirm High speed

after normal speed

adjustment

Adjust with frequency

counter connected.

FIG.1

FIG.1

FIG.2,3,4

FIG.1

Test Tape : MTT-111N(3kHz)

MTT-5511(Blank)

Set

Output Level

Measurement Point

FIG. 1 : Tape Speed & Record Bias Oscillator

Frequency Adjust Circuit

L-CH

Peak

within

1 dB

R-CH

Screw

Angle

Peak

Output Level

L-CH

Peak

R-CH

Peak

within

1 dB

Screw Angle

Adjust with Frequency

Counter Connected

Forward

Side

Reverse

Side

FIG. 2 : Tape Azimuth Adjust Location

(Record/Playback Head)

MTT-114N

(10kHz)

L-CH

Set

Screen Pattern

In Phase 45 90 135 180

Good Wrong

Oscilloscope

V H

Output Level

Measurement Point

FIG. 3 : Tape Azimuth Adjust Head Screw & Waveform

FIG. 4 : Tape Azimuth Adjust Circuit & Waveform

6

Page 8

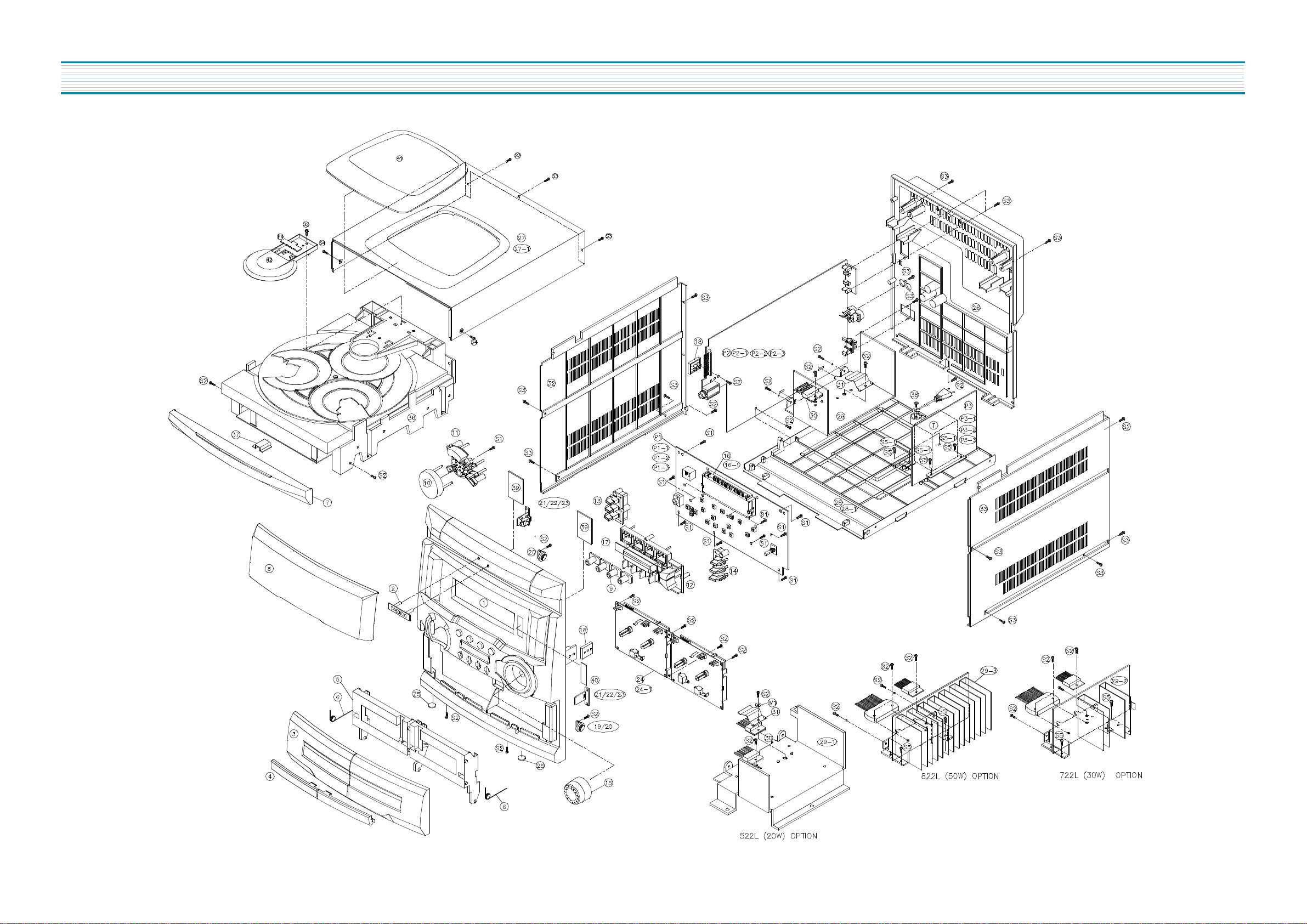

EXPLODED VIEW AND MECHANICAL PARTS LIST

7

Page 9

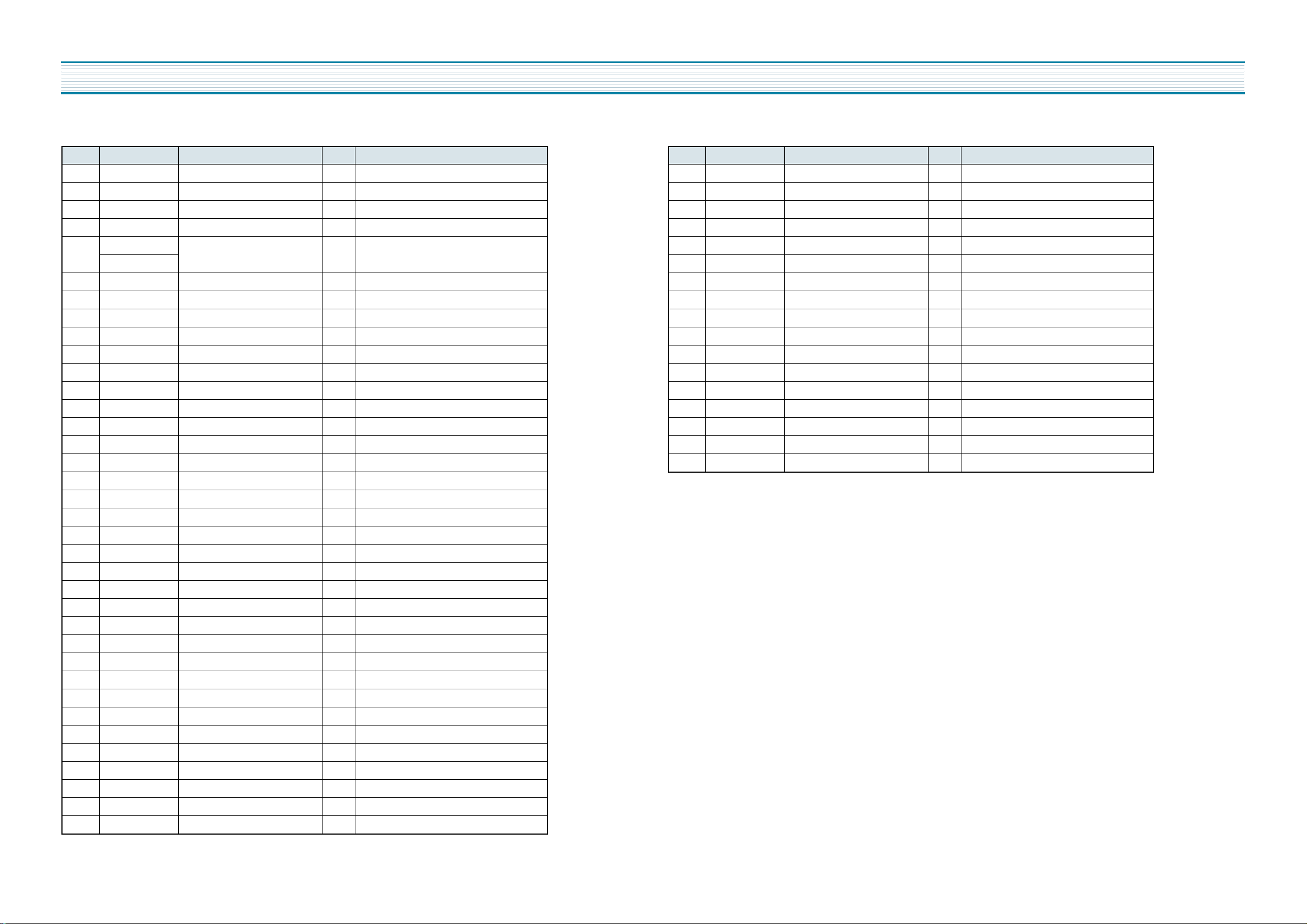

EXPLODED VIEW AND MECHANICAL PARTS LIST

MODEL : AMI-322L / 522L / 722L / 822L

No Part Code Part Name Q’ty Description

1 9CD0307100 PANEL FRONT 1 MIPS

2 9CD1500900 BADGE DAEWOO 1 ABS

3 9CD1810500 DOOR CASSETTE A/B 1 MIPS

4 9CD16153B0 WINDOW DOOR A/B 1 ACRYL

5

6 9CD3007800 SRING DOOR EJECT L/R 1

7 9CD1810600 DOOR CD 1 MIPS

8 9CD1615400 WINDOW FLT 1 ACRYL

9 9CD1337900 KNOB FUNCTION 1 ACRYL

10 9CD1338000 KNOB CD 1 ABS

11 9CD1338100 KNOB POWER 1 ABS

12 9CD1338200 KNOB CONTROL 1 ABS

13 9CD13383L0 KNOB EQ L 1 ABS

14 9CD13383R0 KNOB EQ R 11 ABS

15 9CD1334400 KNOB VOLUME 1 ABS

16 9CD2505600 GUIDE FLT 1 ABS

16-1 9CD2505900 GUIDE FLT 1 ABS (ONLY AMI-822L)

17 9CD0910700 PLATE FILTER 1 PC T0.3

18 9CD2412900 BRKT SIDE 2 ABS X 2EA

19 9CD2603200 DAMPER GEAR B 2 X 2EA

20 9CD2603300 DAMPER BASE B 2 X 2EA

21 9CDOB01900 LOCKER BASE 2 X 2EA

22 9CDOB02000 LOCKER CAM 2 X 2EA

23 9CDOB01600 LOCKER SPRING 2 X 2EA

24 9CD6007000 CASSETTE DECK LOGIC 1 ADR-2138MW

25 9CD4207700 CUSHION FOOT 2 URETHAN X 2EA

26 9CD0411100 COVER BACK 1 MIPS

27 9CD0411000 COVER TOP 1 MIPS

27-1 9CD0409100 COVER TOP 1 MIPS (ONLY AMI-722L/822L)

28 9CD0607500 CHASSIS BOTTOM 1 ABS

28-1 9CD0607100 CHASSIS BOTTOM 1 SECC 1.0T

29 9CD4404500 HEAT SINK 1 1 AL (ONLY AMI-322L)

29-1 9CD4405000 HEAT SINK 2 AL (ONLY AMI-522L)

29-2 9CD4404600 HEAT SINK 3 AL (ONLY AMI-722L)

29-3 9CD4404700 HEAT SINK 5 AL (ONLY AMI-822L)

30 9CD4207900 RUBBER SILICON 1 SILICON RUBBER (ONLY AMI-322L)

9CD1809400

DOOR FRAME A/B 1 ABS

9CD1809500

No Part Code Part Name Q’ty Description

31 9CD2413900 BRACKET HEAT TR 1 SUS 0.3T (ONLY AMI-322L/522L)

32 9CD04112L0 COVER SIDE L 1 MIPS

33 9CD04112R0 COVER SIDE R 1 MIPS

34 9CD0410400 COVER ANT 1 ABS

36 9CD6007000 CD DECK MECHA 1

37 9CD4402800 HEAT SINK 1 BSP 0.5T

38 9CD3102400 WASHER SCREW 1

39 9CD0909800 PLATE FLT PVC SHEET T1.0 X 2EA

40 9CD0910000 PLATE FUNCTION PVC SHEET T0.5

41 9CD1612900 WINDOW TOP ACRYL (ONLY AMI-722L/822L)

42 9CD1002200 DECO TOP ACRYL (ONLY AMI-722L/822L)

S1 7173261011 SCREW TAPTTITE 17 TT2 BIN 2.6 X 10 MFZN X 18EA

S2 7173301011 SCREW TAPTTITE 23 TT2 BIN 3.0X10 MFZN X 13EA

S3 7173301212 SCREW TAPTTITE 14 TT2 BIN 3.0X12 BK X 22EA

S4 7173301612 SCREW TAPTTITE 2 TT2 BIN 3.0X16 BK X 2EA

S5 7173400611 SCREW TAPTTITE 2 TT2 BIN 4.0X6 MFZN X 4EA

S5-1 7173401011 SCREW TAPTTITE 2 TT2 BIN 4.0X10 MFZN

8

Page 10

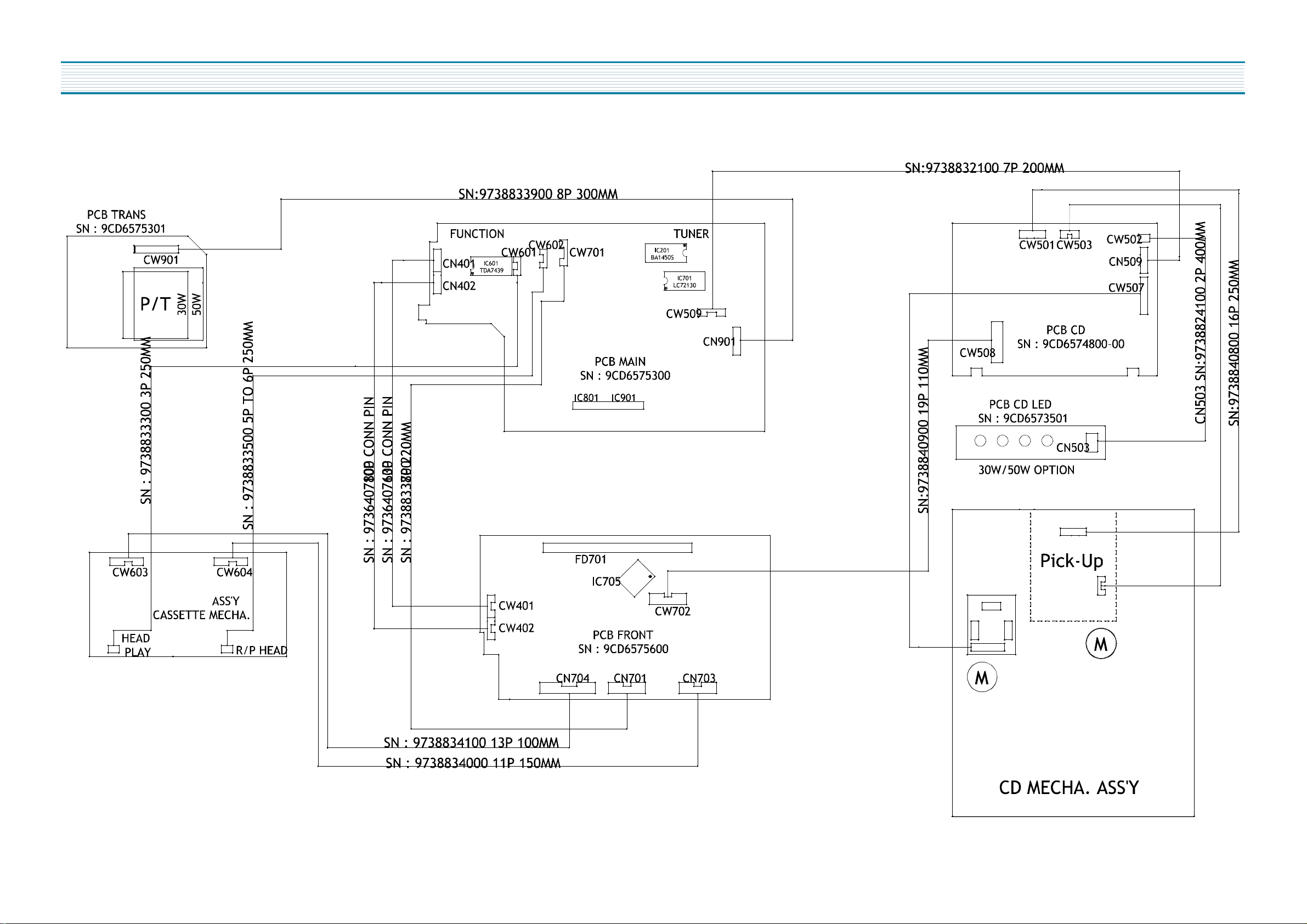

WIRING DIAGRAM

9

Page 11

BLOCK DIAGRAM

10

Page 12

SCHEMATIC DIAGRAM

u

POWER / AMP

11

Page 13

SCHEMATIC DIAGRAM

u

CD

12

Page 14

u

TUNER

SCHEMATIC DIAGRAM

13

Page 15

SCHEMATIC DIAGRAM

u

TUNER-FTZ (OPTIONAL)

14

Page 16

u

SCHEMATIC DIAGRAM

TAPE

15

Page 17

SCHEMATIC DIAGRAM

u

CONTROL

16

Page 18

PCB PATTERN LAYOUT

u

MAIN

17

Page 19

PCB PATTERN LAYOUT

u

CD u CON TROL

18

Page 20

ELECTRICAL PARTS LIST

Part Code Description

9CDC048801 PCB MAIN AS AMI-717L

9CDC053600 PCB FRONT AS AMI-722L

9CDC046100 PCB CD AS AMI-810LN0FR

9CDC047800 PCB PT AS AMI-716LR

9CDM035600 PANEL FRONT AS AMI-322L

9CDM035701 BACK AS AMI-722L

9CDM035900 SPEAKER AS AMI-716L(K23)

9CDG012000 PACKING AS AMI-322L

Part Code Description

9CDC048801 PCB MAIN AS AMI-717L

9CD6575300 PCB MAIN 330X197X1.6T

CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H120J C CERA 50V CH 12PF J (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXB1H101K C CERA 50V B 100PF K (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXB1H271K C CERA 50V B 270PF K (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H473Z C CERA 50V F 0.047MF Z (TAPPING)

CCXB1H472K C CERA 50V B 4700PF K (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

CXCH1H330J C CERA 50V CH 33PF J (TAPPING)

CXCH1H330J C CERA 50V CH 33PF J (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

Part Code Description

CCXB1H331K C CERA 50V B 330PF K (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CXCH1H820J C CERA 50V CH 82PF J (TAPPING)

CXCH1H470J C CERA 50V CH 47PF J (TAPPING)

CCXB1H331K C CERA 50V B 330PF K (TAPPING)

CCXB1H331K C CERA 50V B 330PF K (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXB1H821K C CERA 50V B 820PF K (TAPPING)

CCXB1H821K C CERA 50V B 820PF K (TAPPING)

CCXB1H821K C CERA 50V B 820PF K (TAPPING)

CCXB1H821K C CERA 50V B 820PF K (TAPPING)

CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H473Z C CERA 50V F 0.047MF Z (TAPPING)

CCXB1H391K C CERA 50V B 390PF K (TAPPING)

CCXB1H391K C CERA 50V B 390PF K (TAPPING)

CCXB1H391K C CERA 50V B 390PF K (TAPPING)

CCXB1H391K C CERA 50V B 390PF K (TAPPING)

CCXB1H332K C CERA 50V B 3300PF K (TAPPING)

CCXB1H332K C CERA 50V B 3300PF K (TAPPING)

CCXB1H471K C CERA 50V B 470PF K (TAPPING)

CCXB1H471K C CERA 50V B 470PF K (TAPPING)

CXCH1H560J C CERA 50V CH 56PF J (TAPPING)

CXCH1H560J C CERA 50V CH 56PF J (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

CCXB1H472K C CERA 50V B 4700PF K (TAPPING)

CCXB1H472K C CERA 50V B 4700PF K (TAPPING)

CMXM1H473J C MYLAR 50V 0.047MF J

CMXM1H473J C MYLAR 50V 0.047MF J

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

19

Page 21

ELECTRICAL PARTS LIST

Part Code Description

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H220V C ELECTRO 50V RSS 22MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H228V C ELECTRO 50V RSS 0.22MF (5X11) TP

CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

Part Code Description

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

20

Page 22

ELECTRICAL PARTS LIST

Part Code Description

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

CEYF1E222V C ELECTRO 25V RSS 2200MF (16X25)

CEYF1H222V C ELECTRO 50V RSS 2200MF (18X35.5)

CEYF1H222V C ELECTRO 50V RSS 2200MF (18X35.5)

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

5PE107MS3A FILTER CERA SFE107MS3-A

5PE107MS3A FILTER CERA SFE107MS3-A

5PPCFAZ077 FILTER PCFAZ077

CMXM1H153J C MYLAR 50V 0.015MF J (TP)

CMXM1H103J C MYLAR 50V 0.01MF J (TP)

CMXM1H103J C MYLAR 50V 0.01MF J (TP)

CMXM1H562J C MYLAR 50V 5600 PF J

CMXM1H562J C MYLAR 50V 5600 PF J

CMXM1H183J C MYLAR 50V 0.018MF J

CMXM1H223J C MYLAR 50V 0.022MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H223J C MYLAR 50V 0.022MF J

CMXM1H183J C MYLAR 50V 0.018MF J

CMXM1H562J C MYLAR 50V 5600 PF J

CMXM1H562J C MYLAR 50V 5600 PF J

CCXB1H681K C CERA 50V B 680PF K (TAPPING)

CCXB1H681K C CERA 50V B 680PF K (TAPPING)

CMXM1H223J C MYLAR 50V 0.022MF J

CMXM1H223J C MYLAR 50V 0.022MF J

CMXM1H102J C MYLAR 50V 0.001MF J (TP)

CMXM1H102J C MYLAR 50V 0.001MF J (TP)

Part Code Description

CCXB1H331K C CERA 50V B 330PF K (TAPPING)

CCXB1H331K C CERA 50V B 330PF K (TAPPING)

CMXM1H473J C MYLAR 50V 0.047MF J

CMXM1H473J C MYLAR 50V 0.047MF J

CMXM1H332J C MYLAR 50V 3300 PF J

CMXM1H332J C MYLAR 50V 3300 PF J

CMXM1H223J C MYLAR 50V 0.022MF J

CMXM1H472J C MYLAR 50V 0.0047MF J

CMXM1H472J C MYLAR 50V 0.0047MF J

CMXM1H472J C MYLAR 50V 0.0047MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

CMXM1H104J C MYLAR 50V 0.1MF J

9736407600 CONN AS PIN BASE 53095-1310 13P

9736407800 CONN PIN 53095-1010 10PIN ANGLE

9738833900 CONN AS #22 8P BOARD-IN 300MM

9CD6258800 CONN WAFER 2P S2B-XH-A

9738832100 CONN AS 7P 200 P=2.5 BOARDIN

9738833300 CONN AS UL2851 #28 3P SHIELD 250M

9738833500 CONN AS #28 6P SHIELD 250MM

9738833700 CONN AS #26 8P FLAT 220MM

DZTZ6R2A-- DIODE ZENER MTZ-6.2 52MM TAPPING

DKTZ30A--- DIODE ZENER MTZ 30A

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

D1N4001--- DIODE 1N4001

D1N4001--- DIODE 1N4001

D1N4001--- DIODE 1N4001

D1N4001--- DIODE 1N4001

DRL202---- DIODE RL202

DRL202---- DIODE RL202

D1N5402--- DIODE 1N5402

D1N5402--- DIODE 1N5402

D1N5402--- DIODE 1N5402

D1N5402--- DIODE 1N5402

DZN4148--- DIODE 1N4148 AUTO 52MM

1BA1450S-- IC BA1450S

21

Page 23

ELECTRICAL PARTS LIST

Part Code Description

1LC72130-- IC LC72130

1TDA7479D- IC TDA7479D

1MC7805--- IC MC 7805 (KA7805)

1TDA7439-- IC AUDIO TDA7439

1TA8189N-- IC TA8189N

1BA7755A-- IC SWITCHING BA7755A (HEAD SW)

1BU4094BCF IC BU4094BCF(SOP16)

1LA2000--- IC AMSS LA2000

1STK41422- IC STK-4142-2

1L4959---- IC L4959

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

5CPZ100K2- WIRE JUMPER 10UH

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

Part Code Description

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

22

Page 24

ELECTRICAL PARTS LIST

Part Code Description

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

Part Code Description

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

9736322200 JACK ANTENNA T-646

9CD6313700 JACK RCA S-436P

9766319501 JACK HEADPHONE HTJ-064-05B GOLD

9736320500 JACK SPEAKER CJ-9007-040

5CPZ100K02 COIL PEAKING 10UH K (AXIAL 3.5MM)

5LR0000826 AM RF UNIT RBW07VB-K5020

5107FBK473 COIL DESCRIMINATOR 7X7 BLK KSZ-73S

5P076068-- COIL 6068MPX

5P076068-- COIL 6068MPX

5LC213K828 COIL 20.8MH

5CPZ100K02 COIL PEAKING 10UH K (AXIAL 3.5MM)

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

5L0503K643 COIL BIAS OSC SM-10F 5.04MH

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

W581GY5095 WIRE JUMPER AWG22 1/0.65 SN 5 AUTO

TZTC3194Y- TR KTC3194Y

TKRA107M-- TR KRA107M (KSR2006)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTK117Y-- FET KTK117(Y) AUTO

TZTK117Y-- FET KTK117(Y) AUTO

TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

TZTC3205Y- TR KTC3205Y (2236Y)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZRA111M-- TR KRA111M

TZRA111M-- TR KRA111M

TZRC111M-- TR KRC111M

TZRA107M-- TR KRA107M (KSR2006)

23

Page 25

ELECTRICAL PARTS LIST

Part Code Description

TZRA107M-- TR KRA107M (KSR2006)

TZTA1273Y- TR KTA1273Y(966Y)

TZRC111M-- TR KRC111M

TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

TZRC107M-- TR KRC107M(AUTO)

TZRC111M-- TR KRC111M

TZTA1273-- TR KTA1273

RF01F4780J R FUSIBLE 0.47OHM 1W

RF01F4780J R FUSIBLE 0.47OHM 1W

RV6417223- R SEMI FIXED VM6CK-PV(1S) B 22K OHM

RV1417222- R SEMI FIXED 1/10 2.2K OHM B V6EK-PV1S

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ470J- R CARBON FILM 1/6 47 OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ681J- R CARBON FILM 1/6 680 OHM J

RD-AZ331J- R CARBON FILM 1/6 330 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-4Z475J- R CARBON FILM 1/4 4.7M OHM J

RD-AZ183J- R CARBON FILM 1/6 18K OHM J

RD-AZ183J- R CARBON FILM 1/6 18K OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ470J- R CARBON FILM 1/6 47 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

Part Code Description

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ474J- R CARBON FILM 1/6 470K OHM J

RD-AZ474J- R CARBON FILM 1/6 470K OHM J

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ470J- R CARBON FILM 1/6 47 OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ470J- R CARBON FILM 1/6 47 OHM J

RD-AZ823J- R CARBON FILM 1/6 82K OHM J

RD-AZ823J- R CARBON FILM 1/6 82K OHM J

RD-AZ182J- R CARBON FILM 1/6 1.8K OHM J

RD-AZ182J- R CARBON FILM 1/6 1.8K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

24

Page 26

ELECTRICAL PARTS LIST

Part Code Description

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ331J- R CARBON FILM 1/6 330 OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ820J- R CARBON FILM 1/6 82 OHM J

RD-AZ820J- R CARBON FILM 1/6 82 OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

Part Code Description

RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ333J- R CARBON FILM 1/6 33K OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ151J- R CARBON FILM 1/6 150 OHM J

RD-AZ151J- R CARBON FILM 1/6 150 OHM J

RD-AZ224J- R CARBON FILM 1/6 220K OHM J

RD-AZ224J- R CARBON FILM 1/6 220K OHM J

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ183J- R CARBON FILM 1/6 18K OHM J

RD-AZ183J- R CARBON FILM 1/6 18K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ334J- R CARBON FILM 1/6 330K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ479J- R CARBON FILM 1/6 4.7 OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ333J- R CARBON FILM 1/6 33K OHM J

RD-AZ333J- R CARBON FILM 1/6 33K OHM J

RD-AZ470J- R CARBON FILM 1/6 47 OHM J

25

Page 27

ELECTRICAL PARTS LIST

Part Code Description

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ474J- R CARBON FILM 1/6 470K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ331J- R CARBON FILM 1/6 330 OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ334J- R CARBON FILM 1/6 330K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ563J- R CARBON FILM 1/6 56K OHM J

RD-AZ563J- R CARBON FILM 1/6 56K OHM J

RD-4Z561J- R CARBON FILM 1/4 560 OHM J

RD-4Z561J- R CARBON FILM 1/4 560 OHM J

RD-4Z563J- R CARBON FILM 1/4 56K OHM J

RD-4Z563J- R CARBON FILM 1/4 56K OHM J

RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

RD-4Z222J- R CARBON FILM 1/4 2.2K OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z124J- R CARBON FILM 1/4 120K OHM J

RD-4Z101J- R CARBON FILM 1/4 100 OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z101J- R CARBON FILM 1/4 100 OHM J

RD-4Z222J- R CARBON FILM 1/4 2.2K OHM J

RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

RD-4Z683J- R CARBON FILM 1/4 68K OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-4Z393J- R CARBON FILM 1/4 39K OHM J

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

Part Code Description

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

RD-4Z689J- R CARBON FILM 1/4 6.8 OHM J

RD-4Z689J- R CARBON FILM 1/4 6.8 OHM J

RD-4Z689J- R CARBON FILM 1/4 6.8 OHM J

RD-4Z689J- R CARBON FILM 1/4 6.8 OHM J

RD-4Z681J- R CARBON FILM 1/4 680 OHM J

RD-4Z681J- R CARBON FILM 1/4 680 OHM J

RD-4Z681J- R CARBON FILM 1/4 680 OHM J

RD-4Z681J- R CARBON FILM 1/4 680 OHM J

RD-4Z103J- R CARBON FILM 1/4 10K OHM J

RD-AZ109J- R CARBON FILM 1/6 1 OHM J

RD-AZ109J- R CARBON FILM 1/6 1 OHM J

RD-AZ221J- R CARBON FILM 1/6 220 OHM J

RD-AZ221J- R CARBON FILM 1/6 220 OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

9737612800 PACK TUNER FTA4-460V

5XA7R20000 X-TAL 7.2M

5XA4R332M- X-TAL 4.332M

Part Code Description

9CDC053600 PCB FRONT AS AMI-722L

9CD6578900 PCB FRONT 197X163X1.6T

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H150J C CERA 50V CH 15PF J (TAPPING)

26

Page 28

ELECTRICAL PARTS LIST

Part Code Description

CXCH1H180J C CERA 50V CH 18PF J (TAPPING)

CXCH1H330J C CERA 50V CH 33PF J (TAPPING)

CXCH1H330J C CERA 50V CH 33PF J (TAPPING)

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H223Z C CERA 50V F 0.022MF Z (TAPPING)

CXCH1H330J C CERA 50V CH 33PF J (TAPPING)

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CEXE1A102A C ELECTRO 10V RS 1000MF 13X20

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

9736408300 CONN WAFER 52492-1920 19P BOTTOM

9728801500 CONN AS #26 8P FLAT 270MM

9738834100 CONN AS #26 13P FLAT 100MM

9738834000 CONN AS #26 2.0PITCH 11P FLAT 150

9736407700 PIN WAFER 52084-1310 13P BOTTOM

9736407900 CONN WAFER 52084-1010 10P BOTTOM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

DSVA09MM10 VFD SVA09MM10

1M38199316 IC U-COM M38199

124LC04BP- IC EEPROM 24LC04BP

1MSGEQ5A-- IC MSGEQ5A

1TM97CT38P IC PRE AMP LTM97CT-38P

1BU4094BCF IC BU4094BCF(SOP16)

Part Code Description

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY17J5 WIRE JUMPER AWG22 1/0.65 SN 17.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

27

Page 29

ELECTRICAL PARTS LIST

Part Code Description

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

Part Code Description

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KEE- LED LTL-16KEE(RED)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KEE- LED LTL-16KEE(RED)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

28

Page 30

ELECTRICAL PARTS LIST

Part Code Description

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KEE- LED LTL-16KEE(RED)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KGE- LED LTL-16KGE(GREEN)PI3.1

DLTL16KEE- LED LTL-16KEE(RED)PI3.1

TKRC107M-- TR KRC107-M TAPPING(KSR1006)

TKRC111M-- TR KRC111M (KSR1010)

TKRC111M-- TR KRC111M (KSR1010)

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

TZTA1273Y- TR KTA1273Y(966Y)

TZTA1273Y- TR KTA1273Y(966Y)

TZTA1273Y- TR KTA1273Y(966Y)

TKRC107M-- TR KRC107-M TAPPING(KSR1006)

TKRC107M-- TR KRC107-M TAPPING(KSR1006)

TKRC107M-- TR KRC107-M TAPPING(KSR1006)

TKRA111M-- TR KRA111-M TAPPING(KSR2010)

TKRA111M-- TR KRA111-M TAPPING(KSR2010)

TKRA111M-- TR KRA111-M TAPPING(KSR2010)

TKRA111M-- TR KRA111-M TAPPING(KSR2010)

TKRA111M-- TR KRA111-M TAPPING(KSR2010)

TZRC107M-- TR KRC107M(AUTO)

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ151J- R CARBON FILM 1/6 150 OHM J

RD-AZ181J- R CARBON FILM 1/6 180 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ331J- R CARBON FILM 1/6 330 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ471J- R CARBON FILM 1/6 470 OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ821J- R CARBON FILM 1/6 820 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ151J- R CARBON FILM 1/6 150 OHM J

RD-AZ181J- R CARBON FILM 1/6 180 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ331J- R CARBON FILM 1/6 330 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ471J- R CARBON FILM 1/6 470 OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ821J- R CARBON FILM 1/6 820 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

Part Code Description

RD-AZ151J- R CARBON FILM 1/6 150 OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ333J- R CARBON FILM 1/6 33K OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ182J- R CARBON FILM 1/6 1.8K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ689J- R CARBON FILM 1/6 6.8 OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ689J- R CARBON FILM 1/6 6.8 OHM J

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

29

Page 31

ELECTRICAL PARTS LIST

Part Code Description

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RD-AZ106J- R CARBON FILM 1/6 10M OHM J

RD-AZ334J- R CARBON FILM 1/6 330K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

RD-AZ224J- R CARBON FILM 1/6 220K OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ101J- R CARBON FILM 1/6 100 OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ224J- R CARBON FILM 1/6 220K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ334J- R CARBON FILM 1/6 330K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ334J- R CARBON FILM 1/6 330K OHM J

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

RD-AZ683J- R CARBON FILM 1/6 68K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

Part Code Description

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5S50101001 SW TACT KPT-1105A 1C-1P

5SH162401- SW ENCORDER EC16B24204 24P W/DETENT

5PCSA8MTZ- RESONATOR CSA8MTZ, 8MHZ

5XA32R768- X-TAL DT-38 32.768KHZ 20PPM

Part Code Description

9CDC046100 PCB CD AS AMI-810LN0FR

9CD6574800 PCB CD 247X197

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCZB1E121K C CERA 25V B 120PF K (AXIAL)

CCXF1H473Z C CERA 50V F 0.047MF Z (TAPPING)

CCZB1E222K C CERA 25V B 2200PF K (AXIAL)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

30

Page 32

ELECTRICAL PARTS LIST

Part Code Description

CCXF1H104Z C CERA 50V F 0.1MF Z

CCZB1E682K C CERA 25V B 6800PF K (AXIAL)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCZB1E222K C CERA 25V B 2200PF K (AXIAL)

CZCH1E809K C CERA CH 25V 8PF K AXL 52MM

CCZB1E472K C CERA 25V B 4700PF K (AXIAL)

CZCH1E309K C CERA CH 25V 3PF K AXIAL

CCZB1E102K C CERA 25V B 1000PF K (AXIAL)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H473Z C CERA 50V F 0.047MF Z (TAPPING)

CCZB1E152K C CERA 25V B 1500PF K (AXIAL)

CZCH1H270J C CERA CH 50V 27PF J AXL 52MM

CZCH1H270J C CERA CH 50V 27PF J AXL 52MM

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H473Z C CERA 50V F 0.047MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCZB1E151K C CERA 25V B 150PF K (AXIAL)

CCZB1E151K C CERA 25V B 150PF K (AXIAL)

CCZB1E102K C CERA 25V B 1000PF K (AXIAL)

CCZB1E102K C CERA 25V B 1000PF K (AXIAL)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCZB1E472K C CERA 25V B 4700PF K (AXIAL)

CCZB1E472K C CERA 25V B 4700PF K (AXIAL)

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CCXF1H104Z C CERA 50V F 0.1MF Z

CXCH1H101J C CERA 50V CH 100PF J (TAPPING)

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

Part Code Description

CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXE1C102A C ELECTRO 16V RS 1000MF 13X20

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

CMXM1H333J C MYLAR 50V 0.033MF J (TP)

CMXM1H683J C MYLAR 50V 0.068 MF J

CMXM1H183J C MYLAR 50V 0.018MF J

CMXM1H333J C MYLAR 50V 0.033MF J (TP)

CMXM1H122J C MYLAR 50V 0.0012MF J

CMXM1H122J C MYLAR 50V 0.0012MF J

9738840800 CONN AS FFC 16P P1.0X250MM R

9738840900 CONN AS FFC 19P P1.25X110MM K

9738832100 CONN AS 7P 200 P=2.5 BOARDIN

9CD6259300 CONN WAFER 52807-1610

9CD6259600 CONN WAFER 2503-WS-2P

9CD6259500 CONN WAFER 2001-WS-6P

9CD6259400 CONN WAFER 2001-WS-12P

9736408400 CONN WAFER 52045-1945 19P

DZTZ5R6B-- DIODE ZENER UZ-5.6B

DZTZ3R9B-- DIODE ZENER MTZ3.9B

DZTZ5R6B-- DIODE ZENER UZ-5.6B

DZTZ5R6B-- DIODE ZENER UZ-5.6B

DZN4148--- DIODE 1N4148 AUTO 52MM

DZN4148--- DIODE 1N4148 AUTO 52MM

1KA9220B-- IC CHIP RF KA9220B

1KA9282B-- IC AUDIO DSP KA9282B

31

Page 33

ELECTRICAL PARTS LIST

Part Code Description

1KA9258D-- IC CHIP KA9258D

1DBL2084-- IC DBL2084(D/W)

1KA9270--- IC AUDIO KA9270

1DBL2084-- IC DBL2084(D/W)

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

Part Code Description

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

32

Page 34

ELECTRICAL PARTS LIST

Part Code Description

TKSA928AY- TR KSA928A-Y

TKSA928AY- TR KSA928A-Y

TKSC2331Y- TR KSC2331Y

TKSR1003-- TR KSR1003

TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

RV6417223- R SEMI FIXED VM6CK-PV(1S) B 22K OHM

RV6417223- R SEMI FIXED VM6CK-PV(1S) B 22K OHM

RD-AZ474J- R CARBON FILM 1/6 470K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ154J- R CARBON FILM 1/6 150K OHM J

RD-AZ184J- R CARBON FILM 1/6 180K OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ820J- R CARBON FILM 1/6 82 OHM J

RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ473J- R CARBON FILM 1/6 47K OHM J

RD-AZ124J- R CARBON FILM 1/6 120K OHM J

RD-AZ563J- R CARBON FILM 1/6 56K OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ563J- R CARBON FILM 1/6 56K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ154J- R CARBON FILM 1/6 150K OHM J

RD-AZ183J- R CARBON FILM 1/6 18K OHM J

RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RD-AZ223J- R CARBON FILM 1/6 22K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

Part Code Description

RD-AZ220J- R CARBON FILM 1/6 22 OHM J

RD-AZ124J- R CARBON FILM 1/6 120K OHM J

RD-AZ124J- R CARBON FILM 1/6 120K OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ474J- R CARBON FILM 1/6 470K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ273J- R CARBON FILM 1/6 27K OHM J

RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

RD-AZ100J- R CARBON FILM 1/6 10 OHM J

RD-AZ221J- R CARBON FILM 1/6 220 OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-2Y229J- R CARBON FILM 1/2 2.2 OHM J

RD-AZ121J- R CARBON FILM 1/6 120 OHM J

RD-AZ221J- R CARBON FILM 1/6 220 OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RD-AZ273J- R CARBON FILM 1/6 27K OHM J

RD-AZ273J- R CARBON FILM 1/6 27K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ123J- R CARBON FILM 1/6 12K OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ105J- R CARBON FILM 1/6 1M OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

33

Page 35

ELECTRICAL PARTS LIST

Part Code Description

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ104J- R CARBON FILM 1/6 100K OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-AZ393J- R CARBON FILM 1/6 39K OHM J

RD-4Z100J- R CARBON FILM 1/4 10 OHM J

RD-4Z100J- R CARBON FILM 1/4 10 OHM J

9713550400 PIN WRAPPING 1.0X2.5X15

9713550400 PIN WRAPPING 1.0X2.5X15

9713550400 PIN WRAPPING 1.0X2.5X15

9713550400 PIN WRAPPING 1.0X2.5X15

5PCSA16R93 RESONATOR CERA CSA16.93MXZ04

Part Code Description

9CDC047800 PCB PT AS AMI-716LR

9CD6575301 PCB PT 330X197X1.6T

9736900200 CORD AC KKP419C,KLCE-2F,0.75SQURE

9738833900 CONN AS #22 8P BOARD-IN 300MM

9734600700 CLIP FUSE FC-5N

9734600700 CLIP FUSE FC-5N

5FSGB8012L FUSE GLASS TUBE SEMKO MF51 800MA 250V TL

W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

5TP8066768 TRANS POWER EI=66X50 230V 50HZ

RN-2Y475J- R METAL FILM 1/2 4.7M OHM J

9713550400 PIN WRAPPING 1.0X2.5X15

9713550400 PIN WRAPPING 1.0X2.5X15

Part Code Description

9CDM035600 PANEL FRONT AS AMI-322L

9CD0307100 PANEL FRONT MIPS (334.5 G)

9CD1500900 BADGE DAEWOO ABS HOT STAMPING

9CD18105A0 DOOR CASS A MIPS (39.1 G)

9CD16153A0 WINDOW DOOR A ACRYL (5.0 G)

9CD1809400 DOOR FRAME A ABS

9CD30078L0 SPRING DOOR EJECT(L) SUS D0.9

9CD18105B0 DOOR CASS B MIPS (39.1 G)

9CD16153B0 WINDOW DOOR B ACRYL (5.0 G)

9CD1809500 DOOR FRAME B ABS

9CD30078R0 SPRING DOOR EJECT(R) SUS D0.9

9CD1810600 DOOR CD MIPS

9CD1615400 WINDOW FLT ACRYL (60.4 G)

9CD1337900 KNOB FUNCTION ACRYL (6.2 G)

9CD1338000 KNOB CD ABS (6.3 G)

9CD1338100 KNOB POWER ABS (9.3 G)

9CD1338200 KNOB CONTROL ABS (30.5 G)

9CD13383L0 KNOB EQ L ABS (5.6 G)

9CD13383R0 KNOB EQ R ABS (5.6 G) X 112EA

9CD1334400 KNOB VOLUME ABS

9CD2505600 GUIDE FLT ABS

9CD0910700 PLATE FILTER PC T0.3 X 2EA

7173261011 SCREW TAPPTITE TT2 BIN 2.6X10 MFZN X 172EA

9CD2412900 BRKT SIDE ABS 1.5GR X 2EA

7173261011 SCREW TAPPTITE TT2 BIN 2.6X10 MFZN

9CD2603200 DAMPER GEAR B ACETAL X 2EA

9CD2603300 DAMPER BASE B ABS X 2EA

7173301011 SCREW TAPPTITE TT2 BIN 3X10 MFZN X 2EA

9CD0B01900 LOCKER BASE AMI-221M X 2EA

9CD0B02000 LOCKER CAM AMI-221M X 2EA

9CD0B01600 LOCKER SPRING PW-1 D0.3 X 2EA