Page 1

Service Manual

MINI COMPONENT SYSTEM

Model :

DAEWOO ELECTRONICS CO., LTD.

AMI-225M/MU

AMI-325M/MU

Page 2

Table of Contents

Model No:AMI-225M/MU, 325M/MU

- 1 -

SAFETY PRECAUTIONS......................................................................................... 2

ADJUSTMENTS....................................................................................................... 4

EXPLODED VIEW AND PARTS LIST ...................................................................... 6

WIRING DIAGRAM ................................................................................................... 8

BLOCK DIAGRAM .................................................................................................... 9

SCHEMATIC DIAGRAM ........................................................................................... 10

POWER / AMP ................................................................................................................................ 10

CD ......................................................................................................................................................12

TUNER ...............................................................................................................................................13

TAPE .................................................................................................................................................14

CONTROL .........................................................................................................................................15

PCB PATTERN LAYOUT ........................................................................................ 16

ELECTRICAL PART LIST ....................................................................................... 19

MINI COMPONENT SYSTEM

AMI-225M/MU

AMI-325M/MU

Page 3

Safety Precautions

- 2 -

WARNING

: TO PREVENT FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION :

TO REDUCE THE RISK IF ELECTRIC SHOCK, DO NOT

REMOVE COVER (OR BACK). NO USER SERVICEABLE PARTS

INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULTED "DANGEROUS VOLTAGE"

WITHIN THE PRODUCT'S ENCLOSURE THAT MAY BE

SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK TO PERSONS.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF IMPORTANT OPERATING AND MAINTENANCE

(SERVICING) INSTRUCTIONS IN THE LITERATURE

ACCOMPANYING THE APPLIANCE.

CAUTION

TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS POLARIZED AC

PLUG WITH AN EXTENSION CORD, RECEPTACLE OR OTHER OUTLET

UNLESS THE BLADES CAN BE FULLY INSERTED TO PREVENT BLADE

EXPOSURE.

LASER SAFETY

THIS UNIT EMPLOYS A LASER. ONLY QUALIFIED SERVICE PERSONNEL

SHOULD REMOVE THE COVER OR ATTEMPT TO SERVICE THIS DEVICE

DUE TO POSSIBLE EYE INJURY.

CAUTION :

USE OF ANY CONTROLS, ADJUSTMENTS, OR PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

CAUTION :

TO PREVENT ELECTRIC SHOCK, MATCH WIDE BLADE OF

PLUG TO WIDE SLOT, FULLY INSERT.

ATTENTION :

POUR EVITER LES CHOCS ELECTRIQUES, INTRODUIRE

LA LAME LA PLUS LARGE DE LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER JUSQU'AU FOND.

Important Safety Instructions

- All the safety and operating instructions should be read before

the appliance is operated.

- The safety and operating instructions should be retained for

future reference.

- All warnings on the appliance and in the operating instructions

should be adhered to.

- All operating and use instructions should be followed.

1. Water and Moisture - The appliance should not be

used near

water - for example, near a bathtub, washbowl, kitchen sink,

laundry tub, in a wet basement, or near a swimming pool,

and the like.

2. Carts and Stands - The appliance

should be used only with a cart or

stand that is recommended by th

manufacturer.

3. An appliance and cart combination

should

be moved with care. Quick

stops, excessive force, and uneven

surfaces may cause the appliance

and

cart combination to overturn.

4. Wall or Ceiling Mounting - The appli-

ance

should be mounted to a wall or

ceiling

only as recommended by the

manufacturer.

5. Ventilation - The appliance should be situated so

that its

location or position does not interfere with

its proper

ventilation. For example, the appliance

should not be situated

on a bed, sofa, rug, or

similar surface that may block the

ventilation

openings; or, placed in a built-in installation, such

as a bookcase or cabinet that may impede the flow

of air

through the ventilation openings.

6. Heat - The appliance should be situated away from

heat

sources such as radiators, heat registers,

stoves, or other

appliances (including amplifiers) that

produce heat.

7. Power Sources - The appliance should be

connected to a

power supply only of the type

described in the operating

instructions or as marked

on the appliance.

8. Grounding or Polarization - The precautions that

should be

taken so that the grounding or

polarization means of an

appliance is not defeated.

9. Power - Cord Protection - Power-supply cords

should be

routed so that they are not likely to be

walked on or pinched

by items placed upon or

against them, paying particular

attention to cords at

plugs, convenience receptacles, and the

point where

they exit from the appliance.

10.Protective Attachment Plug - The appliance is equipped with

an attachment plug having overload

protection. This is a

safety feature.

See Instruction Manual for replacement or

resetting of

protective device. If replacement of the plug is

required, be sure the

service technician has used a

replacement plug

specified by the manufacturer that has the

same overload protection as the original plug.

11.Cleaning - The appliance should be cleaned only as

recommended by the manufacturer.

12.Power Lines - An outdoor antenna should be located

away

from power lines.

CAUTION

RISK OF ELECTRIC SHOCKS

DO NOT OPEN

PORTABLE CART

Figure 2

Page 4

Safety Precautions

- 3 -

13.Outdoor Antenna Grounding - If an outside antenna

is

connected to the receiver be sure the antenna

system is

grounded so as to provide some protection against voltage

surges and built-up static

charges. Article 810 of the National

Electrical Code,

ANSI/NFPA 70, provides information with

regard to

proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna-dis

charge unit, size of grounding conductors,location of antennadischarge unit, connection to grounding electrodes and

requirements for the grounding electrode. See Figure 1.

14.Non-use Periods - The power cord of the appliance should be

unplugged from the outlet when left

unused for a long period

of time.

15.Object and Liquid Entry - Care should be taken so

that objects

do not fall and liquids are not spilled into the enclosure through

openings.

16.Damage Requiring Service - The appliance should

be

serviced by qualified service personnel when:

a) The power-supply cord or the plug has been

damaged; or

b) Objects have fallen, or liquid has been spilled

into the

appliance; or

c) The appliance has been exposed to rain; or

d) The appliance does not appear to operate

normally or

exhibits a marked change in

performance; or

e) The appliance has been dropped, or the

enclosure

damaged.

17.Servicing - The user should not attempt to service the

appliance beyond that described in the operating instructions.

All other servicing

should be referred to qualified service

personnel.

ANTENNA DISCHARGE UNIT

(NEC SECTION 810-20)

ANTENNA LEAD

IN WIRE

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250 PART H)

GROUND CLAMP

ELECTRIC

SERVICE

EQUIPMENT

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

EXAMPLE OF ANTENNA

GROUNDING

NEC - NATIONAL ELECTRICAL CODE

Page 5

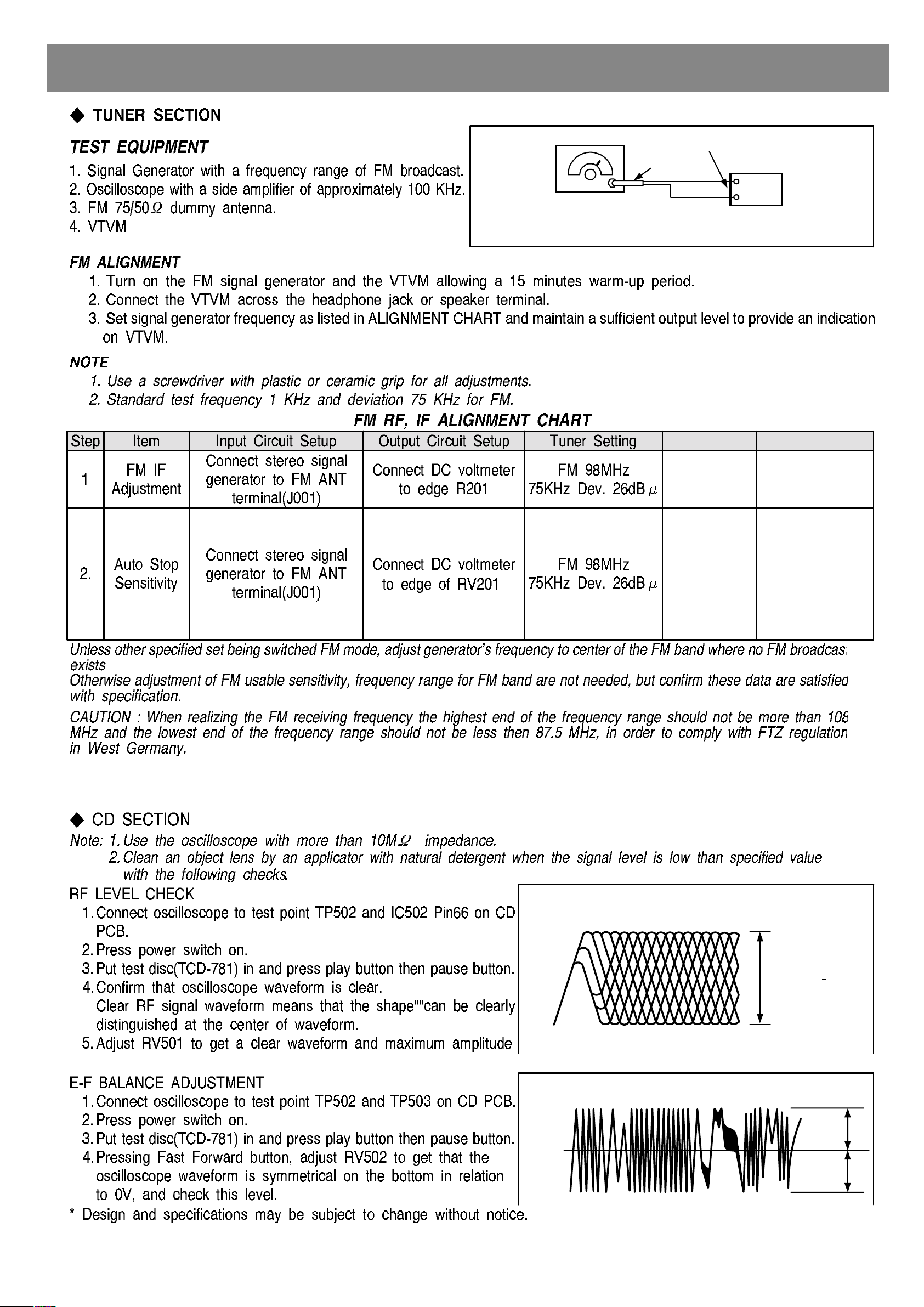

Adjustments

- 4 -

SET

FM Antenna

Terminal(75 ohm)

Carrier Frequency : 98MHz

Output Level : 26dBuV

Modulation:Audio 1kHZ, 75kHz Deviation

FM RF SSG

75 ohm Coaxal

Level : 1.2+0.3Vp-p

RF Signal Waveform

VOLT/DIV : 200mV

TIME/DIV : 50ns

Traverse Waveform

A

B

0V

Check Point

Confirm

: No Adjustment : OPTION

Confi rm st er eo

indicator is

li ghted and L/ R

channel i s

seperated.

Con fi rm F M

wave

Page 6

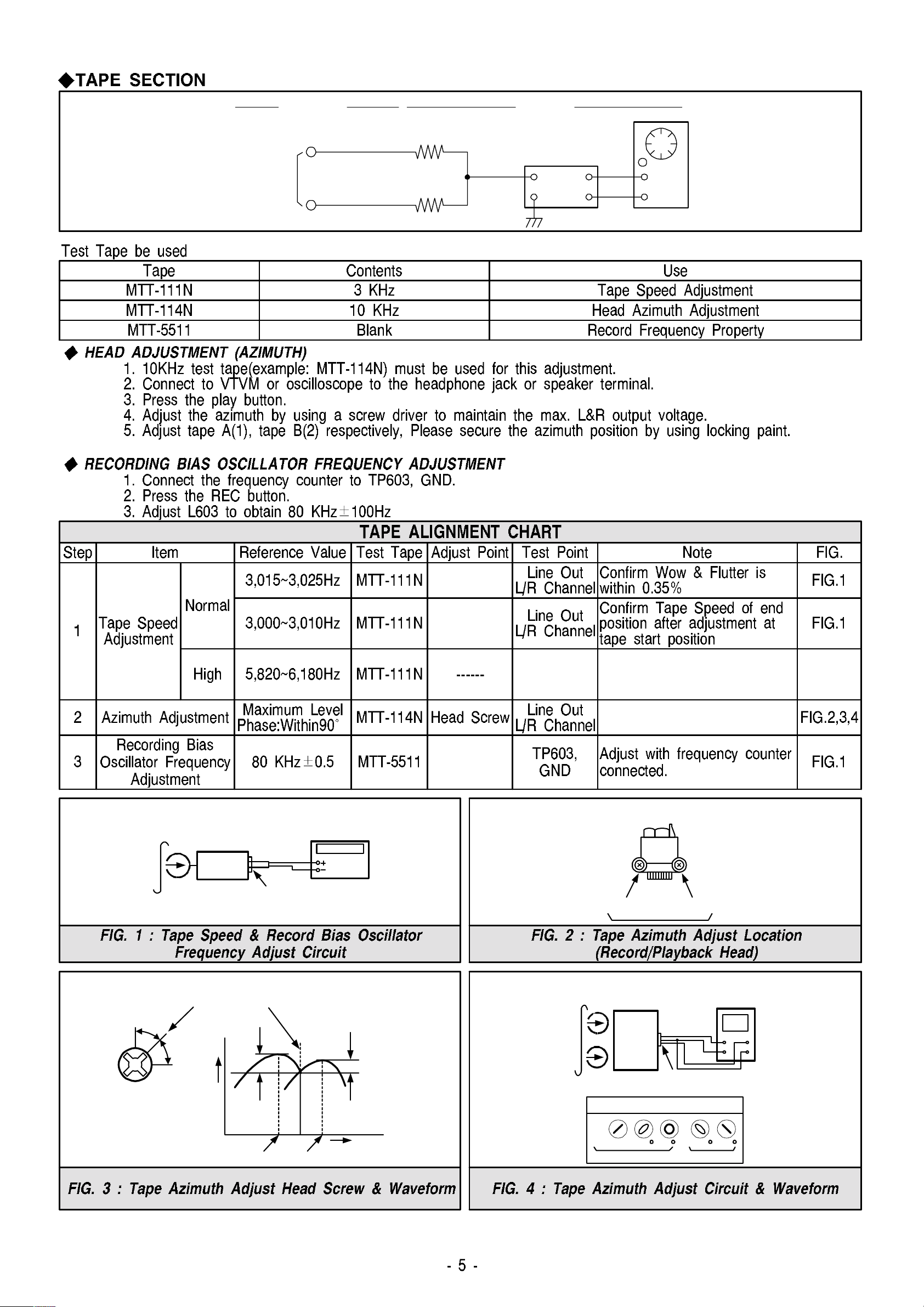

VTVM

Scope

R-CH

L-CH

47 kohm

47 kohm

Input Level

Measurement

Point

Input Point

Output Level

Measurement

Point

Test Tape : MTT-111N(3kHz)

MTT-5511(Blank)

Frequency Counter

Output Level

Measurement Point

Set

Forward

Side

Reverse

Side

Adjust with Frequency

Counter Connected

L-CH

Peak

R-CH

Peak

Screw

Angle

Output Level

within

1 dB

within

1 dB

L-CH

Peak

R-CH

Peak

Screw Angle

VH

Oscilloscope

L-CH

Output Level

Measurement Point

Set

Test Tape

MTT-114N

(10kHz)

Screen Pattern

In Phase 45 90 135 180

Good Wrong

RV701

RV701

L601

Page 7

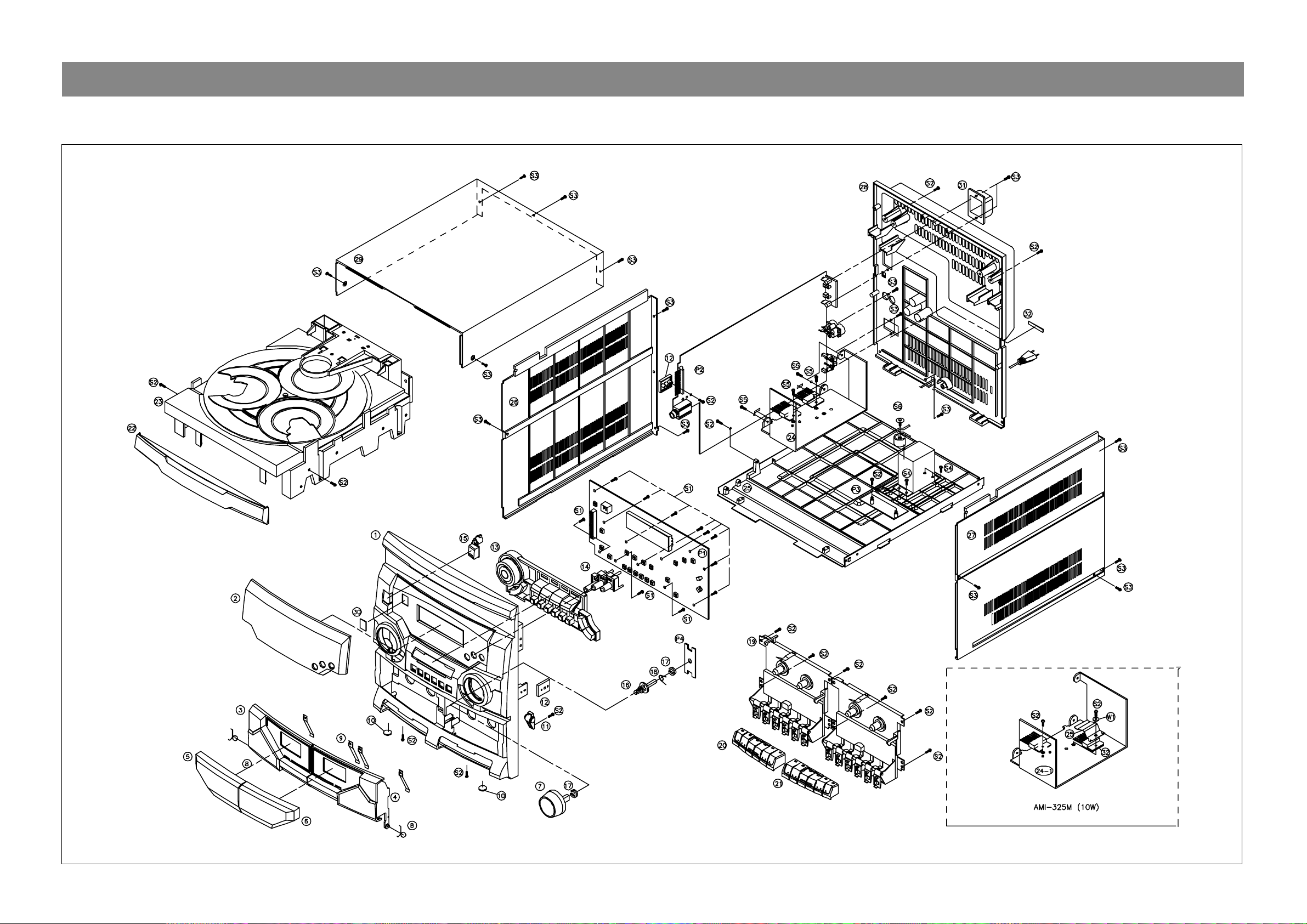

Exploded View and Mechanical Parts List

Model No:AMI-225M/MU, 325M/MU

- 6 -

Page 8

- 7 -

Mechanical Part List

NO Part Name Parts Code Q'ty Comment

1 PANEL FRONT 9CD0307900 1

2 WINDOW FLT 9CD1616400 1

3 DOOR CASS A 9CD18111A0 1

4 DOOR CASS B 9CD18111B0 1

5 WINDOW DOOR A 9CD16163A0 1

6 WINDOW DOOR B 9CD16163B0 1

7 KNOB VOLUME 9CD1339800 1

8 SPRING DOOR EJECT 9CD3004500 2

9 SPRING C HOLDER 9713008900 4

10 CUSHION FOOT 9CD4207700 2

11 DAMPER ASSY

9CD2603000

9CD2603100

1

12 BRAKET SIDE 9CD2412900 2

13 KNOB CONTROL 9CD1339500 1

14 KNOB CD 9CD1339700 1

15 KNOB POWER 9CD1339600 1

16 SHAFT VR 9CD3601900 1

17 SHAFT WASHER 9CD3602000 2

18 SPRING TUNING 9CD3007000 1

19

CASS DECK MECHANISM

9CD6007900 1

OPTION

20 KNOB DECK A 9CD13329R1 1

21 KNOB DECK B 9CD13330R1 1

22 DOOR CD 9CD1811200 1

23 CD DECK MECHSNISM 9CD6006900 1

24 HEAT SINK 05 9CD4405100 1

24-1 HEAT SINK 1 9CD4404500 1 OPTION

25 CHASSIS BOTTOM 9CD0608000 1

26 COVER SIDE L 9CD04115L0 1

27 COVER SIDE R 9CD04115R0 1

28 COVER BACK 9CD0409801 1

29 COVER TOP 9CD0411400 1

30 PLATE EON 9CD0910100 1

31 COVER ANT 9CD0410400 1

OPTION

32 LABEL SPK (6¥Ø) 9CD9309400 1

S1 SCREW TAPPTITE 7173260811 11

S2 SCREW TAPPTITE 7173301011 17

S3 SCREW TAPPTITE 7173301212 18

S4 SCREW TAPPTITE 7173401011 4

S5 SCREW TAPPTITE 7173300811 5

S6 WASHER SCREW 9CD3102400 1

P1 PCB FRONT 9CD6579800 1

P2 PCB MAIN 9CD6580000 1

P3 PCB FUSE 9CD6579700 1

P4 PCB GUIDE 9CD6579801 1

ABS

MIPS

ABS

ABS

ABS

ACETAL

SUS D0.6 ACD-7600

AUTO STOP

ABS

ABS

Description

MIPS

ACRYL

MIPS

MIPS

ACRYL

ACETAL

ACRYL

PW-1

ABS

STS (T=0.2)

URETHAN FOAM RUBBER

DA-12A

MIPS

DCC-01B

AL (5W)

MIPS

AL (10W)

MIPS

MIPS

MIPS

PVC SHEET

ABS

PE FILM

TT2 BIN 3X12 BK

TT2 BIN 4X10 MFZN

TT2 BIN 2.6X8 MFZN

TT2 BIN 3X10 MFZN

34 x 75 x 1.6T

13 x 32 x 1.6T

330 x 197 x 1.6T

247 x 139 x 1.6T

TT2 BIN 3X8 MFZN

TT2 BIN 3X10+D14

Page 9

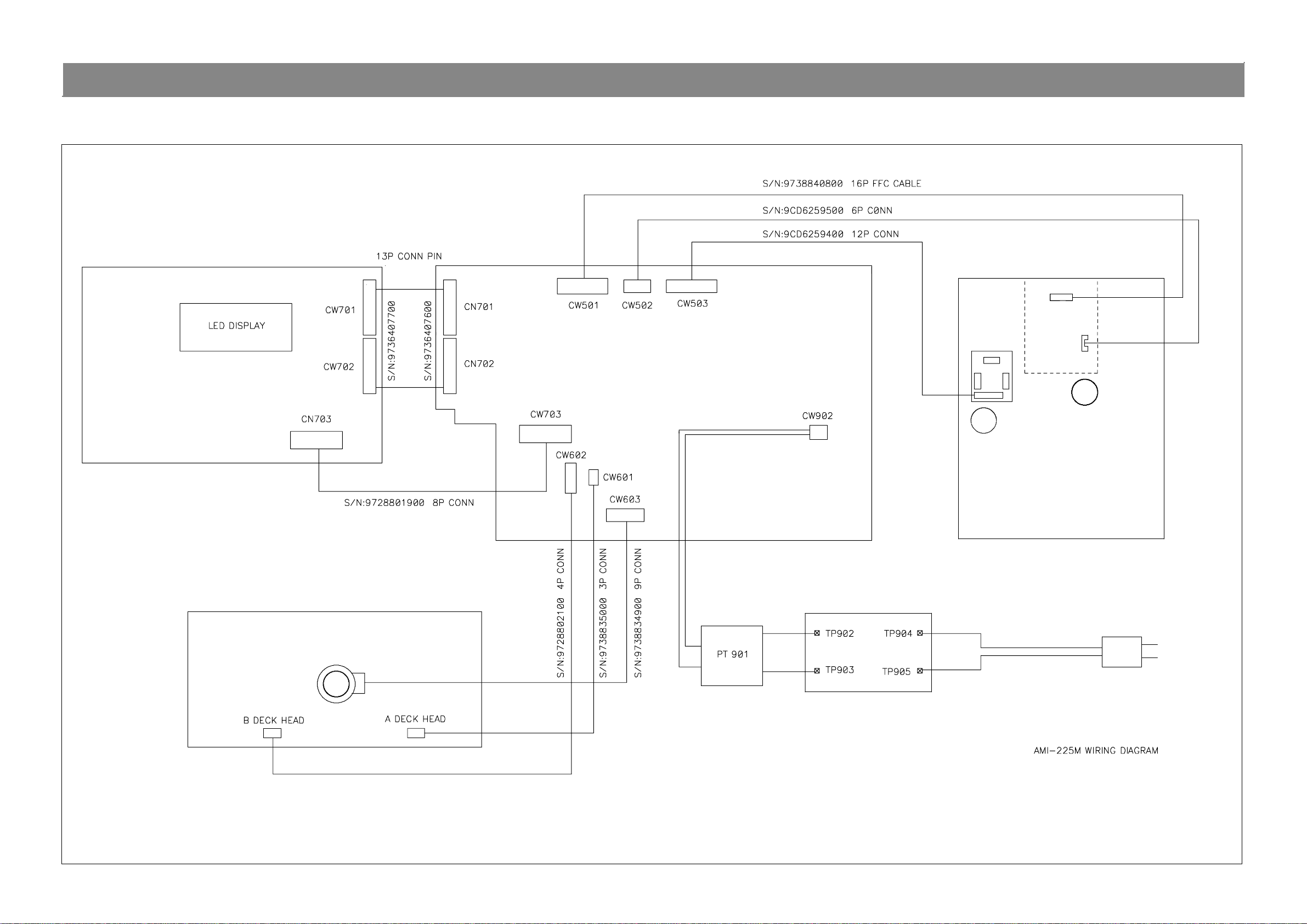

WIRING DIAGRAM

AMI-225M/MU, 325M/MU

Pick-Up

FRONT PCB ASSY

S/N :

CASETTE DECK

M

M

MAIN PCB ASSY

S/N :

MM

MM

CD MECHA. ASS'Y

AC CORD

- 8 -

POWER TRANS

FUSE PCB ASSY

S/N :

A3A3

Page 10

BLOCK DIAGRAM

AMI-225M/MU, 325M/MU

Page 11

Schemetic Diagram

Model No:AMI-225M/MU

Ass'y Name: POWER/AMP

- 10 -

Page 12

Schemetic Diagram

AMI-325M/MU

POWER / AMP

- 11 -

Page 13

Schemetic Diagram

AMI-225M/MU, 325M/MU

CD

- 12 -

Page 14

Schemetic Diagram

Model No:AMI-225M/MU, 325M/MU 2BAND

Ass'y Name: TUNER

MAIN GND

2

2

3

3

10

41 7

5

6

8

9

11 14

6 5 4 9 8 7 11 12

L101

TOKO

KWANGSUNG

CC104 : 12pF

CC104 : 15pF

TOKO : RBW07VB-K5024

KWANGSUNG : KSNT-213M-1

Name

Pin No.

Vtg(V)

IC201

Pin No.

Vtg(V) 1.81.8

#1 : SD ON(0V)

OTHERWISE(5V)

#2 : STEREO ON(0V)

1 2

2.1 4.8

13 14

3

2.142.1

15

2.1

5 6 7 8 9 10 11 12

#2#1

GND 2.9

4.8 3.5 3.8

16 17 18 19 20 21 22 23 24

2.1 2.1 2.1 2.1 2.1#4 #5 4.8 3.5

#3 : NORMAL(V=< 0.5V )

MUTE(1.4V=<V=<2.2V)

SEEK(V>=3.5V)

#4 : FM(0V), AM(1.5V)

#5 : FM(0.2V), AM(0.9V)

#3

OTHERWISE(5V)

Name

Pin No.

1 2

Vtg(V)

2.5

N.C

IC202

Pin No.

12

13

0

Vtg(V)

VCC

#1 : FM(3.7), AM(0)

#3 : FM(3.7), AM(0)

AM/FM

IF

S-CURVE

1

BUFF

1210

13

13

14

304KHz

19K 19K 0

#5 : FM(0), AM(2.4)

#7 : VT

Name

Vtg(V)

CC214

FTZ

X

CE

O

R217

FTZ

JW

CE

4 5 6 7 8 9 10 11

3

0

14

N.C

VCC1#1 #2#7#3 0

15 16 17 18 19 20 21 22

#5 #6

1

#2 : ON TUNING OPERATION(VCC)

#4 : FM(0), AM(12)

#6 : FM(2.4), AM(0)

Q00312Q104 IC205

Q001

E(1)

0

C(2)

0

B(3)

0

JW204 JW205

CC215

X

X

O

O

R218

R219

JW

X

O

O

O

0

R220

X

O

0

012

X

O

JW213

O

X

12

GND

512

L202 R214 R215

L201

O

XOX

CC203

820pF

#40 0

GNDVCC 2.5

REMARK

BASIC : FM

X

TU001

4Gang

3Gang

OO

X

CF002

MJ-A560pF

MS3-A

14

15

11

16

9

18

21 20

VSS VT

N.C

AM OSC

MUTE

FM OSC

ST/MO

PD

19

12

VT-IN FM/AM IF N.C VDD

2

1/2

FTZ OPTION

17

7

AM/FM

8

IF REQ

6

DO

5

CL

C B

4

DI

I/F

3

CE

13

FM

10

X-IN

1

22

X-OUT

- 13 -

Page 15

Schemetic Diagram

Model No:AMI-225M/MU, 325M/MU

Ass'y Name: TAPE

- 14 -

Page 16

Schemetic Diagram

Model No:AMI-225M/MU, 325M/MU

Ass'y Name: CONTROL

- 15 -

Page 17

P.C.B Pattern Layout

Model No:AMI-225M/MU, 325M/MU

Ass'y Name: POWER/AMP/TUNER

- 16 -

Page 18

P.C.B Pattern Layout

Model No:AMI-225M/MU, 325M/MU

Ass'y Name: CD P.C.B

- 17 -

Page 19

P.C.B Pattern Layout

Model No:AMI-225M/MU, 325M/MU

Ass'y Name: FRONT

- 18 -

Page 20

Electrical Parts List

19

225M 225MU 325M 325MU

1 PCB FRONT AS 12000 PCB FRONT AS 9CDC054300 AMI-225M o o

2 PCB FRONT AS 12000 PCB FRONT AS 9CDC054301 AMI-225MU o

3 PCB FRONT AS 12000 PCB FRONT AS 9CDC054302 AMI-325MU o

4 PCB FRONT AS B001 PCB FRONT 9CD6579800 247X139 o o o o

5 PCB FRONT AS CC701~70 4 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

6 PCB FRONT AS CC705~70 7 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

7 PCB FRONT AS CC708 C CERA CZCH1E150J CH 25V 15PF J (AXIAL) o o o o

8 PCB FRONT AS CC709 C CERA CZCH1E180J CH 25V 18PF J (AXIAL) o o o o

9 PCB FRONT AS CC710 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

10 PCB FRONT AS CC711~71 2 C CERA CZCH1E330J CH 25V 33PF J AXIAL 52MM o o o o

11 PCB FRONT AS CC713 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

12 PCB FRONT AS CC714 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

13 PCB FRONT AS CE701 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

14 PCB FRONT AS CE702 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

15 PCB FRONT AS CE703 C ELECTRO CEXF0J102V 6.3V RSS 1000MF 10X12.5 o o o o

16 PCB FRONT AS CE704 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

17 PCB FRONT AS CE705 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

18 PCB FRONT AS CE706 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

19 PCB FRONT AS CE707 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o

20 PCB FRONT AS CN701~70 2 PIN WAFER 9736407700 52084-1310 13P BOTTOM o o o o

21 PCB FRONT AS CN703 CONN 9728801900 8P 150MM o o o o

22 PCB FRONT AS D701~70 4 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

23 PCB FRONT AS IC701 IC EEPROM 124LC04BP- 24LC04BP o o o o

24 PCB FRONT AS IC702 IC 1M38869225 M38869M8A o o o o

25 PCB FRONT AS IC703 IC RESET 1K1A7029AP KIA7029AP o o o

26 PCB FRONT AS IC703 IC 1K1A7029- - KIA7029 o

27 PCB FRONT AS JW712~71 3 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

28 PCB FRONT AS JW714 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

29 PCB FRONT AS JW715 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

30 PCB FRONT AS JW716 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

31 PCB FRONT AS JW717~72 1 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

32 PCB FRONT AS JW722 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

33 PCB FRONT AS JW723~72 4 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

34 PCB FRONT AS JW725~72 7 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

35 PCB FRONT AS JW728~73 4 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

36 PCB FRONT AS JW735~73 6 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

37 PCB FRONT AS JW737 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

38 PCB FRONT AS JW738 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

39 PCB FRONT AS JW739~74 0 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

40 PCB FRONT AS JW741~74 3 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

41 PCB FRONT AS JW744~74 5 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

42 PCB FRONT AS JW746 WIRE JUMPER W581GY17J5 AWG22 1/0.65 SN 17.5 AUTO o o o o

43 PCB FRONT AS JW747~74 8 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

44 PCB FRONT AS JW750 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

45 PCB FRONT AS JW751 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o

46 PCB FRONT AS JW751 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

47 PCB FRONT AS JW752~75 6 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

48 PCB FRONT AS JW760 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

49 PCB FRONT AS LD701 LED DISPLAY DLTG9920M- LTG-9920M 70X24M o o o o

50 PCB FRONT AS Q702~71 8 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

51 PCB FRONT AS R701~70 3 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

52 PCB FRONT AS R704 R CARBON FILM RD-AZ152J - 1/6 1.5K OHM J o o o o

53 PCB FRONT AS R705~70 6 R CARBON FILM RD-4Z152J - 1/4 1.5K OHM J o o o o

54 PCB FRONT AS R707 R CARBON FILM RD-AZ334J - 1/6 330K OHM J o o o o

55 PCB FRONT AS R708~70 9 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

56 PCB FRONT AS R710 R CARBON FILM RD-AZ334J - 1/6 330K OHM J o o o o

57 PCB FRONT AS R711 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o o

58 PCB FRONT AS R712 R CARBON FILM RD-4Z473J - 1/4 47K OHM J o o o

59 PCB FRONT AS R712 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o

60 PCB FRONT AS R713~71 4 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o o

61 PCB FRONT AS R715 R CARBON FILM RD-4Z473J - 1/4 47K OHM J o o o

62 PCB FRONT AS R715 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o

63 PCB FRONT AS R716 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o o

64 PCB FRONT AS R717 R CARBON FILM RD-4Z100J - 1/4 10 OHM J o o o o

65 PCB FRONT AS R718 R CARBON FILM RD-AZ106J - 1/6 10M OHM J o o o o

66 PCB FRONT AS R719 R CARBON FILM RD-AZ334J - 1/6 330K OHM J o o o o

67 PCB FRONT AS R720~73 0 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

Page 21

Electrical Parts List

20

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

68 PCB FRONT AS R731~73 7 R CARBON FILM RD-4Z479J - 1/4 4.7 OHM J o o o

69 PCB FRONT AS R731~73 7 R CARBON FILM RD-4Z339J - 1/4 3.3 OHM J o

70 PCB FRONT AS R738 R CARBON FILM RD-AZ681J - 1/6 680 OHM J o o o o

71 PCB FRONT AS R739 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o o

72 PCB FRONT AS R740 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o

73 PCB FRONT AS R741 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o

74 PCB FRONT AS R742 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o

75 PCB FRONT AS R751~75 7 R CARBON FILM RD-AZ182J - 1/6 1.8K OHM J o o o o

76 PCB FRONT AS R765 R CARBON FILM RD-4Z103J - 1/4 10K OHM J o o o o

77 PCB FRONT AS R766 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

78 PCB FRONT AS R770 R CARBON FILM RD-AZ122J - 1/6 1.2K OHM J o o

79 PCB FRONT AS R770 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o

80 PCB FRONT AS R771 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

81 PCB FRONT AS R773 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

82 PCB FRONT AS R780 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

83 PCB FRONT AS R781 R CARBON FILM RD-AZ151J - 1/6 150 OHM J o o o o

84 PCB FRONT AS R782 R CARBON FILM RD-AZ181J - 1/6 180 OHM J o o o o

85 PCB FRONT AS R783 R CARBON FILM RD-4Z271J - 1/4 270 OHM J o o o o

86 PCB FRONT AS R784 R CARBON FILM RD-AZ331J - 1/6 330 OHM J o o o o

87 PCB FRONT AS R785 R CARBON FILM RD-4Z391J - 1/4 390 OHM J o o o o

88 PCB FRONT AS R786 R CARBON FILM RD-4Z471J - 1/4 470 OHM J o o o o

89 PCB FRONT AS R787 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

90 PCB FRONT AS R788 R CARBON FILM RD-AZ151J - 1/6 150 OHM J o o o o

91 PCB FRONT AS R789 R CARBON FILM RD-AZ181J - 1/6 180 OHM J o o o o

92 PCB FRONT AS R790 R CARBON FILM RD-AZ271J - 1/6 270 OHM J o o o o

93 PCB FRONT AS R791 R CARBON FILM RD-AZ331J - 1/6 330 OHM J o o o o

94 PCB FRONT AS R792 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

95 PCB FRONT AS R793 R CARBON FILM RD-4Z151J - 1/4 150 OHM J o o o o

96 PCB FRONT AS R794 R CARBON FILM RD-4Z181J - 1/4 180 OHM J o o o o

97 PCB FRONT AS R795 R CARBON FILM RD-AZ271J - 1/6 270 OHM J o o o o

98 PCB FRONT AS R796 R CARBON FILM RD-4Z331J - 1/4 330 OHM J o o o o

99 PCB FRONT AS R797 R CARBON FILM RD-AZ391J - 1/6 390 OHM J o o o o

100 PCB FRONT AS RM701 IC 1PNA4612HB PNA4612M00HB o o o o

101 PCB FRONT AS SW701~708 SW TACT 5S50101001 KPT-1105A 1C-1P o o o o

102 PCB FRONT AS SW710~718 SW TACT 5S50101001 KPT-1105A 1C-1P o o o o

103 PCB FRONT AS SW719~720 SW TACT 5S50101008 KPT-1105V 1C-1P o o o o

104 PCB FRONT AS SW721 SW TACT 5S50101001 KPT-1105A 1C-1P o o o o

105 PCB FRONT AS SW722 SW TACT 5S50101001 KPT-1105A 1C-1P o o o o

106 PCB FRONT AS XC701 X-TAL 5XA32R768- DT-38 32.768KHZ 20PPM o o o o

107 PCB FRONT AS XC702 RESONATOR 5PCSA8MTZ- CSA8MTZ, 8MHZ o o o o

108 PCB FUSE AS 13000 PCB FUSE AS 9CDC054500 AMI-225M o

109 PCB FUSE AS 13000 PCB FUSE AS 9CDC054501 AMI-225MU o

110 PCB FUSE AS 13000 PCB FUSE AS 9CDC054701 AMI-325MU o

111 PCB FUSE AS 13000 PCB FUSE AS 9CDC054700 AMI-325M o

112 PCB FUSE AS B901 PCB FUSE 9CD6580001 75X33X1.6T o o o o

113 PCB FUSE AS CD901 CORD AC 9736900200 KKP419C,KLCE-2F,0.75SQURE o o

114 PCB FUSE AS CD901 CORD AC 9736905900 KP 10W SPT-2(2M) NM ULCSA o o

115 PCB FUSE AS F901 FUSE GLASS TUBE 5FSGB3112L SEMKO TL 0.315A 250V MF51 o

116 PCB FUSE AS F901 FUSE GLASS TUBE 5FSGB6312L SEMKO TL 0.63A 250V MF51 o

117 PCB FUSE AS F901 FUSE GLASS TUBE 5FSGB8012L SEMKO MF51 800MA 250V TL o

118 PCB FUSE AS F901 FUSE GLASS TUBE 5FSGB4012L SEMKO TL 400MA 250V MF51 o

119 PCB FUSE AS FC901~90 2 CLIP FUSE 9734600700 FC-5N o o o o

120 PCB FUSE AS PT901 TRANS POWER 5TP8057816 EI=57X30 230V 50HZ o

121 PCB FUSE AS PT901 TRANS POWER 5TP1057815 EI-57X30 127V 60HZ o

122 PCB FUSE AS PT901 TRANS POWER 5TP1066818 EI=66X30 120V 60HZ o

123 PCB FUSE AS PT901 TRANS POWER 5TP8066817 EI=66X30 230V 50HZ o

124 PCB FUSE AS TP901~90 4 PIN WRAPPING 971640400 0 MFZN1.1X1.1 PANASERT o o o o

125 PCB MAIN AS 10000 PCB MAIN AS 9CDC054400 AMI-225M o

126 PCB MAIN AS 10000 PCB MAIN AS 9CDC054401 AMI-225MU o

127 PCB MAIN AS 10000 PCB MAIN AS 9CDC054601 AMI-325MU o

128 PCB MAIN AS 10000 PCB MAIN AS 9CDC054600 AMI-325M o

129 PCB MAIN AS AT001 ANTENNA FM 9736806000 2M ANT PIG TAIL o o

130 PCB MAIN AS AT001 ANTENNA FM 9736805700 2M PIG TAIL o o

131 PCB MAIN AS B001 PCB MAIN 9CD6580000 330X197X1.6T o o o o

132 PCB MAIN AS CC001 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

133 PCB MAIN AS CC002 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

134 PCB MAIN AS CC004 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

Page 22

Electrical Parts List

21

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

135 PCB MAIN AS CC006 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

136 PCB MAIN AS CC102 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

137 PCB MAIN AS CC103 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

138 PCB MAIN AS CC104 C CERA CXCH1H120J 50V CH 12PF J (TAPPING) o o o

139 PCB MAIN AS CC104 C CERA CXCH1H150J 50V CH 15PF J (TAPPING) o

140 PCB MAIN AS CC105 C CERA CXCH1H820J 50V CH 82PF J (TAPPING) o o o o

141 PCB MAIN AS CC201~202 C CERA CCXF1H473Z 50V F 0.047MF Z (TAPPING) o o o o

142 PCB MAIN AS CC203 C CERA CCXB1H471K 50V B 470PF K (TAPPING) o o o o

143 PCB MAIN AS CC205 C CERA CCXB1H472K 50V B 4700PF K (TAPPING) o o o o

144 PCB MAIN AS CC206 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

145 PCB MAIN AS CC207 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

146 PCB MAIN AS CC209 C CERA CCXF1H473Z 50V F 0.047MF Z (TAPPING) o o o o

147 PCB MAIN AS CC210~213 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

148 PCB MAIN AS CC214~215 C CERA CCXB1H562K 50V B 5600PF K (TAPPING) o o o

149 PCB MAIN AS CC214~215 C CERA CCXB1H682K 50V B 6800PF K (TAPPING) o

150 PCB MAIN AS CC251~252 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

151 PCB MAIN AS CC253~254 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

152 PCB MAIN AS CC255 C CERA CXCH1H390J 50V CH 39PF J (TAPPING) o o o o

153 PCB MAIN AS CC256 C CERA CXCH1H330J 50V CH 33PF J (TAPPING) o o o o

154 PCB MAIN AS CC257 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

155 PCB MAIN AS CC258 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

156 PCB MAIN AS CC401~402 C CERA CXCH1H101J 50V CH 100PF J (TAPPING) o o o o

157 PCB MAIN AS CC404 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

158 PCB MAIN AS CC405~406 C CERA CXCH1H101J 50V CH 100PF J (TAPPING) o o o o

159 PCB MAIN AS CC502 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

160 PCB MAIN AS CC503 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

161 PCB MAIN AS CC504 C CERA CCXB1H472K 50V B 4700PF K (TAPPING) o o o o

162 PCB MAIN AS CC505 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

163 PCB MAIN AS CC506 C CERA CCXB1H152K 50V B 1500PF K (TAPPING) o o o o

164 PCB MAIN AS CC507 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

165 PCB MAIN AS CC508~509 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

166 PCB MAIN AS CC510 C CERA CCXF1H333Z 50V F 0.033MF Z (TAPPING) o o o o

167 PCB MAIN AS CC511 C CERA CCXB1H151K 50V B 150PF K (TAPPING) o o o o

168 PCB MAIN AS CC512~513 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

169 PCB MAIN AS CC514 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

170 PCB MAIN AS CC515 C CERA CCXB1H152K 50V B 1500PF K (TAPPING) o o o o

171 PCB MAIN AS CC516 C CERA CCXB1H222K 50V B 2200PF K (TAPPING) o o o o

172 PCB MAIN AS CC517 C CERA CCXF1H153Z 50V F 0.015MF Z o o o o

173 PCB MAIN AS CC518 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

174 PCB MAIN AS CC519 C CERA CCXB1H331K 50V B 330PF K (TAPPING) o o o o

175 PCB MAIN AS CC520 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

176 PCB MAIN AS CC521~522 C CERA CCXB1H472K 50V B 4700PF K (TAPPING) o o o o

177 PCB MAIN AS CC523 C CERA CCXF1H333Z 50V F 0.033MF Z (TAPPING) o o o o

178 PCB MAIN AS CC524 C CERA CCXB1H331K 50V B 330PF K (TAPPING) o o o o

179 PCB MAIN AS CC525 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

180 PCB MAIN AS CC526 C CERA CCXB1H151K 50V B 150PF K (TAPPING) o o o o

181 PCB MAIN AS CC527 C CERA CCXB1H391K 50V B 390PF K (TAPPING) o o o o

182 PCB MAIN AS CC528 C CERA CCXB1H152K 50V B 1500PF K (TAPPING) o o o o

183 PCB MAIN AS CC529 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

184 PCB MAIN AS CC530 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

185 PCB MAIN AS CC531 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

186 PCB MAIN AS CC532~533 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

187 PCB MAIN AS CC534 C CERA CCXF1H333Z 50V F 0.033MF Z (TAPPING) o o o o

188 PCB MAIN AS CC535 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

189 PCB MAIN AS CC536 C CERA CCXF1H104Z 50V F 0.1MF Z o o o o

190 PCB MAIN AS CC537 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

191 PCB MAIN AS CC538 C CERA CCXF1H473Z 50V F 0.047MF Z (TAPPING) o o o o

192 PCB MAIN AS CC539 C CERA CCXF1H103Z 50V F 0.01MF Z (TAPPING) o o o o

193 PCB MAIN AS CC540~541 C CERA CXCH1H330J 50V CH 33PF J (TAPPING) o o o o

194 PCB MAIN AS CC543 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

195 PCB MAIN AS CC544 C CERA CCXB1H331K 50V B 330PF K (TAPPING) o o o o

196 PCB MAIN AS CC545 C CERA CXCH1H309C 50V CH 3PF C o o o o

197 PCB MAIN AS CC546 C CERA CCXB1H682K 50V B 6800PF K (TAPPING) o o o o

198 PCB MAIN AS CC601~602 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

199 PCB MAIN AS CC603~604 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o

200 PCB MAIN AS CC605~606 C CERA CCXB1H331K 50V B 330PF K (TAPPING) o o o o

201 PCB MAIN AS CC607 C CERA CCXB1H102K 50V B 1000PF K (TAPPING) o o o o

Page 23

Electrical Parts List

22

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

202 PCB MAIN AS CC608 C CERA CCXF1H104Z 50V F 0.1MF Z o o o

203 PCB MAIN AS CC611~61 4 C CERA CCXB1H221K 50V B 220PF K (TAPPING) o

204 PCB MAIN AS CC801~80 2 C CERA CCXB1H182K 50V B 1800PF K (TAPPING) o o o o

205 PCB MAIN AS CC809 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

206 PCB MAIN AS CC914 C CERA CCXF1H223Z 50V F 0.022MF Z (TAPPING) o o o o

207 PCB MAIN AS CE001 C ELECTRO CEXF1E101V 25V RSS 100MF (6.3X11) TP o o o o

208 PCB MAIN AS CE101 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

209 PCB MAIN AS CE102 C ELECTRO CEXF1E221V 25V RSS 220MF (8X11.5) TP o o o o

210 PCB MAIN AS CE201 C ELECTRO CEXF1H220V 50V RSS 22MF (5X11) TP o o o o

211 PCB MAIN AS CE202 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

212 PCB MAIN AS CE203 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o o

213 PCB MAIN AS CE204 C ELECTRO CEXF1E330V 25V RSS 33MF (5X11) TP o o o o

214 PCB MAIN AS CE206 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

215 PCB MAIN AS CE207 C ELECTRO CEXF1H478V 50V RSS 0.47MF (5X11) TP o o o o

216 PCB MAIN AS CE208 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

217 PCB MAIN AS CE209~21 0 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

218 PCB MAIN AS CE211 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP o o o o

219 PCB MAIN AS CE214 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

220 PCB MAIN AS CE401~40 8 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

221 PCB MAIN AS CE411~41 6 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

222 PCB MAIN AS CE417 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

223 PCB MAIN AS CE418 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

224 PCB MAIN AS CE501 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

225 PCB MAIN AS CE502 C ELECTRO CEXF1E330V 25V RSS 33MF (5X11) TP o o o o

226 PCB MAIN AS CE503 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

227 PCB MAIN AS CE504 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

228 PCB MAIN AS CE505 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o o

229 PCB MAIN AS CE507 C ELECTRO CEXF1H338V 50V RSS 0.33MF (5X11) TP o o o

230 PCB MAIN AS CE507 C ELECTRO CEXF1H108V 50V RSS 0.1MF (5X11) TP o

231 PCB MAIN AS CE508 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

232 PCB MAIN AS CE509~51 0 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o o

233 PCB MAIN AS CE511 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

234 PCB MAIN AS CE512 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

235 PCB MAIN AS CE513~51 4 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o o

236 PCB MAIN AS CE515~51 6 C ELECTRO CEXF1H478V 50V RSS 0.47MF (5X11) TP o o o o

237 PCB MAIN AS CE517 C ELECTRO CEYF1C471V 16V RSS 470MF 10X12.5 o o o o

238 PCB MAIN AS CE518 C ELECTRO CEYF1C102V 16V RSS 1000MF (10X20) o o o o

239 PCB MAIN AS CE519 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

240 PCB MAIN AS CE520 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

241 PCB MAIN AS CE521~52 2 C ELECTRO CEXF1C101V 16V RSS 100MF (6.3X11) TP o o o o

242 PCB MAIN AS CE523 C ELECTRO CEXF1C221V 16V RSS 220MF (8X11.5) TP o o o o

243 PCB MAIN AS CE601~60 2 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

244 PCB MAIN AS CE603~60 4 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

245 PCB MAIN AS CE605 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

246 PCB MAIN AS CE606 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

247 PCB MAIN AS CE608 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

248 PCB MAIN AS CE609 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP o o o

249 PCB MAIN AS CE610 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP o o o o

250 PCB MAIN AS CE611~61 2 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

251 PCB MAIN AS CE613~61 6 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

252 PCB MAIN AS CE617 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP o o o

253 PCB MAIN AS CE617 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o

254 PCB MAIN AS CE618 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

255 PCB MAIN AS CE619 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

256 PCB MAIN AS CE620 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

257 PCB MAIN AS CE621~62 2 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP o o o o

258 PCB MAIN AS CE623 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP o o o o

259 PCB MAIN AS CE624 C ELECTRO CEXF1H229V 50V RSS 2.2MF (5X11) TP o o o o

260 PCB MAIN AS CE626 C ELECTRO CEXF1H220V 50V RSS 22MF (5X11) TP o o o

261 PCB MAIN AS CE801~80 2 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

262 PCB MAIN AS CE803~80 4 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP o o o o

263 PCB MAIN AS CE805 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP o o o o

264 PCB MAIN AS CE806~80 7 C ELECTRO CEYF1C102V 16V RSS 1000MF (10X20) o

265 PCB MAIN AS CE806~80 7 C ELECTRO CEYF1E102V 25V RSS 1000MF (13X20) o o o

266 PCB MAIN AS CE808 C ELECTRO CEXF1E101V 25V RSS 100MF (6.3X11) TP o o o

267 PCB MAIN AS CE808 C ELECTRO CEXF1C221V 16V RSS 220MF (8X11.5) TP o

268 PCB MAIN AS CE901 C ELECTRO CEXF1V222V 35V RSS 2200MF 16X31.5 o o

Page 24

Electrical Parts List

23

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

269 PCB MAIN AS CE901 C ELECTRO CEXF1H222V 50V RSS 2200MF 18X35.5 o o

270 PCB MAIN AS CE903 C ELECTRO CEYF1V102V 35V RSS 1000MF (13X25) o o o o

271 PCB MAIN AS CF001~00 2 FILTER CERA 5PE107MS3A SFE107MS3-A o o

272 PCB MAIN AS CF001~00 2 FILTER CERAMIC 5PE107MA5- SFE 10.7M5-A o o

273 PCB MAIN AS CF201 FILTER 5PPCFAZ077 PCFAZ077 o o o o

274 PCB MAIN AS CM201~20 2 C MYLAR CMXM1H183J 50V 0.018MF J o o

275 PCB MAIN AS CM201~20 2 C MYLAR CMXM1H223J 50V 0.022MF J o o

276 PCB MAIN AS CM202 C MYLAR CMXM1H223J 50V 0.022MF J o

277 PCB MAIN AS CM405~40 8 C MYLAR CMXM1H104J 50V 0.1MF J o o o o

278 PCB MAIN AS CM409~41 0 C MYLAR CMXM1H272J 50V 2700PF J o o o o

279 PCB MAIN AS CM411~41 2 C MYLAR CMXM1H104J 50V 0.1MF J o

280 PCB MAIN AS CM601~60 2 C MYLAR CMXM1H102J 50V 0.001MF J (TP) o o o o

281 PCB MAIN AS CM603~60 4 C MYLAR CMXM1H223J 50V 0.022MF J o o o o

282 PCB MAIN AS CM605~60 8 C MYLAR CMXM1H102J 50V 0.001MF J (TP) o o o o

283 PCB MAIN AS CM609~61 0 C MYLAR CMXM1H153J 50V 0.015MF J (TP) o o o o

284 PCB MAIN AS CM611 C MYLAR CMXM1H223J 50V 0.022MF J o o o o

285 PCB MAIN AS CM612 C MYLAR CMXM1H332J 50V 3300 PF J o o o o

286 PCB MAIN AS CM613 C MYLAR CMXM1H153J 50V 0.015MF J (TP) o o o o

287 PCB MAIN AS CM614 C MYLAR CMXM1H152J 50V 1500PF J o o o o

288 PCB MAIN AS CM615~61 6 C MYLAR CMXM1H102J 50V 0.001MF J (TP) o o o o

289 PCB MAIN AS CM801~80 2 C MYLAR CMXM1H104J 50V 0.1MF J o o o o

290 PCB MAIN AS CM803~80 4 C MYLAR CMXM1H473J 50V 0.047MF J o o o o

291 PCB MAIN AS CM901~90 3 C MYLAR CMXM1H104J 50V 0.1MF J o o o o

292 PCB MAIN AS CN501 CONN AS 9738840800 FFC 16P P1.0X250MM R o o o o

293 PCB MAIN AS CN601 CONN AS 9738834900 UL 2468 #26 4P+3P+2P 360 o o o

294 PCB MAIN AS CN602 CONN AS 9728802100 UL2547 #28X3CO 4P o o o

295 PCB MAIN AS CN603 CONN AS 9738835000 UL 2851 #28X2C0 3P 260MM o o o

296 PCB MAIN AS CN701~70 2 PIN WAFER 973640770 0 52084-1310 13P BOTTOM o o o o

297 PCB MAIN AS CW101 CONN WAFER 9CD6258800 2P S2B-XH-A o o o o

298 PCB MAIN AS CW501 CONN WAFER 9738842900 16P FFC PIT1.0 o o o o

299 PCB MAIN AS CW502 CONN WAFER 9CD6259500 2001-WS-6P o o o o

300 PCB MAIN AS CW503 CONN WAFER 9CD6259400 2001-WS-12P o o o o

301 PCB MAIN AS CW601 CONN AS 9738834900 UL 2468 #26 4P+3P+2P 360 o o o

302 PCB MAIN AS CW602 CONN AS 9728802100 UL2547 #28X3CO 4P o o o

303 PCB MAIN AS CW603 CONN AS 9738835000 UL 2851 #28X2C0 3P 260MM o o o

304 PCB MAIN AS CW703 CONN 9728801900 8P 150MM o o o o

305 PCB MAIN AS CW902 CONN AS 9728802000 VH-02A 3.96 PITCH 2P o

306 PCB MAIN AS CW903 CONN AS 9728802400 VH-05A 3.96 PITCH 5P o o

307 PCB MAIN AS D201 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

308 PCB MAIN AS D401~40 2 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

309 PCB MAIN AS D501 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

310 PCB MAIN AS D502 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o

311 PCB MAIN AS D601 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

312 PCB MAIN AS D602~60 3 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

313 PCB MAIN AS D605~60 8 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

314 PCB MAIN AS D610~61 1 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

315 PCB MAIN AS D801~80 2 DIODE DZN4148-- - 1N4148 AUTO 52MM o o o o

316 PCB MAIN AS D901~90 2 DIODE DKN4002A- - 1N4002A AUTO 26MM o o o o

317 PCB MAIN AS D904~90 7 DIODE DRL202--- - RL202 o o o o

318 PCB MAIN AS DZ601~60 2 DIODE ZENER DZTZ6R2A- - MTZ-6.2 52MM TAPPING o o o o

319 PCB MAIN AS IC201 IC 1LA1833N- - LA1833N o o o o

320 PCB MAIN AS IC202 IC 1LC72131D- LC72131D o o o o

321 PCB MAIN AS IC205 IC REGULATOR 1KA78L05AZ KA78L05AZ o o o o

322 PCB MAIN AS IC401 IC FUNCTION 1PT2314-- - PT2314 o o o

323 PCB MAIN AS IC501 IC MOTOR DRIVE 1BA5939S- - BA5939S o o o o

324 PCB MAIN AS IC502 IC CHIP RF 1KB9223-- - KB9223 RF+SSP+AF o o o o

325 PCB MAIN AS IC503 IC CHIP DSP 1KS9286B- - KS9286B DSP+DAC o o o o

326 PCB MAIN AS IC601 IC 1TA8189N- - TA8189N o o o o

327 PCB MAIN AS IC602 IC SWITCHING 1BA7755A- - BA7755A (HEAD SW) o o o o

328 PCB MAIN AS IC801 IC 1TDA7499- - TDA7499 o o

329 PCB MAIN AS IC801 IC 1TDA7265- - TDA7265 o o

330 PCB MAIN AS IC901 IC 1L4959--- - L4959 o o o o

331 PCB MAIN AS J001 JACK ANT 9736321900 PAT645 o o

332 PCB MAIN AS J401 JACK RCA 9CD6313700 S-436P o o o o

333 PCB MAIN AS J801 JACK HEADPHONE 9766319501 HTJ-064-05B GOLD o o o o

334 PCB MAIN AS J802 JACK SPEAKER 9736320500 CJ-9007-040 o o o o

335 PCB MAIN AS JW201~202 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

Page 25

Electrical Parts List

24

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

336 PCB MAIN AS JW203 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

337 PCB MAIN AS JW204~205 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

338 PCB MAIN AS JW206 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

339 PCB MAIN AS JW207 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

340 PCB MAIN AS JW208 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

341 PCB MAIN AS JW209 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

342 PCB MAIN AS JW210~211 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

343 PCB MAIN AS JW213 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

344 PCB MAIN AS JW214~215 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

345 PCB MAIN AS JW217 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o

346 PCB MAIN AS JW402 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

347 PCB MAIN AS JW403~404 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

348 PCB MAIN AS JW405 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

349 PCB MAIN AS JW406~407 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

350 PCB MAIN AS JW501~504 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

351 PCB MAIN AS JW505~506 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

352 PCB MAIN AS JW507 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

353 PCB MAIN AS JW508~509 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

354 PCB MAIN AS JW510~511 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

355 PCB MAIN AS JW512 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

356 PCB MAIN AS JW513 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

357 PCB MAIN AS JW514~515 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

358 PCB MAIN AS JW516~517 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

359 PCB MAIN AS JW518 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

360 PCB MAIN AS JW519~522 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

361 PCB MAIN AS JW523 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

362 PCB MAIN AS JW524~526 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

363 PCB MAIN AS JW527~533 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

364 PCB MAIN AS JW534 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

365 PCB MAIN AS JW535~536 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

366 PCB MAIN AS JW537 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

367 PCB MAIN AS JW537 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

368 PCB MAIN AS JW538~540 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

369 PCB MAIN AS JW541~542 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

370 PCB MAIN AS JW543 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

371 PCB MAIN AS JW544 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

372 PCB MAIN AS JW545 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

373 PCB MAIN AS JW546~547 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

374 PCB MAIN AS JW548 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

375 PCB MAIN AS JW549 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o

376 PCB MAIN AS JW549 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

377 PCB MAIN AS JW550~552 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

378 PCB MAIN AS JW553~555 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

379 PCB MAIN AS JW556~557 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

380 PCB MAIN AS JW558~559 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o

381 PCB MAIN AS JW558~559 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

382 PCB MAIN AS JW560 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

383 PCB MAIN AS JW560 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

384 PCB MAIN AS JW561~563 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

385 PCB MAIN AS JW561~563 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

386 PCB MAIN AS JW564 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

387 PCB MAIN AS JW565 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

388 PCB MAIN AS JW566 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

389 PCB MAIN AS JW567 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o

390 PCB MAIN AS JW568 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

391 PCB MAIN AS JW569~570 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

392 PCB MAIN AS JW571 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

393 PCB MAIN AS JW601 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

394 PCB MAIN AS JW602 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

395 PCB MAIN AS JW603~605 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

396 PCB MAIN AS JW606 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

397 PCB MAIN AS JW607 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

398 PCB MAIN AS JW608 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

399 PCB MAIN AS JW610 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

400 PCB MAIN AS JW611 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

401 PCB MAIN AS JW612~613 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

402 PCB MAIN AS JW614~615 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

Page 26

Electrical Parts List

25

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

403 PCB MAIN AS JW616 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

404 PCB MAIN AS JW617~618 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

405 PCB MAIN AS JW619 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

406 PCB MAIN AS JW620 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

407 PCB MAIN AS JW621 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

408 PCB MAIN AS JW801~803 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

409 PCB MAIN AS JW805 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

410 PCB MAIN AS JW806 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o

411 PCB MAIN AS JW806 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

412 PCB MAIN AS JW807 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

413 PCB MAIN AS JW901 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

414 PCB MAIN AS JW902 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

415 PCB MAIN AS JW903 WIRE JUMPER W581GY17J5 AWG22 1/0.65 SN 17.5 AUTO o o o o

416 PCB MAIN AS JW905 WIRE JUMPER W581GY17J5 AWG22 1/0.65 SN 17.5 AUTO o o o o

417 PCB MAIN AS JW906 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

418 PCB MAIN AS JW907 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o

419 PCB MAIN AS JW907 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

420 PCB MAIN AS JW908 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

421 PCB MAIN AS JW910 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o o o o

422 PCB MAIN AS JW911 WIRE JUMPER W581GY7595 AWG22 1/0.65 SN 7.5 AUTO o

423 PCB MAIN AS JW940~941 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

424 PCB MAIN AS JW943 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

425 PCB MAIN AS JW952 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

426 PCB MAIN AS JW957 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

427 PCB MAIN AS JW958 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

428 PCB MAIN AS JW959 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o

429 PCB MAIN AS JW960 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

430 PCB MAIN AS JW961 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o o

431 PCB MAIN AS JW962 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

432 PCB MAIN AS JW963 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o

433 PCB MAIN AS JW965 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO o o o o

434 PCB MAIN AS JW966 WIRE JUMPER W581GY12J5 AWG22 1/0.65 SN 12.5 AUTO o o o o

435 PCB MAIN AS L001 COIL PEAKING 5CPZ100K02 10UH K (AXIAL 3.5MM) o o o o

436 PCB MAIN AS L101 AM RF UNIT 5LR0000834 RBW07VB-K5024 o o o o

437 PCB MAIN AS L251 COIL PEAKING 5CPZ100K02 10UH K (AXIAL 3.5MM) o o o o

438 PCB MAIN AS L601 COIL OSC 5L00000500 0500 10X10 BK o o o o

439 PCB MAIN AS L801~80 2 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o

440 PCB MAIN AS Q001 TR TZTC3194Y- KTC3194Y o o o o

441 PCB MAIN AS Q003 TR TZRA107M- - KRA107M (KSR2006) o o o o

442 PCB MAIN AS Q501 TR TZTA1266Y- KTA1266Y- (AUTO)(1015Y) o o o o

443 PCB MAIN AS Q502 TR TZTA1273Y- KTA1273Y(966Y) o o o o

444 PCB MAIN AS Q503 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o

445 PCB MAIN AS Q503 TR TZRC107M-- KRC107M(AUTO) o

446 PCB MAIN AS Q601~60 2 FET TKTK117Y-- KTK117(Y) o o o o

447 PCB MAIN AS Q603~60 4 TR TZTA1266Y- KTA1266Y- (AUTO)(1015Y) o o o o

448 PCB MAIN AS Q605 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

449 PCB MAIN AS Q607 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

450 PCB MAIN AS Q612 TR TZRC111M-- KRC111M o o o o

451 PCB MAIN AS Q613 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

452 PCB MAIN AS Q614 TR TZRC107M-- KRC107M(AUTO) o o o o

453 PCB MAIN AS Q615~62 0 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

454 PCB MAIN AS Q621 TR TZTA1273Y- KTA1273Y(966Y) o o o o

455 PCB MAIN AS Q801~80 2 TR TZTD1302Y- KTD1302Y AUTO o o o

456 PCB MAIN AS Q801~80 2 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o

457 PCB MAIN AS Q803 TR TZRA111M- - KRA111M o o o o

458 PCB MAIN AS Q804 TR TZTC3198Y- KTC3198Y-(1815Y) (AUTO) o o o o

459 PCB MAIN AS R002 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o o

460 PCB MAIN AS R003 R CARBON FILM RD-AZ470J - 1/6 47 OHM J o o o o

461 PCB MAIN AS R004 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

462 PCB MAIN AS R005 R CARBON FILM RD-AZ332J - 1/6 3.3K OHM J o o o o

463 PCB MAIN AS R006 R CARBON FILM RD-AZ681J - 1/6 680 OHM J o o o o

464 PCB MAIN AS R007 R CARBON FILM RD-AZ331J - 1/6 330 OHM J o o o o

465 PCB MAIN AS R008 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

466 PCB MAIN AS R012 R CARBON FILM RD-AZ331J - 1/6 330 OHM J o o o o

467 PCB MAIN AS R101 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

468 PCB MAIN AS R103~10 5 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

469 PCB MAIN AS R106 R CARBON FILM RD-AZ332J - 1/6 3.3K OHM J o o o o

Page 27

Electrical Parts List

26

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

470 PCB MAIN AS R107 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

471 PCB MAIN AS R109 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

472 PCB MAIN AS R201 R CARBON FILM RD-AZ822J - 1/6 8.2K OHM J o o o o

473 PCB MAIN AS R202 R CARBON FILM RD-AZ273J - 1/6 27K OHM J o o o

474 PCB MAIN AS R202 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o

475 PCB MAIN AS R203 R CARBON FILM RD-AZ822J - 1/6 8.2K OHM J o o o o

476 PCB MAIN AS R204 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

477 PCB MAIN AS R205~20 6 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

478 PCB MAIN AS R207 R CARBON FILM RD-AZ121J - 1/6 120 OHM J o o o o

479 PCB MAIN AS R208 R CARBON FILM RD-AZ332J - 1/6 3.3K OHM J o o o o

480 PCB MAIN AS R209 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

481 PCB MAIN AS R210 R CARBON FILM RD-AZ682J - 1/6 6.8K OHM J o o o o

482 PCB MAIN AS R211 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

483 PCB MAIN AS R212~21 3 R CARBON FILM RD-AZ182J - 1/6 1.8K OHM J o o o o

484 PCB MAIN AS R216 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

485 PCB MAIN AS R217~21 8 R CARBON FILM RD-AZ822J - 1/6 8.2K OHM J o o o o

486 PCB MAIN AS R219~22 0 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

487 PCB MAIN AS R221 R CARBON FILM RD-AZ563J - 1/6 56K OHM J o o o

488 PCB MAIN AS R221 R CARBON FILM RD-AZ333J - 1/6 33K OHM J o

489 PCB MAIN AS R251 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

490 PCB MAIN AS R252 R CARBON FILM RD-AZ470J - 1/6 47 OHM J o o o o

491 PCB MAIN AS R253 R CARBON FILM RD-AZ222J - 1/6 2.2K OHM J o o o o

492 PCB MAIN AS R254 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

493 PCB MAIN AS R255 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

494 PCB MAIN AS R256 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

495 PCB MAIN AS R257~25 8 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

496 PCB MAIN AS R259 R CARBON FILM RD-AZ123J - 1/6 12K OHM J o o o o

497 PCB MAIN AS R260~26 3 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

498 PCB MAIN AS R264~26 5 R CARBON FILM RD-AZ222J - 1/6 2.2K OHM J o o o o

499 PCB MAIN AS R401~40 2 R CARBON FILM RD-AZ123J - 1/6 12K OHM J o o

500 PCB MAIN AS R401~40 2 R CARBON FILM RD-AZ153J - 1/6 15K OHM J o o

501 PCB MAIN AS R403~40 4 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

502 PCB MAIN AS R405~40 6 R CARBON FILM RD-AZ123J - 1/6 12K OHM J o o o o

503 PCB MAIN AS R407~40 8 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

504 PCB MAIN AS R409~41 0 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

505 PCB MAIN AS R411~41 2 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o

506 PCB MAIN AS R411~41 2 R CARBON FILM RD-AZ153J - 1/6 15K OHM J o

507 PCB MAIN AS R413~41 4 R CARBON FILM RD-AZ182J - 1/6 1.8K OHM J o o o o

508 PCB MAIN AS R415~41 6 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

509 PCB MAIN AS R421~42 2 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

510 PCB MAIN AS R423~42 4 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

511 PCB MAIN AS R425~42 6 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

512 PCB MAIN AS R427 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

513 PCB MAIN AS R429 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

514 PCB MAIN AS R431~43 2 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

515 PCB MAIN AS R433~43 4 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

516 PCB MAIN AS R436~43 7 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

517 PCB MAIN AS R441 R CARBON FILM RD-AZ820J - 1/6 82 OHM J o o o o

518 PCB MAIN AS R501 R CARBON FILM RD-AZ124J - 1/6 120K OHM J o o o o

519 PCB MAIN AS R502~50 5 R CARBON FILM RD-AZ393J - 1/6 39K OHM J o o o o

520 PCB MAIN AS R506 R CARBON FILM RD-AZ124J - 1/6 120K OHM J o o o o

521 PCB MAIN AS R507 R CARBON FILM RD-AZ153J - 1/6 15K OHM J o o o o

522 PCB MAIN AS R508~50 9 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

523 PCB MAIN AS R510 R CARBON FILM RD-AZ220J - 1/6 22 OHM J o o o o

524 PCB MAIN AS R511 R CARBON FILM RD-AZ824J - 1/6 820K OHM J o o o o

525 PCB MAIN AS R512 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

526 PCB MAIN AS R513 R CARBON FILM RD-AZ474J - 1/6 470K OHM J o o o o

527 PCB MAIN AS R514 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

528 PCB MAIN AS R515 R CARBON FILM RD-AZ682J - 1/6 6.8K OHM J o o o o

529 PCB MAIN AS R516 R CARBON FILM RD-AZ153J - 1/6 15K OHM J o o o o

530 PCB MAIN AS R517 R CARBON FILM RD-AZ273J - 1/6 27K OHM J o o o o

531 PCB MAIN AS R518 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

532 PCB MAIN AS R519~52 0 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

533 PCB MAIN AS R521 R CARBON FILM RD-AZ154J - 1/6 150K OHM J o o o o

534 PCB MAIN AS R522~52 3 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

535 PCB MAIN AS R524 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

536 PCB MAIN AS R525 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

Page 28

Electrical Parts List

27

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

537 PCB MAIN AS R526 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

538 PCB MAIN AS R527 R CARBON FILM RD-AZ154J - 1/6 150K OHM J o o o

539 PCB MAIN AS R527 R CARBON FILM RD-AZ474J - 1/6 470K OHM J o

540 PCB MAIN AS R528 R CARBON FILM RD-AZ100J - 1/6 10 OHM J o o o o

541 PCB MAIN AS R529~53 0 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

542 PCB MAIN AS R531 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

543 PCB MAIN AS R532 R CARBON FILM RD-AZ683J - 1/6 68K OHM J o o o o

544 PCB MAIN AS R533 R CARBON FILM RD-AZ823J - 1/6 82K OHM J o o o o

545 PCB MAIN AS R534 R CARBON FILM RD-AZ562J - 1/6 5.6K OHM J o o o o

546 PCB MAIN AS R535 R CARBON FILM RD-AZ183J - 1/6 18K OHM J o o o o

547 PCB MAIN AS R536 R CARBON FILM RD-AZ563J - 1/6 56K OHM J o o o o

548 PCB MAIN AS R537 R CARBON FILM RD-AZ273J - 1/6 27K OHM J o o o o

549 PCB MAIN AS R538 R CARBON FILM RD-AZ563J - 1/6 56K OHM J o o o o

550 PCB MAIN AS R539 R CARBON FILM RD-AZ184J - 1/6 180K OHM J o o o o

551 PCB MAIN AS R540 R CARBON FILM RD-AZ153J - 1/6 15K OHM J o o o o

552 PCB MAIN AS R541 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

553 PCB MAIN AS R542 R CARBON FILM RD-AZ683J - 1/6 68K OHM J o o o o

554 PCB MAIN AS R543 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

555 PCB MAIN AS R544 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

556 PCB MAIN AS R545~54 6 R CARBON FILM RD-AZ273J - 1/6 27K OHM J o o o o

557 PCB MAIN AS R547 R CARBON FILM RD-AZ683J - 1/6 68K OHM J o o o o

558 PCB MAIN AS R548 R CARBON FILM RD-AZ333J - 1/6 33K OHM J o o o o

559 PCB MAIN AS R549 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

560 PCB MAIN AS R550 R CARBON FILM RD-AZ333J - 1/6 33K OHM J o o o o

561 PCB MAIN AS R551~55 2 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

562 PCB MAIN AS R553 R CARBON FILM RD-AZ154J - 1/6 150K OHM J o o o o

563 PCB MAIN AS R554 R CARBON FILM RD-AZ105J - 1/6 1M OHM J o o o o

564 PCB MAIN AS R555~55 6 R CARBON FILM RD-2Y150J - 1/2 15 OHM J o o o o

565 PCB MAIN AS R557 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

566 PCB MAIN AS R558 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

567 PCB MAIN AS R559 R CARBON FILM RD-AZ822J - 1/6 8.2K OHM J o o o o

568 PCB MAIN AS R560 R CARBON FILM RD-AZ123J - 1/6 12K OHM J o o o o

569 PCB MAIN AS R561 R CARBON FILM RD-AZ273J - 1/6 27K OHM J o o o o

570 PCB MAIN AS R562~56 3 R CARBON FILM RD-AZ332J - 1/6 3.3K OHM J o o o o

571 PCB MAIN AS R564 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

572 PCB MAIN AS R567 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

573 PCB MAIN AS R568 R CARBON FILM RD-AZ221J - 1/6 220 OHM J o o o o

574 PCB MAIN AS R569 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

575 PCB MAIN AS R570 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

576 PCB MAIN AS R571 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

577 PCB MAIN AS R572~57 3 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

578 PCB MAIN AS R574~57 9 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

579 PCB MAIN AS R580~58 1 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

580 PCB MAIN AS R582 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

581 PCB MAIN AS R601~60 4 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

582 PCB MAIN AS R605~60 6 R CARBON FILM RD-AZ820J - 1/6 82 OHM J o o o o

583 PCB MAIN AS R607~60 8 R CARBON FILM RD-AZ683J - 1/6 68K OHM J o o o o

584 PCB MAIN AS R609~61 0 R CARBON FILM RD-AZ682J - 1/6 6.8K OHM J o o o o

585 PCB MAIN AS R613~61 4 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

586 PCB MAIN AS R615~61 6 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

587 PCB MAIN AS R617~61 8 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

588 PCB MAIN AS R619 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

589 PCB MAIN AS R620 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o

590 PCB MAIN AS R622 R CARBON FILM RD-AZ105J - 1/6 1M OHM J o o o o

591 PCB MAIN AS R623 R CARBON FILM RD-AZ184J - 1/6 180K OHM J o o o o

592 PCB MAIN AS R624 R CARBON FILM RD-AZ563J - 1/6 56K OHM J o o o o

593 PCB MAIN AS R625~62 6 R CARBON FILM RD-AZ184J - 1/6 180K OHM J o o o o

594 PCB MAIN AS R627~62 8 R CARBON FILM RD-AZ151J - 1/6 150 OHM J o o o o

595 PCB MAIN AS R629~63 0 R CARBON FILM RD-AZ224J - 1/6 220K OHM J o o o o

596 PCB MAIN AS R631~63 2 R CARBON FILM RD-AZ682J - 1/6 6.8K OHM J o o o o

597 PCB MAIN AS R633~63 4 R CARBON FILM RD-AZ392J - 1/6 3.9K OHM J o o o o

598 PCB MAIN AS R635~63 6 R CARBON FILM RD-AZ821J - 1/6 820 OHM J o o o o

599 PCB MAIN AS R637~63 8 R CARBON FILM RD-AZ184J - 1/6 180K OHM J o o o o

600 PCB MAIN AS R639~64 2 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

601 PCB MAIN AS R643~64 4 R CARBON FILM RD-AZ183J - 1/6 18K OHM J o o o o

602 PCB MAIN AS R645~64 6 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

603 PCB MAIN AS R647 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

Page 29

Electrical Parts List

28

225M 225MU 325M 325MU

PART-CODE PART-DESC

MODEL

NO ASS'Y LOCATION PART-NAME

604 PCB MAIN AS R648 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o

605 PCB MAIN AS R649 R CARBON FILM RD-AZ683J - 1/6 68K OHM J o o o o

606 PCB MAIN AS R651 R CARBON FILM RD-AZ184J - 1/6 180K OHM J o o o o

607 PCB MAIN AS R652 R CARBON FILM RD-AZ479J - 1/6 4.7 OHM J o o o o

608 PCB MAIN AS R653 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

609 PCB MAIN AS R654 R CARBON FILM RD-AZ271J - 1/6 270 OHM J o o o o

610 PCB MAIN AS R655 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

611 PCB MAIN AS R656 R CARBON FILM RD-AZ333J - 1/6 33K OHM J o o o o

612 PCB MAIN AS R657 R CARBON FILM RD-AZ470J - 1/6 47 OHM J o o o o

613 PCB MAIN AS R658 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

614 PCB MAIN AS R659 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

615 PCB MAIN AS R662 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

616 PCB MAIN AS R663 R CARBON FILM RD-AZ331J - 1/6 330 OHM J o o o o

617 PCB MAIN AS R664 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

618 PCB MAIN AS R665 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

619 PCB MAIN AS R666 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

620 PCB MAIN AS R667~66 8 WIRE JUMPER W581GY6095 AWG22 1/0.65 SN 6 AUTO o o o

621 PCB MAIN AS R669 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

622 PCB MAIN AS R670~67 1 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

623 PCB MAIN AS R672 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o o

624 PCB MAIN AS R674~67 5 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

625 PCB MAIN AS R676 R CARBON FILM RD-AZ105J - 1/6 1M OHM J o o o o

626 PCB MAIN AS R677 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o

627 PCB MAIN AS R677 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o

628 PCB MAIN AS R678 R CARBON FILM RD-AZ224J - 1/6 220K OHM J o o o o

629 PCB MAIN AS R681 R CARBON FILM RD-AZ101J - 1/6 100 OHM J o o o

630 PCB MAIN AS R803~80 4 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o o o

631 PCB MAIN AS R805~80 6 R CARBON FILM RD-AZ473J - 1/6 47K OHM J o o o o

632 PCB MAIN AS R807~80 8 R CARBON FILM RD-AZ102J - 1/6 1K OHM J o o

633 PCB MAIN AS R807~80 8 R CARBON FILM RD-AZ681J - 1/6 680 OHM J o o

634 PCB MAIN AS R809 R CARBON FILM RD-4Z479J - 1/4 4.7 OHM J o

635 PCB MAIN AS R810 R CARBON FILM RD-4Z479J - 1/4 4.7 OHM J o o o o

636 PCB MAIN AS R811 R CARBON FILM RD-4Z479J - 1/4 4.7 OHM J o o o

637 PCB MAIN AS R813~81 4 R CARBON FILM RD-AZ183J - 1/6 18K OHM J o

638 PCB MAIN AS R815~81 8 R CARBON FILM RD-4Z102J - 1/4 1K OHM J o o o o

639 PCB MAIN AS R821 R CARBON FILM RD-AZ154J - 1/6 150K OHM J o o o o

640 PCB MAIN AS R823~82 4 R CARBON FILM RD-AZ104J - 1/6 100K OHM J o o o o

641 PCB MAIN AS R825 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

642 PCB MAIN AS R827 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o

643 PCB MAIN AS R829 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO o o o

644 PCB MAIN AS R831~83 2 R CARBON FILM RD-AZ472J - 1/6 4.7K OHM J o o o o

645 PCB MAIN AS R910 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

646 PCB MAIN AS R911 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

647 PCB MAIN AS R913 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

648 PCB MAIN AS R914~91 5 R CARBON FILM RD-AZ223J - 1/6 22K OHM J o o o o

649 PCB MAIN AS R916 R CARBON FILM RD-AZ103J - 1/6 10K OHM J o o o o

650 PCB MAIN AS RF901~90 2 R FUSIBLE RF01F4780J 0.47OHM 1W o o

651 PCB MAIN AS RV601 R SEMI FIXED RV1417222- 1/10 2.2K OHM B V6EK-PV1S o o o o

652 PCB MAIN AS TP601~60 2 PIN WRAPPING 971355040 0 1.0X2.5X15 o o o

653 PCB MAIN AS TU001 TUNER PACK 9737613201 KST-F401VA-3 o o o o

654 PCB MAIN AS XC201 C DISCRIMINATOR 5P107MG86C CDA10.7MG86N-C o o o o

655 PCB MAIN AS XC251 X-TAL 5XA7R20000 7.2M o o o o

656 PCB MAIN AS XC501 RESONATOR CERA 5PCSA16R93 CSA16.93MXZ04 o o o o

Loading...

Loading...