Page 1

SECTION 9P

DOORS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in B unless otherwise

noted.

TABLE OF CONTENTS

Description and Operation 9P-2. . . . . . . . . . . . . . . . . .

Door Lock Striker 9P-2. . . . . . . . . . . . . . . . . . . . . . . . . .

Childproof Rear Door Lock 9P-2. . . . . . . . . . . . . . . . . .

Power Door Locks 9P-2. . . . . . . . . . . . . . . . . . . . . . . . .

Power Windows 9P-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Strut 9P-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Locator 9P-3. . . . . . . . . . . . . . . . . . . . . . . .

Front Door 9P-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door 9P-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Instructions 9P-7. . . . . . . . . . . . . . . . . . . . . . . . .

On-Vehicle Service 9P-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Door Glass Run 9P-7. . . . . . . . . . . . . . . . . . . . . .

Rear Door Glass Run 9P-8. . . . . . . . . . . . . . . . . . . . . .

Door Lock Striker 9P-9. . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Lock Striker 9P-9. . . . . . . . . . . . . . . . . . . . . . .

Door Lock Striker Adjustment 9P-10. . . . . . . . . . . . . .

Tailgate Lock Striker Adjustment 9P-11. . . . . . . . . . . .

Front Door Lock 9P-13. . . . . . . . . . . . . . . . . . . . . . . . . .

Childproof Rear Door Lock 9P-14. . . . . . . . . . . . . . . . .

Central Door Lock Actuator 9P-16. . . . . . . . . . . . . . . .

Tailgate Lock 9P-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside Door Handle 9P-17. . . . . . . . . . . . . . . . . . . . . . .

Outside Front Door Handle 9P-17. . . . . . . . . . . . . . . .

Outside Rear Door Handle 9P-18. . . . . . . . . . . . . . . . .

Door Lock Cylinder 9P-18. . . . . . . . . . . . . . . . . . . . . . .

Manual Window Regulator 9P-19. . . . . . . . . . . . . . . . .

Power Front Window Regulator 9P-19. . . . . . . . . . . .

Front Door Assembly 9P-20. . . . . . . . . . . . . . . . . . . . .

Rear Door Assembly 9P-21. . . . . . . . . . . . . . . . . . . . . .

Tailgate 9P-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Lock Cylinder 9P-23. . . . . . . . . . . . . . . . . . . . .

Door Hinge 9P-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Hold Open Link 9P-24. . . . . . . . . . . . . . . . . . . . .

Inside Channel Weatherstrip (Standard) 9P-24. . . . .

Inside Channel Weatherstrip (Deluxe) 9P-25. . . . . . .

Door Outside Channel Weatherstrip 9P-25. . . . . . . . .

Door Weatherstrip 9P-26. . . . . . . . . . . . . . . . . . . . . . . .

Door Seal Trim 9P-27. . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Opening Weatherstrip 9P-27. . . . . . . . . . . . . . . .

Manual Window Regulator Handle 9P-28. . . . . . . . . .

Tailgate Strut 9P-28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic and Routing Diagrams 9P-30. . . . . . . . . .

Power Door Locks 9P-30. . . . . . . . . . . . . . . . . . . . . . . .

Power Windows (Front Only) 9P-34. . . . . . . . . . . . . . .

DAEWOO M-150 BL2

Page 2

9P –2 DOORS

DESCRIPTION AND OPERATION

DOOR LOCK STRIKER

The front and the rear door lock strikers each consist of

a striker with two screws threaded into a floating cage

plate in the B-pillars and C-pillars. The door is secured in

the closed position when the door lock fork snaps over

and engages the striker.

CHILDPROOF REAR DOOR LOCK

The childproof rear door locks help prevent passengers,

especially children, from opening the rear doors of the

vehicle from the inside.

In order to activate these locks, move the levers of both

rear doors to the lock position. Then, close both doors.

Rear passengers will be unable to open the doors from

the inside of the vehicle.

In order to deactivate the childproof rear door lock, unlock the door from the inside of the vehicle and open the

door from the outside. Move the lever to the unlock position. The rear door will now work normally.

POWER DOOR LOCKS

The power door locks use a solenoid that is contained in

each door lock assembly. The door locks are activated

by the actuator on the inside door handle or by the lock

cylinder on the driver door only. When the driver door is

locked or unlocked by the actuator or lock cylinder, all

doors are locked or unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical switches

on the front door tirm and operated by a motor at each

window regulator. The windows are lowered by pressing

the switch and raised by pulling up on the switch. The

window will stop movement when the switch is released

or when the window is completely open or closed.

TAILGATE STRUT

This vehicle is equipped with the gas struts. The struts

support the tailgate suitably when opening the tailgate.

The strut contained the high pressure compressed gas.

Therefore, be careful not to take apart, puncture, apply

heat or fire bacause the strut may explode.

DAEWOO M-150 BL2

Page 3

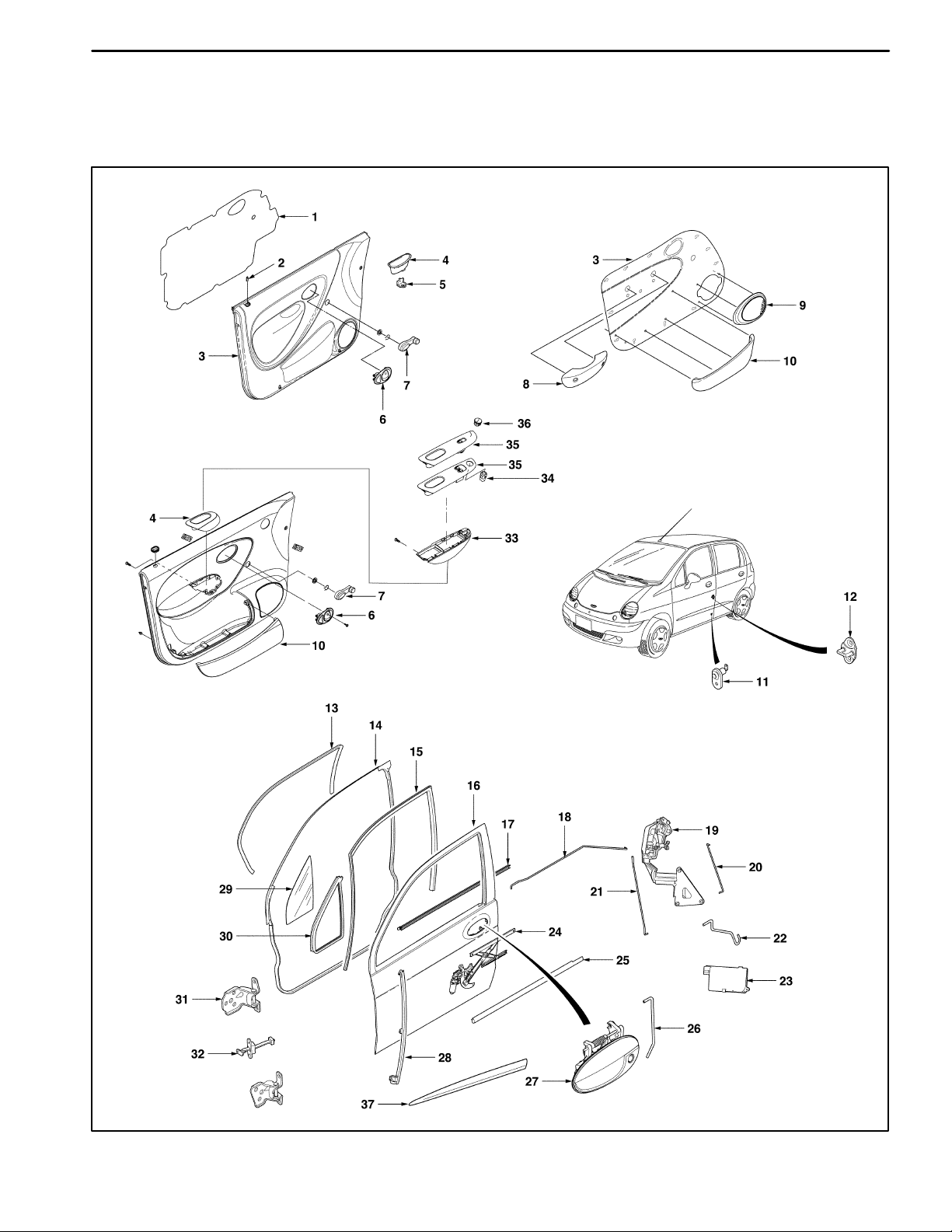

COMPONENT LOCATOR

FRONT DOOR

DOORS 9P–3

DAEWOO M-150 BL2

D19C403A

Page 4

9P –4 DOORS

1. Seal Trim

2. Lock Button

3. Trim Panel

4. Pocket Handle (Deluxe Type)

5. Pocket Handle Bracket (Deluxe Type)

6. Inside handle

7. Manual Regulator Handle

8. Pocket Handle (Standard Type)

9. Door Speaker Cover

10. Map Pocket

11. Contact Switch

12. Striker

13. Opening Weatherstrip

14. Door Weatherstrip

15. Glass Run

16. Front Door

17. Inside Channel Weatherstrip

18. Inside Handle Rod

19. Door Lock

20. Door Lock Cylinder Rod

21. Lock Rod

22. Actuator Rod

23. Actuator

24. Window Regulator

25. Outside Channel Weatherstrip

26. Outside Handle Rod

27. Outside Handle

28. Division Bar

29. Quarter Glass

30. Quarter Glass Run

31. Door Hinge

32. Door Hold Open Link

33. Power Window Switch Cover

34. Mirror Switch

35. Power Window Switch Assembly

36. Mirror switch Blank

37. Door Side Molding

DAEWOO M-150 BL2

Page 5

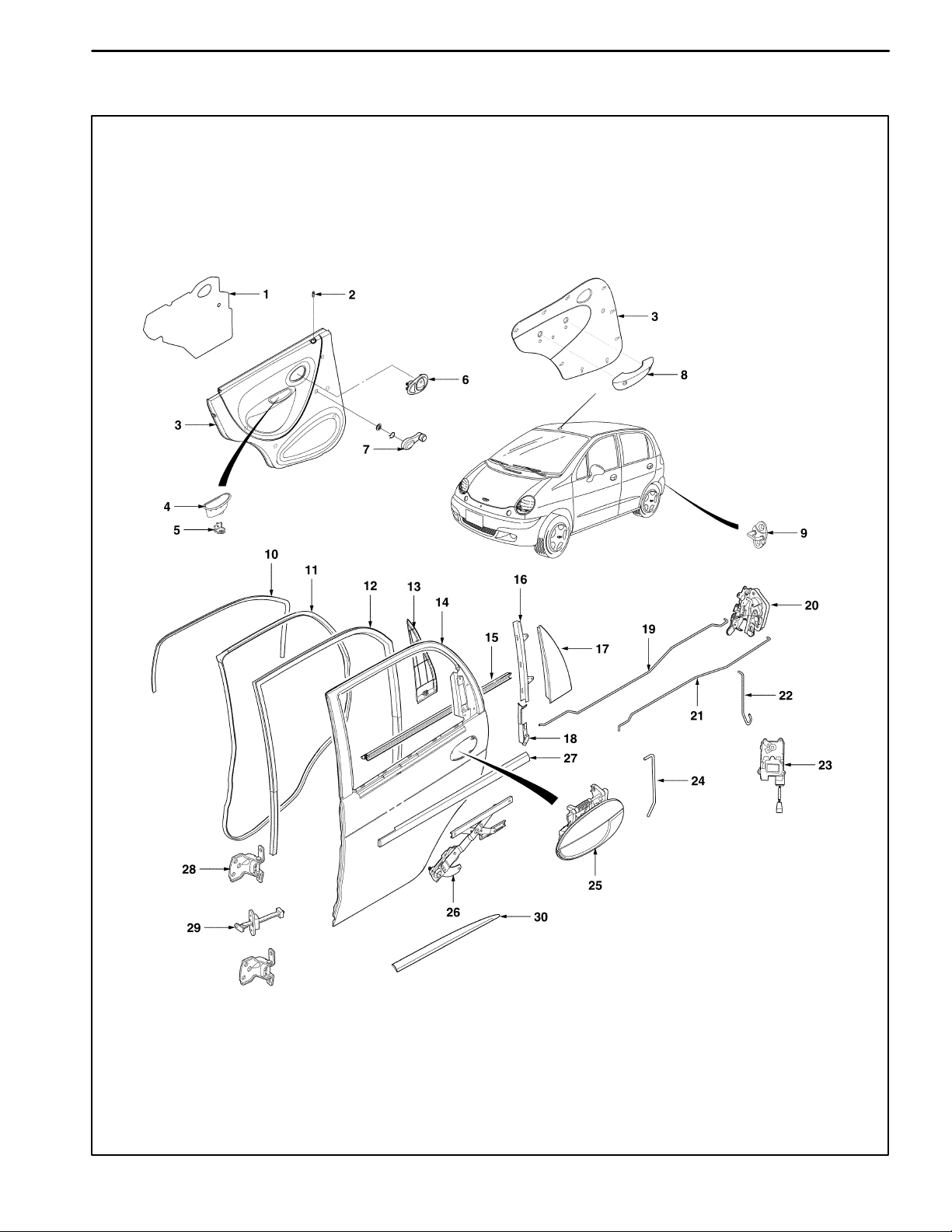

REAR DOOR

DOORS 9P–5

DAEWOO M-150 BL2

D19C404A

Page 6

9P –6 DOORS

1. Seal Trim

2. Lock Button

3. Trim Panel

4. Pocket Handle (Deluxe Type)

5. Pocket Handle Bracket (Deluxe Type)

6. Inside handle

7. Manual Regulator Handle

8. Pocket Handle (Standard Type)

9. Striker

10. Opening Weatherstrip

11. Door Weatherstrip

12. Glass Run

13. Interior Garnish Molding

14. Rear Door

15. Inside Channel Weatherstrip

16. Upper Guide Rail

17. Exterior Garnish Molding

18. Lower Guide Rail

19. Lock Rod

20. Door Lock

21. Inside Handle Rod

22. Actuator Rod

23. Actuator

24. Outside Handle Rod

25. Outside Handle

26. Window Regulator

27. Outside Channel Weatherstrip

28. Door Hinge

29. Door Hold Open Link

30. Door Side Molding

DAEWOO M-150 BL2

Page 7

REPAIR INSTRUCTIONS

ON–VEHICLE SERVICE

FRONT DOOR GLASS RUN

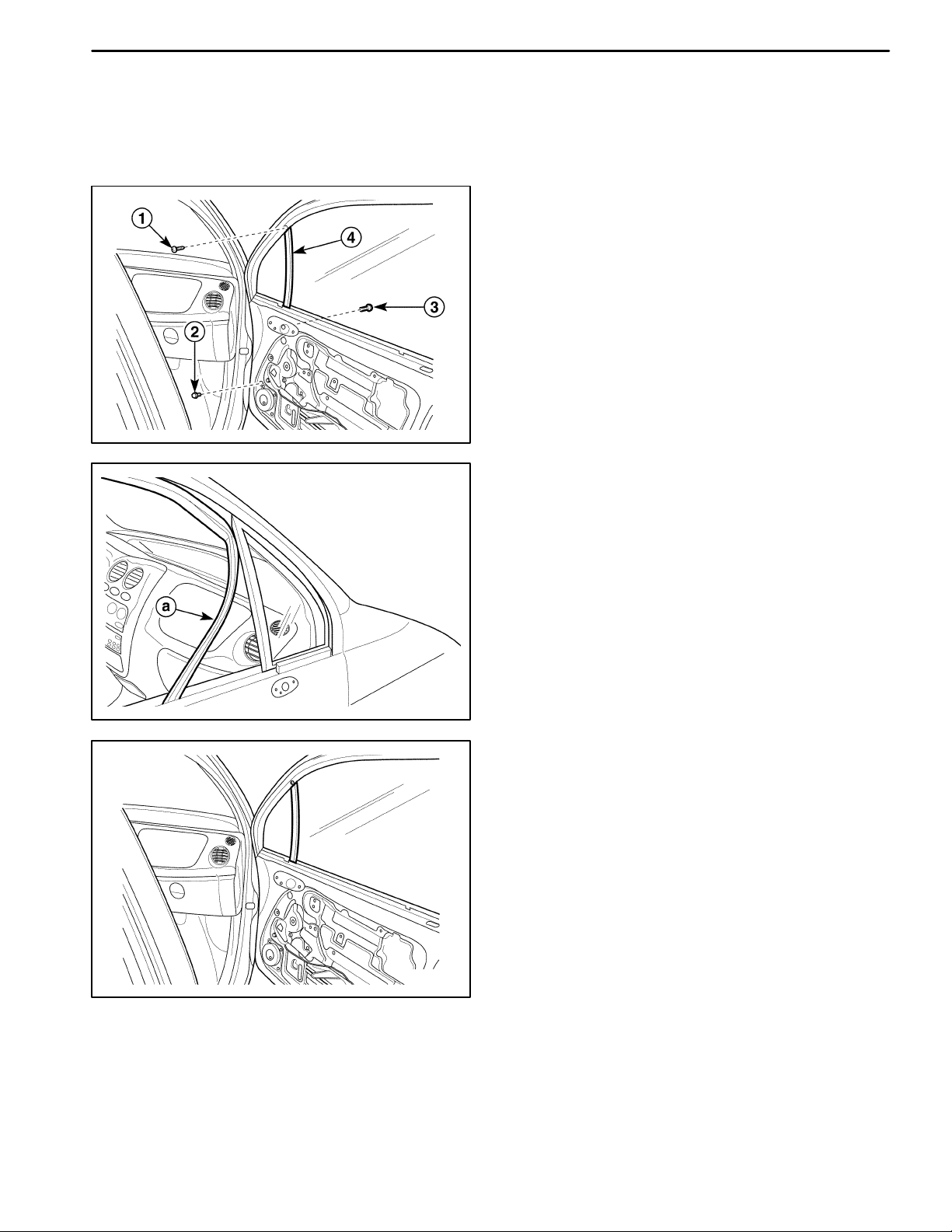

Removal Procedure

1. Remove the front door seal trim from the front door.

Refer to “Door Seal Trim” in this section.

2. Remove the outside rearview mirror from the front

door. Refer to Section 9L, Glass and Mirrors.

3. Remove the guide rail from the door.

D Remove the screws (1).

D Remove the inside bolts (2).

D Remove the outside bolts (3).

D109E521

D Remove the division bar (4).

4. Remove the glass run.

a. Glass run.

DOORS 9P–7

D109E522

D109E526

Installation Procedure

1. Install the glass run.

2. Install the division bar with the bolts and the screws.

3. Install the outside rearview mirror. Refer to Section

9L, Glass and Mirrors.

4. Install the front door seal trim. Refer to “Door Seal

Trim” in this section.

DAEWOO M-150 BL2

Page 8

9P –8 DOORS

D109C566

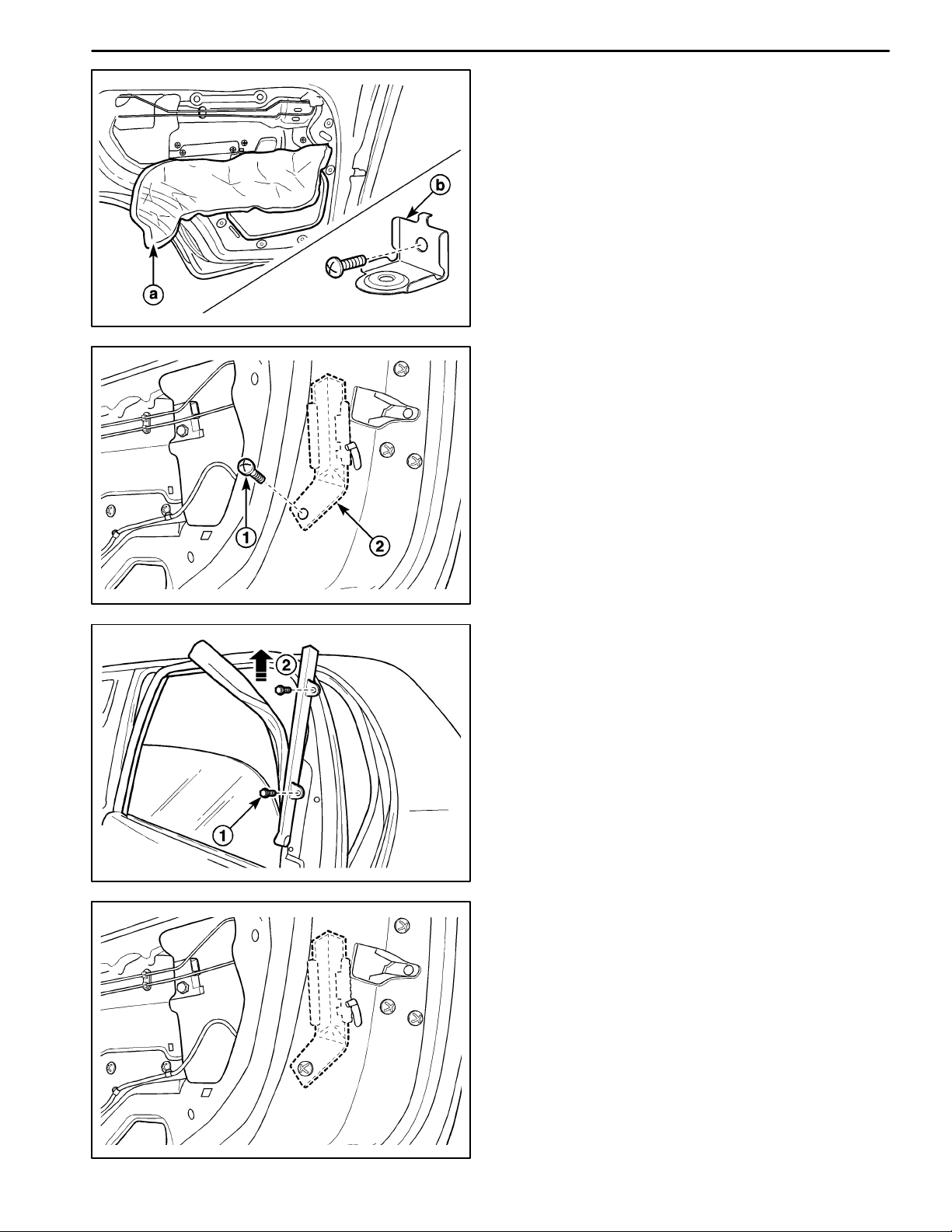

REAR DOOR GLASS RUN

Removal Procedure

1. Remove the inside channel weatherstrip from the

rear door. Refer to Section 9G, Interior Trim.

2. Remove the outside channel weatherstrip from the

rear doors. Refer to Section 9G, Interior Trim.

3. Remove the rear door trim panel. Refer to Section

9G, Interior Trim.

4. Remove the rear door seal trim.

a. Door seal trim.

b. Door pocket handle bracket.

Important: In case of the deluxe type, remove the seal

trim after removing the door pocket handle bracket.

5. Remove the guide piece.

D Remove the screw (1).

D Remove the guide piece (2).

D109C567

D109C568

D109C569

6. Remove the upper guide rail and the glass run.

D Remove the bolts (1).

D Lift up and remove the upper guide rail and the

glass run simultaneously (2).

Installation Procedure

1. Install the upper guide rail and the rear door glass

run.

2. Install the guide piece with the screw.

3. Install the rear door seal trim.

4. Install the rear door trim panel. Refer to Section 9G,

Interior Trim.

5. Install the outside channel weatherstrip to the rear

door. Refer to Section 9G, Interior Trim.

6. Install the inside channel weatherstrip to the rear

door. Refer to Section 9G, Interior Trim.

DAEWOO M-150 BL2

Page 9

D109C570

DOORS 9P–9

DOOR LOCK STRIKER

Removal Procedure

1. Remove the door lock striker.

D Remove the screws (1).

D Remove the door lock striker (2).

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fasteners to prevent premature corrosion.

1. Install the door lock striker with the screws.

D109C571

D109C572

TAILGA T E LOCK STRIKER

Removal Procedure

1. Open the tailgate and suitably support it.

2. Remove the tailgate lock striker.

D Remove the screws (1).

D Disconnect the cable (2).

D Remove the striker (3).

Installation Procedure

Notice: Dissimilar metal in direct contact with each oth-

er may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

1. Connect the cable.

2. Install the tailgate lock striker with the screws.

DAEWOO M-150 BL2

D109C573

Page 10

9P –10 DOORS

D109C574

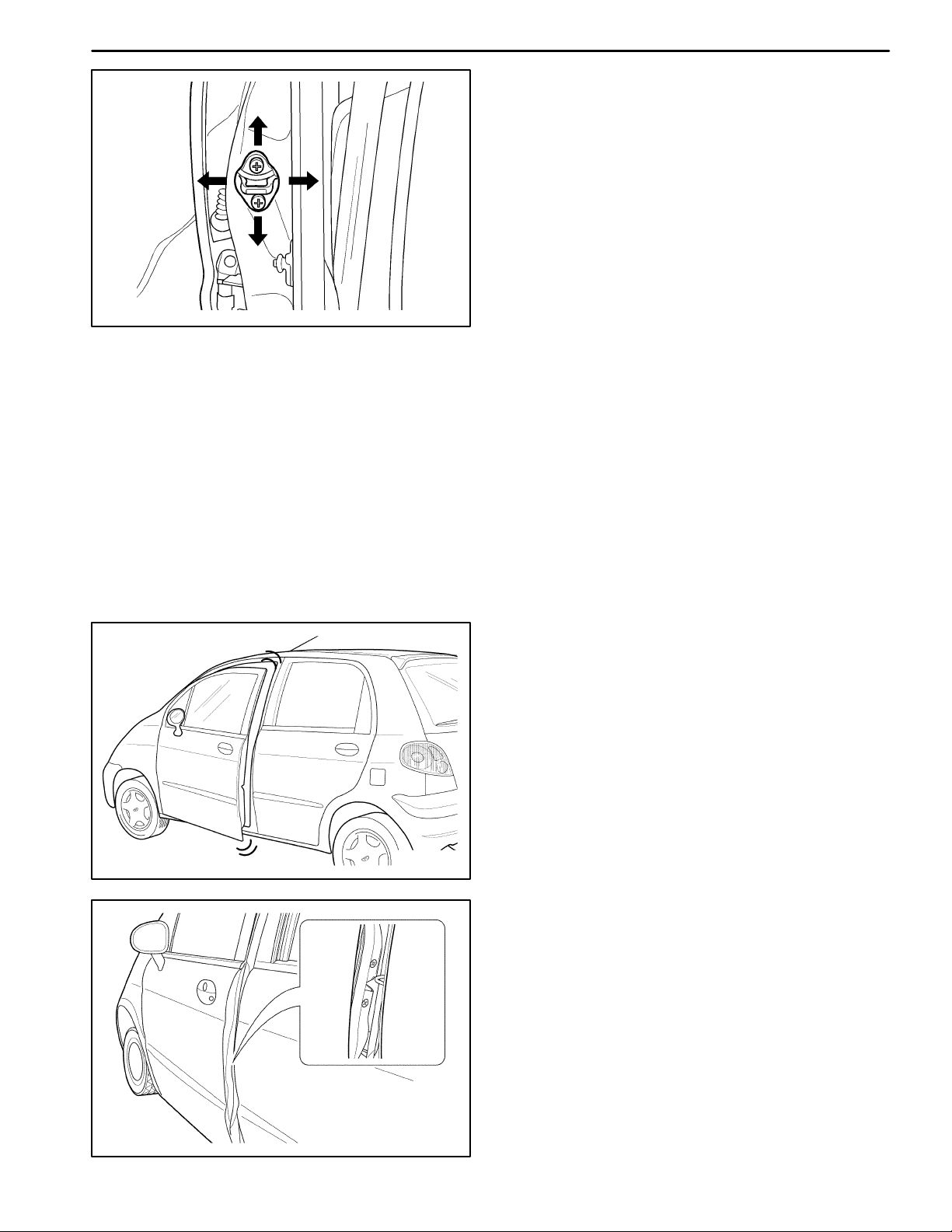

DOOR LOCK STRIKER ADJUSTMENT

Notice: The door lock striker is an important attaching

part that can affect the performance of vital components

and systems and can cause major repair expenses. If

replacement becomes necessary, the door lock striker

must be replaced by one with the same part number or

with an equivalent part if replacement becomes necessary. Do not use a replacement part of lesser quality or

of a substitute design. The specified torque values must

be used during reassembly in order to ensure the proper

retention of the part.

The door lock striker consists of a striker with two

screws that are threaded into a tapped, floating cage

plate located in the appropriate body pillar. This floating

cage plate allows the striker to be easily adjusted in or

out and up or down. The door is secured in the closed

position when the door lock fork snaps over and engages the striker.

D19C575A

Fore/Aft Adjustment

1. The door must be properly aligned.

2. Close the door until the lock fork contacts the striker.

3. Stand next to the door opening and move the door

slowly in and out, just touching the striker each time.

4. The alignment of the lock fork and the striker can be

easily seen. The lock fork should be perpendicular to

and fall near the middle of the striker. The lock fork

should fall near the middle of the striker between the

B-pillar and the end of the striker.

D109C576

DAEWOO M-150 BL2

Page 11

D109C577

D109C574

DOORS 9P–11

5. If a fore or aft adjustment is required, use the following

steps:

D Remove the striker screws (1).

D Remove the spacer in order to move the striker to-

ward the rear of the vehicle (2).

D Add a 2 mm (0.08 inch) spacer in order to move

the striker toward the front of the vehicle.

D Install the striker screws.

6. Perform the up/down or the in/out adjustment. Refer

to ‘‘Up/Down or In/Out Adjustment’’ in this section.

Up/Down or In/Out Adjustment

An adjustment of the striker in the up and down or in a n d

out directions may be necessary for a number of reasons:

vehicle frame dam age as the result o f a collision, inst alla tion of new door weatherstripping, customer complaints

of excessiv e windnoise, or difficulty in opening or closing

the door. In order to adjust the door striker in an up and

down or in and out direction, perf orm the following procedure:

1. The door must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly using

the ends of the striker screws. Move the floating cage

plate to the desired position.

D109C578

Notice: It is important to use a flat-end rotary file in or-

der not to damage the tapped floating cage plate. The

striker screws and the tapped floating cage plate are important attaching parts that could affect the performance

of vital components and systems.

4. If proper adjustment requires that the floating cage plate

be moved more than is possible, use an electric hand

drill and a 3/8- inch rotary file with a flat head in order to

enlarge the body opening in the direction required.

5. Tighten the striker screws to the correct position.

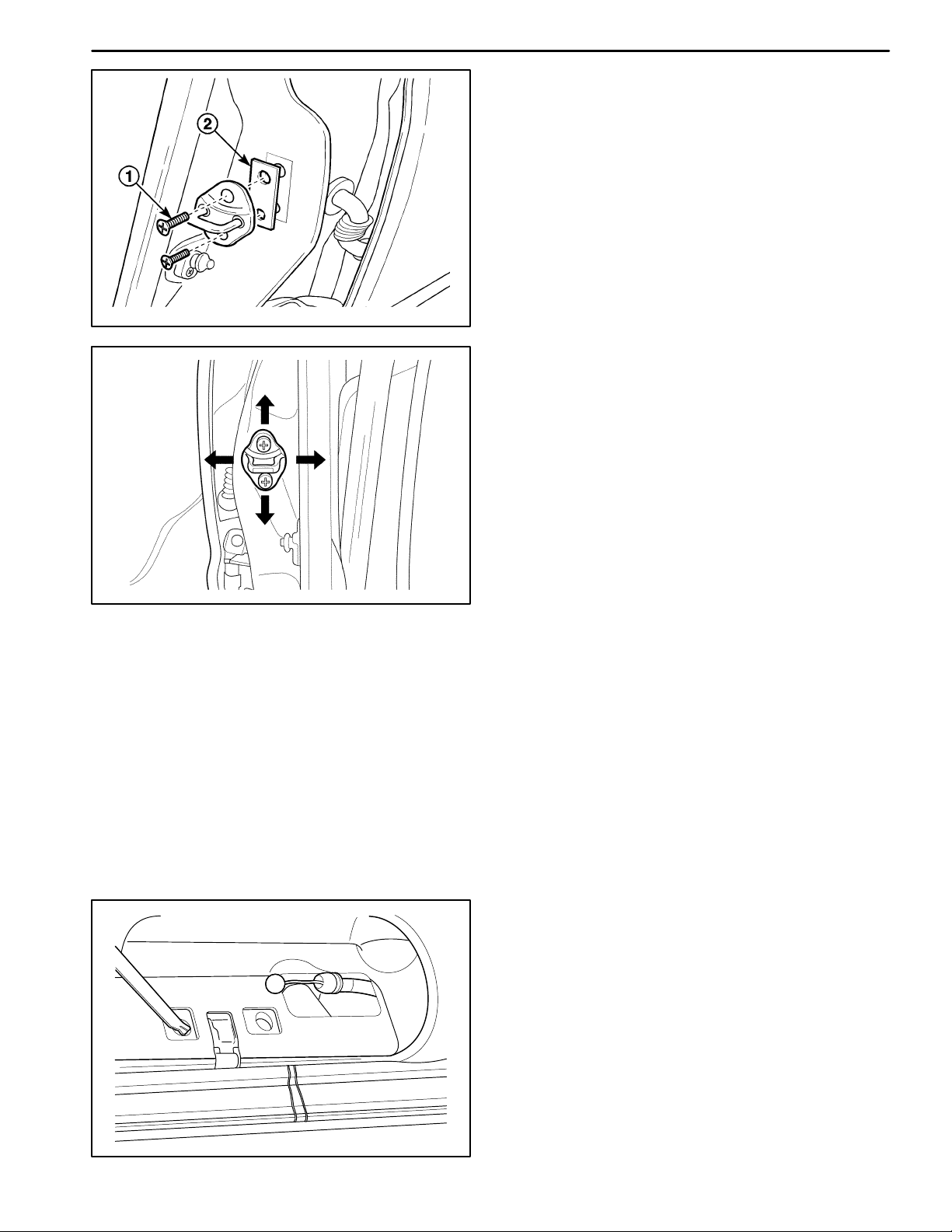

TAILGA T E LOCK STRIKER

ADJUSTMENT

Notice: The tailgate lock striker is an important attaching

part that can affect the performance of vital components

and systems and can cause major repair expenses. If replacement becomes necessary, the tailgate lock striker

must be replaced by one with the same part number or

with an equivalent part if replacement becomes necessary. D o not use a replacement part of lesser quality or of

a substitute design. The specified torque values must be

used during reassembly in order to ensure the proper

retention of the part.

DAEWOO M-150 BL2

Page 12

9P –12 DOORS

D109C578

The tailgate lock striker consists of a striker with two

screws that are threaded into a tapped, floating cage

plate located in the appropriate body pillar. This floating

cage plate allows the striker to be easily adjusted in or

out and up or down. The tailgate is secured in the closed

position when the tailgate lock fork snaps over and engages the striker.

Fore/Aft or In/Out Adjustment

An adjustment of the striker in the fore and aft or in and

out directions may be necessary for a number of reasons:

vehicle frame dam age as the result o f a collision, inst alla tion of new tailgate weatherstripping, customer complaints of ex cessive windnoise, or difficult y in opening or

closing the tailgate. In order to adjust the tailgate striker in

an fore and aft or in and out direct ion, perf orm the following procedure:

1. The tailgate must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly using

the ends of the striker screws. Move the floating cage

plate to the desired position.

Notice: It is important to use a flat-end rotary file in order not to damage the tapped floating cage plate. The

striker screws and the tapped floating cage plate are important attaching parts that could affect the performance

of vital components and systems.

4. If proper adjustment requires that the floating cage plate

be moved more than is possible, use an electric hand

drill and a 3/8- inch rotary file with a flat head in order to

enlarge the body opening in the direction required.

5. Tighten the striker screws to the correct position.

6. Perform the up/down adjustment. Refer to “Up and

Down Adjustment” in this section.

D109C579

DAEWOO M-150 BL2

Page 13

D19C580A

DOORS 9P–13

Up and Down Adjustment

1. The tailgate must be properly aligned.

2. Close the tailgate until the lock fork contacts the striker.

3. Stand next to the tailgate opening and move the tailgate slowly up and down, just touching the striker

each time.

4. The alignment of the lock fork and the striker can be

easily seen. The lock fork should be perpendicular to

and fall near the middle of the striker. The lock fork

should fall near the middle of the striker between the

rear body pillar and the end of the striker.

D109C581

D109C582

5. If a up and down adjustment is required, use the following steps:

D Remove the striker screws (1).

D Remove the spacer in order to move the striker to-

ward the down of the vehicle (2).

D Add a 2 mm (0.08 inch) spacer in order to move

the striker toward the up of the vehicle.

D Install the striker screws.

FRONT DOOR LOCK

Removal Procedure

1. Disconnect the negative battery cable if equipped

with the central door lock system.

2. Remove the seal trim. Refer to “Door Seal Trim” in

this section.

3. Disconnect the outside door handle rod from the door

lock.

a. Outside door handle rod.

b. Key rod.

DAEWOO M-150 BL2

D19C583A

Page 14

9P –14 DOORS

D109C584

D109C585

4. Remove the front door lock.

D Remove the screws (1).

D Remove the front door lock (2).

Important: Disconnect the actuator connector, if

equipped with the central door lock system.

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fasteners to prevent premature corrosion.

1. Install the front door lock with screws.

Important: Connect the actuator connector if equipped

with the central door lock system.

2. Connect the outside door handle rod and the key rod

to the door lock.

3. Install the seal trim. Refer to “Door Seal Trim” in this

section.

4. Connect the negative battery cable, if equipped with

the central door lock system.

D109C566

CHILDPROOF REAR DOOR LOCK

Removal Procedure

1. Disconnect the negative battery cable if equipped

with the central door lock system.

2. Remove the door trim panel. Refer to Section 9G, In-

terior Trim.

3. Remove the door seal trim. Refer to “Door Seal Trim”

in this section.

a. Door seal trim.

b. Door pocket handle bracket.

Important: In case of the deluxe type, remove the seal

trim after removing the door pocket handle bracket.

4. Remove the guide piece.

D Remove the screw (1).

D Remove the guide piece (2).

D109C567

DAEWOO M-150 BL2

Page 15

D109C583

DOORS 9P–15

5. Disconnect the outside door handle rod from the door

lock.

a. Outside door handle rod.

6. Disconnect the door lock from the vehicle.

D Remove the screws (1).

D Remove the door lock (2).

Important: Disconnect the actuator connector if

equipped with the central door lock system.

D109C586

D109C587

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fasteners to prevent premature corrosion.

1. Install the rear door lock with the screws.

Important: Connect the actuator connector if equipped

with the central door lock system.

2. Connect the outside door handle rod to the door lock.

3. Install the guide rail with the screw.

4. Install the seal trim. Refer to “Door Seal Trim” in this

section.

5. Install the door trim panel. Refer to Section 9G, Interi-

or Trim.

6. Connect the negative battery cable if equipped with

the central door lock system.

DAEWOO M-150 BL2

Page 16

9P –16 DOORS

CENTRAL DOOR LOCK ACTUATOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the door seal trim. Refer to “Door Seal T rim”

in this section.

3. Remove the door lock assembly. Refer to “Door Lock”

in this section.

4. Remove the actuator from the door lock assembly.

D Remove the screws (1).

D Remove the actuator (2).

D109C588

Installation Procedure

1. Install the door lock actuator to the door lock assembly with the screws.

2. Install the door lock assembly to the vehicle. Refer to

“Door Lock” in this section.

3. Install the door seal trim. Refer to “Door Seal Trim” in

this section.

4. Connect the negative battery cable.

D109C589

D109C590

TAILGATE LOCK

Removal Procedure

1. Remove the tailgate trim panel. Refer to Section 9G,

Interior Trim.

2. Remove the lock rod from the tailgate lock cylinder.

a. Lock rod.

3. Remove the tailgate lock.

D Remove the screws (1).

D Remove the tailgate lock (2).

D109C591

DAEWOO M-150 BL2

Page 17

D109C592

DOORS 9P–17

Installation Procedure

1. Install the tailgate lock with the screws.

2. Install the lock rod to the tailgate lock cylinder.

3. Install the tailgate trim panel. Refer to Section 9G, In-

terior Trim .

INSIDE DOOR HANDLE

Removal Procedure

1. Removal the inside door handle.

D Remove the screw (1).

D Remove the inside door handle (2).

D109C593

D109C594

Installation Procedure

1. Install the inside door handle with the screw.

OUTSIDE FRONT DOOR HANDLE

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front door lock rods.

3. Remove the outside front door handle.

D Remove the bolts (1).

D Remove the outside front door handle (2).

DAEWOO M-150 BL2

D109C595

Page 18

9P –18 DOORS

Installation Procedure

1. Install the outside front door lock handle with the

bolts.

2. Install the front door lock rods.

3. Connect the negative battery cable.

D109C596

OUTSIDE REAR DOOR HANDLE

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear door lock. Refer to “Childproof Rear

Door Lock” in this section.

3. Remove the outside rear door handle.

D Remove the bolts (1).

D Remove the outside rear door handle (2).

D109C597

D109C598

Installation Procedure

1. Install the outside rear door handle with the bolts.

2. Install the rear door lock. Refer to “Childproof Rear

door Lock” in this section.

3. Connect the negative battery cable.

DOOR LOCK CYLINDER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the outside door handle. Refer to “Outside

Front Door Handle” in this section.

3. Remove the door lock cylinder from the outside door

handle.

D Remove the clip (1).

D Remove the door lock cylinder (2).

D109C599

DAEWOO M-150 BL2

Page 19

D109C600

DOORS 9P–19

Installation Procedure

1. Install the door lock cylinder with the clip.

2. Install the outside door handle. Refer to “Outside

Front Door Handle” in this section.

3. Connect the negative battery cable.

MANUAL WINDOW REGULATOR

Removal Procedure

1. Remove the glass. Refer to Section 9L, Glass and

Mirrors.

2. Remove the window regulator.

D Remove the screws (1).

D Remove the regulator (2).

D109C601

D109C602

D109C603

Installation Procedure

1. Install the regulator with the screws.

2. Install the glass. Refer to Section 9L, Glass and Mir-

rors.

POWER FRONT WINDOW

REGULATOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glass. Refer to Section 9L, Glass and

Mirrors.

3. Remove the window regulator assembly.

D Disconnect the window motor electrical connector

(1).

D Remove the screws (2).

D Remove the window regulator assembly (3).

DAEWOO M-150 BL2

Page 20

9P –20 DOORS

4. Remove the window motor from the window regulator.

D Remove the screws (1).

D Remove the window regulator (2).

Caution: Be careful what you are doing when separating the window motor and the window regulator.

You may be hurt.

D109C604

Installation Procedure

1. Install the window motor to the window regulator with

the screws.

2. I nst all the window regulator assembly with the screws.

3. Connect the window motor electrical connector.

4. Install the glass. Refer to Section 9L, Glass and Mir-

rors.

5. Connect the negative battery cable.

D109C605

D109C606

FRONT DOOR ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector under the instrument panel.

Important: In case of the front passenger door, remove

the glove box in advance.

3. Remove the fender. Refer to Section 9R, Body Front

End.

4. Remove the front door assembly.

D Remove the door hinge bolts (1).

D Remove the door hold open bolt (2).

D Disconnect the body–to–door rubber grommet (3).

D Remove the front door assembly (4).

D109C607

DAEWOO M-150 BL2

Page 21

D19C608A

DOORS 9P–21

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fastener to prevent premature corrosion.

1. Connect the body–to–door rubber grommet.

2. With the aid of another technician, lightly secure the

front door with the bolts.

3. Adjust the door for proper fit.

4. Tighten the hinge–to–body bolts.

5. Install the door hold open link with the bolt.

6. Install the fender. Refer to Section 9R, Body Front

End.

7. Connect the electrical connector.

8. Connect the negative battery cable.

9. Perform the waterleak test. Refer to Section 9I, Wa-

terleak.

10. Check for windnoise. Refer to Section 9J, Windnoise.

D109C609

REAR DOOR ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Pry off the lower B–pillar trim panel. Refer to Section

9G, Interior Trim.

3. Disconnect the rear door electrical connector.

a. Rear door electrical connector.

4. Remove the rear door assembly.

D Remove the door hinge bolts (1).

D Remove the door hold open link bolt (2).

D Disconnect the body–to–door rubber grommet (3).

D Remove the rear door assembly (4).

DAEWOO M-150 BL2

D109C610

Page 22

9P –22 DOORS

D19C611A

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fastener to prevent premature corrosion.

1.Connect the body–to–door rubber grommet.

2. With the aid of another technician, lightly secure the

rear door with the bolts.

3. Adjust the door for proper fit.

4. Install the door hold open link with the bolt.

5. Connect the rear door electrical connector.

6. Connect the negative battery cable.

7. Perform the waterleak test. Refer to Section 9I, Wa-

terleaks.

8. Check for windnoise. Refer to Section 9J, Windnoise.

TAILGATE

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the luggage compartment wheelhouse trim

panel. Refer to Section 9G, Interior Trim.

3. Disconnect the tailgate electrical connector.

a. Tailgate electrical connector.

D109C612

D109C636

4. Remove the tailgate strut. Refer to “Tailgate Strut” in

this section.

5. Remove the tailgate.

D Remove the hinge bolts.

D Disconnect the body–to–tailgate rubber grommet.

D Remove the tailgate.

D19C613A

DAEWOO M-150 BL2

Page 23

D19C614A

D209B113

DOORS 9P–23

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fastener to prevent premature corrosion.

1. Connect the body–to–tailgate rubber grommet.

2. With the aid of another technician, lightly secure the

tailgate with the bolts.

3. Adjust the tailgate for proper fit.

4. Inst all the tailgate strut. Refer to “Tailgate Strut” in this

section.

5. Connect the tailgate electr ical connect or.

6. I nstall the luggage compart ment wheelhouse trim pan -

el. Refer to Section 9G, Interior Trim.

7. Connect the negative battery cable.

TAILGATE LOCK CYLINDER

Removal Procedure

1. Disconnect the negative battery cable.

2. Open the tailgate.

3. Remove the rear window wiper motor assembly. Re-

fer to Section 9D, Wipers/Washer Systems.

4. Remove the tailgate lock cylinder.

D Disconnect the tailgate lock rod (1).

D Remove the nuts from the tailgate lock cylinder (2).

D Remove the tailgate lock cylinder (3).

D209B114

Installation Procedure

1. Install the tailgate lock cylinder.

2. Install the rear window wiper motor assembly. Refer

to Section 9D, Wipers/Washer Systems.

3. Connect the negative battery cable.

DOOR HINGE

Removal Procedure

1. With the aid of another technician, remove the door

hinge.

D Remove the hinge–to–body bolts (1).

D Remove the hinge–to–door bolts (2).

D Remove the door hinge (3).

DAEWOO M-150 BL2

D109C615

Page 24

9P –24 DOORS

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fastener to prevent premature corrosion.

1. With the aid of another technician, install the hinge to

the door and the body with the bolts.

D109C616

DOOR HOLD OPEN LINK

Removal Procedure

1. Remove the door seal trim. Refer to “Door Seal T rim”

in this section.

2. Remove the door hold open link.

D Remove the hinge–to–body bolt (1).

D Remove the hinge–to–door bolts (2).

D Remove the door hold open link (3).

D109C617

D109C618

Installation Procedure

Notice: Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use the correct

fastener to prevent premature corrosion.

1. Install the door hold open link to the door and the

body with the bolts.

2. Remove the door seal trim. Refer to “Door Seal T rim”

in this section.

INSIDE CHANNEL WEATHERSTRIP

(STANDARD)

Removal Procedure

1. Remove the channel weatherstrip.

a. Weatherstrip.

D109C619

DAEWOO M-150 BL2

Page 25

D109C620

DOORS 9P–25

Installation Procedure

1. Install the channel weatherstrip.

INSIDE CHANNEL WEATHERSTRIP

(DELUXE)

Removal Procedure

1. Remove the door trim. Refer to Section 9G, Interior

Trim.

2. Remove the channel weatherstrip from the door trim.

D Straighten the retaining tabs (1).

D Remove the channel weatherstrip (2).

D109C621

D109C622

Installation Procedure

1. Install the channel weatherstrip onto the door trim

panel.

2. Bend the retaining tabs to secure the channel weath-

erstrip to the door trim panel.

3. Install the door trim panel. Refer to Section 9G, Interi-

or Trim.

DOOR OUTSIDE CHANNEL

WEATHERSTRIP

Removal Procedure

1. Remove the channel weatherstrip.

D Remove the screw (1).

D Lift off the outside channel weatherstrip (2).

DAEWOO M-150 BL2

D109C623

Page 26

9P –26 DOORS

Installation Procedure

1. Press the outside channel weatherstrip onto the door.

2. Install the weatherstrip screw.

D109C624

DOOR WEATHERSTRIP

Removal Procedure

1. Remove the door hold open link bolt.

D109C625

D109C626

2. Remove the door weatherstrip.

D Remove the clip (1).

D Remove the weatherstrip pins (2).

Installation Procedure

1. Install the door weatherstrip with the clip and the pins.

2. Install the door hold open link bolt.

D109C627

DAEWOO M-150 BL2

Page 27

D109C566

DOORS 9P–27

DOOR SEAL TRIM

Removal Procedure

1. Remove the door trim panel. Refer to Section 9G, In-

terior Trim.

2. Remove the door seal trim.

a. Door seal trim.

b. Door pocket handle bracket.

Important: In case of the deluxe trim, remove the door

pocket handle bracket in advance.

Installation Procedure

1. Install the door seal trim.

2. Install the door pocket handle bracket for the deluxe

trim.

3. Install the door trim panel. Refer to Section 9G, Interi-

or Trim.

D109C628

D109C629

DOOR OPENING WEATHERSTRIP

Removal Procedure

1. Mark the door opening weatherstrip edge by a soluble

pen.

2. Remove the door opening weatherstrip.

D Take off the rocker trim panel partially (1).

D Take off the lower B–pillar trim panel partially (2).

D Remove the door opening weatherstrip (3).

DAEWOO M-150 BL2

D109C630

Page 28

9P –28 DOORS

Installation Procedure

1. Install the door opening weatherstrip to match the

marking.

2. Install the rocker panel trim and the lower B–pillar

panel trim.

D109C631

MANUAL WINDOW REGULATOR

HANDLE

Removal Procedure

1. Remove the window regulator handle.

D Using a cloth, pull out the clip (1).

D Remove the window regulator handle (2).

D109E543

D109C632

Installation Procedure

1. Install the window regulator handle with the clip.

TAILGATE STRUT

Removal Procedure

1. Open the tailgate and suitably support it.

2. Remove the tailgate strut assembly.

D Remove the end fitting nut from the ball studs (rear

body) (1).

D Removethe end fitting nut from the ball studs (tail-

gate) (2).

D19C634A

DAEWOO M-150 BL2

Page 29

D19C635A

DOORS 9P–29

Installation Procedure

1. Install the tailgate strut with the ball studs.

DAEWOO M-150 BL2

Page 30

9P –30 DOORS

SCHEMATIC AND ROUTING DIAGRAMS

POWER DOOR LOCKS

(LEFT–HAND DRIVE)

D19C201B

DAEWOO M-150 BL2

Page 31

POWER DOOR LOCKS

(RIGHT–HAND DRIVE)

DOORS 9P–31

DAEWOO M-150 BL2

D19C201S

Page 32

9P –32 DOORS

POWER DOOR LOCKS

(W/ ANTI–THEFT CONTROL : LHD)

D19C201S

DAEWOO M-150 BL2

Page 33

POWER DOOR LOCKS

(W/ ANTI–THEFT CONTROL : RHD)

DOORS 9P–33

DAEWOO M-150 BL2

D19C202S

Page 34

9P –34 DOORS

POWER WINDOWS (FRONT ONLY)

D19C202B

DAEWOO M-150 BL2

Loading...

Loading...