Page 1

Service Manual

XGA COLOR MONITOR

Model : 526X

D AEW OO ELECTR ONICS CO., LTD.

Page 2

4

◆ Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components are commonly called Electrostatically Sensitive (ES) Devices.

The typical examples of ES devices are integrated circuits, some field-effect transistors, and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence

of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly,

wipe off any electrostatic charge on your body by touching any known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device which should be removed for

potential shock reasons prior to applying power to the unit under testing conditions.

2. After removing the electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil to prevent electrostatic charge buildup or exposure to the assembly.

3. Only use a grounded-tip soldering iron to solder or unsolder ES devices.

4. Only use an anti-static type solder removal device. Some solder removal devices not classified as “antistatic” can generate enough electrical charges to damage ES devices.

5.

Do not use freon-propelled chemicals. These can generate enough electrical charges to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from the leads of replacement ES devices, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Minimize bodily movements when handling unpackaged replacement ES devices. (Otherwise harmful

motion such as the brushing together clothes fabric or the lifting your foot from a carpeted floor can

generate enough static electricity to damage ES devices).

◆ General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron with appropriate tip size and shape that will maintain

tip temperature between a 550°F-660°F (288°C-316°C) range.

2. Use an appropriate gauge of RMA resin-core solder composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean.

4. Throughly clean the surface to be soldered. Use a small wire-bristle (0.5 inch or 1.25cm) brush with a

metal handle. Do not use freon-propelled spray-on cleaners.

5. Use the following soldering technique:

a. Allow the soldering iron tip to reach normal temperature (550°F to 660°F or 288°C to 316°C)

b. Hold the soldering iron tip and solder strand against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the component lead and the printed circuit foil,

and hold it there until the solder flows onto and around both the component lead and the foil.

d.

Closely inspect the solder area and remove any excess or splashed solder with a small wire-bristle brush.

CAUTION:

Be sure that no power is applied to the chassis or circuit, and observe all other safety

precautions.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

Page 3

5

FIGURE 1. USE SOLDERING IRON TO PRY LEADS

◆ IC Removal/Replacement

Some utilized chassis circuit boards have slotted (oblong) holes through which the IC leads are inserted

and then bent flat against the circuit foil. When holes are slotted, the following technique should be used

to remove and replace the IC. When working with boards using the familiar round hole, use the standard

technique as outlined in paragraphs 5 on the page under the title of general soldering guidelines.

◆ Removal

1. Desolder and straighten each IC lead in one operation by gently prying up on the lead with the

soldering iron tip as the solder melts.

2. Draw away the melted solder with an anti-static suction-type solder removal device (or with

desoldering braid before removing the IC.

◆ Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and solder it.

3. Clean the soldered areas with a small wire-bristle brush. (lt is not necessary to reapply acrylic coating

to the area).

◆ “Small-Signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as possible to the component body.

2. Bend the ends of each of three leads remaining on the circuit board into a “U” shape.

3. Bend the replacement transistor leads into a “U” shape.

4. Connect the replacement transistor leads to the corresponding leads extending from the circuit board

and crimp the “U” with long nose pliers to ensure metal-to-metal contact, then solder each connection.

Page 4

6

◆ Power IC, Transistor or Devices Removal/Replacement

1. Heat and remove all solders from the device leads.

2. Remove the heatsink mounting screw (if applicable).

3. Carefully remove the device from the circuit board.

4. Insert new device in circuit board.

5. Solder each device lead and then clip off excess lead.

6. Replace heatsink.

◆ Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicularly to the circuit board.

3. Observing diode polarity, wrap each lead out of the new diode around the corresponding lead on the

circuit board.

4. Securely crimp each connection and solder it.

5. Inspect the solder joints of the two “original” leads on the circuit board copper side. If they are not

shiny, reheat them and apply additional solder if necessary.

TECHNICAL INFORMATION

CDT Size 15-inch

Diagonal visible image area 14-inch

Dot Pitch 0.28 mm

Synchronization Horizontal 30 - 54 KHz

Vertical 50 - 160 Hz

Plug and Play DDC1/2B/CI

Power Saving EPA, VESA DPMS, Nutek Compliant

Power Source 100-240 Vac, 50/60Hz (Free Voltage)

Power Consumption 70W

Dimension-W x H x D 360 x 381 x 389mm

(set with stand)

Weight-unpacked(lbs/Kg) 25.1/11.4

Operating Temperature 10 ~ 40°C /50 ~ 104°F

Page 5

This color monitor automatically scans all horizontal frequencies from 30KHz to 54KHz, and all vertical frequencies from

50Hz to 160Hz. This color monitor supports IBM PC, PC/XT, PC/AT, personal System/2 (PS/2), Apple Macintosh, and

compatible users crisp text and vivid color graphics display when using the following graphics adapters : (VGA, 8514/A,

Super VGA, VESA and XGA and Apple Macintosh Video Card). And so, this color monitor has a maximum horizontal

resolution of 1024 dots and a maximum vertical resolution of 768 lines for superior clarity of display.

By accepting analog signal inputs which level is zero to 0.7 Volts. This color monitor can display and unlimited palette of

colors depending on the graphics adapter and software being used.

◆ Abbreviations

7

GENERAL INFORMATION

ADJ Adjustment

AFC Automatic Frequency Control

CRT Cathode Ray Tube

Def Deflection

D.Y Deflection Yoke

FBT Flyback Transformer

H.SYNC Horizontal Synchronization

OSC Oscillator

P.S.U Power Supply Unit

PWA Printed Circuit Board Wiring Assembly

R.G.B Red, Green, Blue

V.Sync Vertical Synchronization

Page 6

8

Pin Signal

1 Red

2 Green

3 Blue

4 GND

5 GND

6 GND - Red

7 GND - Green

8 GND - Blue

9 +5Vdc

10 GND - H.Sync

11 GND - V.Sync

12 Bi-directional Data (SDA)

13 Horizontal Sync

14 Vertical Sync (VCLK)

15 Data Clock (SCL)

• Degaussing is always required when adjusting purity or convergence.

• The white balance adjustment has been done by a color analyzer in factroy. The adjustment procedure,

described in the service manual is made by a visual check.

• Allow 20 minutes warm-up time for the display before checking or adjusting only electrical

specification or function.

• Reform the leadwire after any repair work.

◆ Caution For Servicing

• In case of servicing or replacing CRT, high voltage sometimes remains in the anode of the CRT. Completely

discharge high voltage before servicing or replacing CRT to prevent a shock to the serviceman.

Arrangement of 15-pin D-sub connector

PIN CONNECTOR

CAUTIONS FOR ADJUSTMENT AND REPAIR

1

6

15

10

Page 7

9

OPERATION AND ADJUSTMENT

Control Panel

• Launch OSD(On-Screen Display) MENU window.

• Select a sub Menu & function.

• Move a sub Menu & function.

• Increase the value of any selected function.

• Adjust the contrast directly when there is no OSD.

• Move a sub Menu & function.

• Decrease the value of any selected function.

• Adjust the brightness directly when there is no OSD.

MENU

SELECT

ADJUST

MENU

SELECT

Page 8

10

Key Process

•

When you choose the icon on the OSD window, you can exit the OSD screen.

MENU

SELECT

OSD OFF

MENU

MENUMENU

Page 9

11

OSD Functions

ICON CONTROL FUNCTIONS

Adjust the pin corner bottom when the bottom sides of the screen are bowed.

B. PIN CORNER

Adjust the side pin corner balance top when the top sides of the screen are bowed

towards left or right.

T. PIN BALANCE

Adjust the side pin corner balance bottom when the bottom sides of the screen are bowed

towards left or right.

B. PIN BALANCE

Adjust the parallelogram when the screen is leaning left or right.

Adjust the pin corner top when the top sides of the screen are bowed.

T. PIN CORNER

PARALLELOGRAM

Adjust the trapezoid of the screen by moving the lines inward or outward.

Adjust the side balance when the sides of the screen are bowed towards left or right.

PIN BALANCE

TRAPEZOID

Adjust the left and right margins for more convex or more concave margins.

PINCUSHION

Adjust the display height (vertical size).

Adjust the vertical linearity.

V. LINEARITY

V.SIZE

Adjust the position of the display vertically (up or down).

Adjust the display width (horizontal size).

H.SIZE

V. POSITION

Adjust the position of the display horizontally (left or right). H. POSITION

Choose different preset color temperatures or set your own customized color parameters.

COLOR TEMP

Page 10

12

Reset the screen to the Factory Preset Display Settings.

RECALL

ICON CONTROL FUNCTIONS

Display horizontal & vertical frequency and polarity.

STATUS

Adjust the rotation when the screen is tilted left or right (Optional).

ROTATION

Adjust the vertical picture moire cancellation.

V. MOIRE

Adjust the horizontal picture moire cancellation.

H. MOIRE

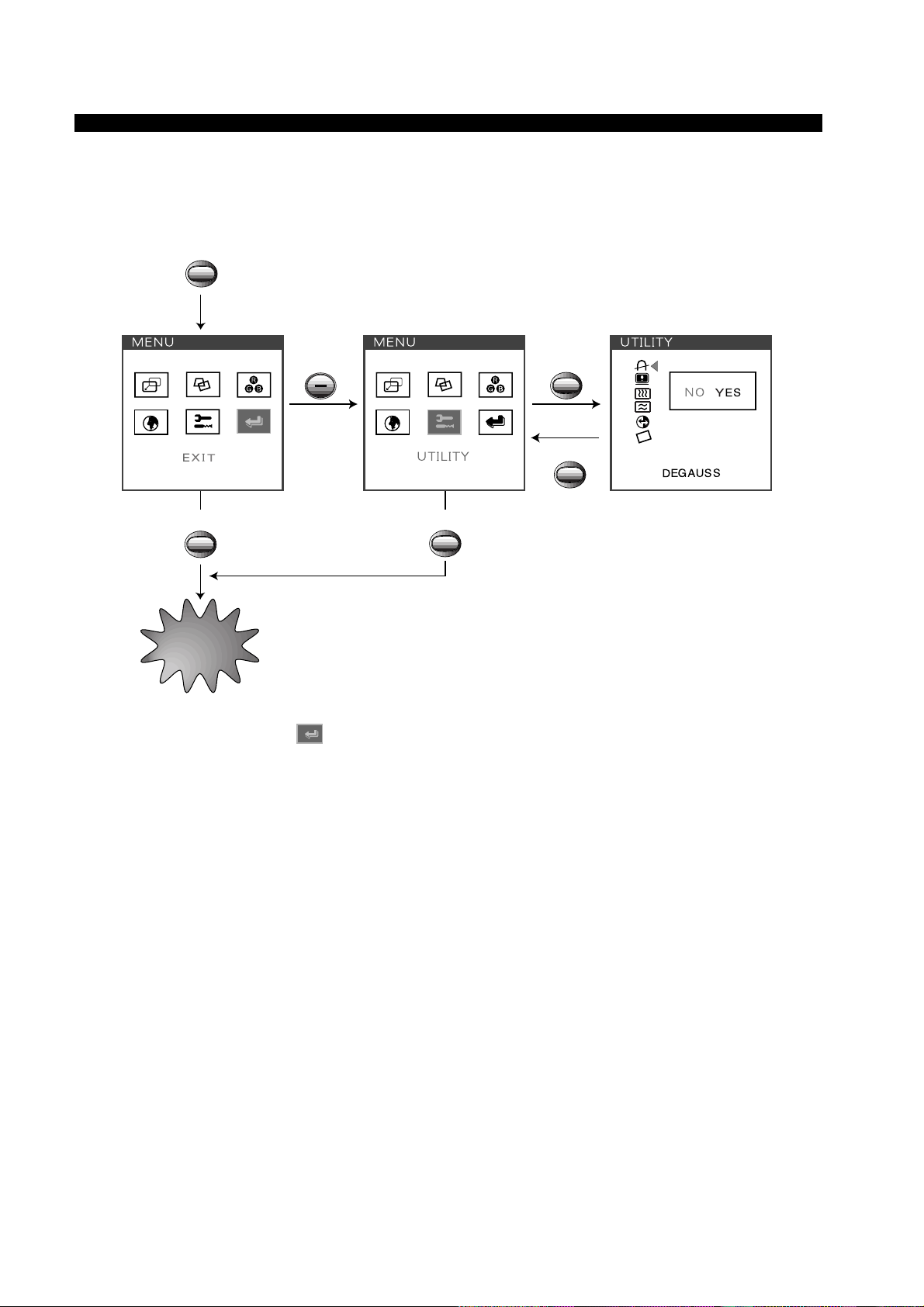

Degaussing keeps the monitor free from unwanted magnetism that can result in color

impurity.

DEGAUSS

Adjust the blue bias.

BLUE BIAS

Select language for OSD (5 languages).

LANGUAGE

Adjust the green bias.

GREEN BIAS

Adjust the red bias.

RED BIAS

Adjust the red gain.

Adjust the green gain.

Adjust the blue gain.

RED GAIN

GREEN GAIN

BLUE GAIN

Page 11

ALIGNMENT PROCEDURE

◆ Standard Adjustment Conditions

1. Power source voltage : 100-240Vac 50/60Hz

2. Aging : Take at least 20 minutes warm-up time.

3. Signals

Video : Analog 0.7Vpp 75Ω terminal positive polarity

Synchronizing : TTL level Negative/Positive Separate

Deflection frequency

Horizontal Frequency : 30KHz - 54KHz

Vertical Frequency : 50Hz - 160Hz

◆ Pre-Adjustment

1. B+ Adjustment

Adjust 6.15Vdc ± 0.05Vdc between P503 and ground at 31.5KHz mode, varying VR001.

Adjust -150Vdc ± 0.5Vdc between P504 and ground at 31.5KHz mode, varying VR501.

◆ Method to launch the factory mode

Step 1. Push the menu button.

Step 2. Push the menu button and plus control button ( + ) for 5 times in same time.

◆ Main Adjustment

1. Setting the Controls

Set the value of items as following.

Contrast : Max.(OSD value up to MAX)

Brightness : Center(Set the OSD value to center)

2. H.size, V.size, H.phase, V.position, Pincushion, Trapezoid

Receive the cross hatch pattern of Factory preset mode.

H.size, V.size, H.phase, V.position, Pincushion, Trapezoid are adjusted at each mode.

In Factory, Auto Alignment was done at each mode. Therefore, Factory preset mode has it’s

own value according to each control.

3. Focus

(a) Set brightness control to center and contrast control to MAX.

(b) Receive all “H” character pattern of 1024 X 768 (48KHz, 60Hz)

(c) Adjust the Focus control of FBT to obtain best Focus.

4. Geometric Distortion Adjustment.

(a) Receive the cross hatch pattern of factory preset mode.

(b) Pincushion, Trapezoid are adjusted the best geometric status.

5. White Balance Adjustment

(a) Select 9300°K on the OSD Menu.

(b) Receive a full white pattern of 54KHz mode signal by using the signal generator.

(c) Set the brightness control to the maximum, the contrast control to the maximum.

(d) Cut off the FBT screen VR.

(e) Receive all the black patterns. The luminance of the screen should be 0.5~1.0 Ft-L by using Screen

VR.

(f) Select the R-BIAS, G-BIAS and B-BIAS on the control menu and adjust the +/– key to get the color

coordinates in x=0.281 ± 0.015, y=0.311± 0.015.

(g) Receive a full white pattern. Adjust the brightness value to the center.

(h) Select the R-GAIN and B-GAIN and adjust the +/– key to get the color coordinates in x=0.281 ±

0.015, y=0.311 ± 0.015.

(i) Adjust the ABL control to get the screen luminance to 30 Ft/L (a full white pattern over 30 Ft/L)

(j) Check if the x, y coordinates of color analyzer is in x=0.281±0.015, y=0.311±0.015.

If the color coordinates is out of range, adjust the R. G. B BIAS & GAIN to get the coorinates in

x=0.281, y=0.311. Make sure that the coordinates is in range.

(k) Select 6550°K on the OSD Menu and set the color coordinates in x=0.313, y=0.329 at the

maximum contrast control and center brightness control

(l) Check if a full white pattern is over 30Ft/L.

13

Page 12

14

6. Static Convergence Adjustment

(a) Apply a magenta cross hatch pattern on display.

(b) Adjust the focus from the best over all focus on the display.

Also adjust the brightness to the desired condition.

(c) Vertical red and blue lines are converged by varying the angle between the two tabs of the 4-pole

magnets.

(d) Horizontal red and blue lines are converged by varying the tabs together, keeping the angle between

them constant.

(e) Apply a yellow cross hatch pattern on display.

(f) Vertical green and red lines are converged by barying the angle between the two tabs of the 6-pole

magnets.

(g) Horizontal green and red lines are converged by varying the tabs together, keeping the angle

between them constant.

Page 13

15

TROUBLESHOOTING HINTS

1. No Character

Are the Contrast &

Brightness Controls in

OSD menu

maximum?

Change the Contrast &

Brightness control value to

maximum

No Raster

Refer to

No Raster

Check the peripheral circuit

of CRT

Check the video output

circuit and its ambient circuit

Trouble in 12V line

of the Main PWB

Check the clamping pulse

circuit

Check the signal cable

No Character

Is whole

screen bright?

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

Rk, Gk, Bk

About 30~35Vpp

No

No

Is CRT

Cathode (Rk, Gk, Bk)

signal level

normal?

Is the

output signal of the

(pin 21,24,26) pre-amp

IC801, normal?

Is clamping

pulse (pin 18 of IC801)

normal?

Is 12V line

normal?

Is input signal

normal?

Trouble in IC801 and

its ambient circuit

5Vp-p

Page 14

16

2. No Raster

Trouble in

power supply

circuit

Trouble in power

supply circuit

Trouble in G1

line

Trouble in FBT or its

pin 4 ambient circuit

High Voltage

trouble in FBT

Trouble in 100Vdc

line of power

supply unit

Refer to trouble

in P.S.U

Refer to trouble in

power supply unit.

Is CRT

heater red-hot?

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Is Heater

Voltage (CRT PWB)

about 6V?

Turn the Brightness

& Contrast control

to set Maximum

No Raster

Is whole

screen bright?

Check

G1 voltage about

-40V?

Is 100Vdc

line normal?

Does

the Brightness

control make screen

bright?

Is CRT

G2 (screen) voltage

about 500V?

Trouble in

CRT

Trouble in FBT

Page 15

17

3. A Missing Color

Is input signal

normal?

One color is

missing

CRT

Cathode (Rk, Gk, Bk)

is normal?

Is video

output IC802 waveform

normal?

Each grid (G1, G2)

voltage normal?

Is the

output of pre-amp

(IC801, KA2500)

pin 21, 24, 26 all

normal?

Check video signal

cable or video card.

Trouble in IC801 or its

ambient circuit

Trouble in

video output

circuit, IC802

or ambient

Trouble in 100Vdc line

Trouble in G1,G2 line

Replace CRT

No

No

No No

No

Yes

Yes Yes

Yes

Yes

RK, GK, BK

About 40V p-p

0.7Vpp

Page 16

18

4. Abnormal OSD Font

Is menu

key selected?

Is OSD Font

exist?

* If menu key selected.

Is Heater

Voltage about 6V?

Abnormal OSD Font

Is the

output of IC803

(pin 12,13, 14)

normal?

Trouble in

Heater voltage

line.

Refer to trouble in P.S.U

Troubie in

IC803 or its

ambient circuit

Trouble in IC803

and its ambient

circuit

One color is

missing

Refer to Missing Color

No

No

Yes

Yes

Yes

Yes

No

Page 17

MODE B+ Voltage

VGA 72Vdc

Super VGA

86Vdc

54KHz 124Vdc

19

5. Horizontal Output Circuit

Is the

B+line voltage

over 175V?

Is the H-out

waveform of IC501

normal?

Trouble in IC501

Trouble in Horizontal

output circuit

(No Raster)

Yes

No

Is the Gate wave

form of

Q553 normal?

Yes

Yes

Yes

Trouble in Q553

Trouble in Q551, Q552

No

No

No

Trouble in Q554 and

its ambient circuit.

10V

0V

11V

0V

66V

Is the Drain

waveform of

Q553 normal?

Trouble in 175V line.

Page 18

20

6. Unstable Picture

6-1. Horizontal

Unstable

picture

Is H.Sync

input pin of IC501

correct?

Check H.Sync Out of

Micom or its ambient

circuits.

Yes

No

Trouble in IC501

Page 19

21

6-2. Vertical

Unstable

picture

Is the

12V,-12Vdc

line voltage is

correct?

Refer to P. S. U

Is the

pulse of pin 5 of

the IC401

correct?

Trouble in

vertical D. Y

No

No

No

Yes

Yes

Is the output

of pin 4 of IC501

all normal?

Check IC401 and

its ambient circuit

Yes

Check the IC501 and

its ambient circuit

50Vp-p

40V

-10V

Page 20

22

7. Focus

Monitor remains

unfocused

Check

Focus VR in

FBT

Is

focus

acceptable?

Trouble in Focus

circuit (FBT)

Yes

OK

No

Page 21

23

8. Convergence

Is

convergence

on the center area

bad?

Is

convergence on the

fringe area bad?

Adjust static

convergence

Refer to

Adjustment

procedure of

convergence

Yes

Adjust D.Y

Location

Yes

No

Poor convergence

Page 22

MODE B+ Voltage

VGA 72Vdc

Super VGA

86Vdc

54KHz 124Vdc

24

9. Abnormal Picture

9-1. Horizontal Size

Trouble in L835,

C543 or their ambient

circuit

Trouble in Horizontal

output circuit

Check the B+ and

anode voltage of CRT.

Trouble in H.OSC/

Deflection Circuit

Refer to Horizontal Output circuit

Is

the DC level

of the base of Q509

changeable?

No

Yes

Is

the DC level

of IC501 pin 5

changeable ?

Yes

Check IC501

pin 5

Is the

collector pulse

of Q554 correct?

Is the

cathode waveform

of D568

correct?

Abnormal

H.Size

=1100Vp-p

80-310Vpp

*

Normally anode voltage

of CRT is approximately,

24KV

*

Scan B+ are as follow :

No

Yes

Yes

No

*

At first, adjust controls in the OSD Menu

Page 23

25

9-2. Vertical Size

Is

changeable the

DC voltage of

IC401 pin 1?

Check the IC4

and its

ambient circuit

Check the IC501 and

its ambient circuit

No

No

Trouble V.OSC/

Deflection Circuit

Refer to V.OSC/Deflection circuit

Yes

Is

the 3.5Vdc of pin

4 of the IC501?

Yes

Abnormal

V.Size

Page 24

26

10. Side-Pincushion Circuit

Side-Pincusion distortion

is excessive or barrel

O.K

Select the

side-pincushion

icon on OSD menu,

and adjust acceptable

position.

Yes

Check IC501 or

their ambient circuit

(pin 13, 14)

Is the pin 5

waveform of IC501

correct

Yes

No

Trouble in IC501

No

Page 25

27

11. Power Supply Unit (P.S.U)

Is the

IC001

O.K?

Replace IC001

No

Is

voltage of C104

50Vdc?

No

Is

voltage of D002

130V (270V)?

Trouble in switching

power transformer T001

or IC001 and its ambient

circuit

Trouble in diode

D001,D002,D003,D004

or peripheral device

No

Is the

waveform of T001

pin5 correct?

Trouble in T001

or D101

No

Trouble in P.S.U

Is

power switch

on?

Switch on

No

Yes

Yes

Yes

Yes

Yes

Yes

Is

voltage of C101

100Vdc?

Trouble in T001 or D102

No

Is

fuse F001

O.K?

Check the power cord outlet

and diode D001,D002,D003,D004

No

A

Page 26

28

Is voltage

of C112

25Vdc?

Trouble in D105

No

Is voltage

of C117 14.3Vdc?

No

Yes

Yes

Yes

Is

voltage of C643

-15Vdc?

Trouble in D643 or vertical

Part.

P.S.U O.K

Trouble in D103 or

horizontal Part.

No

A

Page 27

R,G,B

SCL SDA

EPROM

( 24LC08)

MCU

(KS88C6224)

H.OSC

&

V.DRV

(1888CT)

SCL

H.SYNC

V.SYNC

SDA

DEGAUSSING

CIRCUIT

DEGAUSS CONTROL

DPMS CONT.

OUTPUT

REGULATOR

MAIN

POWER

SYNC

TRANS

(DST-603)

H.DRV

SYNC.

TRIGGERING

SMPS

TRANSFORMER

SMPS

CONTROL

(KA3842)

+12V,+5V

VIDEO

POWER

FBT

H.DY

V.DRV

AMP

(TDA8172)

H.DRV

B+

CONTROL

(uPC1555C)

V. DY

H.SIZE

& G/D

C0NTROL.

H. LIN

COIL

H.CS

BLOCK

H.

IZE FB

AN B+

X-RAY

PROTECT

H/V

CONTROL

(KA7500)

HV.DRV

BUCK

TRANS

LED

H

FBP

G1

CONTROL

G1

MUTE

CLAMP&BLANKING

PULSE

HIGH VOLTAGE

SCREEN &

FOCUS

15PIN

D-SUB

RECEPTACLE

(02WE4E1)

VIDEO

PREAMP

(KA2500)

VIDEO

OUTPUT

AMP

(TDA9532)

OSD IC

(KS2508)

TACT S/W BUTTON

(4 BUTTON)

POWER

TACT

S/W

CRT

BRIGHT CONTROL

R,G,B BIAS

MAIN BLOCK DIAGRAM VIDEO BLOCK DIAGRAM

80V

12V, 5V

100V, 12V

50V, -12V

5V, 6.3V

B+

BUCK L.

H.

YN

V.

YN

F

B

ABL

ADJUST

ROTATION

(OPTION)

Page 28

Page 29

Page 30

34

RESISTOR Description

Example:

CAPACITOR Description

Example:

Fig &

Part No Description

Index

Capacitors

C102 CCXF1H104Z Ceramic 50V 0.1µF Z

C402 CCXB1H331K Ceramic 50V 330PF K

C105 CMXM 2A224J MYLAR 100V 0.22µF J

Allowance

C ± 0.25pF

D ± 0.5%

F ± 1pF

J±5%

K ± 10%

P ± 100% ~ 0%

Z ± 80% ~ –

Fig &

Part No Description

Index

R101

Resistors

RD-4Z820J Carbon: 82J

R102 RD-4Z201J Carbon1/4W-200J

Allowance

F±1%

J±5%

K ± 10%

M ± 20%

G±2%

INFORMATION OF PART DESCRIPTION

Important Safety Notice

Components identified with the International Symbol have special characteristics important for safety.

When replacing any components, use only manufacturer’s specified parts.

Abbreviation of Description

Page 31

C206 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C207 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C208 CCZB1H102K C CERA 50V B 1000PF K

C209 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C210 CCZB1H681K C CERA 50V B 680PF K

C211 CCZB1H681K C CERA 50V B 680PF K

C212 CCZB1H681K C CERA 50V B 680PF K

C213 CCZB1H681K C CERA 50V B 680PF K

C214 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C215 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C231 CCZB1H181K C CERA 50V B 180PF K AXIAL

C232 CCZB1H181K C CERA 50V B 180PF K AXIAL

C301 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

(C1)

C401 CCXB1H271K C CERA 50V B 270PF K (TAPPING)

C402 CMXM2A562J C MYLAR 100V 5600PF J (TP)

C404 CMXL2E104J C MYLAR MEU 250V 0.1MF J

C405 CMXM2A273J C MYLAR 100V 0.027MF J (TP)

C406 CMXL2A224J C MYLAR 100V MEU 0.22MF J

C407 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C408 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C409 CMXL2A224J C MYLAR 100V MEU 0.22MF J

C410 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C411 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C501 CMXM2A333J C MYLAR 100V 0.033MF J (TP)

C502 CEXF1H330V C ELECTRO 50V RSS 33MF (6.3X11) TP

C503 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C504 CMXL1J105J C MYLAR MEU 63V 1MF J

C505 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C506 CCZB1H102K C CERA 50V B 1000PF K

C507 CMXM2A222J C MYLAR 100V 2200PF J (TP)

C508 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C509 CEXF1C331V C ELECTRO 16V RSS 330MF (8X11.5) TP

C510 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C511 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C512 CCZB1H102K C CERA 50V B 1000PF K

C513 CXSL1H391J C CERA 50V SL 390PF J

C514 CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

C515 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C516 CCZB1H101K C CERA 50V B 100PF K

C517 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C518 CCZB1H181K C CERA 50V B 180PF K AXIAL

C519 CCZB1H181K C CERA 50V B 180PF K AXIAL

C520 CCZF1H103Z C CERA 50V F 0.01MF Z

C521 CEXF1C331V C ELECTRO 16V RSS 330MF (8X11.5) TP

C522 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C531 CCXB3A101K C CERA 1KV B 100PF K

00001 9979800516 PCB MAIN T=1.6*246*310

00020 WNA75N031- CORD POWER SP502B+IS14 3ASL/100

B001 5PB14865-- COIL BEAD BI-4865(5TS)

B003 5PB13890-- COIL BEAD BI3890

B004 5PB13890-- COIL BEAD BI3890

(J004)

B005 5PB13890-- COIL BEAD BI3890

(J003)

B101 5PB13857-- COIL BEAD BI3857(AXIAL)

B102 5MBFD3512R COIL BEAD BFD 3512 R2

B301 5PB13857-- COIL BEAD BI3857(AXIAL)

(B1)

B501 5PB13857-- COIL BEAD BI3857(AXIAL)

B502 5PB13857-- COIL BEAD BI3857(AXIAL)

B809 5PB13857-- COIL BEAD BI3857(AXIAL)

B810 5PB13857-- COIL BEAD BI3857(AXIAL)

C001 CL1UC3104M C LINE ACROSS WORLD AC250V 0.1UF M R.47

C004 CH1FDF222M C CERA AC 2.5KV 2200PF M AC250V

C005 CEYP2G221Z C ELECTRO 400V SMH 220MF (25.4*40)

C006 CCXE3D103P C CERA HIKE 2KV 0.01MF P

C007 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C008 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C009 CMXL2A334J C MYLAR MEU 100V 0.33MF J

C010 CMXM2A332J C MYLAR 100V 3300PF J (TP)

C011 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C012 CCXB1H152K C CERA 50V B 1500PF K (TAPPING)

C013 CCXB3A271K C CERA 1KV B 270PF K (TAPPING)

C014 CMXM2A222J C MYLAR 100V 2200PF J (TP)

C015 CCZB1H102K C CERA 50V B 1000PF K

C101 CEXF2C470V C ELECTRO 160V RSS 47MF (13X25) TP

C102 CCXF2H103Z C CERA HIKF 500V 0.01MF Z

C103 CCXB3A471K C CERA 1KV B 470PF K (T)

C104 CEXF1J221V C ELECTRO 63V RSS 220MF (10X20) TP

C105 CCXB3A221K C CERA 1KV B 220PF K (TAPPING)

C106 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C107 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C108 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C109 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C110 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C111 CEXF1J221V C ELECTRO 63V RSS 220MF (10X20) TP

C302 CCXE3D103P C CERA HIKE 2KV 0.01MF P

(C2)

C201 CCZB1H181K C CERA 50V B 180PF K AXIAL

C202 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C203 CXCH1H220J C CERA 50V CH 22PF J (TAPPING)

C204 CXCH1H220J C CERA 50V CH 22PF J (TAPPING)

C205 CEXF1H108V C ELECTRO 50V RSS 0.1MF (5X11) TP

35

LOC PART-CODE PART-NAME PART-DESC LOC PART-CODE PART-NAME PART-DESC

ELECTRICAL P ARTS LIST

The components identified by mark ! have special characteristics important for safety and x-ray radiation.

These should be replaced only with the types specified in the parts list.

!

!

!

!

!

!

Page 32

C828 CCZB1H391K C CERA 50V B 390PF K

C829 CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

C830 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C831 CCXF2H103Z C CERA HIKF 500V 0.01MF Z

CA8019970780032 CONN AS SMH250+51088+20379#28=250

CDT 9979615003 CDT M36KXU110XX61(T)

CGND 9970710243 CRT GND AS 0.12*6*16+BL101NG*2=580

CT301 9979300013 SOCKET CRT PCS629-03A

CW301 9979220009 CONN WAFER SMW250-08

CW801 485923272S CONN WAFER 5267-06A STICK TYPE

CW802 485923282S CONN WAFER 5267-07A STICK TYPE

D001 D2A05----- DIODE 2A05

D002 D2A05----- DIODE 2A05

D003 D2A05----- DIODE 2A05

D004 D2A05----- DIODE 2A05

D005 DD2L20U--- DIODE D2L20U

D006 DHER107--- DIODE HER107

D007 DZN4148--- DIODE 1N4148 AUTO 52MM

D008 DZN4148--- DIODE 1N4148 AUTO 52MM

D101 DRU1P----- DIODE RU 1P (TAPPING)

D102 DRG4------ DIODE RG4

D103 DD2L20U--- DIODE D2L20U

D104 DD2L20U--- DIODE D2L20U

D105 DZN4148--- DIODE 1N4148 AUTO 52MM

D106 DD2L20U--- DIODE D2L20U

D201 DZN4148--- DIODE 1N4148 AUTO 52MM

D202 DZN4148--- DIODE 1N4148 AUTO 52MM

D203 DZN4148--- DIODE 1N4148 AUTO 52MM

D204 DZN4148--- DIODE 1N4148 AUTO 52MM

D231 DZN4148--- DIODE 1N4148 AUTO 52MM

D232 DZN4148--- DIODE 1N4148 AUTO 52MM

D402 D1N4002A-- DIODE 1N4002

D501 DZN4148--- DIODE 1N4148 AUTO 52MM

D502 D1NS4----- DIODE 1NS4

D503 DZN4148--- DIODE 1N4148 AUTO 52MM

D531 D1A5G----- DIODE 1A5G

D554 DDTV32F--- DIODE DTV32F

D556 D1N4937GP- DIODE 1N4937GP (TAPPING)

D561 D1A5G----- DIODE 1A5G

D567 DZN4148--- DIODE 1N4148 AUTO 52MM

D568 DRG4------ DIODE RG4

D569 DER206---- DIODE ER206

D570 DER206---- DIODE ER206

D590 D1A5G----- DIODE 1A5G

D802 DZN4148--- DIODE 1N4148 AUTO 52MM

D804 DZN4148--- DIODE 1N4148 AUTO 52MM

D806 DZN4148--- DIODE 1N4148 AUTO 52MM

D831 DZN4148--- DIODE 1N4148 AUTO 52MM

D832 DZN4148--- DIODE 1N4148 AUTO 52MM

D833 DZN4148--- DIODE 1N4148 AUTO 52MM

D845 DZN4148--- DIODE 1N4148 AUTO 52MM

C535 CMXA2G474J C MYLAR MPA 400V 0.47MF J

C536 CMXM2A223J C MYLAR 100V 0.022MF J TP

C537 CMYF2D624J C MYLAR 200V MPP 0.62MF J

C538 CMXF2D224J C MYLAR MPP 200V 0.22MF J

C540 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C541 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C542 CMXM2A332J C MYLAR 100V 3300PF J (TP)

C543 CMXL1J105J C MYLAR MEU 63V 1MF J

C545 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C546 CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

C547 CEXF2E100V C ELECTRO 250V RSS 10MF (10X20) TP

C548 CMXM2A223J C MYLAR 100V 0.022MF J TP

C550 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C551 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C552 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C553 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C554 CEXF1H220V C ELECTRO 50V RSS 22MF (5X11) TP

C555 CMXM2A393J C MYLAR 100V 0.039MF J (TP)

C556 CMXE2J103J C MYLAR 630V PL 0.01MF J

C557 CMYH3C682J C MYLAR BUP 1.6KV 6800PF J BULK

C558 CMXM2A223J C MYLAR 100V 0.022MF J TP

C559 CMYF2D225J C MYLAR MPP 200V 2.2MF J

C560 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C561 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C577 CCXB2H331K C CERA 500V B 330PF K (TAPPING)

C801 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C802 CCZB1H102K C CERA 50V B 1000PF K

C803 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C804 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C806 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C807 CCZB1H223K C CERA HIBK 50V 0.022MF K AXL 52

C808 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C809 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C810 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C811 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C812 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C813 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C814 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C815 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C816 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C817 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C818 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C819 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C820 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C821 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C822 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C823 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C824 CMXM2A153J C MYLAR 100V 0.015MF J (TP)

C825 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C826 CCZF1H104Z C CERA 50V HIKF 0.1MF Z

C827 CCZB1H391K C CERA 50V B 390PF K

36

LOC PART-CODE PART-NAME PART-DESC LOC PART-CODE PART-NAME PART-DESC

!

!

!

!

!

!

Page 33

Q203 TZTA1024Y- TR KTA1024Y (949Y)

Q231 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q401 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q501 TZTC3202Y- TR KTC3202Y (AUTO)(1959Y)

Q502 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q503 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q504 T1RF630A-- FET IRF630A

Q505 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q506 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q507 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q508 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q509 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q510 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q534 T1RF640--- FET IRF640

Q535 TZTC3206Y- TR KTC3206Y (2229Y)

Q536 T1RF630A-- FET IRF630A

Q537 TZTC3206Y- TR KTC3206Y (2229Y)

Q551 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q552 TZTC3202Y- TR KTC3202Y (AUTO)(1959Y)

Q553 TKSC2383Y- TR KSC 2383-Y

Q554 T2SC5386-- TR H.OUT 2SC5386

Q601 TKSD1273P- TR KSD1273-P

Q801 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

Q802 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

R001 RC-2Z105J- R CARBON COMP 1/2 1M OHM J SR37

R002 RS01Z333J- R M-OXIDE FILM 1W 33K OHM J (TAPPING)

R003 RS01Z333J- R M-OXIDE FILM 1W 33K OHM J (TAPPING)

R004 RS01Z333J- R M-OXIDE FILM 1W 33K OHM J (TAPPING)

R005 RS01Z683J- R M-OXIDE FILM 1W 68K OHM J (TAPPING)

R006 RS01Z683J- R M-OXIDE FILM 1W 68K OHM J (TAPPING)

R008 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R009 RN-AZ1503F R METAL FILM 1/6 150K OHM F

R010 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R011 RD-AZ204J- R CARBON FILM 1/6 200K OHM J

R012 RN-AZ2672F R METAL FILM 1/6 26.7K OHM F

R013 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R015 RD-AZ220J- R CARBON FILM 1/6 22 OHM J

R016 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R017 RW01Z278JN R WIRE WOUND 1W 0.27 OHM J NON-INDUCT

R018 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R019 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R020 RD-4Z560J- R CARBON FILM 1/4 56 OHM J

R101 RD-4Z154J- R CARBON FILM 1/4 150K OHM J

R102 RS01Z470J- R M-OXIDE FILM 1W 47 OHM J (TAPPING)

R103 RD-2Z220J- R CARBON FILM 1/2 22 OHM J

R105 RD-AZ204J- R CARBON FILM 1/6 200K OHM J

R106 RD-2Z220J- R CARBON FILM 1/2 22 OHM J

R107 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R108 RN-AZ4021F R METAL FILM 1/6 4.02K OHM F

R110 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R112 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

DG0015MG0000066 COIL DEGAUSSING DG-526X

DZ001 DUZ18BM--- DIODE ZENER UZ-18BM

DZ002 DUZ18BM--- DIODE ZENER UZ-18BM

DZ101 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ200 DDZ5R6BM-- DIODE ZENER DZ5.6BM

DZ201 DDZ3R6B--- DIODE ZENER DZ3.6B

DZ231 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ232 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ233 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ234 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ235 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ501 DDZ5R1B--- DIODE ZENER DZ-5.1B

DZ532 DDZ15BM--- DIODE ZENER DZ15BM

DZ533 DDZ15BM--- DIODE ZENER DZ15BM

DZ801 DDZ5R1B--- DIODE ZENER DZ-5.1B

F001 5F3CB3122L FUSE CERA SEMKO TL 3.15AH 250V MF51

F001A 9977410900 FUSE CLIP BSP3-H T0.4 SN 5.2

F001B 9977410900 FUSE CLIP BSP3-H T0.4 SN 5.2

GND2 9970700123 CONN AS 4.3+35404-9002+1015#18=50

IC001 1KA3842B-- IC POWER KA3842B

IC101 1KA78R12-- IC REGULATOR KA78R12

IC102 1KA78L05AZ IC REGULATOR KA78L05AZ

IC201 1KS88P6232 IC MICOM KS88P6232N

IC202 124C08---- IC EEPROM 24C08

IC401 1TDA9302H- IC VERTICAL TDA9302H

IC501 1UPC1888CT IC H/V OSC UPC1888CT

IC801 1KA2500--- IC KA2500

IC802 1TDA9533-- IC VIDEO OUTPUT TDA9533

IC803 1DW0SD10-- IC OSD KS2508-02

J132 5PB13890-- COIL BEAD BI3890

L501 5CPZ101K03 COIL PEAKING 100UH K (AXIAL 7MM)

L531 5MH0000070 COIL H-LINEARITY TRL-526X

L801 5CPZ101K02 COIL PEAKING 100UH K (AXIAL 3.5MM)

L802 5CPZ101K02 COIL PEAKING 100UH K (AXIAL 3.5MM)

L803 5CPZ279K02 COIL PEAKING LAL02TB 2.7UH M AXIAL

L804 5CPZ470K02 COIL PEAKING 47UH K (AXIAL 3.5MM)

L831 5CPZ109K02 COIL PEAKING 1UH K (AXIAL 3.5MM)

L832 5CPZ109K02 COIL PEAKING 1UH K (AXIAL 3.5MM)

L833 5CPZ109K02 COIL PEAKING 1UH K (AXIAL 3.5MM)

L834 5MC0000078 COIL CHOKE CH-85B

L835 5MC0000074 COIL CHOKE TCH-526X(110UH)

LED1 DSD50GYW-- LED SD50GYW(GREEN/AMBER)

P001 9979500022 RECEPTACLE BNS-02AB2L-1

PCB 9979800545 PCB CRT T=1.6*61*50 (526X)

PR001 DECPAC140M POSISTOR ECPAC140M290

Q001 T2SK2101-- FET 2SK2101

Q002 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q103 TKTA1281Y- TR KTA1281Y

Q104 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q201 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q202 TZTA1270Y- TR KTA1270Y(AUTO)(562Y)

LOC PART-CODE PART-NAME PART-DESCLOC PART-CODE PART-NAME PART-DESC

37

!

!

!

Page 34

R401 RN-AZ1042F R METAL FILM 1/6 10.4K OHM F

R402 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R403 RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

R404 RD-4Z471J- R CARBON FILM 1/4 470 OHM J

R406 RD-4Z221J- R CARBON FILM 1/4 220 OHM J

R407 RS01Z201J- R M-OXIDE FILM 1W 200 OHM J (TAPPING)

R408 RD-4Z159J- R CARBON FILM 1/4 1.5 OHM J

R409 RD-4Z390J- R CARBON FILM 1/4 39 OHM J

R410 RN-AZ5601F R METAL FILM 1/6 5.6K OHM F

R411 RN-AZ1211F R METAL FILM 1/6 1.21K OHM F

R412 RN-AZ1062F R METAL FILM 1/6 10.6K OHM F

R413 RN-4Z1808F R METAL FILM 1/4 1.8 OHM F

R414 RN-4Z1808F R METAL FILM 1/4 1.8 OHM F

R502 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R503 RD-AZ183J- R CARBON FILM 1/6 18K OHM J

R504 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R505 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R507 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R509 RD-AZ304J- R CARBON FILM 1/6 300K OHM J

R511 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R512 RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

R513 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R514 RD-AZ563J- R CARBON FILM 1/6 56K OHM J

R515 RN-AZ4643F R METAL FILM 1/6 464K OHM F

R516 RN-AZ5622F R METAL FILM 1/6 56.2K OHM F

R517 RN-AZ1701F R METAL FILM 1/6 1.7K OHM F

R518 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

R519 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R520 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R521 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R522 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R531 RS01Z101J- R M-OXIDE FILM 1W 100 OHM J (TAPPING)

R532 RN-AZ1042F R METAL FILM 1/6 10.4K OHM F

R533 RN-AZ1371F R METAL FILM 1/6 1.37K OHM F

R534 RN-AZ1001F R METAL FILM 1/6 1K OHM F

R535 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R540 RD-4Z104J- R CARBON FILM 1/4 100K OHM J

R541 RD-AZ154J- R CARBON FILM 1/6 150K OHM J

R543 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R544 RD-4Z104J- R CARBON FILM 1/4 100K OHM J

R545 RD-AZ154J- R CARBON FILM 1/6 150K OHM J

R547 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R548 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R550 RD-4Z153J- R CARBON FILM 1/4 15K OHM J

R551 RD-4Z562J- R CARBON FILM 1/4 5.6K OHM J

R552 RS02Z301J- R M-OXIDE FILM 2W 300 OHM J (TAPPING)

R553 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R554 RD-4Z560J- R CARBON FILM 1/4 56 OHM J

R555 RD-AZ363J- R CARBON FILM 1/6 36K OHM J

R556 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R557 RW01Z478JN R WIRE WOUND 1W 0.47 OHM J NON-INDUCT

R114 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R115 RD-4Z910J- R CARBON FILM 1/4 91 OHM J

R116 RD-4Z471J- R CARBON FILM 1/4 470 OHM J

R117 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R118 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R119 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R201 RD-AZ151J- R CARBON FILM 1/6 150 OHM J

R202 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

R203 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

R204 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R205 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R206 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R214 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R215 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R216 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R217 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R218 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R219 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R220 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R221 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R222 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R223 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R224 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R226 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R227 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R228 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R229 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R230 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R231 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R232 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R233 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R234 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R235 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R237 RD-AZ124J- R CARBON FILM 1/6 120K OHM J

R238 RD-AZ623J- R CARBON FILM 1/6 62K OHM J

R239 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R240 RD-4Z122J- R CARBON FILM 1/4 1.2K OHM J

R241 RD-4Z122J- R CARBON FILM 1/4 1.2K OHM J

R242 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R243 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R245 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R301 RD-4Z122J- R CARBON FILM 1/4 1.2K OHM J

(R4)

R302 RD-4Z101J- R CARBON FILM 1/4 100 OHM J

(R3)

R303 RD-4Z101J- R CARBON FILM 1/4 100 OHM J

(R2)

R304 RD-4Z101J- R CARBON FILM 1/4 100 OHM J

(R1)

R305 RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

(R5)

LOC PART-CODE PART-NAME PART-DESCLOC PART-CODE PART-NAME PART-DESC

38

Page 35

R822 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R823 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R824 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R825 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R826 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R827 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R828 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R829 RD-4Z154J- R CARBON FILM 1/4 150K OHM J

R831 RD-AZ151J- R CARBON FILM 1/6 150 OHM J

R833 RD-AZ151J- R CARBON FILM 1/6 150 OHM J

R835 RD-AZ151J- R CARBON FILM 1/6 150 OHM J

R837 RD-4Z910J- R CARBON FILM 1/4 91 OHM J

R838 RD-4Z910J- R CARBON FILM 1/4 91 OHM J

R839 RD-AZ330J- R CARBON FILM 1/6 33 OHM J

R840 RD-AZ330J- R CARBON FILM 1/6 33 OHM J

R841 RD-AZ330J- R CARBON FILM 1/6 33 OHM J

R848 RD-AZ106J- R CARBON FILM 1/6 10M OHM J

R849 RD-AZ106J- R CARBON FILM 1/6 10M OHM J

R850 RD-AZ106J- R CARBON FILM 1/6 10M OHM J

R851 RD-AZ123J- R CARBON FILM 1/6 12K OHM J

R852 RD-AZ123J- R CARBON FILM 1/6 12K OHM J

R853 RD-AZ302J- R CARBON FILM 1/6 3K OHM J

R854 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R855 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R856 RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RL001 5SC0101006 SW RELAY KI-S-112M 1C-1P(HR-CR313)

SC001 9970800033 CABLE SIGNAL AS 15P+1C/DDC=1.5M(GY286A)

SG301 4SG0D00104 SPARK GAP S-23 1.5KV

(SG1)

SG302 4SG0D00104 SPARK GAP S-23 1.5KV

(SG2)

SG303 4SG0D00104 SPARK GAP S-23 1.5KV

(SG3)

SW0015S50101Z01 SW TACT KPT-1115VM 1C-1P

SW002 5S50101Z01 SW TACT KPT-1115VM 1C-1P

SW003 5S50101Z01 SW TACT KPT-1115VM 1C-1P

SW004 5S50101Z01 SW TACT KPT-1115VM 1C-1P

SW005 5S50101Z01 SW TACT KPT-1115VM 1C-1P

T001 5RM0000099 TRANS SMPS DMT-526X

T002 5RY0000002 TRANS SYNC DST-603

T501 5RD0000047 TRANS DRIVE DDT-526X

T601 5RH0000125 FBT FFA73336U

TH001 DTP8D13--- THERMISTOR TP8D13

VR001RV6421202P R SEMI FIXED CCT 065AT 2K OHM B TAP

VR501RV6121501P R SEMI FIXED CCT 063BT 500 OHM B TAP

X201 5XE12R000E CRYSTAL QUARTZ HC-49/U 12.00000MHZ 30PPM

R560 RD-4Z100J- R CARBON FILM 1/4 10 OHM J

R561 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R562 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R563 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R564 RD-AZ913J- R CARBON FILM 1/6 91K OHM J

R565 RD-4Z222J- R CARBON FILM 1/4 2.2K OHM J

R566 RD-AZ303J- R CARBON FILM 1/6 30K OHM J

R567 RD-4Z224J- R CARBON FILM 1/4 220K OHM J

R568 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R569 RN-AZ3652F R METAL FILM 1/6 36.5K OHM F

R570 RN-AZ3652F R METAL FILM 1/6 36.5K OHM F

R572 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R573 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R574 RD-4Z303J- R CARBON FILM 1/4 30K OHM J

R575 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R576 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R577 RS01Z152J- R M-OXIDE FILM 1W 1.5K OHM J (TAPPING)

R588 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R589 RD-AZ363J- R CARBON FILM 1/6 36K OHM J

R590 RD-2Z109J- R CARBON FILM 1/2 1 OHM J

R591 RD-4Z474J- R CARBON FILM 1/4 470K OHM J

R592 RN-AZ5622F R METAL FILM 1/6 56.2K OHM F

R594 RN-AZ5622F R METAL FILM 1/6 56.2K OHM F

R595 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R596 RN-AZ3652F R METAL FILM 1/6 36.5K OHM F

R801 RD-AZ303J- R CARBON FILM 1/6 30K OHM J

R802 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R803 RD-AZ622J- R CARBON FILM 1/6 6.2K OHM J

R804 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

R805 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R806 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R807 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R808 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R809 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R810 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R811 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R812 RD-AZ100J- R CARBON FILM 1/6 10 OHM J

R813 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R814 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R815 RD-AZ100J- R CARBON FILM 1/6 10 OHM J

R816 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R817 RD-AZ100J- R CARBON FILM 1/6 10 OHM J

R818 RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

R819 RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

R820 RN-AZ5761F R METAL FILM 1/6 5.76K OHM F

R821 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

LOC PART-CODE PART-NAME PART-DESCLOC PART-CODE PART-NAME PART-DESC

39

!

!

!

!

Loading...

Loading...