Page 1

Installation Instructions

Renaissance® Electric Range

with induction cooktop

Models: RR30NS[-C], RR30NFS[-C], RR30NIS[-C] and RR30NIFS[-C]

Part No. 105910 Rev. C

Page 2

Table of Contents

Important Safety Instructions .....................................................1

Important Information About Safety Instructions.........................1

Safety Symbols in this Manual ...................................................1

General Safety Precautions ........................................................ 2

Product Specifications ................................................................3

Electrical Requirements (Except models ending with -C) ..........3

Electrical Requirements (Models ending with -C) ......................3

Product Dimensions .................................................................... 4

Installation Specifications ........................................................... 5

Cabinet Layout ............................................................................ 5

IMPORTANT:

• Installer: In the interest of safety and to minimize problems, read these installation instructions completely and carefully before you

begin the installation process. Leave these installation instructions with the customer.

• Customer: Keep these installation instructions for future reference and the local building inspector’s use.

Installation Instructions ............................................................... 8

Verify the Package Contents ......................................................8

Installing the Anti-Tip Bracket .....................................................8

Backguard Installation ..............................................................10

Raised Vent Installation ............................................................10

Removing the Oven Door ......................................................... 10

Electrical Connection ................................................................ 10

Installing the Range .................................................................. 16

Re-installing the Oven Door .....................................................16

Verifying Proper Operation .......................................................17

Customer Service Information

If You Need Help...

If you have questions or problems with installation, contact your

Dacor dealer or the Dacor Customer Service Team. For repairs

to Dacor appliances under warranty call the Dacor Distinctive

Service line. Whenever you call, have the model and serial

number of the appliance ready. The model and serial number are

printed on the product data label.

Dacor Customer Service

Phone: (800) 793-0093, extension 2813 (U.S.A. and Canada)

Monday — Friday 6:00

Web site: www.dacor.com

Dacor Distinctive Service (for repairs under warranty only)

Phone: (800) 793-0093, extension 2822 (U.S.A. and Canada)

Monday — Friday 6:00

a.m. to 5:00 p.m. Pacific Time

a.m. to 5:00 p.m. Pacific Time

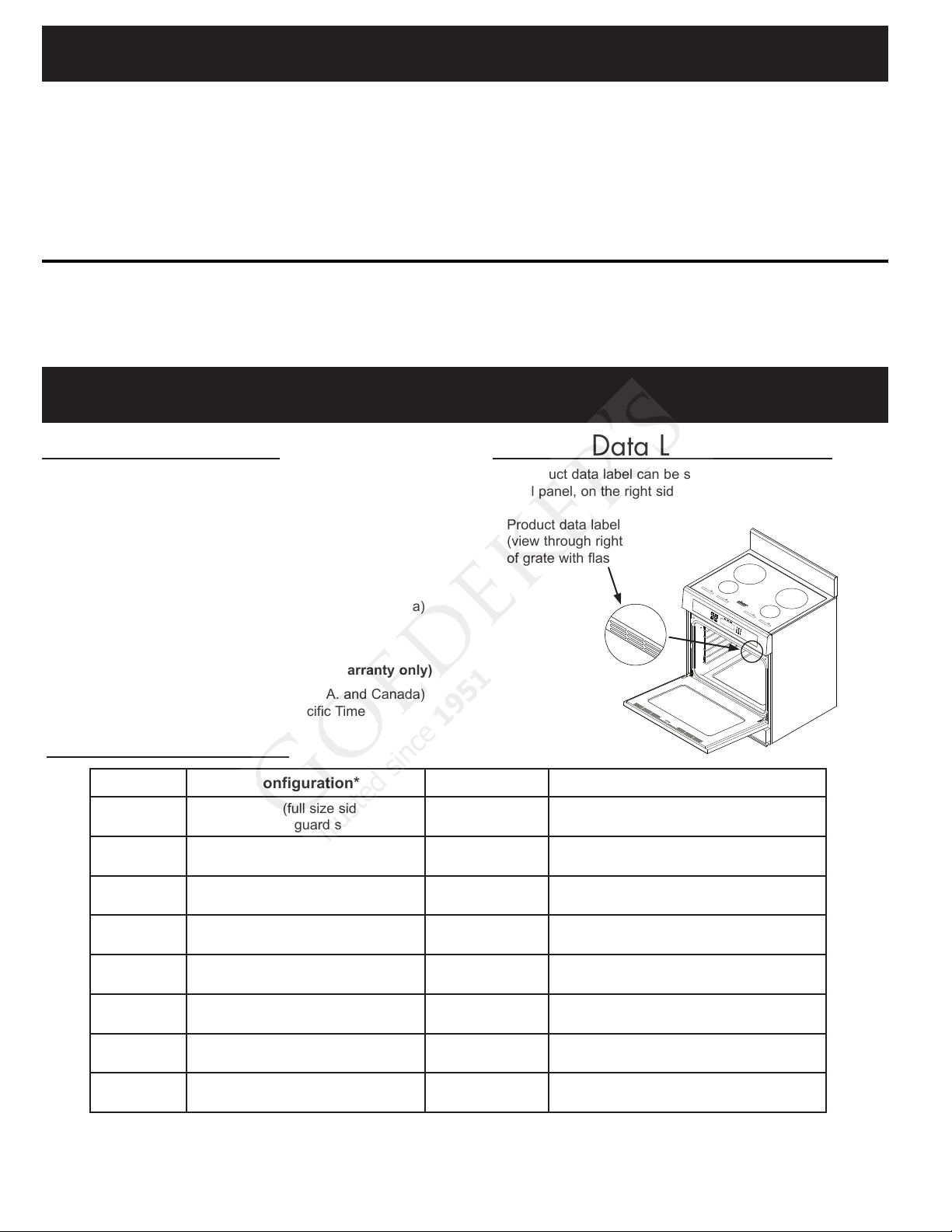

Product Data Label Location

The product data label can be seen through the grill below the

control panel, on the right side.

Product data label

(view through right side

of grate with flashlight)

Model Identification

Model Configuration* Handle Type Electrical Connection**

RR30NS

RR30NS-C

RR30NFS

RR30NFS-C

RR30NIS

RR30NIS-C

RR30NIFS

RR30NIFS-C

* See page 4 for further details.

**See page 3 for further details.

All specifications subject to change without notice. Dacor® assumes no liability for changes to specifications.

Freestanding, (full size side panels),

6-inch backguard standard

Freestanding, (full size side panels),

6-inch backguard standard

Freestanding, (full size side panels),

6-inch backguard standard

Freestanding, (full size side panels),

6-inch backguard standard

Built-in/Slide-in (3” removable side

panels), backguard optional

Built-in/Slide-in (3” removable side

panels), backguard optional

Built-in/Slide-in (3” removable side

panels), backguard optional

Built-in/Slide-in (3” removable side

panels), backguard optional

Mounted on

outside of door

Mounted on

outside of door

Flush handle,

integrated in door

Flush handle,

integrated in door

Mounted on

outside of door

Mounted on

outside of door

Flush handle,

integrated in door

Flush handle,

integrated in door

© 2013 Dacor, all rights reserved.

Power cord not included. Not for

installation in Canada.

Cord connected, for installation in Canada

and U.S.A., where local codes permit.

Power cord not included. Not for

installation in Canada.

Cord connected, for installation in Canada

and U.S.A., where local codes permit.

Power cord not included. May be installed

in Canada and U.S.A.

Cord connected, for installation in Canada

and U.S.A., where local codes permit.

Power cord not included. May be installed

in Canada and U.S.A.

Cord connected, for installation in Canada

and U.S.A., where local codes permit.

Page 3

Important Safety Instructions

Important Information About

Safety Instructions

The Important Safety Instructions and warnings in this manual

are not meant to cover all possible problems and conditions

that can occur. Use common sense and caution when installing,

maintaining or operating this or any other appliance.

Always contact the Dacor Customer Service Team about problems

and conditions that you do not understand.

DANGER

For your safety:

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

• Do not obstruct the flow of ventilation air to the unit.

• Keep the area around the appliance clear and free from

combustible material.

WARNING

Persons with a pacemaker or other medical device should use

caution when standing near an induction cooktop when it is

in use. The electromagnetic field generated by an induction

cooktop may affect operation of a pacemaker or other medical

device. Consult your doctor or medical device manufacturer

about your particular situation.

Safety Symbols in this Manual

DANGER

Immediate hazards that WILL result in severe personal injury or

death.

WARNING

Hazards or unsafe practices that COULD result in severe

personal injury or death.

CAUTION

Hazards or unsafe practices that COULD result in minor

personal injury or property damage.

WARNING

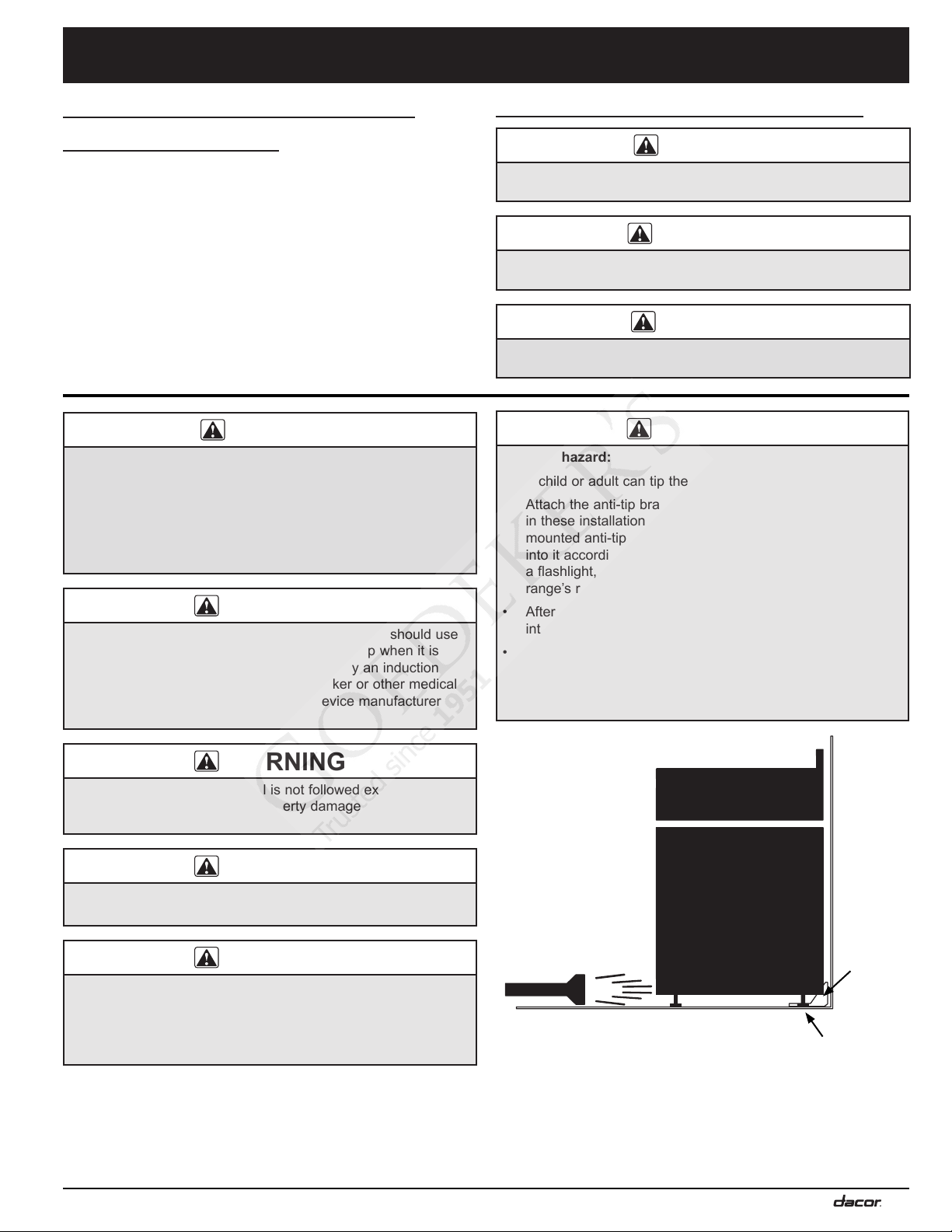

Tip-over hazard:

• A child or adult can tip the range and be killed.

• Attach the anti-tip bracket to the floor or wall as directed

in these installation instructions. Engage the floor or wall

mounted anti-tip bracket by sliding the rear leg on the range

into it according to these installation instructions. Using

a flashlight, be sure that the anti-tip bracket engages the

range’s rear leg as shown below.

• After moving the range, be sure to re-engage the rear leg

into the anti-tip bracket as shown below.

• See the anti-tip bracket installation instructions in this guide

for further details.

• Failure to follow these instructions can result in death or

serious burns to children or adults.

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury

or death.

WARNING

NEVER use this appliance as a space heater to heat or warm

the room. Doing so may result in overheating of the appliance.

WARNING

NEVER cover any slots, holes or passages in the oven bottom

or cover an entire rack with materials such as aluminum foil.

Doing so blocks air flow through the oven and may cause a fire

hazard. Aluminum foil linings may also trap heat, causing a fire

hazard.

READ AND SAVE THESE INSTRUCTIONS

Anti-tip

bracket

Rear leg

1

Page 4

Important Safety Instructions

General Safety Precautions

To reduce the risk of fire, explosion, electric shock, serious injury or death when installing or using this appliance, follow basic safety

precautions, including the following:

WARNING

• Read all instructions before using the appliance.

• Keep packaging materials away from children. Plastic

sheets and bags can cause suffocation.

• If you receive a damaged product, immediately contact

your dealer or builder. Do not install or use a damaged

appliance.

• Improper installation, adjustment, alteration, service

or maintenance can cause personal injury or property

damage. Refer to these instructions and the accompanying

use and care manual. For assistance or additional

information, consult a qualified installer, service agency or

dealer.

• This appliance must be properly installed and grounded by

a qualified installer or service agency according to these

installation instructions prior to use. The installer must

show the customer the location of the circuit breaker panel

or fuse box so that they know where and how to turn off

electric power to the appliance. Dacor is not responsible for

service required to correct a faulty installation. The owner

is responsible to make sure this appliance is properly

installed.

• This appliance is not approved for installation in a mobile

home or recreational vehicle.

• This appliance must not be used in combination with

surface (countertop) ventilation systems. The use of an

overhead hood, or Dacor raised vent is recommended for

ventilation.

• Disconnect the electrical supply before installing or

servicing the appliance.

WARNING

• Install or locate this appliance only in accordance with these

installation instructions.

• This appliance must be grounded. Connect it only to a

properly grounded electrical supply. Refer to Electrical

Requirements.

• Before performing any type of service or installation, make

sure that the electric power to the appliance is turned off at

the circuit breaker panel or fuse box.

• Use this appliance only for its intended use as described in

this manual. Do not use corrosive chemicals or vapors with

this appliance. This type of appliance is not designed for

industrial or laboratory use.

• As with any appliance, close supervision is necessary when

used by children.

• Do not operate this appliance if it has damaged electrical

wires, if it is not working properly or if it has been damaged

or dropped.

• This appliance should be serviced only by qualified service

personnel. Contact the nearest DACOR authorized servicer

at (800) 793-0093, or at www.dacor.com for examination,

repair or adjustment.

• Some products, such as whole eggs, and sealed containers,

such as closed glass jars, may explode and should not be

heated on this cooktop.

2

Page 5

Product Specifications

WARNING

IMPORTANT: Observe all governing codes and ordinances

during planning and installation. Contact your local building

department for further information.

Electrical Requirements (All models

numbers except those ending with -C)

It is the owner’s responsibility to ensure that a licensed electrician

performs the installation of the electrical supply for this appliance.

The electrical installation, including minimum supply wire size,

must comply with the National Electric Code ANSI/NFPA 70 (latest

revision) and local codes and ordinances. A copy of this standard

may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

The correct voltage, frequency and amperage must be supplied

to the appliance from a dedicated, grounded, single phase circuit

that is protected by a properly sized circuit breaker or time-delay

fuse. If a time-delay fuse is utilized, fuse both sides of the line (L1

and L2).

Electrical Specifications

Circuit Requirements Total Connected Load

240 Vac 60 Hz, 4-wire*, 50 Amp. 11.5 kW (48.0 Amp.)

* Two 120 Vac hot (L1 and L2), one neutral (N1) and one ground.

The above electrical specifications are for reference only. See

the range data label for exact specifications. See inside cover for

location.

• The wiring needs to be long enough to allow the range to be

pulled out for service, while remaining connected.

• The wiring connected to the range must:

◊ Meet NEMA standards and have a minimum rating of

250 Volts @ 50 Amp.

◊ Include a strain relief.

◊ Be terminated by tinned leads, closed loop terminals or

open ended spade lugs with upturned ends.

◊ Connect to a junction box or receptacle installed by a

licensed electrician.

The appliance may be connected one of the following ways:

• Using conduit:

◊ A 4-wire conduit connected to a 4-wire junction box, or

◊ A 3-wire conduit (where local code permits) connected to

a 3-wire junction box.

Suggested conduit wiring color code: black, white, red and

green.

• Using an appliance cord:

◊ A 4-wire appliance cord equipped with a NEMA 14-50P

plug connected to a NEMA 14-50R receptacle, or

◊ A 3-wire appliance cord (where local code permits)

equipped with a NEMA 10-50P plug connected to a

NEMA 10-50R receptacle.

Appliance cord plug must be UL listed type SRD or SRDT.

Electrical Requirements

(Models Ending with -C)

Range models RR30NS-C, RR30NFS-C, RR30NIS-C and

RR30NIFS-C come with a factory installed 4-wire appliance cord

with NEMA 14-50P plug.

• For freestanding ranges installed in Canada, a factory

installed 4-wire appliance cord with NEMA 14-50P plug is

required, without modification. For slide-in ranges installed in

Canada and all ranges installed outside of Canada, the 4-wire

appliance cord configuration (-C type) is optional and may be

utilized where local codes permit.

• The NEMA 14-50P plug is designed to plug directly into

a NEMA 14-50R electrical receptacle. It is the owner’s

responsibility to ensure that the required 4-wire electrical

outlet compatible with the power cord is installed by a

licensed electrician as specified below prior to range

installation. The electrical outlet installation, including

minimum supply wire size and grounding, must be in

accordance with all governing codes and ordinances.

• The correct voltage, frequency and amperage must be

supplied to the appliance from a separate, grounded, circuit

that is protected by a properly sized circuit breaker or time

delay fuse. If a fuse is utilized, fuse both sides of the line (L1

and L2). Refer to the ratings on the product data label.

Electrical Specifications

Circuit Requirements Total Connected Load

240 Vac 60 Hz, 4-wire*, 50 Amp. 11.5 kW (48.0 Amp.)

* Two 120 Vac hot (L1 and L2), one neutral (N1) and one ground.

The ratings above are for reference only - refer to the product

data label (see inside cover).

NEMA 14-50P Plug NEMA 10-50P Plug

NEMA 14-50R Receptacle NEMA 10-50R Receptacle

3

Page 6

1” (2.5 cm)

Front of open door

Front of handle

Front panel

Rear of front panel

Backguard thickness

3” (7.6 cm)

backguard*

External handle

shown, some models

have integral handle

(see inside cover)

6” (15.2 cm)

backguard*

*

See table for compatibility

Product width:

29 15/16” (76.0 cm)

35”

(88.9 cm)

to

37”

(94.0 cm)

9” (22.9 cm)

backguard*

A

B

C

D

RR30NI[F]S:

3/8” (9.5 mm)

thick top trim

RR30N[F]S:

full stainless

steel side panels

RR30NI[F]S:

3” (7.6 cm)

partial stainless

steel side panels

(removable)

Product Dimensions

Product tolerances: ±1/16” (±1.6 mm), unless otherwise stated

Product Specifications

4

RR30NS

RR30NFS

(117.5 cm)

(64.8 cm)

(59.4 cm)

(70.8 cm)

Dimension

A

C

D

Dimension RR30NS RR30NIS

B

Available Backguards**

Part Number Description Compatibility

ADRB30E03 3 Inch Optional on all models

ADRB30E06 6 Inch

ADRB30E09 9 Inch Optional on all models

**Models RR30NIS and RR30NIFS come equipped from the factory with a flat

stainless steel trim piece in place of a backguard. A backguard may be purchased

as an optional accessory. Add an additional 1/16 inch to the depth dimensions

above when installing a backguard on models RR30NIS and RR30NIFS.

The trim on models RR30NS and RR30NFS are not compatible with a raised vent.

Models RR30NIS and RR30NIFS are compatible with Dacor raised vent models

ERV30 and ERV3015. Use only these specified raised vent models.

Standard on models RR30NS, RR30NFS

Optional on models RR30NIS, RR30NIFS

46 1/4”

25 1/2”

23 3/8”

27 7/8”

RR30NIS

RR30NIFS

46 1/16”

(117.0 cm)

25 5/16”

(64.3 cm)

23 3/16”

(58.9 cm)

27 11/16”

(70.3 cm)

Page 7

Installation Specifications

Cabinet Layout

WARNING

• Observe all governing codes and ordinances during

planning and installation. Contact your local building

department for further information.

• All minimum cabinet/countertop clearances shown on the

following pages must be met or exceeded.

• To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above surface

units should be avoided.

• The shaded areas shown below denote the location of the

electrical junction box/receptacle. This is the suggested

location. For replacement purposes, the location of the

existing electrical supply may be utilized provided that it does

not interfere with the sides or rear of the range. Verify that the

electrical service meets local building codes.

• Access to the remote circuit breaker panel/fuse box, with the

range in place and operating, must also be allowed for in the

installation.

Cutout tolerances: +1/16” (+1.6 mm), -0,

unless otherwise stated.

• The electrical junction box/receptacle must be located so

that it does not interfere with the range when it is installed

and under operation. In addition, the junction box/receptacle

must be located so the range can be removed for service and

remain connected to power.

Cabinet and Countertop Preparation

• To reduce the risk of personal injury and to reduce

accumulated smoke in the room, Dacor strongly recommends

installing a range hood. A range hood should project

horizontally a minimum of five (5) inches beyond the face of

the cabinets. If installing a range hood, see the range hood

specifications for minimum clearances. If cabinet storage

space is to be provided directly above the range, the risk of

personal injury may be reduced by installing a range hood.

• The range may be installed flush to the rear wall. Dacor

recommends installing a non-combustible material on the rear

wall above the range and up to the range hood or cabinet,

whichever is lower.

• Any openings in the wall behind the appliance and in the floor

under the appliance must be sealed.

13” (33.0 cm)

4

max.

18” (45.7 cm)

min.

Note 2

B

A* B C*

36” (91.4 cm)

30 1/16” min.

(76.3 cm)

recommended

30” (76.2 cm)

min.

*For self rimming installations, see required dimensions

for “A” and “C” on the following pages.

Non-combustible

surface along

back wall

recommended

Suggested

location of

3

utilities

Top of

finished

counter

Note 5

1

30” (76.2 cm) min. vertical clearance from top of the

cooking surface to bottom of uncovered wood or metal

Note 1

4

A

cabinet. 24” (61 cm) min. clearance if bottom of wood

or metal cabinets are protected by not less than 1/4“

(0.6 cm) flame retardant millboard covered with no less

than No. 28 MSG sheet steel 0.015” (0.04 cm) stainless

steel, or 0.024” (0.06 cm) aluminum or 0.020” (0.05 cm)

copper. If installing range hood, also check the hood

specifications for minimum required clearances.

2

Cabinet/countertop depth is at discretion of customer

but cabinet face SHALL NOT protrude further than rear of

C

front panel. See Product Dimensions.

3

Consult local code for requirements.

4

This specification not applicable for cabinets more than

a horizontal distance of 1” (2.6 cm) from edge of range.

5

Cabinet Dimensions

1” (2.6 cm) min. to combustible sidewalls above range

(both sides).

37”

(94.0 cm)

max.

5

Page 8

Installation Specifications

Rear wall or

countertop edge

countertop opening

29 1/4” (74.3 cm)

30 1/16” (76.2 cm)

cabinet opening

below countertop

below countertop

Cabinet face

Notch countertop

to width of cabinets

3/8” min. (9.5 mm)

countertop overhang

1” min. (2.6 cm)

to any combustibles

above counter both sides

20”

(50.8 cm)

to

23”

(58.4 cm)

20”

(50.8 cm)

24 5/8”

(62.5 cm)

max.

Countertop front

Rear wall or

countertop edge

countertop opening

29 1/4” (74.3 cm)

30 1/16” (76.2 cm)*

cabinet opening

below countertop

below countertop

Cabinet face

Notch countertop

to width of cabinets

3/8” min. (9.5 mm)

countertop overhang

1” min. (2.6 cm)

to any combustibles

above counter both sides

23”

(58.4 cm)

24 5/8”

(62.5 cm)

max.

Countertop front

Cut 3” dia. (7.6 cm) holes

at back bottom of cabinet

for ventilation.

Provide ventilation through

cabient both sides,

7 square inches min.

Location may vary.

34 3/4”

(88.3 cm)

to

36 7/8”

(93.7 cm)

(see diagrams)

Countertop

1 5/8 (41.1 cm)

max. thickness

Cabinet Cutouts for Self-Rimming Installation (Models RR30NIS and RR30NIFS Only)

• The self-rimming installation of the RR30NI[F]S range

creates a “built-in” look where the range trim overlaps

and rests on the countertop on both sides and in back.

• IMPORTANT: When installing the range in this

configuration, ventilation must be provided to allow

for cooling of the ranges internal components. See

diagram, left.

• Observe all vertical cabinet clearances on page 5.

• On self-rimming installations when sliding the range into

position, it will stop when the rear of the control panel or

side panels contact the notches toward the front of the

countertop.

Top View - Slide-In, Self-Rimming Installation,

6

Top View - Slide-In, Self-Rimming Installation,

3” Side Panels Installed

3” Side Panels Removed

* To create a “built-in look” on the front of the cabinet,

this dimension may be changed to 29 1/4” (74.3 cm),

with the width at the notches remaining 30 1/16”.

This configuration is only for models RR30NIS and

RR30NIFS with the side panels behind the door

removed.

Page 9

Installation Specifications

Cabinet Cutouts for Self-Rimming Installation with Raised Vent (Models RR30NIS and RR30NIFS Only)

• Trim kit PN ATKR30SR is required for proper

Countertop

1 5/8 (41.1 cm)

max. thickness

34 3/4”

(88.3 cm)

to

36 7/8”

(93.7 cm)

1” min. (2.6 cm)

to any combustibles

above counter both sides

(see diagrams)

Cut 3” dia. (7.6 cm) holes

at back bottom of cabinet

for ventilation.

Provide ventilation through

cabient both sides,

7 square inches min.

Location may vary.

Rear wall or

countertop edge

3/8” min. (1.0 cm)

countertop overhang

installation of a raised vent with this range.

• The self-rimming installation of the RR30NI[F]

S range and ERV30[15] raised vent create a

“built-in” look where the range trim overlaps and

rests on the countertop on both sides and the

raised vent trim overlaps the countertop in back.

The ATKR30SR trim kit, installed on the back of

the range, will cover the front of the raised vent

chassis.

• IMPORTANT: When installing the range in this

configuration, ventilation must be provided to allow

for cooling of the ranges internal components. See

diagram, left.

• Observe all vertical cabinet clearances on

page 5.

• A self-rimming countertop configuration is required

for raised vent installation. On installations with a

raised vent, when sliding the range into position, it

will stop when the rear of the control panel or side

panels contact the notches toward the front of the

countertop.

2 5/8” (6.7 cm)

20 3/8”

(51.8 cm)

to

23 3/8”

(59.4 cm)

25”

(63.5 cm)

max.

Countertop front

27 1/2” (69.9 cm)

raised vent opening

29 1/4” (74.3 cm)

countertop opening

30 1/16” (76.2 cm)

cabinet opening

below countertop

Notch countertop

to width of cabinets

Cabinet face

below countertop

20 3/8”

(51.8 cm)

Top View - Downdraft ERV30[15] with Slide-In, Self-Rimming Installation,

3” Side Panels Installed

1” min. (2.6 cm)

to any combustibles

above counter both sides

27 1/2” (69.9 cm)

Rear wall or

countertop edge

3/8” min. (1.0 cm)

countertop overhang

2 5/8” (6.7 cm)

raised vent opening

25”

(63.5 cm)

max.

29 1/4” (74.3 cm)

countertop opening

30 1/16” (76.2 cm)*

cabinet opening

below countertop

23 3/8”

(59.4 cm)

* To create a “built-in look” on the front of the

cabinet, this dimension may be changed to 29 1/4”

(74.3 cm), with the width at the notches remaining

30 1/16”. This configuration is only for models

RR30NIS and RR30NIFS with the side panels

behind the door removed.

Notch countertop

to width of cabinets

Cabinet face

Countertop front

below countertop

Top View - Downdraft ERV30[15] with Slide-In, Self-Rimming Installation,

3” Side Panels Removed

7

Page 10

Installation Instructions

Verify the Package Contents

Verify that all the components below have been provided. If

any item is missing or damaged, please contact your dealer

immediately. Do not install a damaged or incomplete appliance.

Make sure that you have everything necessary to ensure proper

installation before proceeding.

• Use and care manual

• Anti-tip bracket with screws and anchors

• Oven racks (2) GlideRack type, (1) standard type

• Razor blade scraper

• Dacor Cooktop Cleaning Cream

Installing the Anti-Tip Bracket

Locate the anti-tip bracket included in the parts box.

There are two ways to mount the anti-tip bracket:

• Floor mounting (preferred method).

• Wall mounting (alternate method). Use this method if floor

mounting is not suitable. If any of the conditions below exist,

then the wall mounting method can not be used and the floor

mounting method must be suitable.

The anti-tip bracket may not be mounted to the wall if:

◊ The wall contains metal stud mounting materials that

interfere with the anti-tip bracket mounting screws.

◊ The front panel of the range is further than the maximum

distance from the back wall stated on page 9.

◊ A raised vent is installed.

◊ The flooring is too thick (see Installing the Anti-Tip

Bracket on the Wall).

Installing the Anti-Tip Bracket on the Floor

WARNING

To perform its intended function, the anti-tip bracket must be

attached as instructed to the concrete slab or wood sub-floor

below any floor coverings (including cement board) on top. Do

not attach the anti-tip bracket directly to floor coverings such as

ceramic/asphalt tile or linoleum.

Four (4) plastic anchors are provided along with three sizes

(4 each) of #8 or #12 Phillips head screws for attaching the antitip bracket to the floor. Use both the anchors and four (4) of the

#8 screws when attaching the bracket to a concrete sub-floor. Do

not use the anchors when attaching to a wood sub-floor.

Anti-tip

bracket

1. Determine the location of the range center line and front

panel when the range is in its final position based on the

Product Dimensions on page 4, and the actual cabinet/

cutout dimensions used for the installation.

2. Determine the required position of the anti-tip bracket,

based on the diagram on the facing page. Mark the four (4)

mounting hole locations on the floor with a pencil.

3. Determine the screw size required. The minimum full thread

depth (portion of screw threaded into wood/slab) for wood

is 3/8” (1 cm) and 5/8” (1.6 cm) for concrete. See the table

below to select the correct screw size.

Sub-Floor Type/

Floor Covering Thickness

Concrete or wood sub-floor, no floor

covering over top

Concrete or wood sub-floor, floor

covering up to 1/4” thick

Concrete or wood sub-floor, floor

covering over 1/4” and up to 1/2” thick

Wood sub-floor, floor covering over

1/2” and up to 1 3/16” thick

Concrete sub-floor under floor covering

over 1/2” thick

Wood sub-floor, floor covering

over 1 3/16” thick

* Included with range

** Not included. Determine length based on step 3.

Screw Size

#8 x 1” *

#8 x 1” *

#8 x 1 1/4” *

#12 x 1 3/4” *

Must be purchased

separately **

Must be purchased

separately **

Attaching the bracket to a concrete floor:

• Drill four (4) 3/8” diameter countersink holes through any

existing floor covering down to the concrete slab below.

• Drill the 4 holes for the anchors 1 1/4” (3.2 cm) deep into the

concrete slab using a 3/16” masonry bit. This hole length is

longer than the anchor, but is required for proper installation.

Clear the holes of dust and any other material. Tap each

anchor into the hole until the anchor top is flush with the top

of the concrete slab. Position the anti-tip bracket holes over

the anchor holes. Insert the screws through the 4 holes in

the base of the bracket and thread them into the anchors. Be

sure the screw threads fully engage the anchor body. Tighten

the screws into place.

Attaching the bracket to a wood floor:

• If there is ceramic, asphalt or other hard floor covering over

the wood below, drill 4 countersink holes to allow access to

the wood below for drilling pilot holes.

• Drill 4 pilot holes into the wood floor using a drill bit (1/16”

dia. for #8 screws, 1/8” dia. for #12 screws). Position the antitip bracket holes over the holes in the floor. Insert the screws

into the wood and tighten into place.

Concrete

anchors shown,

do not use for

wood sub-floor

8

Sub-floor

Floor

covering

Screws attached

to sub-floor below

floor covering

Installing the Anti-Tip Bracket on the Wall

1. To use the wall mount option, the range front panel must not

be more than 26 1/4” from the wall and the bracket screws

must be able to thread into the base plate inside the wall

behind. The notches on the sides of the bracket indicate the

minimum required height of the base plate inside the wall and

that any floor covering is not too thick for proper screw thread

engagement.

Page 11

Installation Instructions

To determine if the base plate is high enough:

a. Determine the location of the range center line and front

panel when the range is in its final position based on

the Product Dimensions on page 4 and the actual

cabinet/cutout dimensions used for the installation.

b. Determine and mark the required position of the anti-tip

bracket, based on the diagram below. Push the bracket

up against the wall in the mounting location.

c. Using a pencil, make a dot next to the notches on both

sides of the bracket. Determine if the base plate is as

high at the notches by drilling test holes into the wall at

both dots with a 1/16” drill bit. Drill just deep enough to

see if the bit contacts the base plate. If the bit contacts

the base plate the location will support wall installation

of the anti-tip bracket. If you do not contact the base

plate, or you contact metal stud mounting materials, the

wall mounting method may not be used and the floor

mounting method must be suitable, or the wall must be

modified so that the base plate is above the notches.

4. To install the bracket, place it against the wall in the mounting

location shown below. Using a drill with 1/8” diameter drill bit,

drill four 1 5/8” deep pilot holes perpendicular to the screw

seating surfaces shown. Attach the bracket to the wall as

shown with the four (4) included #12 x 1 3/4 screws.

Anti-tip

bracket

Drywall

Notch

Wall

Base

plate

#8 x 1”, #8 x 1 1/4”

or #12 x 1 3/4 screw,

4 places (see text)

Anchor, 4 places:

use for concrete

Cabinet

face below

countertop

floor only

Anti-tip bracket

front hole locations

Range

center line

C

L

21 3/8”

(54.3 cm)

Front

hole

#12 x 1 3/4” screw,

4 places

Back wall

Cabinet

face below

countertop

Range

center line

Range front

panel

C

L

Top hole, indicates

bracket center line

25 1/4”

(64.1 cm)

to

26 1/4

(66.7 cm)

C

L

Range front

panel

10 1/2”

(26.3 cm)

2 3/16”

(5.6 cm)

Top View - Location of Floor Mounted Anti-Tip Bracket

11 1/2”

(29.2 cm)

Bracket

center line

Top View - Location of Wall Mounted Anti-Tip Bracket

9

Page 12

Installation Instructions

Backguard Installation

If installing a backguard or changing the factory installed

backguard, install it before moving the range into position. Do not

install a backguard if installing a raised vent.

Raised Vent Installation

If installing a raised vent, install it before moving the range into

position. Install trim kit PN ATKR30SR to cover the front of the

raised vent chassis.

Removing the Oven Door

To make the range easier to move, remove the door to reduce

weight.

WARNING

• Do not attempt to disengage the hinge catches with the

door removed from the oven. The hinge springs could

release, causing personal injury.

• Do not lift or carry the oven door by the door handle.

1. Open the door to its fully opened position.

2. Using a flat blade screwdriver, rotate the catch over the

retaining arm on each hinge.

3. Lift the oven door to about a 15° angle from the vertical

position.

4. Hold the door with both hands just below the handle and pull

it away from the oven while continuing to lift.

Electrical Connection

WARNING

• Before proceeding, turn off power to the circuit to which the

appliance will be connected at the circuit breaker panel or

fuse box.

• If the electric service provided does not meet the product

specifications, do not proceed with the installation. Call

the appliance dealer or a licensed electrician. Improper

connection of the electrical wiring can cause an electric

shock hazard and damage the appliance. Dacor is not

responsible for damages resulting from improper installation.

• This range must be connected to a grounded, metallic,

permanent wiring system. Alternatively, a grounding

conductor should be connected to the grounding terminal or

lead on the appliance.

• Do not use a 3-wire connection unless local building codes

permit.

• Do not turn on power to the appliance until the range is

permanently grounded.

• Do not use an extension cord with this appliance. Such use

may result in fire, electrical shock or other personal injury.

• Do not install a fuse in the neutral or ground circuit. A fuse

in the neutral or ground circuit may result in an electrical

shock hazard.

NOTE: If the appliance is connected to a 208 volt power supply,

preheat times and cavity temperature recovery times will be

increased slightly.

NOTE: Model numbers ending with a -C come from the factory

pre-wired. If installing a pre-wired range, skip to Installing the

Range on page 16.

IMPORTANT: When connecting the range wiring, do not

disconnect any of the wires inside the range electrical box unless

instructed to do so.

Before proceeding:

1. Position the range directly in front of the cabinet cutout.

2. Remove the electrical access cover on the back of the range.

There are four possible ways to wire the range:

• 4-wire conduit

• 3-wire conduit (where local codes permit)

• 4-wire appliance cord (where local codes permit)

• 3-wire appliance cord (where local codes permit)

The sections on the following pages give directions for connecting

each type of wiring harness.

10

Page 13

Installation Instructions

Connecting Conduit to the Range

NOTE: See page 14 for instructions to connect an appliance

cord to the range.

1. Remove the range electrical access cover from the back of

the range.

2. If using a 4-wire connection, loosen the grounding screw and

remove the neutral to ground jumper link.

3. Remove the nut from the conduit strain relief (not included).

4. Slide the wires and the end of the strain relief into the hole on

the bottom of the range electrical box.

L1 terminal

Neutral terminal

Jumper link

L2 terminal

Back wire

White wire

Red wire

Conduit strain

relief nut

5. Before connecting the wires, slide the strain relief nut over

the wires and thread it onto the conduit strain relief inside the

box. Tighten into place.

6. Connect the white wire to the neutral terminal inside the box.

7. Connect the black wire to the L1 power supply terminal.

8. Connect the red wire to the L2 power supply terminal.

9. If using a 4-wire connection, connect the green wire to the

grounding screw inside the box.

Bare wire

connections

Loop and

spade terminal

connections

10. Replace the range electrical access cover.

3-Wire Conduit Connection Where Local Codes Permit

L1 terminal

Neutral terminal

L2 terminal

Link removed

Grounding screw

Red wire

Green wire

White wire

Back wire

Conduit strain

relief nut

4-Wire Conduit Connection

11

Page 14

Installation Instructions

Electrical Connection (cont.)

Connecting the Conduit to the House

Electrical Junction Box

WARNING

• Do not connect the green appliance wire to the neutral

(white) supply wire unless local building codes permit.

• Do not ground the appliance to a gas supply pipe or hot

water pipe.

• A grounded cold water pipe must have metal continuity to

electrical ground and must not be interrupted by insulating

materials. Any insulating materials must be jumped with a

length of No. 4 copper wire securely clamped to bare metal

at both ends. See below.

No. 4

copper wire

Connection to house

power supply

Meter or other

insulating device

Metal

water pipe

Clamps

Bare metal

Insulated Pipe Jumper

1. With the range positioned directly in front of the cabinet

cutout, feed the appliance wires into the junction box.

Depending upon local codes, utilize one of the three (3)

methods shown to connect the appliance inside the junction

box.

2. Connect the white wire from the appliance to the neutral

(white) supply wire inside the junction box.

3. Connect the black wire from the appliance to the black (L1)

power supply wire inside the junction box.

4. Connect the red wire from the appliance to the red (L2) power

supply wire inside the junction box.

5. If using a 4-wire connection, connect the green wire to a

grounded supply wire in the junction box or to a grounded

cold water pipe. If connecting to a grounded cold water pipe,

use a separate copper grounding wire (No. 10 minimum) to

connect to the cold water pipe by means of a clamp and an

external grounding connector screw.

6. Replace the junction box cover.

Junction box

RED

RED

GREEN

GREEN

Conduit to

appliance

WHITE

WHITE

BLACK

BLACK

4-Wire Conduit-Junction Box Connection

Wire nut

4 places

12

Page 15

Installation Instructions

Connection to house

power supply

Separate No. 10 (minimum)

copper grounding wire

Connection to house

power supply

Fasten clamp

tightly on pipe

Junction box

Conduit to

appliance

3-Wire Conduit-Junction Box Connection

Wire nut

3 places

Junction box

RED

RED

GREEN

GREEN

Wire nut

4 places

WHITE

WHITE

BLACK

BLACK

Conduit to

appliance

3-Wire Conduit-Junction Box

Connection with External Ground

13

Page 16

Installation Instructions

Electrical Connection (cont.)

Appliance Cord Connections - Where Local

Code Permits

WARNING

Do not connect the green appliance wire to the neutral (white)

supply wire unless local building codes permit.

1. Remove the range electrical access cover from the back of

the range.

2. If using a 4-wire connection, loosen the grounding screw and

remove the neutral to ground jumper link.

3. Remove the conduit bracket from the bottom of the range

electrical box.

Remove link on

4-wire installations

5. Slide the end of the appliance cord into the strain relief from

the bottom of the box. See facing page.

6. Connect the white (neutral) wire to the neutral terminal in the

box.

7. Connect the L1 wire to the L1 power supply terminal inside

the box.

8. Connect the L2 wire to the L2 power supply terminal inside

the box.

9. If using a 4-wire connection, connect the ground wire to

the grounding screw inside the box using a loop or spade

terminal.

Bare wire

connections

Loop and

spade terminal

connections

10. Tighten the strain relief so that the appliance cord is held

snuggly in place.

11. Replace the range electrical access cover.

12. With power turned off at the circuit breaker panel or fuse

box, connect the plug on the end of the appliance cord to the

power receptacle.

Remove conduit

bracket before strain

relief installation

4. Disassemble and remove the strain relief from the appliance

cord (not included). Insert the tabs on the two parts of

the strain relief into the hole on the bottom of the box and

reassemble it so that the tabs are below the box and the

strain relief itself is inside the box.

Strain relief

Bottom of range

electrical box

14

Reassemble with tabs

below and clamp above

Page 17

Installation Instructions

L1

Neutral

Neutral

L2

L2

L1

3-Wire Appliance Cord Plug 4-Wire Appliance Cord Plug

L1 terminal

Neutral terminal Neutral terminal

L2 terminal

L1 terminal

L2 terminal

Ground

Jumper link

Link removed

Ground screw

L1 wire

White wire

L2 wire

Strain relief Strain relief

L2 wire

Green wire

White wire

L1 wire

3-Wire Appliance Cord Connection -

Where Local Codes Permit

4-Wire Appliance Cord Connection -

Where Local Codes Permit

15

Page 18

Installation Instructions

Installing the Range

Peel off the protective layer of plastic that covers the stainless

steel surfaces.

Freestanding Installation

1. Measure from the floor to the countertop and adjust the

leveling legs as required to position the top frame at the

desired height, based on the cabinet and countertop

installation.

2. Carefully slide the range into position in the cutout. As you

slide the unit into place the rear leg should engage the antitip bracket.

3. Using a flashlight look underneath the range and verify that

the anti-tip bracket covers the rear leg. See diagram below.

4. Use a level to make sure that the range does not tilt front to

back or side to side. Re-adjust the legs to level and change

the height if necessary.

Self-Rimming Installation

Installation of the range in the self-rimming configuration is

slightly different from freestanding installation since the range top

overhangs the countertop cutout.

1. Measure from the floor to the countertop.

2. Adjust the leveling legs to position the bottom edge of the

range top trim at countertop height.

3. Carefully slide the range into position in the cutout. As you

slide the unit into place the rear leg should engage the anti-

tip bracket.

4. Using a flashlight look underneath the range and verify that

the anti-tip bracket covers the rear leg. See diagram below.

5. Use a level to make sure that the range does not tilt front to

back or side to side. Re-adjust the legs to level and change

the height if necessary.

Re-installing the Oven Door

WARNING

To avoid personal injury or damage to the door from it

falling off its hinges:

• Make sure that the notch on the bottom of each hinge rests

on top of the lower lip of each hinge receptacle before

attempting to open the oven door.

• Rotate the hinge locks toward the front of the range

immediately after installation of the door.

1. Grasp the oven door on opposite sides and hold it at a 15°

angle from the front of the range. Slide the hinges into the

hinge openings, resting the bottom of the hinge arms on the

hinge receptacles. Continue to hold the door at a 15° angle

with one hand while pushing in on each of the bottom corners

of the door. Push until the notch on the bottom of each hinge

slips over the lower lip of each hinge receptacle.

16

Anti-tip

bracket

Rear leg

2. Lower the door to the fully opened position.

3. Rotate the two hinge locks toward the range.

4. Slowly and carefully open and close the door completely to

ensure that it is properly installed.

Page 19

Installation Instructions

Verifying Proper Operation

1. Remove any packaging from inside the oven.

2. Slide the oven racks onto the supports inside the oven

chamber according to the use and care manual.

3. Prior to operating the range, please read the accompanying

use and care manual carefully. Important safety, service and

warranty information are contained within.

4. Turn on power to the range at the circuit breaker panel or

fuse box.

5. Set the clock according to the use and care manual.

6. Press the BAKE key on the control panel. The default bake

temperature should appear on the display.

7. Press START. After approximately three (3) minutes, check to

make sure the oven is heating.

8. Press CANCEL SECURE.

9. Place a pot 1/4 full with water on one of the cooking

elements. Match the size of the pot to the size of the cooking

element. NOTE: You must use a pot that attracts a magnet

on the pan bottom to test operation.

10. Hold your finger on the ON/OFF key for one second to

activate the control (the diagram next to the ON/OFF key

determines the correct control). “0” will flash on the display.

ON indicator

Power level

Installation Checklist

WARNING

To ensure a safe and proper installation, the installer must

perform the following checklist to ensure that no part of the

installation has been overlooked. Proper installation is the

responsibility of the homeowner.

1. Has the plastic coating been peeled off of the outside of the

range? Have all packaging materials been removed from

inside the oven?

2. Are all of the legs extended down to make contact with the

floor? Is the unit level? See page 16.

3. Is the range secured in place with the provided anti-tip

bracket according to these instructions? See page 8 and

16.

4. Is the range wired and grounded according to these

instructions and in accordance with all applicable electrical

codes? Has the electrical access cover been replaced? See

pages 3 and 10.

5. Is the oven door properly installed according to these

instructions? See page 16.

6. Has proper operation been verified?

7. Has the warranty been activated on-line or the warranty card

been filled out completely and mailed?

ON/OFF

LOW MED HIGH

Cooktop Controls

11. Touch the HIGH key.

12. Once the pot begins to heat, touch LOW, then MED. Verify

that the power level changes.

13. Touchthepowerlevelupkey(▲).Verifythatthepowerlevel

goes up.

14. Touchdown(▼).Verifythatthepowerlevelgoesdown.

15. Touch ON/OFF to turn off the cooktop.

16. If either the oven or cooktop does not operate properly, follow

these troubleshooting steps:

◊ Verify that power is being supplied to the range.

◊ Check the electrical connections to ensure that the

installation has been completed correctly.

◊ Repeat the above tests.

◊ If the appliance still does not work, contact Dacor

Distinctive Service at (800) 793-0093, extension 2822.

Do not attempt to repair the appliance yourself. If you

need service, be sure to have the model and serial

numbers available when you call. See the inside cover

for location. Dacor is not responsible for the cost of

correcting problems caused by a faulty installation.

17

Page 20

Dacor ● 14425 Clark Avenue, City of Industry, CA 91745 ● Phone: (800) 793-0093 ● Fax: (626) 403-3130 ● www.dacor.com

Loading...

Loading...