Page 1

Epicure ®Range

For use with models ER3OD, ER3OD-C, ER3ODSR

Installation Instructions

Part No. 102187 Rev. J

THIS APPLIANCE HAS BEEN TESTED IN ACCORDANCE WITH THE LATEST EDITION

OF ANSI Z21.1 STANDARD FOR HOUSEHOLD GAS COOKING APPLIANCES.

Page 2

All specifications subject to change without notice.

Dacor ®assumes no liability for changes to specifications.

© 2007 Dacor, all rights reserved.

Page 3

Important Safety Instructions .................................................. 1-3

Customer Service Information .................................................... 3

Planning the Installation ........................................................... 4-8

Electrical Requirements 4

Gas Supply Requirements 4

Product Dimensions 5

Cabinet Layout 7

IMPORTANT:

• Installer In the interest of safety and to minimize problems, read these installation instructions completely and carefully before you

begin the installation process Leave these installation instructions with the customer

• Customer Keep these installation instructions for future reference and the local building inspector's use

Installation Instructions .......................................................... 8-20

Preparing for Installation 8

Electrical Connection 12

Gas Connection 17

Final Installation 18

Installing the Burner Knobs 18

Cooktop Assembly 19

Verifying Proper Operation 20

Installation Checklist 20

About Safety Instructions

The Important Safety Instructions and warmngs _nth_s manual

are not meant to cover all possible problems and conditions

that can occur Use common sense and caution when _nstalhng,

maintaining or operating this or any other appliance

Always contact the Dacor Customer Service Team about problems

and conditions that you do not understand

Safety Symbols in this Manual

Immediate hazards that WILL result =nsevere personal injury or

death

Hazards or unsafe practices that COULD result in severe

personal injury or death

Hazards or unsafe practices that COULD result in minor

personal injury or property damage

IMPORTANT: If you smell gas

• Do not use or light any appliance

• Do not touch any electrical switch or use any electrical

devices, including the telephone, in your building

• From a neighbors phone, immediately call the gas supplier

Follow the gas suppher's instructions

• If you cannot contact the gas supplier, call the fire

department

IMPORTANT: Do not store or use combusttble, flammable or

explosive vapors and liquids (such as gasoline) inside or in the

vicinity of this or any other appliance Also keep items that could

explode, such as aerosol cans, away from the burners and the

oven Do not store flammable or explosive materials =nadjacent

cabinets or areas

IMPORTANT: Junked or abandoned appliances are dangerous

and can cause a child entrapment and suffocation hazard

When taking an appliance out of service, immediatelv follow

the instructions below to help prevent accidents:

• Take off the door

Leave the racks in place so children cannot easily climb

inside

• Cut the prongs off the power cable plug and discard them

• Cut the power cable off and discard it separately from the

old appliance

WARNING - NEVER use this apphance as a space heater

to heat or warm the room Doung so may result =ncarbon

monoxide potsomng and overheating of the appliance

WARNING - NEVER cover any slots, holes or passages on

the inside or outs=de of the range or cover an entire rack with

materials such as aluminum foil Doing so blocks air flow

through the oven and may cause carbon monoxide polsomng

Aluminum foil linings may also trap heat, causing a fire hazard

READ AND SAVE THESE INSTRUCTIONS

The burning of gas cooking fuel generates some by-products

that are on the list of substances which are known by the State

of Cahfornta to cause cancer or reproductive harm California

law requires businesses to warn customers of potential

exposure to such substances To minimize exposure to these

substances, always operate this unit according to the use

and care manual, ensuring you provide good ventilation when

cooking with gas

_acor 1

Page 4

General Safety Precautions

To reduce the risk of fire, explosion, electric shock, serious injury or death when installing or using this appliance, follow basic safety

_recautions, including the following:

• Read the accompanying use and care manual completely before operating this appliance.

• Keep packaging materials away from children. Plastic sheets and bags can cause suffocation.

• Ifyou receive a damaged product, immediately contact your dealer or builder. Do not install or use a damaqed appliance.

• This range must be properly installed by a qualified installer according to these installation instructions prior to use. The installer

must show the customer the location of the gas shut off valve and the circuit breaker panel or fuse box so that they know where

and how to turn off the gas supply and electric power to the range.

• If the back wall is made of combustible materials do not operate the range without a backguard or raised vent in place. A fire may

result.

• Do not install, repair or replace any part of the range unless specifically recommended in the literature accompanying it. A

qualified service technician should perform all other service.

• Do not connect this range to the gas supply without the supplied gas pressure regulator installed.

• Before performing any type of service or installation, make sure that the gas supply and electric power to the range are off.

• NEVER block or cover any slots, holes or passages anywhere inside the oven or on the outside of the range or cover an oven

rack with materials such as aluminum foil. See the Getting to Know Your Range section of the use and care manual for the

location of the various air holes (slots).

• Only use the range for cooking tasks expected of a home appliance as outlined in the iterature accompanying it. This range is

not intended for commercial use.

• DO NOT TOUCH THE SURFACES OF THE OVEN OR COOKTOP DURING OR IMMEDIATELY AFTER USE.

• Do not climb on any part of the appliance.

• Never leave this appliance unattended when in use.

• Do not leave children or pets alone or unattended in the area around the range. Do not allow children to play with the controls.

pull on the handle, or touch other parts of the range.

• Do not store items of interest to children on top of or above the range. Children could be burned or injured while climbing on the

appliance.

• Do not attempt to use this appliance in the event of a power failure.

• Do not tamper with the controls. Do not adjust or alter any part of the range unless specifically instructed to do so in these

instructions.

• To prevent the unit from tipping forward and to provide a stable installation, this range must be secured in place with the anti-tip

device as specified in these instructions.

• Clean the cooktop thoroughly before operating it for the first time.

• Keep flammable items, such as paper, cardboard, plastic and cloth away from the burners and other hot surfaces. Do not place

such items in the oven. Do not allow pot holders to touch hot surfaces or gas burners.

• Do not wear loose or hanging apparel while using the range. Do not allow clothing to come into contact with the interior of the

oven or the cooktop and surrounding areas during and immediately after use.

• To avoid a fire hazard, do not hang flammable or heat sensitive objects over the range. If the range is near a window, do not use

long curtains as window treatment. The curtains could blow over the cooktop and create a fire hazard.

• Do not use the oven for storage.

• Do not touch the burner assembly, grates or surrounding surfaces (including the backguard) or the interior surfaces of the oven

during use. After use. make sure these surfaces have had sufficient time to cool before touching them.

• Do not touch the outside surfaces of the range during the self-clean cycle. They will be hot. Venting from the oven may cause the

cooktop and backguard to become hot.

• Make sure that all the cooktop parts are dry before lighting a burner.

• Turn the knobs to the OFF position prior to removing them from the valve stems.

• Do not operate the cooktop without the knobs and trim rings in place.

• For your safety, do not use the oven to cook without the convection filter installed. When the filter is not installed, the spinning fan

blades at the back of the oven are exposed.

• Non-stick coatings, when heated, can be harmful to birds. Remove birds to a separate, well-ventilated room during cooking.

2 _a_ar

Page 5

Topreventdamage,removethemeatprobefromtheovenwhenitisnotbeingused

• Donotlinetheovenwithaluminumfoilorothermaterials.Theseitemscanmeltorburnupduringself-cleaningandcause

permanentdamagetotheoven.

• Donotleavemetalobjects,suchasaluminumfoil,themeatprobe,cookiesheets,etc.onthebottomoftheoven.Objectslefton

thebottomoftheovencoulddamagethebakeelement.Inaddition,theobjectsthemselvescouldbedamaged.

• Thebakeandbroilelementsarebehindglasspanelsonthefloorandceilingoftheovenchamber.Donotcovertheseglass

panelswithcookiesheets,aluminumfoil.pots,pans,etc.Coveringthemcouldcausetheheatingelementstoover-heat,

damagingtheoven.

• Donotexposetheknobsortrimringstodirectflame,hotutensilsorothersourcesofheat.

• Alwaysensurethatthelightfixturelenscoversareinplacewhenusingtheoven.Thelenscoversprotecttheightbulbsfrom

breakagecausedbyhighoventemperaturesormechanicalshock.

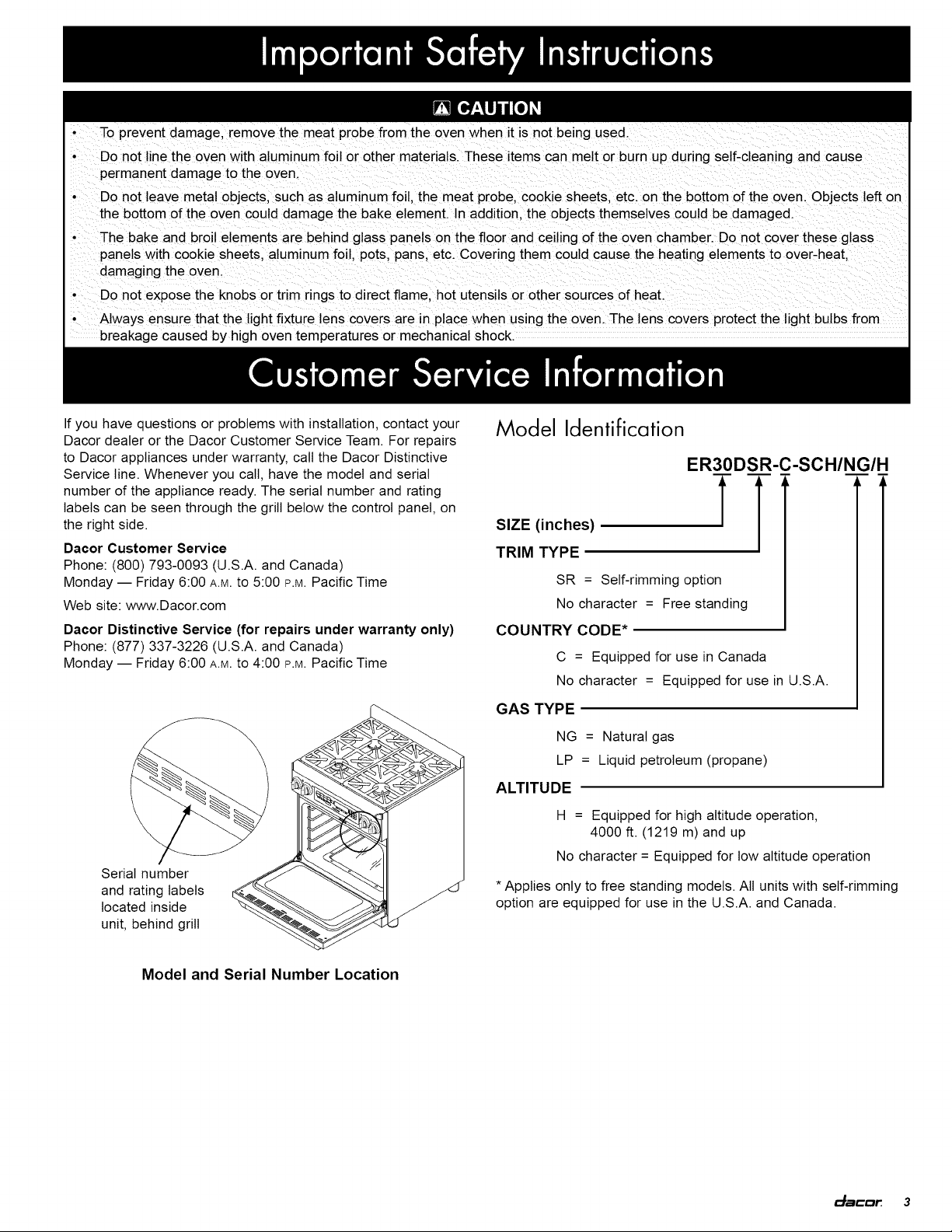

Ifyouhavequestionsorproblemswithinstallation,contactyour

DacordealerortheDacorCustomerServiceTeam.Forrepairs

toDacorappliancesunderwarranty,calltheDacorDistinctive

Serviceline.Wheneveryoucall,havethemodelandserial

numberoftheapplianceready.Theserialnumberandrating

labelscanbeseenthroughthegrillbelowthecontrolpanel,on

therightside.

Dacor Customer Service

Phone: (800) 793-0093 (U.S.A. and Canada)

Monday -- Friday 6:00 A.M.to 8:00 P.M.Pacific Time

Web site: www.Dacor.com

Dacor Distinctive Service (for repairs under warranty only)

Phone: (877) 337-3226 (U.S.A. and Canada)

Monday -- Friday 6:00 A.M.to 4:00 P.M.Pacific Time

Serial number

and rating labels

located inside

unit, behind grill

Model Identification

ER30 DS R-C-SC H/N G/H

SIZE (inches)

TRIM TYPE

SR =

Self-rimming option

No character = Free standing

COUNTRY CODE*

C = Equipped for use in Canada

No character = Equipped for use in U.S.A.

GAS TYPE

NG = Natural gas

LP = Liquid petroleum (propane)

ALTITUDE

H = Equipped for high altitude operation,

4000 ft. (1219 m) and up

No character = Equipped for low altitude operation

* Applies only to free standing models. All units with self-rimming

option are equipped for use in the U.S.A. and Canada.

TT---

Model and Serial Number Location

_acar 3

Page 6

Electrical

IMPORTANT: The information below applies only to freestanding

units equipped for use in the U.S.A. and units with the self-

rimming option.

It is the owner's responsibility to ensure that the electrical

connection of this appliance is performed by a licensed electrician.

The electrical installation, including minimum supply wire size and

grounding, must be in accordance with the National Electric Code

ANSI/NFPA 70-1gg3" (or latest revision) and local codes and

ordinances. A copy of this standard may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

• The correct voltage, frequency and amperage must be

supplied to the appliance from a separate, grounded, circuit

that is protected by a properly sized circuit breaker or time

delay fuse. Refer to the ratings on the range rating label.

ER30D/ER30DSR ELECTRICAL SPECIFICATIONS

Circuit Required Total Connected Load

240 Vac, 60 Hz, 30 Amp. 5.6 kW (24.2 Amp.)

The ratings above are for reference only - refer to the range

rating label (see page 3).

Consult local building codes for the type and minimum wire

gauge to use for the power requirements listed on the rating

label.

Suggested wiring color code: black, white, red and green.

The wiring needs to be tong enough to allow the range

to be pulled out from the wall for service, while remaining

connected. See page 12 for further details.

The wiring to the range must:

0 Have a minimum rating of 250 Volts @ 30 Amp.

0 Include a strain relief

0 Be terminated by tinned leads, closed loop terminals or

open ended spade lugs with upturned ends

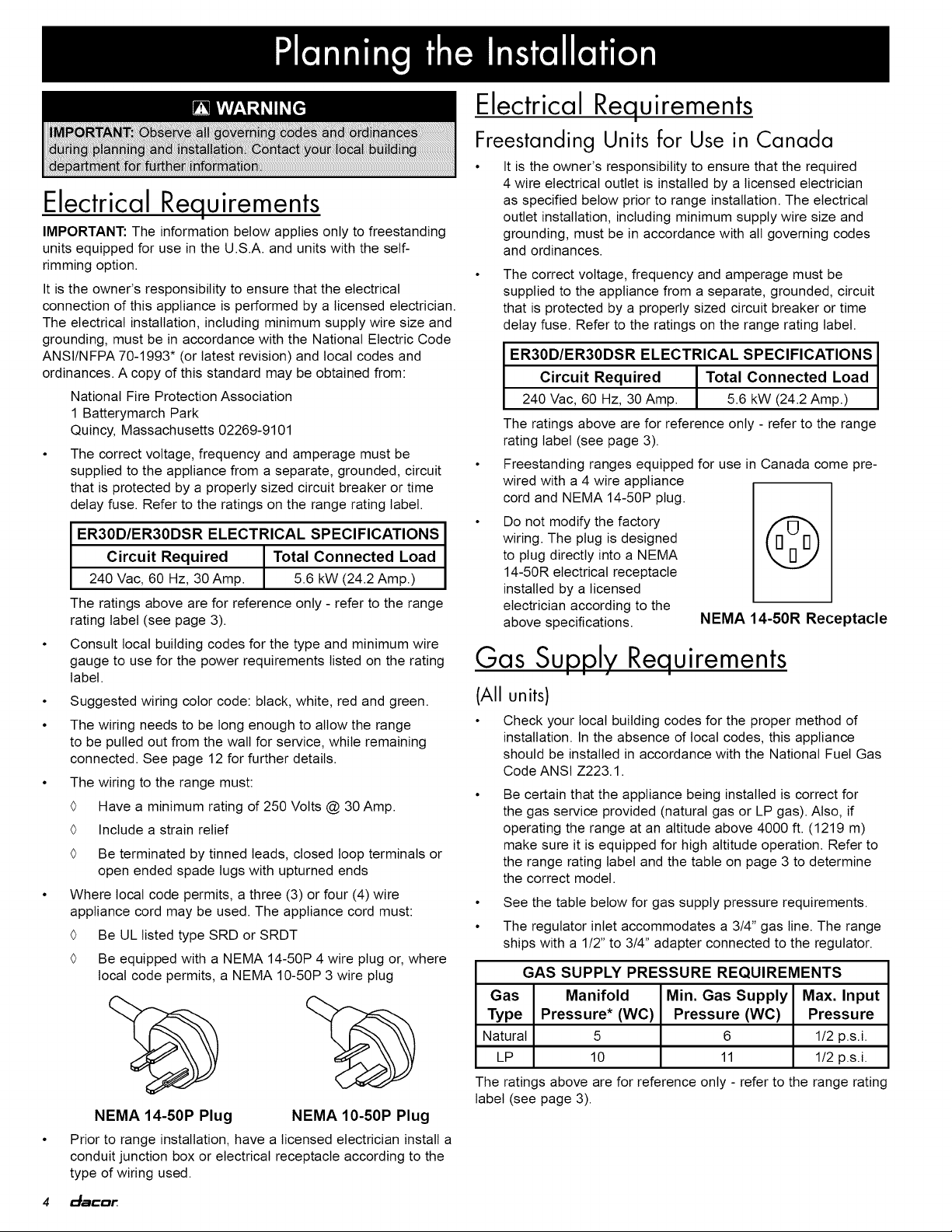

Where local code permits, a three (3) or four (4) wire

appliance cord may be used. The appliance cord must:

0 Be UL listed type SRD or SRDT

0 Be equipped with a NEMA 14-50P 4 wire plug or, where

local code permits, a NEMA 10-50P 3 wire plug

NEMA 14-50P Plug NEMA 10-50P Plug

Prior to range installation, have a licensed electrician install a

conduit junction box or electrical receptacle according to the

type of wiring used.

4 _acar

Requirements

Electrical Requirements

Freestanding Units for Use in Canada

• It is the owner's responsibility to ensure that the required

4 wire electrical outlet is installed by a licensed electrician

as specified below prior to range installation The electrical

outlet installation, including minimum supply wire size and

grounding, must be in accordance with all governing codes

and ordinances

The correct voltage, frequency and amperage must be

supplied to the appliance from a separate, grounded, circuit

that is protected by a properly sized circuit breaker or time

delay fuse. Refer to the ratings on the range rating label.

ER30D/ER30DSR ELECTRICAL SPECIFICATIONS

Circuit Required

240 Vac, 60 Hz, 30Amp.

The ratings above are for reference only - refer to the range

rating label (see page 3).

Freestanding ranges equipped for use in Canada come pre-

wired with a 4 wire appliance

cord and NEMA 14-50P plug.

Do not modify the factory

wiring. The plug is designed

to plug directly into a NEMA

14-50R electrical receptacle

installed by a licensed

electrician according to the

above specifications.

Total Connected Load

5.6 kW (24.2 Amp.)

NEMA 4-50R Receptacle

Gas Supply Requirements

(All units)

• Check your local building codes for the proper method of

installation. In the absence of local codes, this appliance

should be installed in accordance with the National Fuel Gas

Code ANSI Z223.1.

Be certain that the appliance being installed is correct for

the gas service provided (natural gas or LP gas). Also, if

operating the range at an altitude above 4000 ft. (1219 m)

make sure it is equipped for high altitude operation. Refer to

the range rating label and the table on page 3 to determine

the correct model.

• See the table below for gas supply pressure requirements.

• The regulator inlet accommodates a 3/4" gas line. The range

ships with a 1/2" to 3/4" adapter connected to the regulator.

GAS SUPPLY PRESSURE REQUIREMENTS

Gas Manifold Min. Gas Supply Max. Input

Type Pressure* (WC) Pressure (WC) Pressure

Natural 5 6 1/2 p.s.i.

LP 10 11 1/2 p.s.i.

The ratings above are for reference only - refer to the range rating

label (see page 3).

Page 7

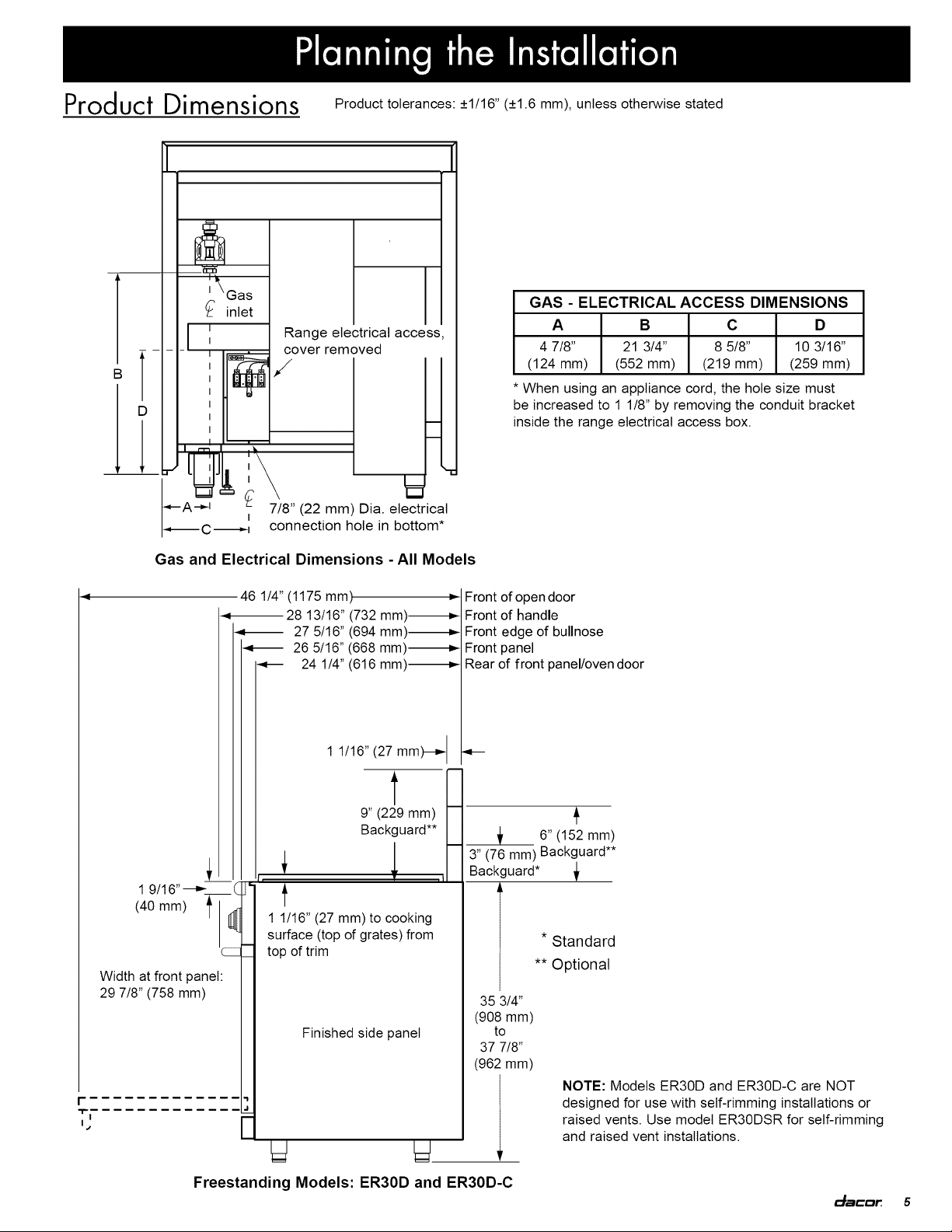

Product Dimensions Product tolerances: +1/16" (+1.6 mm), unless otherwise stated

1

,4

l\Gas

_' inlet

_ _ Range electrical access,

, ,_ cover removed

B

A-_l i 718" (22 mm) Dim. electrical

___C._,_ connection hole in bottom

Gas and Electrical Dimensions -All Models

46 1/4" (1175 mm)

28 13116" (732 mm)-_

27 5/16" (694 mm)-_

26 5/16" (668 mm)-_

24 1/4" (616 mm)-_

GAS - ELECTRICAL ACCESS DIMENSIONS

A B C D

4 7/8" 21 3/4" 8 5/8" 10 3/16"

(124 mm) (552 mm) (219 mm) (259 mm)

* When using an appliance cord, the hole size must

be increased to 1 1/8" by removing the conduit bracket

inside the range electrical access box.

i,

Front of open door

Front of handle

Front edge of bullnose

Front panel

Rear of front panel/oven door

1 9/16" _

(40 mm) t (_

Width at front panel:

29 7/8" (758 mm)

f_

"r I

1 1/16" (27 mm)--_

t

9" (229 mm)

Backguard**

3" (76 mm) Backguard**

i

l,

J' I

1 1/16" (27 mm) to cooking

surface (top of grates) from

top of trim

Finished side panel

]

E

Freestanding Models: ER30D and ER30D-C

Backguard* i

35 3/4"

(908 mm)

37 718"

(962 mm)

#

6" (152 mm)

* Standard

** Optional

to

NOTE: Models ER30D and ER30D-C are NOT

designed for use with self-rimming installations or

raised vents. Use model ER30DSR for self-rimming

and raised vent installations.

_BCD_

Page 8

Product Dimensions (continued)

Product tolerances: +1/16" (+1.6 mm), unless otherwise stated

NOTE: Self-rimming models are not compatible with Dacor

integral backguards.

NOTE: Self-rimming models are designed to allow the trim to

overlap the countertop when configured to the dimensions on

page 8.

1 9/16" _(

(40 mm) f

Width at front panel:

29 7/8" (758 mm)

-i,,,-I

45 5/8" (1159 mm) -_

28 3/16" (716 mm) -_

11/16" (678 mm)-_

11/16" (652 mm)-_-

(600 mm) -_

1/8" (587 mm)

Front of open door

Front of handle

Front edge of bullnose

Front panel

Rear of front panel/oven door

Rear of front panel to

back of chassis

i

15/16" (33 mm) to cooking

(top of grates) from

bottom of trim

35 3/4"

(908 mm)

to

37 7/8"

(962 mm)

Self-Rimming Model ER30DSR

with Standard Trim

Width at front panel:

29 7/8" (758 mm)

-i- I

I#

46 1/8" (1172 mm) -_

'- 28 11/16" (729 mm)-_

26 3/16" (665 mm) -_

24 1/8" (613 mm) -_

_ 27 3/16" (691 mm)

_-- 231/8" (567 mm) ----_

J _. 1_/16"(33mm)tocooking /

Front of open door

Front of handle

Front edge of bullnose

Front panel

Rear of front panel/oven door

Rear of front panel to

back of chassis

surface(topofgrates)from --I

- bottom of trim i2

/

35 3/4"

(908 mm)

to

37 7/8"

(962 mm)

P __

U

Self-Rimming Model ER30DSR

with Optional Raised Vent Trim Kit (ATK30SR) Installed

6 _SCD_

Page 9

Cabinet Layout

• Carefully check the location where the range is to be

installed. For best performance, the range should be placed

away from drafts that may be caused by doors, windows and

heating and air conditionJng outlets.

• To reduce the risk of personal injury and to reduce

accumulated smoke in the room, Dacor strongly recommends

JnstalNnga range hood. A range hood should project

horizontally a minimum of five (5) inches beyond the face of

the cabinets.

• All maximum and minimum dimensions and clearances

shown in the diagram below and on page 8 (as applicable)

must be maintained for safe operation.

• In the freestanding configuration, the range may be installed

flush to the rear walt. For all installations, Dacor highly

recommends installing a non-combustible material on the rear

walt above the range and up to the vent hood or installation

of a backguard. It is not necessary to install non-combustible

materials behind the range below the countertop height.

• Any openings in the walt behind the appliance or in the floor

underneath it must be sealed.

Cutout tolerances: +1/16" (+1.6 mm), -0

Gas and Electrical Service

• The shaded area shown denotes the location of the gas

inlet and the electrical junction box/receptacle. This is the

recommended location. For replacement purposes, the

location of the existing utilities may be utilized provided they

do not interfere with the sides or rear of the range. Check

local building codes for permissible gas valve locations.

• An external manual shut-off valve must be installed between

the gas inlet and the range for the purpose of turning on or

shutting off gas to the appliance.

The installation must allow for the following:

• Access to the gas shut-off valve when the unit is installed.

• Access to the remote circuit breaker panel or fuse box, when

the range is in place.

• The gas supply piping, gas shut-off valve and the electrical

junction box or receptacle must be located so they do not

interfere with the range when it is installed.

• The junction box and gas shut off valve must be located

so that the range can be pulled out for service while the

appliance remains connected.

13" (330 mm)

Max. 4

18" (457 mm):

36 1/2"

(927mm)

Max.

Min.1,4

Non-combustible

surface along

recommended

30" (762 mm)

Min.1

Hood

finished

counter

back wall

Suggested

location of

utilities 3

Vertical to combustible surface from range grate level; if

installing an overhead vent hood, also check the hood

specifications for minimum required clearances.

2 Cabinet/countertop depth is at discretion of customer but

cabinet face MUST NOT protrude further than rear of front

panel, see product dimensions.

3 Consult local code for exact location requirements.

4 Not applicable for cabinets more than a horizontal

distance of 10" (254 mm) from the edge of the range.

FREESTANDING CUTOUT

36" (914 mm)* 30 1/16" (764 mm)*

30" (762 mm)**

See following page for self-rimming cutout

dimensions.

10"(254mm)Min.

combustibleside

wallsabovethe range

(both sides)

DIMENSIONS

F G

* Recommended

** Minimum

Freestanding Cabinet Cutout Dimensions -

Models ER30D and ER30D-C

dacar 7

Page 10

Cabinet Layout (continued)

Non-combustible

rear wall recommeded

_ Combustible side _ ]i_ ' '

10" Min.\ 1/4" Min. (6 mm)

(254 mm) _ Countertop

both sides _ o_erhang

wallaboverange I

-_29 1/2" (749 mm)_ I _ I

countertop opening I ""-.I

30" (762 mm)_ ] H J K

cabinet opening I I

below countertop I I

/

Countertop Height: Min: 35 5/8" (905 mm) Max: 37 3/8" (949 mm)

Top View - Model ER30DSR - Counter/Cabinet Cutout

Dimensions for Self-Rimming Installation

Cabinet face I \ I

below countertop _ _

Notch countertop _1 I

overhang to width of

cabinets Countertop front

APPROVED RAISED VENT MODELS: Use onlv Dacor model

ERV30 or PRV30.

10" Min.-.. 3/8" Min. (10 mm)

Non-combustible (254mm) "_ Countertop

rear wall recommended

"_" _30" (762 mm) .J I | |

__ _ __/___ _ __

. ,. Notchcountertop

Countertop Height: Min: 35 5/8" (905 mm) Max: 37 1/4" (946 mm)

Dimensions - Self-Rimming Installation with Raised Vent

\

I _27 1/2" (699 mm)_ _ f 2 3/8" (60 mm)

raised vent opening - lift

29 1/2"(749 mm) - I / /

countertopopening 4,_ / /

cabinet opening _ [ H J

_Combustible side_ I

wall above range _ | I

_ belowcountertOPbelowcountertop _ _'__ "/llli*

Top View - Model ER30DSR - Counter/Cabinet Cutout

Cabinetface --. I _ I

overhangto width of

bothsides _ overhang

cabinets Countertop front

Notes For All Self-Rimming Installations:

• On installations without a raised vent (see above), when

sliding the range into position, it will stop when the rear of

the control panel contacts the notches toward the front of the

countertop The range trim will partially cover the overhang in

back

On installations with a raised vent (see above right), install

Dacor trim kit ATK30SR When sliding the range into position,

it will stop when the rear of the control panel contacts the

notches toward the front of the countertop The range trim will

partially cover the front of the raised vent chassis in back

Preparing for Installation

IMPORTANT: Within the Commonwealth of Massachusetts, this

appliance must be installed by a licensed plumber or gas fitter

NOTE: When installing a backguard, always install it before

sliding the range into place See page 9

ER30DSR with H J K

no side panels no 23 1/2" 23 1/2" 24" to

raised vent (597 mm) (597 mm) 25 9/16"

3-inch side panels* 20 1/2" 20 1/2" to 21" to

and no raised vent (521 mm) 23 1/2" 25 9/16"

no side panels and 24" 24" 24 1/2" to

raised vent (610 mm) (610 mm) 26 1/16"

3-inch side panels 21" 21" to 24" 21 1/2" to

and raised vent (533 mm) 26 1/16"

Optional side panels (PN ARSP3) cover unfinished chassis sides

when the cabinet face is recessed behind back of control panel.

Parts List

• 2 grates

• 1 small stack burner cap

• 1 small stack burner ring

• 2 large stack burner caps

• 2 large stack burner rings

• 1 crown burner cap

• 1 crown burner ring

• 1 crown burner head

• 1 GlideRack TM oven rack

See the use and care manual for a list of optional accessories.

• 2 standard size racks

• 4 knobs

• Anti-tip bracket w/screws

• Meat probe

• Griddle

• Wok ring

• Stainless steel cleaner

• Literature kit

• Broiler pan/grill

Unpacking the Range

Unpack the range and verify that all required parts have been

provided If any item is missing or damaged, please contact

your dealer immediately Do not install a damaged or incomplete

appliance The customer must report cosmetic issues within 30

days of installation

8 _SCD_

Page 11

Changing the Backguard (models ER30D

and ER3OD-C only)

Models ER30D and ER30D-C come standard with a 3" backguard

installed• The 6" and 9" backguards are optional•

To change the backguard:

1. Remove and retain the three (3) chrome screws on the front

of the existing backguard.

2. Remove and retain the two (2) upper screws on the back of

the side panels.

3. Slide the existing backguard off the unit.

Installing the ATK3OSR Raised Vent Trim

(model ER3ODSRonly)

To install the optional raised vent with self-rimming model

ER30DSR, you must install the optional raised vent trim kit.

To change the trim on model ER30DSR:

1. Remove and retain the seven (7) chrome screws that hold

the existing trim pieces in place.

2. Slide the existing trim pieces off the range.

Kit

4. Place the new backguard over the back of the range.

5. Fasten the backguard using the five (5) existing screws.

New backguard,

height varies

3. Slide the new trim pieces onto the range•

4. Fasten the new trim pieces in place using the existing screws•

Installing the ARSP3 3-Inch Side Panel Kit

(model ER3ODSRonly)

For self-rimming installations with non-standard countertop

depths, installation of the optional side panel kit may be necessary

to cover the sides of the range that protrude from the cabinet.

To install the side panel kit:

1. Open the oven door. Remove and retain the two (2) screws

on the top of the kick panel. The screws are accessed

through the space between the door and the oven opening.

Space between

door and oven

opening _ Remove and

\

retain screws

Continued...

dacar 9

Page 12

ARSP3 Side Panel Kit Installation (cont.)

2. Close the door. Remove and retain the two screws from the

back of the kick panel as shown below. Pull the kick panel

free from the front of the unit.

/

Kick panel

3,

Remove the left end cap retaining screw from under the rim

of the control panel and remove the end cap.

Remove and

retain screw,

both sides

8,

Insert the tabs on the trim piece into the slots on the range.

6.

Use the hex head screw (83023) removed from the side, a

Torx head screw removed from the kick panel and the hex

screws from the kit to attach the side panel to the range.

Three (3) hex head screws attach the side. One (1) Torx head

screw (83709) inserts through the end cap hole to attach

the top of the side panel. One (1) Torx head screw (83709)

inserts through a hole in the front panel to attach the bottom

of the side panel.

Hex screw

Side panel

Hex screw

\

Hex screw Torx screw

4,

Hold the left side panel in position on the side of the range.

Locate the center mounting hole. Remove and retain the

screw attached to the chassis beneath it.

Side panel

Center mounting

hole

Front panel

7. Reinstall the end cap.

8,

Repeat steps 3 to 7 for the right side panel. NOTE: There is

an additional hex screw (83023) in the kit for the right side

panel because the center mounting screw is not reused as

with the left side (do not perform step 4).

Left side only:

Remove and

reuse this screw.

10 _::_acar

/

Page 13

9. With the door closed, reattach the kick panel to the range

by snapping the ball studs on the back of the panel into the

holes on the front panel of the range.

Level and Adjust the Range Height

Raise or lower the range to prepare for final installation:

• For model ER30D and ER30D-C, adjust the height until the

top edge of the trim around the edge of the of the cooktop is

slightly higher than the countertop.

• For model ER30DSR, raise the range until the bottom edge

of the trim around the edge of the of the cooktop is 118"

higher than the countertop.

10. Open the door and reattach the kick panel top screws

removed in step 1.

Space between

door and oven

opening ,Reattach kick panel

existing screws

Rear leg

2 1/8" *

up

_,,_ _ * Distance to floor:

down

Back of range

2 7/16" to 4 9/16"

Install the Anti-Tip Bracket and Foot

1. Locate the anti-tip foot and lower it until it is 1/16" (2 mm) off

the floor.

Back of

" , l rang_e

I Ilml.

IJII IJI,./Anti-tip

_" foot

2. Locate the anti-tip bracket included in the parts box.

Installing a Raised Vent (Optional)

Install the ERV30 or PRV30 raised vent before final installation

of the range. See the raised vent installation instructions, part no.

65335.

IMPORTANT: The ERV30 or PRV30 raised vent attaches to the

narrow back portion of the raised vent/range cutout. It is self-

supporting in the cutout and does not actually attach to the range

itself.

Back of

range

3,

Install the anti-tip bracket on the floor using the four (4)

included screws. See the diagram above for location.

ANTI-TIP BRACKET PLACEMENT

A 6 5/8" (168 mm)

B 6 3/8" (162 mm)

Right side

of range

/

_:_ac.ar 11

Page 14

Removing the Oven Door Electrical Connection

To make the range easier to move, remove the door to reduce

weight.

1. Open the door to its fully opened position.

2. Rotate the catch over the retaining arm on each hinge.

NOTE: Freestanding model ER30D-C is wired for use in Canada

and comes from the factory pre-wired. If installing a pre-wired

range, skip to Gas Supply Connection on page 17.

Retaining arm

3. Lift the oven door to about a 15° angle from the vertical

position.

4. Hold the door with both hands just below the handle and pull

it away from the oven while continuing to lift.

Door Gripping Points

Put slack in

electrical wiring

and gas line

IMPORTANT:

• Make sure that the conduit or appliance cord is tong enough

to allow the range to be pulled out for service without

disconnecting it from power.

• Do not disconnect any of the wires inside the range electrical

box unless instructed to do so.

Electrical access cover

Back

range

12 =::_acar

k]

i _ i[[

Page 15

Connecting the Wiring to the Range

Refer to the range rating label (see page 3) for power

requirements.

There are four possible ways to wire the range:

• 4 wire conduit

• 3 wire conduit (where local codes permit)

• 4 wire appliance cord (where local codes permit)

• 3 wire appliance cord (where local codes permit)

The sections below and on the following pages give directions for

connecting each type of wiring harness.

Connecting Conduit to the Range

NOTE: See pages 16 and 17 for instructions to connect an

appliance cord to the range.

1. Remove the range electrical access cover from the back of

the range.

L1 terminal

Neutral terminal _ _,

Jumper link

L2 terminal

Black wire

White wire

Red wire

Conduit strain

relief nut

,, o_o,%o

O 'O 0

I I-

t t

2. If using a 4 wire connection, loosen the grounding screw and

remove the neutral to ground jumper link.

3. Remove the nut from the conduit strain relief (not included).

4. Slide the wires and the end of the strain relief into the hole on

the bottom of the range electrical box.

5. Before connecting the wires, slide the strain relief nut over

the wires and thread it onto the conduit strain relief inside the

box. Tighten into place.

6. Connect the white wire to the neutral terminal in the box.

7. Connect the black wire to the L1 power supply terminal.

8. Connect the red wire to the L2 power supply terminal.

9. If using a 4 wire connection, connect the green wire to the

grounding screw inside the box.

10. Replace the range electrical access cover.

Bare wire

connections

3 Wire Conduit Connection -

Where Local Code Permits

L1 terminal

Neutral terminal

L2 terminal --..

Link removed

Grounding screw

Red wire --

Green wire --

White wire

Black wire

Conduit strain

relief nut

o,_ o,% o

o ' _o ,o

t

t

O

Loop and

spade terminal

connections

4 Wire Conduit

Connection

t

_BCD_ 13

Page 16

Electrical Connection

(Continued)

Connecting the Conduit to the House

Electrical Junction Box

IMPORTANT: The power supply must be properly polarized•

Reverse polarity wilt result in continuous sparking of the

electrodes, even after flame ignition• If there is any doubt as to

whether the power supply is properly polarized or grounded, have

it checked by a licensed electrician•

1. With the range positioned directly in front of the cabinet

cutout, feed the appliance wires into the junction box.

Depending upon local codes, utilize one of the three (3)

methods shown to connect the appliance to the junction box.

2. Connect the white wire from the appliance to the neutral

(white) supply wire in the junction box.

3. Connect the black wire from the appliance to the black (L1)

power supply wire in the junction box.

4. Connect the red wire from the appliance to the red (L2) power

supply wire in the junction box.

5. If using a 4 wire connection, connect the green wire to a

grounded supply wire in the junction box or to a grounded

cold water pipe. If connecting to a grounded cold water pipe:

0 Use a separate copper grounding wire (No. 10 minimum)

to connect to the cold water pipe by means of a clamp

and an external grounding connector screw•

0 If there are any materials that isolate the cold water pipe

from ground, jumper it with a No. 4 copper wire, clamped

on both ends.

6. Replace the junction box cover•

Connection to

power supply

Junction box

RED

[_RED

.WHITE

•WHITE

BLACK _ /

BLACK

'-t

Connection to appliance

(Page 13)

3 Wire Conduit Connection

to Junction Box

Connection to

power supply

Junction box

RED

WHITE

Wire nut

3 places

/

Wire nut

4 places

14 I::_acar

Connection to appliance

(Page 13)

4 Wire Conduit Connection

to Junction Box

Page 17

Connection to

power supply

Junction box

Connection to appliance

(Page 13)

Separate No. 10 (minimum)

copper grounding wire

Wire nut

4 places

4 Wire Conduit Connection to Junction Box

with External Ground

Metal

water pipe

No. 4

copper wire

Meter

Clamps

Bare

metal

Insulated Pipe Jumper

_::_acar 15

Page 18

Electrical Connection (Continued)

Appliance Cord Connections - Where

Local Code Permits

1. Remove the range electrical access cover from the back of

the range.

2. If using a 4 wire connection, loosen the grounding screw and

remove the neutral to ground jumper link.

3. Remove the conduit bracket from the bottom of the range

electrical box.

5.

Slide the end of the appliance cord into the strain relief from

the bottom of the box.

6.

Connect the white (neutral) wire to the neutral terminal in the

box.

7.

Connect the L1 wire to the L1 power supply terminal in the

box.

8.

Connect the L2 wire to the L2 power supply terminal in the

box.

9.

If using a 4 wire connection, connect the ground wire to

the grounding screw inside the box using a loop or spade

terminal.

10. Tighten the strain relief so that the appliance cord is held

snuggly in place.

11. Replace the range electrical access cover.

L1 terminal

Neutral terminal _

L2 terminal

Jumper link _

Remove link on

4 wire installations

I I

Remove conduit II I o

bracket before strain - "-_"'_11 _'5--

relief installation _

4.

Disassemble and remove the strain relief from the appliance

cord (not included). Insert the tabs on the two parts of

the strain relief into the hole on the bottom of the box and

reassemble it so that the tabs are below the box and the

strain relief itself is inside the box.

Strain relief

/

/

/

L1 wire

White wire

L2 wire

Strain relief

3 Wire Appliance Cord

Connection -

Where Local Code Permits

L1

Neutral

Bottom of range

electrical box

16 _::_acar

/

/

Reassemble with tabs

below and clamp above

L2

10-50P Plug

Page 19

Bare wire

connections

Loop and

spade terminal

connections

L1 terminal

Neutral terminal

L2 terminal

Link removed _ I =

Ground screw _ --_ (_

L2 wire

Green wire

White wire

Strain relief

o

4 Wire Appliance

Cord Connection

L2

L1 wire

Gas Connection

NOTE: The gas pressure regulator is pre-set at the factory for

the type of gas intended for use with the appliance. To verify that

the appliance is compatible with the type of gas available, check

the range rating label (see page 3 for location). Ranges intended

for use with LP gas wilt have "LP" as a part of the model number.

Consult your dealer if the range is not compatible with the type of

gas supplied.

1. Make sure the gas supply valve is in the off position and

power to the range is off.

2. Connect a flexible gas supply line to the gas shut-off valve

previously installed on the stub out. The gas line needs to be

long enough to allow the range to be pulled out for service.

3. Slide the gas line up through the access holes in the chassis

and up to the regulator. Move the wires around inside the

access holes to prevent them from catching on the gas line

as you push it up.

4. Connect the gas line to the regulator.

5. Turn all cooktop

Neutral

/

L1

14-50P Plug

Ground

OFF position,

control valves to the 1Ill

OFF Icon conne

_ _ Regulat°cti°_l

supply and check all

6. Turn on the gas lolesI II/

for leaks using a soap Gas

and water solution, line II j l

7. Turn the gas shut-

lines and connections _]_. __ of rangej_

off valve to the OFF _][[

position.

,ccessI I I/

_::_acar 17

Page 20

Final Installation

1. Peel the protective plastic coating off of the range, including

the range door.

2. Carefully slide the range into position in the cutout. The rear

anti-tip leg should engage the anti-tip bracket.

3. On self-rimming installations, reach under the range and

adjust the legs, lowering the range until the trim just makes

contact with the countertop on all three sides.

4. Use a level to make sure that the range does not tilt front to

back or side to side. Readjust the legs if necessary.

Re-installing the Oven Door

1. Grasp the oven door on opposite sides and hold it at a 15°

angle from the front of the oven. Slide the hinges into the

hinge openings, resting the bottom of the hinge arms on the

hinge receptacles. Continue to hold the door at a 15° angle

with one hand while pushing in on each of the bottom corners

of the door. Push until the notch on the bottom of each hinge

slips over the lower tip of each hinge receptacle.

2. Lower the door to the fully opened position.

3. Rotate the two hinge locks toward the oven.

4. Slowly and carefully open and close the door completely to

ensure that it is properly installed.

5. Remove any packaging from inside the oven.

Installing the Burner Knobs

There are two (2) different types of knobs supplied with the range.

The knobs for the right burners have the words "MAX GRIDDLE"

on them.

NOTE: When installing the knobs, align the "D-shaped" opening

on the back of the knob with the end of the valve shaft. Carefully

push the knob on until it stops.

• Put the knobs with the words "MAX GRIDDLE" on them onto

the right valve shafts.

• Put the remaining knobs on the left valve shafts.

Icons on Left Burner Knobs

18 =::_acar

// : \

Notch on bottom _1 Lower tip

of hinge _ i_.j _ of hinge

J / receptacle

, --.,jj //

Door Installation

Icons on Right Burner Knobs

Page 21

Cooktop Assembly

Remove the burner rings, burner caps and grates from their

shipping packages.

• Install the burners as shown.

• Gently set the grates on top of the spill tray. Put the legs of

each grate inside the corresponding dimples.

Ridge on

bottom of

burner cap

STEP 3: Install burner

cap. Ridge on cap must

surround top of ring.

Spilt tray

Stack burner

Crown burner

STEP 2: Install

burner ring. Line up

ring tabs with head

slots. Twist back

and forth to assure

proper seating.

STEP 1: Install

burner head. Put

locating tab in

keyed hole.

Burner ring

Burner head

Burner base

) eyed

hole

STEP 3: Install burner

caps. Ridge on cap must

surround top of ring.

STEP 2: Turn ring until

it drops into place. Twist /,'f_

bpa:ka nde_ti_hg.t° assureTr_ Berner

STEP 1: Put burner _"

ring on top of head. "__

/L Y'

"_ -- J Burner

Crown Burner Installation Stack Burner Installation

Ridge on

bottom of

burner cap

ring

head

_::_acar 19

Page 22

Verifying Proper Operation

Before operating the range, read the accompanying use and care

manual completely.

1. Before beginning the test procedure, ensure that all cooktop

control valves are in the OFF position, and all burner rings,

burner caps and grates are properly positioned on the

cooktop frame. Turn on the gas supply at the shut-off valve.

2. Plug Jnthe appliance cord, if applicable. Turn on power to the

range at the circuit breaker or fuse box.

3. Set the time of day: Press the clock key. Enter the time on

the number keypad (within 6 seconds). Press START.

4. Press the BAKE key.

5. Enter the temperature of 350°F on the keypad.

6. Press START.

7. The display should show BAKE, and the preheating

temperature.

8. Press the CANCEL-SECURE key to stop the oven heating

process.

g. Test one of the burners by pushing the knob in and turning it

counterclockwise to the NIGH position. It may take up to four

seconds for ignition to occur, at which time the ignitor wilt stop

sparking. If ignition does not occur within four seconds, turn

off the knob, wait for at least five minutes to allow any gas to

dissipate, then repeat the ignition test. After ignition, rotate

the control knob counterclockwise

from HIGH to LOW to adjust the

flame height progressively. When

the range is installed properly, the

flame wilt be steady and quiet.

Itwilt also have a sharp, blue

inner cone that wilt vary in length

proportional to the burner size.

Dacor's Smart Flame TM feature

reduces the flame under the grate

fingers to increase grate life. If the

range is equipped for use with LP

gas, the ends of the flame may be yellow at the

tips, which is normal.

10. Turn the control knob to the OFF position.

11. Repeat the ignition test for all remaining burners.

If either the oven or cooktop does not operate properly, follow

these troubleshooting steps:

1. Verify that power and gas are supplied to the range.

2. Check the electrical connections and gas supply to ensure

that the installation has been completed correctly.

3. Repeat the above bake test or burner ignition test.

4. If the appliance still does not work, contact Dacor Distinctive

Service at (877) 337-3226. Do not attempt to repair the

appliance yourself. Have the model and serial numbers

available when you call. See page 3 for location.

Dacor is not responsible for the cost of correcting problems

caused by a faulty installation.

Normal Flame

OFF Icon

Installation Checklist

Has the plastic coating been peeled off of the outside of the

range? Have all packaging materials been removed from

inside the oven?

[] Are all leveling legs extended down to make contact with the

floor? Is the unit level? See page 11.

[] Is the range secured in place with the provided anti-tip

bracket and foot according to these instructions? See page

11.

[] If the walt in the back of the cooktop combustible, is a

backguard or raised vent installed?

[] Is the range wired and grounded according to these

instructions and in accordance with all applicable electrical

codes? Has the electrical access cover been replaced? See

Pages 4 and 12 to 17.

[] Has the gas supply inlet pressure been measured to ensure

that it does not exceed the maximums stated in these

instructions? See page 4.

[] Is the range connected to the gas supply according to these

instructions and in accordance with all applicable codes? See

page 17.

[] Did the installer check the gas supply for leaks?

[] Is the oven door properly installed according to these

instructions? See page 18.

[] Have the burner knobs been installed in the proper positions?

See page 18.

[] Are the burners and grates properly installed according to

these instructions? See page 19.

[] Has proper operation been verified?

[] Has the warranty been activated on-line or the warranty card

been filled out completely and mailed?

20 =::_ac.al:

Page 23

• • • •

Family Owned

The Life of the Kitchen?

Dacor • 600 Anton Blvd. Suite 1000 Costa Mesa, CA 92626 • Phone: (800) 793-0093 • Fax: (626)403-3130 • www.Dacor.com

American Made

Loading...

Loading...