Page 1

Installation Instructions

Wall Ovens

SAVE AND READ THESE INSTRUCTIONS

TESTED IN ACCORDANCE WITH THE LATEST EDITION OF UL858 STANDARD FOR HOUSEHOLD ELECTRIC

COOKING APPLIANCES.

CONVENTIONS USED IN THESE INSTRUCTIONS

WARNINGS:

Must be followed carefully to avoid personal injury or damage.

NOTES:

Contain helpful hints and tips to facilitate the installation.

IMPORTANT

1. Before beginning installation, please thoroughly read and become familiar with these instructions.

2. Installation and service must be completed by a qualified installer or service agency.

3. Installer: Please leave these Installation Instructions with the owner.

4. Owner: Please keep these instructions for local electrical inspector’s use and for future reference.

5. Read the accompanying Use & Care Manual prior to operating this appliance.

TABLE OF CONTENTS

STEP 1 Package contents verification Page 2

STEP 2 Installation Planning Pages 2-3

STEP 3 Installing the support platform in the cabinet Page 3

STEP 4 Electrical power supply requirements Pages 3-4

STEP 5 Removing the oven door(s) Page 4

STEP 6 Turning of the power supply Page 4

STEP 7 Electrical connection Pages 4-5

STEP 8 Mounting the oven Pages 5-6

STEP 9 Installing the exhaust grill Page 6

STEP 10 Re-installing the oven door(s) Page 6

STEP 11 Verifying oven operation Page 6

Part No. 65030 Rev. C

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNINGS:

To reduce the risk of burns,

electric shock, fire or injury to

persons:

1. Read all instructions before

using the appliance.

2. This appliance must be

grounded. Connect only to a

properly grounded outlet. See

“Grounding Instructions” on

pages 4-5.

3. Install or locate this appliance

only in accordance with these

installation instructions

4. Use this appliance only for

its intended use as described

in this manual. Do not use

corrosive chemicals or vapors

in this appliance. This type of

oven is specifically designed

to heat and cook dry food. It is

not designed for industrial or

laboratory use.

10. Do not immerse the electrical

cord or plug in water.

11. Keep the electrical cord away

from heated surfaces.

NOTES:

1. Some products, such as whole

eggs, and sealed containers

such as closed glass jars may

explode and should not be

heated in this oven.

2. To reduce the risk of fire in the

oven cavity: Do not overcook

food. Carefully attend the

appliance if paper, plastic or

other combustible materials

are placed inside the oven to

facilitate cooking.

3. If materials inside the oven

should ignite, keep the oven

door closed, turn the oven

off and shut off the power at

the fuse or the circuit breaker

panel.

5. As with any appliance, close

supervision is necessary

when used by children.

6. Do not operate this appliance

if it has a damaged electrical

cord or plug. if it is not

working properly or if it has

been damaged or dropped.

7. This appliance should be

serviced only by qualified

service personnel. Contact the

nearest DACOR Authorized

Servicer at (800) 772-7778.

or at www.dacor.com for

examination, repair or

adjustment.

8. Do not cover or block any

openings on the appliance.

9. Do not store or use this

appliance outdoors. Do not

use this product near water

– for example, near a kitchen

sink, in a wet basement or

near a swimming pool, etc.

1

Page 3

Verifying the Package Contents

1 1/2" (38mm)

Typical counter top

36"

(915mm)

"A"

"C"

"B"

1

"D"

3"

4"

Electrical

access

3/4" (19mm)

Support platform

(flush with cutout)

1" (25mm) Minimum

to combustible floor

1

3/4" (19mm)

Support platform

(flush with cutout)

Recommended

electrical

access

1" (25mm) Min.

clear to top of

doors for heat

exhaust

9 5/8"

(244mm)

Recommended

(may be altered)**

"B"

3"

4"

"A"

24"

(610mm)

Minimum interior

cabinet depth

"D"

Alternate

electrical

access

2

31 1/4"

(794mm)

Recommended

(may be altered)

"B"

3"

24"

(610mm)

Min. interior

cabinet depth

"A"

3/4" (19mm)

Support platform

(flush with cutout)

4"

"D"

Alternate

electrical

access

1" (25mm) Min.

clear to top of

doors for heat

exhaust

1

2

Recommended

electrical

access

Verify that all required components have been

provided. If any item is missing or damaged,

please contact your dealer immediately. Do not

install a damaged or incomplete appliance.

• Mounting Screws

• Use & Care Videotape

• Oven Racks

• Broiler Grill and Pan

• Exhaust Grill/Lower Trim

• Rear Top Trim

Installation Planning

A qualified technician must complete the

installation of this built-in appliance. Proper

installation is your responsibility.

Carefully check the location where the oven is

to be installed. The oven should be placed for

convenient access, but away from drafts that

may be caused by doors, windows and HVAC

outlets. Make certain that electrical power can

be provided in the selected location.

Plan the installation so that all minimum

clearances are met or exceeded. Dimensions

shown provide minimum clearances, unless

otherwise noted. Be certain that proper

clearance is provided for the oven door when it

is in the open position.

The specified minimum cabinet depth and width

must be provided. The cabinet depth and width

must completely enclose the recessed portion of

the oven.

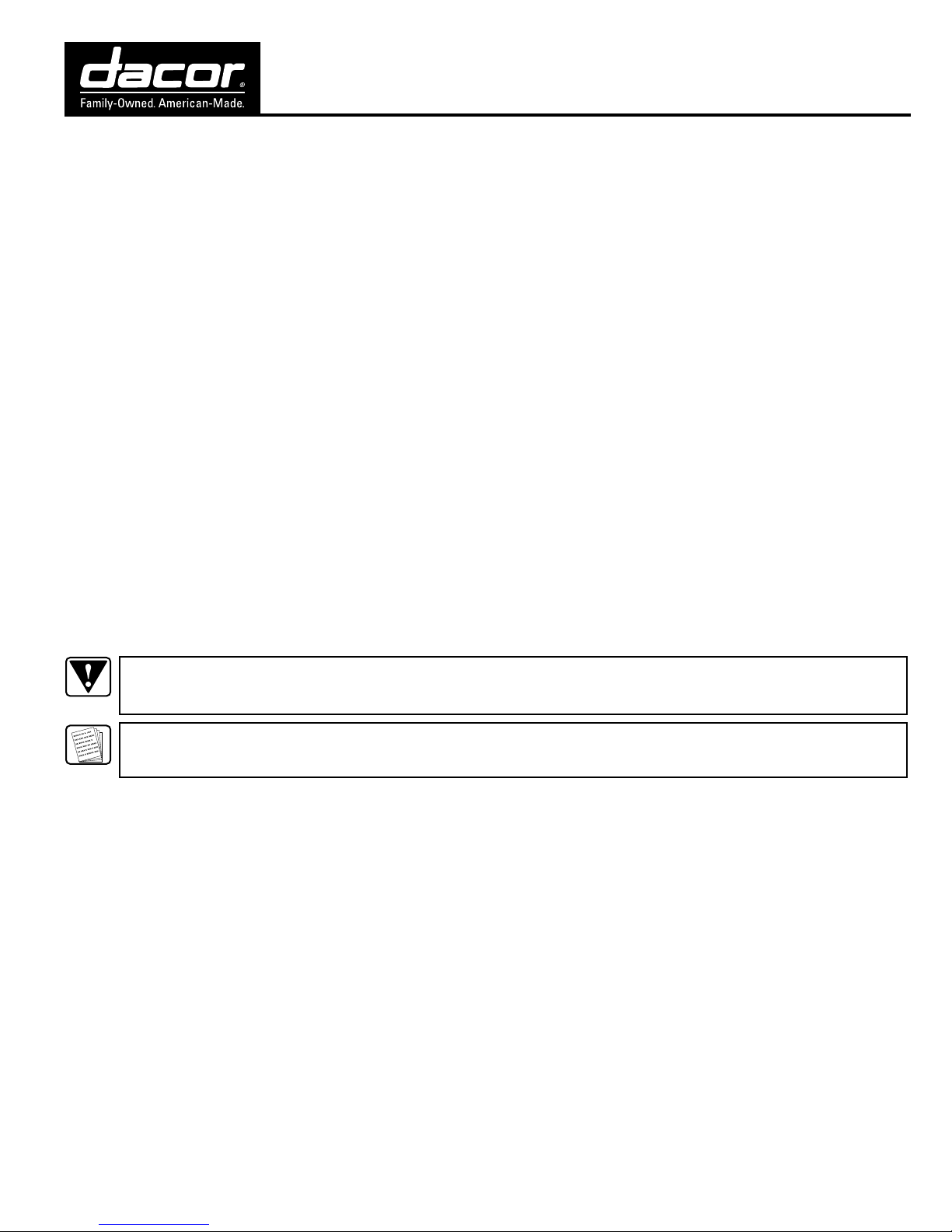

Dacor

Model Number

ECS127

MCS127

Cutout Width

“A”

25 1/2”

(648mm)

ECS130

PCS130

28 1/2”

(724mm)

MCS130

ECS136

34 1/2”

(876mm)

ECS227

MCS227

ECD227

25 1/2”

(648mm)

MCD227

ECS230

PCS230

MCS230

ECD230

28 1/2”

(724mm)

PCD230

MCD230

NOTE:

All dimensional tolerances are

+ 1/16”, - 0” unless otherwise

stated.

Cutout Height

“B”

27 3/8”

(695mm)

27 3/4”

(705mm)

49 1/16”

(1246mm)

Cutout Dimensions

Minimum Cabinet

Overall Depth

“C”

24”

(610mm)

Minimum Cabinet

Width

“D”

27”

(686mm)

30”

(762mm)

36”

(914mm)

27”

(686mm)

30”

(762mm)

Cabinet cutout dimensions must be used as

indicated. All contact surfaces between the

appliance and the cabinet must be solid and

level. The oven support platform must be flush

with the bottom edge of the cabinet cutout.

Make certain that you have everything

necessary to ensure a proper installation before

proceeding.

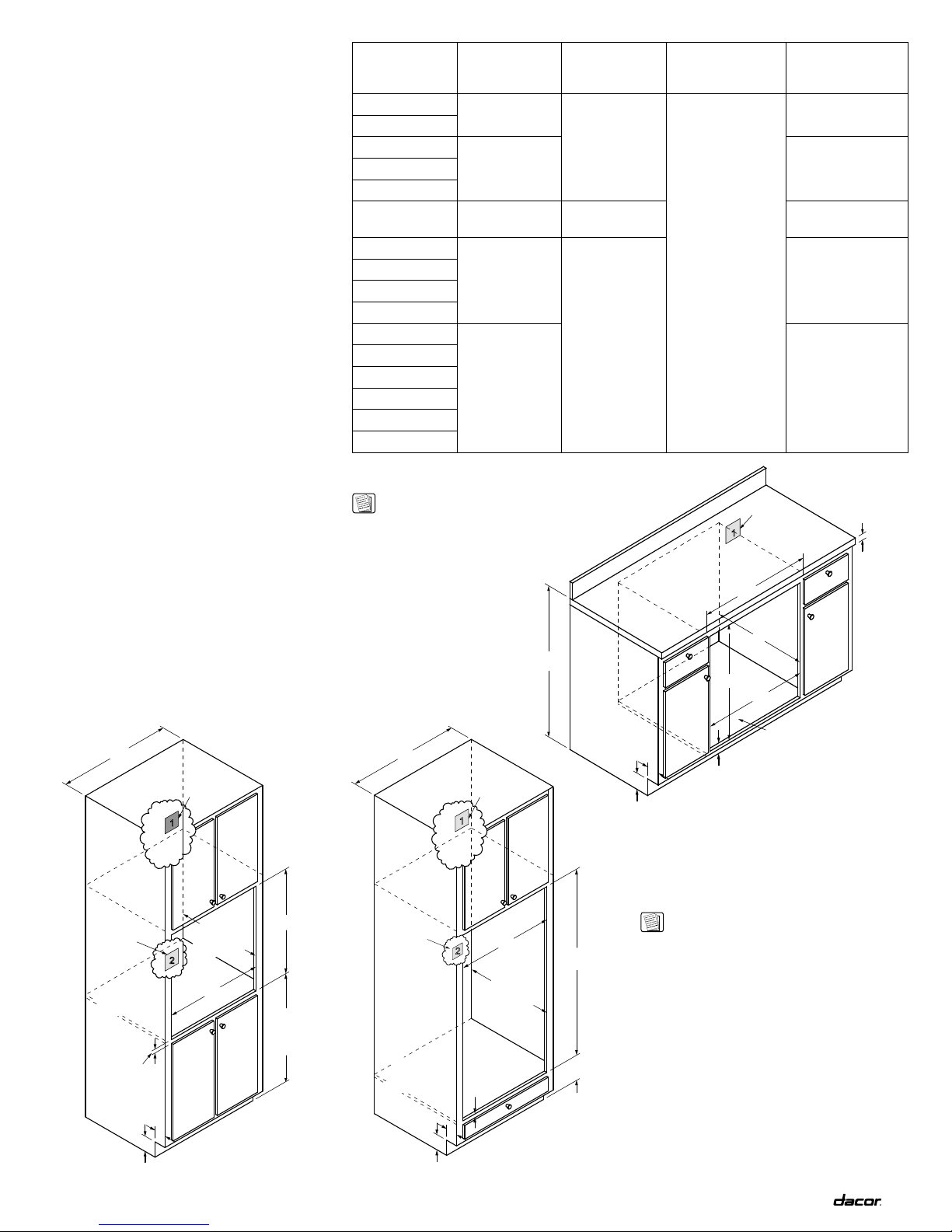

Single Wall Oven

Cutout Dimensions

Double Wall Oven

Cutout Dimensions

Single Wall Oven Installed under-counter

Cutout Dimensions

NOTE:

Electrical junction box may be

located:

1. Above the oven cutout, to the

right.

2. Below the oven platform, to

the right.

2

Page 4

Dacor

"E"

"F"

1"

(25mm)

"G"

"K"

Recess

1 5/16"

(33mm)

"H"

48 5/8"

(1235mm)

"J"

Rotating

elbow

60" (1524mm)

Flexible conduit

3/8"

(10mm)

"G"

"F"

1"

(25mm)

"K"

1 5/16"

(33mm)

"H"

"E"

"J"

60" (1524mm)

Flexible conduit

Rotating

elbow

3/8"

(10mm)

Cooktop

Regulator

Recess

3 5/8"

(92mm)

1"

(25mm)

EPICURE™

1"

(25mm)

MILLENNIA™

2 3/8"

(60mm)

PREFERENCE™

Model

Number

ECS127

MCS127

ECS130

PCS130

MCS130

ECS136

MCS227

MCS227

ECD227

MCD227

ECS230

PCS230

MCS230

ECD230

PCD230

MCD230

Overall

Width

“E”

27”

(686mm)

30”

(762mm)

36”

(914mm)

27”

(686mm)

30”

(762mm)

Overall

Height

“F”

28 3/8”

(721mm)

28 5/8”

(727mm)

49 15/16”

(1270mm)

Overall Dimensions

Chassis

Depth

“G”

23 7/8”

Recess

Width

“H”

5”

(127mm)

6 1/4”

(159mm)

6 3/8”

(162mm)

5”

(127mm)

6 1/4”

(159mm)

Recess

Height

“J”

Recess

Depth

“K”

5 1/4”

(133mm)8”(203mm)

Installing the Support Platform in

the Cabinet

Provide a platform within the cabinet upon which

the oven will be supported. The platform must

be installed level and straight. The top edge of

the platform must be flush with the cutout at the

front of the cabinet. There are no provisions to

level the oven after it has been installed. 3/4”

(19mm) thick plywood is recommended.

NOTE:

An oven that is not level may

provide poor or inconsistent

baking results.

Electrical Power Supply

Requirements

It is the owner ’s responsibility to ensure that

a qualified electrician performs the electrical

connection of this appliance. The electrical

installation, including minimum supply wire size,

must comply with the National Electric Code

ANSI/NFPA 70-1990* (or to the latest revision)

and local codes and ordinances.

*A copy of this standard may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

Overall Dimensions

Handle Projections

Single Wall Oven

(Epicure Shown)

Side View -

Double Wall Oven

Overall Dimensions

(Epicure Shown)

The correct voltage, frequency, and amperage

must be supplied to the appliance from a

separate, grounded, single phase circuit that is

protected by a properly sized circuit breaker or

time-delay fuse. If a time-delay fuse is utilized,

fuse both sides of the line (L1 and L2).

The required voltage, frequency and amperage

ratings are listed on the product data plate

(located inside the intake grill to the right of the

door latch) and in the Table on page 4.

WARNING:

If the electrical service provided

does not meet the product

specifications, do not proceed

with the installation. Call a

licensed electrician to correct.

NOTES:

1. Preheat times and cavity

temperature recovery times

will be increased slightly if

operating on a 120/208 volt

power supply.

2. 208V models should not be

connected to 240V source

power.

3. Power supply must be an

isolated circuit.

3

Page 5

Dacor

®

L

L

®

T

I

M

E

R

1

Hinge Catch

Lift door up to 30° angle, then

pull the door away from the oven.

To remove door, rotate

catch up.

30°

Model Number

ECS127

MCS127

ECS130

PCS130

MCS130

ECS136 n/a

ECS227

MCS227

ECD227

MCD227

ECS230

PCS230

MCS230

ECD230

PCD230

MCD230

Max. 208V

Connected Load

25 Amps

(5.2kW)

39 Amps

(8.1kW)

Electrical Requirements

NOTE:

The four (4) leads supplied with

this appliance are UL recognized

for connection to larger gauge

household wiring. The insulation

of these leads is rated at

temperatures much higher

than the temperature rating of

household wiring. The currentcarrying capacity of the conductor

is governed by the temperature

rating of the insulation around the

wire, rather than the wire gauge

alone.

Removing the Oven Doors

WARNING:

1. Do not attempt to disengage

the hinge catches with the

door removed from the oven.

The hinge springs could

release, causing personal

injury.

2. Do not lift or carry oven door

by the door handle

Max. 240V

Connected Load

22 Amps

(5.2kW)

29 Amps

(7.0kW)

34 Amps

(8.1kW)

Due to the weight of this appliance, removing

the door(s) will significantly reduce the lifting

load, while also providing the installer with a

place to grip the oven when lifting it into place.

Open the door to its fully opened position.

Rotate the catch over the retaining arm on each

hinge. Lift the oven door to about a 30˚ angle

from the horizontal. Pull the door away from the

oven while continuing to lift.

Power

Supply

208/240V

60Hz, 30A

208/240V,

4-wire,

60Hz, 40A

4-wire

Turning Off the Power Supply

Before attempting to connect the appliance to

power, turn off the electrical power supply. Also,

always turn off electrical power to the appliance

prior to servicing it.

WARNING:

Failure to disconnect power may

result in electrical shock or fire

hazard.

Electrical Connection

WARNING:

1. This appliance must be

connected to a grounded,

metallic, permanent wiring

system. Alternatively, a

grounding conductor should

be connected to the grounding

terminal or lead on the

appliance. Failure to do so

may result in an electrical

shock hazard.

2. Do not use an extension cord

with this appliance. Such use

may result in fire, electrical

shock, or other personal

injury.

3. Do not install a fuse in the

neutral or ground circuit. A

fuse in the neutral or ground

circuit may result in an

electrical shock hazard.

Grounding Instructions

The appliance must be connected to the

power supply with copper wire only. The use

of aluminum wire may result in unsatisfactory

connections. Flexible armored or non-metallic,

sheathed copper cable (with grounding wire)

should be used to connect the appliance to the

junction box. A UL-listed connector must be

used to directly connect the cable to the junction

box.

Be certain to locate the junction box such that

the electrical supply may be easily disconnected

in the event that service becomes necessary.

Also, provide extra slack in the cable to allow

the oven to slide forward for servicing.

This appliance must be electrically

grounded.

With the oven positioned directly in front of the

cabinet cutout, feed the appliance conduit to

the electrical junction box. Then, depending

upon local codes, utilize one of the following

techniques to connect the appliance to the

electrical power supply:

Door Removal

4

Page 6

A. Connecting to a Four-Wire

Conduit from

appliance

Cable from

power supply

Wire nut

(4 places)

Junction

box

RED

RED

GREEN

GREEN

WHITE

WHITE

BLACK

BLACK

Conduit from

appliance

Cable from

power supply

Wire nut

(3 places)

Junction

box

RED

RED

GREEN

WHITE

WHITE

BLACK

BLACK

Conduit from

appliance

Cable from

power supply

Wire nut

(4 places)

Junction

box

RED

RED

GREEN

GREEN

WHITE

WHITE

BLACK

BLACK

Separate No. 10 (minimum)

copper grounding wire

Clamp must be

tight on pipe

No. 4

copper wire

Metal

water pipe

Clamps

Bare metal

Meter

Electrical System

1. Separate the green and white appliance

wires.

2. Connect the white appliance wire to the

neutral (white) supply wire in the junction

box.

3. Connect the black appliance wire to the

black (L1) power supply wire in the junction

box.

4. Connect the red appliance wire to the red

(L2) power supply wire in the junction box.

5. Connect the green appliance wire to the

green house grounding wire in the junction

box.

Connecting the Appliance to a Four-Wire Power Supply

WARNING:

Do not connect the green

appliance wire to the neutral

(white) junction box wire unless

local building codes permit.

Connecting the Appliance Ground to Supply Neutral

B. Connecting the Green Appliance

Wire to the Neutral (White)

Supply Wire – Where Local

Codes Permit

1. Connect the green and white appliance

wires to the neutral (white) supply wire in

the junction box.

2. Connect the black appliance wire to the

black (L1) power supply wire in the junction

box.

3. Connect the red appliance wire to the black

(L2) power supply wire in the junction box.

C. Connecting the Green Appliance

Wire to a Grounded Junction

Box Wire or Grounded Cold

Water Pipe – Where Local

Codes Permit

1. Separate the green and white appliance

wires.

2. Connect the black appliance wire to the

black (L1) power supply wire in the junction

box.

3. Connect the red appliance wire to the black

(L2) power supply wire in the junction box.

4. Connect the red appliance wire to the red

(L2) power supply wire in the junction box

5. Connect the green appliance wire to a

grounded wire in the junction box or to a

grounded cold water pipe.

6. If connecting to a grounded cold water

pipe, a separate copper grounding wire

(No. 10 minimum) must be connected to a

grounded cold water pipe by means of a

clamp and then to an external grounding

connector screw.

WARNINGS:

1. Do not ground the appliance

to a gas supply pipe or hot

water pipe.

2. Do not turn on power to the

appliance until the oven is

permanently grounded.

3. Grounded cold water pipe

must have metal continuity

to electrically ground and

must not be interrupted by

insulating materials. Any

insulating materials must be

jumped as shown in Figure 10

below with a length of No. 4

copper wire securely clamped

to bare metal at both ends.

Mounting the Oven

WARNINGS:

1. Failure to install the mounting

screws may result in

movement or tipping of the

oven during use and personal

injury.

2. Do not block the oven air

exhaust located at the bottom

of the oven. Blocking the

intake may cause cabinet

damage and poor baking

performance.

5

Connecting the Appliance Ground to a Grounded Junction Box Wire or Cold Water Pipe.

Page 7

Exhaust Grill

#8 Screw

Secure oven to

cabinet with

screws provided

Single Ovens – 4 screws

Double Ovens – 6 screws

Lift the wall oven up to the cabinet cutout, using

the upper edge of the cavity opening and the

bottom of the oven case side as gripping points.

Use extreme caution when lifting the appliance

as it is heavy. Be certain to take all necessary

safety precautions.

Resting the oven on the cabinet-mounting

platform, slide the oven into the recessed area

until the rear edge of the oven frame is flush

with the cabinet face and the oven is centered

within the cutout. Ensure that the electrical

conduit slides through the opening in the cabinet

platform or coils above the oven chassis as

the oven is slid into place. The cable must be

placed into the recessed area located along the

rear vertical edge of the oven or coiled above

the oven chassis. Do not trap the appliance

cable between the oven case back and the rear

wall.

For the single ovens and the upper cavity of the

double ovens, locate the mounting holes found

in the sides of the oven frame. Using a 1/16”

drill, drill four pilot holes for the #6 x 3/4” screws

provided in the instruction envelope. Install the

screws through the oven frame and into the

cabinet to secure the oven. Do not over-tighten

the screws.

Attaching the Exhaust Grill

WARNING:

Failure to fully rotate the hinge

catches will cause them to bend

when the door is closed. This will

make closing the door impossible.

NOTE:

You may need to loosen the side

mounting screws a little to align

the Exhaust Grill mounting holes.

Tighten the side mounting screws

after attaching the Exhaust Grill.

For double ovens, complete Verifying Oven

Operation for both the upper and lower doors.

For stainless steel ovens, peel off the protective

layer of plastic that covers the door panel.

Verifying Oven Operation

Slide the oven racks onto the support racks

within the cavity. Place the broiler pan and tray

on a rack within the oven, if desired.

Turn on the power supply to the oven. Set the

time of day by pressing the Clock touch pad

then pressing the TIME•TEMP key.

Press the BAKE selector pad for the upper oven

or single oven. Select a temperature of 350˚F

by pressing the TIME•TEMP “+” key. The oven

should now be heating. After approximately

three (3) minutes, the lower heating element

should glow red. Press the CANCEL•SECURE

pad to stop the oven heating process. It may

take longer than three (3) minutes when ovens

are running at voltages lower than 240V. If

checking the operation of the double oven,

repeat the bake test for the lower oven.

Oven Gripping Points

Repeat the mounting procedure for the lower

cavity if installing a double oven.

Installing the Exhaust Grill

With the oven now secured to the cabinet, install

the Exhaust Grill by mounting it to the oven with

the two screws provided.

NOTE:

You may need to loosen the side

mounting screws a little to align

the Exhaust Grill mounting holes.

Tighten the side mounting screws

after attaching the Exhaust Grill.

Installing the Cabinet Mounting Screws

Reinstalling the Oven Doors

WARNING:

Failure to fully rotate the hinge

catches will cause them to bend

when the door is closed. This will

make closing the door impossible.

Grasp the oven door on opposite sides and

lift it until the door hinges are aligned with the

openings in the oven frame. Holding the door at

about a 30˚ angle from the horizontal, slide the

hinges into the openings until the bottom hinge

arms drop fully into the hinge receptacles. Lower

the door to the fully opened position, and then

rotate the two hinge catches toward the oven.

Open and close the door completely to ensure

that it is properly installed.

Press the BROIL selector pad for the upper

oven or single oven. Select a temperature of

350˚F by pressing the TIME•TEMP “+” key. The

oven should now be heating. After approximately

three (3) minutes, the upper heating element

should glow red. Press the CANCEL•SECURE

pad to stop the oven heating process. It may

take longer than three (3) minutes when ovens

are running at voltages lower than 240V. If

checking the operation of the double oven,

repeat the broil test for the lower oven.

WARNINGS:

If the oven does not operate

properly, follow these

troubleshooting steps:

1. Verify that power is being

supplied to the oven.

2. Check the electrical

connections to ensure that

the installation has been

completed correctly.

3. Repeat the above bake test.

4. If the appliance still does

not work, contact an

authorized DACOR service

company at (800) 772-7778.

Do not attempt to repair the

appliance yourself. DACOR

is not responsible for service

required to correct a faulty

installation.

6

Page 8

Web Site: www.dacor.com

For a Dealer/Service: (800) 772-7778

Corporate Phone: (800) 793-0093

Loading...

Loading...