PRELIMINARY

Frequency Generator for Integrated Core Logi c

Features

• Maximized EMI suppression using Cypress’s Spread

Spectrum technology

• Low jitter and tightly controlled clock skew

• Highly integrated device provi ding clocks requ ired for

CPU, core logic, and SDRAM

• Two copies of CPU clock

• Nine copies of SDRAM clock

• Seven copies of PCI clock

• One copy of synchronous APIC clock

• Three copies of 66-MHz outputs

• Two copies of 48-MHz outputs

• One copy of selectable 24- or 48-MHz clock

• One copy of double strength 14.31818-MHz reference

clock

• Power-down control

• SMBus interface for turning off unused clocks

Key Specifications

CPU, SDRAM Outputs Cycle-to-Cycle Jitter: .............250 ps

APIC, 48-MHz, 3V66, PCI Outputs

Cycle-to-Cycle Jitter:............................... ....................500 ps

CPU, 3V66 Output Skew:...........................................175 ps

SDRAM, APIC, 48-MHz Output Skew:....................... 250 ps

PCI Output Skew:....................................................... 500 ps

CPU to SDRAM Skew (@ 133 MHz) .......................± 0.5 ns

CPU to SDRAM Skew (@ 100 MHz).................4.5 to 5.5 ns

CPU to 3V66 Skew (@ 66 MHz)........................7.0 to 8.0 ns

3V66 to PCI Skew (3V66 lead).......................... 1.5 to 3.5 ns

PCI to APIC Skew.....................................................± 0.5 ns

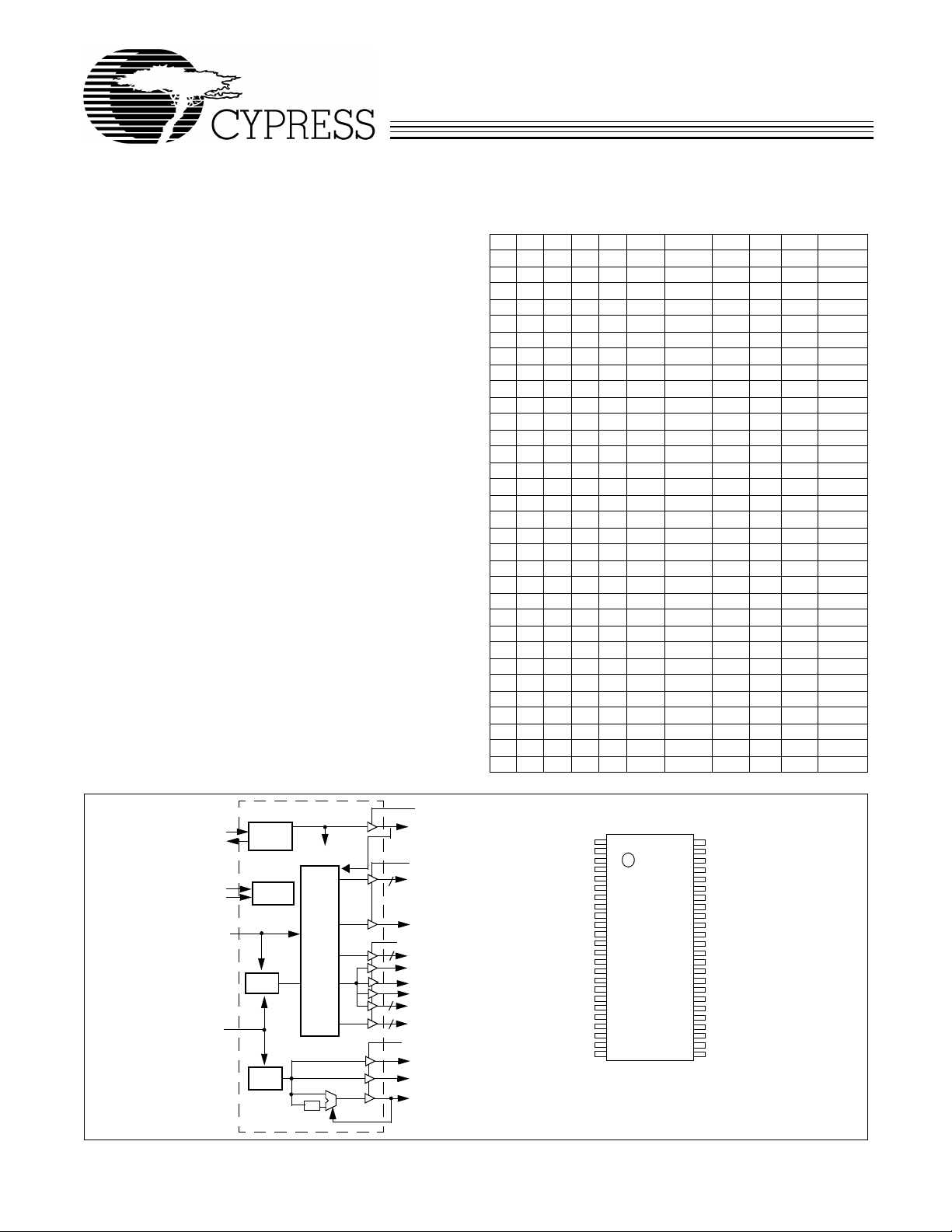

Block Diagram

PWR_DWN#

SDATA

SCLK

(FS0:4*)

X1

XTAL

X2

OSC

SMBus

Logic

PLL 1

PLL2

PLL REF FREQ

Divider,

Delay,

and

Phase

Control

Logic

/2

VDDQ3

REF2X/FS3*

VDDQ2

CPU0:1

2

APIC

VDDQ3

3V66_0:2

2

PCI0/FS0*

PCI1/FS1*

PCI2/FS2*

PCI3:6

5

SDRAM0:8

9

VDDQ3

48MHz_0

48MHz_1/FS 4*

SI0/24_48#MHz*

W219B

with 133-MHz FSB

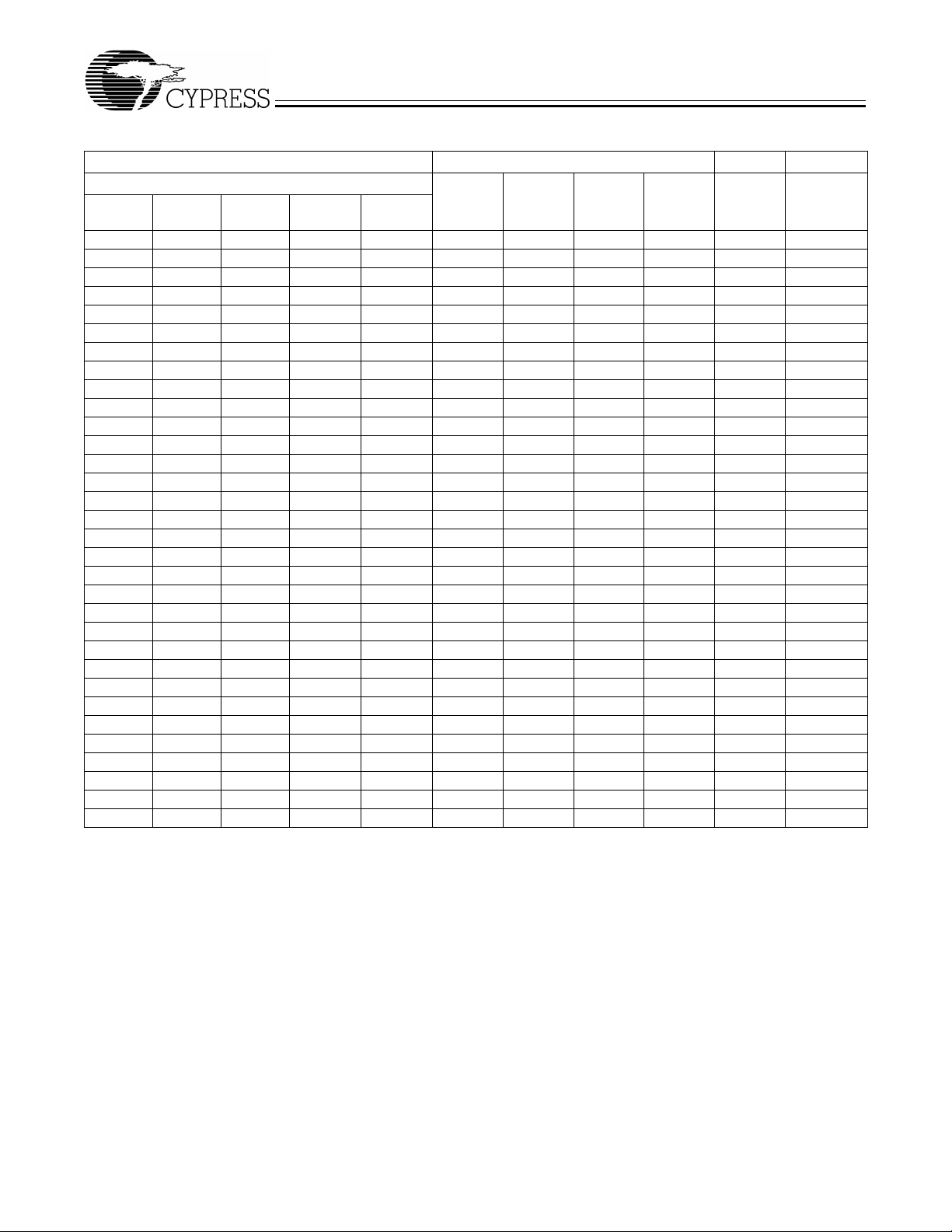

Table 1. Frequency Selections

FS4 FS3 FS2 FS1 FS0 CPU SDRAM 3V66 PCI APIC SS

0 0 0 0 0 75.3 113.0 75.3 37.6 18.8 OFF

0 0 0 0 1 95.0 95.0 63.3 31.6 15.8 –0.6%

0 0 0 1 0 129.0 129.0 86.0 43.0 21.5 OFF

0 0 0 1 1 150.0 113.0 75.3 37.6 18.8 OFF

0 0 1 0 0 150.0 150.0 75.0 37.5 18.7 OFF

0 0 1 0 1 110.0 110.0 73.0 36.6 18.3 OFF

0 0 1 1 0 140.0 140.0 70.0 35.0 17.5 OFF

0 0 1 1 1 144.0 108.0 72.0 36.0 18.0 OFF

0 1 0 0 0 68.3 102.5 68.3 34.1 17.0 OFF

0 1 0 0 1 105.0 105.0 70.0 35.0 17.5 OFF

0 1 0 1 0 138.0 138.0 69.0 34.5 17.0 OFF

0 1 0 1 1 140.0 105.0 70.0 35.0 17.5 OFF

0 1 1 0 0 66.8 100.2 66.8 33.4 16.7 ±0.45%

0 1 1 0 1 100.2 100.2 66.8 33.4 16.7 ±0.45%

0 1 1 1 0 133.6 133.6 66.8 33.4 16.7 ±0.45%

0 1 1 1 1 133.6 100.2 66.8 33.4 16.7 ±0.45%

1 0 0 0 0 157.3 118.0 78.6 39.3 19.6 OFF

1 0 0 0 1 160.0 120.0 80.0 40.0 20.0 OFF

1 0 0 1 0 146.6 110.0 73.3 36.6 18.3 OFF

1 0 0 1 1 122.0 91.5 61.0 30.5 15.2 –0.6%

1 0 1 0 0 127.0 127.0 84.6 42.3 21.1 OFF

1 0 1 0 1 122.0 122.0 81.3 40.6 20.3 –0.6%

1 0 1 1 0 117.0 117.0 78.0 39.0 19.5 OFF

1 0 1 1 1 114.0 114.0 76.0 38.0 19.0 OFF

1 1 0 0 0 80.0 120.0 80.0 40.0 20.0 OFF

1 1 0 0 1 78.0 117.0 78.0 39.0 19.5 OFF

1 1 0 1 0 166.0 124.5 83.0 41.5 20.7 OFF

1 1 0 1 1 133.6 133.6 89.0 44.5 22.2 OFF

1 1 1 0 0 66.6 100.0 66.6 33.3 16.6 –0.6%

1 1 1 0 1 100.0 100.0 66.6 33.3 16.6 –0.6%

1 1 1 1 0 133.3 133.3 66.6 33.3 16.6 –0.6%

1 1 1 1 1 133.3 100.0 66.6 33.3 16.6 –0.6%

Pin Configuration

REF2x/FS3*

VDDQ3

VDDQ3

3V66_0

3V66_1

3V66_2

FS0*/PCI0

FS1*/PCI1

FS2*/PCI2

VDDQ3

48MHz_0

FS4*/48MHz_1

SI0/24_48#MHz*

VDDQ3

Note:

1. Internal 250K pull-down or pull up resistors present on inputs

marked with * or ^ respectively. Design should not rely solely on

internal pull-up or pull down resistor to set I/O pins HIGH or LOW

respectively.

GND

GND

GND

PCI3

PCI4

PCI5

PCI6

GND

1

2

X1

3

X2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

[1]

VDDQ2

48

47

APIC

46

VDDQ2

45

CPU0

44

CPU1

43

GND

42

VDDQ3

41

SDRAM0

40

SDRAM1

SDRAM2

39

W219B

38

37

36

35

34

33

32

31

30

29

28

27

26

25

GND

SDRAM3

SDRAM4

SDRAM5

VDDQ3

SDRAM6

SDRAM7

SDRAM8

GND

PWR_DWN#

SCLK

VDDQ3

GND

SDATA

^

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

Document #: 38-07220 Rev. *A Revised December 21,2002

PRELIMINARY

I

W219B

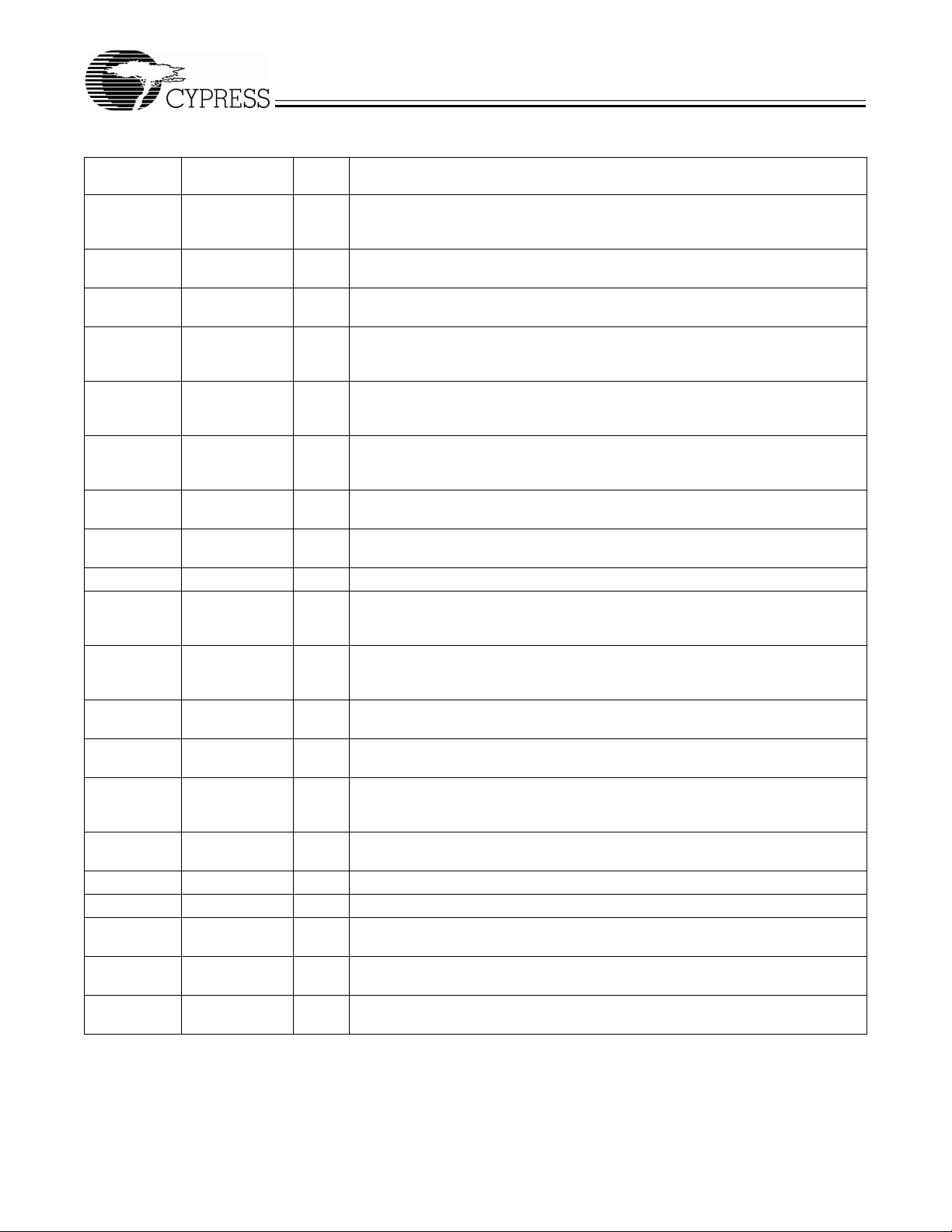

Pin Definitions

Pin Name Pin No.

REF2x/FS3 1 I/O Reference Clock with 2x Drive/Frequency Select 3: 3.3V 14.3 18-MHz c lock out-

X1 3 I Crystal Input: This pin has dual functions. It can be used as an external 14.318-

X2 4 I Crystal Output: An input connection for an external 14.318-MHz crystal connec-

PCI0/FS0 11 I/O PCI Clock 0/Frequency Selection 0 : 3.3V 33-MHz PCI clock outputs. This pin also

PCI1/FS1 12 I/O PCI Clock 1/Frequency Selection 1 : 3.3V 33-MHz PCI clock outputs. This pin also

PCI2/FS2 13 I/O PCI Clock 2/Frequency Selection 2 : 3.3V 33-MHz PCI clock outputs. This pin also

PCI3:6 15, 16, 18, 19 O PCI Clock 3 through 6: 3.3V 33-MHz PCI clock outputs. PCI0:6 can be individually

3V66_0:2 7, 8, 9 O 66-MHz Clock Output: 3.3V output clocks. The operating frequency is controlled

48MHz_0 21 O 48-MHz Clock Output: 3.3V fixed 48-MHz, non-spread spectrum clock output.

48MHz_1/

FS4

SIO/

24_48#MHz

PWR_DWN# 29 I Power Down Control: LVTTL-compatible input that places the device in power-

CPU0:1 45, 44 O CPU Clock Outputs: Clock outputs for the host bu s inter face. O utput fre quenc ies

SDRAM0:8 41, 40, 39, 37,

APIC 47 O Synchronous APIC Clock Outputs: Clock outputs ru nning syn chrono us wi th the

SDATA 25 I/O Data pin for SMBus circuitry.

SCLK 28 I Clock pin for SMBus circuitry.

VDDQ3 2, 6, 17, 24, 27,

VDDQ2 46, 48 P 2.5V Power Connection: Power supply for IOAPIC and CPU o utput buffers. Con-

GND 5, 10, 14, 20, 26,

22 I/O 48-MHz Clock Output/Frequency Selection 4: 3.3V fixed 48-MHz, non-spread

23 I/O Clock Output for Super I/O: This is the input clock for a Super I/O (SIO) device.

36, 35, 33, 32,

31

34, 42

30, 38, 43,

Pin

Type Pin Description

put. This pin also serves as the select strap to determine device ope rating frequency

as described in Table 1.

MHz crystal connection or as an external reference frequency input.

tion. If using an external reference, this pin must be left unconnected.

serves as the s elect st rap to det ermine d evice operating frequenc y as de scribed in

Table 1.

serves as the s elect st rap to det ermine d evice operating frequenc y as de scribed in

Table 1.

serves as the s elect st rap to det ermine d evice operating frequenc y as de scribed in

Table 1.

turned off via SMBus interface.

by FS0:4 (see Table 1).

spectrum clock ou tput. This pin al so serv es as the select strap t o determi ne devi ce

operating frequency as described in Table 1.

During power-up, it als o serves as a selection s trap. If it is sampled HIGH, the output

frequency for SIO is 24 MHz. If the input is sampled LOW, the output is 48 MHz.

down mode when held LOW.

depending on the configuration of FS0:4. Voltage swing is set by VDDQ2.

O SDRAM Clock Outputs: 3.3V outputs for SDRAM. The operating frequency is

controlled by FS0:4 (see Table 1).

PCI clock outputs. Voltage swing set by VDDQ2.

P 3.3V Power Con nection: Power supply for SDRAM output buffers, PCI outpu t buff-

ers, reference output buffers and 48-MHz output buffers. Connect to 3.3V.

nect to 2.5V or 3.3V.

G Ground Connections: Connect all ground pins to the common system ground

plane.

Document #: 38-07220 Rev. *A Page 2 of 15

PRELIMINARY

W219B

Power-on

Reset

Timer

Output Three-state

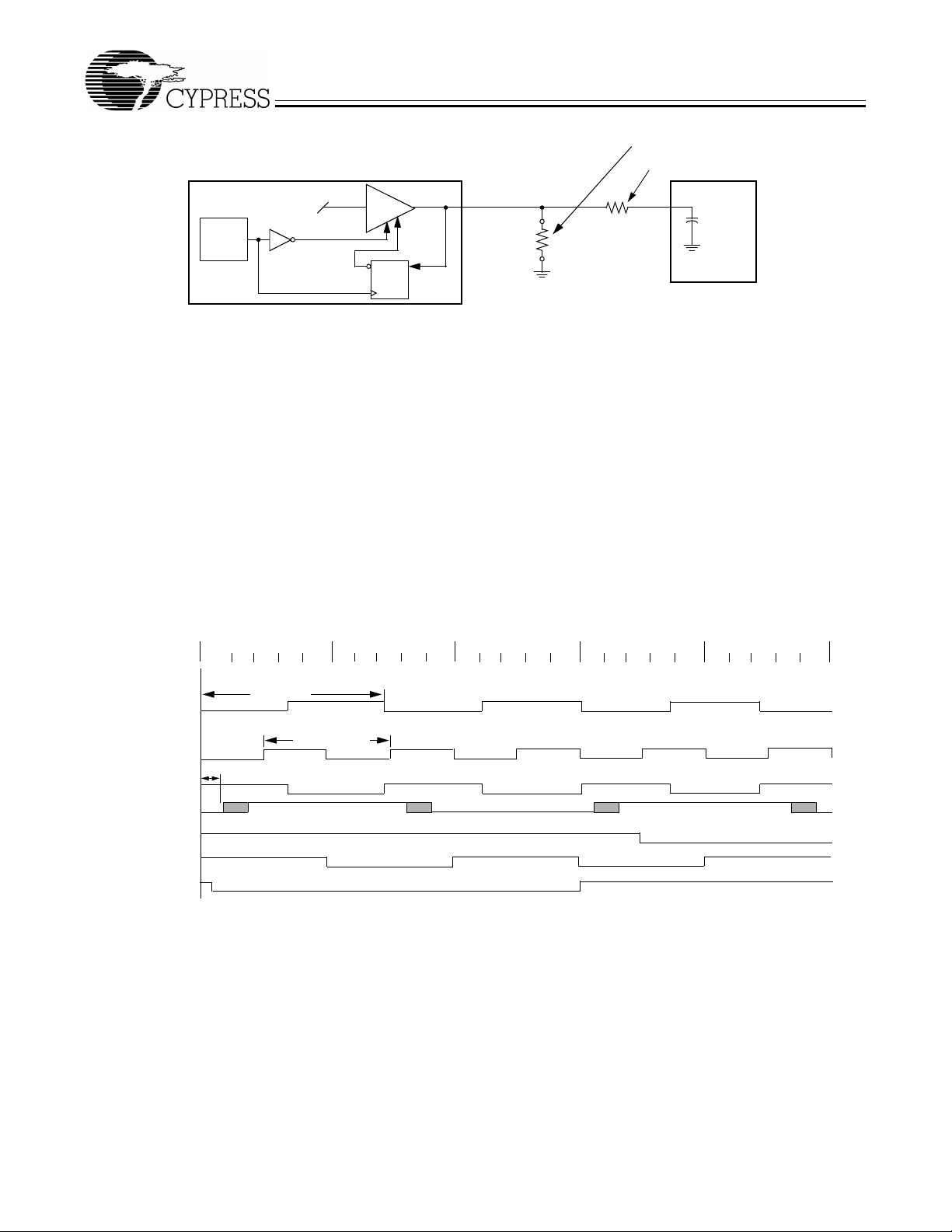

Figure 1. Input Logic Selection Through Resistor Load Option

Overview

The W219B is a highl y i nteg rate d frequency timing gene rator,

supplying all the requi red clock sou rces for an Intel® architec-

ture platform using graphics integrated core logic.

Functional Description

I/O Pin Operation

Pin # 1, 1 1, 12, 13, 22, and 23 are dual-purpose l/O pins . Upon

power-up the pin acts as a logic input. An external 10-kΩ strapping resistor should be used. Figure 1 shows a suggested

method for strapping resistor conn ec tio ns .

After 2 ms, the pin becomes an output. Assuming the power

supply has stabilized by then, the specified output frequency

Output

Buffer

Hold

Output

Low

QD

Data

Latch

W219B

Output Strapping Resistor

Series Termination Resistor

Clock Load

10k

Ω

is delivered on the pins. If the power supply has not yet

reached full value, o utput frequen cy initia lly may be below target but will increase to target once supply voltage has stabilized. In either case, a short output clock cycle may be produced from the CPU clock outputs when the outputs are

enabled.

Offsets Among Clock Signal Groups

Figure 2 and Figure 3 represent the phase relationship amon g

the different groups of clo ck outputs from W219B when it is

providing a 66-MHz CPU clock and a 100-MHz CPU clock,

respectively. It should be noted that when CPU clock is operating at 100 MHz, CPU clock output is 180 degrees out of

phase with SDRAM clock outputs.

CPU 66-MHz

SDRAM 100-MHz

3V66 66-MHz

PCI 33-MHz

REF 14.318-MHz

USB 48-MHz

APIC

0 ns

CPU 66 Period

SDRAM 100 Period

Hub-PC

Figure 2. Group Offset Waveforms (66.8 CPU Clock, 100.2 SDRAM Clock)

40 ns30 ns20 ns10 ns

Document #: 38-07220 Rev. *A Page 3 of 15

CPU 100-MHz

SDRAM 100-MHz

3V66 66-MH z

PCI 33-MHz

REF 14.318-MHz

USB 48-MHz

APIC

0 ns

PRELIMINARY

40 ns30 ns20 ns10 ns

CPU 100 Period

SDRAM 100 Period

Hub-PC

W219B

Figure 3. Group Offset Waveforms (100.2 CPU Clock, 100.2 SDRAM Clock)

Power-Down Control

W219B provides one PWRDWN # s ignal to pla ce the d evic e in low-p ower mo de. In low -powe r mode , the PLLs a re turne d of f an d

all clock outputs are driven LOW.

0 ns 25 ns 50 ns 75 ns

Center

1 2

VCO Internal

CPU 100MHz

3V66 66MHz

APIC 33MHz

PCI 33MHz

PwrDwn

SDRAM 100MHz

REF 14.318MHz

USB 48MHz

Figure 4. PWRDWN# Timing Diagram

Notes:

2. Once the PWRDWN# signal is sampled LOW for two consecutive rising edges of CPU, clocks of interest will be held LOW on the next HIGH-to-LOW transition.

3. PWRDWN# is an asynchronous input and metastable conditions could exist. This signal is synchronized inside W219B.

4. The shaded sections on the SDRAM, REF, and USB clocks indicate “Don’t Care” states.

5. Diagrams shown with respect to 100 MHz. Similar operation when CPU is 66 MHz.

[2, 3, 4, 5]

Document #: 38-07220 Rev. *A Page 4 of 15

PRELIMINARY

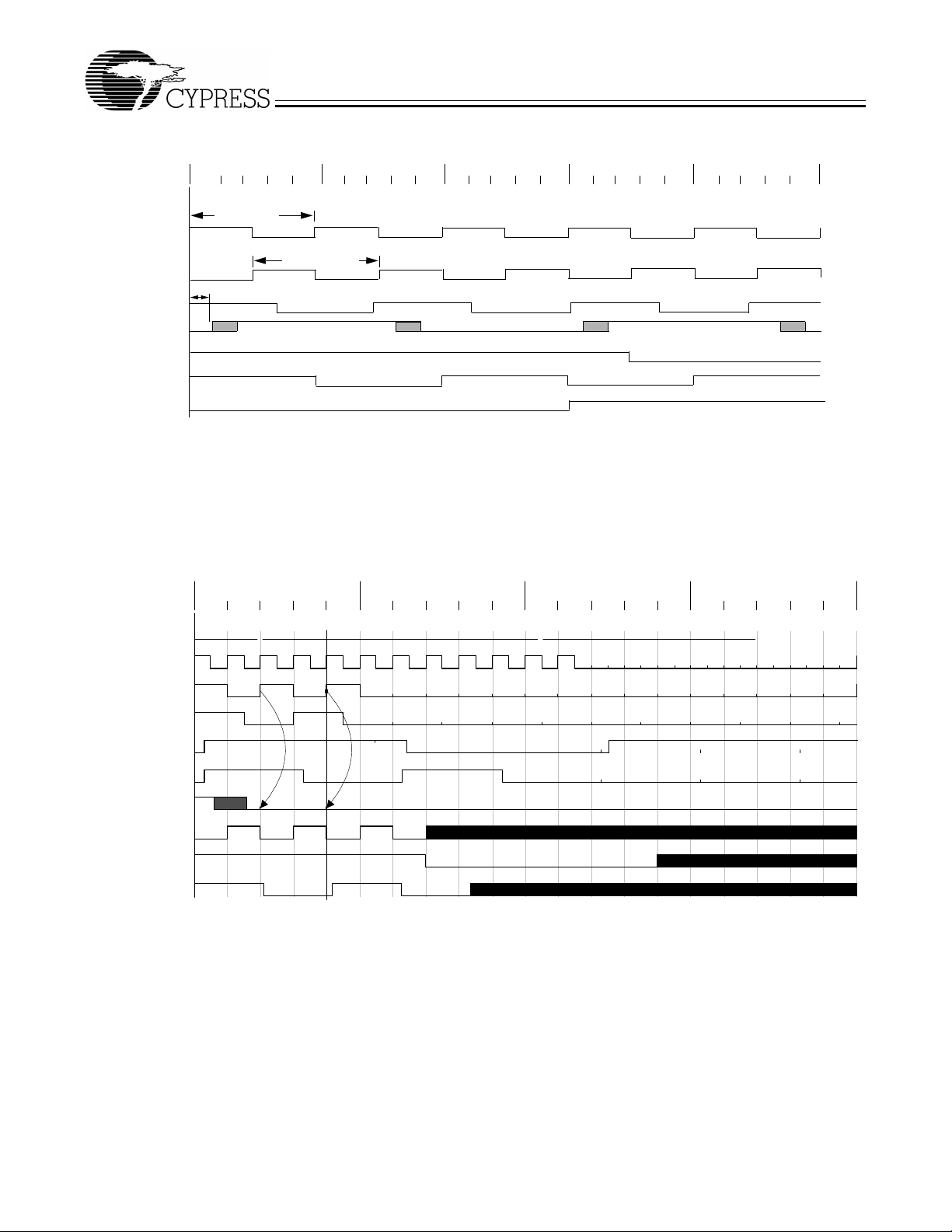

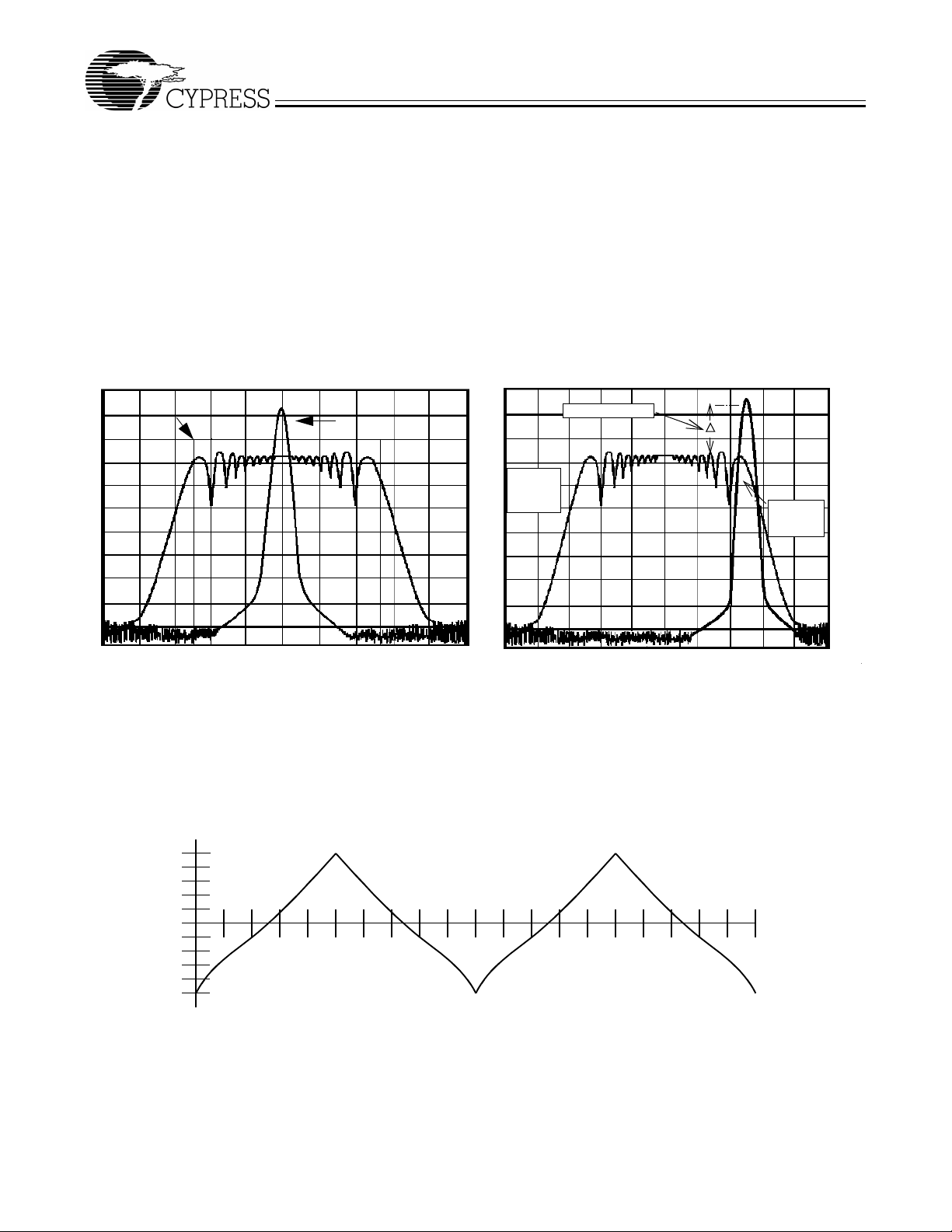

Spread Spectrum Frequency Timing Generator

The device generates a clock that is frequency modulated in

order to increase th e bandwidt h that it occu pies. By inc reasing

the bandwidth of the fundamental and its harmonics, the amplitudes of the radiated electromagnetic emissions are reduced. This effect is depicted in Figure 5.

As shown in Figure 5, a harmonic of a modulated clock has a

much lower amplit ude than that of an unmodulated si gnal. The

reduction in amplitude is dependent on the harmonic number

and the frequency deviation or spread. The equation for the

reduction is:

dB = 6.5 + 9*log

SSFTG

Amplitude (dB)

(P) + 9*log10(F)

10

Typical Clock

W219B

Where P is the pe rcentage of deviation and F is the frequenc y

in MHz where the reduction is measured.

The output clock is modulated with a waveform depicted in

Figure 6. This waveform, as discusse d in “Spread Spectrum

Clock Generation for the Reduction of Radiated Emi ssions” by

Bush, Fessler, and Hardin produces the maximum reduction

in the amplitude of radiated electromagnetic emissions. The

deviation selected for this chip is ±0.45% or –0.6% of the selected frequency. Figure 6 details the Cypress spreading pattern. Cypress does of fer option s with more spread a nd greater

EMI reduction. Con tact your l ocal Sales re presen tative for d etails on these devices.

EMI Reduction

Spread

Spectrum

Enabled

Amplitude (dB)

Non-

Spread

Spectrum

Frequency Span (MHz)

Center Spread

Frequency Span (MHz)

Down Spread

Figure 5. Clock Harmonic with and without SSCG Modu lation Frequency Do main Representation

MAX.

10%

20%

30%

40%

50%

60%

70%

80%

FREQUENCY

MIN.

90%

100%

10%

20%

30%

40%

50%

60%

70%

80%

Figure 6. Typical Modulation Profile

90%

100%

Document #: 38-07220 Rev. *A Page 5 of 15

PRELIMINARY

1 bit 7 bits 1 1 8 bits 1

Start bit Slave Address R/W Ack Command Code Ack Byte Count = N

Ack Data Byte 1 Ack Data Byte 2 Ack ... Data Byte N Ack Stop

1 bit 8 bits 1 8 bits 1 8 bits 1 1

Figure 7. An Example of a Block Write

Serial Data Interface

The W219B features a two-pin, serial data interface that can

be used to configure inte rnal regi ster settin gs that con trol particular device functions .

Data Protocol

The clock driver s eri al protocol accepts onl y blo ck w ri tes fro m

the controller . The bytes must be accessed i n sequential order

from lowest to highest byte with the ability to stop after any

complete byte has been transferred. Indexed bytes are not

allowed.

A block write beg ins with a slave address and a wri te condition.

After the comm and code the core logic issues a byt e count

which describes how many more bytes will follow in the message. If the host had 20 bytes to send, the first byte would be

the number 20 (14h), followed by the 20 bytes of data. The

byte count may n ot be 0. A block writ e com mand i s all owed to

Table 2. Example of Possible Byte Count Value

Byte Count Byte Notes

MSB LSB

0000 0000 Not allowed. Must have at least one byte.

0000 0001 Data for functional and frequency select register (currently byte 0 in spec)

0000 0010 Reads first two bytes of data. (byte 0 then byte1)

0000 0011 Reads first three bytes (byte 0, 1, 2 in order)

0000 0100 Reads first four bytes (byte 0, 1, 2, 3 in order)

0000 0101 Reads first five bytes (byte 0, 1, 2, 3, 4 in order)

0000 0110 Reads first six bytes (byte 0, 1, 2, 3, 4, 5 in order)

0000 0111 Reads first seven bytes (byte 0, 1, 2, 3, 4, 5, 6 in order)

0010 0000 M ax. byte count supported = 32

transfer a maximum of 32 data bytes. The slave receiver address for W219B is 11010010. Figure 7 shows an example of

a block write.

The command code and the byte count bytes are required as

the first two bytes of any transfer. W219B expects a command

code of 0000 0000. The byte count byte is the number of additional bytes required for the transfer, not counting the command code and byte count bytes. Additionally, the byte count

byte is required to be a minimum of 1 byt e and a max imum of

32 bytes to satisfy the above requirement. Table 2 shows an

example of a possible byte count value.

A transfer is considered val id a fter th e ac k nowl edge bit corresponding to the byte coun t is read by th e co ntro lle r. The command code and byte count bytes are ignored by the W219B.

However, these bytes must be included in the data write sequence to maintain proper byte allocation.

[6]

[7]

[7]

W219B

Table 3. Serial Data Interface Control Functions Summary

Control Function Description Common Application

Output Disable Any individual clock output(s) can be disabled.

(Reserved) Reserved func tion for future dev ice revision or pro-

Notes:

6. The acknowledgment bit is returned by the slave/receiver (W219B).

7. Bytes 6 and 7 are not defined for W219B.

Document #: 38-07220 Rev. *A Page 6 of 15

Disabled outputs are act iv ely held LOW.

duction device testing.

Unused outputs are di sable d to redu ce EMI and system power. Examples are clock outputs to unused

PCI slots.

No user application. Register bit mu st be written as 0.

PRELIMINARY

Serial Configuration Map

1. The serial bits will be read by the clock driver in the followin g

order:

Byte 0 - Bits 7, 6, 5, 4, 3, 2, 1, 0

Byte 1 - Bits 7, 6, 5, 4, 3, 2, 1, 0

Byte N - Bits 7, 6, 5, 4, 3, 2, 1, 0

Byte 0: Control Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Function

Bit 7 - Reserved 0 Reserved

Bit 6 - Reserved 0 Reserved

Bit 5 - Reserved 0 Reserved

Bit 4 - Reserved 0 Reserved

Bit 3 - Reserved 0 Reserved

Bit 2 23 24/48 MHz 1 (Active/Inactive)

Bit 1 21, 22 48 MHz 1 (Active/Inactive)

Bit 0 - Reserved 0 Reserved

Byte 1: Control Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Description

Bit 7 32 SDRAM7 1 (Active/Inactive)

Bit 6 33 SDRAM6 1 (Active/Inactive)

Bit 5 35 SDRAM5 1 (Active/Inactive)

Bit 4 36 SDRAM4 1 (Active/Inactive)

Bit 3 37 SDRAM3 1 (Active/Inactive)

Bit 2 39 SDRAM2 1 (Active/Inactive)

Bit 1 40 SDRAM1 1 (Active/Inactive)

Bit 0 41 SDRAM0 1 (Active/Inactive)

[8]

[8]

2. All unused register bits (reserved and N/A) should be written to a “0” level.

3. All register bits labeled “Initialize to 0" must be written to

zero during initial ization. Failure to do so may result in higher than normal operating current. The controller will read

back the written value.

W219B

Byte 2: Control Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Description

Bit 7 -- Reserved 0 Reserved

Bit 6 19 PCI6 1 (Active/Inactive)

Bit 5 18 PCI5 1 (Active/Inactive)

Bit 4 16 PCI4 1 (Active/Inactive)

Bit 3 15 PCI3 1 (Active/Inactive)

Bit 2 13 PCI2 1 (Active/Inactive)

Bit 1 12 PCI1 1 (Active/Inactive)

Bit 0 11 PCI0 1 (Active/Inactive)

Note:

8. Inactive means outputs are held LOW and are disabled from switching. These outputs are designed to be configured at power-on and are not expected to be

configured during the normal modes of operation.

Document #: 38-07220 Rev. *A Page 7 of 15

[8]

PRELIMINARY

Byte 3: Reserved Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Description

Bit 7 31 SDRAM8 1 (Active/Inactive)

Bit 6 - Reserved 0 Reserved

Bit 5 - Reserved 0 Reserved

Bit 4 - Reserved 0 Reserved

Bit 3 47 APIC 1 (Active/Inactive)

Bit 2 - Reserved 0 Reserved

Bit 1 - Reserved 1 Reserved

Bit 0 - Reserved 0 Reserved

Byte 4: Reserved Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Function

Bit 7 - SEL3 0 See Table 4

Bit 6 - SEL2 0 See Table 4

Bit 5 - SEL1 0 See Table 4

Bit 4 - SEL0 0 See Table 4

Bit 3 - FS(0:4) Override 0 0 = Select operating frequency by FS(0:4) strapping

1 = Select operating frequency by SEL(0:4) bit settings

Bit 2 - SEL4 0 See Table 4

Bit 1 - Reserved 0 Reserved

Bit 0 - Test Mode 0 0 = All output enable

1 = All output three-stated

W219B

Byte 5: Reserved Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Description

Bit 7 - Reserved 0 Reserved

Bit 6 - Reserved 0 Reserved

Bit 5 - Reserved 0 Reserved

Bit 4 - Reserved 0 Reserved

Bit 3 - Reserved 0 Reserved

Bit 2 - Reserved 0 Reserved

Bit 1 - Reserved 0 Reserved

Bit 0 - Reserved 0 Reserved

Byte 6: Reserved Register (1 = Enable, 0 = Disable)

Bit Pin# Name Default Pin Description

Bit 7 - Reserved 0 Reserved

Bit 6 - Reserved 0 Reserved

Bit 5 - Reserved 0 Reserved

Bit 4 - Reserved 0 Reserved

Bit 3 - Reserved 0 Reserved

Bit 2 - Reserved 1 Reserved

Bit 1 - Reserved 1 Reserved

Bit 0 - Reserved 0 Reserved

Document #: 38-07220 Rev. *A Page 8 of 15

PRELIMINARY

Table 4. Additional Frequency Selections through Serial Data Interface Data Bytes

Input Conditions Output Frequency

Data Byte 4, Bit 3 = 1

Bit 2

SEL_4

0 0 0 0 0 75.3 113.0 75.3 37.6 18.8 OFF

0 0 0 0 1 95.0 95.0 63.3 31.6 15.8 –0.6%

0 0 0 1 0 129.0 129.0 86.0 43.0 21.5 OFF

0 0 0 1 1 150.0 113.0 75.3 37.6 18.8 OFF

0 0 1 0 0 150.0 150.0 75.0 37.5 18.7 OFF

0 0 1 0 1 110.0 110.0 73.0 36.6 18.3 OFF

0 0 1 1 0 140.0 140.0 70.0 35.0 17.5 OFF

0 0 1 1 1 144.0 108.0 72.0 36.0 18.0 OFF

0 1 0 0 0 68.3 102.5 68.3 34.1 17.0 OFF

0 1 0 0 1 105.0 105.0 70.0 35.0 17.5 OFF

0 1 0 1 0 138.0 138.0 69.0 34.5 17.0 OFF

0 1 0 1 1 140.0 105.0 70.0 35.0 17.5 OFF

0 1 1 0 0 66.8 100.2 66.8 33.4 16.7 ±0.45%

0 1 1 0 1 100.2 100.2 66.8 33.4 16.7 ±0.45%

0 1 1 1 0 133.6 133.6 66.8 33.4 16.7 ±0.45%

0 1 1 1 1 133.6 100.2 66.8 33.4 16.7 ±0.45%

1 0 0 0 0 157.3 118.0 78.6 39.3 19.6 OFF

1 0 0 0 1 160.0 120.0 80.0 40.0 20.0 OFF

1 0 0 1 0 146.6 110.0 73.3 36.6 18.3 OFF

1 0 0 1 1 122.0 91.5 61.0 30.5 15.2 –0.6%

1 0 1 0 0 127.0 127.0 84.6 42.3 21.1 OFF

1 0 1 0 1 122.0 122.0 81.3 40.6 20.3 –0.6%

1 0 1 1 0 117.0 117.0 78.0 39.0 19.5 OFF

1 0 1 1 1 114.0 114.0 76.0 38.0 19.0 OFF

1 1 0 0 0 80.0 120.0 80.0 40.0 20.0 OFF

1 1 0 0 1 78.0 117.0 78.0 39.0 19.5 OFF

1 1 0 1 0 166.0 124.5 83.0 41.5 20.7 OFF

1 1 0 1 1 133.6 133.6 89.0 44.5 22.2 OFF

1 1 1 0 0 66.6 100.0 66.6 33.3 16.6 –0.6%

1 1 1 0 1 100.0 100.0 66.6 33.3 16.6 –0.6%

1 1 1 1 0 133.3 133.3 66.6 33.3 16.6 –0.6%

1 1 1 1 1 133.3 100.0 66.6 33.3 16.6 –0.6%

Bit 7

SEL_3

Bit 6

SEL_2

Bit 5

SEL_1

Bit 4

SEL_0

CPU SDRAM 3V66 PCI APIC

W219B

Spread

Spectrum

Document #: 38-07220 Rev. *A Page 9 of 15

DC Electrical Characteristics

PRELIMINARY

[9]

W219B

DC parameters must be sustainable under steady state (DC) conditions.

Absolute Maximum DC Power Supply

Parameter Description Min. Max. Unit

V

DDQ3

V

DDQ2

T

S

3.3V Core Supply Voltage –0.5 4.6 V

2.5V I/O Supply Voltage –0.5 3.6 V

Storage Temperature –65 150 °C

Absolute Maximum DC I/O

Parameter Description Min. Max. Unit

V

i/o3

V

i/o3

3.3V Core Supply Voltage –0.5 4.6 V

2.5V I/O Supply Voltage –0.5 3.6 V

ESD prot. Input ESD Protection 2000 V

DC Operating Requirements

Parameter Description Condition Min. Max. Unit

V

DD3

V

DDQ3

V

DDQ2

V

DD3 =

V

ih3

V

il3

I

il

V

DDQ2 =

V

oh2

V

ol2

V

DDQ3 =

V

oh3

V

ol3

V

DDQ3 =

V

poh3

V

pol3

3.3V±5%

2.5V±5%

3.3V±5%

3.3V±5%

3.3V Core Supply Voltage 3.3V±5% 3.135 3.465 V

3.3V I/O Supply Voltage 3.3V±5% 3.135 3.465 V

2.5V I/O Supply Voltage 2.5V±5% 2.375 2.625 V

3.3V Input High Voltage V

DD3

2.0 V

+ 0.3 V

DD

3.3V Input Low Voltage GND – 0.3 0.8 V

Input Leakage Current

[10]

0<Vin<V

DDQ3

–5+5µA

2.5V Output High Voltage Ioh=(–1 mA) 2.0 V

2.5V Output Low Voltage Iol=(1 mA) 0.4 V

3.3V Output High Voltage Ioh=(–1 mA) 2.4 V

3.3V Output Low Voltage Iol=(1 mA) 0.4 V

PCI Bus Output High Voltage Ioh=(–1 mA) 2.4 V

PCI Bus Output Low Voltage Iol=(1 mA) 0.55 V

C

in

C

xtal

C

out

L

pin

T

a

Note:

9. Multiple Supplies: The voltage on any input or I/O pin cannot exceed the power pin during power-up. Power supply sequencing is NOT required.

10. Input Leakage Current does not include inputs with pull-up or pull-down resistors.

Input Pin Capacitance 5 pF

Xtal Pin Capacitance 13.5 22.5 pF

Output Pin Capacitance 6 pF

Pin Inductance 0 7 nH

Ambient Temperature No Airflow 0 70 °C

Document #: 38-07220 Rev. *A Page 10 of 15

AC Electrical Characteristics

TA = 0°C to +70°C, V

= 14.31818 MHz

f

XTL

Parameter Description

T

Period

T

HIGH

T

LOW

T

RISE

T

FALL

T

Period

T

HIGH

T

LOW

T

RISE

T

FALL

T

Period

T

HIGH

T

LOW

T

RISE

T

FALL

Host/CPUCLK Period 15.0 15.5 10.0 10.5 7.5 8.0 ns 11

Host/CPUCLK High Time 5.2 N/A 3.0 N/A 1.87 N/A ns 14

Host/CPUCLK Low Time 5.0 N/A 2.8 N/A 1.67 N/A ns

Host/CPUCLK Rise Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

Host/CPUCLK Fall Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

SDRAM CLK Period 10.0 10.5 10.0 10.5 10.0 10.5 ns 11

SDRAM CLK High Time 3.0 N/A 3.0 N/A 3.0 N/A ns 14

SDRAM CLK Low Time 2.8 N/A 2.8 N/A 2.8 N/A ns

SDRAM CLK Rise Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

SDRAM CLK Fall Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

APIC CLK Period 60.0 64.0 60.0 N/A 60.0 64.0 ns 11

APIC CLK High Time 25.5 N/A 25.5 N/A 25.5 N/A ns 14

APIC CLK Low Time 25.3 N/A 25.30 N/A 25.30 N/A ns

APIC CLK Rise Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

APIC CLK Fall Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

= 3.3V±5%, V

DDQ3

PRELIMINARY

[9]

= 2.5V±5%

DDQ2

66.6-MHz Host 100-MHz Host 133-MHz Host

W219B

Unit NotesMin. Max. Min. Max. Min. Max.

T

Period

T

HIGH

T

LOW

T

RISE

T

FALL

T

Period

T

HIGH

T

LOW

T

RISE

T

FALL

, tp

tp

ZL

, tp

tp

LZ

t

stable

Notes:

11. Period, jitter, offset, and skew measured on rising edge at 1.25 for 2.5V clocks and at 1.5V for 3.3V clocks.

12. T

HIGH

13. T

LOW

14. The time specified is measured from when V

operating within specification.

15. T

RISE

0.4V and V

3V66 CLK Period 30.0 N/A 30.0 N/A 30.0 N/A ns 11, 13

3V66 CLK High Time 12.0 N/A 12.0 N/A 12.0 N/A ns 14

3V66 CLK Low Time 12.0 N/A 12.0 N/A 12.0 N/A ns

3V66 CLK Rise Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

3V66 CLK Fall Time 0.4 1.6 0.4 1.6 0.4 1.6 ns 15

PCI CLK Period 15.0 16.0 15.0 16.0 15.0 16.0 ns 11, 12

PCI CLK High Time 5.25 N/A 5.25 N/A 5.25 N/A ns 14

PCI CLK Low Time 5.05 N/A 5.05 N/A 5.05 N/A ns

PCI CLK Rise Time 0.5 2.0 0.5 2.0 0.5 2.0 ns 15

PCI CLK Fall Time 0.5 2.0 0.5 2.0 0.5 2.0 ns 15

Output Enable Delay (Al l outputs) 30.0 N/A 30.0 N/A 30.0 N/A ns

ZH

Output Disable Delay

ZH

(All outputs)

All Clock Stabilization from

12.0 N/A 12.0 N/A 12.0 N/A ns 15

12.0 N/A 12.0 N/A 12.0 N/A ms 15

Power-Up

is measured at 2.0V for 2.5V outputs, 2.4V for 3.3V outputs.

is measured at 0.4V for all outputs.

and T

are measured as a transition through the threshold region Vol = 0.4V and Voh = 2.0V (1 mA) JEDEC specification for 2.5V outputs, and Vol =

FALL

= 2.4V for 3.3V.

oh

achieves its nominal operating level (typical condition V

DDQ3

= 3.3V) until the frequency output is stable and

DDQ3

Document #: 38-07220 Rev. *A P age 11 of 15

PRELIMINARY

Group Skew and Jitter Limits

Output Group Pin-Pin Skew Max. Cycle-Cycle Jitter Duty Cycle Nom Vdd

CPU 175 ps 250 ps 45/55 2.5V 1.25V

SDRAM 250 ps 250 ps 45/55 3.3V 1.5V

APIC 250 ps 500 ps 45/55 2.5V 1.2 5V

48MHz 250 ps 500 ps 45/55 3.3V 1.5V

3V66 175 ps 500 ps 45/55 3.3V 1.5V

PCI 500 ps 500 ps 45/55 3.3V 1.5V

REF N/A 1000 ps 45/55 3.3V 1.5V

Test Poi nt

Test Load

T

PERIOD

Duty Cycle

Clock Output Wave

2.5V Clocking

Interface

1.25

Output

Buffer

T

HIGH

2.0

0.4

W219B

Skew, Jitter

Measure Point

T

LOW

T

RISE

3.3V Clocking

Interface

2.4

1.5

0.4

T

RISE

T

FALL

T

PERIOD

Duty Cycle

T

HIGH

T

T

FALL

LOW

Figure 8. Output Buffer

Ordering Information

Ordering Code Package Name Package Type

W219B H 48-pin SSOP (300 mils)

Intel is a registered trademark of Intel Corporation.

Document #: 38-07220 Rev. *A Page 12 of 15

Layout Example

PRELIMINARY

C1

10 µF

G

+2.5V Supply

FB

0.005 µF

G

G

G

G

+3.3V Supply

FB

10 µF

0.005 µF

C4

G G

1

2

G

3

4

5

G

6

VDDQ3

C3

G

VG

G

G

V

G

7

8

G

9

10

11

G

W219B

12

VDDQ2

G

V

48

G

47

V

46

G

45

44

43

G

V

42

G

41

40

39

G

38

G

37

W219B

C2

3.3V

13

G

14

15

G

16

VG

17

G

18

19

G

20

21

22

23

G

24

C1 & C3, C5 = 10 – 22

Each supply plane or strip should have a

C5

20µF

G

0.1

µ

F

C6

G

FB = Dale ILB1206 - 300 (300

Ceramic Caps

= VIA to GND plane layer

G

Note:

All VDD by pass capacitors = 0.1 µF

5

Ω

VDDQ3

(Core)

Ω @ 100 MHz) or TDK ACB2012L-120

V = VIA to respectiv e supply plane trace

36

G

35

V

34

G

33

32

31

30

G

29

28

G

V

27

G

26

G

25

C2 & C4 = 0.005

µF

ferrite bead and capacitors

µF

G

G

C6 = 0.1 µF

Document #: 38-07220 Rev. *A Page 13 of 15

ng so indemnifies Cypress Semiconductor against all charges.

Package Diagram

PRELIMINARY

48-Pin Shrink Small Outline Package (SSOP, 300 mils)

W219B

Document #: 38-07220 Rev. *A Page 14 of 15

© Cypress Semiconductor Corporation, 2001. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circuitry embodied in a Cypress Semiconductor product. No r does it convey or imply any license under patent or other rights. Cypress Semiconductor does not autho rize

its products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

Semiconductor products in life-support systems application implies that the manufacturer assume s all risk of such use and in doi

PRELIMINARY

Document Title: W219B Frequency Generator for Integrated Core Logic with 133-MHz FSB

Document Number: 38-07220

REV. ECN NO.

** 110485 10/21/01 SZV Change from Spec number: 38-00884 to 38-07220

*A 122837 12/21/02 RBI Add Power up Requirements to Electrical Characteristics

Issue

Date

Orig. of

Change Description of Change

W219B

Information

Document #: 38-07220 Rev. *A Page 15 of 15

Loading...

Loading...