Cynergy Cynosure Dermatology Laser Service manual

Cynergy

TECHNICAL GUIDE

850-1265-000, Rev. 4

™

CYNOSURE

Where art and science meet.

®

This manual is intended for both U.S. and International distribution.

™ Cynergy is a trademark of Cynosure, Inc.

® Cynosure is a registered trademark of Cynosure, Inc.

© 2005 Cynosure, Inc. All rights reserved.

Document #850-1265-000, Rev. 4, 7/06

Table of Contents

Glossary of Symbols and Abbreviations.................................................................................7

Section 1 Introduction.......................................................................................................9

Disclaimer.......................................................................................................................9

Contacting Customer Service .........................................................................................9

About the Laser.............................................................................................................10

Figure 1–Cynergy, Cynergy PL and Cynergy III .............................................10

About the Technical Guide ...........................................................................................11

Section 2 Equipment Safety............................................................................................13

Introduction...................................................................................................................13

Potential Hazards ..........................................................................................................13

Optical Hazard ..................................................................................................13

Electrical Hazard...............................................................................................14

Grounding .........................................................................................................14

Fire Hazard........................................................................................................15

Chemical Hazard...............................................................................................15

Potential Chemical Accidents and Appropriate Responses..............................15

Hot-Water Hazard.............................................................................................15

Section 3 Laser System Controls....................................................................................17

Calibration.....................................................................................................................17

Memory.........................................................................................................................17

Operating Modes, User .................................................................................................17

Normal Operation .............................................................................................17

System Check....................................................................................................18

Performance Diagnostic Routine ......................................................................18

Cynergy MultiPlex............................................................................................18

Operating Modes, Service.............................................................................................19

Accessing Testall Mode....................................................................................19

Accessing CV Mode .........................................................................................19

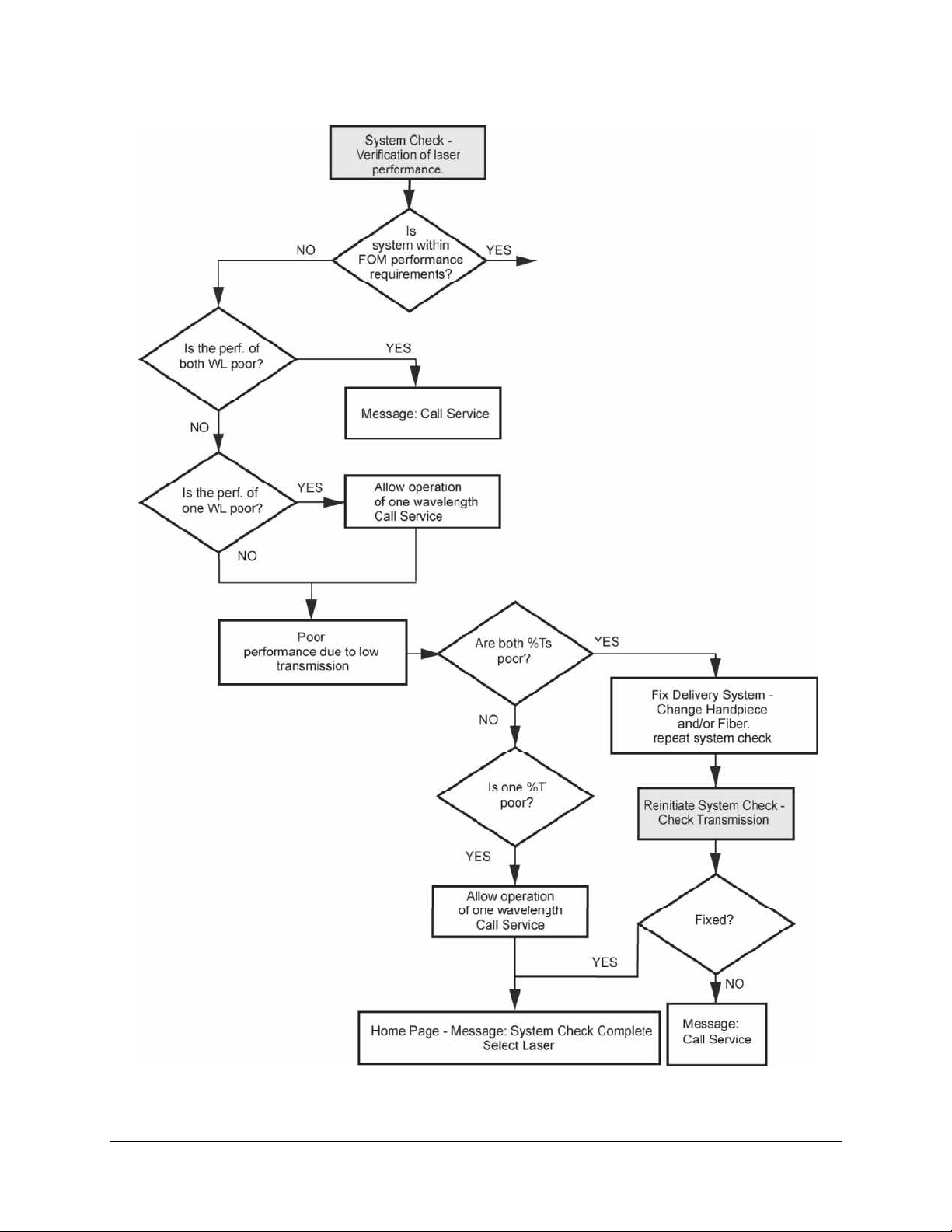

Figure 2A–Performance Diagnostic Flow Diagram .........................................20

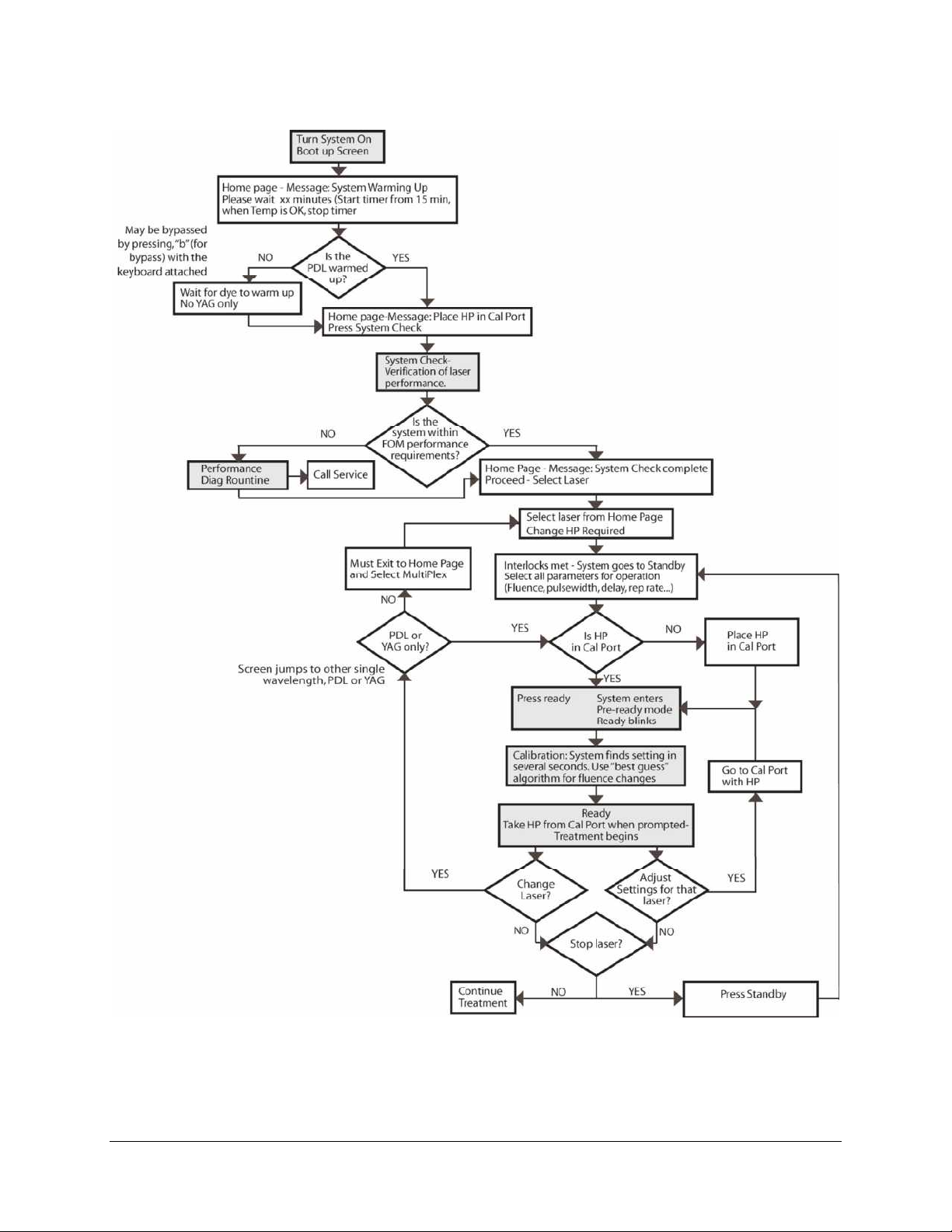

Figure 2B–Normal Operation Flow Diagram...................................................21

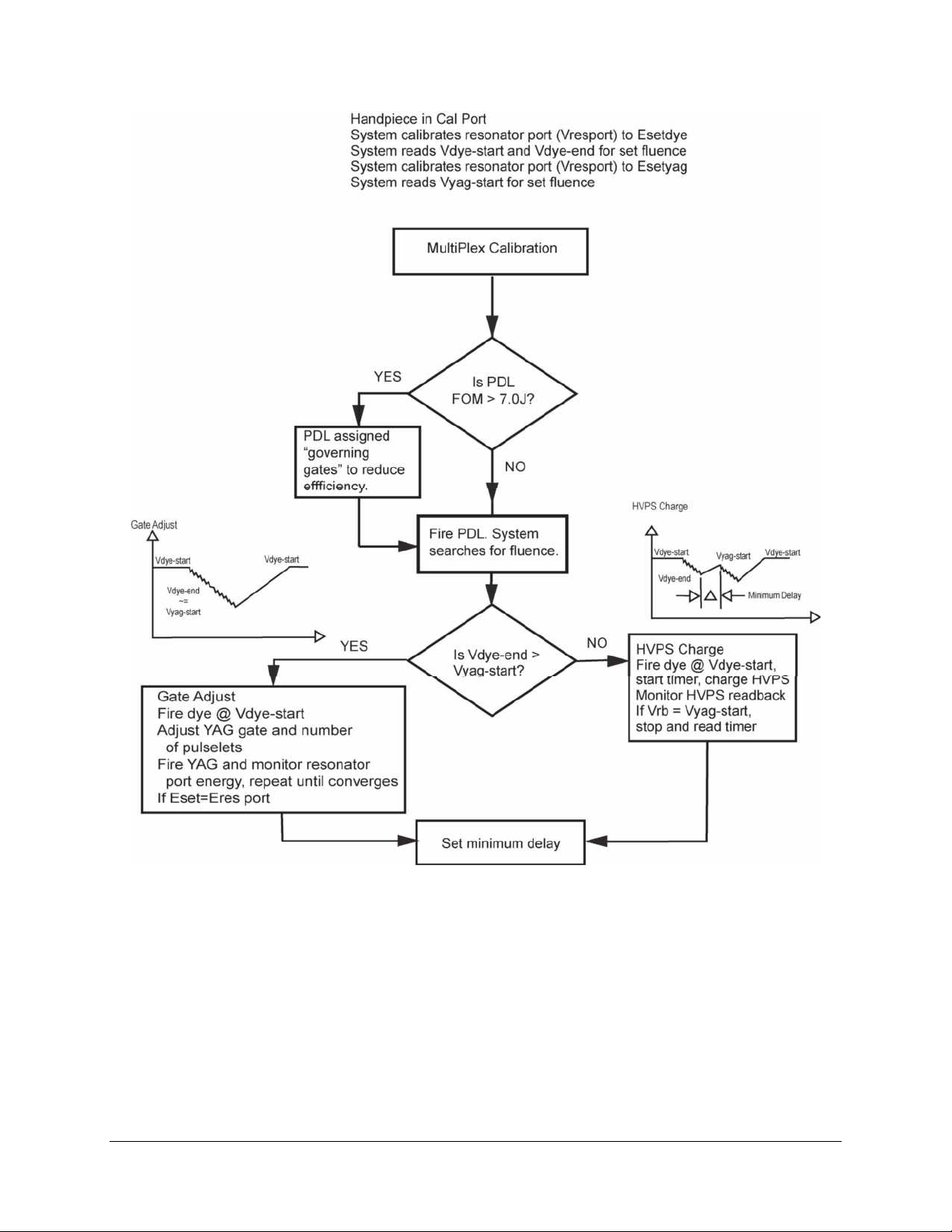

Figure 2C–Cynergy MultiPlex Flow Diagram .................................................22

Section 4 Laser Description............................................................................................23

Main Modules ...............................................................................................................23

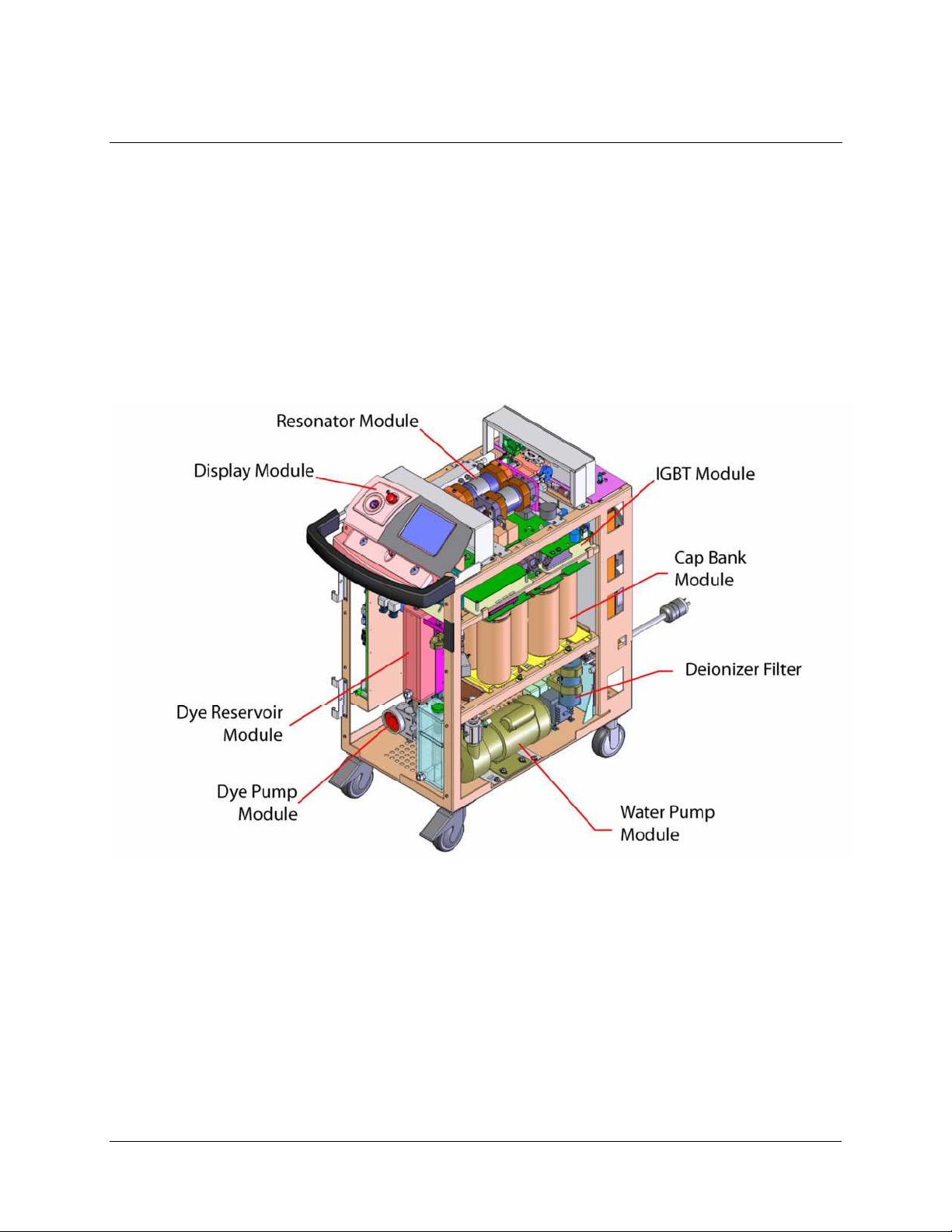

Figure 3A–Main Modules, Front View ............................................................23

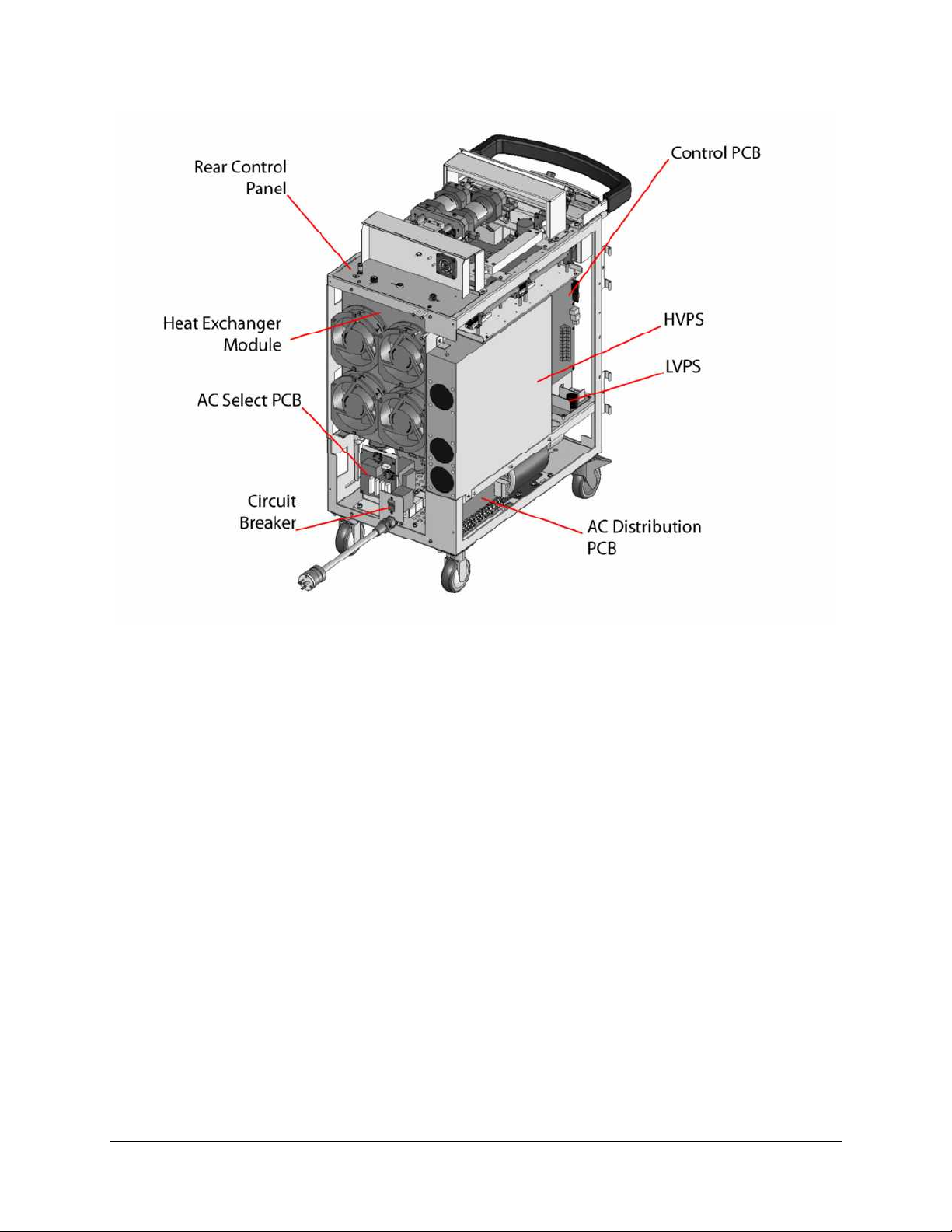

Figure 3B–Main Modules, Rear View..............................................................24

Cynergy Technical Guide 850-1265-000, Rev. 4 1 of 112

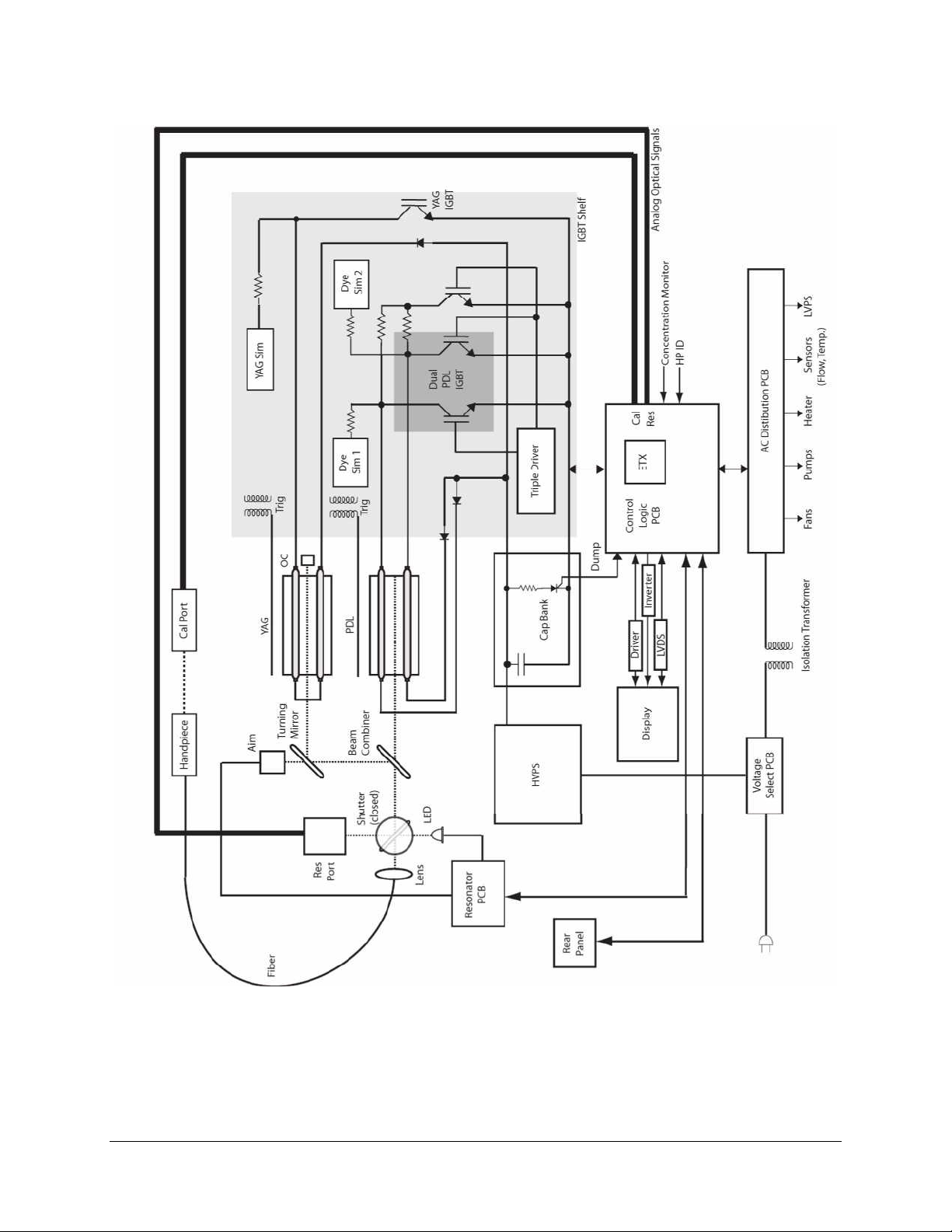

Figure 4–Cynergy System Block Diagram.......................................................25

High Voltage Power Supply Module............................................................................26

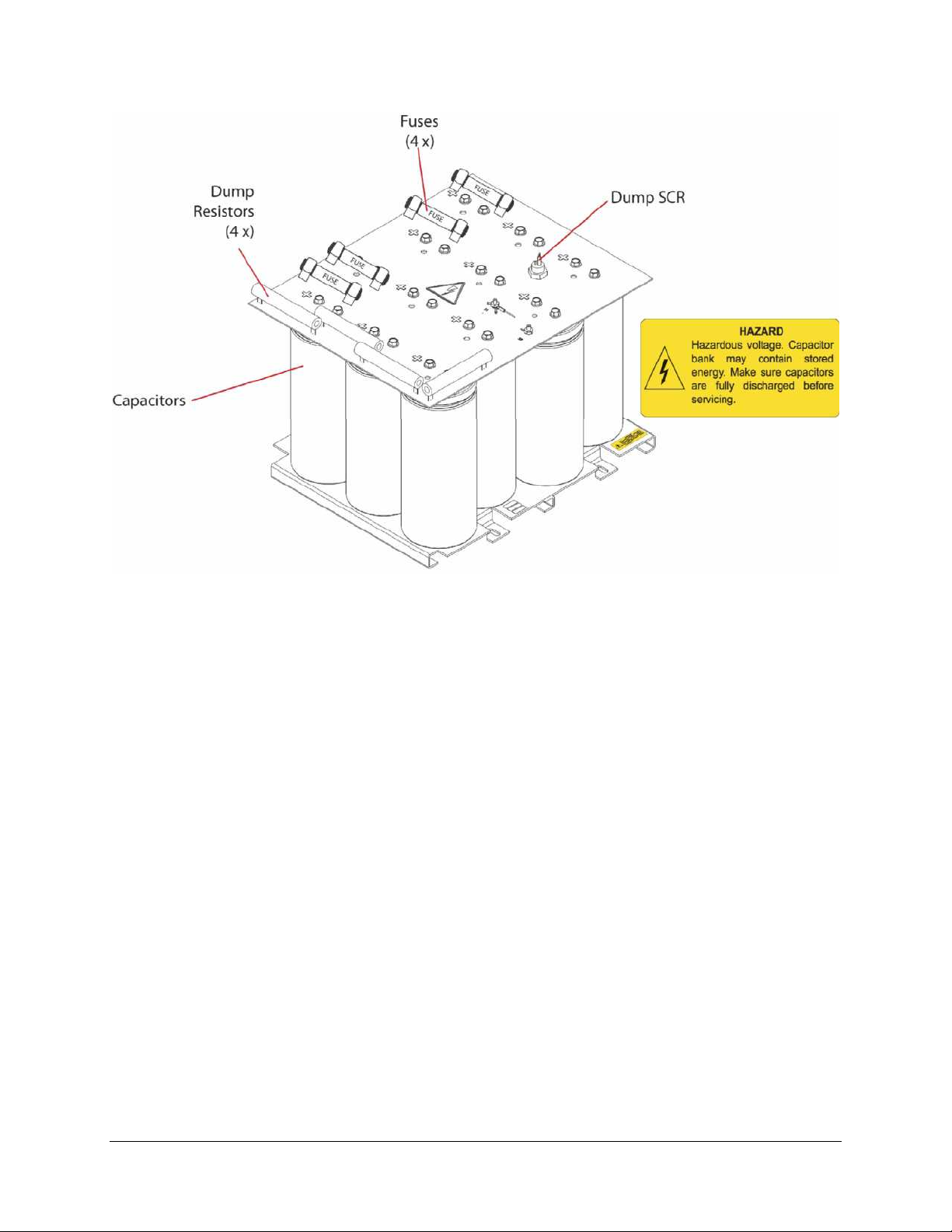

Capacitor Bank Module ................................................................................................26

Figure 5–Capacitor Bank Module.....................................................................27

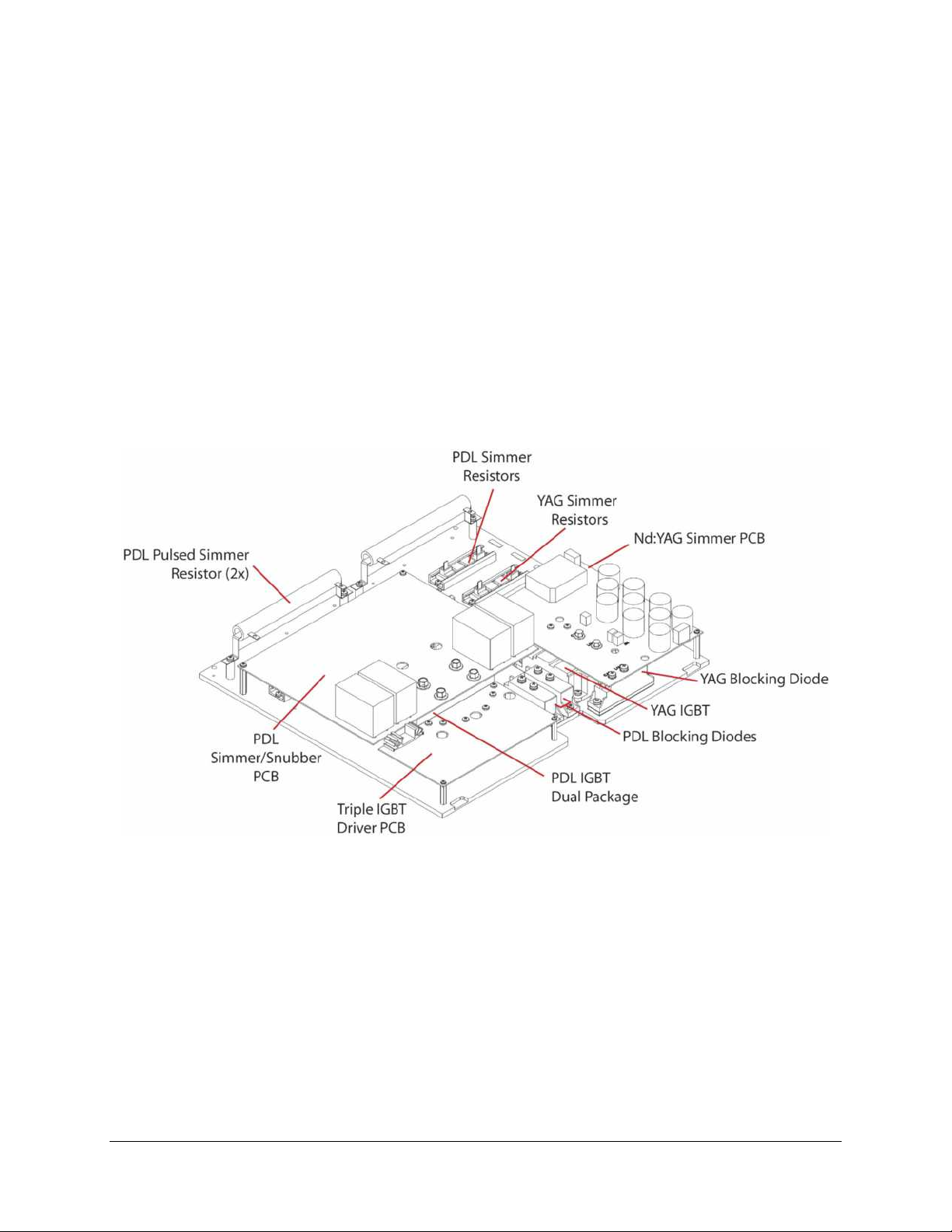

IGBT/Simmer Module..................................................................................................28

Figure 6–IGBT/Simmer Module.......................................................................28

Figure 7–Snubber Circuit..................................................................................29

Front Control Panel Module .........................................................................................30

Figure 8–Front Panel Display/Control Module ................................................30

Cal Port Assembly ............................................................................................30

Laser Control Board......................................................................................................31

Microcontroller .................................................................................................31

Optical Detectors ..............................................................................................31

Figure 9–Diagram, Laser Control PCB ............................................................31

High Voltage Controls ......................................................................................31

Software Controls .............................................................................................32

I/O Ports............................................................................................................32

Temperature Sensors.........................................................................................32

Figure 10–Control PCB ....................................................................................33

Rear Control Panel Module ..........................................................................................34

Figure 11–Rear Control Panel Module.............................................................34

Frame with Electrical Module ......................................................................................35

Figure 12A–Frame w/Electrical Module, Front View......................................35

Figure 12B–Frame w/Electrical Module, Rear View .......................................36

Resonator Rail Module .................................................................................................37

Figure 13A–Resonator Rail Module, Side View ..............................................37

Figure 13B–Resonator Rail Module, Top View...............................................38

Nd:YAG Laser Head.........................................................................................38

PDL Laser Head................................................................................................39

Resonator Reflectors.........................................................................................39

Fiber Block........................................................................................................39

Figure 14A–Fiber Block, Assembly .................................................................40

Figure 14B–Fiber Block, Beam Path................................................................41

Circulation Systems ......................................................................................................42

Water Circulation System.................................................................................42

Dye Circulation System ....................................................................................42

Figure 15–Circulation Systems Flow Diagram ................................................43

Figure 16–Dye Tank .........................................................................................44

Figure 17–Dye Concentration Sensor...............................................................45

2 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Figure 18–Dye Pump ........................................................................................45

Heat Exchanger Module ...............................................................................................46

Figure 19–Heat Exchanger Module..................................................................46

Water Pump Module.....................................................................................................47

Figure 20–Water Pump Module........................................................................47

Delivery System............................................................................................................48

Trigger Switches ...............................................................................................48

Figure 21–Delivery System ..............................................................................48

Section 5 Installation.......................................................................................................49

Section 6 Routine Maintenance/Service Equipment ....................................................51

Routine Maintenance ....................................................................................................51

Service Equipment........................................................................................................51

Hand Tools........................................................................................................51

Electrical Equipment.........................................................................................52

Optical Equipment ............................................................................................52

Miscellaneous Equipment.................................................................................52

Section 7 Servicing–Panel Removal...............................................................................53

Overview.......................................................................................................................53

Removing the Top Cover..............................................................................................53

Accessing the Laser Resonator .....................................................................................54

Removing the Side Panels ............................................................................................54

Removing the Rear Sub-Panels and Rear Panel ...........................................................54

Rear Sub-Panels................................................................................................54

Rear Panel .........................................................................................................54

Removing the Front Door .............................................................................................54

Section 8 Evaluating Performance/Planning a Fix.......................................................55

System Check–Display Results ....................................................................................55

System Check–Performance Criteria............................................................................55

Resonator Performance.................................................................................................56

Figure 22–Resonator Performance ...................................................................56

System Check or Laser Cal Condition Table................................................................57

System Check–Troubleshooting ...................................................................................58

Primary Optical Diagnostic Routine.................................................................58

Figure 23A–‘Primary Diagnostic Routine’ Flowchart .....................................58

PFN Diagnostic Routine ...................................................................................59

Laser Head Diagnostic Routine ........................................................................60

Figure 23B–‘Laser Head Diagnostic Routine’ Flowchart ................................60

Beam Train Diagnostic Routine........................................................................61

Figure 23C–‘Beam Train Diagnostic Routine’ Flowchart................................61

Cynergy Technical Guide 850-1265-000, Rev. 4 3 of 112

Section 9 Servicing–Laser Heads and Beam Train ......................................................63

Dye Kit Methodology ...................................................................................................63

Dye Kit Assessment..........................................................................................63

Dye Kit Assessment Checklist..........................................................................64

Dye Injection.....................................................................................................64

Figure 24–‘Dye Injection’ Diagnostic Routine Flowchart ...............................65

Fiber Block Removal Procedure...................................................................................66

SMA/Focus Lens Removal...............................................................................66

Fiber Block Removal ........................................................................................66

Quantifying Laser Output, PDL....................................................................................66

Verify FOM, PDL.........................................................................................................67

Resonator Alignment Procedure, PDL .........................................................................68

Rough Resonator Alignment.............................................................................69

Resonator Optics Inspection/Replacement Procedure, PDL ........................................70

Pump Chamber Replacement Procedure ......................................................................70

Quantifying Laser Output, YAG...................................................................................71

Verify FOM, YAG........................................................................................................71

Resonator Alignment Procedure, YAG ........................................................................72

Resonator Optics Inspection/Replacement Procedure, YAG .......................................73

Flashlamp Inspection/Replacement Procedure.............................................................74

Figure 25–Flashlamps.......................................................................................74

Beam Combiner Inspection/Replacement Procedure ...................................................75

Fiber Alignment Procedure, PDL .................................................................................75

Turning Mirror Inspection/Replacement Procedure .....................................................75

Fiber Alignment Procedure, YAG ................................................................................76

Handpiece Inspection/Repair/Replacement..................................................................77

Fiber Inspection/Replacement Procedure .....................................................................78

Focus Lens Inspection/Replacement Procedure ...........................................................79

Calibration Procedures..................................................................................................79

Section 10 Servicing–Electrical Modules ........................................................................81

Replacing the Front Control Panel Module ..................................................................81

Calibrating the Touch Screen........................................................................................81

Replacing and Calibrating the ETX PCB .....................................................................81

Section 11 Servicing–HVPS Module................................................................................83

Replacing the High Voltage Power Supply Module.....................................................83

Calibrating the HVPS ...................................................................................................83

Section 12 Servicing–IGBT/Simmer Module..................................................................85

Replacing IGBT/Simmer Module Shelf .......................................................................85

Replacing Low Voltage Power Supply.........................................................................85

Replacing IGBT Triple Driver PCB, PDL....................................................................86

4 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Replacing Simmer/Snubber PCB, PDL ........................................................................86

Replacing the Trigger Transformers.............................................................................86

Replacing the Simmer Transformers ............................................................................86

Section 13 Servicing–Capacitor Bank Module ...............................................................87

Removing the Cap Bank Module..................................................................................87

Replacing a Cap Bank Fuse ..........................................................................................87

Section 14 Servicing–Water Pump Module ....................................................................89

Draining the Coolant System........................................................................................89

Draining the Water........................................................................................................89

Replacing the Water Pump ...........................................................................................89

Replacing the Water Flow Switch ................................................................................90

Section 15 Servicing–Heat Exchanger Module...............................................................91

Replacing the Heat Exchanger Module ........................................................................91

Replacing the Temperature Sensor(s)...........................................................................91

Replacing the Deionizer (DI) Cartridge........................................................................92

Calibrating the Dye Concentration Monitor .................................................................92

Calibrating the Dye Temperature..................................................................................92

Section 16 Servicing–Dye Res/Dye Pump Modules........................................................93

Replacing the Dye Flow Switch ...................................................................................93

Replacing the Dye Pump ..............................................................................................93

Replacing the Dye Concentration Monitor...................................................................94

Section 17 Servicing–Frame w/Electrical Module..........................................................95

Replacing the Voltage Selection PCB ..........................................................................95

Replacing the AC Distribution PCB.............................................................................95

AC Fuses.......................................................................................................................95

Section 18 Servicing–Calibration Procedures ................................................................97

Schedule for Calibration ...............................................................................................97

Overview.......................................................................................................................97

Required Equipment .....................................................................................................98

Calibration Procedures..................................................................................................98

Calibrating the Resonator Port, YAG ...........................................................................99

Calibrating the Resonator Port, PDL ..........................................................................100

Calibrating the Cal Port, YAG....................................................................................101

Calibrating the Cal Port, PDL.....................................................................................102

Section 19 Servicing–Final Check..................................................................................103

Final Check Procedure................................................................................................103

Section 20 Troubleshooting ............................................................................................105

Troubleshooting ..........................................................................................................105

Cynergy Technical Guide 850-1265-000, Rev. 4 5 of 112

Faults...............................................................................................................105

Fault Code Table.............................................................................................105

Self Test ..........................................................................................................107

Troubleshooting Chart ....................................................................................108

Transferring Diagnostic Data..........................................................................109

Figure 26A–USB Access Panel Location.......................................................109

Figure 26B–USB Slot Location......................................................................110

Appendix A Laptop Computer..........................................................................................111

Attaching a Laptop Computer.....................................................................................111

HyperTerminal Setup..................................................................................................111

6 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

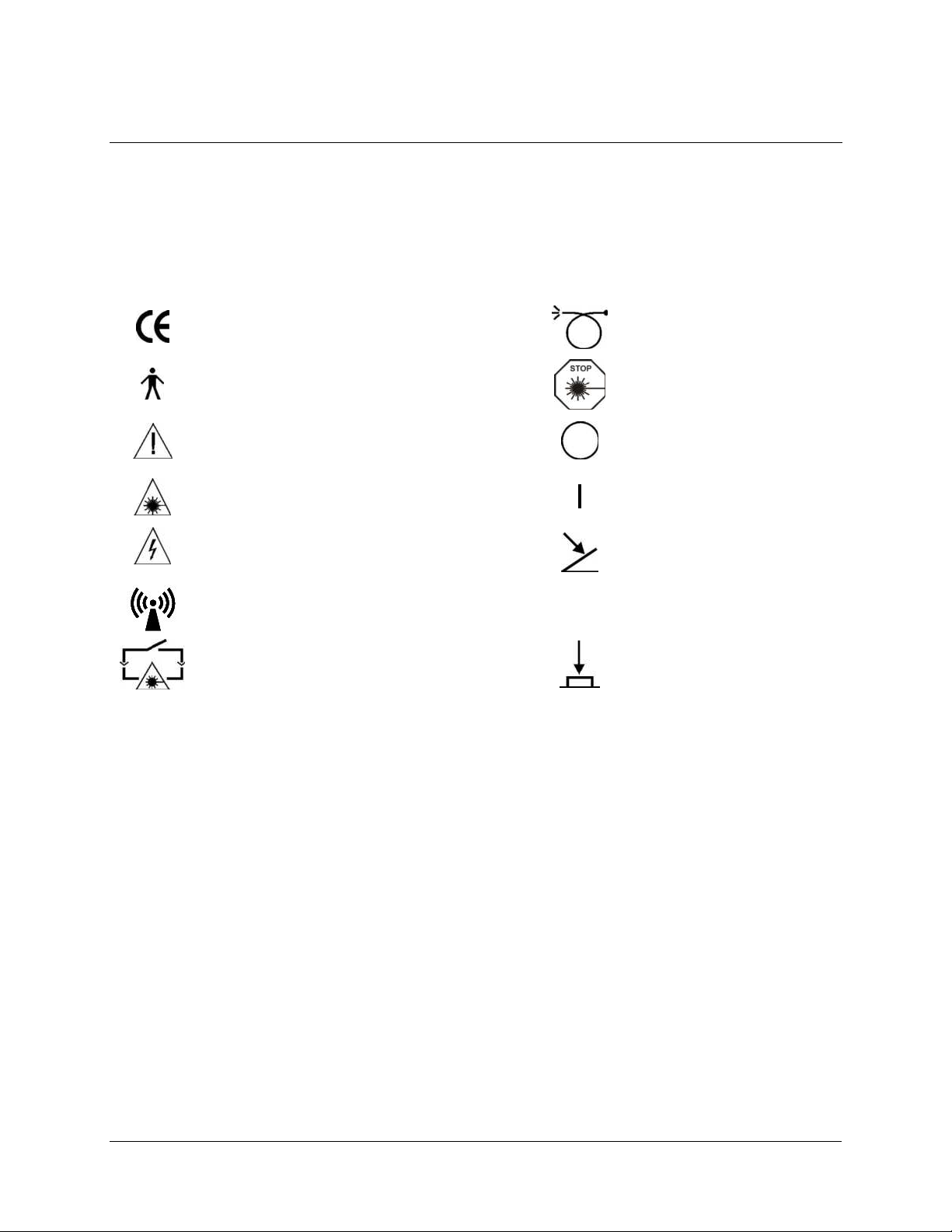

Glossary of Symbols and Abbreviations

The following international symbols and abbreviations may be used on the Cynergy lasers and/or

in this manual.

Symbols

Declaration of Conformity to

Medical Device Directive 93/42/EEC

CE Mark to Directive 93/465/EEC

Type B applied part per EN60601-1: 1990

Attention, consult accompanying documents

Laser Hazard Warning

Dangerous Voltage

Non-ionizing Radiation

Remote Interlock Connector per

EN60601-2-22: 1996

Abbreviations

Other

Symbols

Optical Fiber Applicator

per EN60601-2-22: 1996

Emergency Laser Stop

per EN60601-2-22: 1996

Off—power disconnection

from mains

On—power connection to

mains

Foot Switch

Hand Switch

°C Degrees Celsius V Volts

A Amperes DVM Digital Voltmeter

mA Milliamp Hz Hertz

µA Microamp J Joule

AC Alternating Current

cm Centimeter

mm Millimeter

nm Nanometer

CW Continuous Wave

Cynergy Technical Guide 850-1265-000, Rev. 4 7 of 112

J/cm² Joule per square centimeter

kW Kilowatt

ms Millisecond

Ω Ohms

mΩ Milliohms

This page has been intentionally left blank.

8 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Section 1 Introduction

Disclaimer

The Cynergy Technical Guide is written specifically for service technicians and customers who

have received formal training in the servicing of Cynosure laser systems. Cynosure requires that

all technicians who plan to service these lasers attend an authorized training program.

Information on service training programs may be obtained by contacting Customer Service, see

contact information on page 9.

The technical guide provides useful information about the maintenance and servicing of the

laser. It is not intended to be a complete guide.

Cynosure does not accept responsibility for personal injury or property damage resulting from

the servicing of Cynosure equipment by its customers or by third parties, except where such

injury or damage is a direct result of Cynosure’s negligence. Customers, by accepting the service

manual, agree to indemnify Cynosure against any claims alleging personal injury or property

damage resulting from the servicing of Cynosure equipment by the customer or by third parties,

except where such injury or property damage is a direct result of Cynosure’s negligence. These

limitations include situations where Cynosure personnel advise customers on the repair of

Cynosure equipment over the telephone.

Any servicing of Cynosure equipment by individuals who have not completed a current

Cynosure training program for that equipment will void Cynosure’s product warranty.

Contacting Customer Service

If there is a technical problem with the laser, contact the Cynosure Service Department.

Normal Business Hours Monday–Friday, 7:30 am–7:00 pm EST

Call: 1-888-523-2233;

or fax to (978) 256-6556 or (978) 256-4888.

After Hours and Weekends Call: 1-888-692-2966.

If there is a question regarding clinical information call Cynosure.

Normal Business Hours Monday–Friday, 9:00 am–5:00 pm EST

Call: 1-800-886-2966 ext. 443

Cynergy Technical Guide 850-1265-000, Rev. 4 9 of 112

About the Laser

The Cynergy laser system manufactured by Cynosure is considered to be the ultimate vascular

lesion laser workstation. It combines a high performance pulsed dye laser (PDL) operating at

585 nm± 2% with a high performance YAG laser (1064 nm) delivered through one delivery

system and selectable with the touch of a button. In addition, selected models of the laser have

the capability of delivering both wavelengths in one pulse, separated by a selectable delay, for

added clinical benefit.

There are two upgrade paths that are planned for this product. One path involves taking a V-Star

in this chassis and adding the YAG resonator and controls to become a Cynergy. The other takes

a Cynergy and adds the MultiPlex option which allows the user to deliver both wavelengths in a

single pulse.

Figure 1–Cynergy, Cynergy PL and Cynergy III

To further augment the versatility of the workstation, the Cynergy laser serves as a platform for

an intense pulsed light source, the Cynergy PL™. Combining the Cynergy with the Cynergy PL

yeilds a complete system called the Cynergy III™. The technical guide for the Cynergy PL is

covered in another document. This guide covers all aspects of the Cynergy laser, including PDL,

YAG and MultiPlex options.

™ Cynergy PL and Cynergy III are trademarks of Cynosure, Inc.

10 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

About the Technical Guide

The technical guide provides information on the following topics:

♦ Equipment Safety

♦ Laser Description

♦ Theory of Operation

♦ Installation

♦ Service Procedures

♦ Routine Maintenance

♦ Troubleshooting

♦ Calibration Procedures

The Cynergy Technical Guide applies to the Cynergy and the Cynergy MultiPlex systems.

The Cynergy Service Manual, doc. 850-1270-100, includes this technical guide, the operator

manual, and a comprehensive drawing set and procedures that will aid in the understanding of

salient mechanical and electrical assemblies. Additionally, electrical schematics and technical

illustrations are provided. It is important to check the revision level of controlled drawings as

designs change. Upon request, Cynosure will provide circuit diagrams, component part lists,

descriptions, calibration instructions, or other information not already contained within the

service manual to assist appropriately qualified technical personnel to repair those parts of the

laser system that are designated by Cynosure as repairable. “Appropriately qualified technical

personnel” refers to personnel who have undergone Cynosure’s Service Training Course for the

Cynergy laser system and have been authorized in its repair.

Service personnel are encouraged to familiarize themselves with the laser and its operation.

Make sure all components within the laser can be identified. Understand the Performance

Criteria as outlined on page 55. Follow the Troubleshooting Sequence to restore performance if

the laser does not meet or exceed the defined performance criteria.

WARNING: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Cynergy Technical Guide 850-1265-000, Rev. 4 11 of 112

This page has been intentionally left blank.

12 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Section 2 Equipment Safety

Introduction

As with any electrical equipment, there are potential hazards involved with the operation and

servicing of the laser system. This section of the technical guide identifies these potential hazards

and suggests precautions to avoid them.

Potential Hazards

Optical Hazard

The PDL side of the Cynergy laser generates laser light at a wavelength of 585 nm ± 2% with a

maximum energy of approximately 8 joules delivered from the handpiece. The YAG side

generates laser light at a wavelength of 1064 nm with a maximum energy of approximately 63

joules delivered from the handpiece. Greater energies can be generated from the laser head

especially during service operations. At these wavelengths and energy levels, serious and

permanent damage to the eyes can occur when there is direct or even indirect optical exposure.

WARNING: Do not look directly at laser resonator as the flashlamps fire or severe and

permanent eye damage may occur. These lasers produce laser light each time the

flashlamps fire. Make certain to wear the correct laser eyewear for the wavelength you are

servicing.

Please adhere to the following precautions to avoid optical damage during the operation or

servicing of the laser:

♦ Ensure that everyone present during service procedures wears the appropriate protective

eyewear recommended by Cynosure.

♦ Never look directly into the laser light, even while wearing protective eyewear.

♦ Mark treatment rooms clearly to avoid unexpected entry during treatment or servicing.

♦ Limit entry to the treatment or servicing room to trained, necessary personnel only.

♦ Cover windows and other openings in the treatment room to avoid the inadvertent escape

of laser light.

♦ Cover reflective objects, such as jewelry or mirrors, which could reflect the laser beam to

an area other than the intended treatment area.

♦ Put the laser into the standby mode when the laser is not in use.

♦ Ensure that everyone present during service procedures can shut down the laser in an

emergency.

Cynergy Technical Guide 850-1265-000, Rev. 4 13 of 112

Electrical Hazard

The system requires 220 VAC ± 10%, 30 A, 50-60 Hz, single-phase electrical service to operate.

WARNING: Even when the laser is off and the AC line cord is disconnected, DC

voltages on various laser components, such as capacitors may exist. This can present a

potentially fatal electrical hazard during service procedures.

Take the following precautions to avoid electrical shock during servicing:

♦ Always turn the laser off and disconnect the AC line cord from the receptacle before

removing the protective housing of the laser system.

♦ With the laser off, allow the dump resistors to dissipate the energy in the pulse forming

network capacitors to a safe level, approximately 45 seconds. Monitor the voltage on the

capacitors with a DVM probe to ensure it is at a safe level.

IMPORTANT: The Cynergy laser system, the capacitor bank does not dump when

going between laser states (Ready to Standby) or between laser wavelengths. The

only time it dumps is when the user selects Utility. The capacitor bank voltage is

displayed on the screen as a quick reference, but the voltage on the lamps should

still be checked with a DVM prior to servicing.

♦ If it is necessary to test or adjust any electrical component while the system power is on,

be careful not to touch any electrical components with bare fingers; use appropriate

probes or insulated tools only.

♦ Become familiar with the electrical schematics and layout of the system before

attempting to service the laser.

If the AC must be connected during service routines, exercise caution around mains connected

components, such as power supply feeds, circuit breakers, key switches, etc. A remote interlock

fault condition will reduce high voltage electrical hazards to service personal. This fault

condition disables the high voltage power supply control and simmer circuits, as well as ensuring

that the dump relay is closed, grounding the potential of the pulse forming network. When

possible, remove the remote interlock plug during “live” service routines.

Grounding

Even when the laser is turned off and the AC line cord disconnected, high DC voltage levels may

remain. Before performing any procedure, use a shorting stick

to ground all interior components.

The main capacitor bank stores large amounts of electrical energy. Measure the voltage on the

capacitor bank before attempting any service. Ground the capacitor bank with a shorting stick for

at least five seconds.

WARNING: Do not attempt to short directly (i.e., with a screwdriver) or a potentially fatal

electrical shock can occur.

14 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Fire Hazard

When the laser beam contacts any exterior surfaces, the surface absorbs the laser energy, which

raises the surface temperature of any flammable substance. Service personal must take the

following precautions.

♦ Always keep a small fire extinguisher and water in the treatment room.

♦ Never direct the laser beam onto any surface except a power meter or an appropriate

beam dump.

Chemical Hazard

The Cynergy laser uses a dye medium. Handle the dye with care, both to protect against toxicity

and against staining. Operators should follow these precautions:

♦ Wear rubber or plastic gloves when handling the dye.

♦ Do not dispose of dye down drains.

♦ Return empty dye bottles and used filters to Cynosure.

♦ Avoid spillage on fabrics or on any porous material.

Potential Chemical Accidents and Appropriate Responses

The following table lists potential chemical accidents and their appropriate emergency responses.

Chemical Accident Appropriate Emergency Response

Ingestion of dye or solvent Drink water, induce vomiting, and seek immediate

medical attention.

Excessive inhalation of dye or solvent Go outdoors and inhale fresh air.

Seek medical attention if symptoms appear.

Eyes exposed to dye or dye solvent Rinse eyes with water.

Seek medical attention if symptoms appear.

Skin exposed to dye or dye solvent Immediately wash the exposed skin area with plain

water, then with soap and water.

Hot-Water Hazard

The laser system can possibly reach 65 °C in normal operation. This water is very hot and could

scald. Do not perform any maintenance on the water system while hot. Always let the system

cool down before changing the deionizing filter or adding deionized or distilled water.

Cynergy Technical Guide 850-1265-000, Rev. 4 15 of 112

This page has been intentionally left blank.

16 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Section 3 Laser System Controls

Calibration

At the factory or during field tests, both the calibration port and resonator port must be calibrated

for the system to accurately measure output energy. The resonator port will act similar to the

modular Elite laser, where the full energy will be measured. Initially, the resonator port will have

to be calibrated at two points for the two wavelength checkpoints used in System Check. The

resonator will be used for transmission data only.

Once the two ports are carefully calibrated, the user simply adjusts the laser to the settings they

want and either wait 5 seconds for the laser to calibrate automatically, or press the screen where

indicated by the instructions on the display to initiate the calibration process. For any change,

even fluence (the handpiece must be in the cal port) the laser automatically fires into the cal port

and adjusts the PFN voltage to match the setting. During this period, CAL appears in the upper

left area of the display. Once the laser arrives at the settings, the upper left will toggle to READY

indicating that the handpiece can be removed from the cal port and treatment begun.

Memory

The system defaults to the lower fluence settings on the first start-up after a System Check, but

later memorizes the last settings and uses them at start up. This avoids having to set the laser

each day or set when switching between lasers.

Operating Modes, User

Normal Operation

In normal operation before the warm-up, a self-check is conducted by the laser to test shutters,

simmer circuits, etc. Afterwards, the system warms up for typically less than 15 minutes. During

the warm-up period, the system checks the dye concentration. If low, the system will boost the

dye concentration until it reaches an acceptable level. Normally this will not significantly delay

the warm-up, but in extreme cases this may take up to 30 minutes to resolve itself. After the dye

concentration has reached an acceptable level, the system will not adjust the dye concentration

unless the laser is restarted.

Cynergy Technical Guide 850-1265-000, Rev. 4 17 of 112

System Check

System Check consists of testing the laser at one set of operating parameters per wavelength to

determine basic, acceptable performance. This is often referenced to as Figure of Merit (FOM)

performance.

First: After the laser has warmed up, the dye laser is fired at 750V, 0.5 ms and an output > 4.0

Joules must be recorded at the resonator port and the transmission must be greater than

50%. (A warning is provided at 65% and the output governed). A minimum of three

shots should be taken with a sampling of the last.

Second: After the laser has warmed up, the YAG laser is fired at 750V, 5 ms and an output >25

Joules must be recorded at the resonator port and the transmission must be greater than

50%. (A warning is provided at 65% and the output governed). A minimum of three

shots should be taken with a sampling of the last.

If upon start-up, the laser cannot meet the minimum acceptable performance, the microprocessor

determines the root of the problem in the Performance Diagnostic routine.

Performance Diagnostic Routine

The system determines which laser, if any, is not performing and which transmission, if any, is

unacceptable. The system signals for the operator to change handpieces/fibers, notifies the user

that only one laser can be used and that service is required, or notifies the user that both lasers

are unusable and to call for service.

Cynergy MultiPlex

The Cynergy MultiPlex mode consists first of a PDL pulse, set at any fluence for a 7- or 10-mm

HP followed by a YAG laser pulse with similar adjustments. Pulse widths are controlled by

8 pulse groups that assign clinically relevant pulse width combinations to the two lasers. The

available delay between pulses will vary for different pulse groups. The delay between pulses is

variable, but not without limitations. NOTE: The health of the two laser systems are relative to

one another will affect the minimum possible delay time. Refer to the Cynergy Operator Manual

Specification section for pulse group information.

18 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Operating Modes, Service

The above descriptions pertain to the User Mode Program that incorporates safety features, error

and warning codes, feed back control of the settings and insures accurate calibrations. Two other

modes of operation are Testall and CV (Constant Voltage).

Testall allows service personnel to turn on and off individual or groups of functions for test

purposes. CV displays the voltage and does not calibrate to a set fluence, but allows operation at

a set voltage. Both have many of the safety features defeated and are only used by service

personnel.

Accessing Testall Mode

1. Attach a laptop as detailed in “Appendix A” starting on page 111.

2. Turn on the laser and press “q” and press enter to access the DOS prompt.

3. Type “TN” and then enter to access Testall Mode.

Accessing CV Mode

1. Attach a laptop as detailed in “Appendix A” starting on page 111.

2. Turn on the laser and press “q” and press enter to access the DOS prompt.

3. Type “CV” and then enter to access CV Mode.

Cynergy Technical Guide 850-1265-000, Rev. 4 19 of 112

Figure 2A–Performance Diagnostic Flow Diagram

20 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Figure 2B–Normal Operation Flow Diagram

Cynergy Technical Guide 850-1265-000, Rev. 4 21 of 112

Figure 2C–Cynergy MultiPlex Flow Diagram

22 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Section 4 Laser Description

This section of the manual gives a detailed description the laser system including block

diagrams, identification of the main modules and their related components, and a description of

the control philosophy, display and user interface.

Main Modules

Refer to Figures 3A and 3B for the location of the main modules that comprise the laser system.

Figure 3A–Main Modules, Front View

Cynergy Technical Guide 850-1265-000, Rev. 4 23 of 112

Figure 3B–Main Modules, Rear View

Figure 4 shows the relationships of the main components in the Cynergy laser. The diagram

indicates AC is brought into the laser through the voltage select PCB, and then is directed to the

HVPS directly and to the isolation transformer. At the AC distribution PCB, the AC is separated

into circuits with their own solid-state relays and fusing. The main signals to the control system

are shown including two analog optical signals used for calibration. The HVPS charges a

capacitor bank, whose charge is gated through the flashlamps by IGBTs on the IGBT shelf under

the resonator assemblies. The two-lamp, series drive circuit for the YAG laser is identical to the

drive circuit on the Modular Elite, sharing many of the same parts. The two-lamp, parallel-drive

circuit is more complex for the dye laser; it involves two IGBTs to switch the current through the

individual lamps and another to drive a pulsed simmer. These three IGBTs are driven from the

triple diver PCB. The simmer current is initiated in both heads by striking the trigger

transformers and a separate DC low-current supply provides a soft, blue glow.

24 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Figure 4–Cynergy System Block Diagram

NOTE: See schematic, 105-1865-000 for a detailed system-wiring diagram.

Cynergy Technical Guide 850-1265-000, Rev. 4 25 of 112

High Voltage Power Supply Module

The High Voltage Power Supply (HVPS) is a modular inverter capacitor-charging power supply.

This device accomplishes the primary energy conversion for the laser. It converts input power of

220 VAC, 50 or 60 Hz, to a controlled, high-voltage direct current. One of two charge rates,

1000J/sec or 4000J/sec, may be set externally by a toggle switch. A software controlled lowvoltage analog signal is used to set the appropriate HVPS output voltage level during laser

operation. When enabled, the power supply charges the capacitor bank through the capacitor

bank fuses. The laser control board also inhibits, enables and regulates high voltage output level

depending on the state of the laser.

For demonstration purposes, the system can operate at reduced power with 120VAC, 15Arms

input power. In the “low charge rate” or 120V mode, the power supply will charge the 24,000µF

capacitor bank in 5.3 seconds (from 750 to 1000VDC). This setting substantially reduces the

laser pulse repetition frequency and is intended for demo purposes only. In the “high charge rate”

or normal operating mode, the power supply will charge the 24,000µF in 1.3 seconds (750 to

1000VDC). To select the power supply charge rate, see section on setting the voltage” in the

Cynergy Quick Install Guide.

The power supply control voltage set’s the capacitor bank voltage and is a 0 to 8Vdc analog

signal which corresponds to “150V

pin 5 on the control interface cable. The enable/reset signal or the on/off control for the power

supply is controlled by grounding pin 1 on the control interface cable. Applying a <1 volt signal

to pin 1, the power supply receives an inhibit signal to turn it off and resets the fault latch.

Applying + 15VDC to pin 1, enables that power supply to turn it on. A read back signal is

generated in the power supply and is transmitted to the front control module through pin 7 on the

control interface cable. This read back is an analog output of 0 to 8 volts and is “1V/150V.” The

end of charge indication is transmitted through pin 13. This signal goes low when the power

supply has reached the programmed output voltage (pin 5).

If the power supply charges for more than 20 seconds and does not reach the program voltage,

pin 2 goes high indicating an overload condition. This will provide a power supply fault and the

laser will go into a fault condition. Power supply fault conditions are sent out on pins 2 and 6.

/V.” This control voltage goes into the module through

OUT

Capacitor Bank Module

WARNING: High Voltage Danger! The capacitor bank stores dangerous voltage and

energy levels during laser operation. Please handle with extreme caution.

The capacitor bank module, see Figure 5, consists of twelve 18,000 µF, 400-volt capacitors

coupled in a series/parallel configuration to provide a 1200-volt, 17.3-kilojoule stored energy

source. This large amount of stored energy must be regarded carefully.

Only a fraction of this stored energy is drained off for a given laser pulse. In a fault condition,

the stored energy is discharged through an electronic dump circuit within the module.

26 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Figure 5–Capacitor Bank Module

To protect the power supply from damaged capacitors, there is fuse protection in the module.

There are four 40-amp, 1000-volt, slow-blow fuses. Each fuse is connected to one of the four

triad-connected, high-voltage capacitors. The fuse is designed to protect the storage capacitors

against any excessive current draw that may occur with a short, such as a flashlamp or another

capacitor shorting to ground.

The capacitor bank module also houses the electronic dump circuit. The electronic dump is

turned ON and OFF by an optical signal from the control board through fiber TX4 to RX1,

opto transistor, on the capacitor fuse bank PBC. An optical signal is illuminated when the laser

goes into standby and ready modes. The optical signal turns on RX1, which shorts capacitor C10

keeping SCR Q1, and allowing the HVPS capacitors to charge to the required voltage. When the

signal to RX1 is turned OFF, the opto transistor will turn off causing C10 to charge through R17

to about 30-34 volts, and allowing the voltage to dump through the diac (D1). This discharge is

the trigger to turn on the SCR (Q1). This allows a direct circuit from the capacitors through four

50-watt, 25-ohm resistors to the ground plane, and the high voltage will discharge. When all of

the capacitor voltage goes to zero volts, the current through the SCR stops and the SCR turns off.

There is also a signal that goes through TX1 to tell the CPU/Control PCB that the laser is in

dump mode. TX1 is also used for the fuse short signal. If TX1 turns on and the laser is not in the

dump mode, a fuse short condition is recorded and displayed on the front panel.

Cynergy Technical Guide 850-1265-000, Rev. 4 27 of 112

IGBT/Simmer Module

WARNING: Use extreme caution while working in the high voltage subsystem. High

voltage may be present at any time! Electrical shock or burns can occur. Limit access to

factory-trained personnel.

The Insulated Gate Bipolar Transistor (IGBT)/Simmer module is shown in Figure 6. Four

IGBTs are used in the Cynergy laser. A single IGBT is used to energize the YAG laser. Two

IGBTs, driven in parallel, are used to energize the PDL. A fourth, smaller IGBT, is used to

provide pulsed simmering for the PDL. The driver for the YAG IGBT is found on the

IGBT/simmer PCB. As its name suggests it provides two functions: simmering and IBGT

driving. The two IGBTs for the dye laser are driven by the triple IGBT driver PCB. Mounted on

it is the small IGBT for the pulsed simmer, while it is mounted on the dual IGBT for energizing

the dye laser. Simmering capability for the dye lamps and snubbing for the IGBTs that energize

the dye laser are provided by the snubber /simmer PCB, which is mounted to the upper tier of the

dual IGBT.

Figure 6–IGBT/Simmer Module

One of the unique features of the Cynergy laser is that both the YAG laser and the PDL use the

energy stored in the capacitor bank PCB. Each driver board has its own isolated power supply,

mounted to each PCB, ensuring that each IGBT is isolated from primary side AC power and

power coming from the LVPS. This will be discussed further in the section on Laser Control.

Important functions of the YAG/IGBT driver board are to control, monitor and report operation

of the IGBT using fiber-optic input and output. For example if is an optical pulse of 5msec is

received by the IGBT driver board from the laser control board, the driver board will generate an

electrical gate pulse for 5msec. This activates the IGBT device for 5msec. Optical transmitters

pass on fault status to the laser control board.

28 of 112 850-1265-000, Rev. 4 Cynosure, Inc.

Loading...

Loading...