Page 1

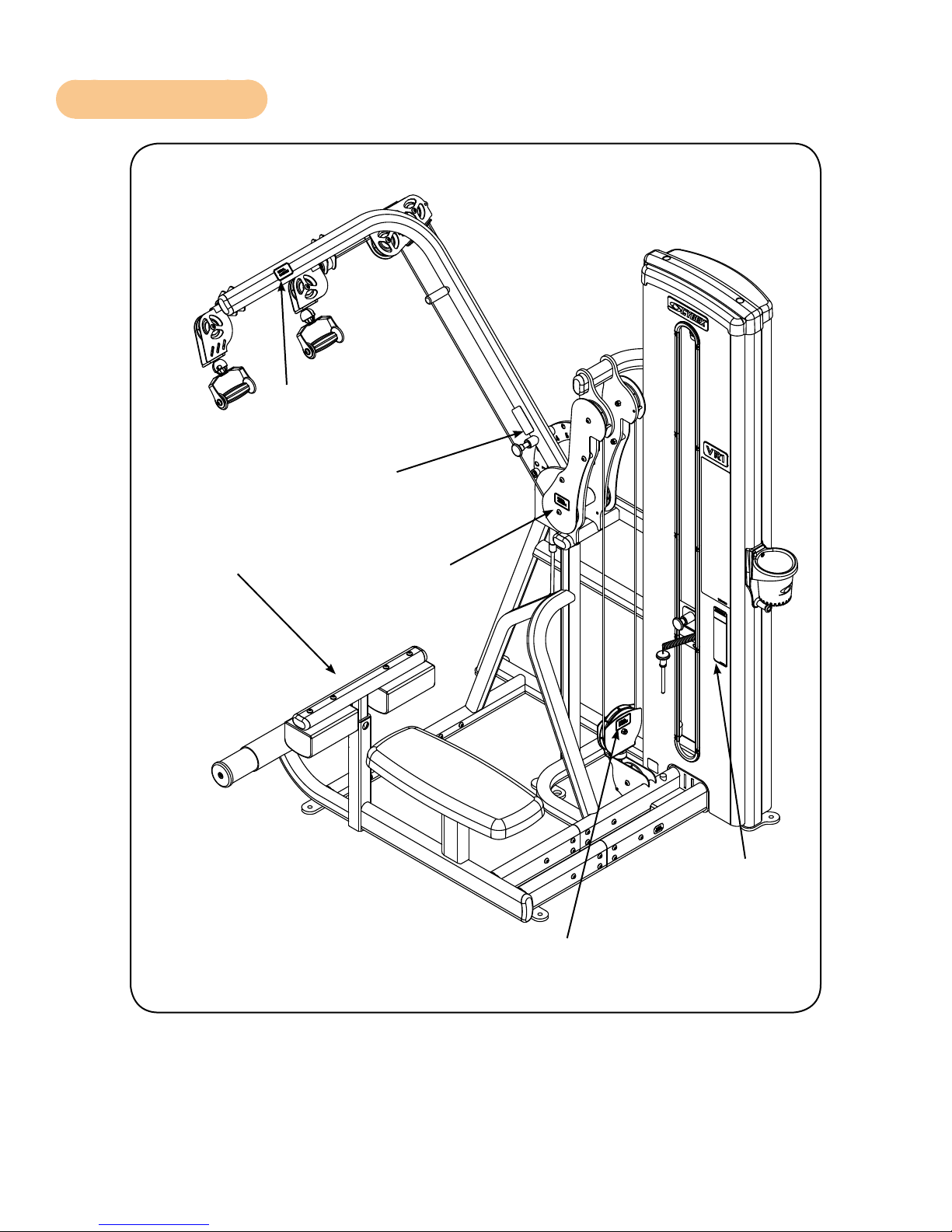

VR1® Lat/Row

Owner’s Manual

Strength Systems

Part Number 13250-999-4 E

www.cybexintl.com

Page 2

Table of Contents

Safety

Safety Guidelines And Practices ............... 3

Securing Equipment ......................... 6

Warnings and Cautions ...................... 7

Label Placement............................ 8

Assembly

Machine Specications....................... 9

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assembly Procedures........................ 9

Environment and Storage.................... 13

Exercise

Intended Use ............................. 14

Instructions ............................... 14

Maintenance

Daily Procedures .......................... 15

Weekly Procedures ........................ 18

Yearly Procedures ......................... 20

Cable Adjustment .......................... 21

Belt Adjustment............................ 22

Customer Service

Product Registration........................ 23

Contacting Service ......................... 23

Ordering Parts ............................ 24

Return Material Authoriazation (RMA) .......... 24

Damaged Parts............................ 25

Cybex® and the Cybex logo are registered trademarks of Cybex International, Inc.

VR1® and its mark are registered trademarks of Cybex International, Inc.

DISCLAIMER: Cybex International, Inc., makes no representations or warranties regarding the contents of this manual. We reserve the right to revise

this document at any time or to make changes to the product described within it without notice or obligation to notify any person of such revisions or

changes.

© Copyright 2012, Cybex International, Inc. All rights reserved. Printed in the United States of America.

10 Trotter Drive Medway, MA 02053 • 508-533-4300 • FAX 508-533-5183 www.cybexintl.com • 13250-999-4 E • February 2012

Page 3

Cybex Owner’s Manual

Safety

Safety Guidelines And Practices

Cybex International partners with equipment owners to establish the safest and most effective setup

of Cybex equipment. Cybex International urges each facility owner to carefully follow all safety

precautions. Following theses precautions are the best protection against personal injury or damage

to equipment or facility.

The most important safety precaution is to maximize stability for every piece of equipment. The

equipment should be securely anchored to the oor. It is imperative the oor be level.

Cybex recommends that all tness equipment be used in a supervised area. It is recommended that

the equipment be located in an access controlled area. Control is the responsibility of the owner. The

extent of control is at the discretion of the owner.

It is the responsibility of the purchaser/owners of Cybex products to read and understand the owner’s

manual, and warning labels; as well as instruct all individuals, whether end users or supervising

personnel, on proper usage of the equipment.

Read the Owner’s Manual carefully before assembling, servicing, or using the equipment. In an

institutional environment, it is the facility owner’s responsibility to properly instruct users on the proper

operation of the equipment and to warn them of the potential hazards.

Follow and enforce the User Safety Precautions to protect both the user and the equipment.

Keep children away from selectorized strength equipment. Teenagers or disabled users must be

supervised.

Do not allow anyone, including trainers, to use equipment in a manner other than shown on the

instructional placards located on every machine.

It is the responsibility of the facility owner and/or owner of the equipment to instruct users on proper

operation of the equipment and review all labels.

WARNING: Serious injury or death could occur if these safety precautions are not

followed:

User Safety Precautions

• Read all warnings posted on the machine. Warnings are posted on each machine to alert the

user to potential problems. Following warning labels will prevent injury or equipment damage.

• Read and understand warning labels and instructional placards prior to exercising. Obtain

instruction prior to use. Each machine has instructions posted on the equipment for proper

use.

3

Page 4

Cybex Owner’s Manual

• Use the selectorized and plate loaded machines as shown on placards. DO NOT modify the

machine.

• Never pin the weights in an elevated position. DO NOT use the machine if found in this condition.

Seek assistance from oor staff. Weights pinned up have the potential to fall if the user pulls the

pin. Floor staff should lower the weights to prevent potential problems.

• Be certain that the weight pin is completely inserted (for selectorized strength equipment that

employ weight stacks). If the pin is not completely inserted the user may accidentally drop the

weights if the pin falls out.

• Never use dumbbells or other means to incrementally increase the weight resistance. Use only

those means provided by the manufacturer for the equipment. Altering the machine design by

adding additional weight as with dumbbells or other means can injure the user, may damage the

equipment, and will void the warranty.

• Set up, anchor, and operate selectorized strength equipment on a solid level surface. If the oor is

not level the equipment is not stable.

• DO NOT wear loose or dangling clothing or jewelry while using selectorized strength equipment.

Stay clear of all moving components. Loose clothing or dangling jewelry can become entangled in

moving parts and potentially cause severe injury or damage.

• Consult a physician prior to commencing an exercise program. If at any time during exercise you

feel faint, dizzy or experience pain, stop and consult your physician. Users must be responsible

and cautious with the condition of their own health. Consulting a physician before beginning a

program can alert the user to the personal risk if health is an issue.

• Use a spotter for Free Weight equipment. A spotter adds an additional level of safety.

• DO NOT exceed the maximum specied user weight. Too much weight on a machine may prevent

it from proper function or damage the machine.

• DO NOT use if equipment appears damaged or inoperable upon inspection. If the equipment

appears damaged or inoperable- contact the oor staff.

• DO NOT attempt to x a broken or jammed equipment. Notify oor staff. It is the owner’s

responsibility to repair broken or jammed equipment.

• DO NOT use if guards are missing or damaged. A missing or broken guard should be replaced by

a qualied technician. Guards prevent things from interfering with function.

• DO NOT remove any labeling from equipment. Replace any damaged labels. Labels give users

specic information and alerts. Replacing damaged labels ensures users can read the labels for

information provided.

Facility Safety Precautions

• Read the Owner’s Manual carefully before assembling, servicing or using the equipment.

• It is the sole responsibility of the user/owner or facility operator to ensure that regular maintenance

is performed.

4

Page 5

Cybex Owner’s Manual

• Inspect the equipment for worn or loose components prior to use. Tighten/replace any loose or

worn components before to using. Pay close attention to belts, cables, grips or pulleys and their

connections. Always look for potential problems in equipment condition. Loose components should

be tightened to function properly. Replacing worn components maintains the equipment is in the

best condition for regular use.

• To maximize stability, securely anchor each machine to the oor using the anchor holes provided

in each machine. Each machine must be set up, anchored, and operated on a solid level surface.

Do not install equipment on an uneven surface!

Death or serious injury will occur if the

DANGER !

following requirements are not met:

• Ensure that all users are properly trained on how to use the equipment.

• Verify there is enough room for safe access and operation of the equipment. Spacing requirements

for each piece of equipment vary depending on placement. The Assembly section gives equipment

dimensions but it is up to the facility to verify there is clearance between and around each machine

to operate without interference.

• Perform regular maintenance checks on the equipment as detailed in the Maintenance section

of this manual. Inspect all areas most susceptible to wear, including, (but not limited to) cables,

pulleys, belts, and grips.

Cybex is not able to anchor the equipment due to local building codes.

The owner is responsible for the actual anchoring of equipment.

Consult with a professional contractor.

Use fasteners having a minimum of 500 lbs. tensile capacity -- Cybex

recommends 3/8” grade 2 bolts or better.

If legs/frame does not contact surface, DO NOT pull down with

anchors. Shim any leg or frame not in contact with surface using at

washers.

• Immediately replace worn or damaged components. If unable to immediately replace worn or

damaged components then remove from service until the repair is made.

• Use only Cybex supplied components to maintain/repair the equipment.

• Keep a repair log of all maintenance activities.

• Display the Facility Safety Sign so it is visible and prominent.

5

Page 6

Cybex Owner’s Manual

Securing Equipment

Do not use machine until it is properly anchored.

The machine has holes in the feet, which allow for ease in anchoring to the oor. All anchoring holes

must be used to maximize stability. Equipment must be secured to a solid, level surface to eliminate

rocking, tipping, or falling over due to incorrect usage and misuse.

The solid, level surface should not deviate more than 1/8” over a 10’ distance or as dened and

required by local building and architectural codes.

Anchoring of equipment must be completed by a qualied licensed contractor.

Due to the wide variation of ooring on which machines may be anchored or installed, verify

anchoring method and anchoring fasteners with a qualied and licensed contractor.

A minimum pull out force of 220 lbs/100 kgs is required for each anchor position.

PROPER USAGE

Use equipment only as described in the manual or on the placards located on each machine. Failing

to follow proper instructions may result in injury.

STANDARD COMPLIANCE

Cybex products meets applicable ASTM and EN Standards.

6

Page 7

Cybex Owner’s Manual

MATERIAL:

EXCEPT AS NOTED

GENERAL

TOLERANCES:

REMOVE ALL BURRS

BREAK SHARP EDGES

.005/.010 R

SURFACE FINISH

DIMENSIONS

IN INCHES

WARNING

SERIOUS INJURY

COULD OCCUR IF

THESE PRECAUTIONS

ARE NOT OBSERVED

2. Read and understand warning labels

and user manual prior to exercising.

Obtain instruction prior to use.

1. Obtain a medical exam prior to

beginning an exercise program.

3. Keep body and clothing free from

and clear of all moving parts.

4. Inspect machine prior to use. DO

NOT use if it appears damaged or

inoperable.

5. DO NOT attempt to fix a broken or

jammed machine. Notify floor staff.

6. Use the machine only for the

intended use. DO NOT modify the

machine.

7. Be sure that the weight pin is

completely inserted. Use only the pin

2.25

12 PT ARIAL FONT

R .25

4 PLACES

INSET .06

WHITE

SAFETY ORANGE PMS 152

BLACK TRIANGLE W/ ORANGE

EXCLAMATION POINT, BLACK LETTERS

23 PT ARIAL BOLD FONT

8.00

8.25 PT ARIAL FONT

WHITE BACKGROUND

BLACK LETTERS

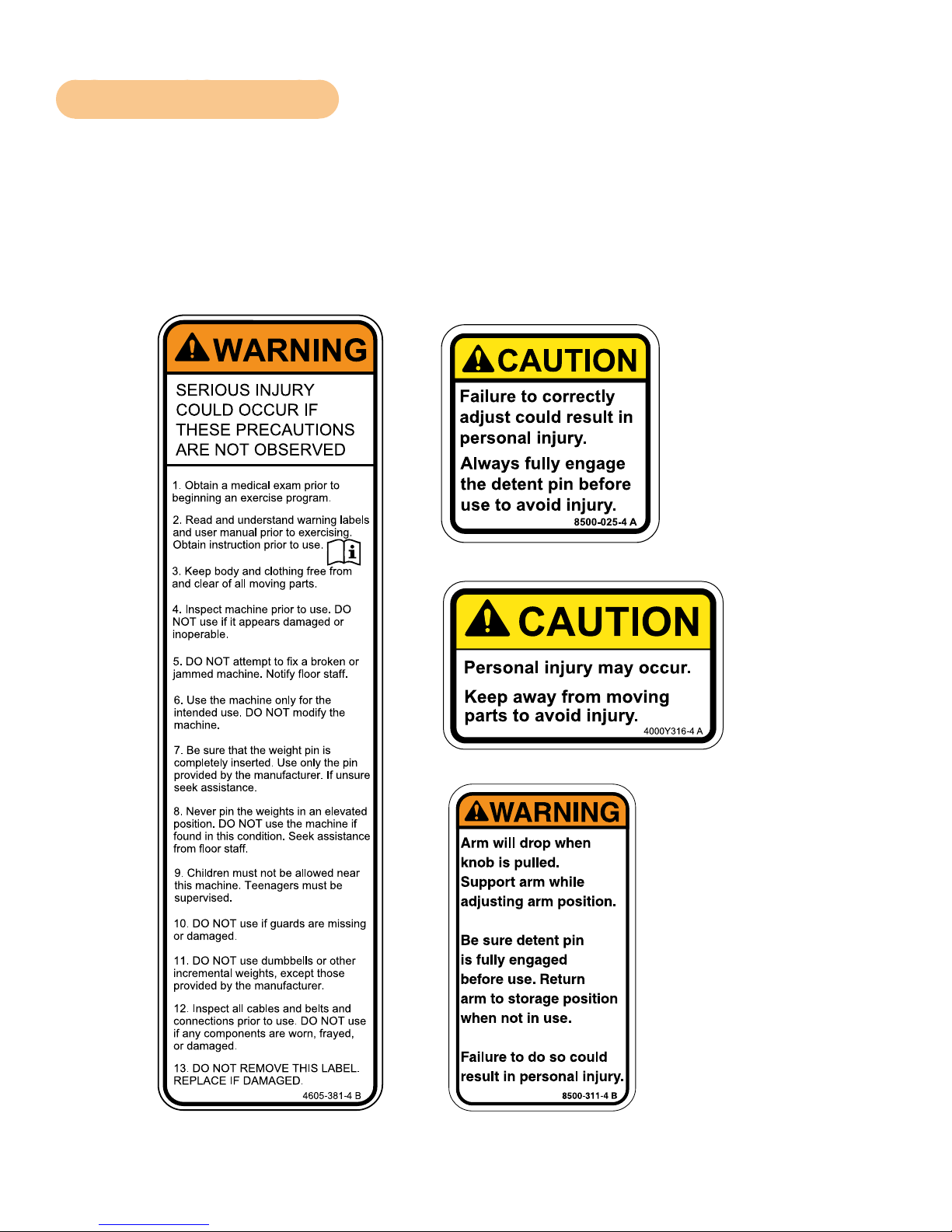

Warnings and Cautions

Warning decals indicate a potentially hazardous situation that could result in death or serious injury if

the precautions are not observed.

Caution decals indicate a potentially hazardous situation, which, if not avoided, could result in minor

or moderate injury.

The diagram following the decals show where each decal is located.

CAUTION

Personal injury may occur.

Keep away from moving

parts to avoid injury.

4000Y316-4 A

7

Page 8

Label Placement

Cybex Owner’s Manual

4000Y316-X

8500-311-X

8500-025-X

4000Y316-X

4605-381-X

4000Y316-X

8

Page 9

Cybex Owner’s Manual

Assembly

Machine Specifications

Total Weight and Size VR1 Lat/Row 13250 Standard Stack

Weight Machine Dimensions at Rest Machine Dimensions in Use

496 Lbs 73” L x 50” W x 77” H Same

225 Kg 185 cm L x 127 cm W x 211 cm H Same

Total Weight and Size VR1 Lat/Row 13250 Standard Stack

Weight Machine Dimensions at Rest Machine Dimensions in Use

426 Lbs 73” L x 50” W x 77” H Same

194 Kg 185 cm L x 127 cm W x 211 cm H Same

Tools Required

• 7/32” Allen wrench

• 3/4” Socket or wrench

• Hammer

• 3/16” Pin punch

Two people will be required for this procedure. It is the responsibility of the facility owner/owner of the

equipment to ensure that there is appropriate clearance around each machine to allow for safe use

and passage.

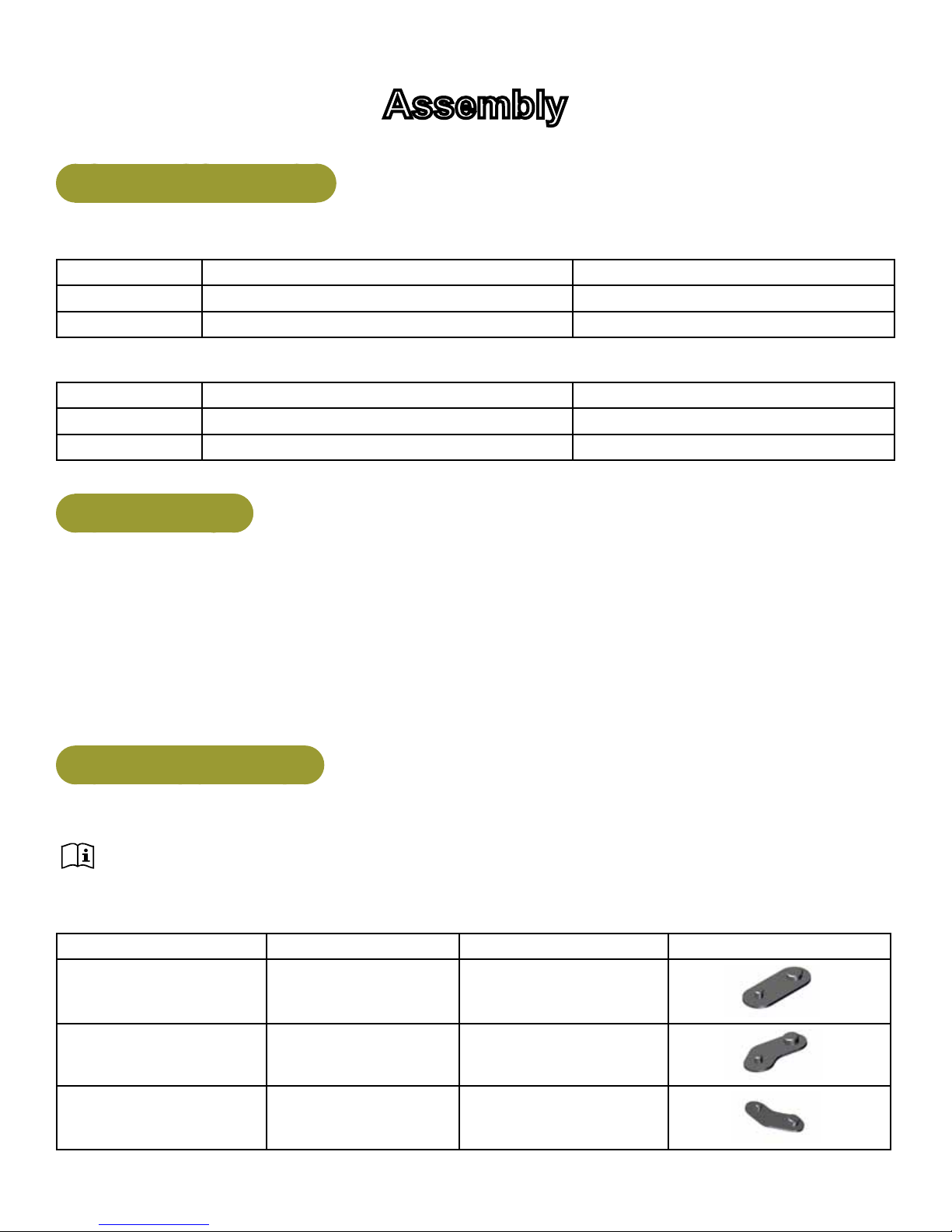

Assembly Procedures

Two people will be required for this procedure.

Read and understand all instructions thoroughly before assembling this unit. Check all items

carefully. If there is damage, see the Customer Service section of this manual for proper procedure to

return, replace, or reorder parts.

Qty Part Number Description Diagram

5 13000-353 Foot Pad

1 13000-354 Foot Pad

1 13000-355 Foot Pad

9

Page 10

Cybex Owner’s Manual

WEIGHT PLATE DETAIL

LIGHT STACK 13000-032

STANDARD STACK

WEIGHT PLATE DETAIL

STANDARD STACK

1

1

1

14

1

14

4800-557

13000-552

4700-337

13000-032

4700-338

13000-036

Move to desired location

If Then

If machine can be

moved without

adding or removing

weight stacks.

Decal, Weight Plate (10-150) (Light)

Decal, Weight Plate (10-220) (Standard)

Weight Stack Plate (Light)

Weight Plate Pack (Light)

Weight Stack Plate (Standard)

Weight Plate Pack (Standard)

Two people will be required for this procedure

1. Move to desired location.

2. Remove the four shipping cones using a 3/4” socket or wrench.

3. Attach foot pads to each foot of frame.

If machine needs

weight stacks

removed before

moving to desired

If Then

Two people will be required for this procedure

1. Remove the two Button Head Socket Cap Screws (BHSCS)

securing the top cap to the frame using a 7/32” Allen wrench.

BHSCS

location.

Top Cap

2. Remove top cap and BHSCS.

3. Lift shroud up and out of machine.

Shroud

10

Page 11

Cybex Owner’s Manual

If Then

4. Remove guide rod caps. Guide rod cap contains a compression

spring that will y if grasp is not released slowly. Slide spring loaded

guide rod cap down guide rod until cap is clear of frame. Slowly

release grasp of guide rod cap and remove.

If machine needs

weight stacks

removed before

moving to desired

location.

Guide

Rod Cap

Compression

Spring

Guide

Rods

Compression

Guide

Rod Cap

Spring

5. Remove guide rod cap and springs.

6. Repeat procedure for opposite guide rods.

7. Remove spiral pin securing cable end to top weight using a 3/16”

pin punch and hammer.

Cable End

Spiral

Pin

8. Remove lifting post.

9. Remove weight plates

10. Move machine to desired position.

11. Remove the four shipping cones using a 3/4” socket or wrench.

12. Attach foot pads to each foot of frame.

Top Weight

11

Page 12

Cybex Owner’s Manual

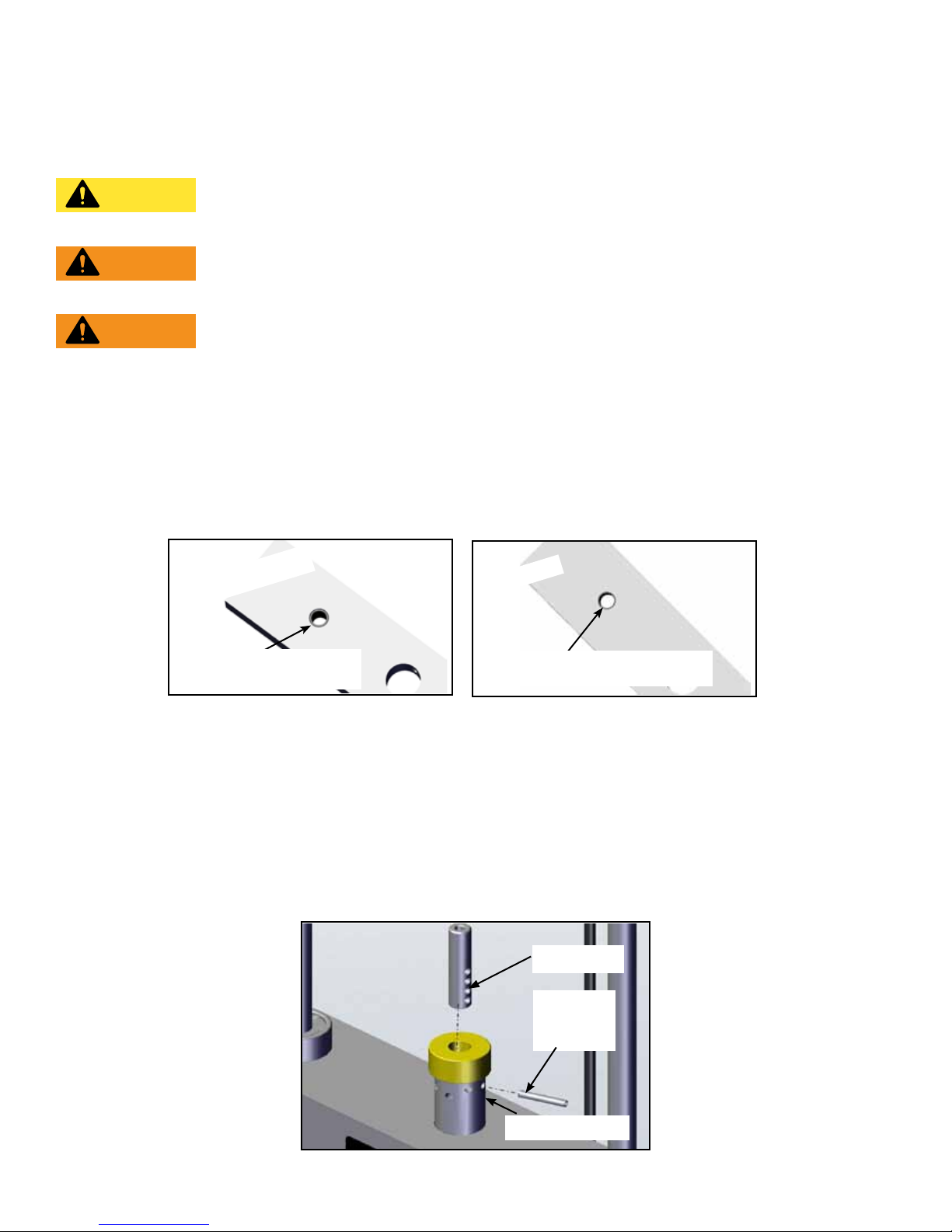

Securelyanchormachinetotheoor

Cybex strongly recommends to maximize stability, equipment must be secured to a solid level

surface.

CAUTION: Cybex is not responsible for the actual anchoring of equipment. Consult with

a professional contractor.

WARNING: Use fasteners having a minimum of 500 lbs. tensile capacity (3/8’’ grade 2

bolts or better).

WARNING: If legs/frame does not contact surface, DO NOT pull down with anchors. Shim

any leg or frame not in contact with surface using at washers.

Install weight plates

1. Install individual weight plates one at at time.

2. Position each weight plate so wide edges of bushings face upward and narrow edges

of bushings face downward.

CORRECT

Wide bushing

edge faces upward

WRONG

The narrow bushing edge

must face downward.

3. Install lifting post.

4. Snap guide rods into position.

Cable routing

1. Verify cable is routed through top of pulley bracket and then route cable end to top weight

connector.

2. Pull cable tight and secure in place with spiral pin using a 3/16” pin punch and a hammer.

Cable End

Spiral

Pin

Top Weight

12

Page 13

Cybex Owner’s Manual

3. Place weight stack pin in each plate to verify proper installation.

4. Lift top weight up and down simulating normal operation (without selecting any resistance).

5. Verify that the cable is moving smoothly and is routed straight from the pulley bracket to the

top of the weight plate connector.

Install back shroud

1. Place shroud into position.

2. Secure top in place using two BHSCS and 7/32” Allen wrench.

Verify proper operation

Environment and Storage

Static Electricity

To reduce static electricity increase the humidity.

Humidity

The unit is designed to function normally in an environment with a relative humidity range of 30% to

75%. The unit can be shipped and stored in an environment with a relative humidity range of 10% to

90%.

Temperature

The unit is designed to function normally in an environment with an ambient temperature range of

50° F (10° C) to 104° F (40° C). The unit can be shipped and stored in an environment with a relative

humidity range of 10% to 90%.

Do not install, use, or store the unit in an area of high humidity, such as near a steam room, sauna,

indoor pool or outdoors. Extensive exposure to water vapor, chlorine and/or bromine could adversely

affect the equipment.

13

Page 14

Cybex Owner’s Manual

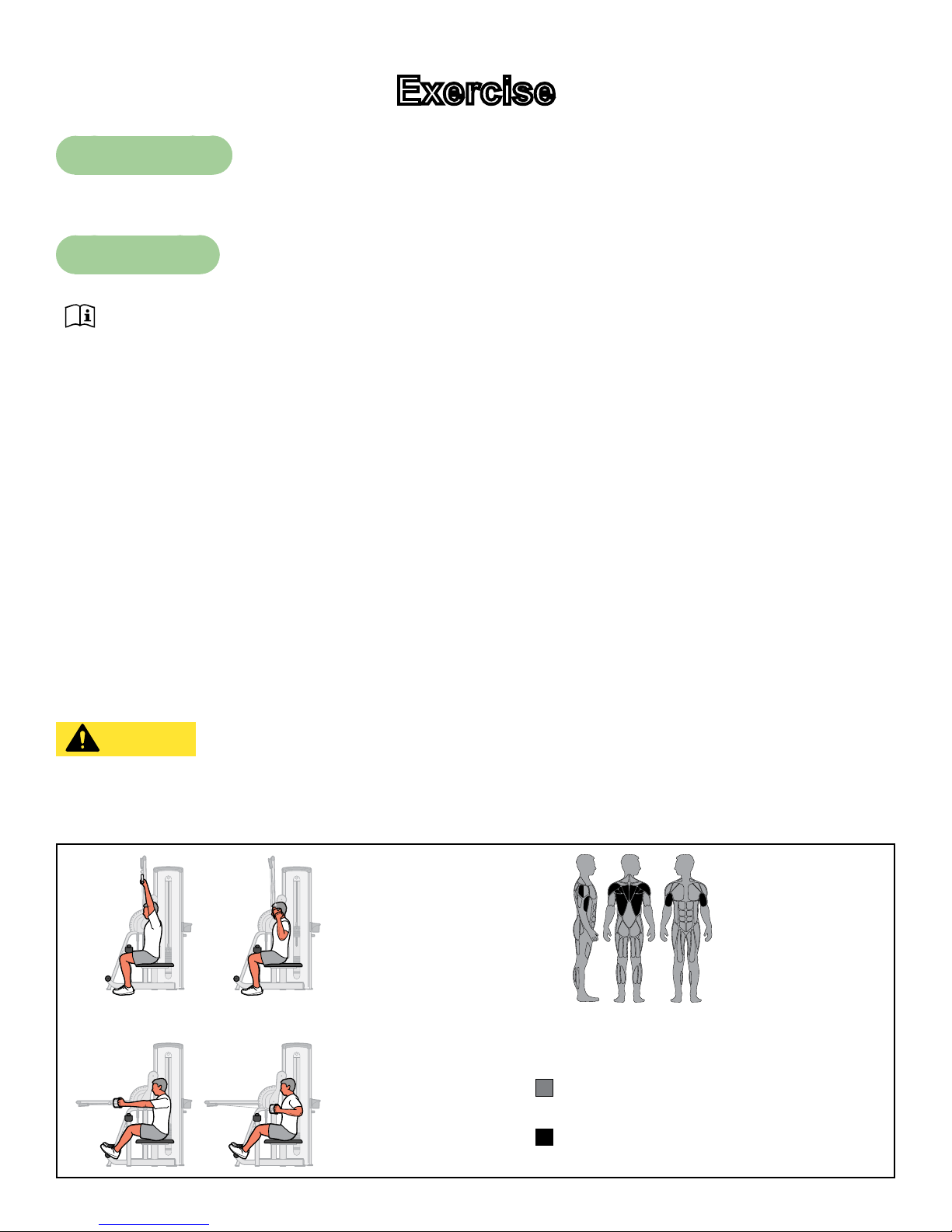

Exercise

Intended Use

The intended commercial use of this machine is to aid exercise and improve general physical tness.

Instructions

Read and understand all instructions and warnings prior to using this machine in the Safety

section of the Owner’s Manual.

All adjustment points on the machine have yellow handles or knobs.

Lat Pull -

1. Adjust arm assembly to the vertical position.

2. Adjust thigh pad for stabilization during exercise.

3. Grasp handles and sit with with thighs under pad.

Row -

1. Adjust arm assembly to the horizontal position.

2. Grasp handles and sit with thighs under pad and feet on foot rest.

Lat Pull -

1. Pull handles down until elbows are by sides and hands are approximately level with shoulders.

2. Row - Pull handles back to chest.

CAUTION: Serious injury can result if precautions are not followed. Use equipment

only as described in placards located on each machine. Failure to use in the

manner depicted can result in injury.

LAT/ROW

START/FINISH

LAT PULL

START/FINISH

ROW

14

Motions Developed

Shoulder Flexion, Elbow Extension

Muscles Used

Latissimus Dorsi, Teres Major, Biceps,

Lower Trapezius, Middle Trapezius,

Rear Deltoid, Rhomboid

Page 15

Cybex Owner’s Manual

NOTE: All inspections

and repairs must be

performed by trained

service personnel only.

Maintenance

All preventive maintenance activities must be performed on a regular basis. Performing routine

preventive maintenance actions can aid in providing safe, trouble-free operation of all Cybex Strength

Systems equipment.

Cybex is not responsible for performing regular inspection and maintenance actions for your

machines. Instruct all personnel in equipment inspection and maintenance actions and also in

accident reporting/recording. Cybex representatives are available to answer any questions that you

may have.

All inspections and repairs must be performed by trained service personnel only. Cybex will

void warranty if non-Cybex replacement parts are used.

CAUTION

Use only Cybex replacement

parts when servicing.

Failure to do so could result

in personal injury.

Daily Procedures

When using strong cleaning agents such as rubbing alcohol or bleach, it is advisable to rst test in an

inconspicuous area. Other cleaning agents may contain harsh or unknown solvents and are subject to

formula changes by the product manufacturer without notice. Should you desire to use other cleaning

agents, carefully try them in an inconspicuous area to determine potential damage to the material.

Never use harsh solvents or cleaners which are intended for industrial applications. To clean stained

or soiled areas, a soft white cloth is recommended. Avoid use of paper towels.

Cleaning products may be harmful/irritating to your skin, eyes, etc. Use protective gloves and eye

protection. Do Not inhale or swallow any cleaning product. Protect surrounding area/clothing from

exposure. Use in well ventilated area. Follow all product manufacturer’s warnings. CYBEX and

its vendors cannot be held responsible for damage or injuries resulting from the use or misuse of

cleaning products.

15

Page 16

Clean Upholstery

Cybex Owner’s Manual

If Then

1. Prepare a solution of 10% household

liquid soap and warm water.

2. Apply with a soft damp cloth.

Light Soiling

MoreDifcultStains

3. If necessary, apply a solution of liquid

cleanser with a soft bristle brush.

4. Dampen a clean soft cloth in water and

wipe residue away.

1. Prepare a solution of 10% household

bleach (sodium hypochlorite) and 90%

water. Dampen a soft white cloth in the

solution.

2. Rub gently on the stained area.

3. Dampen a clean soft cloth in water and

rinse area.

4. If stains are still present, a full strength

household bleach may be used. Allow

bleach to puddle on the affected area

or apply with a bleached-soaked cloth

for approximately 30 minutes. Dampen

a clean soft cloth in water, and rinse

area to remove any remaining bleach

concentration.

1. Dampen a soft white cloth with rubbing

alcohol.

MoreDifcultStains(AlternativeMethod)

Restoring Luster

Clean Frames

Wipe down all frames using a mild solution of warm water and car wash soap. Be sure to dry

thoroughly. AVOID acid or chlorine based cleaners and also cleaners containing abrasives as these

could scratch or damage the equipment.

2. Gently rub stained area.

3. Dampen a clean soft cloth in water and

rinse area.

1. Apply a light coat of furniture wax for 30

seconds.

2. Lightly rub area using a clean white cloth.

16

Page 17

Cybex Owner’s Manual

Clean Chrome

Clean chrome tubes, rst using chrome polish and then using a car wax seal. Neutral cleaners with a

pH between 5.5 and 8.5 are recommended. Be sure to dry thoroughly. AVOID acid or chlorine based

cleaners and also cleaners containing abrasives as these could scratch or damage the equipment.

Guidelines for cleaning front panel:

Use clean soft cloths or sponges for application of cleaners and again for washing and rinsing. Follow

up each application with warm water rinse.

• DO NOT use abrasives or high alkaline cleaners.

• DO NOT leave cleaners on for long periods, wash immediately.

• DO NOT apply cleaners in direct sunlight or at elevated temperatures.

• DO NOT use scrapers, squeegees, or razors.

• DO NOT clean with gasoline.

Compatible Cleaners and Detergents:

• Formula 409

• Top Job

• Joy

• Palmolive

• Windex with Ammonia D

To Minimize Fine or Hairline Scratches:

Mild automotive polish applied and removed with a soft clean cloth will help ll scratches.

Suggested Polishes:

• Johnson Paste Wax

• Mirror Glaze #10 Plastic Polish (by Mirror Bright Polish Co.)

• Novus Plastics Polish #1, #2 (By Novus Inc.)

17

Page 18

Cybex Owner’s Manual

Weekly Procedures

Inspect All Nuts and Bolts

Tighten all loose nuts and bolts as required.

WARNING: Serious injury or death may result if the following precautions are not

followed. Replace all worn cables and belts. Worn cables and belts can fail if

not replaced.

Inspect cables and belts

Inspect all cables and belts for wear or damage and proper tension. When inspecting cables and

belts, run ngers on the cable or belt, paying particular attention to bends in cables and attachment

points. The following conditions may indicate a worn cable:

Cables

Condition of Cable Diagram

A tear or crack in the cable sheath

that exposes the cable

A kink in the cable

A curled sheath

Necking - A stretched cable sheath

18

Page 19

Belts

Cybex Owner’s Manual

Condition of Belt 3D View 3D or Side View

Peeling of the belt’s skin.

Wave in belt

Belt is necked down (narrow section)

Cracks or splits

One or more strands of kevlar is

hanging out, or if there is a signicant

amount of frayed kevlar.

Replace belt if any

section is over 1/32”

(.03) narrower than the

rest of belt

Examine edge of belt (both sides).

Replace belt if any section is

narrower than the rest.

19

Page 20

Cybex Owner’s Manual

CAUTION: Personal injury or property damage may occur if the following precautions

are not followed. Do not use if less than 1/8” of material remains to the edge.

Replace all worn handles immediately. Failure to replace worn handles can

result in injury or property damage.

Inspect bars and handles for wear, paying particular attention to tab area connection points.

Replace bar if less

than 1/8” of material

remains to the edge.

Attachment

Hole

Inspection Action

Inspect bars and handles for wear, paying

particular attention to tab area connection points.

Inspect snap links for proper latching (indicates

wear).

Inspect all labeling for readability, including

instructional placards, warning and caution

decals.

Inspect all weight stacks for proper alignment

and operation.

Inspect guide rods for lubrication.

Yearly Procedures

Replace all cables and belts annually

Replace all worn handles immediately.

Replace all loose or worn grips immediately.

Replace all worn labeling immediately.

Correct all improper alignment and operation

issues immediately.

Wipe Weight Stack Guide Rods clean over entire

length. Lubricate with a light coat of medium

weight automotive engine oil.

20

Page 21

Cybex Owner’s Manual

Cable Adjustment

Tools Required

9/16” Wrench (2)

Four types of cable tension adjustment are used on Cybex Strength Systems:

Cable

Adjustment

Jam Nut

Adjustment

Rod End

Adjustment

Description Diagram

This type of adjustment uses a jam

nut and a tension adjustment nut at

the cable cam end as the primary

adjustment. The other end of the

cable usually contains a roll pin

adjustment.

This type of adjustment uses a

socket head cap screw (SHCS)

securing a cable rod end bearing to

the machine. Primary adjustment

is by turning the rod end bearing.

The other end of the cable usually

contains a roll pin cable adjustment.

Jam

Cable

End

SHCS

Nut

Tension

Adjustment

Nut

Jam Nut

Cable Rod End

Bearing

Nylon

Locknut

Roll Pin

Adjustment

This type of adjustment uses a roll

pin and series of holes in the weight

stack top weight connector.

This type of adjustment uses an

Cam End

Adjustment

adjustment bolt on the pulley

bracket. Loosen nut and rotate cam

bolt to adjust cable.

21

Roll

Pin

Nut

Top Weight

Connector

Cam Bolt

Adjustment

Page 22

Cybex Owner’s Manual

Belt Adjustment

Tools Required

• 7/32” Wrench

• Torque wrench (lbs-in)

Belt Adjustment Action

1. Using a 7/32” Allen wrench loose set screws.

2. Pull belt tight.

Loose Belt

3. Secure belt in place with set screws.

4. Torque set screws to 300-350 lb-in.

5. Verify that the belt is moving smoothly and is routed straight from

the top pulley bracket to the to weight belt clamp

22

Page 23

Cybex Owner’s Manual

Customer Service

Product Registration

To register product do the following:

1. Visit www.cybexintl.com.

2. Locate Product Registration in the Support section.

3. Fill out form completely.

4. Click the Submit button to register product.

Contacting Service

Hours of phone service are Monday through Friday from 8:30 a.m. to 6:00 p.m. Eastern Standard

Time.

For Cybex customers living in the USA, contact Cybex Customer Service at 888-462-9239.

For Cybex customers living outside the USA, contact Cybex Customer Service at 508-533-4300 or

fax 508-533-5183. email address internationaltechhelp@cybexintl.com

Find information on the web at www.cybexintl.com.

To contact us online go to www.cybexintl.com. Select Support > Service. In the left navigation panel,

click Get Service - Service Request Form. Fill out form completely and click the Submit Query button.

23

Page 24

Cybex Owner’s Manual

Ordering Parts

TTo order parts online go to www.cybexintl.com. Select Support > Parts / Ordering. In the left

navigation panel, click Parts Diagrams - Current Products. Select from the drop down boxes.

To speak with a customer service representative, call 888-462-9239 (for customers living within the

USA) or 508-533-4300 (for customers outside the USA).

The following information located on the serial number decal will assist our Cybex representatives in

serving you.

• Unit Serial Number, Product Name and Model Number

• Part Description and Part Number if you have it. All parts can be found on the web at

www.cybexintl.com

• Shipping Address

• Contact Name

• Include a description of the problem.

In addition to your shipping address and contact name, your account number is helpful but not

required. You may also fax orders to 508-533-5183.

Return Material Authoriazation (RMA)

The Return Material Authorization (RMA) system is used when returning material for placement,

repair or credit. The system assures that returned materials are properly handled and analyzed.

Follow the following procedures carefully.

Contact your authorized Cybex dealer on all warranty-related matters. Your local Cybex dealer will

request a RMA from Cybex, if applicable. Under no circumstances will defective parts or equipment

be accepted by Cybex without proper RMA and an Automated Return Service (ARS) label.

Please contact Cybex Customer Service for the return of any item that is defective.

Provide the technician with a detailed description of the problem you are having or the defect in the

item you wish to return. Provide the model and serial number of your Cybex equipment.

At Cybex’s discretion, the technician may request that you return the problem part(s) to Cybex for

evaluation and repair or replacement. The technician will assign you a RMA number and will send

you an ARS label. The ARS label and the RMA numbers must be clearly displayed on the outside

of the package that contains the item(s) to be returned. Include the description of the problem, the

serial number of the equipment and the name and address of the owner in the package along with the

part(s).

Merchandise returned without an RMA number on the outside of the package or shipments sent COD

will not be accepted by the Cybex receiving department.

24

Page 25

Cybex Owner’s Manual

Damaged Parts

Materials damaged in shipment should not be returned for credit. Shipping damages are the

responsibility of the carrier (UPS, Federal Express, trucking companies, etc.)

Apparent Damage

Upon receipt of your shipment, check all items carefully. Any damage seen with a visual check must

be noted on the freight bill and signed by the carrier’s agent. Failure to do so will result in the carriers

refusal to honor your damage claim. The carrier will provide you with the required forms for ling such

claims.

Concealed Damage

Damage not seen with a visual check upon receipt of a shipment but notices later must be reported

to the carrier as soon as possible. Upon discovery of the damage, a written or phone request to

the carrier asking them to perform an inspection of the materials must be made within ten days of

the delivery date. Keep all shipping containers and packing materials as they will be needed in the

inspection process. The carrier will provide you with an inspection report and the necessary forms for

ling a concealed damage claim. Concealed damage claim is the carrier’s responsibility.

25

Page 26

Page 27

Page 28

10 Trotter Drive Medway, MA 02053 • 508-533-4300 • FAX 508-533-5183

www.cybexintl.com

Loading...

Loading...