Page 1

J

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

~

@

Cybex 900T Treadmill Service Manual

Cardiovascular Systems

Cybex and the Cybex logo are registered trademarksofCybex International, Inc. Bioflex and the Bioflex logo are registered

trademarks of Cybex International, Inc. Polar is a registered trademarkofPolar.

DISCLAIMER:

Cybex International, Inc.

makesnorepresentationsorwarranties

regarding

the

contentsofthis

manual. We

reserve

the

righttorevise

this

documentatany

timeorto

make

changestothe

product

described

within

it

without

notice

or

obligationtonotify

any

person

of

such

revisionsorchanges.

© 2001, Cybex International, Inc. All rights reserved. Printed

in

United StatesofAmerica.

10 Trotter Drive Medway, MA

02053·

888-GO-CYBEX·

888-462-9239·

508-533-4300·

FAX

508-533-5183

www.eCybex.com.techhelp@cybexintl.com.techpubs@cybexintl.com • SM-16106 Rev A • June 2001

Page 2

~

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 3

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Cybex

900T

Treadmill

Service

Manual

About

This Manual

For your convenience, all measurements and voltage requirements are listed in both English

and metric units. English values are listed first, followed by metric units in parentheses. For

example:

1"

(2.54 em).

The 900T Treadmill is a newer model that has replaced the former 685 model. This manual,

part number SM-16106, should be referred

to

for

685 service questions. An Owner's Manual

is shipped with each 900T Treadmill.

To

purchase a copyofany manual, order online at

www.eCybex.com, fax your order

to

508-533-5383 or contact Cybex Customer Service at

888-462-9239 or 508-533-4300.

To

contact Cybex with comments about this manual you may send email

to

techpubs@cybexintl.com.

FCC

Compliance

Information

! WARNING: Changesormodifications to this unit

not

expressly

approvedbythe party

responsible for compliance

could

void the user's authority to operate

the equipment.

This equipment has been tested and foundtocomply with the limits

for

a Class A digital

device, pursuant

to

Part 15ofthe FCC Rules. Operation is subjecttothe following

two

conditions:

(1)

This device may not cause hannful interference, and

(2)

this device must

accept any interference received, including interference that may cause undesired operation.

Pagei

Page 4

Pageii

Cybex 900T Treadmill

Service

Manual

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 5

Cybex 900T Treadmill Service Manual

Table of Contents

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Front Pages

About

this Manual i

FCC Compliance Information

i

TableofContents .iii

1 Safety

Important Voltage Information 1-1

Grounding Instructions 1-1

Important Safety Instructions 1-2

Caution Decals

1-4

2 Technical Specifications

Specifications 2-1

Bioflex 2-2

3 Preventive Maintenance

Regular Maintenance Activities 3-1

Cleaning Your Treadmill 3-1

Running Belt Maintenance

3-2

Other Preventive Maintenance

3-6

Service Schedule

3-7

Log Sheet

3-8

4 Troubleshooting

Diagnostic Test

Mode

4-1

Diagnostic Menu 4-1

LED Functions

4-6

Motor

Current & Voltage

4-7

Speed Sensor Adjustment

4-9

Error Codes 4-10

Flow Charts 4-13

5 Removal & Replacement

Running Belt & Deck 5-1

Drive Belt

5-4

Front Roller

5-4

Rear Roller

5-4

Drive

Motor

5-5

Drive

Motor

Cleaning

5-8

Motor

Brushes 5-12

Elevation

Motor

5-14

Limit Switch Assembly 5-17

PWM Module 5-18

Display Board

5-20

EPROM 5-21

Contact Heart Rate Board 5-22

CSAFE Board 5-24

Display Cable 5-25

Display Overlays 5-26

Handrail Assembly 5-28

6 Diagrams

Parts List 6-1

Exploded View

6-3

900T Schematic

6-4

7 Customer Service

Contacting Service 7-1

Serial

Number

7-1

Retum Material Authorization (RMA)

..

7-1

Damaged Parts 7-2

Page

iii

Page 6

Cybex 900T Treadmill Service

Manual

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 7

Cybex

900T

Treadmill

Service

Manual

IMPORTANT: Read all instructions

and

warnings before using the treadmill.

Important

Voltage

Infonnation

Page

1-1

Front Pages

About this Manual i

FCC Compliance Infoonation

..

i

Table

of

Contents

iii

1

Safety

~

Voltage Information 1-1

Grounding Instructions

.....

1-1

Important SafetyInstructions

1-2

Caution Decals . . . . . . . ...1-4

2

Technical

Specificatiolls

~

2-1

Bioflex

2-2

3 Preventive

Maintenance

Regular

MarnenMCe

Activities

3-1

Cleaning YourTreadmill. .

..

3-1

Running Belt Maintenance . 3-2

Other Preventive

Maintenance

~

Service Schedule 3-7

Log

Sheet

3-8

4

TroubIeshooUlg

Diagnostic Test

Mode

4-1

Diagnostic

Menu

4-1

LED Functions

4-6

Motor

Current & Voltage

4-7

Speed

Sensor

Adjustment..4-9

Error

Codes

4-10

Flow Charts

4-13

5

Removal

& RepIac:ement

Running Belt & Deck 5-1

Drive

Belt 5-4

Front Roller 5-4

Rear

Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning

5-8

Motor

Brushes. . . . . . . ...5-12

Elevation

Motor

5-14

Umit Switch Assembly 5-17

PWM

Module

5-18

Display Board

5-20

EPROM

5-21

Contact Heart

Rate

Board .

5-22

CSAFE

Board

5-24

Display Cable

5-25

Display Overlays

5-26

Handrail Assembly

5-28

6

Diagrams

Parts

Ust

6-1

Exploded

VIeW

6-3

900T Schematic 6-4

7 Customer Service

Contacting Service

7-1

Serial Number

7-1

Return Material Autt1orization

(RMA)

7-1

Damaged

Parts.

. . . . . . ...7-2

This treadmillisfor use on a

nominal 115

VAG

±15%, 60

/ DANGER:

Improper

connectionofthe

equipment-grounding

conductor

can

result

in

a

riskofelectric

shock.

Check

withaqualified

electrician

or

service

providerifyou

are

in

doubt

as

to

whether

the

treadmillisproperly

grounded.

Seekaqualified

electriciantoperform

any

modifications

to

the

cord

or

plug.

Cybexisnot

responsible

for

injuries

or

damages

as

a

resultofcord

or

plug

modification.

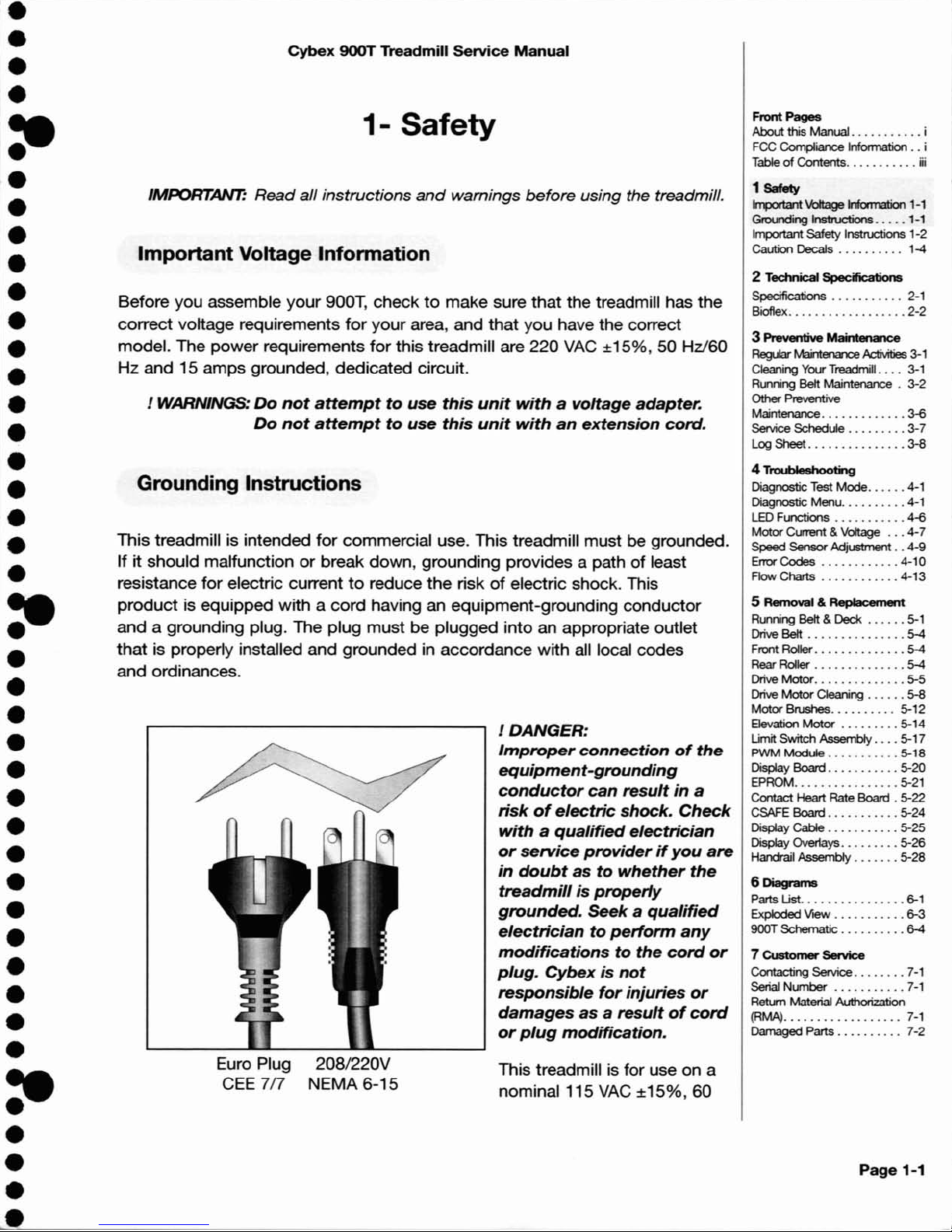

208/220V

NEMA 6-15

Euro Plug

GEE

7/7

Grounding

Instructions

1-

Safety

Before you assemble your 900T, checktomake sure that the treadmill has the

correct voltage requirements

for

your area, and that you have the correct

model. The power requirements

for

this treadmill are 220

VAG

±15%, 50 Hz/60

Hz and 15 amps grounded, dedicated circuit.

/ WARNINGS:

Do

not

attempt

to

use

this

unit

withavoltage

adapter.

Do

not

attempt

to

use

this

unit

with

an

extension

cord.

This treadmill is intended

for

commercial use. This treadmill must be grounded.

If it should malfunction

or

break down, grounding provides a path of least

resistance for electric current

to

reduce the riskofelectric shock. This

product

is equipped with a cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into an appropriate outlet

that

is properly installed and grounded in accordance with all local codes

and ordinances.

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Page 8

Page

1-2

Cybex 900T Treadmill

service

Manual

Hz

and20ampsora

220

VAC

±15%,

50 Hz/60 Hz and15amps

grounded,

dedicated

circuit.

Make sure

that

the

treadmill is connectedtoan outlet having

the

same

configuration as

the

plug. Do

not

use a

ground

plug adaptertoadapt

the

power

cordtoa

non-grounded

outlet.

Important

Safety

Instructions

(Save These Instructions)

J

DANGER:

To

reduce

the

riskofelectric

shock,

always

unplug

this

treadmill

from

the

electrical

outlet

immediately

after

usingitand

before

cleaning

it.

JWARNING:

Serious

injury

could

occurifthese

precautions

are

not

observed.

To

reduce

the

riskofbums,

fires,

electric

shock,orinjury:

•

Obtain

a medical exam before beginning any exercise program.

• Keep children

away

from the treadmill. Teenagers

and

disabled

persons

must

be

supervised while using.

•

Stop

exercising if you feel faint, dizzy,orexperience pain at any

time

while exercising

and

consult

your

physician.

•

Use

the

treadmill handrails

for

support

andtomaintain balance.

.•

Use

caution when mounting and dismounting

the

treadmill.

•

Disconnect

all

power

before servicing

the

treadmill.

• Use a

dedicated

line when operating

the

treadmill.

•

Connect

the

treadmilltoa properly grounded

outlet

only.

•

Do

not

operate electrically powered treadmills in

damporwet

locations.

• Keep

the

running belt clean and

dry

at all times.

•

Stop

and

place

the

treadmill at 0 degrees incline (level)

after

each

use.

•

Do

not

leave

the

treadmill unattended when

plugged

in and running. After turning

off

the

treadmill,

don't

leave it until it

comestoa

complete

stop

and is level.Todisconnect,

turn

all controlstothe

STOPorOFF position, and

then

remove

the

plug from

the

outlet.

•

Inspect

the

treadmill

for

wornorloose

components

before each use.

Do

not

use until

wornordamaged

parts are replaced.

• Maintain and replace worn parts regularly. Refer

to

"Preventive Maintenance" Section

of

Owner's

Manual.

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 9

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Cybex 900T Treadmill service Manual

• Do not operate the treadmill if

the

cord is damaged, if

the

treadmill is not

working properly,

or

if the treadmill has been

droppedordamaged. Seek

service from a qualified technician.

• Do

not

place

the

cord near heated surfacesorsharp edges.

• Do

not

use the treadmill outdoors.

• Do

not

operate

the

treadmill aroundorwhere aerosol (spray)orwhere

oxygen products are being used.

• Read

and

understand the Owner's Manual completely before using the

treadmill.

• Read and understand emergency

stop

procedures.

• Read and understand all warnings posted on the treadmill.

• Replace any warning label if damaged, worn

or

illegible.

• Do

not

wear

looseordangling clothing while using

the

treadmill.

• Always wear proper footwear on

or

around exercise equipment.

• Keep all

body

parts, hair, towels, water bottles, and the like free and clear

of

moving parts.

• Set

up

and

operate the treadmillona solid, level surface. Do

not

operate

in recessed areas or on plush carpet.

• Provide

the

following clearances: 39 inches(1m)ateach side, 78 inches

(2m)at

the

back, and enough room

for

safe access and passage at the

front

of

the

treadmill. Be sure

your

treadmill is clearofwalls, equipment,

and

other

hard surfaces.

• Do

not

attempt

repairs, electricalormechanical. Seek trained repair

personnel when servicing. Contact

the

nearest authorized Cybex dealer

or

other

competent

repair service.

• Use

Cybex

factory parts when replacing partsonthe

treadmill.

• Do

not

modify

the

treadmill in any way.

• Do

not

use attachments unless recommended

for

the

treadmill by Cybex.

• Report any malfunctions, damageorrepairstothe

facility.

• Do

not

use the treadmill if you exceed 400 Ibs.

(181

kg). This is

the

rated

maximum

user weight.

Front

Pages

About this Manual i

FCC

Compliance Information..i

Table

of

Contents iii

1

Safety

ImportantVoltage Infoonation 1-1

Grounding

Instructions

.....

1-1

Important Safety Instructions 1-2

Caution Decals . . . . . . . ...1-4

2 Technical Specifications

Specifications . . . . . . . . .

..

2-1

Bioflex

2-2

3 Preventive Maintenance

Regular Maintenance

Activities

3-1

Cleaning

Your

Treadmill. ...3-1

Running

Belt

Maintenance . 3-2

Other

Preventive

Maintenance

3-6

Service Schedule

3-7

Log

Sheet

3-8

4 Troubleshooting

Diagnostic Test

Mode

4-1

Diagnostic

Menu

4-1

LED Functions

4-6

Motor

Current & Voltage

4-7

Speed SensorAdjustment..4-9

Error

Codes

4-10

Flow

Charts

4-13

5 Removal &

Replacement

Running Belt & Deck 5-1

Drive Belt 5-4

Front Roller 5-4

Rear Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning

5-8

Motor

Brushes

5-12

Elevation

Motor

5-14

Umit Switch Assembly

5-17

PWM

Module

5-18

Display Board

5-20

EPROM 5-21

Contact Heart Rate Board .

5-22

CSAFE Board

5-24

Display Cable

5-25

Display Overlays

5-26

Handrail Assembly

5-28

6

Diagrams

Parts

Ust

6-1

Exploded

VieW

6-3

900T

Schematic

6-4

7

Customer

5ervice

Contacting Service 7-1

Serial

Number

7-1

Retum

Material Authorization

(RMA)

7-1

Damaged Parts. . . . . . . .

..

7-2

Page

1-3

Page 10

Page

1-4

Cybex 900T Treadmill service Manual

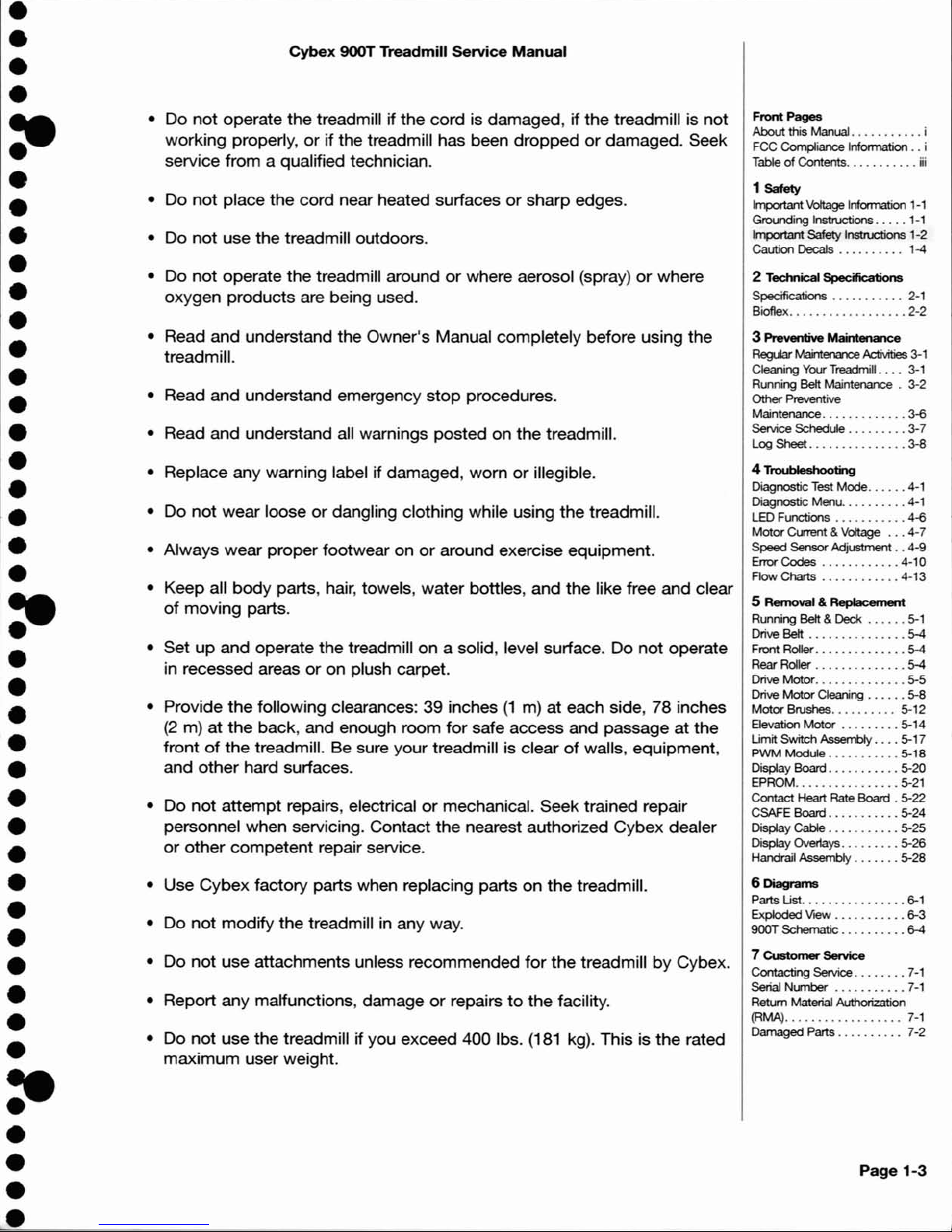

Caution Decals

Caution decals indicate a potentially hazardous situation, which, if

not

avoided, may result

in

minorormoderate injury. The caution decals used on the 900T are shown below.Toreplace

any worn

or

damaged labelsdooneofthe following: Visit eCybex.comtoshop for parts

online, or download the parts order form and fax your order

to

508-533-5183.Tospeak with a

customer service representative, in most areas call 888-GO-CYBEX

or

888-462-9239.

Otherwise call 508-533-4300.

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-:

•

•

•

Page 11

Cybex 900T Treadmill Service Manual

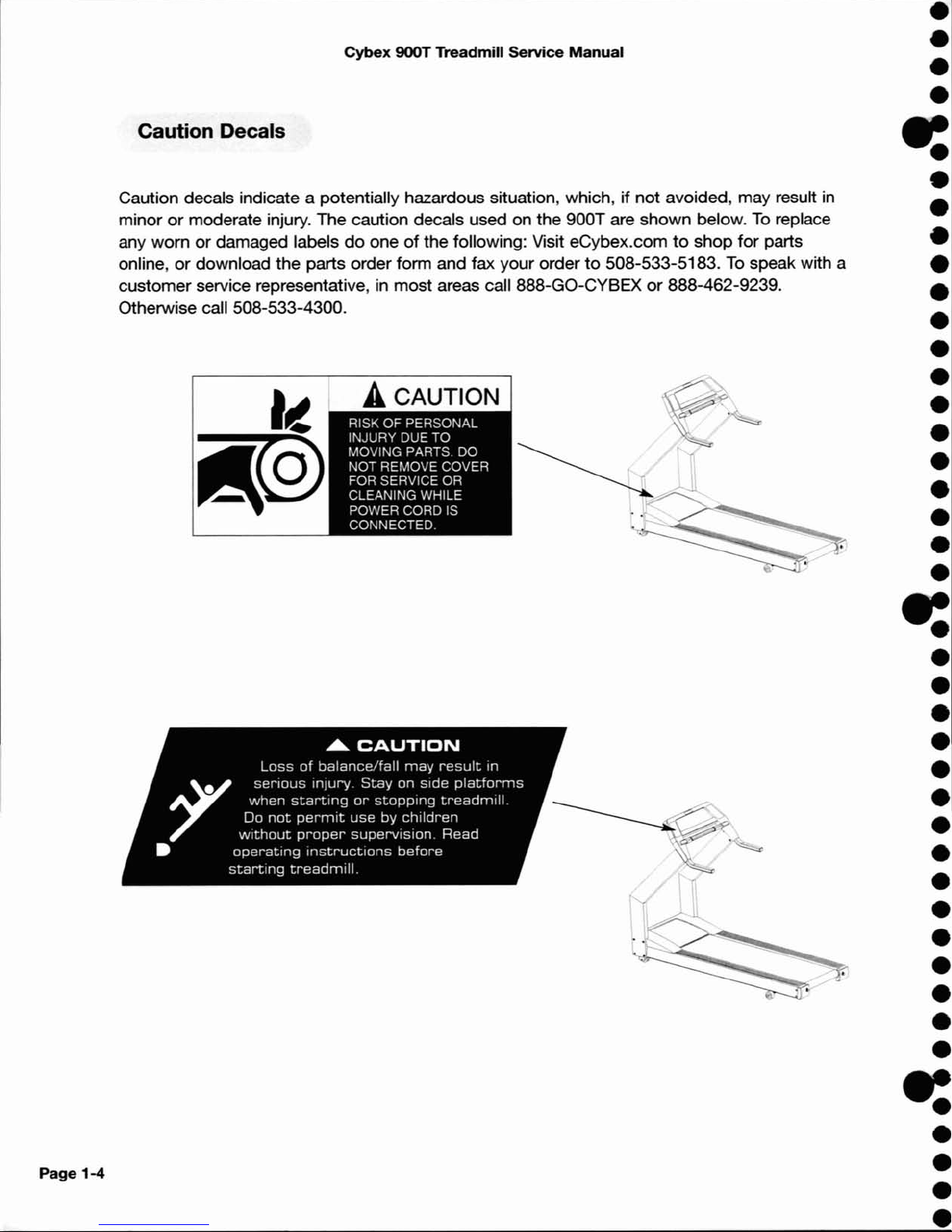

CAUTION

Page 1-5

Front

Pages

About this Manual i

FCC

Compliance Information

..

i

Table

of

Contents

iii

2

Tecfv1icaI

Spec:ifications

Specifications . . . . . . . . .

..

2-1

Bioflex

2-2

1Safety

I~

Voltage

Information

1-1

Grounding Instructions

.....

1-1

Important Safety Instructions 1-2

Caution Decals . . . . . . . .

..

1-4

3 Preventive Maintenalce

RegUar

Marnencrlc:e

Activities

3-1

Cleaning

Your

Treadmill. ...3-1

Running

Belt Maintenance . 3-2

Other Preventive

Maintenance 3-6

Service Schedule 3-7

Log Sheet 3-8

4

TI"CIWIeehootin

Diagnostic

Test

Mode 4-1

Diagnostic

Menu

4-1

LED

FlI1CIions

4-6

Motor

CUI'1'ent

& Voltage 4-7

Speed

Sensor

Adjustment..4-9

Error

Codes 4-10

Flow Charts 4-13

5 Removal & Replacement

Running

Belt &

Deck

5-1

Drive

Belt

. . . . . . . . . . . . . . . 5-4

Front

Roller 5-4

Rear

Roller

5-4

Drive

Motor 5-5

Drive

MotorCleaning 5-8

Motor Brushes. . . . . . . .

..

5-12

Elevation Motor 5-14

Limit Switch

Assembly

5-17

PWM Module 5-18

Display Board 5-20

EPROM

5-21

Contact Heart

Rate

Board . 5-22

CSAFE

Board 5-24

Display Cable 5-25

Display 0vet1ays 5-26

Handrail Assembly 5-28

6 Diagr.-ns

Parts Ust. . . . . . . . . . . . . ...6-1

Exploded View 6-3

900T Schematic 6-4

7

Customer

Service

Contacting Service

7-1

Serial Number

7-1

Return

Material

Authorization

(RMA)

7-1

Damaged Parts 7-2

DO

NOT

USE

EXCESSIVE

FORCE

TO

TIGHTEN

BELT

CAUTION

DO NOT OPEN

REFERTOQUALIFIED

SERVICE

PERSONNEl.

SEE

INSTRUCTIONS

MANUAL.

HIGH VOLTAGE UNDER COVER

NO

USER SERVICEABLE PARTS INSIDE

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

>.

Page 12

Page

1-5

Cybex

900T Treadmill

service

Manual

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-=

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 13

Cybex

900T

Treadmill

Service

Manual

I

......

E-------

82"

(208

cm)------

...

I

2 - Technical Specifications

2 Technical Specifications

Specifications . . . . . . . . . . . 2-1

Bioflex 2-2

Page

2-1

Front

Pages

About

this Manual i

FCC Compliance Information

..

i

Table

of

Contents iii

1

Safety

Important Voltage Information

1-1

Grounding Instructions

.....

1-1

Important Safety Instructions 1-2

Caution OecaIs . . . . . . . .

..

1-4

3 Preventive

Maintenance

RegUar

Maintenance

Activities

3-1

Cleaning Your Treadmill

....

3-1

Running Belt Maintenance . 3-2

Other

Preventive

Maintenance

3~

Se!vice Schedule 3-7

LogShee1 3-8

4 Troubleshooting

Diagnostic Test

Mode

4-1

Diagnostic Menu

4-1

LED Functions

4~

Motor

Current & Voltage 4-7

Speed

Sensor

Adjustment..4-9

Error

Codes

4-10

Row

Charts 4-13

5

Removal&Replacement

Running Belt &

Deck

5-1

Drive Belt 5-4

Front Roller 5-4

Rear Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes 5-12

Elevation

Motor

5-14

Umit Switch Assembly 5-17

PWM

Module

5-18

Display Board 5-20

EPROM 5-21

Contact Heart

Rate

Board . 5-22

CSAFE Board 5-24

Display Cable 5-25

Display Over1ays 5-26

Handrail Assembly 5-28

6

Diagrams

Parts Ust

6-1

Exploded

VieW

6-3

900T

Schematic 6-4

7

Customer

Service

Contacting Service

7-1

Serial Number 7-1

Retum

Material Authorization

(RMA)

7-1

Damaged

Parts .... . . . 7-2

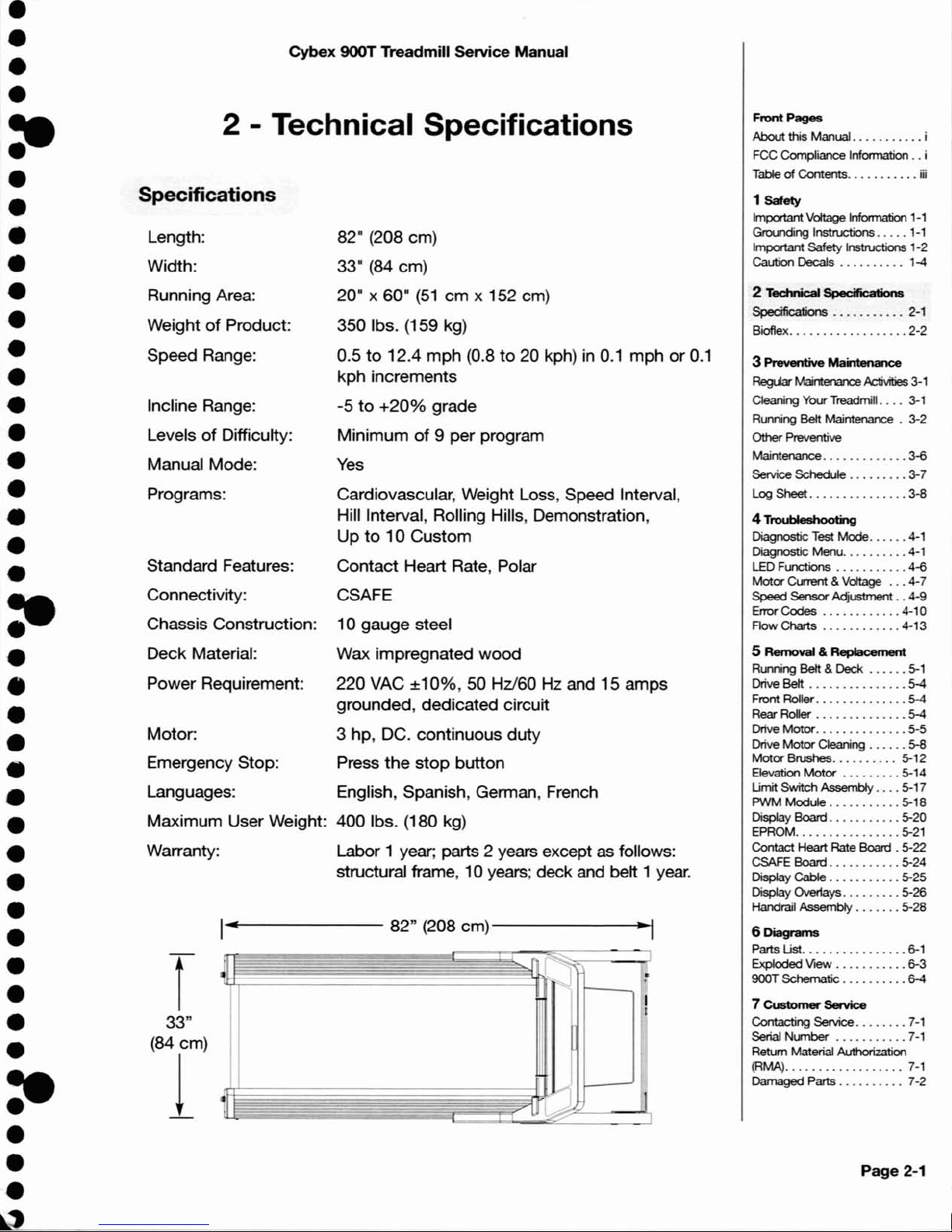

82" (208 cm)

33" (84 cm)

20" x 60"

(51

cm

x 152 cm)

350 Ibs. (159 kg)

0.5

to

12.4 mph (0.8to20 kph)in0.1

mphor0.1

kph increments

-5

to

+20%

grade

Minimum

of

9 per program

Yes

Cardiovascular, Weight Loss, Speed Interval,

Hill Interval, Rolling Hills, Demonstration,

Up

to10Custom

Contact Heart Rate, Polar

CSAFE

10 gauge steel

Wax impregnated

wood

220 VAC

±10%,

50 Hz/60 Hz and 15 amps

grounded, dedicated circuit

3 hp, DC. continuous duty

Press

the

stop

button

English, Spanish, German, French

400 Ibs. (180 kg)

Labor 1 year; parts 2 years except as follows:

structural frame, 10 years; deck and belt 1

year.

Length:

Width:

Running Area:

Weight

of

Product:

Speed Range:

Incline Range:

Levels

of

Difficulty:

Manual Mode:

Programs:

Standard Features:

Connectivity:

Chassis Construction:

Deck Material:

Power Requirement:

Motor:

Emergency Stop:

Languages:

Maximum User Weight:

Warranty:

Specifications

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

~,

Page 14

Page

2-2

Cybex 900T Treadmill Service Manual

Bioflex

The Bioflex system used on the 900T is optimized

for

lateral stability. This is accomplished

through

the use of a 10 gauge steel frame and critically

damped

rear wheels. The heavy

gaugeofthe steel frame provides a rigid structuretotransfer

the

landing

shocktothe

damped

wheels so that they can effectively absorb the impact.

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 15

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Cybex 900T Treadmill Service Manual

3 - Preventive Maintenance

Regular Maintenance

Activities

Preventive maintenance activities

must

be performedtomaintain normal

operation

of

your treadmill. Keeping a log sheetofall maintenance actions will

assist you

in

staying current with all preventive maintenance activities. See Log

Sheet in this chapter.

Cleaning Your Treadmill

When cleaning your treadmill spray a mild cleaning agent, such as a water and

dishsoap solution, on a clean cloth first,

and

then wipe

the

treadmill with the

damp

cloth.

NOTE: Do

not

spray cleaning solution directly on the treadmill. Direct

spraying

could

cause damage to the electronics

and

may void the

warranty.

! WARNING: To

prevent

electrical

shock,

be

sure

that

powerisshut

off

and

the

treadmillisunplugged

from

the

electrical

outlet

before

perfonning

any

cleaningormaintenance

procedures.

After

Each

Use

-

Wipeupany liquid spills immediately. After each workout,

use a cloth

to

wipeupany remaining perspiration from

the

handrails and

painted surfaces.

Be careful not

to

spillorget excessive moisture between

the

edgeofthe

display panel and the console, as this

might

create an electrical hazard

or

cause failureofthe electronics.

As

Needed

- Vacuum any dustordirt

that

might

accumulate underoraround

the

900T. Motors are especially susceptibletodust

and dirt, and restricted

airflow can prevent adequate cooling

that

could shorten

motor

life. Cleaning

this area should be

done

as often as indicated in

the

Service Schedule.

! WARNING:

Keep

wet

items

away

from

inside

parts

of

the

treadmill.

Electrical

shock

could

occur

evenifthe

treadmill

is

unplugged.

Avoid

touching

the

wire

connections

at

the

endofthe

blue

capacitor

mounted

on

topofthe

aluminum

box

nexttothe

drive

belt.

Front

Pages

About

this Manual i

FCC

Compliance

Information

..

i

Table

of

Contents iii

1

Safety

ImportantVoltage Infoonation

1-1

Grounding Instructions

.....

1-1

Important Safety Instructions 1-2

Caution

Decals... ....

...

1-4

2 Tec:hnicaI Spec:ificatiol18

Specifications . . . . . . . . ...2-1

Bioflex

2-2

3

Preventive

Maintenance

FlegU<r

Mairtenance

Activities

3-1

Cleaning

Your

Treadmill. ...3-1

Running

Belt

Maintenance . 3-2

Other Preventive

Maintenance

3-6

Service Schedule

3-7

Log

Sheet

3-8

4

Troubleshooting

Diagnostic Test Mode 4-1

Diagnostic

Menu

4-1

LED Functions

4-6

Motor

CuTent & Voltage 4-7

Speed

Sensor Adjustment

..

4-9

Error

Codes

.4-10

Flow Charts 4-13

5 Removal &

Replacement

Running Belt & Deck 5-1

Drive

Belt 5-4

Front Roller 5-4

Rear Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes. . . . . . . ...5-12

Elevation

Motor

5-14

Umit

Switch

Assembly

5-17

PWM

Module

5-18

Display

Board 5-20

EPROM 5-21

Contact Heart Rate Board . 5-22

CSAFE Board 5-24

Display

Cable

5-25

Display Overlays

5-26

Handrail

Assembly

5-28

6

Diagrams

Parts

Ust

6-1

Exploded

VieW

6-3

900T Schematic

6-4

7

Customer

Service

Contacting Service 7-1

Serial

Number

7-1

Return Material

Authorization

(RMA)

7-1

Damaged

Parts 7-2

Page

3-1

Page 16

Page

3-2

Cybex

900T Treadmill

Service

Manual

To

clean the

motor

components, you

must

remove the

two

Phillips head screws that hold the

motor

cover in place. Lift the cover, and

put

it and the screws aside. Use a vacuum

attachment

or

hand vacuumtoclean

the

exposed elevation assembly, drive motor, lower

electronics and the surrounding areas.

Also use a

dry

cloth

for

the areas that you can't reach with the vacuum cleaner. If the machine

has not been used

for

some timeoris excessively dirty, use a

dry

clothtowipe all exposed

areas. Replace the cover and screws when finished.

With

the

helpofanother person, lift

the

rearofthe treadmill and roll it back from its present

position

soasto

vacuum

the

floor area underneath the unit. Wipe clean the undersideofthe

900T

to

prevent dirt and

dust

build-up. When finished, return the treadmilltoits normal

position.

Contact

Heart

Rate

Grips

- Contaminants, such as hand lotions, oils or body powder, may

come

off

on the contact heart rate grips. These can reduce sensitivity and interfere with the

heart rate signal. It is recommended that the user have clean hands when using the contact

heart rate. Clean the grips using a cloth dampened with a cleaning solution containing alcohol.

The grips are the only part

of

the treadmill you should use a cleaning solution containing alcohol.

In

addition, the nickel plating on the 900T may become tarnished and blackened with time.

This may reduce sensitivity and interfere with the heart rate signal. Use

an

emery cloth

to

remove

the

tarnish from

the

exposed nickel plating on

the

heart rate grips.

Running Belt

Maintenance

Belt

and

Deck

- Clean

the

belt and the

deck

surfacestominimize the effectoffriction

between

the

wood

deck

and the running belt. Clean the undersideofthe running belt and the

topofthe running

deck

surface by wiping them with a clean dry towel. This should be done

often

to

prevent premature wearofthe deck, running belt, and the drive

motor

system. See

the

Service Schedule in this chapter

to

determine the minimum recommended cleaning.

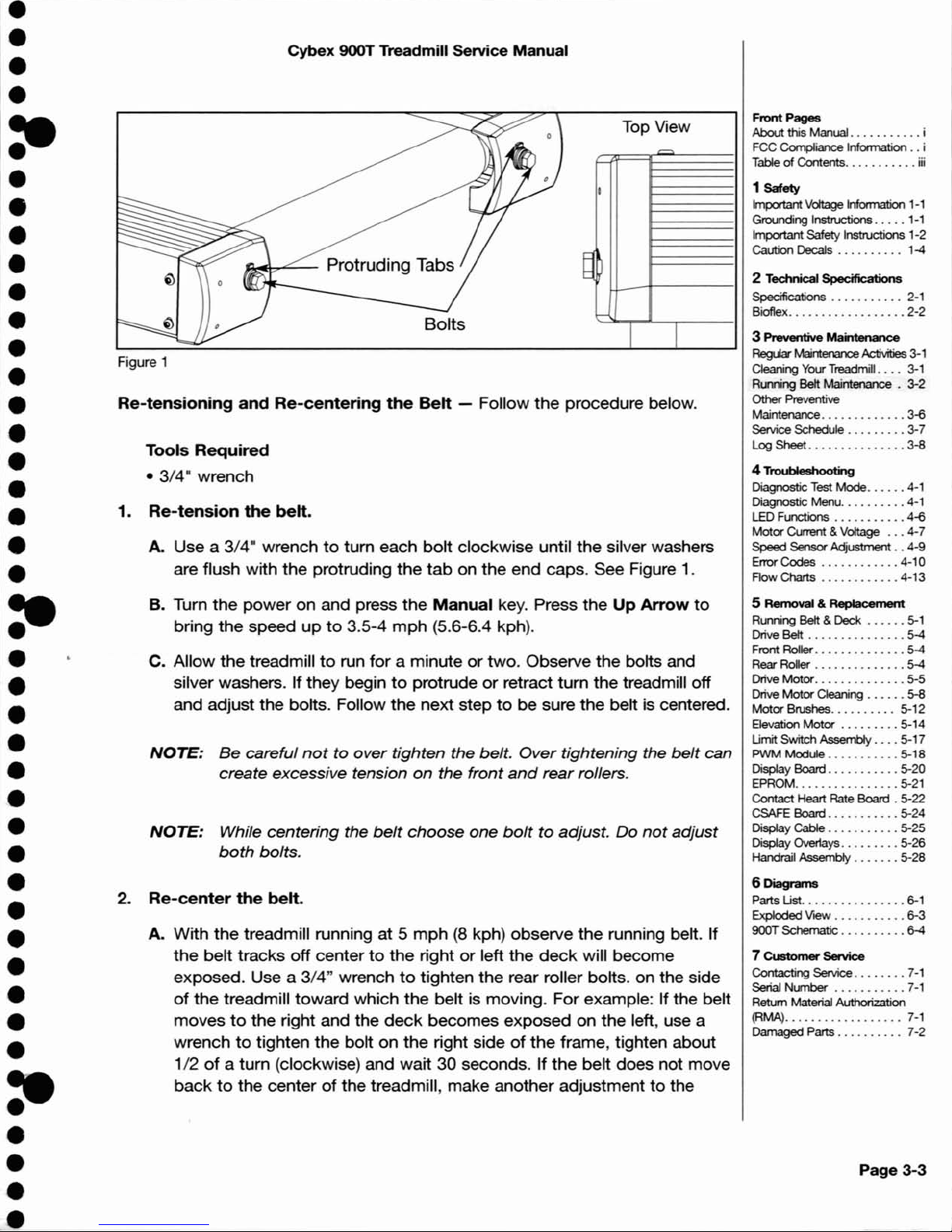

The running belt may become loose and slip on the drive roller with each foot plant. The 900T

is equipped with visual indicators

of

belt tension. These are located at the rearofthe treadmill

where the

two

3/4·

bolts protrude from the plastic end caps. See Figure 1. These are

designed

to

indicate if

the

running belt is at the proper tensiontoinsure safe operationofthe

unit. If

the

belt has become loose,

the

silver colored washer located under the bolt will move

out slightly from

the

protruding

tab

molded in the end cap. See the Service Schedule in this

chapter

to

determine the minimum recommended checkingofthe belt tension.

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

~

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 17

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:-

•

•

•

Cybex 900T Treadmill Service

Manual

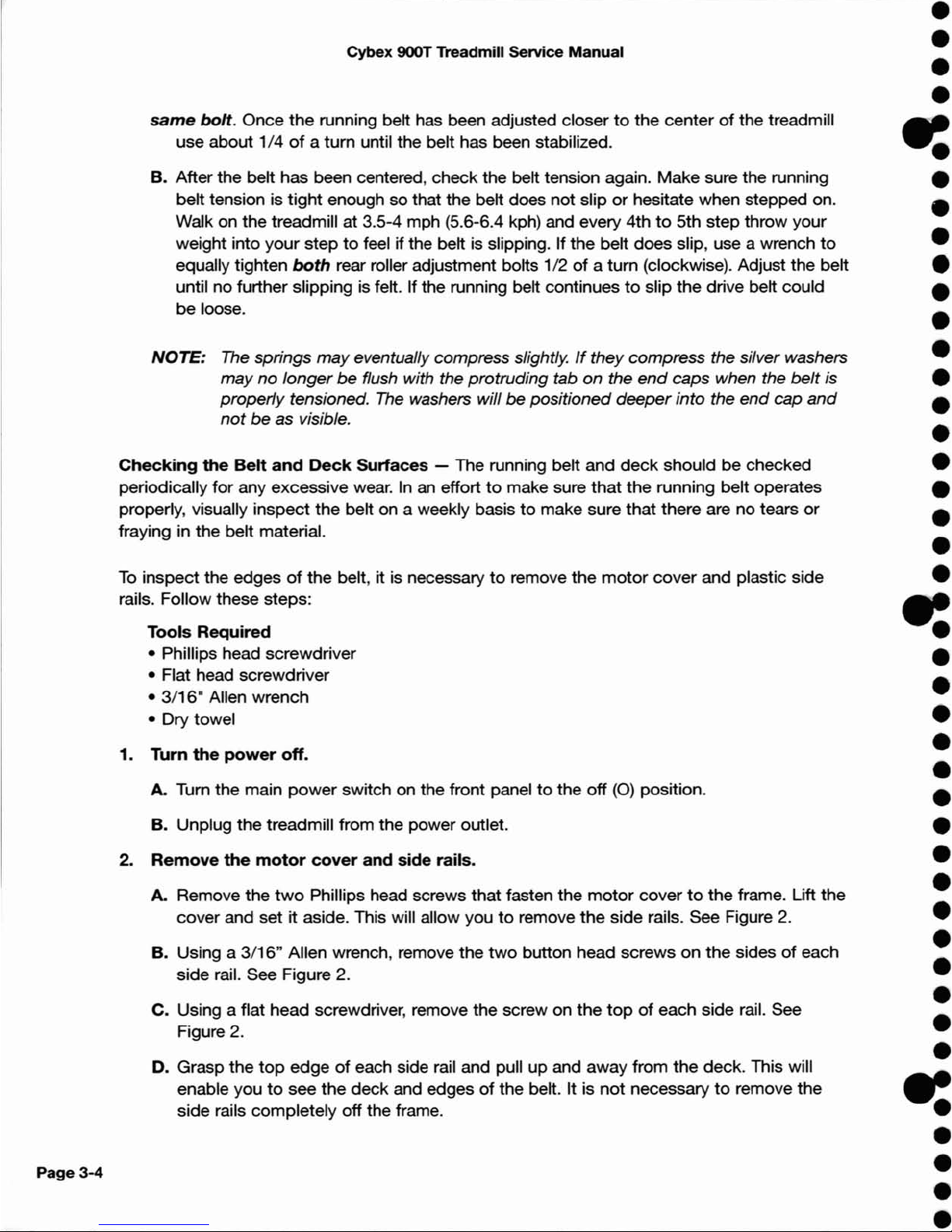

Top View

.Q,ooI!b-""---

Protruding Tabs

Bolts

Figure 1

Re-tensioning

and

Re-centering

the

Belt

- Follow

the

procedure below.

Tools

Required

•

3/4

10

wrench

1.

Re-tension

the

belt.

A.

Use a 3/4" wrenchtoturn each

bolt

clockwise until the silver washers

are flush with the protruding

the

tab

on the end caps. See Figure 1.

B. Turn

the

power on and press

the

Manual

key. Press the

Up

Arrow

to

bring the speedupto

3.5-4

mph

(5.6-6.4 kph).

c.

Allow

the

treadmilltorun for a minuteortwo. Observe the bolts and

silver washers. If they begin

to

protrudeorretract turn the treadmill off

and adjust the bolts. Follow the next step

to

be sure the beltiscentered.

NOTE:

Be

careful

nottoover

tighten the belt.

Over

tightening the

belt

can

create excessive tension

on

the front

and

rear

rollers.

NOTE:

While

centering

the

belt

choose

one

bolttoadjust. Do

not

adjust

both

bolts.

2.

Re-center

the

belt.

A. With the treadmill running at 5

mph(8kph) observe the running belt. If

the

belt tracks off centertothe

right or left the

deck

will become

exposed. Use a

3/4" wrench

to

tighten the rear roller bolts. on the side

of

the treadmill toward which the beltismoving. For example: If the belt

moves

to

the right and the

deck

becomes exposed on the left, use a

wrench

to

tighten the bolt on the right sideofthe

frame, tighten about

1/2

of

a turn (clockwise) and wait30seconds. If

the

belt does not move

backtothe centerofthe treadmill, make another adjustmenttothe

Front

Pages

About

this Manual i

FCC Compliance Information

..

i

Table

of

Contents iii

1

Safety

Important Voltage Information 1-1

Grounding Instructions

.....

1-1

Important

Safety Instructions 1-2

Caution Decals . . . . . . . .

..

1-4

2

Technical

Specifications

Specifications 2-1

Bioflex

2-2

3

Preventive

Maintenance

RegtW

Maintenance

Activities 3-1

Cleaning Your

Treadmill. ...3-1

Running Belt Maintenance .

3-2

Other

Preventive

Maintenance

3~

Service Schedule

3-7

Log Sheet

3-8

4 Troubleshooting

Diagnostic

Test

Mode 4-1

Diagnostic Menu 4-1

LED Functions

4~

Motor

Current & Voltage'"4-7

Speed Sensor Adjustment..4-9

Error Cocles

4-10

Row Charts

4-13

5 Removal &

Replacement

Running Belt & Deck 5-1

Drive

Belt . . . . . . . . . . . . . . .

5-4

Front Roller

5-4

Rear Roller

5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes 5-12

Elevation

Motor

5-14

Limit

Switch

Assembly

5-17

PWM

Module

5-18

Display

Board

5-20

EPROM 5-21

Contact Heart

Rate

Board .

5-22

CSAFE Board

5-24

Display Cable

5-25

Display Overlays 5-26

Handrail Assembly

5-28

6

Diagrams

Parts List 6-1

Exploded

VieW

6-3

900T Schematic 6-4

7

Customer

Service

Contacting Service 7-1

Serial

Number

7-1

Return Material Authorization

(RMA)

7-1

Damaged Parts 7-2

Page 3-3

Page 18

Page

3-4

Cybex 900T Treadmill Service

Manual

same

bolt.

Once

the

running belt has been adjusted

closertothe

centerofthe

treadmill

use

about

1/4ofa

turn

until the belt has been stabilized.

B. After

the

belt has been centered,

check

the

belt tension again.

Make

sure

the

running

belt tension is

tight

enough so that

the

belt does

not

sliporhesitate when stepped on.

Walk on

the

treadmill at 3.5-4 mph (5.6-6.4 kph) and every 4thto5th

step

throw

your

weight into

your

steptofeel if the belt is slipping. If

the

belt

does

slip, use a wrench

to

equally tighten

both

rear roller adjustment bolts

1/2ofa

turn

(clockwise). Adjust

the

belt

until

no

further slipping is felt. If the running belt continuestoslip

the

drive belt could

be

loose.

NOTE: The springs may eventually compress slightly.Ifthey compress the silver washers

may no

longerbeflush with the protruding tabonthe

end

caps when the

belt

is

properly tensioned.

The

washers willbepositioned deeper into the

end

cap

and

not

be

as visible.

Checking

the

Belt

and

Deck

Surfaces

- The running belt

and

deck

should

be checked

periodically

for

any excessive wear.Inan

efforttomake sure

that

the

running belt operates

properly, visually

inspect

the

belt on a weekly basistomake sure

that

there are no tears

or

fraying in

the

belt material.

To

inspect

the

edgesofthe

belt, it is necessarytoremove

the

motor

cover

and plastic side

rails. Follow these steps:

Tools

Required

• Phillips head

screwdriver

• Flat head

screwdriver

•

3/16·

Allen

wrench

• Dry towel

1.

Turn

the

power

off.

A. Turn

the

main

power

switch on the

front

paneltothe

off

(0)

position.

B. Unplug

the

treadmill from

the

power

outlet.

2.

Remove

the

motor

cover

and

side

rails.

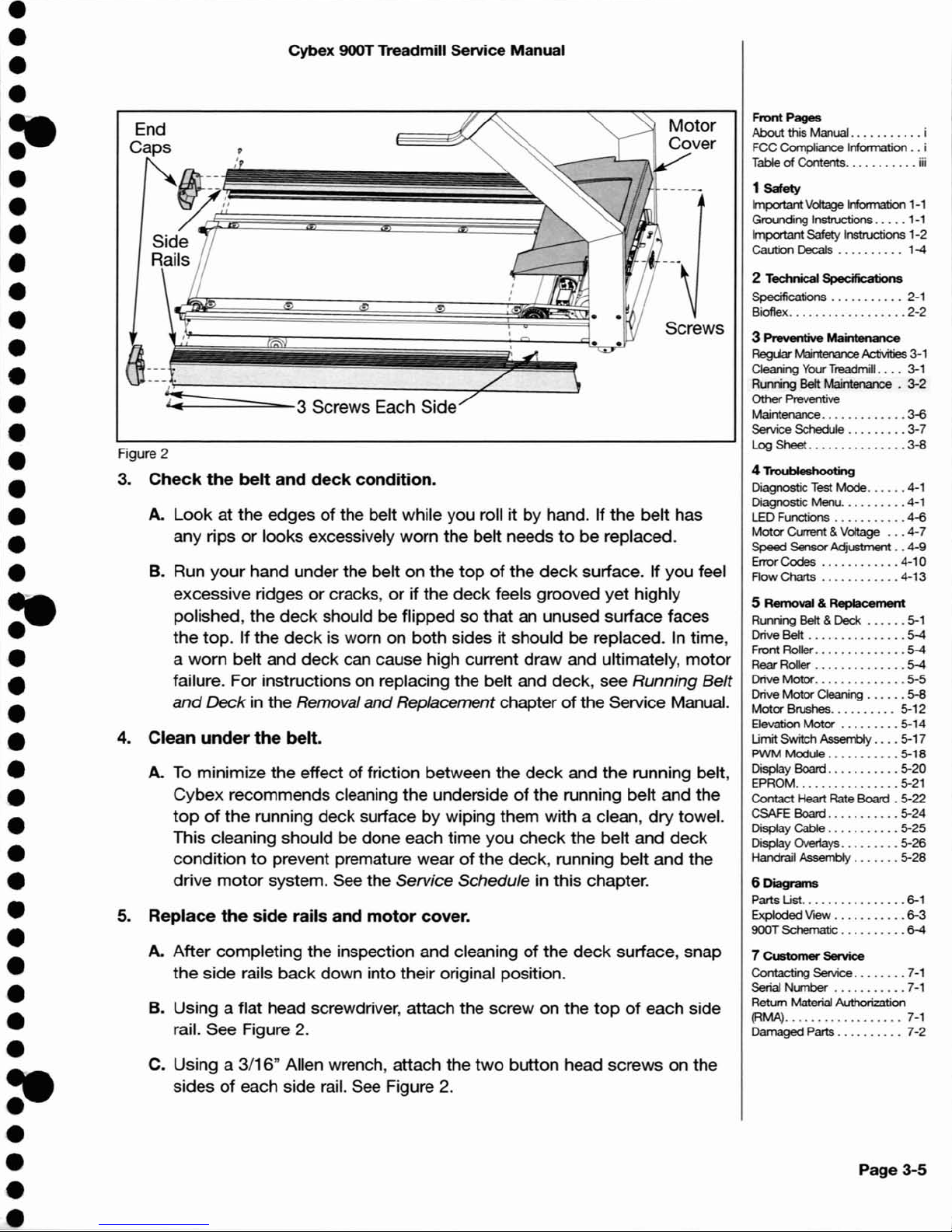

A. Remove

the

two

Phillips head screws

that

fasten

the

motor

covertothe

frame. Lift

the

cover

and set it aside. This will allow youtoremove

the

side

rails. See Figure 2.

B. Using a

3/16"

Allen wrench, remove

the

two

button head

screwsonthe

sidesofeach

side

rail. See Figure 2.

C. Using a flat

head

screwdriver, remove

the

screw on

the

topofeach side rail. See

Figure 2.

D. Grasp

the

top

edgeofeach side rail and pull up and

away

from

the

deck. This will

enable

youtosee

the

deck

and edgesofthe

belt. It is

not

necessarytoremove

the

side rails

completely

off

the

frame.

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 19

4.

Clean

under

the

belt.

Front

Pages

About

this Manual i

FCC Compliance Information

..

i

Table

of

Contents iii

2 Technical Specifications

Specifications . .

.. ..

. . ...2-1

Bioflex 2-2

Page 3-5

1

Safety

ImportantVoltage Information 1-1

Grounding

Instructions

.....

1-1

Important Safety Instructions 1-2

Caution Decals

..

........

1-4

3

Preventive

Maintenance

RegUar

Maintenance

Activities

3-1

Cleaning Your

Treadmill. ...3-1

Running Belt Maintenance . 3-2

Other

Preventive

Maintenance 3~

Service Schedule 3-7

LogSheErt

3-8

4

Troubleshooting

Diagnostic Test Mode 4-1

Diagnostic Menu 4-1

LED Functions

4~

Motor

Current & Voltage

4-7

Speed Sensor Adjustment..4-9

Error Codes

4-10

Flow Charts

4-13

5 Removal & Replacement

Running Belt &

Deck

5-1

Drive Belt 5-4

Front Roller

5-4

Rear Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes 5-12

Elevation

Motor

5-14

Umit

Switch Assembly 5-17

PWM

Module

5-18

Display Board

5-20

EPROM 5-21

Contact Heart Rate Board . 5-22

CSAFE Board 5-24

Display Cable 5-25

Display Overlays

5-26

Handrail Assembly 5-28

6

Diagrams

Parts Ust 6-1

Exploded

VieW

........•.•

6-3

900T Schematic 6-4

7

Customer

Service

Contacting

Service

7-1

Serial Number 7-1

Retum Material Authorization

(RMA)

7-1

Damaged Parts...... . 7-2

Screws

~=======---3

Screws Each

Side

,

I

I

~'~,'I~~~

Side

Rails

Cybex

900T

Treadmill Service Manual

B. Run

your

hand under the belt on the

topofthe

deck

surface. If you feel

excessive ridges

or

cracks,orif the

deck

feels grooved yet highly

polished, the

deck

should be flipped so that an unused surface faces

the

top.

If the

deck

is worn on both sides it should be replaced.Intime,

a

worn

belt and

deck

can cause high current draw and ultimately,

motor

failure. For instructions on replacing the belt and deck, see Running

Belt

and

Deck in the Removal andReplacement chapterofthe Service Manual.

C. Using a

3/16"

Allen wrench, attach the

two

button head screws on the

sides

of

each side rail. See Figure 2.

A. After completing the inspection and cleaning

of

the

deck

surface, snap

the

side rails back down into their original position.

B. Using a flat head screwdriver, attach the screw on the

topofeach side

rail. See Figure 2.

A. Look at the edges

of

the belt while you roll it by hand. If the belt has

any rips

or

looks excessively worn the belt needstobe replaced.

End

Caps

A.

To

minimize

the

effect of friction between the

deck

and the running belt,

Cybex

recommends cleaning the undersideofthe running belt and the

topofthe

running deck surfacebywiping them with a clean,

dry

towel.

This cleaning should be done each time you check the belt and

deck

conditiontoprevent premature wearofthe deck, running belt and the

drive

motor

system. See the Service Schedule in this chapter.

5.

Replace

the

side

rails

and

motor

cover.

Figure 2

3.

Check

the

belt

and

deck

condition.

•

•

•

•

:-

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

=-

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Page 20

Page

3-6

Cybex 900T Treadmill Service

Manual

D. Lower the

motor

coverinplace and tighten the

two

Phillips screws. See Figure

2.

Other

Preventive

Maintenance

Cybex recommends that

the

following maintenance activities be completedbya qualified

service technician. These activities should be perfonned at the recommended intervals listed

in the

Service Schedule (located in this chapter):

Measure the

motor

brushes and replace worn motor brushes

Rotate, flip and replace the running deck.

Replace the running belt

Check the current

draw

Measure motor voltage at maximum speed, with no load

Refer

to

the 900T Service Manual

for

detailed procedures when completing the tasks listed

above. If you need

to

order a manual, call Cybex at 888-GO-CYBEX, 888-462-9239 or

in

some areas call 508-533-5183.

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

~

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-=

•

•

•

Page 21

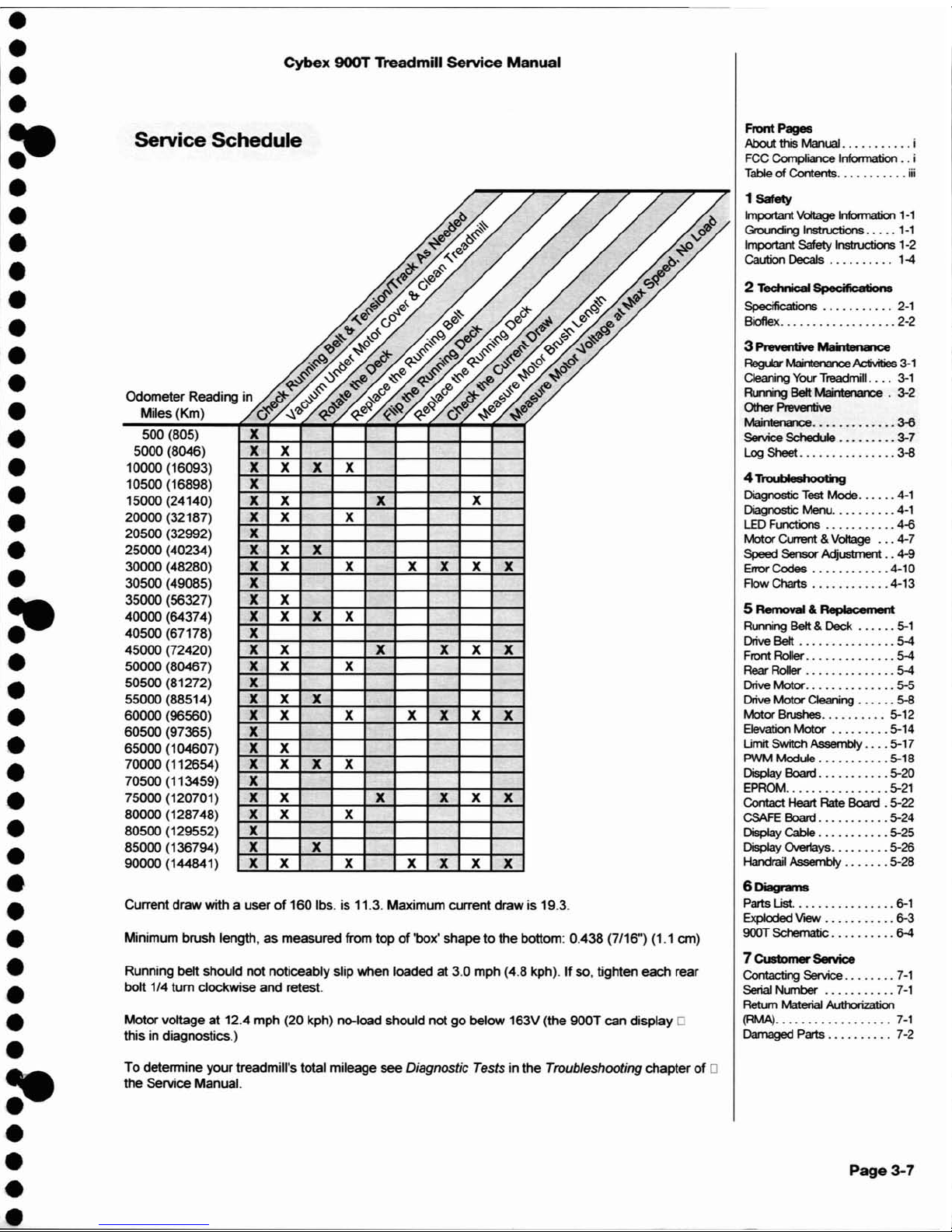

Current

draw

with a user

of

160 Ibs. is 11.3. Maximum current drawis 19.3.

Cybex

900T

Treadmill

Service

Manual

Front

Pages

About this

MMuaI

i

FCC

CompIia1ce

Information

..

i

Table

of Contents

iii

Page 3-7

1

Safety

Important

Voltage

Information

1-1

Gn:x.rong

Instructions

.....

1-1

Important Safety Instructions 1-2

Caution Decals . . . . . . . .

..

1-4

2 Technic:aI Spec;ificatiolI8

Specifications . . . . . . . . . . .

2-1

Bioflex.

. . . . . . . . . . . .

.....

2-2

3 Preventive Mai1tenan:e

RegLW Maintellalce

Ac1ivilies

3-1

Cleaning

Your

Treadmill. .

..

3-1

Fbring

Belt Maintelwlce . 3-2

Other

Preventive

~

~

Service

SchecUe 3-7

Log Sheet 3-8

4 TroubIeehooting

Diagnostic Test Mode

4-1

Diagnostic Menu 4-1

LED

Functions 4-6

Motor

Current & Voltage 4-7

Speed

Sensor

Adjustment

..

4-9

Error

Codes 4-10

Flow Charts 4-13

5 Removal & Replacement

Running Belt &

Deck

5-1

Drive Belt 5-4

Front

Roller

........•.....

5-4

Rear RoIer 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes 5-12

EJevation

Motor 5-14

Umit Switch Assembly 5-17

PWM Module 5-18

Display Board 5-20

EPR~

5-21

Contact

Heart Rate Board . 5-22

CSAFE

Board 5-24

Display Cable 5-25

Display 0vet1ays 5-26

Handrail Assembly 5-28

6Di11grams

Parts

List.

. . . . . . . . . . . . .

..

6-1

Exploded

VIeW

6-3

900T

Schematic

6-4

7Cl.I8tomer Service

Contacting

Service

7-1

Serial Number

7-1

Return Material Authorization

(RMA)

7-1

Damaged Parts . . . . . . . .

..

7-2

x

x

x

x x x x

x x x

x

x x x x x x x

x

x x x

x x x x

x x x x x x

x x x

x

x x x x

x

x x x x x x

x x x

x x

x

xx

x x x x x

x

x x x x

x x x

xx

x x x x x

x x

x x

x x

Service Schedule

500 (805)

5000 (8046)

1ססoo

(16093)

10500 (16898)

15000 (24140)

20000 (32187)

20500 (32992)

25000 (40234)

3ססoo

(48280)

30500 (49085)

35000 (56327)

40000 (64374)

40500 (67178)

45000 (72420)

5ססoo

(80467)

50500 (81272)

55000 (88514)

6ססoo

(96560)

60500 (97365)

65000 (104607)

7ססoo

(112654)

70500 (113459)

75000 (120701)

80000 (128748)

80500 (129552)

85000 (136794)

90000 (144841)

Running belt should

not

noticeably slip when loaded at 3.0 mph (4.8 kph).Ifso, tighten each rear

bolt 1/4

tum

clockwise and retest.

Minimum brush length,

as

measured from topof'box' shapetothe bottom: 0.438 (7/16") (1.1 em)

To

detennine yourtreadmill's total mileage see Diagnostic Tests in the Troubleshooting chapterof0

the Service Manual.

Motor voltage at 12.4 mph (20 kph) no-load should not

go

below 163V(the 900T can display 0

this in diagnostics.)

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

I~

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 22

Page

3-8

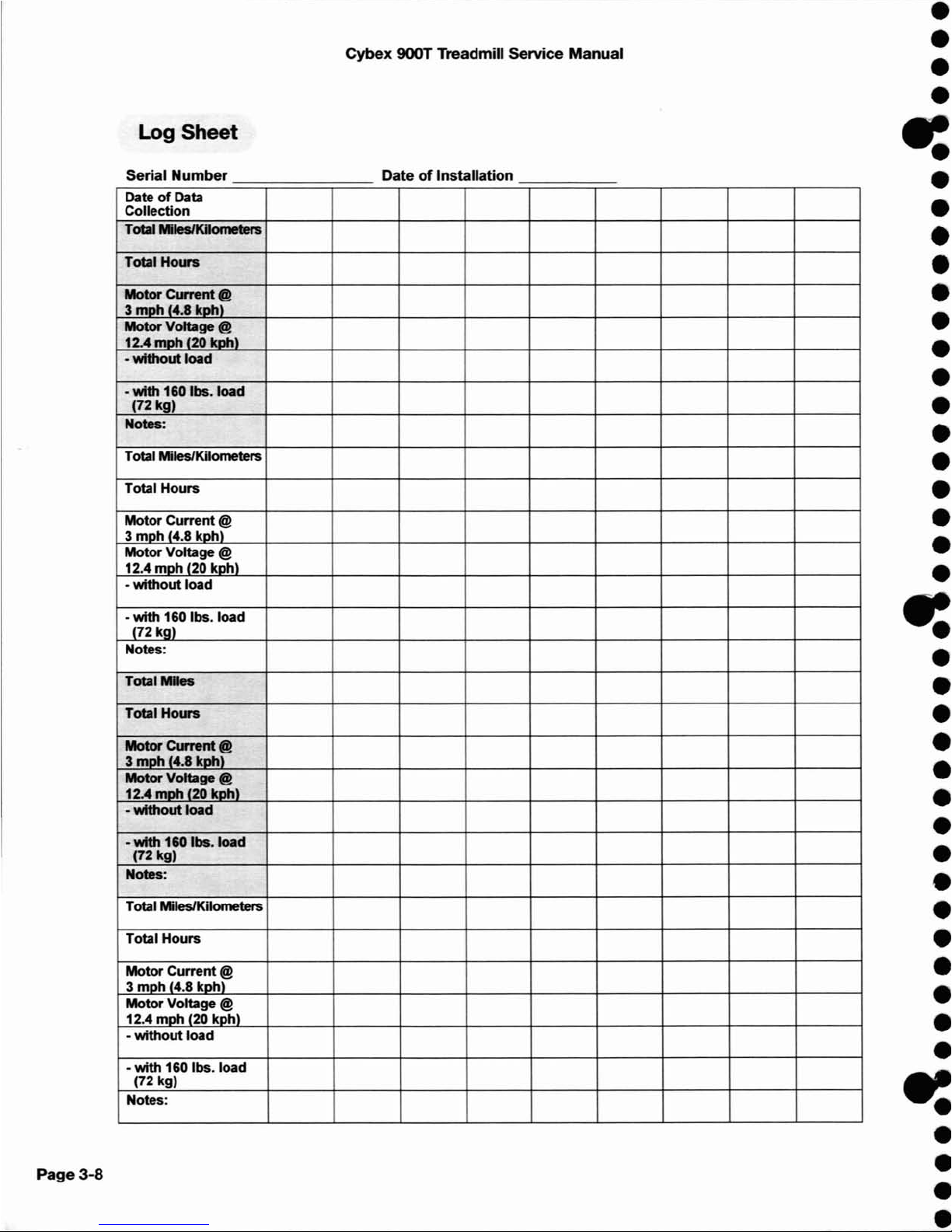

Log

Sheet

Serial Number

DateofData

Collection

Total MIesIKiIomeIers

TotalHotn

Motor

Cwrent

@

3

mph

(4.8 koh)

Motor

Voltage @

12.4

moh'2O

koh)

-

without

load

•

with

160 Ibs. load

(72 kg)

Notes:

Total Miles/Kilometers

Total Hours

Motor Current

@

3

moh

(4.8

kohl

MotorVoltage @

12.4

moh

(20

kohl

-

without

load

-

with

160 Ibs. load

(72 kg)

Notes:

Total

Miles

Total Hours

Motor

Current

@

3

moh

(4.8

koh)

Motor Voltage @

12.4

moh

'20

koh)

-

without

load

-with

160 Ibs. load

(72 kg)

Notes:

Total Miles/Kilometers

Total Hours

Motor Current

@

3 mDh '4.8

kohl

MotorVoltage @

12.4 moh (20

kohl

-

without

load

-

with

160

Ibs.load

(72 kg)

Notes:

Cybex

900T Treadmill Service

Manual

DateofInstallation

•

•

•

•

~

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

~

•

•

•

•

Page 23

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:-

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Cybex

900T Treadmill

Service

Manual

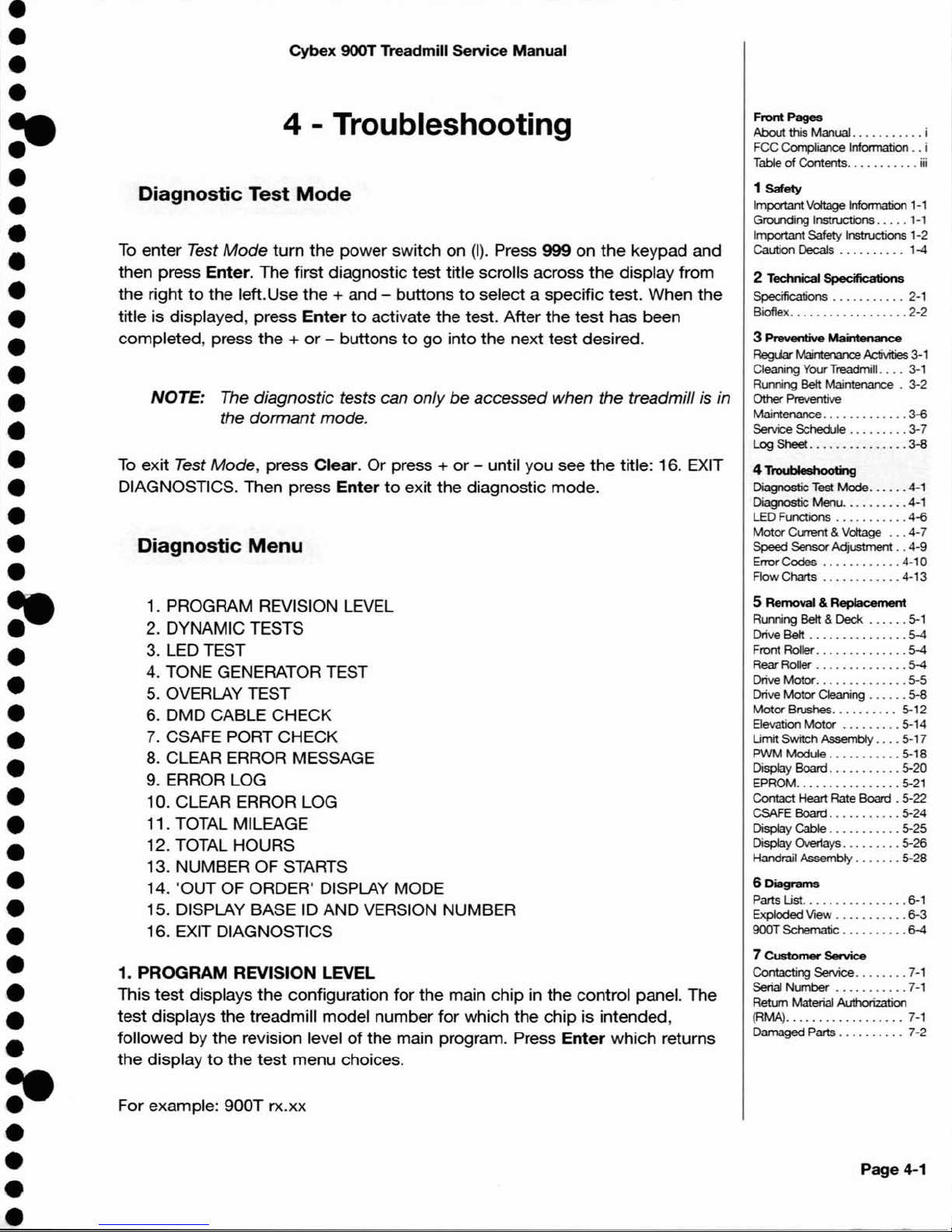

4 - Troubleshooting

Diagnostic

Test

Mode

To

enter

Test

Mode

turn

the power switch on

(I).

Press 999 on the keypad and

then press Enter. The first diagnostic test title scrolls across

the

display from

the right

to

the left.Use the + and - buttonstoselect a specific test. When the

title is displayed, press

Entertoactivate the test. After the test has been

completed, press

the+or

- buttonstogo into the next test desired.

NOTE:

The diagnostic tests can onlybeaccessed when the treadmill is in

the

dormant

mode.

To

exit Test Mode, press Clear. Or press +or- until you see

the

title: 16. EXIT

DIAGNOSTICS. Then press

Entertoexit the diagnostic mode.

Diagnostic

Menu

1. PROGRAM REVISION LEVEL

2. DYNAMIC TESTS

3. LED TEST

4. TONE GENERATOR TEST

5.

OVERLAY TEST

6.

DMD CABLE CHECK

7.

CSAFE PORT CHECK

8.

CLEAR ERROR MESSAGE

9. ERROR LOG

10. CLEAR ERROR LOG

11. TOTAL MILEAGE

12. TOTAL HOURS

13. NUMBER OF STARTS

14. 'OUT OF ORDER' DISPLAY MODE

15. DISPLAY BASE

10 AND VERSION NUMBER

16. EXIT DIAGNOSTICS

1. PROGRAM REVISION LEVEL

This

test

displays

the

configuration for the main chip in the control panel. The

test

displays the treadmill model number

for

which the chip is intended,

followed by the revision level

of

the main program. Press

Enter

which returns

the display

to

the

test

menu choices.

For example: 900T rx.xx

Front

Pages

About

this Manual i

FCC Compliance Information

..

i

TableofContents iii

1

Safety

ImportantVoltage Information

1-1

Grounding Instructions

.....

1-1

Important Safety Instructions 1-2

Caution Decals . . . . . . . .

..

1-4

2 Technical Specifications

Specifications . . . . . . . . ...2-1

Bioflex

2-2

3 Preventive

Maintenance

Reguar Maintenance

Activities

3-1

Cleaning Your Treadmill

....

3-1

Running

Belt

Maintenance . 3-2

Other Preventive

Maintenance

3-6

Service

Schedule 3-7

Log

Sheet

3-8

4 TroubIeshooU1g

Diagnostic

Test

Mode 4-1

Diagnostic Menu 4-1

LED Functions 4-6

Motor

Current & Voltage

4-7

Speed

Sensor

Adjustment..4-9

Error

Codes

4-10

Flow

Charts

4-13

5 Removal &

Replacement

Running

Belt

&

Deck

5-1

Drive

Belt . . . . . . . . . . . . . . .

5-4

Front Roller

5-4

Rear Roller

5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes

5-12

Bevation

Motor

5-14

Umit

Switch

Assembly

5-17

PWM

Module

5-18

Display

Board

5-20

EPROM 5-21

Contact Heart Rate

Board

. 5-22

CSAFE

Board

5-24

Display Cable

5-25

Display Overlays

5-26

Handrail Assembly

5-28

6

Diagrams

Parts Us!. . . . . . . . . . . . . . . . 6-1

Exploded View

6-3

900T

Schematic 6-4

7

Customer

Service

Contacting Service 7-1

Serial

Number

7-1

Retum Material Authorization

(RMA) 7-1

Damaged Parts . . . . . . . .

..

7-2

Page

4-1

Page 24

Page

4-2

Cybex

900T Treadmill Service

Manual

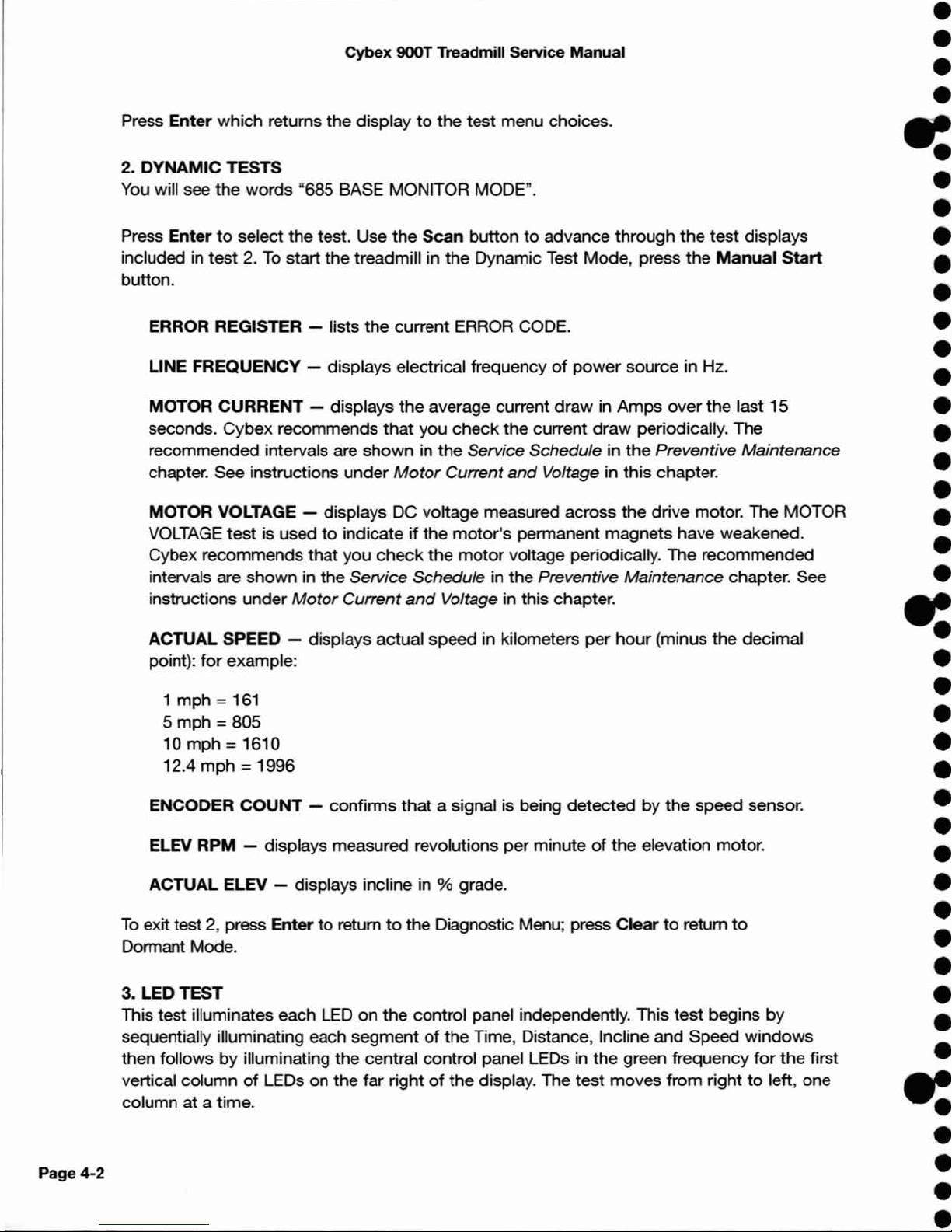

Press

Enter

which returns the displaytothe test menu choices.

2. DYNAMIC TESTS

You

will see

the

words "685 BASE MONITOR MODE".

Press

Entertoselect the test. Use

the

Scan

buttontoadvance through

the

test displays

included in test 2.

To

start the treadmill in the Dynamic Test Mode, press the

Manual

Start

button.

ERROR REGISTER - lists the current ERROR CODE.

LINE FREQUENCY - displays electrical frequency

of

power

source in Hz.

MOTOR CURRENT - displays

the

average current

draw

in Amps over the last 15

seconds. Cybex recommends that you check the current

draw

periodically. The

recommended intervals are shown in the Service Schedule in

the

Preventive Maintenance

chapter. See instructions under

Motor

Current

and

Voltage in this chapter.

MOTOR VOLTAGE - displays DC voltage measured across

the

drive motor. The MOTOR

VOLTAGE

test

is usedtoindicate if the

motor's

permanent magnets have weakened.

Cybex recommends that you

check

the

motor

voltage periodically. The recommended

intervals are shown

in

the Service Schedule in the Preventive Maintenance chapter. See

instructions under

Motor

Current

and

Voltage in this chapter.

ACTUAL SPEED - displays actual speed in kilometers per hour (minus the decimal

point):

for

example:

1 mph =

161

5 mph =805

10 mph

=1610

12.4 mph

=1996

ENCODER

COUNT

- confirms that a signal is being detected by

the

speed sensor.

ELEV RPM - displays measured revolutions per minuteofthe

elevation motor.

ACTUAL ELEV - displays incline in % grade.

To

exit test 2, press Entertoreturntothe Diagnostic Menu; press Cleartoreturn

to

Dormant Mode.

3. LED TEST

This test illuminates each

LEDonthe

control panel independently. This test begins

by

sequentially illuminating each segmentofthe Time, Distance, Incline and Speed

windows

then followsbyilluminating the central control panel LEDs in the green frequency

for

the first

vertical column

of

LEDs on the far rightofthe display. The test moves from righttoleft, one

column at a time.

•

•

•

•

-=

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 25

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

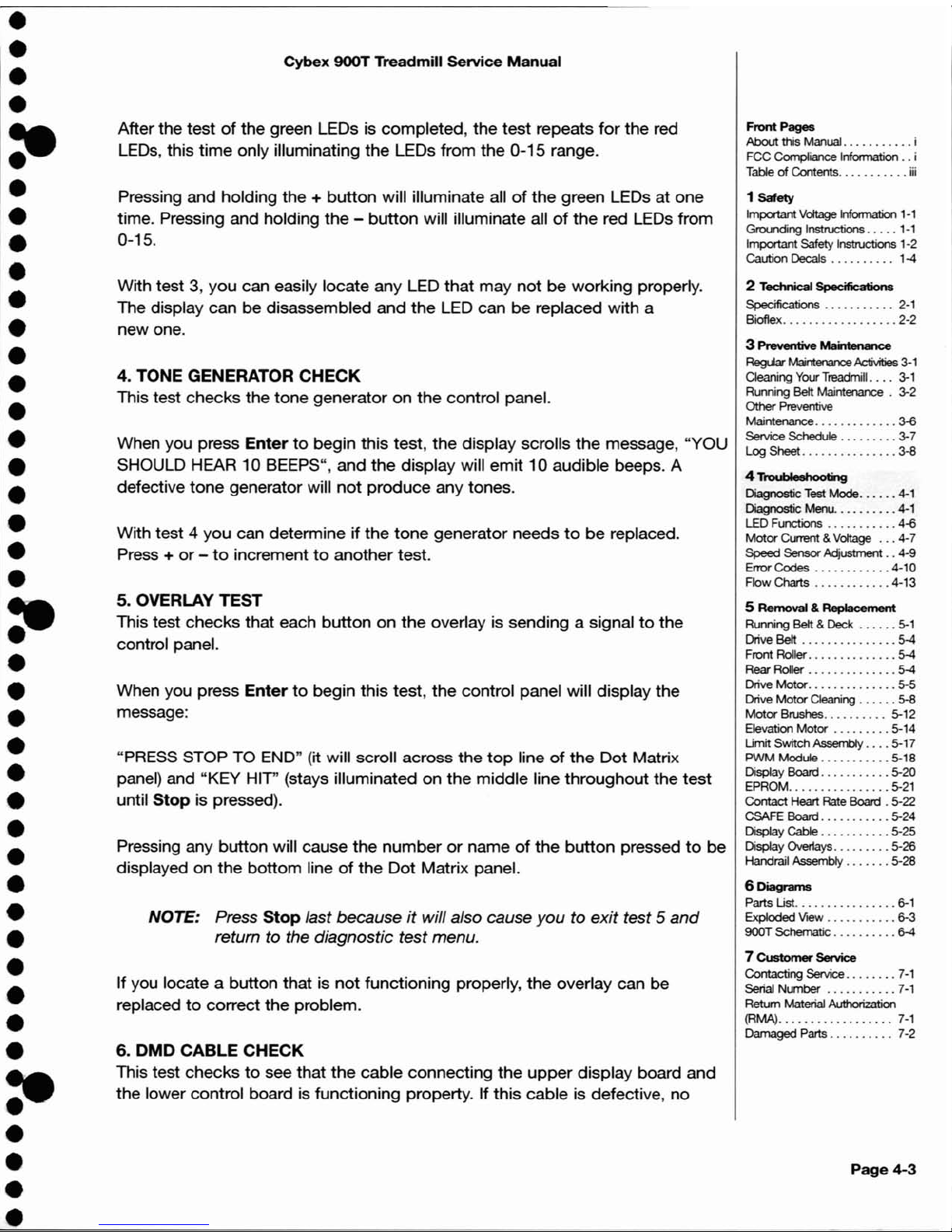

Cybex

900T

Treadmill

Service

Manual

After the testofthe green LEOs is completed, the

test

repeats

for

the red

LEOs,

this

time

only illuminating the LEOs from the 0-15 range.

Pressing and holding the

+ button will illuminate all

of

the

green LEOs at one

time. Pressing and holding

the-button

will illuminate allofthe red

LEOs

from

0-15.

With test 3, you can easily locate any LED that may

notbeworking properly.

The display can be disassembled and the LED can be replaced with a

new one.

4. TONE GENERATOR

CHECK

This test checks the tone generator on the control panel.

When you press

Entertobegin this test, the display scrolls

the

message, "YOU

SHOULD HEAR 10 BEEPS", and the display will emit 10 audible beeps. A

defective tone generator will

not

produce any tones.

With test 4 you can determine if the tone generator needs

tobereplaced.

Press

+

or-to

incrementtoanother test.

5. OVERLAY TEST

This test checks that each button on the overlay is sending a signal

to

the

control panel.

When you press

Entertobegin this test, the control panel will display the

message:

"PRESS STOP TO END"

(it will scroll across the

top

lineofthe Dot Matrix

panel) and "KEY

HIT'

(stays illuminated on the middle line throughout the

test

until

Stop

is pressed).

Pressing any button will cause the

numberornameofthe

button

pressedtobe

displayed on

the

bottom lineofthe Dot Matrix panel.

NOTE: Press

Stop

last becauseitwill also cause

youtoexit

test 5

and

return to the diagnostic

test

menu.

If you locate a button that is

not

functioning properly, the overlay can be

replaced

to

correct the problem.

6.

DMD

CABLE

CHECK

This test checkstosee that

the

cable connecting the

upper

display board and

the lower control board

is

functioning property. If this cable is defective, no

Front

Pages

About

this Manual i

FCC

Compliance Information

..

i

Table

of

Contents

iii

1

Safety

ImportantVoltage Infoonation

1-1

Grounding Instructions

.....

1-1

ImportantSafety Instructions 1-2

Caution Decals . . . . . . . .

..

1-4

2

TeetV1icaI

Spec:ifications

Specifications . . . . . . . . ...2-1

Bioflex 2-2

3 Preventive Maintenance

RegUar

Maintenance

Activities

3-1

Cleaning

Your

Treadmill. ...3-1

Running

Belt

Maintenance . 3-2

Other

Preventive

Maintenance

3~

Service

Schedule 3-7

Log

Sheet.

3-8

4

TroubIeehooting

Diagnostic Test Mode 4-1

Diagnostic

Menu

4-1

LED Functions

4~

Motor

Current & Voltage 4-7

Speed

SensorAdjustment

..

4-9

Error~

4-10

Flow

Charts 4-13

5 Removal &

Replacement

Running

Belt

&

Deck

5-1

Drive Belt . . . . . . . . . . . . . . . 5-4

Front

Roller

5-4

Rear

Roller

5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes 5-12

Elevation

Motor

5-14

Umit

Switch Assembly 5-17

PWM

Module 5-18

Display Board 5-20

EPROM

5-21

Contact Heart Rate Board . 5-22

CSAFE Board 5-24

Display Cable 5-25

Display Overlays 5-26

Handrail

Assembly 5-28

6

Diagrams

Parts

Ust

6-1

Exploded

VieW

.........•.

6-3

900T

Schematic 6-4

7 CustomerService

Contacting Service

7-1

Serial

Number

7-1

Retum

Material

Authorization

(RMA)

7-1

Damaged Parts 7-2

Page

4-3

Page 26

Page

4-4

Cybex

900T

Treadmill

Service

Manual

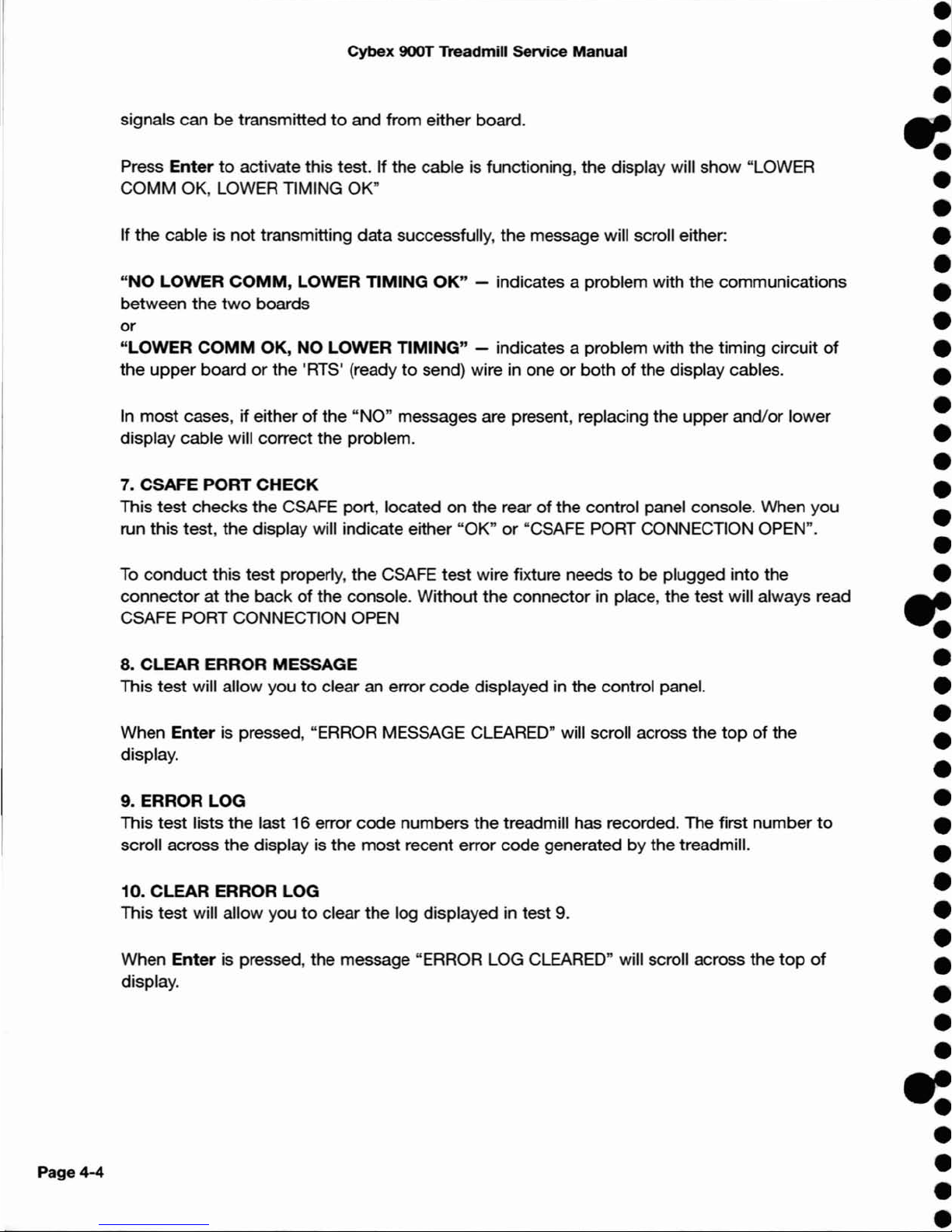

signals can be transmittedtoand from either board.

Press

Entertoactivate this test. If the cable is functioning, the display will

show

"LOWER

COMM

OK, LOWER TIMING OK"

If

the

cable is not transmitting

data

successfully,

the

message will scroll either:

"NO

LOWER

COMM,

LOWER TIMING

OK"

- indicates a problem with the communications

between

the

two

boards

or

"LOWER

COMM

OK, NO LOWER

TIMING"

- indicates a problem with the timing circuit

of

the

upper

board or

the

'RTS' (readytosend) wireinone or bothofthe display cables.

In

most

cases, if eitherofthe

"NO"

messages are present, replacing the upper and/or lower

display cable will correct the problem.

7. CSAFE PORT

CHECK

This test checks the CSAFE port, located on the rearofthe control panel console. When you

run this test,

the

display will indicate either

"OK"or"CSAFE PORT CONNECTION OPEN".

To

conduct

this test properly, the CSAFE

test

wire fixture needstobe plugged into the

connector at

the

backofthe console. Without

the

connector in place, the test will always read

CSAFE PORT CONNECTION OPEN

8.

CLEAR

ERROR MESSAGE

This

test

will allow youtoclear an error

code

displayedinthe control panel.

When

Enter

is pressed, "ERROR MESSAGE CLEARED" will scroll across the

topofthe

display.

9. ERROR LOG

This test lists the last 16 error

code

numbers

the

treadmill has recorded. The first number

to

scroll across the displayisthe

most

recent error code generated by the treadmill.

10.

CLEAR

ERROR LOG

This test will allow you

to

clear the log displayed in test

9.

When

Enter

is pressed, the message "ERROR LOG CLEARED" will scroll across the

top

of

display.

•

•

•

•

-=

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

e:

•

•

•

Page 27

•

•

•

•

:e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:-

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

:e

•

•

•

Cybex

900T

Treadmill

Service

Manual

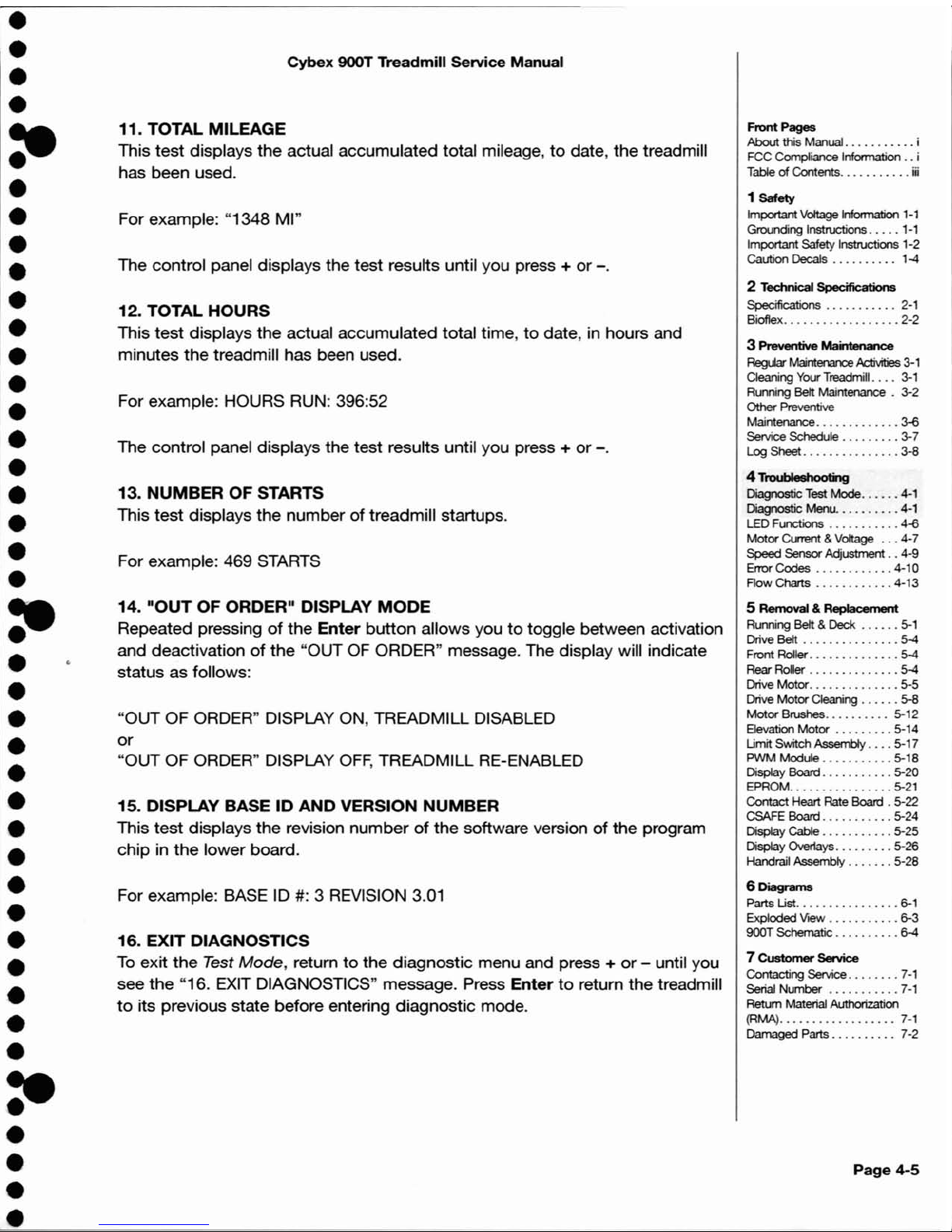

11.

TOTAL

MILEAGE

This

test

displays

the

actual accumulated total mileage,todate,

the

treadmill

has been used.

For example: "1348

MI"

The control panel displays the test results until you press +

or-.

12.

TOTAL

HOURS

This

test

displays

the

actual accumulated total time,todate, in hours and

minutes

the

treadmill has been used.

For example: HOURS RUN: 396:52

The control panel displays the test results until you press

+ or

-.

13.

NUMBER

OF

STARTS

This

test

displays

the

numberoftreadmill startups.

For example: 469 STARTS

14.

"OUT

OF

ORDER"

DISPLAY

MODE

Repeated pressingofthe

Enter

button

allows youtotoggle between activation

and deactivation

of

the

"OUT OF ORDER" message. The display will indicate

status as follows:

"OUT

OF ORDER" DISPLAY ON, TREADMILL DISABLED

or

"OUT

OF ORDER" DISPLAY

OFF,

TREADMILL RE-ENABLED

15. DISPLAY BASE

ID

AND

VERSION

NUMBER

This

test

displays

the

revision

numberofthe

software versionofthe program

chip in

the

lower board.

For example: BASE

10 #: 3 REVISION 3.01

16.

EXIT

DIAGNOSTICS

To

exit

the

Test Mode, returntothe

diagnostic menu and press +or- until you

see

the

"16. EXIT DIAGNOSTICS" message. Press

Entertoreturn

the

treadmill

to

its previous state before entering diagnostic mode.

Front

Pages

About this Manual i

FCC Compliance Information

..

i

Table

of

Contents

iii

1

Safety

ImportantVoltage Information

1-1

Grounding Instructions

.....

1-1

Important Safety Instructions 1-2

caution

Decals . . . . . . . ...1-4

2 Technical

Specifications

Specifications . . . . . . . . ...2-1

Bioflex 2-2

3 Preventive Maintenance

ReglJar

MaintenanceActivities 3-1

Cleaning YourTreadmill

....

3-1

Running

Belt

Maintenance . 3-2

Other Preventive

Maintenance 3-6

Service Schedule 3-7

Log Sheet

3-8

4 TroubIeehoota1g

Diagnostic Test Mode 4-1

Diagnostic

Menu 4-1

LED Functions

4-6

Motor

Ct.JTent

& Voltage 4-7

Speed

Sensor

Adjustment..4-9

Enor

Codes

4-10

Row

Charts

4-13

5 Removal &

RepIacemMt

Running Belt & Deck 5-1

Drive

Belt

5-4

Front Roller. . . . . . . . . . . . . . 5-4

Rear Roller 5-4

Drive

Motor

5-5

Drive

Motor

Cleaning 5-8

Motor

Brushes. . . . . . . ...5-12

Elevation

Motor

5-14

Limit

Switch

Assembly 5-17

PWM

Module 5-18

Display Board 5-20

EPROM 5-21

Contact

Heart

Rate Board . 5-22

CSAFE Board 5-24

Display

Cable

5-25

Display Overlays 5-26

Handrail Assembly 5-28

6

Diagrams

Parts List 6-1

Exploded

VieW

6-3

900T Schematic 6-4

7

Customer

Service

Contacting Service

7-1

Serial

Number

7-1

Retum Material Authorization

(RMA)

7-1

Damaged Parts 7-2

Page

4-5

Page 28

Page

4-6

Cybex

900T Treadmill

Service

Manual

LED Functions

The model 900T is equipped with diagnostic LEOs in the PWM module and the on the display

panel that are used

to

indicate a problem.

PWM

LEOs

In the 900T PWM, there are 2 LEDs in the

power

supply circuit that indicate proper voltage

to

the

display panel.

LED

1 -

LED1

is located on the PWM's printed circuit board (PCB) in

the

cornerofthe

board

near the display cable connector. This

LED

is usedtoverify that the PWM is supplying

the

proper

+SVDC outputtothe display assembly

for

the

normal operationofthe display's

microprocessor. This

LED

should be lit at all times while

power

is appliedtothe

PWM. If LED

1 is

not

lit, this shows that the PWM is not supplying +SVOCtothe

display and the PWM

should be replaced.

LED

2 - LED 2 is located near the centerofthe PCB, closetothe

transformer. This LED is

usedtoindicate the statusofthe DC voltage coming from the transformer on the PWM's

PCB. This voltage is the main source for the

power