Page 1

Cybex Modular

www.cybexinternational.com

Owner’s and Service Manual

Strength Systems

Part Number 55620 H

Page 2

Page 3

Cybex Modular

Owner’s and Service Manual

Strength Systems

Part Number 55620 H

DISCLAIMER: Cybex International, Inc., makes no representations or warranties regarding the contents of this manual. We reserve the right to

revise this document at any time or to make changes to the product described within it without notice or obligation to notify any person of

such revisions or changes.

© Copyright 2009 Cybex International, Inc. All rights reserved.

Printed in the United States of America.

10 Trotter Drive Medway, MA 02053 • 508-533-4300 • FAX 508-533-5183

www.cybexinternational.com • techhelp@cybexintl.com • techpubs@cybexintl.com • 55620 H • July 2009

Page 4

Page 5

i Table of Contents

1 Safety

Safety......................... 1-1

Warning/Caution Decals .......... 1-2

Regular Maintenance Activities ..... 1-21

Using Proper Form .............. 1-21

2 Exercises

(Lower Body)

Seated Leg Press -5652/5322 ..... 2-1

Leg Extension/Leg Curl -

5653/5607 .................... 2-3

(Upper Body)

Low Row (5651/5302) ............ 2-5

Lat Pulldown - 5601.............. 2-7

Chest Press - 5640 .............. 2-9

Pressing Station - 5647/5306 ...... 2-11

Shoulder Press - 5639 ........... 2-13

Tricep Pressdown - 5603.......... 2-15

Tricep Extension - 5641........... 2-17

Arm Curl - 5644 ................. 2-19

(Multi Station)

Cable Crossover -

5648/5649/5650/5311 ........... 2-21

Cable Column -

5605/5633/5315/5316 ........... 2-23

Assisted Chin-Up/Dip - 5611 and

SS Assisted Chin-Up/Dip - 5345 . . 2-25

3 Customer Service

Contacting Service............... 3-1

Ordering Parts .................. 3-1

Returning Goods ................ 3-2

Damaged Parts ................. 3-3

4 Assembly

Weight Stack Installation .......... 4-1

Handle Rack ................... 5631

Modular Mover ................. 5632

Seated Leg Press ............... 5652/5322

Leg Extenstion/Leg Curl .......... 5653/5307

Table of Contents

Page i

5 Maintenance

Daily Procedures ................ 5-1

Weekly Procedures .............. 5-4

Yearly Procedures ............... 5-6

“As Required” Procedures......... 5-6

6 Assembly and Service

Modular Center Post ............. 5600

Tandem Center Post ............. 5629

Lat Pulldown ................... 5601

Tricep Pressdown ............... 5603

45 Degree Back Extension ........ 5608

Bent Leg Abdominal Board ........ 5610

Blank ......................... 5624

Leg Raise Chair ................. 5645

Cable Column .................. 5605

Cable Column .................. 5633

Cable Column .................. 5315/5316

Assist Dip/Chin ................. 5611

Single Station Dip/Chin ........... 5345

Shoulder Press ................. 5639

Chest Press .................... 5640

Tricep Extension ................ 5641

Arm Curl....................... 5644

Low Row ...................... 5651/5302

Pressing Station ................ 5647/5306

Cable Crossover ................ 5648/5649

5650/5311

Seated Leg Press ............... 5652/5322

Leg Extension/Leg Curl ........... 5653/5307

Page 6

Page 7

Page 1-1

1 - Safety

Safety

Read the Owner’s Manual carefully before assembling, servicing or using the equipment.

It is the responsibility of the facility owner and/or owner of the equipment to instruct users on

proper operation of the equipment and review all labels.

! WARNING: Serious injury could occur if these safety precautions are not observed:

USER SAFETY PRECAUTIONS

• Obtain a medical exam prior to beginning an exercise program.

• Read and understand warning labels and user manual prior to exercising. Obtain

instruction prior to use.

• Keep body and clothing free from and clear of all moving parts.

• Inspect machine prior to use. DO NOT use if it appears damaged or inoperable.

• DO NOT attempt to fix a broken or jammed machine. Notify floor staff.

• Use the machine only for the intended use. DO NOT modify the machine.

• Be sure that the weight pin is completely inserted. Use only the pin provided by the

manufacturer. If unsure seek assistance.

• Never pin the weights in an elevated position. DO NOT use the machine if found in this

condition. See assistance from floor staff.

• Children must not be allowed near these machines. Teenagers must be supervised.

• DO NOT use if guards are missing or damaged.

• DO NOT use dumbbells or other incremental weights, except those provided by the

manufacturer.

• Inspect all cables and belts and connections prior to use. DO NOT use if any components

are worn, frayed or damaged.

• DO NOT remove any labeling from equipment. Replace any damaged labels.

• Stop exercising if you feel faint, dizzy or experience pain at any time while exercising and

consult your physician.

Cybex Modular Owner’s Manual

Page 8

Cybex Modular Owner’s Manual

Facility Safety Precautions

• Read the Owner’s Manual carefully before assembling, servicing or using the equipment.

• Securely anchor each machine to the floor using the anchor holes provided in each

machine.

• Make sure that each machine is set up and operated on a solid level surface. Do not

install equipment on an uneven surface.

• Make sure that all users are properly trained on how to use the equipment.

• Make sure there is enough room for safe access and operation of the equipment.

• Perform regular maintenance checks on the equipment. Also pay close attention to all

areas most susceptible to wear, including (but not limited to) cables, pulleys, belts and

grips.

• Immediately replace worn or damaged components. If unable to immediately replace worn

or damaged components then remove from service until the repair is made.

• Use only Cybex supplied components to maintain/repair the equipment.

• Keep a repair log of all maintenance activities.

• Inspect all cables and belts and connections prior to use. DO NOT use if any components

are worn, frayed, or damaged.

NOTE: It is the sole responsibility of the user/owner or facility operator to ensure that regular

maintenance is performed.

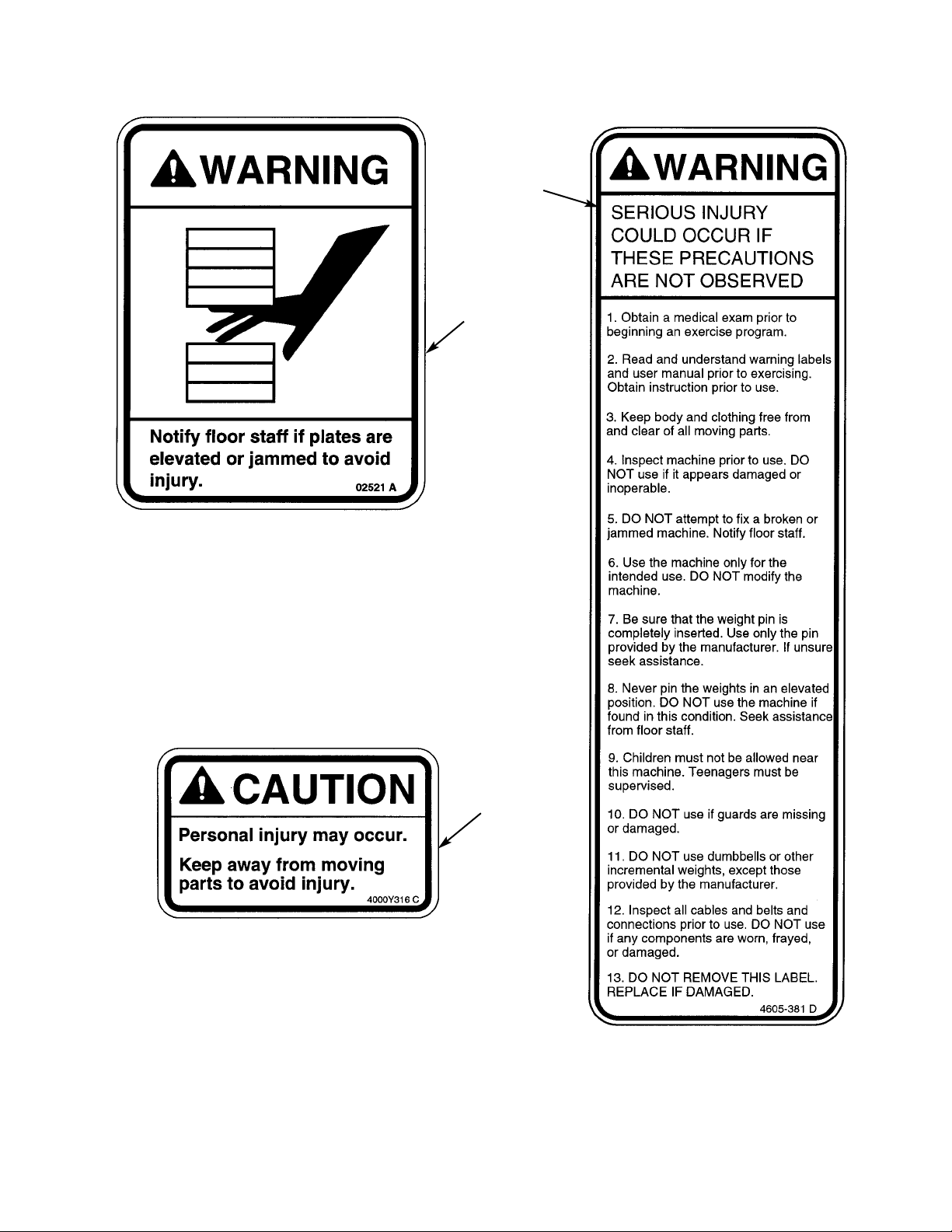

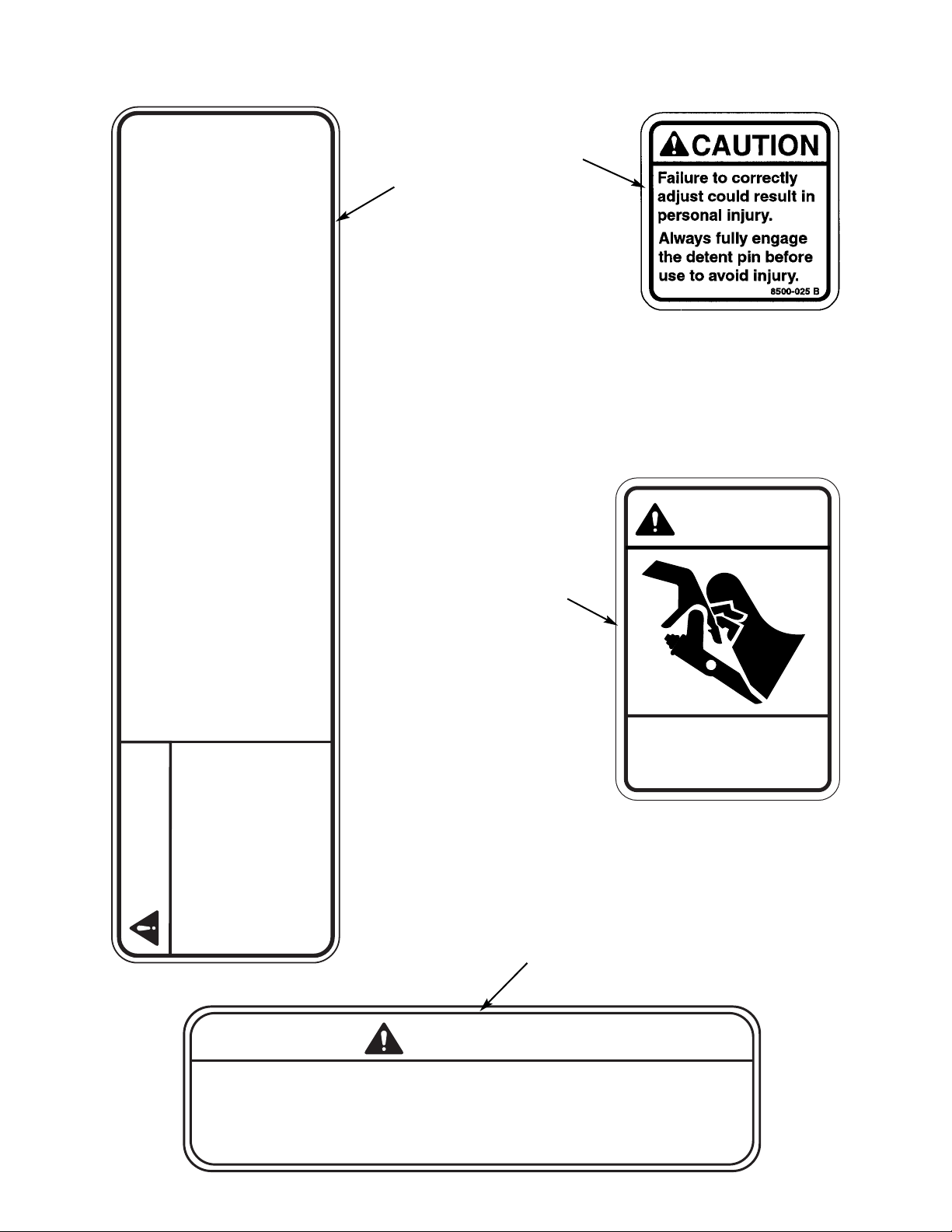

Warning/Caution Decals

Warning decals indicate a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Caution decals indicate a potentially hazardous situation, which, if not avoided, could result in

minor or moderate injury.

The warning and caution decals are shown on the following page. The diagrams following the

decals show where each decal is located.

Page 1-2

NOTE: Cybex is not responsible for the actual anchoring of equipment. Consult

with a professional contractor.

NOTE: Use fasteners having a minimum of 500 lbs. tensile capacity (3/8” grade 2

bolts or better).

NOTE: If legs/frame does not contact surface, DO NOT pull down with anchors.

Shim any leg or frame not in contact with surface using flat washers.

Page 9

Cybex Modular Owner’s Manual

Page 1-3

A

B

C

Page 10

Cybex Modular Owner’s Manual

Page 1-4

CAUTION

350 LBS MAXIMUM LOAD

DO NOT EXCEED MAXIMUM CROSS TUBE LOAD.

PERSONAL INJURY MAY RESULT.

5649-329 A

G

E

.

D

F

10. DO NOT use if guards are missing

or damaged.

11. DO NOT use dumbbells or other

incremental weights, except those

provided by the manufacturer.

12. Inspect all cables and belts and

connections prior to use. DO NOT use

if any components are worn, frayed,

or damaged

4800-381 C

13. DO NOT REMOVE THIS LABEL.

REPLACE IF DAMAGED.

6. Use the machine only for the

intended use. DO NOT modify the

machine.

7. Be sure that the weight pin is

completely inserted. Use only the pin

provided by the manufacturer. If unsure

seek assistance.

2. Read and understand warning

labels and user manual prior to

exercising. Obtain instruction

1. Obtain a medical exam prior to

beginning an exercise program.

prior to use.

WARNING

SERIOUS INJURY

9. Children must not be allowed near

this machine. Teenagers must be

8. Never pin the weights in an elevated

position. DO NOT use the machine if

found in this condition. Seek assistance

4. Inspect machine prior to use. DO

3. Keep body and clothing free from

NOT use if it appears damaged or

and clear of all moving parts.

COULD OCCUR IF

THESE PRECAUTIONS

ARE NOT OBSERVED

supervised.

from floor staff.

inoperable.

5. DO NOT attempt to fix a broken or

jammed machine. Notify floor staff.

CAUTION

Keep away from moving

parts. Failure to do so could

result in personal injury.

8500-026 A

Page 11

Cybex Modular Owner’s Manual

Page 1-5

Lat Pulldown - 5601

B

D

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 12

Cybex Modular Owner’s Manual

Page 1-6

Tricep Pressdown - 5603

D

B

B

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 13

Cybex Modular Owner’s Manual

Page 1-7

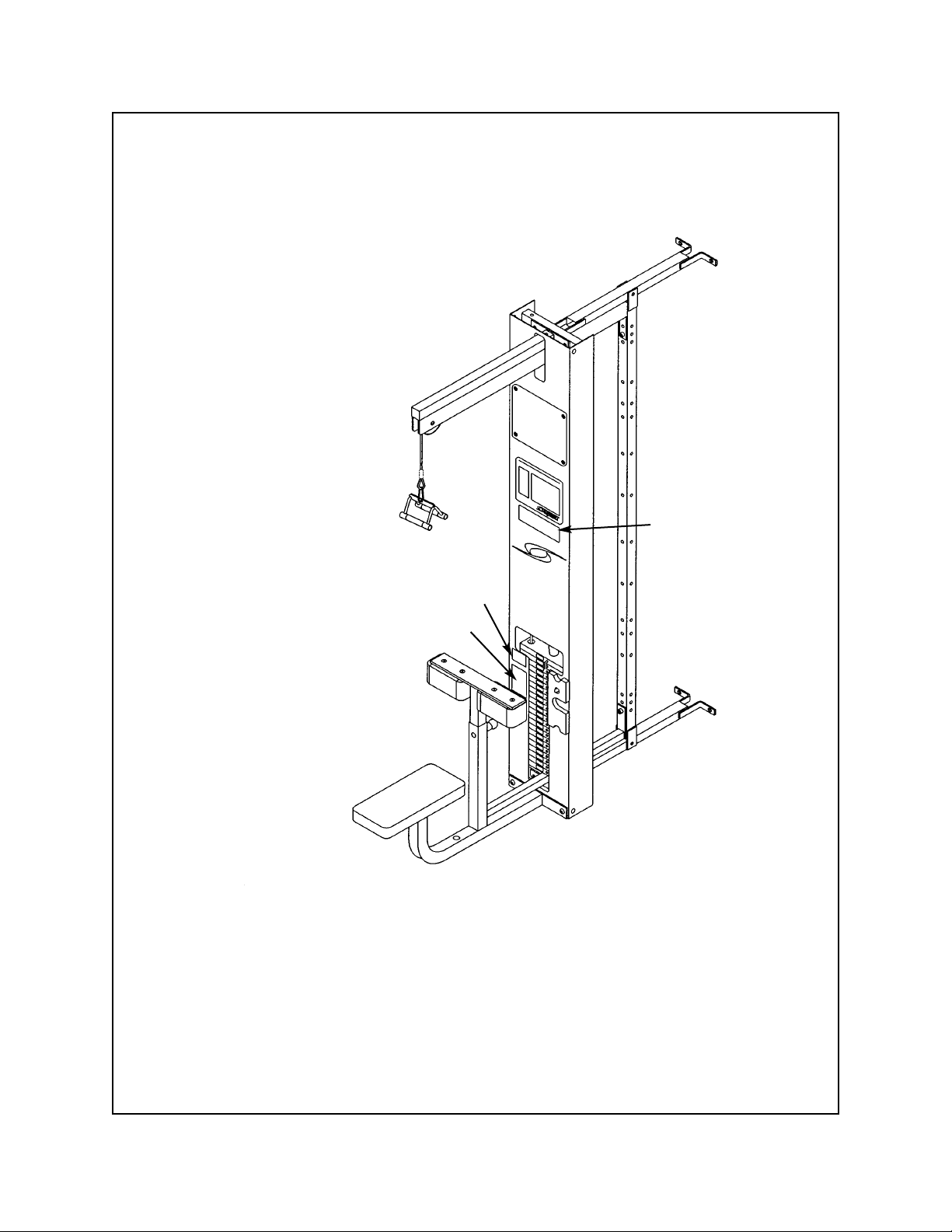

Cable Column - 5605/5315/5316/5633

B

A

D

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

5605 - Modular without Booms

5633 - Modular with Booms

5315 - Free Standing without Booms

5316 - Free Standing with Booms

Page 14

Cybex Modular Owner’s Manual

Page 1-8

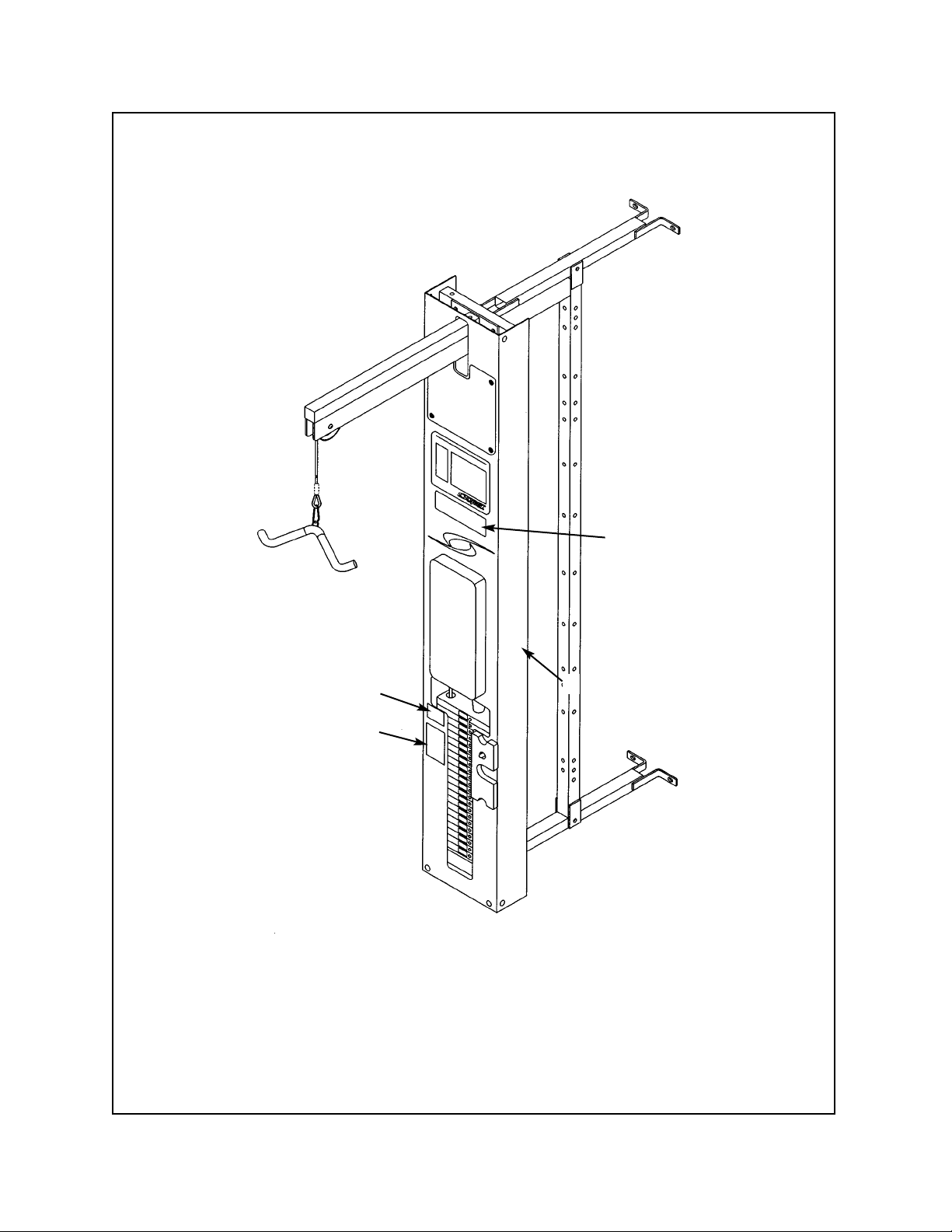

Assist Chin Up/Dip - 5611

D

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

B

5345 - Single Station Chin-Up/Dip

Page 15

Cybex Modular Owner’s Manual

Page 1-9

D

Low Row - 5651 and 5302

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

B

Page 16

Cybex Modular Owner’s Manual

Page 1-10

Shoulder Press - 5639

A

B

D

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 17

Cybex Modular Owner’s Manual

Page 1-11

C

Chest Press - 5640

B

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

C. Warning Decal.................... 4605-381

DESCRIPTION PART NO.

Page 18

Cybex Modular Owner’s Manual

Page 1-12

Tricep Extension - 5641

D

B

A

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 19

Arm Curl - 5644

B

A

D

Cybex Modular Owner’s Manual

Page 1-13

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 20

Cybex Modular Owner’s Manual

Page 1-14

Pressing Station - 5647 and 5306

D

A

B

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

DESCRIPTION PART NO.

Page 21

Cybex Modular Owner’s Manual

Page 1-15

Cable Crossover - 5311, 5648, 5649 and 5650

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

E. Caution Decal .................... 5649-329

F. Caution Decal .................... 8500-025

DESCRIPTION PART NO.

E

D

A

F

B

Page 22

Cybex Modular Owner’s Manual

Page 1-16

Seated Leg Press - 5652 and 5322

D

A

B

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

F. Caution Decal .................... 8500-025

DESCRIPTION PART NO.

F

Page 23

Cybex Modular Owner’s Manual

Page 1-17

Leg Extension/Leg Curl - 5653 and 5307

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

D. Warning Decal.................... 4800-381

F. Caution Decal .................... 8500-025

G. Caution Decal .................... 8500-026

DESCRIPTION PART NO.

G

D

F

Product No. 5307 - Freestanding

Product No. 5653 - Modular

G

B

A

F

F

F

Page 24

Regular Maintenance Activities

Preventative maintenance activities must be performed to maintain normal operation of your

equipment. Keeping a log sheet of all maintenance actions will assist you in staying current

with all preventative maintenance activities. The preventative maintenance actions are

described in detail in Chapter 5. Briefly, they include:

Daily

1. Clean upholstery.

Weekly

1. Inspect all nuts and bolts for looseness. Tighten as required.

2. Inspect all cables for damage or wear (see Chapter 5). Immediately discontinue use if a

cable is worn or damaged.

3. Check for worn handles, worn snap links, and worn warning labeling. Replace all worn

parts immediately.

4. Inspect weight stacks for proper alignment and operation. Correct all improper alignment

and operation issues immediately.

5. Lubricate guide rods using automotive engine oil only.

Yearly

1. Replace all cables at least annually.

As Required

1. Inspect grips and replace as necessary.

Using Proper Form

Before working out, read and understand the exercises located on the placard and in

Chapter 2.

Cybex Modular Owner’s Manual

Page 1-18

Page 25

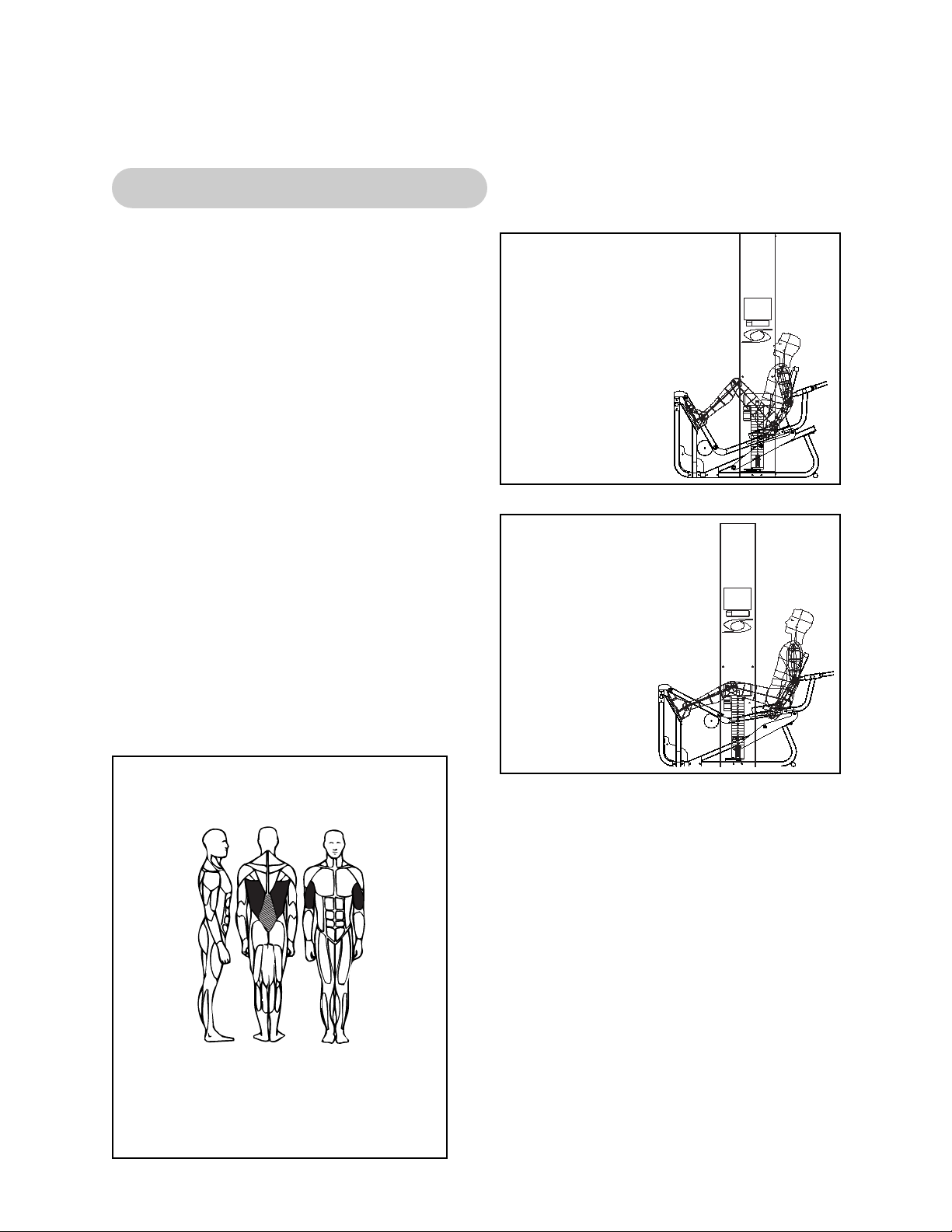

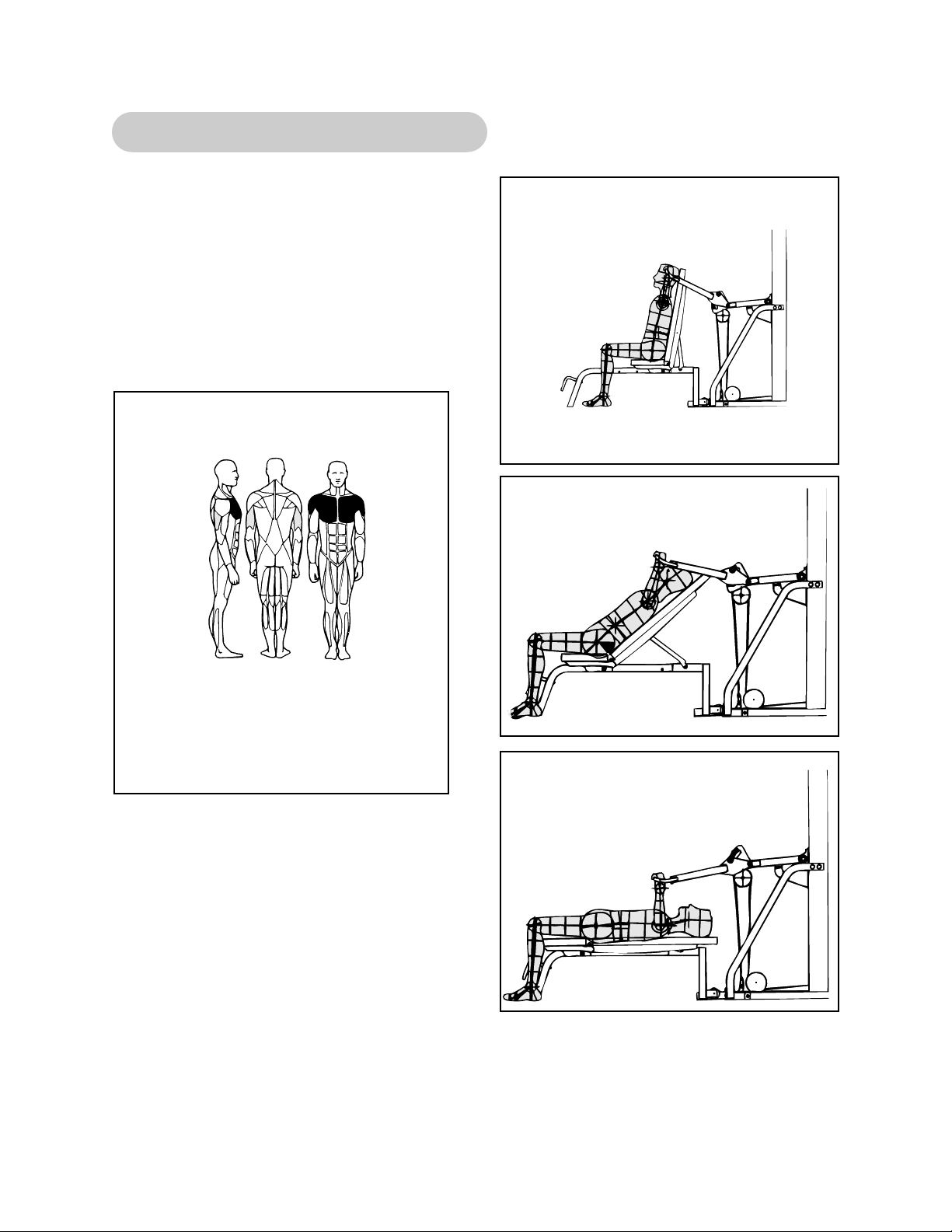

1. Select appropriate resistance.

2. Adjust seat mechanism to desired starting

position.

3. Located feet securely on foot plates and

position yourself squarely in seat.

4. Lift/lower resistance with smooth, controlled

movements.

NOTE: Do not hyperextend (lock) knees

during movement.

NOTE: The appropriate starting position

will allow your feet to be securely

located on the foot plates, legs

to be placed at approximately 90

degrees and your back squarely

positioned against back pad.

NOTE: Maintain proper back positioning

during exercise to reduce chance of

back injury.

2 - Exercise

Page 2-1

Cybex Modular Owner’s Manual

5652/5322 - Modular Seated Leg Press

MUSCLES TRAINED

Primary - Pectoralis Major

Secondary - Anterior Deltoid, Triceps

(Basic Press) and Biceps

(Advanced Press)

Start Position

Stop Position

Page 26

Page 2-2

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 27

Page 2-3

Cybex Modular Owner’s Manual

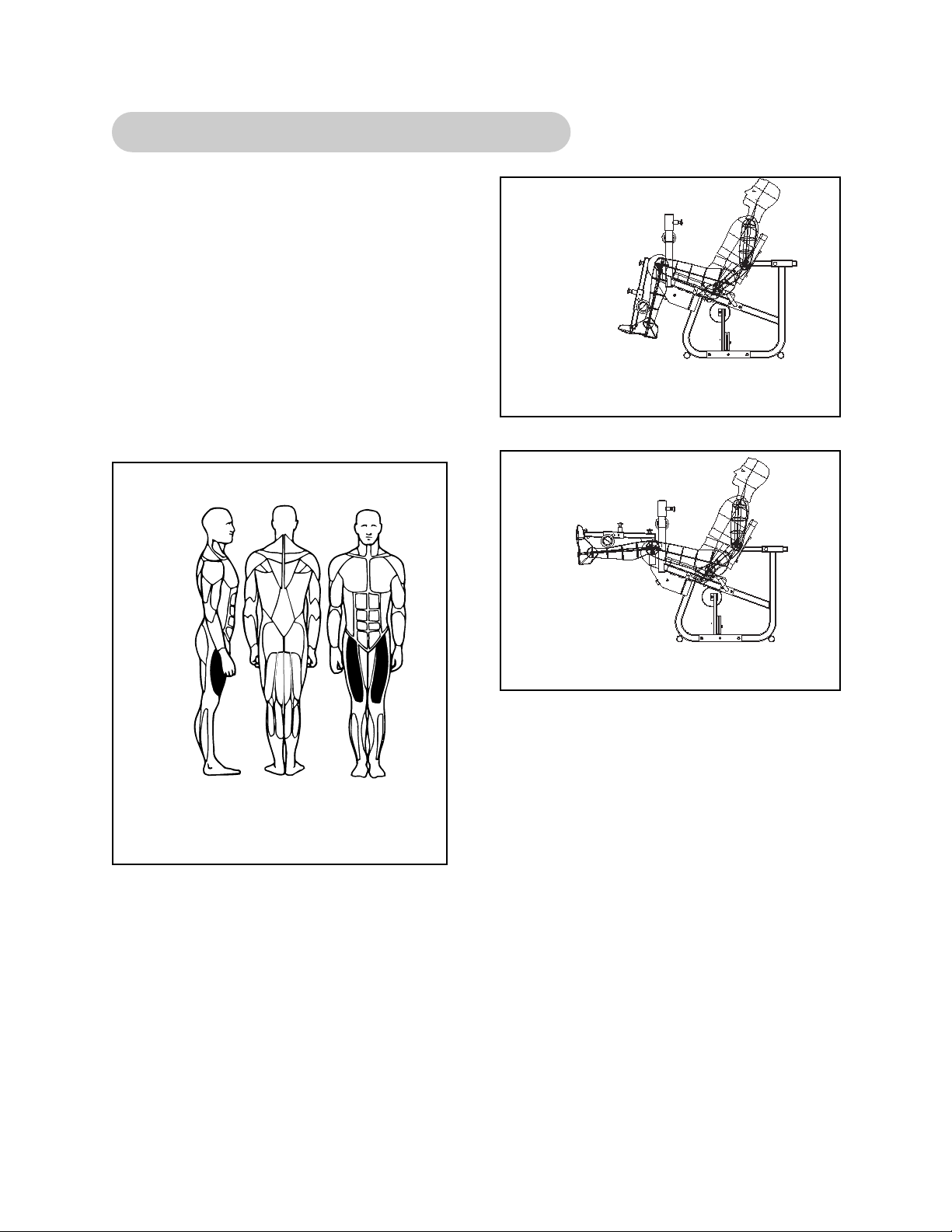

5653/5307 - Modular Leg Extension/Leg Curl

1. Select appropriate resistance.

2. Adjust back pad so that center of knees align

with machine’s axis of rotation.

3. Pull detent pin on input arm, lowering arm

into one of the two start positions.

4. Pull detent pin and adjust height of lower leg

pads to a height comfortable above ankles.

5. Lift/lower resistance with smooth, controlled

movements without resting.

MUSCLES TRAINED

Primary - Pectoralis Major

Secondary - Anterior Deltoid, Triceps

(Basic Press) and Biceps

(Advanced Press)

Start Position

Stop Position

Start Position

Stop Position

Page 28

Page 2-4

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 29

Page 2-5

Cybex Modular Owner’s Manual

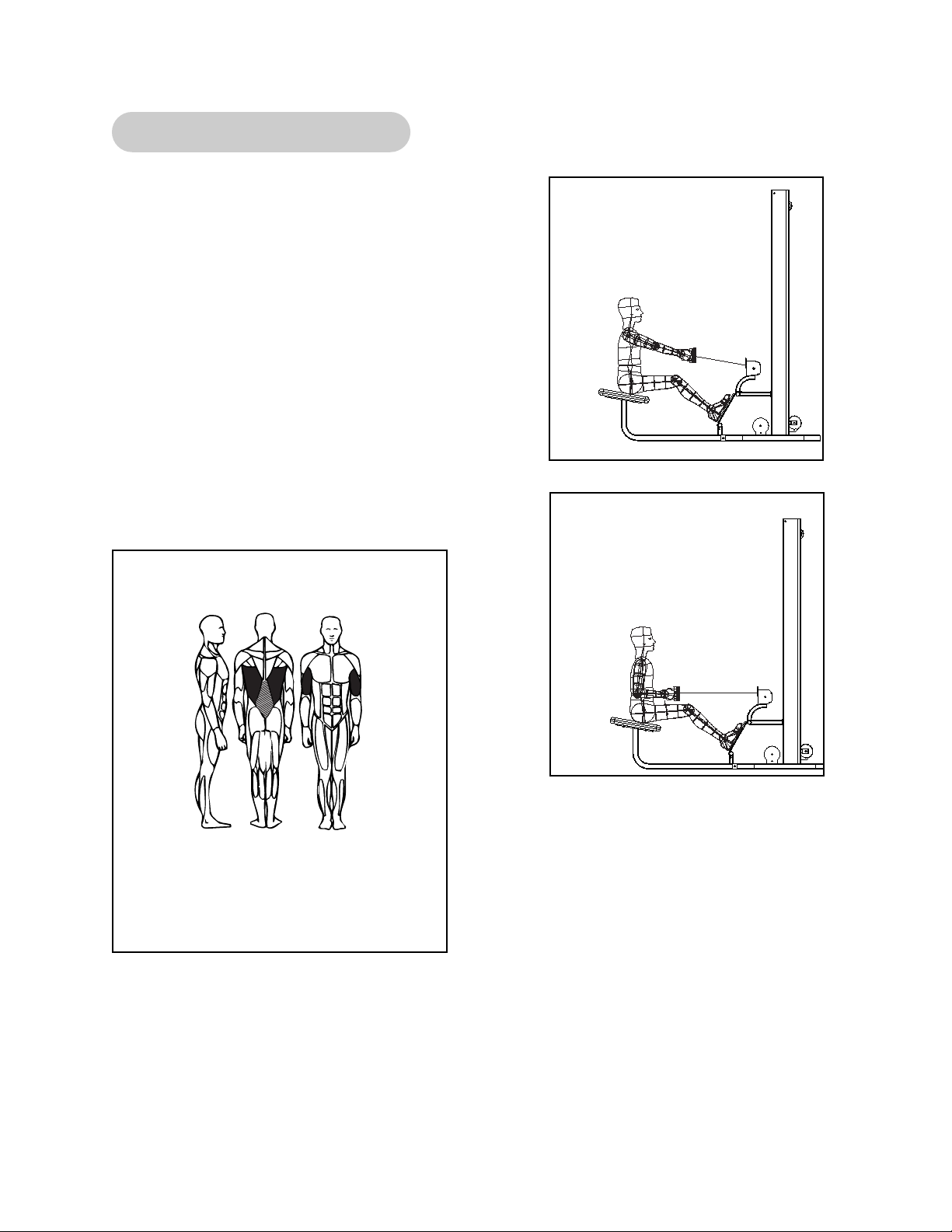

5651/5302 - Modular Low Row

1. Select appropriate resistance.

2. Grasp handle and position feet securely on

foot plate.

3. Position yourself comfortably on seat and

maintain a slight bend in the knees.

4. Throughout the exercise keep back straight

and upright.

5. Lift/lower resistance with smooth, controlled

movements.

NOTE: For optimum performance and safety,

avoid excessive bending of spine

during exercise.

MUSCLES TRAINED

Primary - Biceps and Latissimus Dorsi

Secondary - Erector Spinae

Start Position

Stop Position

Page 30

Page 2-6

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 31

Page 2-7

Cybex Modular Owner’s Manual

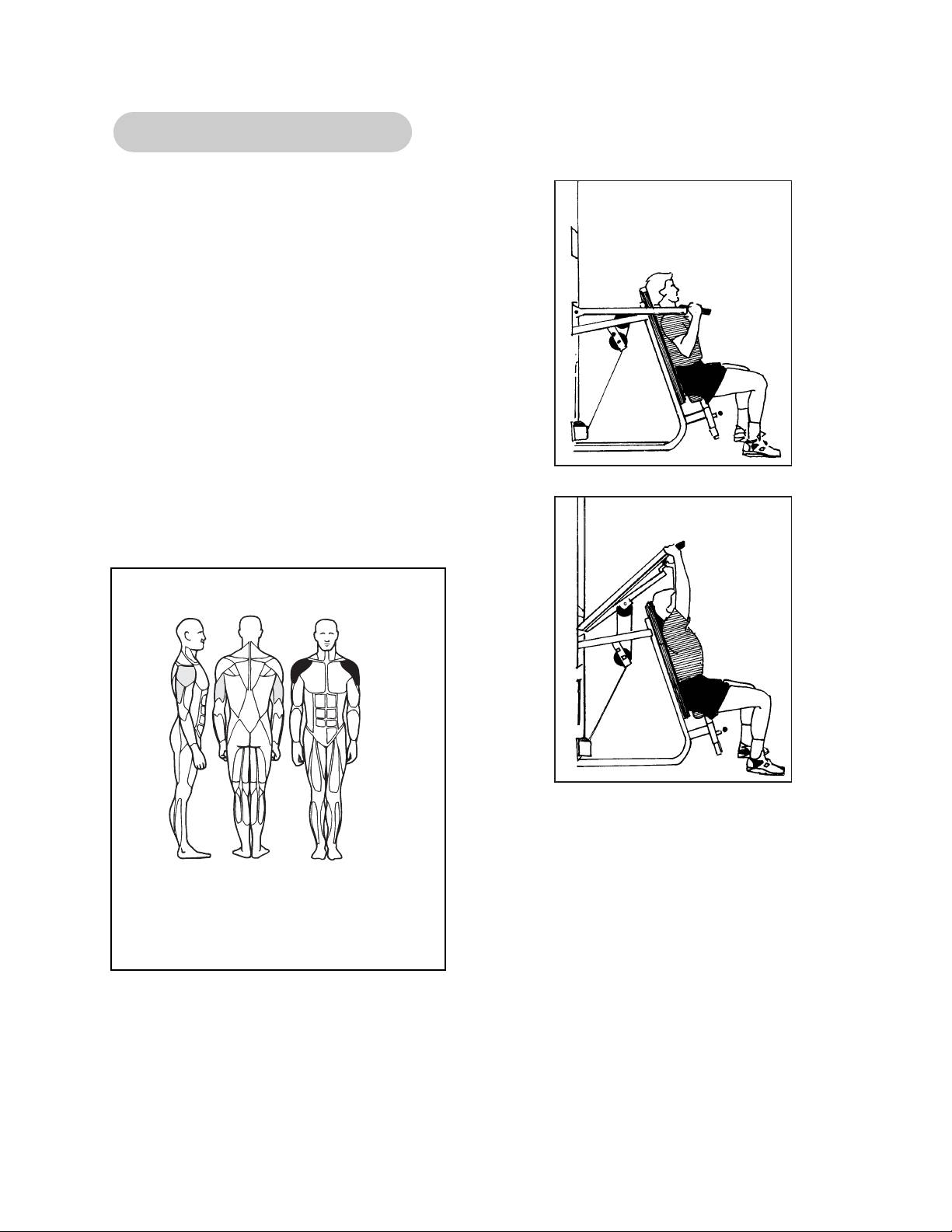

5601 - Modular Lat Pulldown

1. Adjust thigh pads to allow access and stabilization while

exercising.

2. Slect appropriate resistance.

3. Grasp bar and sit down, securing knees under thigh pads.

4. Lean back slightly at hips and maintain position throughout

movement.

5. With chest up and shoulders held back, pull bar down in front

to upper part of chest. Your elbows should move down to the

sides of your body.

6. Return to the start position and repeat.

7. Lift/lower resistance with smooth, controlled movements.

NOTE: Grasping the bar excessively wide or narrow, does not increase muscular

effectiveness. It only decreases your range of motion.

Read and understand all instructions and warnings prior to using this machine. See Chapter 1,

Safety in the Modular Owner’s Manual or consult with floor staff.

MUSCLES TRAINED

Primary - Latissimus Dorsi, Teres Major

Secondary - Biceps, Rhomboids and

Lower Trapezius

Page 32

Page 2-8

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 33

Page 2-9

Cybex Modular Owner’s Manual

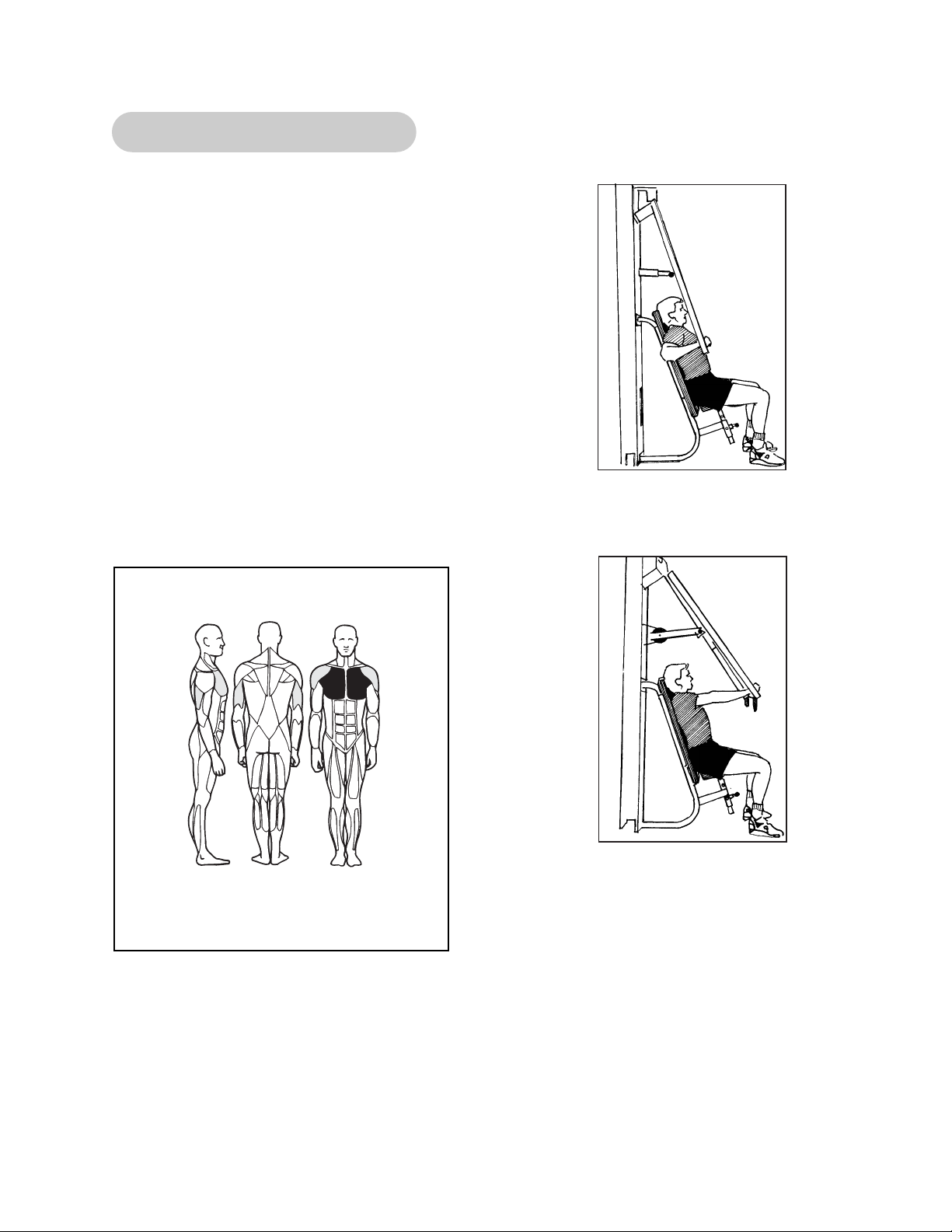

5640 - Modular Chest Press

1. Adjust seat height so that handles are at

mid-chest.

2. Adjust handle position so that when grasped,

upper arms are straight to side.

3. Select appropriate resistance.

4. Grasp handles.

5. Position elbows out to side, level with handles.

6. With chest up and shoulders held back, press

handles forward with a smooth, controlled

movement.

7. Lift/lower resistance with smooth, controlled

movements.

MUSCLES TRAINED

Primary - Pectoralis Major

Secondary - Anterior Deltoid and

Triceps

Start Position

Stop Position

Page 34

Page 2-10

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 35

Page 2-11

Cybex Modular Owner’s Manual

5647/5306 - Modular Pressing Station

1. Select appropriate resistance.

2. Adjust the bench back pad angle (flat, 30, 40,

60, 80).

3. Adjust pressing arm to desired position.

4. Lift/lower resistance with smooth, controlled

movements.

MUSCLES TRAINED

Primary - Pectoralis Major, Anterior

Deltoids (depending upon bench

angle)

Secondary - Triceps

Start Position

Start Position

Stop Position

Page 36

Page 2-12

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 37

Page 2-13

Cybex Modular Owner’s Manual

5639 - Modular Shoulder Press

1. Adjust seat height so that handles are level

with shoulders.

NOTE: Range of motion may be reduced by

selecting a lower seat position.

2. Select appropriate resistance.

3. Grasp either set of handles.

TIP: The parallel handles will help reduce

shoulder impingement and may be more

comfortable for some users.

4. Press straight up with a smooth, controlled

movement.

5. Return to the start position and repeat.

MUSCLES TRAINED

Primary - Anterior Deltoids

Secondary - Middle Deltoids and

Triceps

Start Position

Stop Position

Page 38

Page 2-14

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 39

Page 2-15

Cybex Modular Owner’s Manual

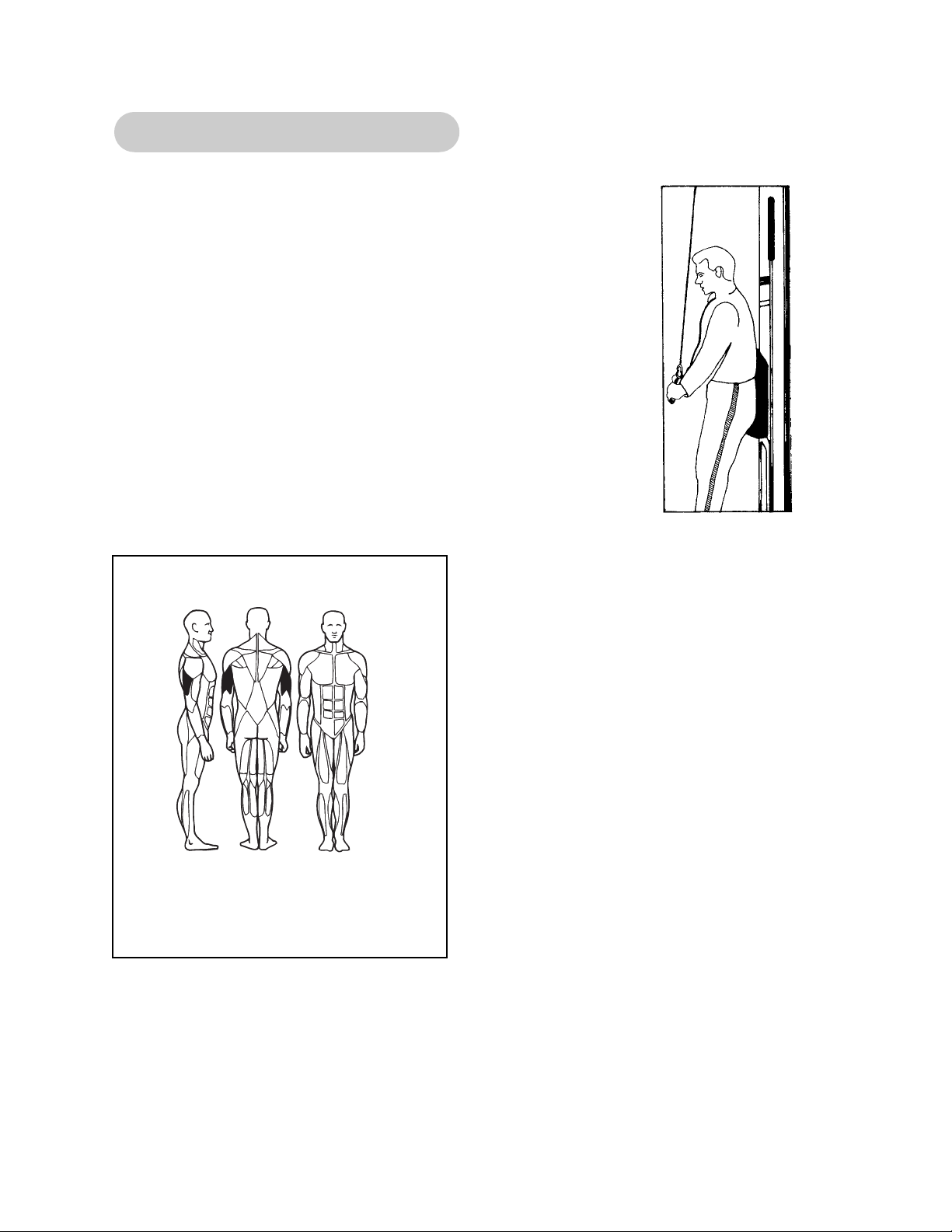

5603 - Modular Tricep Pressdown

1. Select appropriate resistance.

2. Attach the desired handle to the clip.

3. Position yourself with your hips and back firmly against

back pad.

4. While leaning forward slightly, extend your arms downward

maintaining your elbows in a stationary position.

5. Return to the start position and repeat.

6. Lift/lower with smooth, controlled movements.

NOTE: The appropriate grip position allows you to keep

your chest up and shoulders held back while

extending your arms.

MUSCLES TRAINED

Primary - Triceps

Page 40

Page 2-16

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 41

Page 2-17

Cybex Modular Owner’s Manual

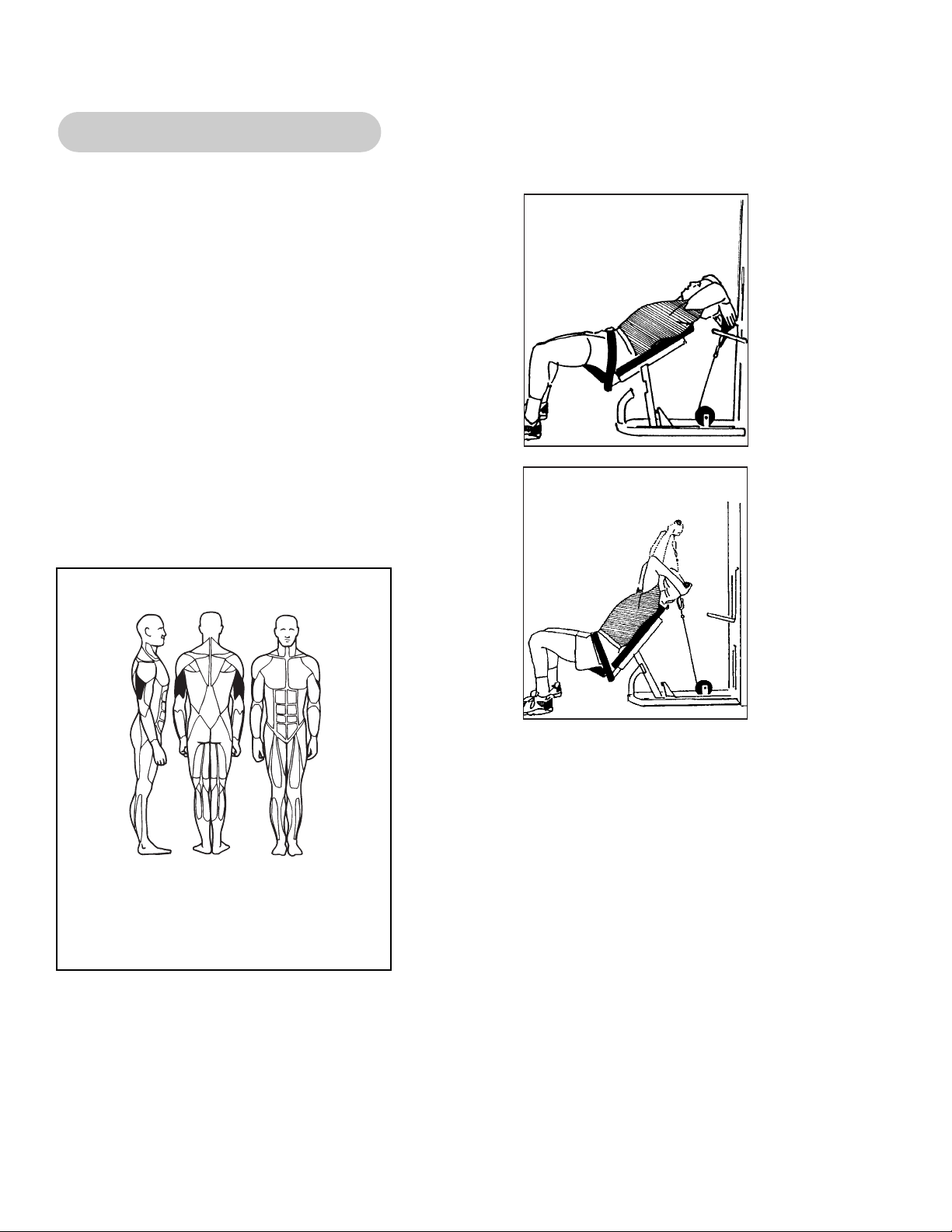

5641 - Modular Tricep Extension

1. Select appropriate resistance.

2. Position yourself in chair, attaching seat belt

to assist in stabilization.

3. Pivot chair backwards to grasp handle. Lower

seat back down to begin exercise.

4. Maintain elbows in a stationary position while

extending arms overhead.

5. Lift/lower resistance with smooth, controlled

movements.

6. When exercise is complete, lean chair

backwards to replace handle. Ensure

handle has been securely replaced before

letting go.

MUSCLES TRAINED

Primary - Triceps

Start Position

Stop Position

Page 42

Page 2-18

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 43

1. Adjust seat height to allow your upper arms to

rest on pad.

2. Select appropriate resistance.

3. Grasp bar, position arms parallel on pad.

4. Lower your shoulders, pressing your arms

firmly into the pad, elevating your elbows

slightly.

5. Curl arms as far as possible, maintaining your

elbow position.

6. Return to the start position and repeat.

7. Lift/lower resistance with smooth, controlled

movements.

Page 2-19

Cybex Modular Owner’s Manual

5644 - Modular Arm Curl

MUSCLES TRAINED

Primary - Biceps

Secondary - Brachioradialis and

Bracialis

Start Position

Stop Position

Page 44

Page 2-20

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 45

Page 2-21

Cybex Modular Owner’s Manual

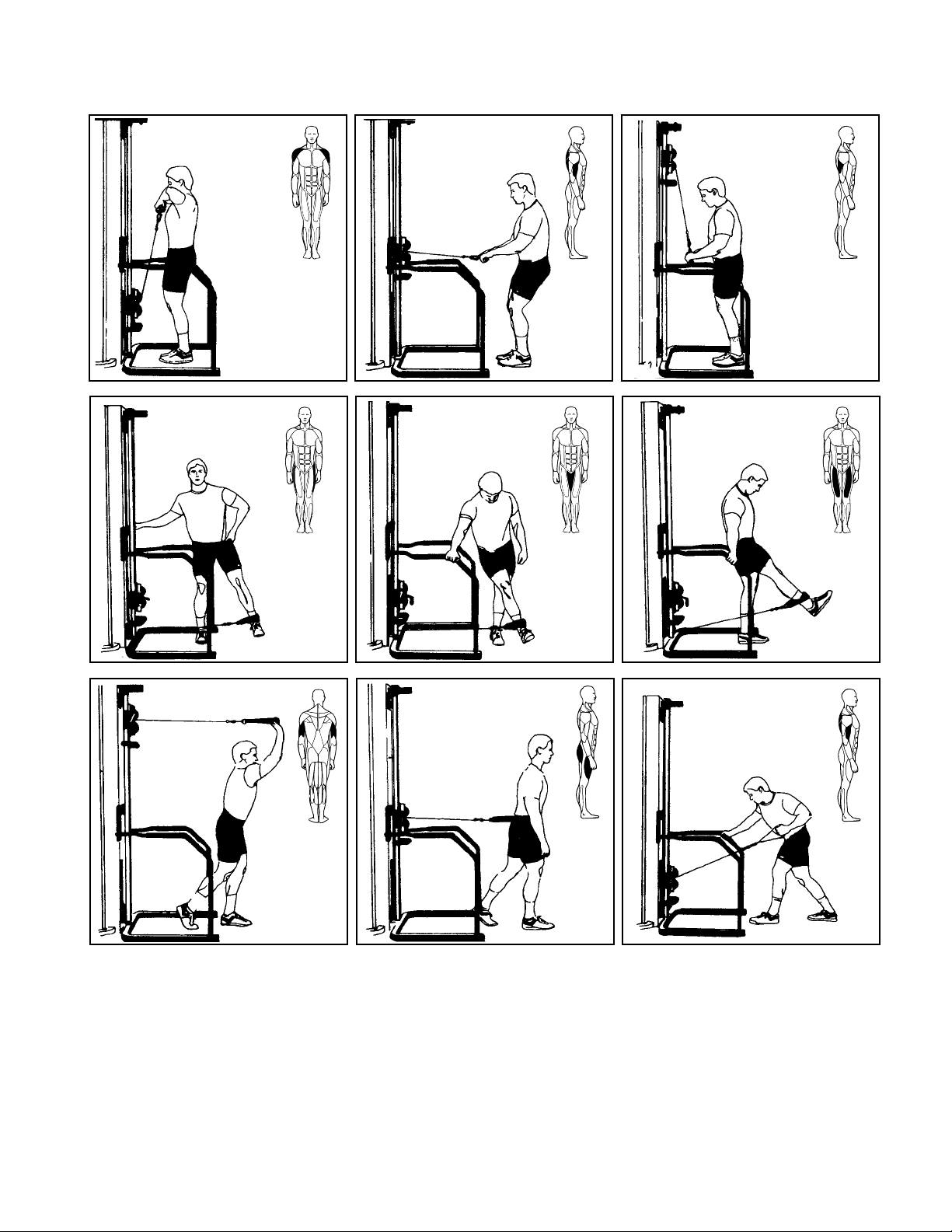

5648/5649/5650/5311 - Modular Cable Crossover

The Cable Crossover is a very versatile machine. With the use of various handles, virtually

every body part can be trained.

1. Select appropriate resistance.

2. Adjust pulley height by grasping handle, pulling detent pin, sliding mechanism to desired

height. Ensure that pin is locked into place before releasing handle.

3. Grasp handle securely and lift/lower resistance with smooth, controlled movements.

NOTE: Exercises may be performed in either linear or diagonal patterns.

Pectoralis Major

Anterior Deltoid

Rotator Cuff Pectoralis Major

Anterior Deltoid

Pectoralis Major

Anterior Deltoid

Pectoralis Major

Page 46

Page 2-22

Cybex Modular Owner’s Manual

Latissimus Dorsi

Teres Major

Triceps

Side Deltoid

Triceps

Latissimus Dorsi

Biceps

Biceps

Glutes

Hamstrings

Hip AbductorsHip Adductors

Page 47

Page 2-23

Cybex Modular Owner’s Manual

5605.5633/5315/5316 - Modular Cable Column

The Cable Column is a very versatile machine. With the use of various handles, virtually every

body part can be trained.

1. Select appropriate resistance.

2. Adjust pulley height by grasping handle, unlocking twist knowb, sliding mechanism to the

desired height. Ensure that the twist knob has been locked before releasing handle.

3. Grasp handle securely and lift/lower resistance with smooth, controlled movements.

NOTE: Exercises may be performed in either linear or diagonal patterns.

Pectoralis Major

Anterior Deltoid

Side Deltoid

Pectoralis Major Pectoralis Major

Rotator Cuff

Latissimus Dorsi

Teres Major

Page 48

Page 2-24

Cybex Modular Owner’s Manual

Deltoids

Hip Abductors

Latissimus Dorsi

Biceps

Hip Adductors

Triceps

Hip Flexors

Quadriceps

Triceps

Quadriceps

Glutes

Latissimus Dorsi

Biceps

Page 49

Page 2-25

Cybex Modular Owner’s Manual

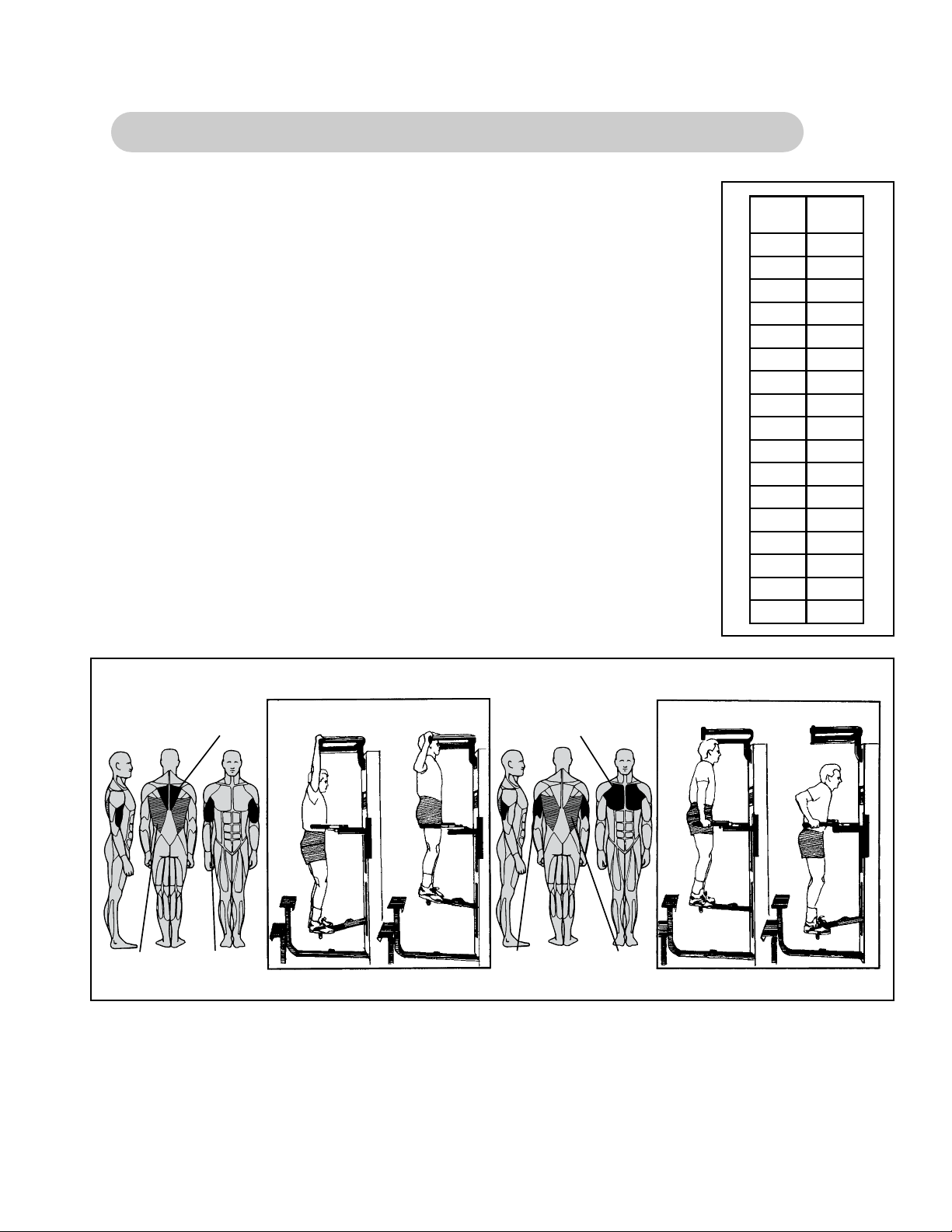

5611 Modular Assisted Chin-Up/Dip and 5345 - Single Station Dip/Chin

1. Select assisted (foot support down) or unassisted (foot support

pivots up against tower) dip or chin exercise.

2. Select appropriate resistance.

3. Select wide or narrow grip position.

4. Grasp exercise handles securely.

5. For assisted dip or chin exercise, place feet firmly on the foot support.

6. Lift/lower body with smooth, controlled movements.

NOTE: Exit machine from top step only! Do not exit machine from ground level.

Plate

No.

18

19

20

Assist

(Pounds)

164

225

286

347

408

469

5210

5811

6412

7013

7614

8215

8816

9417

100

106

112

Muscles Trained

Rhomboids

Latissimus Dorsi Biceps

Start

Finish

Muscles Trained

Pectoralis Group

Triceps

Latissimus Dorsi

Start

Finish

Page 50

Page 2-26

Cybex Modular Owner’s Manual

This page intentionally left blank

Page 51

Cybex Modular Owner’s Manual

Page 3-1

Contacting Service

3 - Customer Service

Hours of phone service are Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern

Standard Time.

For Cybex customers living in the USA, contact Cybex Customer Service at 800-766-3211.

Your options at this number include:

• Press 63 to place a parts order or to check parts order status.

• Press 64 to speak to a technical support representative regarding troubleshooting or to

schedule a field service call.

• Press 65 to check status of a repair order only and you have your RRM number.

• Press 66 to check status of a dispatched field service call and you have your inquiry

number.

• Press 67 for service of a medical or isokinetic product.

• Press 0 to go to the Cybex operator.

For Cybex customers living outside the USA, contact Cybex Customer Service at 508-533-

4300 or fax 508-533-5183.

Order parts and find information on the web at www.eCybex.com or by e-mail at

techhelp@cybexintl.com.

Ordering Parts

Visit eCybex.com to shop for parts online or fax your order to 508-533-5183.

To speak with a customer service representative, call 800-766-3211 (for customers living within the USA) or 508-533-4300 (for customers outside the USA). You may also contact us

through email at techhelp@cybexintl.com

Having the following information ready when calling will assist our Cybex representatives in

serving you:

• Unit Serial Number

• Product Name

The unit serial number and product name can be found on the serial number decal. See

Chapter 6 for exact location of serial number decal.

• Part Description

• Part Number

Part descriptions and part numbers are located in Chapter 6 of this manual.

Page 52

Cybex Modular Owner’s Manual

Page 3-2

The Return Material Authorization (RMA) system outlines the procedures to follow when

returning material for placement, repair, or credit. The system assures that returned materials

are properly handled and analyzed. Follow the following procedures carefully.

Contact your authorized Cybex dealer on all warranty-related matters. Your local Cybex

dealer will request a RMA from Cybex, if applicable. Under no circumstances will defective

parts or equipment be accepted by Cybex without proper RMA and an Automated Return

Service (ARS) label.

1. Call the Customer Service Hotline listed above for the return of any time that is

defective.

2. Provide the technician with a detailed description of the problem you are having or

the defect in the item you wish to return.

3. Provide the model and serial number of your Eagle equipment

4. At Cybex’s discretion, the technician may request that you return the problem

part(s) to Cybex for evaluation and repair or replacement. The technical will assign

you a RMA number and will send you an ARS label. The ARS label and the RMA

numbers must be clearly displayed on the outside of the package that contains the

item(s) to be returned. Include the description of the problem, the serial number of

the Eagle equipment and the name and address of the owner in the package along

with the part(s).

5. Forward the package through UPS to Cybex.

Attn: Customer Service Department

Cybex International, inc.,

10 Trotter Drive

Medway, MA 02053

NOTE: Merchandise returned without an RMA number on the outside of the package or

shipments sent C.O.D. will not be accepted by the Cybex receiving department.

Return Material Authorization (RMA)

• Shipping Address

• Contact Name

In addition to your shipping address and contact name, your account number

is helpful but not required.

Page 53

Cybex Modular Owner’s Manual

Page 3-3

Materials damaged in shipment should not be returned for credit. Shipping damages are the

responsibility of the carrier (UPS, Federal Express, trucking companies, etc.)

Apparent Damage - Upon receipt of your shipment, check all items carefully. Any damage

seen with a visual check must be noted on the freight bill and signed by the carriers agent.

Failure to do so will result in the carriers refusal to honor your damage claim. The carrier will

provide you with the required forms for filing such claims.

Concealed Damage - Damage not seen with a visual check upon receipt of a shipment but

notices later must be reported to the carrier as soon as possible. Upon discovery of the damage, a written or phone request to the carrier asking them to perform an inspection of the

materials must be made within ten days of the delivery date. Keep all shipping containers and

packing materials as they will be needed in the inspection process. The carrier will provide

you with and inspection report and the necessary forms for filing a concealed damage claim.

Concealed damage claim is the carriers responsibility.

Damaged Parts

Page 54

Cybex Modular Owner’s Manual

Page 3-4

This page intentionally left blank

Page 55

4 - Assembly

Page 4-1

Cybex Modular Owner’s Manual

TOOLS REQUIRED

• 5/16” Allen wrench

• Soft hammer

• Medium weight automotive engine oil

NOTE: Refer to the appropriate Assembly & Parts Instruction sheet (weight stack diagrams)

when performing the procedure listed below.

1. Remove the two socket head cap screws securing the guide rods.

2. Carefully lean guide rods away from column.

3. Remove guide rod collets and plastic caps.

4. Wipe guide rods clean over entire length. Lubricate with light coating of medium weight

automotive engine oil.

5. Install each weight plate one at a time, starting with the last plate (going from highest

numerical value to lowest). NOTE: For 15 and 25 weight plate stacks, the first plate installed

has no number. NOTE: When installing weight plates, position plates so wide edges of bushings

face upward and narrow edges of bushings face downward. See example below..

6. Install top weight.

7. Replace plastic caps and guide rod collets on guide rods.

8. Return guide rods to full upright position.

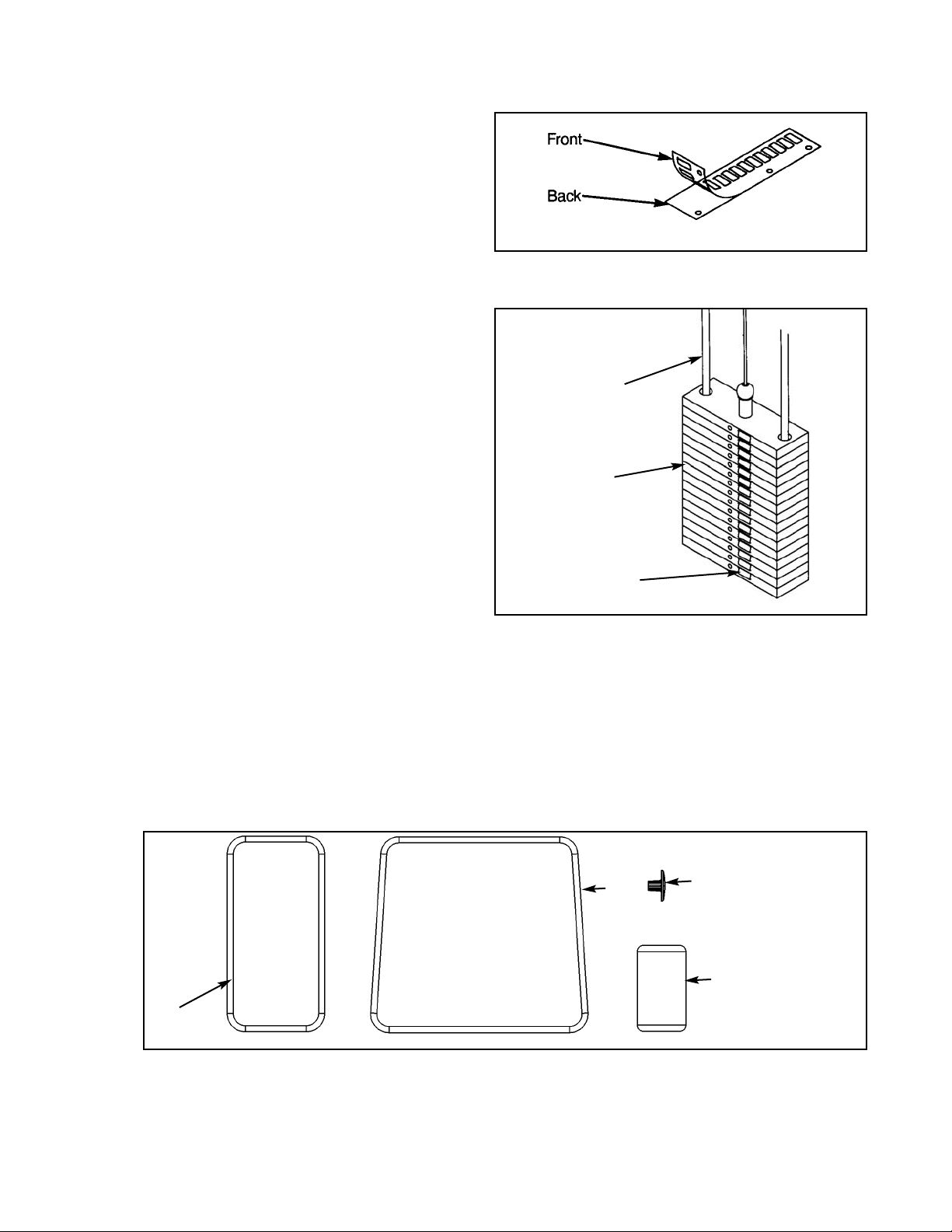

Weight Stack Installation

NOTE: Refer to Chapter 6 (Assembly and Service) for further assembly information.

CORRECT

NARROW bushing

edge

WIDE bushing

edge faces upward

NOTE: The narrow

bushing edge must

face downward.

WRONG

Page 56

Cybex Modular Owner’s Manual

Page 4-2

9. Insert both socket head cap screws that were removed in step 1 and tighten securely.

10. Insert cable end into top weight and align cable fitting opening with opening in top

weight for proper cable tension. NOTE: See Cable Adjustment and Installation Section.

11. Using a hammer drive roll pin through top plate connector and cable fitting. Assure pin is

flush with top plate collar.

12. Insert selector pin into each plate to assure proper alignment. See Cable Adjustment and

Installation section if selector pin does not fit smoothly, or if cable appears to have

excessive slack.

13. Place half weight on weight peg (if applicable).

Page 57

Cybex Modular Owner’s Manual

Page 4-3

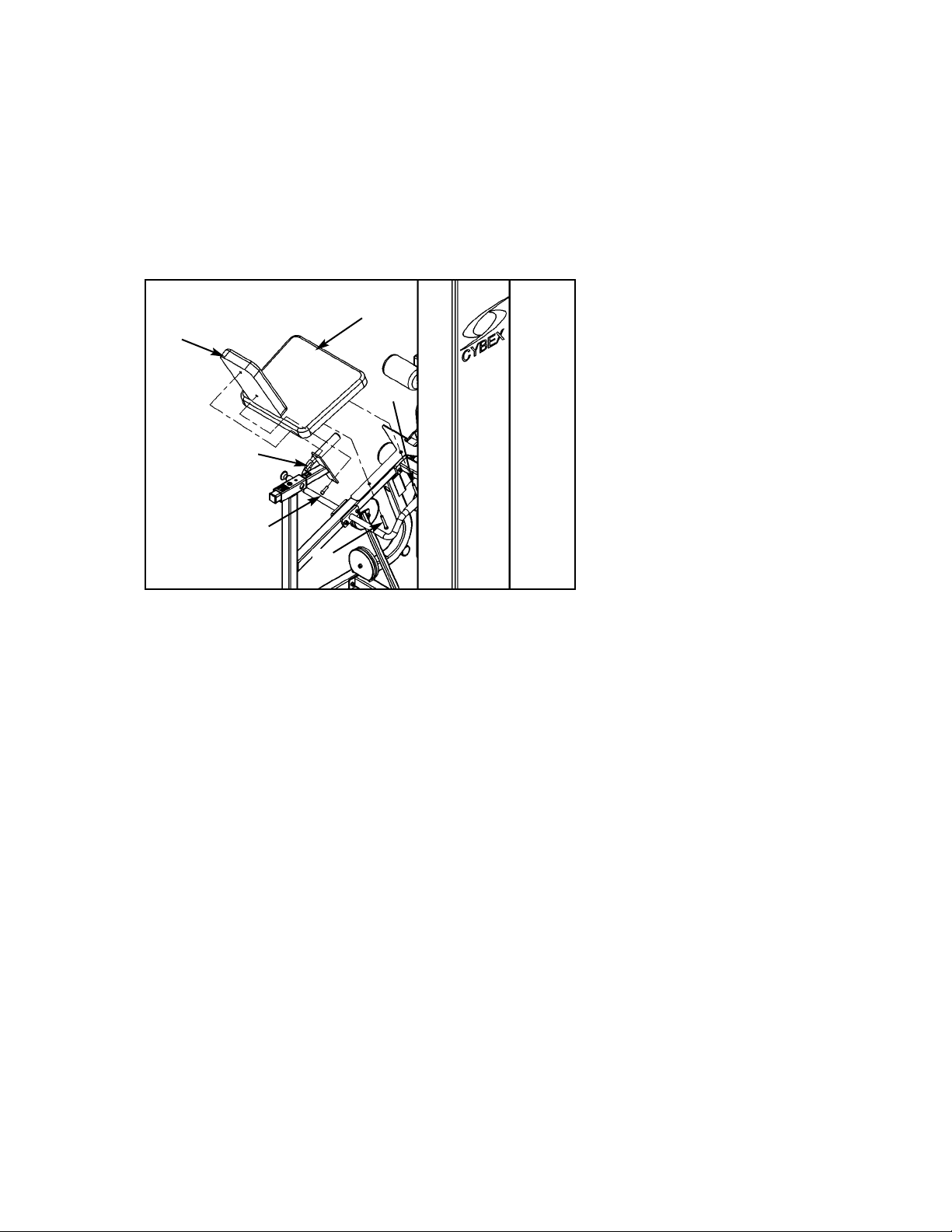

MODULAR HANDLE RACK

5631 ASSEMBLY & PARTS

A. Handle Rack....................... 5631

DESCRIPTION PART NO.

A

Page 58

Cybex Modular Owner’s Manual

ITEM QTY PART NO. DESCRIPTION

1 1 01930 Handle Rack

2 4 PU060205 Rubber Bumper .88" T

3 2 JC780417 BHSCS .50-13 x 1.00

4 2 HN784000 Hex Nut .50-13

5 2 JS388300 Lockwasher .50

6 1 01937 Mounting Plate

5631 - Handle Rack

TOOLS REQUIRED

• 5/16" Allen wrench

• 3/4" Wrench

MOUNTING HANDLE RACK ON MODULAR UNITS

1. Install mounting plate (item 6) between towers with BHSCS (item 3),

hex nut (item 4), and lockwasher (item 5).

2. Remove paper backing from one of the pieces of tape that is located on backside of Handle Rack

(item 1). Place a rubber bumper (item 2) on the tape. Repeat this step until all four bumpers have

been placed on the Handle Rack.

3. Hang handle rack (item 1) over top edge of mounting plate (item 6).

NOTE: Be sure that the rubber bumpers rest against the perforated panel.

MOUNTING HANDLE RACK ON ANY UNITS WITH A BACK COVER

1. Remove paper backing from the four pieces of tape located on backside of Handle Rack (item 1).

2. Secure Handle Rack to back cover of unit.

MOUNTING HANDLE RACK TO A WALL

1. Remove paper backing from one of the pieces of tape that is located on backside of Handle Rack

(item 1). Place a rubber bumper (item 2) on the tape. Repeat this step until all four bumpers have

been placed on the Handle Rack.

2. Position handle rack against the wall (or mounting surface). Mark holes on the

wall through the four mounting holes in the Handle Rack.

3. Secure Handle Rack to the wall using the proper tools and hardware.

NOTE: This machine shipped with an Owner’s Manual. Additional copies can be obtained by contacting

your dealer or a Cybex Representative at 1-888-462-9239.

Page 59

Cybex Modular Owner’s Manual

Page 4-5

Page 60

Cybex Modular Owner’s Manual

Page 4-6

This page intentionally left blank

Page 61

Cybex Modular Owner’s Manual

Page 4-7

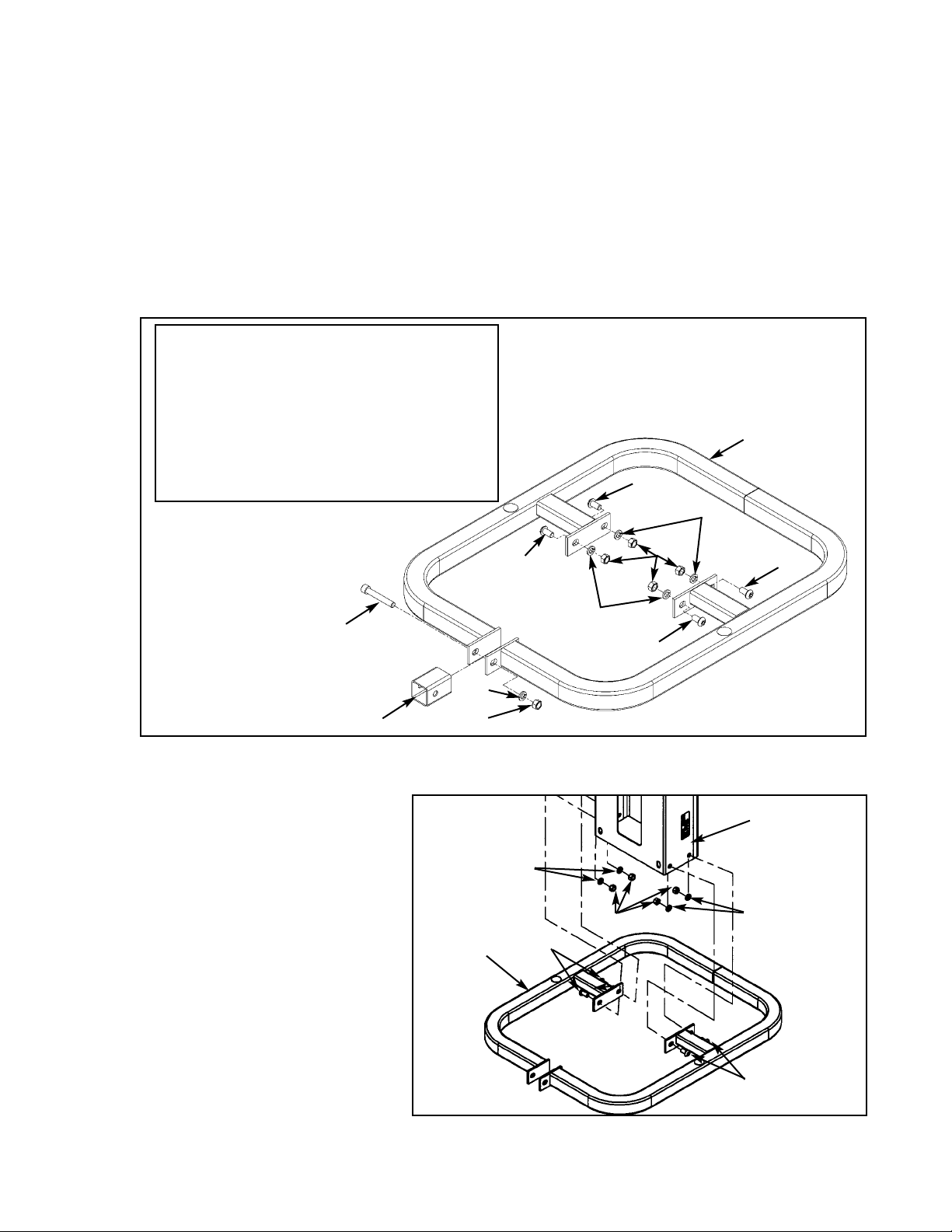

Modular Mover

5632

TOOLS REQUIRED

• 3/8” Allen wrench

• 3/8” Allen wrench

CAUTION!! When raising or lowering modular unit, keep hands and feet clear of columns, angle

supports and frame attachments.

1. Read and understand all instructions thoroughly before performing this procedure.

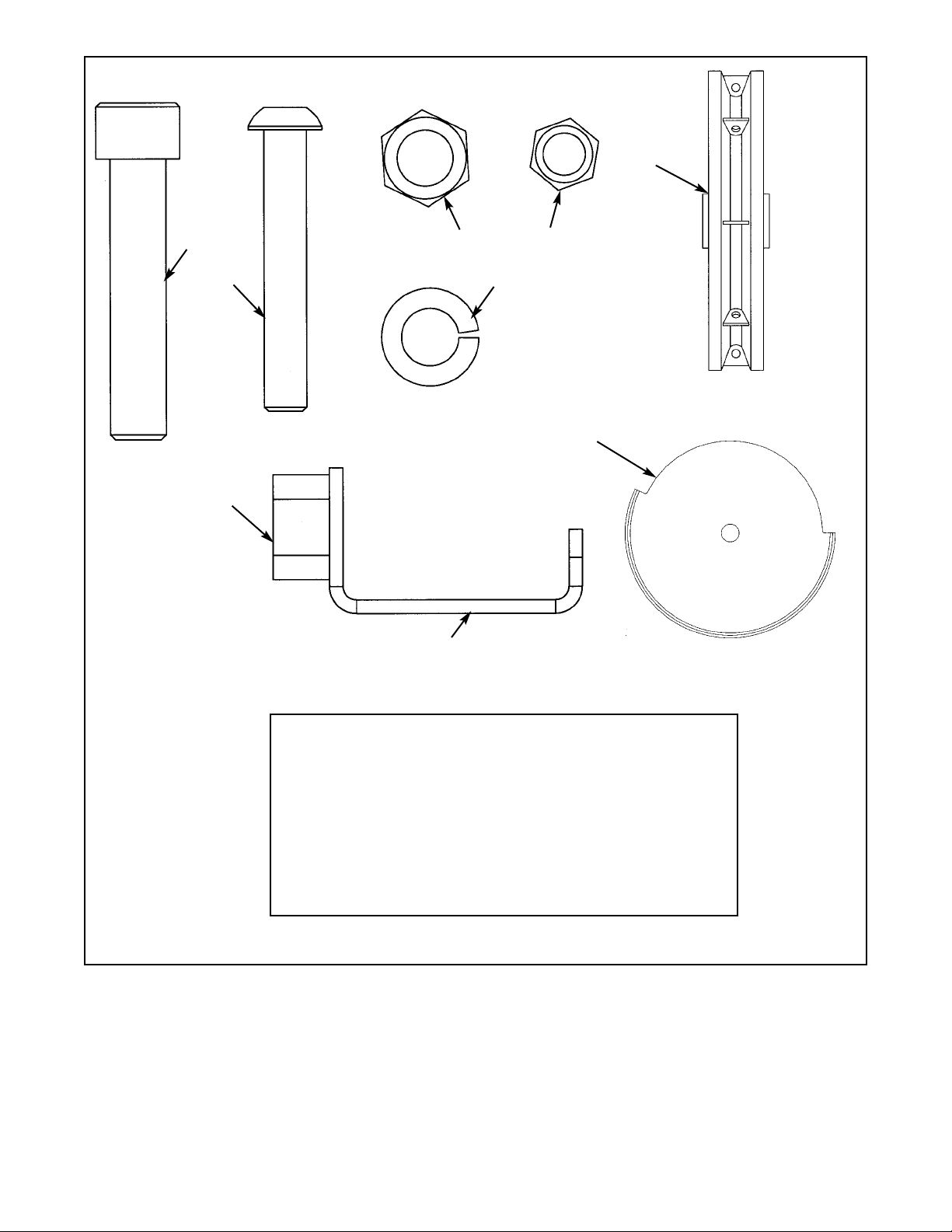

2. Verify you received the items shown in Figure 1.

Assembly Instructions

A. Handle Jack ...................... 01950

B. Jack Handle

C. Modular Mover .................. 01941

D. Lifting Bracket ................... 01951

E. Hex Nut.............................. HN784000

F. Split Lockwasher ............... JS388300

G. SHCS .500-13 x 2.75 ........ JC782832

DESCRIPTION PART NO.

3. Remove all perforated screens and set aside.

4. Remove all side stations (if applicable).

5. Install lifting bracket to the center of post using two

socket head cap screws. After tightening screws in

step 3, place hydraulic jack under lifting bracket

and raise modular unit approximately 1” off the

floor. See Figure 2.

Figure 1

Figure 2

A

B

C

D, E, F, G

Page 62

Cybex Modular Owner’s Manual

Page 4-8

6. Install lift dolly and tighten in place using T-handle on dolly. See Figure 3.

7. Repeat step 4 for each remaining position around the modular unit. NOTE: If a leg Curl/Leg

Extension is next to an O.C. Cable Column, then do not install lift dolly in this position.

8. After lift dollies have been secured in place, the modular unit can be lowered and the hydraulic

jack can be removed.

9. Move modular unit to desired location. NOTE: When moving modular unit be sure to support any

pieces attached to the columns.

10. Position modular unit as desired. Install hydraulic jack and raise unit. Remove lift dollies and

lower modular unit.

11. Remove lifting bracket from center post.

12. Reattach any side stations.

13. Reattach perforated screens to the modular unit. Be sure screens are secured.

Figure 3

Page 63

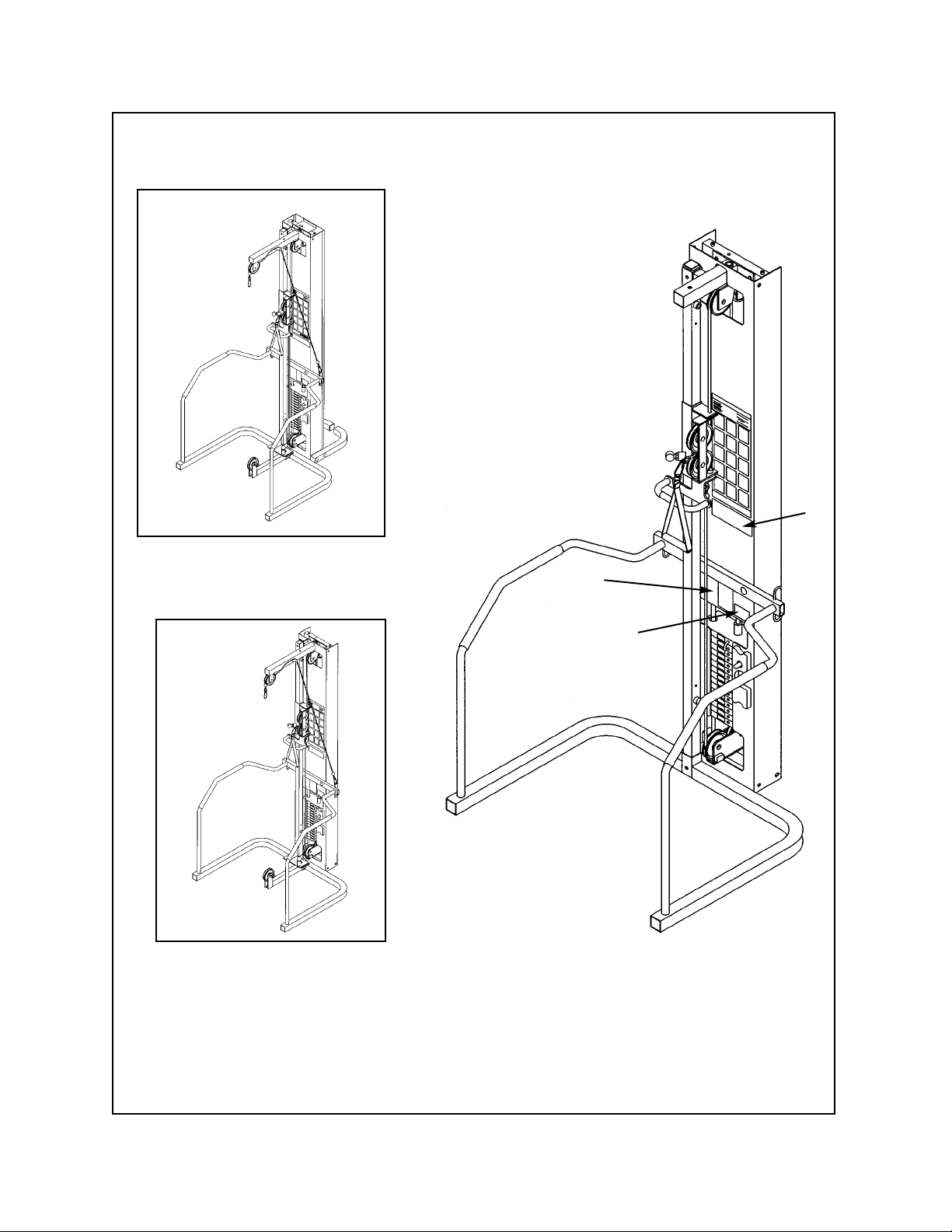

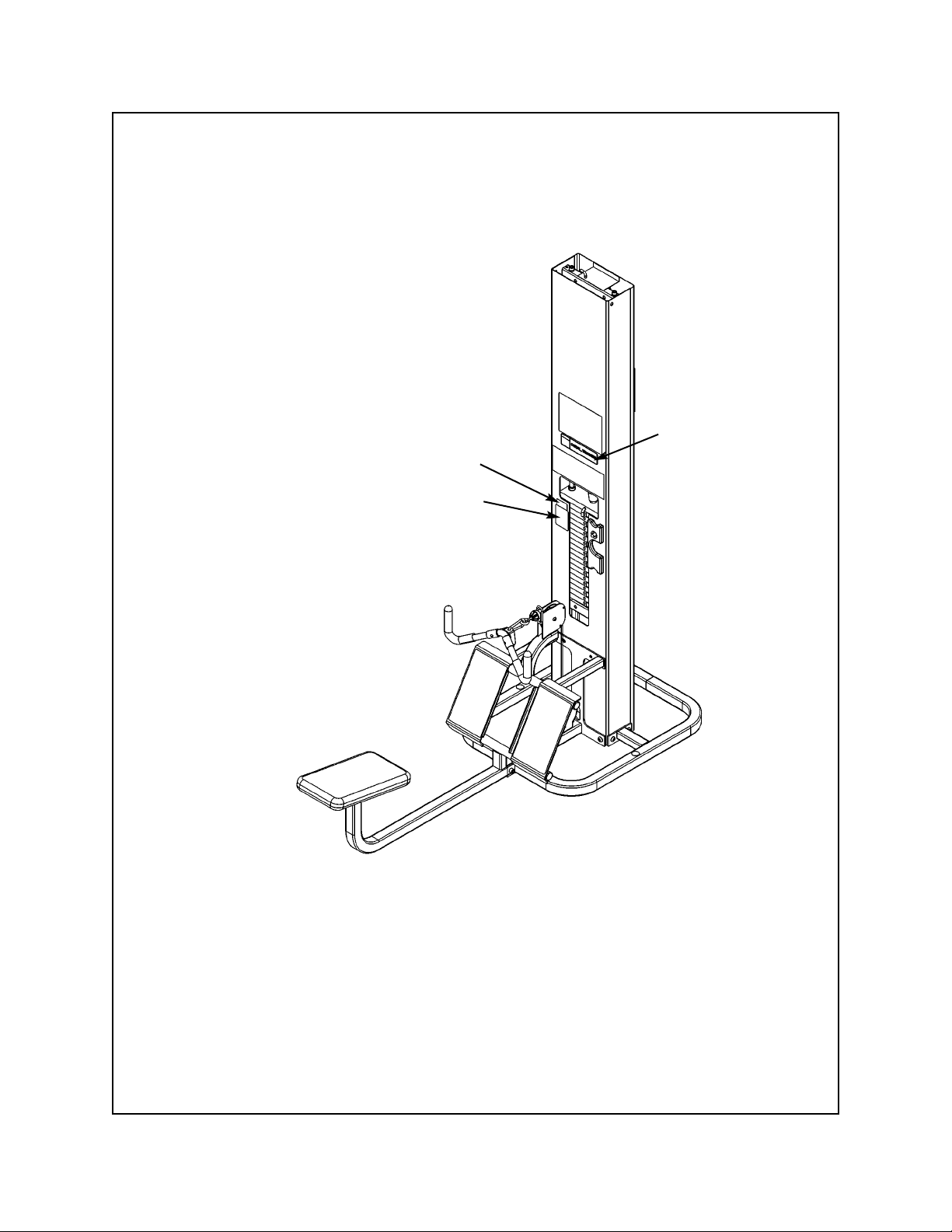

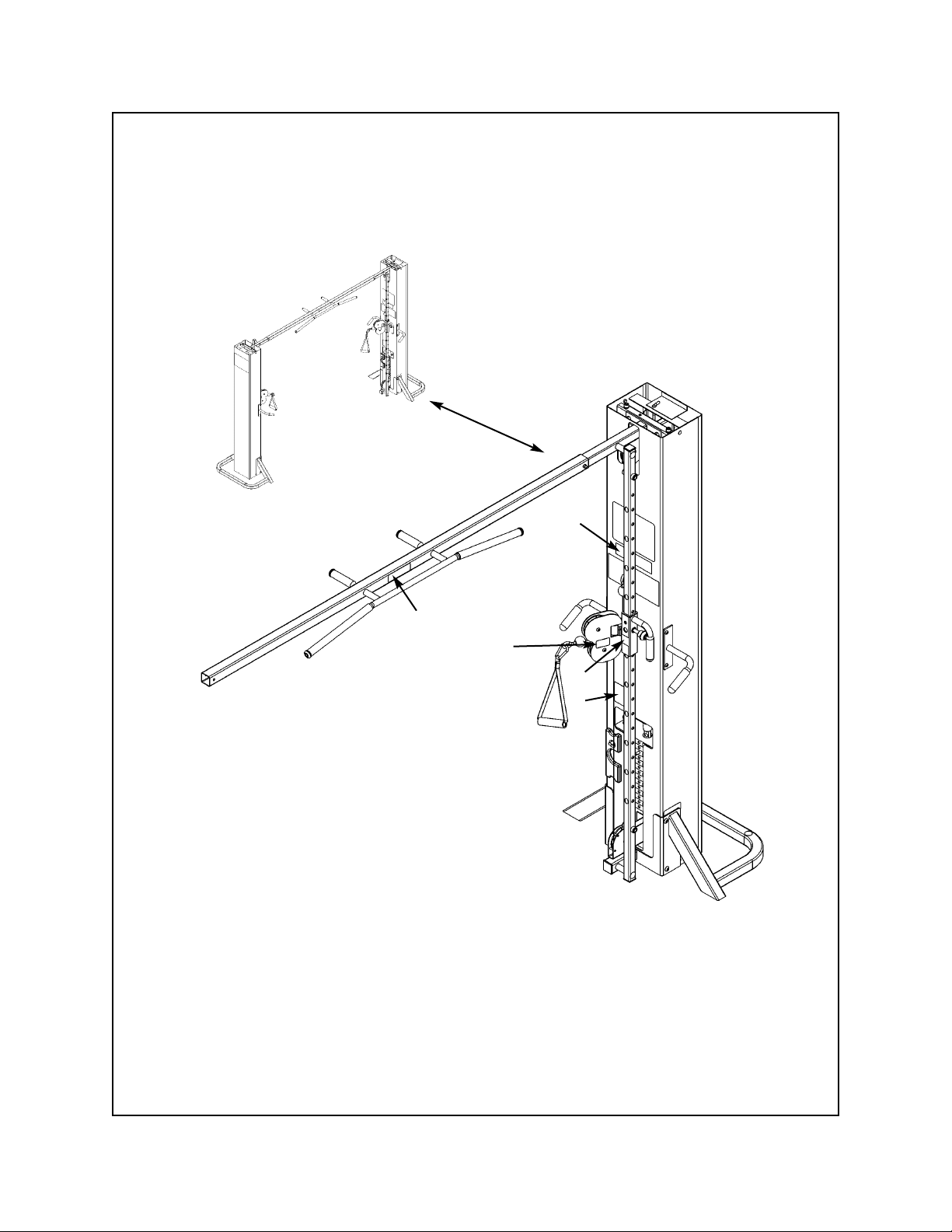

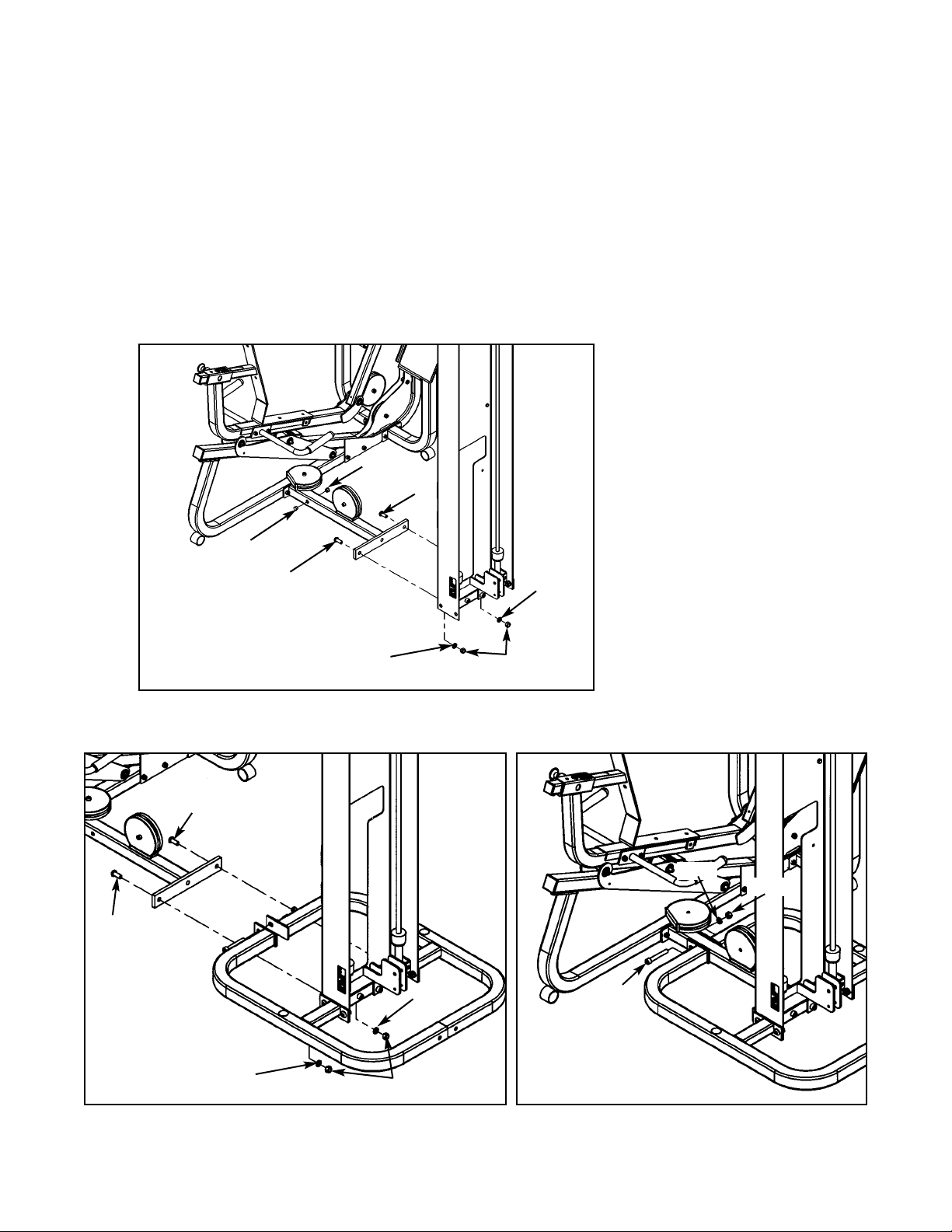

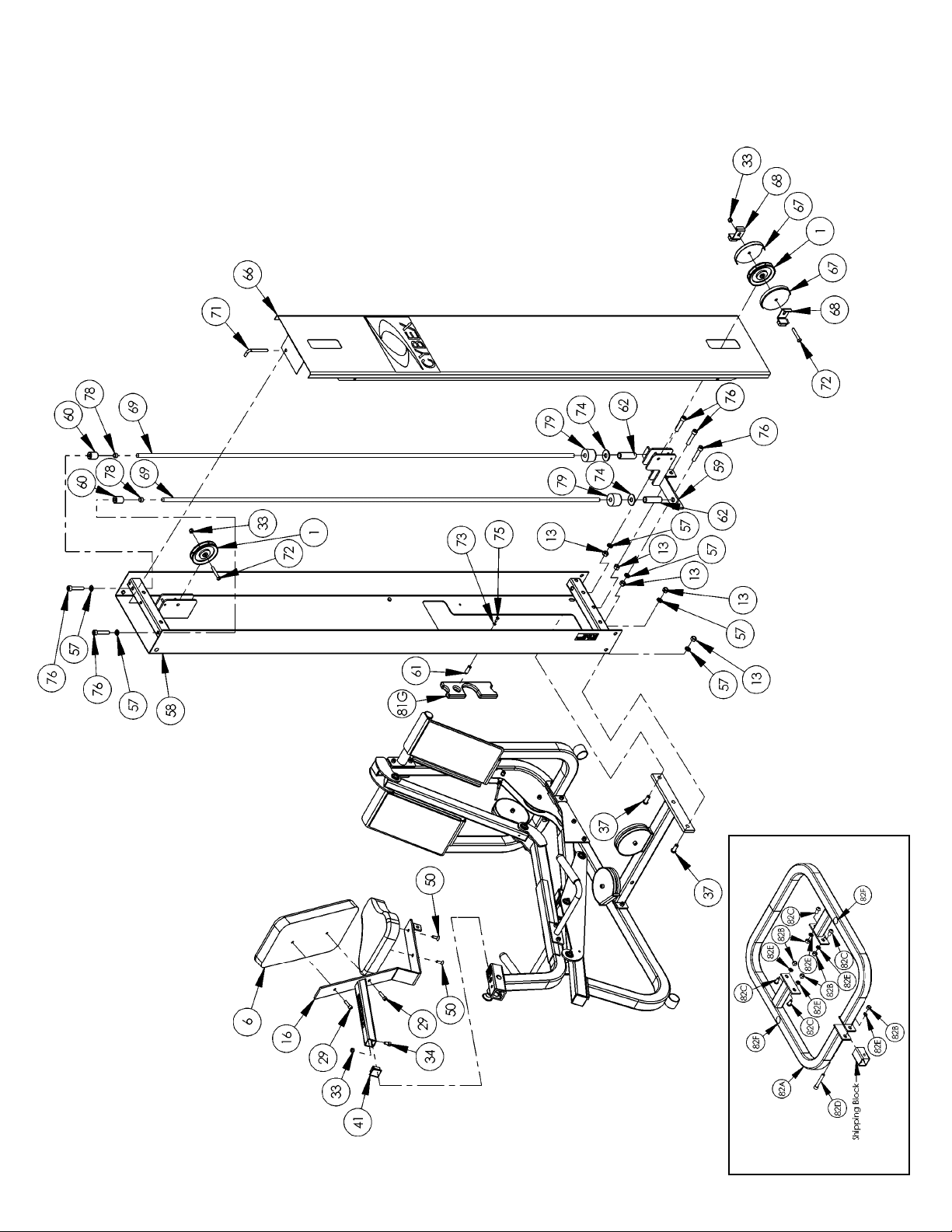

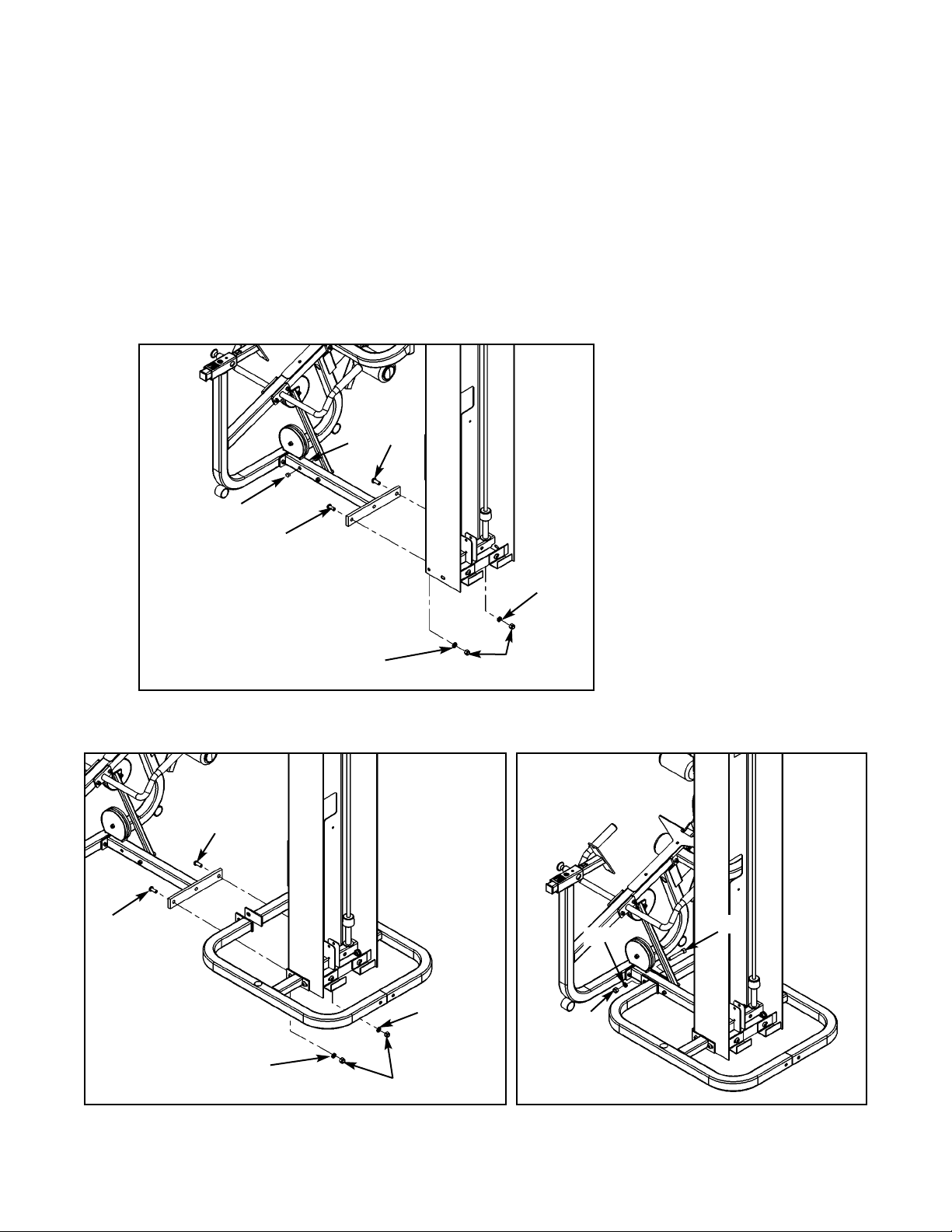

Modular Seated Leg Press

5652 - Modular/Tandem configuration

5322 - Free Standing configuration

TOOLS REQUIRED

• 5/32” Allen wrench

• 7/32” Allen wrench

• 5/16” Allen wrench

• 3/8” Allen wrench

• 9/16” Socket/wrench

• 3/4” Socket/wrench

• Rubber mallet

• Step ladder

NOTE: A minimum of two people will be required to assemble the Leg Press configuration.

1. Read and understand all instructions thoroughly before assembling the Leg Press (see steps

A - C).

A. Locate the Modular Assembly & Service manual that you received with your order. If you did

not receive a manual contact Cybex Customer Service and ask for part number 55620.

B. If you are assembling the Leg Press station into a Tandem configuration, locate and review the

Tandem Center Post instructions contained with the Tandem configuration (this sheet is also

located in the Modular Assembly & Service manual). Skip step 1 in the Tandem Center Post

instructions.

C. If you are assembling the Leg Press station into a Modular configuration, locate and review

the Modular Center Post instructions contained with the Modular configuration. Skip step 1 in

the Modular Center Post instructions.

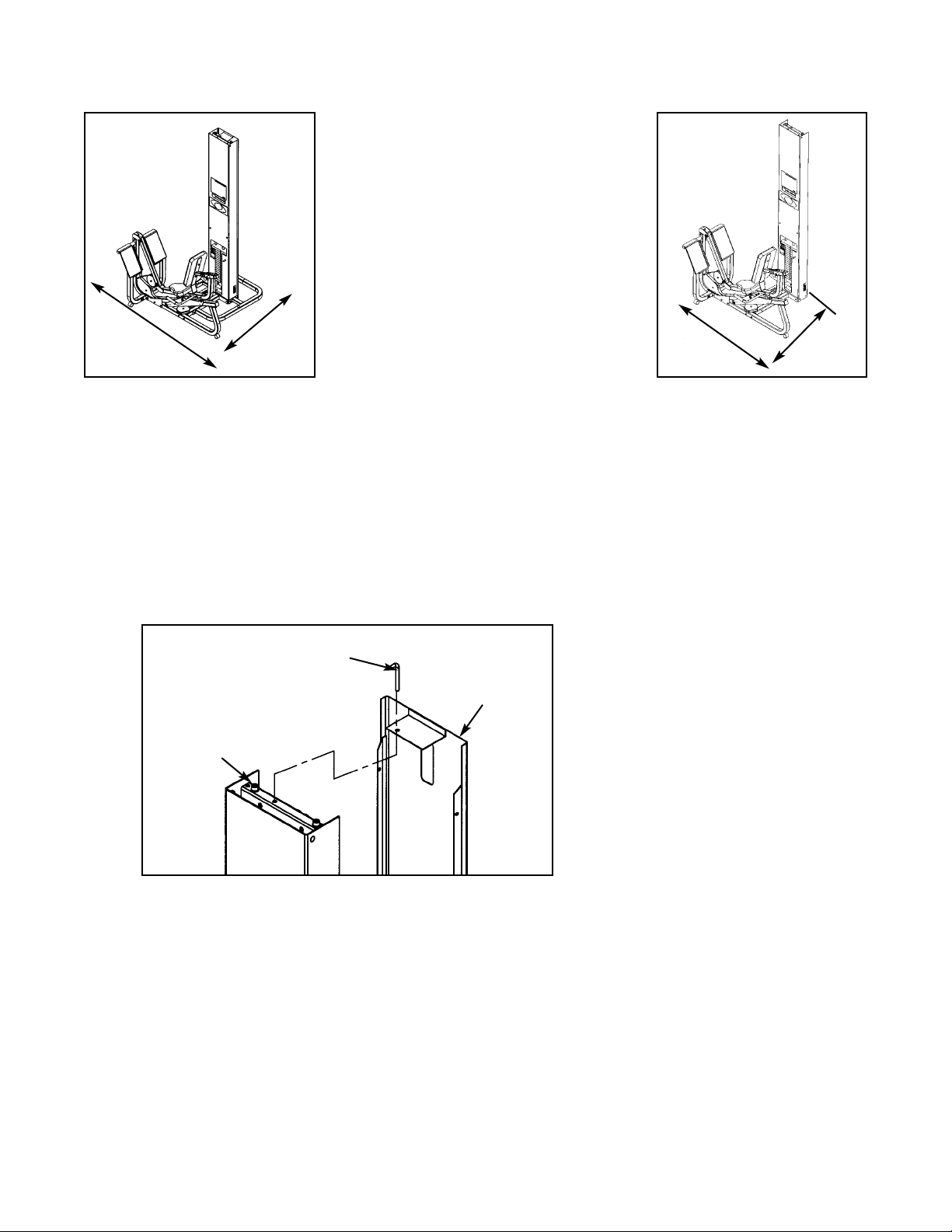

2. Verify you have received the appropriate configuration (see steps 2A - 2C, Figures 1 and 2).

• Hammer

• Utility knife

• Automotive engine oil

Assembly Instructions

Unpacking

A. If you ordered the Modular/Tandem

configuration (5262):

Shipping Package Part Number

• Leg Press Column 5562-9x

• Leg Press Package 5652-50

• Weight Package 4700S040

• Weight Package 4700S129

• Top Weight Package 4700-027

• Cushion Set 8630-010

B. If you ordered the Free Standing

configuration (5322):

Shipping Package Part Number

• Leg Press Column 5322-9x

• Leg Press Package 5652-50

• Leg Press Stabilizer 5302-51

• Weight Package 4700S040

• Weight Package 4700S129

• Top Weight Package 4700-027

• Cushion Set 8630-010

Cybex Modular Owner’s Manual

Page 4-9

Page 64

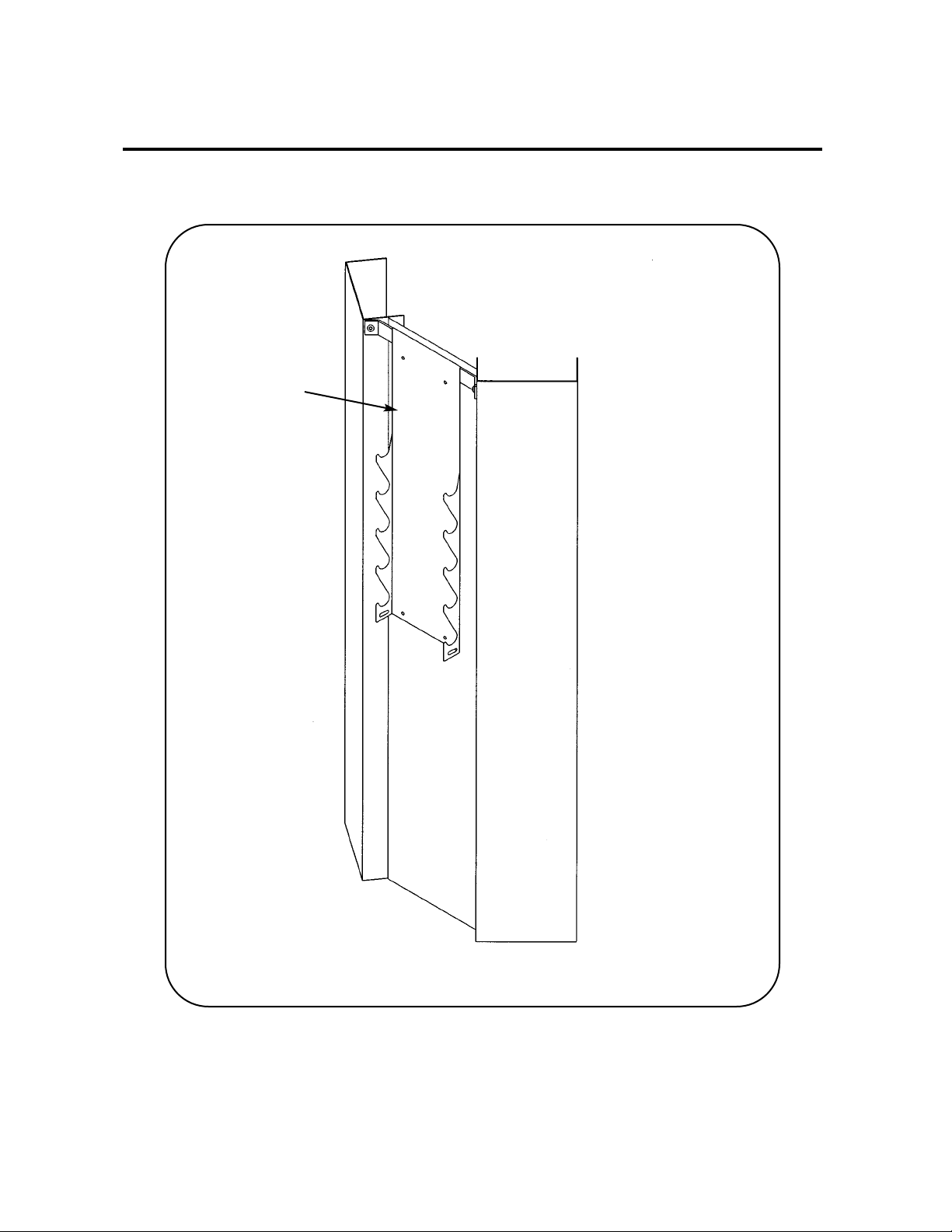

3. Unpack the carton containing the column (see steps 3A - 3I and Figures 3 - 8).

A. Locate and open the Leg Press Column carton.

B. The column should be laying so that the back side is facing upward.

C. For Free Standing units containing a back cover, remove the pin (#83) securing the back

cover (#66). Remove back cover by sliding it then lifting it upward. See Figure 3.

Figure 3

D. Remove the shipping supports securing the pulley mount and two hardware packs located

inside the column.

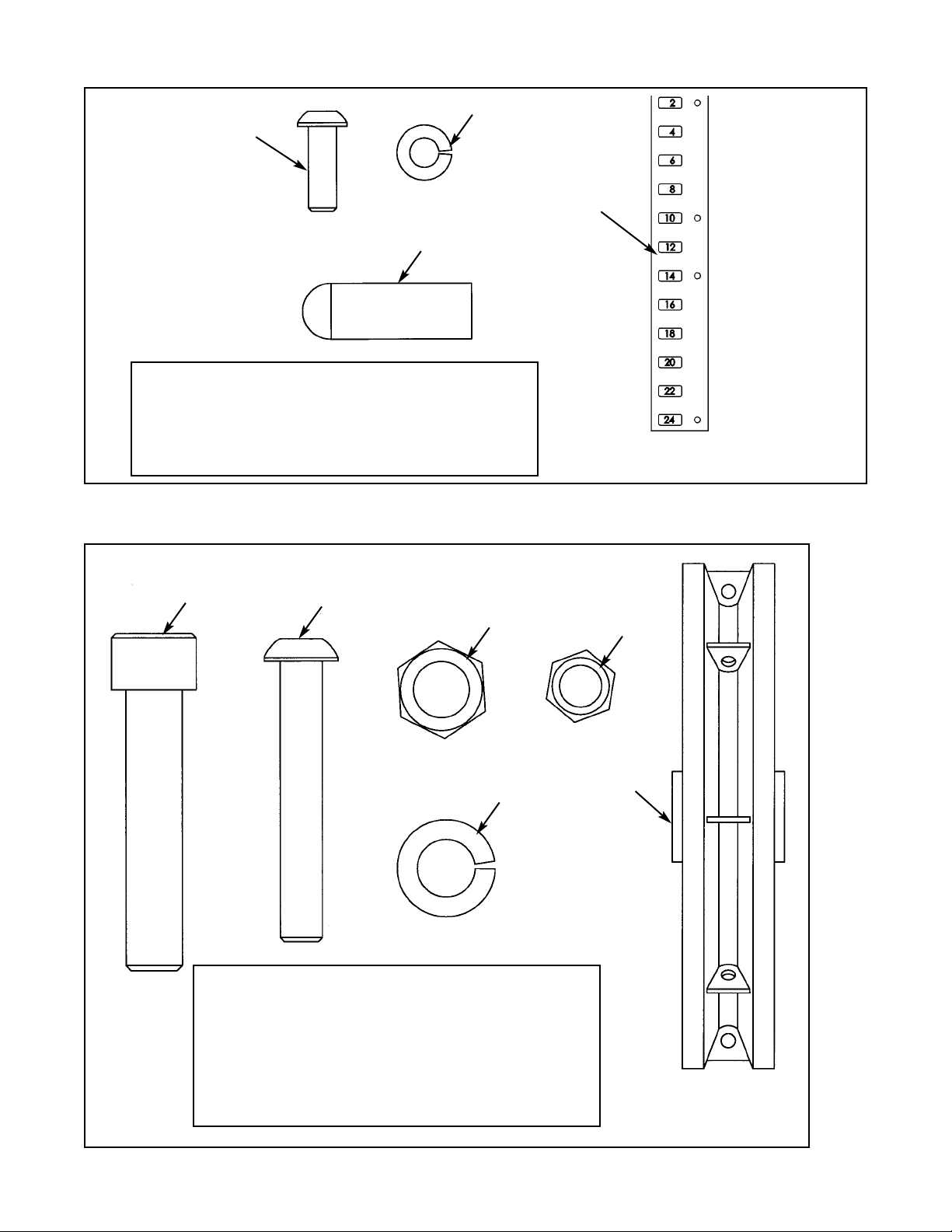

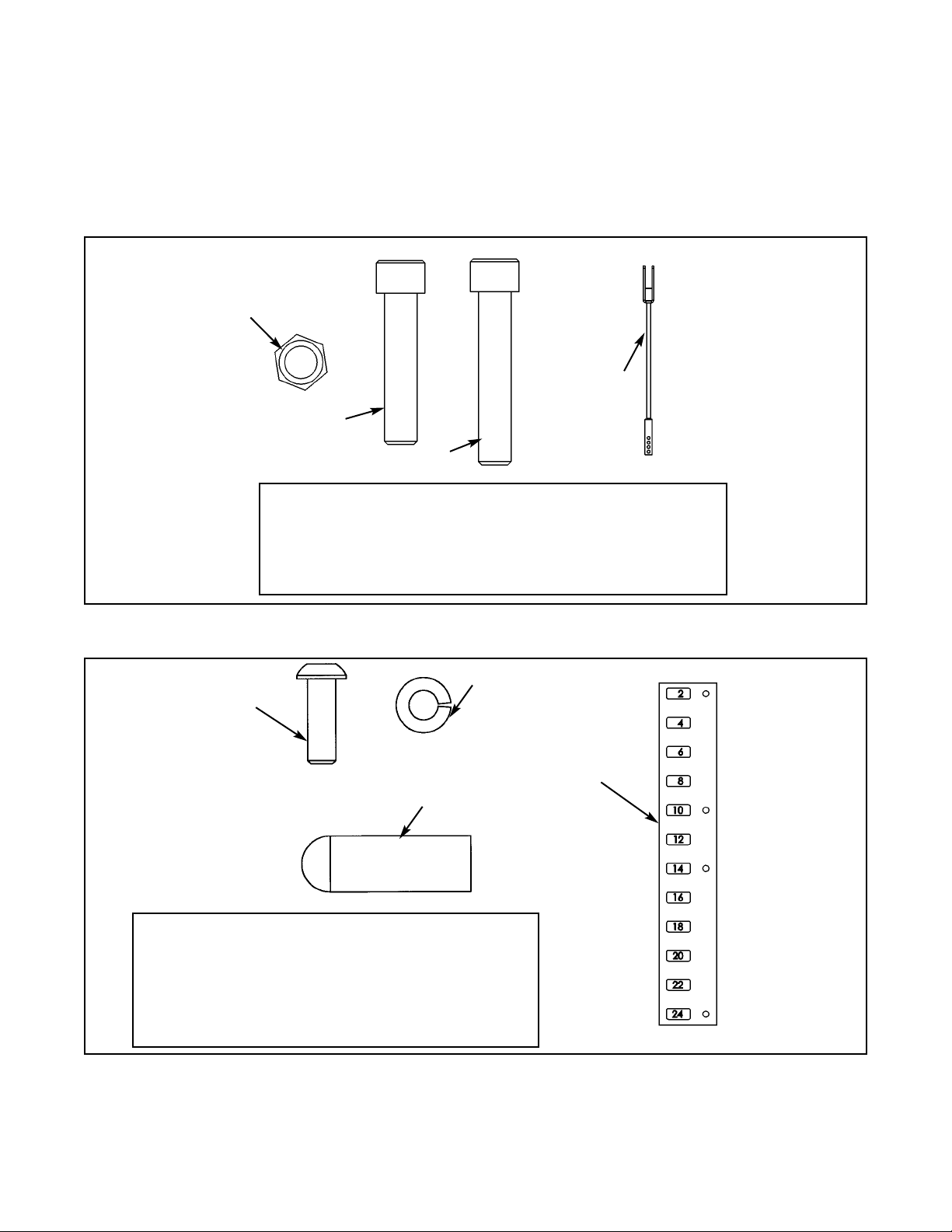

E. Verify contents of both hardware packs. See Figures 4 - 6.

NOTE: Figures 4 and 5 are for the Free Standing configuration.

Figures 5 and 6 are for the Tandem/Modular configuration.

83

Column

66

Figure 1

Figure 2

C. Carefully place shipping

packages near area of

installation.

D. For Free Standing configurations,

allow a minimum amount 92” x

89” for operating space. See

Figure 1.

E. For Modular/Tandem

configurations, allow a minimum

of 92” x 76” for operating space.

See Figure 2.

92”

89”

92”

76”

Cybex Modular Owner’s Manual

Page 4-10

Page 65

Figure 4

1 2 08014 Pulley Assembly

13 2 HN784000 Hex Nut .50-13

33 2 HN704901 Nylon Locknut .375-16

42 2 PU060201 Bumper

57 2 JS38800 Split Lockwasher .500

67 2 5301-310 Pulley Guard

68 2 5301-311 Stop

72 2 HC700430 BHSCS .375-16 x 2.50

76 3 JC782830 SHCS .50-13 x 2.50

ITEM QTY PART NO. DESCRIPTION

76

72

57

13

33

1

42

67

68

Cybex Modular Owner’s Manual

Page 4-11

Page 66

Figure 5

61 1 02106 Half Weight Peg

65 1 4800-515 Weight Plate Decal

73 1 HS308300 Split Lockwasher .250

75 1 JC620415 BHSCS .250-20 x .75

ITEM QTY PART NO. DESCRIPTION

Figure 6

1 2 08014 Pulley Assembly

72 2 HC700430 BHSCS .375-16 x 2.50

33 2 HC704901 Nylon Locknut .375-16

13 3 JC620415 Hex Nut .500-13

76 3 JC782830 SHCS .500-13 x 2.50

57 2 JS388300 Split Lockwasher .500

ITEM QTY PART NO. DESCRIPTION

73

61

75

65

76

72

13

33

57

1

Cybex Modular Owner’s Manual

Page 4-12

Page 67

G. Locate the pulley mount (#59), three SHCS .500-13 x 2.50 (#76), three split lockwashers

.500 (#57) and three hex nuts .500-13 (#13).

H. Attach pulley mount (#59) to column as shown in Figure 8. Securely tighten hardware.

Figure 8

76

57

13

13

57

F. Remove both SHCS .500-

13 x 2.50 #76), both split

lockwashers (#57) and both

guide rod collets (#60)

securing guide rods (#69).

Remove guide rods from

column.

Figure 7

I. Reinstall both guide rods. NOTE: Do not securely tighten guide rods at this time.

76

57

57

60

69

59

Column

Cybex Modular Owner’s Manual

Page 4-13

Page 68

82C

82E

82B

82E

82C

82C

82C

82D

82E

82B

82A

Shipping Block

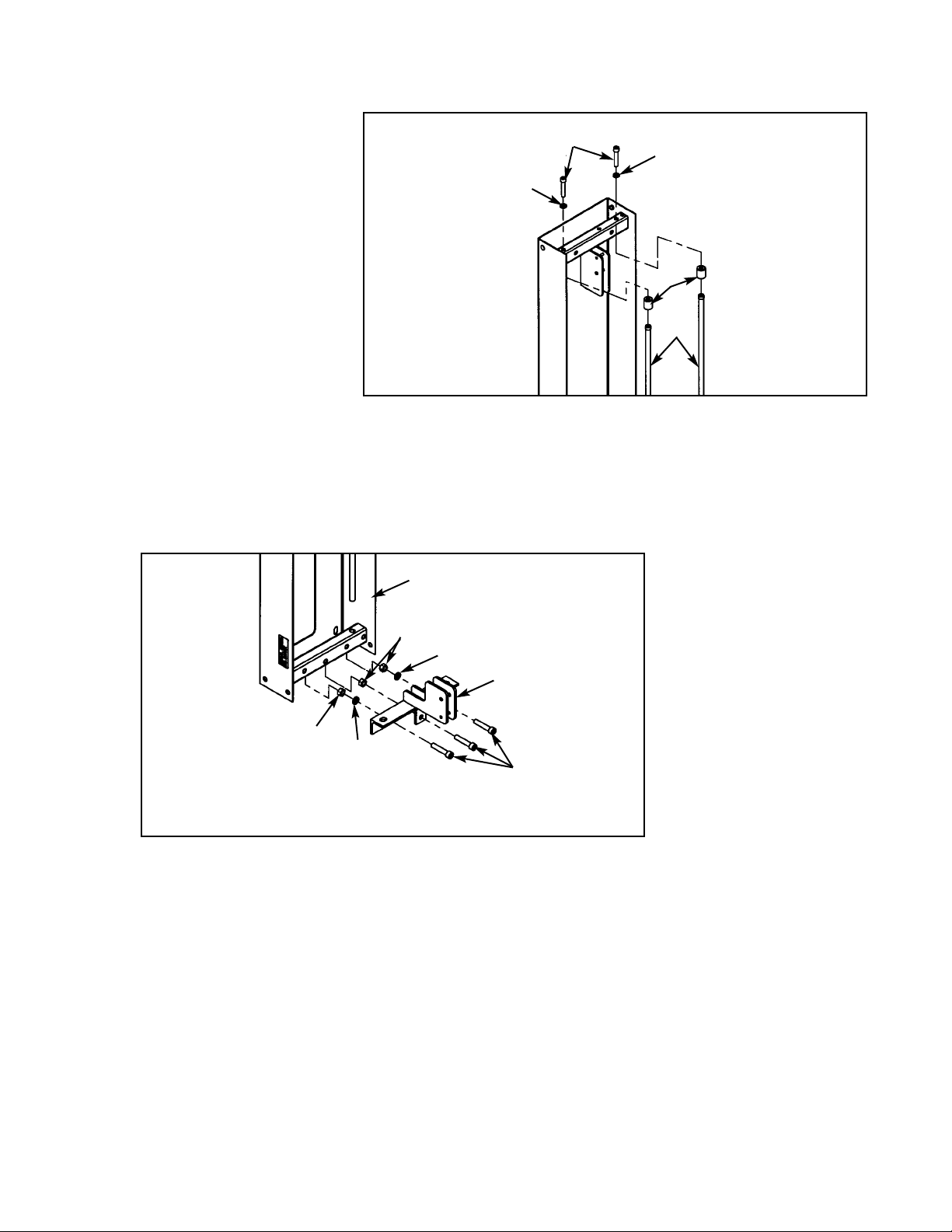

4. Attach column to the appropriate configuration (see steps 4A - 4E, Figures 9 and 10).

NOTE: For Free Standing configuration, see steps 4A - 4C then go to step 5.

For Tandem configuration see step 4D then go to step 5.

For Modular configurations see step 4E then to go step 5.

A. Place base (#82A) in area where the station will be used.

B. Remove the hardware from the base (#82A) as shown in Figure 9.

82A 1 5301-200 Base

82B 5 HN784000 Hex Nut .50-13

82C 4 JC780417 BHSCS .50-13 x 1.00

82D 1 JC782836 SHCS .50-13 x 3.25

82E 5 JS388300 Split Lockwasher .50

1 Shipping Block

ITEM QTY PART NO. DESCRIPTION

Figure 9

C. With an assistant, carefully place column into stabilizer (#82A) then attach hardware as shown

in Figure 10.

82C

82C

Figure 10

82B

82E

82E

82A

Column

Cybex Modular Owner’s Manual

Page 4-14

Page 69

D. For the Tandem configuration, attach both columns to frame as shown in the Tandem Center

Post & Dome Installation instruction sheet.

E. For the Modular configuration, install angle braces onto each column. See the exploded-view

diagram shown in the Modular Center Post Installation Instruction sheet

5. Install the Leg Press Assembly to the appropriate configuration (see steps 5A - 5F and

Figures 11 - 13B).

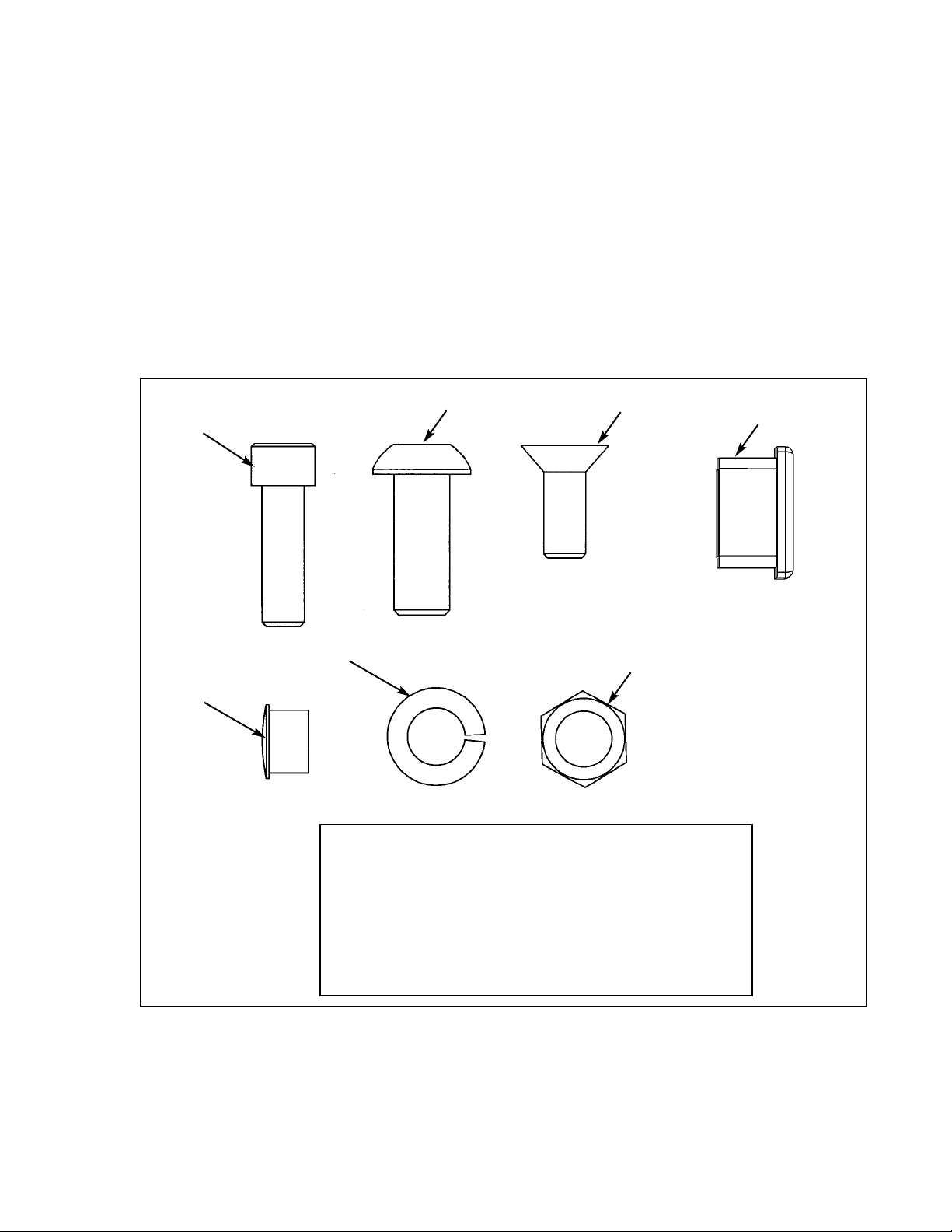

A. Locate the Leg Press assembly and hardware pack.

B. Verify contents of hardware pack. See Figure 11.

Figure 11

13 2 HN784000 Hex Nut .50-13

29 2 JC702820 SHCS .375-16 x 1.25

37 2 JC780420 BHSCS .50-13 x 1.25

41 1 PP090211 Plastic Insert 1.500 Sq x 10-14 G

50 2 JC700917 FHSCS .375-16 x 1.00

57 2 JS388300 Split Lockwasher .500

77 2 PN660201 Hole Plug

ITEM QTY PART NO. DESCRIPTION

37

50

29

77

57

13

41

Cybex Modular Owner’s Manual

Page 4-15

Page 70

Figure 12

C. Locate two BHSCS .50-13 x 1.25 (#37), two split lockwashers (#57), two hex nuts .50-13

(#13) and two hole plugs (#77). For the Free Standing configuration, also locate (from step 4B)

one SHCS .50-13 x 3.25 (#82D), one split lockwasher .50 (#82E) and one hex nut .50-13

(#82B).

D. Install the Leg Press Assembly to the column. See Figure 12 for Modular/Tandem

configurations and Figures 13A and 13B for Free Standing configuration.

E. Install hole plugs (#77) to the Leg Press Assembly (Modular/Tandem configurations only). See

Figure 12.

Figure 13A

Figure 13B

82D

82E

82B

77

77

57

57

13

37

37

57

57

13

37

37

Cybex Modular Owner’s Manual

Page 4-16

Page 71

F. For Modular configuration only, see step 4 of the Modular Center Post installation instructions,

part number 55600.

6. Install weight stack (see steps 6A - 6M, Figures 14 and 15).

A. Locate the half weight pin (#61), BHSCS .250-20 x .75 (#75) and split lockwasher (#73) from

the column hardware pack shown in Figure 5.

B. Install the half weight peg as shown in Figure 14.

Figure 14

C. Locate the top weight package and verify the contents. See Figure 15.

2 1 4800-250 Top Weight Assembly

8 1 HP286819 Spiral Pin

12 1 4700M005 Rubber Boot

14 1 5310P044 Weight Selector Pin

21 1 C-ZA00200 Half Weight

ITEM QTY PART NO. DESCRIPTION

Figure 15

75

73

61

2

12

8

14

21

Cybex Modular Owner’s Manual

Page 4-17

Page 72

D. Verify that you received the appropriate number of weight plates.

E. Remove the two SHCS securing the guide rods.

F. Carefully lean guide rods away from column.

G. Remove guide rod collets and plastic caps.

H. Wipe guide rods clean over entire length. Lubricate with light coating of medium weight

automotive engine oil.

I. Install each weight plate one at a time.

J. Install top weight.

K. Replace plastic caps and guide rod collets on guide rods.

L. Return guide rods to full upright position.

M. Insert both SHCS that were removed in step 6A.

NOTE: Do not secure top weight at this time.

Cybex Modular Owner’s Manual

Page 4-18

Page 73

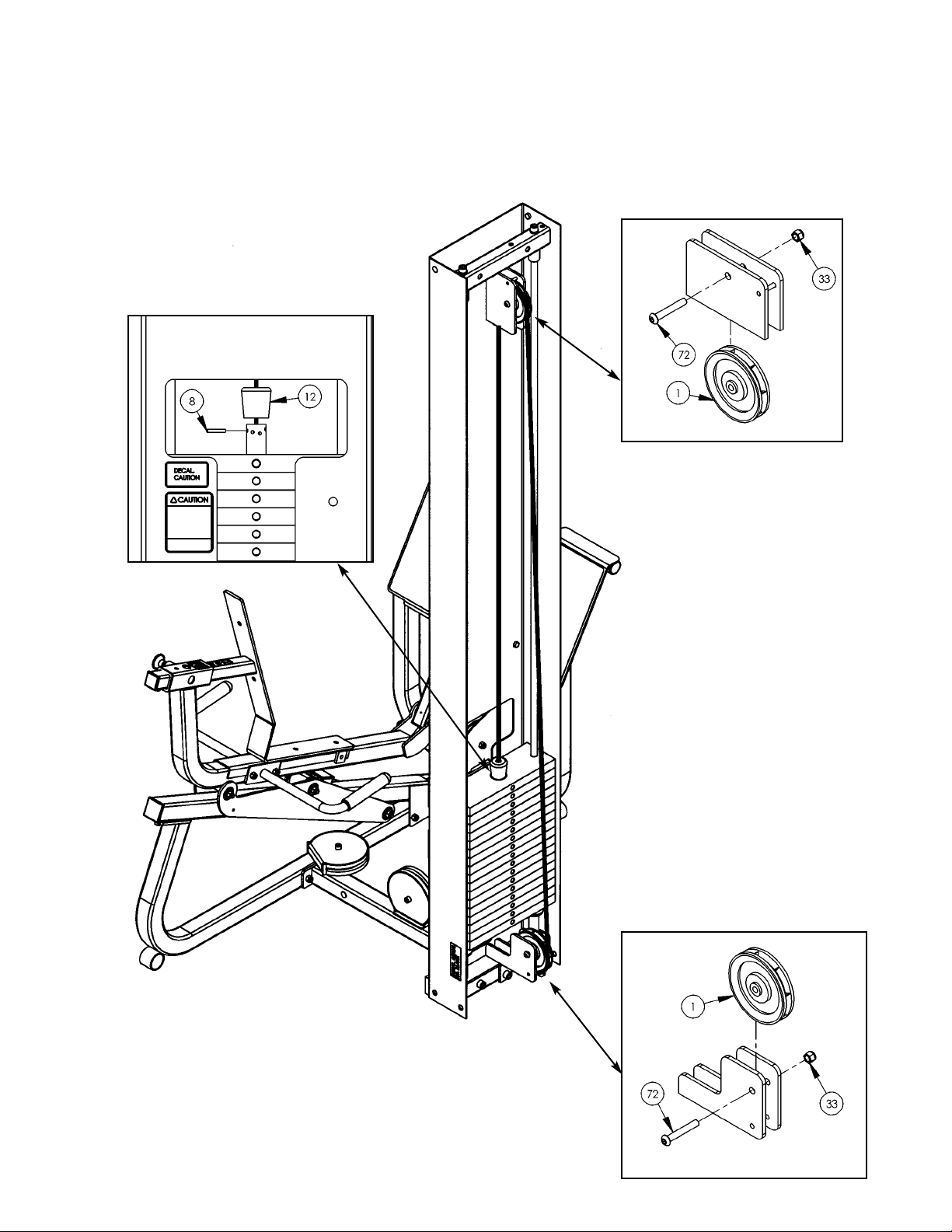

7. Routing Cable - Modular/Tandem configuration

only (see steps 7A - 7I, Figures 16 and 17).

NOTE: For Free Standing configuration see

step 8.

A. Install upper assemblies to any stations within

the Modular/Tandem configuration that

contain upper assemblies. See the Modular

and Tandem installation instructions.

B. Locate two pulleys (#1), two BHSCS .375-16 x

2.50 (#72) and two nylon locknuts .375-16

(#33).

C. At the same time, install pulley to lower pulley

bracket and route cable using one pulley (#1),

one BHSCS .375-16 x 2.50 (#72) and one

nylon locknut .375-16 (#33). See Figure 16.

D. Route cable to upper pulley bracket and

install pulley/route cable using one pulley (#1),

one BHSCS .375-16 x 2.50 (#72) and one

nylon locknut .375-16 (#33). See Figure 16.

E. Route cable downward to top plate.

F. Slide rubber boot (#12) onto cable end. See

Figures 16 and 17.

G. Insert cable end into top weight and align

cable fitting opening with opening in top

weight for proper cable tension as shown in

Figure 17. See the Owner’s Manual for proper

cable adjustment.

H. Using a hammer, drive roll pin (#8) through top

plate connector and cable fitting. Assure pin is

flush with top plate collar.

I. Insert selector pin into each weight plate to

assure proper alignment. See the Cable

Adjustment and Installation section of the

Owner’s Manual if the selector pin does not fit

smoothly or if cable appears to have

excessive slack.

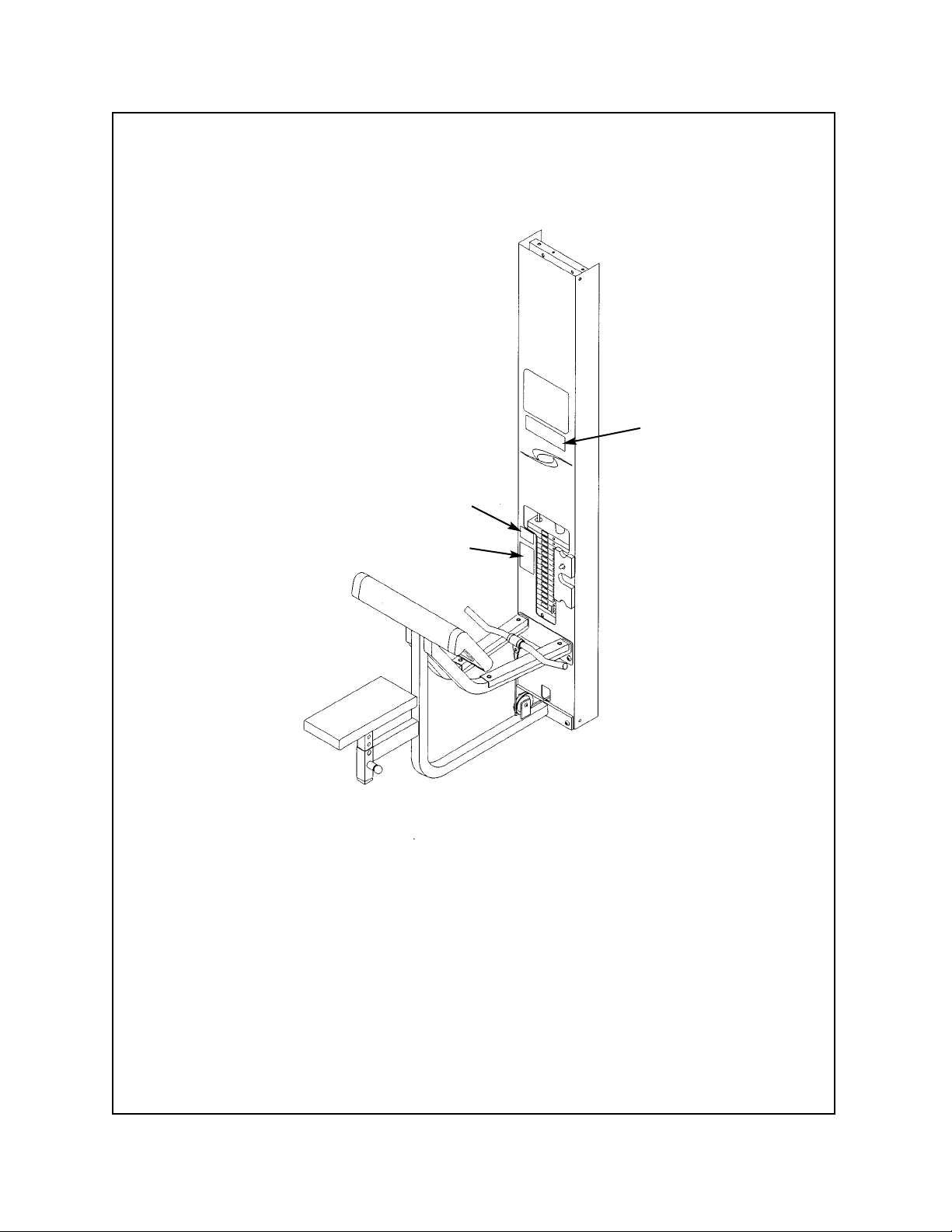

1

72

33

33

72

1

Figure 17

12

8

Cybex Modular Owner’s Manual

Page 4-19

Page 74

Figure 18

8. Routing Cable - Free Standing configuration only (see steps 8A - 8J and Figures 18 - 22).

A. Locate the back cover (#66), two pulleys (#1), two BHSCS .375-16 x 2.50 (#72), two nylon

locknuts .375-16 (#33), two stop brackets (#68)/bumpers (#42) and two pulley guards (#67).

B. Route cable through lower slot in back cover (#66) and place back cover onto back of

column. See Figure 18.

C. With top part of back cover (#66) leaned back, route cable/install pulley (#1) using one

BHSCS .375-16 x 2.50 (#72) and one nylon locknut .375-16 (#33). See Figure 19.

Figure 19

66

NOTE:Route cable through

back cover onto back

of column.

Cable

Cable

1

72

33

66

Cybex Modular Owner’s Manual

Page 4-20

Page 75

D. Install lower pulley using one pulleys (#1), one BHSCS .375-16 x 2.50 (#72), one nylon

locknut .375-16 (#33), two stop brackets (#68)/bumpers (#42) and two pulley guards (#67).

See Figure 20.

Figure 20

Figure 22

E. Route cable downward to top plate.

F. Slide rubber boot (#12) onto cable end. See Figure 21.

G. Insert cable end into top weight and align cable fitting

opening with opening in top weight for proper cable

tension as shown in Figure 21. See the Owner’s

Manual for proper cable adjustment.

H. Using a hammer, drive roll pin (#8) through top plate connector and cable fitting. Assure pin is

flush with top plate collar.

I. Insert selector pin into each weight plate to assure proper alignment. See the Cable

Adjustment and Installation section of the Owner’s Manual if the selector pin does not fit

smoothly or if cable appears to have excessive slack.

J. Secure back cover (#66) using weight selector pin (#71). See Figure 22.

1

33

67

67

68

42

42

68

72

71

66

Figure 21

12

8

Cybex Modular Owner’s Manual

Page 4-21

Page 76

9. Install Weight Plate Decal and Half Weight

(see steps 9A - 9H, Figures 23 and 24).

A. Locate the weight plate decals.

B. Place weight plate decals on weight plates

according to steps listed below and

Figures 23 and 24.

C. Slowly and carefully peel off back side of

decal. NOTE: When peeling off back cover,

make sure that the decals remain attached to

the front sticker.

D. Align holes in decal with appropriate holes in

weight stack. NOTE: Do not allow the

adhesive to touch weight stack at this time.

E. Insert a guide pin through each hole of the

template. NOTE: A guide pin can be any-

thing that fits through the weight stack hole,

such as a weight stack selector pin.

F. Carefully align decal and rub it onto weight

plates.

G. Carefully remove front side, leaving decals

adhering to weight plates. See Figure 24

H. Locate half weight and install it on the half weight peg.

10. Install the back and seat cushions (see steps 10A - 10I and Figures 25 - 28).

A. Locate the cushion box and verify the contents as shown in Figure 25.

Figure 23

Decal

Weight Stack

Guide Rod

Figure 24

Figure 25

6

9

Cybex Modular Owner’s Manual

Page 4-22

Page 77

Figure 26

D. Locate seat cushion bracket, back cushion (#6), seat cushion (#9), two FHSCS .375-16 x 1.00

(#50) and two SHCS .375-16 x 1.25 (#29).

E. Install seat and back cushions as shown in Figure 27.

Figure 27

B. Locate the back cushion (#6), seat cushion (#9), two SHCS. .375-16 x 1.25 and two FHSCS

.375-16 x 1.00.

C. Remove the SHCS and nylon locknut securing the cushion post. See Figure 26.

Nylon

Locknut

SHCS

Cushion

Post

6

9

29

29

50

50

Cybex Modular Owner’s Manual

Page 4-23

Page 78

F. Locate plastic insert (#41).

G. Install cushion assembly onto frame.

H. Secure cushion assembly using SHCS and hex nut (removed from step 10C). See Figure 27.

I. Install plastic insert as shown in Figure 28.

41

Nylon

Locknut

SHCS

Figure 28

11. Verify proper operation.

Cybex Modular Owner’s Manual

Page 4-24

Page 79

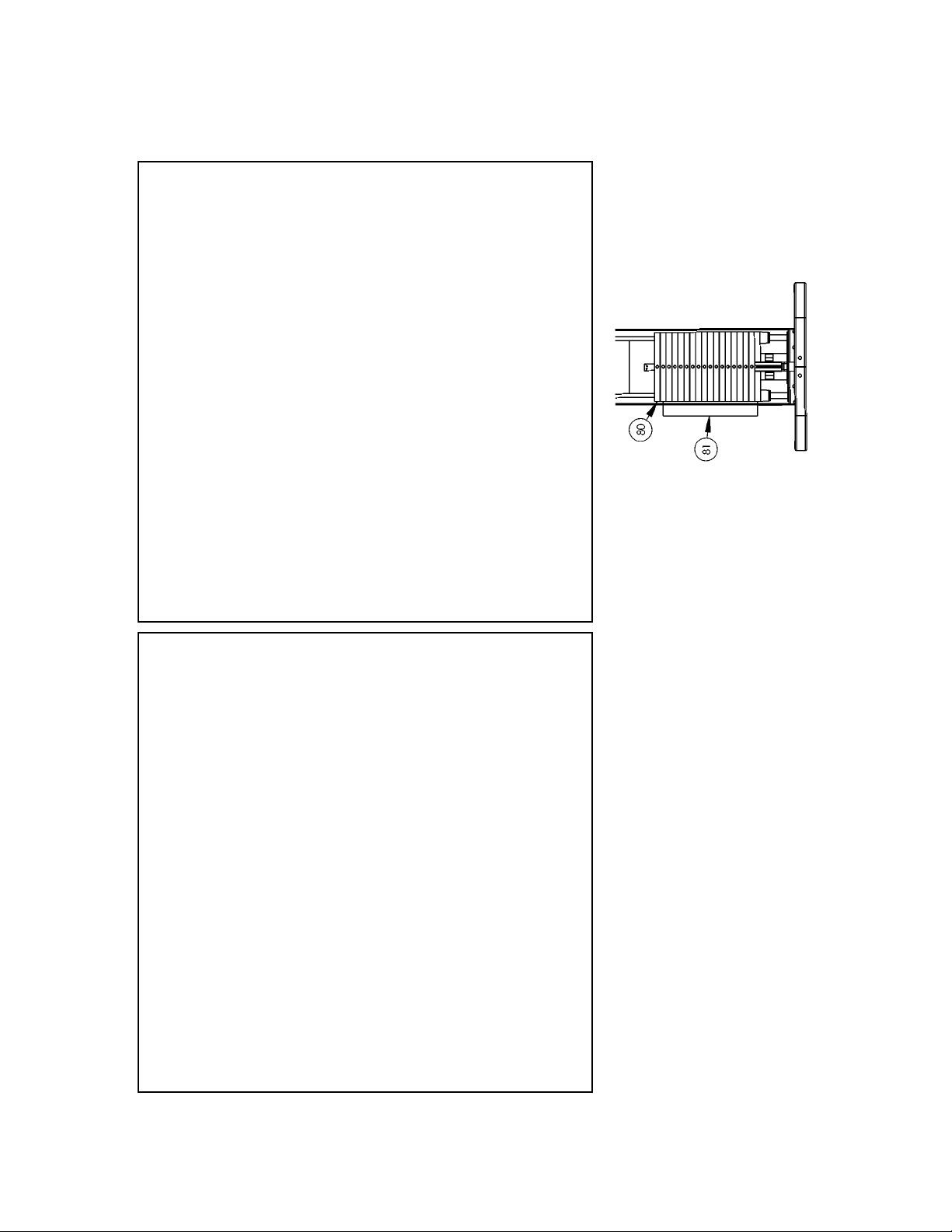

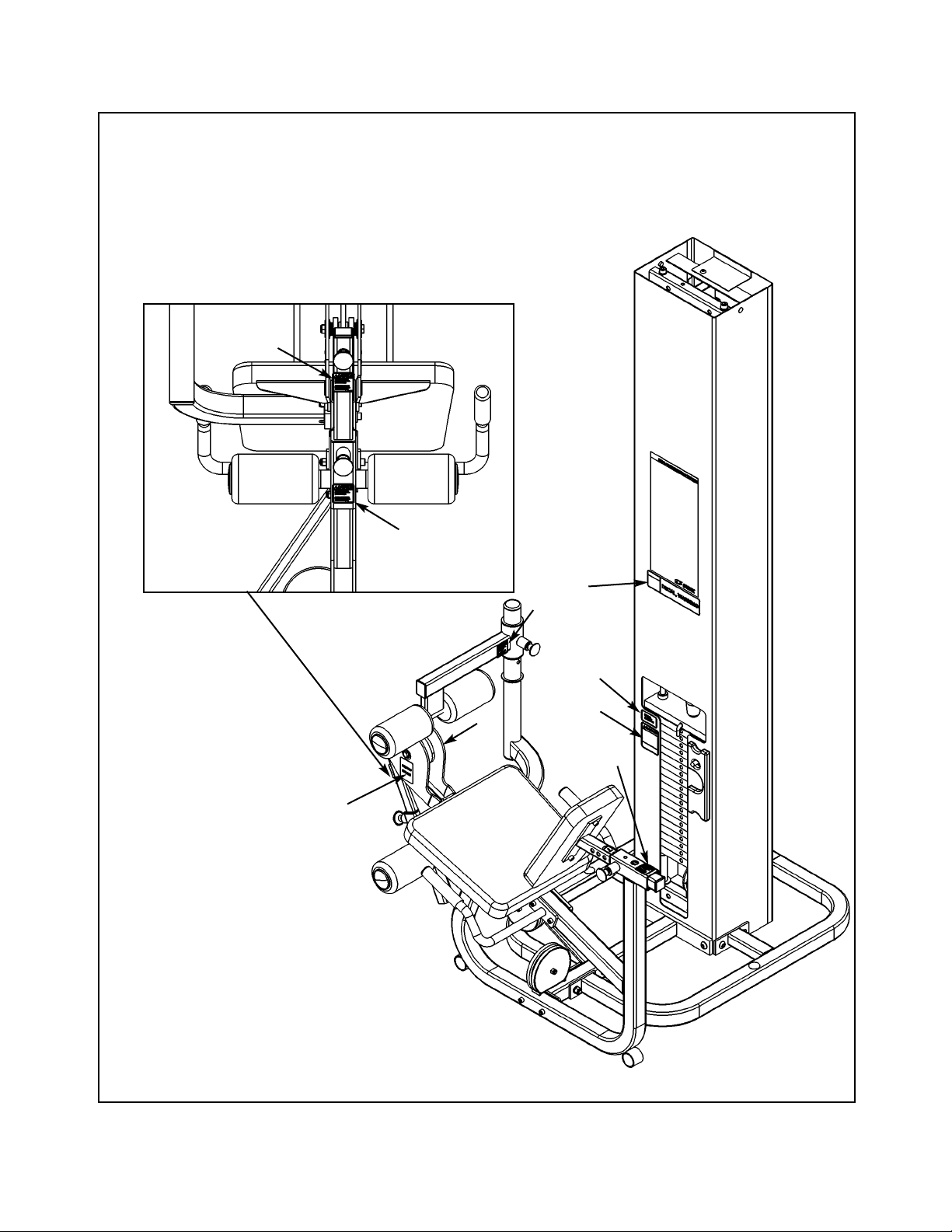

12. Verify warning decals are present and not damaged (see decals below and Figure 28).

A

D

B

C

Cybex Modular Owner’s Manual

Page 4-25

WARNING

Notify floor staff if plates are

elevated or jammed to avoid

injury.

02521 A

Page 80

A. Warning Decal ................... 4000Y316

B. Caution Decal .................... 4000Y316

C. Warning Decal ................... 4800-381

D. Caution Decal .................... 8500-025

DESCRIPTION PART NO.

D

Figure 28

A

B

C

C

Cybex Modular Owner’s Manual

Page 4-26

Page 81

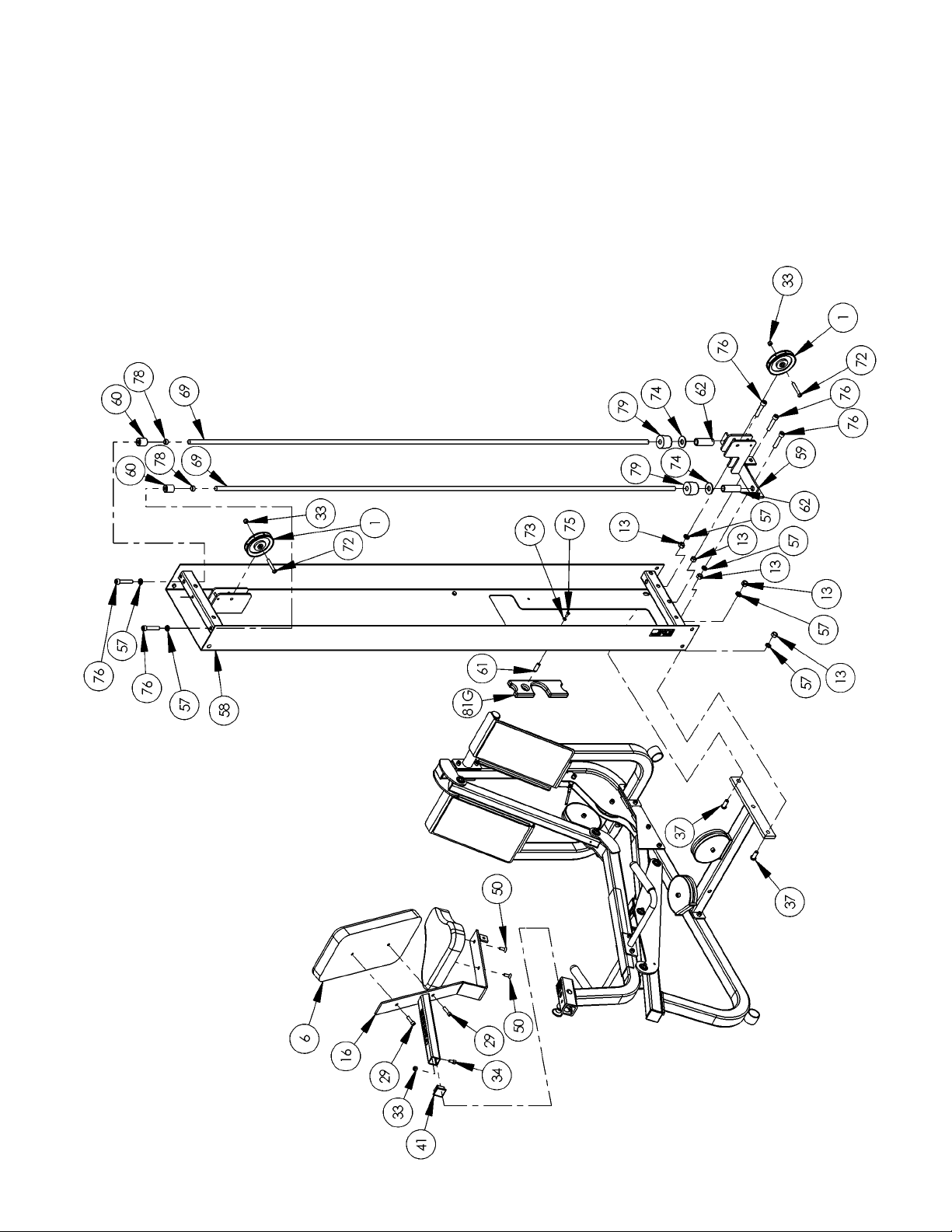

1 2 08014 Pulley

6 1 4106S055-0 Back Cushion

13 5 HN784000 Hex Nut .50-13

16 1 8630-202 Seat Tube

29 2 JC702820 SHCS .375-16 x 1.25

33 3 HN704901 Nylon Locknut .375-16

34 1 JC702814 SHCS .375-16 x .625

37 2 JC780420 BHSCS .50-13 x 1.25

41 1 PP090211 Plastic Insert 1.50 Sq x 10-14 G

50 2 JC700917 FHSCS .375-16 x 1.00

57 4 JS388300 Split Lockwasher .50

58 1 01243 Column

59 1 01247 Pulley Mount

60 2 01755 Guide Rod Collet

61 1 02106 Half Weight Peg

62 2 02330 Spacer 3.00 Weight

66 1 5301-201 Cover

• 67 2 5301-310 Pulley Guard

• 68 2 5301-311 Stop

69 2 5310M035 Weight Rod .625 Dia. x 85.31

70 1 55652 Instruction Modular Leg Press (not shown)

71 1 5310P044 Weight Select Pin

72 2 HC700430 BHSCS .375-16 x 2.50

73 1 HS308300 Split Lockwasher .25

74 2 HS760106 Flat Washer 1.75 x .68 x .140

75 1 JC620415 BHSCS .25-20 x .75

76 5 JC782830 SHCS .50-13 x 2.50

77 2 PN660201 Plug

78 2 PP080204 Plastic Cap .625 ID x .68 OD

79 2 PR060005 Bumper

80 17 4005C062 Weight Stack 4 x 12

81 1 4700-027 Top Weight Assembly

81B 1 4700M005 Rubber Boot (not shown)

81C 1 4800-256 Top Weight 18-4 x 12

81E 1 5310P044 Weight Selector Pin (not shown)

81G 1 C-ZA000200 Half Weight

• 82 1 5301-51 Modular Base Assembly

• 82A 1 5301-200 Base

• 82B 5 HN78400 Hex Nut .50-13

• 82C 4 JC780417 BHSCS .50-13 x 1.00

• 82D 1 JC782836 SHCS .50-13 x 3.25

• 82E 5 JS388300 Split Lockwasher .50

• 82F 2 PP080202 Plastic Insert 1.19 Dia. x 11 G

5322/5562 - Modular Seated Leg Press

ITEM QTY PART NO. DESCRIPTIONITEM QTY PART NO. DESCRIPTION

• For freestanding units only.

Cybex Modular Owner’s Manual

Page 4-27

Page 82

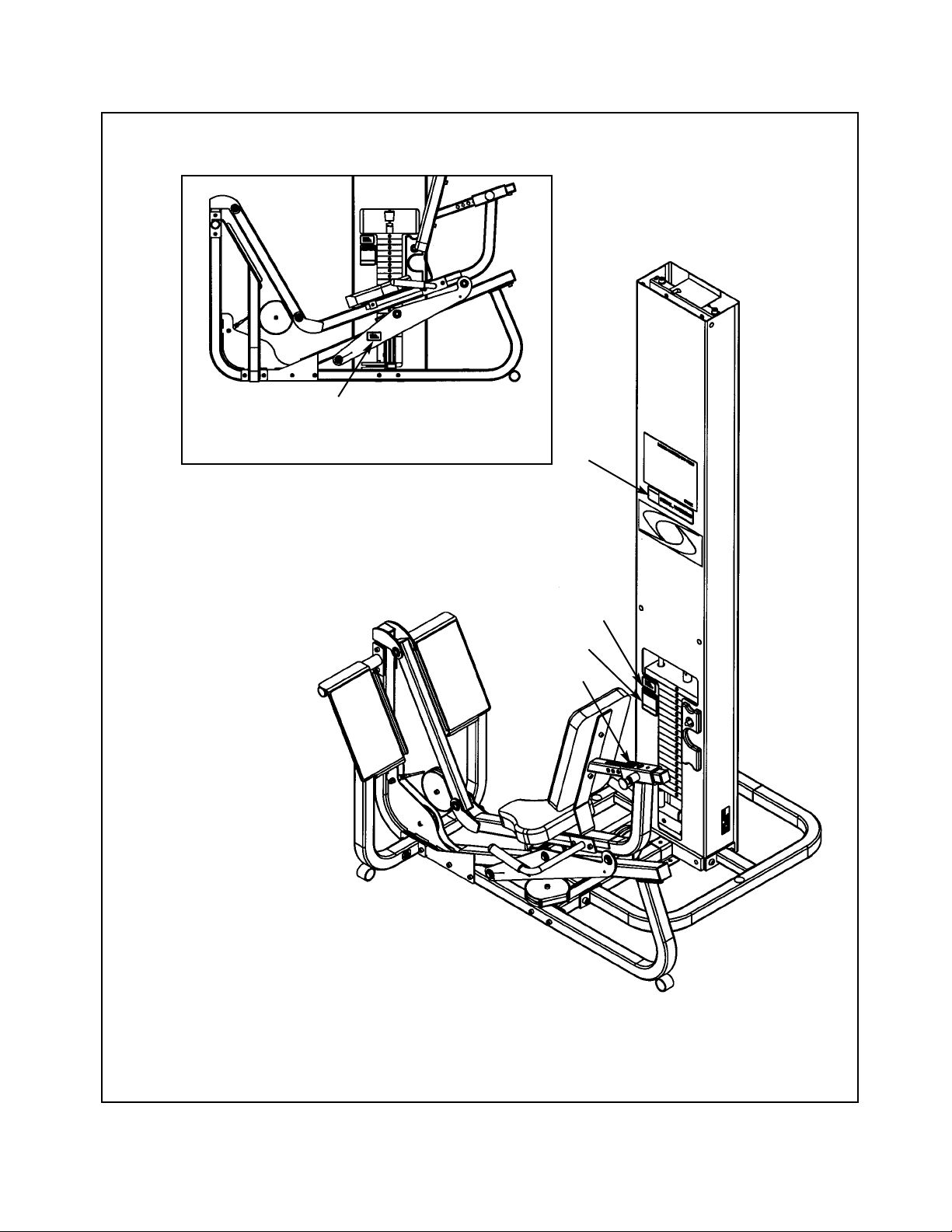

5362 - Modular/Tandem Configuration

Cybex Modular Owner’s Manual

Page 4-28

Page 83

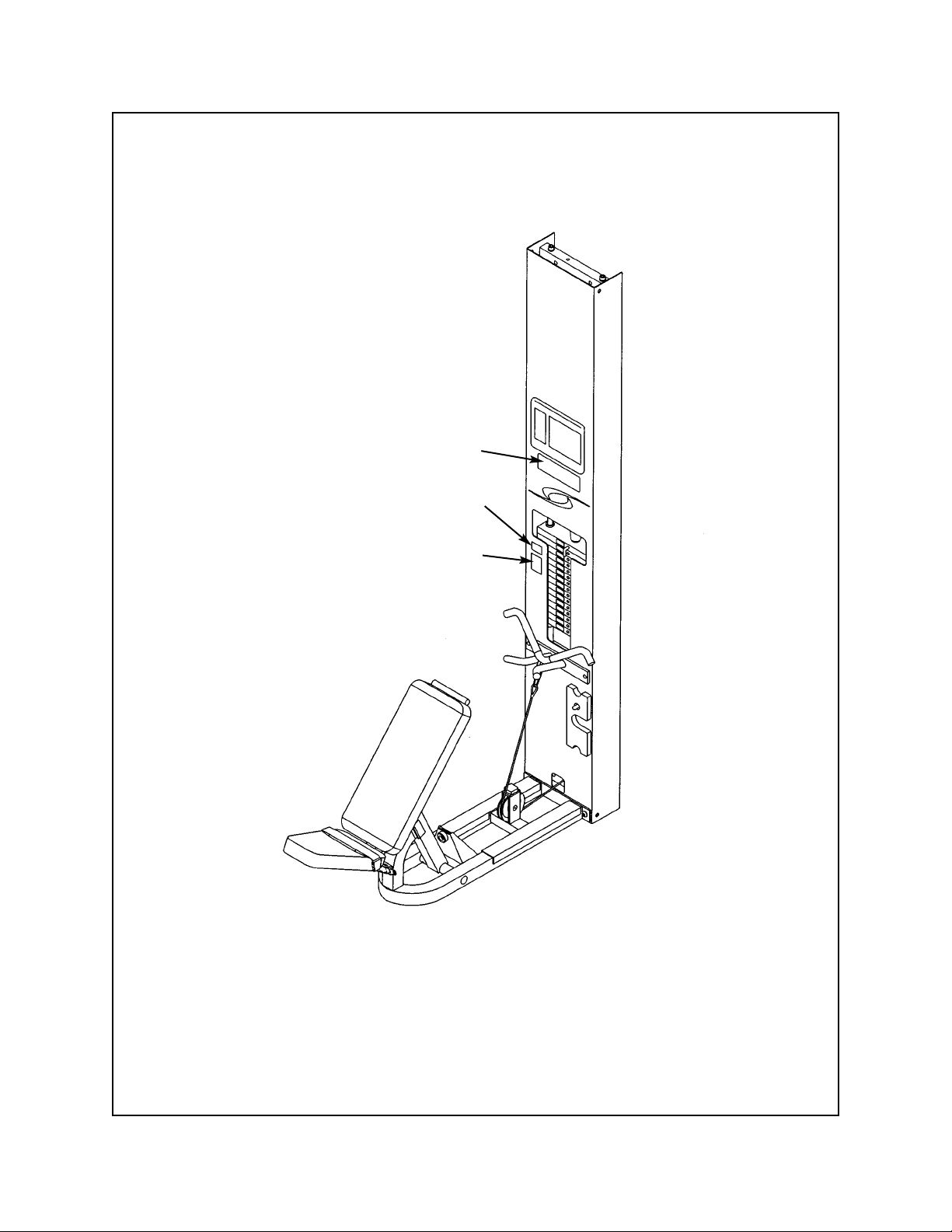

5322 - Free Standing Configuration

Cybex Modular Owner’s Manual

Page 4-29

Page 84

Cable Routing

Cybex Modular Owner’s Manual

Page 4-30

Page 85

Cybex Modular Owner’s Manual

Page 4-31

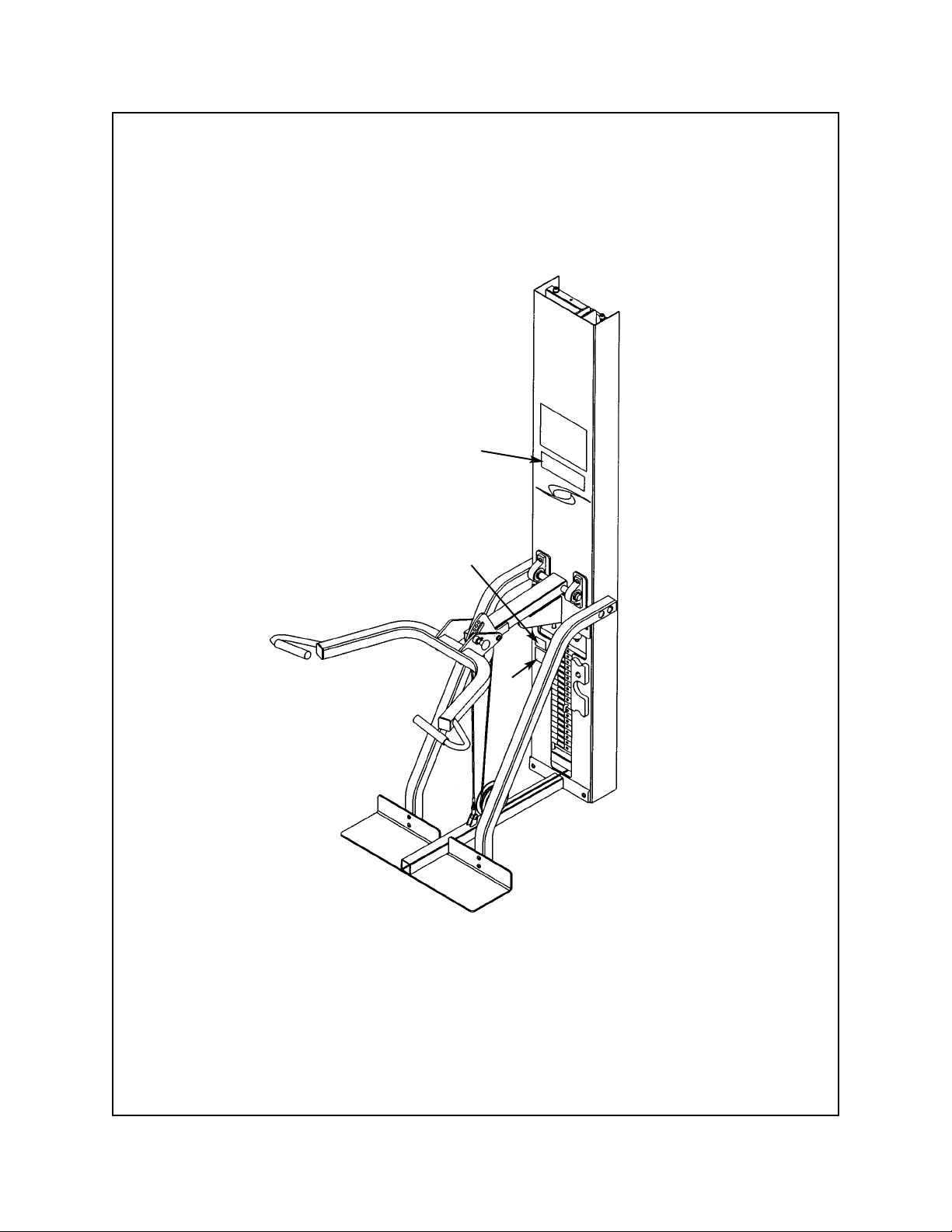

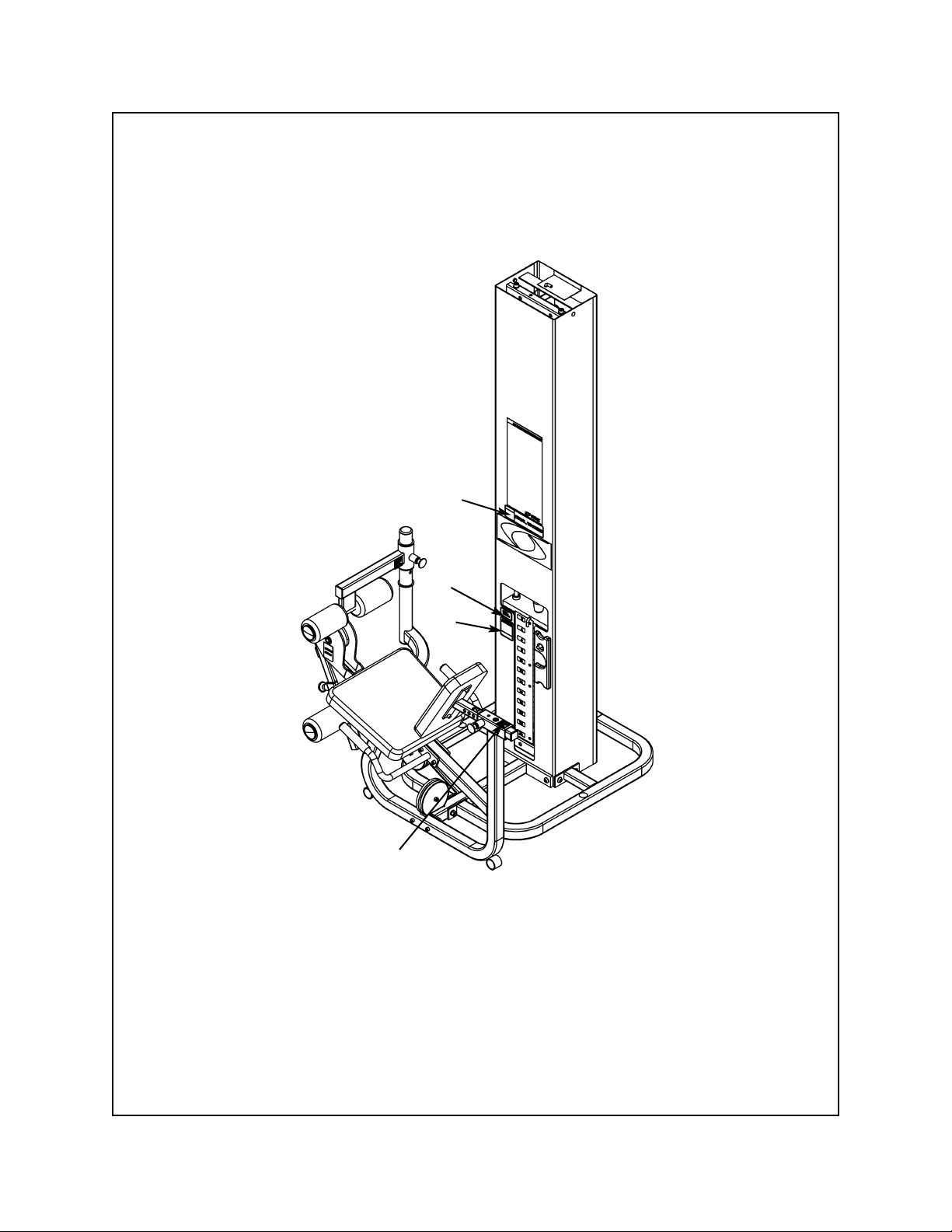

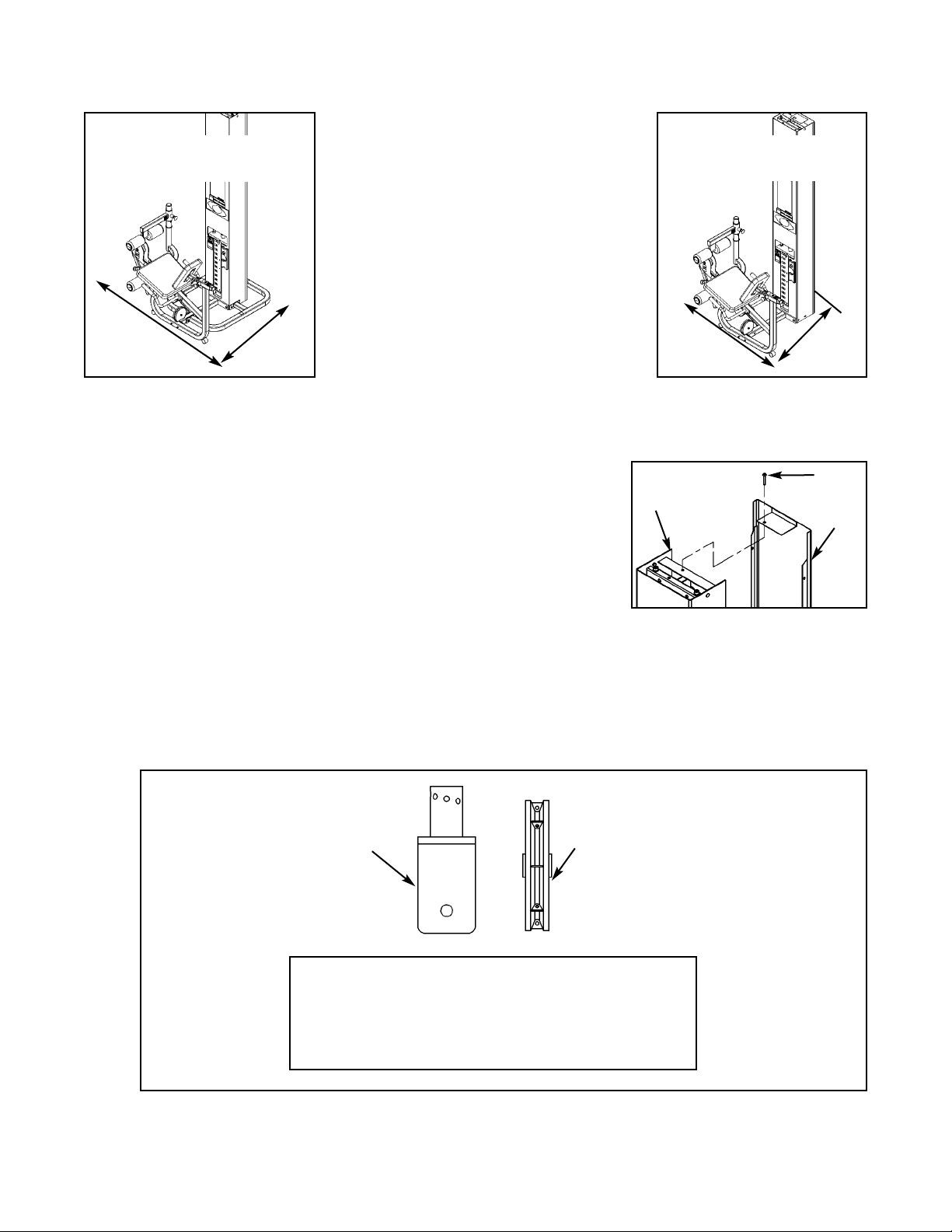

Modular Leg Extension/Leg Curl

5653 Modular/Tandem Configuration

5307 Free Standing Configuration

TOOLS REQUIRED

• 5/32” Allen wrench

• 7/32” Allen wrench

• 5/16” Allen wrench

• 3/8” Allen wrench

• 9/16” Socket/wrench

• 3/4” Socket/wrench

• Rubber mallet

• Step ladder

NOTE: A minimum of two people will be required to assemble the Leg Extension/Leg Curl.

1. Read and understand all instructions thoroughly before assembling the Leg Extension/Leg

Curl (LE/LC) (see steps A - C).

A. Locate the Modular Assembly & Service manual that you received with your order. If you did

not receive a manual contact Cybex Customer Service and ask for part number 55620.

B. If you are assembling the Leg Extension/Leg Curl station into a Tandem configuration, locate

and review the Tandem Center Post instructions contained with the Tandem configuration (this

sheet is also located in the Modular Assembly & Service manual). Skip step 1 in the Tandem

Center Post instructions.

C. If you are assembling the Leg Extension/Leg Curl station into a Modular configuration, locate

and review the Modular Center Post instructions contained with the Modular configuration.

Skip step 1 in the Modular Center Post instructions.

2. Verify you have received the appropriate configuration (see steps 2A - 2C, Figures 1 and 2).

• Hammer

• Utility knife

• Automotive engine oil

Assembly Instructions

Unpacking

A. If you ordered the Modular/Tandem

configuration (5653):

Shipping Package Part Number

• LE/LC Column 5653-9x

• LE/LC Package 5653-50

• Weight Package 4700S040

• Weight Package 4700S043

• Top Weight Package 4700-010

• Cushion Set 8640-011

B. If you ordered the Free Standing

configuration (5307):

Shipping Package Part Number

• LE/LC Column 5307-9x

• LE/LC Package 5653-50

• LE/LC Stabilizer 5302-51

• Weight Package 4700S040

• Weight Package 4700S043

• Top Weight Package 4700-010

• Cushion Set 8640-011

Page 86

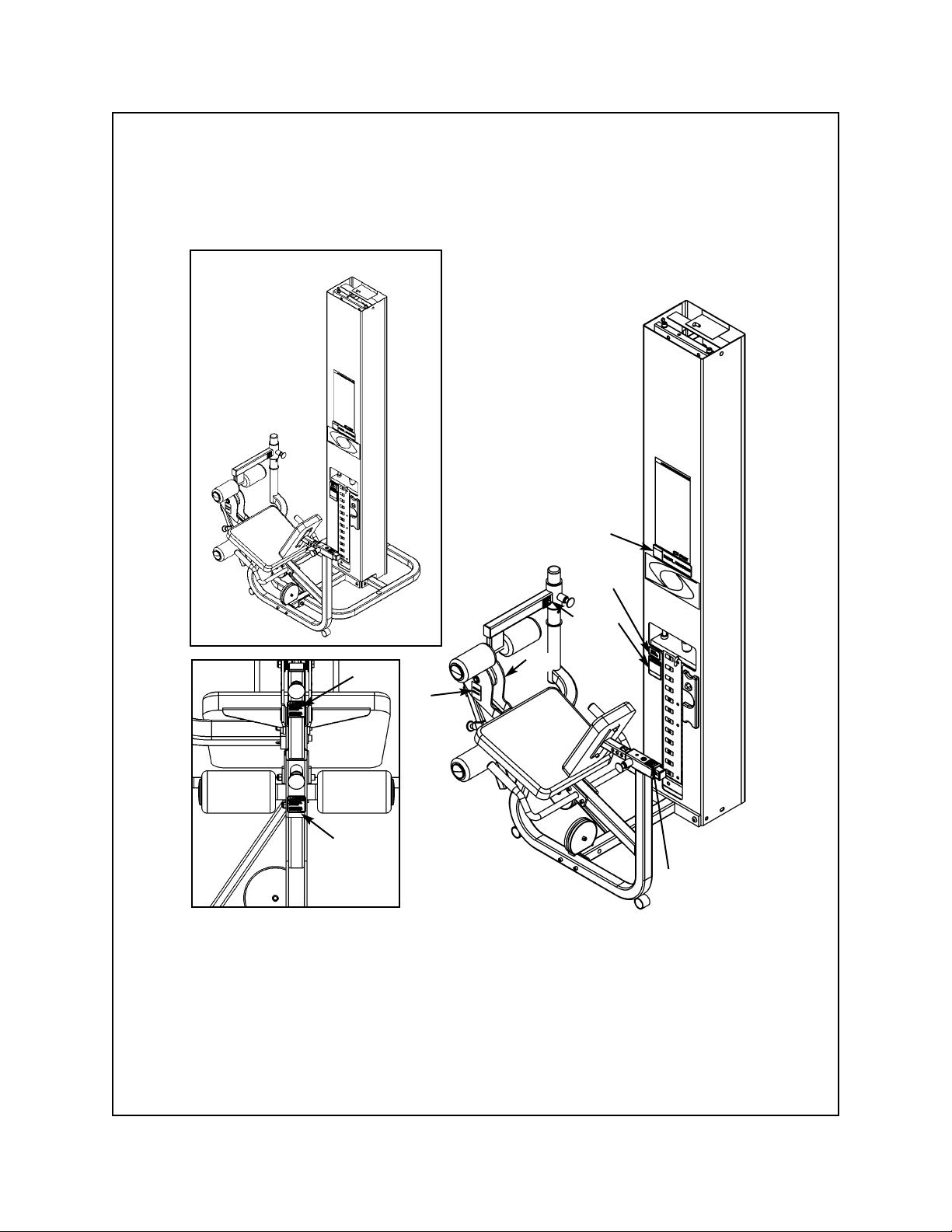

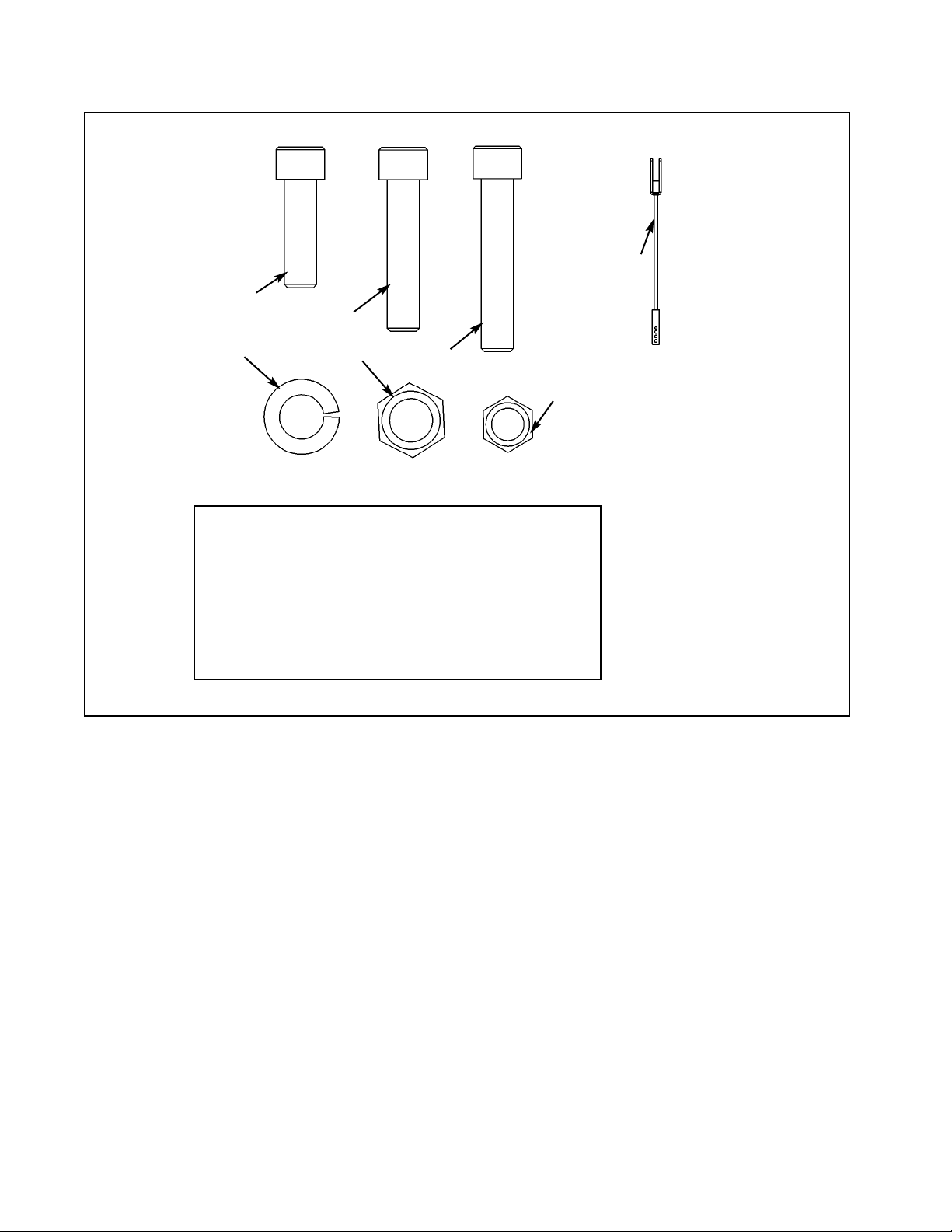

3. Unpack the carton containing the column (see steps 3A - 3F and Figures 3 - 7).

A. Locate and open the Leg Extension/Leg Curl Column carton.

B. The column (#78) should be laying so that the back side is

facing upward.

C. For Free Standing units containing a back cover, remove the

BHSCS .375-16 x 2.00 (#69) securing the back cover (#74).

Remove back cover by sliding it then lifting it upward. See

Figure 3.

D. Remove any shipping supports and the carton located inside the column.

E. Verify contents of the carton. See Figure 4.

Figure 3

69

78

74

Figure 1

Figure 2

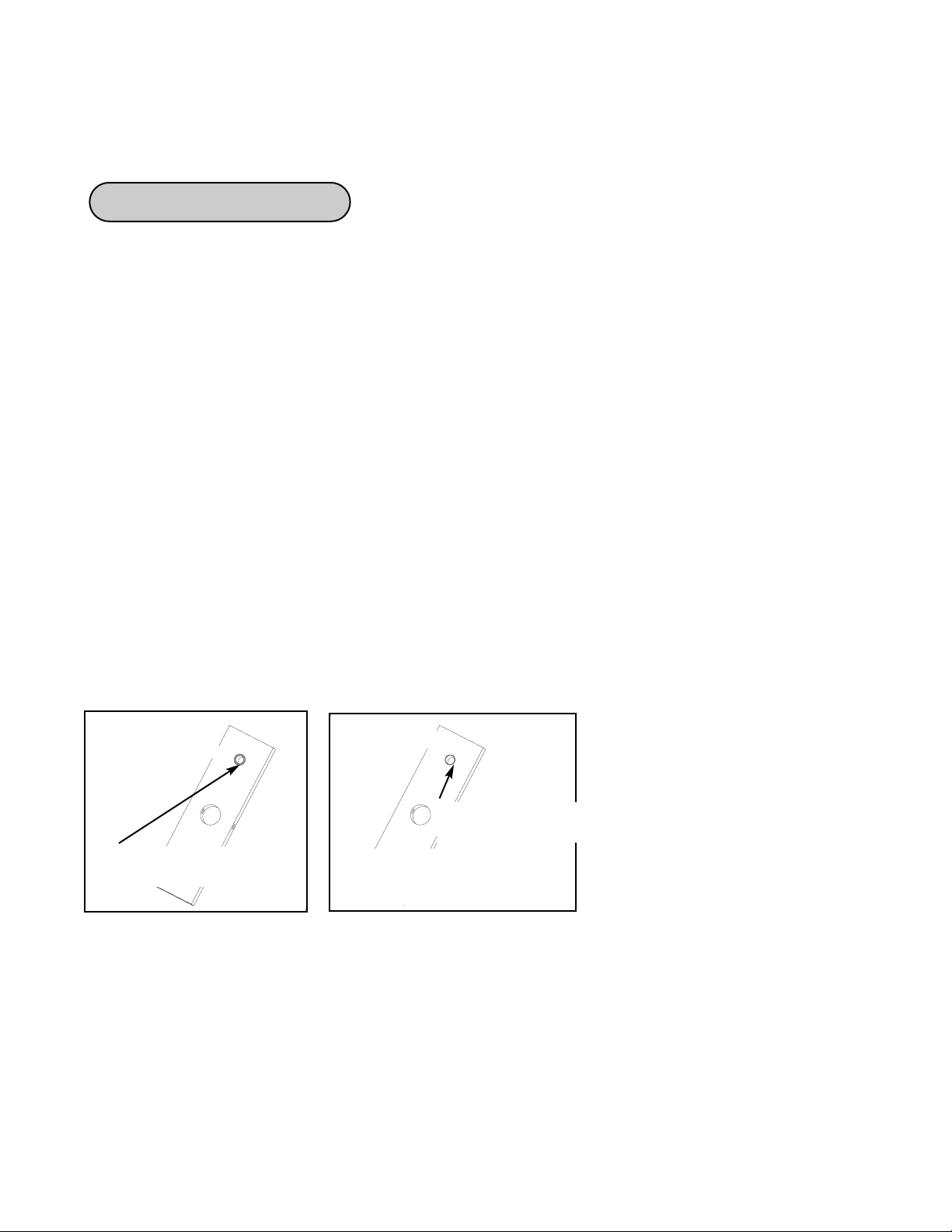

C. Carefully place shipping

packages near area of

installation.

D. For Free Standing configurations,

allow a minimum amount 88” x

76”. See Figure 1.

E. For Modular/Tandem

configurations, allow a minimum

of 88” x 67”. See Figure 2.

1 3 08014 Pulley Assembly 4.50

40 1 02120 Pulley Mount

1 Hardware Pack

1 Hardware Pack

ITEM QTY PART NO. DESCRIPTION

40

1

Figure 4

88”

76”

88”

67”

Minimum space required

during operation.

Minimum space required

during operation.

Cybex Modular Owner’s Manual

Page 4-32

Page 87

Figure 5

26 1 HC702826 SHCS .375-16 x 2.00

29 3 JC702824 SHCS .375-16 x 1.75

53 1 5653-003 Weight Stack Cable

57 4 HN704901 Nylon Locknut .375-16

ITEM QTY PART NO. DESCRIPTION

57

26

29

F. Remove both hardware packs from the carton and verify the contents of each. See

Figures 5 - 7.

NOTE: Figures 5 and 6 are for the Free Standing configuration.

Figures 6 and 7 are for the Tandem/Modular configuration.

Figure 6

67 1 02106 Half Weight Peg

73 1 4800-515 Weight Plate Decal

82 1 HS308300 Split Lockwasher .25

84 1 JC620415 BHSCS .25-20 x .75

1 55653 Assembly Instructions

ITEM QTY PART NO. DESCRIPTION

82

67

84

73

53

Cybex Modular Owner’s Manual

Page 4-33

Page 88

Figure 7

26 1 HC702826 SHCS .375-16 x 2.00

29 3 JC702824 SHCS .375-16 x 1.75

53 1 5653-003 Weight Stack Cable

57 4 HC704901 Nylon Locknut .375-16

59 4 JC702820 SHCS .50-13 x 1.25

64 4 HN784000 Hex Nut .50-13

87 4 JS388300 Split Lockwasher .50

ITEM QTY PART NO. DESCRIPTION

59

29

26

57

64

87

53

Cybex Modular Owner’s Manual

Page 4-34

Page 89

4. Attach column to the appropriate configuration (see steps 4A - 4F, Figures 8 and 9).

NOTE: For Free Standing configuration, see steps 4A - 4C then go to step 5.

For Tandem configuration see step 4D and 4E then go to step 5.

For Modular configurations see step 4D and 4F then go to step 5.

A. Place the base assembly (#65) in area where the station will be used.

B. Remove the hardware from the base (#65A) as shown in Figure 8.

65 1 5302-51 Base Assembly

65A 1 5301-200 Base

65B 5 HN784000 Hex Nut .50-13

65C 4 JC780417 BHSCS .50-13 x 1.00

65D 1 JC782836 SHCS .50-13 x 3.25

65E 5 JS388300 Split Lockwasher .50

1 Shipping Block

ITEM QTY PART NO. DESCRIPTION

Figure 8

C. With an assistant, carefully place

column (#78) into stabilizer

(#65A) then attach hardware as

shown in Figure 9.

65C

65C

Figure 9

65B

65E

65C

65E

65B

65E

65C

65C

65C

65D

65E

65B

65A

Shipping Block

65E

65A

78

Cybex Modular Owner’s Manual

Page 4-35

Page 90

D. For Tandem and Modular configurations, locate four SHCS .50-13 x 1.25 (#59), four split

lockwashers .50 (#87) and four hex nuts .50-13 (#64). See Figure 7 (hardware pack).

E. For the Tandem configuration, using the hardware located in step 4D, attach both columns to

frame as shown in the Tandem Center Post & Dome Installation instruction sheet.

NOTE: The generic column shown in the Tandem and Modular instruction sheets will slightly

differ in appearance than the Leg Extension/Leg Curl Column (an angle bracket is used

instead of a tube).

F. For the Modular configuration, using the hardware located in step 4D, install angle braces

onto each column. See the exploded-view diagram shown in the Modular Center Post

Installation Instruction sheet.

5. Install the Leg Extension/Leg Curl Assembly to the appropriate configuration (see steps 5A 5F and Figures 10 - 12B).

A. Locate the Leg Extension/Leg Curl assembly and hardware pack.

B. Verify contents of hardware pack. See Figure 10.

Figure 10

38 1 HP286819 Spiral Pin

39 1 8640-330 Spring Pin 10 mm x 90 mm Black

60 2 JC780420 BHSCS .50-13 x 1.25

61 2 PN660201 Hole Plug

64 2 HN784000 Hex Nut .50-13

87 2 JS388300 Split Lockwasher .50

90 2 JC702820 SHCS .375-16 x 1.25

ITEM QTY PART NO. DESCRIPTION

87

39

60

64

38

64

61

Cybex Modular Owner’s Manual

Page 4-36

Page 91

Figure 11

C. Locate two BHSCS .50-13 x 1.25 (#60), two split lockwashers .50 (#87), two hex nuts .50-13

(#64) and two hole plugs (#61). For the Free Standing configuration, also locate (from step 4B)

one SHCS .50-13 x 3.25 (#65D), one split lockwasher .50 (#65E) and one hex nut .50-13

(#65B).

D. Install the Leg Extension/Leg Curl Assembly to the column. See Figure 12 for

Modular/Tandem configurations and Figures 12A and 12B for Free Standing configuration.

E. Install hole plugs (#61) to the Leg Extension/Leg Curl Assembly (Modular/Tandem

configurations only). See Figure 11.

Figure 12A

Figure 12B

65B

65E

65D

60

60

87

87

64

60

60

87

87

64

61

61

Cybex Modular Owner’s Manual

Page 4-37

Page 92

F. For Modular configuration only, see step 4 of the Modular Center Post installation instructions,

part number 55600.

6. Install weight stack (see steps 6A - 6O, Figures 13 - 15).

A. Locate the half weight peg (#67), BHSCS .25-20 x .75 (#84) and split lockwasher (#82) from

the column hardware pack shown in Figure 5.

B. Install the half weight peg (#67) as shown in Figure 13.

Figure 13

C. Locate the top weight package and verify the contents. See Figure 14.

63 1 4700-010 Top Weight Assembly

63B 1 4700M005 Rubber Boot

63C 1 4700-307 Top Weight 20-4 x 12

63E 1 5310P044 Weight Selector Pin

63G 1 C-ZA00200 Half Weight

63H 1 HP286819 Spiral Pin

ITEM QTY PART NO. DESCRIPTION

Figure 14

84

82

67

63C

63B

63H

63E

63G

Cybex Modular Owner’s Manual

Page 4-38

Page 93

D. Verify that you received 20 weight plates.

E. Remove the two SHCS securing the guide rods.

F. Carefully lean guide rods away from column.

G. Remove guide rod collets and plastic caps.

H. Wipe guide rods clean over entire length. Lubricate with light coating of medium weight

automotive engine oil.

I. Install each weight plate one at a time. NOTE: Do not install the second weight and top

weight at this time.

J. Locate the spring pin 10 mm x 90 mm black (#39).

K. Slide the top weight plate onto second plate and carefully pound

the spring pin into the second weight plate hole, securing second

plate to the top plate. See Figure 15. NOTE: Insert pin so that it is

flush with the weight plate.

L. Install top weight.

M. Replace plastic caps and guide rod collets on guide rods.

N. Return guide rods to full upright position.

O. Insert both SHCS that were removed in step 6E (securing guide rods).

NOTE: Do not secure top weight at this time.

Figure 15

39

Pin

second

weight

Cybex Modular Owner’s Manual

Page 4-39

Page 94

Figure 16

7. Routing Cable (see steps 7A - 7J and Figure 16).

A. Install upper assemblies to any stations within the

Modular/Tandem configuration that contain upper

assemblies. See the Modular and Tandem

installation instructions.

B. Locate weight stack cable (#53), four pulleys (#1),

pulley mount (#40), three SHCS .375-16 x 1.75

(#29), one SHCS .375-16 x 2.00 (#26) and four

nylon locknuts .375-16 (#57) and one spiral pin

(#38).

C. Route cable to inside of column (#78). See Figure

16, letter D.

D. At the same time, install pulley to lower pulley

bracket and route cable (#53) using one pulley

(#1), one SHCS .375-16 x 1.75 (#29) and one

nylon locknut .375-16 (#57). See Figure 16,

letter D. Set cable down.

E. Attach one end of the weight stack cable (#53) to

the frame as shown in Figure 16 (using one SHCS

.375-16 x 1.75 (#29) and one nylon locknut .37516 (#57). See Figure 16, letter E.

F. NOTE: Do not install hanging pulley in this step.

At the same time, route cable (#53) and install the

last pulley before the weight stack (using one

SHCS .375-16 x 1.75 (#29) and one nylon locknut

.375-16 (#57). See Figure 16, letter F.

G. Pick up the other cable and install the pulley

mount (#40). Drive a spiral pin (#63H) through

cable end and pulley mount as shown in Figure

16, letter G.

H. Wrap a portion of the weight stack cable (#53)

around the last pulley (#1) to be installed. At

the same time, route cable (#53) and install

pulley (#1) using one SHCS .375-16 x 2.00

(#26) and one nylon locknut (#57).

I. Route cable downward to top plate. Slide rubber

boot (#63B) onto cable. Drive a spiral pin through

top plate connector and cable end. The top

weight should be snug (just resting on the next

plate). See Figure 16, letter H.

J. Slide rubber boot over top weight connector.

1

53

57

57

29

1

29

1

26

57

53

38

C

D

I, J

E, F

G

63B

63H

78

40

NOTE:

See the Modular

Assembly & Service

Manual for proper roll

pin adjustment (if

necessary).

Cybex Modular Owner’s Manual

Page 4-40

Page 95

K. For Free Standing units, place back cover (#74) to column (#78) into position (bottom first)

and secure using the BHSCS .375-16 x 2.00 (#69) that was removed from step 3C. See

Figure 17.

Figure 17

69

74

78

Cybex Modular Owner’s Manual

Page 4-41

Page 96

8. Install Weight Plate Decal and Half Weight

(see steps 9A - 9H, Figures 19 and 20).

A. Locate the weight plate decals.

B. Place weight plate decals on weight plates

according to steps listed below and Figures

18 and 19.

C. Slowly and carefully peel off back side of

decal. NOTE: When peeling off back cover,

make sure that the decals remain attached to

the front sticker.

D. Align holes in decal with appropriate holes in

weight stack. NOTE: Do not allow the

adhesive to touch weight stack at this time.

E. Insert a guide pin through each hole of the

template. NOTE: A guide pin can be any-

thing that fits through the weight stack hole,

such as a weight stack selector pin.

F. Carefully align decal and rub it onto weight

plates.

G. Carefully remove front side, leaving decals

adhering to weight plates. See Figure 19.

H. Locate half weight and install it on the half weight peg.

10. Install the back and seat cushions (see steps 10A - 10I and Figures 20 - 21).

A. Locate the cushion box and verify the contents as shown in Figure 20.

Figure 18

Decal

Weight Stack

Guide Rod

Figure 19

Figure 20

36

37

11

33

Cybex Modular Owner’s Manual

Page 4-42

Page 97

Figure 21

B. Locate the back cushion (#36), seat cushion (#37), four cushions 4.00 Dia. x 7.00 L x .875

(#11), four plastic inserts (#33) and two SHCS .375-16 x 1.25 (#59).

C. Install back cushion (#36) using two SHCS .375-16 x 1.25 (#59) as shown in Figure 21.

D. Install seat cushion (#37) using two SHCS .375-16 x 3.00 (#27) secured into the frame.

Remove the hex nut and washer then install each SHCS into the cushion. See Figure 21.

37

90

36

27

90

27

Cybex Modular Owner’s Manual

Page 4-43

Page 98

11. Verify proper operation.

12. Verify warning decals are present and not damaged (see decals below and Figure 22).

A

D

B

C

E

Cybex Modular Owner’s Manual

Page 4-44

WARNING

Notify floor staff if plates are

elevated or jammed to avoid

injury.

02521 A

Page 99

A. Warning Decal ................... 02521

B. Caution Decal .................... 4000Y316

C. Warning Decal ................... 4800-381

D. Caution Decal .................... 8500-025

E. Caution Decal .................... 8500-026

DESCRIPTION PART NO.

D

Figure 22

A

B

C

D

D

E

D

E

Cybex Modular Owner’s Manual

Page 4-45

Page 100

1 3 08014 Pulley

26 2 HC702826 SHCS .375-16 x 2.00

27 2 HC702834 SHCS .375-16 x 3.00

29 3 JC702824 SHCS .375-16 x 1.75

36 1 4800-021 Back Cushion

37 1 4800-015 Seat Cushion

38 1 HP286819 Spiral Pin

39 1 8640-330 Spring pin 10 mm x 90 mm Black

40 1 02120 Pulley Mount

53 1 5653-003 Weight Stack Cable

57 3 HN704901 Nylon Locknut .375-16

58 2 HN784900 Nylon Locknut .50-13

59 4 JC782820 SHCS .375-16 x 1.25

60 2 JC780420 BHSCS .50-13 x 1.25

61 2 PN660201 Hole Plug

62 20 4000C062 Weight Plate 4 x 12

63 1 4700-010 Top Weight Assembly

63A 2 4700-019 Bearing Flange .62 x .92 x 1.50 Lg

63B 1 4700M005 Rubber Cap

63C 1 4700-307 Top Weight 20-4 x 12

63D 1 4700M004 Cable Connector

63E 1 5310P044 Weight Selector Pin

63F 2 BR030206 Retaining Ring

63G 1 C-ZA000200 Half Weight

63H 1 HP286819 Spiral Pin

64 4 HN784000 Hex Nut .50-13

65 1 5302-51 Modular Base Assembly

65A 1 5301-200 Base

65B 5 HN784000 Hex Nut .50-13

65C 4 JC780417 BHSCS .50-13 x 1.00

65D 1 JC782836 SHCS .50-13 x 3.25

65E 5 JS388300 Split Loackwasher .50

66 2 01755 Guide Rod Collet - Long

67 1 02106 Half Weight Peg

69 1 HC700426 BHSCS .375-16 x 2.00

74 1 5310C029 Back Cover

75 2 5310M035 Weight Rod .625 Dia. x 85.31

78 1 5653-200 Column

79 2 5653-302 Weight Spacer 4.00

82 1 HS308300 Split Lockwasher

83 4 HS760106 Flat Washer 1.75 .688 .140 T

84 1 JC620415 BHSC .25-20 x .75

86 2 JC782830 SHCS .50-13 x 2.50

87 6 JS388300 Split Lockwasher .50

88 2 PP080204 Plastic Cap .625 ID x .68 OD

89 2 PR060005 Bumper Weight

90 2 JC7082820 SHCS .375-16 x 1.25

5307/5653 - Leg Extension/Leg Curl Station

ITEM QTY PART NO. DESCRIPTION ITEM QTY PART NO. DESCRIPTION

Cybex Modular Owner’s Manual

Page 4-46

Loading...

Loading...