IT

. S811 Soft Starter

User Manual

November 2006 — Revision 6

Supersedes June 2006 — Revision 5

IT

. S811 Soft Starter User Manual

November 2006

Important Notice – Please Read

The product discussed in this literature is subject to terms and conditions outlined in Eaton

Electrical Inc. selling policies. The sole source governing the rights and remedies of any

purchaser of this equipment is the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE

OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton

Electrical Inc. be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability or otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

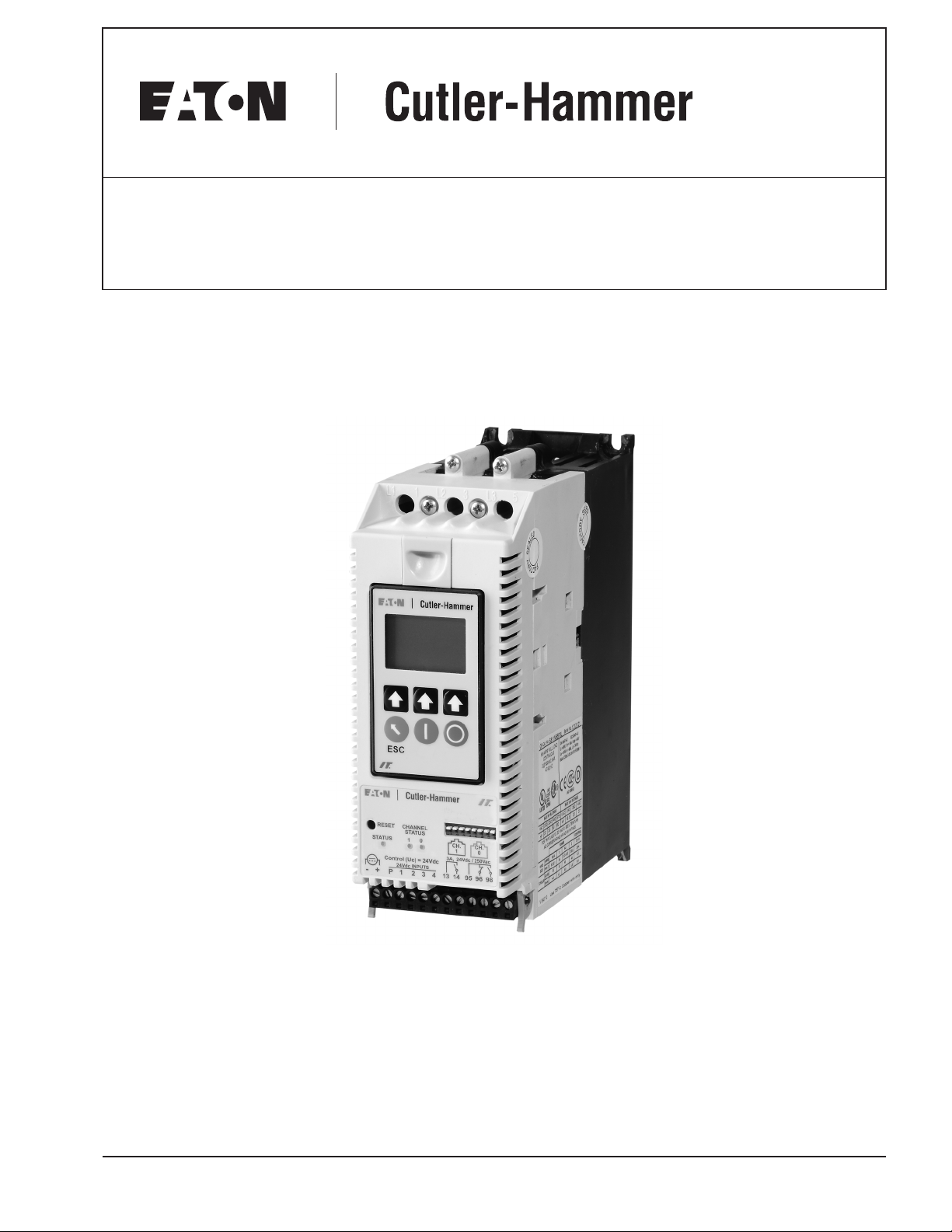

Cover Photo: The Cutler-Hammer

®

Intelligent Technologies ( IT. ) Soft Starter

MN03902002E

For more information visit: www.EatonElectrical.com

i

IT

. S811 Soft Starter User Manual

Table of Contents

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

SAFETY

The Meaning of Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

IT. Soft Starter Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Dangers, Warnings, Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

CHAPTER 1 — OVERVIEW

General Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Appearance Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

CHAPTER 2 — RECEIPT/UNPACKING

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CHAPTER 3 — INSTALLATION

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Control Wiring Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

CHAPTER 4 — SPECIFICATIONS

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

CE Conformance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Short Circuit Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 5 — FUNCTIONAL DESCRIPTION

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

QCPort Network Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

CHAPTER 6 — CONFIGURATION

Programming the S811 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

S801 to S811 Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

CHAPTER 7 — SETUP AND STARTING

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

CHAPTER 8 — TROUBLESHOOTING

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Before You Begin to Troubleshoot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Define the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

CHAPTER 9 — PARTS AND SERVICE

Renewal Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

November 2006

ii

For more information visit: www.EatonElectrical.com

MN03902002E

IT

November 2006

Table of Contents, Continued

APPENDIX A — PARAMETERS

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

APPENDIX B — PROTECTION

Thermal Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Overload Trip Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

S811 and Motor Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

APPENDIX C — RATINGS, COOLING AND POWER LOSSES

FOR A LINE CONNECTED MOTOR

Horsepower and kW Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Power Losses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

APPENDIX D — RATINGS, COOLING AND POWER LOSSES

FOR AN INSIDE-THE-DELTA CONNECTED MOTOR

Horsepower and kW Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Power Losses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

APPENDIX E — MOTOR/APPLICATION CONSIDERATIONS

Using MOVs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Squirrel Cage Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Wye-Delta Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Part Winding Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Dual Voltage Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Multi-Speed Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Other Winding Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Power Factor Correction Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

APPENDIX F — SPECIAL FUNCTION OPTIONS

Pump Control Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Extended Ramp Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

APPENDIX G — USER INTERFACE — DIM

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Button Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Areas of the Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Parameter Navigation/Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Access Level (Password) Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

DIM System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-13

DIM Setup Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-14

APPENDIX H — QCPORT NETWORK

QCPort Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-3

Auto and Hand/Local Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-5

APPENDIX I — QCPORT PARAMETER DESCRIPTIONS

Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Configuration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-6

. S811 Soft Starter User Manual

MN03902002E

For more information visit: www.EatonElectrical.com

iii

. S811 Soft Starter User Manual

List of Figures

Figure 1-1: The Cutler-Hammer Intelligent Technologies ( IT. ) S811 Soft Starter . . . . . . 1-2

Figure 3-1: Warning Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2: Power Wiring Alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

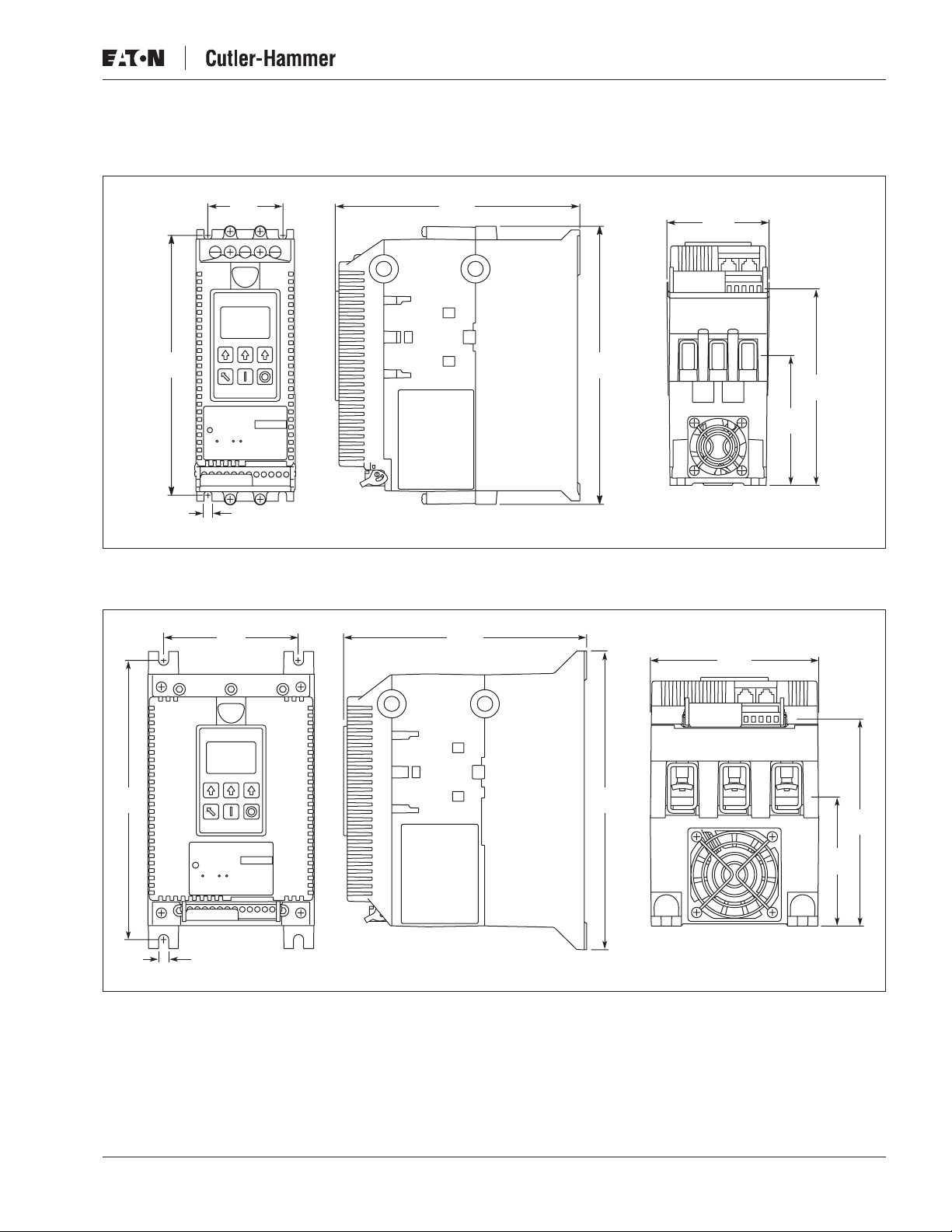

Figure 3-3: N Frame (65 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4: R Frame (110 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

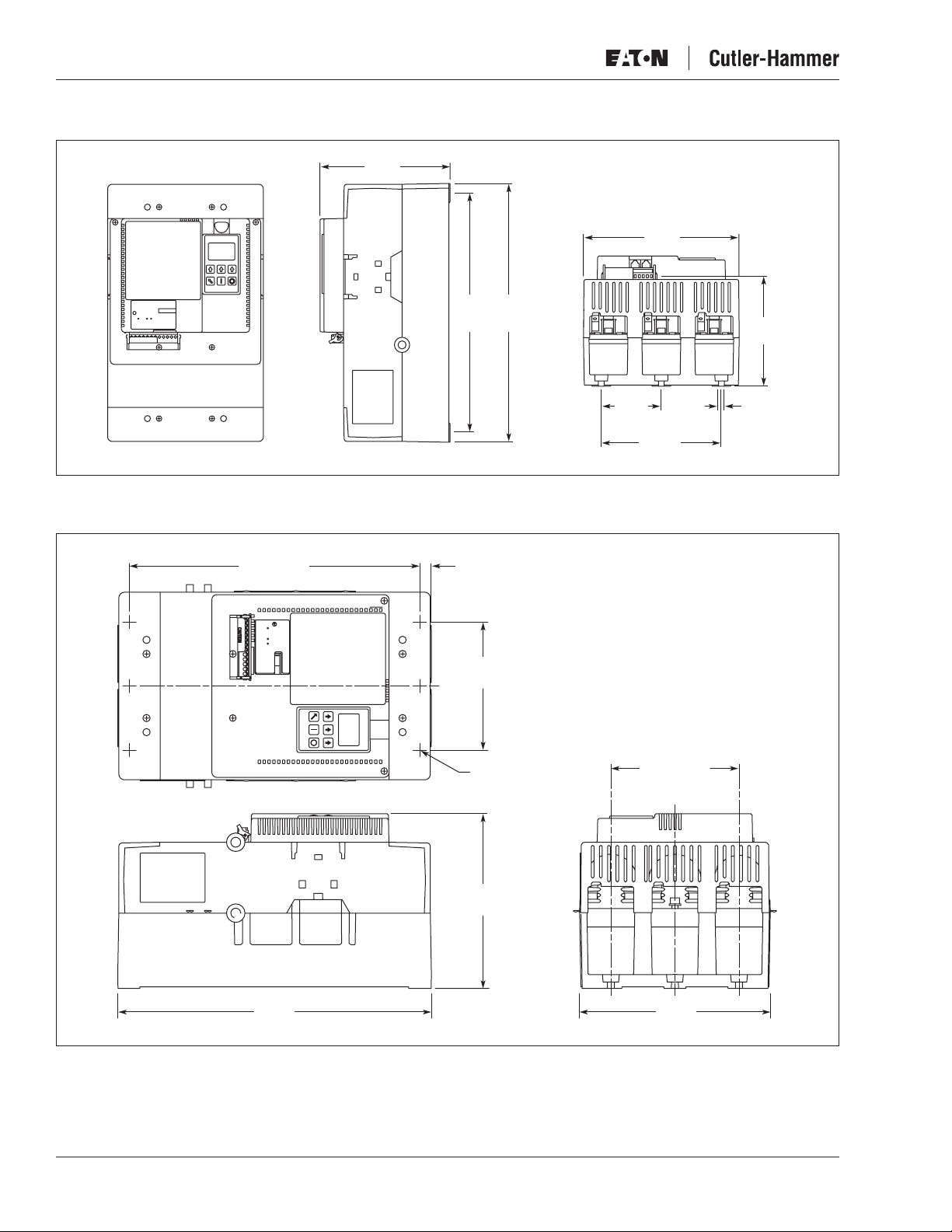

Figure 3-5: T Frame (200 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-6: U Frame (200 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

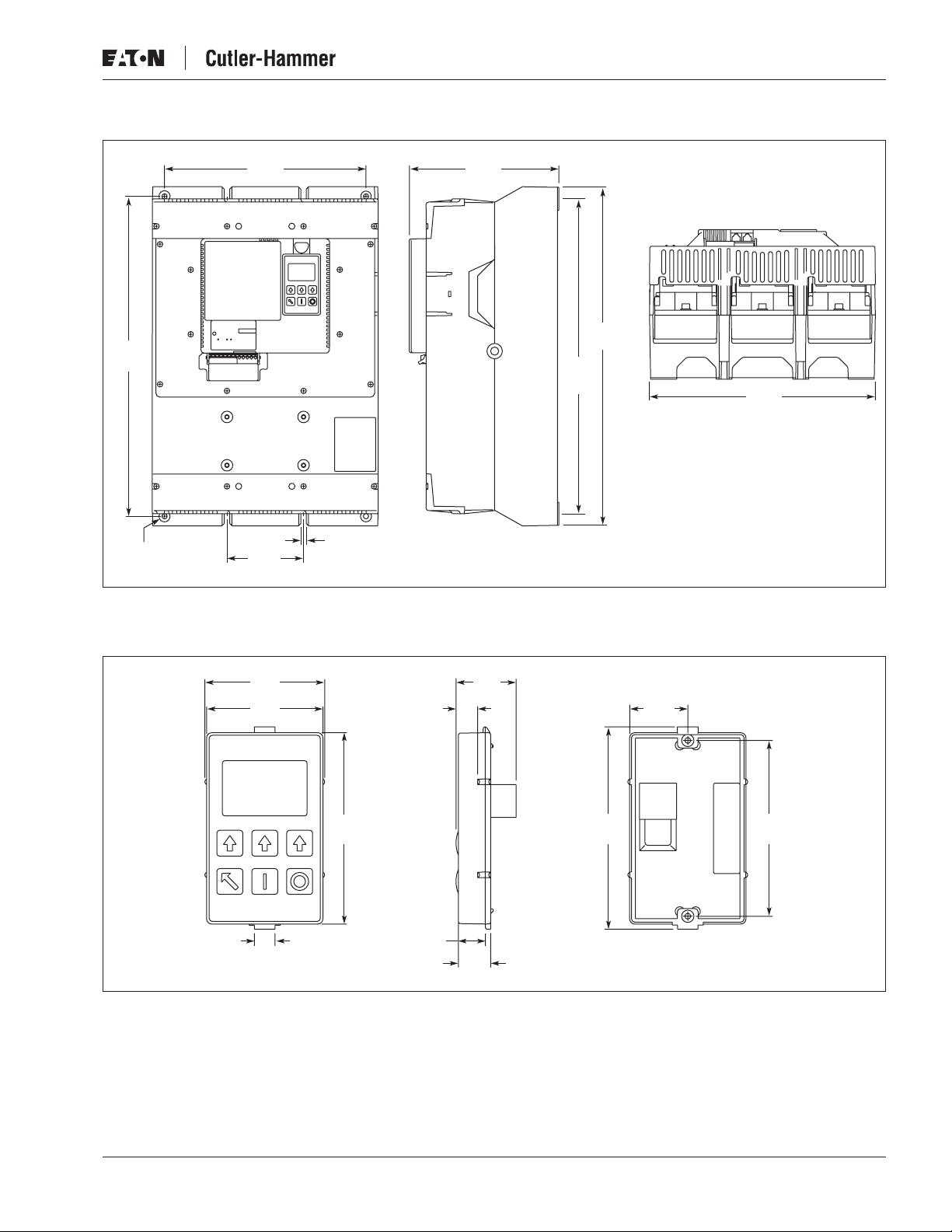

Figure 3-7: V Frame (290 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-8: EMA91 Digital Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-9: Line Connected Soft Starter Power Wiring Diagram . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-10: Delta Connected Soft Starter Power Wiring Diagram

for a 6-Lead Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-11: Delta Connected Soft Starter Power Wiring Diagram

for a 12-Lead Low Voltage Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-12: Delta Connected Soft Starter Power Wiring Diagram

for a 12-Lead High Voltage Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-13: V Frame Shown with Terminal Cover Removed

and EML30 Lug Kit Installed on Load Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-14: Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-15: Basic Connection Diagram for 24V DC 3-Wire Pushbutton

STOP/START/JOG/RESET and 24V DC Fault/Ready and Bypass Indication . . . . . . . 3-16

Figure 3-16: Basic Connection Diagram for 24V DC 2-Wire Switch

HAND/OFF/AUTO/RESET and 24V DC Fault/Ready and Bypass Indication . . . . . . . 3-17

Figure 3-17: Basic Connection Diagram for Use of DIM Control Only . . . . . . . . . . . . . . 3-17

Figure 3-18: 24V DC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 3-19: 120V AC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 3-20: 24V DC Control with Edge Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Figure 5-1: Line Connected Soft Starter SCRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Figure 5-2: Ramp Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-3: Current Limit Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-4: Soft Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 6-1: Digital Interface Module (DIM) — Display Mode . . . . . . . . . . . . . . . . . . . . . . 6-1

Figure 6-2: Digital Interface Module (DIM) — Parameter Edit Mode . . . . . . . . . . . . . . . . 6-2

Figure 8-1: Start Command Troubleshooting Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Figure 8-2: Main Troubleshooting Flowchart #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Figure A-1: Navigation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Figure B-1: Overload Trip Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure F-1: IT. Soft Starter DIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Figure F-2: Pump Start Ramp and Soft Pump Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Figure G-1: DIM (Digital Interface Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Figure G-2: Display Mode LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Figure G-3: Parameter Edit Mode LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Figure G-4: Fault Mode LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Figure G-5: Soft Key Functions Above Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Figure G-6: Predefined Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-4

Figure G-7: Status Bar on LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Figure G-8: Device Connection (User Display Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Figure G-9: Connection Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Figure G-10: Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

Figure G-11: Connection Destination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

Figure G-12: HAND/AUTO Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

IT

November 2006

iv

For more information visit: www.EatonElectrical.com

MN03902002E

IT

November 2006

List of Figures, Continued

Figure G-13: Motor Control Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

Figure G-14: Bar Indicates Menu Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Figure G-15: Bar Indicates Item Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Figure G-16: Bar Indicates Edited Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-9

Figure G-17: Use MORE to Highlight Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-10

Figure G-18: Setting Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Figure G-19: Changing Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

Figure G-20: Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

Figure H-1: QCP Network Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-2

Figure H-2: Two-Wire QCPort System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

Figure H-3: Three-Wire QCPort System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-4

Figure H-4: S811 Motor Control Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-6

List of Tables

. S811 Soft Starter User Manual

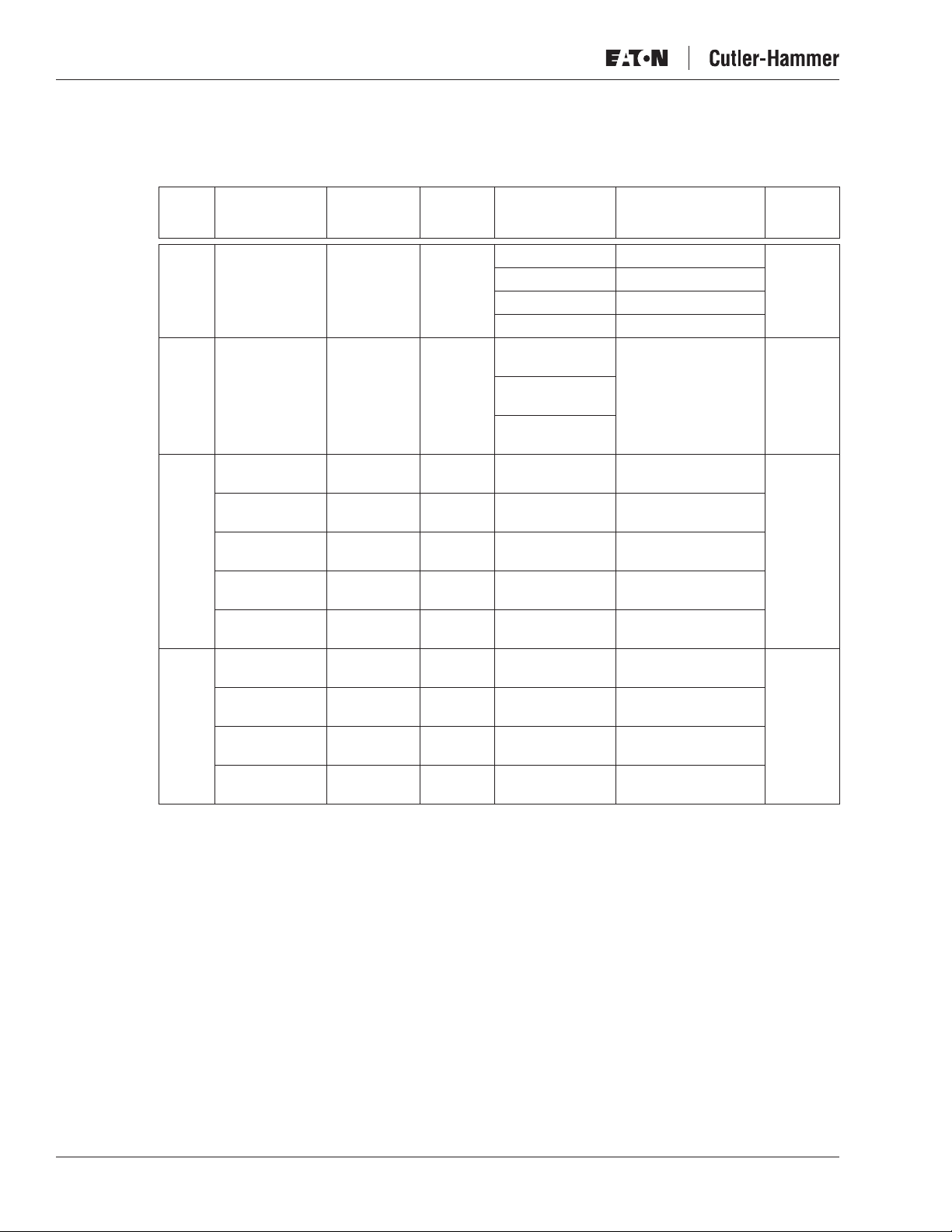

Table 3-1: Required Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-2: Weight Support Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-3: Line and Load Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Table 3-4: 12-Pin Terminal Block Wiring Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Table 3-5: S811 Terminal Block Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Table 3-6: 24V DC Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Table 3-7: 24V DC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Table 4-1: Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-2: Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-3: Agency Standards and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-4: EMC Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-5: Short Circuit Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 6-1: S801 to S811 Setup Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 8-1: Start Command Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Table 8-2: Troubleshooting – Status LED OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-3: Troubleshooting – Status LED GREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-4: Troubleshooting Fault Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Table 8-5: Resetting the S811 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Table 9-1: DIM – Digital Interface Module Renewal Parts. . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Table A-1: Monitoring — Menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-2: Diagnostics — Menu 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table A-3: Soft Start Confg — Menu 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-4: Overload Config — Menu 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-5: Protection Setup — Menu 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Table A-6: Network Setup — Menu 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Table A-7: Network Status — Menu 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Table A-8: LCD DIM Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table B-1: Overload — Adjustment Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Table B-2: Thermal Motor Overload Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table B-3: Motor Parameters Required for Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Table B-4: Instantaneous Over Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Table B-5: Motor Stall Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Table B-6: SCR Over Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Table B-7: Motor Jam Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-8: Motor Over Current Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-9: Motor Under Load Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-10: Current Imbalance Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

MN03902002E

For more information visit: www.EatonElectrical.com

v

. S811 Soft Starter User Manual

List of Tables, Continued

Table B-11: Phase Loss Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Table B-12: Motor Voltage Phase Reversal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Table B-13: Voltage Imbalance Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Table B-14: Under Voltage Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-15: Over Voltage Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-16: Fault Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-17: S811 Protection Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Table C-1: 15 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 40°C . . . . . . . . . C-1

Table C-2: 25 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 40°C . . . . . . . . . C-2

Table C-3: 15 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 50°C . . . . . . . . . C-3

Table C-4: 50 Second Ramp, 2 Starts per Hour, 300% Current Limit @ 50°C . . . . . . . . . C-4

Table C-5: 15 Second Ramp, 4 Starts per Hour, 450% Current Limit @ 40°C . . . . . . . . . C-5

Table C-6: 30 Second Ramp, 4 Starts per Hour, 450% Current Limit @ 40°C . . . . . . . . . C-6

Table C-7: > 30 Second Ramp, > 4 Starts per Hour or >300% Current Limit . . . . . . . . . . C-7

Table C-8: Maximum Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Table D-1: 15 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 40°C Ambient . D-1

Table D-2: 25 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 40°C Ambient . D-2

Table D-3: 15 Second Ramp, 4 Starts per Hour, 300% Current Limit @ 50°C Ambient . D-3

Table D-4: 50 Second Ramp, 2 Starts per Hour, 300% Current Limit @ 50°C Ambient . D-4

Table D-5: 15 Second Ramp, 4 Starts per Hour, 450% Current Limit @ 40°C Ambient . D-5

Table D-6: 30 Second Ramp, 4 Starts per Hour, 450% Current Limit @ 40°C Ambient . D-6

Table D-7: Severe Duty Inside-the-Delta Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Table D-8: Maximum Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Table E-1: MOV Kit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Table G-1: Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Table G-2: Reconfiguring All Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-13

Table G-3: LCD DIM Setup Menu Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-14

IT

November 2006

vi

For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Peligro

Advertencia

Precaución

!

Aviso

Safety

Eaton’s electrical business has made every effort to provide you with the safest motor starters on

the market. However, we wish to point out how to safely operate and troubleshoot your starter.

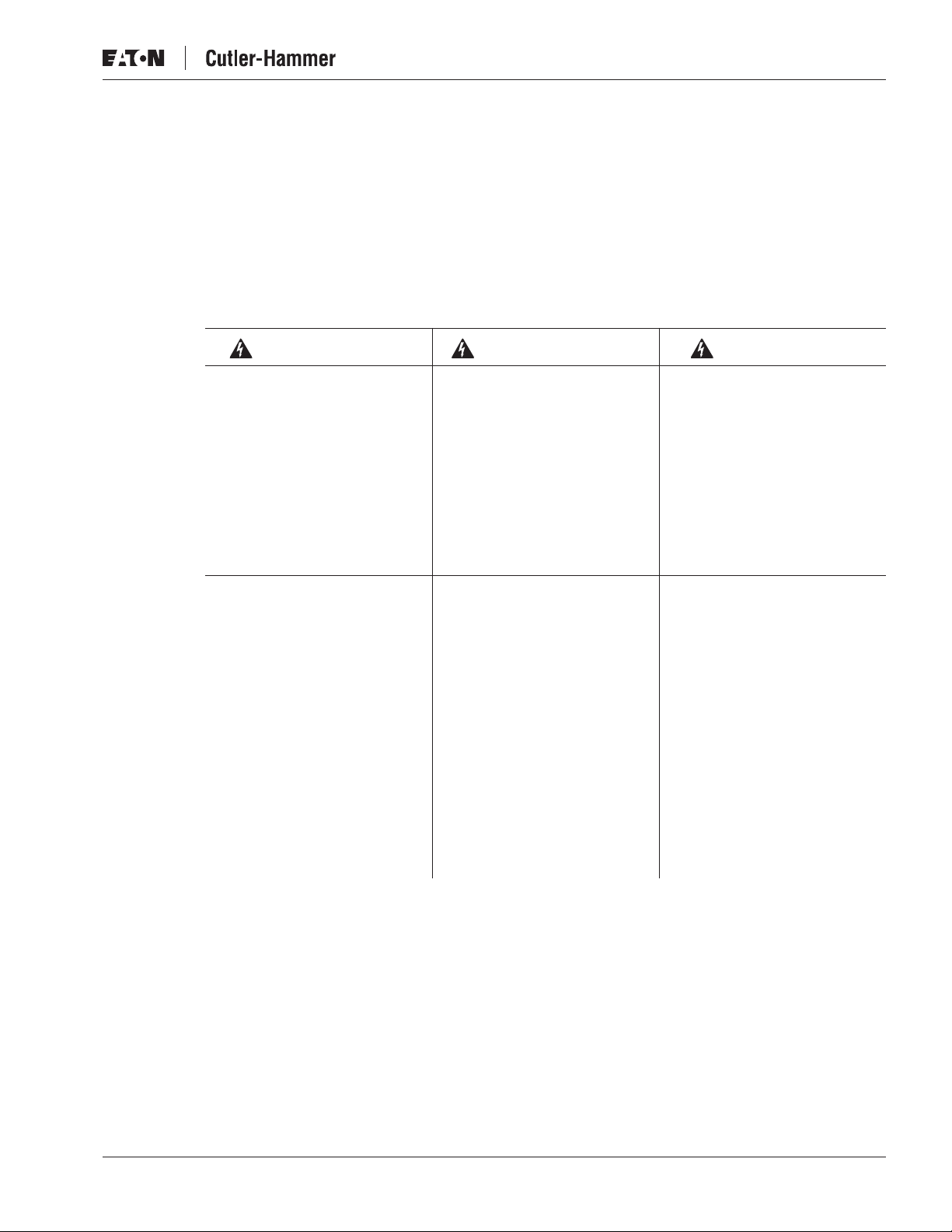

The Meaning of Safety Statements

You will find various types of safety information on the following pages and on the labels

attached to the equipment. This section explains their meaning.

The Safety Alert Symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

!

Le symbole d’alerte signifie ATTENTION ! SOYEZ VIGILANT !

VOTRE SECURITE EST EN JEU !

!

IT

. S811 Soft Starter User Manual

El símbolo de alerta de seguridad significa ¡ATENCIÓN! ¡ESTÉ

ALERTA! ¡SU SEGURIDAD ESTÁ EN JUEGO!

!

Danger Danger

Danger means that failure to

follow the safety statement

result in serious personal injury,

death, or substantial property

damage.

Warning Avertissement

Warning means that failure to

follow the safety statement

result in serious personal injury,

death, or substantial property

damage.

Caution

!

Caution means that failure to

follow the safety statement

result in minor or moderate

personal injury or property

damage.

will

could

may

Danger signifie que l’inobservation

de l’énoncé de sécurité

des blessures corporelles graves,

la mort ou des dégâts matériels

substantiels.

Avertissement signifie que

l’inobservation de l’énoncé de

sécurité

blessures corporelles graves, la

mort ou des dégâts matériels

substantiels.

Attention signifie que

l’inobservation de l’énoncé de

sécurité

blessures corporelles mineures

ou modérés ou des dégâts

matériels.

pourrait

Attention

!

peut

entraîner des

entraînera

entraîner des

Peligro significa que si no se

respeta la indicación de seguridad,

se

producirán

graves, la muerte o daño

considerable a la propiedad.

Advertencia significa que si no se

respeta la indicación de

seguridad se

lesiones personales graves, la

muerte o daños considerables a

la propiedad.

Precaución significa que si no se

respeta la indicación de

seguridad, se

lesiones personales menores o

moderadas, o daños a la

propiedad.

lesiones personales

pueden

pueden

producir

producir

MN03902002E

Notice Avis

Notice means that failure to

follow these instructions

cause damage to the equipment

or cause it to operate improperly.

could

For more information visit: www.EatonElectrical.com

Avis signifie que l’inobservation

de ses instructions

entraîner des dégâts à ou le

mauvais fonctionnement de

l’équipement.

pourrait

Aviso significa que si no se

siguen estas instrucciones, se

pueden

o provocar que funcione de

manera incorrecta.

producir daños al equipo

vii

. S811 Soft Starter User Manual

. Soft Starter Safety Statements

IT

IT

November 2006

The following safety statements relate to the installation, operation and troubleshooting of

Cutler-Hammer

®

Motor Starters.

Notice Avis Aviso

Make sure you read and

understand the procedures in

this manual before you attempt

to operate or set up the

equipment.

Bien lire et comprendre les

procédures contenues dans ce

manuel avant de tenter le

fonctionnement ou la mise en

place de l’équipement.

Asegúrese de leer y entender los

procedimientos en este manual

antes de intentar operar o

configurar el equipo.

Warning Avertissement Advertencia

This instruction manual should

be used for proper installation,

setup and operation of the

starter. Improperly installing and

maintaining this product can

result in serious personal injury

or property damage. Before

attempting installation, setup or

operation, read and understand

all of this manual.

Ce manuel d’instructions doit

être utilisé pour l’installation,

mise en place et opération réglés

d’un démarreur. La mauvaise

installation et entretien de ses

produits pourraient entraîner des

blessures corporelles graves ou

des dommages matériels. Avant

de tenter l’installation ou

l’entretien, bien lire et

comprendre ce manuel en entier.

Este manual de instrucciones

debe utilizarse para la correcta

instalación, configuración y

operación del arrancador. La

instalación o el mantenimiento

inadecuado de este producto

puede ocasionar serias lesiones

personales o daños al material.

Antes de intentar la instalación,

la configuración o la operación

lea y entienda todo el manual.

Danger High Voltage Danger Haute Tension Peligro alto voltaje

There can be line voltage

potential at the motor load

terminals even with the starter in

the OFF state. This is due to the

possible leakage across the

thyristors. Unit does not provide

galvanic isolation. Always

disconnect input power before

servicing the starter or motor.

Notice Avis Aviso

Power factor capacitors: Do not

connect power factor correcting

capacitors to the load side of the

starter. They will cause the

starter to fail. If capacitors are

used, they must be connected to

the line side of the starter, as far

upstream as possible.

Il peut exister une tension de

ligne potentielle aux bornes de

charge du moteur bien que le

démarreur soit dans en état

d’arrêt. Cela s’explique du fait de

fuites possibles à travers les

redresseurs au silicium. Le

produit ne fournit pas l’isolement

galvanique. Toujours débrancher

l’alimentation avant de travailler

sur le démarreur ou le moteur.

Condensateurs de compensation :

Ne pas raccorder ces appareils

au côté charge du démarreur.

Cela entraînera la défaillance du

démarreur. Si des condensateurs

sont utilisés, ils doivent être

raccorder au côté ligne du

démarreur, aussi loin amont que

possible.

Aun con el motor desactivado,

puede haber voltaje de línea en

los terminales de la carga del

motor. Esto se debe a una

posible fuga a través de los

tiristores. La unidad no brinda

aislamiento galvánico.

Desconecte siempre la

alimentación antes de trabajar

sobre el arrancador o el motor.

Capacitores correctores del factor

de potencia: No conecte estos

capacitores del lado de la carga

del arrancador. Esto ocasionará

la falla de este último. Si se usan

capacitores, deben conectarse del

lado de la línea del arrancador,

tan lejos de la entrada como sea

posible.

viii

For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Peligro alto voltaje

Peligro alto voltaje

Dangers, Warnings, Cautions and Notes

Dangers

Danger High Voltage Danger Haute Tension

IT

. S811 Soft Starter User Manual

Hazardous voltage can cause

electric shock and burns. To

avoid shock hazard, disconnect

all power to the controller, motor

or other control devices before

any work is performed on this

equipment. Failure to do so will

result in personal injury, death or

substantial property damage.

Do not apply a disconnect device

on the output of the

Starter unless a means to turn off

the soft starter when disconnect

switch is open is utilized.

Opening disconnect while the

Soft Starter is operating may

cause a malfunction. Closing

disconnect switch while the

Soft Starter is operating will

result in a soft starter failure and

potential equipment damage and

personnel hazard.

IT.

Soft

IT.

IT.

Une tension électrique

dangereuse peut causer des

chocs électriques et des brûlures.

Pour éviter des chocs électriques,

débrancher l’alimentation du

contrôleur, du moteur ou des

autres appareils de contrôle

avant d’y effectuer du travail.

L’inobservation de ces

instructions entraînera des

blessures corporelles graves, la

mort ou des dégâts matériels

substantiels.

Ne pas appliquer un appareil de

sectionnement sur la sortie du

démarreur progressif

qu’un moyen d’éteindre le

démarreur progressif quand

l’interrupteur de sectionnement

est ouvert soit utilisé. Le fait

d’ouvrir l’interrupteur de

sectionnement pendant le

fonctionnement du démarreur

progressif

défaillance. Le fait d’éteindre

l’interrupteur de sectionnement

pendant le fonctionnement du

démarreur progressif

entraînera la défaillance du

démarreur progressif et des

dégâts à l’équipement ou risque

au personnel.

IT.

peut entraîner une

IT.

à moins

IT.

Voltajes peligrosos que pueden

causar descargas eléctricas y

quemaduras. Para evitar

descargas eléctricas, desconecte

la alimentación del controlador,

del motor u otros dispositivos de

control antes de efectuar

cualquier trabajo en el equipo. El

incumplimiento de estas

medidas ocasionará lesiones

personales, la muerte o daños

importantes al material.

No aplique un dispositivo de

desconexión a la salida del

arrancador IT. Soft Starter a

menos que se utilice un medio

para apagar el arrancador

cuando el interruptor de

desconexión está abierto. La

apertura del interruptor de

desconexión mientras el

arrancador IT. está operando

puede ocasionar un

funcionamiento incorrecto. El

cierre del interruptor de

desconexión mientras el

arrancador IT. está operando

producirá una falla de dicho

arrancador, como también

potenciales daños a los equipos

y riesgo para el personal.

MN03902002E

Danger High Voltage Danger Haute Tension

Hazardous voltage can cause

electric shock and burns. Always

disconnect power before

proceeding with any work on this

product.

For more information visit: www.EatonElectrical.com

Une tension électrique

dangereuse peut causer des

chocs électriques et des brûlures.

Il faut toujours débrancher

l’alimentation électrique avant de

travailler sur ce produit.

Voltajes peligrosos que pueden

causar descargas eléctricas y

quemaduras. Siempre

desconecte la energía eléctrica

antes de efectuar cualquier

trabajo en el equipo.

ix

. S811 Soft Starter User Manual

Dangers, continued

Danger High Voltage Danger Haute Tension Peligro alto voltaje

November 2006

IT

Warnings

The S811 has the ability to

respond to commands from an

automated network controller.

Consequently the soft starter

may start unexpectedly in

response to these commands. To

insure the safety of personnel

and equipment, always remove

power before accessing the

electrical and/or mechanical

equipment.

Danger High Voltage Danger Haute Tension Peligro alto voltaje

Do not work on energized

equipment unless absolutely

required. If troubleshooting

procedure requires equipment to

be energized, all work must be

performed by properly qualified

personnel, following appropriate

safety practices and

precautionary measures.

Le S811 à la capacité de répondre

aux commandes d’un contrôleur

de réseau automatisé. Donc le

démarreur progressif peut

démarrer soudainement en

réponse à ces commandes. Pour

s’assurer la sécurité du

personnel et de l’équipement,

toujours débrancher

l’alimentation avant d’accéder à

l’équipement électrique et/ou

mécanique.

Ne pas travailler sur

d’équipement sous tension sauf

si c’est absolument nécessaire.

Si des méthodes de dépannage

exigent que l’équipement soit

sous tension, tout travail doit être

faire par du personnel qualifié,

suivant des pratiques de sécurité

et des mesures de précaution

appropriées.

El S811 tiene la capacidad de

responder a comandos de un

controlador de red automatizado.

Por lo tanto, el arrancador suave

podría arrancar de improviso en

respuesta a estos comandos.

Para garantizar la seguridad del

personal y del equipo, siempre

desconecte la energía antes de

acceder al equipo eléctrico o

mecánico.

No trabaje en equipos en

funcionamiento, a menos que

sea absolutamente necesario. Si

un procedimiento de solución de

problemas requiere que el equipo

permanezca encendido, todo el

trabajo lo debe realizar personal

adecuadamente calificado,

respetando las prácticas de

seguridad y las medidas

preventivas correspondientes.

Warning Avertissement Advertencia

After mounting the unit, remove

and discard the lifting eye and

packaging bolts before

continuing with the installation

process.

Warning Avertissement Advertencia

Make sure you read and

understand all of the safety

statements in the safety section

of this manual before you begin

troubleshooting.

Après que l’appareil sera

supporté, enlever et jeter les

œillets de levage et les boulons

de l’emballage avant de

poursuivre l’installation.

S’assurer de bien lire et

comprendre les énoncés de

sécurité dans le passage de

sécurité de ce manuel avant de

commencer le dépannage.

Después de montar la unidad,

retire y elimine la argolla de

izada y los pernos de embalaje

antes de continuar con el

proceso de instalación.

Antes de comenzar a solucionar

problemas, asegúrese de leer y

comprender todas las

indicaciones de seguridad que

aparecen en la sección de

seguridad de este manual.

x

For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Precaución

!

Precaución

!

Precaución

!

Cautions

IT. S811 Soft Starter User Manual

Caution

!

The S811V soft starter weighs

approximately 100 Lbs. (45 kg).

To prevent personal injury or

equipment damage, use proper

lifting equipment (such as a floor

crane) to safely lift and install the

soft starter. A lifting eye is

provided at the line end of the

soft starter.

Caution

!

Only apply 24V DC to the

terminal block unless specified

otherwise in this manual. All

control wiring is 22 – 12 AWG

(0.33 – 2.5 mm

this caution could result in severe

damage to the controller.

Never megger a motor while it is

connected to the IT. Soft Starter.

Disconnect the leads at the IT.

Soft Starter before meggering

the motor.

2

). Failure to follow

Caution

!

Attention

!

Le démarreur progressif S811V

pèse environ 45 kg (100 livres).

Pour éviter des blessures

corporelles ou des dégâts

matériels, utiliser une machine

de levage appropriée (comme

une grue d’atelier) pour soulever

et installer le démarreur

progressif sans encombre. Un

œillet de levage est prévu au côté

ligne du démarreur progressif.

Attention

!

Appliquer seulement 24V CC à la

barrette à bornes sauf ce manuel

offre d’avis contraire. Tout le

câblage de commande est de

calibre 0,33 – 2,5 mm

AWG). L’inobservation de cet

énoncé pourrait entraîner des

dégâts matériels au contrôleur.

Attention

!

Ne jamais régler un moteur alors

qu’il est branché au démarreur

progressif IT. Débrancher les fils

au démarreur progressif IT.

Avant de régler le moteur.

2

(22 – 12

El arrancador suave S811V pesa

aproximadamente 45 kg (100 lb.).

Para evitar que se produzcan

lesiones personales o daños al

equipo, use el equipo para elevar

adecuado (como un brazo de

elevación) a fin de levantar e

instalar con seguridad el

arrancador suave. Se

proporciona una argolla de izada

en el extremo de del arrancador

suave.

Aplique sólo 24 V CC al bloque

de terminales, a menos que se

especifique lo contrario en este

manual. Todo el cableado de

control es de 0.33 – 2.5 mm

(22 – 12 AWG). Si no respeta esta

precaución, se pueden producir

daños graves al controlador.

Nunca efectúe pruebas del motor

con un megóhmetro mientras

esté conectado al arrancador

Soft Starter IT. Desconecte los

cables en el arrancador IT. antes

de usar el megóhmetro.

2

MN03902002E

For more information visit: www.EatonElectrical.com

xi

IT. S811 Soft Starter User Manual

Notes

Notice Avis Aviso

November 2006

The S811V Soft Starter includes

mounting hardware (8 1/4-20 x

1.5 Allen hex head cap screws

and special washers). Do not

substitute for this hardware. See

Figure 3-7 on Page 3-7 for panel

hole locations. Applicable codes

or standards must be considered

before locating and mounting the

soft starter. The four special

rectangular/rounded washers

must be used on the two

innermost mounting holes on

both the line and load side of the

soft starter.

Le démarreur progressif S811V

inclut des matériels de support

(vis à tête hexagonale

8-1/4-20 x 1,5 et des rondelles

spéciales). Ne substituer pas

pour ces matériels. Consulter la

Figure 3-7 de la Page 3-7 pour les

locations des trous dans le

panneau. Tenir compte des

normes et des codes existants

avant de localiser et de monter le

démarreur progressif. Les quatre

rondelles rectangulaires/

circulaires spéciales doivent être

utiliser aux deux trous de

support les plus intérieurs sur le

côté ligne et le côté charge du

démarreur progressif.

El arrancador suave S811V

incluye piezas metálicas de

montaje (tornillos Allen de

cabeza hexagonal de 8 1/4-20 x

1.5 y arandelas especiales). No

las sustituya. Consulte la

Figura 3-7 que aparece en la

página 3-7 para conocer las

ubicaciones de los orificios del

panel. Antes de ubicar y montar

el arrancador suave, se deben

considerar los códigos o las

normas pertinentes. Las cuatro

arandelas rectangulares/

redondas especiales se deben

usar en los dos orificios de

montaje que se encuentren más

al interior, en los lados de línea y

de carga del arrancador suave.

xii For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Chapter 1 — Overview

General Introduction

The Cutler-Hammer® Intelligent Technologies S811 IT. Soft Starter from Eaton’s electrical

business is an electronic, self-contained, panel- or enclosure-mounted motor soft-starting

device. It is intended to provide three-phase induction motors with a smooth start, both

mechanically and electrically. The S811 Soft Starters utilize six SCRs connected in a full wave

power bridge. Varying the SCR conduction period controls the voltage applied to the motor.

This in turn controls the torque developed by the motor. After the motor reaches speed,

contacts are closed to bypass the SCRs.

The S811 has built-in communications capabilities through Cutler-Hammer QC (Quick

Connect) Port. The S811 Soft Starter utilizes a DIM (Digital Interface Module) that allows the

user to configure the device and read system parameters. The DIM includes an easy-to-read

LCD display and keypad to scroll through the menus. The DIM allows the user to modify

control parameters, enable or disable protections, set communication variables, monitor

system parameters such as line voltages and currents and access the fault queue.

The S811 is designed to fulfill the industrial service requirements for applications such as

Chillers, Pumps and Machine Tools that require less than 85% of the motor’s rated starting

torque for worst case starting condition.

IT. S811 Soft Starter User Manual

The S811 meets all relevant specifications set forth by NEMA ICS 1, ICS 2 and ICS 5, UL 508,

IEC 60947-4-2, CE and CSA.

This user manual covers everything you need to know in order to install, set up, operate,

troubleshoot and maintain the S811.

However, no publication can take into account every possible situation. If you require further

assistance with any aspect of this product, or a particular application, please contact us.

For contact information, please see Chapter 9.

MN03902002E

For more information visit: www.EatonElectrical.com

1-1

IT. S811 Soft Starter User Manual

General Appearance Notes

November 2006

Digital Interface

Module (DIM)

Load Output

Line Input

Mounting Slots

Base

QC Port CH0 Network

Address Switch

Detachable 12-Pin Locking

Control Terminal Block

Figure 1-1: The Cutler-Hammer Intelligent Technologies (IT.) S811 Soft Starter

1-2 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Chapter 2 — Receipt/Unpacking

General

Upon receipt of the unit, verify that the catalog number and unit options stated on the

shipping container match those stated on the order/purchase form.

Inspect the equipment upon delivery. Report any crate or carton damage to the carrier prior

to accepting the delivery. Have this information noted on the freight bill. Eaton is not

responsible for damage incurred in shipping.

Unpacking

Remove all packing material from the unit. Be sure to remove all packing material from lug

locations. Also, make sure no packing material blocks the airflow near the fans. For V frame

units, verify mounting hardware has been included with shipment.

Check the unit for any signs of shipping damage. If damage is found after unpacking, report it

to the freight company. Retain the packaging materials for carrier to review.

Verify that the unit’s catalog number and options match those stated on the order/purchase

form.

IT. S811 Soft Starter User Manual

Storage

It is recommended that the unit be stored in its original shipping box/crate until it is to be

installed.

The unit should be stored in a location where:

● The ambient temperature is -58°F – 158°F (-50°C – 70°C)

● The relative humidity is 0% – 95%, non-condensing

● The environment is dry, clean and non-corrosive

● The unit will not be subjected to high shock or vibration conditions

MN03902002E

For more information visit: www.EatonElectrical.com

2-1

November 2006

Advertencia

Precaución

!

Chapter 3 — Installation

Mounting

Models S811N, S811R and S811T

The S811 is easy to mount. It does not require any special tools.

To aid you with panel layout, refer to the dimension drawings in Figures 3-3 through 3-7 of

this manual. Drill and tap holes per mounting hole location as shown.

To mount the unit, use all the hardware specified in Table 3-1 on Page 3-8. Tighten to the

torque specified.

The T frame S811 is supplied with a lifting eye mounted on the center phase of the line end of

the device. This will aid in mounting the unit.

Warning Avertissement

IT. S811 Soft Starter User Manual

After mounting the unit, remove

and discard the lifting eye and

packaging bolts before

continuing with the installation

process.

Model S811V10

IMPORTANT: For model S811V10xxx, see additional installation requirements noted

on Page 3-4.

The S811V soft starter weighs

approximately 100 Lbs. (45 kg).

To prevent personal injury or

equipment damage, use proper

lifting equipment (such as a floor

crane) to safely lift and install the

soft starter. A lifting eye is

provided at the line end of the

soft starter.

Caution

!

Après que l’appareil sera

supporté, enlever et jeter les

œillets de levage et les boulons

de l’emballage avant de

poursuivre l’installation.

Attention

!

Le démarreur progressif S811V

pèse environ 45kg (100 livres).

Pour éviter des blessures

corporelles ou des dégâts

matériels, utiliser une machine

de levage appropriée (comme

une grue d’atelier) pour soulever

et installer le démarreur

progressif sans encombre. Un

œillet de levage est prévu au côté

ligne du démarreur progressif.

Después de montar la unidad,

retire y elimine la argolla de

izada y los pernos de embalaje

antes de continuar con el

proceso de instalación.

El arrancador suave S811V pesa

aproximadamente 45 kg (100 lb.).

Para evitar que se produzcan

lesiones personales o daños al

equipo, use el equipo para elevar

adecuado (como un brazo de

elevación) a fin de levantar e

instalar con seguridad el

arrancador suave. Se

proporciona una argolla de izada

en el extremo de del arrancador

suave.

MN03902002E

For more information visit: www.EatonElectrical.com

3-1

IT. S811 Soft Starter User Manual

Notice Avis Aviso

November 2006

The S811V soft starter includes

mounting hardware (8 1/4-20 x

1.5 Allen hex head cap screws

and special washers). Do not

substitute for this hardware. See

Figure 3-7 on Page 3-7 for panel

hole locations. Applicable codes

or standards must be considered

before locating and mounting the

soft starter. The four special

rectangular/rounded washers

must be used on the two

innermost mounting holes on

both the line and load side of the

soft starter.

Le démarreur progressif S811V

inclut des matériels de support

(vis à tête hexagonale

8-1/4-20 x 1,5 et des rondelles

spéciales). Ne substituer pas

pour ces matériels. Consulter la

Figure 3-7 de la Page 3-7 pour les

locations des trous dans le

panneau. Tenir compte des

normes et des codes existants

avant de localiser et de monter le

démarreur progressif. Les quatre

rondelles rectangulaires/

circulaires spéciales doivent être

utiliser aux deux trous de

support les plus intérieurs sur le

côté ligne et le côté charge du

démarreur progressif.

El arrancador suave S811V

incluye piezas metálicas de

montaje (tornillos Allen de

cabeza hexagonal de 8 1/4-20 x

1.5 y arandelas especiales). No

las sustituya. Consulte la

Figura 3-7 que aparece en la

página 3-7 para conocer las

ubicaciones de los orificios del

panel. Antes de ubicar y montar

el arrancador suave, se deben

considerar los códigos o las

normas pertinentes. Las cuatro

arandelas rectangulares/

redondas especiales se deben

usar en los dos orificios de

montaje que se encuentren más

al interior, en los lados de línea y

de carga del arrancador suave.

Drill and tap the eight mounting holes. Thread the two lower middle screws (with special flat

washer and lockwasher) into the panel before lifting the soft starter. These two screws will

assist in mounting. Special mounting hardware is included with the soft starter. Hardware

supplied must be used.

Hook lifting equipment to the soft starter lifting eye. If you are using a crane, minimize the

chain length between the boom and the soft starter. Make sure that the back of the soft

starter is oriented to the panel-mounting surface. Make sure that the lifting equipment hook

is fully engaged with the soft starter lifting eye before lifting.

Slowly lift the soft starter to about 2 in. (5 cm) above the mounting location. Then move it

back against the mounting panel. Carefully lower the soft starter onto the two mounting

screws. Make sure the screws align with the slots on the load end of the soft starter, and that

the two washers are between the soft starter base and the screw head.

Install and tighten the remaining six mounting screws, washers and lockwashers. Then

tighten the two lower middle screws. Tighten all eight screws to 50 Lb-in (5.6 N•m).

Disengage and remove the lifting equipment.

Warning Avertissement Advertencia

After mounting the unit, remove

and discard the lifting eye and

packaging bolts before

continuing with the installation

process.

Après que l’appareil sera

supporté, enlever et jeter les

œillets de levage et les boulons

de l’emballage avant de

poursuivre l’installation.

Después de montar la unidad,

retire y elimine la argolla de

izada y los pernos de embalaje

antes de continuar con el

proceso de instalación.

3-2 For more information visit: www.EatonElectrical.com

MN03902002E

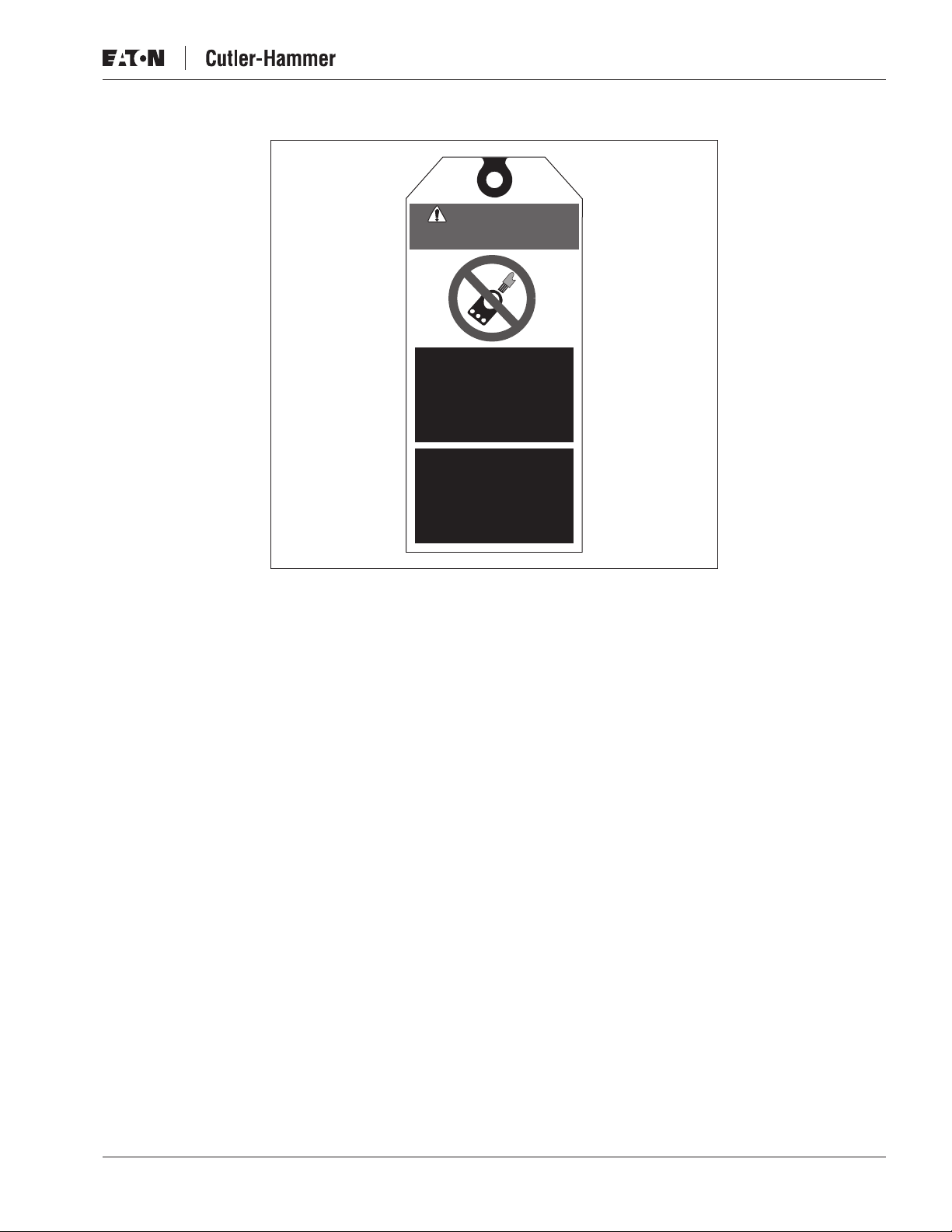

November 2006

WARNING

AVERTISSEMENT

REMO VE LIFTING EYE

BEFO REWIRING

NOT AN ELECTRICAL

CONNECTION

CAN CAUSESEVERE IN JURY,

DEATH, OR DAMAGE

EQUIPMENT

RETIRER L’OEI LLET DE

LEVAGE AVAN T DE CÂBLE

PAS UNE CONNEXION

´

E

PEUT CAUSERDES BLESSURES

DOMMAGES Á L’ QUIPEMENT

LECTRIQUE

GRAVES, LA MORT OU DES

´

E

IT. S811 Soft Starter User Manual

R

Figure 3-1: Warning Tag

MN03902002E

For more information visit: www.EatonElectrical.com

3-3

IT. S811 Soft Starter User Manual

S811V10xxx Installation Requirements

1. Install the device in a minimum enclosure size 30 ft3.

2. Two (2) forced air ventilation fans with a min. 500 ft3/min, at a location for “air in” —

bottom right or left corner and “air out” — opposite upper right or left corner.

3. RD circuit breaker.

4. For power wiring: Use four (4) 500 MCM cables for each phase between RD circuit

breaker and Soft Starter.

OPTIONAL: Two (2) 3" x 1/4" bus with a 1/4" spacer per terminal.

Note: See Figure 3-2 for alternative layouts.

5. Line and load service entrance wiring must not cross in the enclosure.

12"

Minimum

Distance

RD

Circuit

Breaker

S811V10xxx

IT.

Soft Starter

Line Service

(4) 350

MCM/Terminal

(4) 500 MCM or

(2) 3 x 1/4" Bus

with 1/4"

Space/Terminal

Line Service

(4) 350

MCM/Terminal

RD

Circuit

Breaker

Isolation

Contactor

S811V10xxx

IT.

Soft Starter

6"

Minimum

Distance

6"

Minimum

Distance

November 2006

Figure 3-2: Power Wiring Alternatives

3-4 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Dimensions

IT. S811 Soft Starter User Manual

6.87

(1 74 .5 )

1.97

(50.0)

.22 (5.5)

Typ. 4 Places

3.54

(90.0)

6.47

(164.4)

7.38

(187.4)

Figure 3-3: N Frame (65 mm)

Approximate Dimensions in Inches (mm)

6.66

(169.2)

2.66

(67.6)

(111.3)

4.38

3.46

(88.0)

5.35

(135.9)

7.44

(189.0)

MN03902002E

.27 (6.8)

Typ. 4 Places

7.92

(201.2)

Figure 3-4: R Frame (110 mm)

Approximate Dimensions in Inches (mm)

For more information visit: www.EatonElectrical.com

3.49

(88.5)

5.53

(140.5)

3-5

IT. S811 Soft Starter User Manual

6.39

(162.4)

11. 77

12.71

(299.0)

(322.9)

Slots

Figure 3-5: T Frame (200 mm)

Approximate Dimensions in Inches (mm)

2.95

(75.0)

Slots

7.67

(194.8)

5.91

(150.0)

Slots

November 2006

5.40

(137.2)

.28 (7.1)

Slots Typ.

6 Places

11.77 (299.0)

Mounting

12.72

(323.1)

.47

(11.9)

5.20 (132.0)

Mounting

C

L

Mounting Slots

for M6 (1/4) Screws

(Up to 6 Quantity)

7.08

(179.9)

5.20 (132.0)

Pole Centers

C

L

7.73

(196.3)

Figure 3-6: U Frame (200 mm)

Approximate Dimensions in Inches (mm)

3-6 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

IT. S811 Soft Starter User Manual

15.63

(397.0)

.26 (6.5) Dia.

Typ. 4 Places

9.84

(250.0)

3.74

(95.0)

7.35

(186.6)

.27 (6.7) Dia.

Typ. 4 Places

Figure 3-7: V Frame (290 mm)

Approximate Dimensions in Inches (mm)

15.16

(385.0)

Slots

16.57

(420.8)

11.05

(280.6)

1.83

(46.4)

1.77

(45.0)

.91

(23.2)

.49

(12.5)

.31

(8.0)

2.91

(74.0)

.29

(7.5)

.41

(10.5)

Figure 3-8: EMA91 Digital Interface Module

Approximate Dimensions in Inches (mm)

3.08

(78.3)

.89

(22.5)

2.68

(68.0)

MN03902002E

For more information visit: www.EatonElectrical.com

3-7

IT. S811 Soft Starter User Manual

Required Mounting Hardware

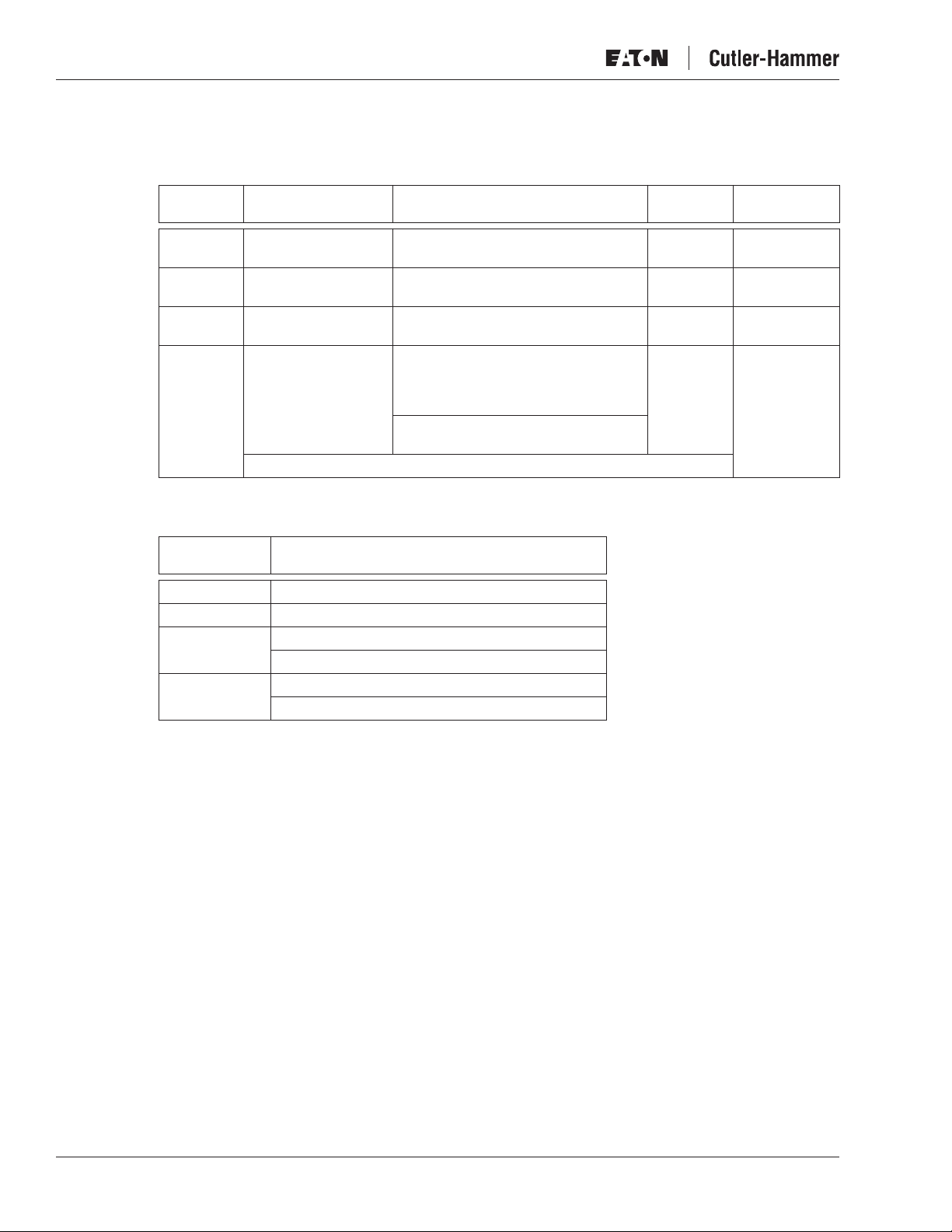

Table 3-1: Required Mounting Hardware

Frame

Size Screw Size Washer Size

Quantity

Required

November 2006

Torque

Required

N #10 – 32 x 0.5 Standard #10 Lockwasher and

R 1/4 – 20 x 0.625 Standard 1/4 Lockwasher and

T & U 1/4 – 20 x 0.625 Standard 1/4 Lockwasher and

V 1/4 – 20 x 1.5

Grade 8 Allen head

hex cap screws

Included with V Frame Units

Weight Support Requirements

Table 3-2: Weight Support Requirements

Frame

Size Weight of Unit

N 5.8 Lbs. (2.6 Kg)

R 10.5 Lbs. (4.8 Kg)

T & U 48 Lbs. (21.8 Kg) with lugs

41 Lbs. (18.6 Kg) without lugs

V 103 Lbs. (46.8 Kg) with lugs

91 Lbs. (41.4 Kg) without lugs

Flat Washer

Flat Washer

Flat Washer

Quantity: 4

ID: 0.270

OD: 0.495 – 0.505

Max. 0.055 Thick

Quantity: 4

Special Washer

4 15 Lb-in

(1.7 N•m)

4 25 Lb-in

(2.8 N•m)

6 30 Lb-in

(3.4 N•m)

8 50 Lb-in

(5.6 N•m)

3-8 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Peligro alto voltaje

Power Wiring

Using the wiring diagrams in Figures 3-9 – 3-12, 3-15, 3-16 and 3-17 and Table 3-3 below as

guides, connect the line, Motor, and Power Supply wiring in accordance with appropriate

local and national codes.

Note: To provide optimum motor protection the Line and Motor power wiring should be

Safety Notices

IT. S811 Soft Starter User Manual

tightly bundled and run perpendicular to the orientation of the S811.

Danger High Voltage Danger Haute Tension

Hazardous voltage can cause

electric shock and burns. To

avoid shock hazard, disconnect

all power to the controller, motor

or other control devices before

any work is performed on this

equipment. Failure to do so will

result in personal injury, death or

substantial property damage.

Do not apply a disconnect device

on the output of the IT. Soft

Starter unless a means to turn off

the soft starter when disconnect

switch is open is utilized.

Opening disconnect while the IT.

Soft Starter is operating may

cause a malfunction. Closing

disconnect switch while the IT.

Soft Starter is operating will

result in a soft starter failure and

potential equipment damage and

personnel hazard.

Une tension électrique

dangereuse peut causer des

chocs électriques et des brûlures.

Pour éviter des chocs électriques,

débrancher l’alimentation du

contrôleur, du moteur ou des

autres appareils de contrôle

avant d’y effectuer du travail.

L’inobservation de ces

instructions entraînera des

blessures corporelles graves, la

mort ou des dégâts matériels

substantiels.

Ne pas appliquer un appareil de

sectionnement sur la sortie du

démarreur progressif IT. à moins

qu’un moyen d’éteindre le

démarreur progressif quand

l’interrupteur de sectionnement

est ouvert soit utilisé. Le fait

d’ouvrir l’interrupteur de

sectionnement pendant le

fonctionnement du démarreur

progressif IT. peut entraîner une

défaillance. Le fait d’éteindre

l’interrupteur de sectionnement

pendant le fonctionnement du

démarreur progressif IT.

entraînera la défaillance du

démarreur progressif et des

dégâts à l’équipement ou risque

au personnel.

Voltajes peligrosos que pueden

causar descargas eléctricas y

quemaduras. Para evitar

descargas eléctricas, desconecte

la alimentación del controlador,

del motor u otros dispositivos de

control antes de efectuar

cualquier trabajo en el equipo. El

incumplimiento de estas

medidas ocasionará lesiones

personales, la muerte o daños

importantes al material.

No aplique un dispositivo de

desconexión a la salida del

arrancador IT. Soft Starter a

menos que se utilice un medio

para apagar el arrancador

cuando el interruptor de

desconexión está abierto. La

apertura del interruptor de

desconexión mientras el

arrancador IT. está operando

puede ocasionar un

funcionamiento incorrecto. El

cierre del interruptor de

desconexión mientras el

arrancador IT. está operando

producirá una falla de dicho

arrancador, como también

potenciales daños a los equipos

y riesgo para el personal.

MN03902002E

Note: Short circuit protection must be applied on the line side of the soft starter.

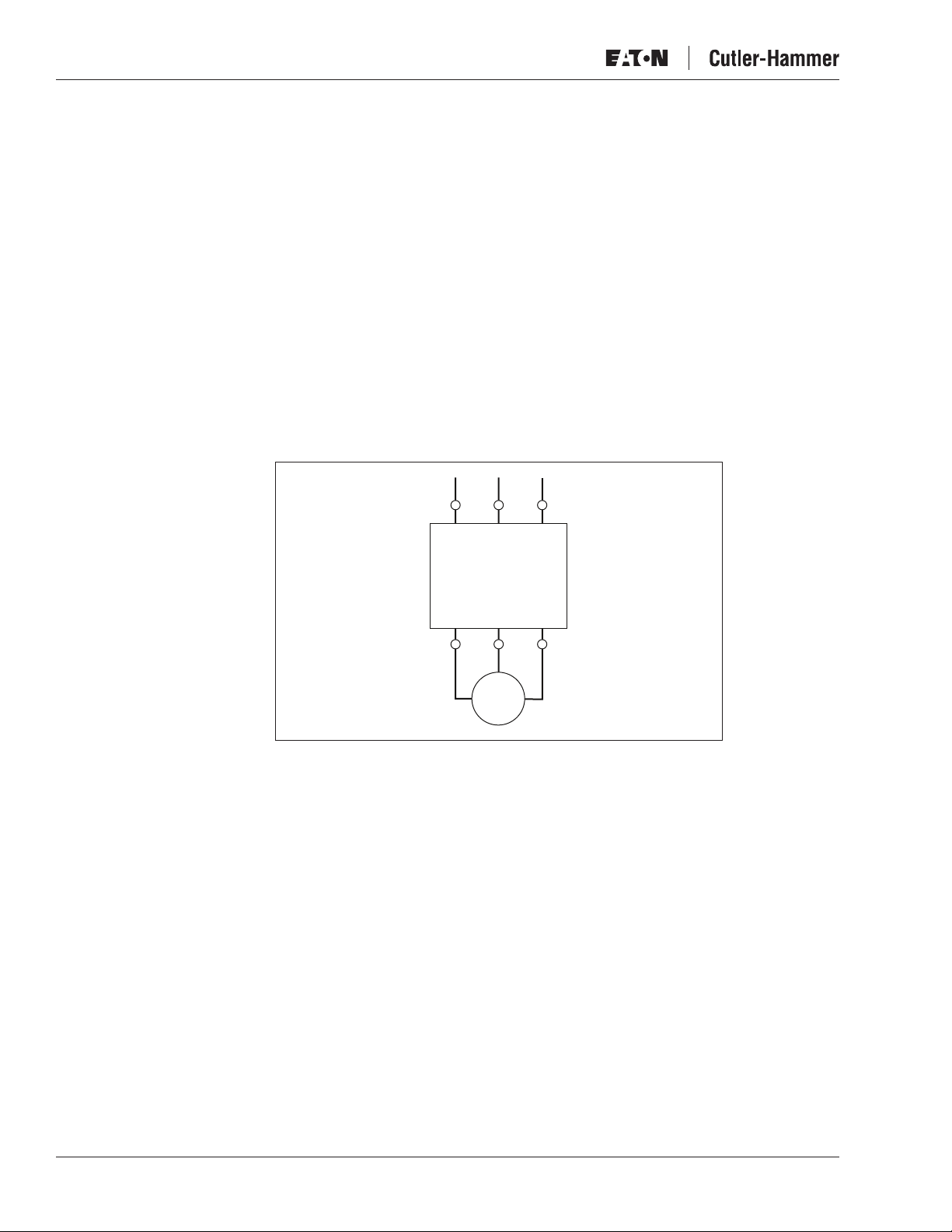

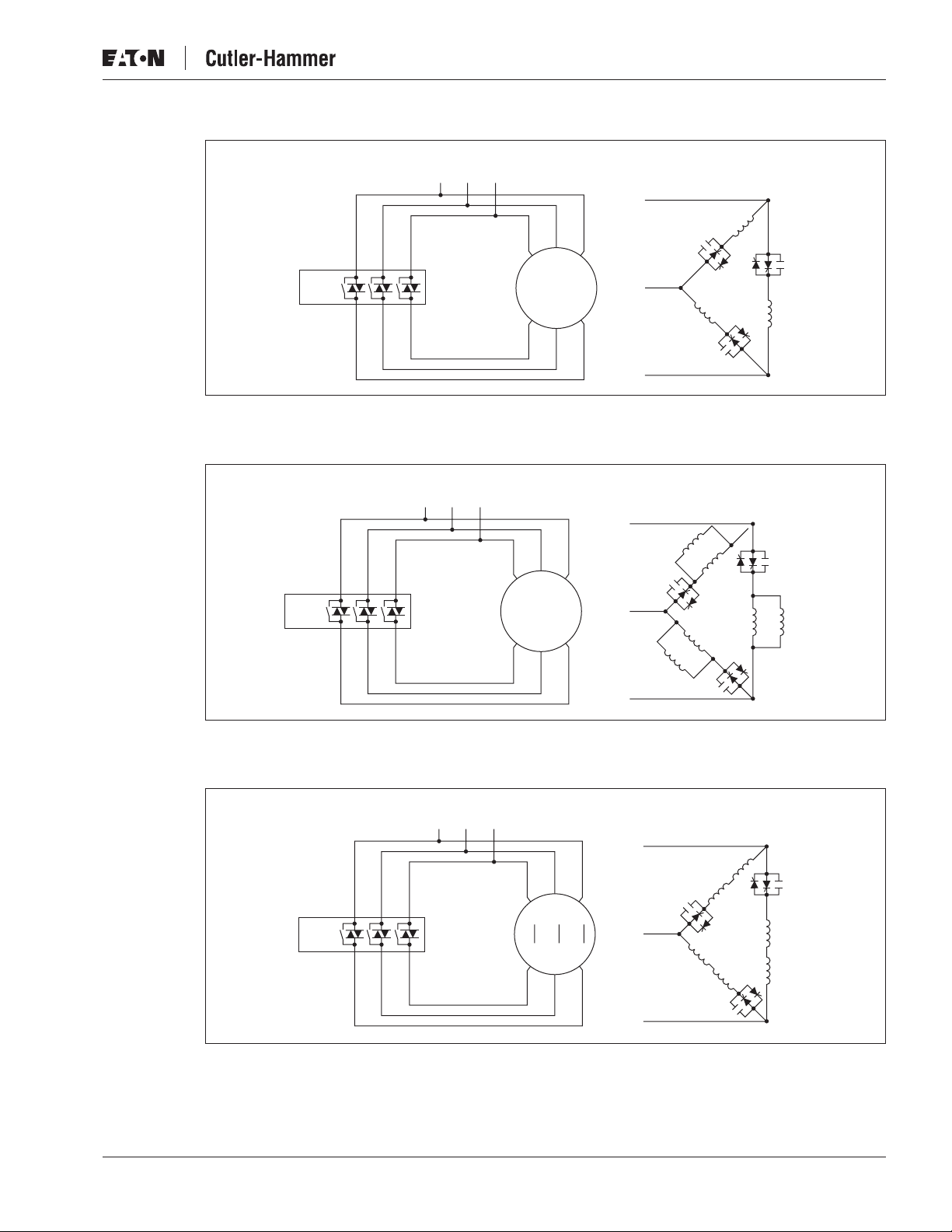

The S811 can be wired in both line connected and inside-the-delta connected configurations.

If a line configuration is desired then the three-phase line feeding and the three main motor

leads should be connected for normal across-the-line starting as shown in Figure 3-9. For

inside-the-delta connected configurations be sure to consult Figures 3-10, 3-11 and 3-12.

Note: Only soft starters with catalog numbers S811xxxxxD may be connected in an insidethe-delta configuration. Refer to the motor nameplate for correct wiring information. Contact

Eaton if a special motor wiring requirement exists before wiring your starter.

For more information visit: www.EatonElectrical.com

3-9

IT. S811 Soft Starter User Manual

By factory default, the S811 is to be connected with an ABC phase rotation on the incoming

power wiring. If the motor turns in the incorrect direction upon energization, exchange two

phases at the motor terminal box or at the output terminals of the soft starter. Changing the

input wiring will cause a voltage phase reversal trip.

If the input phase sequence to the S811 must be ACB, the incoming phase sequence

protection will need to be set to ACB. Setting ACB as the incoming phase sequence causes

the ABC incoming phase sequence to cause a voltage phase reversal trip.

IMPORTANT: The reversing contactor must never be switched while the soft starter is

operating. In order to gain the full benefit of the S811 with a reversing contactor, the S811

needs to be OFF when switching the direction. The soft starter settings must account for

catching a motor spinning in the opposite direction upon soft restarts. The time required for

slowing the motor to a stop and then ramping up to speed in the opposite direction adds to the

overall starting time. This will also impact the overload protection setting.

See the Motor/Application Considerations in Appendix E of this manual for information on

typical motor winding configurations.

November 2006

1L1 3L2

S811

2T1 4T2 6T3

5L3

M

3

˜

Figure 3-9: Line Connected Soft Starter Power Wiring Diagram

3-10 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

IT. S811 Soft Starter User Manual

Supply

S811

1L13L25

2T14T26

L1S L2S

L3

T3

L3S

T5 T4 T6

Motor

T2

T3

T1

L3

L2

L2

T4

L1

T1

T2

T1

T2

T5

L3

T3

T3

T6

L1

Figure 3-10: Inside-the-Delta Connected Soft Starter Power Wiring Diagram

for a 6-Lead Motor

S811

1L13L25

2T14T26

L3

T3

Supply

L1S L2S

L3S

T11

T5

T3

T9

T10T4T12

T6

Motor

T2

T1

T8

T7

L3

L2

L1

Low Voltage

L2

T10

12-Lead

T8

T4

T7

T11

T2

T2

T1

T1

T5

L3

T3

T3

T6

L1

T9

T12

Figure 3-11: Inside-the-Delta Connected Soft Starter Power Wiring Diagram

for a 12-Lead Low Voltage Motor

S811

1L13L25

2T14T26

T3

L3

Supply

L1S L2S

L3S

T11

T3

T10 T12

Motor

T8

T5

T2

T7

T4

T6

T9

T1

L3

L2

L1

12-Lead

High Voltage

T5

T2

L2

T10

T7

T4

T2

T1

T1

T8

T11

L3

T3

T3

T6

T9

T12

L1

MN03902002E

Figure 3-12: Inside-the-Delta Connected Soft Starter Power Wiring Diagram

for a 12-Lead High Voltage Motor

For more information visit: www.EatonElectrical.com

3-11

IT. S811 Soft Starter User Manual

Line and Load power wiring data is shown in Table 3-3.

Table 3-3: Line and Load Power Wiring

Frame

Size Lug Kit Options

Number of

Conductors Lug Type

Wire Sizes

Cu 75°C

Only

Torque

Requirements

November 2006

Number

of Kits

Required

N Supplied

Standard with

Box Lugs

1 Box Lug 2 AWG 50 Lb-in (5.6 N•m) N/A

4 – 6 AWG 45 Lb-in (5.0 N•m)

8 AWG 40 Lb-in (4.5 N•m)

10 – 14 AWG 35 Lb-in (4.0 N•m)

R Supplied

Standard with

Box Lugs

1 Box Lug 14 – 8 AWG

(2.5 – 10 mm

6 – 4 AWG

(16 – 25 mm

3 – 3/0 AWG

(27 – 95 mm

T & U EML22 2 — 4 – 1/0 MCM

(21.2 – 53.5 mm

EML23 1 — 4/0 – 500 MCM

(107 – 240 mm

EML24 2

— 4/0 – 500 MCM

(107 – 240 mm

EML25 1 — 2/0 – 300 MCM

(70 – 150 mm

EML26 2 — 2/0 – 300 MCM

(70 – 150 mm

V EML28 2

— 4/0 – 500 MCM

(107 – 240 mm

EML30 4

— 4/0 – 500 MCM

(107 – 240 mm

EML32 6

— 4/0 – 500 MCM

(107 – 240 mm

EML33 4 — 2/0

Requires special lug cover. Check with Eaton for availability.

CSA approved 350 MCM – 500 MCM

– 300 MCM

(70

– 150 mm

90 – 100 Lb-in

2

)

(10.1 – 11.3 N•m)

2

)

2

)

250 Lb-in (28.3 N•m) 2

2

)

250 Lb-in (28.3 N•m)

2

)

250 Lb-in (28.3 N•m)

2

)

225 Lb-in (25.5 N•m)

2

)

225 Lb-in (25.5 N•m)

2

)

250 Lb-in (28.3 N•m) 2

2

)

250 Lb-in (28.3 N•m)

2

)

250 Lb-in (28.3 N•m)

2

)

225 Lb-in (25.5 N•m)

2

)

N/A

3-12 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Peligro alto voltaje

Lugs for T, U and V Frame

T, U and V frame units are supplied standard without lugs. If lugs are needed, they can be

ordered through your local Eaton distributor. Each lug kit contains three lugs, mounting

hardware, and instructions for use on either line or load side of the IT. Soft Starter. Catalog

numbers and wire ranges for lug kits are listed in the table above.

Lug Installation

IT. S811 Soft Starter User Manual

Danger High Voltage Danger Haute Tension

Hazardous voltage can cause

electric shock and burns. Always

disconnect power before

proceeding with any work on this

product.

Une tension électrique

dangereuse peut causer des

chocs électriques et des brûlures.

Il faut toujours débrancher

l’alimentation électrique avant de

travailler sur ce produit.

Voltajes peligrosos que pueden

causar descargas eléctricas y

quemaduras. Siempre

desconecte la energía eléctrica

antes de efectuar cualquier

trabajo en el equipo.

Note: For additional motor and system protection, a Metal Oxide Varistor (MOV) may be

installed on the line side of the unit. An MOV can also be installed on the load side of

the Soft Starter if additional protection is desired. Generally, it is more common to use

a MOV on the line side. Refer to the instructions provided with the MOV kit.

1. For T, U and V Frame Soft Starters, remove line and load terminal covers by removing

the screws that hold each cover (and the MOV, if installed) onto the unit.

Note: For N and R Frame Soft Starters, it is not necessary to remove the covers in order

to wire the device. Proceed to step 3.

2. After screws are removed, slide covers off of unit. Set the covers and screws aside.

3. Position lugs and install lug mounting screws according to instructions provided with

the kit. Tighten lug mounting screws provided with the kit to 120 Lb-in (13.6 N•m).

4. Wire the appropriate line and load conductors to the IT. Soft Starter (as required by NEC

and local codes based on the device rating).

5. Torque bolts as directed by Table 3-3 on Page 3-12 of this manual.

MN03902002E

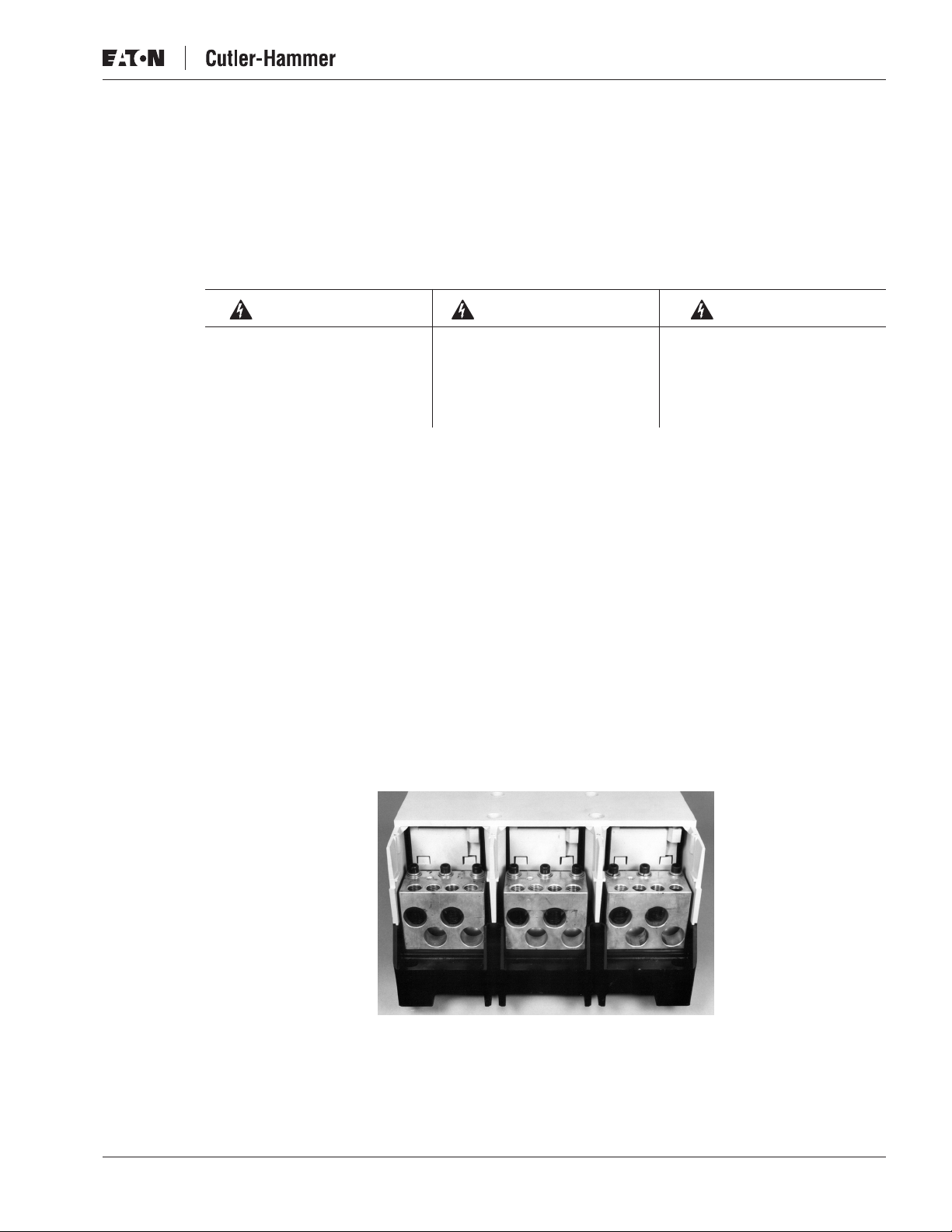

Figure 3-13: V Frame Shown with Terminal Cover Removed

and EML30 Lug Kit Installed on Load Side

For more information visit: www.EatonElectrical.com

3-13

IT. S811 Soft Starter User Manual

6. Slide the line and load covers back into place on the soft starter.

7. Reinstall the cover screws through the cover and the MOV, if installed.

8. Insert two outer cover screws through cover.

9. Align cover and torque all cover screws to 5 Lb-in (0.6 N•m). Do not overtighten screws.

Control Wiring Inputs

Control wiring is connected to the S811 by a 12-pin terminal block located at the front of the

unit. Using the wiring diagrams in Figures 3-15, 3-16 and 3-17 and Tables 3-4 and 3-5 as

guides, connect the control wiring as required for your application.

November 2006

Caution

!

Only apply 24V DC to the

terminal block unless specified

otherwise in this manual. All

control wiring is 22 – 12 AWG

(0.33 – 2.5 mm

this caution could result in severe

damage to the controller.

2

). Failure to follow

Appliquer seulement 24V CC à la

barrette à bornes sauf ce manuel

offre d’avis contraire. Tout le

câblage de commande est de

calibre 0,33 – 2,5 mm

AWG). L’inobservation de cet

énoncé pourrait entraîner des

dégâts matériels au contrôleur.

Attention

!

2

(22 – 12

Precaución

!

Aplique sólo 24 V CC al bloque

de terminales, a menos que se

especifique lo contrario en este

manual. Todo el cableado de

control es de 0.33 – 2.5 mm

(22 – 12 AWG). Si no respeta esta

precaución, se pueden producir

daños graves al controlador.

2

Figure 3-14: Terminal Block

Table 3-4 provides the 12-pin terminal block wiring capacity and torque requirements for the

control wiring.

Table 3-4: 12-Pin Terminal Block Wiring Capacity

Wire Size

22 – 14 AWG

(0.33 – 2.5 mm

12 AWG

(4.0 mm

2

)

Number of

Conductors

2

)

2 3.5 Lb-in (0.4 N•m)

1 3.5 Lb-in (0.4 N•m)

Torque

Requirements

3-14 For more information visit: www.EatonElectrical.com

MN03902002E

November 2006

Input Descriptions

IT. S811 Soft Starter User Manual

The IT. Soft Starter has the following control inputs:

Table 3-5: S811 Terminal Block Control Wiring

Terminal

Block

Name

Circuit

Common

Power + — 24V DC nominal

Permissive P Hardwired

Input 1 1 START 24V DC only

Input 2 2 JOG 24V DC only

Input 3 3 HAND/AUTO 24V DC only

Input 4 4 Fault RESET 24V DC only Input 4 is Fault RESET. Energizing this

Relay1

Form A

NO Contact

Form C

Common

Relay2

Form C

NC Contact

Relay2

Form C

NO Contact

Designation

(Pin)

- — Negative Power supply connections:

13 Common 3 Amps, @ 230V

14 NO De-

95 Common Form C Common

96 NC De-

98 NO De-

Factory

Default Input Connections

– Connect power supply negative to pin

“–” and to system ground

– Connect +24V DC output to pin “+”

Note: To avoid voltage drop during

bypass contactor inrush, a minimum of

14 AWG wire should be used between

the power supply and the “+” and “–”

inputs at the S811 terminal block.

Pin “P”, permissive, must be energized

(+24V DC) to enable operation of the unit.

If power is removed from the permissive

circuit at any time, the unit will begin a

STOP command. If a soft stop is selected,