Cutler Hammer, Div of Eaton Corp S801 Catalog Page

(

Reduced Voltage Motor Starters

2

Solid-State Starters

Type S801, Intelligent Technologies (IT.) Soft Starters

4

13

13

April 2007

Contents

Description Page

Type S801, Intelligent

Technologies

Product Description. . . . . . . . 2

Application Description. . . . . 2

Features . . . . . . . . . . . . . . . . . 2

Benefits. . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . 2

Catalog Number

Selection . . . . . . . . . . . . . . .

Product Selection . . . . . . . . . 5

Options . . . . . . . . . . . . . . . . . . 11

Accessories . . . . . . . . . . . . . . 11

Standards and

Certifications . . . . . . . . . . . .

Technical Data and

Specifications . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . 14

IT. ) Soft Starters

S801

Product Description

Eaton’s Cutler-Hammer

Technologies (

Reduced Voltage Soft Starters is very

compact, multi-functional, easy to

install and easy to program. Designed

to control acceleration and

deceleration of 3-phase motors, the

line is available for current ranges

from 12 amp all the way through 1000

amp applications and is suitable for

mounting in motor control centers or

in enclosed control (NEMA 1, 4, 4X and

12) applications.

IT. ) S801 Line of

®

Intelligent

Application Description

The S801 line of IT. Soft Starters is

designed to be the smallest, most

compact soft starter in the market

today. With this small size, it can easily

fit in place of existing soft starter

designs, wye-delta starters or acrossthe-line NEMA and IEC starters. This

feature allows easy retrofits of existing

Motor Control Centers or Enclosures

and saves the expense of replacing

existing structure or adding a new one

to house a soft starter.

The product is designed to work with

3-phase motors in a Delta (3-lead)

configuration. The S801 works with all

motors from fractional horsepower up

to motors requiring 1000 amps of

steady state current. The built-in overload (in ranges from 12 – 1000 amps)

and run bypass contactor make installation and setup quick and easy. The

overload also offers some advanced

protective functions to give additional

motor protection.

With the pump control option, it is the

number one soft starter available for

pumping applications. The unique soft

stopping control provides a smooth

transition for stopping a motor and

eliminates the “water-hammer” effect

that can damage pipes, valves and

pumps.

Features

■

Built-in overload protection

Built-in run bypass contactor

■

■

Adjustable ramp times

Adjustable torque control

■

■

Adjustable kick start control

■

Programmable overload settings,

31 – 100% (3.2:1) of rated current

for the unit

Physically fits in place of most

■

NEMA and IEC starters

Easy to use control interface

■

module

■

Soft stop control

■

Multiple trip class settings

(5, 10, 20 and 30)

■

Six SCR control

Optional pump control

■

Benefits

Reduced wear on belts, gears,

■

chains, clutches, shafts and

bearings

■

Allows for controlling the inrush

current to the motor

■

Reduced inrush current leads to

more stable power grid and can

lower peak demand charges

Elimination of water-hammer in

■

pumping applications

■

Less shock to product on conveyor

lines and material handling gear

■

24V DC control enhances personnel

and equipment safety

Operation

Overload Functionality

Overtemperature

Protects the device from overheating.

Starter will shutdown at 110°C.

Jam

Selectable protective feature, unit trips

to prevent damage to motor during

normal run.

Stall

Selectable protective feature, unit trips

to protect system in event motor can

not get to rated speed in the defined

ramp period.

Phase Loss

Selectable protective feature, trips

under voltage loss condition to any

phase.

Phase Reversal

Selectable protective feature, trips

when phase rotation is something

other than A-B-C.

Kick Start

Selectable feature which provides a

current “kick” of up to 550% of full load

current for 0 to 2.0 seconds. This

provides the additional torque required

at startup to break free a motor.

Ramp Start

Provides a constant increase in torque

to the motor.

Current Limit Start

Limits the maximum current available

to the motor during the startup phase.

Soft Stop

Allows for a controlled stopping of a

frictional load.

Shorted SCR Detection

Monitors for shorted SCR in the power

polls.

For more information visit: www.eaton.com

CA03902005E

April 2007

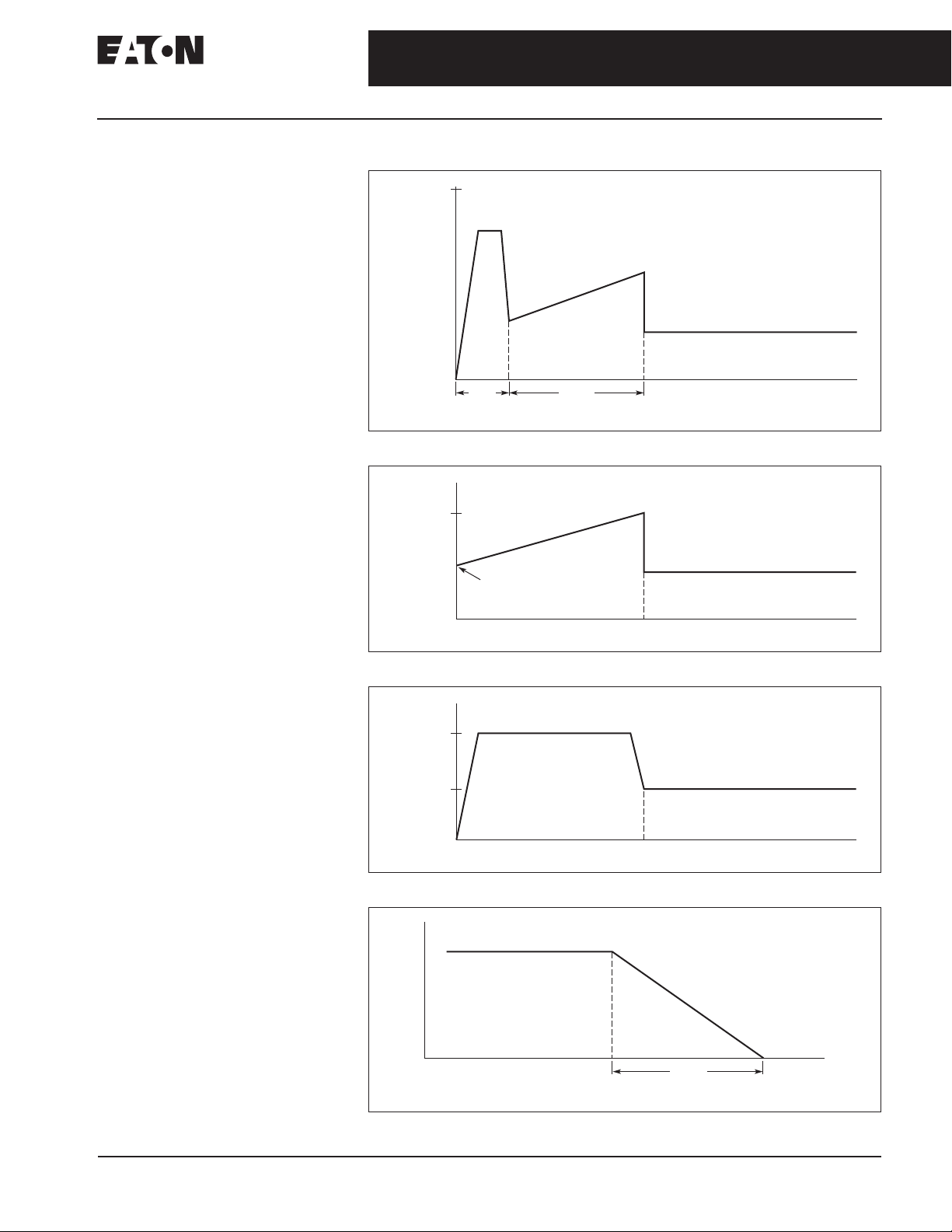

Starting Characteristics

Kick Start

Provides an initial boost of current

to the motor to help break free the

rotor and start spinning the motor.

0 – 85% of locked rotor torque.

■

■

0 – 2.0 seconds duration.

Ramp Start

The most commonly used form of soft

start. This allows you to set the initial

torque value (of the ramp) and then

raises it to full voltage conditions.

■

Adjustable initial torque =

0 – 85% of locked rotor torque.

■

Adjustable ramp time =

.5 – 180 seconds (can be extended

with factory modification).

Reduced Voltage Motor Starters

Solid-State Starters

Type S801, Intelligent Technologies (IT.) Soft Starters

100%

Locked Rotor Torque

Kick

Start

Figure 1. Starting Characteristics — Kick Start

100%

Initial

Locked Rotor Torque

Torque

Ramp

Time (Seconds)

Time (Seconds)

3

Run (FLA)

Run (FLA)

Current Limit

This mode of soft starting is used

when it becomes necessary to limit the

maximum starting current due to long

start times or to protect the motor.

■

Maximum current of 0 – 85% locked

rotor current.

■

Adjustable ramp time =

.5 – 180 seconds (can be extended

with factory modification).

Soft Stop

Used when an extended coast-to-rest

period is desired. Often used with high

friction loads where a sudden stop

may cause system or product damage.

■

Stop time = 0 – 60 seconds.

Figure 2. Starting Characteristics — Ramp Start

Max.

Allowed

Current

100%

FLA

Time (Seconds)

Figure 3. Starting Characteristics — Current Limit

Run

Time (Seconds)

Run

Ramp

Figure 4. Starting Characteristics — Soft Stop

CA03902005E For more information visit: www.eaton.com

Reduced Voltage Motor Starters

4

Solid-State Starters

Type S801, Intelligent Technologies (IT.) Soft Starters

Catalog Number Selection

Table 1. S801 Open Soft Starters Catalog Numbering System

S 8 0 1 N 6 6 N 3 S

April 2007

S = IT. Soft Starter

801 = Non-combination Soft Starter

Ampacity Rating

N37 = 37 amps

N66 = 66 amps

R10 = 105 amps

R13 = 135 amps

T18 = 180 amps

T24 = 240 amps

T30 = 304 amps

U36 = 360 amps

U42 = 420 amps

Not available on U-Frame.

U-Frame 500 Amp unit does not have IEC Certification.

U50 = 500 amps

V36 = 360 amps

V42 = 420 amps

V50 = 500 amps

V65 = 650 amps

V72 = 720 amps

V85 = 850 amps

V10 = 1000 amps

B = Level Sensing

D = Inside the Delta

L = Extended Ramp Start

S = Standard Soft Starter

Overload

W = Without CIM (Control

Interface Module)

3 = 3-Pole Device

N = No Options

P = Pump Control

V = 690 Volt Option

65 mm, Catalog Number S801N 110 mm, Catalog Number S801R

200 mm, Catalog Number S801T

290 mm, Catalog Number S801V

For more information visit: www.eaton.com

CA03902005E

Loading...

Loading...