10

10

18

Solid-State Soft Start Motor Controller and Starter

Application Note

February 2005

Supersedes January 2001

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Basic Motor and Soft Start Theory

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AC Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AC Motor Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Induction Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control of AC Motors . . . . . . . . . . . . . . . . . . . . . . . . . 3

Soft Start Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Soft Start Applications . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Reduced Voltage Starting Methods . . . . . . . . 5

Basic Mechanics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calculating Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calculating Horsepower . . . . . . . . . . . . . . . . . . . . . . . 7

Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pulley/Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2

WK

Reflected to the Motor Shaft . . . . . . . . . . . . . . . 8

Speed Reducer Selection . . . . . . . . . . . . . . . . . . . . . . 9

Gear Reducer Selection . . . . . . . . . . . . . . . . . . . . . . . 9

Gear Reducer — Overhung Load . . . . . . . . . . . . . . . . 9

Other Gear Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controllers and Starters, Theory and Application

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Benefits of Using Soft Start Controllers and

Starters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Principles of Soft Start Controllers and

Starters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical Soft Start Adjustments . . . . . . . . . . . . . . . . . 11

Motor Application Considerations . . . . . . . . . . . . . . 12

Installation Compatibility . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . 2

. . . . 10

Load Types and Characteristics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Load Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Other Functional Considerations . . . . . . . . . . . . . . . 13

Typical Load Torque . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controller and Starter Selection

Selection Considerations . . . . . . . . . . . . . . . . . . . . . . 15

Selecting a Soft Start for a Machine . . . . . . . . . . . . . 15

Measuring Machine Torque . . . . . . . . . . . . . . . . . . . . 16

Soft Start Application Questions . . . . . . . . . . . . . . . . 16

Soft Starter Application Data Worksheet . . . . . . . . . 17

Formulae, Conversions and Tables

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How to Calculate Torque . . . . . . . . . . . . . . . . . . . . . . 18

How to Calculate Horsepower . . . . . . . . . . . . . . . . . . 18

How to Calculate Surface Speed . . . . . . . . . . . . . . . . 18

How to Calculate Horsepower for Pumps . . . . . . . . 18

How to Calculate Horsepower for Fans and

Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Calculate Horsepower for Conveyors . . . . . 18

How to Calculate Accelerating Torque . . . . . . . . . . . 18

How to Calculate Maximum Motor Torque . . . . . . . 19

How to Calculate WK

How to Calculate Equivalent WK

Electrical Formulae . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Induction Motor Formulae . . . . . . . . . . . . . . . . . . . . . 20

Tables of Conversions and Abbreviations . . . . . . . . 20

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . 18

2

. . . . . . . . . . . . . . . . . . . . . . . . 19

2

at Motor Shaft . . 19

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 2

Introduction

About This Guide

The following material is intended to

acquaint the user with the theory and

operation of solid-state soft start

motor controllers and starters. This

material will enable the user to better

select the controller or starter and take

into consideration the parameters necessary for proper application to a

given load.

The reference material provided is for

the convenience of the user. It is taken

from current handbooks and standards such as NEC, NEMA, IEEE and

others. It is intended as reference

material for standard applications and

may not cover all actual and special

applications. Experienced factory

application engineers are available to

assist users in the application of motor

controllers and starters for most motor

loads. Specific ratings and external

signals used for control and logic are

the user’s responsibility.

The user must determine the final

suitability and acceptability for controllers and starters used on specific

equipment.

Basic Motor and Soft Start

Theory

Introduction

A solid-state soft start controller or

starter controls the starting torque and

current of an AC motor electronically.

They can be used in almost any

application such as:

■

commercial – HVAC fans and pumps

■

general industrial – fans, pumps,

conveyors, material handling and

processing equipment

■

others – forest products, mining,

metals and printing

The guide provides the basics required

to evaluate motor controller and

starter application needs.

Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

AC Motor Types

AC motors can be divided into two

main types: Induction and Synchronous. In this guide we will only cover

the use of a three-phase induction

motor and soft starter device, although

in some cases a soft starter device

may be used with a single-phase

motor.

Induction Motors

The induction motor is the simplest

and most rugged of all electric motors.

The typical varieties are the standard

induction motor and the wound rotor

motor.

Three-Phase

The three-phase induction motor is

divided into four classifications

according to NEMA. (Note that there

are IEC design standards which differ

somewhat from the NEMA versions.)

The classification or design, is determined by the locked rotor torque and

current, breakdown torque, pull-up

torque and the percent slip. The

speed-torque curve and characteristics

of each design are given below. These

characteristics apply for operation

from fixed frequency and voltage as

normally supplied from commercial

utility power sources at 60 Hz.

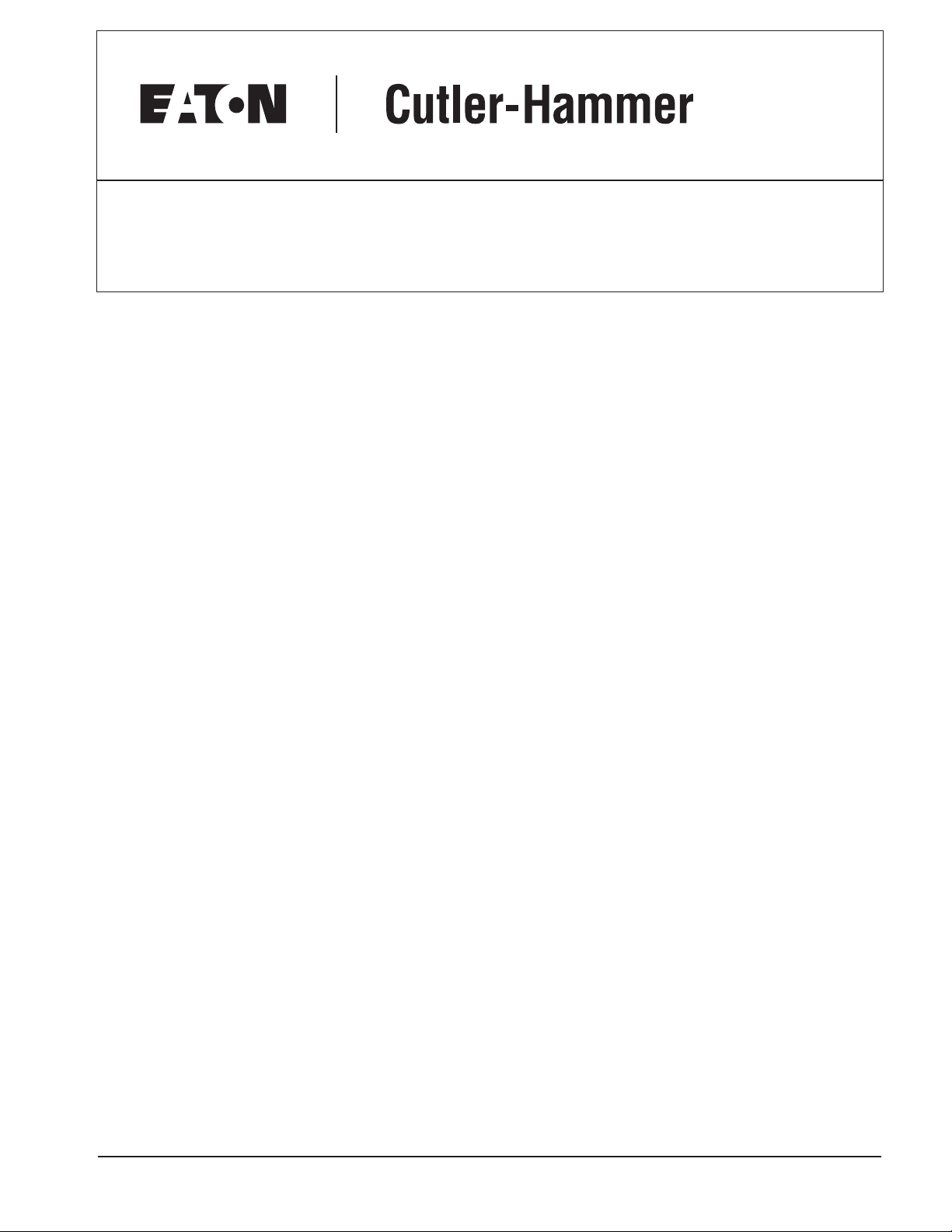

■

Design A motors have a slightly

higher breakdown, and lower starting torque than Design B motors.

The slip is usually 3 to 5% or less.

The major difference between the

Design A and Design B motor is that

the starting current is limited on the

Design B, but not on the Design A.

Design A motors are applied to the

same applications as Design B

motors. Design A motors may be

used with solid-state soft start

devices.

%

Rated

Tor qu e

300

200

Breakdown

(Maximum)

To rq ue

■

Design B motors are general pur-

pose type motors and account for

the largest share of the induction

motors sold. The slip of a Design B

motor is approximately 3 to 5% or

less. Design B motors are used on

applications where starting torque

requirements are low such as general industry, fans, blowers and centrifugal pumps and compressors.

Design B motors are often used with

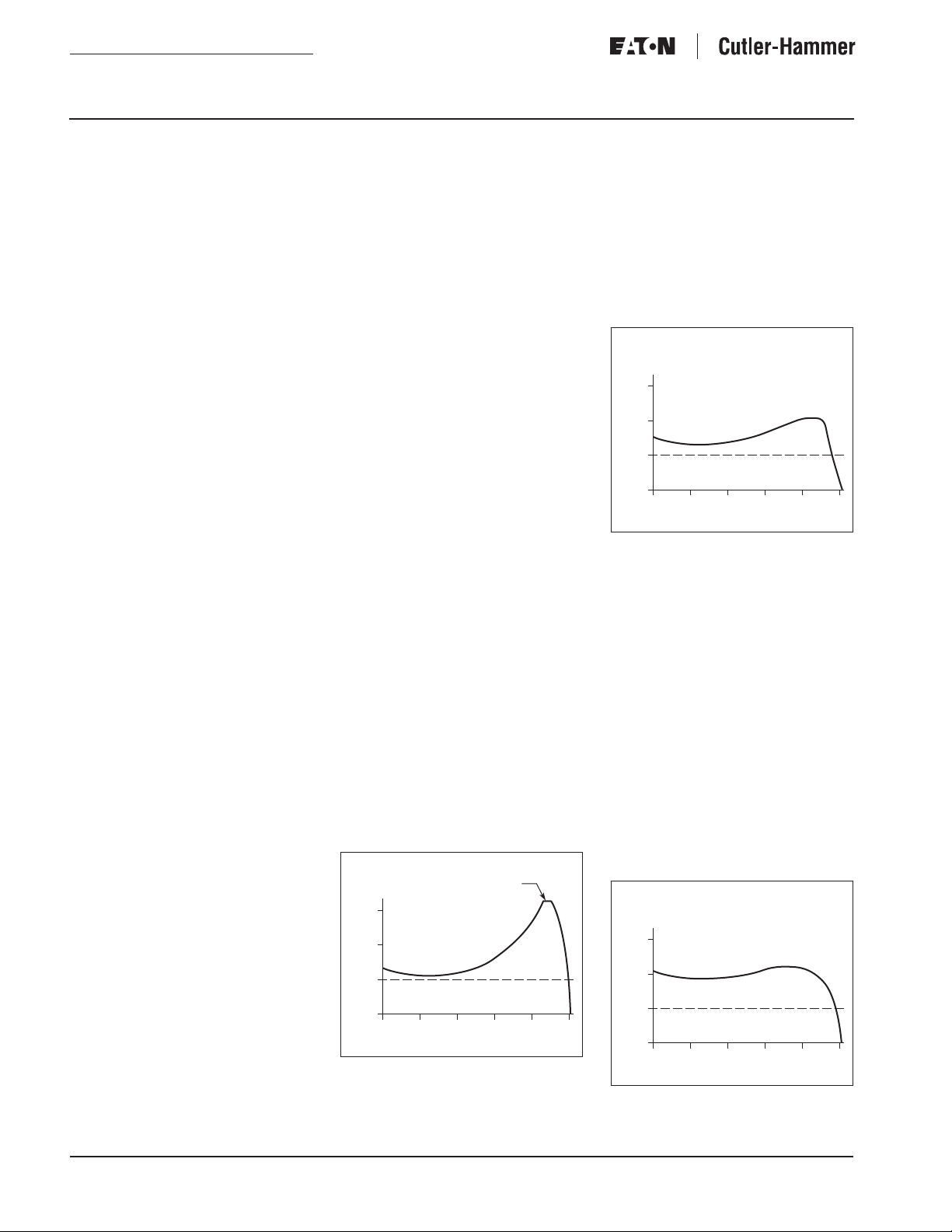

solid-state soft start devices.

%

Rated

Tor qu e

300

200

100

0

020406080100

% Rated Speed

Figure 2. Design B Polyphase Motor

Design C motors have a high start-

■

ing torque with a normal starting

current and low slip. The Design C

motor is usually used where breakaway loads are high at starting, but

are normally run at rated full load,

and are not subject to high overload

demands after running speed has

been reached. The slip of the Design

C motor is 5% or less. Design C

motors are often used where high

starting torques under loaded conditions are required including crushers, agitators, reciprocating pumps

and high friction conveyors. Care

must be exercised when using a

Design C motor with a soft start controller or starter to assure that the

application starting torque and time

to start requirements can be met.

%

Rated

Tor qu e

300

AC Motors

Cutler-Hammer

and starters operate with standard

motors. In most cases, an existing

motor sized for another method of soft

start, can be directly applied. For new

installations the user must understand

the nature of the application in terms

of the load characteristic requirements

and the motor capability when used

with a soft start controller or starter.

®

soft start controllers

100

0

02040

% Rated Speed

Figure 1. Design A Polyphase Motor

For more information visit: www.EatonElectrical.com

60 80

100

200

100

0

020406080100

% Rated Speed

Figure 3. Design C Polyphase Motor

AP03902001E

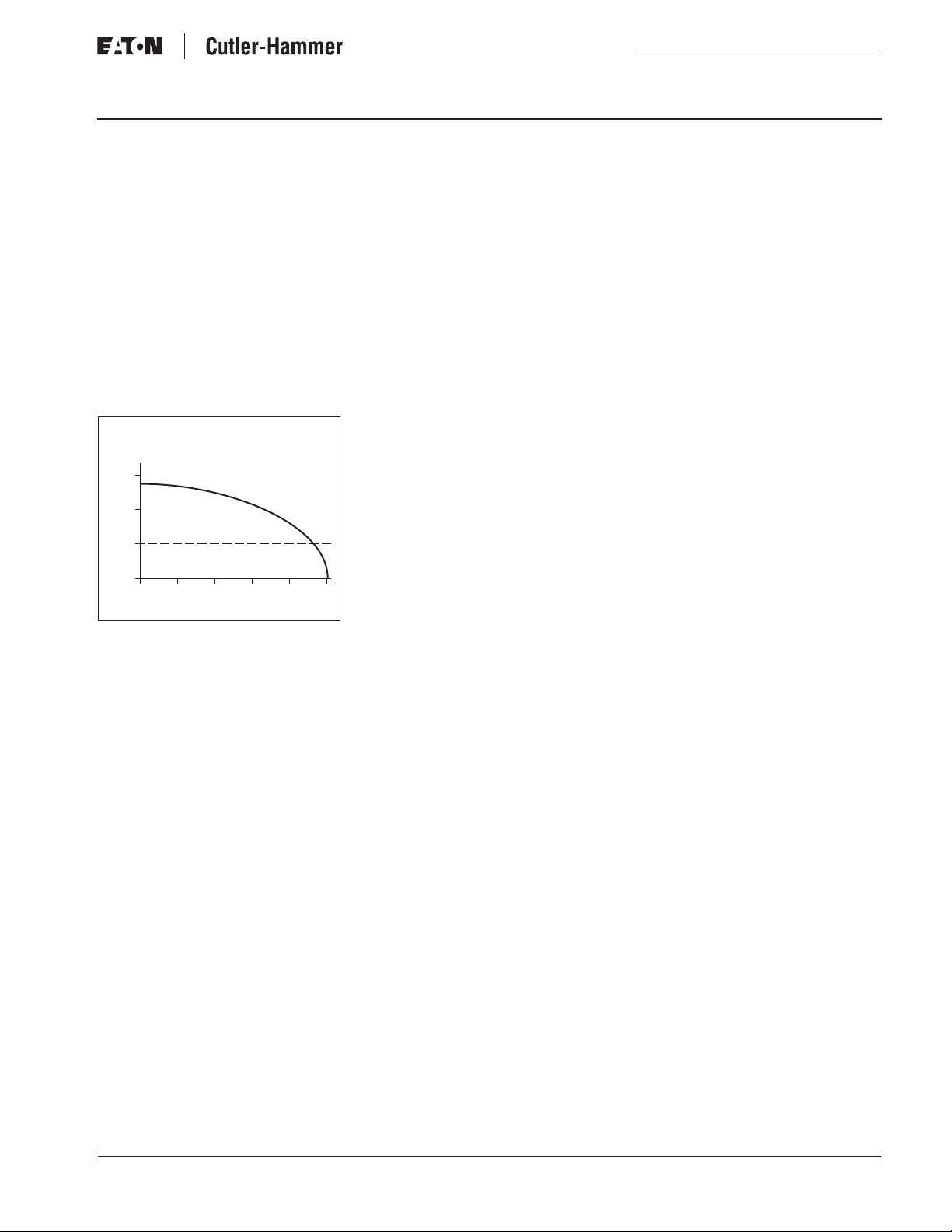

■

Design D motors have high slip,

high starting torque, low starting

current and low full load speed.

Because of the high amount of slip,

the speed will vary if fluctuating

loads are encountered. The slip of

this type of motor is approximately

5 to 13%. Design D motors are used

on applications with high peak loads

with flywheels like punch presses,

shears, hoists, oil well pumps and

extractors. Care must be exercised

when using a Design D motor with a

soft start controller or starter, since

the limitation of the starting torque

or increase of the starting time may

cause thermal concerns for the

motor and soft start.

%

Rated

Tor que

300

200

100

0

020406080

% Rated Speed

Figure 4. Design D Polyphase Motor

100

Wound Rotor Motors

The wound rotor motor allows controllable speed and torque compared to

the conventional induction motor.

Wound rotor motors are generally

started with a secondary resistance in

the rotor. As the resistance is reduced,

the motor will come up to speed. Thus

the motor can develop substantial

torque while limiting the locked rotor

current. The secondary resistance can

be designed for continuous service to

dissipate the heat produced by continuous operation at reduced speed and

frequent start/stops or acceleration of

a large inertia load. This external resistance gives the motor a characteristic

that results in a large drop in rpm for a

small change in load. Reduced speed

typically can be provided down to

approximately 50% of rated speed,

although at a very low efficiency.

These motors are sometimes used (in

large horsepower ratings) in slip

recovery systems. In these systems

the external (secondary) resistance

element is replaced with a solid-state

circuit to convert the rotor slip energy

to useful AC power. These motors can

be used with a soft starter in some

applications. The use is dependent

Solid-State Soft Start

Motor Controller and

Starter

upon why the motor’s secondary resistance was selected and how the use of

the soft starter will impact the load

requirements. If the rotor resistance

was selected to be stepped through

various sizes to provide a gentle start,

a soft starter can likely be used. If the

resistor is just a single value and was

selected to give high starting torque,

the use of a soft starter might not

allow the same level of torque to be

generated. The application requirements must be determined.

Enclosures

The basic protective enclosures for AC

motors are: open dripproof (ODP),

totally enclosed fan cooled (TEFC),

totally enclosed non-ventilated (TENV)

and totally enclosed air over (TEAO).

Other special enclosures available

include: pipe-ventilated, weather protected, water cooled and explosion

proof.

Ventilation

The system for ventilating motors

depends on the type of motor enclosure as mentioned previously and

described below:

ODP (Open Dripproof) – The ODP

■

motor is ventilated (cooled) by

means of a shaft mounted internal

fan which drives air through the

open ends of the motor and discharges it out the sides. These

motors are often supplied as

protected, fully-guarded or

splash-proof.

TEFC (Totally Enclosed Fan Cooled)

■

– This type of motor is cooled by air

passing over the outer frame of the

motor. The air is supplied by a shaft

mounted fan opposite the shaft end

of motor.

TENV (Totally Enclosed Non-

■

Ventilated)

a shaft mounted internal fan used to

circulate air within the motor to prevent hot spots. No external fan or air

is supplied. These are suitable for

very dirty and contaminant laden

environments that would clog most

exposed cooling fans. These motors

dissipate their heat through their

frames and are thus oversized compared to other enclosure types.

They are generally available only in

smaller hp ratings (up to 7-1/2 hp).

– This type of motor has

Application Note

Effective: February 2005 Page 3

■

TEAO (Totally Enclosed Air Over) –

This type of motor is cooled by

externally provided air blowing over

the frame. The air may be supplied

by an integrally mounted blower

and motor or from a separate

source. This type of ventilation

provides constant cooling under

all operating conditions.

■

Special Enclosures – The Pipe-

Ventilated motor is available for

either an open or totally enclosed

type of enclosure and is used in very

dirty environments. Ventilating air

(supplied by the User) enters and

exits the motor through inlet and

outlet ducts or pipes. The air is circulated by means either integral or

external to the motor.

The Weather-Protected motor uses

an open type enclosure for ventilation. The motor is constructed to

minimize the entrance of rain, snow

and airborne particles to the electrical parts of the motor. External air

can be circulated through the motor

for cooling.

Totally Enclosed Air-to-Air and

Totally Enclosed Water-to-Air cooled

enclosures are normally used on

high horsepower motors that generate large amounts of heat. A heat

exchanger is used for both types to

remove the heat generated by the

motor. An AC motor driven blower

circulates air through the windings

and heat exchanger tubes. The heat

in the heat exchanger is removed by

either an external air system (air-toair) or water provided by the user

(water-to-air cooled).

Explosion Proof motors are

designed to operate in hazardous

environments such as explosive

vapors, coal or grain dust and other

classified areas. These are selected

on the basis of the appropriate

Class, Group, and Division of hazard, as defined by the National Electrical Code (NEC).

Control of AC Motors

The most common control of an AC

motor is by using a motor starter. This

device connects the motor to the commercial AC power line. It is rated to

operate with the typical high starting

(inrush) current that occurs when a

motor is directly connected to the utility line. A motor starter also contains a

protective device known as a motor

overload. This device is designed to

protect the motor from continued

overloads and stalling due to excessive machine loads on starting or jamming when operating.

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 4

With the above method of control, AC

motors will operate as described by

their NEMA (or IEC) characteristics for

their design type on industrial AC

power. This includes a prescribed

overload capability, regulation due to

slip, starting inrush current and starting (locked rotor) torque. The load on

the driven machine determines the

acceleration time and motor load (or

overload).

Special control hardware is available

to modify some of the above characteristics. Part winding, autotransformer and wye-delta motor starters

will reduce the inrush current when

starting an AC motor. But using these

devices does not provide for a soft

controlled stepless start.

Solid-state soft start motor controllers

and starters have the ability to control

the starting characteristics to match

the application requirements, such as

acceleration and deceleration time,

starting and overload current and

motor torque. In addition, motor

protection may be provided for a

number of potential damaging circumstances by the soft starter (a soft start

controller does not provide any motor

protection).

Soft Start Basics

Why do we want to use a reduced voltage soft starter?

The first reason is to limit the inrush

current that a motor draws from the

utility when it is first started. This is a

concern because the large starting current may cause the line voltage to dip,

impacting other loads which are sensitive to low voltages. There may also be

a concern if the utility limits the peak

current which can be drawn or charges

for exceeding the limit.

The second is reduced mechanical

system stress. When the large inrush

current occurs, there are significant

magnetic forces created in the motor

windings. These cause some parts of

the winding to be attracted to each

other and other parts repulsed. This

mechanical shock can damage the

winding insulation leading to early failure. The mechanical shock of the high

torques produced with the large starting current can cause failure of system

elements such as the motor shaft, belting, gear box, drive train and damage

to fragile product.

Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

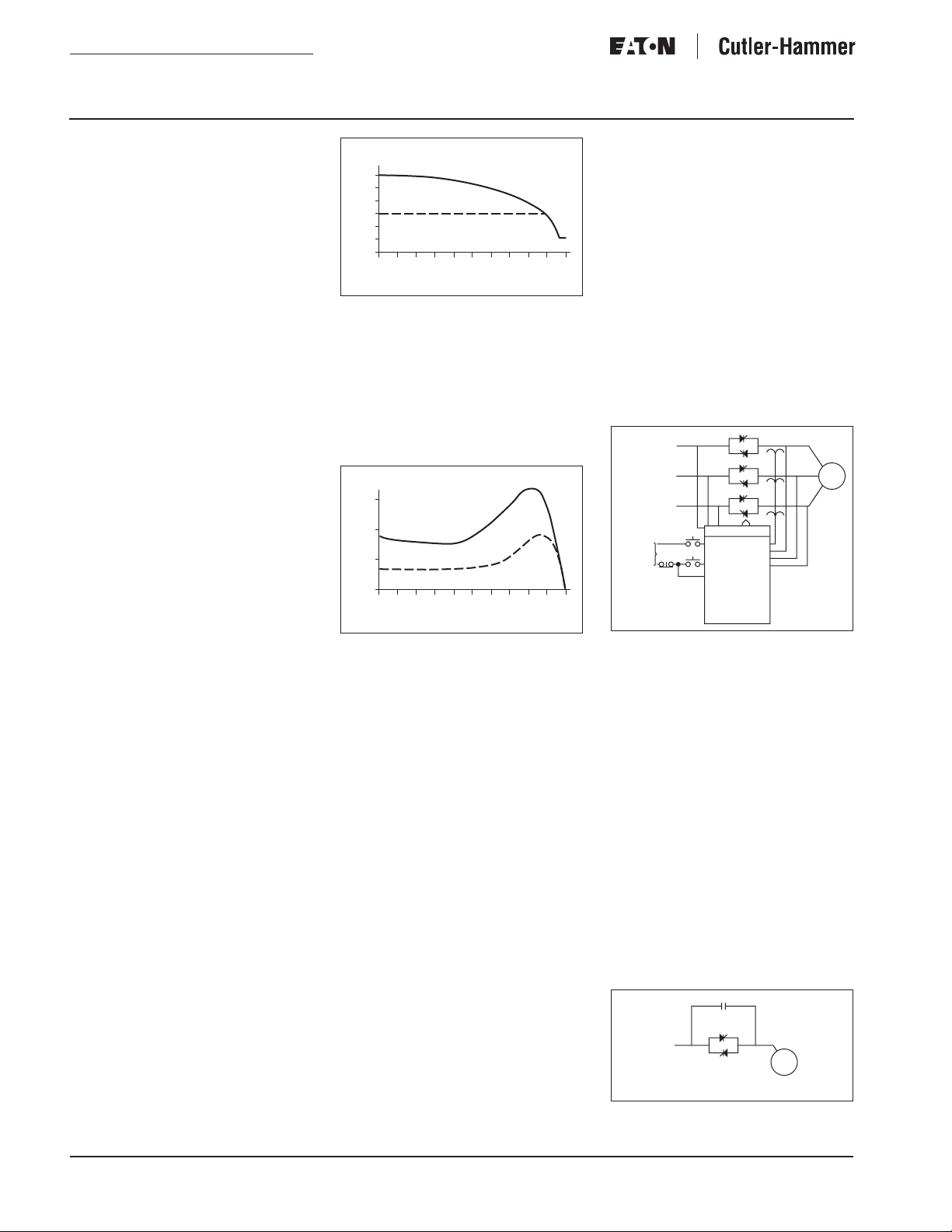

Current

600

Figure 5. Motor Current vs. Speed

This graph shows the impact of using

a soft start. For this motor, the initial

current when it is started is 600 percent, or six times the motor’s full load

current rating. The soft starter can be

set to reduce this current, for example

in this case to 300 percent. This limits

the inrush current on the utility line.

Tor qu e

300

200

100

Figure 6. Motor Torque vs. Speed

As a result of the reduction in current,

the motor’s ability to generate torque

is also reduced. The upper curve

shows the same motor started across

the line. The initial torque is about 180

percent with a peak torque of over 300

percent. With the soft start limiting the

current, the torque speed curve is

reduced, reducing mechanical stress.

The torque available from the motor at

reduced current is equal to the locked

rotor or starting torque, times the

square of the reduced current divided

by the locked rotor current. Thus if we

reduce the current from 600 percent to

300 percent, the torque varies as the

square of this reduction. The torque is

thus reduced to 25 percent of the

across the line starting torque.

How Does Torque Vary?

Where:

T

T

I

1

I

2

V

V

Full Voltage Starter

%

Solid-State Starter

0

Speed RPM

%

Full Voltage

%

%

0

T2T

= Torque at recued current/voltage

2

= torque at locked rotor current

1

= Locked rotor current

Starter

Solid-State Starter

Speed RPM

2

I

2

T

≈=

----

1

I

1

V

2

------

1

V

1

2

= Reduced current

= Full voltage

1

= Reduced voltage

2

100

100

%

%

Some soft starters control voltage

instead of current. The torque available varies proportionately with the

square of the ratio of the reduced

voltage to the normal line voltage.

When the operator depresses the

START button, the soft starter logic

issues an ON command to the power

module, causing the SCRs to turn on

and gently increase the voltage across

the motor terminals, or the current

into the motor based on the adjustments made to the soft start logic.

When the SCRs are fully on, the motor

reaches full voltage.

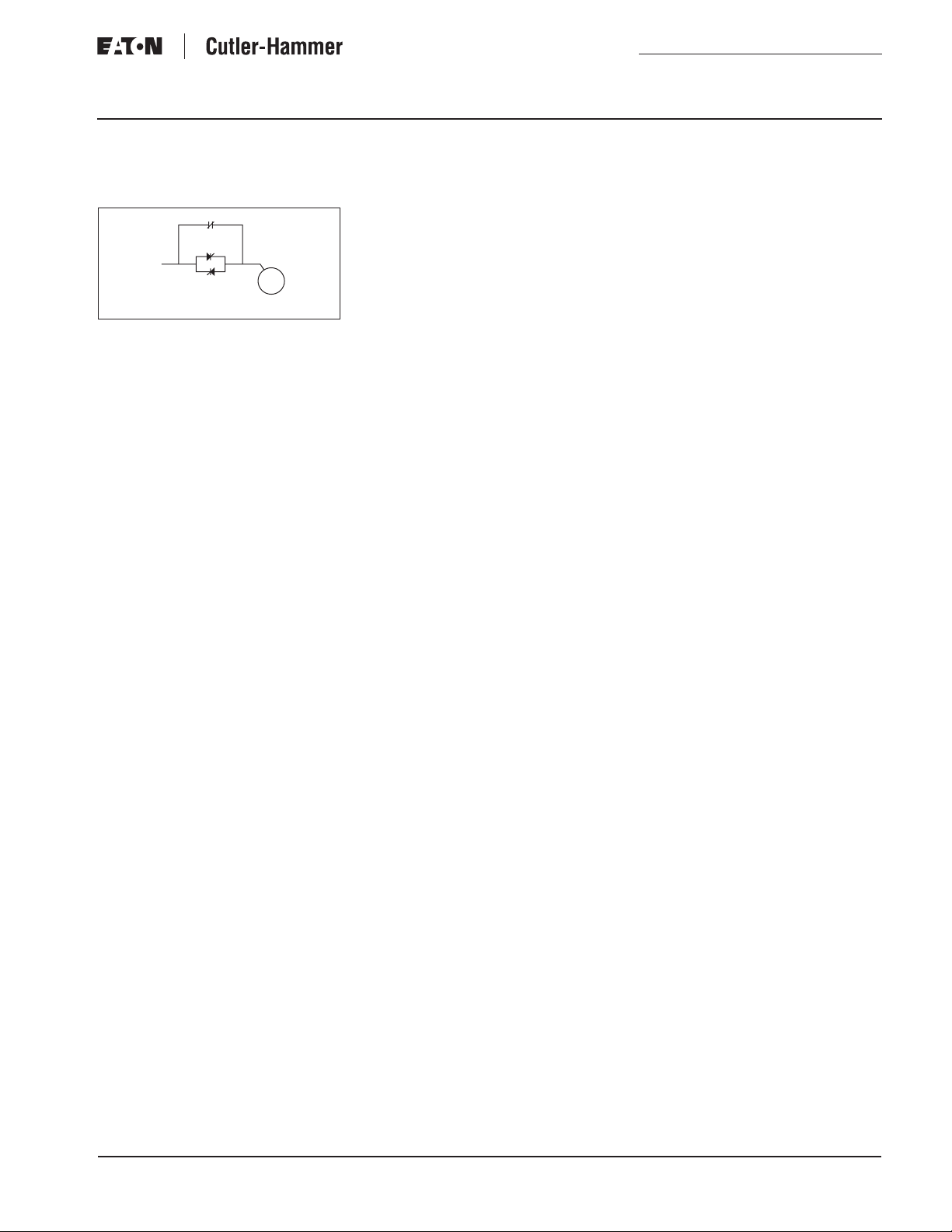

A block diagram of a typical soft start

starter would look like

L1

3-Phase

Power

Supply

Control

Power

Stop

L2

L3

Reset

Start

Figure 7 .

Control Logic

• Current limit

• Running

overload

protection

• Phase loss

protection

• Undervoltage

protection

• Energy saver

control

Motor

Figure 7. Typical Block Diagram

This solid-state starter utilizes six full

current rated SCRs as its power

devices. The logic circuit monitors

three-phase input voltage, three-phase

output voltage, and the three output

currents. From these inputs it can provide starting current limitation, running overcurrent protection, phase

loss and undervoltage protection.

This starter interfaces with standard

control circuits.

In some products a bypass contactor

may be closed to provide higher operating efficiency after the SCRs are fully

Figure 8 is a single-phase leg of the

on.

soft starter with the SCRs turning on

and becoming the current path for

power to flow from the utility to the

motor.

A

Motor

Figure 8. SCRs as Current Path

For more information visit: www.EatonElectrical.com

AP03902001E

Solid-State Soft Start

Motor Controller and

Starter

Application Note

Effective: February 2005 Page 5

After the motor has come up to speed,

the bypass contactor closes and it

becomes the current path for the

motor.

A

Motor

Figure 9. Bypass Contactor as Path

At this time the SCRs no longer conduct any current.

Bypass operation eliminates the SCR

losses once the motor is up to speed,

resulting in significantly lower heat

generation. Soft starters with internal

run bypass mode are typically much

smaller and lighter than devices without run bypass.

Soft Start Applications

We would like to identify problems

that can be solved by the use of a soft

starter. One challenge is that it can be

difficult for the user to recognize a

problem as a problem. Frequently the

problem is mistaken for a normal

operational or maintenance issue.

It is the intent of this section to help

to determine solutions, using soft

starters for both new and retrofit

installations.

Typical problems can be categorized

as mechanical, motor, starting equipment, inrush current, or fragile product

related.

Typical mechanical problems are:

stretching, squealing or breaking of

drive belts; breakage of gear boxes; couplings wearing out prematurely; shaft

breakage within the drive train; and,

water hammer in hydraulic systems.

To get an idea of the effect of starting

torque on the mechanical system, lets

consider an automobile. If you were to

put the transmission in neutral and

quickly press the accelerator to the

floor, you would feel the car reacting

to the sudden increase in motor torque

as it rotates slightly in response to the

torque being developed by the engine.

This same type of effect is what causes

these mechanical problems, except

that the torque levels may be considerably greater than those experienced

with an automobile.

Motor problems include: motor insulation deterioration or premature winding failure due to the mechanical

stresses put on the winding during

starting, or the high temperatures

imposed by high starting currents;

mechanical stresses on the system

such as foundation bolts or mounting

failures, bearing lock-up and failure,

and motor shaft cracking and breakage; coupling failures; and, excessive

energy losses due to duty cycle or frequent start/stop operation.

Benefits of Using Soft Start Starters:

■ Controlled starting – Limited start-

ing current, reduction of power line

disturbance on starting, lower

power demand on starting.

■ Controlled acceleration – Soft start,

adjustable acceleration based on

time or load, reduced motor size for

pure inertial load acceleration.

■ Adjustable torque limiting – Protects

machinery from damage, protects

process or product.

■ Controlled stopping – Soft slow

down, timed stopping, fast reversal

with much less stress on AC motor

than plug reverse.

Typical Fixed Speed Applications:

■ Conveyors, belts, chains, screws,

bulk material, packaged material

■ Fans, blowers, compressors, pumps

■ Machine tools, grinders, lathes,

stamping presses

■ Custom machinery, labelers, pack-

aging machines, bottle washers,

wire drawing, textiles, etc.

■ Extruders

■ Process machinery, kilns, grinders,

blenders, agitators. See the section

on load types for particular evaluation of specific loads.

Other Reduced Voltage Starting

Methods

There are several reduced voltage

starting methods that predate solidstate soft start motor controllers and

starters. Table 1 illustrates these meth-

ods and their typical applications.

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 6 Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

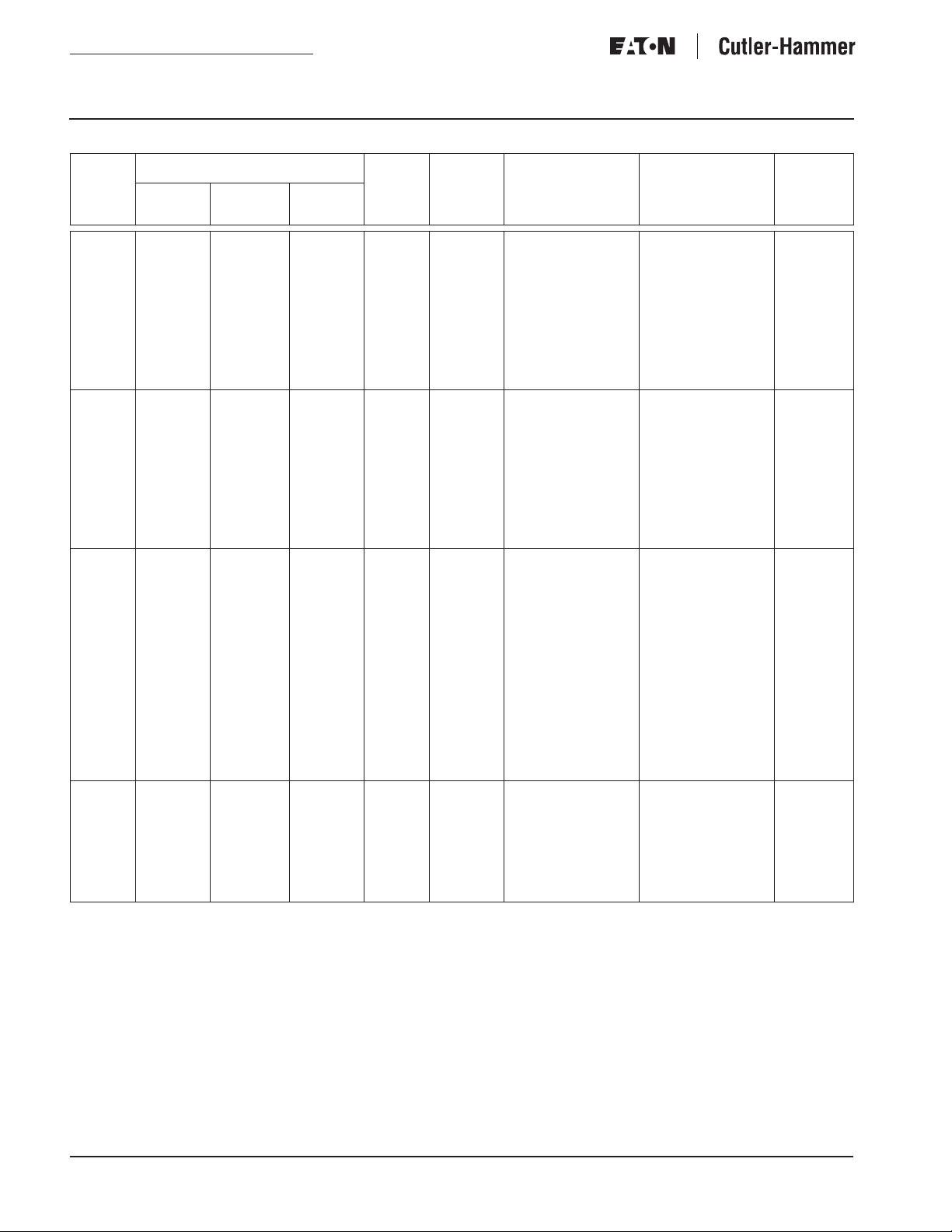

Table 1. Comparison of Electromechanical Soft Starters

Type of

Starter

Autotransformer8065

Primary

Resistor

Part

Winding

Wye Delta 100 33 33 Open

Starting Characteristics in Percent of Full

Transition Extra

Voltage Values

% Line

Voltage at

Motor

50

% Motor

Locked Rotor

Amps

64

42

25

% of Motor

Locked

Rotor Torque

64

42

25

Closed No

65 65 42 Closed Yes

100 65 48 Closed Yes (but very

(Closed

available

for about

30% price

adder)

Acceleration

Steps

Available

uncommon)

No

Advantages Disadvantages Applications

■ Provides highest

torque per ampere of

line current

■ 3 different starting

torques available

through

■ In lower horsepower

ratings is most

expensive design

■ Low power factor

■ Large physical size

Blowers

Pumps

Compressors

Conveyors

autotransformer taps

■ Suitable for relatively

long starting periods

■ Motor current is

greater than line

current during starting

■ Smooth acceleration –

motor voltage

increases with speed

■ High power factor

during start

■ Less expensive than

autotransformer

starter in lower

horsepower ratings

■ Available with as

■ Low torque efficiency

■ Resistors give off heat

■ Starting time in excess

of 5 seconds requires

expensive resistors

■ Difficult to change

starting torques under

varying conditions

Belt and gear

drives

Conveyors

Textile

machines

many as 5 accelerating

points

■ Least expensive

reduced voltage

starter

■ Most dual voltage

motors can be started

part winding on lower

voltage

■ Small physical size

■ Unsuited for high

inertia, long starting

time loads

■ Requires special motor

design for voltage

higher than 230 volts

■ Motor will not start if

the torque demanded

Reciprocating

compressors

Pumps

Blowers

Fans

by the load exceeds

that developed by the

motor when the first

half of the motor is

energized

■ First step of

acceleration must not

exceed 5 seconds or

else motor will

overheat

■ Suitable for high

inertia, long

acceleration loads

■ High torque efficiency

■ Ideal for especially

stringent inrush

restrictions

■ Ideal for frequent

■ Requires special motor

■ Low starting torque

■ During open transition

there is a high

momentary inrush

when the delta

contactor is closed

Centrifugal

compressors

Centrifuges

starts

For more information visit: www.EatonElectrical.com AP03902001E

Solid-State Soft Start

Motor Controller and

Starter

Application Note

Effective: February 2005 Page 7

Basic Mechanics

Introduction

In order to apply a soft start properly,

certain mechanical parameters must

be taken into consideration. This section explains what these parameters

are and how to calculate or measure

them.

Torque

Torque is the action of a force producing or tending to produce rotation.

Unlike work (which only occurs during

movement) torque may exist even

though no movement or rotation

occurs.

Torque consists of a force (Lb.) acting

upon a length of a lever arm (Ft.). The

product of these two factors produces

the term lb-ft, which is the unit of measurement for torque (see Figure 10).

Mathematically, it is expressed as:

Torque (lb-ft) = Force (Lbs.) x

Distance (Ft.)

Example:

Torque = Force x Distance

Torque = 50 Lbs. x 1 Ft.

Torque = 50 lb-ft

Because most power transmission is

based upon rotating elements, torque

is important as a measurement of the

effort required to produce work.

Force

Lever Arm – 1 Ft.

Figure 10. Calculating Torque

Calculating Torque

Acceleration Torque Required for Rotating

Motion

Some machines must be accelerated

to a given speed in a certain period of

time. The torque rating of the motor

may have to be increased to accomplish this objective. The following

equation may be used to calculate the

average torque required to accelerate

a known inertia (WK

must be added to all the other torque

requirements of the machine when

determining the motor’s required peak

torque output.

2

). This torque

50 Lbs.

2

WK

xdN

-------------------------

T

=

308t

Where:

T = Acceleration Torque (lb-ft)

2

= Total system inertia (lb-ft2) that

WK

the motor must accelerate. This value

includes motor rotor, speed reducer

and load.

dN = Change in speed required (rpm)

t = Time to accelerate total system load

(seconds)

Note: The number substituted for (WK2) in

this equation must be in units of lb-ft

The same formula can also be rearranged to determine the minimum

acceleration time of a given system, or

if a motor can accomplish the desired

change in speed within the required

time period.

Rearranged Equation:

2

xdN

WK

-------------------------=

t

308T

2

.

Calculating Horsepower

Note: The following equations for calculating horsepower are to be used for estimating purposes only. These equations do not

include any allowance for machine friction,

windage or other factors. These factors

must be considered when selecting a motor

for an application. Once the machine torque

is determined, the required horsepower is

calculated using the formula:

TxN

hp

-------------=

5250

Where:

hp = Horsepower

T = Torque (lb-ft)

N = Speed of motor at rated load (rpm)

If the calculated horsepower falls

between standard available motor

ratings, select the higher available

horsepower rating. It is good practice

to allow some margin when selecting

the motor horsepower. Also note that

the motor’s torque output is reduced

during a soft start. The load requirements must be related to the soft

starter settings.

For many applications, it is possible

to calculate the horsepower required

without actually measuring the torque.

The following equations will be

helpful:

Conveyors

hp =

(Vertical)

hp =

(Horizontal

Where:

F/W = force/weight in Lbs.

V = Velocity in feet per minute

Coef. = Coefficient of friction

F / W (lbs) x V (fpm)

33,000 x Efficiency

F / W (lbs) x V (fpm) x Coef

)

33,000 x Efficiency

Fans and Blowers

hp =

cfm x Pressure (psi)

33,000 x Efficiency of Fan

hp =

cfm x Pressure (lb-ft

2

)

229 x Efficiency of Fan

cfm x (Inches of Water Gauge)

hp =

6356 x (Efficiency of Fan)

Pumps

gpm x Head (ft.) x (Specific Gravity)

hp =

Where:

psi = pounds per square inch

cfm = cubic feet per minute

gpm = gallons per minute

Specific gravity of water = 1.0

1 cubic foot per second = 448 gpm

1 psi = a head of 2.309 ft. for water

weighing 62.36 lbs. per cu. ft. at 62°F.

Efficiency of fan or pump = %/100

Displacement pump efficiency:

Displacement pumps vary between 85

and 90% efficiency depending on size

of pumps.

Centrifugal pump efficiency (at design

point):

500 to 1000 gal. per min. = 70 to 75%

1000 to 1500 gal. per min. = 75 to 80%

Larger than 1500 gal. per min. =

80 to 85%

3960 x (Efficiency of Pump)

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 8 Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

Inertia

Inertia is a measure of a body’s resistance to changes in velocity, whether

the body is at rest or moving at a constant velocity. The velocity can be

either linear or rotational.

2

The moment of Inertia (WK

) is the

product of the weight (W) of an object

and the square of the radius of gyra-

2

tion (K

). The radius of gyration is a

measure of how the mass of the object

is distributed about the axis or rotation. Because of the distribution of

mass, a small diameter cylindrical part

has a much lower inertia than a large

diameter part.

The inertia calculations for typical

shapes follow.

WK2 or WR

2

WR2 refers to the inertia of a rotating

member that was calculated by

assuming the weight of the object

was concentrated around its rim at a

distance R (radius) from the center.

2

refers to the inertia of a rotating

WK

member that was calculated by

assuming the weight of the object was

concentrated at some smaller radius,

K (termed the radius of gyration). To

determine the WK

2

of a part, the

weight is normally required.

Calculations

When performing calculations, be consistent with the formulae and units

used. Common mistakes are substituting inches for feet, etc.

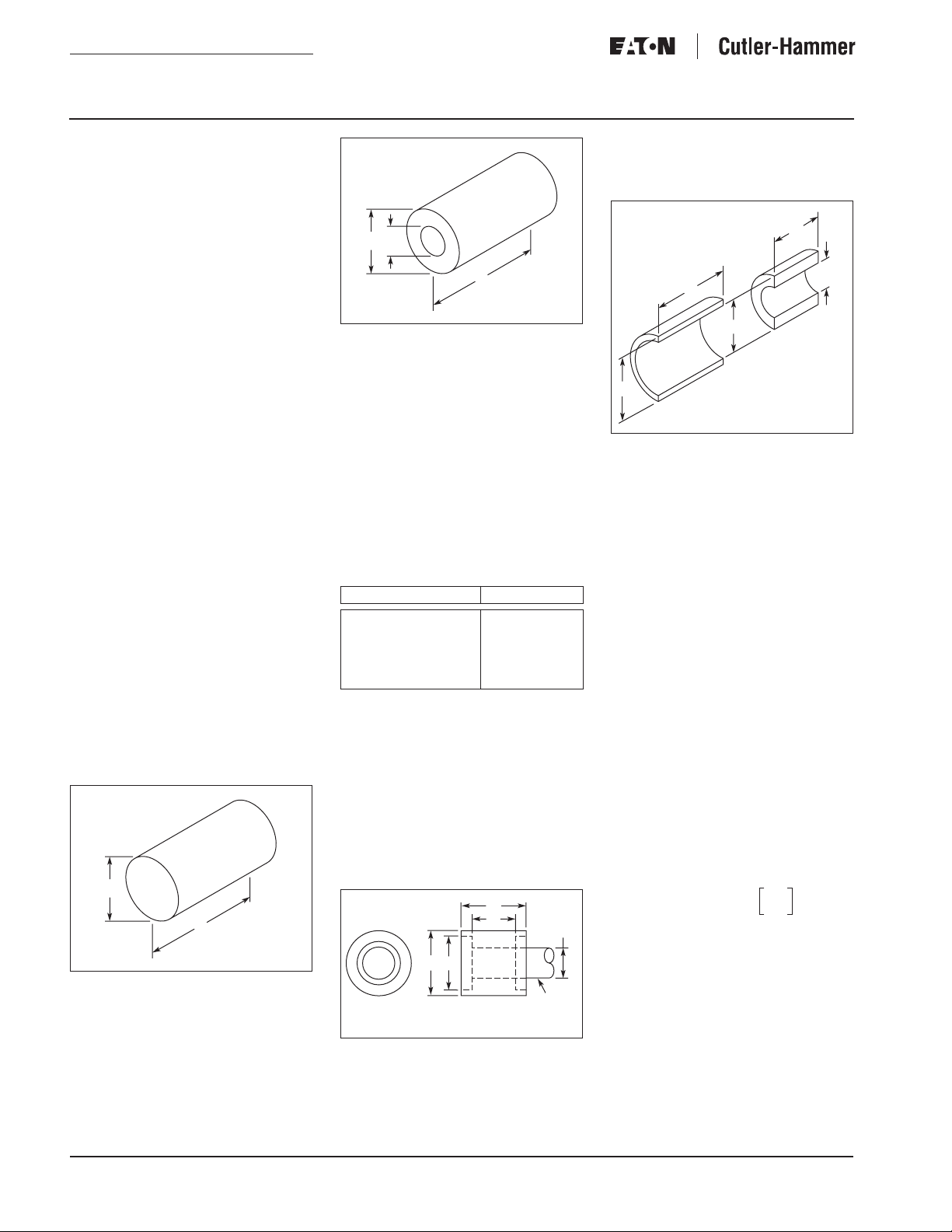

Cylinders

D

L

Figure 11. Solid Cylinder

Equations:

2

WK

= .000681 x p x L x (D)

4

D1D

2

L

Figure 12. Hollow Cylinder

Equations:

2

WK

= .000681 x p x L (D

4

- D1 4)

2

Where:

2

= inertia of a cylinder (lb-ft2)

WK

p = density of cylinder material in lb-in

(see density chart below)

= inside diameter of cylinder

D

1

(inches)

= outside diameter of cylinder

D

2

(inches)

L = Length of cylinder (inches)

Table 2. Common Material Densities (p)

Aluminum

Brass

Cast Iron

Steel

Rubber

Paper

0.0977

0.3110

0.2816

0.2816

0.0341

0.0250 to 0.0420

Pulley/Gear

To calculate the inertia of a pulley or

gear, divide up the piece (shown in

Figure 13) as shown in Figure 14.

Using the same equation for calculating hollow cylinders, perform the calculations of each separate part and

add them together for a total inertia.

End View

2

and WK

1

Note: WK

inertia calculations.

Figure 13. Complete Pulley/Gear

2

are the separate

2

3"

2.5"

Side View

3"

2"

1.375"

Motor

Shaft

In this example the pulley is made of

steel. We will divide it up to calculate

as shown.

3"

2.5"

3"

Figure 14. Pulley/Gear Components

3

WK

2

1

Equations:

2

= .000681 x p x L (D

WK

4

2

Calculations:

2

= .000681 x 0.2816 x 3 x

WK

1

4

– 2.54)

(3

= .0241 lb-ft

2

WK

= .000681 x 0.2816 x 2 x

2

(2.5

= .0136 lb-ft

Total Inertia = WK

2

4

– 1.3754)

2

2

+ WK

1

.0136

= .0377 lb-ft

2

WK2 Reflected to the Motor Shaft

In most mechanical systems not all the

moving parts operate at the same

speed. If speeds of the various parts

have a continuous fixed relationship

to the motor speed, the equation can

be used to convert all of the various

inertia values to an equivalent WK

applied to the motor shaft.

WK2 of Rotating Parts

2

WK

---------------DR()

2

N

--------N

Equivalent WK2 = WK2

Where:

2

= inertia of the moving part

WK

N = speed of the moving part (rpm)

= speed of the driving motor (rpm)

N

M

When using speed reducers, and the

machine inertia is reflected back to the

motor shaft, the equivalent inertia is

equal to the machine inertia divided by

the square of the drive reduction ratio.

2

Equivalent WK

=

2"

1.375"

2

WK

2

- D1 4)

2

= .0241 +

2

2

M

2

For more information visit: www.EatonElectrical.com AP03902001E

Solid-State Soft Start

Motor Controller and

Starter

Application Note

Effective: February 2005 Page 9

Where:

DR = drive reduction ratio =

Input

1 hp

3 lb-ft

1750 RPM

Reducer

N

---------

Output

(Less Efficiency)

76.5 lb-ft

57.5 Rpm

Gear

(30:1)

M

N

1 hp

Figure 15. Gear Reducer Characteristics

WK2 of Linear Motion

Not all driven systems involve rotating

motion. The equivalent WK

2

of linearly

moving parts can also be reduced to

the motor shaft speed as follows:

2

WV()

2

=

Equivalent WK

-----------------------------

39.5 NM()

2

Where:

W = weight of load (Lbs.)

V = linear velocity of rack and load or

conveyor and load (fpm)

= speed of the driving motor (rpm)

N

M

This equation can only be used where

the linear speed bears a continuous

fixed relationship to the motor speed,

such as a conveyor.

Speed Reducer Selection

The motor should always be coupled

to the driven machine by a power

transmission that will permit maximum motor rpm at maximum

machine speed. The power transmission may be a simple belt-sheave or

sprocket-chain arrangement or a

compact gear reducer. In most applications requiring speed reductions

greater than 5:1, the gear reducer

may be the most economical choice.

Gear Reducer Selection

A gear reducer transmits power by an

arrangement of various forms of

gears. It provides an efficient, positive

method to change speed, direction,

and torque. This may mean a change

of speed with a corresponding change

in torque, or a change in output direction or position. A common result is a

combination of the above.

The gear reducer serves as a torque

amplifier, increasing the torque by a

factor proportional to the reducer

ratio, less an efficiency factor. See

Figure 13.

A 1 hp, 1750 rpm motor has an output

torque of 3 lb-ft. If a 30:1 ratio reducer

with 85% efficiency is used, the

reducer output torque will be

3x30x0.85 = 76.5 lb-ft.

A typical application involves selecting

a gear reducer that permits the drive

motor to operate at nameplate speed

when the driven machine is at maximum speed. The gear reducer should

also provide adequate torque to drive

the machine.

Application Example

A 1750 rpm motor is selected for a

machine which is to operate at 57.5

rpm maximum speed and requires

70 lb-ft of torque.

To find the answer, the following two

steps must be accomplished.

1. Determine the required ratio:

Reducer =

Ratio

Maximum Motor rpm

Maximum Driven

Machine rpm

1750

Reducer Ratio = = 30.4 or a 30:1

Note: When the calculated reducer ratio is

not close to a standard speed reducer ratio,

a chain, belt or additional gears with further

reduction are necessary (located on the

input or output side).

-------------

57.5

ratio

2. Determine the motor torque &

horsepower

A 30:1 gear reducer is selected which

is capable of supplying 70 lb-ft of output torque. Since the machine torque

requirement is known, this value is

divided by the reduction ratio and an

efficiency factor, to arrive at the

required motor torque (TM).

TM =

Required torque (lb-ft)

Reducer Ratio x

Efficiency Factory

70

------------------------

TM = = 2.75 lb-ft

30 0.85×

Since a 1 hp, 1750 rpm motor delivers

3 lb-ft of torque, it is chosen for this

application along with a 30:1 gear

reducer with a minimum of 70 lb-ft

output torque.

Where the reduction ratio permits the

use of a chain or belt, the same formulae are used as with the reducers.

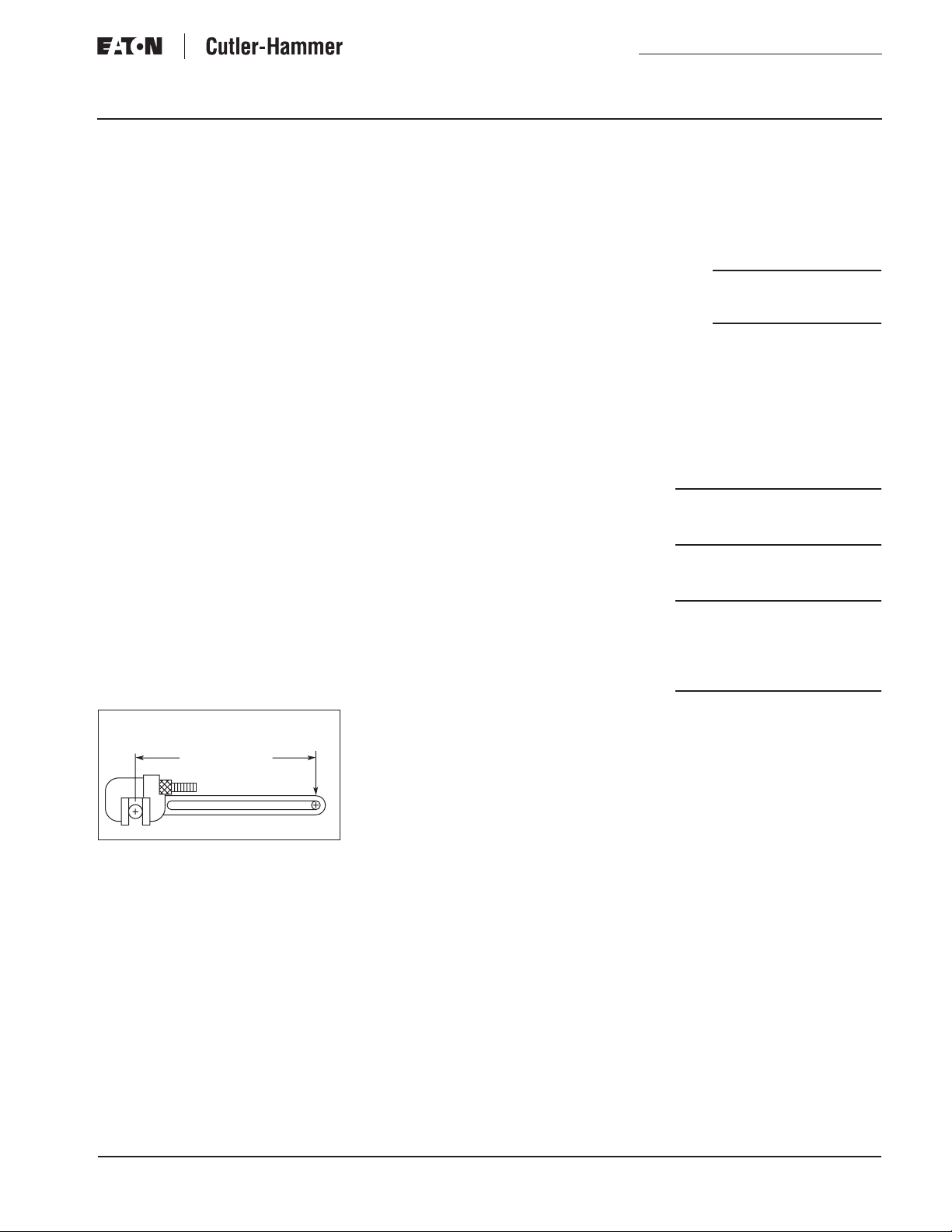

Gear Reducer — Overhung Load

An overhung load (OHL) is defined as

dead weight the gear reducer bearings

can support on an output shaft at a

distance equal to the shaft diameter.

This distance is measured from the

outside end of the bearing housing

along the shaft (see Figure 16). If the

acting load is at a point different from

the OHL point, it must be converted to

the reference point and compared to

the manufacturer’s catalog value.

Overhung Load

Reference Points

Side

Thrust

Side

Thrust

Output

Side

Gear

Reducer

Figure 16. Overhung Load

When a gear reducer is driven by a

belt, chain or gear drive, or when the

gear reducer drives a driven unit

through a belt, chain or gear drive,

an overhung load (side thrust) is

produced. The overhung load must

not exceed the rating of the gear

reducer as listed by the manufacturer.

The magnitude of the overhung load

should always be kept to a minimum.

Excessive loads could lead to fatigue

failure of either the bearing or shaft.

The sprocket or pulley should always

be located as close to the gear housing

as possible.

Increasing the sprocket or pulley diameter results in a reduced overhung

load. Use the following equation to

determine the overhung load:

=2 x Shaft Torque (lb-in) x K

OHL

(lb. )

Diameter (in)

Where:

Diameter is of the sprocket, sheave,

pulley or gear.

Note: K is a constant which is:

1.00 for chain drives

1.25 for gears or gear-belt drives

1.50 for V belt drives

2.50 for flat belt drives

Input

Side

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 10 Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

No overhung loads are encountered

when the gear reducer is directly coupled to the motor and/or the driven

machine shaft. However, care must

be taken in aligning the shafts to

avoid pre-loading the bearings by

misalignment.

Other Gear Issues

1. Service Factor — The application

determines the amount of shock

load the gearbox will be subjected

to. Based on the operating hours

per day and the degree of shock

loading, the gearbox may need to

be oversized with a service factor

of up to 250%.

2. Thermal Rating — It is possible

that the gearbox will have a

mechanical rating larger than its

thermal rating. The gearbox manufacturer should advise under

what situations this might occur.

Controllers and Starters,

Theory and Application

Introduction

Soft Start Controller and Starter

Description — A soft start controller or

starter gently starts a motor limiting

both the initial torque levels and current levels to meet given application or

utility power system requirements.

Soft start controllers and starters are

used with three-phase motors. The

controller or starter interfaces with

normal operator or machine controls

as used in conjunction with a standard

across the line starter.

Benefits of Using Soft Start

Controllers and Starters

Soft starts are used for a number of

reasons, either to provide a required

starting characteristic or to prevent or

reduce a machine or system related

problem such as:

■ Mechanical

❑ Belts stretching, squealing, or

breaking

❑ Gears breaking

❑ Couplings wearing out

❑ Drive train shafts breaking

■ Motor

❑ Motor insulation deterioration or

premature winding failure

❑ Foundation bolts and mounting

failures

❑ Bearing lock-up and failure

❑ Motor shaft cracking and breaking

❑ Excessive energy consumption

■ Starting Equipment

❑ Contact pitting and wear

❑ Coil burnout

❑ Mechanical failure

■ Inrush Current

❑ Voltage dips causing electrome-

chanical starter coils to drop out

❑ Soft supply lines may mean the

starting current will not be acceptable to the utility

❑ Lighting brown outs or electronic

control hiccups

■ Fragile Product

❑ Materials chip, crack, spill or

break

❑ Positioned products are shifted

Basic Principles of Soft Start

Controllers and Starters

The following description applies to

the operation of a soft starter which is

used to control the motor torque or

current during the start sequence and

also provides, at minimum, motor

overload protection. A soft start

controller does not control torque or

current nor provide motor protection.

An adjustment is provided on the soft

start controller for initial starting

torque which is based on setting an

initial start voltage.

The soft starter controls motor current

or torque by controlling the voltage

applied to the motor. The voltage is

controlled by changing the phase

angle at which the silicon controlled

rectifiers, SCRs, are gated (or turned)

on. Once turned on, the SCRs stay on

until the magnitude of the current

through them passes through zero

each half cycle of the AC waveform.

Conduction phase angle may be considered as beginning at the zero

degree crossing of a phase through

zero VAC, and progressing back in

time towards 180 degrees, as seen in

Figure 17. At a 180 degree conduction

phase angle, full voltage is applied to

the motor phase, since the SCR conducts through the full 180 degrees. At

0 degrees no voltage is applied. As the

conduction phase angle is gradually

phased back from 0 degrees towards

180 degrees on subsequent gatings of

the SCRs, the effective voltage to the

motor increases, resulting in higher

current and motor torque. With the

proper feedback and control algorithms, current and torque can be controlled during start and stop.

800

600

180° 0°

400

200

0

-200

-400

180° 0°

-600

-800

30° 45° 60° 90° 155° Full On

Conduction Phase Angle

Figure 17. SSRV SCR Phase-Up

The effect of controlling the voltage or

current applied to the motor can be

seen in Figure 18 with the starting current being shown at the normal across

the line level, and at a current limit

level of 500% and 400%. As a result of

the current being limited to a lower

level, the torque developed by the

motor is also limited to a lower level.

As was noted in basic theory section of

this guide, the torque varies as the

square of the motor current. Figure 18

illustrates this.

For more information visit: www.EatonElectrical.com AP03902001E

Solid-State Soft Start

Motor Controller and

Starter

Application Note

Effective: February 2005 Page 11

% Torque

and

Current

700

600

500

400

300

200

100

0

0102030405060708090

Current Limit 1

Current Limit 2

Line StartingTorque

Available Torque 1

Available Torque 2

% Synchronous Speed

Note: When Current = Line Starting Current,

Available Torque = Line Starting Torque

Line Starting

Current

See

Note

Figure 18. Effects of Current Limiting on Motor Torque

Where:

= available torque at reduced

T

AV

current

= torque at full voltage and line

T

R

current

= reduced current

I

A

= current at full voltage

I

R

For example, a motor has an initial

across-the-line starting current of

670% and a torque capability of 150%

of its nameplate rating at start. If the

initial starting current is limited to

500%, the available torque will be limited to 83.5%.

= 150% = 83.5%

T

AV

2

500

----------

670

This same proportionality holds true

across the entire motor start time. The

available torque will be reduced until

the current being drawn drops below

the limited value and equals the normal across-the-line current. At this

point the available starting torque

equals the normal across-the-line

starting torque.

This means that to have a successful

motor start the available torque must

always be greater than the load’s

required torque. If the load torque is

greater than the available torque the

motor will not start.

The second element to be considered

is the acceleration time of the motor.

The available torque must exceed the

load torque by a great enough margin

to assure that the motor will have

enough acceleration torque available

to start in the desired start time.

Load Characteristics

There are three basic components

which contribute to the required

torque that must be considered. The

first is friction, the second inertia, and

the third the driven process. Each of

these can affect the motor and starter

choice. In this guide we are paying

specific attention to their effects on the

starter selection.

Friction

Friction can determine how difficult it

is to initially start the load. The higher

the friction at start, the larger the

amount of the motor’s torque that is

required to breakaway the mechanical

system and begin rotation. The friction

levels at start are often referred to

as stiction. After the load begins to

rotate, the friction levels tend to

decrease, reducing the motor torque

requirements.

Inertia

Inertia determines how quickly a load

can be accelerated or decelerated. The

larger the inertia, the longer the time it

will take to accelerate it up to full

speed with a given acceleration torque

level, or vice versa the larger the acceleration torque required to accelerate it

up to full speed in a given time.

Driven Process

Often times the driven process is

entirely a frictional load such as a

conveyor or an inertial load such as a

centrifuge. In some cases the driven

process may require torque in addition

to that to overcome friction or to accelerate it. For example a centrifugal load

will likely have a low friction require-

100

%FLA Current (Line Start)

500% FLA I Limit

400% FLA I Limit

% Rated Motor Torque

(Full Voltage)

% Rated Motor Torque

@ 500% I Limit

% Rated Motor Torque

@ 400% I Limit

ment, and may have a low inertia, but

has a process torque requirement

which varies with the square of speed.

When first started the load torque is

virtually zero, but as the speed

increases the load torque increases

quickly until it reaches full load at full

speed. A centrifugal pump has low

friction and typically low inertia and its

driven load requirement varies with

speed. The starter would be sized

purely on the basis of the driven load.

A centrifugal fan has low friction but

often high inertia, so the starter would

be sized on the basis of both the

driven load torque and the acceleration torque requirements.

Typical Soft Start Adjustments

Ramp Start

In order to properly start the motor

and minimize time at zero speed when

first starting, an initial current or

torque level is set for the soft start to

apply at start-up. For most applications, this initial value is set to just

break away the motor and its load. In

the case of a large friction load, a kick

start would be used instead, as noted

below, because of the large torque

required for breakaway.

Tor qu e

100%

Initial

To rq ue

(T2)

t

r

Start

Time (Seconds)

Figure 19. Ramp Start

After the initial step torque is applied,

the motor torque is increased linearly

by increasing the soft start output voltage over a user selected ramp time

(note that the torque generated during

this time period can approach the

motor’s locked rotor value dependent

upon the settings and the load requirements). At the completion of the ramp

time, the motor and load should be at

full speed and the motor current at its

normal level.

Full

Vol tage

Run

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 12 Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

Current Limit Start

If a requirement exists for the motor

and load to start with a controlled

torque level, a current limit start can

be chosen. In this case the motor

torque level is set and it is held at this

value during start-up, until the load

requirements fall below this value or

the ramp time expires.

Tor que

Initial

To rq ue

(T2)

100%

t

r

Start Run

Time (Seconds)

Full

Vol tage

Figure 20. Current Limit Start

Kick Start

A kick start allows the motor to draw

greater current at start to develop

additional torque to breakaway a high

friction load. After a time delay the

current is reduced to the normal

preset starting level. The kick start

current level and time duration are

programmable.

Tor que

T

1

T

2

Kick Start

t

k

t

r

Start Run

Time (Seconds)

Full

Voltage

Figure 21. Kick Start

Ramp Stop

In some high friction load applications,

the user may desire that the load does

not stop suddenly. A ramp stop can be

applied to lengthen the stopping

period beyond the normal coast down

value. This stop works by gradually

decreasing the motor voltage thus

extending the stop time.

Percent

Voltage

100%

Run

Coast

to Stop

Soft

Stop

t

s

Soft Stop

Tim e (Seconds)

Figure 22. Ramp Stop

Note: This is not an electronic brake function, and cannot make the load stop faster

than its normal coast-to-stop time. This feature can only extend the stop time. In some

applications the motor will come to a stop

in less than the selected stop time, if the

load torque requirements are too high and

the stop time is set too long.

Motor Application Considerations

Motor Sizing

Motors are sized for use with a soft

starter or controller as they would be

for any other reduced voltage starting

device. If a large number of starts will

be made in a short period of time, the

motor must be able to thermally and

mechanically withstand this. In many

cases the soft start will be better for

the motor because of the reduction in

winding stress.

Multiple Motor Operation

The use of multiple motors connected

to one soft starter is not recommended

because of loss of motor protection. If

it is desired to do this, individual overload protection must be supplied for

each motor.

Motor Protection

Motor overload protection is provided

as required as a standard feature of

a soft starter. Soft start controllers

do not provide any motor overload

protection and require separate user

supplied overload devices as required

by the applicable codes.

Installation Compatibility

The successful application of a soft

starter or controller requires the assurance that it will be compatible with the

environment in which it will be

installed. The following are some of

the aspects of compatibility which

should be considered.

Cooling Air

Even though a soft starter or controller

is very efficient, the heat produced can

be substantial. The electronic circuitry

is subject to immediate failure if its

operating temperature limits are

exceeded. Junction temperatures of

SCRs typically can only increase 20 –

25°C from full load to failure level, so it

is important to remove heat through

the usual mechanisms of radiation,

conduction (heatsinks) or convection

(fans). Soft starters with run bypass

mode will significantly reduce the heat

generated once the motor is up to

speed, reducing enclosure sizes and/or

ventilating requirements. The enclosure must be located away from direct

sunlight and hot surfaces. The room

temperature must be kept within the

specified limits and adequate cooling

air must be allowed to flow around the

enclosure. Excessively moist, corrosive or dirty air must be prevented

from entering the enclosure.

Power Factor Correction Capacitors

Power factor correction capacitors

must not be connected on the soft

starter or controller output or at the

motor terminal box. To do so would

result in SCR failure. Power factor

correction should be done on a plantwide basis. If capacitors must be

located at the soft start input, they

should be connected as far upstream

from the soft start as possible.

Input Harmonics

During operation no harmonic currents

are caused by the use of a soft start.

During motor starting, harmonic currents may be drawn from the utility line,

but the duration of such is very short.

Load Types and

Characteristics

Introduction

The process of selecting a soft start is

dependent upon the characteristics of

the load to which it is being applied.

It is important to understand its torque

characteristics and how they vary

at start as well as during normal

operation.

When considering load characteristics,

the following should be evaluated:

■ What type of load is associated with

the application?

■ Does the load have a shock compo-

nent?

■ Are large inertial loads involved?

■ What are the motor considerations?

■ Are there frequent starts and stops?

For more information visit: www.EatonElectrical.com AP03902001E

Solid-State Soft Start

Motor Controller and

Starter

Application Note

Effective: February 2005 Page 13

Motor loads can be classified into

three basic components that contribute to load torque, friction, inertia and

the driven process, as was noted previously. The driven process can be

broken down into a few basic load

types.

Load Types

Constant Torque Load

This type of load is frequently encountered. In this group, the torque

demanded by the load during start and

run is constant. The load requires the

same amount of torque at start and

during normal operation. Loads of this

type are essentially friction loads. In

other words, the constant torque

characteristic is needed to overcome

friction. This load can be difficult to

start with a soft starter, and still limit

current, because it means that a high

level of current must be used to start

the load moving and maintain its

movement.

Examples of this type of load are conveyors, extruders and surface winders.

Variable Torque Load

With this type of load, the torque is

directly proportional to some mathematical power of speed, usually varying linearly with speed or speed

squared (Speed

2

).

An example of a load which varies linearly with speed is a mixer. Loads that

vary as the square of speed are centrifugal fans, pumps and blowers. These

types of loads require much lower

torque at low speed than at full speed.

Other Functional Considerations

Shock Loads

Soft starts for crushers, separators,

grinders, conveyors, winches, cranes

and vehicular systems often must

manage loads which range from a

small fraction of the rated load to

several hundred percent.

Under these conditions the soft starter

must function properly yet protect the

motor and driven equipment. Many

soft starters provide additional motor

protection beyond that of electromagnetic starters, such as jam, stall and

underload. The soft starter must be

appropriately sized for the load as well

as have its protective features adjusted

as required by the application.

Note: A soft start controller does not provide any motor or driven load protection. It

only provides a soft start capability.

Inertial Load

A high inertia load may require oversizing of the motor and soft start to

account for the heating caused by the

long acceleration times.

Duty Cycle

Certain applications may require cyclic

overloads or frequent start/stop cycles

which may result in severe motor

heating if not considered in the selection process.

Most motors and soft starts have a

specified duty cycle capability.

Typical Load Torque

Table 3. Typical Load Torque Requirements

Name of Application Load Torque as Percent of Full-Load Drive Torque

Breakaway Accelerating Peak Running

Actuators:

Screw-down (rolling mills)

Positioning

Agitators:

Liquid

Slurry

Blowers, centrifugal:

Valve closed

Valve open

Blowers, positive-displacement, rotary, bypassed

Calendars, textile or paper

Card machines, textile

Centrifuges (extractors)

Chippers, wood, starting empty

Compressors, axial-vane, loaded

Compressors, reciprocating, start unloaded

Conveyors, belt (loaded)

Conveyors, drag (or apron)

Conveyors, screw (loaded)

Conveyors, Shaker-type (vibrating)

Coolers, hot solids, rotary (loaded)

Cranes, traveling:

Bridge motion

Trolley motion

Hoist motion

Draw presses (flywheel)

Drill presses

Edgers (starting unloaded)

Elevators, bucket (starting loaded)

Elevators, freight (loaded)

Elevators, man lift

200

150

100

150

100

100

150

175

200

150

175

100

100

150

100

150

110

100

100

30

40

40

75

40

50

40

50

50

25

40

50

110

110

110

100

130

150

100

150

140

300

200

200

175

125

125

50

40

60

40

50

50

50

30

125

100

100

100

100

100

100

100

125

200

100

100

100

100

100

100

100

100

190

200

150

200

150

100

100

40

75

AP03902001E For more information visit: www.EatonElectrical.com

Application Note

Page 14 Effective: February 2005

Solid-State Soft Start

Motor Controller and

Starter

Table 3. Typical Load Torque Requirements — Continued

Name of Application Load Torque as Percent of Full-Load Drive Torque

Breakaway Accelerating Peak Running

Elevators, personnel (loaded)

Escalators, stairways (starting unloaded)

Extruders (rubber or plastic)

Fans, centrifugal, ambient:

Valve closed

Valve open

Fans, centrifugal, hot gases:

Valve closed

Valve open

Fans, propeller, axial-flow

Feeders, belt (loaded)

Feeders, distributing, oscillating drive

Feeders, screw compacting rolls

Feeders, screw, filter-cake

Feeders, screw, dry

Feeders, vibration motor-driven

Frames, spinning, textile

Grinders, metal

Hoists, skip

Indexers

Ironer, laundry (mangles)

Jointers, woodworking

Kilns, rotary (loaded)

Looms, textile, without clutch

Machines, boring (loaded)

Machines, bottling

Machines, buffing, automatic

Machines, cinder-block, vibrating

Machines, keyseating

Machines, polishing

Mills, flour, grinding

Mills, rolling metal:

Billet, skelp and sheet, bar

Brass and copper finishing

Brass and copper roughing

Merchant mill trains

Plate

Reels, wire or strip

Rod

Sheet and tin (cold rolling)

Strip, hot

Structural and rail finishing

Structural and rail roughing

Tub e

Tube piercing and expanding

Tube reeling

Mills, rubber

Mills, saw, band

Mixers, chemical

Mills, concrete

Mixers, dough

Mixers, liquid

Mixers, sand, centrifugal

Mixers, sand, screw

Mixers, slurry

Mixers, solids

Planers, metalworking

Planers, woodworking

Plows, conveyor, belt (ore)

Positioners, indexing (machine tool)

Presses, pellet (flywheel)

Presses, printing, production type

Presses, punch (flywheel)

Puller, car

Pumps, adjustable-blade, vertical

Pumps, centrifugal, discharge open

Pumps, oil-field, flywheel

Pumps, oil, lubricating

Pumps, oil fuel

Pumps, propeller

110

150

100

150

150

150

175

150

100

150

250

125

150

150

150

120

100

150

100

175

175

100

175

150

175

150

150

100

150

150

150

50

25

25

25

25

40

50

25

50

50

50

25

50

50

50

40

50

40

90

40

40

40

50

50

50

50

40

50

50

50

50

50

40

40

40

40

150

150

110

200

110

120

150

100

100

100

150

125

150

200

125

125

125

150

150

100

100

110

100

125

100

100

100

125

125

150

125

150

200

150

110

100

200

150

150

100

75

60

60

50

50

50

75

50

75

75

30

30

30

30

50

30

30

30

30

30

30

75

75

50

75

75

40

100

100

100

100

100

175

100

100

100

100

100

100

100

100

100

100

150

125

125

125

150

100

100

100

100

100

100

200

200

200

200

250

100

200

200

200

200

250

200

250

200

200

200

100

100

100

100

100

100

100

175

150

150

200

100

150

150

100

100

125

100

200

150

150

100

50

70

For more information visit: www.EatonElectrical.com AP03902001E

Solid-State Soft Start

Motor Controller and

Effective: February 2005 Page 15

Application Note

Starter

Table 3. Typical Load Torque Requirements — Continued

Name of Application Load Torque as Percent of Full-Load Drive Torque

Breakaway Accelerating Peak Running

Pumps, reciprocating, positive-displacement

Pumps, screw-type, started dry

Pumps, screw-type, primed, discharge open

Pumps, slurry-handling, discharge open

Pumps, turbine, centrifugal, deep-well

Pumps, vacuum (paper-mill service)

Pumps, vacuum (other applications)

Pumps, vacuum, reciprocating

Pumps, vane-type, positive-displacement

Rolls, bending

Rolls, crushing (sugarcane)

Rolls, flaking

Sanders, woodworking, disk or belt

Saws, band, metalworking

Saws, circular, metal, cutoff

Saws, circular, wood, production

Saws, edger (see Edgers)

Saws, gang

Screens, centrifugal (centrifuges)

Screens, vibrating

Separators, air (fan-type)

Shakers, foundry or car

Shears, flywheel-type

Shovels, dragline, hoisting motion

Shovels, dragline, platform motion

Shovels, large, digging motion

Shovels, large, platform motion

Te nsion-maintaining drives

Textile machinery

To ols, machine

To ols, machine, broaching, automatic

To ols, machine, lathe, metal production

To ols, machine, mill, boring production metal

To ols, machine, milling, production

To ols, machine, planer, production, metal (See Planers, metalworking)

To ols, machine, shaper, metal, automatic

Vehicles, freight

Vehicles, passenger

Walkways, mechanized

Washers, laundry

Winches

175

150

150

150

150

150

100

150

100

100

100

200

100

125

75

50

60

40

50

30

30

30

25

50

60

40

50

40

50

50

50

50

50

50

50

50

50

50

25

30

30

100

100

100

100

60

60

150

150

110

50

50

50

50

30

30

60

150

100

150

50

150

100

200

100

100

100

150

150

200

125

100

75

200

400

50

75

150

175

100

100

100

100

150

100

150

175

100

125

100

100

100

150

150

150

125

100

120

100

100

200

100

100

100

150

200

100

100

150

200

200

100

100

100

70

70

90

Controller and Starter

Selection

value several times full-load torque.

The peak torque varies because of a

change in load conditions or mechanical nature of the machine. The motor

Selection Considerations

When selecting a soft starter or controller for an application, the following

points should be considered:

Environment

The environment in which the motor

and soft start will be placed is of prime

concern. Conditions such as ambient

temperature, cooling air supply, the

presence of gas, moisture and dust

should all be considered when choosing the soft start, its enclosure and

protective features.

Torque Requirements

The starting, peak and acceleration

torques are to be considered. Starting

torque requirements can vary from a

torque available to the driven machine

must be more than that required by

the machine from start to full speed.

The greater the excess torque, the