Page 1

IT.

24V DC Power Supplies

Application Note

Electromechanical

Contactors and Starters

Why is 24V DC control power becoming more prevalent in industry? There

are several main drivers — safety concerns, reduction in product size and

cost, functionality and reliability

improvement, and the growing availability of 24V DC products such as

sensors, instrumentation systems,

PLC I/O, and other signal, conditioning

and power control devices.

This application note is intended to

help in the selection of the proper

24V DC power supply, by taking into

account the continuous (sealed) and

inrush (peak) current or wattage

demands of multiple devices,

when connected to a single 24V DC

power supply.

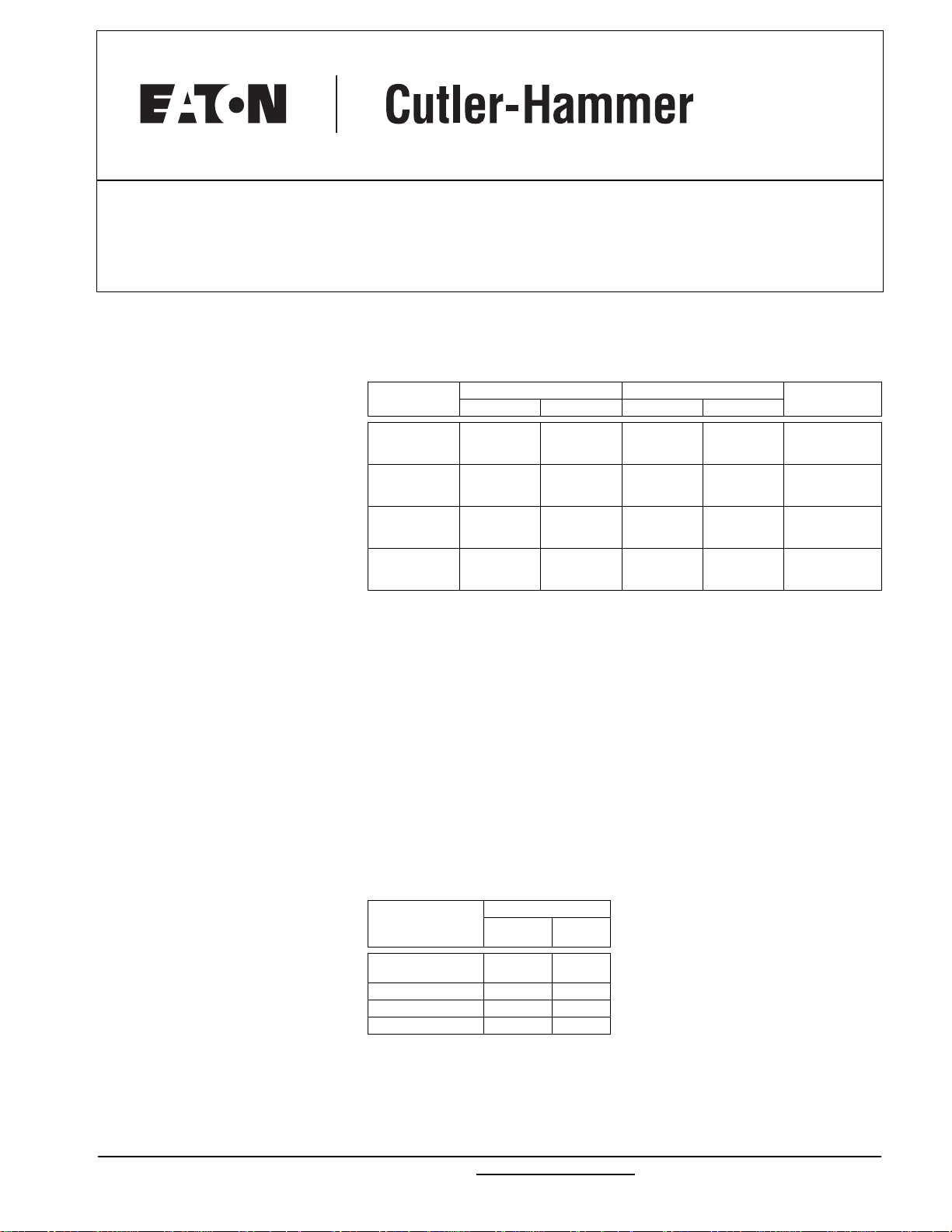

The characteristics of interest for the available Cutler-Hammer

supplies are shown in the following table.

Table 1. 24V DC Power Supplies

Catalog

Number

PSS10E

PSS25E

PSS10F

PSS25F

PSS55A

PSS55B

PSS55C

PSS160E

PSS160C

PSS300E

PSS300C

PSS600C

Before sizing the power supply, the

continuous and inrush watts or

amperes of each load must be identified. This is not much different than

adding up the volt-ampere requirements when sizing a control power

transformer. In addition, the sequence

of operation of the devices needs to be

determined to ensure that the worst

case conditions are used in sizing the

power supply.

For example, a system being designed

requires:

tors,

one

indicating lamps, and

relay. The power requirements for each

device are given in the following table.

Table 2. Power Requirements

Device Watts Per Device

A-Frame IEC

Contactor

C-Frame IEC Starter 3.6 90.0

Indicating Lamp 1.2 1.2

Auxiliary Relay 1.2 7.2

Continuous (Sealed) Inrush (Peak) Input

Wattage Amperes Wattage Amperes

10

25

10

25

55

55

55

—

—

—

—

—

0.4

1.0

0.4

1.0

2.3

2.3

2.3

—

—

—

—

—

20

165

20

165

250

250

250

—

—

—

—

—

0.8

6.5

0.8

6.5

10.4

10.4

10.4

—

—

—

—

—

In the first example,

will be operated at the same time

available line voltage is 230V AC. Two

calculations are required — the first, to

determine the continuous wattage

requirement and the second, for the

peak wattage.

■

Continuous watts = sum of continuous (sealed) watts of each device.

Continuous watts = (2 x 1.3) +

(1 x 3.6) + (3 x 1.2) + (1 x 1.2).

two

IT.

A-Frame IEC contac-

C-Frame IEC starter,

one

auxiliary

three

Continuous watts = 11.

■

Peak watts = sum of inrush (peak)

watts of each device.

Peak watts = (2 x 20) + (1 x 90) +

(3 x 1.2) + (1 x 7.2).

Peak watts = 140.8.

In this case, a PSS25E power supply

Continuous

(Sealed)

1.3 20.0

Inrush

(Peak)

would be chosen, since it has a continuous rating of 25 watts and a peak

rating of 165 watts which are appropriate for the calculated 24V DC

power requirements.

IT.

24V DC power

Voltage VAC

90 – 260

90 – 260

360 – 500

360 – 500

90 – 140

180 – 260

360 – 500

90 – 260

360 – 500

90 – 260

360 – 500

360 – 500

all of the devices

. The

Page 2

Application Note

Page 2

As a second example, the same

devices will be used but the operation

will be different. In this case the

designer wants to be able to

device while all of the others are operating

. The worst case peak power

requirements will occur when all of the

other devices are operating and the

C-Frame starter is picked up. Again,

two calculations are required, one for

the continuous (sealed) and one for the

inrush (peak) power requirements.

Continuous watts = sum of continu-

■

ous (sealed) watts of each device.

Continuous watts = (2 x 1.3) +

■

(1 x 3.6) + (3 x 1.2) + (1 x 1.2).

Continuous watts = 11.

■

■

Peak watts = sum of continuous

(sealed) watts of each operating

device plus the inrush (peak) watts of

the worst case device being picked up.

■

Peak watts = (2 x 1.3) + (3 x 1.2) +

(1 x 1.2) + (1 x 90).

■

Peak watts = 97.4.

In this case the PSS25E power supply

would be chosen to meet the calculated requirements.

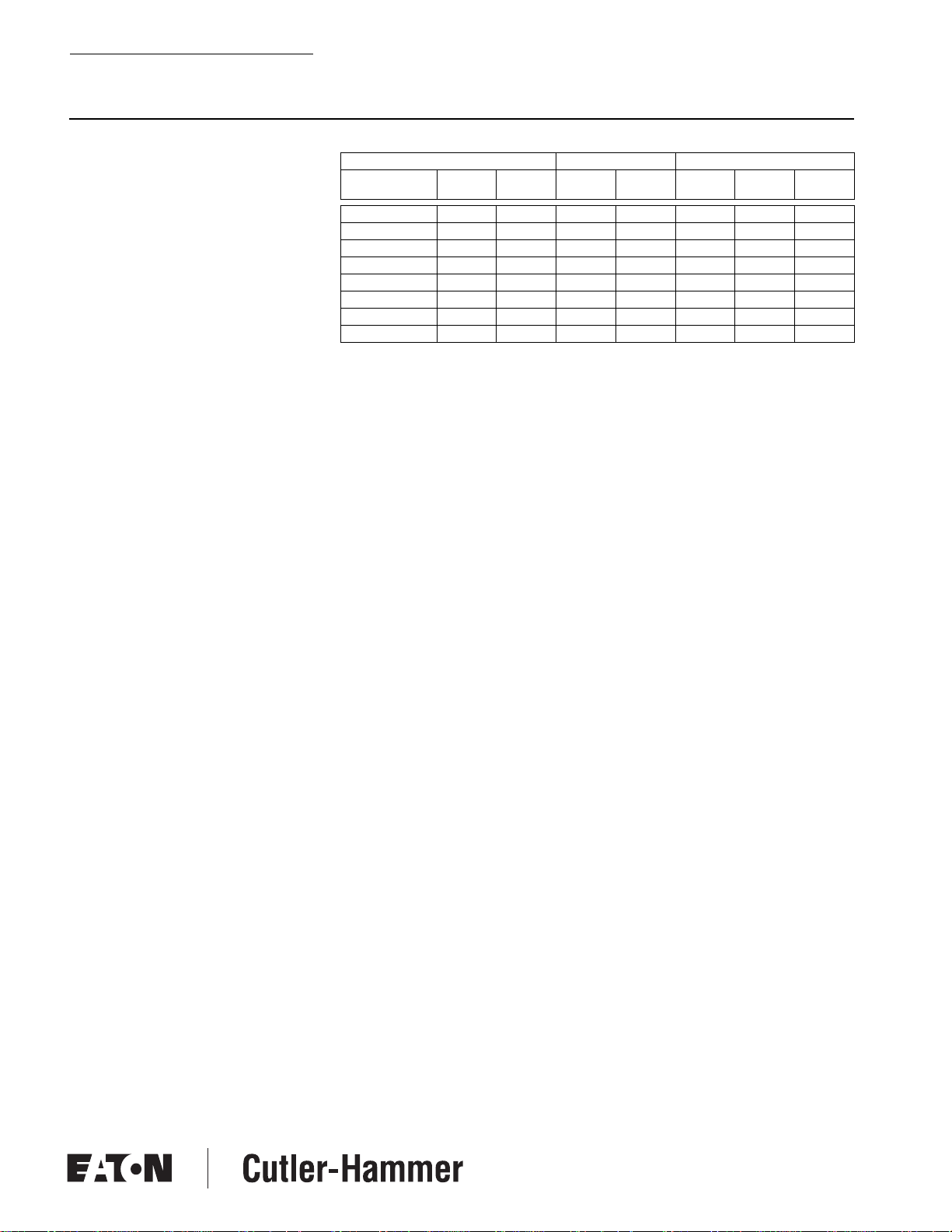

It must also be noted that the power

requirements above are based on the

devices being operated in a 20ºC (68°F)

environment. If the temperature differs

from 20ºC (68°F), the wattage requirements will change for many devices.

The device instruction literature will

supply information as to which if any

factors are to be used for other operating temperatures. As an example, for

the

IT.

IEC contactor and starter products, the following table is published in

the User Manual, pub49400, which

provides an equation for determining

power requirements at temperatures

different than 20ºC (68°F).

Effective: February 2002

close any

IT.

24V DC Power Supplies

Table 3. 24V DC Power Supply Requirements at 20°C (68°F)

Contactor/Starter Size Sealed In Inrush

Catalog

1

Number

E_11A_ _X3N A 27 1.3 0.054 20 0.83 30

E_11B_ _X3N B 45 3.7 0.15 80 3.3 50

E_01B_ _ _3A B 45 3.2 0.13 80 3.3 50

E_11C_ _X3N C 54 4.2 0.18 90 3.8 50

E_01C_ _ _3A C 54 3.6 0.15 90 3.8 50

E_ _1D_ _ _3_ D 76 5.0 0.21 130 5.4 65

E_ _1E_ _ _3_ E 105 5.6 0.23 140 5.8 85

E_ _1F_ _ _3_ F 140

1

Indicates missing digit of the catalog number may have multiple values.

2

Consult factory.

Note: At other temperatures expressed in °C, for either inrush or sealed, use the 20°C value

from the table in the following:

Watts = W

For example, inrush requirements for a D-Frame starter at -25°C would be:

Watts = 130 [1.1-0.005(-25)] = 160

Amps = 5.4 [1.1-0.005(-25)] = 6.6

Frame mm Wattage Amperes Wattage Amperes Duration

22222

[1.1-0.005(T)] and Amps = A

20

[1.1-0.005(T)]

20

(msecs)

In addition, operation at ambient temperatures greater than the 24V DC power

supply temperature rating will require that the power supply be derated. See

the applicable power supply installation manual.

© 2002 Eaton Corporation

All Rights Reserved

Printed in USA

Publication No. AP03903001E

February 2002

Loading...

Loading...