Cutler Hammer, Div of Eaton Corp PowerXL Series VFD Quick Start Guide

PowerXL DH1 Series VFD

Quick Start Guide

Effective April 2018

Supersedes November 2017

CONTENTS

Step 1—PowerXL Series Overview . . . . . . . . . . . 1

Step 2—Keypad Operation Overview . . . . . . . . . 3

Step 3—Menu Navigation . . . . . . . . . . . . . . . . . . 6

Step 4—Startup Wizard . . . . . . . . . . . . . . . . . . . . 8

Step 5—Standard Parameter List . . . . . . . . . . . . 10

Appendix A—Fault and Warning Codes . . . . . . . 40

Go to Eaton.com/DH1

Documents Tab: User manuals for DH1

Software Tab: To download Power Xpert inControl

and software support

Step 1—PowerXL Series Overview

Step 1—PowerXL Series Over view

This chapter describes the purpose and contents of this

manual, the receiving inspection recommendations and the

PowerXL Series Open Drive catalog numbering system.

How to Use this Manual

The purpose of this manual is to provide you with information

necessary to install, set and customize parameters, start up,

troubleshoot and maintain the Eaton PowerXL Series variable

frequency drive (VFD). To provide for safe installation and

operation of the equipment, read the safety guidelines at the

beginning of this manual and follow the procedures outlined

in the following chapters before connecting power to the

PowerXL Series VFD. Keep this operating manual handy and

distribute to all users, technicians and maintenance

personnel for reference.

Receiving and Inspection

The PowerXL Series VFD has met a stringent series of

factory quality requirements before shipment. It is possible

that packaging or equipment damage may have occurred

during shipment. After receiving your PowerXL Series VFD,

please check for the following:

Check to make sure that the package includes the Instruction

Leaflet, Quick Start Guide, User Manual CD and accessory

packet. The accessory packet includes:

●

Rubber grommets

●

Control cable grounding clamps

●

Additional grounding screw

Inspect the unit to ensure it was not damaged during

shipment.

Make sure that the part number indicated on the nameplate

corresponds with the catalog number on your order.

If shipping damage has occurred, please contact and file a

claim with the carrier involved immediately.

If the delivery does not correspond to your order, please

contact your Eaton Electrical representative.

Note: Do not destroy the packing. The template printed

on the protective cardboard can be used for marking

the mounting points of the PowerXL VFD on the wall

or in a cabinet.

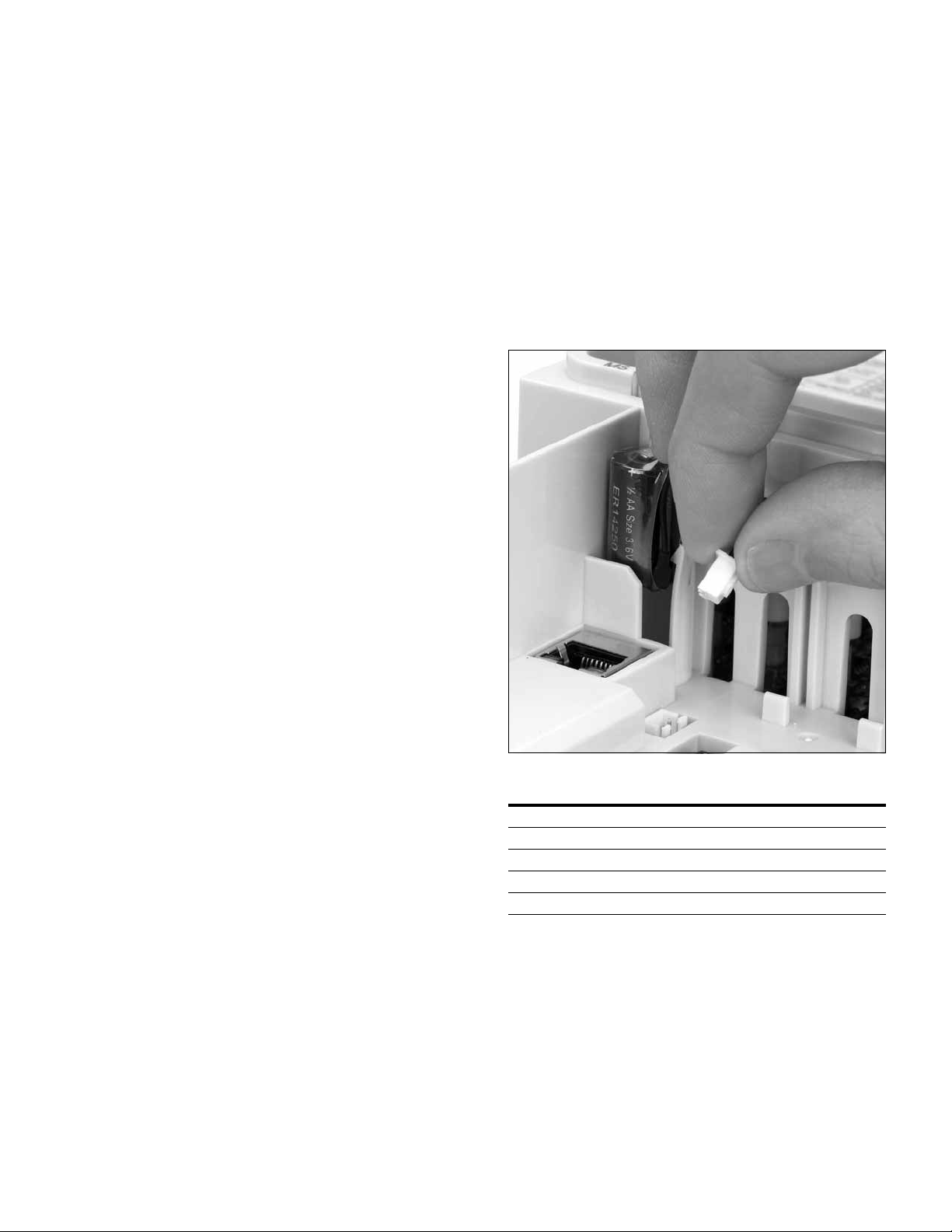

Real Time Clock Battery Activation

To activate the real time clock (RTC) functionality in the

PowerXL Series VFD, the RTC battery (already mounted in

the drive) must be connected to the control board.

Simply remove the primary drive cover, locate the RTC

battery directly below the keypad, and connect the white

2-wire connector to the receptacle on the control board.

Figure 1. RTC Battery Connection

Table 1. Common Abbreviations

Abbreviation Definition

CT Constant torque with high overload rating (150%)

VT Variable torque with low overload rating (110%)

I

H

I

L

VFD Variable Frequency Drive

High Overload (150%)

Low Overload (110%)

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 1

Step 1—PowerXL Series Overview

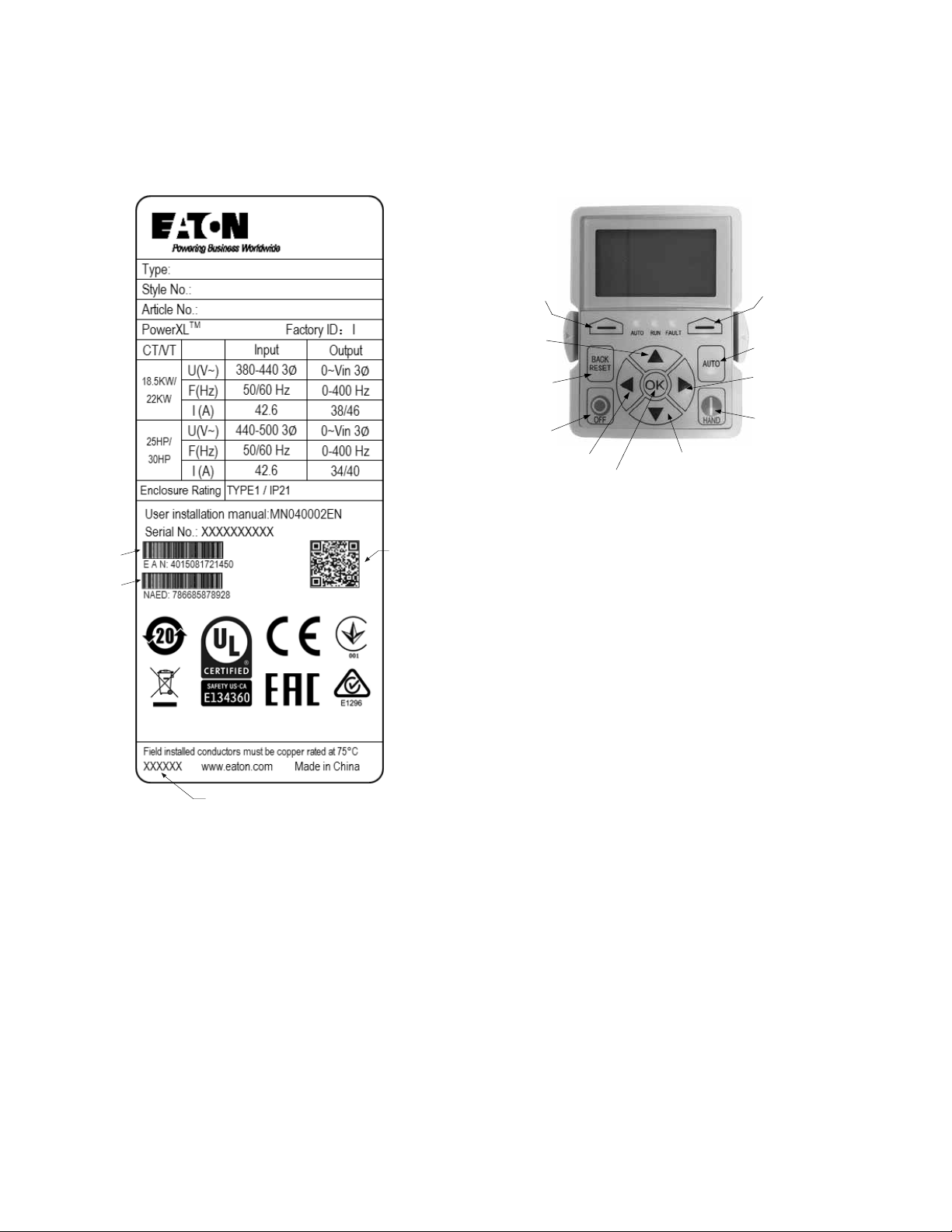

DH1-343D3FN-N21C

9712-1014-XX

9712-1014-XX

DH1 VFD

Contains

SN, PN,

Type, Date

Contains

EAN Code

Date Code: 20131118

Contains

NAED Code

Programmable

Soft Key 2

Change Control

Place to Auto

Move Cursor

Right

Start/Hand Button

Stop/Off Button

Back/Reset

Button

Increase

Value Scroll

Menu Up

Programmable

Soft Key 1

Decrease Value

Scroll Menu Down

Move Cursor

Left

Enter Menu

Conrm Selection

Rating Label

Figure 2. Rating Label

Keypad Overview

Figure 3. Keypad and Display

Carton Labels (U.S. and Europe)

Same as rating label shown above.

2 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

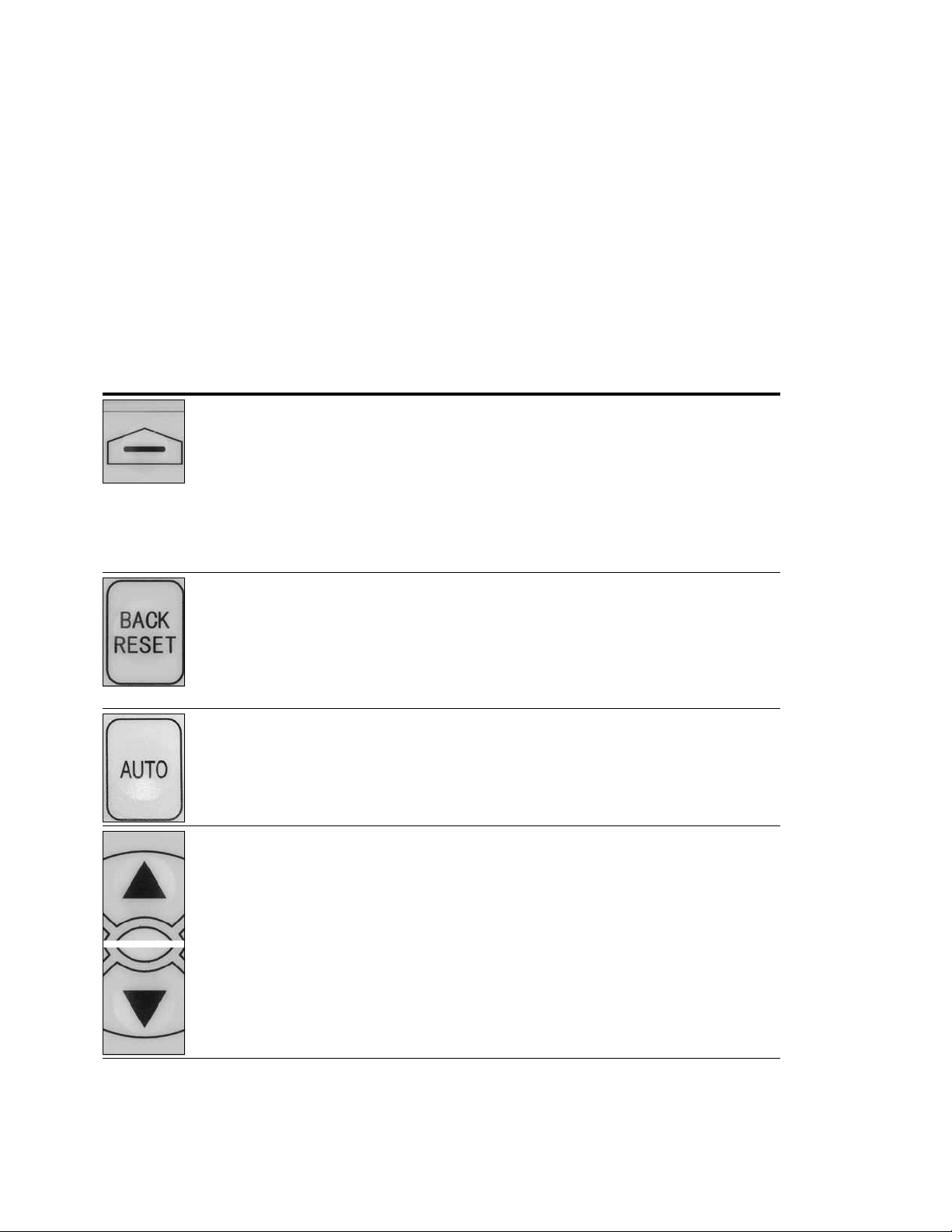

Step 2—Keypad Operation Overview

The keypad is the interface between the drive and the user.

It features an LCD display, 3 LED lights and 11 buttons. With

the control keypad, it is possible to control the speed of a

motor, to supervise the state of the equipment and to set the

frequency converter’s parameters. See Figure 3.

Keypad Buttons

Step 2—Keypad Operation Over view

Buttons Description

Table 2. Keypad Buttons

Icon Button Description

Soft Key 1,

Soft Key 2

Back/Reset Back/Reset:

Auto Auto:

Soft Key 1, Soft Key 2:

The functions of these two buttons shall be the following:

Forward/Reverse, this shall change motor’s run direction.

Reset, this shall ask MCU to reset after some parameters are modified.

• Menu, this shall return to main menu.

• Details, this shall display the details of the fault.

• Bypass, this shall make drive go into bypass.

• Jog, this shall activate jog.

• Favorite, this shall add this parameter to the Favorite menu.

• Delete, this shall delete this parameter from the Favorite menu.

This button has three integrated functions. The button operates as backward button during

normal mode.

In edit mode, it is used as cancel operate. It is also used to reset faults when faults occur.

• Backs up one step.

• Cancels Modify in edit mode.

• Resets the active faults (all the active faults shall be reset by pressing this button

more than 2s in any page).

This button switches the drive into the auto control place.

Up

Down

Up and Down Arrows:

• Move either up or down a menu list to select the desired menu item.

• Editing a parameter bit by bit, while the active digit is scrolled.

• Increase/decrease the reference value of the selected parameter.

• In parameter comparison mode, scroll through the parameters of which current value

is different from comparison parameter value.

• In parameter page when in read mode, move to the previous or next brother

parameter of this parameter.

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 3

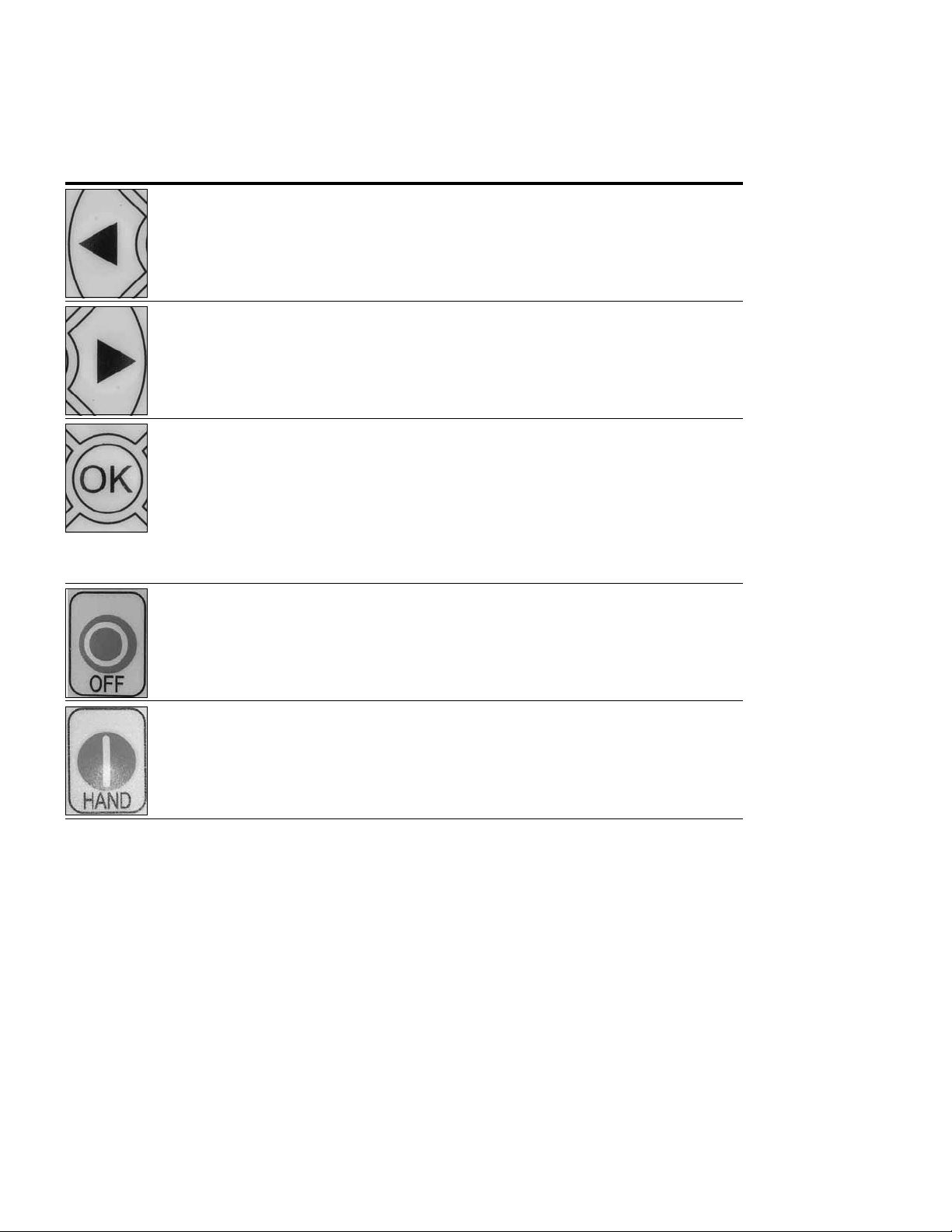

Step 2—Keypad Operation Over view

Table 2. Keypad Buttons, continued

Icon Button Description

Left Left Arrow:

• Navigation button, movement to left when editing a parameter digit by digit.

• Backs up one step.

Right Right Arrow:

• Enter parameter group mode.

• Enter parameter mode from group mode.

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter bit by bit edit mode from whole edit mode.

• Navigation button, movement to right when editing a parameter bit by bit.

OK OK:

• To clear all the Fault History if pressed for more than 5s (including 5s) in any page.

• This button is used in the parameter edit mode to save the parameter setting.

• To confirm the start-up list at the end of the Start-Up Wizard.

• To confirm the comparison item in parameters comparison mode.

The following is the same with Right key:

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter group mode.

• Enter parameter mode from group mode.

Stop/Off Stop/Off:

This button operates as the motor stop button for normal operation and places the drive in the

off control location. The Default is for this button to always be active. It can be changed in

Parameter P4.1.3 to only when “Keypad” is selected as the control source.

• Motor stop from the keypad.

• Transitions drive into an Off control location preventing start from any control source.

Start/Hand Start/Hand:

This button operates as motor start button for normal operation when the “Keypad” is

selected as the active control source, as well as selects the Hand control place location.

• When Keypad is the reference place after hitting the start button, it will jump directly

to the Keypad Ref Screen.

• Places drive into Hand Control place. Hitting start again if keypad is in the control

location will start the Drive.

4 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

Step 2—Keypad Operation Over view

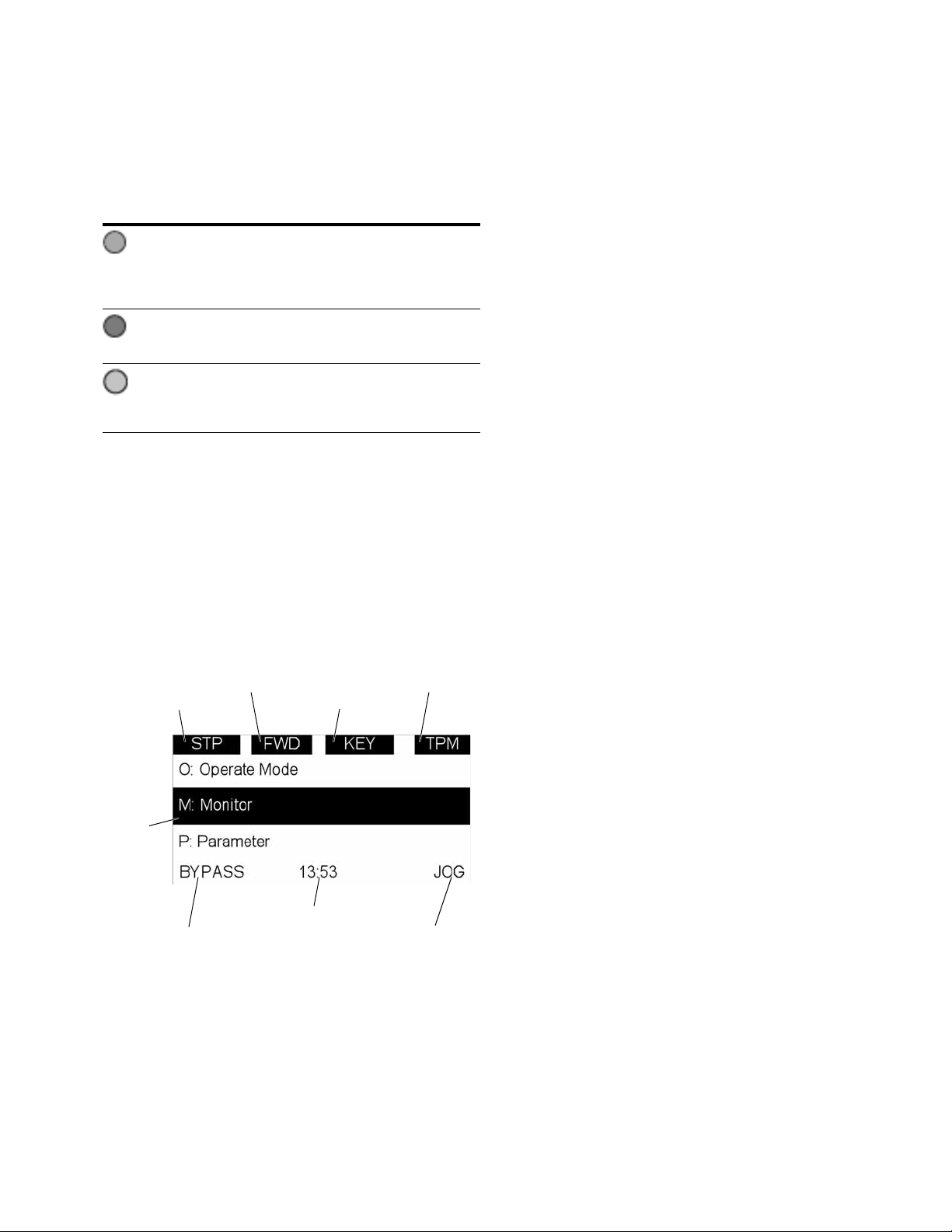

Drive Status

Direction Status

Control Place

Menu Location

Soft Key 2

Function Label

Soft Key 1

Function Label

Real Time Clock

(hh:mm)

Active

Selection

LED Lights

Table 3. LED State Indicators

Indicator Description

Run:

Indicates that the VFD is running and controlling the load in

Run

Drive or Bypass.

Blinks when a stop command has been given but the drive is

still ramping down.

Fault:

Turn on when there is one or more active drive fault(s).

Fault

Hand/OFF/Auto:

Hand: If the Hand or Off control place is selected,

Auto

turn off the light.

Auto: If the Auto control place is selected, turn on the light.

LCD Display

The keypad LCD indicates the status of the motor and the

drive and any faults in motor or drive functions. On the LCD,

the user sees information about the current location in the

menu structure and the item displayed.

Overview

Five lines shall be displayed in the screen. General view is as

following in Figure 4.

Figure 4. General View of LCD

The lines definition is as below:

The first line is State line, shows:

●

RUN / STP / NRD / FIM / TFM—If motor is running, the

run state shall display “RUN”, otherwise the state display

“STP”. “RUN” blinks when the stop command is sent but

the drive is decelerating. “NRD” is displayed if the drive is

not ready or does not have a signal. “FIM” is displayed to

indicate it is in Fire Mode and the drive is in a Run state.

“TFM” is displayed when in the Fire Mode Test Mode and

the drive is in a Run State.

●

FWD / REV / JOG—If the motor running the direction is

clockwise, it displays “FWD”, otherwise displays “REV”

for counter clockwise. If “Jog” is displayed, it indicates

Jog mode is active.

●

KEY / I/O / BPS / RBP / BUS / OFF—If it is in bypass

currently, display “BPS”; when run command is given, it

will go to “RBP”; otherwise, if the current control source

is I/O terminal, display “I/O”. If it is keypad, then display

“KEY”; otherwise display “BUS.” When indicates “OFF”, it

indicates the drive will not accept a command from the

Hand or Auto Control place.

●

PAR / MON / FLT / OPE / QSW / FAV / TPM / BUx—

If the current page is parameter menu, display “PAR”;

If monitor menu, then display “MON”; If fault menu, then

display “FLT”; If operation menu, then display “OPE”;

If quick start wizard, then display “QSW”; If optional card

menu, then display “BOA”; If favorite menu, then display

“FAV”; If main menu, then display “TPM”. “BUx” indicates

the drive being a backup drive when in the redundant drive

system.

The second line is Code line, which shows the menu code.

The third line is Name line, which shows the menu name or

parameters name.

The fourth line is Value line, which shows the submenu

name or parameters value.

The fifth line is Soft key line, the functions of Soft key 1 and

Soft key 2 are changeable, and the real time is in the middle.

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 5

Step 3—Menu Navigation

Step 3—Menu Navigation

Menu Structure

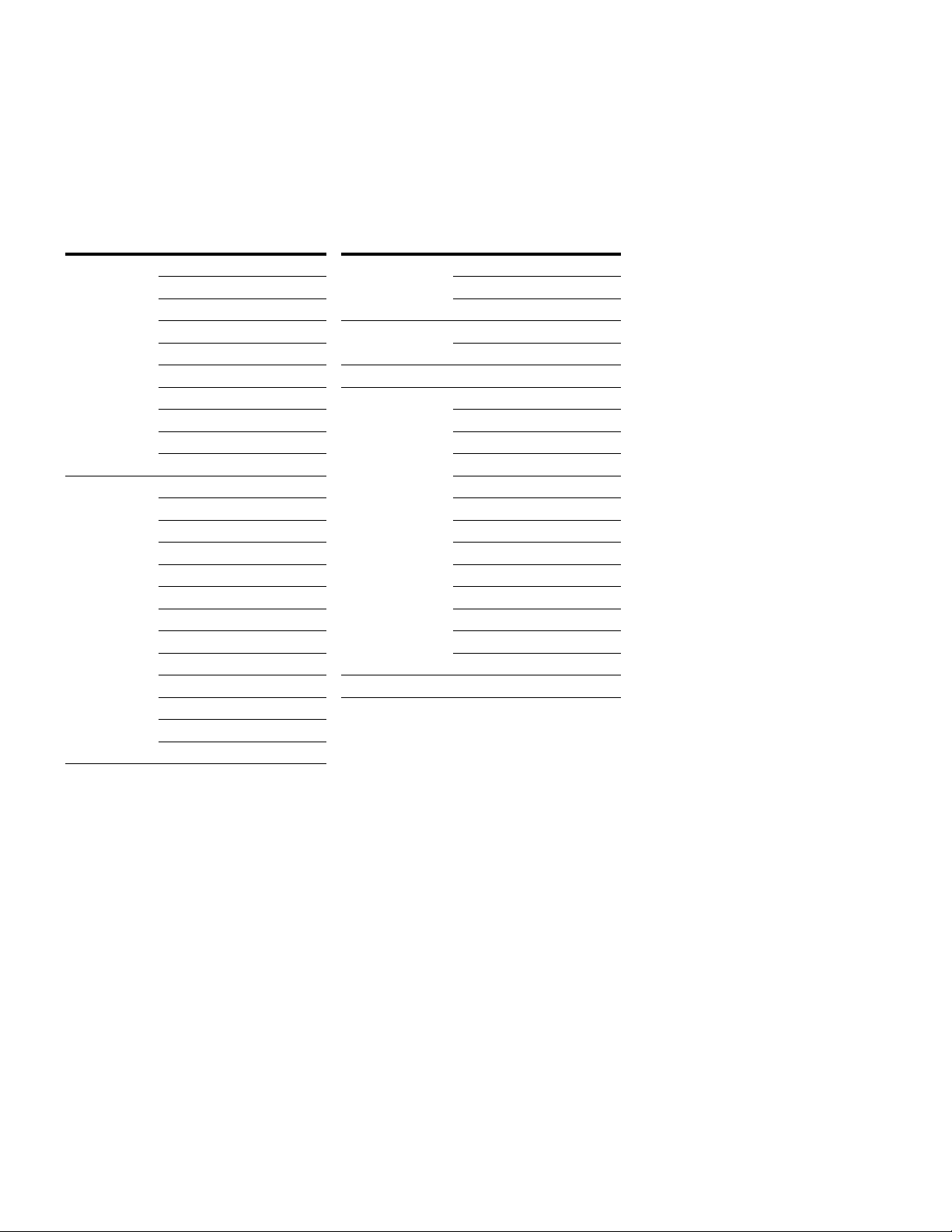

Table 4. Keypad Menu

Item Description Item Description

Monitor M1—Basic Fault F1—Active Fault

M2—IO Status F2—History Fault

M3—Optional Boards F3—Fault Log

M4—Energy savings Option Boards B1—Slot A

M5—FB Monitor Menu B2—Slot B

M6—PID Monitor Favorite

M7—Timer/Interval Control Operate Mode O1—Output Frequency

M8—User Defined Output O2—Freq Reference

M9—MWH Monitor O3—Motor Speed

M10—Multi-Monitoring O4—Motor Current

Parameters P1—Basic Parameter O5—Motor Torque

P2—Inputs O6—Motor Power

P3—Outputs O7—Motor Voltage

P4—Drive Control O8—DC-link Voltage

P5—Motor Control O9—Unit Temperature

P6—Protections O10—Motor Temperature

P7—PID Controller 1 R11—Keypad Reference

P8—PID Controller 2 R12—PID1 Keypad Set Point 1

P9—Fire Mode R13—PID1 Keypad Set Point 2

P10—Bypass Startup Wizard S—Startup Wizard

P11—Real Time Clock

P12—Communication

P13—System

Note: Will vary depending on application selected.

6 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

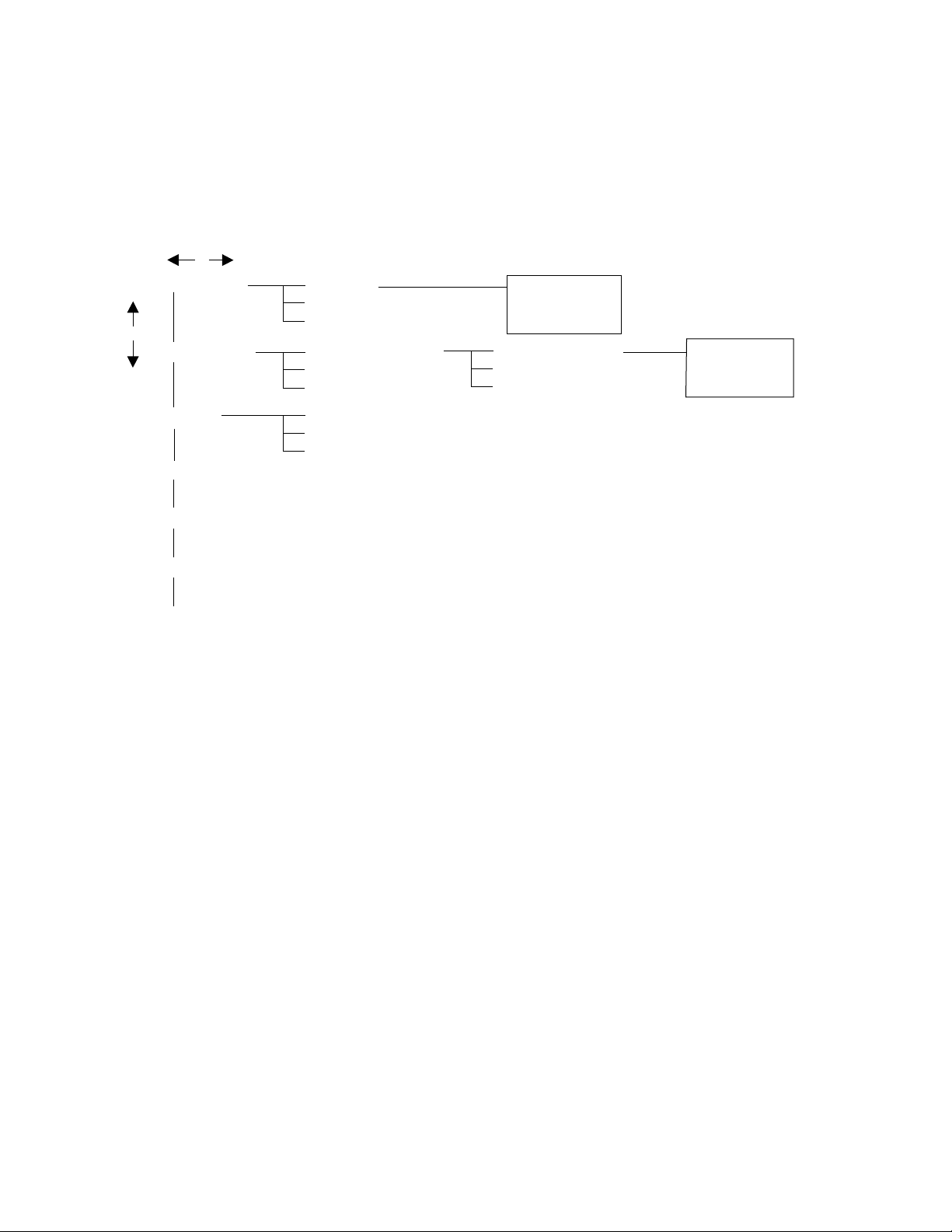

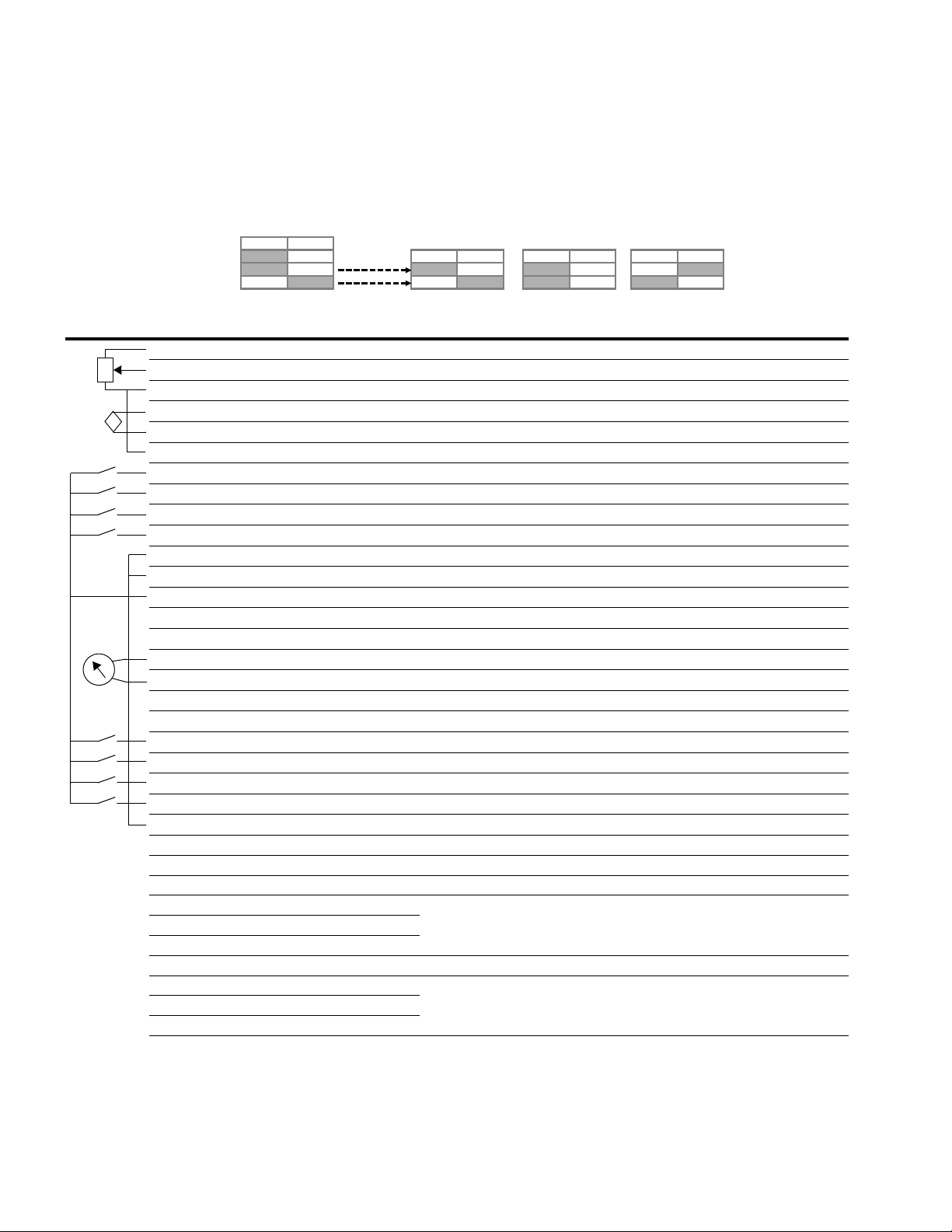

Menu Navigation

Back/left key Right/OK key

UP key

Down key

M – Monitor

P – Parameters

F – Fault

B – Optional Boards

T – Favorite

O – Operate Mode

…

…

…

M1 – Basic

M10 – Multi-Monitoring

P1 – Basic Parameters

P13 – System

F1 – Active Fault

F2 – History Fault

P1.1 – Min Frequency

P1.16 – Auto 2 Reference

M1.1

S – Startup Wizard

F3 – Fault Log

Output Frequency

0.00 Hz

P1.1

Min Frequency

0.00 Hz

This section provides basic instruction on navigating each

section in the menu structure.

Figure 5. Main Menu Navigation

Step 3—Menu Navigation

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 7

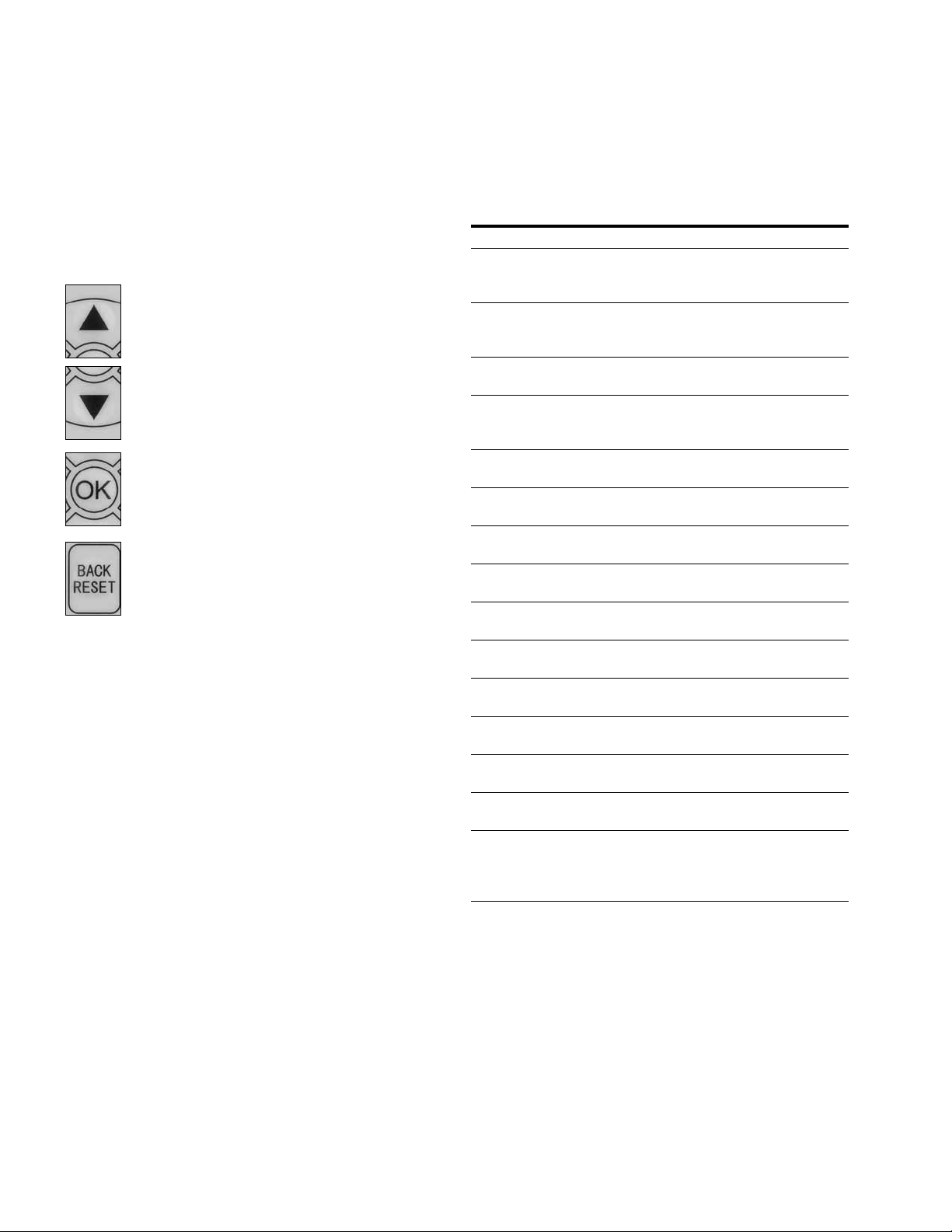

Step 4—Startup Wizard

Step 4—Startup Wizard

Startup Wizard

In the Startup Wizard, you will be prompted for essential

information needed by the drive so that it can start

controlling your process. In the Wizard, you will need

the following keypad buttons:

Up/Down buttons.

Use these to change value.

OK button.

Confirm selection with this button, and enter into

next question.

Back/Reset button.

If this button was pressed at the first question,

the Startup Wizard will be cancelled.

Once you have connected power to your Eaton PowerXL

frequency converter, and the Startup Wizard is enabled,

follow these instructions to easily set up your drive.

Table 5. Startup Wizard Instructions

Item Description

1 Startup Wizard Press OK?

2 Application 0 = Basic

1 = PID

2 = Advanced

3 Language 0 = English

1 = ѝ᮷

2 = Deutsch

4 Real Time Clock yy.mm.dd

hh:mm:ss

5 Daylight Saving 0 = Off

1 = EU

2 = US

6 Min Frequency Min: 0.00Hz

Max: Max Frequency

7 Max Frequency Min: Min Frequency

Max: 400.00Hz

8 Motor Nom Current Min: 0.1A

Max: 500.0A

9 Current Limit Min: Ih*1/10

Max: Ih*2

10 Motor Nom Speed Min: Ih*1/10

Max: Ih*2

11 Motor PF Min: 0.30

Max: 1.0

12 Motor Nom Voltage Min: 180V

Max: 690V

13 Motor Nom Frequency Min: 30.00 Hz

Max: 400.00 Hz

14 Accel Time 1 Min: 0.1 sec

Max:3000.0 sec

15 Decel Time 1 Min: 0.1 sec

Max:3000.0 sec

16 Hand Control Place 0 = Keypad

1 = I/O Terminal Start 1

2 = I/O Terminal Start 2

3 = Fieldbus

8 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

Table 5. Startup Wizard Instructions, continued

Item Description

17 Hand Reference 0 = AI1

1 = AI2

2 = Slot A: AI1

3 = Slot B: AI1

4 = AI1 Joystick

5 = AI2 Joystick

6 = Keypad

7 = Fieldbus

9 = Max Frequency

10 = AI1 + AI2

11 = AI1 –AI2

12 = AI2 –AI1

13 = AI1 * AI2

14 = AI1 or AI2

15 = Min(AI1,AI2)

16 = Max(AI1,AI2)

17 = PID1 Control Output

18 = PID2 Control Output

18 Auto 1 Control Place 0 = I/O Terminal Start 1

1 = Fieldbus

2 = I/O Terminal Start 2

3 = Keypad

19 Auto 1 Control Reference 0 = AI1

1 = AI2

2 = Slot A: AI1

3 = Slot B: AI1

4 = AI1 Joystick

5 = AI2 Joystick

6 = Keypad

7 = Fieldbus

9 = Max Frequency

10 = AI1 + AI2

11 = AI1 –AI2

12 = AI2 –AI1

13 = AI1 * AI2

14 = AI1 or AI2

15 = Min(AI1,AI2)

16 = Max(AI1,AI2)

17 = PID1 Control Output

18 = PID2 Control Output

20 Bypass Enabled 0 = Disabled

1 = Enabled

21 Application Mini-Wizard Press OK?

Step 4—Startup Wizard

Now the Startup Wizard is done. It won’t show again when

next power up. If you want to reset it, please set the Startup

Wizard (P13.1.17) or select it from the main menu screen to

enable and cycle the power to the drive.

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 9

Step 5—Standard Parameter List

Step 5—Standard Parameter List

Introduction

The Basic Application is designed for preloaded application

sets for use with HVAC specific terminology and functions.

It has the patent Active Energy Control algorithm that will

improve your efficiency as well as minimize losses in your

motor throughout the defined speed range. It provides the

ability for the user to define its Hand and Auto control and

reference signals with the standard Off condition as well.

In addition there is the ability to scale the analog input and

output signals to be read based off the desired motor

response. There are also 8 digital inputs, 3 relay outputs, and

1 digital output that can be programmed to allow for control

schemes that require the drive to have certain functions. It

provides full customization on the motor control sequence

with the ability to be in frequency or speed control mode, and

tuning of the V/Hz curve can be selected. Drive/Motor

protections can be customized to defined actions for added

user control. Below is a list of other features that are

available in the Basic Application.

Basic Application includes functions:

●

Bypass control

●

Fire mode

●

Pre heat/cold weather mode

●

Hand/Off/Auto in individual button for easy change of

control mode

●

Programmable protections

●

Programmable digital/analog input/output function

●

Programmable start/stop signal logic

●

Voltage and current limiters

●

Energy Savings Calculator

●

Two independent set of Acceleration/Deceleration ramps

●

Skip frequency

●

Start source (Local/Remote control function)

●

Reference source

●

Flying start

●

Volts per Hertz control programmable

●

Real time clock—RTC time display

●

Auto restart on fault to drive or bypass

●

Programmable switching frequency

●

Multi-preset speeds

●

Fan control

●

DC brake

I/O Controls

“Terminal To Function” (TTF) Programming

The design behind the programming of the digital inputs in

the DH1 drive is to use “Terminal To Function”

programming, which is composed of multiple functions that

get assigned a digital input to that function. The parameters

in the drive are set up with specific functions and by defining

the digital input and slot in some cases, depending on which

options are available. For use of the drives control board

inputs, they will be referred to as DigIN:1 through DigIN:8.

When additional option cards are used, they will be defined

as DigIN:X:IOY:Z. The X indicates the slot that the card is

being installed in, which will be either A or B. The IOY

determines the type of card it is, which would be IO1 or IO5.

The Z indicates which input is being used on that available

option card.

“Function To Terminal” (FTT) Programming

The design behind the programming of the relay outputs and

digital output in the DH1 drive is to use “Function To

Terminal” programming. It is composed of a terminal, be it a

relay output or a digital output, that is assigned a parameter.

Within that parameter, it has different functions that can be

set.

The parameters of the Standard Application are explained in

Appendix A of application manual.

The explanations are arranged according to the parameter

number. For the DI function, we use Terminal programming

method to function (TTF), where there is a fixed input that

gets programmed to a list of functions. This allows for

multiple inputs to be used for different functions. Connecting

a certain input with a certain parameter function is done by

give a parameter an appropriate value. The value is formed

by the location of the input, either being on the standard

control board or an external option board and the slot it is

located in.

10 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

Step 5—Standard Parameter List

Force Open/Force Close Selection

The Force Open Selection would make the selected function

always off. Essentially this is a virtual switch that is always

open. The Force Close Selection would make the selected

function always on. Essentially this is a virtual switch that is

always closed. These options are assigned to a function if we

want to force a state without using a hardware input.

The standard options are DigIn: Force Open—indication that

the parameter function is always going to be open, that being

said depending on the logic of the function this could mean

the function is always not active or always active. When the

selection of a function is DigIN: Force Closed—indication that

the parameter function is always going to be closed, that

being said again depending on the location of the function

this could mean the function is always active or not active.

Examples of these options would be ID190 Start Signal 1,

when set to “Force Open” and the drive is

looking at I/O terminals for control, in this case the drive

would never start since this Function is always Open. If this

function is set to “Force closed” the drive would always be

in a start mode when in that control location.

Example:

If we set Run Enable to Force Closed the drive is always

enabled. If we set the same function to Force Open the drive

would never be Enabled. If a Digital input is to be used to

activate this Run Enable the function should be assigned to a

hardware input (See below for DIGIN Selections).

DIGIN Selection

This allows Assignment of a hardware digital input to a

function, this is set in a format of DigIN:X where X is one of

the 8 Digital inputs on the Main control board.

Example:

If we set Run Enable to DigI11

N:6 the drive will be enabled when digital input 6 (Terminal 8)

is closed, and would not be enabled when digital input 6

(Terminal 8) is open.

Option Board digIN Selection

This allows Assignment of a hardware digital input on an

option card to a function, this is set in a format of DigIN:

Y:IO1:X where Y is the slot the option card is inserted on the

Main control board and X is the Input on the Board and IO1 is

the type of option board used.

Example:

If we set Run Enable to DigIN:A:IO5:6 the drive will be

enabled when digital input 6 is closed on the IO5 option card

which is inserted in Slot A, and would not be enabled when

digital input 6 on the option card is open.

Timer Channel Selection

A Time Channel is a virtual path to link the digital output of a

timer function to a digital input function. To utilize this feature

a timer or interval would need to be assigned to a time

channel 1 through 3, and the input function to be controlled

would need to be assigned to the same time channel.

Example:

If we set Run Enable to DigIN:TimeChannel1 the drive will be

enabled when the timer assigned to Time Channel 1 is active

or High, and would not be enabled when the Time Channel is

inactive or Low.

Table 6. Drive Communication Ports

Port Communication

RJ45 Keypad Port

Upload/Download Parameters USB to RJ45

Remote Mount Keypad Ethernet

Upgrade Drive Firmware USB to RJ45

RJ45 Ethernet Port

Upload/Download Parameters Ethernet

BACnet/IP Communications Ethernet

Modbus TCP Communications Ethernet

RS-485 Serial Port

Upload/Download Parameters

Upgrade Drive Firmware Two-Wire Twisted Pair

Modbus RTU Communications Two-Wire Twisted Pair

BACnet MS/TP Communications Two-Wire Twisted Pair

Note

1

Shielded wire recommended.

1

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 11

Step 5—Standard Parameter List

Control I/O Configuration

●

Run 240 Vac and 24 Vdc control wiring in separate conduit

●

Communication wire to be shielded

Table 7. Analog Signals/Galaxy I/O Interface

External

Wiring

1

Signal

Pin

Name Signal

1 +10V Ref. Output Voltage — 10 Vdc Supply Source

Res

2 AI1+

2

Analog Input 1 0–10V Voltage Speed Reference (Programmable to 4 mA to 20 mA)

3 AI1– Analog Input 1 Ground — Analog Input 1 Common (Ground)

4 AI2+

i

5 AI2– Analog Input 2 Ground — Analog Input 2 Common (Ground)

2

Analog Input 2 4 mA to 20 mA Current Speed Reference (Programmable to 0–10V)

6 GND I/O Signal Ground — I/O Ground for Reference and Control

7 DIN5 Digital Input 5 Preset Speed B0 Sets frequency output to Preset Speed 1

8 DIN6 Digital Input 6 Fire Mode Enables drive into Fire Mode

9 DIN7 Digital Input 7 Bypass Start (TI–) Enables drive into Bypass mode waiting for drive start

10 DIN8 Digital Input 8 Force Auto (TI+) Input forces drive into Auto Control place

11 CMB DI5 to DI8 Common Grounded Allows source input

12 GND I/O Signal Ground — I/O Ground for Reference and Control

13 24V +24 Vdc Output — Control voltage output (100 mA max.)

14 DO1 Digital Output 1 Ready Shows the drive is ready to run

15 24Vo +24 Vdc Output — Control voltage output (100 mA max.)

16 GND I/O Signal Ground — I/O Ground for Reference and Control

17 AO1+ Analog Output 1 Output Frequency Shows Output frequency to motor 0–60 Hz (4 mA to 20 mA)

18 AO2+ Analog Output 2 Motor Current Shows Motor current of motor 0–FLA (4 mA to 20 mA)

19 24Vi +24 Vdc Input — External control voltage input

20 DIN1 Digital Input 1 Run Forward Input starts drive in forward direction (start enable)

21 DIN2 Digital Input 2 Run Reverse Input starts drive in reverse direction (start enable)

22 DIN3 Digital Input 3 External Fault Input causes drive to fault

23 DIN4 Digital Input 4 Fault Reset Input resets active faults

24 CMA DI1 to DI4 Common Grounded Allows source input

25 A/+ RS-485 Signal A — Fieldbus Communication (Modbus, BACnet)

26 B/– RS-485 Signal B — Fieldbus Communication (Modbus, BACnet)

27 R3NO Relay 3 Normally Open Fault Relay output 3 shows VFD is Faulted

28 R1NC Relay 1 Normally Closed Bypass Run Relay output 1 shows VFD is in a bypass run state

29 R1CM Relay 1 Common

30 R1NO Relay 1 Normally Open

31 R3CM Relay 3 Common Fault Relay output 3 shows VFD is Faulted

32 R2NC Relay 2 Normally Closed Run Relay output 2 shows VFD is in a drive run state

33 R2CM Relay 2 Common

34 R2NO Relay 2 Normally Open

Notes

1

The above wiring demonstrates a SINK configuration. It is important that CMA and CMB are wired to ground (as shown by dashed line).

If a SOURCE configuration is desired, wire 24 V to CMA and CMB and close the inputs to ground. When using the +10 V for AI1, it is

important to wire AI1—ground (as shown by dashed line). If using +10 V for AI1 or AI2, terminals 3, 5, and 6 need to be jumpered together.

2

AI1+ and AI2+ support 10K potentiometer.

Default

Setting Description

12 PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com

Step 5—Standard Parameter List

Basic Application—Parameters List

On the next pages you will find the lists of parameters within the respective parameter

groups. The parameter descriptions are given in Appendix A of application manual. The

descriptions are arranged according to the parameter number.

Column explanations:

Code = Location indication on the keypad; shows the operator the present parameter number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; given if available

Default = Value preset by factory

ID = ID number of the parameter

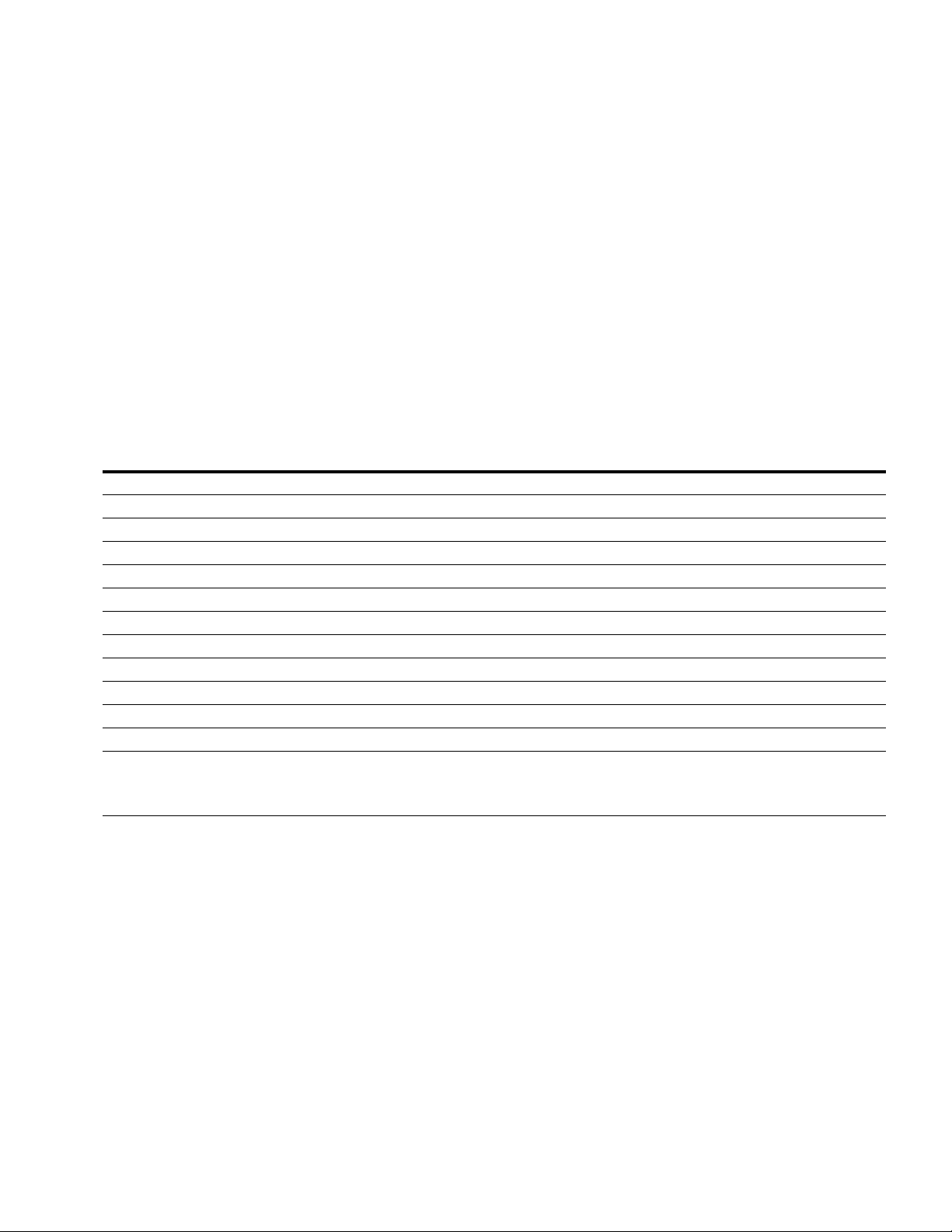

Monitor

Table 8. Basic—M1

Code Parameter Min. Max. Unit Default ID Note

M1.1 Output Frequency Hz 1

M1.2 Freq Reference Hz 24

M1.3 Motor Speed rpm 2

M1.4 Motor Current A 3

M1.5 Motor Torque % 4

M1.6 Motor Power % 5

M1.7 Motor Voltage V 6

M1.8 DC-link Voltage V 7

M1.9 Unit Temperature °C 8

M1.10 Motor Temperature % 9

M1.11 Latest Fault Code 28

M1.12 Instant Motor Power kW 1686

M1.13 RTC Battery Status 583 0 = Not Installed

1 = Installed

2 = Change Battery

3 = OverVoltage

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

PowerXL DH1 Series Variable Frequency Drives MN040039EN—April 2018 www.eaton.com 13

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Loading...

Loading...