Instruction Leaflet IL040029EN

Effective December 2017

Supersedes March 2014

PowerXL DH1 Series VFD

Instruction Leaflet Инструкция по монтажу Asennusohje Instrukcja montażu

Montageanweisung Montagehandleiding Návod k montáži Navodila za montažo

Notice d’installation Montagevejledning Paigaldusjuhend Návod na montáž

Instrucciones de montaje Οδηγίες εγκατάστασης Szerelési utasítás Монтажни инструкции

Istruzioni per il montaggio Instruções de montagem Montāžas instrukcija Instrucţiuni de montaj

ᆹ㻵䈤᰾ Monteringsanvisning Montavimo instrukcija

en

Electric Current! Danger to Life!

Only skilled or instructed persons may carry out the following operations.

de

Lebensgefahr durch elektrischen Strom!

Nur Elektrofachkräfte und elektrotechnisch unterwiesene Personen dürfen die im Folgenden beschriebenen Arbeiten ausführen.

fr

Tension électrique dangereuse !

Seules les personnes qualifiées et averties doivent exécuter les travaux ci-après.

es

¡Corriente eléctrica! ¡Peligro de muerte!

El trabajo a continuación descrito debe ser realizado por personas cualificadas y advertidas.

it

Tensione elettrica: Pericolo di morte!

Solo persone abilitate e qualificate possono eseguire le operazioni di seguito riportate.

zh

䀖⭥ড䲙ʽ

ݱ䇨уъӪઈ઼䗷уъ䇝㓳ⲴӪઈ䘋㹼 лࡇᐕDŽ

ru

Электрический ток! Опасно для жизни!

Только специалисты или проинструктированные лица могут выполнять следующие операции.

nl

Levensgevaar door elektrische stroom!

Uitsluitelijk deskundigen in elektriciteit en elektrotechnisch geinstrueerde personen is het toegestaan, de navolgend beschrevene werkzaamheden uit te voeren.

da

Livsfare på grund af elektrisk strøm!

Kun uddannede el-installatører og personer der e instruerede i elektrotekniske arbejdsopgaver, må udføre de nedenfor anførte arbejder.

el

Προσοχή, κίνδυνος ηλεκτροπληξίας!

Οι εργασίες που αναφέρονται στη συνέχεια θα πρέπει να εκτελούνται μόνο από ηλεκτρολόγους και ηλεκτροτεχνίτες.

pt

Perigo de vida devido a corrente eléctrica!

Apenas electricistas e pessoas com formação electrotécnica podem executar os trabalhos que a seguir se descrevem.

sv

Livsfara genom elektrisk ström!

Endast utbildade elektriker och personer som undervisats i elektroteknik får utföra de arbeten som beskrivs nedan.

Hengenvaarallinen jännite!

Vain pätevät sähköasentajat ja opastusta saaneet henkilöt saavat suorittaa seuraavat työt.

EATON www.eaton.com 1

Instruction Leaflet IL040029EN

Effective December 2017

PowerXL DH1 Series VFD

cs

Nebezpečí úrazu elektrickým proudem!

Níže uvedené práce smějí provádět pouze osoby s elektrotechnickým vzděláním.

et

Eluohtlik! Elektrilöögioht!

Järgnevalt kirjeldatud töid tohib teostada ainult elektriala spetsialist vői elektrotehnilise instrueerimise läbinud personal.

hu

Életveszély az elektromos áram révén!

Csak elektromos szakemberek és elektrotechnikában képzett személyek végezhetik el a következőkben leírt munkákat.

lv

Elektriskā strāva apdraud dzīvību!

Tālāk aprakstītos darbus drīkst veikt tikaielektrospeciālisti un darbam ar elektrotehniskām ekārtām instruētās personas!

lt

Pavojus

Tik elektrikai ir elektrotechnikos specialistai gali atlikti žemiau aprašytus darbus.

gyvybei

dėl elektros srovės!

pl

Porażenie prądem elektrycznym stanowi zagrożenie

dla życia!

Opisane poniżej prace mogą przeprowadzać tylko wykwalifikowani elektrycy oraz osoby odpowiednio poinstruowane w zakresie elektrotechniki.

sl

Življenjska nevarnost zaradi električnega toka!

Spodaj opisana dela smejo izvajati samo elektrostrokovnjaki in elektrotehnično poučene osebe.

sk

Nebezpečenstvo ohrozenia života elektrickým prúdom!

Práce, ktoré sú nižšie opísané, smú vykonávat’ iba elektroodborníci a osoby s elektrotechnickým vzdelaním.

bg

Опасност за живота от електрически ток!

Операциите, описани в следващите раздели, могат да се извършват само

от специалисти-електротехници и инструктиран електротехнически

персонал.

ro

Atenţie! Pericol electric!

Toate lucrările descrise trebuie efectuate numai de personal de specialitate calificat şi de persoane cu cunoştiinţe profunde în electrotehnică.

2 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

Series Power Part Options

D H1 – 3 4 011 N N – C 21 C

Basic naming

D = Drive

Series

G1 = General purpose

H1 = HVAC

DH1 - Output current rating (CT)

208–240 V 380–500 V 525–600 V

4D8 = 4.8A, 1.0HP, 0.75KW

6D6 = 6.6A, 1.5HP, 1.1KW

7D8 = 7.8A, 2.0HP, 1.5KW

011 = 11A, 3.0HP, 2.2KW

012 = 12.5A, - HP, 3.0KW

017 = 17.5A, 5.0HP, 3.7KW

025 = 25A, 7.5HP, 5.5KW

031 = 31A, 10HP, 7.5KW

048 = 48A, 15HP, 11KW

061 = 61A, 20HP, 15KW

075 = 75A, 25HP, 18.5KW

088 = 88A, 30HP, 22KW

114 = 114A , 40HP, 30KW

143 = 143A, 50HP, 37KW

170 = 170A, 60HP, 45KW

211 = 211A, 75HP, 55KW

261 = 261A, 100HP, 75KW

312 = 312A, 125HP, 90KW

Phase reference

3 = 3~ INPUT/3~ OUTPUT

Input/output voltage rating

2 = 230 V (208–240 V, –15%, +10%)

4 = 400 V (380–500 V, –15%, +10%)

5 = 600 V (525–600 V, –15%, +10%)

3D3 = 3.3A, 1.5HP, 1.1KW

4D3 = 4.3A, 2.0HP, 1.5KW

5D6 = 5.6, 3.0HP, 2.2KW

7D6 = 7.6A, 4.0HP, 3KW

9D0 = 9A, - HP, 4KW

012 = 12A, 7.5HP, 5.5KW

016 = 16A, 10HP, 7.5KW

023 = 23A, 15HP, 11KW

031 = 31A, 20HP, 15KW

038 = 38A, 25HP, 18.5KW

046 = 46A, 30HP, 22KW

061 = 61A, 40HP, 30KW

072 = 72A, 50HP, 37KW

087 = 87A, 60HP, 45KW

105 = 105A, 75HP, 55KW

140 = 140A, 100HP, 75KW

170 = 170A, 125HP, 90KW

205 = 205A, 150HP, 110KW

261 = 261A, 200HP, 132KW

310 = 310A, 250HP, 160KW

4D5 = 4.5A, 3HP, 2.2KW

7D5 = 7.5A, 5.0HP, 3.7KW

010 = 10A, 7.5HP, 5.5KW

013 = 13.5A, 10HP, 7.5KW

018 = 18A, 15HP, 11KW

022 = 22A, 20HP, 15KW

027 = 27A, 25HP, 18.5KW

034 = 34A, 30HP, 22KW

041 = 41A, 40HP, 30KW

052 = 52A, 50HP, 37KW

062 = 62A, 60HP, 45KW

080 = 80A, 75HP, 55KW

100 = 100A, 100HP, 75KW

125 = 125A, 125HP, 90KW

144 = 144A, 150HP, 110KW

208 = 208A, 200HP, 132KW

250 = 250A, 250HP, 160KW

Internal brake chopper

N = No brake chopper

B = Brake chopper

Internal EMC filter

D = DC choke only

E = EMC filter only

F = Internal EMC filter and DC choke

N = No EMC filter, no DC choke

C = Coated

Enclosure (IP rating)

00 = IP00/Open Type

20 = IP20/Open Type

21 = IP21/Type 1

54 = IP54/Type 12

Display option

C = LCD (graphical)

N = No display

Coating of boards

IP00 FR7 and FR8 is not avaliable for 230V input product or with the PowerXL DH1 Product

IP20 FR0 will be avalible in June 2018

EATON www.eaton.com 3

Instruction Leaflet IL040029EN

PowerXL DH1 Series VFD

Effective December 2017

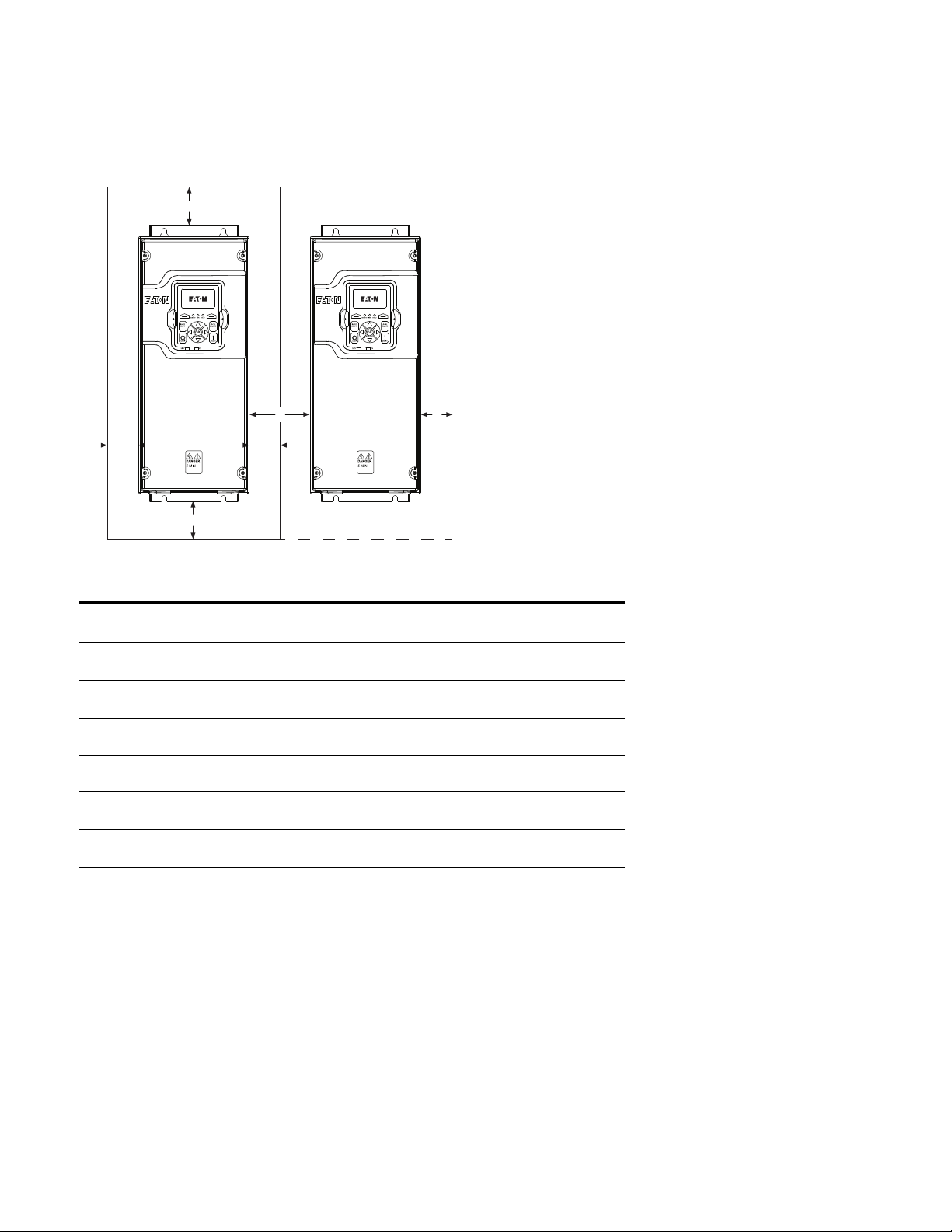

Dimensions and weights—Dimensões e pesos—Encombrements et poids—Abmessungen und Gewichte—

Dimensioni e pesi—Afmetingen en gewichten—Dimensioner og vægt—Διαστάσεις και βάρη—

Dimensiones y pesos—Mått och vikter—Mitat ja painot—Rozměry a hmotnosti—Mõõdud ja kaalud—

Méretek és tömeg—Izmēri un svars—Matmenys ir masė—Wymiary i ciężary—Mere in teže—

Rozmery a hmotnosti—Размери и тегло—Dimensiuni şi greutăţi—Размеры и вес— ቪረ઼䟽䟿

H2

H1

Frame

Approximate dimensions in inches (mm)

size

FR0

FR1 7.91

FR2 9.63

FR3 10.44

FR4 11.57

FR5 13.41

FR6 14.61

Note

6.83

10.58

(173.5)

(268.7)

12.87

(327.0)

(200.9)

16.50

(419.0)

(244.7)

21.97

(558.0)

(265.1)

24.80

(630.0)

(294.0)

34.98

(888.5)

(340.7)

40.75

(371)

FR0 is not available till June 2018.

(1035)

W4

W3

10.16

(258.0)

12.28

(312.0)

15.98

(406.0)

21.46

(545.0)

24.31

(617.5)

29.65

(753.0)

33.27

(845)

9.54

(242.3)5(127.0)

11.50

(292.0)

14.96

(380.0)

20.41

(518.5)

23.26

(590.7)

27.83

(707.0)

31.38

(797)

6.02

(153.0)

6.61

(167.8)

8.06

(204.6)

9.36

(237.7)

11.34

(288.0)

19.13

(486)

4.97

(126.3)

4.80

(122.0)

5.28

(134.0)

7.24

(184.0)

9.13

(232.0)

11.10

(282.0)

18.90

(480)

D

4.26

(108.3)

3.94

(100.0)

3.54

(90.0)

4.92

(125.0)

8.07

(205.0)

8.66

(220.0)

15.75

(400)

4.26

(108.3)

3.94

(100.0)

3.54

(90.0)

4.92

(125.0)

8.07

(205.0)

8.66

(220.0)

15.75

(400)

H3

0.28

(7.0)

0.28

(7.0)

0.28

(7.0)

0.35

(9.0)

0.35

(9.0)

0.35

(9.0)

0.35

(9)

W2

W1

Weight

lb (kg)D H1 H2 H3 W1W2W3W4Ø

4.41

(2.0)

14.33

(6.5)

23.37

(10.6)

49.82

(22.6)

77.60

(35.2)

154.32

(70.0)

246.91

(112)

4 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

Mounting—Montaje—Montage—Montaggio—Montering—Τοποθέτηση—Montagem—Asennus—

Montáž—Paigaldamine—Felszerelése—Montāža—Montavimas—Montaż—Montaža—Монтаж—

Montarea—Монтаж— ᆹ㻵

C

B A

A

D

Frame

size

FR0

A

In (mm)

0 0 3.94

FR1 0.79

(20)

FR2 1.18

(30)

B

In (mm)

1.58

(40)

2.36

(60)

FR3 0 0 7.87

FR4 0 0 11.81

FR5 3.15

(80)

FR6 3.15

(80)

Notes

kW ratings are at 400 V / 50 Hz.

Minimum clearances A and B for drives with Type 12 (IP54) enclosure is 0 mm (in) for FR1, FR2, FR3, FR4, FR6.

The above guidelines apply unless testing has been completed to validate a design outside of these recommendations.

FR0 is not available till June 2018.

6.30

(160)

6.30

(160)

A

C

In (mm)

(100)

3.94

(100)

6.30

(160)

(200)

(300)

11.81

(300)

15.75

(400)

D

In (mm)

1.97

(50)

1.97

(50)

2.36

(60)

3.15

(80)

3.94

(100)

7.87

(200)

12.99

(330)

Cooling air required

CFM (m3/h)

16.5

(28)

14

(24)

55

(94)

85

(144)

153

(260)

232

(395)

230V: 435 (739)

480V/600V: 400 (679)

EATON www.eaton.com 5

Instruction Leaflet IL040029EN

Effective December 2017

PowerXL DH1 Series VFD

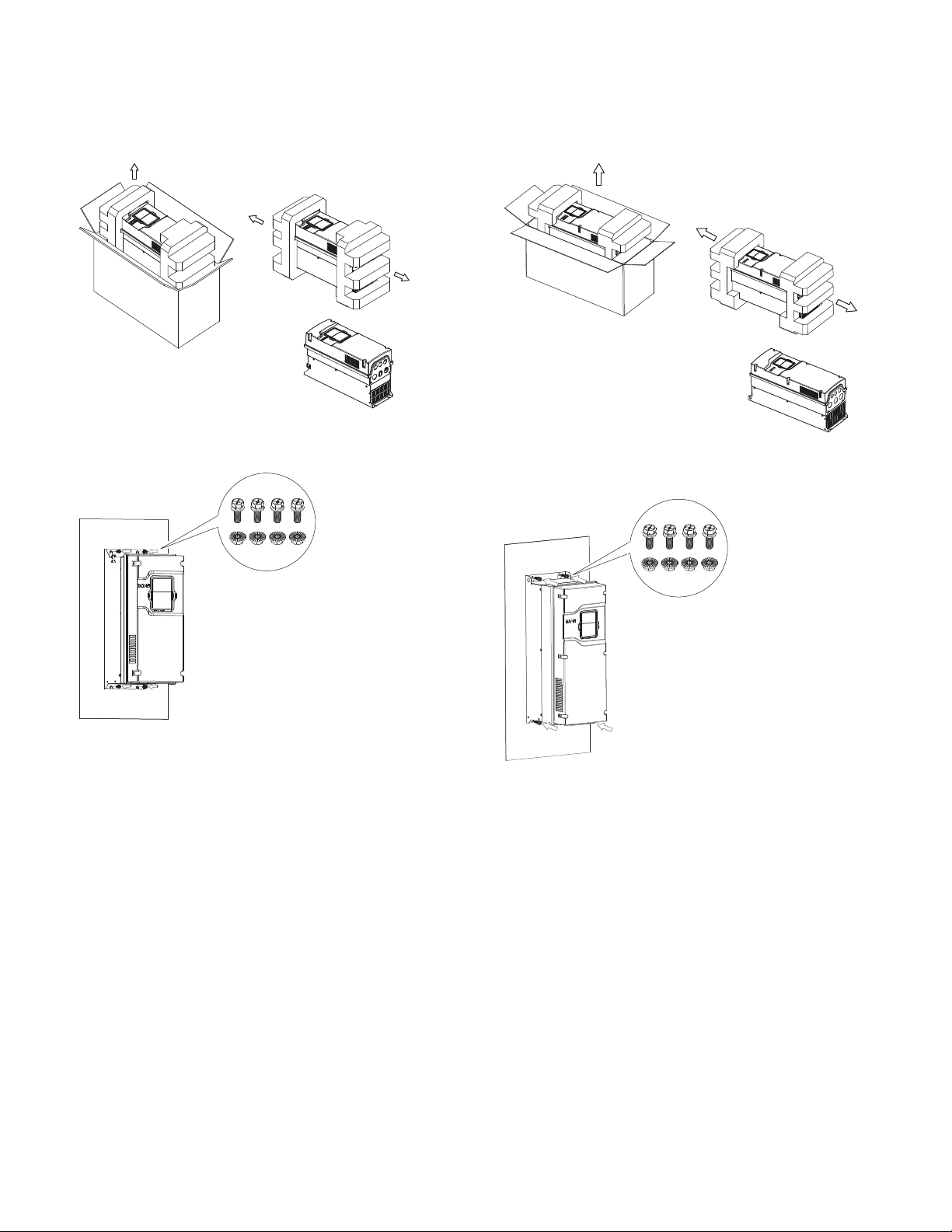

FR0 mounting instructions

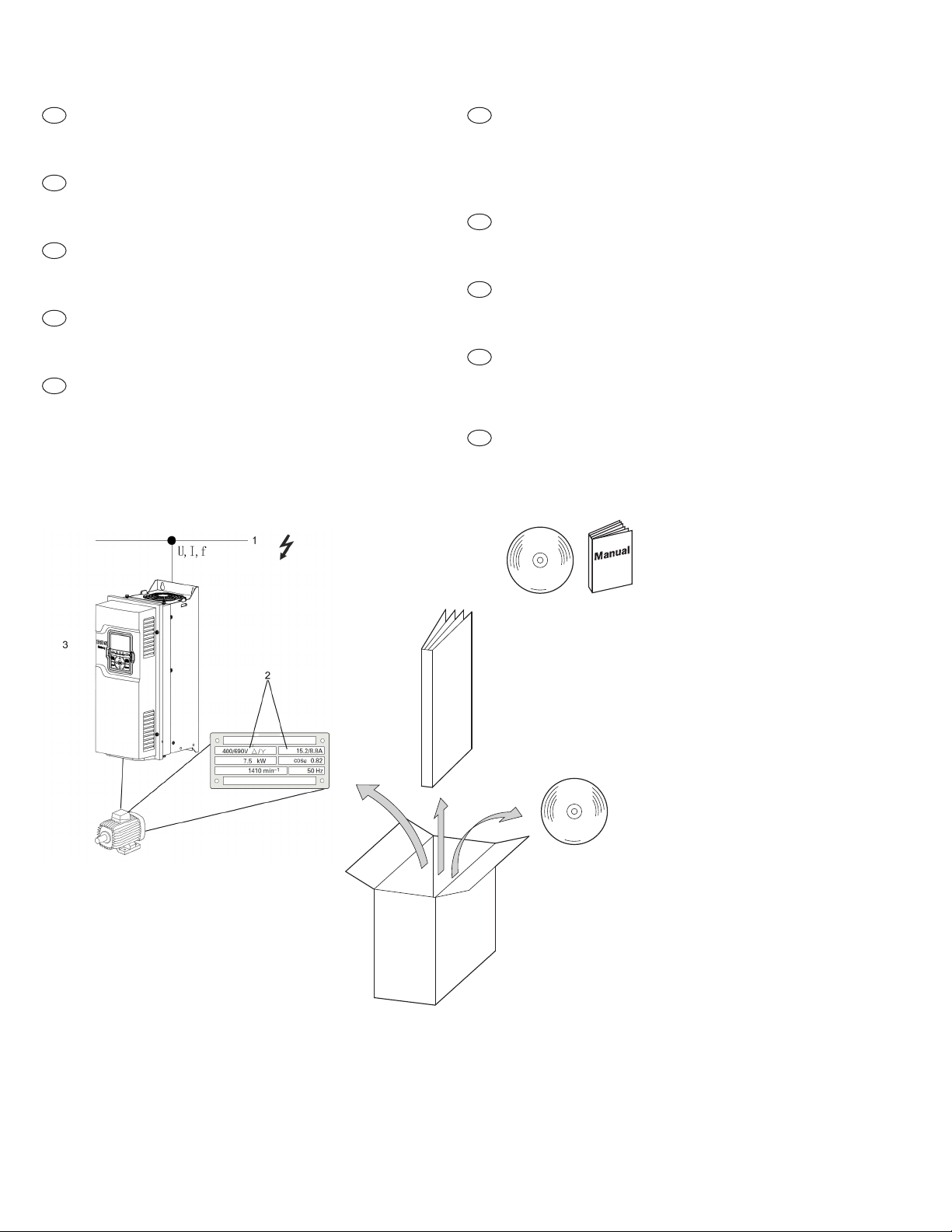

Step 1: Lift the drive out from the carton, remove the packaging

Step 2: Attach the drive to the mounting plate with four M5X15

screws and four M5 nuts.The opening dimension on the

mounting plate should follow required dimension (refer

to the drive mounting template printed on the outside

carton)

The drive can be mounted vertically or horizontally

according to customer's need.

SCREW:4-M5*15

NUT:4-M5

FR1 mounting instructions

Step 1:

Step 2:

Screw: Four M5x15

or 3/16 inch

Nut: Four M5

or 3/16 inch

Vertical mounting

Horizontal mounting

Step 3: 1. EN version FR0 or US version FR0 with EMC kit

1)Input wiring: Run the L1,L2, L3 wires through a

magnetic ring and wind one lap, fix the L1,L2, L3 wires

and magnetic ring with a cable tie, then connect the

L1,L2, L3 wires to input terminals. Connect the input

grounding wire to the bottom metal plate with a M4*10

screw.)

Output wiring: a ttach a L shape EMC grounding plate to

the bottom of drive with two M4*8 flat screws. Connect

the output U, V, W wires to output terminals. Connect

the output grounding wire to the bottom metal plate

with a M4*10 screw. Clamp the output cable shield to

the L shape EMC grounding plate with a small

rectangular EMC grounding plate and two M4*15

screws.

2. US version FR0 without EMC kit, there are no

magnetic ring and EMC grounding plates, but it is

necessary to connect the output cable shield to the

bottom metal surface with a M4*10 screw

SCREW: 2-M4*10

SCREW: 2-M4*8flat

SCREW: 2-M4*15

Output cable

Magnetic ring

Cable tie

Input power wires

Input grounding wire

Note

FR0 is not available till June 2018.

6 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

FR2 mounting instructions

Step 1:

Step 2:

FR3 mounting instructions

Step 1:

Step 2:

Screw: Four M5x15

or 3/16 inch

Nut: Four M5

or 3/16 inch

Screw: Four M6x15

or 1/4 inch

Nut: Four M6

or 1/4 inch

EATON www.eaton.com 7

Instruction Leaflet IL040029EN

Effective December 2017

FR4 mounting instructions

Step 1:

PowerXL DH1 Series VFD

Step 2:

Screw: Four M8x15

or 3/8 inch

Nut: Four M8

or 3/8 inch

8 EATON www.eaton.com

PowerXL DH1 Series VFD

FR5 mounting instructions

Step 1:

Step 2:

Instruction Leaflet IL040029EN

Effective December 2017

Step 3:

Step 4:

Screw: Four M8x20

or 3/8 inch

Nut: Four M8

or 3/8 inch

EATON www.eaton.com 9

Instruction Leaflet IL040029EN

Effective December 2017

FR6 mounting instructions

Step 1: Remove the carton from the drive.

PowerXL DH1 Series VFD

Step 4: Attach the drive to the mounting plate with four

M8x20 or 3/8-inch screws and four M8 or 3/8-inch

nuts with an M8 or 2/8-inch wrench. The opening

dimensions on the mounting plate should follow

required dimensions (refer to the drive mounting

template printed on the outside carton).

SCREW:4-M8*20

NUT:4-M8

Step 2: Remove the four screws (used to fix the drive to

the pallet) with an M8 or 3/8-inch wrench.

Step 3: Use a hook to lift the drive.

10 EATON www.eaton.com

PowerXL DH1 Series VFD

Warning!

en

Connect only in voltage-free state!

Instruction Leaflet IL040029EN

Effective December 2017

es

¡Advertencia!

¡Conectar únicamente en estado sin tensión!

fr

Avertissement !

Raccordez l’appareil uniquement hors tension !

de

Warnung!

Nur im spannungsfreien Zustand anschließen!

it

Avvertimento!

Collegare solo in assenza di tensione!

nl

Waarschuwing!

Alleen in spanningsloze toestand aansluiten!

da

Advarsel!

Må kun tilsluttes i spændingsfri tilstand!

el

Προειδοποίηση!

Συνδέστε μόνο όταν δεν επικρατεί τάση!

pt

Atenção!

Ligar apenas com a tensão desligada!

sv

Varning!

Får endast anslutas i spänningsfritt tillstånd!

Varoitus!

Kytke vain jännitteettömässä tilassa!

cs

Varování!

Připojujte jen při zcela odpojeném napájení!

et

Hoiatus!

Ühendada ainult pingevabas olekus!

hu

Figyelmeztetés!

Csak feszültségmentes állapotban csatlakoztassa!

lv

Brīdinājums!

Pieslēgt tikai tad, kad nenotiek sprieguma padeve!

lt

Perspėjimas!

Prijungti tik tada, kai išjungta įtampa!

pl

Ostrzeżenie!

Podłączać zawsze po uprzednim odłączeniu od zasilania elektrycznego!

sl

Opozorilo!

Napravo priključite le, ko ni pod napetostjo!

sk

Varovanie!

Napájat˙ len v stave bez napätia!

bg

Предупреждение!

Свързвайте само, когато уреда не е под напрежение!

ro

Atenţie!

Conectaţi doar când aparatul nu se află sub tensiune!

ru

Предупреждение!

Подключать только в обесточенном состоянии!

zh

䆖

ᗵ享൘ᯝ⭥⣦ᘱл䘋㹼䘎᧕ʽ

Ground wiring

(FR1–FR4)

No. 2 Phillips

(FR5)

No. 3 Phillips

(FR1–FR3)

PE

15

(FR1–FR3)

25

(FR4–FR6)

M4, 10 in-lb (1.1 Nm)

(FR4)

M4, 14 in-lb (1.6 Nm)

(FR5)

M6, 35 in-lb (4.0 Nm)

EATON www.eaton.com 11

Instruction Leaflet IL040029EN

Effective December 2017

Rubber grommet installation instructions

PowerXL DH1 Series VFD

Step 1:

D1 (Cable)

Step 2:

D2 (Grommet)

Step 3:

D1 ≤ D2 ≤ D1 + 2 mm

Step 5:

Step 6:

Step 4:

Self-Locking Cable Ties

12 EATON www.eaton.com

PowerXL DH1 Series VFD

Input power and motor cable stripping lengths

Instruction Leaflet IL040029EN

Effective December 2017

Frame

Size

FR0

FR1 0.39

FR2 0.59

FR3 0.59

FR4 0.98

FR5 1.10

FR6 0.98

Power connection tightening torque

Frame

Size

FR0

Power Wiring in Inches (mm) Motor Wiring in Inches (mm)

A1 B1 C1 D1 A2 B2 C2 D2

0.39

(10)

(10)

(15)

(15)

(25)

(28)

(25)

Power wire

in-lb (Nm)

5.3 (0.6) 14 (1.6) 4.5 (0.5)

5.12

(130)

1.77

(45)

1.77

(45)

1.57

(40)

2.56

(65)

6.10

(155)

4.72

(120)

0.39

(10)

0.39

(10)

0.59

(15)

0.59

(15)

0.98

(25)

1.10

(28)

0.98

(25)

5.12

(130)

1.38

(35)

1.77

(45)

1.97

(50)

4.72

(120)

9.45

(240)

7.87

(200)

Ground wire

in-lb (Nm)

0.39

(10)

0.39

(10)

0.59

(15)

0.59

(15)

0.98

(25)

1.10

(28)

0.98

(25)

Control wire

in-lb (Nm)

FR1 5.3 (0.6) 10 (1.1) 4.5 (0.5)

FR2 15.6 (1.8) 10 (1.1) 4.5 (0.5)

FR3 40 (4.5) 10 (1.1) 4.5 (0.5)

FR4 95 (10.7) 14 (1.6) 4.5 (0.5)

FR5 354 (40.0) 35 (4.0) 4.5 (0.5)

FR6 480 (54.2) 35 (4.0) 4.5 (0.5)

Notes

Strip the motor and power cables as shown above.

Both UL® and IEC tools may be used.

Applies to strained wire, solid wire, or ferrule installations.

FR0 is not available till June 2018.

3.15

(80)

1.77

(45)

1.57

(40)

1.57

(40)

2.56

(65)

6.10

(155)

4.72

(120)

0.39

(10)

0.39

(10)

0.59

(15)

0.59

(15)

0.98

(25)

1.10

(28)

0.98

(25)

1.97

(50)

1.38

(35)

1.57

(40)

1.97

(50)

4.72

(120)

9.45

(240)

7.87

(200)

EATON www.eaton.com 13

Instruction Leaflet IL040029EN

PowerXL DH1 Series VFD

Effective December 2017

Cable and fuse guidelines

North America cable and fuse sizes—208 Vac to 240 Vac ratings

NEC

motor amp

rating

at 208 V

Frame size

FR0

Amp

suffix

208 V

input

current

(VT/I

)

L

NEC

motor amp

rating

at 230 V

4D8 5.6 4.2 4.6 4.8 10 14 14 26–10 18–10

6D6 7.6 6 6.6 6.6 10 14 14 26–10 18–10

7D8 9 6.8 7.5 7.8 15 14 14 26–10 18–10

FR1 4D8 4.4 4.2 4.6 4.8 10 14 14 24–10 18–10

6D6 6.1 6 6.6 6.6 10 14 14 24–10 18–10

7D8 7.2 6.8 7.5 7.8 10 14 14 24–10 18–10

011 10.2 9.6 10.6 11 15 14 14 24–10 18–10

012 11.6 — — 12.5 15 12 12 24–10 18–10

FR2 017 16.3 15.2 16.7 17.5 20 10 10 20–6 12–6

025 23.2 22 24.2 25 30 8 10 20–6 12–6

031 29 28 30.8 31 35 8 10 20–6 12–6

FR3 048 44.2 42 46.2 48 60 6 6 6–2 14–4

061 56 54 59.4 61 80 4 6 6–2 14–4

FR4 075 64.6 68 74.8 75 100 3 4 6–1/0 10–1/0

088 78 80 88 88 110 2 4 6–1/0 10–1/0

114 94.3 104 114 114 125 1/0 3 6–1/0 10–1/0

FR5 143 129 130 143 143 175 3/0 3 1/0–350 kcmil 8–250 kcmil

170 157 154 169 170 200 4/0 3 1/0–350 kcmil 8–250 kcmil

211 189 192 211 211 250 300 3 1/0–350 kcmil 8–250 kcmil

FR6 261 242.8 248 273 261 400 2*2/0 3 2*(1/0–300 kcmil) 3–300 kcmil

312 290.3 312 343 312 400 2*4/0 3 2*(1/0–300 kcmil) 3–300 kcmil

Notes

Line and motor cable size is selected according to UL 508C Table 40.3 for copper conductor rated 75 °C. Use only with copper wire rated 75 °C here.

Size requirements for other different wire types are defined in the National Electrical Code

Earthing conductor size is determined by the maximum overcurrent device rating used ahead of the drive according to UL 508C Table 6.4.

If power cubes or bypass are used, a UL listed Class RK5, J, T or equivalent fuse is recommended.

FR0 is not available till June 2018.

Current

(VT/I

)

L

at 40 °C

®

, ANSI/NFPA® 70.

Recommended

fuse

rating

NEC®

wire size (AWG) Terminal connection size (AWG)

Line and

motor Ground

Line and

motor Ground

14 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

International cable and fuse sizes—208 Vac to 240 Vac Ratings

Frame size

FR0

Amp

suffix

current

(VT/I

L

)

4D8 5.6 4.8 10 3*1.5+1.5 0.2–6 solid or

208 V input

Current

)

(VT/I

L

at 40 °C

Fuse

rating

(gG/gL)

Mains and

motor cable

Cu (mm

2

)

Terminal cable size

Main terminal

Cu (mm2)

Earth terminal

Cu (mm2)

0.75–6

0.2–4 stranded

6D6 7.6 6.6 10 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

7D8 9 7.8 16 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

FR1 4D8 4.4 4.8 6 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

6D6 6.1 6.6 10 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

7D8 7.2 7.8 16 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

011 10.2 11 16 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

012 11.6 12.5 16 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

FR2 017 16.3 17.5 20 3*4+4 0.5–16 4–16

025 23.2 25 32 3*4+4 0.5–16 4–16

031 29 31 32 3*6+6 0.5–16 4–16

FR3 048 44.2 48 50 3*16+16 16–35 2.5–25

061 56 61 63 3*16+16 16–35 2.5–25

FR4 075 64.6 75 80 3*25+16 16–50 6–50

088 78 88 100 3*35+16 16–50 6–50

114 94.3 114 125 3*50+25 16–50 6–50

FR5 143 129 143 160 3*70+35 50–185 10–120

170 157 170 200 3*95+50 50–185 10–120

211 189 211 250 3*150+95 50–185 10–120

FR6 261 242.8 261 400 2*(3*70+35) 2*(50–150) 35–150

312 290.3 312 400 2*(3*95+50) 2*(50–150) 35–150

Notes

Line and motor cable size is selected according to IEC 60364-5-52:2009 Table B.52.4 for copper conductor with PVC insulation with a wiring condition of ambient temperature 30 °C in air and an installation

method of “B2” (cables in conduit and cable trunking systems). For other wiring conditions, please refer to the standard of IEC 60364-5-52:2009 for suitable cable sizes.

Earthing conductor size is determined by the cross-sectional area of phase conductors according to IEC/EN 61800-5-1:2007 Table 5. So if phase conductor size is changed, earthing conductor size should also be changed accordingly.

If power cubes or bypass are used, a Class gG/gL fuse is recommended.

FR0 is not available till June 2018.

EATON www.eaton.com 15

Instruction Leaflet IL040029EN

Effective December 2017

PowerXL DH1 Series VFD

North America cable and fuse sizes—440 Vac to 500 Vac ratings

Current

(VT/I

at 40 °C

Frame size

FR0

Amp

suffix

Input current

(VT/IL)

amp rating

at 460 V

3D3 3.8 3 3 10 14 14 26–10 18–10

NEC motor

NEC

)

L

fuse

rating

Recommended

wire size (AWG)

Line and

motor Ground

Terminal connection

size (AWG)

Line and

motor Ground

4D3 4.3 3.4 3.4 10 14 14 26–10 18–10

5D6 6 4.8 4.8 10 14 14 26–10 18–10

7D6 9.6 7.6 7.6 15 14 14 26–10 18–10

FR1 3D3 2.8 3 3 10 14 14 26–10 18–10

4D3 3.2 3.4 3.4 10 14 14 26–10 18–10

5D6 4.5 4.8 4.8 10 14 14 26–10 18–10

7D6 7.1 7.6 7.6 10 14 14 26–10 18–10

9D0 8.4 — 7.6 15 14 14 26–10 18–10

012 10.2 11 11 15 14 14 26-10 18–10

FR2 016 13 14 14 20 12 12 20–6 12–6

023 19.6 21 21 30 10 10 20–6 12–6

031 25.2 27 27 35 8 8 20–6 12–6

FR3 038 31.7 34 34 50 6 8 6–2 14–4

046 37 40 40 60 6 8 6–2 14–4

061 48.1 52 52 80 4 6 6–2 14–4

FR4 072 59.3 65 65 100 4 4 6–1/0 10–1/0

087 70.3 77 77 110 3 4 6–1/0 10–1/0

105 87.6 96 96 125 1 3 6–1/0 10–1/0

FR5 140 114.4 124 124 175 2/0 3 1/0–350 kcmil 8–250 kcmil

170 144 156 156 200 3/0 3 1/0–350 kcmil 8–250 kcmil

205 166.1 180 180 250 250 kcmil 3 1/0–350 kcmil 8–250 kcmil

FR6 261 226.4 240 240 400 2*2/0 3 2*(1/0–300 kcmil) 3–300 kcmil

310 284.9 302 302 400 2*4/0 3 2*(1/0–300 kcmil) 3–300 kcmil

Notes

Line and motor cable size is selected according to UL 508C Table 40.3 for copper conductor rated 75 °C. Use only with copper wire rated 75 °C here.

Size requirements for other different wire types are defined in the National Electrical Code, ANSI/NFPA 70.

Earthing conductor size is determined by the maximum overcurrent device rating used ahead of the drive according to UL 508C Table 6.4.

If power cubes or bypass are used, a UL listed Class RK5, J, T or equivalent fuse is recommended.

FR0 is not available till June 2018.

16 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

International cable and fuse sizes—380 Vac to 440 Vac ratings

Frame size

FR0

Amp

suffix

current

(VT/I

L

)

3D3 4.3 3.3 6 3*1.5+1.5 0.2–6 solid or

400 V input

Current

)

(VT/I

L

at 40 °C

Fuse

rating

(gG/gL)

Mains and motor

cable Cu (mm

2

)

Terminal cable size

Main terminal

Cu (mm2)

Earth terminal

Cu (mm2)

0.75–6

0.2–4 stranded

4D3 5.5 4.3 10 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

5D6 7.1 5.6 10 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

7D6 9.6 7.6 16 3*1.5+1.5 0.2–6 solid or

0.75–6

0.2–4 stranded

FR1 3D3 3.1 3.3 6 3*1.5+1.5 0.2–6 solid or

4D3 4 4.3 6 3*1.5+1.5 0.75–6

0.2–4 stranded

0.75–6

5D6 5.2 5.6 10 3*1.5+1.5 0.75–6

7D6 7.1 7.6 16 3*1.5+1.5 0.75–6

9D0 8.4 9 16 3*1.5+1.5 0.75–6

012 11.2 12 16 3*1.5+1.5 0.75–6

FR2 016 15 16 20 3*4+4 0.5–16 4–16

023 21.5 23 25 3*4+4 0.5–16 4–16

031 29 31 32 3*6+6 0.5–16 4–16

FR3 038 35.2 38 40 3*16+16 16–35 2.5–25

046 42.6 46 50 3*16+16 16–35 2.5–25

061 55.7 61 63 3*16+16 16–35 2.5–25

FR4 072 65.7 72 80 3*25+16 16–50 6–50

087 79.4 87 100 3*35+16 16–50 6–50

105 97 105 125 3*50+25 16–50 6–50

FR5 140 129 140 160 3*70+35 50–185 10–120

170 157 170 200 3*95+50 50–185 10–120

205 189 205 250 3*120+70 50–185 10–120

FR6 261 246.2 261 400 2*(3*70+35) 2*(50–150) 35–150

310 292.4 310 400 2*(3*95+50) 2*(50–150) 35–150

Notes

Line and motor cable size is selected according to IEC 60364-5-52:2009 Table B.52.4 for copper conductor with PVC insulation with a wiring condition of ambient temperature 30 °C in air and an installation

method of “B2” (cables in conduit and cable trunking systems). For other wiring conditions, please refer to the standard of IEC 60364-5-52:2009 for suitable cable sizes.

Earthing conductor size is determined by the cross-sectional area of phase conductors according to IEC/EN 61800-5-1:2007 Table 5. So if phase conductor size is changed, earthing conductor size should also be changed accordingly.

If power cubes or bypass are used, a Class gG/gL fuse is recommended.

FR0 is not available till June 2018.

EATON www.eaton.com 17

Instruction Leaflet IL040029EN

Effective December 2017

PowerXL DH1 Series VFD

North America cable and fuse sizes—525 Vac to 600 Vac ratings

NEC wire

Size (AWG) Terminal connection size (AWG)

Frame size Amp suffix

575 V input

current (VT/IL)

NEC motor amp

rating at 575 V

Current (VT/I

at 40 °C

)

Recommended

L

fuse rating

Line and

motor Ground Line and motor Ground

FR1 4D5 4.2 3.9 4.5 10 14 14 26–10 18–10

7D5 7 6.1 7.5 10 14 12 26–10 18–10

010 9.3 9 10 15 14 10 26–10 18–10

FR2 013 12.5 11 13.5 20 12 10 20–6 12–6

018 16.7 17 18 30 10 10 20–6 12–6

022 20.4 22 22 35 10 8 20–6 12–6

FR3 027 25.2 27 27 40 6 8 6–2 14–4

034 31.7 32 34 45 6 8 6–2 14–4

041 38.2 41 41 50 6 6 6–2 14–4

FR4 052 48.1 52 52 70 4 6 6–1/0 10–1/0

062 57.4 62 62 80 4 6 6–1/0 10–1/0

080 73 77 80 125 2 4 6–1/0 10–1/0

FR5 100 91.3 99 100 150 1/0 4 1/0–350 kcmil 8–250 kcmil

125 114.1 125 125 175 2/0 4 1/0–350 kcmil 8–250 kcmil

144 132.9 144 144 200 3/0 4 1/0–350 kcmil 8–250 kcmil

FR6 208 202.8 192 208 400 2*1/0 3 2*(1/0–300 kcmil) 3–300 kcmil

250 243.8 242 250 400 2*2/0 3 2*(1/0–300 kcmil) 3–300 kcmil

Notes

Line and motor cable size is selected according to UL 508C Table 40.3 for copper conductor rated 75 °C. Use only with copper wire rated 75 °C here.

Size requirements for other different wire types are defined in the National Electrical Code, ANSI/NFPA 70.

Earthing conductor size is determined by the maximum overcurrent device rating used ahead of the drive according to UL 508C Table 6.4.

If power cubes or bypass are used, a UL listed Class RK5, J, T or equivalent fuse is recommended.

18 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

EATON www.eaton.com 19

Instruction Leaflet IL040029EN

Effective December 2017

Control board layout

PowerXL DH1 Series VFD

Fan Power Wire

STO

AI Mode Selection

Control I/O

Terminals

Removable

EMC Screw

Connect DSP Part

to Power Board

Keypad

AUTO

AUTO

123

ON

OFF HAND

Connect MCU Part

to Power Board

Battery (Standard)

RJ45, BACnet,

IP Modbus TCP

Optional Card A

Optional Card B

ON

1

RS-485 Terminating

Resistor

Removable

MOV Screw

Line Ground

Clamp Location

Grounding

Strap Location

Line Side Motor

20 EATON www.eaton.com

Motor Ground

Clamp Location

Grounding

Strap Location

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

Factory-set control terminal functions

I/O connection

External wiring Pin Signal name Signal Default setting Description

1 +10 V Ref. Output Voltage — 10 Vdc Supply Source

Res

2 AI1+

Analog Input 1 0–10 V Voltage Speed Reference (Programmable to 4 mA to 20 mA)

3 AI1– Analog Input 1 Ground — Analog Input 1 Common (Ground)

4 AI2+

i

5 AI2– Analog Input 2 Ground — Analog Input 2 Common (Ground)

Analog Input 2 4 mA to 20 mA Current Speed Reference (Programmable to 0–10 V)

6 GND I/O Signal Ground — I/O Ground for Reference and Control

7 DIN5 Digital Input 5 Preset Speed B0 Sets frequency output to Preset Speed 1

8 DIN6 Digital Input 6 Preset Speed B1 Sets frequency output to Preset Speed 2

9 DIN7 Digital Input 7 Emergency Stop (TI–) Input forces VFD output to shut off

10 DIN8 Digital Input 8 Force Remote (TI+) Input takes VFD from Local to Remote

11 CMB DI5 to DI8 Common Grounded Allows source input

12 GND I/O Signal Ground — I/O Ground for Reference and Control

13 24 V +24 Vdc Output — Control voltage output (100 mA max.)

14 DO1 Digital Output 1 Ready Shows the drive is ready to run

15 24 Vo +24 Vdc Output — Control voltage output (100 mA max.)

16 GND I/O Signal Ground — I/O Ground for Reference and Control

17 AO1+ Analog Output 1 Output Frequency Shows Output frequency to motor 0–60 Hz (4 mA to 20 mA)

18 AO2+ Analog Output 2 Motor Current Shows Motor current of motor 0–FLA (4 mA to 20 mA)

19 24 Vi +24 Vdc Input — External control voltage input

20 DIN1 Digital Input 1 Run Forward Input starts drive in forward direction (start enable)

21 DIN2 Digital Input 2 Run Reverse Input starts drive in reverse direction (start enable)

22 DIN3 Digital Input 3 External Fault Input causes drive to fault

23 DIN4 Digital Input 4 Fault Reset Input resets active faults

24 CMA DI1 to DI4 Common Grounded Allows source input

25 A/+ RS-485 Signal A — Fieldbus Communication (Modbus, BACnet)

26 B/- RS-485 Signal B — Fieldbus Communication (Modbus, BACnet)

27 R3NO Relay 3 Normally Open At Speed Relay output 3 shows VFD is at Ref. Frequency

28 R1NC Relay 1 Normally Closed Run Relay output 1 shows VFD is in a run state

29 R1CM Relay 1 Common

30 R1NO Relay 1 Normally Open

31 R3CM Relay 3 Common At Speed Relay output 3 shows VFD is at Ref. Frequency

32 R2NC Relay 2 Normally Closed Fault Relay output 2 shows VFD is in a fault state

33 R2CM Relay 2 Common

34 R2NO Relay 2 Normally Open

Notes

The above wiring demonstrates a SINK configuration. It is important that CMA and CMB are wired to ground (as shown by dashed line). If a SOURCE configuration is desired,

wire 24 V to CMA and CMB and close the inputs to ground. When using the +10 V for AI1, it is important to wire AI1—to ground (as shown by dashed line). If using +10 V for

AI1 or AI2, terminals 3, 5, and 6 need to be jumpered together.

AI1+ and AI2+ block that it can support 10K potentiometer.

EATON www.eaton.com 21

Instruction Leaflet IL040029EN

Effective December 2017

ଋጲڎ

PowerXL DH1 Series VFD

1PXFS9-ጆѴú% ଌ҃ଋጲڎ

H

ᑭ ֵଠᤗζՁՏሥ Ѣԇ᳭ᝢϘζՁ

1 +10V

2 AI1+

Res

3 AI1–

4 AI2+

i

5 AI2–

6GND

7 DIN5

8 DIN6

9 DIN7

10 DIN8

11 CMB

12 GND

13 24V

14 DO1

15 24Vo

16 GND

17 AO1+

18 AO2+

19 24Vi

20 DIN1

21 DIN2

22 DIN3

23 DIN4

24 CMA

25 A/+

26 B/-

27 R3NO

28 R1NC

29 R1CM

30 R1NO

31 R3CM

32 R2NC

33 R2CM

34 R2NO

ԟᏥᣤѢႂԌ

ഴᣤЙ1

ഴᣤЙ1ଋڠ

ഴᣤЙ2

ഴᣤЙ2ଋڠ

I/OζՁଋڠ

ஜߙᣤЙ5

ஜߙᣤЙ6

ஜߙᣤЙ7

ஜߙᣤЙ8

DI5ᒯDI8ၸ

I/O ζՁଋڠ

+24 Vdc ᣤѢ

ஜߙᣤѢ1

+24Vdc ᣤѢ

I/OζՁଋڠ

ഴᣤѢ1

ഴᣤѢ2

+24VDC ᣤЙ

ஜߙᣤЙ1

ஜߙᣤЙ2

ஜߙᣤЙ3

ஜߙᣤЙ4

DI1ᒯDI4ၸ

RS-485 ζՁA

RS-485 ζՁB

ፘႂ٧3 ࣡

ፘႂ٧1࣡

ፘႂ٧1ၸ

ፘႂ٧1࣡

ፘႂ٧3ၸ

ፘႂ٧2࣡

ፘႂ٧2ၸ

ፘႂ٧2࣡

-

0-10V

-

4-20mA

-

-

ᮔᤳB0

ᮔᤳB1

ጊপϢᢻ

҃ᤉር

ࣂଋڠ

-

-

эܫࡂ

-

-

ᣤѢᮟည

ႂႂึ

-

ൣՓᤁᛠ

ԥՓᤁᛠ

ܰᦉᬩ

ᬩܬ

ࣂଋڠ

-

-

Ҫᤳ

ᤁᛠ

Ҫᤳ

ᬩ

10 Vdc ႂຸ

ႂԌᤳԟᏥԺᎃር˝4-20mAὈ

ၸଋڠὈ

ഴᣤЙ

ႂึᤳԟᏥԺᎃር˝0-10VὈ

ഴᣤЙ2 ၸଋڠὈ

I/O ଋڠὋၸԟᏥ֖ଌ҃

߿ᮟညᣤѢᒯᮔᤳ1

߿ᮟညᣤѢᒯᮔᤳ2

ᣤЙ҃VFDᣤѢС

ᣤЙ࠱VFDఴڠԪ˝ᤉር

ЉႂຸᣤЙ

I/OଋڠὋၸԟᏥ֖ଌ҃

ଌ҃ႂԌᣤѢణܷϘ100mAὈ

௬ᇧԪᮟ٧ࣂэܫݝᤁᛠ

ଌ҃ႂຸᣤѢ 100mAὈ

I/OଋڠὋၸԟᏥ֖ଌ҃

௬ᇧႂᄉᣤѢᮟည 0-60Hz 4-20mAὈ

௬ᇧႂᄉႂႂึ 0-FLA (4-20mA)

ܰᦉଌ҃ႂԌᣤЙ

ᣤЙൣՓᡐҮԪᮟ٧ᡐҮըၸὈ

ᣤЙԥՓᡐҮԪᮟ٧ᡐҮըၸὈ

ᣤЙᤴԪᮟ٧Ԧၶᬩ

ᣤЙܬథᬩ

ЉႂຸᣤЙ

ဗڣጲᝬModbusὋ BACnetὈ

ဗڣጲᝬModbusὋ BACnetὈ

ፘႂ٧ᣤѢ3௬ᇧVFDܪԟᏥᮟည

ፘႂ٧ᣤѢ1௬ᇧVFDܪᤁᛠ࿃খ

ፘႂ٧ᣤѢ3௬ᇧVFDܪԟᏥᮟည

ፘႂ٧ᣤѢ2௬ᇧVFDܪᬩ࿃খ

22 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

A/+

A/-

EATON www.eaton.com 23

Instruction Leaflet IL040029EN

Effective December 2017

Caution!

en

In the territory of the EU Directive, the frequency-controlled devices and their accessories must be taken into operation only when the machine has been determined to fulfill the protection requirements of Machinery Safety Directive 89/392/EEC.

Ensure EMC-compliant installation. Lay control and communication cables spatially separated from the motor cable.

Ensure a large contact area connection between

cable screen and PE.

p

PowerXL DH1 Series VFD

es

¡Atención!

En el campo de aplicación de la normativa CE, los dispositivos controlados por

frecuencia y sus correspondientes accesorios sólo deberán ponerse en

marcha cuando se asegure que la máquina cumple con las exigencias de

seguridad de la normativa de máquinas 89/392/CEE.

El montaje debe cumplir CEM. Los cables de mando y de conexión a red se

deben instalar independientemente del cable de conexión al motor. El cable

apantallado

contacto.

fr

En application des directives européennes, les convertisseurs de fréquence et leurs accessoires ne doivent être mis en service que s’il a été vérifié que la machine répond aux exigences de la directive machines 89/392/CEE.

Montage conforme aux règles de la CEM. Eloigner les câbles de commande et de réseau des câbles puissance. Relier le blindage au PE en assurant de grandes surfaces de contact.

de

Im Geltungsbereich der EG-Richtlinien dürfen die frequenzgesteuerten Geräte und deren Zubehör nur dann in Betrieb genommen werden, wenn festgestellt wird, dass die Maschine die Schutzanforderungen der Maschinenrichtlinie 89/392/EWG erfüllt.

EMV-gerechter Aufbau. Steuer- und Netzleitungen räumlich getrennt von der

Motorleitung verlegen.

it

Nel campo di validità delle direttive CE, gli apparecchi a controllo di frequenza e i loro accessori possono essere messi in esercizio soltanto se si verifica che la macchina soddisfa i requisiti di sicurezza della direttiva macchine 89/392/CEE

Montaggio secondo CEM. Disporre i cavi comandi e di alimentazione separati

dal cavo del motore. Collegare lo schermo del cavo

superficie.

nl

Binnen het geldigheidsgebied van de EC-richtlijnen mogen de

frequentiegeregelde apparaten en de toebehoren daarvan alleen in bedrijf

worden genomen, wanneer wordt vastgesteld, dat de machine aan de

veiligheidseisen van de machinerichtlijn 89/392/EWG voldoet.

EMC-conforme constructie. Besturings- en netkabels ruimtelijk gescheiden van

de motorkabel leggen.

verbinden.

da

I det område, hvor EF-direktiverne er gældende, må det frekvensstyrede udstyr og dets tilbehør kun tages i anvendelse, hvis det konstateres, at maskinen opfylder beskyttelseskravene i maskindirektivet 89/392/EØF.

EMC-korrekt installation. Træk styre- og netledninger rumligt adskilt fra

motorledningen.

ledningsafskærmning og PE.

el

Στο πεδίο εφαρμογής των οδηγιών της ΕΚ, οι ελεγχόμενες μέσω συχνότητας

συσκευές και τα παρελκόμενά τους επιτρέπεται να τίθενται σε λειτουργία μόνο

εφόσον διαπιστωθεί ότι το μηχάνημα πληροί τις απαιτήσεις προστασίας της

οδηγίας της ΕΚ για τα μηχανήματα 89/392/ΕΟΚ.

Κατασκευή σύμφωνα με τις απαιτήσεις ΗΜΣ. Εγκαθιστάτε τους αγωγούς

ελέγχου και δικτύου

θωράκιση των αγωγών σε μεγάλη επιφάνεια με τη γείωση.

se debe conectar a masa utilizando una amplia superficie de

p

Attention !

Vorsicht!

Leitungsschirm großflächig mit PE verbinden.

p

Attenzione!

con PE con un’ampia

p

Voorzichtig!

Kabelafscherming over groot oppervlak met PE

p

Forsigtig!

Sørg for en stor kontaktflade mellem PES

p

Προσοχή!

ανεξάρτητα από τον αγωγό του κινητήρα.

Συνδέετε τη

p

pt

Cuidado!

No âmbito das directivas da CE, os aparelhos comandados por frequência e os respectivos acessórios só podem ser postos em operação se for comprovado que a máquina atende às exigências de protecção da directiva de máquinas 89/392/CE.

Estrutura com compatibilidade electromagnética. Dispor os fios de comando e

de rede separados do fio do motor.

cabo (PES) com o PE.

sv

Se upp!

I giltighetsområdet för EG-direktiven får de frekvensstyrda apparaterna och deras tillbehör endast tagas i drift när man fastställt att maskinen uppfyller skyddskraven i maskindirektiv 89/392/EEC.

EMC-anpassad uppbyggnad. Styr- och nätledningar dras avskilda från

motorledningarna.

Varo!

EU-direktiivien voimassaoloalueella taajuusohjatut laitteet ja niiden varusteet saa ottaa käyttöön vain silloin, kun todetaan, että kone täyttää konedirektiivin 89/392/ETY suojausvaatimukset.

EMC-mukainen rakenne. Ohjaus- ja verkkojohdot on asennettava

tilaulotteisesti erotettuina. Johdonsuoja on liitettävä laajasti maadoitukseen

cs

Pozor!

V rozsahu platnosti směrnic ES smí být frekvenčně řízené přístroje a jejich

příslušenství uvedeny do provozu jedině tehdy, pokud je zjištěno, že stroj

splňuje požadavky ochrany stanovené směrnicí 89/392/EHS o strojních

zařízeních.

Nástavba odpovídající směrnici EMC. Řídicí a sít’ová vedení pokládejte

prostorově oddělená od vedení motoru.

s PE.

et

Ettevaatust!

EÜ-direktiivi kehtivuspiirkonnas võib sagedusjuhitavaid seadmeid ja nende lisaseadmeid kasutusele võtta ainult siis, kui on kindlaks tehtud, et masin vastab masinadirektiivi 89/392/EMÜ kaitsenõuetele.

Elektomagnetilisele ühilduvusele vastav ehitus. Juhtimis- ja võrgukaablid

paigaldada mootori toitekaablist ruumiliselt eraldatuna.

ühendada ulatuslikult talitlusmaandusega.

hu

Vigyázat!

Az EK irányelvek hatályossági területén a frekvenciavezérelt készülékeket és

azok tartozékait csak akkor szabad üzembe helyezni, ha megállapítást nyert,

hogy a gép megfelel a gépek biztonságáról szóló, 89/392/EGK számú irányelv

biztonsági követelményeinek.

Elektromágnesesen összeférhető kivitelt biztosítson. A motorvezetékektől

térben elkülönítve vezesse vezérlő és hálózati vezetékeket.

csatlakoztassa a védőföldeléshez a vezetékárnyékolást.

lv

Ievērot piesardzību!

Valstīs, kurās ir spēkā EK direktīvas, ierīču ar frekvenčvadību un to piederumu ekspluatāciju drīkst sākt tikai tad, ja ir konstatēta iekārtas atbilstība Mašīnu direktīvā 89/392/EEK ietvertajām aizsardzības prasībām.

EMS atbilstoša uzbūve. Vadības un tīkla kabeļus izvietot atsevišķi no motora

kabeļa

Vada ekrānu plašā virsmā savienot ar PE.

p

Förbind ledningsskärm över ett brett område med PE.

p

Ligar uma área grande da blindagem do

p

Stínění vedení spojte velkoplošně

p

Kaabli kaitseekraan

p

Nagy felületen

p

p.

24 EATON www.eaton.com

PowerXL DH1 Series VFD

Instruction Leaflet IL040029EN

Effective December 2017

lt

Atsargiai!

EB direktyvų taikymo srityje dažniniu būdu valdomus įrenginius ir jų priedus leidžiama pradėti naudoti tik tada, kai nustatoma, kad įrenginys atitinka Mašinų direktyvos 89/392/EEB keliamus apsaugos reikalavimus.

Montažas turi atitikti EMS reikalavimus. Valdymo ir duomenų tinklo kabelius

išdėstyti atokiai nuo variklio kabelio.

sujungti su įžeminimu.

pl

Ostrożnie!

Na obszarze obowiązywania dyrektyw WE urządzenia sterowane częstotliwościowo wolno wprowadzać do eksploatacji tylko wtedy, gdy zostanie stwierdzone, że maszyna spełnia wymagania ochronne dyrektywy maszynowej 89/392/EWG.

Konstrukcja zgodna z dyrektywą w sprawie kompatybilności

elektromagnetycznej (EMC). Przewody sterowania i zasilania elektrycznego

należy układać oddzielnie od przewodu silnika.

Ekranowanie połączyć z przewodem uziemiającym na większej powierzchni.

p

sl

Pozor!

Na območju veljavnosti direktiv ES je zagon frekvenčno krmiljenih naprav in njihovega pribora dovoljen le tedaj, ko je bilo ugotovljeno, da stroj ustreza varnostnim zagtevam Direktive o strojih 89/392/EGS.

Montaža v skladu z EMZ. Krmilne in omrežne vodnike napeljite ločeno od

vodnikov motorja

vodnikom.

sk

Pozor!

V krajinách, ktoré spadajú pod pôsobnosť smerníc ES smú byť rádiovo

ovládané zariadenia a ich príslušenstvo uvedené do prevádzky len ak je

zabezpečené, že stroj spĺňa ochranné ustanovenia smernice č. 89/392/EHS

o strojových zariadeniach.

Montáž v súlade s požiadavkami elektromagnetickej kompatibility. Ovládacie

a siet˙ové vedenia uložte v priestore oddelene od vedenia motora.

Zabezpečte veľkú kontaktnú plochu medzi káblovým tienením a PE.

Oklep vodnika na veliki površini povežite z zaščitnim

p

Kabelio ekraną dideliu paviršiumi

p

p

bg

Внимание!

В сферата на действие на изискванията на ЕС устройствата с честотно

управление и техните допълнителни устройства могат да бъдат

приведени в употреба, само ако се установи, че оборудването

съответства на изискванията за безопасност на машинно оборудване

спрямо 89/392/EWG.

Монтаж с електромагнитна съвместимост. Полагане на контролните и

мрежови проводници пространствено отделно от проводника

двигателя.

PE.

ro

În cadrul sferei de aplicare a directivelor UE dispozitivele controlate prin

frecvenţă şi accesoriile acestora au voie să fie puse în funcţiune doar dacă se

stabileşte că aparatul îndeplineşte cerinţele Directivei 89/392/CEE privind

maşinile.

Montajul trebuie să fie compatibil EMC. Poziţionaţi cablurile de control şi de

reţea la distanţă de cablul motorului.

între izolaţia cablului şi PE.

ru

В сфере действия директив ЕС устройства с частотным управлением и их

оснащение должны вводиться в эксплуатацию только в том случае, если

установлено, что данное оборудование соответствует требованиям по

защите Директивы о машинном оборудовании 89/392/EWG.

Сборка соответственно электромагнитной совместимости. Линии

управления и электросети прокладывать в пространственном отношении

отдельно от линии двигателя.

площади.

zh

ṩᦞ⅗ⴏ䇮༷а㠤ᙗ㿴㤳ˈᆹ㻵仁⦷᧗ࡦ䇮༷৺ަ䝽Ԧᰦˈᓄ⺞؍䇮༷┑䏣ᵪಘ㿴㤳

(:* ѝޣҾ䇮༷؍ᣔⲴ㾱≲DŽ

S᤹➗⭥⻱ެᇩ㿴㤳↓⺞ᆹ㻵DŽᓄሶ᧗ࡦ⭥㔶઼⭥Ⓚ⭥㔶о⭥ᵪ⭥㔶࠶ᔰDŽ

བྷ䶒〟䟷⭘ 3( 㼩⭥㔶DŽ

Осигурете по-голяма конкактна площ между силовия екран и

p

Precauţie!

Asiguraţi o suprafaţă de contact mare

p

Осторожно!

cиловой экран соединять с PE по большой

p

⌘

на

EATON www.eaton.com 25

Instruction Leaflet IL040029EN

Effective December 2017

UL cautions, warnings, and instructions

PowerXL DH1 Series VFD

Wiring warnings for electrical practices and wire sizes

The Cautions, Warnings, and Instructions in this section summarize

the procedures necessary to ensure an inverter installation complies

with Underwriters Laboratories

en

Warning!

Use 60/75 °C Cu wire only or equivalent.

en

Warning!

Open Type Equipment.

en

Warning!

Suitable for use on a circuit capable of delivering not more

than 5,000 rms symmetrical amperes:

• 240 V maximum for DH1-32 models

• 500 V maximum for DH1-34 models

• 600 V maximum for DH1-35 models

®

guidelines.

Circuit breaker and fuse sizes

The adjustable frequency drive’s connections to input power must

include UL listed inverse time circuit breakers with 600V rating, or

UL listed fuses.

Terminal tightening torque and wire size

The wire size range and tightening torque for field wiring terminals

are presented.

Wire connectors

en

Warning!

Field wiring connections must be made by a UL listed and CSA certified ring lug terminal connector sized for the wire gauge being used. The connector must be fixed using the crimping tool specified by the connector manufacturer.

Cable

PE

Cable

Cable

Cable support

Terminal (ring lug)

Motor overload protection

DH1 adjustable frequency drives provide solid-state motor overload

protection, which depends on the proper setting of the following

parameter: P7.2 “current limit.“

Set the rated current [Amperes] of the motor(s) with the above

parameters. The setting range is 0.2 * rated current to 2 * rated

current,

씮 manual MN040002EN.

en

Warning!

When two or more motors are connected to the inverter, they cannot be protected by the electronic overload protection. Install an external thermal relay on each motor.

Technical support contact information

26 EATON www.eaton.com

Loading...

Loading...